Siemens 550-506, 550-507 Installation Instructions Manual

CE Compliant Dual Duct Controller — Two Air

Velocity Sensors — Electronic Output

Product Description

Required Tools

Installation Instructions

Document No. 550-308

Rev. 1, July, 2001

These instructions explain how to field install or

replace a CE Compliant Dual Duct Controller — Two

Air Velocity Sensors — Electronic Output with or

without Autozero Modules.

Shipping carton includes a controller assembly

(controller board and cover), a mounting rail, Autozero

Modules with brackets (optional), and two self-tapping

screws.

For CE compliance, ferrite filter(s) and an alternate

room sensor cable must be used (see Product

Numbers).

NOTE: Keep the controller assembly in its static-proof

bag until installation.

Product Numbers

Product Description

550-506 Dual Duct Controller — Two Air Velocity

Sensors — Electronic Output

550-507 Dual Duct Controller — Two Air Velocity

Sensors — Electronic Output with Autozero

Modules

588-100A 25-ft (7.6-m)

588-100B 50-ft (15.2-m)

588-100C

550-705 clamp-on ferrite filter 10 pack

2-RJ11 room

temperature

sensor cable

100-ft (30.48-m)

Caution Notation

CAUTION:

Equipment damage or loss of

data may occur if the user

does not follow procedure as

specified.

• Electro-Static Discharge (ESD) wrist strap

• Small flat-blade screwdriver

• Medium flat-blade screwdriver

• Medium-duty electric drill

• 1/4-inch (6.35 mm) hex nut bit

• Portable Operator’s Terminal with Controller

Interface Software (CIS) Rev. 2.0 or higher

(controller replacement only)

Additional tools needed if not using self-tapping

option:

• 1/4-inch (6.35 mm) hex nut driver

• 1/8-inch (3 mm) bit

Prerequisites

• Room temperature sensor installed (optional)

• Air velocity sensors installed in ducts

• 24 Vac Class 2 power source

• Supply power to the unit is OFF

• Autozero Modules with brackets are on hand

(optional)

• If required, controller enclosure installed

Expected Installation Time

New controller installation 10 min.

Replacement with removable terminal

blocks

Replacement without removable

terminal blocks

NOTE: You may require additional time for

database work at the field panel.

6 min.

16 min.

Page 1 of 9

Document Number 550-308

Installation Instructions

Rev. 1, July, 2001

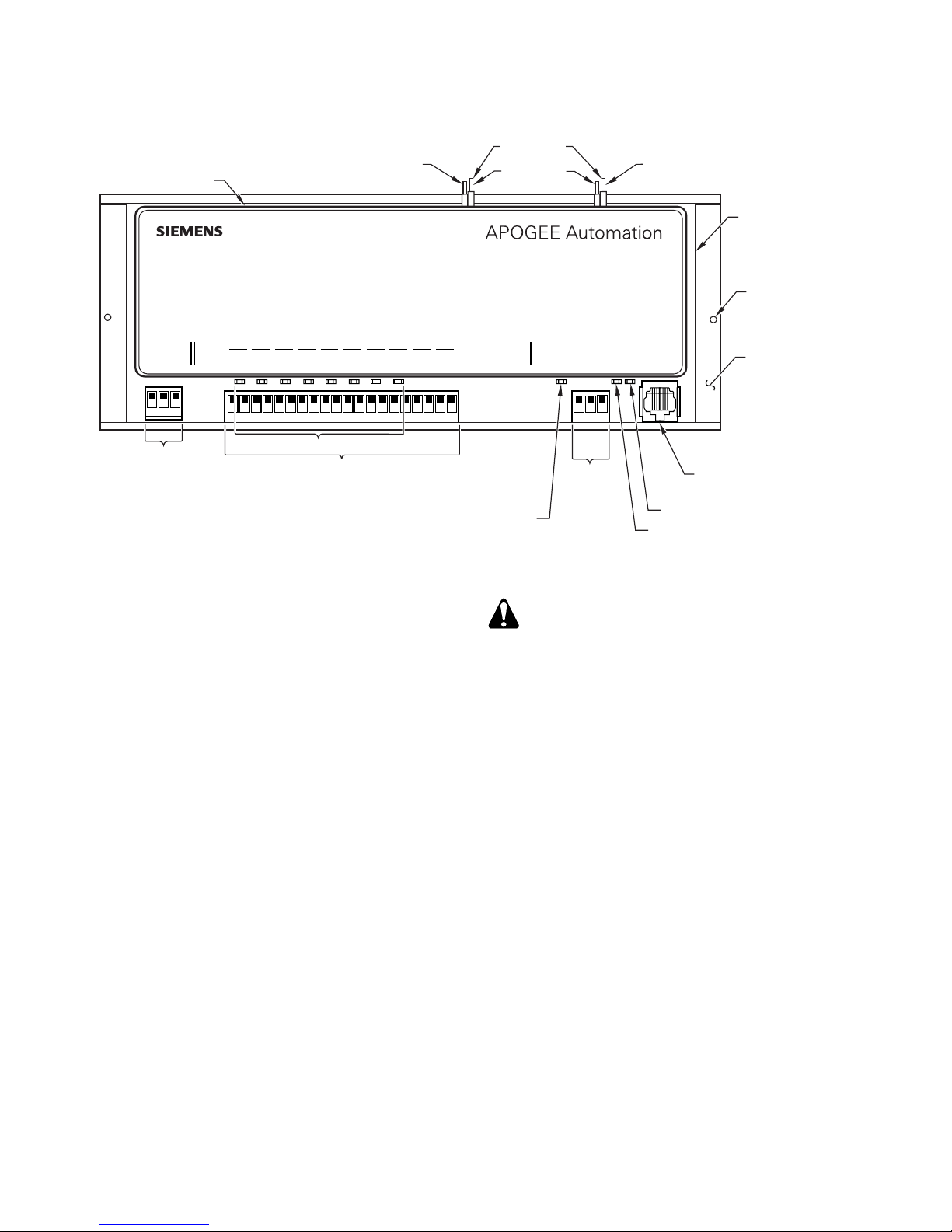

COVER

24 V-A C

C H GND

DO1

NO C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

DO2

NO C

DO3

NO C

DO4

NO C

DO5

NO C

DO6

NO C

DO7

NO C

DO8

NO C

AIR VELOCITY

HI

DI3

DI2

AI3

SENSOR PORTS

LO

HI

BST

FLN TRUNK

+ - S

RX TX

LO

RTS

CONTROLLER

BOARD

MOUNTING

HOLE

(2)

MOUNTING

RAIL

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

DO LEDS

INPUT / OUTPUT TERMINATIONS

TEC0321R1

H

C

E

POWER

TRUNK

TERMINATIONS

Figure 1. CE Compliant Dual Duct Controller — Two Air Velocity Sensors without Autozero Modules.

New Installation Instructions

1. Using the mounting rail as a template (Figure

1), mark the screw holes where you will install

the controller assembly.

2. Do one of the following:

• If using the self-tapping screws provided:

Using the drill and the hex nut bit, fasten the

mounting rail.

• If not using the self-tapping screws: Drill

two 1/8-inch (3 mm) pilot holes, then fasten

the mounting rail with No. 6 or No. 8 screws.

3. Place the ESD wrist strap on your wrist and

attach it to a good earth ground.

4. Carefully remove the controller assembly from

the anti-static bag. Center it over the mounting

rail and snap it securely into place.

5. Connect the Floor Level Network (FLN). See

Figure 4.

6. Connect the point wiring as shown in Figure 7.

NOTE: Wiring to DI3/AI3 requires a clamp-on

ferrite filter (Figure 6). Strain relief must be

provided to ensure long-term effectiveness

due to added weight of the filter.

-

+

S

BST LED

FLN

TRUNK

TERMINATIONS

ROOM TEMPERATURE

TRANSMIT LED

RECEIVE LED

SENSOR / MMI PORT

CAUTION:

The Controller’s Digital Outputs (DOs)

control 24 Vac loads only. The maximum

rating is 12 VA for each DO. Use an

interposing 220V 4-relay module for any of

the following:

• VA requirements higher than

maximum.

• 110 or 220 Vac.

• DC power.

• Separate transformers used to

power the load.

NOTES: 1. Each DO provides a Normally Open (NO)

and a Common (C) terminal. Terminate

both connections of a 24 Vac load directly

to the controller board. Actuators use two

DOs and require three connections.

2. The 24 Vac “H” terminal is switched

through a TRIAC to the NO terminations

when the associated DO is energized.

7. If using Autozero Modules, refer to the

Installation Instructions (540-199), which are

included.

8. After the Autozero Modules are installed,

connect the Autozero Module wires to the

controller at DO7.

Page 2 of 9 Siemens Building Technologies, Inc.

Document Number 550-308

Installation Instructions

Rev. 1, July, 2001

9. After viewing Figure 6, install a clamp-on ferrite

filter on the room temperature sensor cable and

plug the cable into the RTS port on the controller

(Figure 1). Use only an approved 588-100 series

cable as described in the Product Numbers

section. Consider strain relief to ensure longterm effectiveness due to added weight of the

filter.

10. Connect the power trunk as shown in Figure 5.

DO NOT apply power to the controller.

11. Connect the tubing from the air velocity sensor

pickups to the HI and LO ports on the controller,

or on the Autozero Modules (if present). Make

sure that the “HI” and the “LO” pressure sides of

the sensors are connected to the corresponding

“HI” and “LO” sensor ports on the controller or

Autozero Modules (Figure 2).

The installation is complete.

Replacement Instructions

CAUTION:

Replacement of a TEC requires you to

record, re-enter, or update the initial point

values of the controller being replaced.

These are the points marked with an

asterisk (*) on the CIS display.

a. Obtain a field panel Point Definition

Report for the LCTLR point. Record the

values in Table 1.

b. View the initial value block. (This

information is valid only since the last

update was made). Record the values in

Table 1.

c. Delete the LCTLR point from the field

panel.

3. Replace the old controller as follows:

a. Remove power from the controller.

b. If the old controller has the RTS plug

between the FLN and point terminations,

disconnect the wires from the power trunk

terminal block. If the old controller has the

RTS plug on the opposite end of the board

from the power trunk terminal block, remove

the power trunk terminal block.

c. Remove, in order, the controller’s:

• FLN terminal block

• Point wiring

• Room temperature sensor

d. Remove the old controller assembly from the

mounting rail.

NOTE: CIS Rev. 2.0 or higher is required for

controller replacement.

1. Place the ESD wrist strap on your wrist and

attach it to a good earth ground.

2. Before disconnecting the old controller, do one

of the following:

NOTE: If the new controller has a newer

firmware revision than the old

controller, skip to the third bullet.

• If the old controller communicates with the

field panel, update the controller initial values

at the field panel.

• If the old controller does not communicate

with the field panel, but communicates with

CIS, or is stand-alone, record the initial

values in Table 1.

• If the old controller is not communicating or

has a newer firmware revision, use the

following steps to update the field panel:

e. Carefully remove the new controller

assembly from the anti-static bag. Center it

over the mounting rail and snap it securely

into place.

f. If the old controller has the RTS plug

between the FLN and point terminations,

remove all terminal blocks (except the power

trunk) from the new controller. If the old

controller has the RTS plug on the opposite

end of the board from the power trunk

terminal block, remove all terminal blocks.

g. Plug, in order, the controller’s:

• Pre-wired FLN

• Point wiring

NOTE: Wiring to DI3/AI3 requires a clamp-on

ferrite filter (Figure 6). Strain relief

must be provided to ensure long-term

effectiveness due to added weight of

the filter.

Siemens Building Technologies, Inc. Page 3 of 9

Loading...

Loading...