Siemens 546-00303A Installation Instructions Manual

Fume Hood Monitor

Product Description

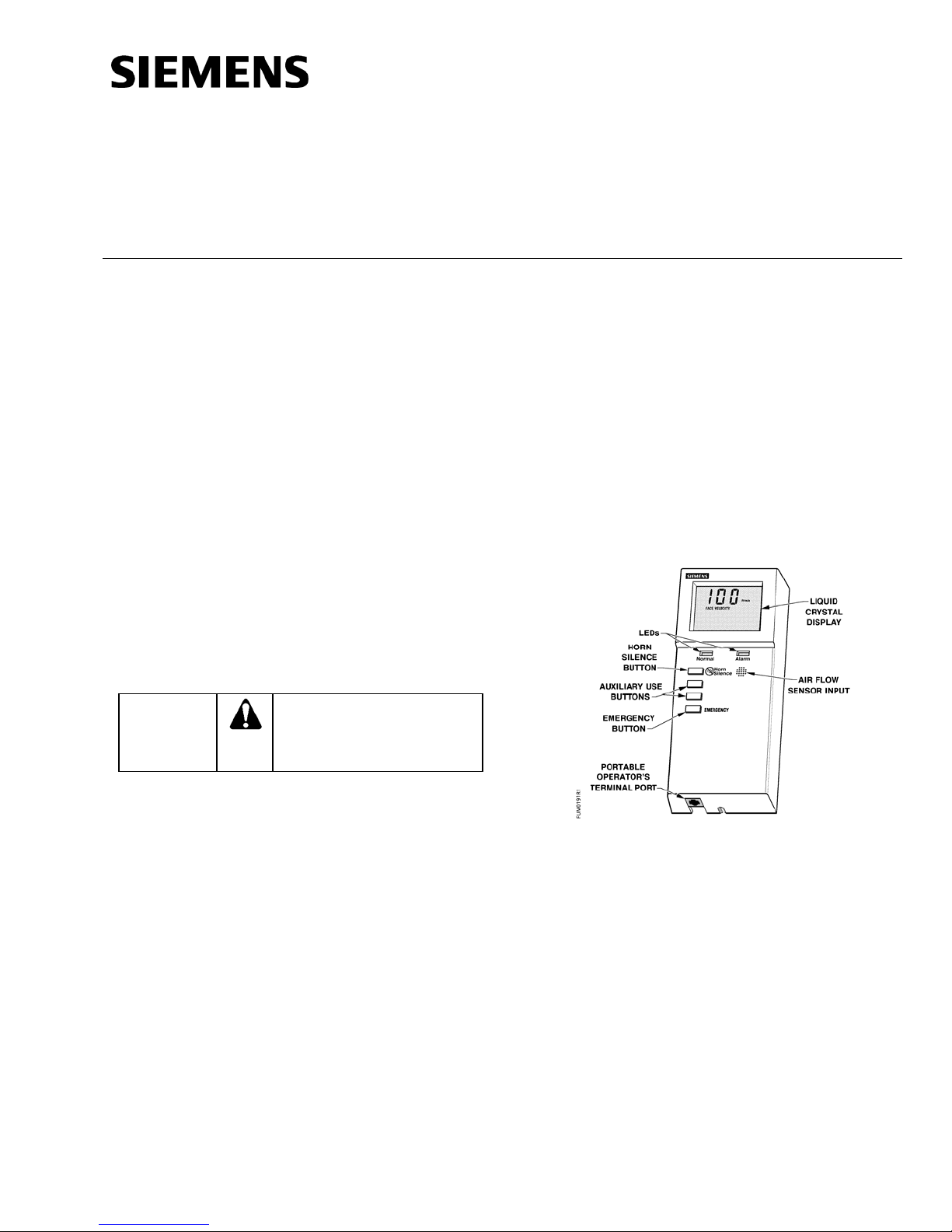

The Fume Hood Monitor (FHM) (Figure 1) provides

visual and audible alarms to alert a fume hood user

of airflow conditions. The mounting plate is designed

for fume hoods with or without existing cutouts. This

kit contains:

• Fume Hood Monitor with mounting plate

• Three removable wire connectors

• Four sheet metal screws

• Two machine screws

• 2 ft. (0.6 m) air sensor hose

• Plastic sidewall adapter and lock ring

Installation Instructions

Document No. 546-00310

November 15, 2006

Expected Installation Time

27 minutes

Prerequisites

• Power cable in place

If using a field panel:

• Floor Level Network (FLN) cable from the

field panel to the FHM in place

If using an external alarm or auxiliary DI

connection:

• External alarm or auxiliary DI cable from

source to FHM in place

Product Numbers

546-00303A Fume Hood Monitor

546-00303B Fume Hood Monitor mounting plate

Warning/Caution Notations

CAUTION:

Equipment damage or loss of

data may occur if the user

does not follow procedure as

specified.

Required Tools

For a fume hood with an existing cutout:

• Medium-duty electric drill

• 1/2-inch. (13.0 mm) drill bit

• Small flat-blade screwdriver

• Small Philips screwdriver

• Wire strippers

For a fume hood without an existing cutout:

• Medium-duty electric drill

• 1/8-inch (3.0 mm) drill bit

• 1/2-inch (13.0 mm) drill bit

• Metal-cutting saw or 3/ 4 in. and 1 in. drill bits

or hole saws

• Small flat-blade screwdriver

• Small Philips screwdriver

• Wire strippers

Figure 1. Fume Hood Monitor.

Instructions

NOTE: Mount the FHM so that the fume hood

operator can easily read its display and

can easily reach its buttons. This height is

approximately 4-1/2 ft. to 5 ft.

(1.4 to 1.5 m) from the floor.

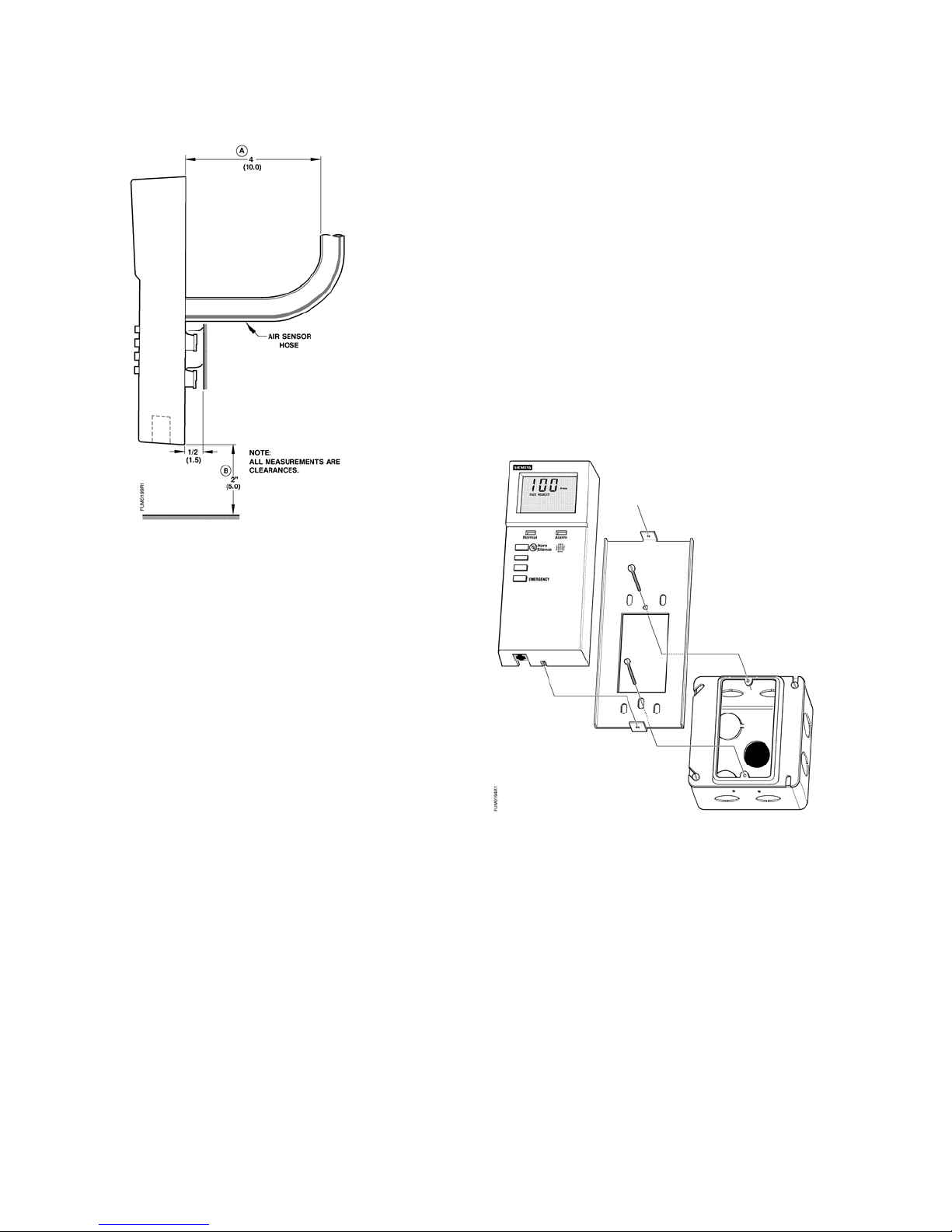

1. Choose the mounting location for the FHM. The

FHM should be mounted directly on the fume

hood and can be mounted over a pre-existing

cutout on the fume hood. See Figure 2 for

installation clearance requirements.

Page 1 of 6

Document No. 546-00310

Installations Instructions

November 15, 2006

Mounting Plate Installation with an

Existing Cutout

1. See Figure 3. If the fume hood is provided with a

2 inch × 4 inch (5.0 × 10.0 cm) cutout with an

electric utility box, then use the provided

machine screws to attach the mounting plate to

the electric utility and skip to Sidewall Hole

Mounting.

If the fume hood has no electric utility box,

make sure that the cutout provides enough

clearance for the air sensor hose and to

connect the power, FLN, external alarm, and

auxiliary DI wires. Then continue to Step 2.

Figure 2. Installation Clearance Requirements.

NOTE: Clearance is needed to prevent the sensor

air hose from bending or kinking, and to

insert the Portable Operator’s Terminal

Cable.

2. Confirm that an earth ground is connected to the

mounting plate. To do this, make sure that the

following conditions are met:

a. The conduit junction box is grounded, or

b. The fume hood enclosure is grounded, or

c. A separate wire is connected between the

earth ground and the mounting plate.

3. Continue with one of the following mounting

methods: Mounting Plate Installation with an

Existing Cutout or Mounting Plate Installation

without an Existing Cutout.

Figure 3. Installation with an Existing Cutout.

2. Position the bracket over the opening and mark

the locations of the two mounting holes.

3. Using the 1/8-inch (3.0 mm) drill bit, drill the two

mounting holes.

4. Using the screws provided, attach the mounting

plate to the mounting surface.

Page 2 of 6

Siemens Building Technologies, Inc.

5. Proceed to Sidewall Hose Mounting.

Loading...

Loading...