Siemens 540-103, 540-104, 540-803 Installation Instructions Manual

Installation Instructions

Document No. 540-320

July 15, 2009

Constant Volu

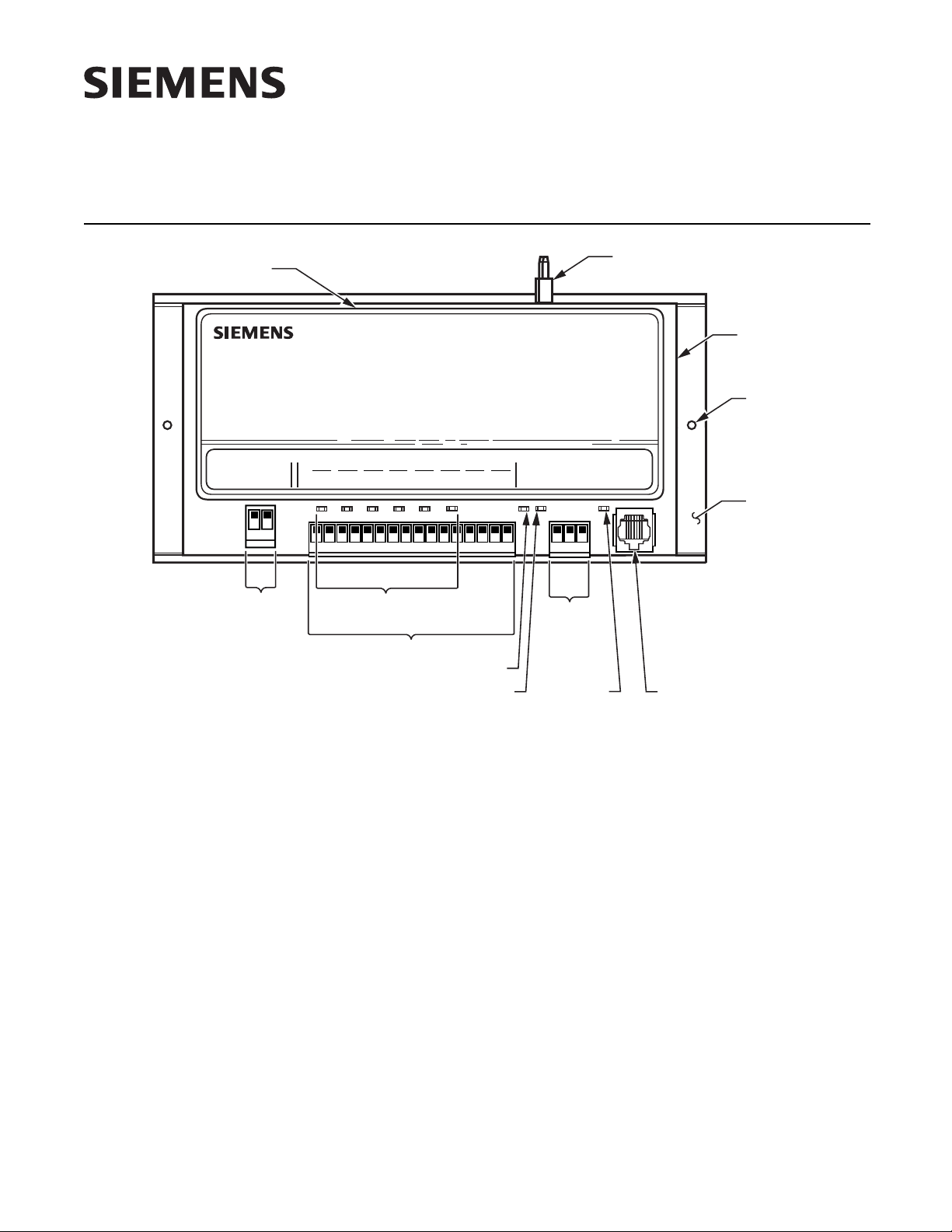

COVER

TERMINATIONS

TEC0200R6

me Controller—Electronic Output

SENSOR PORTS

24 V-AC

CEH

CH

POWER

TRUNK

DO 1 DO 2 DO 3 DO 4 DO 5

NO C NO C NO C NO C NO C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

DO LEDS

INPUT/OUTPUT TERMINATIONS

DO 6 DI 3 DI 2 FLN

NO C

AI 3

TRANSMIT LED

RECEIVE LED

TX RX + - S

FLN TRUNK

TERMINATIONS

TRUNK

BST RTS

+-

S

BST LED ROOM TEMPERATURE

AIR VELOCITY

CONTROLLER

BOARD

MOUNTING

HOLE

(2)

MOUNTING

RAIL

SENSOR/MMI PORT

Figure 1. Constant Volume Controller—Electronic Output.

Control Applications

2030, 2032, 2033

2130, 2132, 2133 (Secure Mode Applications)

Product Description

These instructions explain how to field install or

replace a Constant Volume Controller—Electronic

Output with or without Secure Mode or optional

Autozero Module.

Shipping carton includes a controller assembly

(controller board and cover), a mounting rail,

Autozero Module and bracket (optional), and two

self-tapping screws.

tem Number: 540-320-07, Rev. CA

I

Product Numbers

540-103

540-104

540-803

Constant Volume

Controller—Electronic Output

Constant Volume

Controller—Electronic Output

with Autozero Module

Constant Volume

Controller—Electronic Output

for Trane

...continued on next page

age 1 of 6

P

Document No. 540-320

Installation Instructions

July 15, 2009

540-804

540-103C Constant Volume

540-104C Constant Volume

Constant Volume

Controller—Electronic Output

with Autozero Module for Trane

Controller—Electronic Output

with Secure Mode

Controller—Electronic Output

with Autozero Module and Secure

Mode

CAUTION:

Keep the unit in its static-proof bag until

installation.

Accessories

540-628P25

(pack of 25)

Parts for CE Compliance:

550-705

588-100 series

540-155

550-002

Low cost temporary temperature

sensor that enables space control if

the permanent room or duct sensor is

not installed.

Clamp-on ferrite filter (10 pack)

Approved 2-RJ11 RTS cable in 25’,

50’, or 100’ (7.6-m, 15.2-m, 30.48-m)

Metal Small Equipment Controller

Enclosure

Large Equipment Controller Enclosure

•Smallflat-blade screwdriver

• Cabling and connectors. See the section.

• Cordless drill/driver set

Prerequisites

• MBC or RBC enclosure mounted with at least

one open slot on the C-BUS and AC power

connected.

• CE Compliance requirements met, if needed.

• Termination blocks installed, if any.

• Authorized modem installed if connection to a

public telephone network is required.

• One 115V or 230V receptacle (depending on

device) to power the Trunk Interface II.

If the controller is b eing installed on a box

with1ormorestagesofelectricheat,

the 550-809 MOV with pre-terminated

spade connectors must be installed across

the manufacturer-supplied airflow switch.

MOV’s can be installed at the time the

controller is factory mounted; coordinate

with the box manufact urer prior to order

.

placement. For field installation, see Metal

Oxide Varistor Kit Installation Instructions

(540-986).

Instructions

Warning/Caution Notations

All wiring must confo rm to NEC and local

codes and regulations.

CAUTION:

Equipment damage or loss of data may

occur if you do not follow the procedures

as specified.

1. Secure the mounting rail (Figure 1) in the

controller’s desired location.

2. Place the ESD wrist strap on your wrist and attach

it to a good earth ground.

Expected Installation Times

10 minutes.

3. Remove the controller from the static proof bag

and snap it into place on the mounting rail.

4. Connect the FLN (Figure 2).

Required Tools and Materials

• Flat-blade screw dr

Page 2 of 6 Siemens Building Technologies, Inc.

iver (1/8-inch blade width).

Loading...

Loading...