Siemens 4N33, 4N32 Datasheet

)

)

.

.

Ω

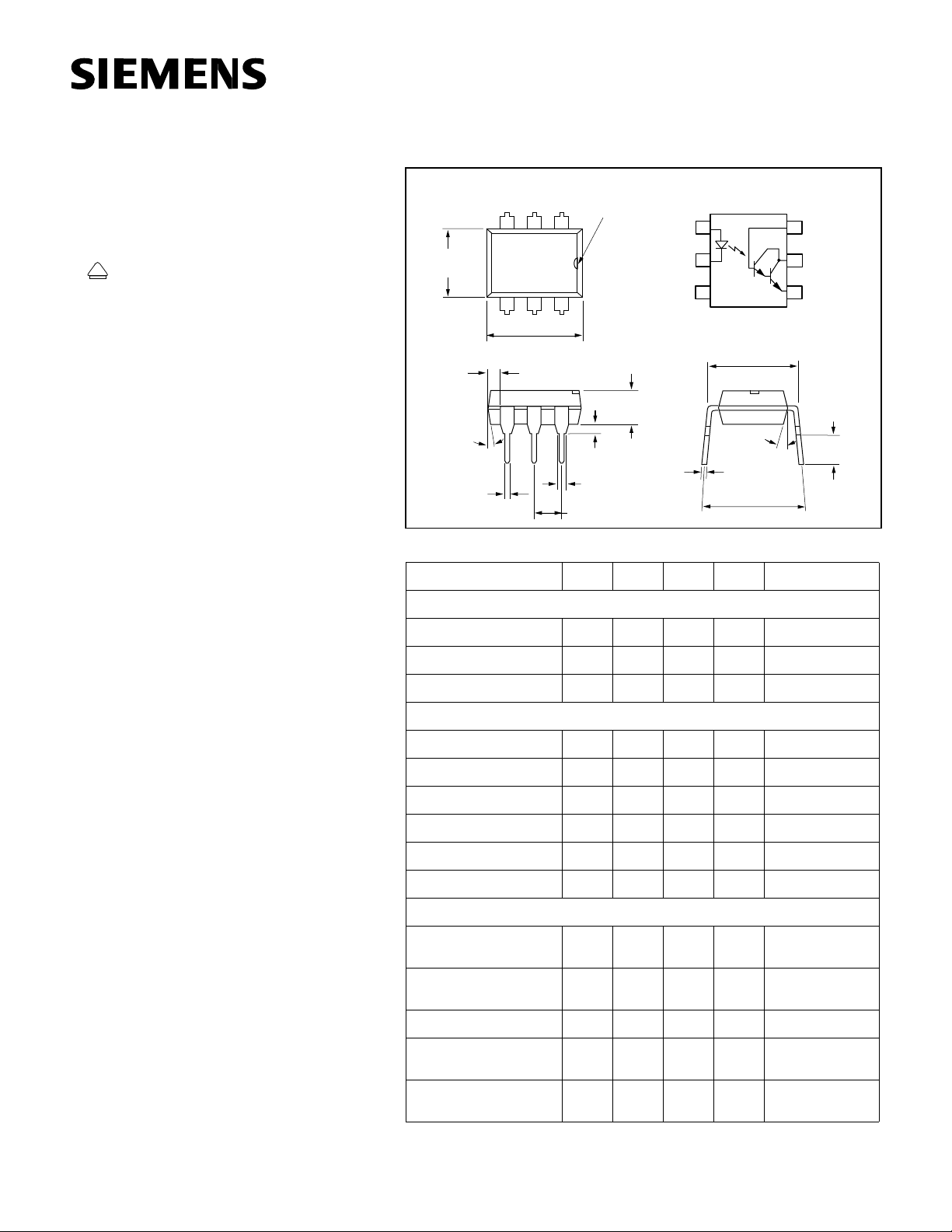

4N32/4N33

PHOTODARLINGTON

OPTOCOUPLER

FEATURES

Dimensions in inches (mm)

• Very High Current Transfer Ratio, 500% Min.

• High Isolation Resistance, 10

11

Typical

• Standard Plastic DIP Package

• Underwriters Lab File #E52744

V

• VDE Approvals #0884 (Available with

DE

Option 1)

DESCRIPTION

The 4N32 and 4N33 are optically coupled isolators

with a Gallium Arsenide infrared LED and a silicon

photodarlington sensor. Switching can be

achieved while maintaining a high degree of isolation between driving and load circuits. These optocouplers can be used to replace reed and mercury

relays with advantages of long life, high speed

switching and elimination of magnetic fields.

Maximum Ratings

Emitter

Peak Reverse Voltage........................................3 V

Continuous Forward Current.........................60 mA

Power Dissipation at 25 °

Derate Linearly from 55 °

C..........................100 mW

C....................1.33 mW/ ° C

Detector

Collector-Emitter Breakdown Voltage,

BV

.......................................................... 30 V

CEO

Emitter-Base Breakdown Voltage,

BV

............................................................. 8V

EBO

Collector-Base Breakdown Voltage,

BV

.......................................................... 50 V

CBO

Emiter-Collector Breakdown Voltage,

BV

............................................................ 5 V

ECO

Collector (load) Current...............................125 mA

Power Dissipation at 25 °

Derate Linearly from 25 °

C Ambient...........150 mW

C......................2.0 mW/ ° C

Package

Total Dissipation at 25 ° C Ambient .............250 mW

Derate Linearly from 25 °

Isolation Test V oltage.........................5300 VAC

C......................3.3 mW/ ° C

RMS

Between Emitter and Detector,

Standard Climate: 23 °

C/50%RH,

DIN 50014

3

248 (6.30)

256 (6.50)

4

5

.335 (8.50)

.343 (8.70)

.039

(1.00)

min.

4°

typ.

.018 (0.45)

.022 (0.55)

Electrical Characteristics (T

Parameter Min. Typ. Max. Unit Condition

Emitter

Forward Voltage 1.25 1.5 V I

Reverse Current 0.1 100 µ AV

Capacitance 25 pF V

Detector

BV

*30 VI

CEO

*50 VI

BV

CBO

BV

*8 VI

EBO

BV

*510VI

ECO

I

CEO

H

FE

Package

Pin One ID.

12

6

.130 (3.30)

.150 (3.81)

.020 (.051) min.

.031 (0.80)

.035 (0.90)

.100 (2.54) typ.

=25 ° C)

A

NC

1

2

3

.300 (7.62)

typ.

18° typ.

.010 (.25)

.014 (.35)

.300 (7.62)

.347 (8.82)

Anode

Cathode

1.0 100 nA V

13K I

6

Base

5

Collector

4

Emitter

.110 (2.79

.150 (3.81

=50 mA

F

=3.0 V

R

=0 V

R

=100 µ A, I

C

=100 µ A, I

C

=100 µ A, I

C

=100 µ A, I

E

=10 V, I

CE

=0.5 mA

C

=0

F

=0

F

=0

F

=0

F

=0

F

Leakage Path........................................ 7 mm min.

Air Path...................................................7 mm min.

Isolation Resitance

V

=500 V/25 ° C...................................... ≥ 10

IO

V

=500 V/100 ° C.................................... ≥ 10

IO

12

11

Storage Temperature ...................–55 ° C to +150 ° C

Operating Temperature ...............–55 °

Lead Soldering Time at 260 °

C....................10 sec.

C to +100 ° C

Current Transfer Ratio 500 % I

Ω

V

Ω

CEsat

Coupling Capacitance 1.5 pF

Turn On Time 5

Turn Off Time 100 µ sI

*Indicates JEDEC registered values

5–1

1.0 V I

µ sV

=10 mA,

F

V

=10 V

CE

=2 mA,

C

I

=8 mA

F

=10 V,

CC

I

=50 mA

C

=200mA,

F

R

=180 Ω

L

Figure 1. Forward voltage versus forward current

C

C

C

0

V

V

5

C

V

V

V

O

1.4

1.3

Ta = -55°

1.2

1.1

Ta = 25°

1.0

0.9

Ta = 100°

0.8

VF - Forward Voltage - V

0.7

100101.1

IF - Forward Current - mA

Figure 5. Non-saturated and saturated HFE versus

base current

1000

8000

6000

4000

2000

HFE - Forward Transfer Gain

Ta = 25°

0

.01 .1 1 10 100

Ib - Base Current - µA

Vce = 5

Vce = 1

Figure 2. Normalized non-saturated and saturated

CTRce versus LED current

1.2

Normalized to:

Vce = 5 V

1.0

IF = 10 mA

0.8

Ta = 25 °C

0.6

0.4

0.2

0.0

NCTRce - Normalized CTRce

.1 1 10 100 1000

IF - LED Current - mA

Vce = 5 V

Vce =1V

Figure 3. Normalized non-saturated and saturated collector-emitter current versus LED current

10

Normalized to:

Ta = 25°C

IF = 10 mA

1

Vce = 5 V

.1

.01

NIce - Normalized Ice

.001

IF - LED Current - mA

Vce = 5 V

Vce = 1V

101.1

100

Figure 4. Normalized collector-base photocurrent

versus LED current

Figure 6. Low to high propagation delay versus

collector load resistance and LED current

80

Ta = 25°C, Vcc = 5

Vth = 1.5 V

60

40

Delay - µs

20

0

tpLH - Low/High Propagation

0 5 10 15 20

IF - LED Current - mA

1KΩ

220Ω

470Ω

100Ω

Figure 7. High to low propagation delay versus

collector load resistance and LED current

20

15

10

delay - µs

5

0

tpHL - High/Low Propagation

0 5 10 15 20

1KΩ

100Ω

IF - LED Current - mA

Ta = 25°C

Vcc = 5 V

Vth = 1.5

Figure 8. Switching waveform and switching schematic

10

Normalized to:

Ta = 25°C

Vcb = 3.5 V

1

IF = 10 mA

.1

.01

NIcb - Normalized Icb

.001

.1 1 10 100

I

F

V

CC

R

L

t

D

t

O

R

t

PLH

I

F

V

VTH=1.5 V

t

PHL

t

t

S

F

IF - LED Current - mA

5–2

4N32/33

Loading...

Loading...