Siegenia KFV GENIUS 2.1 PANIC Assembly Instructions Manual

KFV

GENIUS 2.1 PANIC

Electro-mechanical systems

ASSEMBLY INSTRUCTIONS

Contents

2

03.2017

KFV

GENIUS 2.1 PANIC

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Target group of this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Multi-point lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Installation conditions and requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.8 Maintenance and service notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.9 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.10 Visual indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.10.1 Instructions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.11 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.12 Other types of indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.13 Screw recommendation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

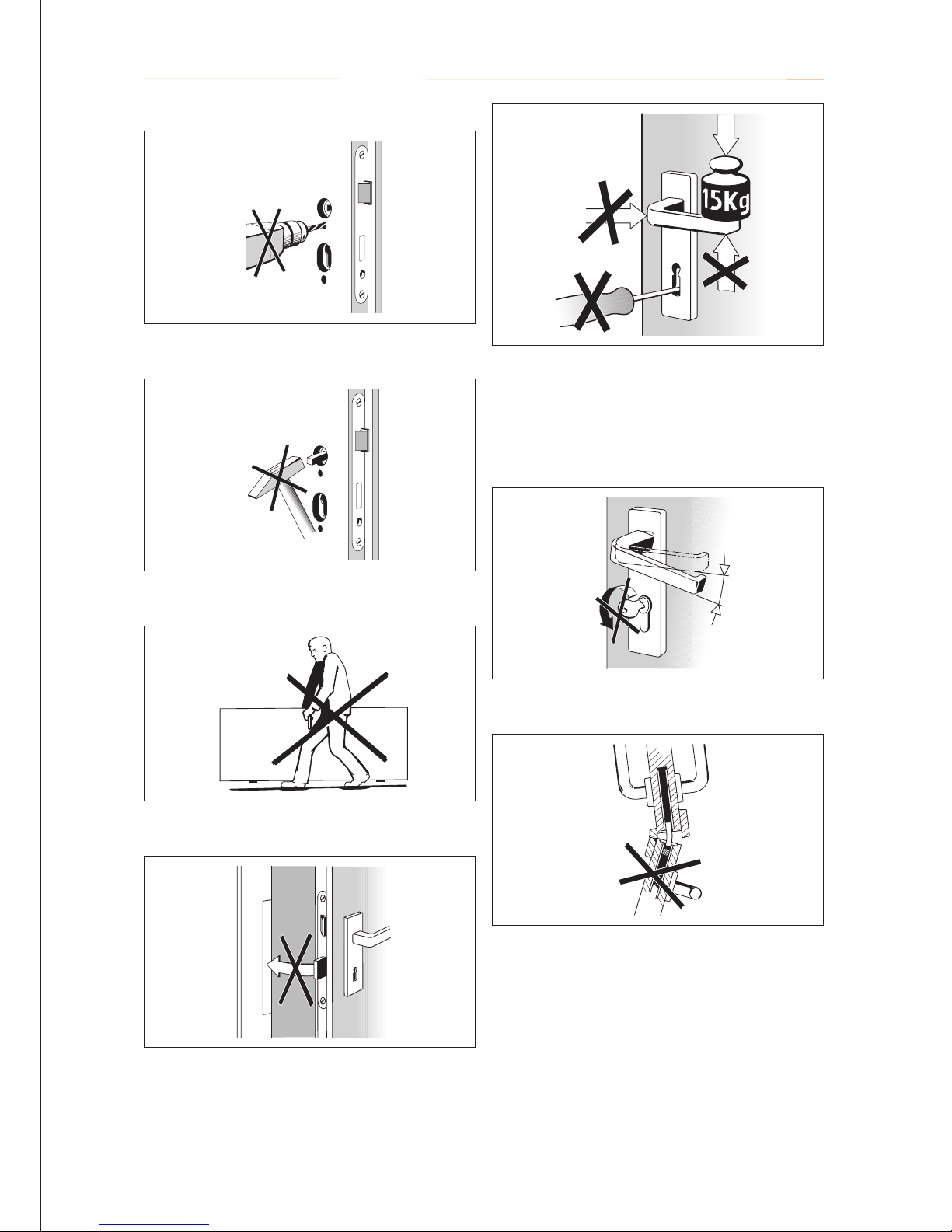

1.14 Causes of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Personal protective equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Heavy components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Sharp edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Swarf flying around rapidly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Electric voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Assembly of sash side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

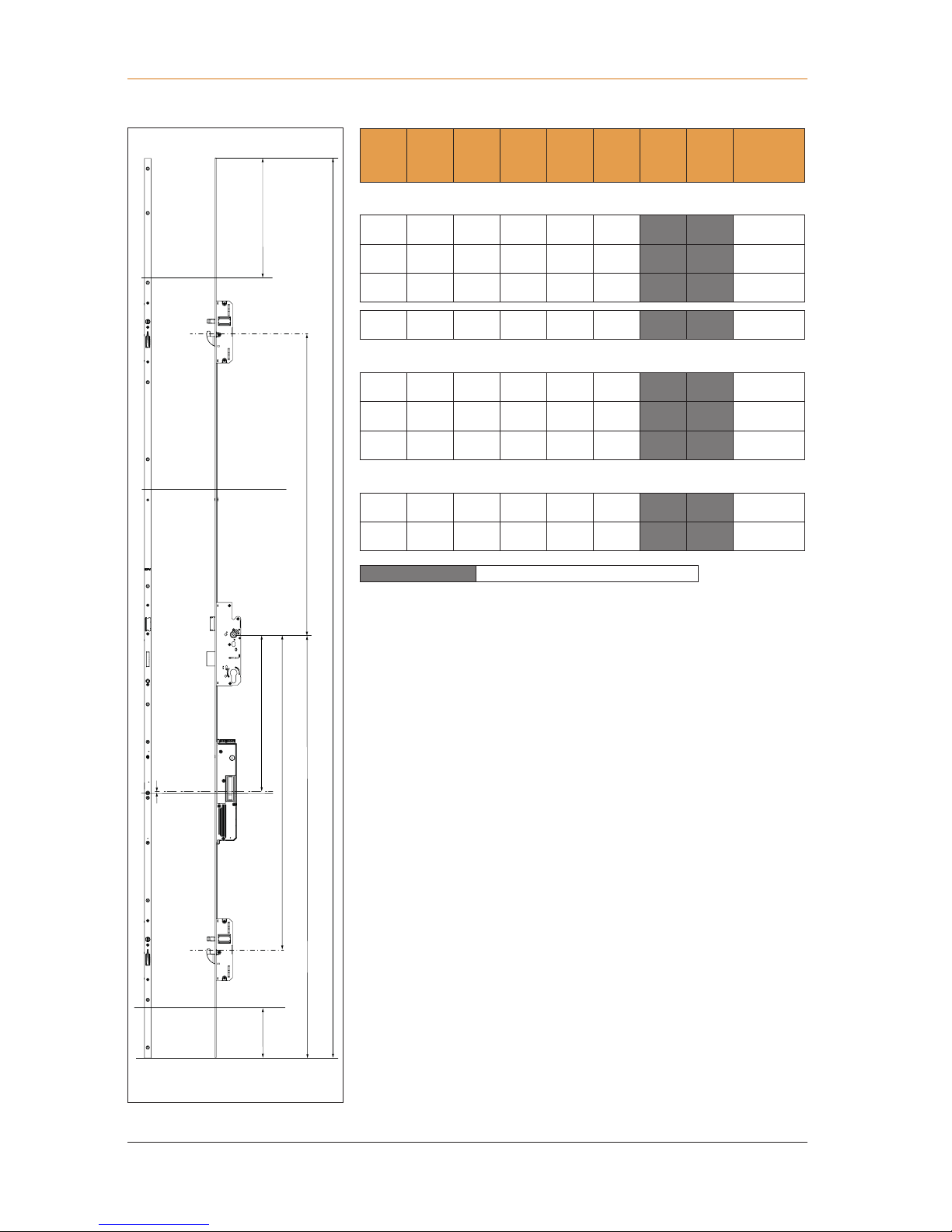

3.1 Delivery options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

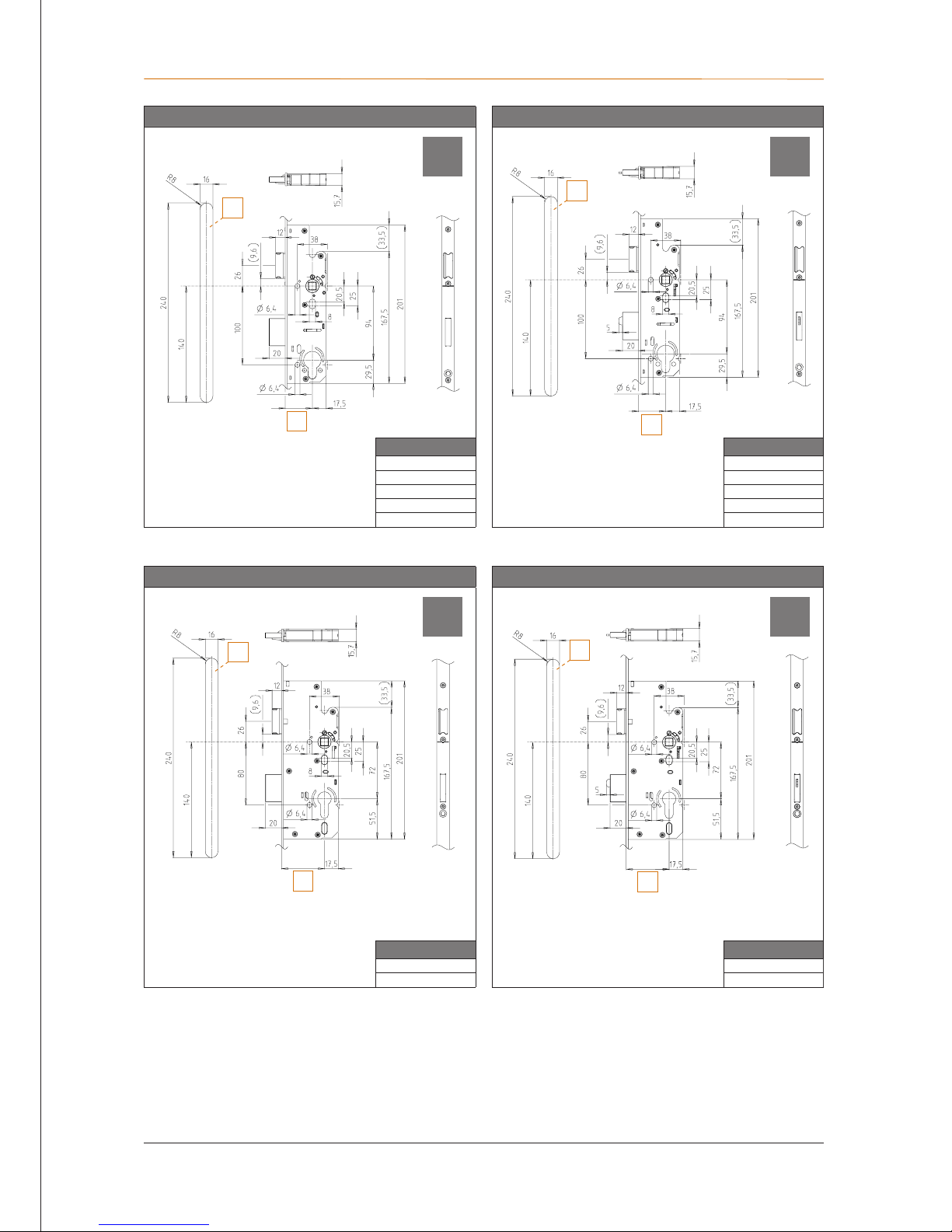

3.2 Component dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Cutting the door leaf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Main locks and auxiliary boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Change DIN orientation of the latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 GENIUS 2.1 PANIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.7 Wiring diagram GENIUS 2.1 PANIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.8 Wiring allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.9 Establish plug connections GENIUS 2.1 PANIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.10 Screwing on the multi-point lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Frame side assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1 Milling the door frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Assembling the frame parts and magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 The different magnet types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2 Mounting the striker plates in aluminium and PVC frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contents

303.2017

KFV

GENIUS 2.1 PANIC

4.2.3 Mounting the striker plates in timber frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.4 Mounting the locking rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Adjustment of airgap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Adjustment of frame parts and AT piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.5 Correct the Q adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.6 Adjustment of AT-piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5. Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 Functional test when the door is open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.1 Testing the panic function (cylinder operated lock E / switching function B) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.2 Testing the profile cylinder (cylinder operated lock E / switching function B) . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Electromechanical test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.3 Testing the panic function (cylinder operated lock E / switching function B) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.4 Testing the function of the profile cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.5 Testing the function of the optional access control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.6 Functional disorder of the lever handle/ push bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.7 Functional disorder of the profile cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.8 Functional disorder of the magnetic field sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3.9 Functional disorder due to block movement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4 Manual adjustment of the magnetic sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6. Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2.2 Product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2.3 Disclaimer of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Introduction

Assembly instructions GENIUS 2.1 PANIC

4

03.2017

KFV

1. Introduction

Please read these assembly instructions carefully before you

begin the assembly work. Follow the instructions in Chapter2

"Safety", in order to prevent personal injury or disturbance.

The Quick Reference GENIUS 2.1 PANIC,

enclosed in the product, must be handed over to

the end user.

Keep a copy of the cover side with the attached

sticker in a safe place.

If any additional documents are provided to the end

user, the contents of the provided KFV documentation

must be taken into consideration.

1.1 Validity

These instructions describe the operation of the GENIUS 2.1

PANIC multi-point lock and are valid unless revoked.

1.2 Target group of this documentation

This documentation is intended for use by specialists only.

All work described in this document is to only be performed

by experienced professionals with training and practice

in the installation, commissioning and maintenance of the

GENIUS 2.1 PANIC multi-point lock and its individual

components. Safe and proper assembly of this electronic

door lock is not possible without expert knowledge.

All work on a 230 V AC mains power supply may only be

performed by a qualified electrician.

1.3 Correct use

The GENIUS 2.1 PANIC multi-point lock is a special lock for

locking and unlocking doors automatically.

The GENIUS 2.1 PANIC multi-point lock can be used as a

panic lock in accordance with EN 1125 (version EP or PE) or

also as an emergency exit lock in accordance with EN 179

(version EP or EE).

• The GENIUS PANIC multi-point lock is a unit consisting of

a multi-point lock with the GENIUS 2.1 drive, the actuating

hardware in accordance with EN 1125 (horizontal

actuating bar) or EN 179 (lever handle) and the frame

parts (striker plates, locking rails, bottom bushing, etc.)

Only mutually tested and certified components may be

installed. Any change of this combination (even a partial

change) is inadmissible.

• Use the GENIUS 2.1 PANIC multi-point lock only when it

is in a technically sound condition. Do not modify the unit's

components in any way.

• Use the GENIUS 2.1 PANIC multi-point lock only with

genuine KFV accessories.

• When used in fire escape doors or smoke protection

doors, the locks must be used in combination with an

uninterruptible power supply (UPS)!

• The GENIUS 2.1 PANIC multi-point lock is suitable for

installation in timber, aluminium, steel and PVC entry

doors for residential buildings.

• The GENIUS 2.1 PANIC multi-point lock may only be

used:

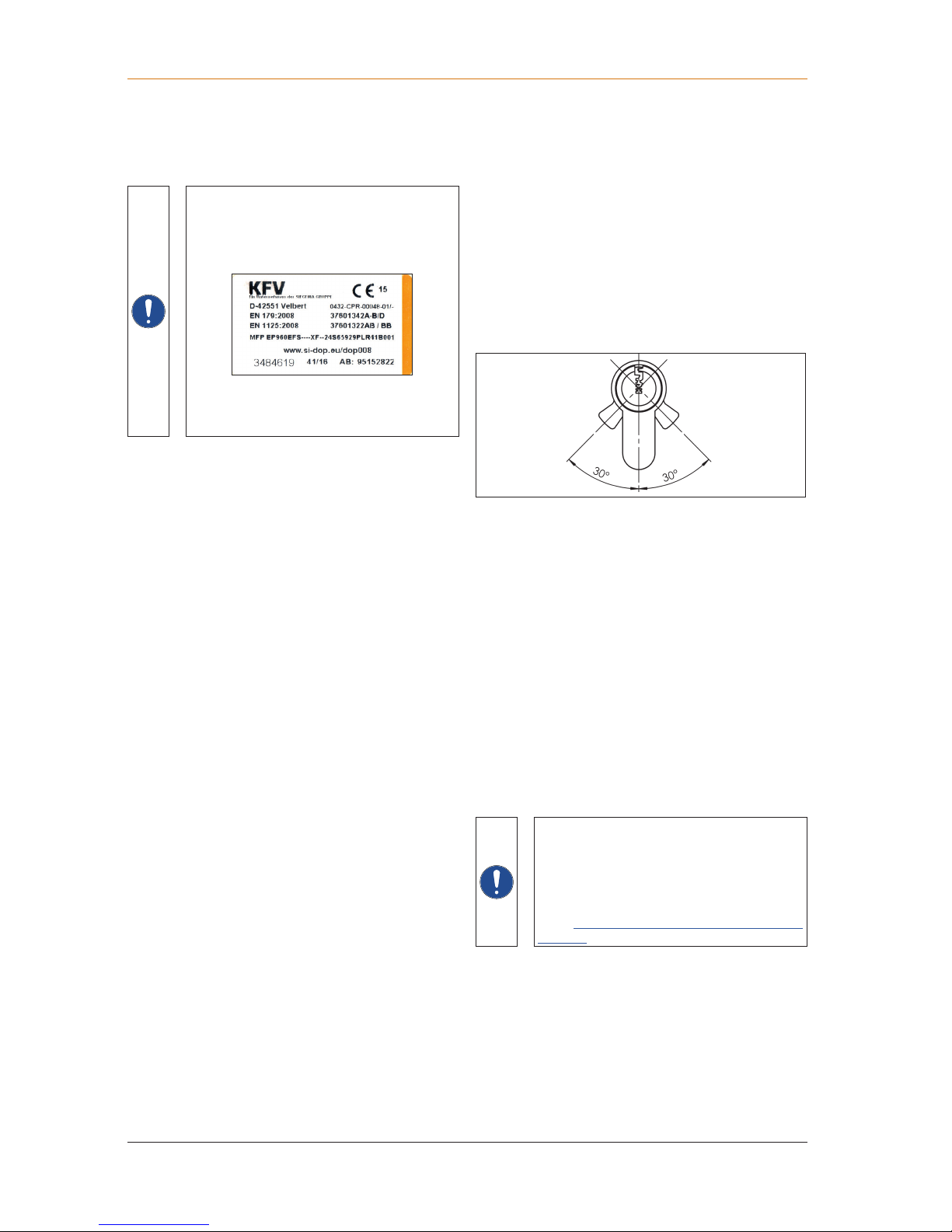

• with cylinder locks with free-running catches in which the

catch can always be freely turned

• with cylinder locks with rigid catch in which the catch

is locked in a key withdrawal position inside the

range of -30° to +30°.

• All assembly and electrical installation work must be

carried out according to our assembly and installation

instructions by a qualified electrician. Wiring the unit

incorrectly can irreparably damage its electronic

components.

1.3.1 Multi-point lock

• Only KFV frame parts with Q adjustment may be used.

• Repair of the GENIUS 2.1 PANIC multi-point lock is not

permissible. If it is damaged, the GENIUS 2.1 PANIC

multi-point lock must be replaced. The GENIUS 2.1

PANIC multi-point lock must be replaced once it reaches

the service life indicated below.

• Primary sash ("active sash") – 1- and 2-sash doors:

200,000 activations of the operating handle

• GENIUS 2.1 drive

100,000 locking and unlocking actions (motorised)

If energy-carrying cables are routed in parallel

to data cables (ISDN, DSL, etc.), this could lead

to interference e.g. in the speed of the data

transmission.

We recommend that you use the shielded KFV

cable.

See: Product catalogue KFV GENIUS and

A-opener

1.4 Improper use

• The multi-point lock is not designed to accommodate

changes to its shape or seal which arise as a result of

differences in temperature or changes to the building.

Assembly instructions GENIUS 2.1 PANIC

Introduction

503.2017

KFV

• Always use the transport locks matching the respective

airgap (for example distance blocks) to keep the sash in

position during transport.

• If possible, always transport the door element in the

intended installation position so that the resulting reactive

forces will be ablated in accordance with the constructive

design for the intended installation position.

1.7 Installation conditions and requirements

• Local building laws and regulations must be observed

before and during door installation in addition to the

following requirements and conditions:

• Observe the milling dimensions

• Position the frame parts according to the specifications,

observing the horizontal and vertical adjustment

accurately.

• Before installing the multi-point lock, check the dimensional

accuracy of the door and the door frame. The multi-point

lock must not be installed if the door and/or the frame is

warped and/or damaged.

• Install the multi-point lock and accessories according to

our assembly instructions. Use the clamp included in the

delivery for assembly.

• Remove any splinters from the lock mortise after milling.

• Once the lock is installed, do not perform mechanical

work on the door (such as drilling or milling). Do not drill

into or through the main lock under any circumstances.

• Observe the specified positions and sizes when drilling

the holes.

• Follow the hardware manufacturer's instructions when

drilling the holes for the lever handle/hardware.

• Install hardware components and cylinder flush without

overtightening the screws or screwing them in at an angle.

• Fasten handle set by hand only and do not use force

when installing the spindle.

• Adhere to the gap between the secondary sash and the

frame parts:

• in accordance with DIN 18251-3 = 3.5 ±1.5 mm

• Operating elements should not impede each other.

• Check that any existing block setting is packed correctly.

• Surface treatment of the door and door frame must take

place before the multi-point lock is installed. Treating

these surfaces at a later stage can reduce the functional

capacity of the multi-point lock.

• Use only acid-free neutral-cure sealants to prevent

corrosion of components and/or the door.

• Cylinder locks with rigid catch in which the catch is locked

in a key withdrawal position outside the range of -30°

to +30° may not be used. This includes cylinder locks in

which the catch position can be adjusted manually so that

a catch position outside of the range from -30° to +30°

is possible to reach.

• The GENIUS 2.1 PANIC multi-point lock must not be used

in doors for wet rooms or rooms in which the air contains

aggressive or corrosive components.

• Foreign objects and/or materials which impede or

prevent proper use must not be placed within the opening

range, the multi-point lock or the striker plates.

• The GENIUS 2.1 PANIC multi-point lock must not be

interfered with and/or modified.

• Locking elements must not be misused to hold the door

open.

• Movable or adjustable locking pieces (e.g. deadbolt,

latch) must not be painted over.

1.5 Installation location

• The multi-point lock is suitable for installation in singlesash and double-sash doors in permanent buildings.

• The multi-point lock may only be installed in doors that

have been fitted in a technically sound manner.

• The door design must permit use of the multi-point lock.

• All work on the 230 V AC mains power supply must be

carried out in compliance with the current German VDE

regulations (e.g. VDE 0100) and any relevant countryspecific requirements.

• All-pole safety isolation should be used when fitting the

network connection cable on-site.

• The use of any additional devices to keep the door closed

(with the exception of a door closer, motorised door drive,

block lock and escape door monitor) is not permitted.

If an additional system is installed, it must not impede

operation of the door by children, the elderly or infirm.

• Only KFV frame parts with Q adjustment may be used.

• Opening/closing/locking: It must be possible to open and

close the door easily. A protruding latch and /or deadbolt

must not impede the opening of the door.

1.6 Transport

• Always transport the multi-point lock in a vertical position,

whether uninstalled or installed in the door leaf.

• It is essential to handle the multi-point lock with care and

not to expose it to hard impacts.

• Do not carry the door by the lever handle or hardware

when transporting it.

• Considerable reactive forces could be generated as

a result of wobbling movement during transport which

could cause damage or incorrect loading of the installed

components.

Introduction

Assembly instructions GENIUS 2.1 PANIC

6

03.2017

KFV

1.8 Maintenance and service notes

• Monthly testing and maintenance must be carried out in

accordance with DIN EN 179 (Appendix maintenance

instructions) or DIN EN 1125 (Appendix maintenance

instructions). You will find more information on this in

chapter "Maintenance" of the Operating instructions

"Electro-mechanical systems"

• Never use cleaning agents that are aggressive or

contain solvents, as these may damage the surface of the

components.

• Both the contractor and the user must be trained in the

operation and maintenance of the multi-point lock.

1.9 Dimensions

All measurements are given in mm.

1.10 Visual indicators

1.10.1 Instructions and symbols

This symbol designates hazards that could

damage the product or something in the

surrounding area.

This symbol indicates special features and

designates facts that require increased

attention.

1.11 Explanation of symbols

Milling cutter or drill diameter

Groove length

Groove depth from component

Groove depth from profile

Through hole

for metal profiles

for timber profiles

for PVC profiles

1.12 Other types of indicators

Below is a list of symbols used in these assembly instructions

and their meanings:

• Items of text following this marker are found in lists.

► Items of text with this marking in front of them are

instructions that must be followed in the specified order.

" " Items of text in quotation marks are cross-references to other

chapters or sections.

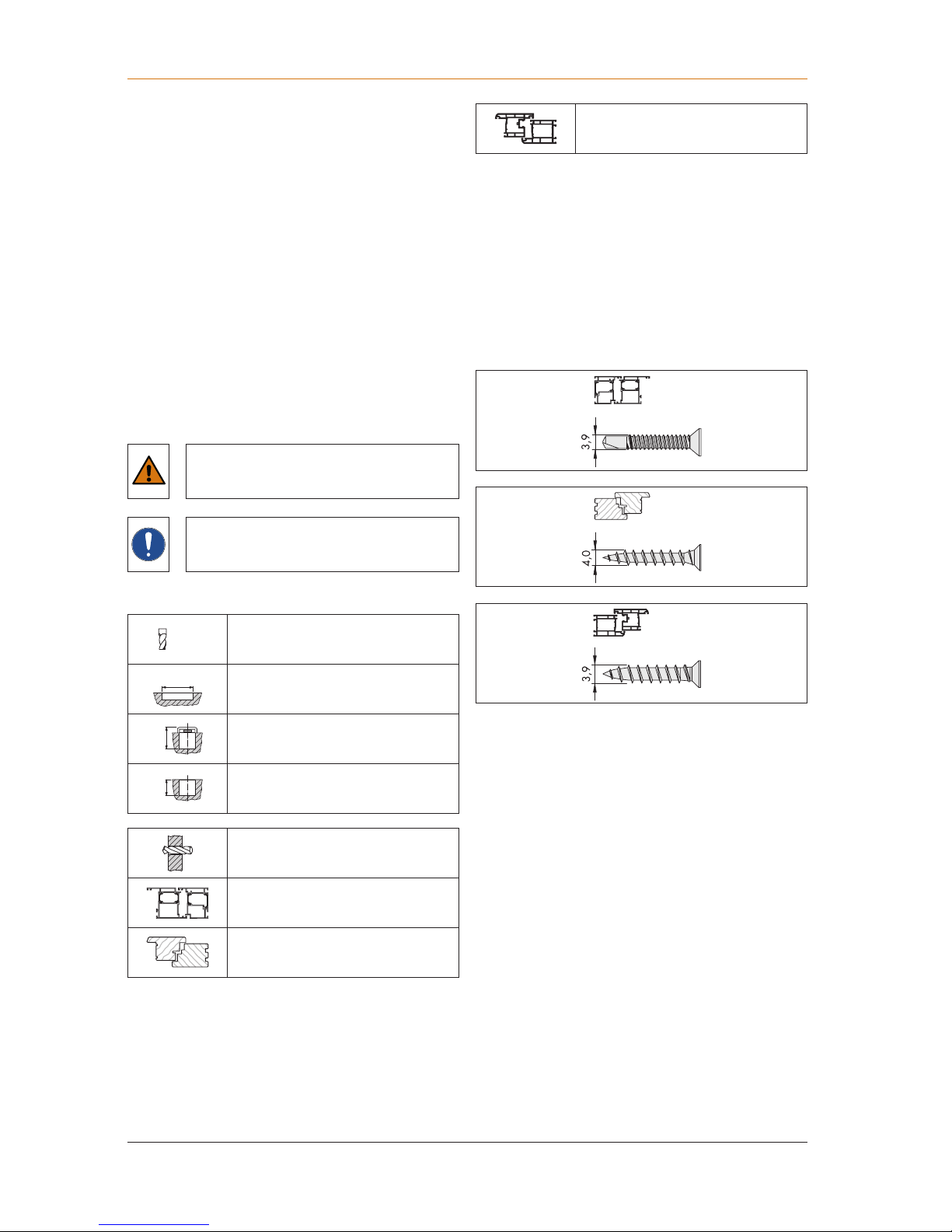

1.13 Screw recommendation

Assembly instructions GENIUS 2.1 PANIC

Introduction

703.2017

KFV

Force must be exerted on the lever handle only in the normal

direction of rotation.

A maximum force of 150 N may be applied to the lever

handle in the direction of actuation.

The lock or multi-point lock must be locked only with the

associated key (and not with foreign objects).

The lever handle and key must not be operated at the same

time.

Double-leaf doors must not be forced open using the

inactive sash.

1.14 Causes of damage

Do not drill through the door leaf in the area of the gear

box/boxes when the lock or the multi-point lock is installed.

The spindle must not be hit through the lock nut with force.

The door leaf must not be carried using the lever handle as

a grip.

None of the locking elements may be excluded when the

door is open.

Safety

Assembly instructions GENIUS 2.1 PANIC

8

03.2017

KFV

2. Safety

Before starting the assembly work, read the following safety

instructions carefully. They are designed to keep you safe

and prevent hazards, injuries and material losses.

2.1 Personal protective equipment

You will need the following protective equipment for the

assembly work:

• Safety shoes

• Protective gloves

• Protective goggles

2.2 Heavy components

Lifting off the door presents a risk of foot injuries.

• Always wear safety shoes.

2.3 Sharp edges

Cropping metal components creates sharp edges. This

presents a risk of cutting injuries.

• Wear suitable protective gloves.

• Deburr the sharp edges.

2.4 Swarf flying around rapidly

During milling work, there will be swarf flying around rapidly.

This presents a risk of eye injuries.

• Wear protective goggles.

2.5 Electric voltage

There is a risk of electric shock during all work on

230VAC mains power supply.

• All work on a 230 V AC mains power supply may only

be performed by a qualified electrician.

• Establish an all-pole safety isolation and secure against

unintentional reconnection before carrying out work on

the 230 V AC mains power supply.

Assembly instructions GENIUS 2.1 PANIC

Assembly of sash side

903.2017

KFV

3. Assembly of sash side

3.1 Delivery options

GENIUS 2.1 PANIC with AS 2600 GENIUS 2.1 PANIC is available in two versions:

Cylinder operated lock E

The door can be completely opened against the direction of

escape with the key or the GENIUS 2.1 PANIC. After using

the escape function, access against the direction of escape

is blocked again once the door closes and it is not possible

to escape back into the building.

Operation:

Emergency opening in the direction of escape: Open door

using the lever handle or horizontal actuating bar.

Locking in Night mode: the door is automatically locked.

Opening against the direction of escape: unlock and open

the door using the key. Turn the key to the unlocking stop.

Locking in Day mode: there is no automatic locking. Lock the

door with the key. Turn the key to the locking stop to lock the

multi-point lock completely.

Switching function B:

Opening the door against the direction of escape using the

lever handle is only possible after unlocking with the key or

by using the motor unlocking via GENIUS. After using the

escape function, access against the direction of escape is

blocked again once the door closes and it is not possible to

escape back into the building.

Operation:

• Emergency opening in the direction of escape: Open

door using the lever handle or horizontal actuating bar.

• Locking in Night mode: the door is automatically locked.

• Manual opening against the direction of escape: unlock

and open the door using the key. Turn the key to the

unlocking stop. Open door using the lever handle or

horizontal actuating bar.

• Timed opening against the direction of escape: GENIUS

via Terminal 0/1 or switch the button to Day mode. Open

door using the lever handle or horizontal actuating bar

• Locking in Day mode: there is no automatic locking. Lock

the door with the key. Turn the key to the locking stop to

lock the multi-point lock completely.

Assembly of sash side

Assembly instructions GENIUS 2.1 PANIC

10

03.2017

KFV

3.2 Component dimensions

I

K

C

B

F

G

A

F + 1 mm

Size

variants

A B C F G I K

suitable for

sash rebate

height

PZ dimension 92

B001 2170 760 730 380

1020 290 130

1881 2170

B002 2170 760 730 380

1050 290 160

1881 2170

B004 2400 760 980 380

1050 270 130

2171 2400

B166 1855 760 730 380

952

1755 2170

PZ dimension 94

B001 2170 760 730 380

1020 290 130

1881 2170

B002 2170 760 730 380

1050 290 160

1881 2170

B004 2400 760 980 380

1050 270 130

2171 2400

PZ dimension 72

B002 2170 760 730 380

1050 290 160

1881 2170

B004 2400 760 980 380

1050 270 130

2171 2400

Dimensions I + K

= can be shortened

Assembly instructions GENIUS 2.1 PANIC

Assembly of sash side

1103.2017

KFV

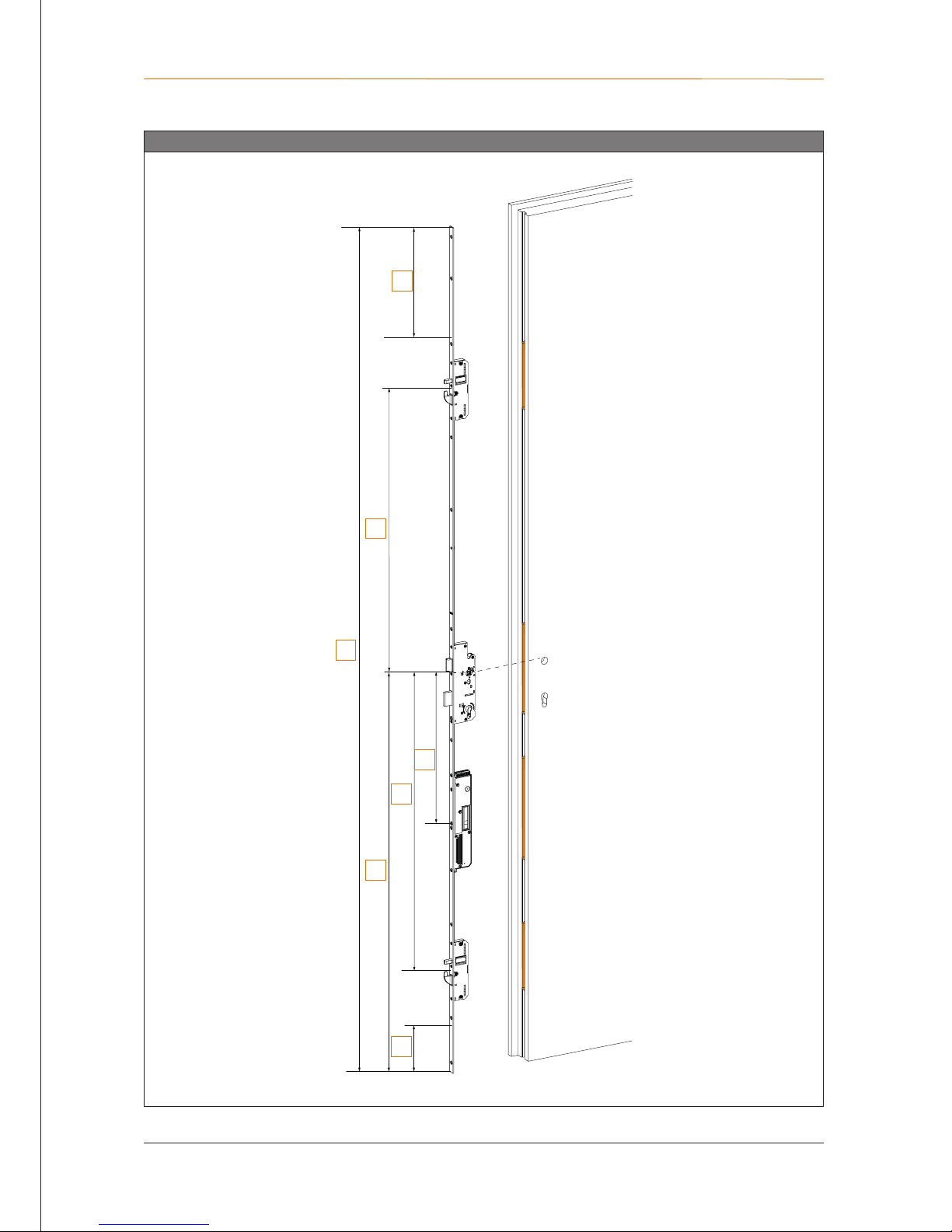

3.3 Cutting the door leaf

Routed pockets

I

K

C

B

G

A

F

A

G

K

B

F

C

I

Assembly of sash side

Assembly instructions GENIUS 2.1 PANIC

12

03.2017

KFV

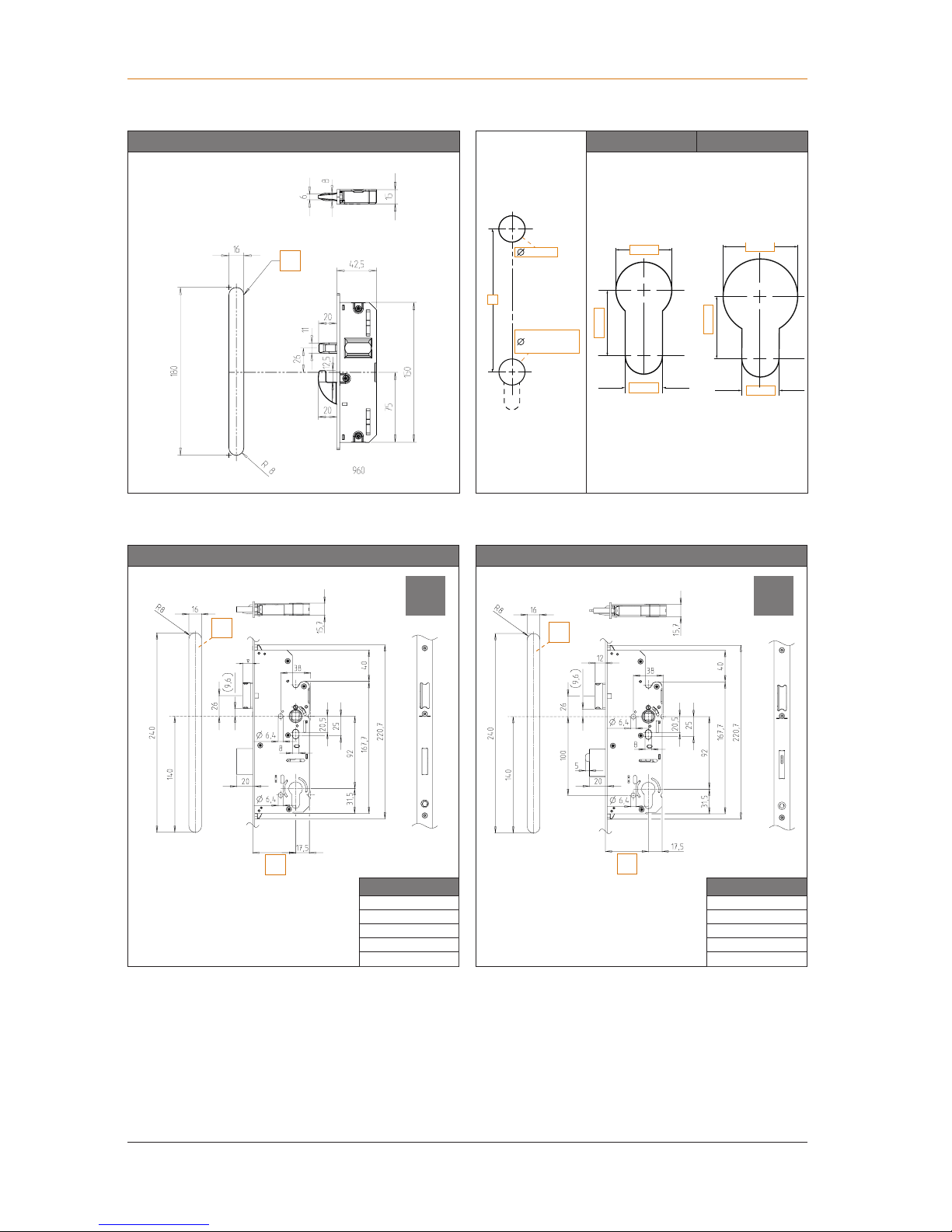

3.4 Main locks and auxiliary boxes

Auxiliary box PZ RZ

12 mm

21 mm

18 mm

12 mm

20 mm

24 mm

[A]

milling depth = route depth + 1 mm

Main lock type P, backset 30-55, PZ dimension 92 Main lock type Z, backset 45, PZ dimension 92

Backset [D]

35

40

45

55

65

Backset [D]

35

40

45

55

65

[A]

milling depth = route depth (backset + 17.5 mm) + 1 mm

[A]

milling depth = route depth (backset + 17.5 mm) + 1 mm

B

18 mm

PZ = 18 mm

RZ = 24 mm

P Z

A

A

D

A

D

Assembly instructions GENIUS 2.1 PANIC

Assembly of sash side

1303.2017

KFV

Main lock type P, backset 35-55, PZ dimension 94 Main lock type Z, backset 45, PZ dimension 94

Backset [D]

35

40

45

55

65

Backset [D]

35

40

45

55

65

[A]

milling depth = route depth + 1 mm

[A]

milling depth = route depth + 1 mm

Main lock type P, backset 55 and 65, PZ dimension 72 Main lock type Z, backset 55 and 65, PZ dimension 72

Backset [D]

55

65

Backset [D]

55

65

[A]

milling depth = route depth + 1 mm

[A]

milling depth = route depth + 1 mm

P Z

P Z

A

D

A

D

A

D

A

D

Assembly of sash side

Assembly instructions GENIUS 2.1 PANIC

14

03.2017

KFV

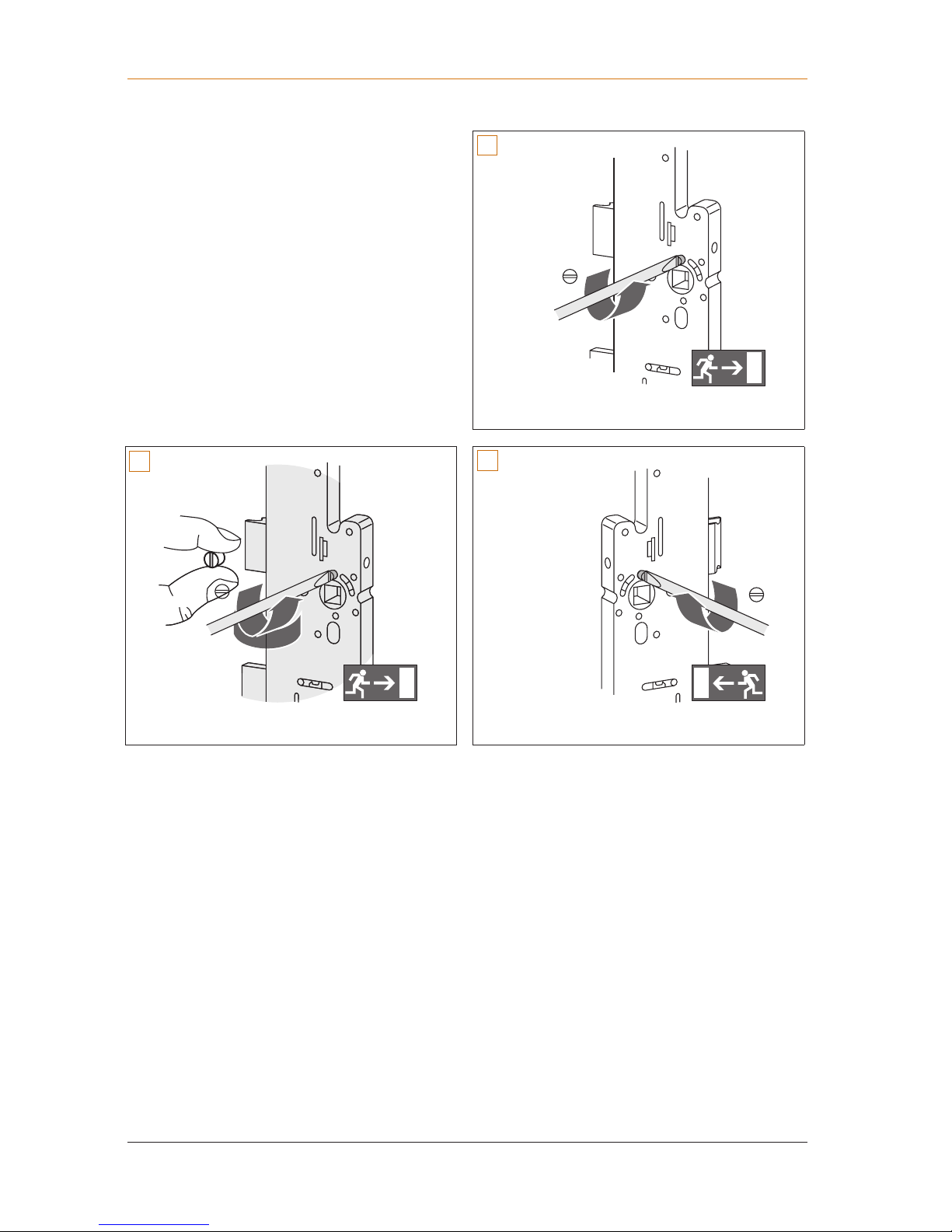

3.5 Change DIN orientation of the latches

The direction of escape can be changed by unscrewing

the grub screw above the nut and screwing it onto the

opposite side.

1

2

3

Loading...

Loading...