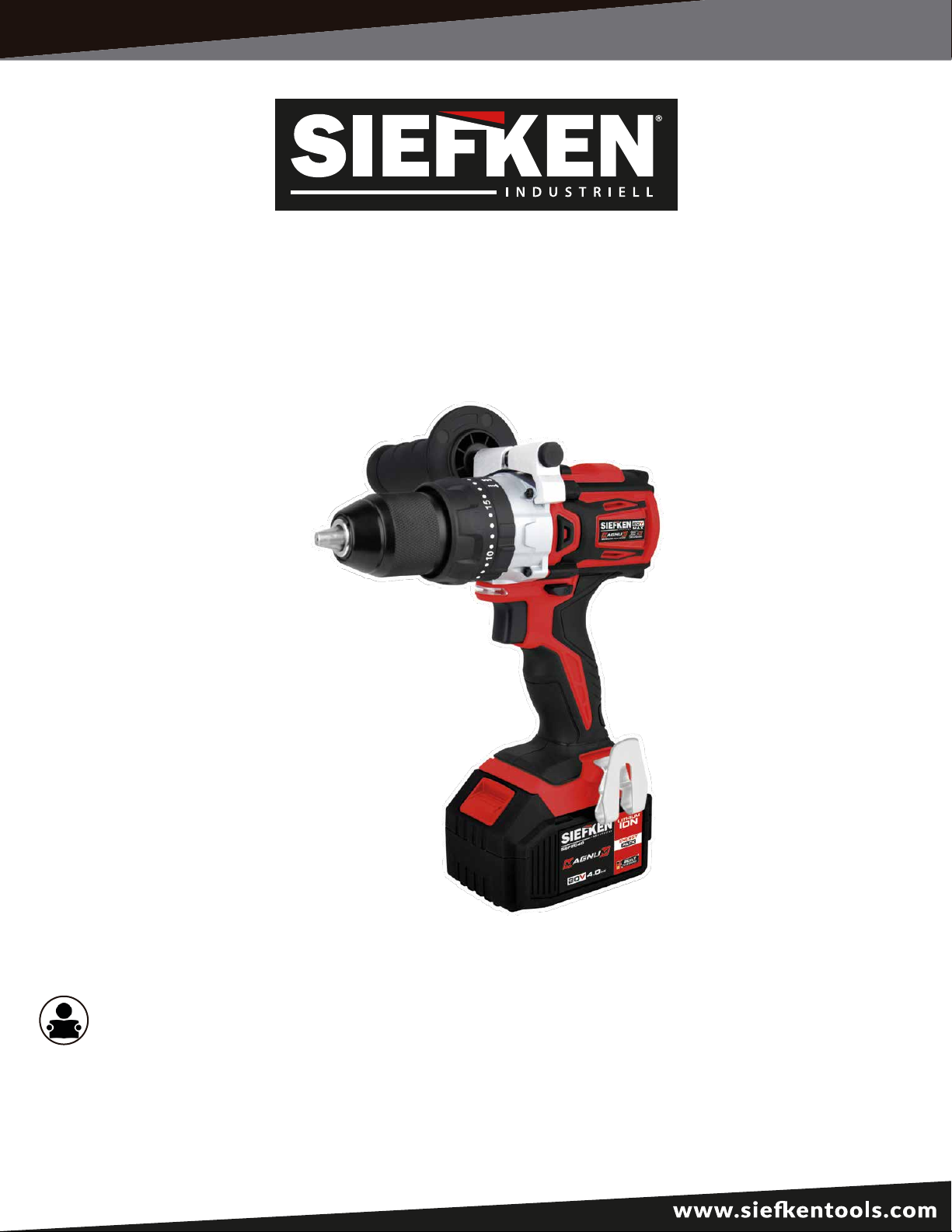

User´s manual

20V - Li - ion BATTERY

BRUSHLESS CORDLESS IMPACT DRILL

SBS001

Operating Instructions

Please read the operation instructions meticulously and pay particular attention to the safety instructions.

BRUSHLESS TECH series

CONTENT

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

Safety instructions

Specications

Features

Operation

Maintenance

Warranty

1

7

8

9

17

18

Care for the environment!

It must not be disposed of with household waste! This product contains electrical or electronic

components that must be recycled. Take the product for recycling at the sites assigned to your

area, Ejm: the local recycling station.

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

1.GENERAL SAFETY RULES

FOR ALL BATTERY OPERATED TOOLS

1.1 WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in electric shock, re and/or serious

personal injury.

1.2 Work Area

1.2.1 Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

1.2.2 Flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes. Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gases, or dust.

1.2.3 Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

1.3 Electrical Safety

1.3.1 Do not abuse the cord. Never use the cord to carry the tool. Keep cord away from heat,

oil, sharp edges, or moving parts. Replace damaged cords immediately. Damaged cords may

create a re.

Applies only to tools with a separable battery pack:

1.3.2 A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specied charger for the battery. A charger that may be suitable for one type

of battery may create a risk of re when used with another battery.

1.3.3 Use battery operated tool only with specically designated battery pack. Use of any other

batteries may create a risk of re.

1

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

1.4 Personal Safety

1.4.1 Stay alert, watch what you are doing, and use common sense when operating a power

tool. Do not use tool while tired or under the inuence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in serious personal injury.

1.4.2 Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

1.4.3 Avoid accidental starting. Be sure switch is in the locked or o position before inserting

battery pack. Carrying tools with your nger on the switch or insetting the battery pack into a

tool with the switch on invites accidents.

1.4.4 Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is

left attached to a rotating part of the tool may result in personal injury.

1.4.5 Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enable better control of the tool in unexpected situations.

1.4.6 Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

1.5 Tool Use and Care

1.5.1 Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

1.5.2 Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

1.5.3 Do not use tool if switch does not turn it on or o. A tool that cannot be controlled

with the switch is dangerous and must be repaired.

2

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

1.5.4 Disconnect battery pack from tool or place the switch in the locked or o position before

making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

1.5.5 Store idle tools out of reach of children and other untrained persons. Tools are dangerous

in the hands of untrained users.

1.5.6 When battery pack is not in use, keep it away from other metal objects like: paper clips,

coins, keys, nails, screws, or other small metal objects that can make a connection from one

terminal to another. Shorting the battery terminals together may cause sparks, burns, or a re.

1.5.7 Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools

with sharp cutting edge are less likely to bind and are easier to control.

1.5.8 Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may aect the tool's operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

1.5.9 Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool may create a risk of injury when used on another tool.

1.6 Service

1.6.1 Tool service must be performed only by qualied repair personnel. Service or maintenance performed by unqualied personnel may result in a risk of injury.

1.6.2 When servicing a tool, use only identical replacement parts.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety precautions should always be followed to

reduce the risk of tire, electric shock and personal injury, including the following. Read all these

instructions before attempting to operate this product and save these instructions.

3

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

For safe operations:

1. Keep work area clean

- Cluttered areas and benches invite injuries.

2. Consider work area environment

- Don't expose power tools to rain. Don't use power tools in damp or wet locations. Keep work

area well lit. Don't use power tools in presence of ammable liquids or gases.

3. Guard against electric shock

- Prevent body contact with grounded surfaces (e.g. pipes, radiators, ranges refrigerators).

4. Keep children away

- Do not let visitors contact tool or extension cord. All visitors should be kept away from work

area.

5. Store idle tools

- When not in use, tools should be stored in dry, high, or locked-up place, out of the reach of

children.

6. Don't force tool

- It will do the job better and safer at the rate for which it was intended.

7. Use right tool

- Don't force small tools or attachments to do the job of a heavy duty tool. Don't use tools for

purposes not intended; for example don't use circular saw for cutting tree limbs or logs.

8. Dress property

- Do not wear loose clothing or jewelry. They can be caught in moving parts. Rubber gloves

and non-skid food wear am recommended when working outdoors. Wear protective hair

covering to contain long hair.

9. Use safety glasses

- Also use face or dust mask if cutting operation is dusty.

4

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

10. Don't abuse cord

- Never carry tool by cord or yank it to disconnect it from receptacle. Keep cord from heat, oil

and sharp edges.

11. Secure work

- Use clamps or a vise to hold work it's safer than using your hand and it trees both hands to

operate tout.

12. Don't overreach

- Keep proper footing and balance at all times.

13. Maintain tools with care

- Keep tools clean for better and safer performance. Fellow instructions for lubricating and

changing accessories,inspect tool cords periodically and if damaged, have repaired by autho

rized service facility. Inspect extension cords periodically and replace if damaged. Keep hand

les dry, clean and free from oil and grease.

14. Disconnect tools

- When not in use, before servicing, and when changing accessories such as blades, bits and

cutters.

15. Remove adjusting keys and wrenches

- Form the habit of checking to sea that keys and adjusting wrenches are removed from tool

before turning it on.

16. Avoid unintentional starting

-Don't carry plugged-in tool with nger on switch. Be sure switch is o when plugging in.

17. Outdoor use extension cords

- When tool is used outdoors, use only extension cords intended for use outdoors and sat

marked.

18. Stay alert

- Watch what you are doing. Use common sense. Do not operate fool when you are tired.

5

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

19. Check damaged parts

- Before further use of the tool, a guard or other part that is damaged should be carefully checked to

determine that it will operate properly and per form its intended function. Check for alignment of

moving parts, binding of moving parts,breakage of parts, mounting, and any other conditions that may

aect its operation. A guard of other part that is damaged should be properly repaired or replaced by an

authorized service canter unless otherwise indicated elsewhere in this instruction manual. Have defective switches replaced by an authorized service center. Do not use tool if switch does not turn it on and O.

20. Warning

- The use of any other accessory or attachment other than recommended in this operating instruction or

the original catalogue may present a risk of personal injury.

21. Have your toot repaired by an expert

- This electric appliance is in accordance with the relevant salty rules. Repairing of electric appliances may

be carried out only by experts otherwise it may cause considerable danger for the user.

Important charging notes

1. Do not store in locations where the temperature may exceed 40ºC.

2. Charge only at ambient temperatures between 4ºC and 40ºC .

3. Charge only using the charger provided with the tool as other chargers might use dierent

amperages and can damage or destroy your battery and /or screwdriver

4. Unplug charger before attempting to clean.

5. Do not immerse charger in water or any other liquid.

6. Charging time around 1-2hours

Caution: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack

breaks or cracks, return it to a service center for recycling.

Warning! Do not allow liquid to enter charger. Electric shock could result. To cool the battery pack after

use, avoid placing the charger in a warm environment such as in a metal shed or a non-insulated trailer.

6

Specications

No load speed

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

20VVoltaje

Brushless Tech motorMotor

2 MechanicsGears

O-500RPMSpeed 1

0-1800RPMSpeed 2

0-8.000/0-28.800BPMImpact force

Torque settings

Max. capacity

Sound pressure level

Sound power level

50 NmMax. torque

20 +

13mmSteel

13mmConcrete

30mmWood

/2" Metal without key with lock Chuck capacity

1.3 KgWeight

LPA=71.03dB (A), K=3dB (A)No load

LPA=74.6dB (A), K=3dB (A)Perforation in concrete

LWA=82.03dB (A), K=3dB (A)No load

LWA=85.6dB (A), K=3dB (A)Perforation in concrete

Vibration

Perforation In metal

Drill Screw Without hammer

AH, D=1.892m/s² <2.5m/ s², K=1.5m/ s²

AH, D=O.887m/ s² <2.5m/ s², K=1.5m/ s²

AH, ID=10.12m/s², K=1.5m/ s²Perforation in concrete

7

Features

1. Side handle

2. Metal chuck

3. Torque settings

4. Handle

5. Battery input

6. Belt Holder

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

1

2

3

6

4

5

ADJUSTABLE TORQUE

The drill has a 20+3 position clutch.

TWO-SPEED GEAR BOX

The two-speed gear box is designed for drilling or driving at LOW or HIGH speeds. A slide

switch is located on top of your drill for selecting the appropriate speed.

VARIABLE SPEED

The variable-speed trigger switch delivers higher speed with increased pressure and lower

speed with decreased trigger pressure.

KEYLESS CHUCK

The keyless chuck allows you to hand-tighten or release the drill bit in the chuck jaws.

FORWARD/REVERSE/CENTER LOCK

The direction-of-rotation selector located above the trigger switch changes the direction of bit

rotation. Setting the trigger switch in the OFF (center lock) position helps to reduce the

possibility of accidental starting when not in use.

LED WORK LIGHT

Pressing the trigger switch illuminates the LED worklight, located on the front of the Drill Driver.

This feature provides extra light for increased visibility.

8

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

OPERATION

CHARGING THE BATTERY

WARNING: The charger and battery pack are specically designed to work together so do not attempt to

use any other devices. Never insert or allow metallic objects into your charger or battery pack connections because an electrical failure and hazard will occur.

Your battery pack is UNCHARGED and you must charge once before use. The charger is designed to use

standard household 230volt 50Hz power.

1. Plug the charger adapter into a suitable power supply. The red light will on;

2. A discharged battery at normal ambient temperature will take approximately 1-2 hour to reach full

charge. When charging is complete, the red light will o and only the green light will be illuminated.

BATTERY AND CHARGER SAFETY FEATURES

OVER CHARGING PROTECTION

The over charging protection will ensure that the battery is never overcharged. When the battery has

reached its fully charge capacity, the charger will automatic shut o, protecting the internal components

of the battery from being damaged.

OVER DISCHARGE PROTECTION

An internal component of the battery pack is an over discharge protector. This feature will stop the

battery from discharging beyond the recommended lowest safety voltage.

OVER HEAT PROTECTION

The battery has an internal thermister cut o censor which will cease the charging cycle if the battery

becomes hot during the charging process. This thermister censor will also stop the battery from operating should the battery become too hot during the operation of the tool. This can happen when the tool

is overloaded or being used for extended periods of time. Up to 30 minutes in cooling time may be

required depending on ambient temperature and operation being performed.

9

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

OVER CURRENT PROTECTION

Should the battery be overloaded and the maximum current draw be exceeded, the battery will

temporarily stop working to protect the internal components. The battery will resume to normal

operation once the excessive current draw has returned to normal safe level. This may take a few

seconds.

SHORT CIRCUIT PROTECTION

If the battery pack was to short circuit the short circuit protector would immediately stop the battery

pack from operating. This will ensure that no further internal components of the battery or the tool

is damaged.

INSTALLING AND REMOVING THE BATTERY PACK FROM THE TOOL

TO REMOVE BATTERY PACK:

Press the pushlock button (5) and pull the battery pack (4) out of the equipment as shown in Fig.

10

TRIGGER SWITCH & REVERSING BUTTON

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

The drill is turned ON and OFF by pulling and releasing the trigger switch

(1). The farther the trigger is depressed, the higher the speed of the drill. A forward/reverse control

button determines the direction of the tool and also serves as a lock o button.

To select forward rotation, release the trigger switch and depress the forward/reverse control button to

the left. To select reverse, depress the forward/reverse control button the opposite direction.

NOTE: The center position of the control button locks the tool in the o position. When changing the

position of the control button, be sure the trigger is released.

ELECTRIC BRAKE

To stop the Drill Driver, release the trigger switch and allow the tool to come to a complete stop. The electric brake quickly stops rotating. This feature engages automatically when you release the trigger switch.

11

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

Perforación en metal; Utilice un broca de acero al perforar en metal

NOTA: Asegúrese de que la broca esta siempre fría, use un líquido no inamable.

1. Sujete la pieza de trabajo. La pieza de trabajo debe quedar plana sobre el banco de trabajo.

2. Marque la posición de los agujeros con un punzón.

3. No fuerce la herramienta - no presione con demasiada fuerza el taladro. Comience a perforar a baja velocidad para que el taladro no se deslice lejos de la marca de perforación. Continuar perforando a velocidad

normal.

NOTA: El taladro puede atascarse en agujeros profundos. En tal caso, el taladro o la herramienta pueden

dañarse si el torque es demasiado alto. Suelte de forma inmediata el interruptor de alimentación si el

taladro se atasca. Cambie la rotación al sentido contrario a las agujas del reloj y opere el taladro a baja velocidad.

Perforación en plástico; Utilice una broca de acero para taladrar en plástico y siga las instrucciones para

perforar en madera.

MODO ATORNILLADOR

NOTA:

Compruebe que la punta está correctamente insertada antes de empezar a trabajar.

No apriete demasiado los tornillos – hay riesgo de dañar la cabeza del tornillo o la rosca.

Apriete de Tornillos

1. Ajuste el selector de rotación en sentido horario.

2. Coloque la punta de forma vertical sobre la cabeza del tornillo. De lo contrario, el tornillo puede dañarse.

3. Presione la broca rmemente contra el tornillo y apriete el tornillo.

4. Cuando el tornillo haya entrado, suelte el interruptor de encendido antes de dejar de presionar el tornillo, de lo contrario puede dañar el tornillo o la cabeza del tornillo. La punta o herramienta puede dañarse si

no suelta el interruptor de alimentación inmediatamente.

12

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

TWO - SPEED GEAR BOX SWITCH

The drill has a two-speed gear box switch designed for drilling or driving at LOW or HIGH speeds. A slide

switch is located on the top of the drill to select either LOW or HIGH speed. When using drill in the LOW

speed range, the speed will decrease and the drill will have more power and torque.

When using drill in the HIGH speed range, the speed will increase and the drill will have less power and

torque. Use LOW speed for high power and torque applications and HIGH speed for fast drilling or driving

applications.

Use LOW speed for starting holes without a center punch, drilling metals or plastic, drilling ceramics, or in

applications requiring a higher torque. HIGH speed is better for drilling wood and wood composites and

for using abrasive and polishing accessories.

NOTE: Avoid running the drill at LOW speed for extended periods of time. Running at LOW speed under

constant usage may cause the drill to become overheated. If this occurs, cool the drill by running it without

a load at HIGH speed.

CAUTION: Never change gears while the tool is running. Failure to obey this caution could result in serious

damage to the drill.

LED WORKLIGHT

The LED worklight, located on the front of the Drill/Driver, will illuminate when the trigger switch is depressed. This provides additional light on the surface of the workpiece for operation in lower-light areas. The

LED worklight will turn o when the trigger switch is released.

TORQUE ADJUSTMENT RING

13

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

This tool is tted with a torque adjustment ring to select the operating mode and to set the torque for tightening screws. Large screws and hard workpiece materials require a higher torque setting than small

screws and soft workpiece materials.

For drilling in wood, metal and plastics, set the collar to the drilling position symbol. For screwdriving, set

the ring to the desired setting. If you do not yet know the appropriate setting, proceed as follows:

1. Set the collar to the lowest torque setting.

2. Tighten the rst screw.

3. If the clutch ratchets before the desired result is achieved, increase the ring setting and continue tighte

ning the screw.

4. Repeat until you reach the correct setting. Use this setting for the remaining screws.

Function adjustment

It has Screw/Drill/Impact

14

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

Select the function

Driving

Turn the selector until the arrow on the appliance points to

Turn the Torque adjustment ring from (1) to (20) until the desired result is obtained.

Drilling

Turn the selector until the arrow on the appliance points to

Drilling with Impact Function

Turn the selector until the arrow on the appliance points to

DRILLING

1. Use sharp drill bits only.

2. Check the direction of rotation selector for the correct setting (forward or reverse).

3. Support and secure work properly, as instructed in the Safety Instructions.

4. Use appropriate and required safety equipment, as instructed in the Safety Instructions.

5. Secure and maintain work area, as instructed in the Safety Instructions.

6. Run the drill very slowly, using light pressure, until the hole is started enough to keep the drill bit from

slipping out of it.

7. Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting but not so much

as to stall the motor or deect the bit.

8. Hold the drill rmly with two hands to control its twisting action.

9. DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF AND ON IN AN ATTEMPT TO START IT. DAMAGE

TO THE DRILL CAN RESULT.

10. Minimize stalling on breakthrough by reducing pressure and slowly drilling through the last part of the

hole.

11. Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

15

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

DRILLING IN WOOD

For maximum performance, use high speed steel or brad point bits for wood drilling.

1. Begin drilling at a very low speed to prevent the bit from slipping o the starting point.

2. Increase speed as the drill bit bites into the material.

3. When drilling “through” holes, place a block of wood behind the workpiece to prevent

ragged or splintered edges on the back side of the hole.

DRILLING IN METAL

For maximum performance, use high speed steel bits for metal or steel drilling.

1. When drilling metals, use light oil on the drill bit to keep it from overheating. The oil will prolong the life

of the bit and increase the drilling action.

2. Begin drilling at a very low speed to prevent the bit from slipping o the starting point.

3. Maintain a speed and pressure which allows cutting without overheating the bit. Applying too much

pressure will:

• Overheat the drill

• Wear the bearings

• Bend or burn bits

• Produce o-center or irregular-shaped holes

WARNING! Always wear safety goggles or safety glasses with side shields during power tool operation or

when blowing dust. If operation is dusty, also wear a dust mask.

WARNING! To ensure safety and reliability, all repairs should be performed by a qualied service technician

at Authorized Service Center.

MAINTENANCE

Your tool requires no additional lubrication or maintenance. There are no user serviceable parts in your

power tool. Never use water or chemical cleaners to clean your power tool. Wipe clean with a dry cloth.

Always store your power tool in a dry place. Keep the motor ventilation slots clean. Keep all working controls free of dust.

16

BRUSHLESS TECH series

BRUSHLESS CORDLESS IMPACT DRILL

Occasionally you may see sparks through the ventilation slots. This is normal and will not damage your

power tool.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various

types of commercial solvents. Use clean clothes to remove dirt, dust, oil, grease,

etc.

WARNING! To avoid serious personal injury, always remove the battery pack from the tool when cleaning

or performing any maintenance.

WARNING! When servicing, use only identical replacement parts. Use of any other parts may create a

hazard or cause product damage. To ensure safety and reliability, all repairs should be performed by a qualied service technician at an Authorized Service Center.

17

BRUSHLESS CORDLESS IMPACT DRILL

Built

to Exceed

BRUSHLESS TECH series

3

AÑOS

unbeatable

WARRANTY

Unübertrefflich Garantie

NO COST

SERVICE

Service ohne Kosten

TOTAL

SATISFACTION

Total Zufrieden

3 YEAR WARRANTY

Each tool SIEFKEN INDUSTRIELL has warranty to the original buyer from being free of defects in materials and labor.

Its subjected to certain exceptions, SIEFKEN will fix or replace any part of any power tool, after examinated, and if its determined by siefkenn like material

defective or labor by a period of (3) years*, after the date of the purchase, at least theres any other thing pointed out. The power tool must be returned to

the SIEFKEN service center location or the service center authorized by SIEFKEN, the shipment must be paid and secure. Must include a copy of the proof

of purchase with the returned product. This warranty does not apply to damages that SIEFKEN determines that are as a result of maintenance done by

someone who does not belonged to siefken service center or associates, also by incorrect use, alterations, abuse, natural usage nor accidents.

FREE SERVICE

Siefken includes in its tools 5 free preventive maintenance by year during the warranty time of the tool.

Also, any corrective service will have a 1 year warranty. (Does not apply for service done by any person that does not belong to the siefken staff, also like

damaged made by incorrect use, alterations, abuse, natural usage nor accidents)

TOTAL SATISFACTION

If the siefken tool do not satisfies the need in work, during the 30 days after your purchase you will be able to change your power tool with on of the same

reference but with more capacity just by paying the difference.

To make this warranty valid you should present the warranty policy sealed or the original invoice and return the entire product, without any damages, with

its accessories and original packaging to the distribution network or service centers.

18

Loading...

Loading...