Siebring FOX, COYOTE Operator's Manual

FOX / COYOTE OPERATOR’S MANUAL

4/10/19

Phone: 888-475-3317 www.siebringmfg.com Fax: 712-475-3490

TABLE OF CONTENTS:

1. Cover

2. Table of Contents

3. Warranty / Shading Information

4. Features

5. Accessories

6. General Safety

7. Consumer Product Safety Commission Warning

8. Precautions / Back-flush Procedures

9. Operating Instructions / Cordage Chart

10. Operating Instructions (continued)

11. How it works

12. Tank & Components

13. Tank & Component Diagram

14. Unloader Description

15. Unloader Diagram – Spray Mode

16. Unloader Diagram – By-pass Mode

17. Pump / plumbing – By-pass mode

18. Pump / plumbing – Re-circulate mode

19. Flow Diagram – Pump / Plumbing

20. Flow Diagram – Typical system

21. Electrical Diagram – Low Voltage

22. Electrical Diagram – High Voltage

23. Troubleshooting Index

24. Troubleshooting (continued)

25. Troubleshooting (continued)

26. Troubleshooting (continued)

27. Troubleshooting (continued) / Winterizing

28. Parts List

29. Parts Diagrams

30. Parts Diagrams (continued)

31. Warning & Caution Labels

32. Warning & Caution Labels (continued)

Included: ELEY Hose Reel Instructions, CAT 2SF Data Sheet, CAT SF Service

Manual & Honda Manual (if applicable).

2

CONDITION OF SALE

SIEBRING MANUFACTURING, INC.

GEORGE, IA 51237

Pursuant to Magnuson-Moss Warranty Federal Trade Commission Improvement Act

P.L. 93-637, 88 STAT.2183-2193; U.P.C. 2301-2312 (Jan. 4, 1975), the following

limited warranty will now replace all prior warranties issued by Siebring

Manufacturing, Inc.

We warrant the equipment manufactured by us to be free from defects in material

and workmanship under normal use and service, our obligation under this warranty

being limited to replacing at our factory any product, or parts thereof, which shall

within one year after delivery thereof to the original purchaser be returned to us with

transportation (UPS Ground) charges prepaid, and which our examination shall

disclose to our satisfaction to have been thus defective. We neither assume nor

authorize any other person to assume for us any other liability in connection with

such equipment. “Overnight”, “Next Day” or any shipping method other than UPS

Ground will the responsibility of the customer. This warranty shall not apply to any

equipment which shall have been repaired or altered outside of our factory in any

way so as to affect its stability and reliability, nor which has been subject to misuse,

negligence or accident, nor to any equipment, which shall have been operated

beyond factory rated capacity. We shall not be liable for consequential damages

caused by defective materials, equipment or parts warranted by their respective

manufacturers.

Siebring MFG will not warranty any sprayer manufactured with brass components that has

been used to apply Zerotol or similar products. Sprayer warranties on units manufactured

with stainless steel pumps and associated components will be honored.

Any implied warranty (including the warranty of merchantability), to the extent

permitted by law, is excluded.

We will not grant any allowance for any repairs or alterations without written approval

of an executive officer, and we reserve the right to make changes in design, or to

make additions to, or improvements in, our products without imposing any

obligations upon the company to install them on products previously manufactured.

Shading:

Continental Products Company’s “Kool Ray” liquid shading products are the only brands

authorized for use in the Siebring “Mist R’ Drench,” “Fox” and “Kruser” line of sprayers.

DO NOT USE LATEX PAINT!

Use of unauthorized products can damage the sprayer pump and components and will

void the warranty.

Prior to applying shading, install a 0° tip and a 50 mesh screen (not included) in the filter

bowl assembly.

3

1

FOX Features & Accessories

2

3

10

4

11

5

7

8

6

1. Bypass Valve

2. Liquid filled gauge

3. Oil filler cap

4. Oil sight glass

5. Brake to prevent unwanted spool run-off

6. Crank Handle

7. Reel Lock

8. Filter Bowl Assembly

9. Quick Disconnect

10. Bottom Tank Drain

11. Included Accessories (see next page)

- 2 Spray guns

- 2 - 18” & 1 - 12” wand

9

- 1 - 12” curved (hook) extension

- 3 piece misting tip & water breaker

- Back-flush fitting

- 0° & 15° pressure nozzles

4

3

3

7. 12” Hook

8. Backflush fitting

9. 12” Extension

10. Disk

11. Core

12. Brass Strainer

9

12

2

11 10

6 5 4

4

8

1

7

2

1. Small water breaker

2. 18” extension (2)

3. Gun (2)

4. Cap

5. 0° Tip

6. 15° Tip

Fox, MD83, MD83BW, MD100, MD200 Included Accessories:

5

GENERAL SAFETY

1. WARNING – Do not pump flammable or explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in explosive atmospheres. The pump should only be used

with liquids compatible with the pump component materials. Failure to follow this

warning can result in personal injury and/or property damage and will void the product

warranty.

2. Do not run the pump faster than maximum recommended speed.

3. Do not attempt to pump at pressures higher than rated, motor damage may result.

4. Maximum liquid temperature through pump is 140°.

5. Make certain that the power source conforms with the requirements of your equipment

(see cord chart on page 8).

6. Do not operate machine with belt guard, shaft guard or similar safety devices

removed.

7. Prior to servicing, disconnect power, stop engine.

8. Relieve system pressure prior to servicing.

9. Drain all liquids from system before servicing.

10. Secure quick couplers on lines and guns before starting the pump. A loose quick

coupler may cause a hose whip around under pressure causing personal injury and/or

property damage.

11. Check hoses for weak or worn conditions before each use. Make certain that all

connections are tight and secure.

12. Periodically inspect the pump and system components. Perform routine maintenance

as required. See maintenance section in this manual, CAT pump Service Manual and

Honda engine manual as applicable.

13. Electric motors must be adequately grounded.

14. Do not operate a gasoline engine in an enclosed area. Be sure the area is well

ventilated.

15. Gasoline is a highly combustible fuel. The improper use, storage or handling of

gasoline can be dangerous. Never fill or touch a hot engine.

16. Do not handle a pump or motor with wet hands or when standing on a wet or damp

surface.

17. Use only pipe, hose and fittings rated for the maximum P.S.I.G. rating of the pump. If

an unloader is used, use pipe, hose and fittings rated for the pressure at which the

unloader bypass operates.

6

WASHERS DANGEROUS, SAFETY PANEL WARNS

The U.S. Consumer Product Safety Commission has issued a warning to

consumers who use electrically powered pressure washers for cleaning milk tanks,

spray tanks, and other farm equipment.

According to a federal safety alert, consumers can receive a fatal electrical shock

from pressure washers if the power cord connections become wet or an internal

short exists.

Since pressure washers are used to spray water, the power cord, washer and

consumer are often wet, and this can be fatal, especially if the machine is not

properly grounded, the report explained.

Consumers should not use adaptor plugs to connect the three-wire plug to a twoprong household receptacle without properly grounding the adaptor plug. Power

cord connections should never be allowed to lie in water.

The commission urges these precautions:

- Always plug a three-wire grounded pressure washer into a properly grounded

receptacle. If possible, use a receptacle protected by a ground fault circuit

interrupter (GFCI).

- Check all flexible cords, plugs and sockets before each use. Replace any

damaged items.

- If an extension cord must be used, use the heavy-duty three-wire, properly

grounded type, and keep the power cord connection out of the water and away from

the item being washed.

- Wear eye protection when using sprayers or pressure washers.

- Wear rubber-soled footwear when operating the washer.

- Never cut or splice the power cord or extension cords.

- Do not leave hoses or cords where they can be run over and damaged.

- Never remove the grounding prong from the power cord plug.

- Never operate the washer after it has tripped a ground fault interrupter or circuit

breaker without first having it examined by a competent repair person.

- Never allow children to operate a pressure washer, and keep them away from the

washer when an adult is using it.

- Never spray the cleaner at yourself or others. The pressure can cause the water

and cleaner to blast under the skin.

- Never start the washer until you have checked to make sure all coupler hose

connections are in place and locked.

FOR MORE INFORMATION, CONSUMERS CAN CALL THE CPSC TOLL-FREE

HOTLINE, 800-638-CPSC.

7

FOX PRECAUTIONS

ALWAYS - RINSE AND FLUSH OUT THE FOX AFTER EACH USE.

ALWAYS - DRAIN ANY REMAINING FLUIDS FROM THE SPRAYER TO

PROTECT IT FROM FREEZING.

ALWAYS - READ AND FOLLOW ALL DIRECTIONS OF THE CHEMICAL

MANUFACTURER (CHECK MSDS).

ALWAYS - PUT FRESH, CLEAN WATER IN THE FOX AND TEST THE

SPRAYER FOR PROPER OPERATION BEFORE ADDING ANY SPRAYS.

ALWAYS - WEAR PROTECTIVE GEAR WHEN MIXING OR APPLYING ANY

CHEMICALS. THIS INCLUDES MASK, RESPIRATOR, GLOVES,

GOWN, ETC.

ALWAYS - MAINTAIN THE FOX IN GOOD REPAIR. THIS WILL HELP

PREVENT LEAKS, ETC. AND ADD TO THE LIFE OF THE MACHINE.

BACKFLUSH PUMP FITTINGS FOR FOX SPRAYER

PARTS INCLUDED:

1 – 50MP QUICK COUPLER

1 – GARDEN HOSE SCREEN

1 – ¾ X ½ SWIVEL ADP. (S11) GARDEN HOSE FITTING

HOW TO USE

**TANK MUST BE EMPTY**

1. DISCONNECT BLACK RUBBER SUCTION HOSE FROM TANK AT QUICK

COUPLER

2. SNAP SUPPLIED FITTINGS INTO HOSE QUICK COUPLER

3. ATTACH GARDEN HOSE TO FITTING

4. TURN ON WATER SUPPLY

5. RUN PUMP/SPRAY TO FLUSH PUMP

*** WINTERIZE PUMP IF FREEZING TEMPERATURES ARE EXPECTED ***

8

FOX SPRAYER OPERATING INSTRUCTIONS

PRIOR TO START UP

Completely uncrate unit. Inspect for shipping damages that could interfere with unit

operation. Check for crating/shipping materials lodged in pump/motor assembly, belt

drive (if applicable) steering mechanism and wheel & tire area. Check for foreign debris

in sprayer tank.

Read this manual and comply with all of the safety instructions. Familiarize yourself with

the operating instructions and component location prior to using the unit.

If you have a gas engine powered unit, read and familiarize yourself with the Honda

Owner’s Manual.

Read and be familiar with the CAT Pump manual and operating instructions.

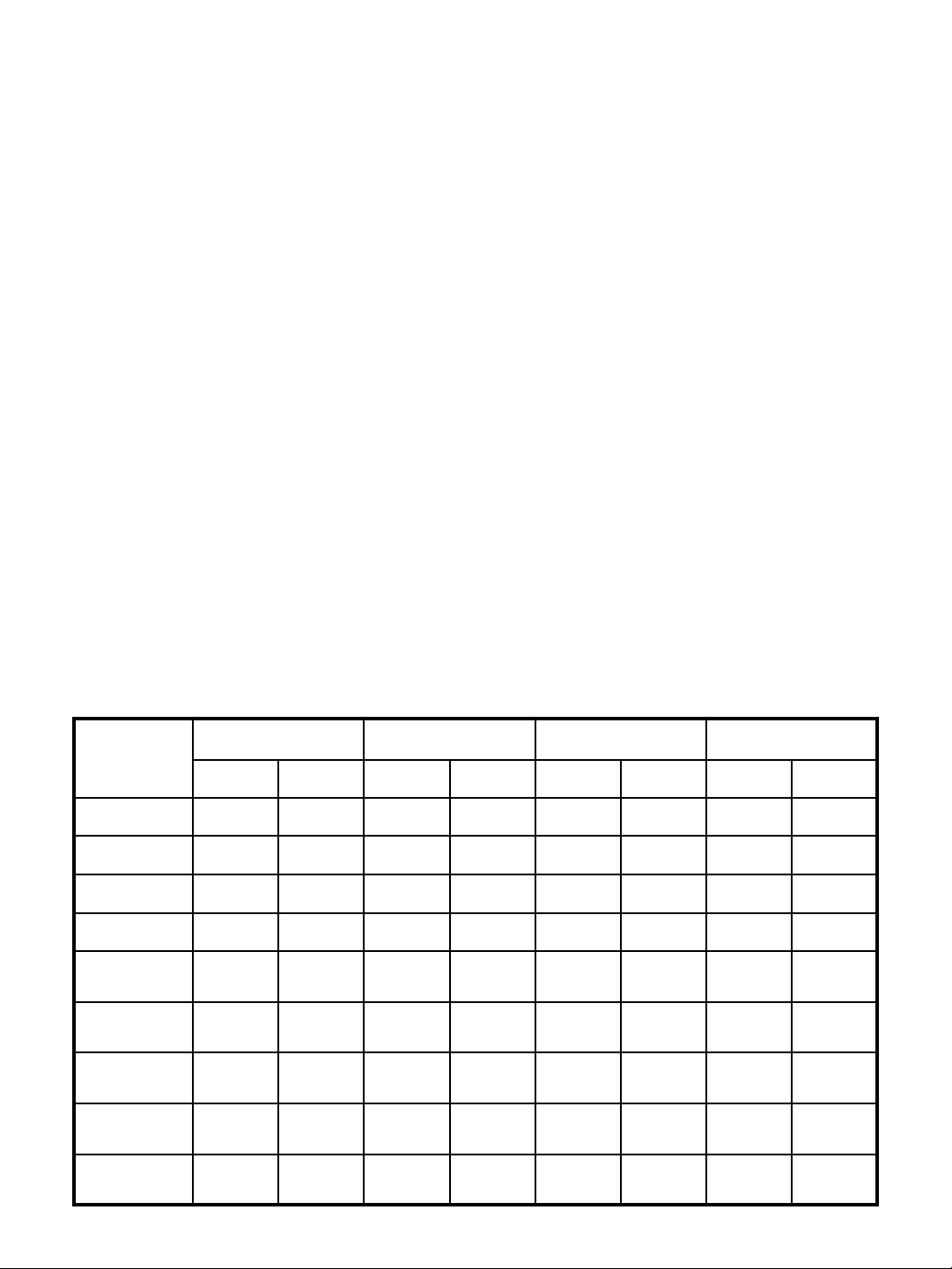

If electrically powered unit, ensure adequate power and extension cords are available to

operate the unit (see chart below).

Wire Size for 115 & 230 Volt Single Phase Circuits

Distance – Motor to Fuse or Motor to Meter Box

MOTOR

HP

1/4 # 14 # 14 # 10 # 12 # 8 # 10 # 6 # 8

1/3 # 12 # 14 # 10 # 12 # 6 # 10 # 4 # 8

1/2 # 10 # 12 # 8 # 10 # 6 # 8 # 4 # 6

3/4 # 10 # 12 # 6 # 10 # 4 # 8 # 2 # 6

1 # 8 # 10 # 6 # 8 # 4 # 6 # 4

1 ½ # 4 # 10 # 0 # 8 # 6 # 4

2 # 8 # 6 # 4 # 2

3 # 8 # 6 # 4 # 2

100 FT. 200 FT. 300 FT. 500 FT.

115V 230V 115V 230V 115V 230V 115V 230V

5 # 6 # 4 # 2 # 0

9

Loading...

Loading...