Page 1

SIEB & MEYER

Drive Amplier SD2B /

SD2B plus

Hardware Description

W

P-TD-0000312.8

2019-09-09

Page 2

Copyright

Translation of the original instructions, Copyright © 2019 SIEB & MEYER AG

All rights reserved.

This manual or extracts thereof may only be copied with the explicit authorization of

SIEB & MEYER AG.

Trademarks

All product, font and company names mentioned in this manual may be trademarks or registered

trademarks of their respective companies.

SIEB & MEYER worldwide

For questions regarding our products and technical problems please contact us.

W

SIEB & MEYER AG

Auf dem Schmaarkamp 21

21339 Lueneburg

Germany

Phone: +49 4131 203 0

Fax: +49 4131 203 2000

support@sieb-meyer.de

http://www.sieb-meyer.de

SIEB & MEYER Asia Co. Ltd.

4 Fl, No. 532, Sec. 1

Min-Sheng N. Road

Kwei-Shan Hsiang

333 Tao-Yuan Hsien

Taiwan

Phone: +886 3 311 5560

Fax: +886 3 322 1224

smasia@ms42.hinet.net

http://www.sieb-meyer.com

SIEB & MEYER Shenzhen Trading Co. Ltd.

Room A208, 2/F,

Internet Innovation and Creation services base

Building (2),

No.126, Wanxia road, Shekou, Nanshan district,

Shenzhen City, 518067

China

Phone: +86 755 2681 1417 / +86 755 2681 2487

Fax: +86 755 2681 2967

sm_china_support1@163.com

http://www.sieb-meyer.cn

2 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 3

W

Chapter Overview

About this Manual

General Information 2

Safety Instructions 3

Unit Assembly Complying EMC 4

Drive Amplifier SD2B / SD2B plus 5

Device variant SD2B 6

Device variant SD2B plus 7

Connector Pin Assignment 8

1

Connection Examples 9

Status Display and Error Messages 10

General Information Regarding the Wiring 11

Electric Performance Dimensioning 12

Safety Circuit / Restart Lock (STO) 13

Appendix 14

Index

15

Drive Amplifier SD2B / SD2B plus - Hardware Description 3

Page 4

Chapter Overview

W

4 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 5

W

1 About this Manual ............................................................. 9

1.1 Illustration of Warnings ............................................................................... 9

1.2 Illustration of General Notices ...................................................................

1.3 Abbreviations ............................................................................................ 10

2 General Information ........................................................ 11

3 Safety Instructions ........................................................... 13

3.1 Standards and Regulations ....................................................................... 13

3.2 Working on the Device .............................................................................. 13

3.3 Appropriate Use ........................................................................................

3.4 Reasonably Foreseeable Misuse .............................................................. 15

3.5 Transport and Storage .............................................................................. 15

3.6 Installation ................................................................................................. 16

3.7 Electrical Connection ................................................................................ 17

3.8 Operation ..................................................................................................

3.9 Maintenance ............................................................................................. 19

3.10 Disposal .................................................................................................... 19

3.11 Legal Warranty .......................................................................................... 20

Content

10

14

18

4 Unit Assembly Complying EMC ...................................... 21

5 Drive Amplifier SD2B / SD2B plus .................................. 23

5.1 Type Plate ................................................................................................. 23

5.2 Device Designation ................................................................................... 24

5.3 Functional Overview of the Device Variants .............................................

25

6 Device variant SD2B ....................................................... 27

6.1 Operating Instructions ............................................................................... 27

6.2 Block Diagram ........................................................................................... 28

6.3 Dimensions/Mounting ............................................................................... 29

6.4 Technical Data .......................................................................................... 30

6.5 Connectors ................................................................................................ 31

7 Device variant SD2B plus ............................................... 33

7.1 Block Diagram ........................................................................................... 33

7.2 Dimensions/Mounting ...............................................................................

7.3 Technical Data .......................................................................................... 36

7.4 Connectors ................................................................................................ 37

35

8 Connector Pin Assignment .............................................. 39

8.1 Operation of the Terminal Connectors ...................................................... 39

8.1.1 Spring-cage Connection ........................................................................................ 39

8.1.2 Push-in Technology .............................................................................................. 39

8.2 ID switch ................................................................................................... 39

8.3 X2 – Motor Connection ............................................................................. 40

8.4 X4 – DC Power Supply ............................................................................. 40

8.5 X6 – Logic Supply ..................................................................................... 41

Drive Amplifier SD2B / SD2B plus - Hardware Description 5

Page 6

Content

8.6 X9 – Inputs/Outputs .................................................................................. 41

8.7 X10 – COM1 / Operating Terminal ............................................................ 42

8.8 X11 – USB ................................................................................................ 43

8.9 X12 – DC Power Supply ...........................................................................

8.10 X13 – Motor Connection ........................................................................... 44

8.11 X14 – Inputs/Outputs / Safety Circuit (STO) ............................................. 44

8.12 X15 – Encoder 0 .......................................................................................

8.13 X16 – Encoder 1 / Encoder Emulation ...................................................... 46

9 Connection Examples ..................................................... 47

9.1 X2/X13 – Motor Phases ............................................................................ 47

9.2 X4 – Decoupling of the Main Voltage ........................................................ 48

9.3 X4/X6 – DC Power Supply Unit ................................................................. 48

9.4 X9 – Inputs/Outputs ..................................................................................

9.4.1 Digital Inputs ......................................................................................................... 49

9.4.2 Digital Outputs ....................................................................................................... 49

9.4.3 Analog Input .......................................................................................................... 50

9.5 X9/X14 – Temperature Sensor of the Motor ............................................. 50

9.6 X10 – Bus Connection ..............................................................................

9.6.1 COM1 – RS232 ..................................................................................................... 51

9.6.2 CAN Bus ............................................................................................................... 52

9.7 X12/X14 – DC Power Supply Unit ............................................................. 53

9.8 X14 – In/Out / STO .................................................................................... 53

9.8.1 Digital Inputs ......................................................................................................... 53

9.8.2 Digital Outputs ....................................................................................................... 54

9.8.3 Analog Input .......................................................................................................... 55

9.8.4 safety circuit (STO) ............................................................................................... 55

9.8.4.1 Wiring with OSSD ................................................................................................. 55

9.8.4.2 Wiring without OSSD ............................................................................................ 56

9.9 X15, X16 – Incremental Encoder with TTL Signals ................................... 56

9.10 X16 – ENC1/EMU ..................................................................................... 57

9.10.1 Encoder Emulation ................................................................................................

9.10.2 Hall Sensor 5.3 V .................................................................................................. 58

9.10.3 PULSE IN 5.3 V .................................................................................................... 58

W

43

45

49

51

57

10 Status Display and Error Messages ................................

10.1 List of the Operating States ...................................................................... 59

10.2 List of Drive Error Messages .....................................................................

10.3 List of Warning Messages ......................................................................... 64

10.4 Message of the Quick Stop Functions ...................................................... 65

59

60

11 General Information Regarding the Wiring ...................... 67

11.1 Cable Requirements ................................................................................. 67

11.1.1 Motor Cable ........................................................................................................... 69

12 Electric Performance Dimensioning ................................ 71

12.1 Components .............................................................................................. 71

12.1.1 Output Stage ......................................................................................................... 71

12.1.2 Power Supply ........................................................................................................ 71

12.1.3 Motor ..................................................................................................................... 72

6 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 7

W

12.2 Power Consumption of a Drive ................................................................. 74

13 Safety Circuit / Restart Lock (STO) ................................. 75

13.1 Functional Description of the Restart Lock ............................................... 76

13.2 Wiring Example ......................................................................................... 77

13.3 Requirements and Standards ................................................................... 78

Content

14 Appendix .........................................................................

14.A Specification of Device Firmware ..............................................................

14.B Manufacturers ........................................................................................... 83

14.B.1 SIEB & MEYER Accessories ................................................................................ 83

14.B.1.1 Connectors of the Series SD2B / SD2B plus ........................................................ 83

14.B.1.2 Blocking Diode ...................................................................................................... 83

14.B.1.3 Operating Terminal ............................................................................................... 83

14.B.1.4 USB>RS232/485 Converter 050201 ..................................................................... 83

14.B.2 Phoenix Contact .................................................................................................... 84

81

81

15 Index ............................................................................... 85

Drive Amplifier SD2B / SD2B plus - Hardware Description 7

Page 8

Content

W

8 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 9

W

1 About this Manual

This chapter descirbes symbols, signal words and abbreviations used in this manual.

More documentation can be downloaded from the SIEB & MEYER website

under http://www.sieb-meyer.de/downloads.html.

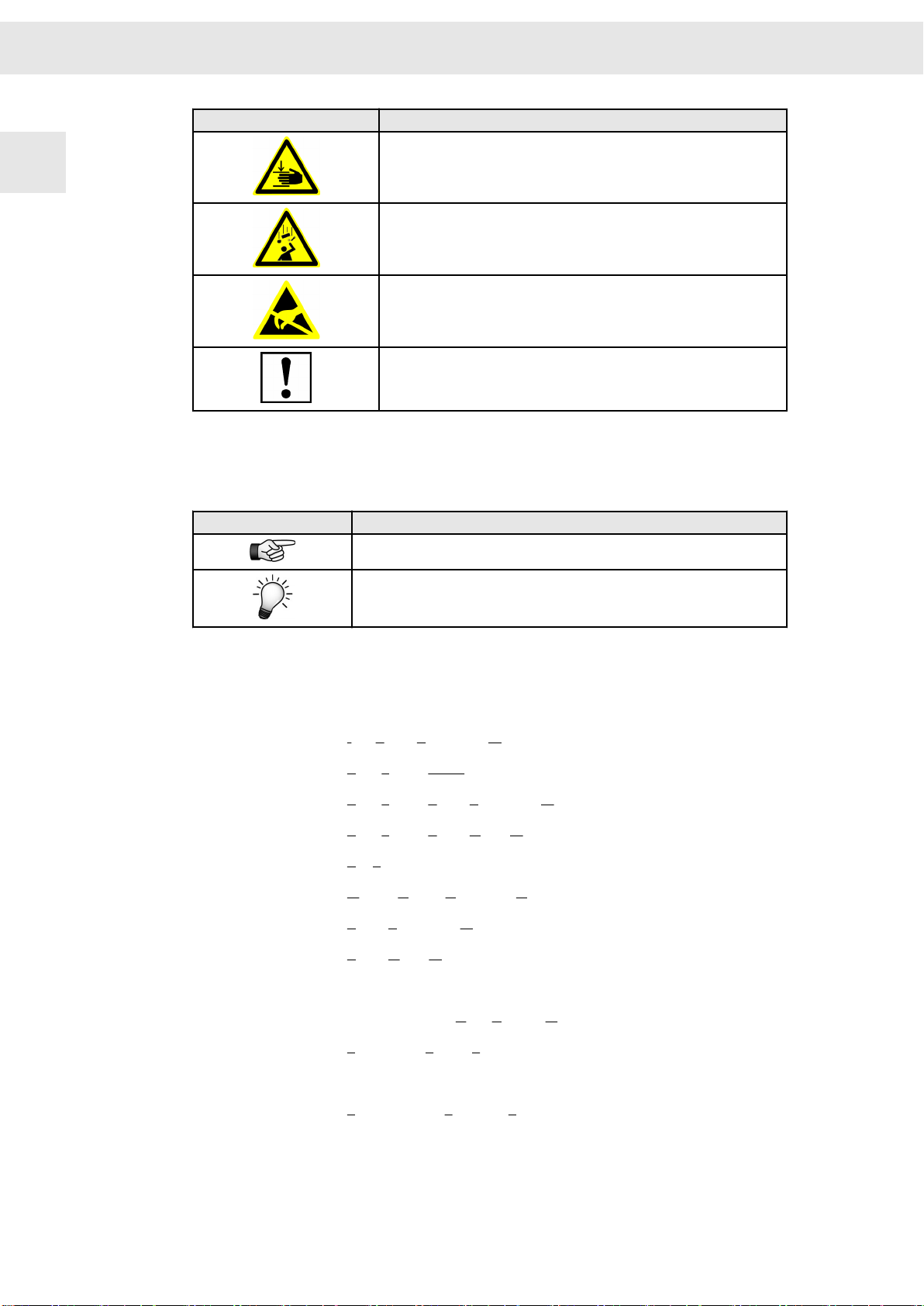

1.1 Illustration of Warnings

Depending on their degree of risk, warnings are classified into different levels. In the

manual, the different levels and types of dangers are represented as follows:

About this Manual

1

[1] Risk level (signal word/warning color)

Classification of the risk

[2] Safety symbol

Risk of injury

[3] Risk symbol

Graphic representation of the source of risk

Risk levels

Risk Level

Risk symbols

Risk symbol

Description

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or property damage.

Indicates a hazardous situation which, if not avoided, may result in prop‐

erty damage.

Description

General hazardous situation

Risk of injury due to electric shock

Risk of injury due to hot surfaces

Drive Amplifier SD2B / SD2B plus - Hardware Description 9

Page 10

About this Manual

W

Risk symbol Description

1

Potentially risk of injury when working on machines with open covers/

doors

Risk of injury due to flying objects

Destruction risk of electrostatically sensitive components

Risk of property damage

1.2 Illustration of General Notices

Symbol Description

Hint with additional, further information

Tip with suggestions and useful information

1.3 Abbreviations

FPAM flux pulse amplitude modulation

HSBLOCK high-speed block commutation

HSPAM high-speed pulse amplitude modulation

HSPWM high-speed pulse width modulation

n.c. not connected

OSSD Output Signal Switching Device

PAM pulse amplitude modulation

PWM pulse width modulation

SERVO servo control

STO safety function: Safe Torque Off

SVC sensorless vector control

VF V/f Characteristic Curve

VCC voltage at the common collector

VECTOR vector control

10 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 11

W

2 General Information

This manual describes the drive amplifiers of the series SD2B / SD2B plus. These

devices allow operation of high-dynamic servo motors as well as synchronous and

asynchronous high-frequency spindles.

The devices are equipped with interfaces for different sensor systems and allow the

operation of motors with Hall and incremental sensors. Motor systems without any

sensors are also supported, whereas different customized control methods are avail‐

able. In addition, the devices can drive rotary and linear motors. Thus, the number of

device variants is reduced for the machine manufacturer.

This manual provides information on:

▶ Safety instructions and application advice

▶ Notes about the electromagnetic compatibility

▶ Description of the device (block diagram, type plate, module designation)

▶ Technical data, dimensions

▶ Connector pin assignment

▶ Wiring examples

▶ Status and error messages

▶ General information regarding the wiring (cables and line cross-sections)

General Information

2

This manual has the following demands on the trained staff of machine manufacturers:

Transport: only by skilled employees familiar with handling electrostatically

sensitive components.

Installation: only by experts with electromechanical experience

Initial operation: only by experts with experience in the fields of electrical engi‐

neering / drive technology

Information concerning the initial operation and parameterization of the

digital drive amplifier can be found in the manual of the software

master2

More documentation can be downloaded from the SIEB & MEYER website

under http://www.sieb-meyer.de/downloads.html.

.

drive‐

Drive Amplifier SD2B / SD2B plus - Hardware Description 11

Page 12

General Information

W

2

12 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 13

W

3 Safety Instructions

These safety instructions include important information regarding your safety

and must be observed during installation and operation of SIEB & MEYER

devices. Read them carefully and keep them for later use.

Also adhere to safety instructions in the product documentation and on the

device.

3.1 Standards and Regulations

SIEB & MEYER devices comply with the regulations of the following standards and

directives:

▶ Low-Voltage Directive 2014/35/EU:

EU declaration of conformity, DIN EN 61800-5-1

▶ EMC Directive 2014/30/EU:

EU manufacturer's certificate, DIN EN 61800-3

▶ Machinery Directive 2006/42/EC:

EU manufacturer's certificate, DIN EN 61800-5-2 (safety functions)

Safety Instructions

3

SIEB & MEYER products are no products according to the EU Machinery

Directive. The appropriate use of SIEB & MEYER devices in machines and

installations is prohibited until the manufacturer of the machine or installation

confirms the CE conformity of the complete machine or installation.

If the mechanics or the electronics of the device are modified, the conformity

with the EC/EEC directives and thus the label will expire.

3.2 Working on the Device

WARNING

Trained staff only

To avoid risks of serious injuries and material damage any works regarding instal‐

lation, initial operation and maintenance must be carried out by trained staff only.

Furthermore, electricians who connect feed-in systems must be approved by the

local DSO (distribution system operator).

Trained staff, according to this fundamental safety instruction, are persons familiar

with the installation, mounting, initial and permanent operation of the product and

they are qualified appropriately for the work. The standards DIN VDE 0100 and

DIN VDE 0110 as well as the national accident prevention regulations shall be

considered!

When installing feed-in systems adhere to all applicable regulations, special safety

instructions and technical connection conditions of the local DSO.

Drive Amplifier SD2B / SD2B plus - Hardware Description 13

Page 14

Safety Instructions

W

DANGER

Risk of serious damage to property and personal injury may occur:

▶ when covers are removed illegally,

▶ due to improper use,

▶ when either the installation or the operation is incorrect

Observe the corresponding notes and information in the product documentation of

3

your device.

WARNING

Risk of injuries and material damage due to illegal modifications

Only change the settings of the device after having contacted SIEB & MEYER.

All Information and advice attached to the device, such as safety instructions or danger

warnings and technical data (type plate) are:

▶ not to be removed

▶ not to be damaged

▶ to be kept readably (no covers, no paint over or the like)

3.3 Appropriate Use

Use the device according to its appropriate use only. Consider the corresponding infor‐

mation regarding the application fields of the device in the product documentation.

The device is intended for use within an enclosed cabinet by the OEM or end user to

comply with pollution degree 2 or equivalent environmental conditions. That means:

Ensure to avoid conductive impurities and humidity during the operation.

SIEB & MEYER products are not suitable for use in areas exposed to explosion

hazards (ATEX zones) without approriate housing.

Terms according to DIN EN 61800

Before initial operation, make sure that the machine will not expose danger (e.g.

runaway moves). The conformity with the safety standards DIN EN 60204-1 and DIN

EN 61800-5-1 must be ensured.

The manufacturer of the system or the machine has to meet the requirements of the

legal values regarding the Electromagnetic Compatibility (EMC). SIEB & MEYER units

can be operated in industrial areas, provided that the attached EMC information has

been taken into consideration.

SIEB & MEYER tests all products in its own EMC laboratory to ensure that the prod‐

ucts meet the respective standards, when they are installed properly.

Installation of the device differing from the product documentation and the manual

"EMC Guidelines" means that the machine manufacturer has to carry out new meas‐

urements to comply with the regulations.

SIEB & MEYER devices meet the requirements of the Low-Voltage Directive

2014/35/EU. The harmonized standards of DIN EN 50178 and DIN EN 60204-1 in

14 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 15

W

Safety Instructions

combination with the standards DIN EN 60947 and DIN EN 61800-5-1 are applied

consequently.

Technical data and the connection specification can be found in the respective product

documents.

Line filters

If adequate interference suppression measures are applied and the appropriate use in

industrial applications of the device is ensured SIEB & MEYER devices comply with

the EMC Directive EMC Directive 2014/30/EU in terms of the EMC Product Standard

(PDS) DIN EN 61800-3.

The use of line filters helps reaching the following:

▶ Resistance to interference. The electronic system is protected against high-

frequency disturbances, possibly infiltrated via the mains cable.

▶ Protection against radiation. High-frequency disturbances are reduced to legally

authorized measure. This prevents effects of the transients to adjacent compo‐

nents or devices.

▶ Products, not equipped with an integrated AC supply line filter must be operated

with an upstream line filter.

▶ Using SIEB & MEYER devices in residential or business areas as well in small

businesses requires additional interference suppression.

For detailed information refer to the manual "EMC Guidelines", chapter "EMC

Product Standard DIN EN 61800-3 for PDS".

3

Refer to the product documentation of your device to find out whether or not

your device is equipped with a line filter. For detailed information on line

filters refer to the manual "EMC Guidelines".

3.4 Reasonably Foreseeable Misuse

The Machinery Directive defines a "reasonably foreseeable misuse" as "use of machi‐

nery in a way not intended in the instructions but which may result from predictable

human behavior".

SIEB & MEYER products are no products according to the EU Machinery Directive.

During design and construction of the machine as well as in the operation manual the

machine manufacturer is obliged to give consideration to the intended (appropriate)

use of the machine and risks arising from reasonably foreseeable misuse of the

machine.

To avoid injuries and material damage any use, installation and setup of

SIEB & MEYER products by non-experts which exceed the technical data specified in

the product documentation (high voltages, temperatures etc.) is considered to be not

intended use and forbidden. Adhere to the safety instructions on the device and in the

product documentation.

3.5 Transport and Storage

Avoid improper mechanical load of the device. The following points must especially be

taken into consideration:

▶ Protect the device against mechanical damage (max. acceleration = 40 m/s²).

▶ Protect the device against dirt and humidity.

Drive Amplifier SD2B / SD2B plus - Hardware Description 15

Page 16

Safety Instructions

W

Make sure that dust plugs are plugged on optical fiber connectors equipped with

them during transport of the device. Otherwise, recommissioning is potentially not

possible.

▶ Never touch electronic components.

The following climatic conditions apply to the storage. If required, appropriate meas‐

ures must be taken to ensure these climatic conditions (installation of heating/air condi‐

tioning systems etc.):

▶ The storage area must be clean (dust-free, if possible), dry and well-ventilated.

▶ No storage in the open.

3

▶ The storage temperature must be in the range of −25 °C to +55 °C (−13 °F to

+131 °F). Shortly it may be +70 °C (+158 °F).

▶ The relative humidity on the storage premises must be in the range of 5 % to 75 %

(no bedewing).

▶ Sudden changes of the temperature or the humidity should be prevented.

▶ Avoid stacking of the devices during transport and storage.

The maximum storage period is 2 years. Electrolytic capacitors produce high leakage

currents when a voltage is applied after a long storage period without applied voltage

and must be reformed. For this, the operating voltage is applied via a 1 kΩ series

resistor for one hour. Please contact the SIEB & MEYER service department for

details.

3.6 Installation

NOTICE

Damage of electrostatically sensitive components due to improper handling

Never touch electronic components.

Consider specific mounting instructions for your device.

Mechanical installation conditions for the system according to DIN EN 61800-2:

Vibrations must remain within the limit values of the IEC 60721-3-3, class 3M1,

standard for fixed equipment.

Frequency [Hz]

2 ≤ f < 9 0,3 Not applicable

9 ≤ f < 200 Not applicable 1

Tab. 1: Vibration limits of the system

Vibrations which exceed these limits, or the use on mobile equipment, are considered

as abnormal mechanical conditions.

Amplitude [mm] Acceleration [m/s²]

Operating conditions:

The following requirements are to be considered for the installation and the operation

of the device. Noncompliance with theses requirements is regarded as abnormal oper‐

ating condition:

▶ The device is conceived according to DIN EN 61800-1 / DIN EN 50178 for the dirt

level 2. That means: Ensure to avoid conductive impurities during the operation.

▶ Devices with air cooling only can be loaded to their maximum up to a height of

1000 m above MSL (3281 ft above MSL). For an operation in areas higher than

16 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 17

W

Safety Instructions

1000 m (3281 ft) above MSL the capacity must be reduced by 1.5 % per 100 m

(328 ft).

The maximum site altitude is 2000 m (6562 ft) above MSL.

▶ The device must be protected against harmful gas, oil vapor and salty air at the

place of installation.

▶ The ambient air must not contain aggressive, grinding, electrically conductive or

flammable substances as well as any amount of dust.

▶ The maximum relative humidity during operation is 85% (no condensation).

▶ The admissible ambient temperature during operation is +5 °C to +40 °C (+41 °F

to +104 °F). Extreme and sudden changes of the temperature should be

prevented.

─ Ensure power derating for devices used under ambient temperatures over

+40 °C (+104 °F) (see technical data). The following applies:-1.5 % per

1 °C.Note: F=C×9/5+32; C=(F-32)×5/9

─ Devices with polyester film at the front panel: The polyester films must not be

exposed to direct sunlight for extended periods of time. In conditions of high

humidity (>80 %) the ambient temperature must not exceed +40 °C (+104 °F).

The polyester films must not come in contact with benzyl alcohol or methylene

chloride.

▶ Make sure that the aeration elements are free and open, so that the air circulation

is not restricted.

3

3.7 Electrical Connection

DANGER

Risk of serious injuries due to touch voltages

After electric devices have been switched off touch voltages may occur depending

on the device up to 4 minutes. Longer construction-related discharge times are

possible. Refer to the product documentation of your device.

All work at and within the units must only be carried out, when the units are turned

off, the mains supply is cut and the DC bus is completely discharged.

Never touch energized parts after a device has been switched. off.

Consider the applicable VDE regulations and accident prevention regulations (e.g.

VBG 1 and VBG 4).

DANGER

Risk of serious injuries due to improper connection to earth

Incorrect or insufficient connection of the system to earth may cause dangerous

currents.

Connection to earth must be realized according to the instructions in the product

documentation of your device.

The electrical installation must be carried out according to the relevant electrical codes

(e.g. appropriate wire gauges, fuse protection and connections of ground conductors

must be considered).

Drive Amplifier SD2B / SD2B plus - Hardware Description 17

Page 18

Safety Instructions

W

SIEB & MEYER device are conceived for connection to TN mains. For

detailed information regading the connection to TN mains or other mains

refer to the manual "EMC Guidelines", chapter "Connection to Different

Supply System Types".

Recommendations for the installation complying EMC (e.g. shields, connection to earth

and line installations) can be found in the technical manuals of your device (only for

machine manufacturers). The manufacturer of the system or machine has to meet the

requirements of the legislation regarding the EMC.

3

➮ Consider that the mains supply must be protected via an overload release with

restricted guidance for each mains phase. The mains line should only be

connected, when the work is completed.

➮ Before turning on the unit the first time, make sure that the connected machine will

not have runaway axes.

➮ Never connect capacitive loads to the output phases of the servo amplifiers and

frequency converters.

➮ Prevent cable loops. Therefore, the units must only be connected to earth at the

provided PE connection for the mains supply line and the racks only at the

provided earth screw.

DANGER

Connection of the power supply unit

This product may cause touch current in the protective earthing conductor. The

current in the protective earthing conductor can exceed 3.5 mA AC or 10 mA DC.

Pay attention to the local safety regulations for electric equipment with high

leakage currents, in particular the minimum cross-section of the protective earthing

conductor.

Operation with residual current device (RCD)

For detailed information regarding the operation with residual current device

(RCD) refer to the manual "EMC Guidelines", chapter "Safety-relevant

Aspects, Residual Current Device (RCD)".

3.8 Operation

WARNING

Risk of serious injuries due to moving machine parts

During the operation of an installation with open doors or removed covers, persons

may seriously be injured by moving machine parts.

Keep the doors closed during the operation and do not remove covers.

18 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 19

W

Safety Instructions

WARNING

Risk of injuries and material damage due to flying parts

Persons may be injured or material be damaged, if screws of the front panels and

housing parts are not fastened.

Before the initial operation of the installation ensure that all screws are tightened.

3

WARNING

Risk of burn due to hot surfaces

During operation the units can have hot surfaces according to their protection

system. In particular this applies to ventilation inlets and outlets.

Never touch device parts during operation apart from operating units.

When using ferrite rings temperatures may exceed 80°C in some cases.

Only use cables suitable for temperatures over 90 °C. This corresponds to the

flammability rating UL 94V-0, RTI 105°C.

Consider the relevant notes in the manual.

Systems, into which servo amplifiers and frequency converters are mounted, possibly

must be equipped with additional protective devices according to the valid safety

instructions (e.g. law about technical material, rules for prevention of accidents, etc.).

3.9 Maintenance

The unit must be checked regularly for cleanness and functionality depending on the

ambient pollution. This applies in particular for installed fans.

3.10 Disposal

Make sure to consider country-specific waste and disposal laws and statutes

for the disposal of packing material, used batteries and irreparable devices.

SIEB & MEYER products meet the requirements of the following directive:

▶ 2011/65/EU (EU-directive RoHS 2 on the restriction of the use of hazardous

substances in electrical and electronic equipment)

SIEB & MEYER products do not exceed the limits of the directive 2011/65/EU for

hazardous substances.

SIEB & MEYER products labeled with the adjacent symbol also meet

the regulations of the following directive:

▶ SJ/T 11364-2014 (China RoHS 2 on the restriction of the use of

hazardous substances in electrical and electronic equipment)

SIEB & MEYER products labeled with the symbol above do not exceed

the limits of the directive SJ/T 11364-2014 for hazardous substances.

Drive Amplifier SD2B / SD2B plus - Hardware Description 19

Page 20

Safety Instructions

W

3.11 Legal Warranty

SIEB & MEYER products are liable to a legal warranty of at least one year. Any claims

for the products beyond this warranty shall be declared in an additional contractual

agreement between SIEB & MEYER and the customer.

Claims for damages are excluded:

▶ due to improper use of the device

▶ when the device has been installed nonstandard or improperly, especially by elec‐

3

tricians without license

▶ when the device has been employed although the protection equipment was

defective

▶ when the maximum permissible input voltage has been exceeded

▶ due to improper operation

▶ when the device or its equipment have been modified

▶ when the device was affected by foreign material or force majeure

NOTICE

Due diligence of the machine manufacturer

A first programming carried out by SIEB & MEYER does not release the machine

manufacturer from his duty to check the programmed values for correctness.

20 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 21

W

Unit Assembly Complying EMC

4 Unit Assembly Complying EMC

The EU guidelines for electromagnetic compatibility (EMC) must be consid‐

ered for the initial operation of all SIEB & MEYER devices.

The manual "EMC Guidelines" is available in German and English and includes:

▶ EMC rules

▶ information regarding the professional grounding and wiring

▶ safety-relevant aspects

▶ extracts from the EMC product standard

▶ possibilities for the connection to different supply system types

Availability:

▶ PDF file under www.sieb-meyer.de/downloads.html

4

Drive Amplifier SD2B / SD2B plus - Hardware Description 21

Page 22

Unit Assembly Complying EMC

W

4

22 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 23

W

Drive Amplifier SD2B / SD2B plus

5 Drive Amplifier SD2B / SD2B plus

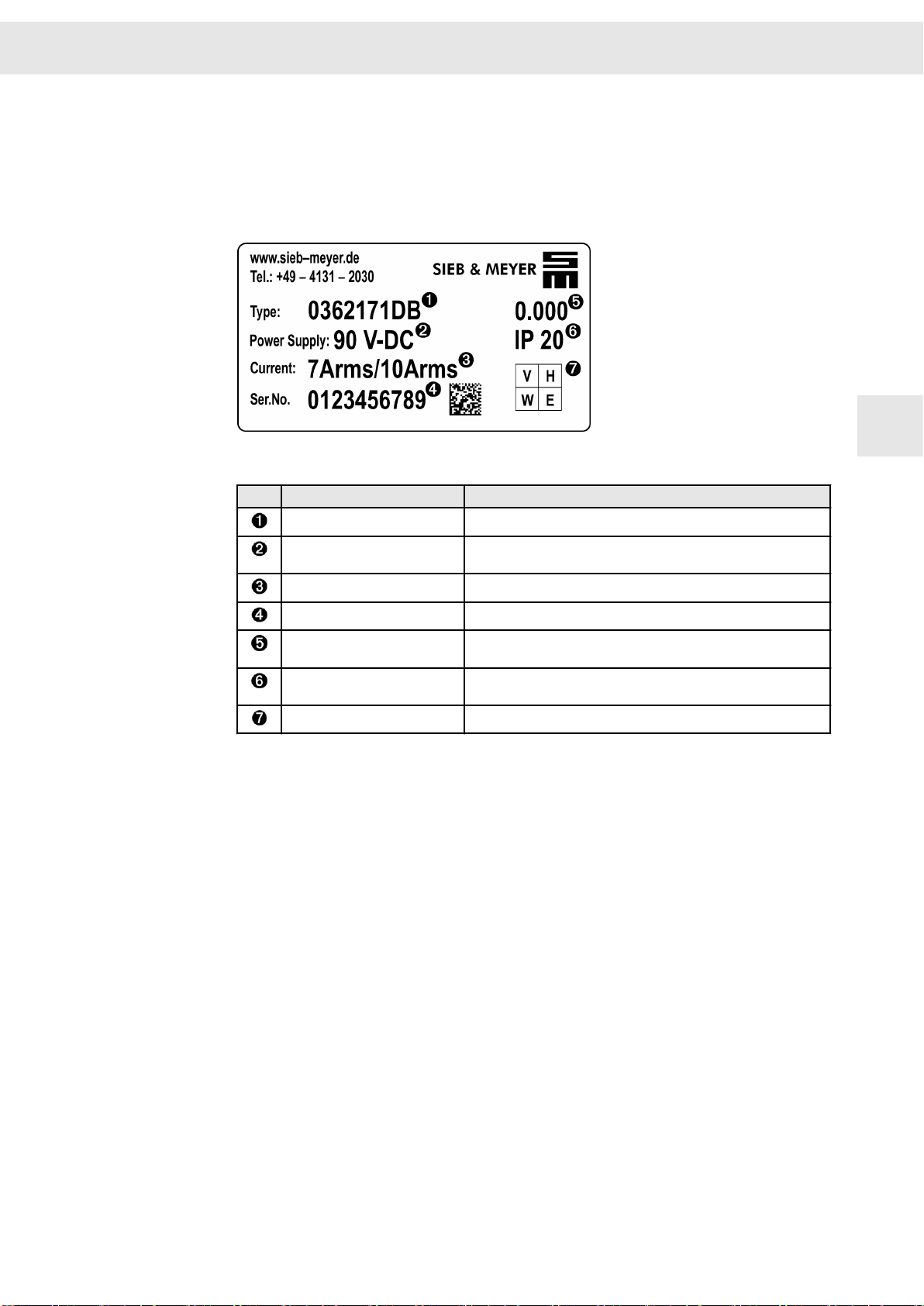

5.1 Type Plate

Fig. 1: Example of type plate (SD2B plus)

No. Meaning Explanation

Device designation Composed of module type and performance range as letter code

5

Supply voltage Indicates the maximum voltage range (if this row is left blank, an

Rated current/peak current Applies to the output stage; indicated as RMS value

Serial number Indicates the individual number of the device

Device version Indicates the version of the hardware; if no version is existent,

IP Code Indicates the level of protection of the device against touching or

QA label

external power supply unit is necessary)

0.000 is indicated here

intrusion of solid objects (1st digit) and water ingress (2nd digit)

Drive Amplifier SD2B / SD2B plus - Hardware Description 23

Page 24

Drive Amplifier SD2B / SD2B plus

W

5.2 Device Designation

e.g.0362170DB 3.000

Device type Device version

0 3 6 X X X X - x y

Current range

5

Specific type code

Module type

Performance

range

Voltage class

▶ B = up to 90 V

▶ see technical data

▶ 7X = drive amplifiers SD2B / SD2B plus

70 = SD2B (without housing)

71 = SD2B plus (with housing)

▶ 21 = series SD2x

DC

Device version X.XXX

Serial counter. If no version is existent, 0.000 is indicated here. If a device is

exchanged by a device of another version, please contact SIEB & MEYER to check

whether the devices are compatible or not.

In addition the device version indicates the update capability of the internal device soft‐

ware, e.g. BIOS, FPGA or Firmware.

24 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 25

W

Drive Amplifier SD2B / SD2B plus

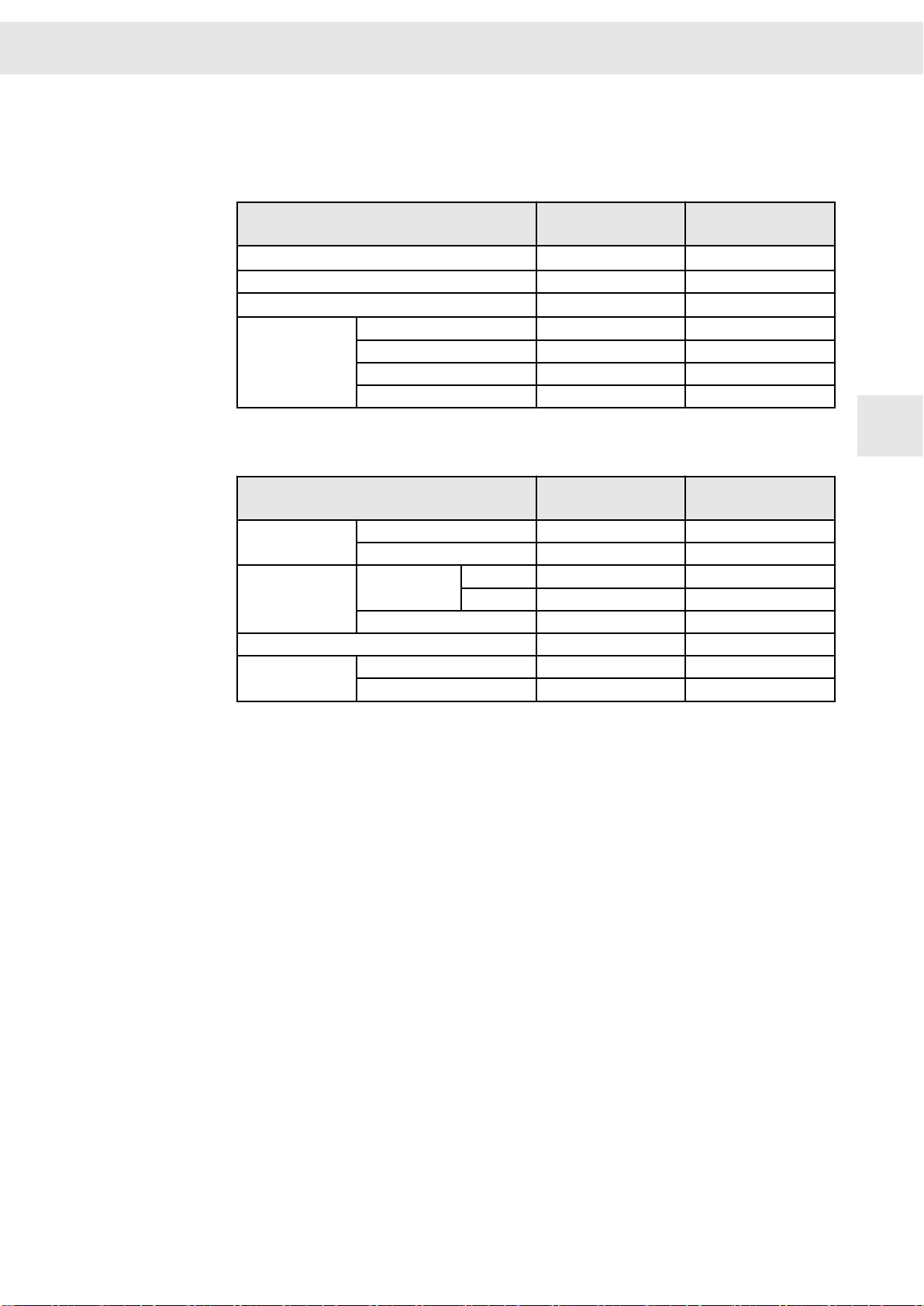

5.3 Functional Overview of the Device Variants

The following tables show the properties and the supported drive function of the

devices SD2B and SD2B plus.

General properties

Max. output power S1

Mains supply: External DC power supply ✔ ✔

DC link: fix

Interfaces

(1)

The maximum output power S1 applies at a voltage supply of 80 VDC.

(2)

The fix DC voltage supply depends on the used external power supply unit.

Drive function (up to … kHz output frequency) SD2B

SERVO / VECTOR

HSBLOCK / FPAM

HSPWM – –

HSPAM / VF

(2)

(1)

X9 (I/O)

X11 (USB) – ✔

X14 (I/O, safety) – ✔

X15/X16 (encoder 0/1) – ✔

SERVO – ✔ (up to 2 kHz)

SVC ✔ (up to 2 kHz) ✔ (up to 2 kHz)

HSBLOCK (with

sensor)

FPAM (sensorless) – –

VF-PWM ✔ (up to 2 kHz) ✔ (up to 2 kHz)

VF-PAM – –

PWM (Hall) – ✔ (up to 6 kHz)

PAM (Hall) – –

SD2B

(0362170DB)

660 VA 940 VA

✔ ✔

✔ –

(0362170DB)

SD2B plus

(0362171DB)

SD2B plus

(0362171DB)

5

Drive Amplifier SD2B / SD2B plus - Hardware Description 25

Page 26

Drive Amplifier SD2B / SD2B plus

W

5

26 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 27

W

6 Device variant SD2B

Device variant SD2B

6

Fig. 2: Device view of SD2B (0362170DB)

6.1 Operating Instructions

With its single-board design the device is to be integrated into the customer's electrical

construction on a sufficient cooling surface.

DANGER

Operating voltages above 48 V

In order to avoid personal injuries provide for protection against contact when oper‐

ating voltages above 48 V are reached (e.g. install the device in a switch cabinet).

WARNING

Hot surfaces

During operation the heat sink and components can reach temperatures above

80 °C.

Do not touch the device during operation.

Make sure that there are no combustible materials near by the device and that the

heat sink is not covered during mounting and operation.

Take measures to protect the device against contamination, in particular due to

conductive or aggressive materials. Contamination can cause malfunctions and shortcircuits.

Drive Amplifier SD2B / SD2B plus - Hardware Description 27

Page 28

Device variant SD2B

W

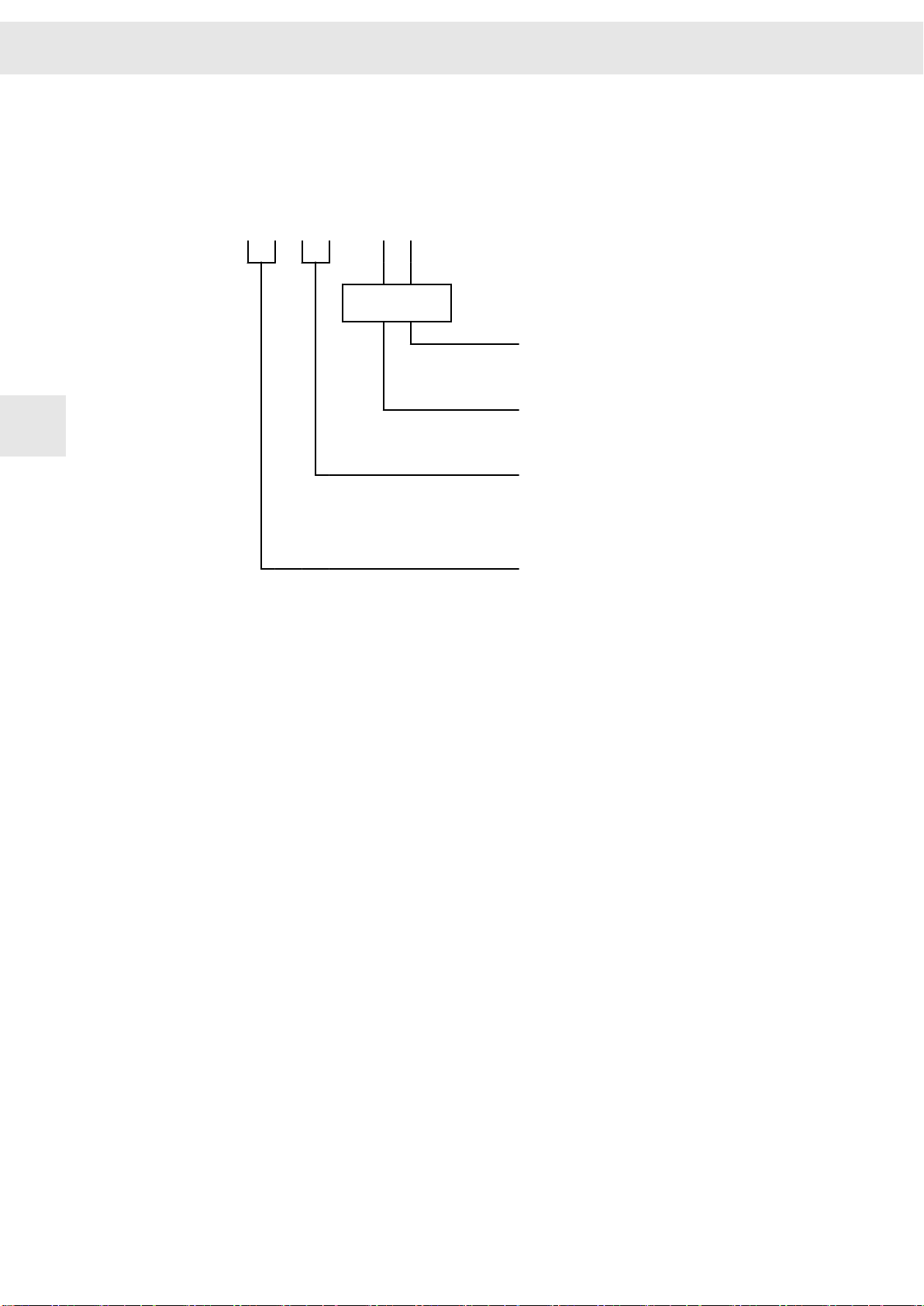

6.2 Block Diagram

The following block diagram shows the functional groups and connection options of the

device.

6

Fig. 3: Block diagram SD2B

28 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 29

W

6.3 Dimensions/Mounting

Device variant SD2B

6

Fig. 4: Dimensions SD2B in mm (inch)

▶ vertical mounting at spacers and heat sink: 4 M3 bolts

▶ wall mounting at heat sink: 2 M4 bolts

Drive Amplifier SD2B / SD2B plus - Hardware Description 29

Page 30

Device variant SD2B

6.4 Technical Data

Device variant 0362170DB

W

Parameterized supply voltage

(1)

Continuous phase current of output stage (±3 %)

Peak phase current of output stage (±3 %)

24 V

DC

7 A

(when mounted to cooling surface of the installation)

rms

10 A

(when mounted to cooling surface of the installation)

rms

48 V

DC

80 V

DC

(2)

(2)

Max. time for peak current 10 s

Max. output frequency 2000 Hz

Output frequency stability ≤ 0.2 %

Supply voltage

(3)

Output voltage

S

at I

(7 A

Output power

S

6

Logic supply

(4)

rated

S

at I

rated

) 190 VA 390 VA 660 VA

rms

(10 A

) 270 VA 550 VA 940 VA

rms

24 VDC (-10 %) to

24 VDC (+15 %)

16 V

AC

24 VDC (-10 %) to

48 VDC (+15 %)

33 V

AC

18 – 28 VDC (0.5 A)

24 VDC (-10 %) to

80 VDC (+15 %)

55 V

AC

Internal ballast resistor 22 Ω / 50 W

Maximum braking power 50 W 200 W for 5 s 450 W for 2 s

Ballast threshold 35 V

Overvoltage threshold 40 V

DC

DC

65 V

70 V

DC

DC

100 V

110 V

DC

DC

Undervoltage threshold 15 V

DC

Ambient temperature range 5 °C to 50 °C at a maximum relative humidity of 85 % (without moisture

condensation)

100 % rated current up to max. 40 °C. At higher temperatures the power

must be reduced by 1.5 % per 1 °C.

IP Code

(1)

Adjustable via software

drivemaster2

: from device version 4.100 and software version 1.14.100 onwards

IP00

For SD2B / SD2B plus with a device version < 4.100 the column 80 VDC applies. Device version 4.0xx can

be reconfigured to reach version 4.100, see “TIE_SD2B_AdjustableSupplyVoltage.pdf”.

(2)

Minimum size of cooling surface: 6 dm² (natural convection)

(3)

Admissible voltage ripple: max. 10 %

The supply voltage is protected by a fuse on the device: 10 A medium slow (5 × 20 mm)

(4)

The logic voltage is necessary to maintain the error messages. It is protected by an electronic fuse on the

device.

30 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 31

W

Device variant SD2B

NOTICE

Voltage peaks during braking operation

During braking of high inertial masses and/or when using short braking times the

DC main voltage can increase significantly depending on the parameterized supply

voltage.

▶ supply voltage 24 VDC → max. overvoltage 40 V

▶ supply voltage 48 VDC → max. overvoltage 70 V

▶ supply voltage 80 VDC → max. overvoltage 110 V

The connected power supply unit must be designed for this voltage. If not, you

need to decouple the main voltage by means of a blocking diode to avoid damage

to the power supply unit (see connection example

6.5 Connectors

DC

DC

DC

page 48).

6

Fig. 5: Connectors of SD2B (top view)

You can order the appropriate connector kit for SD2B at SIEB & MEYER

(article No. 32299576).

Drive Amplifier SD2B / SD2B plus - Hardware Description 31

Page 32

Device variant SD2B

W

6

32 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 33

W

Device variant SD2B plus

7 Device variant SD2B plus

Fig. 6: Device view of SD2B plus (0362171DB)

7.1 Block Diagram

The following block diagram shows the functional groups and connection options of the

device.

7

Drive Amplifier SD2B / SD2B plus - Hardware Description 33

Page 34

Device variant SD2B plus

W

7

Fig. 7: Block diagram SD2B plus

34 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 35

W

7.2 Dimensions/Mounting

Device variant SD2B plus

Fig. 8: Dimensions SD2B plus in mm [inch]

Mounting Instructions

▶ The device is mounted horizontally or vertically to a mounting wall. The mounting

surface is used for cooling.

▶ The mounting surface must be able to dissipate a heat output of 25 W at a

housing temperature of 60 °C for each device.

▶ With vertical mounting several device can be mounted next to each other without

any space in-between.

7

Fig. 9: Mounting options

Drive Amplifier SD2B / SD2B plus - Hardware Description 35

Page 36

Device variant SD2B plus

7.3 Technical Data

Device variant 0362171DB

W

Parameterized supply voltage

(1)

Continuous phase current of output stage (±3 %)

Peak phase current of output stage (±3 %)

24 V

DC

10 A

(when mounted to cooling surface of the installation)

rms

12 A

(when mounted to cooling surface of the installation)

rms

48 V

DC

80 V

DC

(2)

(2)

Max. time for peak current 10 s

Max. output frequency 2000 Hz

Output frequency stability ≤ 0.2 %

Supply voltage

Output voltage

Output power

Logic supply

(3)

S

at I

rated

(10 A

) 270 VA 560 VA 940 VA

rms

S

S

at I

(12 A

rated

(4)

) 330 VA 680 VA 1140 VA

rms

24 VDC (-10 %) to

24 VDC (+15 %)

16 V

AC

24 VDC (-10 %) to

48 VDC (+15 %)

33 V

AC

18 – 28 VDC (0.5 A)

24 VDC (-10 %) to

80 VDC (+15 %)

55 V

AC

Internal ballast resistor 22 Ω / 50 W

7

Maximum braking power 50 W 200 W for 5 s 450 W for 2 s

Ballast threshold 35 V

Overvoltage threshold 40 V

DC

DC

65 V

70 V

DC

DC

100 V

110 V

DC

DC

Undervoltage threshold 15 V

DC

Max. power loss 25 W

Ambient temperature range 5 °C to 50 °C at a maximum relative humidity of 85 % (without moisture

condensation)

100 % rated current up to max. 40 °C. At higher temperatures the power

must be reduced by 1.5 % per 1 °C.

IP Code

(1)

Adjustable via software

(2)

Minimum size of cooling surface: 6 dm² (natural convection)

(3)

Admissible voltage ripple: max. 10 %

(4)

The logic voltage is necessary to maintain the error messages. It is protected by an electronic fuse on the

drivemaster2

: from software version 1.14.100 onwards

IP20

device.

36 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 37

W

7.4 Connectors

Device variant SD2B plus

Fig. 10: Connectors of SD2B plus

You can order the appropriate connector kit for SD2B plus at SIEB &

MEYER (article No. 32299587).

7

Drive Amplifier SD2B / SD2B plus - Hardware Description 37

Page 38

Device variant SD2B plus

W

7

38 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 39

W

Connector Pin Assignment

8 Connector Pin Assignment

8.1 Operation of the Terminal Connectors

8.1.1 Spring-cage Connection

The individual conductors are fixed in

the terminal by means of spring-cage

connection. In order to plug and unplug

a conductor proceed as follows:

▶ Push a screwdriver into the desig‐

nated groove above the chamber

to operate the spring-cage connec‐

tion as shown in the figure.

▶ Put the conductor into the

chamber / remove the conductor

from the chamber.

▶ Release the screwdriver.

Solid wires or conductors with ferrules can be put directly into the chamber

without the help of a screwdriver.

8.1.2 Push-in Technology

Terminals using the push-in connection

technology (PIT) work on the pressure

spring principle:

The contact spring presses the cable

against the conducting copper bar. The

special spring profile allows direct and

tool-free wiring of solid and stranded

cables previously assembled with

ferrule or compressed conductor ends.

▶ When the cable is inserted into the

clamping unit the spring opens

automatically.

▶ To open the clamp and loosen the

cable use a screw driver.

8

8.2 ID switch

➮ Set the address for the module by means of the address selection switch.

16 adresses are available: 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C, D, E, F.

The addresses of several devices in a system must be different from each

other to ensure that they can be identified by the software.

Drive Amplifier SD2B / SD2B plus - Hardware Description 39

Page 40

Connector Pin Assignment

8.3 X2 – Motor Connection

4-pole Combicon connector, suitable for mating connector MSTB 2,5/ 4-ST-5,08

(Phoenix)

Mating connector X2

Specification of terminal connections

▶ Conductor cross-section solid/stranded: 0.75 – 2.5 mm²

▶ Tightening torque: 0.5 – 0.6 Nm

Related topics

Connection example: "X2/X13 – Motor Phases", page 47

Pin I/O Name Meaning

1 O U Motor phase U

2 O V Motor phase V

3 O W Motor phase W

4 PE Protective conductor

W

8.4 X4 – DC Power Supply

8

3-pole Combicon connector, suitable for mating connector MSTB 2,5/ 3-ST-5,08

(Phoenix)

Mating connector X4

Voltage range: 24 to 80 VDC, voltage ripple max. 10 %

Specification of terminal connections

▶ Conductor cross-section solid/stranded: 0.75 – 2.5 mm²

▶ Tightening torque: 0.5 to 0.6 Nm

Pin Name Meaning

1 DC+ DC power supply +

2 DC− DC power supply −

3 PE Protective conductor

NOTICE

Wiring error

To prevent wiring errors and subsequent damage to the device you must always

wire all pins (incl. pin 2 / DC−) with adequate conductor cross-section.

40 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 41

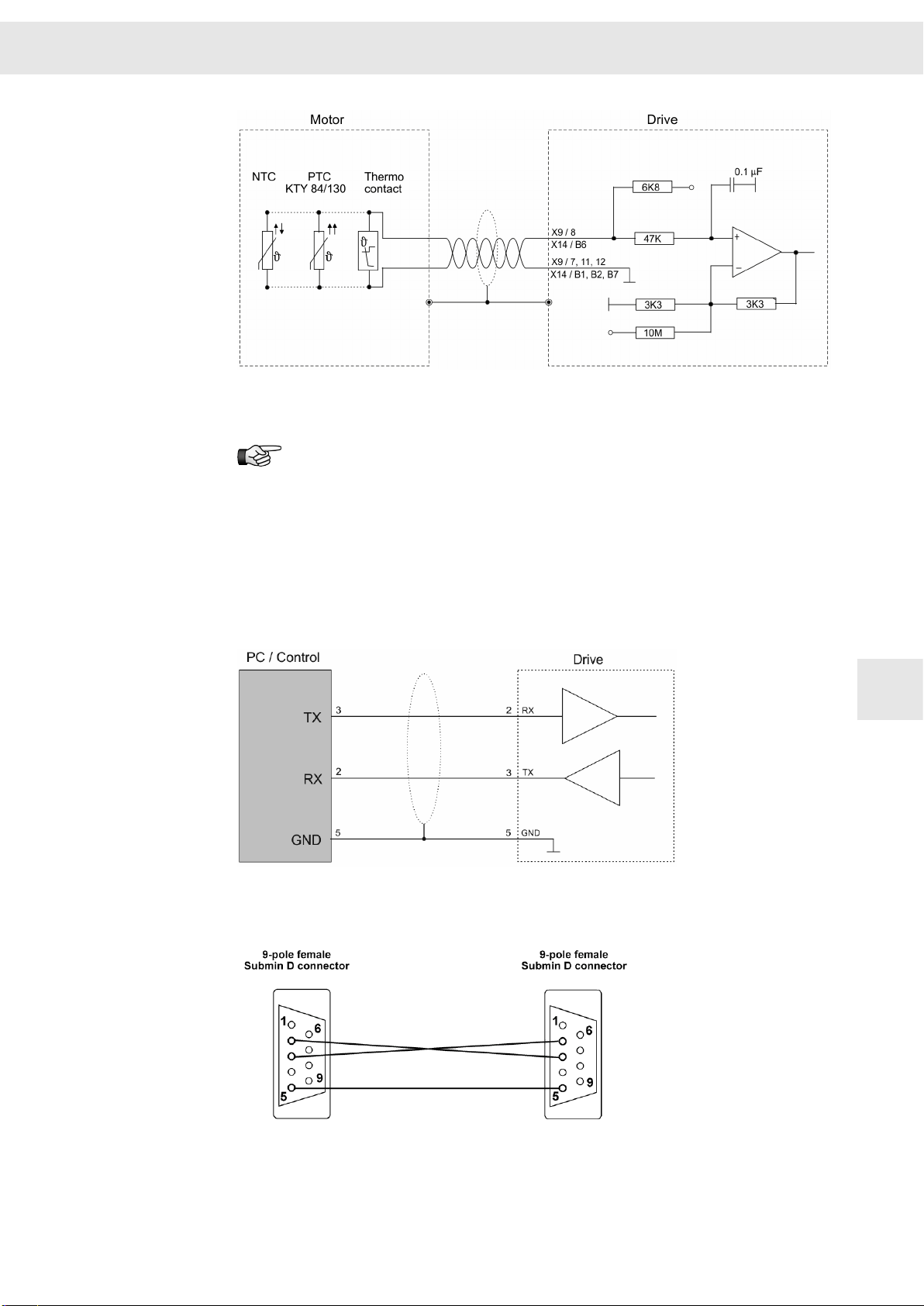

W

Connector Pin Assignment

NOTICE

Voltage peaks during braking operation

During braking of high inertial masses and/or when using short braking times the

DC main voltage can increase significantly depending on the parameterized supply

voltage.

▶ supply voltage 24 VDC → max. overvoltage 40 V

▶ supply voltage 48 VDC → max. overvoltage 70 V

▶ supply voltage 80 VDC → max. overvoltage 110 V

The connected power supply unit must be designed for this voltage. If not, you

need to decouple the main voltage by means of a blocking diode to avoid damage

to the power supply unit (see connection example

Related topics

Connection example: "X4/X6 – DC Power Supply Unit", page 48

8.5 X6 – Logic Supply

2-pole Combicon connector, suitable for mating connector MSTB 2,5/ 2-ST-5,08

(Phoenix)

Mating connector

X6

Pin I/O Name Meaning

1 I +24V Logic supply +24 VDC (0.5 A)

2 I/O GND Ground

DC

DC

DC

page 48).

8

Always connect GND.

Voltage range: 24 VDC, voltage ripple max. 10 %

Specification of terminal connections

▶ Conductor cross-section solid/stranded: 0.2 to 2.5 mm²

▶ Tightening torque: 0.5 to 0.6 Nm

Related topics

Connection example: "X4/X6 – DC Power Supply Unit", page 48

8.6 X9 – Inputs/Outputs

The available functions of the inputs and outputs are different depending on the drive

function. You must set the desired function for each input/output in the software

master2

.

drive‐

Drive Amplifier SD2B / SD2B plus - Hardware Description 41

Page 42

Connector Pin Assignment

12-pole Mini-Combicon connector, suitable for mating connector MC 1,5/ 12-ST-3,81

(Phoenix)

Mating connector

X9

(1)

You can set the desired type of the output driver in the software

Pin I/O Name Meaning

1 I IN0

2 I IN1

3 O OUT0

4

5 O OUT2

6 O VCC_10 10 V voltage supply for analog input

7 I/O GND Ground

8 I Temp Temperature sensor of the motor (against

9 I AIN0+ ±10 V analog input

10 I AIN0− Reference point of AIN0+ (pin 9)

11 I/O GND Ground

12 I/O GND Ground

O OUT1

Digital 24 VDC input

Digital output

▶ low-side driver: max. 500 mA, max. 40 V

▶ high-side driver: max. 100 mA

GND)

(1)

drivemaster2

.

W

Specification of terminal connections

▶ Conductor cross-section solid/stranded: 0.14 to 1.5 mm²

▶ Tightening torque: 0.22 to 0.25 Nm

Related topics

8

Connection examples: "X9 – Inputs/Outputs", page 49

Connection example: "X9/X14 – Temperature Sensor of the Motor", page 50

8.7 X10 – COM1 / Operating Terminal

9-pole male submin D connector

X10

Pin I/O Name Meaning

1 O VCC 5.3 V (power supply for optional oper‐

ating terminal, short-circuit proof)

2 I RX Receive data

3 O TX Transmit data

4 I/O CAN_L CAN_L

5 I/O GND Ground

6 I RX2 Receive data 2

7 O TX2 Transmit data 2

8 I/O CAN_H CAN_H

9 I/O GND Ground

Stud bolt flange: max. tightening torque = 0.7 Nm

Related topics

Connection examples: "X10 – Bus Connection", page 51

42 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 43

W

8.8 X11 – USB

Communication interface to the connected PC

4-pole female USB connector, type B

X11

8.9 X12 – DC Power Supply

3-pole Combicon connector, suitable for mating connector FKCN 2,5/ 3-ST-5,08

(Phoenix)

Mating connector X12 Pin Name Meaning

Pin I/O Name Description

1 - VCC 5 V voltage supply for USB

2 I/O DN Data−

3 I/O DP Data+

4 I/O GND Ground

1 DC+ DC power supply +

2 DC− DC power supply −

3 PE Protective conductor

Connector Pin Assignment

8

Voltage range: 24 to 80 VDC, voltage ripple max. 10 %

Specification of terminal connections

▶ Conductor cross-section solid: 1 to 1.5 mm²

▶ Conductor cross-section stranded: 1 to 2.5 mm²

▶ Connection method: push-in spring connection (handling: see page 39)

NOTICE

Wiring error

To prevent wiring errors and subsequent damage to the device you must always

wire all pins (incl. pin 2 / DC−) with adequate conductor cross-section.

Related topics

Connection example: "X12/X14 – DC Power Supply Unit", page 53

Drive Amplifier SD2B / SD2B plus - Hardware Description 43

Page 44

Connector Pin Assignment

8.10 X13 – Motor Connection

4-pole Combicon connector, suitable for mating connector FKCN 2,5/ 4-ST-5,08

(Phoenix)

Mating connector X13

Specification of terminal connections

▶ Conductor cross-section solid: 1 – 1.5 mm²

▶ Conductor cross-section stranded: 1 – 2.5 mm²

▶ Connection method: push-in spring connection (handling: see page 39)

Pin I/O Name Meaning

1 O U Motor phase U

2 O V Motor phase V

3 O W Motor phase W

4 PE Protective conductor

W

Related topics

Connection example: "X2/X13 – Motor Phases", page 47

8.11 X14 – Inputs/Outputs / Safety Circuit (STO)

8

2 ×12-pole Mini-Combicon connector, suitable for mating connector DFMC 1.5/12ST-3.5 (Phoenix)

Mating

connector

X14

Pin

A1 I/O GND Ground

A2 I 24V IN Logic feed-in 24 V

A3 O

A4 O

A5 I SAFE B / OSSD2 Enable of the safety circuit

A6

A7

A8 O OUT4 Digital output

A9 O OUT3 Digital output

A10 O OUT2 Digital output

A11 O OUT1 Digital output

A12 O OUT0 Digital output

B1 I/O GND Ground

B2 I/O GND Ground

I/O Name Meaning

24V OUT

24V OUT

I SAFE A / OSSD1 Enable of the safety circuit

I/O GND Ground

(1)

(1)

Logic supply 24 V

Logic supply 24 V

▶ Permanent load approx. 15 mA/24 V

▶ Startup peak current is negligible under

normal conditions.

▶ Continous load at 24 V > 160 mA/24 V,

dependent on the device performance

▶ Startup peak current per device can exceed

8 A/24 V during the first 2 ms.

44 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 45

W

Connector Pin Assignment

Mating

connector

X14

B3 I A IN− Reference point for AIN+ (pin B4)

(1)

The 24 V output is not suited to supply external safety circuits because an external voltage source is

necessary to comply with the applicable standards.

Pin

B4 I A IN+ Analog input

B5 I VCC10 10 V supply voltage

B6 I TEMP Motor temperature (to be connected towards

B7 I/O GND Ground

B8 I IN4 Digital input

B9 I IN3 Digital input

B10 I IN2 Digital input

B11 I IN1 Digital input

B12 I IN0 Digital input

I/O Name Meaning

GND)

The power supply unit is only activated when SAFE A and SAFE B are

connected. If the safety function is not required, pin A5 and pin A6 must be

bridged to pin A4.

Specification of terminal connections

▶ Conductor cross-section solid/stranded: 0.2 to 1.5 mm²

▶ Connection method: spring-cage connection (handling: see page 39)

Related topics

Connection examples: "X14 – In/Out / STO", page 53

Connection example: "X9/X14 – Temperature Sensor of the Motor", page 50

Connection example: "X12/X14 – DC Power Supply Unit", page 53

Safety function STO: "Safety Circuit / Restart Lock (STO)", page 75

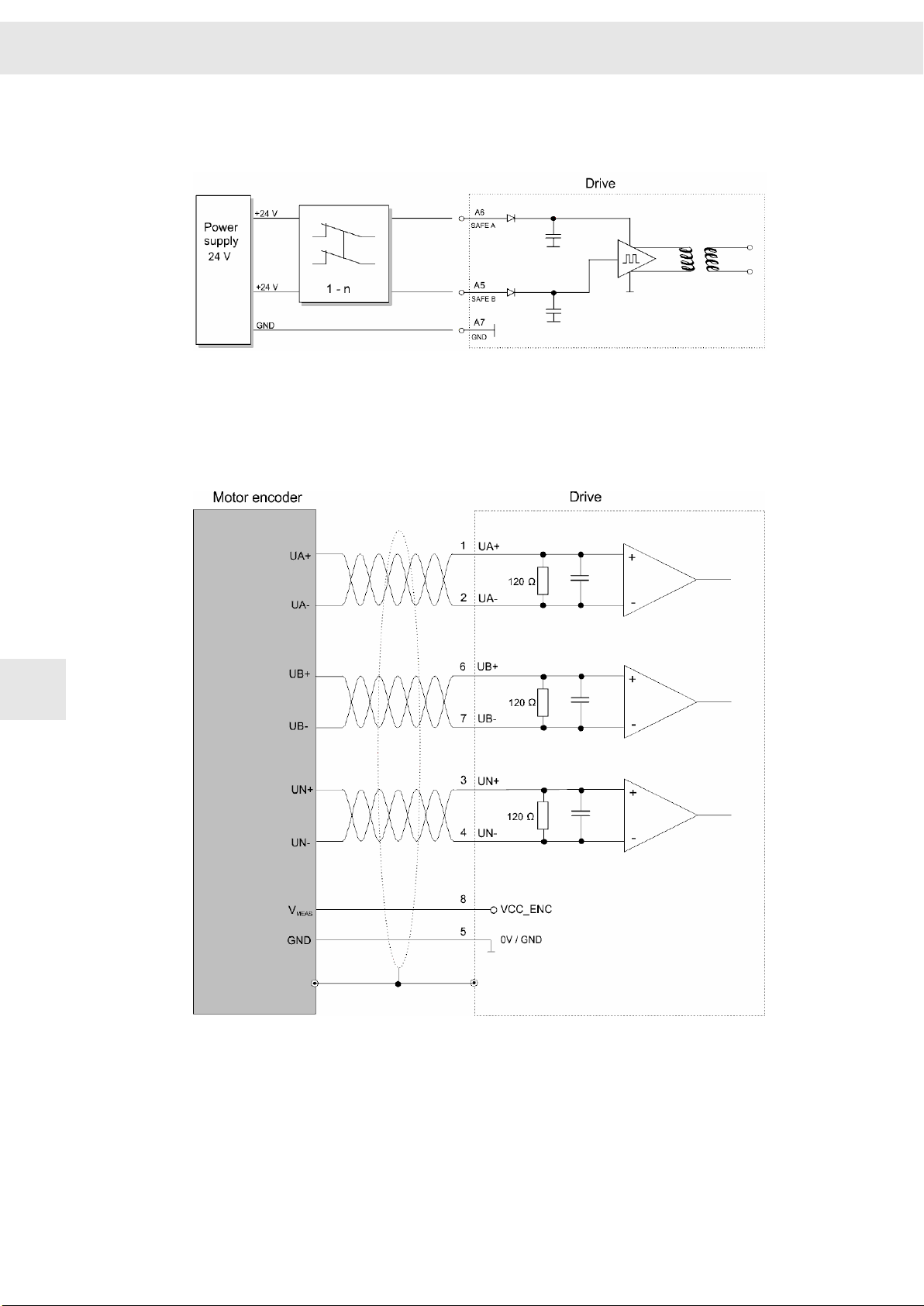

8.12 X15 – Encoder 0

Encoder 0 input, e.g. for length measuring systems

9-pole female submin D connector

X15

Pin I/O Name Meaning

1 I UA+ Track A+

2 I UA- Track A-

3 I UN+ Zero pulse+

4 I UN- Zero pulse-

5 I/O GND Ground

6 I UB+ Track B+

7 I UB- Track B-

8 O VCC_ENC 5.3 V supply voltage

9 I ERR Measuring system error

8

Stud bolt flange: max. tightening torque = 0.7 Nm

Drive Amplifier SD2B / SD2B plus - Hardware Description 45

Page 46

Connector Pin Assignment

Related topics

Connection example: "X15, X16 – Incremental Encoder with TTL Signals", page 56

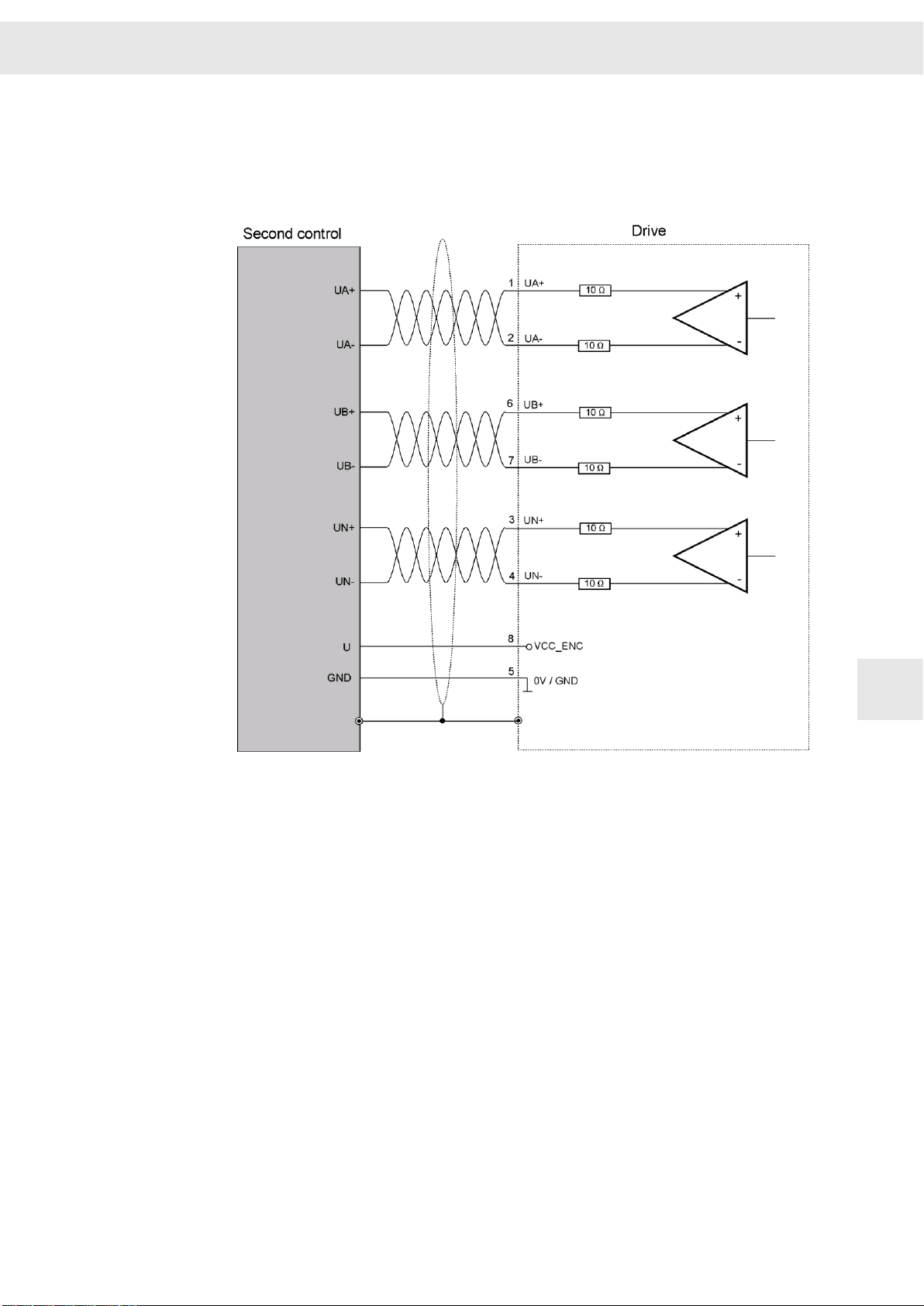

8.13 X16 – Encoder 1 / Encoder Emulation

Encoder 1 input and encoder emulation output e.g. for depth measuring systems

Hall sensor input (5.3 V), PULSE IN (5.3 V)

9-pole female submin D connector

X16 Pin I/O Name Meaning

1 I/O UA+ Track A+

2 I/O UA- Track A-

3 I/O UN+ Zero pulse+

4 I/O UN- Zero pulse-

5 I/O GND Ground

6 I/O UB+ Track B+

7 I/O UB- Track B-

8 O VCC_ENC 5.3 V supply voltage

9 I ERR Measuring system error

W

Stud bolt flange: max. tightening torque = 0.7 Nm

8

Related topics

Connection example: "X15, X16 – Incremental Encoder with TTL Signals", page 56

Connection example: "Encoder Emulation", page 57

Connection example: "Hall Sensor 5.3 V", page 58

Connection example: "PULSE IN 5.3 V", page 58

46 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 47

W

9 Connection Examples

The following sections provide connection examples for the individual connectors of

the device.

9.1 X2/X13 – Motor Phases

Connection Examples

Ground the motor housing in the machine!

DANGER

9

Dangerous shock currents

Earthing and shielding measures are required to protect devices and persons. To

ensure the safety of the operator earthing must be carried out with low impedance.

With respect to the ground connection one of the following actions must be done:

▶ connect the motor housing to the ground of the machine or

▶ connect the ground terminal of the motor connector to the central ground point

of the machine.

Consider the following with regard to shielding: Always use shielded motor cables!

Drive Amplifier SD2B / SD2B plus - Hardware Description 47

Page 48

Connection Examples

9.2 X4 – Decoupling of the Main Voltage

Decoupling of the main voltage by means of a blocking diode:

You can order the appropriate blocking diode module at SIEB & MEYER

(article No. 036210082). For a description of the module and more connec‐

tion examples refer to the technical information “TIE_036210082_Blocking‐

Diode_SD2B.pdf”.

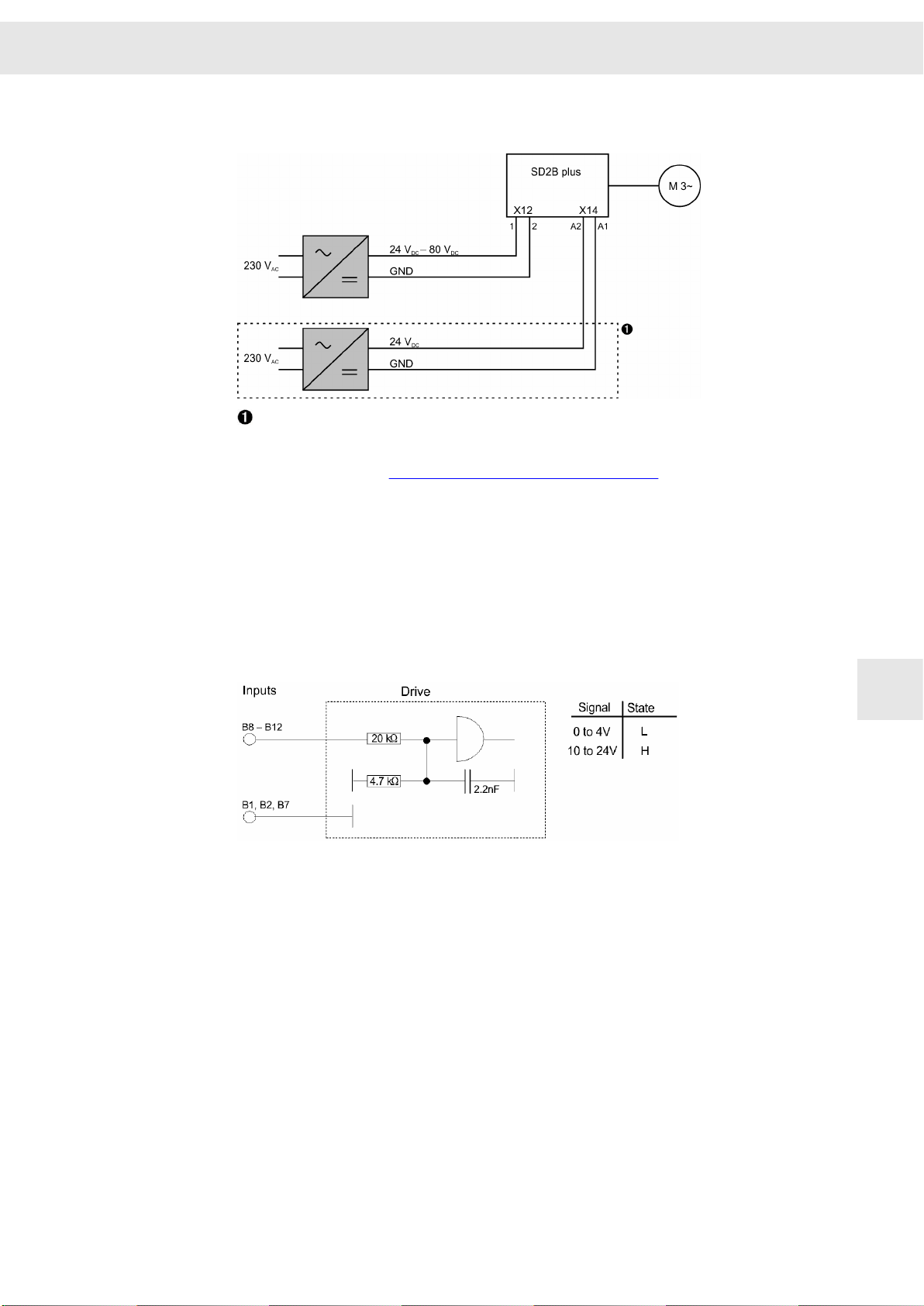

9.3 X4/X6 – DC Power Supply Unit

W

The following examples show different options for the connection of the power supply

unit to SD2B for main and logic supply.

Setup 1: 24 VDC logic and main voltage supply (one power supply unit)

9

Setup 2: 24 VDC logic supply and 48 VDC main voltage supply (two power supply units)

48 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 49

W

Setup 3: 24 VDC logic supply and 72 VDC main voltage supply (two power supply units

connected in series)

9.4 X9 – Inputs/Outputs

9.4.1 Digital Inputs

Connection Examples

The meanings of the digital inputs can be defined by parameters.

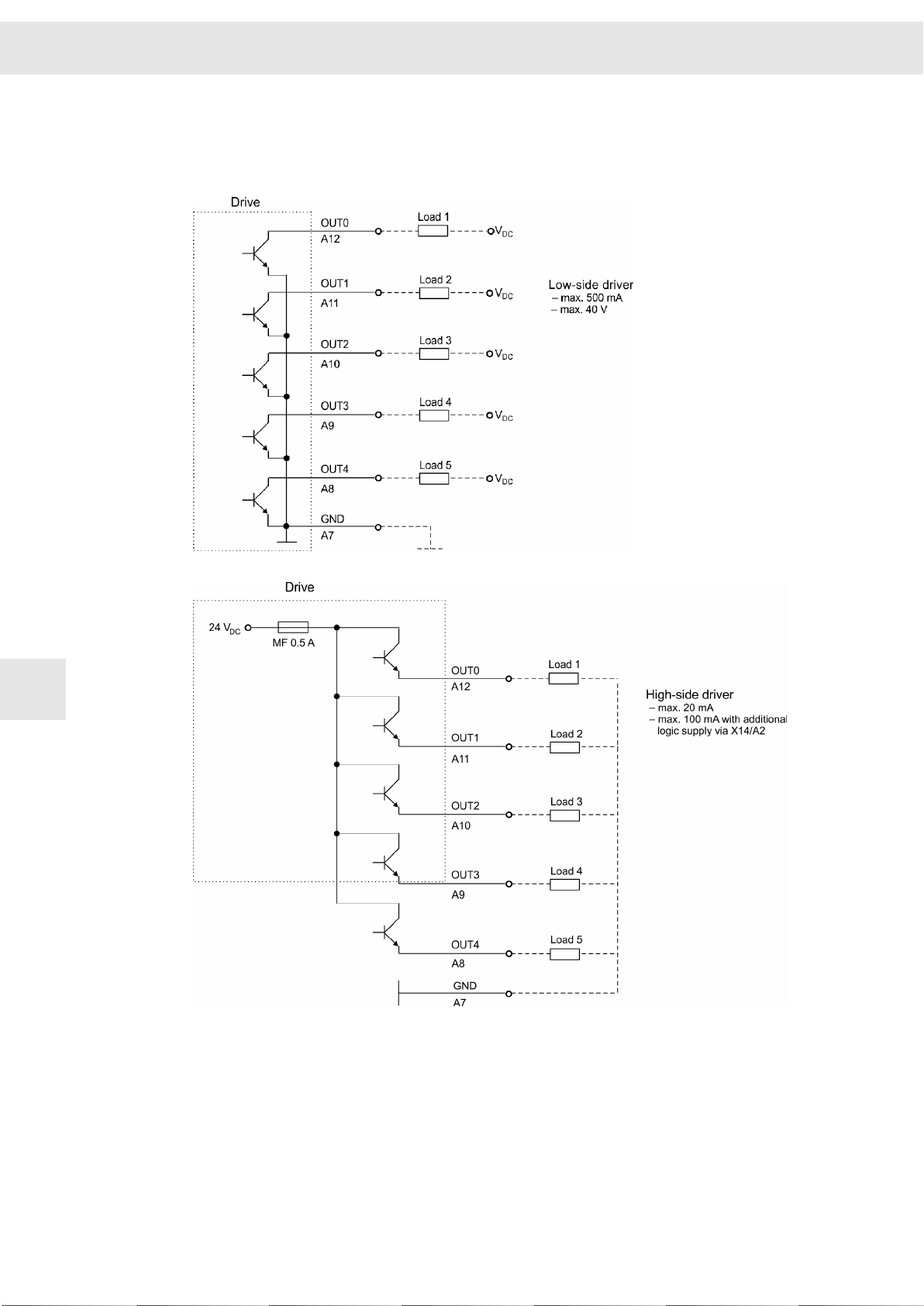

9.4.2 Digital Outputs

The output driver can operate as low-side driver or as high-side driver. You can set the

desired driver type in the software

drivemaster2

9

.

Drive Amplifier SD2B / SD2B plus - Hardware Description 49

Page 50

Connection Examples

9.4.3 Analog Input

W

9

Voltage interface with input voltage range: ±10 V

Can also be connected to potentiometer (500 Ω – 5 kΩ)

9.5 X9/X14 – Temperature Sensor of the Motor

INPUT/OUTPUT: The thermal motor protection is evaluated via these connectors.

The drive amplifier supports evaluating the temperature monitoring integrated in the

motor. The NTC/PTC behavior of the monitoring is defined in the software (motor para‐

meters). The controller is deactivated as soon as the critical motor temperature is

reached.

You can configure “None”, “PTC / Thermo switch”, “NTC”, “KTY84/130”, “KTY83/122”

and “PT1000”.

50 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 51

W

Connection Examples

The temperature sensor must have an internal resistor between 250 Ω and 2 kΩ.

If no motor temperature sensor is connected, the input must be connected

with GND.

9.6 X10 – Bus Connection

9.6.1 COM1 – RS232

If you connect X10 to a standard RS232 interface of a PC (9-pole male submin D

connector), the used cable must look like this:

9

Drive Amplifier SD2B / SD2B plus - Hardware Description 51

Page 52

Connection Examples

Additional RS232 connection available:

9.6.2 CAN Bus

The CAN interface is designed according to ISO 11898. It is a two-wire connection with

differential signals. ISO 11898 specifies a bus cable with two signal lines, CAN_H and

CAN_L. The lines have a rated impedance of 120 Ohm. The signal lines are connected

to a terminating resistor (120 Ohm) at both ends of the bus cable (see figure).

W

9

The total length of the bus cable must not exceed the specified lengths. The following

table indicates physical limitations valid for specific transmission rates:

Baud rate

50 kBd 1000 m

125 kBd 500 m

250 kBd 250 m

500 kBd 100 m

1000 kBd 25 m

The number of bus nodes is also limited by the specification according to ISO 11898.

The limiting value is between 32 and 100 bus nodes. depending on the used cable and

transmission rate. For further information on the maximum number of bus nodes refer

to the document “CAN Physical Layer” by the user organization CiA e. V.

Max. bus length

52 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 53

W

Connection Examples

9.7 X12/X14 – DC Power Supply Unit

The logic supply at X14 is required under the following conditions:

▶ maintaining the error messages after switch-off is desired

▶ higher output currents of the digital outputs (> 20 mA), see connection

example section 9.8.2 "Digital Outputs", page 54

9.8 X14 – In/Out / STO

9.8.1 Digital Inputs

The meanings of the digital inputs can be defined by parameters.

9

Drive Amplifier SD2B / SD2B plus - Hardware Description 53

Page 54

Connection Examples

9.8.2 Digital Outputs

The output driver can operate as low-side driver or as high-side driver. You can set the

desired driver type in the software

drivemaster2

W

.

9

54 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 55

W

9.8.3 Analog Input

Voltage interface with input voltage range: ±10 V

Connection Examples

Can also be connected to potentiometer (500 Ω – 5 kΩ)

9.8.4 safety circuit (STO)

See also chapter 13 "Safety Circuit / Restart Lock (STO)", page 75.

9.8.4.1 Wiring with OSSD

OSSD = Output Signal Switching Device

9

Drive Amplifier SD2B / SD2B plus - Hardware Description 55

Page 56

Connection Examples

9.8.4.2 Wiring without OSSD

OSSD = Output Signal Switching Device

9.9 X15, X16 – Incremental Encoder with TTL Signals

W

9

Encoder signals: 5V

56 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 57

W

9.10 X16 – ENC1/EMU

9.10.1 Encoder Emulation

Connection Examples

The transmission meets the requirements of the standard TIA/EIA-422-B with a voltage

differential of at least. ±0.9 V.

9

Drive Amplifier SD2B / SD2B plus - Hardware Description 57

Page 58

Connection Examples

9.10.2 Hall Sensor 5.3 V

W

9

9.10.3 PULSE IN 5.3 V

58 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 59

W

Status Display and Error Messages

10 Status Display and Error Messages

The 7-segment display shows status and error messages.

A status message is made up of 1 to 5 digits and displayed as sequence. All messages

end with dot behind the last digit. When the first digit is 'E.', there is a permanent error.

If the cause of an error can be specified, the display indicates the actual error code

followed by a hyphen and a one-digit sub error code.

Devices with older firmware do not feature the sub error code.

Examples:

1. Permanent display 0

▶ Controller is switched off.

▶ No error.

2.

3.

4.

5.

6.

7.

8.

Permanent display 1

Permanent display 1.

→ →

→ →

→ → → →

→ →

→ →

Sequential display

Sequential display

Sequential display

Sequential display

▶ Controller is switched on.

▶ No error.

▶ Controller is switched on.

▶ No error.

▶ Dot calls additional attention to PI limit.

▶ Controller is switched off due to error E40.

▶ The error is not present anymore.

▶ Controller is switched off due to error E40.

▶ The error is still present (indicated by the dot

behind 'E').

Sequential display

▶ Controller is switched off due to error E11.

▶ The error is still present (indicated by the dot

behind 'E').

▶ Sub error code 4 is indicated as cause.

▶ Controller is in boot loader mode: Display appears

short-time when the device is booted and when

the system software is loaded.

▶ Drive address: During booting of the devices the

set address of the drive is displayed short-time

(here A01)

10

10.1 List of the Operating States

Code

0 Ready to switch on

1 Controller active

1. Controller active, controller is limited / PI limit

2 Mains 'Ready for operation' not present yet

L Boot loader active (during boot / software load)

Drive Amplifier SD2B / SD2B plus - Hardware Description 59

Description

Page 60

Status Display and Error Messages

10.2 List of Drive Error Messages

The following messages apply to the entire SD2x drive series. According to

the device type or operating mode, certain messages may not appear.

Code Error message Error reaction Possible reason

W

E03

(0x103)

(259d)

E05

(0x105)

(261d)

E06

(0x106)

(262d)

E07

(0x107)

(263

d

Interpolation error (interpolated

position control)

1 Acceleration limit exceeded

2 Speed limit exceeded

3 Index error

Error caused by warning

Digital Input 'External Hardware'

0 Digital input 0 Digital input “External Hardware

1 Analog input 0: broken cable 1 Minimum current monitoring of

2 Analog input 1: broken cable 2 Minimum current monitoring of

3 Analog input 0 and 1: broken

cable

Error in internal hardware

)

Motor is stopped by quick stop

ramp and drive is disabled

(controlled standstill).

Motor is stopped by quick stop

ramp and drive is disabled

(controlled standstill).

Motor is stopped by parameterdriven ramp and drive is disabled

(controlled standstill).

Motor is stopped by quick stop

ramp and drive is disabled

(controlled standstill).

▶ Faulty motion profile of the higher-

ranking control

▶ Parameter-driven monitoring

stopped the drive.

Monitoring of external hardware:

OK” is not connected to 24 V.

analog input 0 has triggered.

analog input 1 has triggered.

3 Minimum current monitorings of

analog inputs 0 and 1 have trig‐

gered.

▶ Overload in digital outputs

▶ SD2B plus: Operating voltage not

available

10

E09

(0x109)

(265

d

E10

(0x10A)

(266

d

E11

(0x10B)

(267

d

Hiperface / EnDat OEM data

incorrect

)

drive-setup-tool heartbeat

)

Communication / bus system error

1

▶

SERVOLINK 4

)

2

▶

DNC 8 Byte

3

▶

CAN bus

4

▶

EtherCAT

1

Faulty telegram ID

2

Zero data telegram

3

CRC error

4

Synchronization error

5

Configuration error

6

NMT error

7

Addressing error

1

2, 3, 4

4

No "Ready" for startup ▶ Number of motor pole pairs in

Motor is stopped by quick stop

ramp and drive is disabled

(controlled standstill).

Motor is stopped by parameterdriven ramp and drive is disabled

(controlled standstill).

1

1

1, 4

4

EnDat/Hiperface encoder does not

match the parameter set.

▶

drive-setup-tool

communicate with the drive in the

parameterized monitoring time.

Monitoring of bus communication led to

switch-off:

1 Faulty reference value telegram

2 Higher-ranking control not active

3 Check sum error, interferences

during transmission

4 Drive telegram not synchronized

5 Faulty configuration of mailbox,

PDO, watchdog or synchronization

6 Control channel of bus system

was not active during switch-on

(pre-operational)

7 Faulty drive address

was not able to

60 Drive Amplifier SD2B / SD2B plus - Hardware Description

Page 61

W

Status Display and Error Messages

Code Error message Error reaction Possible reason

E12

(0x10C)

(268d)

E15

(0x10F)

(271

d

E17

(0x311)

(785d)

E18

(0x312)

(786d)

E25

(0x319)

(793d)

E26

(0x31A)

(794

d

8

Node Guarding

9

EEPROM error

10

Heartbeat / Watchdog

Mains 'Ready for operation' is

missing

Endat / Hiperface communication

faulty

)

FPGA power output stage shut‐

down

Error in spindle selection

Power supply load too high

Motor temperature too high

)

3

4

2, 3, 4

8 Communication node monitoring:

monitoring time expired (configu‐

rable)

9 Error in EtherCAT EEPROM

10 Heartbeat monitoring: monitoring

time expired (configurable)

Motor is stopped by parameterdriven ramp and drive is disabled

(controlled standstill).

Motor is stopped by quick stop

ramp and drive is disabled

(controlled standstill).

Motor is stopped immediately. ▶ Overload in power supply unit

Motor is stopped immediately. ▶ Spindle selection was not valid at

Drive is stopped by limitation of

motor torque.

Motor is stopped by error ramp

and current limitation.

▶ Power output stage was switched

on, when mains supply was discon‐

nected/interrupted.

▶ Communication of EnDat/Hiperface

is faulty.

“Switch on”.

▶ Output power of drive is greater

than rated power of power supply

unit, since the dimensioning of

drive and motor are not compatible.

▶ Wrong parameters entered for the

motor or wrong dimensioning of the

motor

E27

(0x31B)

(795

d

E28

(0x31C)

(796d)

E29

(0x31D)

(797d)

E30

(0x31E)

(798

d

E31

(0x31F)

(799

d

E33

(0x521)

(1313

E34

(0x522)

(1314

Ambient temperature too high

)

Power output stage temperature

too high

Motor load too high (Motor I²t)

Power output stage load too high

(I²t)

)

Speed error or slip too high

)

Power supply load monitoring ->

mains voltage too high

d

)

Power supply load monitoring ->

mains voltage too low

d

)

Motor is stopped by error ramp

and current limitation.

Motor is stopped by error ramp

and current limitation.

Motor is stopped by error ramp

and current limitation.

Motor is stopped by error ramp

and current limitation.

SERVO / VECTOR: Drive is

limited by current monitoring via

short-circuit of the motor phases.

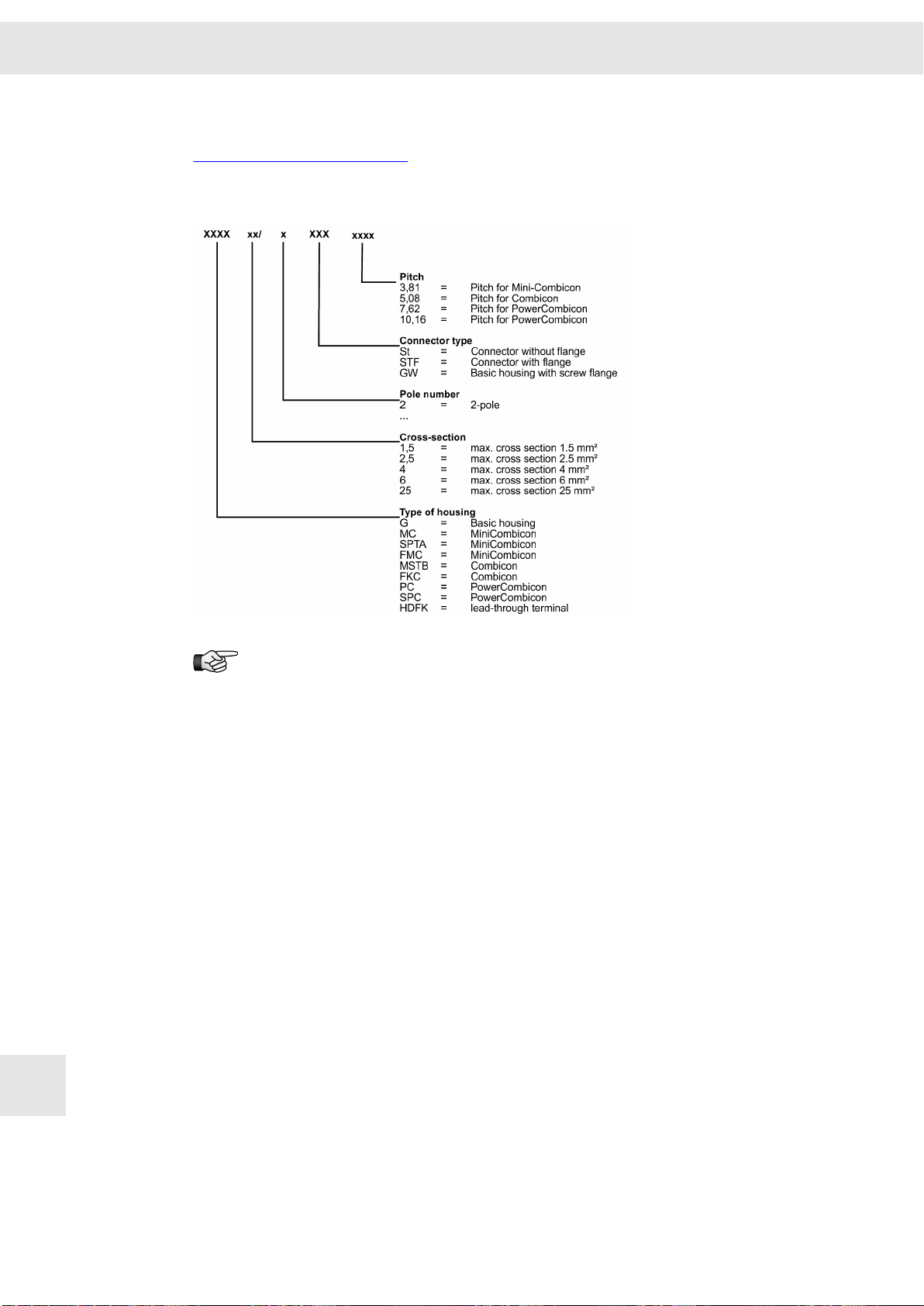

(1)