PLUS II

Dynamic Mattress Replacement System

User Instructions

www.sidhil.com

CONTENTS

Important Notice

Before operating this medical equipment, it is

important to read this manual and understand

the operating instructions and safety

precautions. Failure to do so could result in

injury and/or damage to the product.

If you have any questions, please see contact

information on rear cover.

INTRODUCTION ..................................... 4

SAFETY PRECAUTIONS ......................... 5

PRODUCT OVERVIEW............................ 6

INSTALLATION ....................................... 7

OPERATION ............................................ 9

Control Unit Panel ................................ 9

Mattress Function ................................ 9

Use of Incontinence Products ............. 11

Static Mode ....................................... 11

Removal & Transport Function ............ 12

Mains Supply Power Failure ................ 12

TROUBLESHOOTING ........................... 13

CLEANING ............................................ 15

MAINTENANCE .................................... 16

TECHNICAL SPECIFICATION ................. 17

WARRANTY INFORMATION ................. 23

3

INTRODUCTION

Plus II Dynamic Mattress Replacement System

Thank you for choosing a Plus II Dynamic Mattress Replacement System. This user manual should

be read carefully before using the mattress as it contains important information regarding safe

operation and maintenance in order to provide long lasting and reliable service.

Please ensure that you understand all the instructions, if you have any questions concerning the

operation and maintenance of the mattress please contact your supplier who will provide you with

expert professional advice.

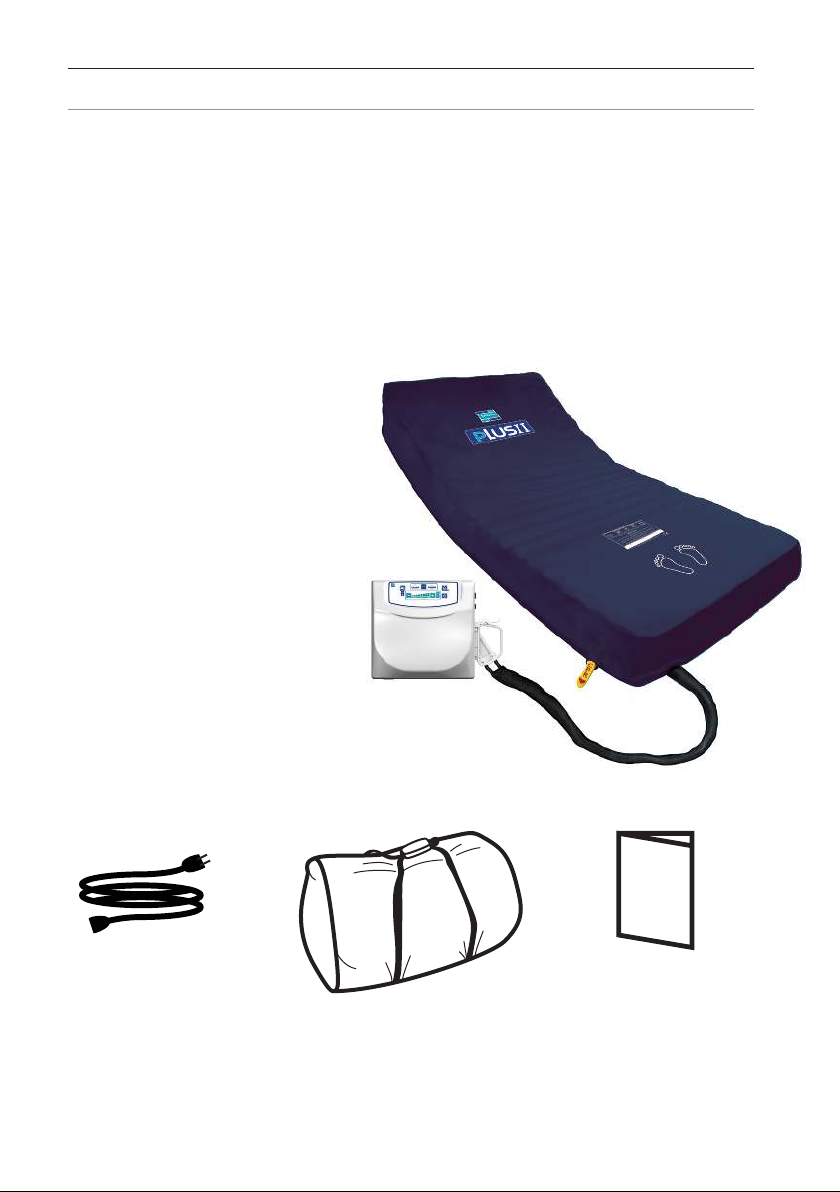

Plus II Mattress System

The box contains an assembled

mattress system consisting of:

A. Plus II Alternating Dynamic System

B. Digital Control Unit

C. Power Cord

D. Carry Bag

E. User Manual

C.

D. E.

A.

B.

4

SAFETY PRECAUTIONS

In General Control Unit

Do not use this equipment in the

presence of flammable anaesthetics.

Keep away from sources of heat and

naked flames.

Bed frames used with the systems

can vary greatly depending on the specific

healthcare setting (i.e. hospitals, nursing

homes, home care etc). It is the responsibility

of the carer to carry out the necessary risk

assessments to ensure the safety of the

patient. This includes, but is not limited to,

the appropriate use of side rails to prevent

falls and/or patient entrapment.

Minimise articles (e.g. bedding) between

the mattress surface and patient, and secure

bed sheets loosely so as not to affect the

alternating cell movement.

The control unit is tested and CE marked

in line with Medical Device Directive (93/42/

EEC).

Only plug into a mains socket using the

mains cable supplied with the system.

Exposure of the control unit to any liquid

while it is plugged in could result in a severe

electrical hazard.

Only use fuses that have the same

specified rating. Using fuses with higher

ratings could result in damage and/or injury.

(See Technical Specification).

The control unit is a precision electronic

product. Use care when handling or

transporting. Dropping or other sudden

impacts may result in damage to the unit.

Do not open the control unit – risk of

electrical shock. Do not attempt to repair or

service the control unit. Repairs and service

should be conducted by suitably trained

personnel. If the control unit is not functioning

properly, or has been damaged, unplug the

unit and take it out of service immediately

(See contact information on rear cover for

repair and service information).

Do not place any objects or items, such

as blankets, on or over the control unit.

The mains cable to the control unit should

be correctly positioned to avoid a tripping

hazard and/or damage to the cable. It is

recommended to place the cable under the

bed frame and attach it to a mains socket by

the head end of the bed.

5

PRODUCT OVERVIEW

Alternating Mattress System (see Technical Specification)

The Plus II Dynamic Mattress Replacement

System is intended to provide comfort and

pressure relief to patients vulnerable to

pressure damage. It is designed for use on

both standard and profiling bed frames. Ideally,

patients allocated to this system will have

some degree of independent mobility or can be

repositioned according to individual needs.

The maximum patient weight limit is

177kg (28 Stone).

Mattress

This system includes three static head cells

to provide static support for optimum user

comfort, while air pressure in the other cells

is alternated over a 12 minute cycle. This

provides regular periods of pressure reduction

to aid blood and lymphatic flow to vulnerable

tissue

Control Unit

The control unit provides the air supply to the

mattress.

• It is controlled via a touch panel with

integrated digital display. The alarm sounds

when low pressure is detected or when

power is interrupted. The alarm mute

function silences the alarm for a maximum

of 20 minutes – the alarm resumes if the

cause of failure is not resolved. The alarm

will sound for up to two hours following an

interruption to power.

• The control unit includes a back up battery

for the audible alarm. This battery is

continuously re-charged and will last the life

time of the product.

• Functions on the control panel adjust the 8

comfort level settings.

• When a fault condition exists a warning LED

is illuminated with an audible alarm.

The visible and audible alarm function has a

number of indications depending on the cause

of the failure (see’Troubleshooting’ section).

If the mains cable becomes detached the

alternation sequence is suspended and the

mattress cells remain inflated and/or deflated

based on the current cycle. The audible alarm

will sound.

6

INSTALLATION

Any damaged or missing components should be reported to your supplier as soon as possible.

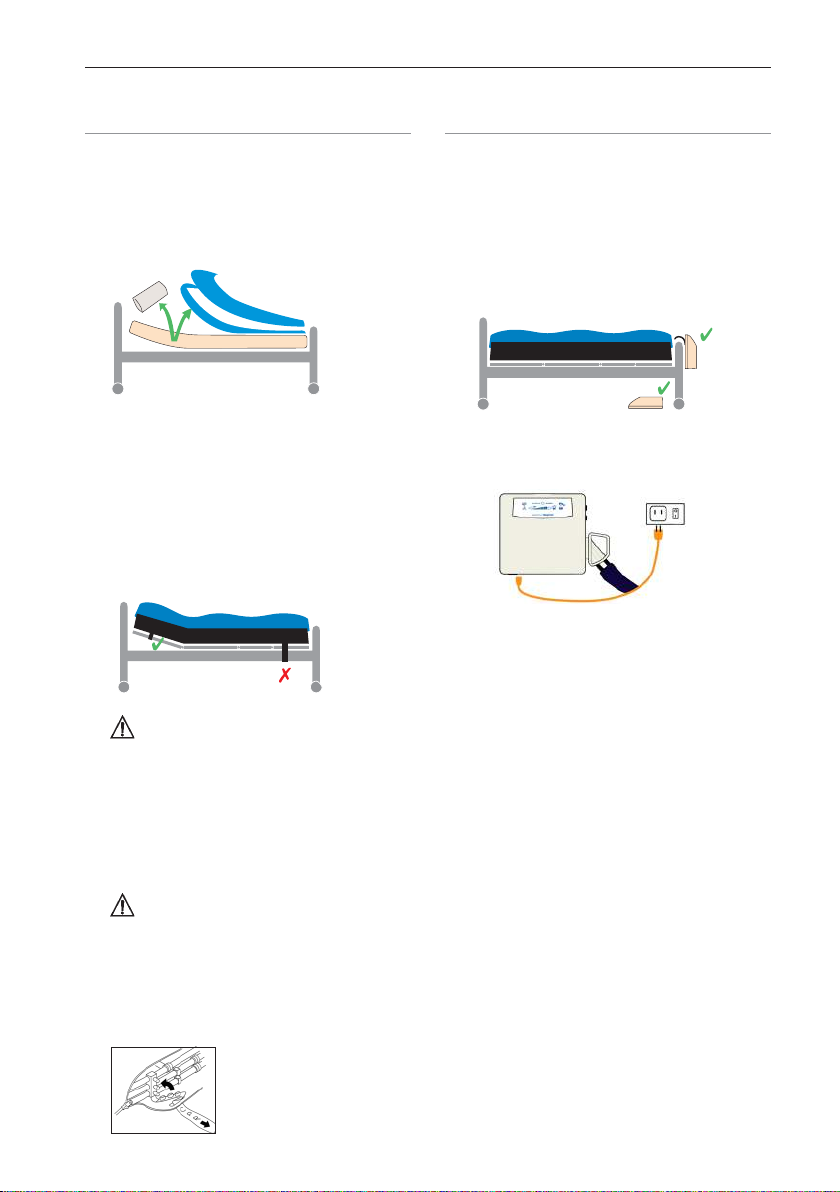

System Installation Control Unit Activation

The following describes the procedures for

initial system set up:

a. Remove all covers, sheets and mattress

from the bed.

b. On a standard bed, position the mattress

on top of the bed frame, top cover facing

upwards and air hoses at the foot of the bed

for control unit positioning.

c. Attach to the bed by securing the

adjustable straps loosely under each

section of the bed.

On a profiling bed, secure the

adjustable straps around the moveable

sections of the bed frame.

d. To avoid any risk of damage to the mattress

ensure there are no sharp objects which

may come in contact with it.

Check that the attachment of

the mattress does not interfere with the

movement or operation of the bed.

e. Ensure the CPR tag sealing connectors are

pushed firmly onto the air pipes.

a. Position the control unit by hanging the

hooks over the foot board or place unit

on the floor under the bed with the front

facing upwards. Ensure the rear of the unit

is not obstructed by carpet, rugs etc. It is

advisable to place the unit on a firm surface.

b. Attach the air connector handle to the

control unit. Ensure air hoses do not kink

between frame and control unit.

c. Insert mains cable into the control unit, plug

into a mains socket.

Press the power button for at least two

d.

seconds to activate the control unit.

pressure LED’s will flash indicating the system

has activated. The system will be ready for use

in a maximum of 50 minutes.

e. When initial inflation is complete, the 4th

pressure LED and the alternating mode

LED will illuminate to indicate the system is

ready for use (system automatically defaults

to alternating mode at start-up)

f. Once inflated, ensure the straps that attach

the mattress to the bed frame are secure

and hold the mattress in place, adjust as

necessary.

g. Once the mattress is fully inflated, the

bedding can be replaced. Secure sheets

loosely enough to ensure they do not

interfere with cell alternation.

The

.

7

INSTALLATION

To attach the handle to the control unit:

1) Depress the lever on the top of the handle.

2) Aligning the ports on the handle with those

on the control box, firmly push the handle into

position.

3) Release the lever, ensuring this has engaged

onto the catch connected to the control box.

To remove the handle from the control unit:

1) Depress the lever on the top of the handle.

2) Pull the handle away from the control unit.

1

2

8

OPERATION

Control Unit Panel

A Power Button

Turns system on/off by pressing for at least two

seconds.

B Alarm LED

The red LED flashes and an audible alarm

sounds when a fault condition has arisen in the

control unit or mattress.

C Alarm Mute Button

Silences the audible alarm. The audible alarm

will resume after 20 minutes if cause of failure is

unresolved.

The audible alarm also sounds when the power

is switched off – press alarm mute to silence.

D A/S Button

Selecting alternating mode cyclically inflates

and deflates the cells in sequence.

Selecting static mode fully inflates all cells with

no dynamic alternation.

Static mode will automatically revert to

alternation mode after 1 hour for patient safety.

E Pressure ‘+/-’ Buttons

Press ‘+/-’ to increase or decrease the

pressure setting. There are 8 available

pressure settings from soft to firm (18mmHg to

60mmHg; 6mmHg per step). The green LED’s

illuminate to indicate which of the 8 settings is

operational.

C

D

Max Button

F

Pressing the ‘max’ button facilitates rapid

inflation to the maximum pressure setting

(60mmHg), the orange ‘static’ LED will

illuminate. After 20 minutes, the system

automatically reverts back to the previous

pressure setting for patient safety.

If this function requires cancellation prior to

the system automatically switching back to

the previous setting either the ‘max’ or ‘A/S’

buttons can be pressed.

G Control Unit Lock / Unlock Button

Pressing for at least 2 seconds locks the

control unit settings – an audible tone sounds

and an amber LED illuminates to indicate

the system is locked. When locked, only the

alarm mute and lock / unlock buttons remain

operational.

Pressing again for at least 2 seconds unlocks

the control unit (alarm sounds and amber LED

extinguishes).

The control unit will automatically unlock

in the event of a power failure.

G

E F

9

AB

OPERATION

Mattress Function

Establishing Pressure (supine patient)

With the patient lying supine (face upwards),

use the ‘+/-’ functions to establish the best

setting for effective support and comfort.

Before changing or lowering the pressure,

ensure the system is working effectively by

performing a ‘bottoming out’ test.

Once the system has been set for the patient,

re-check after approximately 20-30 minutes to

ensure the patient is comfortable and that the

unit is functioning correctly.

Bottoming Out Test

When altering the pressure setting, ensure

the patient is not bottoming out (insufficiently

supported by the air cells).

1. Ensure the system is in alternation mode.

2. With the patient lying in a supine position,

unzip top cover just past the sacral

(buttocks) region.

3. Slide a hand along a deflated cell under the

patient’s sacral area. The inner static cell

will remain inflated but a hand should slide

easily between patient and static cell.

4. If a hand can pass under the sacral area the

patient is adequately supported and

pressure can be lowered as required.

5. Repeat bottoming out test if pressure has

been lowered.

Establishing Pressure (upright

position)

When moving the patient to a sitting or more

upright position, the pressure may need to be

increased to provide added support and to

avoid bottoming out.

It is important to return to the original

pressure setting when the patient returns to

the supine position.

Wait a minimum of 12 minutes between

pressure adjustment and patient assessment,

it may take a full cycle for the system to

adjust.

CPR Function

Rapid deflation of the mattress may be required

for emergency treatment or system deflation.

Firmly pull the release CPR tag from the side of

the mattress to rapidly deflate the entire system.

To re-inflate the system after the CPR tag has

been pulled, replace the CPR tag ensuring all

sealing connectors are firmly attached (see

image opposite) and restart the control unit.

Wait for the mattress system to reach optimal

pressure.

A bottoming out test must be performed

after mattress inflation, following rapid

deflation.

Re-inflation settings could be different

to setting prior to deflation. Ensure correct

pressure setting is selected.

10

OPERATION

To gain access to the sealing connectors,

unzip the top cover past the CPR tag.

Push together keeping both halves

parallel to each other.

C

P

R

Use of Incontinence Products

Incontinence products such as sheets or

pads can be used with this system. However,

product performance is likely to reduce due

to the patient experiencing less pressure relief

when using these aids.

If incontinence products are to be used it

is recommended that regular patient skin

checks are performed to ensure skin integrity is

maintained.

Static Mode

Patients should always be nursed on the

mattress in alternating mode but the static

mode maybe selected for short intervals if

a patient is finding it difficult to tolerate the

alternating mode. (This could occur if, for

example, the patient is in pain, nauseated or

perhaps having difficulty in getting off to sleep).

When static is selected all cells inflate at the

pressure at which the mattress is set, thereby

offering a non moving surface. The digital

control system will return to alternating mode

after one hour, if not manually selected by the

user. This is a safety mechanism to ensure

patients are not left on a constantly inflated

surface. It should be used only after assessing

the risk to the patient’s skin.

To select static mode depress the ‘A/S’ button,

the static LED will illuminate. The pressure can be

adjusted to suit using the pressure adjustment

‘+/-’ functions on the front of the control unit.

11

OPERATION

System Removal

1.

Turn off the control unit by pressing the

power button for at least 2 seconds and

unplug the mains cable.

2. Remove the air connection handle from the

control unit and disconnect the CPR tag.

3. Place the control unit and mains cable on

top of the mattress and detach the mattress

from the bed frame.

4. Once air has been released from all cells,

roll up the mattress and return all items to

the carry bag for safe keeping.

Mains Supply Power Failure

If it is known there is to be a power cut in

advance, follow the instructions detailed under

the heading ‘Transport Function’ prior to the

power going off.

In the event of an unplanned power cut:

1. Remove the air connection handle from

the control unit and seal with the attached

transport cap.

Transport Function

1. Before patient transport, switch modes

from alternating to static and wait for 12

minutes for all cells to inflate.

2. Remove the air connection handle from

the control unit, sealing with the attached

transport cap (see image below).

3. Turn off the control unit.

Mattress will stay inflated under normal

conditions for up to 30 hours.

C

2. Turn off the control unit.

Mattress will stay inflated under normal

conditions for up to 30 hours.

C

12

TROUBLESHOOTING

The red alarm LED flashes, and an audible alert sounds, to indicate the control unit or mattress

pressure has failed. The LED will remain illuminated until appropriate pressure is restored. The

audible alarm can be silenced by pressing the alarm mute button.

The system has five different alarm signals, identified by five different pressure setting illumination

sequences. The signals and corresponding pressure setting LED displays are illustrated below:

Alarm/Fault Cause Solution

Control unit does not

operate; no display

LED’s illuminate

Alarm LED

+ audible alarm

Alarm LED

+ audible alarm

The control

unit may not be

attached to a

power socket or

a fuse may need

replacing

Initial failure

(within 50 minutes)

Pressure too low 1. Reset the alarm – turn off power and press the

1. Check the mains cable is firmly plugged into a

wall socket and the control unit. Check the mains

power is switched on (to ensure socket is working

plug in a lamp or other fused electrical device).

2. Check the mains plug fuse (3A) then check control

unit fuse (1A) – see Section ‘Maintenance’.

Do not try to open the control unit.

Opening the unit could cause personal injury or

equipment damage.

1. Reset the alarm – turn off power and press the

alarm mute button.

2. Check the handle is intact, ensuring all four sealing

connectors are firmly fitted to the control unit and

the air hoses. Check the CPR tag is attached and

all sealing connectors are firmly secure.

3. Check all air hoses along the inside of the mattress

– each should be firmly connected. Check each air

cell is securely attached to its connecting air pipe.

4. Check all cells, pipes and hoses for any air leakage.

5. Switch on power.

alarm mute button.

2. Check the handle is intact, ensuring all four sealing

connectors are firmly fitted to the control unit and

the air hoses. Check the CPR tag is attached and

both sealing connectors are firmly secure.

3. Check all air hoses along the inside of the mattress

– each should be firmly connected. Check each air

cell is securely attached to its connecting air pipe.

4. Check all cells, pipes and hoses for any air leakage.

5. Switch on power.

13

Alarm/Fault Cause Solution

TROUBLESHOOTING

Alarm LED

+ audible alarm

Alarm LED

+ audible alarm

Alarm LED

+ audible alarm

Pressure too high 1. Reset the alarm – turn off power and press the

alarm mute button.

2. Disconnect the air hoses to reduce pressure –

reconnect when pressure has decreased.

3. Check for twists in the air hoses between mattress

and control unit.

4. Switch on power.

Alternating

mode failure (no

alternation)

Power down

1. Reset the alarm – turn off power and press the

alarm mute button.

2. Disconnect the air hoses to reduce pressure –

reconnect when pressure has decreased.

3. Switch on power.

1. Press the alarm mute button to silence the audible

alarm.

2. Check the mains cable is firmly plugged into a

wall socket and the control unit. Check the mains

power is switched on (to ensure socket is working

plug in a lamp or other fused electrical device).

3. Check the mains plug fuse (3A) then check the

control unit fuse (1A) – see section ‘Maintenance’.

Do not try to open the control unit. Opening

the unit could cause personal injury or equipment

damage.

Patient is sinking or

bottoming out

The pressure may

be set too low

for the patient’s

weight

1. Increase the pressure setting by pressing the ‘+’

button.

2. To check effective system performance, conduct a

bottoming out test as described previously.

If the above actions fail to rectify the problem

please contact your local authorised service

provider or Sidhil Limited.

14

CLEANING

Infection Control

Routine cleaning for infection control must

be carried out in accordance with your local

infection control policy or regulatory body.

Cleaning the Control Unit

Disconnect the mains cable from the

power socket before attempting to clean the

control unit.

Do not immerse the power unit in water.

Ensure the mains cable and power unit

are dry before use.

The control unit can be cleaned by wiping

down with a damp cloth soaked in a sodium

hypochlorite solution (1000 ppm available

chlorine) and dried with a clean dry cloth.

The power unit is not IP rated therefore

care should be taken to ensure only a damp

cloth is used.

Cleaning the Mattress

Before attempting to clean the mattress the

top cover should be checked for physical signs

of damage that may lead to strike-through

(ingress of fluid through cover). This is achieved

by unzipping the top cover and looking for

signs of staining to the white underside. Any

evidence of strike-through will require a new

cover to be fitted to the system.

The cover must not be reused if strike-

through is evident.

Wipe down with a disposable soft cloth

moistened with a mild detergent and diluted in

warm water (40˚C), dry thoroughly before use.

Wipe down with a solution of Sodium

Hypochlorite or similar (up to 1,000ppm

Chlorine), dry thoroughly before use.

In extreme cases 10,000ppm Chlorine

can be used but the following process must

be adhered to: 1) Wipe cover down using

cold water 2) Clean with Chlorine solution 3)

Finally wipe cover again using cold water.

The top cover may also be decontaminated

using Ethylene Oxide or the Draeger method.

Additional infection control and routine cleaning

must be carried out in accordance with your

local infection control policy.

Do not use Phenol based cleaning agents (e.g.

Stericol, Hycoline, Clearsol etc.).

Mattress Cover Cleaning Instructions

71 C

Machine Wash at 71˚C

Do Not Iron

Do Not Bleach

Do Not Dry Clean Tumble

Dry on Low Heat

If the above washing instructions

are not followed the warranty will be

invalidated.

15

MAINTENANCE

Only authorised service personnel or Sidhil service engineers should carry out repairs or service

activities. Failure to do so may result in the product warranty becoming void. The mattress system

must be serviced once yearly, as a minimum. Sidhil also recommends that the carer performs

frequent visual and operational inspections. If there are any signs of damage or the system is not

performing as it should withdraw it from service until the system has been repaired and is fit for use

again.

Air Filter Replacement

See service manual for control unit air filter

maintenance and replacement.

Good filter maintenance is critical to

maintain an optimal operating system.

Failure to keep the filters clean will result

in system downtime and increase repair

costs. It is recommended that the air filter

be replaced annually. Replacement air

filters are available; please see contact

information on rear cover.

Fuse Replacement - Control Unit

1. Switch off the power supply to the control

unit.

2. Remove the mains cable from the control

unit.

3. Insert a small flat head screwdriver into the

groove in the fuse holder, and turn anticlockwise (quarter turn).

4. Remove the used fuse from the fuse holder

clip and discard.

5. Insert a new fuse into the fuse holder clip.

Push fuse holder into the control unit

against the force of the spring and turn

clockwise with the screwdriver (quarter

turn).

16

TECHNICAL SPECIFICATION

Control System Digital micro controller

Cycle Time 12 minutes

Supply Voltage 230V, 50Hz

0.2A for Control Unit

Fuse Rating Mains Plug – 3AMP

Control Unit – 1AMP (x1)

Power Rating 12VA

Standards CE marked in line with Medical Devices Directive (93/42/EEC)

No. of Cells 21 cells which includes:

3 static head cells

18 alternating cells with cell-in-cell function

Cell Height 215mm

Alternating therapy AB pattern

Maximum patient weight 177kgs 28 Stone

Mattress Length 2000mm ± 20mm

Replacement Width 880mm ± 20mm

Dimensions Height 220mm ± 10mm

Weight 10.8kgs

Control Height 270mm

Unit Width 290mm

Dimensions Depth 120mm

Weight 3.5kgs

Cell material 210D PA/TPU

Base material 420D PA/TPU

Cover material Biocompatible PU/knitted PES, two-way stretch, 195 g/m²

Hose Connection Push on connector handle

Emergency CPR Rapid release tag

Mode of Operation Non-continuous

Operating (Storage/ Air humidity 30% to 75% (10% to 70%)

Transport) Environment Ambient temperature 10°C to 40°C (-10°C to 60°C)

Classification Class II equipment Type B applied part

IEC60601-1 IPX0 Not category AP/APG equipment

All product specifications are subject to change without notice.

17

TECHNICAL SPECIFICATION

Definition of Symbolys Used

The following symbols may appear in this manual, on the Control Unit, or on its accessories.

Some of the symbols represent standards and compliances associated with the Control Unit

and its use.

Caution: Consult accompanying documents

Class II equipment

Manufacturer

Serial number

Type B applied part

DISPOSAL: Do not dispose of this product as unsorted municipal waste.

Collection of such waste separately for special treatment is necessary.

18

TECHNICAL SPECIFICATIONTECHNICAL SPECIFICATION

Declaration

– electromagnetic emissions- for all ME EQUIPMENT and

ME SYSTEMS

Guidance and manufacture’s declaration – electromagnetic emission

The Plus II is intended for use in the electromagnetic environment specified below. The customer or

the user of the Plus II should ensure that it is used in such an environment.

Emission test Compliance Electromagnetic

environment

– guidance

RF emissions

CISPR 11

RF emission

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/ flicker

emissions

IEC 61000-3-3

Group 1 The Plus II uses RF energy

only for its internal function.

Therefore, its RF emissions

are very low and are not likely

to cause any interference in

nearby electronic equipment.

Class B The Plus II is suitable for use in

all establishments, including

Class A

Complies

domestic establishments and

those directly connected to

the public low-voltage power

supply network that supplies

buildings used for domestic

purposes.

19

TECHNICAL SPECIFICATION

Declaration – electromagnetic immunity

Guidance and manufacture’s declaration – electromagnetic immunity

The Plus II is intended for use in the electromagnetic environment specified below. The customer or

the user of the Plus II should ensure that it is used in such an environment.

Immunity test IEC 60601

test level

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge IEC 610004-5

Voltage dips,

short interruptions

and voltage

variations on

power supply

input lines

EC 61000-4-11

Power frequency

(50Hz) magnetic

field

IEC 61000-4-8

NOTE UT is the a.c. mains voltage prior to application of the test level.

±6 kV contact

±8 kV air

±2 kV for power

supply lines

± 1 kV line(s) to

line(s)

<5% UT (>95% dip

in UT) for 0.5 cycle

40% UT (60% dip

in UT) for 5 cycles

70% UT (30%

dip in UT) for 25

cycles

<5% UT (>95%

dip in UT) for 5 sec

3A/m 3A/m Power frequency magnetic

Compliance

level

±6 kV contact

±8 kV air

±2kV for power

supply lines

±1 kV differential

mode

<5% UT (>95%

dip in UT) for 0.5

cycle

40% UT (60% dip

in UT) for 5 cycles

70% UT (30% dip

in UT) for 25 cycles

<5% UT (>95%

dip in UT) for 5 sec

Electromagnetic

environment

– guidance

Floors should be wood, concrete

or ceramic tile. If floor are covered

with synthetic material, the relative

humidity should be at least 30%.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of the Plus

II requires continued operation

during power mains interruptions,

it is recommended that the Plus II

be powered from an uninterruptible

power supply or a battery.

fields should be at levels

characteristic of a typical location

in a typical commercial or hospital

environment.

20

TECHNICAL SPECIFICATIONTECHNICAL SPECIFICATION

Declaration – electromagnetic immunity – for ME EQUIPMENT and ME SYSTEMS

that are not LIFE-SUPPORTING

Guidance and manufacture’s declaration – electromagnetic immunity

The Plus II is intended for use in the electromagnetic environment specified below. The customer or

the user of the Plus II should ensure that it is used in such an environment.

Immunity

test

Conducted

RF

IEC 610004-6

Radiated

RF

IEC 610004-3

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with

accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey

should be considered. If the measured field strength in the location in which the Plus II is used exceeds the applicable

RF compliance level above, the Plus II should be observed to verify normal operation. If abnormal performance is

observed, additional measures may be necessary, such as reorienting or relocating the Plus II.

b. Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

IEC 60601

test level

3 V

rms

150 kHz to

80 MHz

3 V/m

80 MHz to

2.5 GHz

Compliance

level

3 V

rms

3 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the CT515,

including cables, than the recommended separation

distance calculated from the equation applicable to the

frequency of the transmitter

Recommended separation distance

d = 1.167√P

d = 1.167√P 80 MHz to 800 MHz

d = 2.333√P 800 MHz to 2.5 GHz

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as determined

by an electromagnetic site survey,a should be less than

the compliance level in each frequency range.

Interference may occur in the

vicinity of equipment marked

with the following symbol:

b

21

TECHNICAL SPECIFICATION

Recommended separation distances between portable and mobile RF

communications equipment and the EQUIPMENT or SYSTEM – for ME

EQUIPMENT or ME SYSTEM that are not LIFE-SUPPORTING

Recommended separation distances between portable and mobile RF

communications equipment and the Plus II Alternating Control Unit

The Plus II is intended for use in an electromagnetic environment in which radiated RF disturbances

are controlled. The customer or the user of the Plus II can help prevent electromagnetic interference

by maintaining a minimum distance between portable and mobile RF communications equipment

(transmitters) and the

communications equipment.

Rated maximum

output power of

transmitter (W)

0.01 0.117 0.117 0.233

0.1 0.369 0.369 0.738

1 1.167 1.167 2.333

10 3.689 3.689 7.379

100 11.667 11.667 23.333

For transmitters rated at a maximum output power not listed above, the recommended separation

distance d in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to

the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption

and reflection from structures, objects and people.

Plus II as recommended below, according to the maximum output power of the

Separation distance according to frequency of

transmitter (m)

150 KHz to 80 MHz

d = 1.167√P

80 MHz to 800 MHz

d = 1.167√P

800 MHz to 2.5 GHz

d = 2.333√P

22

WARRANTY INFORMATION

Sidhil Ltd guarantees this product is free from defects in material and workmanship under normal

use for two (2) years from the date of purchase from Sidhil Ltd and its subsidiary companies or

its authorised dealers. All implied warranties, including but not limited to those implied warranties

of fitness and merchantability, are limited in the total duration of one year from date of purchase.

Proof of purchase must be presented with any claim. Except as provided herein, Sidhil Ltd,

product warranty does not cover damage caused by misuse or abuse, accident, the attachment

of any unauthorised accessory, alteration to the product, or any other conditions whatsoever that

are beyond the control of Sidhil Ltd.

Sidhil Ltd and its subsidiary companies shall have no liability or responsibility to customer or

any other person or entity with respect to any liability, loss or damage caused direct or indirectly

by use or performance of the product or arising out of any breach of this warranty, including

but not limited to any damages resulting from inconvenience, loss of time, property, revenue,

or profit or any indirect, special, incidental or consequential damages, even if Sidhil Ltd or their

subsidiary companies or authorised dealers has been advised of the possibility of such damages.

In the event of a product defect during the warranty period you should contact Sidhil Ltd or their

authorised dealer who will at its option unless otherwise provided by law; a) correct the defect by

product repair without charge for parts and labour b) replace the product with one of the same or

similar design or c) refund the purchase price. All replaced parts and products on which refund is

made become the property of Sidhil Ltd. New or reconditioned parts and products may be used

in the performance of warranty service. Repaired or replaced parts and products are warranted

for the remainder of the original warranty period. You will be charged for repair or replacement of

the product made after the expiration of the warranty period.

This warranty does not cover; a) damage or failure by or attributes to acts of God, abuse,

accident, misuse, improper or abnormal usage, failure to follow instructions, improper installation

or maintenance, alterations, lightning or other incidence of excess voltage or current, b) any

repairs other than those provided by a Sidhil Ltd authorised technician, c) consumables such as

fuses, d) cosmetic damage, e) transportation, shipping or insurance costs or f) costs of product

removal, installation setup service adjustment or re-installation.

This limited two year warranty gives you specific legal rights and you may also have other rights.

Sidhil Ltd cannot be held responsible for any injury or incident which relates to the use of the

Dynamic Mattress range in conjunction with accessories manufactured by companies other than

Sidhil Ltd. All products carry the CE mark in accordance with EC Directive on Medical Devices

(93/42/EEC).

Sidhil has a policy of continual product improvement and reserves the right to amend

specifications covered in this brochure.No part of this brochure may be reproduced without the

written approval of Sidhil Ltd.

23

CONTACT INFORMATION

Tel: 01422 233000 Fax: 01422 233010

Email: sales@sidhil.com www.sidhil.com

Sidhil Business Park, Holmfield, Halifax, HX2 9TN

A member of the Siddall & Hilton Ltd. Group of Companies

(93/42/EEC)

Certificate No. FM14550

INSTRUC/PLUSII - 05-08-2011 - REV3

Loading...

Loading...