Siddons Solarstream MAHRW015WAA Owner's Manual

www.siddonssolarstream.com

To be read in conjunction with the

Installation and User Manual for models:

ELECTRONIC SPLIT HEAT PUMP

OWNER'S MANUAL

For externally coiled tanks with

refrigeration line connections

Model MAHRW015WAA

AIR TO WATER HEAT PUMP

264SSAD, 264SSBD

327SSAD, 327SSBD

Notice

1.1 Save this manual for future reference.

1.2 In order to use this product better and more safely, please read this manual carefully before

installation and initial operation.

1.3 Children or persons with physical, sensory or mental disability should not play with nor operate

this appliance.

1.4 This appliance must be installed by qualified and experienced technicians/tradespeople.

Improper installation of this appliance may cause damage and danger.

1.5 This appliance must be installed in accordance with Australian wiring regulations including an

isolating switch from the supply mains and grounded power supply consistent with the power

requirements of this appliance.

1.6 The installation of this appliance must comply with the model's wiring chart in this manual and

its power requirements as stated on the rating label on the side of the heat pump.

1.7 Do not install this appliance close to flammable or explosive materials, or naked flames.

1.8 A filter in the mains water supply inlet is recommended and should be checked/cleaned

periodically.

1.9 Checking and cleaning of the evaporator fin coil is recommended for good air flow.

1.10 The battery should be removed from this appliance's controller at the end of its operating life

and disposed of safely.

Content

1

1

1

1

2

2

3

7

4

4

4

5

5

5

5

5

6

10

12

13

I. Specification........................................................................

1. How it works ................................................................................

2. Stainless Steel Hot Water Storage Tank.........................................

3. Flexible installation......................................................................

II. Electronic Split Heat Pump..................................................

1. Technical parameters for the main unit ...........................................

2. Electronic Split Heat Pump Dimensions .........................................

3. Heat Pump check .........................................................................

III. Technical Guide..................................................................

1. Starting Current and Peak Current.................................................

2. Electrical wiring...........................................................................

3. Gas Levels and Pressures.............................................................

4. Electronic expansion valve............................................................

IV. Digital Controller................................................................

1. Operation & Adjustment of the Digital Controller..............................

2. Use of Digital Controller....................................................

3. Operation date setting...................................................................

V. System Malfunction Schedule..............................................

VI. Wiring diagram .. .......................................................... ......

RETROFITT ING TO AN EX ISTING SIDDONS C OILED TANK

This new Elec troni c Split heat pump model has i mprov ed features over the prev ious me chanical heat pump.

New feature s inclu de:

* Electroni c tank se nsor probe replacing th e mecha nical Klixon tank therm ostat for regulating th e on/off

function of t he heat p ump

* Electroni c tank se nsor probe replacing th e mecha nical Klixon tank therm ostat f or regulating th e over

temperatu re func tion of the compressor; t his can b e reset by turning p ower to t he heat pump on/off.

* Electroni c tank se nsor probe for activati ng the de -ice function; o n older u nits from 2005, this will r eplac e

the mechani cal Kli xon evaporator thermo stat fo r regulating the de-ice f uncti on

* Pressure sw itche s

* LED display u nit tha t provides diagnostic i nform ation and monitoring of k ey oper ating paramete rs (ref er

Section IV) . Note, t he LED display unit can be pl aced un der the heat pump lid on top of t he elec trical

wiring post o r place d onto a wall using the senso r exten sion lead provided with t he heat p ump)

REFRIGERA NT: This El ectronic Split heat pum p is char ged with 1.5KG of R1 34A refr igera nt, whereas the

older style M echan ical Split heat pump is cha rged wi th 1.5kg of R417a refrige rant.

CONNECTIN G THE NEW H EAT PUMP

* Locate the he at pump a t least 75mm clear of a wall on t he air in let side and at leas t 1m clea r of a wall or

fence on the ai r outle t side.

* Ensure all re frige rant is purged from the exi sting s ystem.

* Connect the e xisti ng refrigeration line s to the ne w refrigeration lines s uppli ed with new electronic he at

pump by brazi ng them t ogether.

* Ensure the ne w heat pu mp and tank and connected w ith no re frigerant leakage.

* Evacuate th e air fro m the refrigerat ion lin es and th e 40m condenser co il wrap ped aro und the tank.

* Fully open bo th refr igeration valves on the h eat pum p to charge the whole syste m.

* Mark the tech nical l abel on the tank, deletin g refer ence to R417a refr igera nt char ge and write in R134 a.

* The digital con troll er can be placed inside the h eat pum p box on top of the term inal bl ock after the heat

pump has been s et, clo ck and timer (if required ) or it can b e fixed onto a wall by using th e exten sion lead

provided. M ake sur e the digital controlle r is prot ected from the weather.

* Fit the drain p lug and c onnect a plastic hose to ta ke the co ndensate water f rom the e vaporator away to a

drain from un derne ath the heat pump. Ang le the he at pump slightly toward s the dra in plug to enable the

condensat e water t o flow easily towards the d rain pl ug. Periodically chec k the dra in plug for any blockages .

* If the heat pum p is moun ted on a wall or on top of a roof, ma ke sure the heat pump’s feet ar e mount ed on

top of rubber p ads to pr event vibration from be ing tra nsmitted.

* It is fine to con nect th e heat pump to off-pea k power b ut keep in mind the heat pump w ill ope rate about

25% more effici ently w ith a 10 degree rise in the amb ient ai r temperature.

* We recommend in stall ing a pool pump timer set bet ween 12 :00pm and 5.00pm i f conne cting to a

continuou s tariff to e nsure one operating cyc le at the w armest time of day f or grea ter efficiency.

CONNECTIN G THE SEN SOR PROBE TO THE TANK

You will need to fit the t ank water temperature s ensor p robe against the storag e tank wa ll, underneath the

insulatin g foam an d seal with silicone. Her e are the k ey installation point s:

* Make a small ho le with a s crewdriver hard again st the st orage tank 50-75mm long t o fit the p robe tightly

* Push the sens or prob e in right to the end of the hole

* Seal the hole w ith sil icone to ensure the probe g ets a goo d reading from the tank wal l, unaffected by the air

* Secure the se nsor pr obe lead so it cannot fall ou t of posi tion

* Fine tuning a djust ment to the probe cut off/on se ttings can be made if neces sary (r efer Section IV)

I¡General

1

2. Hot Water Storage Tank

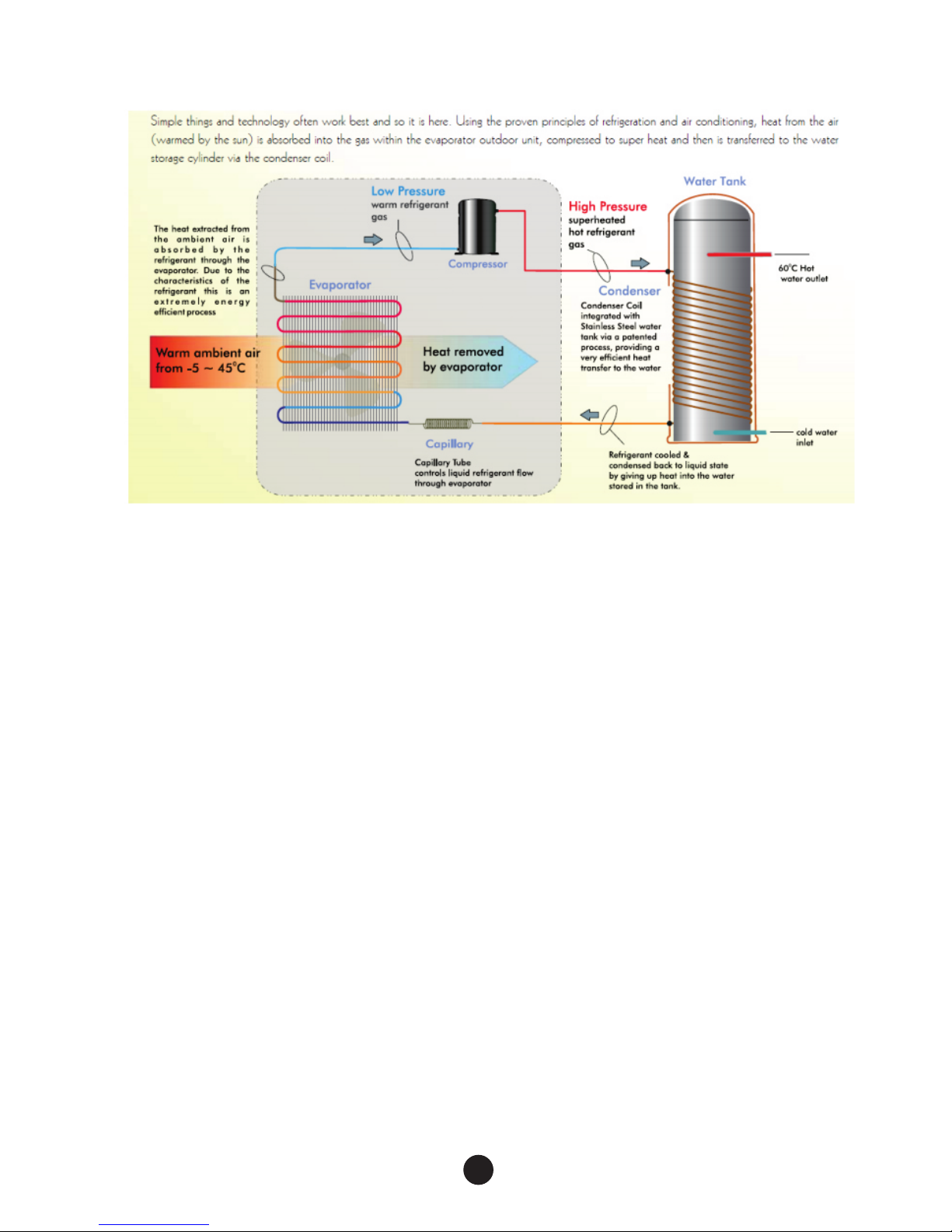

1. How it works

3. Flexible installation

The condenser coil for t he Siddons Solarstream mod el MAHRW01 5WAA, with 1.5 hors epower

rotary compressor, is d esigned to operate with a 40m x 3/ 8inch copper condenser coi l wrapped

around a stainless ste el storage tank, insulated o n the casing side with at least 50 mm of foam

insulation and conductive on the water side, or equi valent. Th e coil should either be tightl y

wrapped around the sto rage tank or an equivalent int ernal coil can be used if the inle t water has low

mineral content, typ ically water coming from res ervoir from a mountain catchment, such as exists

in Tasma nia, Melbourne, Canberra a nd Sydney. For other locations, check with your local plumber.

The split system allow s flexible design options an d with the storage tank instal led inside or outside.

It is best for the heat pump t o be installed outside and mad e accessible for any mainten ance. Also

the outlet fan should ha ve at least 1m unimpeded dista nce for the air to blow out.

Installations may va ry from the side by side configu ration of heat pump and water tank to placement

of the heat pump up to 9 metre s distant from the water tank including up to 3 metres above such as

installation of the he at pump on a roof with water tank on t he ground.

The Heat Pump comes pre- charged with 1.5kg of ozone fr iendly R134a refrigerant . This is sufficien t

to charge a side by side sys tem with 2m connection lines a fter it has been connected. For Heat

Pumps installed with e xtension lines, the refrig erant charge should be sligh tly greater than 1.5kg,

allow 30 grams extra per a dditional metre to ensure th e correct refrigeration ch arge in the system.

2

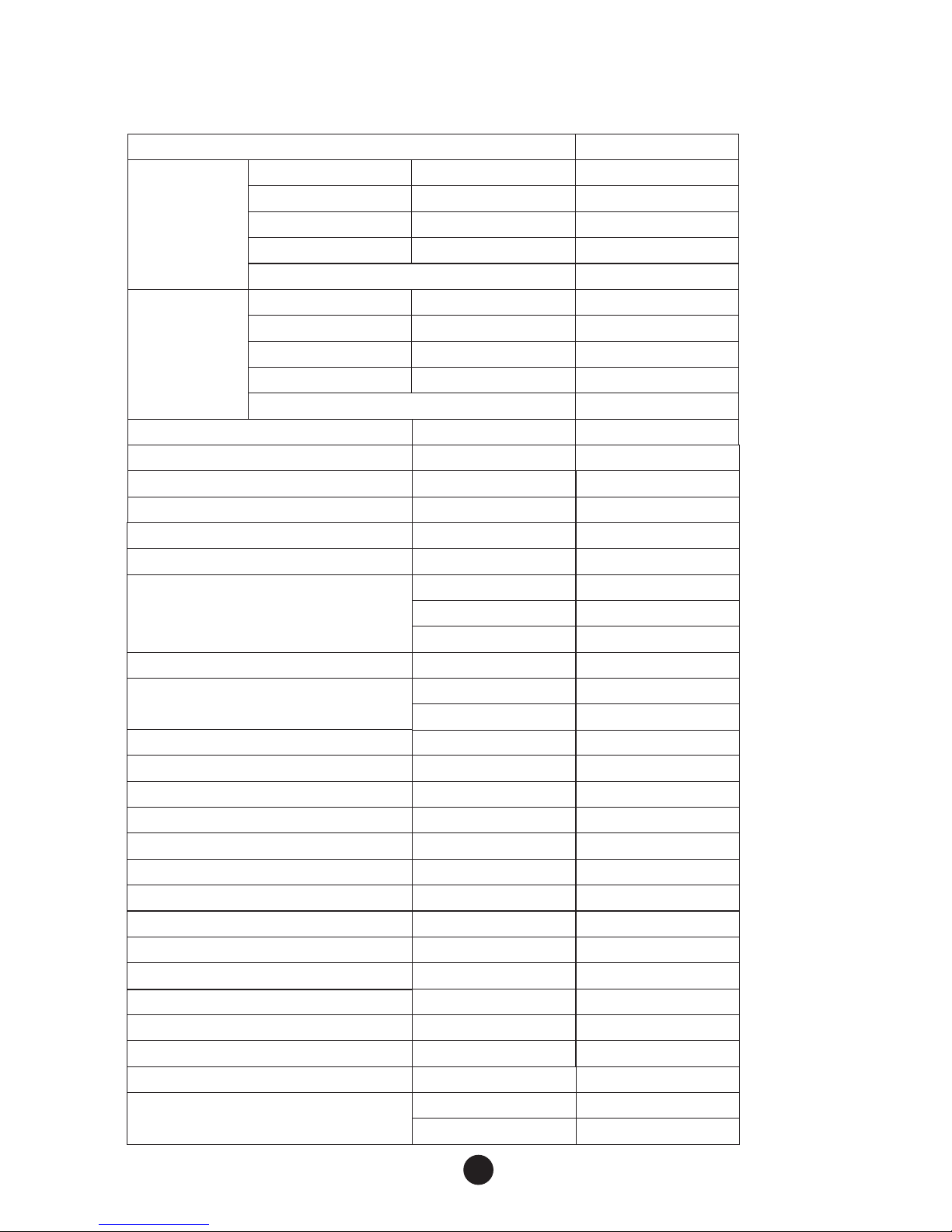

MODEL

COOL ING

HEATING

RATE D CA PACITY

RATE D CU RR ENT

RATE D PO WE R INPUT

EER

STAR R ATING

HEATIN G CA PACI TY

RATE D CU RR ENT

RATE D PO WE R INPUT

EER

STAR R ATING

W

A

W

WW

W

A

W

WW

MAHRW 01 5WA A

3500

4.7

1080

3.15

3500

4.5

1020

3.2

4.5

4

POWER SUP PLY

MAX OPERAT ION CUR RE NT

NOISE LEV EL IN DO OR/OUTD OO R

VOLUMET RI C CAPACI TY

DEHUMID IF ICATIO N CAPACI TY

REFRIGE RA NT TY PE/CHAR GE

Ph/V/Hz

A

dB(A)

3

m / h

L/h

/(g)

1/~220- 24 0/50

10.2

53

620

1.5

R134a /15 00 (g)

INDOOR/ OU TDOOR U NI T

DIMENSI ON ( mm)

NET WEI GH T IND OO R/OUTDO OR

COMPRES SO R TYP E

LCD REMOT E CO NTROL

TEM PE RATURE S ET TING RANG E

OPERATIO N MODES

FAN SPEEDS

24-HOUR O N/ OFF TIM ER

W

D

H

Kg

Liquid

Gas

¡

780

258

540

Kg

10/40

CONNECT IO N PIPE SI ZE m m( inch)

COMPRES SO R TYP E

LCD REMOT E CO NTROL

TEM PE RATURE S ET TING RANG E

OPERATIO N MODES

FAN SPEEDS

24-HOUR O N/ OFF TIM ER

UP/DOWN L OU VER

LEFT/RI GH T LOU VE R

HI-POWE R

SLEEP MOD E

DRY M ODE

LED DISPL AY ON FR ON T PANE L

LIQUID

GAS

6.35(1/ 4)

9.52(3/ 8)

Rotary

Y

O

C

16-30

4

3

Y

Automat ic

Manual

Y

Y

Y

Y

2

M

model

brand

TB36G

Mitsubi sh i

SOFT START

APPLICAT ION AREA *

Compressor

N

18-30

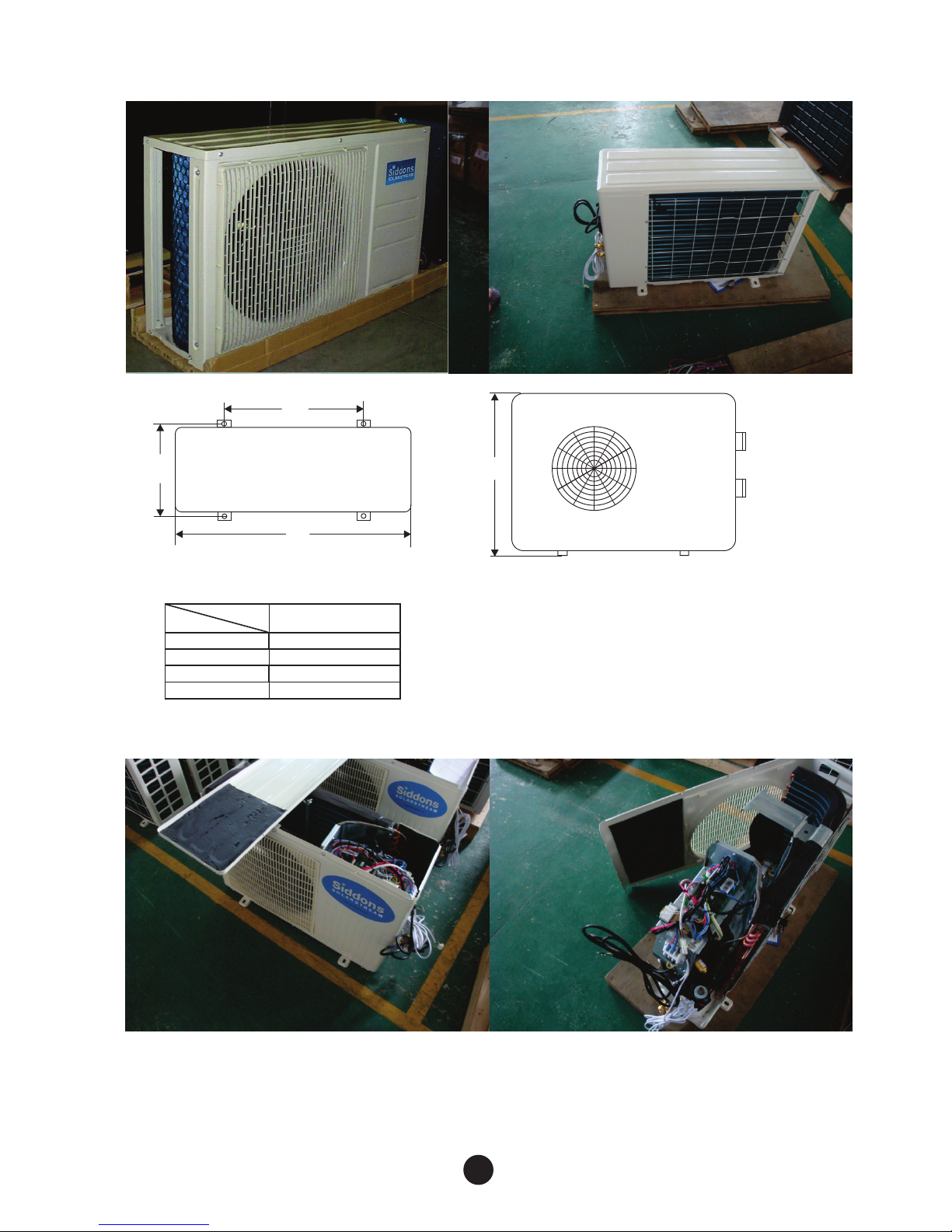

1. Technical parameters for the main unit

II Electronic Split Heat Pump

A

B

C

D

Size

Units: mm

MAHRW

280

505

805

542

B

A

C

D

015WA A

2. Electronic Split Heat Pump Dimensions

The heat comes apart easily. Firstly remove the lid, then unscrew the brace on

top of the fan to the front panel, then the screws along the base of the casing

working from the front RHS corner along the base to the left to the back plate

on the opposite corner. Unscrew the two screws connecting the back plate.

3

Loading...

Loading...