Sicma TR 200, TR 225, TR 255, TR 280 Use And Maintenance Manual

002~00

S

Shredder

903631002~00

TR 200•225•255•280

USE AND MAINTENANCE MANUAL

TRANSLATION OF ORIGINAL INSTRUCTIONS

TR shredder

- 2 -

INDICE

1. INTRODUCTION 5

1.1 SOME NOTES REGARDING THE USER MANUAL 5

1.2 DECLARATION OF CONFORMITY 6

1.3 LIST OF RESIDUAL RISKS 7

1.4 GENERAL DELIVERY NOTES 8

1.5 SHREDDER IDENTIFICATION AND MANUAL CODE 9

1.6 DECLARED USE 10

1.7 SHREDDER COMPOSITION 11

1.8 OPTIONAL 12

2. SAFETY 13

2.1 DEFINITIONS 13

2.2 CONVENTIONAL SYMBOLS 13

2.3 SAFETY PRESCRIPTIONS 14

2.4 OPERATOR REQUISITES 14

2.5 CLOTHING AND PPE 15

2.6 MACHINE USE 15

2.7 SAFETY DEVICES 16

2.8 REASONABLY PREDICTABLE INCORRECT USE 16

2.9 POSITION OF PICTOGRAMS ON THE MACHINE 17

3. UNLOADING AND UNPACKING THE SHREDDER 19

3.1 SHREDDER PROTECTED BY HEAT-SHRINKABLE FILM 19

3.2 SHREDDER IN WOODEN CRATE 20

4. TECHNICAL FEATURES 22

5. START-UP 23

5.1 3-POINT HITCH CONNECTION 23

5.2 CARDAN SHAFT CONNECTION 25

5.3 CHECK THE STABILITY OF THE TRACTOR-SHREDDER COMPLEX 26

5.4 ROAD TRANSPORT 26

5.5 MACHINING 27

6. STOPS 29

7. ADJUSTMENTS 30

7.1 WORKING HEIGHT ADJUSTMENT 30

7.2 ADJUSTING BELT TENSION 31

8. ROUTINE MAINTENANCE 32

8.1 CONTROL AND REPLACEMENT OF THE OIL IN THE SPEED INCREASING GEAR UNIT 33

8.2 GREASING 34

8.3 REPLACING THE DRIVE BELTS 35

8.4 REPLACING KNIVES/HAMMERS 36

9. CARDAN SHAFT 37

10. CLEANING 38

11. STORAGE AND WINTERING 38

12. SCRAPPING 39

13. QUICK CONSULTATION TABLES 39

13.1 COUPLING TORQUE TABLE 39

13.2 TROUBLESHOOTING TABLE 40

- 3 -

TR shredder

13.3 MAINTENANCE TABLE 41

14. SPARE PARTS 42

15. WARRANTY 42

TR shredder

- 4 -

Congratulations on your purchase of the

002~00

TR Shredder

The TR shredder is manufactured by SICMA S.p.A, which has been producing agricultural machines for over 40 years.

The TR shredder has all safety and quality requisites required for this type

of equipment.

Remember that to obtain the best performance and make the best of the

production features, it is necessary to know the instructions and information

contained in this manual and follow the same.

1. INTRODUCTION

1.1 SOME NOTES REGARDING THE USER MANUAL

Remember that the USER MANUAL is not an accessory of the shredder but

is an INTEGRAL part and a SAFETY MEASURE (EN 12100-1).

For this reason:

• kept in a good state;

• it must be kept near to the equipment;

• pass it to any operator user, maintenance technician, handler or successive owner.

903631002~00

Shredder

Tr180•200•220•250•280

USE AND MAINTENANCE MANUAL

TRANSLATION OF ORIGINAL INSTRUCTIONS

In this way, the shredder can be used in the best way for all functions for

which it has been manufactured and in maximum safety.

The manual must not be damaged, it must remain integral (do not rip the

sheets), must be kept away from humidity and heat. During consultation it

must not be covered in grease or its legibility deteriorated.

If this manual is lost or damaged, ask for a copy from the Manufacturer or

nearest Dealer.

To ease consultation, the manual has been divided into parts so that every

phase is described well.

With these arrangements, SICMA intends to unmistakably call the operator's attention to the dangerous situations that may occur.

- 5 -

TR shredder

1.2 DECLARATION OF CONFORMITY

The machine is delivered accompanied by the following Declaration of Conformity.

EC DECLARATION OF CONFORMITY

The company

Sicma s.p.a. - C.da Cerreto, 39 - 66010 Miglianico (Ch) - Italy

Tel.: +39 0871 95841 - Fax: +39 0871 950295

e-mail: info@sicma.it - http://www.sicma.it

hereby declares that:

product: SHREDDER

model: TR

serial number:

complies with the essential requirements for safety and health of Directive 2006/42/CE.

To fulfil the above mentioned Directive have been applied the following harmonised standards:

- UNI EN 745:2010, UNI EN ISO 4254-1:2010, UNI EN ISO 12100-1:2009, UNI EN ISO 12100-2:2009

and the technical standards and specifications

- ISO 11684:1995, ISO 13852:1996, UNI 9456:1989.

The person authorised to compile the technical file is Mr. Lorenzo Aurora

Miglianico, 29-12-2009

Lorenzo Aurora

AMMINISTRATORE UNICO

TR shredder

- 6 -

1.3 LIST OF RESIDUAL RISKS

Even though SICMA has done everything possible to be in line with stateof-the-art safety and in compliance with all Directives, Laws and Standards

available, some residual risks still exist:

• CUT/CRUSHING HAZARD DUE TO CONTACT WITH TOOLS (rotor)

• ENTANGLEMENT/DRAGGING HAZARD (rotor and Cardan shaft)

• OVERTURNING/CRUSHING HAZARD (shredder)

• BURNS HAZARD (gear transmission box)

• CUT/SHEARING HAZARD

Therefore, anyone using the machine or performing maintenance on the

same, must be trained and aware of the fact that dangers exist and in spite

the use of protections to reduce them, it is not possible to eliminate them

totally.

The staff assigned to these operations must always have the use and maintenance manual available for consultation.

The use and maintenance manual states all indications requested from

point 1.7.4 (User instructions) of Attachment 1 of the Machinery Directive

and specifi c request is made to comply with the prescriptions, so as not to

cause accidents that can injure persons.

- 7 -

TR shredder

1.4 GENERAL DELIVERY NOTES

The shredder has been manufactured in compliance with the 2006/42/CE

Directive and has been designed observing the guide lines of the Technical

Standards relative to the shredder.

Therefore, the machine does not represent a danger for the operator if used

according to the instructions in this manual and on condition that the safety

devices are kept constantly effi cient.

SICMA INFORMS THAT ANY MODIFICATION OR TAMPERING OF THE

SHREDDER OR ANY OPERATION

PERFORMED IN DISAGREEMENT

WITH WHAT WRITTEN IN THIS

MANUAL, ESPECIALLY FAILURE TO

COMPLY WITH THE SAFETY PROVISIONS, AS WELL AS MAKING THE

WARRANTY NULL AND VOID, RELIEVES SICMA FROM ANY LIABILITY

FOR DAMAGE TO OBJECTS AND INJURY TO PERSONS.

Some of the devices described in this

manual may not be present on your

machine, depending on the chosen

set-up and the market of destination.

It must be remembered that all technical values refer to the standard shredder (see Chap. 4 “Technical Features”)

and the drawings and any other docu-

ment delivered along with the shredder

are the property of SICMA, which reserves all rights and reminds that they

cannot be made available to third parties without its written approval.

Therefore, any reproduction, even partial, of the text and illustrations is prohibited.

The information, descriptions and illustrations contained in this manual refl ect the state of the art of the machine at the moment it was put on the

market.

The Manufacturer reserves the right, at any time, to apply modifi cations to

the machinery for technical or commercial reasons. Such modifi cations do

not oblige the Manufacturer to intervene on machines sold up until that moment, nor to consider this publication inadequate.

Any integration that the Manufacturer will consider opportune to supply later

on must be preserved together with the manual and be considered an integral part of the same.

The shredder and its parts and/or accessories are normally delivered by

lorry or container.

On receipt of the machine, check that:

• the supply corresponds with the order specifi cations (see transport doc-

ument or packing-list)

• there is no damage to the shredder or accessories

• in the event of damage or missing pieces, inform the SICMA or its area

representatives, the carrier or its insurance immediately in detail and/

or with photos

• the spare parts or equipment supplied are sometimes in separate con-

tainers.

TR shredder

- 8 -

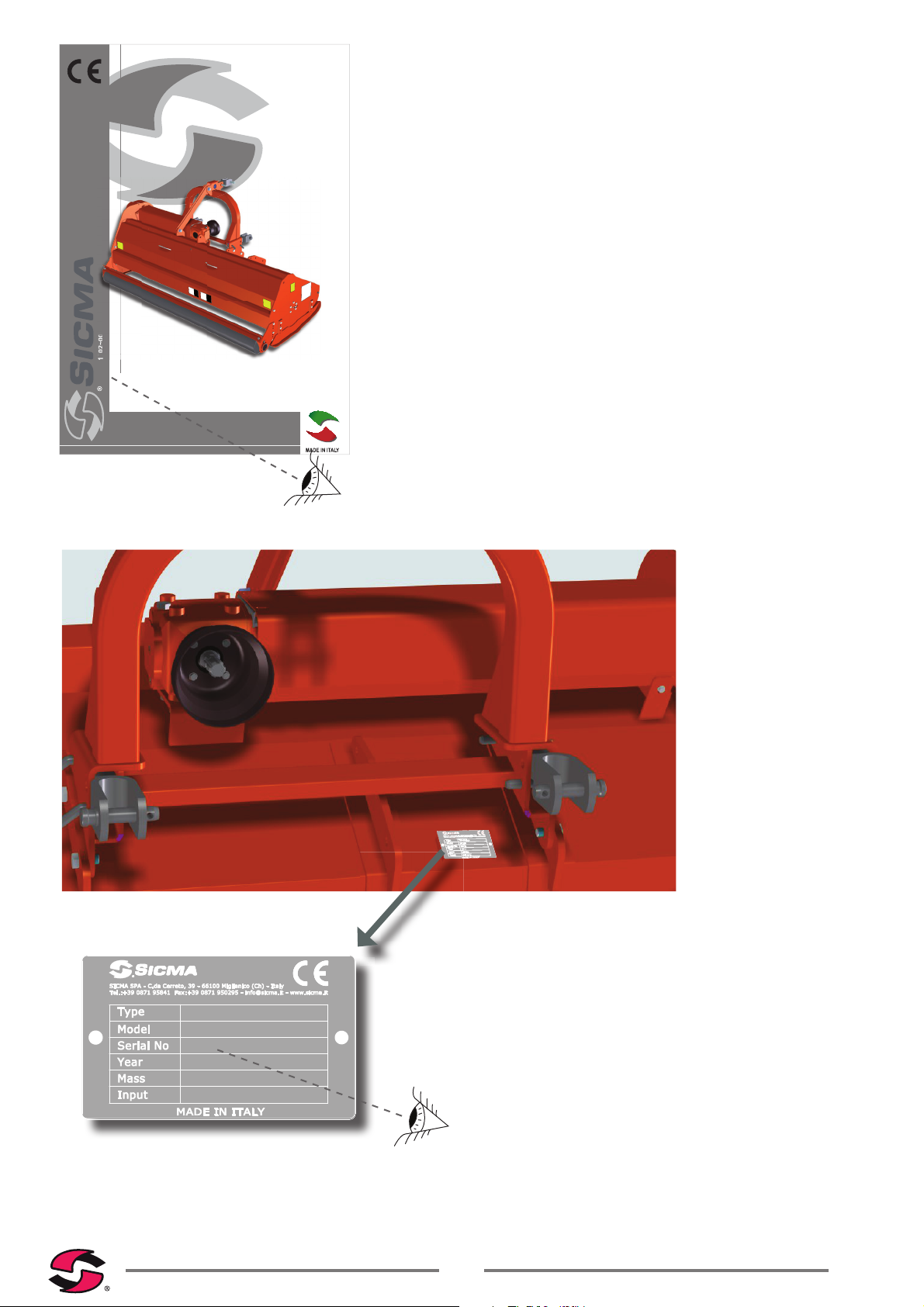

1.5 SHREDDER IDENTIFICATION AND MANUAL CODE

002~00

For any after-sales requests or information regarding the shredder, contact

SICMA or its after-sales centres always stating the model and the serial

number given on the plate.

The identifi cation code of this manual is written on the cover.

Write the number in a safe place so that if this manual is lost or damaged,

another copy can be requested from SICMA or the nearest dealer by also

stating the serial number visible in the marking.

903631002~00

Tr180•200•220•250•280

USE AND MAINTENANCE MANUAL

TRANSLATION OF ORIGINAL INSTRUCTIONS

Shredder

Shredder

TR 200

00218

2012

688 Kg

540 rpm

- 9 -

TR shredder

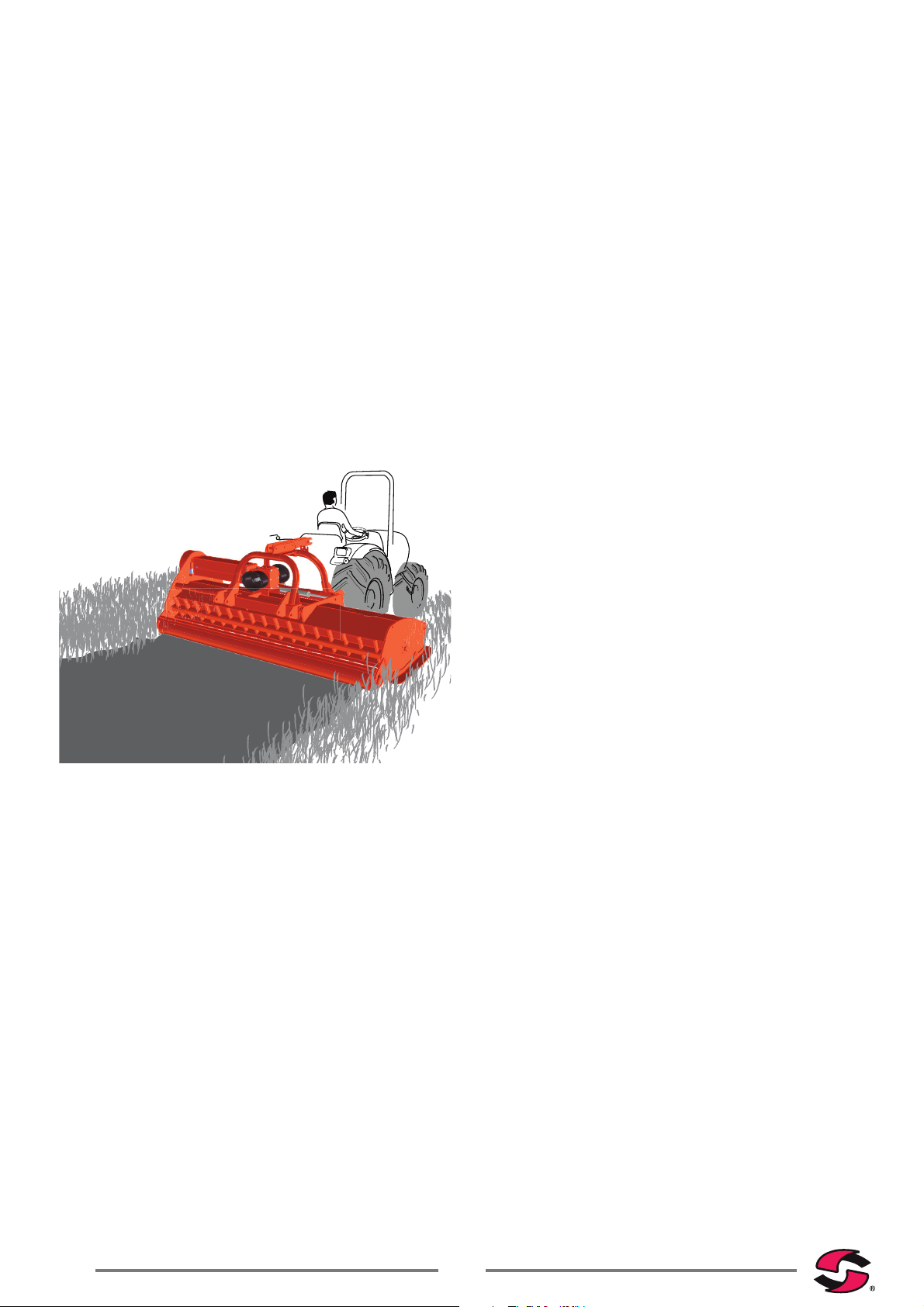

1.6 DECLARED USE

The TR shredder has been designed to be used exclusively in the agricultural sector, for mowing grass, maize stalks, maize and branches up to a

diameter of about 8 cm. according to the type of tool used.

Te machine is carried by the tractor via 3-point hitch and acts on the material

via the rotation of the tool-holder shaft, which turns at high speed activated

by the tractor PTO via cardan connection.

The machine is not suitable to be used in other sectors than in agriculture.

USE ENVIRONMENT

The shredder works:

• in open fi elds, on non friable land, not excessively stony with a maxi-

mum gradient of 3°

• in environments with a temperature from 0˚ ÷ 50˚ C.

IMPROPER USE

Any use different to that declared is to be considered improper.

Sometimes the operator uses the shredder incorrectly, below fi nd some examples the must NOT BE PERFORMED.

The operator must not:

• connect the shredder to a Cardan shaft with higher

or lower power transmission capacity.

• work in reverse gear,.

• couple the shredder to vehicles of unsuitable power or weight

• assemble the shredder without securing the rebound tie rods of the three-point hitch of the tractor’s elevator

• lift the equipment when the PTO is rotating

• make curves or reverse with the shredder lowered.

Remember that the shredder is developed only for the purpose of the declared use.

Any other use is to be considered improper.

TR shredder

- 10 -

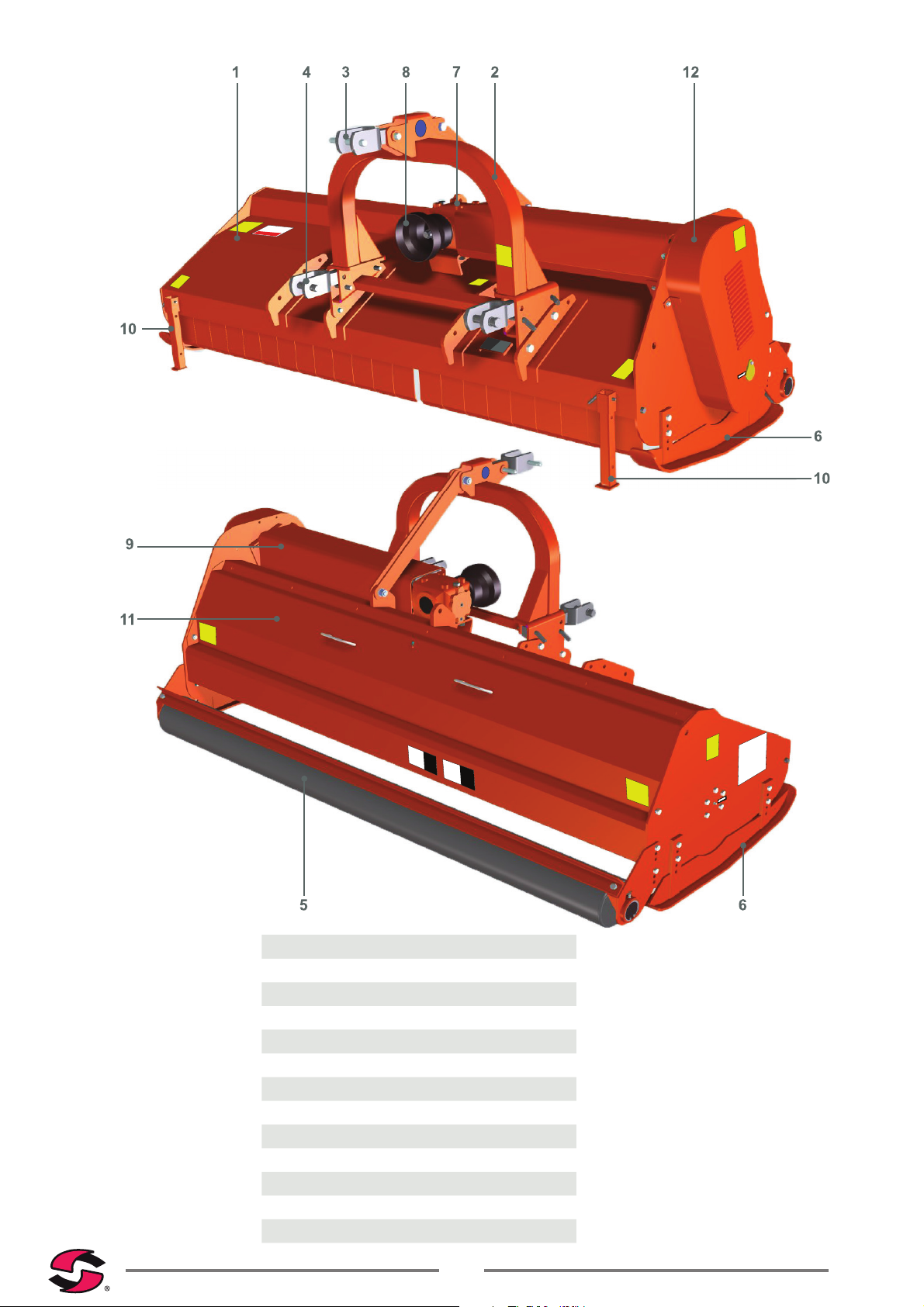

1.7 SHREDDER COMPOSITION

N° Description

1 Chassis

2 Arc

3 Upper three-point pin

4 Lower three-point pin

5 Stabilising wheel

6 Side skids

7 Gear transmission unit

8 Cardan joint protection

9 Cardan transmission guard

10 Parking foot

11 Rear bonnet

12 Belt drive guard

- 11 -

TR shredder

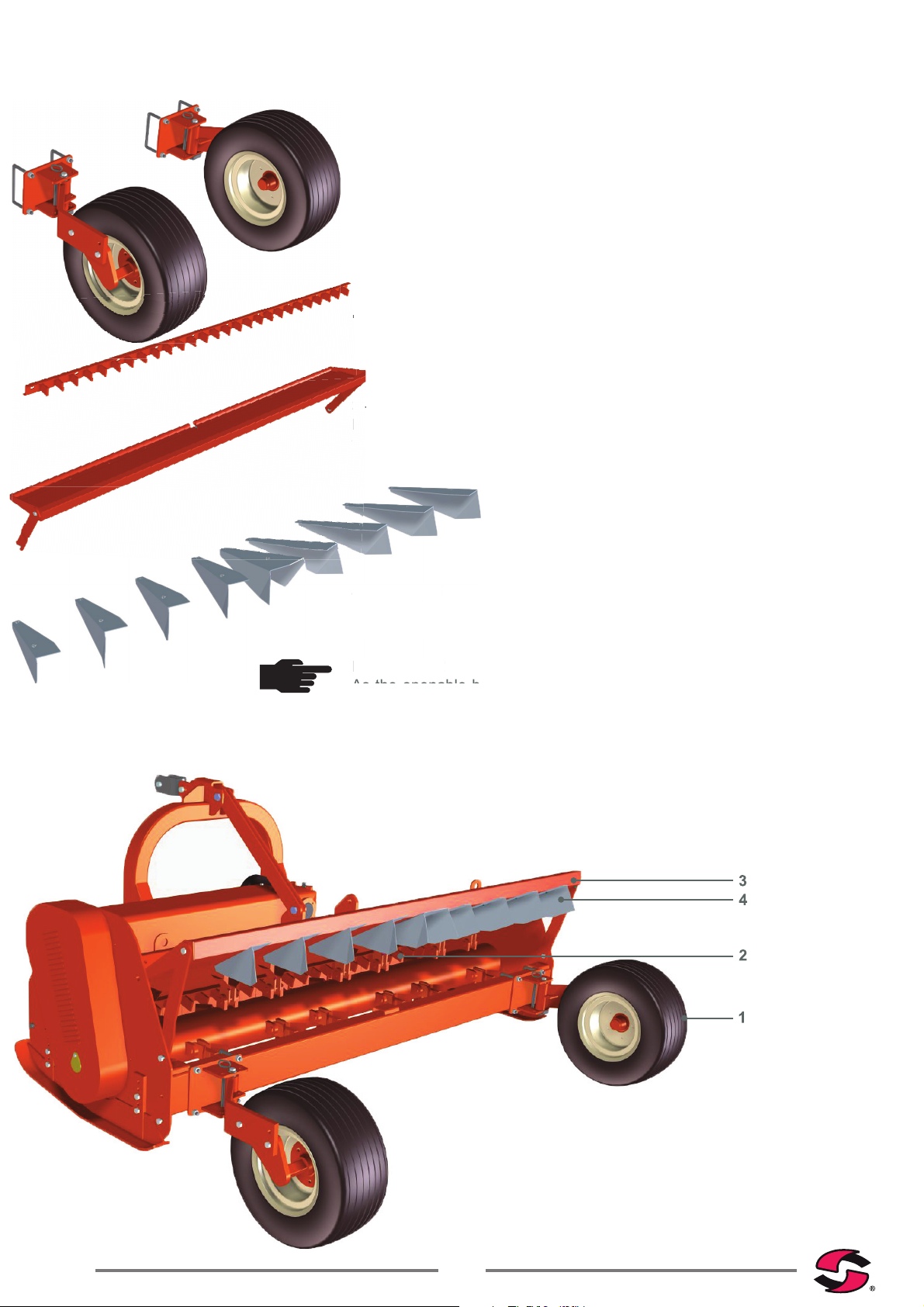

1.8 OPTIONAL

r3k

fr

o

4- BALES

p

d

The following imag

te

Below fi nd a list of the different optionals which can be requested according

to personal requirements:

1 - PIVOTING WHEELS

They are used instead of the rear wheel and allow to keep the the outlet of

the shredded material completely free, thus preventing annoying clogging,

which would lead to obstruction of the expelling area.

2 - BEATER BAR

Mounted inside the mowing chamber, it reduces the dimensions of the material shredded via teeth, which act as counter-blades for every pair of knives.

3 - OPENABLE REAR BONNET

If kept open via the two side arms, it allows to spread the shredded material

from the rear.

4 - BAFFLES

Mounted on the openable bonnet, they guide the ejection of shredded ma-

ounted on the o

terial, widening and making the spreading area uniform.

terial, widening an

IMPORTANT!

IMPORTANT!

As the openable bonnet and its baffl es do not respect the CE Standards,

they cannot be marketed and used in countries that are art of the EUROPEAN COMMUNITY.

The following image shoes the shredder complete with all optionals.

e shoes the shredder comple

TR shredder

- 12 -

2. SAFETY

During consultation of this use and maintenance manual and on the equipment itself, it is possible to fi nd several symbols whose meanings are illus-

trated below.

2.1 DEFINITIONS

DANGER

A potential source of physical injury or damage to health.

DANGEROUS AREA

Any area within and/or in proximity of a machine in which the presence of a

person constitutes a risk for the safety and health of the same.

The dangerous area is the area around the machine (attached to the tractor) up to a distance of 1 metre.

EXPOSED PERSON

Any person that is totally or partially inside a dangerous area.

CRITICAL AREA

The critical area is that between the tractor and the equipment (Cardan

shaft area).

ZERO ENERGY STATE

The state into which the shredder must be taken before any cleaning, lubrication and maintenance operation is performed.

The shredder is at the ZERO ENERGY STATE when it is positioned on fl at

land, disconnected from the Cardan Shaft and resting on its safety feet.

2.2 CONVENTIONAL SYMBOLS

ATTENTION GENERAL HAZARD

Informs the staff assigned that the operation described has the risk of physical injury if not performed with respect to the Safety Standards.

NOTE

Informs the staff assigned of information whose content is of relevant consideration and importance.

WARNING

Informs the staff assigned of information whose content can cause slight

injury to persons or damage to the machine if not respected.

MACHINE OPERATOR OR DRIVER

Identifi es qualifi ed staff, i.e. with specifi c skills, as the operations are com-

pletely manual, therefore refer to the preparation and sensitivity of the machine driver to obtain the best qualitative results. It is therefore prohibited for

the operator to perform operations that are the responsibility of the maintenance technician.

- 13 -

TR shredder

MECHANICAL MAINTENANCE STAFF

Qualifi ed technician able to intervene on mechanical parts in order to make

all regulations, maintenance interventions and repairs necessary.

EXTRAORDINARY INTERVENTIONS

Any maintenance interventions highlighted by the symbol at the side are to

be requested from the manufacturer or authorised workshops.

PERSONAL PROTECTIONS (PPE)

The presence of one of the symbols at the side imposes the use of the corresponding PPE by the operator, as the risk of accident is implicit.

RECOMMENDATION

It refers to a work mode experimented on fi eld, knowing well that every op-

erator will develop his own way of operating.

TR shredder

2.3 SAFETY PRESCRIPTIONS

Even though SICMA has applied all possible safety devices on the equipment, it must be remembered that it can be dangerous for health if not used

correctly. It is therefore advised to read and comply with the safety prescriptions listed below.

Before using the equipment, all operators MUST have read and understood

the safety prescriptions and the entire user manual.

• The machine is not suitable to be used in other sectors than in agricul-

ture.

• Any use different to that specifi ed is to be considered improper.

• The manual must always be on hand, in a way to consult it when neces-

sary. If it should be lost or damaged, request a replacement copy from

SICMA.

• Do not climb onto, sit on or rest on the equipment for any reason,

whether it is on or in the zero energy state.

2.4 OPERATOR REQUISITES

• The machine must only be used by one operator driving the tractor.

• The machine must be used exclusively by authorised, instructed and

trained operators. The operator, besides having read and understood

the instructions contained in this manual, must also be suffi ciently pre-

pared on the proper use of the machine and must have a driving license. The operator must contact the dealer or the manufacturer if in

doubt regarding use of the machine or interpretation of this manual.

• The operator must make sure that no person or animal stops within the

radius of action of the same during machine functioning. Never activate

the machine near to persons standing or transiting within the radius of

action of the machine.

• Do not use the machine if you are tired, ill or under the effect of alcohol,

medicines or drugs.

• The correct operator position is in the tractor driving seat. From this

position he must also control that there are no persons exposed in the

- 14 -

Loading...

Loading...