Sicma TB-110, TB-125, TB-140, TB-155 Instruction Manual

Sicma S.p.A.

Miglianico (CH)

page 1

ATTENTION

Read carefully this manual before

using the equipement

903694002~00

Instruction manual

SHREDDERS

T

B

Sicma S.p.A.

Miglianico (CH)

page 2

Sicma S.p.A.

Miglianico (CH)

page 3

Sicma S.p.A.

Miglianico (CH)

page 4

SICMA S.p.A.

c.da Cerreto, 19 - 66010 Miglianico (CH)

Telefono +39 (0)871 95841 -Telefax +39 (0)871 950295

web: www.sicma.it - e-mail: sicma@sicma.it

Jobber

© SICMA joint-stock company

All rights reserved

Printed in Italy

Società Industriale Costruzione Macchine Agricole

No part of this manual shall be reproduced, copied or disseminated by any means without SICMA

joint-stock company prior authorization in writing.

SICMA joint-stock company reserves the right to make any necessary changes without giving prior

notice in order to optimize the quality and safety of its products and without committing itself to

update this manual every time a change takes place.

This booklet provides an accurate description of the operating instructions and maintenance

activities to be carried out on the shredder you bought. We congratulate you on your choice and

remind you that reading and following scrupulously all prescriptions here contained will assure the

regular working of your machine and especially a high degree of safety.

The manufacturer therefore declines all responsibility as for the onset of problems caused

by a lack of compliance with the instructions and/or negligence of the operator.

This manual is divided into chapters and paragraphs and its pages are progressively numbered in

order to present information in a clear and concise way. Information, thus, can be found through the

keywords used as chapters’ title and especially consulting the index.

Sicma S.p.A.

Miglianico (CH)

page 5

INDEX

General information

Symbols Page 6

Identification plates Page 6

Allowed use Page 7

Main parts Page 7

Improper use Page 8

Technical features Page 8

Safety labels Page 9

Safety

Safety in the workplace

Page 10

Operator’s requirements Page 10

Work clothing Page 10

General safety rules Page 11

Instructions to prevent fire Page 12

Road transport – Handling and transport Page 13

Set up

Maintenance

Maintenance of the machine Page 25

First check, every 8, 50, 500,

1000 hours

Page 25

Cutters/hammers check Page 26

Drive belts replacement Page 27

Replacement of oleodynamic pipes Page 28

Failures chart Page 28

Spare parts ordering Page 29

Tightening chart for nuts and bolts Page 29

Attachment to the tractor Page 14

Attachment to the cardan shaft Page 17

Hydraulic connection Page 17

Use of the machine Page 17

Working speed Page 18

Detachment of the machine Page 18

Storage Page 18

Scrapping Page 19

Working height adjustment Page 20

Side shift regulation Page 21

Adjustment of belts tensioner Page 22

Adaption to tractors with at 1000 rpm Page 23

Cutters Page 23

Sicma S.p.A.

Miglianico (CH)

page 6

GENERAL INFORMATION

Information, descriptions and pictures herein contained reflect the state-of the-art achieved at that

moment when the machine is distributed.

The Manufacturer retains the right to carry out, at any time, possible modifications on the machines,

in order to meet technical or commercial requirements. Such modifications shall not oblige the

Manufacturer either to intervene on the equipments distributed up to that moment, or to deem this

publication inappropriate.

Should the Manufacturer decide to inform about further additions, the latter shall be kept together

with the manual and considered as an integral part hereof.

SYMBOLS

This booklet contains three “safety graphic symbols” to highlight as many danger levels or important

information:

It draws the operator’s attention to situations which can

jeopardize people’s safety.

It draws the attention to situations which jeopardize the

machine efficiency but not people’s safety.

It highlights general information which does not endanger

people’s safety or the efficiency of the parts.

IDENTIFICATION PLATES

Identification plates are placed on every shredder and are structured as follows:

CE plate

model of shredder

(example)

dimension

(example)

When asking for information or technical service, always

specify the machine type and width.

Sicma S.p.A.

Miglianico (CH)

page 7

ALLOWED USE

The TB shredder has been designed exclusively for agricultural use and is suitable for shredding

grass, shrubs and branches up to approx. 3 cm, depending on the specific type of tool the machine

is provided with.

The machine is carried by the tractor by means of a three-point connection and is powered by the

tractor through a PTO shaft.

The machine is not intended for any purpose other than agricultural use.

Any use of the machine other than the above mentioned one

shall be considered as not allowed and dangerous.

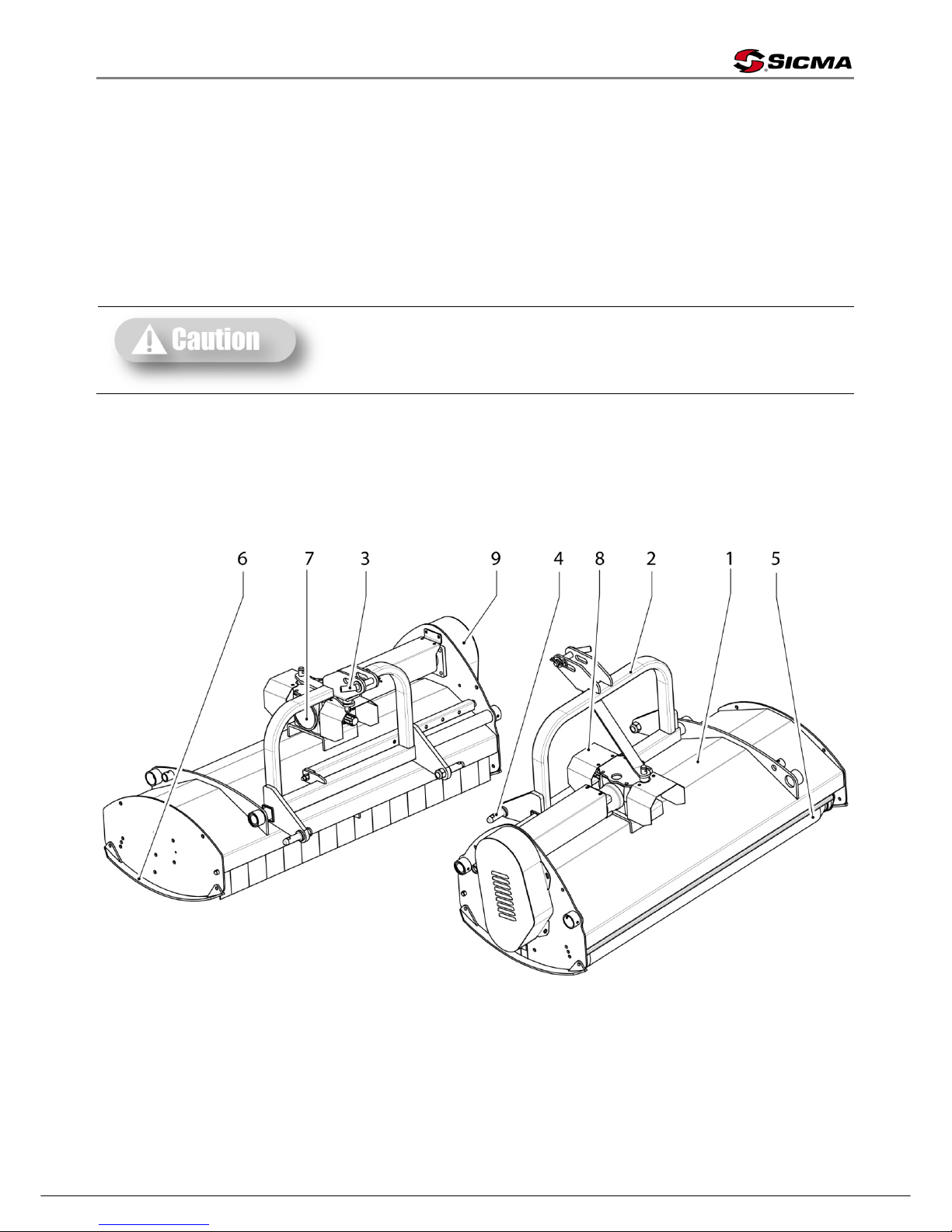

MAIN PARTS TERMINOLOGY

The machine consists in a working equipment based on a rotor having horizontal axes and moving at

high frequency. On such rotor the shredding tools are mounted.

The shredder is made of the following parts:

1) Frame

2) Shifting bow

3) Upper three-point hitch

4) Lower three-point hitch

5) Stabilizing roller

6) Side skids

7) Speed multiplier

8) PTO guard

9) Transmission case

Sicma S.p.A.

Miglianico (CH)

page 8

IMPROPER USE

When using SICMA shredders it is particularly forbidden:

- The attachment to vehicles of unsuitable power or weight.

- To assemble the machine without securing the rebound tie rods of the three-point hitch of

the tractor’s elevator.

- To work in excessively stony grounds

- To use the machine without inserting the check-pins when supplied.

- To work in excessive slopes.

- To lift the machine when the power takeoff is engaged.

- To approach the machine when wearing inappropriate work clothing.

To get on the machine while it is being used or transported

Technical features

Manufacturer:

Sicma S.p.A.

Via Cerreto,19 | 66010 MIGLIANICO (CH)

Tel. +39 0871 95841 | fax +39 0871 950295

VAT no. 00227220696

Internet: www.sicma.it

e-mail: sicma@sicma.it

MODEL

TB-110 TB-125 TB-140 TB-155

Total width mm

1225 1377 1529 1681

Working width mm

1100 1250 1400 720

Length mm

720 720 720 720

Height mm

700 700 700 700

No. of tools

Smooth

hammers 26 30 34 38

Toothed

hammers

- - - -

Knives 52 60 68 76

Minimum power

required by tractor

HP 15-35 15-35 15-35 15-35

Connection to

tractor

cat 1

nd

1

nd

1

nd

1

nd

PTO speed rpm

540-

1000

540-

1000

540-

1000

540-

1000

Shaft rotation rpm

2080 2080 2080 2080

Weight (manual

traversable)

kg

158 173 188 203

lbs

348 381 414 447

Weight ( Hydraulic

traversable)

kg

153 168 183 189

lbs

337 370 403 436

Sicma S.p.A.

Miglianico (CH)

page 9

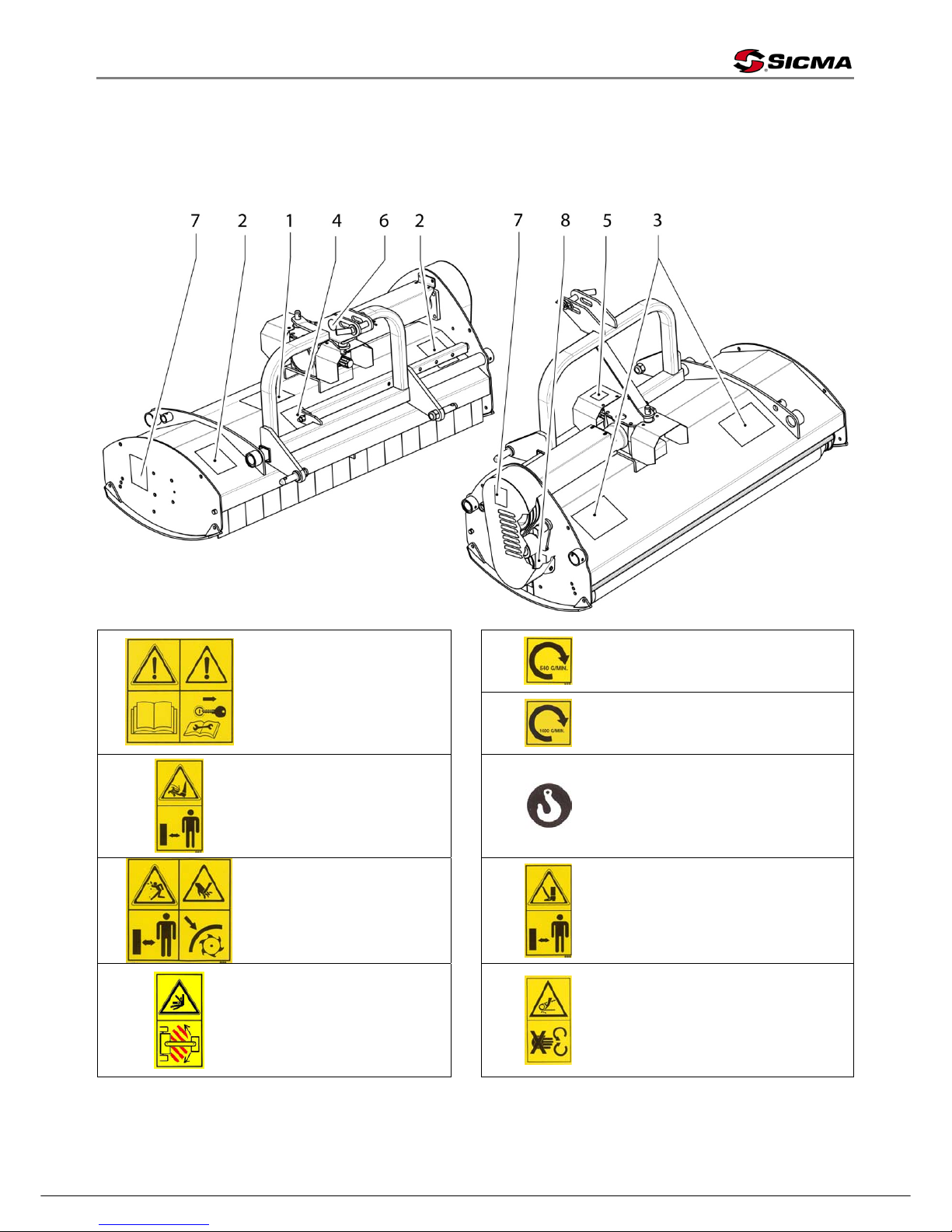

SAFETY LABELS

The safety labels and the information on the machine, listed in the following table, must be

necessarily carried out; failure to carry out these warnings can cause death or severe injuries. Make

sure that the labels are always present and legible, should this not be the case contact your nearest

SICMA dealer to replace the missing or illegible ones.

1

Attention: read carefully all

instruction and safety rules before

using the machine.

Stop engine and remove key

before starting maintenance or

repairs..

5

Use a 540 rpm power takeoff.

5

Use a 1000 rpm power takeoff.

2

Danger of feet injuries: rotating

tools, keep away from the

machine.

6

Hooking point for the machine’s lifting.

3

Thrown objects: keep a safety

distance from the machine.

Danger of hands injuries: do not

open or remove safety guards

while the machine is operating.

7

Danger of feet injuries: keep a safety

distance from the machine.

4

Risk of crushing, hazardous area

resulting from moving the

machine.

8

Danger of hands injuries: keep safety

guards in position while operating.

Sicma S.p.A.

Miglianico (CH)

page 10

SAFETY

SAFETY IN THE WORKPLACE

Most of the accidents which take place while the operator is using the machine or the equipment or

during their maintenance or repair are caused by a lack of compliance with the basic safety

precautions.

It is necessary, therefore, to become more and more conscious of the potential risks of one’s action

by constantly paying attention to its effects.

If potentially dangerous situations are known, accidents can be prevented!

OPERATOR’S REQUIREMENTS

All operators using the equipment must be competent and meet necessarily the following features:

Physical: good eyesight, coordination and capability of carrying out all functions required for the

machine’s use.

Mental: capability of understanding and applying the established rules and safety precautions.

Users must pay attention and be sensible for their own and other people’s safety.

Training: users must have read and studied this manual, its eventual enclosed graphs and schemes

and its identification and danger plates. They must be skilled and trained on any use or maintenance

activities.

WORK CLOTHING

When working and especially when executing repair or maintenance activities, it is necessary to

wear the following clothing and safety accessories:

- Overalls or other comfortable clothing, not too loose to prevent

the possibility that parts of them might be caught in

the moving parts.

- Protective gloves for hands.

- Protective glasses or faceplate to protect eyes and face.

- Protective helmet for the head.

- Safety shoes

- Headphones for the Protection of hearing

Wear only personal safety accessories in good condition and

complying with the rules in force.

Loading...

Loading...