Sicma MA Series, ML Series, MLI 140, MA 120, MP Series Instruction And Maintenance Manual

...

ORIGINAL INSTRUCTIONS

Shredder

MA - ML - MP

INSTRUCTION AND MAINTENANCE MANUAL

Shredder MA- ML-MP

- 3 -

SUMMARY

Par. Title P.

1. INTRODUCTION 5

2. GENERAL DESCRIPTION OF THE MACHINE 6

2.1 MILLING MACHINE COMPOSITION 7

3. GENERAL SAFETY INSTRUCTIONS 8

4. IDENTIFICATION OF THE MACHINE 9

4.1 IDENTIFICATION PLATE 9

4.2 IDENTIFICATION MARKINGS 10

4.3 INSPECTION OF MACHINE UPON DELIVERY 10

4.4 TECHNICAL DATA 11

5. SAFETY REGULATIONS: ADHESIVES AND WARNINGS 12

5.1 ADHESIVE LABELS DESCRIPTION 13

6. UNLOADING AND UNPACKING 14

7. INSTALLATION OF THE MACHINE 15

7.1 APPLICATION TO THE TRACTOR 15

7.2 TRANSPORTING THE SHREDDER 16

7.3 SPECIAL PROTECTIONS ON THE TRACTOR 17

7.4 ADAPTATION OF THE CARDAN SHAFT 18

8. RULES FOR USE OF THE SHREDDER 19

8.1 POSITION OF THE MACHINE IN RELATION TO THE GROUND 20

8.1.1 Adjustment of the levelling roller 20

8.1.2 Adjustment of slide rails 21

8.1.3 Adjustment third arm 21

8.1.4 Work positions of the machine 22

8.1.5 Start of work 22

9. ORDINARY MAINTENANCE 23

9.1 ADJUSTMENT OF THE BELTS AND REPLACEMENT 24

9.2 REPLACEMENT OF KNIVES OR HAMMERS 25

9.3 TABLE OF TIGHTENING TORQUES 26

9.4 SPECIAL ACCESSORIES: - OPENING HOOD 26

9.5 TABLE OF LUBRICANTS 27

10. PROBLEMS AND SOLUTIONS 27

11. TEMPORARY SHUTDOWN OF THE SHREDDER 28

12. DISMANTLING 28

13. TECHNICAL ASSISTANCE 28

14. WARRANTY 28

14.1 EXPIRY OF THE WARRANTY 29

11. TEMPORARY SHUTDOWN OF THE SHREDDER 29

12. DISMANTLING 29

13. TECHNICAL ASSISTANCE 30

14. WARRANTY 30

14.1 Expiry of the warranty 30

- 4 -

Shredder MA-ML-MP

ATTENTION !

IT IS PROHIBITED TO USE THE SHREDDER WITHOUT CONSULTING THE INSTRUCTION AND MAIN-

TENANCE MANUAL

Read this manual carefully; in case of dif! culty in understanding do not use

the machine and if clari! cation is required request information from your au-

thorised retailer or from the manufacturer.

Shredder MA- ML-MP

- 5 -

1. INTRODUCTION

This manual is an integral part of the product and must be kept in an appropriate manner, allowing easy consultation by the operator at any time. It

is advisable to make a copy of this manual.

This manual is accompanied by the "DECLARATION OF CONFORMITY"

that certi! es compliance with the regulations in force and that must be presented to parties that expressly request it.

In addition, this declaration shows the "SERIAL NUMBER" of the machine.

Upon delivery check correspondence of the serial number of the machine.

Where there correspondence of the numbers is incorrect, immediately contact the retailer to check the details.

"Sicma" thanks you for having chosen this excellent product.

During operation you will have the opportunity to appreciate the quality of

use and durability of your machine.

In order to maximise the qualities of this machine, it is advisable to spend a

little of your valuable time reading this manual. Superior knowledge of the

machine will pay dividends in terms of duration, safety and quality in the

productive use.

In case of uncertainty, please contact the authorised retailer that will advise

you, offering the appropriate support in the shortest time possible.

Your "SHREDDER" was designed exclusively

for agriculture use. Any other use of the machine is to be considered abusive and is wholly at the risk of the user. In such case the legal

warranty ceases.

Appropriate use also involves compliance with

the instructions of service and maintenance

prescribed by the manufacturer.

Only authorised persons that are informed

about the possible risks must use, repair and

maintain the machine.

The relevant instructions for the prevention of

accidents must be observed as well as all the

other general technical provisions, the Highway Code and regulations relating to health

and safety.

Never make any changes to the machine under your own initiative. Where this is the case,

no liability can be held for any damage caused

to persons or property. In this case the legal

warranty also ceases with immediate effect .

"Sicma" reserves the right to suspend at any time the production of certain

models, to vary the characteristics and the design without being committed

in any shape or form to provide notice thereof and is not obliged to apply

these changes to models that have already been produced.

Ap

- 6 -

Shredder MA-ML-MP

2. GENERAL DESCRIPTION OF THE MACHINE

ATTENTION!

Where the shredder is delivered packaged, the elements of the packaging

must not be left discarded as potential sources of risk. Remove the above

to the appropriate collection places if they are contaminants and/or biodegradable.

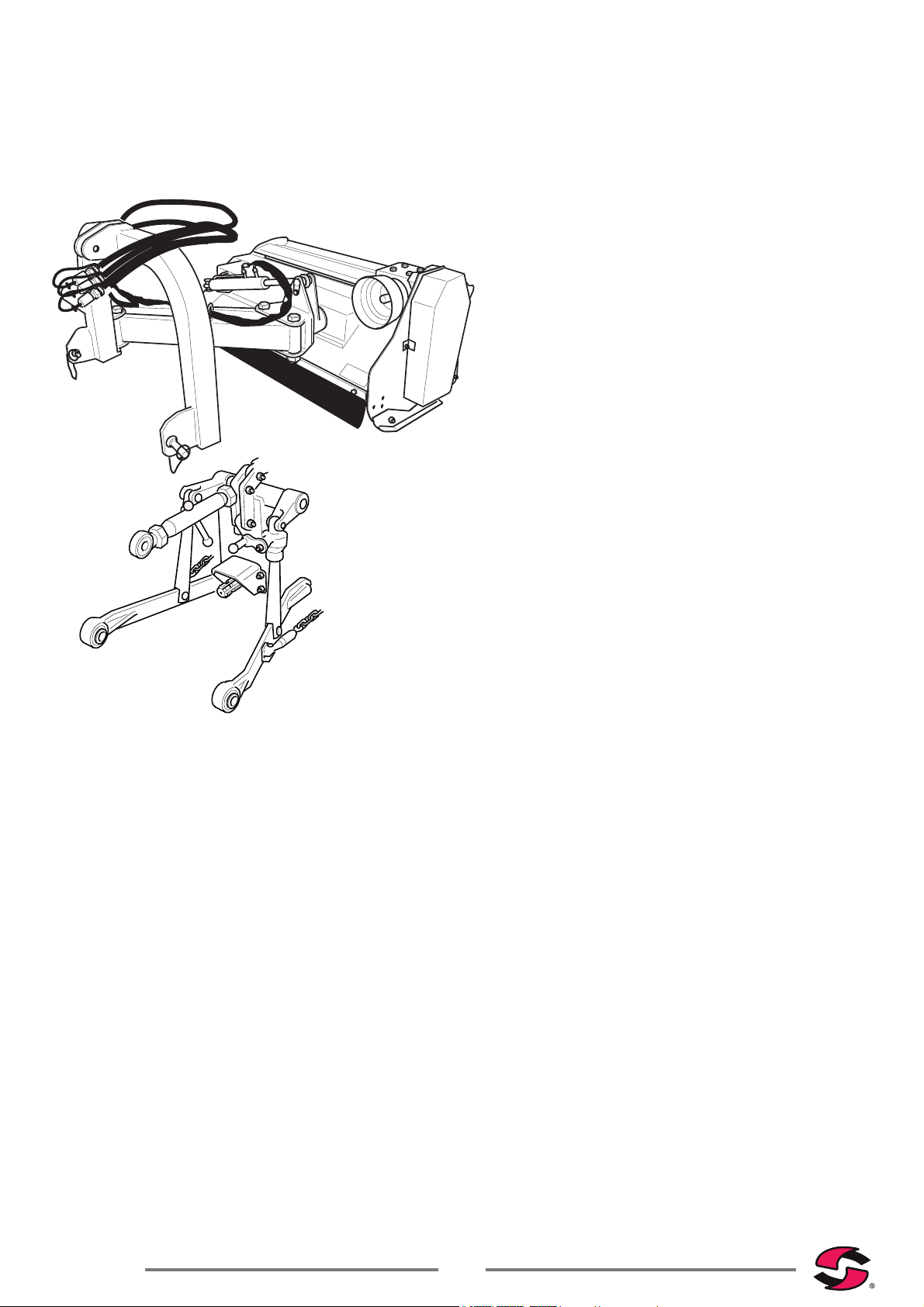

Fig. 1

Shredder MA

Fig. 2

Lifting unit

- 3 arms

The shredder series MA, ML, MP consist of a body of steel that supports all

the parts of the machine; it is designed in such a way as to ensure perfect

working of the product without the need for high powers, in compliance with

the applicable safety standards.

The articulation is secured to the main frame that allows the machine to

be tilted; two arms are connected to the joint for lateral movement, and the

three-point connection is attached to the arms.

The machine is able to perform rotations with respect to the ground of 65°

and 90° by means of a hydraulic control, operated exclusively on board the

tractor; in addition the shredder, via the hydraulic control arms can perform

lateral movements.

Within the body is housed the rotor supported by high strength bearings and

driven by transmission belts that take motion from the side transfer of the

box to the gears or revolution multiplier. The rotor is dynamically balanced

for homogeneous rotation without vibration.

The number of knives or hammers with which the rotor is equipped guarantee perfect shredding of the material and adequate ventilation.

Shredder MA- ML-MP

- 7 -

At the time of purchase the shredder is as shown in Fig. 1, and is designed

to be installed on the rear of the tractor that will need to be ! tted with a "universal" rear hydraulic 3-point lift unit, second category, for the models MA,

ML and third category for the mod. MP suitable to withstand the weight and

absorption characteristics of the shredder.

The hitch is shown in Fig. 2

ATTENTION!

Before performing any operation carefully read the safety requirements

shown here.

2.1 Shredder composition

Fig. 3

Main

elements

No. Description

1 Three-point connection

2 Quick coupling hydraulic connec-

tions

3 Support arm and movement

4 Foot support

5 3° point plug

6 Main frame

7 "EC" rubber protection

8 Protection cardan joint

9 Slide rail

10 Power take-off (PTO 540 RPM)

11 Transmission belt housing

12 Gear box

13 Openable hatch for maintenance

14 Machine tilt articulation

4

3

2

1

14 12 11

5 6 7 8 9

10

13

- 8 -

Shredder MA-ML-MP

3. GENERAL SAFETY INSTRUCTIONS

It is recommended to carefully read these annotations in order to avoid situations of danger.

1) In addition to the information in this manual it is also similarly important

to respect the general provisions relating to safety, provided for the users of

agricultural machines by current legislation of each country.

2) Observe the decals on the machine, especially those that relate to safety.

3) Only start the shredder in the resting position on the ground and horizontal to the ground.

4) Never exceed the speed of the prescribed PTO (540 rpm).

5) Secure the protector tube of the cardan shaft against the rotation by connecting the chains in order to prevent rotation of the protective elements of

the cardan shaft.

6) Lower the machine to the level of the ground before putting it in the work

position. Ensure there are no persons in the range of action of the machine.

7) Ensure that the security devices are perfectly ! tted and ef! cient before

starting work.

8) Pay special attention on stony ground, ensuring that there are no persons

in the immediate vicinity.

9) Before any interventions on the shredder, ensure that all the rotary members are stationary and switch off the tractor by removing the start key.

10) During transfer onto public roads, observe the Highway Code.

11) Use particular caution during the operations of coupling and uncoupling

of the tool from the tractor.

12) Before leaving the tractor, secure the tool and lower it until resting on the

ground. Switch off the tractor and remove the start key.

13) Before engagement and release of the machine at the three-point hitch,

lock the hydraulic lifting controls of the tractor in order to avoid, even inadvertently, the hydraulic lift being activated resulting in movement of the

shredder.

14) Ensure that the maximum loads permitted for the three-point hitch are

respected.

15) Perform assembly and disassembly of the cardan shaft only with the

PTO disabled and the engine of the tractor off with the ignition key removed.

16) Before engaging the PTO, ensure that the speed and direction of rotation of the power take-off of the tractor are compatible with the shredder.

17) Never engage the PTO with the engine running.

18) Before engaging the PTO, ensure there are no persons in the work

area.

19) Do not allow anyone to stand near the PTO when this is engaged.

20) Before accessing the tool ensure that this is completely stopped and

that the engine of the tractor is stopped and the PTO is off.

Shredder MA- ML-MP

- 9 -

21) Periodically check the tightness of screws and nuts. Where necessary

tighten with reference to the tightening table in paragraph 9.3.

22) During maintenance work performed with the tool raised, ensure that

it is securely in the elevated position safely through the use of appropriate

supports.

In the case of repairs please contact specialist workshops.

23) Dispose of oil and grease by observing the relevant rules in force.

IMPORTANT !

The shredder models MA, ML, MP were designed and manufactured for

agricultural use and designed to operate, in accordance with the manufacturer's instructions, within the limits shown in this manual. No liability is

assumed for any damage to property or persons caused by improper use

of the machine.

4. IDENTIFICATION OF THE MACHINE

4.1 Identi" cation plate

Shredder

MA140

00218

2014

147 Kg

540 rpm

Fig. 4

Identi! cation plate

Fig. 5

Plate position

- 10 -

Shredder MA-ML-MP

4.2 Identi• cation markings

The shredders of the company Sicma models "MA, MLI, MLE, MPI, MPE"

are available in the following work widths and models :

Internal transmission unit External transmission unit

Model Work width mm Model Work width mm

MA 120 1150

MA 140 1350

MLI 140 1330 MLE 140 1330

MLI 160 1530 MLE 160 1530

MPI 180 1800 MPE 180 1800

MPI 200 1960 MPE 200 1960

4.3 Inspection of machine upon delivery

At the time of delivery of the shredder check the entire supply, ensuring in

particular the presence of the instruction and maintenance manual that is an

integral part of the machine.

The following items must be delivered together with the shredder:

- no. 1 shredder operation and maintenance manual Fig.6

- no. 1 operation and maintenance manual for cardan shaft Fig.7

- no. 1 declaration of conformity Fig.8

Lorenzo Aurora

AMMINISTRATORE UNICO

EC DECLARATION OF CONFORMITY

The company

Sicma s.p.a. - C.da Cerreto, 39 - 66010 Miglianico (Ch) - Italy

Tel.: +39 0871 95841 - Fax: +39 0871 950295

e-mail: info@sicma.it - http://www.sicma.it

hereby declares that:

product: SHREDDER

model: MA

serial number:

complies with the essential requirements for safety and health of Directive 2006/42/CE.

To fulfil the above mentioned Directive have been applied the following harmonised standards:

- UNI EN 745:2010, UNI EN ISO 4254-1:2010, UNI EN ISO 12100-1:2009, UNI EN ISO 12100-2:2009

and the technical standards and specifications

- ISO 11684:1995, ISO 13852:1996, UNI 9456:1989.

The person authorised to compile the technical file is Mr. Lorenzo Aurora (amministratore unico)

Miglianico, 10-01-2014

Fig. 8

Declaration of conformity

ORIGINAL INSTRUCTIONS

Shredder

MA - ML - MP

INSTRUCTION AND MAINTENANCE MANUAL

Fig. 6

Instruction and maintenance manual

Fig. 7

Instruction and maintenance manual

Loading...

Loading...