Page 1

WSU/WEU26-3

Single-beam Photoelectric Safety Switch

OPERATING INSTRUCTIONS

en

Page 2

Operating Instructions

WSU/WEU263

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 3

Operating Instructions

WSU/WEU263

Contents

Contents

1 About this document.........................................................................................................5

1.1 Function of this document....................................................................................5

1.2 Target group ..........................................................................................................5

1.3 Scope ..................................................................................................................... 5

1.4 Depth of information............................................................................................. 5

1.5 Abbreviations.........................................................................................................6

1.6 Terminology, symbols used ..................................................................................6

2 On safety.............................................................................................................................7

2.1 Qualified safety personnel.................................................................................... 7

2.2 Applications of the device.....................................................................................7

2.3 Correct use ............................................................................................................8

2.4 General safety notes and protective measures ..................................................8

2.5 Environmental protection .....................................................................................9

2.5.1 Disposal ............................................................................................... 9

2.5.2 Separation of materials ...................................................................... 9

3 Product description.........................................................................................................10

3.1 Special features ..................................................................................................10

3.2 Operating principle of the device .......................................................................10

3.2.1 Scanning range .................................................................................11

3.2.2 Restart interlock................................................................................11

3.2.3 External device monitoring (EDM)....................................................11

3.2.4 Front screen heating.........................................................................11

3.3 Structure and function........................................................................................12

3.4 Application example............................................................................................13

4 Mounting ..........................................................................................................................14

4.1 Preparation for mounting ...................................................................................14

4.1.1 Safety distance for access protection..............................................14

4.1.2 Minimum distance to reflective surfaces ........................................17

4.1.3 Mutual interference of systems in close proximity .........................18

4.2 Mechanical mounting .........................................................................................18

4.2.1 Deflector mirror .................................................................................20

5 Electrical installation......................................................................................................22

5.1 Important information for the installation .........................................................22

5.2 System connection..............................................................................................23

5.2.1 Pin assignment sender .....................................................................23

5.2.2 Tested ................................................................................................23

5.2.3 Pin assignment receiver ...................................................................24

5.3 Arc-suppression...................................................................................................25

5.4 Cross-circuit monitoring......................................................................................25

5.5 Overcurrent protection (fuse) .............................................................................25

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Page 4

Contents

WSU/WEU263

6 Commissioning................................................................................................................ 26

6.1 Aligning sender and receiver .............................................................................26

6.1.1 Alignment using the diagnostics LEDs ............................................ 26

.1.2 Alignment using the AR60 laser alignment aid ..............................27

6

6.2 Test notes............................................................................................................ 28

6.2.1 Tests before the initial commissioning............................................28

6.2.2 Daily functional checks of the protective device ............................28

6.2.3 Regular inspection of the protective device by qualified

safety personnel ...............................................................................29

7 Care and maintenance ...................................................................................................30

8 Fault diagnosis ................................................................................................................31

8.1 In the event of faults or errors ........................................................................... 31

8.2 SICK support .......................................................................................................31

8.3 Status displays of the diagnostics LEDs ........................................................... 31

9 Technical specifications ................................................................................................ 33

10 Ordering information ...................................................................................................... 36

10.1 Devices................................................................................................................ 36

10.2 Deflector mirror................................................................................................... 36

10.3 Accessories ......................................................................................................... 36

10.4 Dimensional drawings ........................................................................................ 37

Operating Instructions

11 Annex................................................................................................................................ 40

11.1 Compliance with EU directives........................................................................... 40

11.2 Checklist for the manufacturer.......................................................................... 41

11.3 List of tables .......................................................................................................42

11.4 List of illustrations ..............................................................................................42

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 5

Operating Instructions Chapter 1

WSU/WEU263

About this document

1 About this document

lease read this chapter carefully before you work with these operating instructions and

P

the WSU/WEU26@3 single-beam photoelectric safety switches, referred to in the following

as WSU/WEU26@3 devices.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

configuration, electrical installation, commissioning, operation and maintenance of the

WSU/WEU26@3 devices.

These operating instructions do not provide instructions for operating machines on which

the WSU/WEU26@3 devices are, or will be, integrated. Information on this is to be found in

the appropriate operating instructions for the machine.

1.2 Target group

These operating instructions are addressed to planning engineers, machine designers and

operators of plants and systems which are to be protected by the WSU/WEU26@3 devices.

They are also addressed to people who integrate the WSU/WEU26@3 devices into a

machine, initialise its use, or who are in charge of servicing and maintaining the device.

1.3 Scope

These operating instructions are original operating instructions.

These operating instructions are only applicable to the WSU/WEU26@3 single-beam

photoelectric safety switch with one of the following entries on the type label in the field

Operating Instructions:

• 8013336

• 8013336/YTA4

This document is part of SICK part number 8013336 (operating instructions

“WSU/WEU26@3 single-beam photoelectric safety switch” in all available languages).

1.4 Depth of information

These operating instructions contain the following information on the WSU/WEU26@3

devices:

• mounting,

• electrical installation,

• commissioning,

• application,

Planning and using protective devices such as the WSU/WEU26@3 devices also require

specific technical skills which are not detailed in this documentation.

When operating the WSU/WEU26@3 devices, the national, local and statutory rules and

regulations must be observed.

General information on accident prevention using opto-electronic protective devices can

be found in the brochure “Guidelines Safe Machinery – Six steps to the safe machine”.

• error diagnosis and troubleshooting,

• part numbers,

• conformity and approval,

• care and maintenance.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

Page 6

Chapter 1 Operating Instructions

WSU/WEU263

About this document

Note

EDM

ESD

ESPE

LED

OSSD

Recommendation

Note

Red, Yellow,

Green

Take action …

We also refer you to the SICK homepage on the Internet at www.sick.com.

Here you will find information on:

• sample applications,

• these operating instructions in different languages for viewing and printing,

• EU declaration of conformity and other documents.

1.5 Abbreviations

External device monitoring

Electro-static discharge

Electro-sensitive protective equipment

Light Emitting Diode

Output signal switching device

1.6 Terminology, symbols used

Recommendations are designed to give you some assistance in your decision-making

process with respect to a certain function or a technical measure.

Refer to notes for special features of the device.

LED symbols describe the state of a diagnostics LED. Examples:

Red The red LED is illuminated constantly.

Yellow The yellow LED is flashing.

Green The green LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

WARNING

Warning!

A warning notice indicates an actual or potential risk or health hazard. They are designed

to help you to prevent accidents.

Read carefully and follow the warning notices!

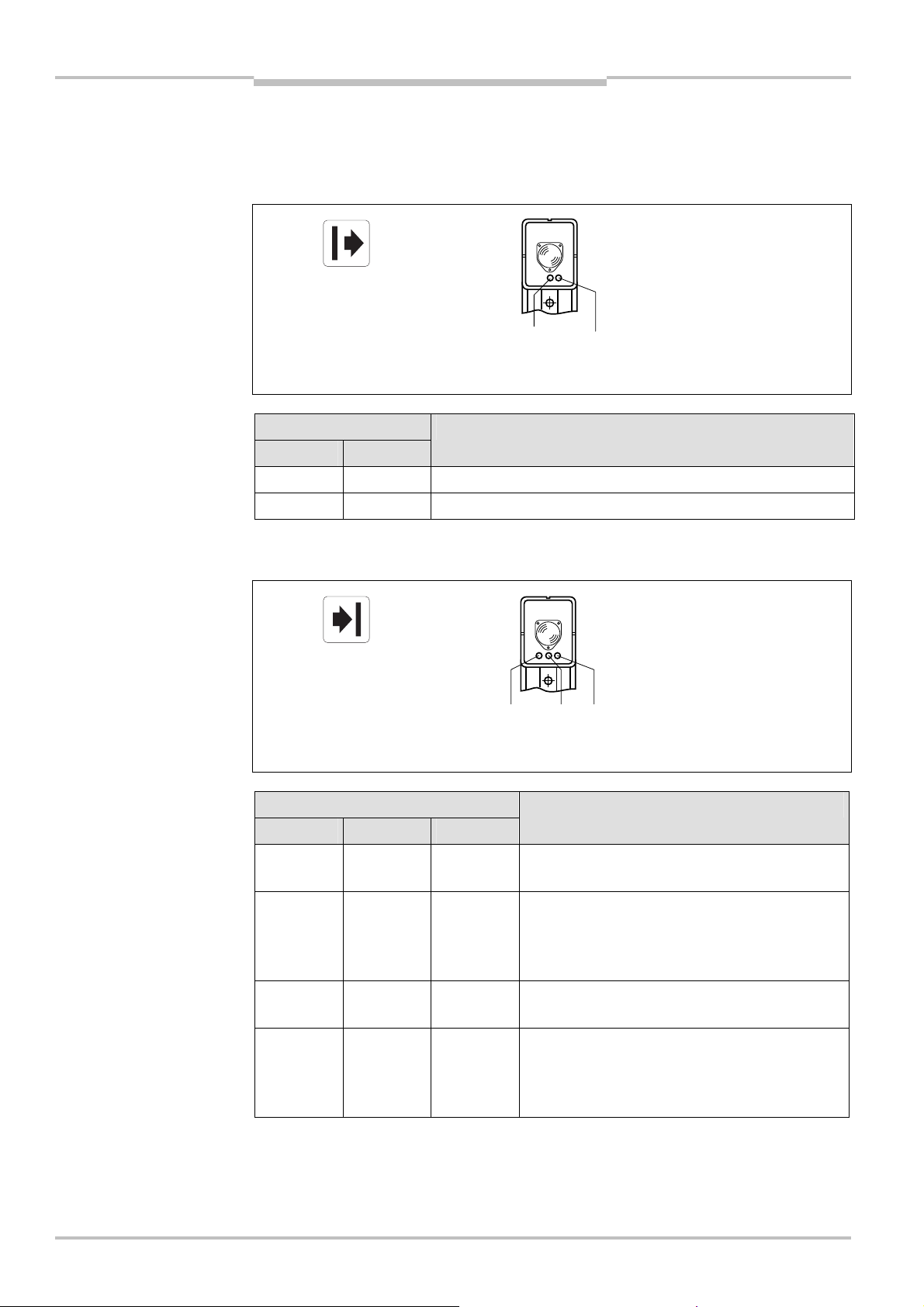

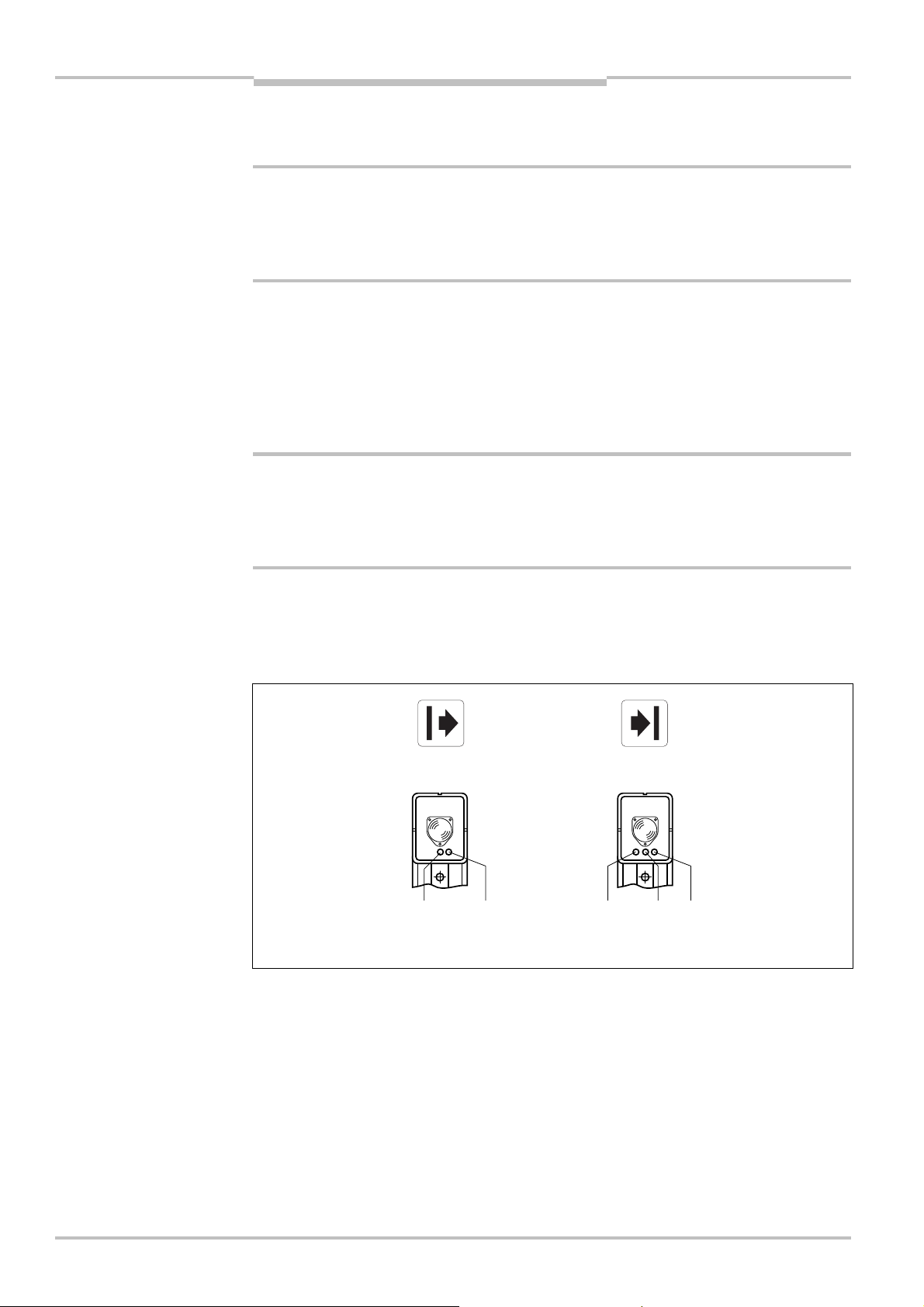

Sender and receiver

In drawings and diagrams, the symbol denotes the sender and the symbol denotes

the receiver.

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and

diagrams of this document as a movement of a machine part. In practical operation, there

may be a number of different dangerous states:

• machine movements,

• electrical conductors,

• visible or invisible radiation,

• a combination of several risks and hazards.

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 7

Operating Instructions Chapter 2

WSU/WEU263

On safety

2 On safety

his chapter deals with your own safety and the safety of the equipment operators.

T

Please read this chapter carefully before working with the WSU/WEU26@3 devices or with

the machine protected by the WSU/WEU26@3 devices.

2.1 Qualified safety personnel

The WSU/WEU26@3 devices must be mounted, commissioned and serviced only by

qualified safety personnel. Qualified safety personnel are defined as persons who

have undergone the appropriate technical training

and

who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

who have access to these operating instructions.

WARNING

2.2 Applications of the device

The WSU/WEU26@3 devices are electro-sensitive protective equipment (ESPE), type 4 in

accordance with IEC 61496-1 and IEC 61496-2 and may for this reason be used in

controllers of safety category 4 in accordance with EN ISO 13849, SILCL3 in accordance

with EN 62061 or up to PL e in accordance with EN ISO 13849. The WSU/WEU26@3

devices are used for:

hazardous area protection,

access protection.

The photoelectric switch must be installed such that the hazardous area can only be

reached by interrupting the light path between sender and receiver. It must not be possible

to start the plant/system as long as personnel are within the hazardous area.

The WSU/WEU26-3 devices are intended only for use in industrial environments. When

used in residential areas it can cause radio interferences.

Please refer chapter 3.4 on page 13 for an illustration of the protection mode and an

example application.

Only use the WSU/WEU263 devices as an indirect protective measure!

Opto-electronic protective devices as the WSU/WEU26@ 3 devices cannot provide any

protection against parts thrown out or against radiation. Transparent objects are not

detected.

Depending on the application, mechanical protective devices may be required in addition

to the WSU/WEU26@3 devices.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

Page 8

Chapter 2 Operating Instructions

WSU/WEU263

On safety

2.3 Correct use

he WSU/WEU26@3 devices may only be used as specified in chapter 2.2 “Applications of

T

the device”. They are only allowed to be used by qualified safety personnel and only on the

machine on which they have been installed and initialised by qualified safety personnel as

per these operating instructions.

All warranty claims against SICK AG are forfeited in the case of any other use, or

alterations being made to the WSU/WEU26@3 devices, even as part of their mounting or

installation.

2.4 General safety notes and protective measures

Safety notes

WARNING

Please observe the following items in order to ensure the correct and safe use of the

WSU/WEU26@3 devices.

• National/international rules and regulations apply to the installation, commissioning,

use and periodic technical inspections of the WSU/WEU26@3 devices, in particular:

– Machinery Directive,

– Work Equipment Directive,

– the work safety regulations/safety rules,

– other relevant safety regulations.

• Manufacturers and operators of the machine on which the WSU/WEU26@3 devices are

used are responsible for obtaining and observing all applicable safety regulations and

rules.

• It is imperative the test notes from page 28 of these operating instructions (“Tests

before the first commissioning”, “Daily functional checks of the protective device”,

“Regular inspection of the protective device by qualified safety personnel”) are followed.

• The tests must be carried out by qualified safety personnel or specially qualified and

authorised personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

• The operating instructions must be made available to the operator of the machine where

the WSU/WEU26@3 devices are used. The machine operator is to be instructed in the

use of the device by qualified safety personnel and must be instructed to read the

operating instructions.

• The external voltage supply for the devices must be capable of buffering brief mains

voltage failures of 20 ms as specified in EN 60204. Suitable power supplies are

available as accessories from SICK.

• A safety extra-low voltage SELV/PELV must be used to supply power to the

WSU/WEU26@3 devices.

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 9

Operating Instructions Chapter 2

Tab. 1:

Overview on disposal

WSU/WEU263

On safety

2.5 Environmental protection

he WSU/WEU26@3 devices are constructed in such a way that they adversely affect the

T

environment as little as possible. The devices use only a minimum of power and natural

resources.

At work, always act in an environmentally responsible manner. For this reason please note

the following information on disposal.

2.5.1 Disposal

Always dispose of unserviceable or irreparable devices in compliance with local/national

rules and regulations with respect to waste disposal.

Note

We would be pleased to be of assistance on the disposal of this device. Contact your local

SICK representative.

Information on the individual materials in the WSU/WEU26@3 is given in chapter 9

“Technical specifications” from page 33.

2.5.2 Separation of materials

by components

WARNING

Only appropriately trained personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the

different materials in the WSU/WEU26@3 devices.

Separate the housing from the rest of the parts (in particular the circuit board).

Send the separated parts for recycling as appropriate (see Tab. 1).

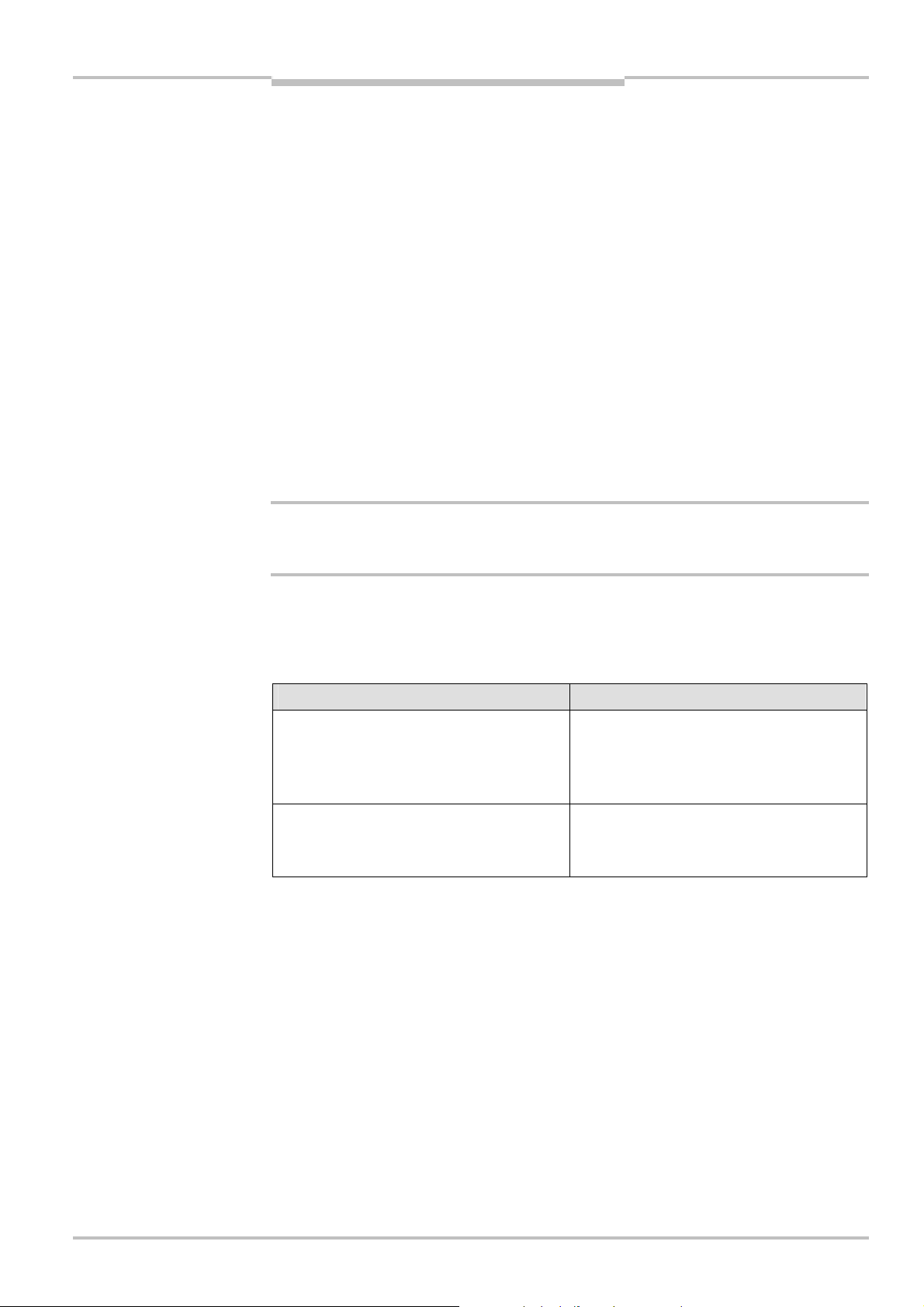

Components Disposal

Product

Housing

Circuit boards, cable, connector and

electrical connecting pieces

Packaging

Cardboard, paper

Polyethylene packaging

Metal recycling (aluminium)

Electronic recycling

Paper/cardboard recycling

Plastic recycling

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

Page 10

Chapter 3 Operating Instructions

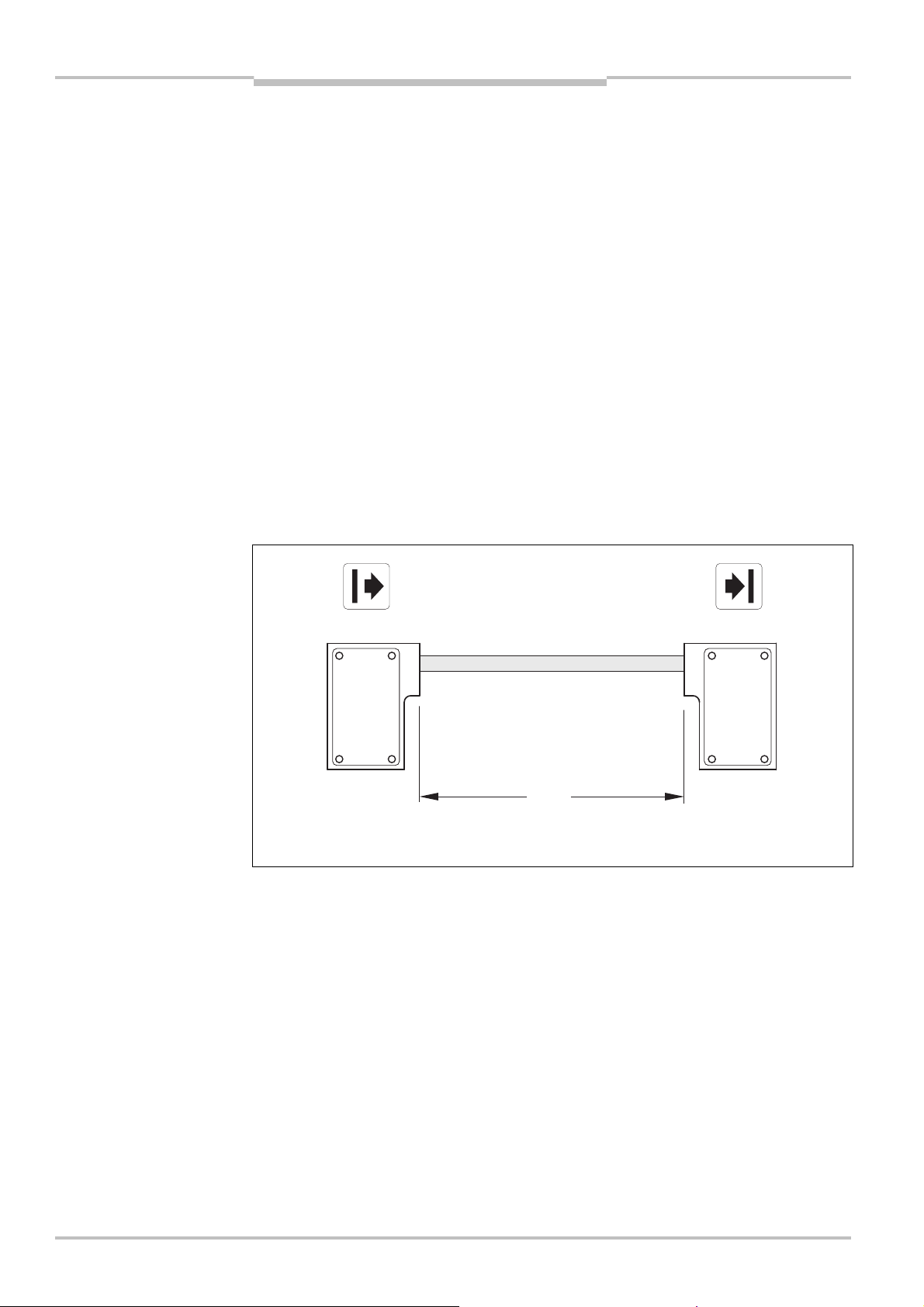

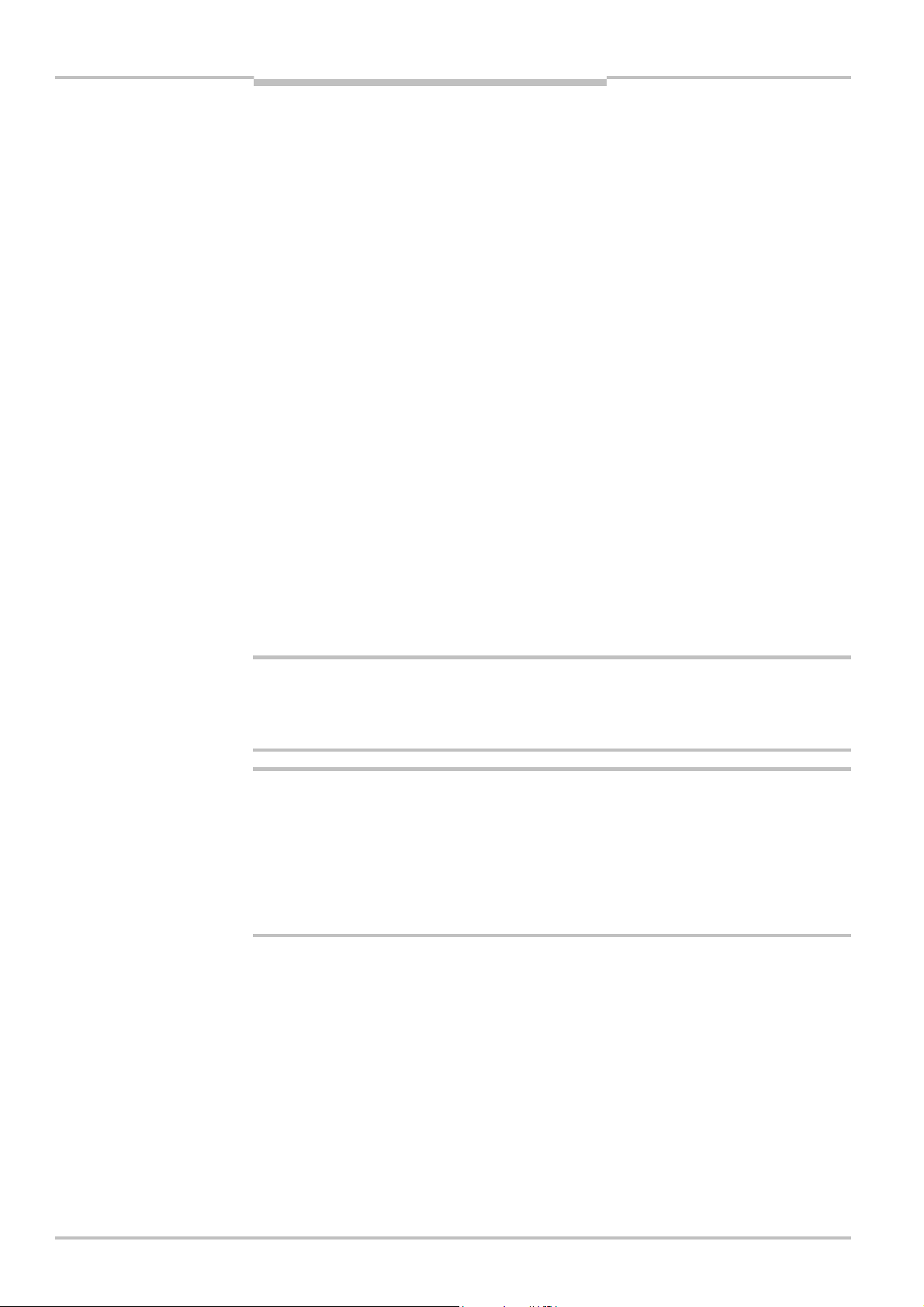

F

ig. 1:

Key data for the

0.5 ... 20 m

Light path between se

nder and receiver

WSU/WEU263

Product description

3 Product description

his chapter provides information on the special features, the operating principle, the

T

structure and the function of the WSU/WEU26@3 devices.

Please read this chapter before mounting, installing and commissioning the

WSU/WEU26@3 devices.

3.1 Special features

• relay outputs

• rugged type of construction

• high operating range up to 70 m

• front screen heating

3.2 Operating principle of the device

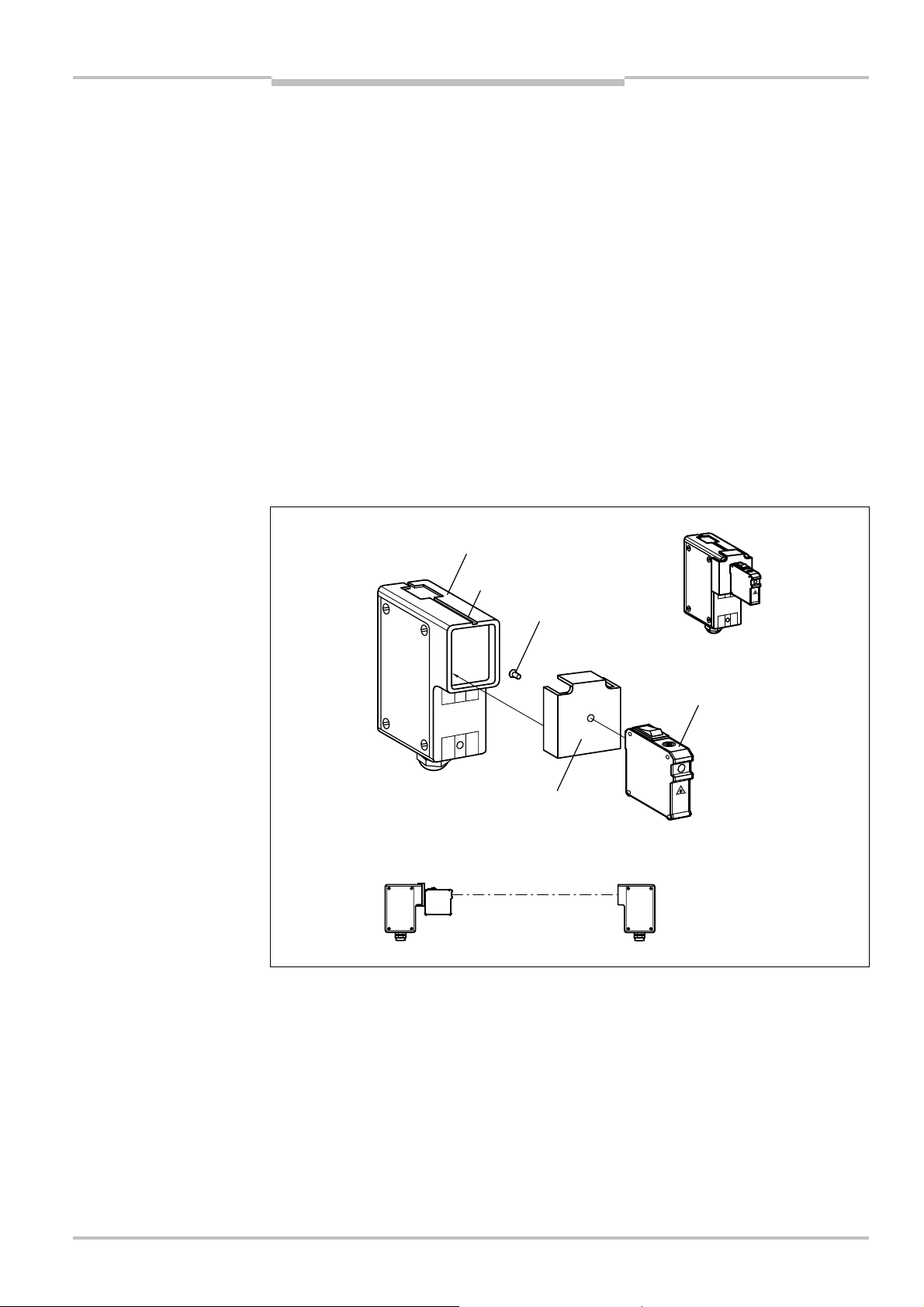

The single-beam photoelectric safety switch consists of a WSU26-3 sender unit and a

WEU26-3 receiver. The sender unit WSU26-3 emits a beam of light that is received by the

receiver unit WEU26-3.

WSU/WEU26&3 devices

WSU26-3 WEU26-3

RW

15 ... 70 m

If the light beam is interrupted by an object, a switching command is triggered. The

machine or plant controller that evaluates this message must then bring the dangerous

movement to a halt.

Sender and receiver units are equipped with LEDs for the operational check. Their function

as diagnostic elements is described in chapter 6 “Commissioning”.

The diagnostics LEDs are used for fault diagnosis (see chapter 8 “Fault diagnosis”).

The WSU/WEU26@3 devices are not equipped with an internal restart interlock.

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 11

Operating Instructions Chapter 3

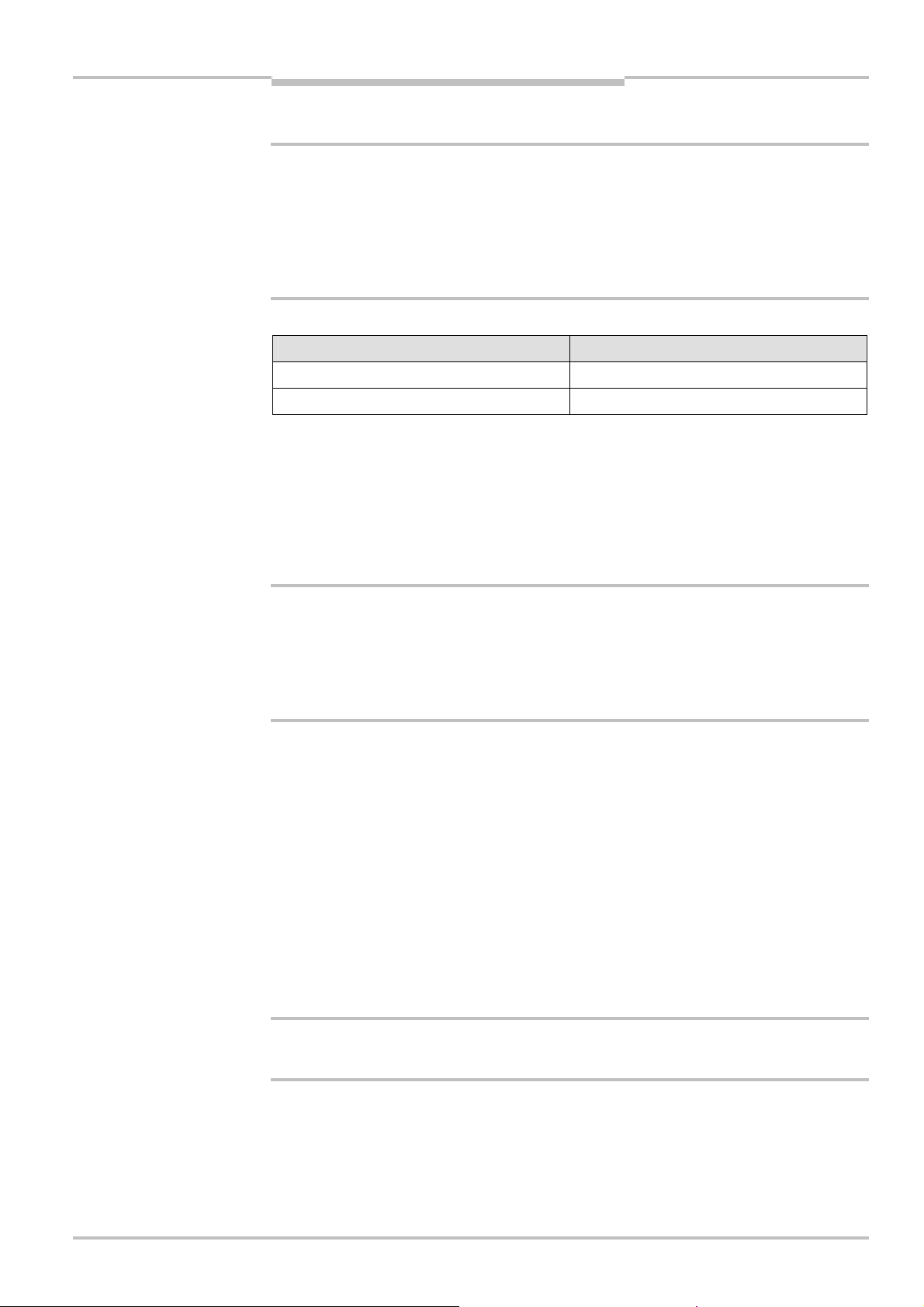

Tab. 2:

Receiver variants

WSU/WEU263

WARNING

Note

Product description

3.2.1 Scanning range

Use the receiver with the permitted operating range to suit the length of the light path

between the sender and receiver!

• If the operating range is too low, the single-beam photoelectric safety switch may not

switch to green.

• If the operating range is too large, the single-beam photoelectric safety switch may

malfunction due to reflections. This would mean that the operator is at risk.

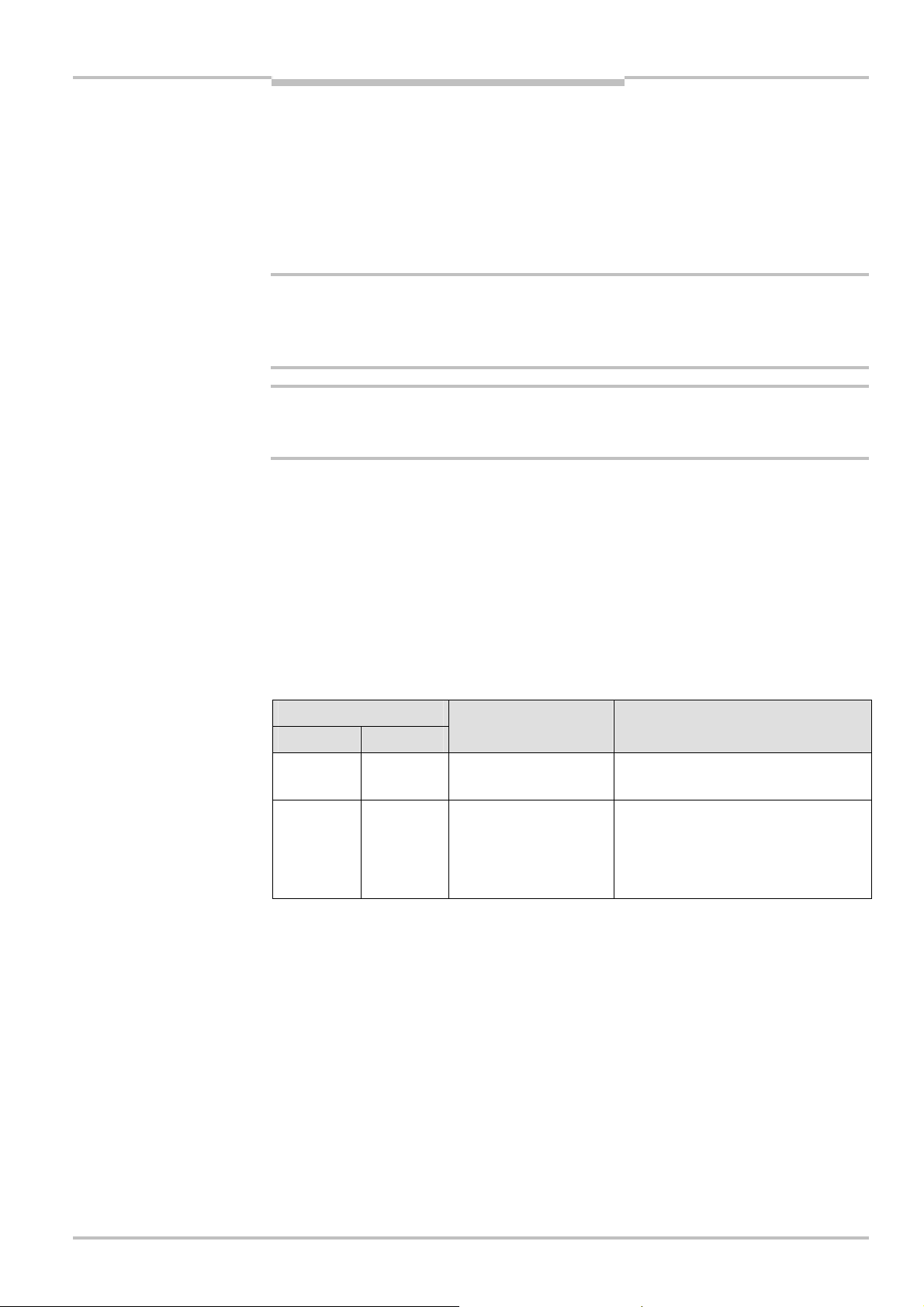

Two receiver with different scanning ranges are available:

Receiver Operating range

WEU26-3-103A00 0.5 ... 20 m

WEU26-3-203A00 15 ... 70 m

3.2.2 Restart interlock

The WSU/WEU26@3 devices do not have an internal restart interlock. It is only possible to

implement a restart interlock for the machine externally. During this process the

WSU/WEU26@3 devices have no control over the restart.

A restart interlock prevents the machine starting again after an error or an interruption of

the light path.

WARNING

Note

WARNING

Always operate the application with restart interlock!

Ensure an external restart interlock is always activated on the machine. The

WSU/WEU26@3 devices are unable to verify if the external restart interlock of the machine

is operable. If you deactivate the external restart interlock, the operator of the machine will

be at acute risk of injury.

3.2.3 External device monitoring (EDM)

The WSU/WEU26@3 devices do not have any feature for monitoring the downstream

contactors. External device monitoring on the downstream contactors is only possible with

an external circuit. You will find additional explanations on the connection of downstream

contactors in chapter 5.2 “System connection”.

An EDM checks if the downstream contactors actually de-energize when the protective

device is tripped.

3.2.4 Front screen heating

Sender and receiver have front screen heating. The front screen heating counteracts the

formation of droplets, mist, frost and ice.

Ensure the optical properties of the front screen are not changed by the formation of

droplets, mist, frost or ice, otherwise there will be a hazard for the operator.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Page 12

Chapter 3 Operating Instructions

Fig. 2:

Diagnostics LEDs

Tab. 3:

Diagnostics LEDs

Fig. 3:

Diagnostics LEDs

Tab. 4:

Diagnostics LEDs

WSU/WEU263

Product description

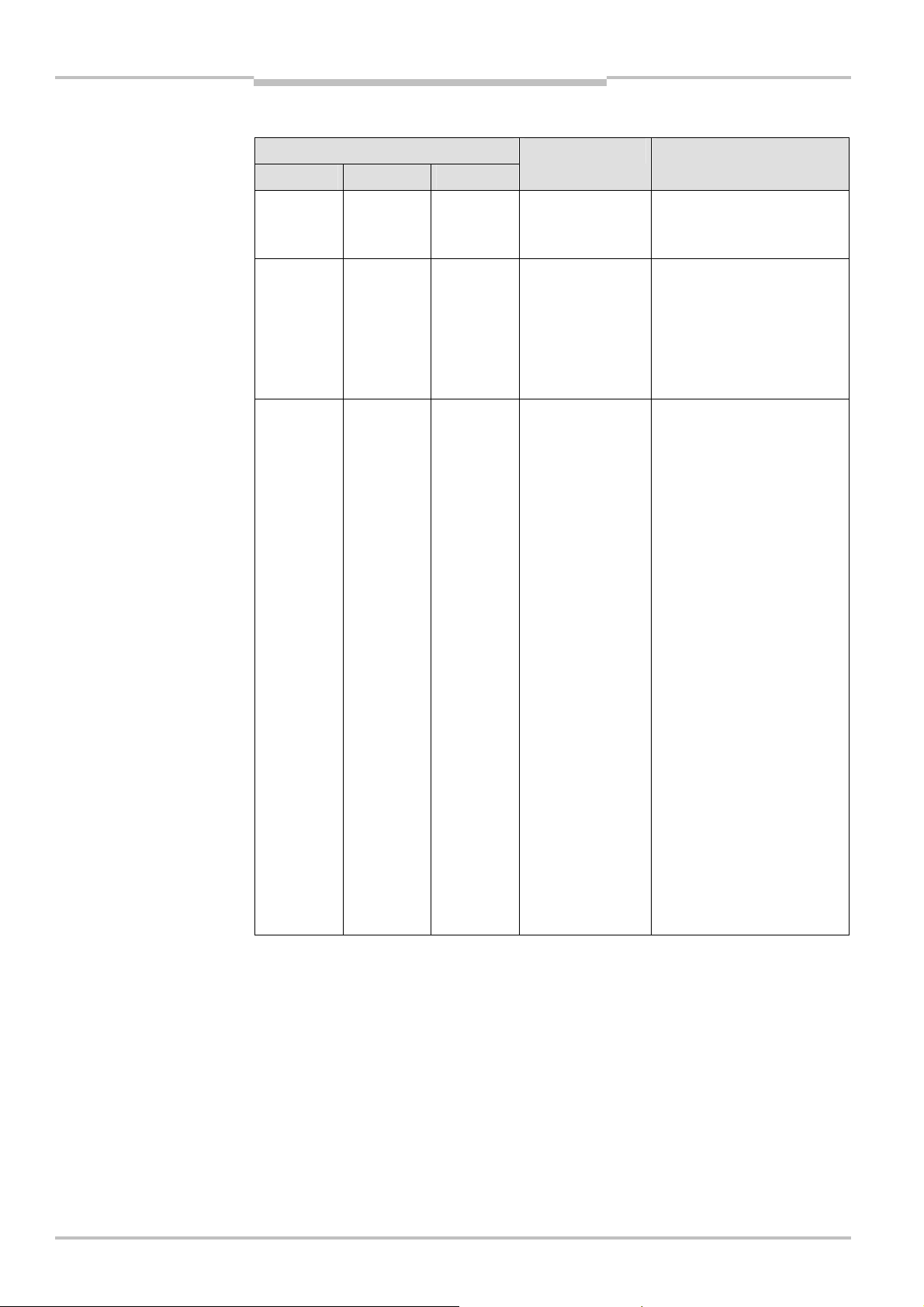

3.3 Structure and function

he WSU/WEU26@3 devices are equipped with diagnostics LEDs:

T

Diagnostics LEDs of the sender

WSU26-3

WSU26-3

Yellow Red

WSU26-3

WEU26-3

WEU26-3

Display

Yellow Red

Meaning

Device on, test inactive

Device on, test active, test contacts open

Diagnostics LEDs of the receiver

WEU26-3

Green Yellow Red

Display

Green Yellow Red

Output signal switching devices on, light path

Meaning

unoccupied

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Output signal switching devices off, light path

interrupted or inadequate alignment or device

not yet ready after switch on (see technical

specifications)

Output signal switching devices on, light path

unoccupied, weak signal

Output signal switching devices off, light path

interrupted or inadequate alignment. Prior to the

complete interruption of the light path the signal

was weak.

Subject to change without notice

Page 13

Operating Instructions Chapter 3

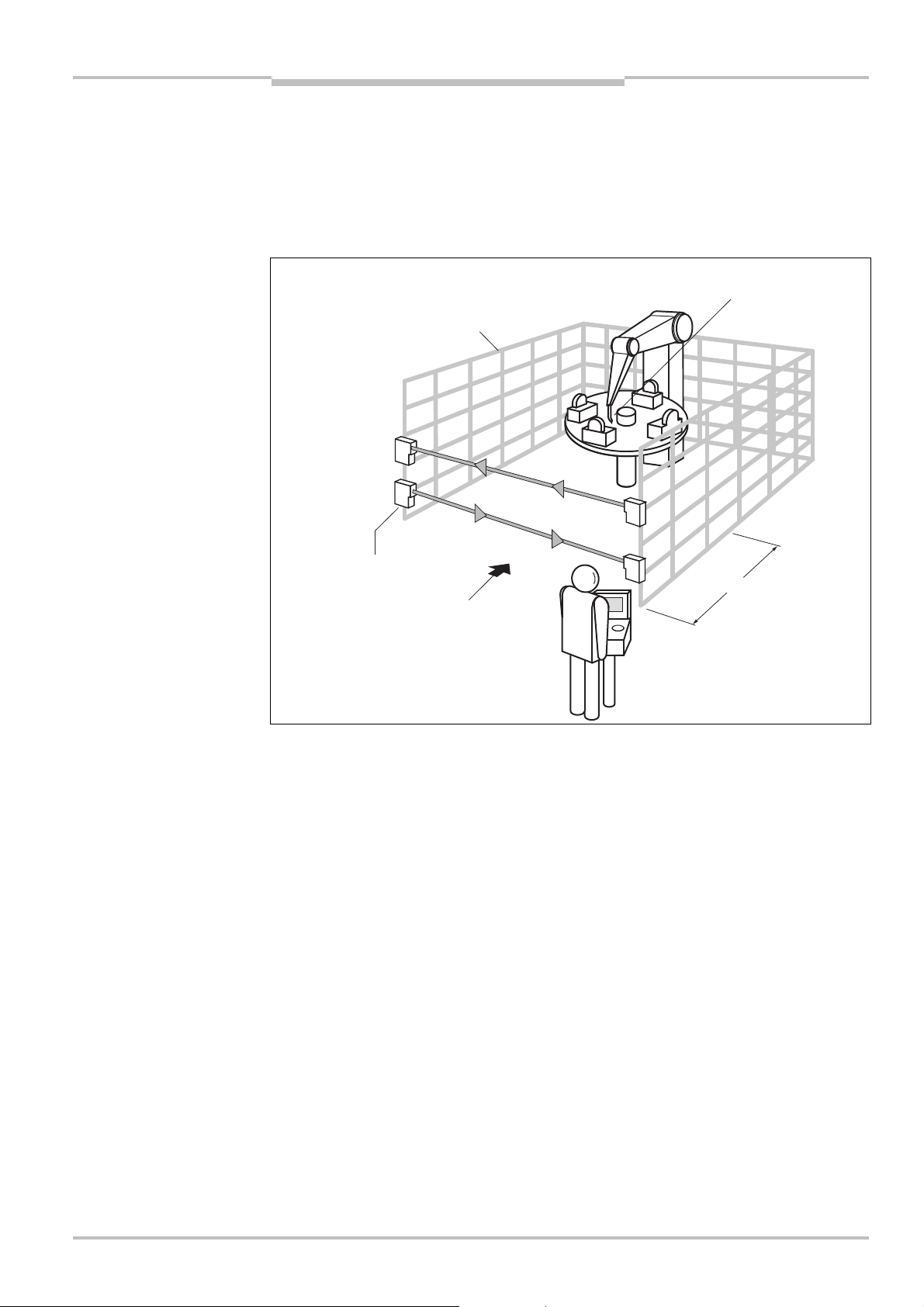

Fig. 4:

Access guarding with

Access guarding with

M

echanical protection

Direction of entry

into the hazardous

WSU/WEU263

Product description

3.4 Application example

he WSU/WEU26@3 devices are used as access protection for hazardous areas on

T

machines or systems (Fig. 4). The devices are permanently mounted in the access area

with the necessary safety distance from the nearest hazardous point. If the light beam is

interrupted by an object, a switching command is triggered. The machine or plant

controller that evaluates this message must then bring the dangerous movement to a halt.

WSU/WEU26&3

WSU/WEU26@3

Hazardous point

S

area

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Page 14

Chapter 4 Operating Instructions

WSU/WEU263

Mounting

4 Mounting

his chapter describes the preparation and completion of the installation of the

T

WSU/WEU26@3 devices:

• calculating the necessary safety distance,

• calculating the distance from reflective surfaces,

mounting the device.

•

The following steps are necessary after mounting:

• complete the electrical connections (chapter 5),

• alignment of senders and receivers (chapter 6.1),

• testing the installation (chapter 6.2).

No protective function without sufficient safety distance!

WARNING

The reliable protective effect of the single-beam photoelectric safety switches depends on

the WSU/WEU26@3 devices being mounted with the correct safety distance from the

hazardous point.

4.1 Preparation for mounting

4.1.1 Safety distance for access protection

A safety distance must be maintained between the protective field and the hazardous

point. This safety distance ensures that the hazardous point can only be reached after the

dangerous state of the machine has been completely stopped.

The safety distance as per EN ISO 13855 and EN ISO 13857 depends on:

• stopping/run-down time of the machine or system (The stopping/run-down time is

shown in the machine documentation or must be determined by taking a

measurement.),

• response time of the entire protective device,

• reach or approach speed,

• number of beams/beam separation.

Under the authority of OSHA and ANSI the safety distance as specified by

ANSI B11.19 (Annex D) E.4.2.3.3.5 and Code of Federal Regulations, Volume 29,

Part 1910.217 ... (h) (9) (v) depends on:

• stopping/run-down time of the machine or system (The stopping/run-down time is

shown in the machine documentation or must be determined by taking a

measurement.),

• response time of the entire protective device,

• reach or approach speed,

• other parameters that are stipulated by the standard depending on the application.

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 15

Operating Instructions Chapter 4

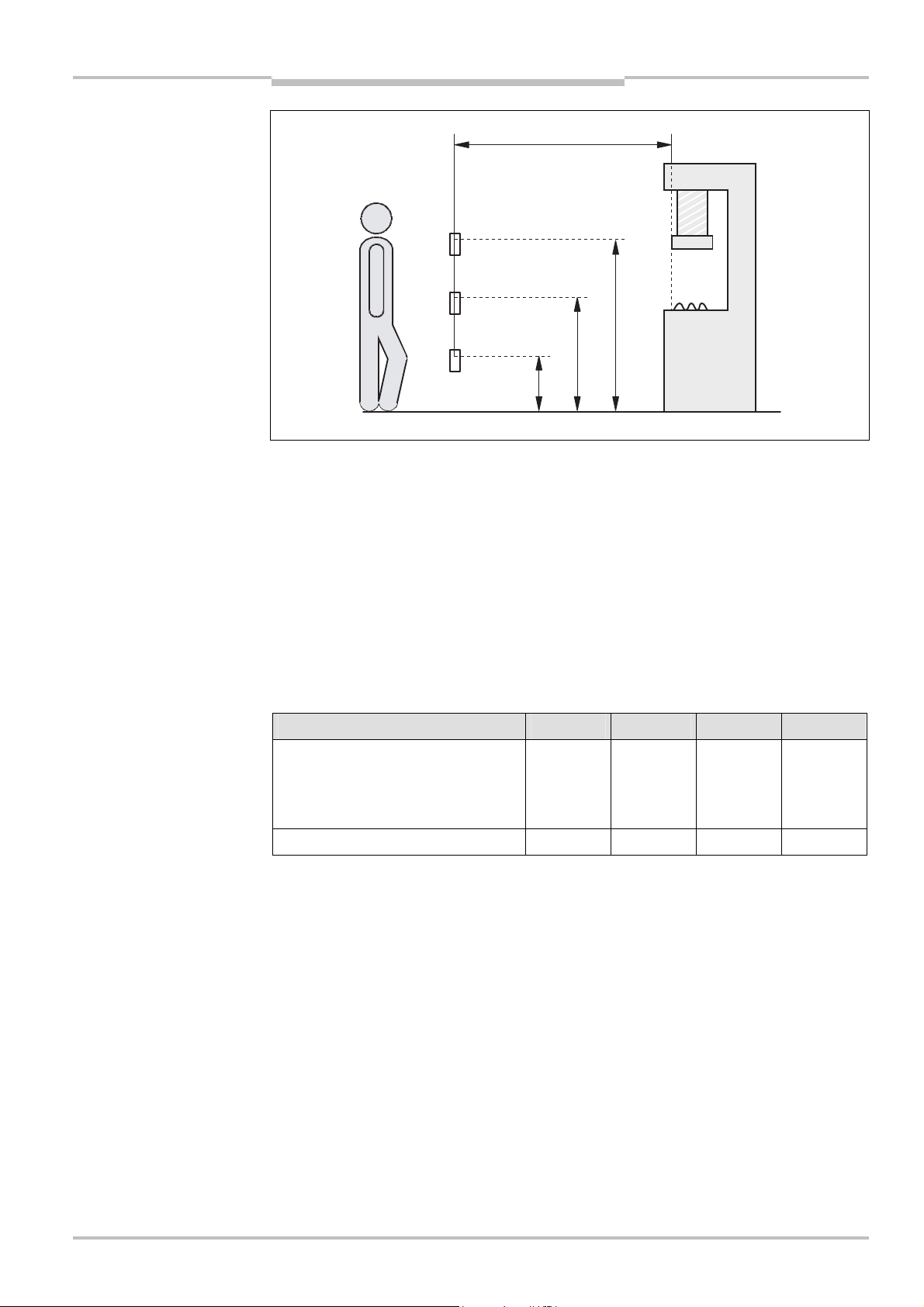

Fig. 5:

Safety distance S to

Tab. 5:

Height of the beams

Hazardous

WSU/WEU263

Mounting

the light beam

Note

Safety distance S (D

)

S

1.100

oint

p

700

WSU/WEU26@3

300

How to calculate the safety distance S according to EN ISO 13855 and EN ISO 13857:

The following calculation shows an example calculation of the safety distance. Depending

on the application and the ambient conditions, a different calculation may be necessary.

First, calculate S using the following formula:

S = K × T + C [mm]

Where ...

T = Stopping/run-down time of the machine + response time of the WSU/WEU26@3

devices after light path interruption [s]

S = Safety distance [mm]

K = Approach speed 1.6 [m/s]

C = Depending on the number of beams (1, 2, 3 or 4), see Tab. 5

above the floor

Number of beams 1 2 3 4

Height of the beams above the floor

[mm]

750 400

900

300

700

1,100

300

600

900

1,200

C 1,200 850 850 850

Example:

Access guarding with two beams C = 850 mm

Stopping/run-down time of the machine = 290 ms

Response time after light path interruption = 22 ms

Approach speed = 1.6 m/s

T = 290 ms + 22 ms = 312 ms = 0.31 s

S = 1,600 × 0.31 + 850 = 1,346 mm

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Subject to change without notice

Page 16

Chapter 4 Operating Instructions

WSU/WEU263

Note

Note

Mounting

How to calculate the safety distance DSaccording to ANSI B11.19 (Annex D)

E.4.2.3.3.5 and Code of Federal Regulations, Volume 29, Part 1910.217 … (h) (9) (v):

he following calculation shows an example calculation of the safety distance. Depending

T

on the application and the ambient conditions, a different calculation may be necessary.

First, calculate D

D

= HS× (TS+ TC+ Tr+ Tbm) + Dpf

S

Where ...

D

= The minimum distance in inches (or millimetres) from the hazardous point to the

S

protective device

= A parameter in inches/second or millimetres/second, derived from data on

H

S

approach speeds of the body or parts of the body. Often 63 inches/second is

used for H

T

= Stopping/run down time of the machine tool measured at the final control

S

element

= Stopping/run-down time of the control system

T

C

T

= Response time of the entire protective device after light path interruption

r

T

= Additional response time allowed for brake monitor to compensate for wear

m

b

Any additional response times must be accounted for in this calculation.

D

= An additional distance added to the overall safety distance required. This value is

pf

based on intrusion toward the hazardous point prior to actuation of the electrosensitive protective equipment (ESPE). For applications that can be reached over,

the value D

arms or the detectable object size is greater than 63 mm, the value D

using the following formula:

s

.

S

= 1.2 m. For beam arrangements that permit reaching in with the

f

p

f

p

= 0.9 m.

WARNING

WARNING

Maintain the safety distance!

The WSU/WEU26@3 devices are to be fitted such that when the light beam is interrupted,

the hazardous point is only reached when the dangerous state is no longer present.

Risk of failure to detect!

Persons who are in the hazardous area but not in the light path between sender and

receiver are not detected by the WSU/WEU26@3 devices. It is therefore to be ensured that

the hazardous area is fully visible and any dangerous state can only be initiated if there

are no personnel in the hazardous area.

The WSU/WEU26@3 devices are not allowed to be used for hand and finger protection.

The applicable legal and official regulations apply to the use and mounting of the

protective device. These regulations vary depending on the application.

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 17

Operating Instructions Chapter 4

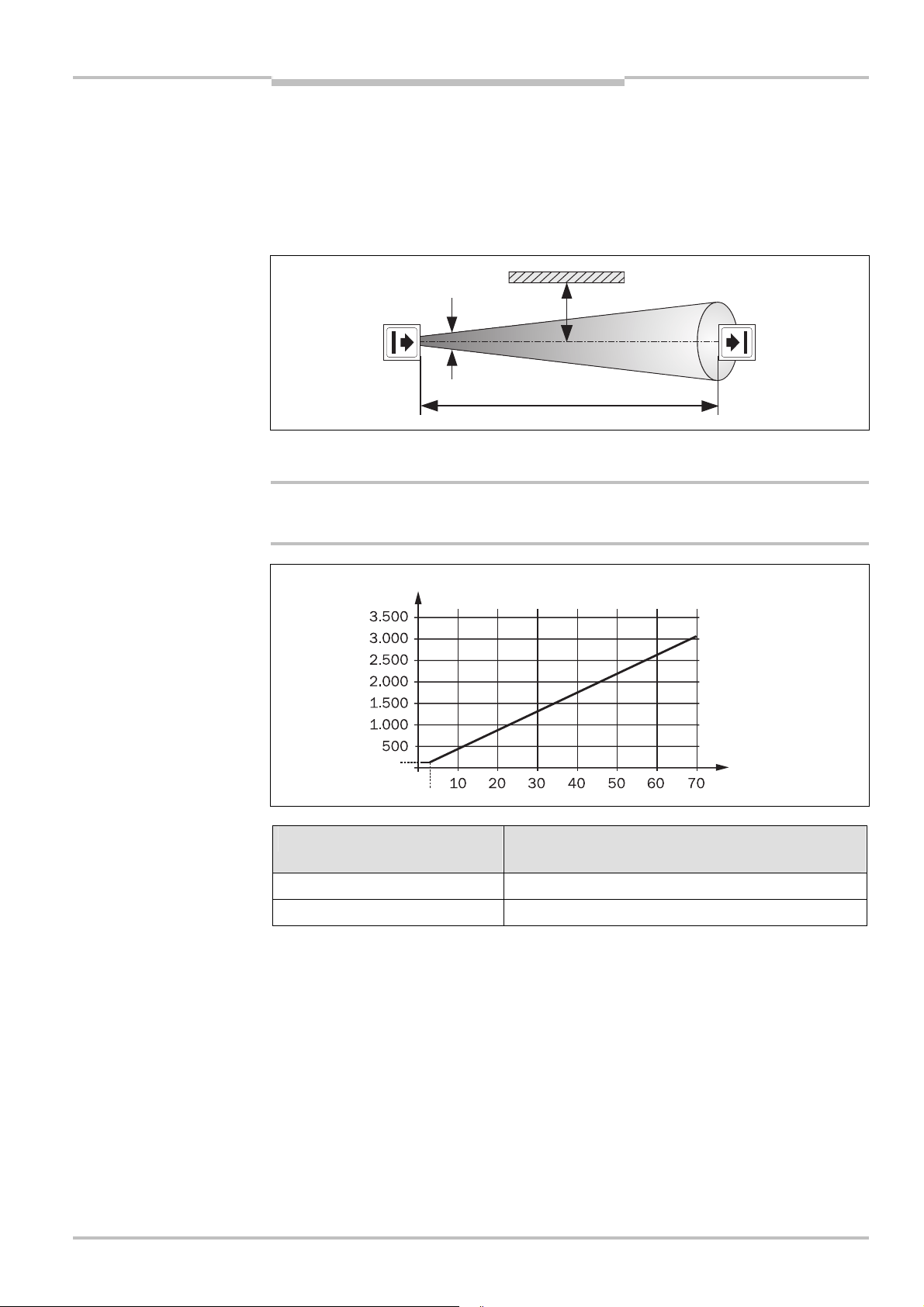

Fig. 6:

Minimum distance to

Fig. 7:

Graph, minimum

Tab. 6:

Formula for the

Reflective surface

Field of view

Minimum

Distance D sender

–

receiver

WSU/WEU263

reflective surfaces

Mounting

4.1.2 Minimum distance to reflective surfaces

The light beams from the sender may be deflected by reflective surfaces. This can result in

failure to identify the object.

Therefore all reflective surfaces and objects (e.g. material bins) must be a minimum

distance a from the light path between sender and receiver of the WSU/WEU26@ 3 devices.

The minimum distance a depends on the distance D between sender and receiver.

distance a

Note

WARNING

distance from reflective

surfaces

calculation of the minimum

distance to reflective

surfaces

Sender and receiver optics have the same field of view.

The minimum distances to reflective surfaces only apply when the light path is clear. On

the usage of transparent guard windows, these values may change.

a [mm]

131

3

Distance D [m] sender – receiver Calculation of the minimum distance a

from reflective surfaces

D Q 3 m a [mm] = 131

D [m]

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Subject to change without notice

D > 3 m a [mm] = tan (2.5°) x 1,000 x D [m] = 43.66 x D [m]

Page 18

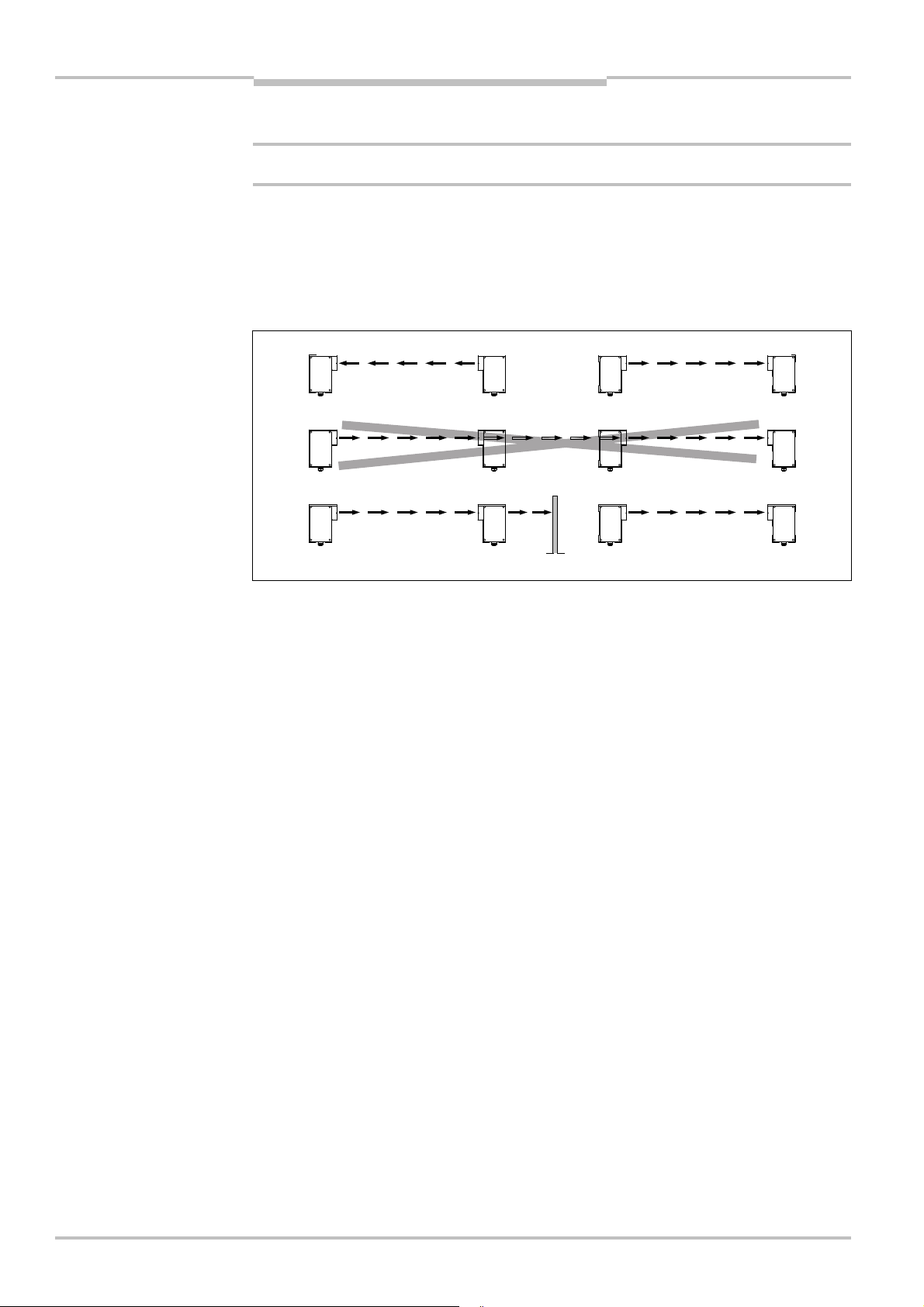

Chapter 4 Operating Instructions

Fig. 8:

Mounting two

WSU/WEU263

Mounting

4.1.3 Mutual interference of systems in close proximity

Prevent the mutual interference of systems mounted in close proximity!

WARNING

WSU/WEU26&3 devices in

series

If several WSU/WEU26@3 devices operate in close physical proximity, the sender beams

from one device may interfere with the receiver for another device such that the protective

function of the different WSU/WEU26@3 devices is no longer ensured and there is a hazard

for the operator. You must avoid such mounting scenarios or take appropriate measures,

e.g. by mounting non-reflective sight protection walls or by reversing the transmission

direction of a device.

WEU

WSU WSU

WEU

Note

WSU

WSU

WEU

WEU

WSU

WSU

WEU

WEU

4.2 Mechanical mounting

WSU26-3 and WEU26-3 are to be mounted to suit the local conditions on one of the sides

of their housing or using the mounting bracket. The mounting bracket significantly eases

alignment. The device can be operated in any position. WSU26-3 and WEU26-3 are,

however, to be mounted such that the axis of the beam emitted by the WSU26-3 is always

aligned with the axis of the WEU26-3 optics (alignment sight, see Fig. 18, page 27).

The mounting brackets are to be attached such that all fixing screws are easily accessibly

for alignment. Fig. 9 shows examples. The devices are to be attached such that it is

possible to align with the related device opposite using the alignment sight.

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 19

Operating Instructions Chapter 4

Fig. 9:

Mounting possibilities

Mounting bracket

WSU/WEU263

using mounting brackets

Mounting

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Subject to change without notice

Part number 2007900

Page 20

Chapter 4 Operating Instructions

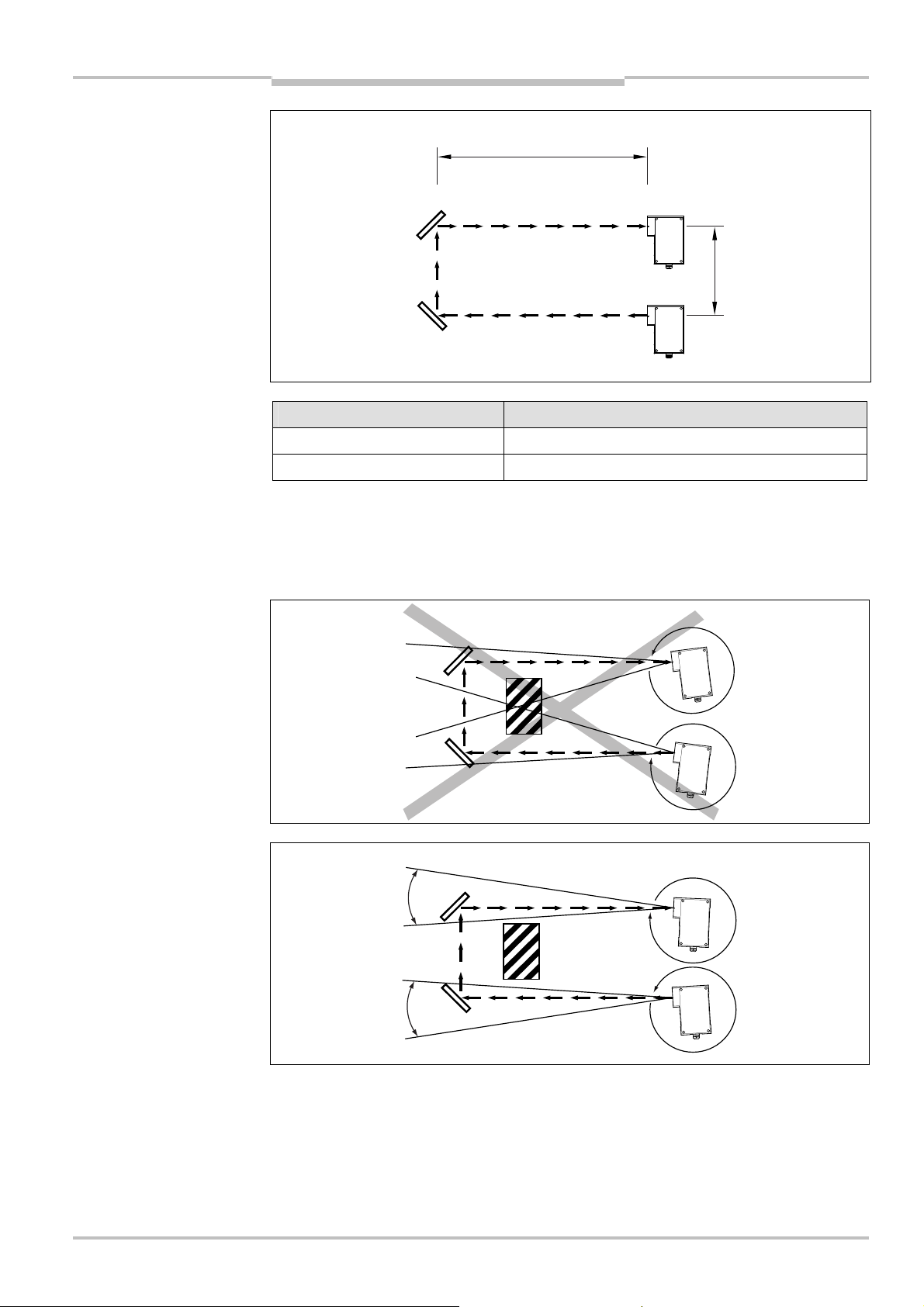

Tab. 7:

Reduction in the

Fig. 10:

Hazardous area

Deflector mirror

Deflector mirror

Deflector mirror

Mirror deflection

Safety distance

Hazardous area

Machine

Machine

Hazardous area

WSU/WEU263

Mounting

4.2.1 Deflector mirror

With the WSU/WEU26@3 and deflector mirrors, access protection on several sides can be

realised (Fig. 10).

Note

The usage of deflector mirrors reduces the effective scanning range of the system

WSU/WEU26@3 as specified in Tab. 7.

Note

The usage of mirrors (Fig. 11) requires very precise alignment. It is recommended to use

the AR60 laser alignment aid. The AR60 alignment aid is available as an accessory (Tab.

17, page 36).

scanning range on the usage

of deflector mirrors with

= 90°

protected on several sides

Number of mirrors WEU26-3 with short scanning range WEU26-3 with long scanning range

1 0.5 ... 18 m 14.2 ... 63 m

2 0.5 ... 16 m 13.5 ... 56 m

3 0.5 ... 14.3 m 12.8 ... 50 m

4 0.5 ... 12.8 m 12.2 ... 45 m

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

possible

too short

Machine

Subject to change without notice

Page 21

Operating Instructions Chapter 4

Fig. 11:

Two-beam protection

Tab. 8:

Distances of the

Fig. 12:

Incorrect alignment

Fig. 13:

Correct alignment of

D

eflector mirror

Deflector mirror

Distance deflector mirror

–

WSU/WEU26

-

3

Deflector mirror

Deflector mirror

Field of view 5°

Fie

ld of view 5°

Deflector mirror

Deflector mirror

WSU/WEU263

with one system

WSU/WEU26&3

Mounting

90˚

W

EU

deflector mirrors

of sender and receiver

Note

90˚

WSU

WEU26-3 receiver Distance deflector mirror – WSU/WEU26-3

500 mm

Low scanning range 0.5 ... 7.5 m

High scanning range > 7.5 m

If there are reflective surfaces in the area of the light path between the sender and

receiver or such surfaces may occur, the alignment of the system must be adjusted:

Sender and receiver must always be aligned such that there are no reflecting surfaces in

the area of the field of view (see Fig. 13).

90˚

Reflective surface

WEU

90˚

WSU

sender and receiver

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Subject to change without notice

90˚

90˚

WEU

Reflective surface

WSU

Page 22

Chapter 5 Operating Instructions

WSU/WEU263

Electrical installation

5 Electrical installation

5.1 Important information for the installation

Switch the entire machine/system off line!

WARNING

The machine/system could inadvertently start up while you are connecting the devices.

Ensure that the entire machine/system is disconnected during the electrical installation.

Notes:

• The WSU/WEU26@3 single-beam photoelectric safety switch meets the interference

suppression requirements (EMC) for industrial use (interference suppression class A).

When used in residential areas it can cause interference.

• A safety extra-low voltage SELV/PELV must be used to supply power to the

WSU/WEU26@3 devices.

• The external voltage supply must bridge a brief mains failure of 20 ms (EN 60204).

Suitable power supplies are available as accessories from SICK.

• Prior to opening the cover (see chapter 10.4 “Dimensional drawings”) all cables for the

supply voltage and the relay connections must be electrically isolated.

• Only open the device with appropriate protection against ESD, i.e. pay attention to

earthing. In the device only touch the connection terminals, not the other parts of the

electronics. All work on the open device is only allowed to be undertaken by qualified

safety personnel.

• If the cover is open, the device does not provide any protective function.

• The connecting cables must be laid directly to the terminal strip.

• After mounting, the firm seating of the connecting cables in the connection terminals

must be checked.

• Observe torque figure for the protective conductor connection (“PE”) (see chapter 5.2

“System connection”, Tab. 9/Tab. 10, Fig. 14/Fig. 15).

• On the installation of another PG connector, it is necessary to comply with the torque

data for the PG connector (see chapter 10.4 “Dimensional drawings”).

• Prior to screwing in place the cover, the seal must be checked for contamination and

damage. Fasten the cover to the related torque (see chapter 10.4 “Dimensional

drawings”).

• After opening the cover, the complete commissioning function test must be performed

(see chapter 6 “Commissioning”).

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 23

Operating Instructions Chapter 5

Tab. 9:

Assignment of the

Fig. 14:

Assignment of the

WSU/WEU263

Electrical installation

5.2 System connection

5.2.1 Pin assignment sender

sensor contacts, sender

WSU26-3

sensor contacts, sender

WSU26-3

Note

Note

Pin Designation

1/2 Voltage supply 24 V DC

3 Ground 0 V

10

11

PE Protective earth

The torque for the PE connection is 2.0 ± 0.5 Nm.

Connect the contacts on the WSU26-3 only to circuits that comply with the requirements

for safety extra-low voltage (SELV/PELV).

5.2.2 Tested

Test contacts

PE

1/2

+ 24 V

3 10 11

0 V

Note

WARNING

The test makes it possible to check the loads connected. For this purpose the electrical

connection between test contacts 10 and 11 on the WSU26-3 is interrupted for a certain

amount of time (see chapter 9 “Technical specifications”). As a result the sender does not

emit a beam of light and simulates an interruption to the light path.

The test must be performed by the machine controller during the unhazardous phase (e.g.

an unhazardous movement). If the test is not successful, the machine must receive a shut

down signal from the machine controller.

To operate the WSU/WEU26@3 devices without testing, a wire jumper must be connected

between the test contacts 10 and 11 on the WSU26-3.

Use test function for the purpose described!

The test input is only allowed to be used in the manner described.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Subject to change without notice

Page 24

Chapter 5 Operating Instructions

Tab. 10:

Assignment of the

Fig. 15:

Assignment of the

Electrical installation

WSU/WEU263

5.2.3 Pin assignment receiver

sensor contacts, receiver

WEU26-3

Note

sensor contacts, connection

diagram WEU26-3 on UE43

Pin Designation

1/2 Voltage supply 24 V DC

3 Ground 0 V

4

Safety relay, normally open contact

5

6

Safety relay 1/2, normally closed contacts connected in parallel internally

7

8

Safety relay 2, normally open contact

9

PE Protective earth

Both normally open contacts are to be used for safety-related functions. In a subsequent

dual-channel circuit the two normally open outputs are to be connected to a safety

controller with a suitable level of safety (see Fig. 15).

The normally closed contacts are not allowed to be used for safety-related functions.

If the downstream logic is realised using discrete contactors, they must be positively

guided and externally monitored. The monitoring cannot be provided by the WEU26-3.

The torque for the PE connection is 2.0 ± 0.5 Nm.

+ 24 V

0 V

PE

32/1

A1

UE43-2MF2D2

A2

4

S1

5

S11

+

+

S33 S34 S35

1K

2K

76

S12 S31 S21 S22 13 23 31

CH1+ CH2+

RESET

98

2K2

K

3K3

K

1K 2K

1K

2K

1K

2K

+ VE/L

322414

– VE/N

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Note

The cross-circuit monitoring on the connecting cables between the normally open contacts

4 and 5 or 8 and 9 on the WEU26-3 is provided by the safety controller UE43.

Subject to change without notice

Page 25

Operating Instructions Chapter 5

Fig. 16:

Circuit for an

Tab. 11:

Examples for arc

-

Supply

Contact in the

Consumer

R

WSU/WEU263

Electrical installation

5.3 Arc-suppression

n case of an inductive load: Use arc-suppression elements!

I

WARNING

inductive load

Suitable arc-suppressors must be connected in parallel with the inductance. Connection in

parallel with the output contact is not permitted. Please also note that the selection of the

suppressors can increase the total switch off times.

uppression diodes should not be used as arc-suppressors, as they considerably increase

S

the switch off time. RC elements are more suitable than varistors.

WEU26-3

suppressors

WARNING

voltage

Supply voltage Part No. R C

115 ... 230 V 6001224 220 U 0.22 VF

24 V 6001225 100 U 2.2 VF

Design: encapsulated in plastic; Connection wires NYAF Ø 0.5 with cable lug; Mounting

using adhesive film or cable tie.

C

5.4 Cross-circuit monitoring

The cables for the relay contacts are not monitored for cross-circuits by the WEU26-3.

Suitable measures

Take suitable measures for cross-circuit monitoring.

These can be:

• laying cables from the WEU26-3 to the loads protected against cross-circuits,

• screening output cables separately and connecting screen to 0 V,

• integration of the two normally open contacts at different voltage levels.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Subject to change without notice

5.5 Overcurrent protection (fuse)

A fuse is to be installed in the control circuit with a rating to suit the maximum current on

the output relay.

Page 26

Chapter 6 Operating Instructions

Fig. 17:

WSU26

-

3 sender unit

WSU/WEU263

Commissioning

6 Commissioning

ommissioning requires a thorough check by qualified safety personnel!

C

WARNING

WARNING

Before you operate a system protected by the WSU/WEU26@3 devices for the first time,

make sure that the system is first checked and released by qualified safety personnel.

Please read the notes in chapter 2 “On safety”.

The device is switched on by applying the supply voltage to the sender and receiver unit.

After max. 10 s the WSU/WEU26@3 devices are ready for operation.

6.1 Aligning sender and receiver

After all parts have been mounted and connected, the related sender and receiver must

be aligned in relation to each other.

Secure the plant/system. No dangerous movement possible!

Ensure that the dangerous state of the machine is (and remains) switched off! During the

alignment process, the outputs of the WSU/WEU26@3 devices are not allowed to have any

effect on the machine.

and WEU26-3 receiver unit

6.1.1 Alignment using the diagnostics LEDs

Switch on power supply. The yellow diagnostics LED of the WSU26-3 must light up.

Align devices such that the green diagnostics LED on the WEU26-3 illuminates.

WSU26-3 WEU26-3

Yellow Red

For optimal alignment the sender and receiver, the boundaries are to be determined by

pivoting the sender unit and receiver unit horizontally and vertically. On leaving the related

optical area, the yellow diagnostics LED on the WEU26-3 starts to illuminate. Then fasten

sender and receiver in the middle of the optical area determined.

Green Yellow Red

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 27

Operating Instructions Chapter 6

F

ig. 18:

Mounting the laser

Fixing screw

Adapter for

WSU26@3 sen

der

WEU26@3 receiver

Alignment sight

Alignment aid AR60

WSU/WEU263

Commissioning

6.1.2 Alignment using the AR60 laser alignment aid

At large scanning ranges or in case of the usage of deflector mirrors, the laser alignment

aid AR60 significantly simplifies alignment. The AR60 alignment aid is available as an

ccessory (Tab. 17, page 36).

a

Screw the adapter to the AR60,

mount the AR60 in front of the sender (clamp),

switch on AR60,

attach a piece of white cardboard or with cardboard reflective tape to the receiver (beam

array is easier to detect),

align sender such that the laser beam array is incident on the middle of the receiver

optics,

fasten sender in this position,

switch off AR60,

remove AR60,

repeat the process starting from the receiver,

switch on sensors.

alignment aid AR60

WSU/WEU26@3

M4 × 10

WSU/WEU26@3

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

Page 28

Chapter 6 Operating Instructions

WSU/WEU263

Commissioning

6.2 Test notes

6.2.1 Tests before the initial commissioning

Check the protective device as described below and in accordance with the applicable

standards and regulations.

To ensure the correct function, check as described in chapter 6.2.2 “Daily functional

checks of the protective device”.

Number of sender and receiver must match, the distance between them must comply

with the operating range stated in the technical specifications.

It must only be possible to access the hazardous area through the light path between

sender and receiver.

It must not be possible to climb over, to crawl beneath or to circumnavigate the

protective device.

Additionally, check the effectiveness of the protective device mounted to the machine,

using all selectable operating modes as specified in the checklist (see chapter 11.2

“Checklist for the manufacturer”). Use this checklist as a reference before

commissioning the system for the first time.

Ensure that the operating personnel of the machine protected by the WSU/WEU26@3

devices are correctly instructed by qualified safety personnel before being allowed to

operate the machine. Instructing the operating personnel is the responsibility of the

machine owner.

6.2.2 Daily functional checks of the protective device

The effectiveness of the protective device must be checked daily or prior to the start of

work by a specialist or by authorised personnel, using the correct test rod.

Testing the light path between sender and receiver:

Completely cover each light beam with a test rod that is not transparent to light (at

least 30 mm diameter) at the following positions:

• immediately in front of the sender,

• in the middle between sender and receiver (or between the deflector mirrors),

• immediately in front of the receiver,

• on the use of deflector mirrors, immediately before and after the deflection.

This must produce the following result:

• The red diagnostics LED must illuminate on the receiver for the related single-beam

photoelectric safety switch

and

• as long as the light beam is interrupted, it must not be possible to initiate the

dangerous state.

Do not operate the machine if during the test the green diagnostics LED on the receiver

is lit!

WARNING

If the green diagnostics LED on the receiver lights up during the test even for a short

period, work must stop at the machine. In this case the installation of the WSU/WEU26@3

devices must be checked by qualified safety personnel.

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 29

Operating Instructions Chapter 6

WSU/WEU263

Commissioning

Further tests

Check the protective device for damage or wear, particularly the mounting, the electrical

onnection and the connection cable, the housing and the front screen.

c

Check whether the access to the hazardous area is only possible by interrupting the light

path between sender and receiver (e.g. correct mounting of mechanical protective

devices).

Check whether the protective device is effective for the set operating mode.

6.2.3 Regular inspection of the protective device by qualified safety personnel

Check the system, following the inspection intervals specified in the national rules and

regulations. This procedure ensures that any changes on the machine or manipulations

of the protective device after the initial commissioning are detected.

If major changes have been made to the machine or the protective device, or if the

single-beam photoelectric safety switch has been modified or repaired, check the plant

again as per the checklist in the annex.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Subject to change without notice

Page 30

Chapter 7 Operating Instructions

WSU/WEU263

Care and maintenance

7 Care and maintenance

he WSU/WEU26@3 devices are maintenance-free. The integrated relay contacts are

T

subject to normal wear. The front screen of the sensors should be regularly cleaned and

also if contaminated.

Note

Note

Note

Avoid scratches and misting of the front screens as well as the formation droplets, frost

nd ice on the front screens, as the optical properties may change.

a

Do not use aggressive cleaning agents.

Do not use abrasive cleaning agents.

Static charges cause dust particles to be attracted to the front screen. You can reduce this

effect by using the antistatic plastic cleaner (SICK part number 5600006) and the SICK

lens cloth (part number 4003353).

How to clean the front screen:

Use a clean and soft brush to remove dust from the front screen.

Now wipe the front screen with a clean and damp cloth.

After cleaning, check the position of sender and receiver to ensure that the protective

device cannot be bypassed (climbing over, crawling beneath or standing behind).

Verify the effectiveness of the protective device as described in chapter 6.2 “Test notes”.

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 31

Operating Instructions Chapter 8

Tab. 12:

Diagnostics LEDs

WSU/WEU263

Fault diagnosis

8 Fault diagnosis

his chapter describes how to identify and rectify errors and malfunctions during the

T

operation of the WSU/WEU26@3 devices.

8.1 In the event of faults or errors

Cease operation if the cause of the malfunction has not been clearly identified!

WARNING

WARNING

Stop the machine if you cannot clearly identify or allocate the error or if you cannot safely

rectify the malfunction.

Complete function test after rectification of fault!

After rectifying a fault, perform a complete function test as per chapter 6.2 “Test notes”.

8.2 SICK support

WSU26-3

If you cannot remedy an error with the help of the information provided in this chapter,

please contact your local SICK representative.

8.3 Status displays of the diagnostics LEDs

This section describes the meaning of the diagnostics LED and how to respond.

Diagnostics LEDs of the sender

Display

Yellow Red

No operating voltage,

(1 Hz,

power up

delay 10 %)

Possible cause Rectification of the error

Check the supply voltage and

or voltage too low

System error Switch the device off for at least

activate, if necessary.

3 seconds and then back on again.

If the error continues to occur:

Replace the device.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Subject to change without notice

Page 32

Chapter 8 Operating Instructions

Tab. 13:

Diagnostics LEDs

WSU/WEU263

Fault diagnosis

Diagnostics LEDs of the receiver

WEU26-3

Display

Green Yellow Red

Possible cause Rectification of the error

No operating

voltage, or voltage

too low

System error Switch the device off for

(1 Hz,

power up

delay 10 %)

(1 Hz,

power up

delay 90 %)

Error in the supply

voltage or

unknown sender

detected

Check the supply voltage

and activate, if necessary.

at least 3 seconds and

then back on again.

If the error continues to

occur:

Replace the device.

Switch the device off for

at least 3 seconds and

then back on again.

Check whether the power

supply complies with the

specification (see

chapter 5.1 on page 22).

Check whether the power

supply complies with the

technical specifications

(see chapter 9 on

page 33).

Check the distance from

reflective surfaces (see

chapter 4.1.2 on page 17)

and from other singlebeam photoelectric safety

switches.

Mount non-reflective field

of view guards, if

necessary.

If the error continues to

occur:

Replace the device.

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 33

Operating Instructions Chapter 9

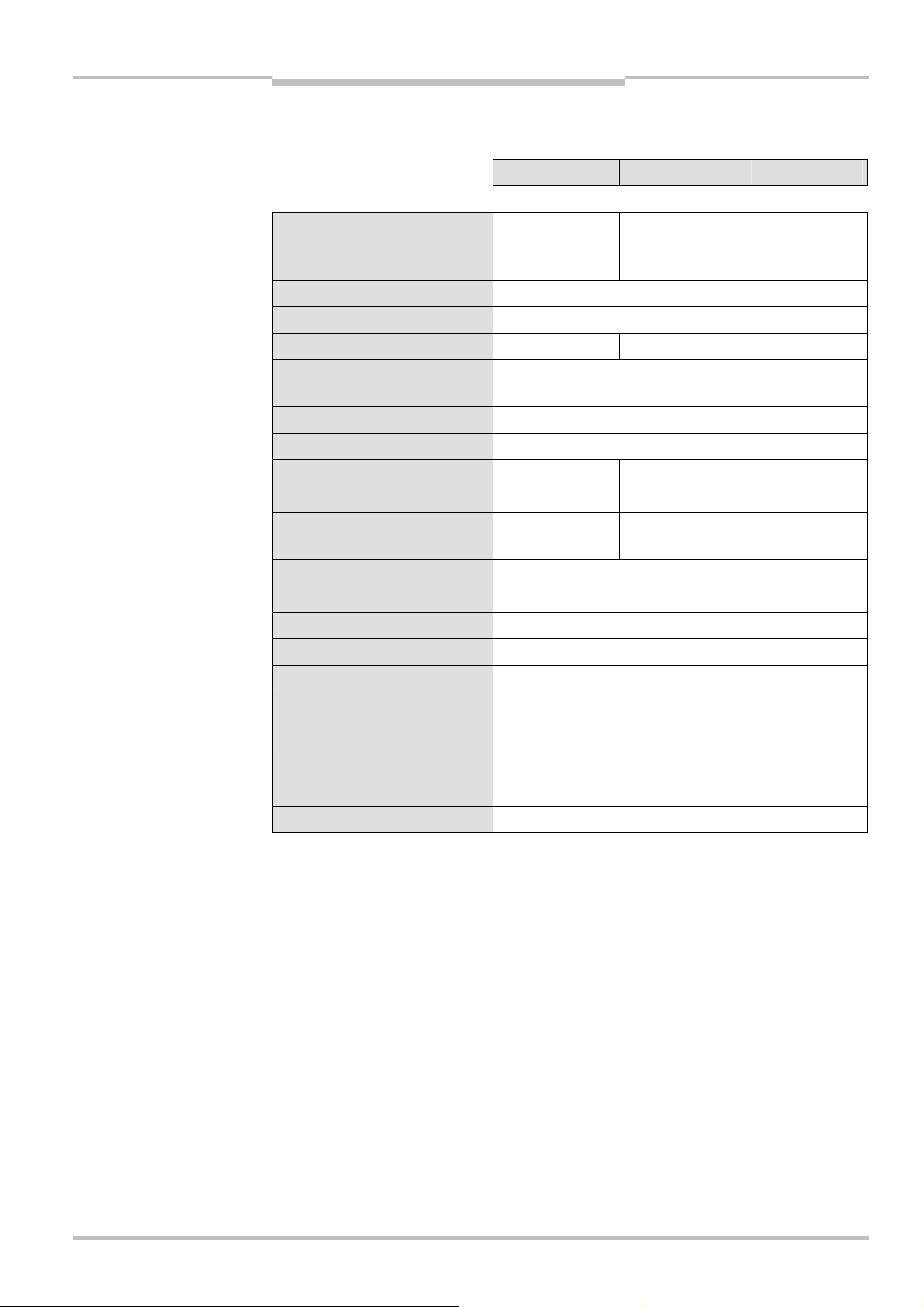

Tab. 14:

Technical

WSU/WEU263

Technical specifications

9 Technical specifications

specifications

Minimum Typical Maximum

General system data

Operating range

WEU26-3-103A00

WEU26-3-203A00

0.5 m

15 m

20 m

70 m

Number of beams 1

Synchronisation optical, without separate synchronisation cable

Detection capability 30 mm

Protection class

(EN 50178:1998)

)

1

I

Enclosure rating (IEC 60529) IP 67

Operating mode Protective operation without start and restart interlock

Supply voltage V

Residual ripple

Power-up delay of receiver and

2)

S

)

3

19.2 V DC 24 V DC 28.8 V DC

±10 %

5 s 10 s

sender before ready

Type Type 4 (IEC 61496)

Safety integrity level

Category Category 4 (EN ISO 13849)

Performance Level

B

value AC-15, 230 V, 0.4 A: 1 x 106switching operations

10d

PFHd (mean probability of a

4)

)

4

SIL3 (IEC 61508), SILCL3 (EN 62061)

PL e (EN ISO 13849)

AC-15, 230 V, 2.0 A: 2.6 x 10

DC-13, 24 V, 0.6 A: 1 x 10

DC-13, 24 V, 1.5 A: 2 x 10

4.0 x 10

5

6

switching operations

5

switching operations

–9

switching operations

dangerous failure per hour)

TM(mission time) 20 years (EN ISO 13849)

1)

Safety extra-low voltage SELV/PELV is mandatory.

2)

The external voltage supply must be capable of buffering brief mains voltage failures of 20 ms as specified in

EN 60204. Suitable power supplies are available as accessories from SICK.

3)

The maximum supply voltage limits must not be exceeded, minimum levels must be achieved.

4)

For detailed information on the exact design of your machine/system, please contact your local SICK

representative.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Subject to change without notice

Page 34

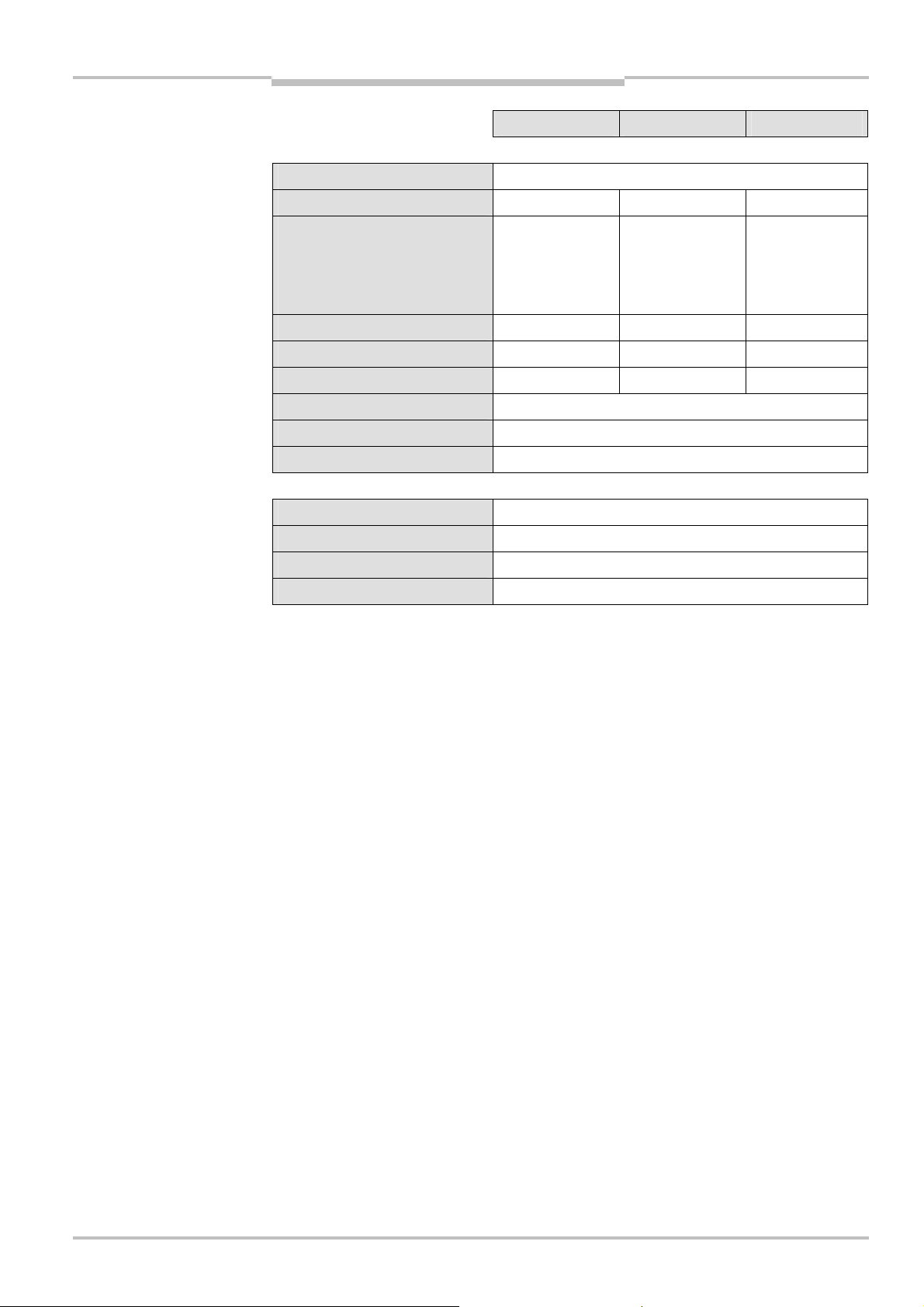

Chapter 9 Operating Instructions

WSU/WEU263

Technical specifications

Minimum Typical Maximum

Sender unit

Wavelength 950 nm

Test input

Type of circuit:

– Duration of the actuation of

the normally closed contact

– Response time to test input

Volt-free normally closed contact or wire jumpers

)

between the test contacts

0 ms

5

1

150 ms

200 ms

signal

Power consumption 6 W

Weight 1 kg

Receiver unit

Outputs Volt-free relay contacts, 2 normally open contacts,

1 normally closed contact (2 normally closed contacts

connected in parallel internally)

Contact material Ag alloy with Au coating

Switching frequency 0.2 Hz

Switching voltage 10 V DC

10 V AC

30 V DC

230 V AC

Switching current 20 mA 2 A

Mechanical life relay contacts Z 107switching operations

Electrical service life of relay

5

switching operations

Z 10

contacts with reference loads

Reference loads by usage

category

AC-15 with 230 V, 2 A,

AC-1 with 230 V, 2 A,

DC-1 with 24 V, 2 A,

DC-13 with 24 V, 1.5 A

Response time 22 ms

Switch-off time 80 ms

Power consumption 8 W

Weight 1 kg

1)

Connect the contacts on the WSU26-3 only to circuits that comply with the requirements for safety extra-low

voltage (SELV/PELV).

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 35

Operating Instructions Chapter 9

WSU/WEU263

Technical specifications

Minimum Typical Maximum

Operational data

Connection Cable gland (PG 13.5)

Core cross-section 0.2 mm

2

1.5 mm

2

Cable length for cross-section1)

– 0.25 mm

– 0.75 mm

– 1.5 mm

2

2

2

14 m

42 m

83 m

Ambient operating temperature –25 °C +55 °C

Storage temperature –25 °C +70 °C

Air humidity (non-dewing) 15 % 95 %

Dimensions see Dimensional drawings

Vibration resistance 5 g, 10 ... 55 Hz according to EN 60068-2-6

Shock resistance 10 g, 16 ms according to EN 60068-2-29

Environmental data

Housing Aluminium alloy ALSI12(CU)

Front screen Polycarbonate (scratch-resistant coating)

Circuit boards Glassfibre reinforced epoxy resin

Packaging Corrugated cardboard

1)

When using copper cables ([ = 0.018 U mm2/m).

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 35

Subject to change without notice

Page 36

Chapter 10 Operating Instructions

Tab. 15:

Ordering

Tab. 16:

Ordering

Tab. 17:

Ordering

WSU/WEU263

Ordering information

10 Ordering information

10.1 Devices

information devices

information deflector mirrors

Part Type Part number

Single-beam photoelectric safety switch:

Sender unit

Single-beam photoelectric safety switch:

Receiver unit, scanning range 0.5 m ... 20 m

Single-beam photoelectric safety switch:

Receiver unit, scanning range 15 m ... 70 m

WSU26/3-103A00 1047984

WEU26/3-103A00 1047985

WEU26/3-203A00 1048379

10.2 Deflector mirror

Part Type Part number

Deflector mirror PSK1 1005229

Bracket for PSK1 deflector mirror BEF-GH 2009292

Spring fastening for deflector mirror PSK1 BEF-4AAAAHST3 2012473

Deflector mirror PSK 45 5306053

Deflector mirror PNS75-008 1026647

10.3 Accessories

information accessories

Part Type Part number

Mounting bracket WSU/WEU BEF-4WNAEFAL1 2007900

Alignment aid AR60 1015741

Adapter for alignment aid AR60 4031156

PG expansion, PG 13.5 auf PG 21 5306052

PG cable entry PG 21 in the case of the usage

of two cables

Power supply, voltage supply 24 V DC, 2.1 A 7028789

Power supply, voltage supply 24 V DC, 3.9 A 7028790

Arc-suppression element RC-A

0.22 µF + 220 U (115 ... 230 V)

Arc-suppression element RC-AD

2.2 µF + 100 U (24 V)

Dust protection tube 1003556

Weather protection 1003619

Test rod bracket BEF-3WNAAAAL1 2052249

Test rod, 30 mm 2022602

5305978

6001224

6001225

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 37

Operating Instructions Chapter 10

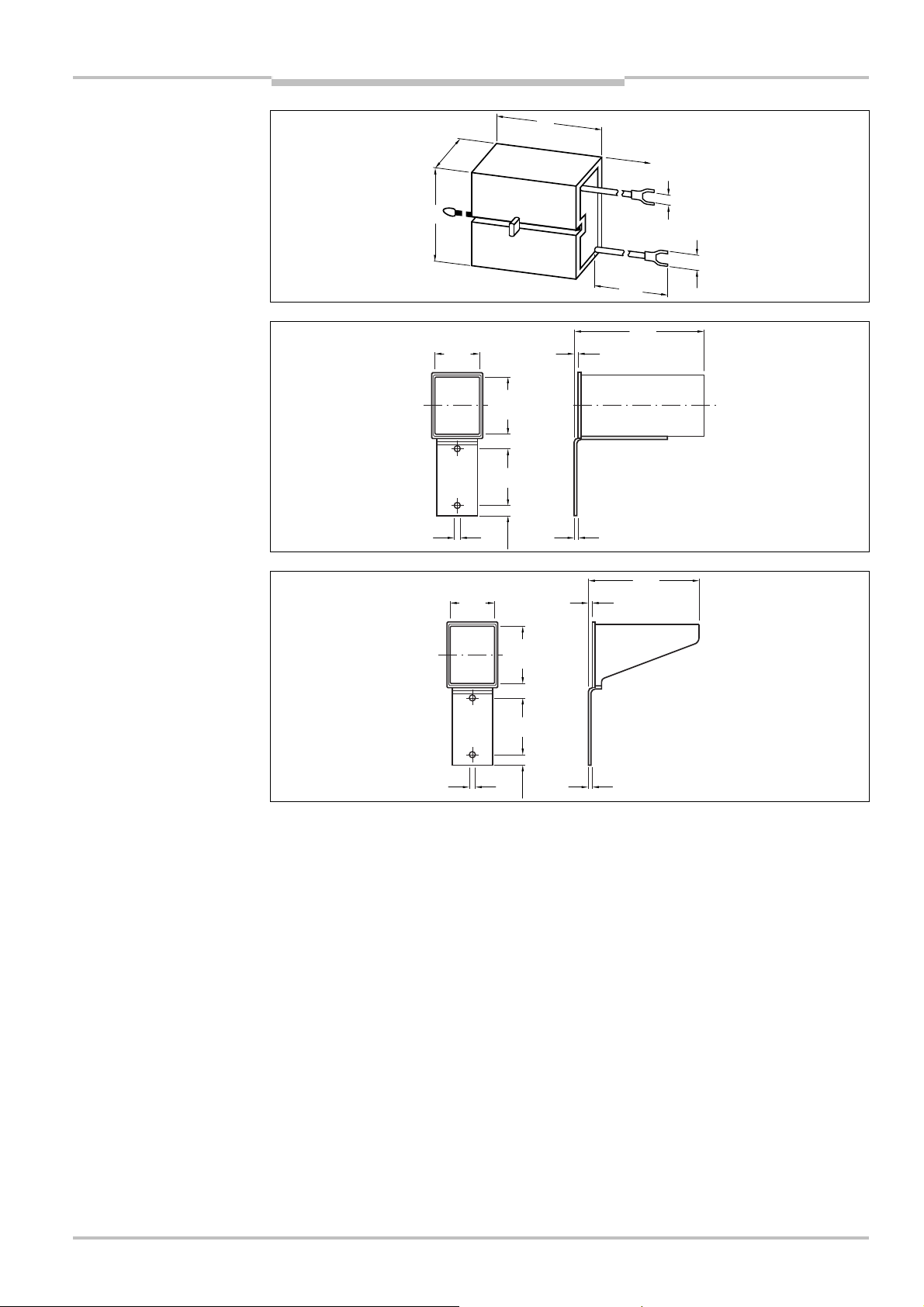

Fig. 19:

WSU/WEU26

-

3

Fig. 20:

Deflector mirr

or

Fig. 21:

Bracket for PSK1

Cover

Cover screws

Torque:

PG13.5

Ordering information

WSU/WEU263

10.4 Dimensional drawings

PSK1

65

156

65

14

18 ± 0.5 Nm

50

67

34

M6 x 8

17.5

128

15.5

116

torque:

2.0 ± 0.5 Nm

65

95

96

deflector mirror 1

124

149

160

177

7

ø

38

96

100

M8 x 30 SW13

20

26

40

43

22

M6 M6

16.5

33.5

63

14

8.5

20

58

71

M8 x 30 SW13

2.5

10

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 37

Subject to change without notice

Page 38

Chapter 10 Operating Instructions

Fig. 22:

Spring fastening for

Fig. 23:

Deflector mirro

r

Fig. 24:

Mounting bracket

Fig. 25:

Arc-su

ppression

Ordering information

WSU/WEU263

deflector mirror PSK1

PSK45 (M = Middle of the

mirror surface)

80

96.5

M

WSU/WEU

76

40.5

64.5

64.5

8.5

46.5

39.5

40

°

45

8.5

146.5

6.5

65

65

6

51

82

51

6.5

20˚

60˚

69.5

9

8.5

63

ø 5.5

80

9

element 115 ... 230 V

38 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

27

13

20

250

3.8

6.3

135

Subject to change without notice

Page 39

Operating Instructions Chapter 10

Fig. 26:

Arc-suppression

Fig. 27:

Dust protection tube

Fig. 28:

Weather protectio

n

Ordering information

WSU/WEU263

element 24 V

35

15

30

5

0.5

65.565

7

11.8

250

3.8

6.3

135

140

4

3

119

50.5

65.565

73

12.3

4

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 39

Subject to change without notice

Page 40

Chapter 11 Operating Instructions

WSU/WEU263

Annex

11 Annex

11.1 Compliance with EU directives

EU declaration of conformity (excerpt)

The undersigned, representing the following manufacturer herewith declares that the

product is in conformity with the provisions of the following EU directive(s) (including all

applicable amendments), and that the respective standards and/or technical

specifications are taken as the basis.

Complete EU declaration of conformity for download: www.sick.com

40 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 41

Operating Instructions Chapter 11

WSU/WEU26-3

Annex

11.2 Checklist for the manufacturer

Κ

Checklist for the manufacturer/installer for the installation of electro-

sensitive protective equipment (ESPE)

Details about the points listed below must be present at least during initial commissioning – they are, however,

dependent on the respective application, the specifications of which are to be controlled by the manufacturer/installer.

This checklist should be retained and kept with the machine documentation to serve as reference during recurring

tests.

1.

Have the safety rules and regulations been observed in compliance with the

directives/standards applicable to the machine?

2. Are the applied directives and standards listed in the declaration of conformity? Yes No

3.

Does the protective device comply with the required PL/SIL claim limit and PFHd in accordance

with EN ISO 13849-1/EN 62061 and the required type in accordance with IEC 61496-1?

4.

Is the access to the hazardous area/hazardous point only possible through the protective field

of the ESPE?

5.

Have appropriate measures been taken to protect (mechanical protection) or monitor

(protective devices) any persons or objects in the hazardous area when protecting a hazardous

area or hazardous point, and have these devices been secured or locked to prevent their

removal?

6.

Are additional mechanical protective measures fitted and secured against manipulation which

prevent reaching under, over or around the ESPE?

7.

Has the maximum stopping and/or stopping/run-down time of the machine been measured,

specified and documented (at the machine and/or in the machine documentation)?

8.

Has the ESPE been mounted such that the required minimum distance from the nearest

hazardous point has been achieved?

9. Are the ESPE devices correctly mounted and secured against manipulation after adjustment? Yes No

10. Are the required protective measures against electric shock in effect (protection class)? Yes No

11.

Is the control switch for resetting the protective device (ESPE) or restarting the machine present

and correctly installed?

12.

Are the outputs of the ESPE (OSSD) integrated according to required PL/SILCL compliant with

EN ISO 13849-1/EN 62061 and does the integration correspond to the comply with the circuit

diagrams?

13.

Has the protective function been checked in compliance with the test notes of this

documentation?

14. Are the specified protective functions effective at every operating mode that can be set? Yes No

15. Are the switching elements activated by the ESPE, e.g. contactors, valves, monitored? Yes No

16. Is the ESPE effective over the entire period of the dangerous state? Yes No

17.

Once initiated, will a dangerous state be stopped when switching the ESPE on or off and when

changing the operating mode, or when switching to another protective device?

18.

Has the information label for the daily check been attached so that it is easily visible for the

operator?

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

This checklist does not replace the initial commissioning, nor the regular inspection by qualified safety personnel.

8013338/YTA4/2016-03-24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 41

Subject to change without notice

Page 42

Chapter 11 Operating Instructions

Annex

WSU/WEU26-3

11.3 List of tables

Tab. 1: Overview on disposal by components ...................................................................9

Tab. 2: Receiver variants................................................................................................ 11

Tab. 3: Diagnostics LEDs WSU26-3 ............................................................................... 12

Tab. 4: Diagnostics LEDs WEU26-3................................................................................ 12

Tab. 5: Height of the beams above the floor.................................................................. 15

Tab. 6: Formula for the calculation of the minimum distance to reflective surfaces..... 17

Tab. 7: Reduction in the scanning range on the usage of deflector mirrors with

= 90°.............................................................................................................. 20

Tab. 8: Distances of the deflector mirrors...................................................................... 21

Tab. 9: Assignment of the sensor contacts, sender WSU26-3....................................... 23

Tab. 10: Assignment of the sensor contacts, receiver WEU26-3 ..................................... 24

Tab. 11: Examples for arc-suppressors............................................................................ 25

Tab. 12: Diagnostics LEDs WSU26-3 ............................................................................... 31

Tab. 13: Diagnostics LEDs WEU26-3................................................................................ 32

Tab. 14: Technical specifications..................................................................................... 33

Tab. 15: Ordering information devices............................................................................. 36

Tab. 16: Ordering information deflector mirrors............................................................... 36

Tab. 17: Ordering information accessories ...................................................................... 36

42 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013338/YTA4/2016-03-24

Subject to change without notice

Page 43

Operating Instructions Chapter 11

WSU/WEU26-3

Annex

11.4 List of illustrations

Fig. 1: Key data for the WSU/WEU26-3 devices............................................................10

Fig. 2: Diagnostics LEDs WSU26-3 ...............................................................................12

Fig. 3: Diagnostics LEDs WEU26-3 ................................................................................12

Fig. 4: Access guarding with WSU/WEU26-3.................................................................13

Fig. 5: Safety distance S to the light beam ....................................................................15

Fig. 6: Minimum distance to reflective surfaces............................................................17

Fig. 7: Graph, minimum distance from reflective surfaces............................................17

Fig. 8: Mounting two WSU/WEU26-3 devices in series .................................................18

Fig. 9: Mounting possibilities using mounting brackets.................................................19

Fig. 10: Hazardous area protected on several sides........................................................20

Fig. 11: Two-beam protection with one system WSU/WEU26-3 ......................................21

Fig. 12: Incorrect alignment of sender and receiver........................................................21

Fig. 13: Correct alignment of sender and receiver...........................................................21

Fig. 14: Assignment of the sensor contacts, sender WSU26-3........................................23

Fig. 15: Assignment of the sensor contacts, connection diagram WEU26-3 on