Page 1

TECHNICAL DESCRIPTION

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

‡ EASY INSTALLATION †

‡ UNIVERSAL USABILITY†

‡ SOLID CONSTRUCTION †

Page 2

Contents

SICK WSU 26/2 – WEU 26/2

1 General Introduction 3

2 Device/System

Construction 4

3 Description of Function 4

4

Possible Areas of Application

and Application Conditions

4.1 Possible Areas

of Application 5

4.2 Application Conditions 5

5 Mechanical Arrangement

and Mounting 6

5.1 Safety Distance 6

5.2 Mechanical Mounting 7

5.3 Multiple Safeguarding 8

5.3.1 Mutual Interference 8

5.4 Corner Mirrors 10

6 Mounting 11

6.1 Mounting Requirements 11

6.2 Detecting Reflections 11

7 Electrical Connection 13

7.1 General 13

7.2 Wiring Diagram 14

12 Technical Data 25

13 Dimensional Drawing 26

14

At a glance: What is new?

15 Selection Table,

WSU/WEU 32

15.1 Conversion List 33

5

16 Selection Table,

Accessories 34

Standards and

Regulations

To be observed in use

and installation

Approvals

EU Europe

EC prototype test conducted by

31

BG - Berufsgenossenschaft

(Trade association)

Fachausschuß Eisen und Metall III

(Technical committee

for iron and metal III)

Graf-Recke-Str. 69

D-40239 Düsseldorf

Approval number: 97074

8 Commissioning 22

8.1 Alignment of WSU and

WEU 22

8.2 Alignment of WSU and

WEU with Alignment Aid

AR 60 22

8.3 Checking 22

9 Maintenance 23

10 Commissioning 23

11 Malfunctions 23

11.1 Diagnostic Elements 23

This technical description must be observed when installing and

commissioning the WSU 26/2 - WEU 26/2. Inspection and

commissioning must be carried out by specialists, if this is specified in the

directives or guidelines.

2

Warning

Failure to observe

may result in

dangerous operation

Usage

Information regarding

how to use the

product correctly

and efficiently

Generally recognized technical

regulations and quality assurance

system ISO 9000 are carefully

applied during the development

and production of SICK

products.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 3

SICK WSU 26/2 – WEU 26/2

1 General Introduction

1 General Introduction

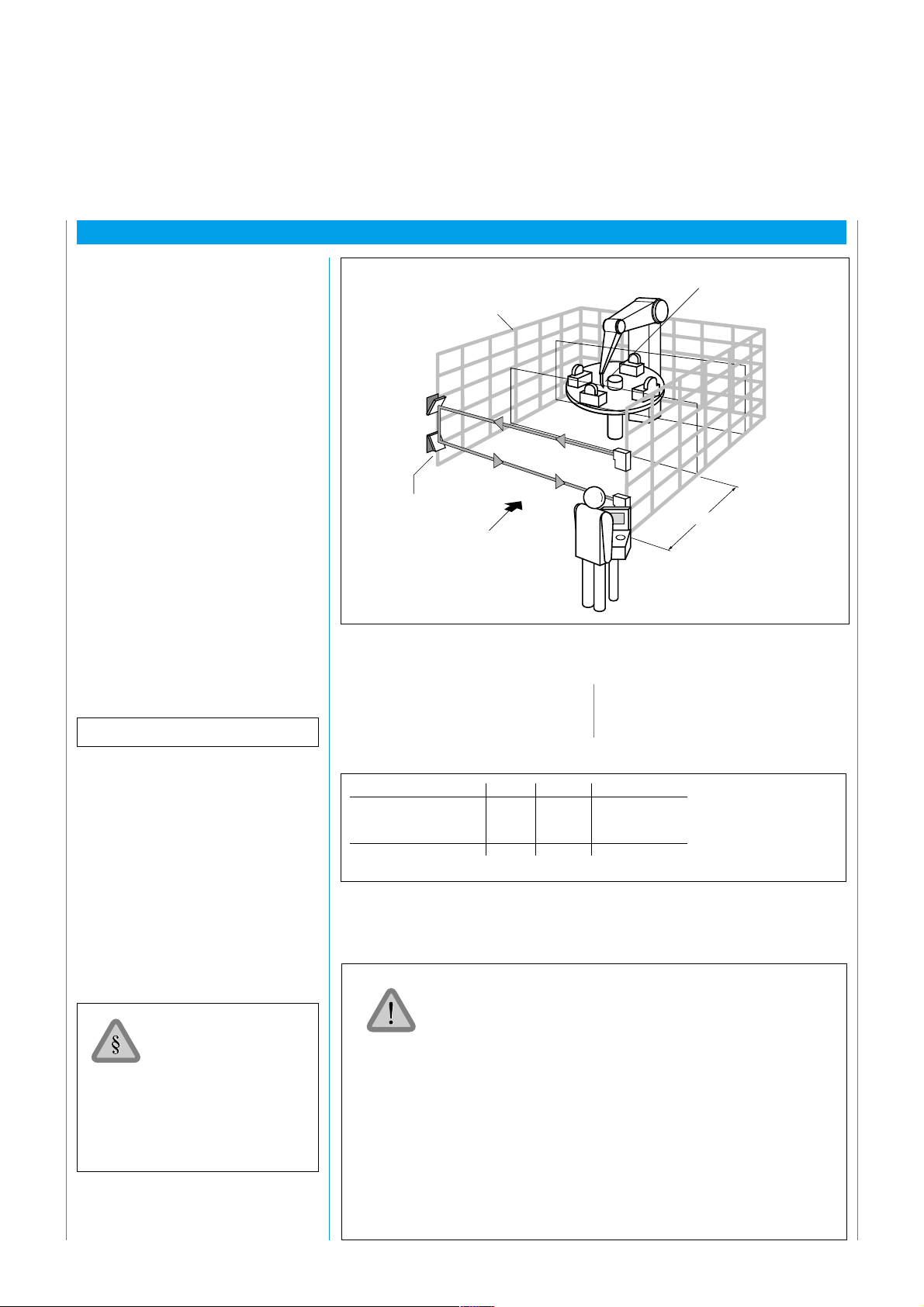

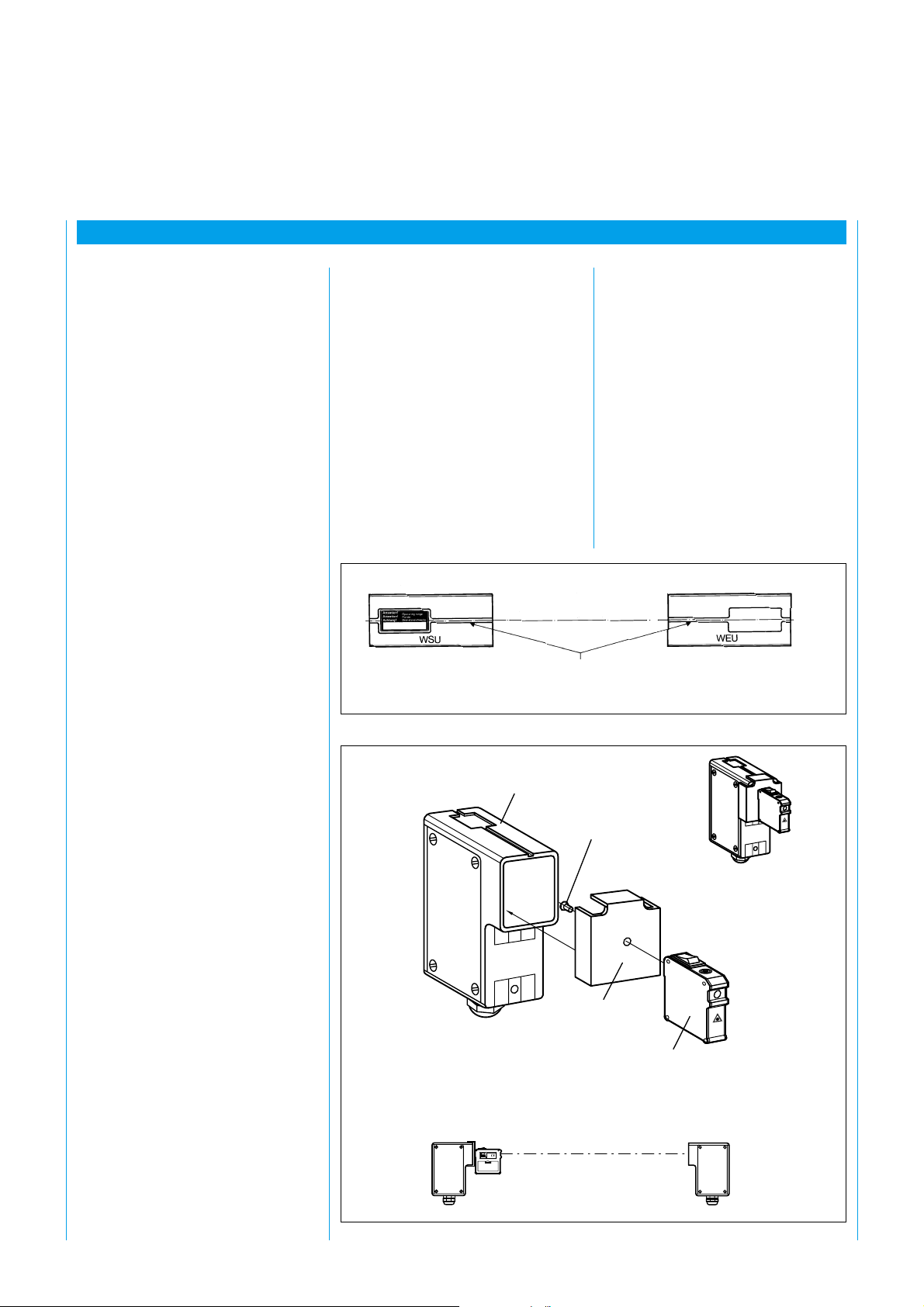

The WSU 26/2 / WEU 26/2

photoelectric safety switch is a single-beam non-contact protective

system. It consists of a WSU light

sender and a WEU light receiver.

The light beam between the

emitting and receiving units

provides access protection for

hazardous areas.

The safety switch is designed for

industrial applications. Its features

include

‡ universal usability

‡ easy installation

‡ solid construction

‡ heated front screen, i.e. it can be

deployed even in unfavorable

ambient conditions.

The WSU/WEU complies with

safety requirements according to

pr EN 50.100, safety category type 4.

The following key data are

applicable in practical use:

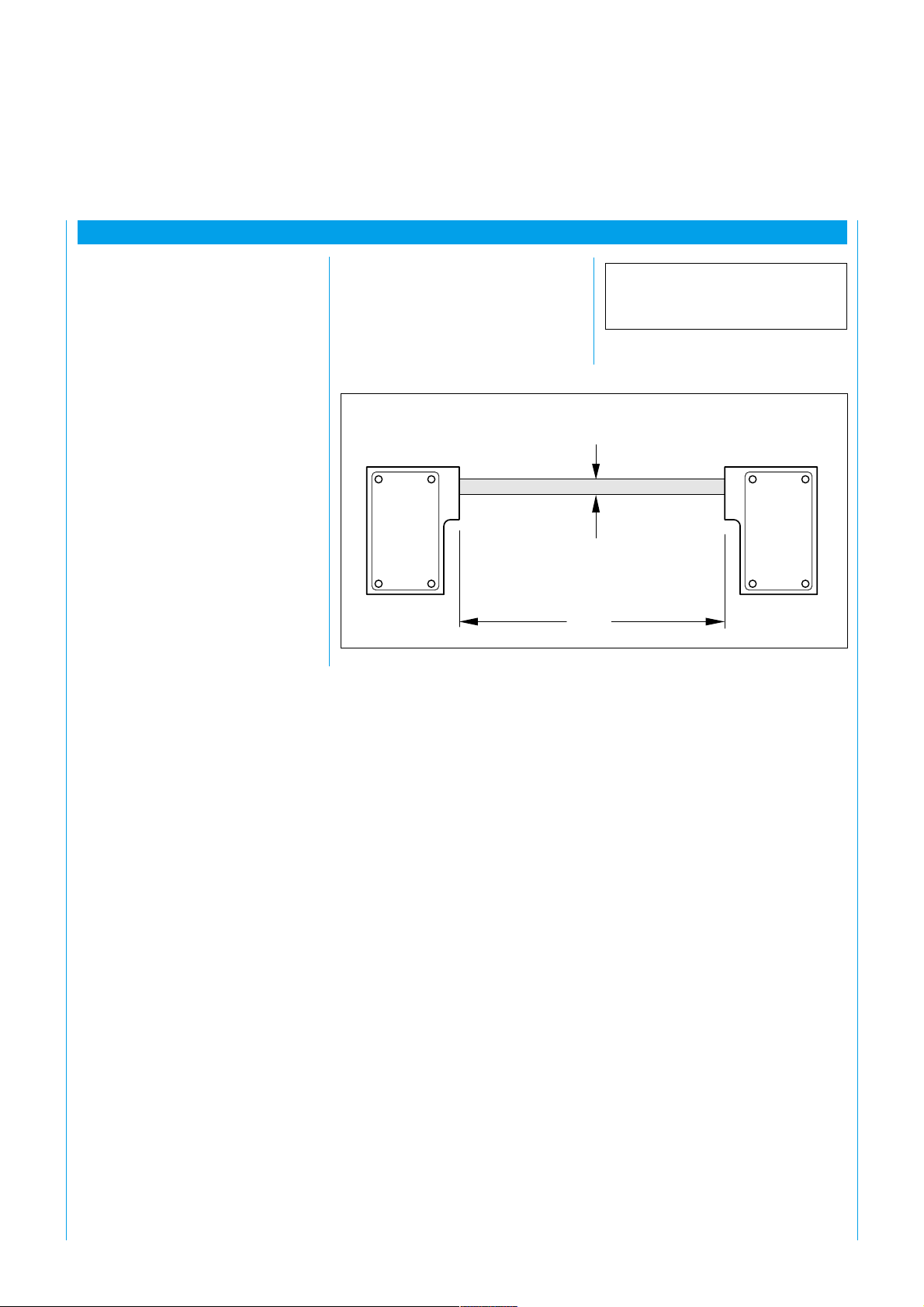

Beam diameter

WSU WEU

Fig. 1: System construction of the WSU 26/2 / WEU 26/2 photoelectric safety switch

Scanning range 0.5 ... 18 m

15 ... 70 m

Beam diameter 23 mm

23 mm

Range

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

3

Page 4

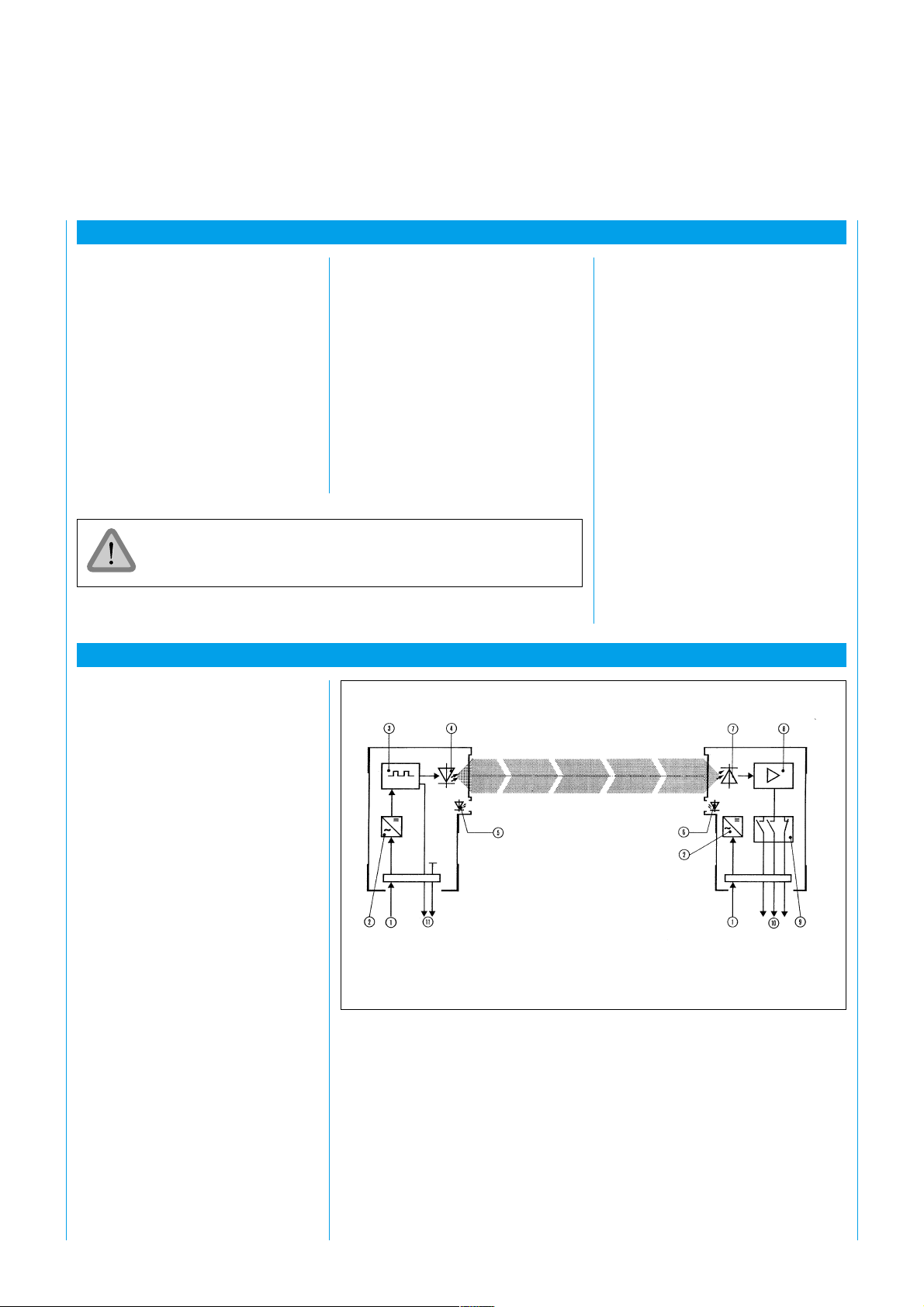

3 Description of Function

2 Device/System Construction

SICK WSU 26/2 – WEU 26/2

The WSU/WEU comprises:

‡ WSU 26/2 sender unit and

‡ WEU 26/2 receiver unit

Each complete break in the light

beam between the light sender and

light receiver triggers a signal which

can be used to immediately stop

the dangerous movement of the

power-driven machinery

(abbreviated as ”PDM”).

The WSU/WEU 26/2 must not be used as a hand or finger guard.

3 Description of Function

The WSU and WEU are mounted

separately in die-cast housings. Each

has its own power supply (Fig. 2).

The WSU contains a clock

generator and the sender diode.

The diode emits infrared pulses at

the clock rate set by the generator,

which are evaluated by the receiver

unit WEU if the light path is

uninterrupted.

The WEU contains the output

relays A and B, which pick up if the

light path is uninterrupted.

If the light path or the connection

between terminals 10 and 11 on

the WSU is interrupted (testing),

both relays are released.

The WSU 26/2 / WEU 26/2 serves

as a protective cut-off device to

protect hazardous areas on powerdriven machinery. The machinery

may be:

‡ plastics machinery

‡ stackers

‡ settling machinery

in the stoneworking industry

‡ machining centers

1 Connection

for power supply

2 Power supply

3 Clock generator

4 Sender diode

5 LED, WSU

6 LED, WEU

7 Photoelectric converter

8 Amplifier

9 Relay with positively-driven contacts

10 Outputs

11 Test contact

Fig. 2: Principle of function of the WSU/WEU 26/2, AC version

4

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 5

SICK WSU 26/2 – WEU 26/2

4 Possible Areas of Application and Application Conditions

4 Possible Areas of Application

4.1 Possible Areas

of Application

The WSU/WEU provides access

protection for hazardous areas

(Fig. 3).

4.2 Application

Conditions

Safe cut-off can only be effected

when the light beam diameter of

23 mm is fully covered.

The protective function of the

WSU/WEU is ensured when the

conditions set out in the adjacent

box are met.

The power-driven machinery (”PDM”) must be

controllable by electrical means.

The dangerous movement of the machine must be able

to be stopped at any time.

The WSU/WEU must be positioned so that entry into

the hazardous area is only possible by breaking the light

beam.

The command unit must be positioned so that it cannot

be activated from the hazardous area.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

5

Page 6

5 Mechanical Arrangement

5 Mechanical Arrangement and Mounting

SICK WSU 26/2 – WEU 26/2

5.1 Safety distance

The WSU/WEU must be attached

such that, if the light beam is

broken during hazardous

movement of the machinery, the

point-of-operation can only be

reached when this hazardous

movement has ceased. For this

purpose, a safety distance S must

be maintained between the nearest

boundary of the point-of-operation

and the light beam (Fig. 4). The

safety distance depends on the

machine stopping time and on the

approach speed of the personnel.

The machine stopping time must be

determined by repeating

measurements under practical

conditions. 1.6 m/s is the

recommended approach speed.

The safety distance is calculated as

follows:

S = v (t

+ t2) + C

1

Mechanical

safeguarding

Entry/exit

guarding

with

WSU/WEU

Fig. 4: Safety distance to light beam

Direction

of entry

into

hazardous

area

Table 1 shows which C value must

be used for which application.

Point-of-operation

S

S Safety distance (mm)

v Approach speed

1.6 m/s

t

Machine stopping time (ms)

1

t

Response time of WEU (22 ms)

2

C Dependent on number of beams

(1, 2, or 3), see Table 1

pr EN 999

Safety of machinery

Approach speed of body parts

for arrangement of protective

systems

6

Number of beams 01 02 03

Height of beam(s) 750 400 0300

above floor (mm) 900 0700

1100

C 1200 850 0850

Table 1: Height of beams above floor

The WSU/WEU must be attached such that, if the light beam is

broken during hazardous movement of the machinery, the pointof-operation can only be reached when the power-driven

machinery is no longer in a hazardous state.

For this purpose, a safety distance must be maintained between the

light beam and the nearest boundary of the point-of-operation.

This safety distance is determined according to pr EN 999.

People within the hazardous area but outside the light beam are

not detected. It must, however, be ensured that any hazardous

state can only be initiated when there is no one in the hazardous

area.

Use and mounting of the protective systems is subject to the relevant official rules and regulations. These provisions differ depending

on the area of application.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 7

SICK WSU 26/2 – WEU 26/2

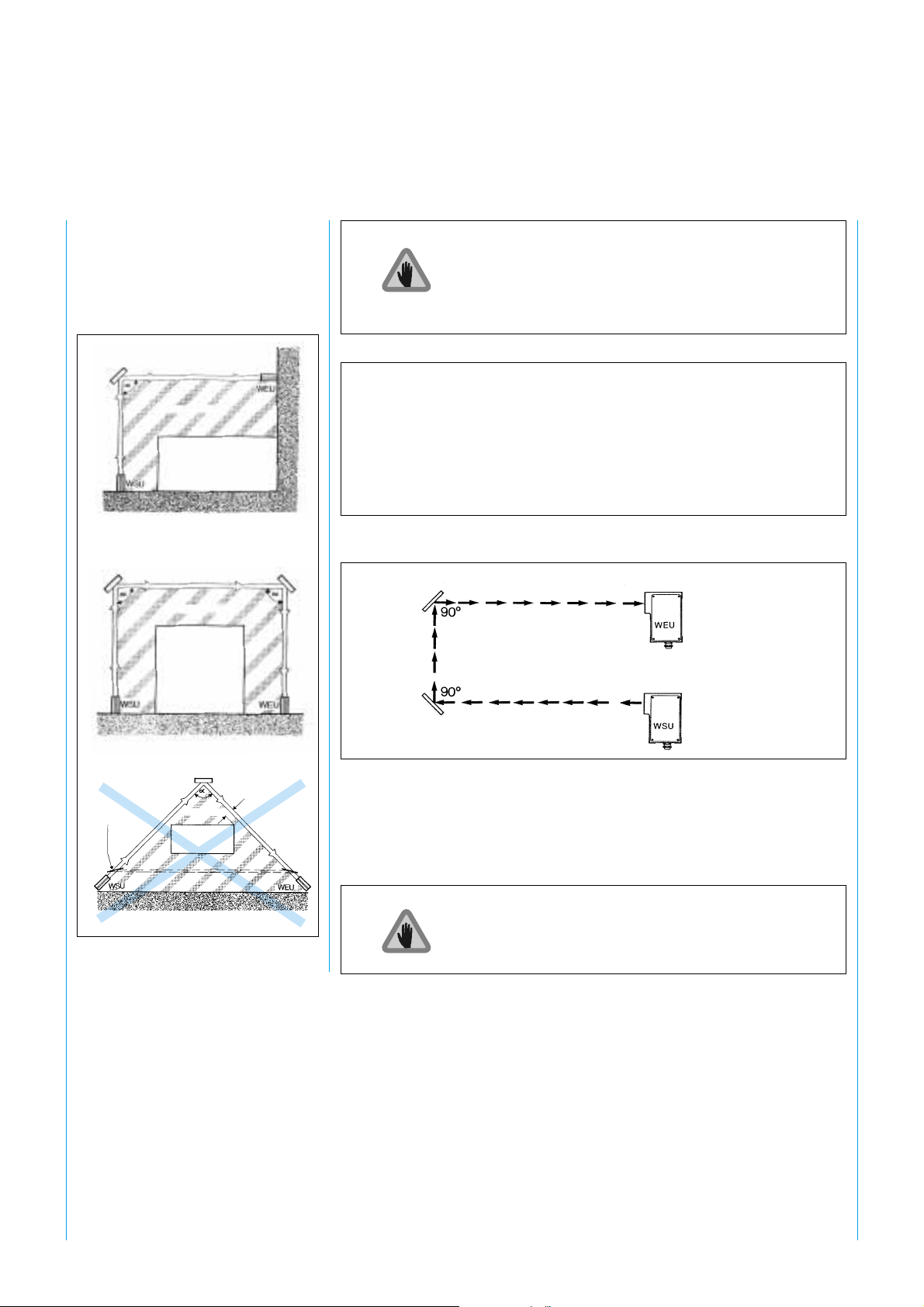

5.2 Mechanical Mounting

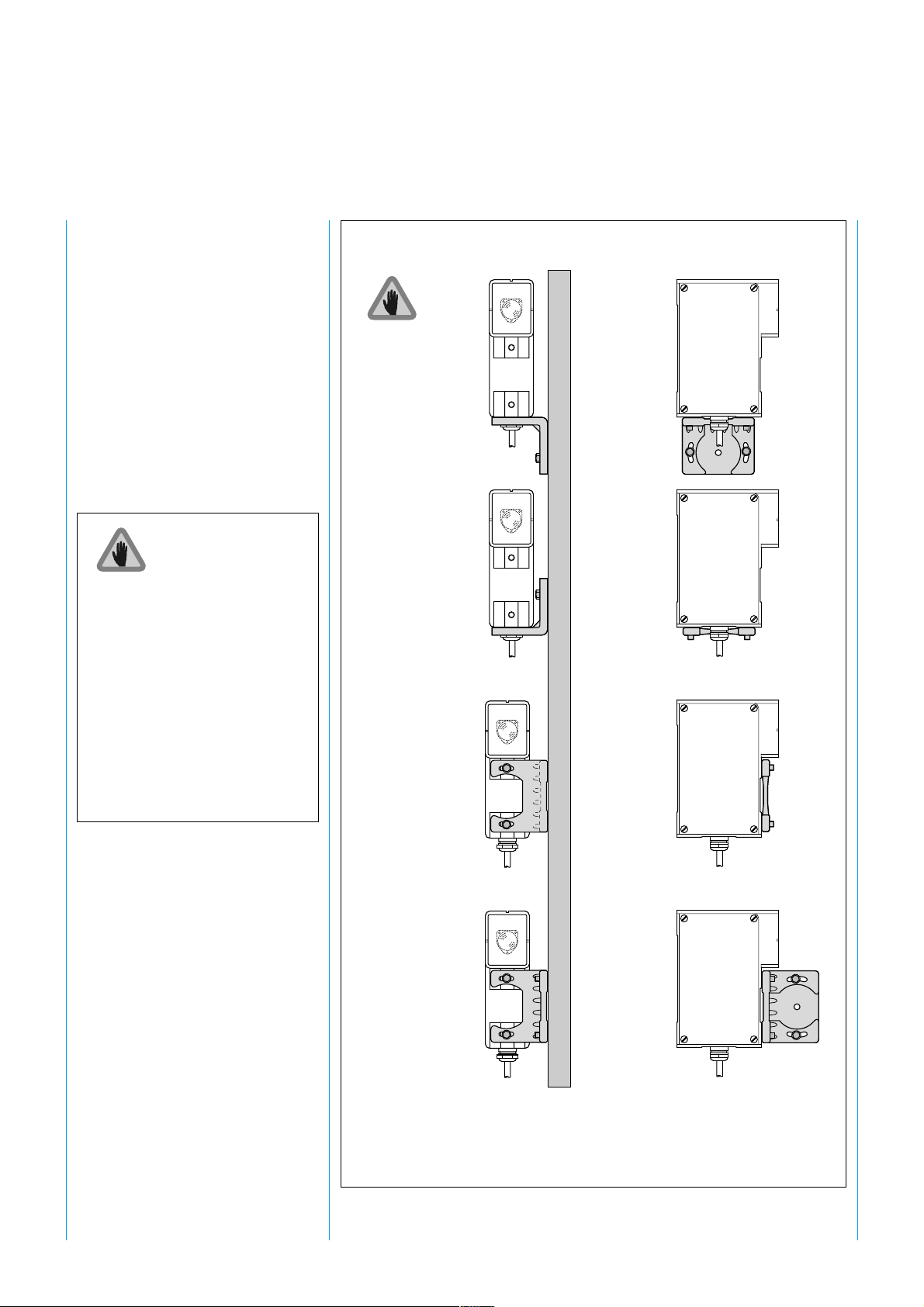

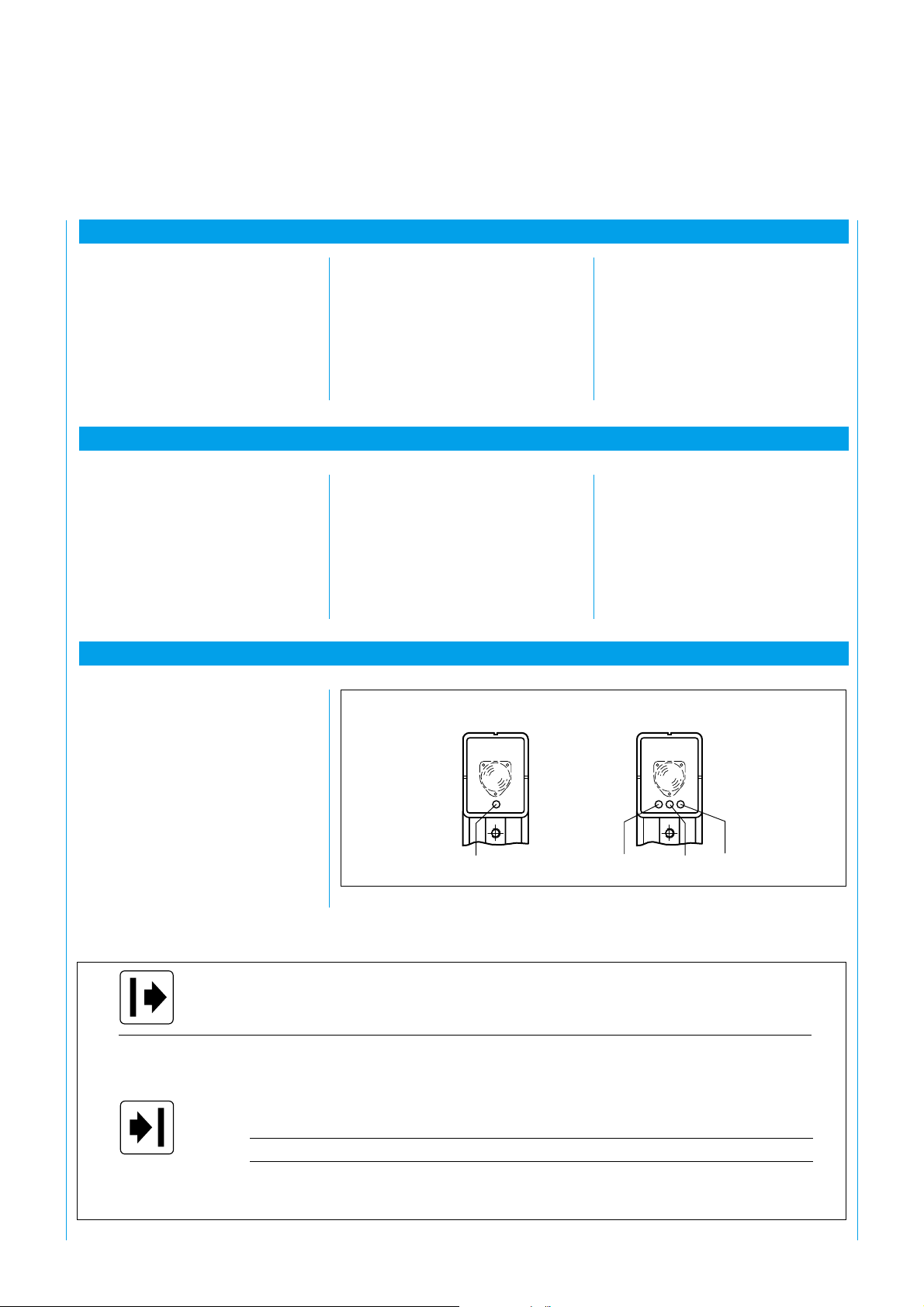

The WSU and WEU units can be

mounted on one of the sides of

their housing or using the mounting

bracket, depending on site

circumstances. The mounting

bracket greatly assists alignment.

The devices can be mounted in any

operating position. However, the

WSU and WEU should be

mounted such that the axis of the

light beam emitted by the WSU

always matches the axis of the

WEU optic (alignment sight).

The mounting brackets should be

affixed so that all fixing screws are

easily accessible for alignment

purposes. Figure 5 shows examples.

The devices should be attached

such that the opposing device can

be aligned in the alignment sight.

When using the

15 + PE plug,

mounting modes

a and b

are not possible.

Order number

Mounting bracket

2 007 900

a

b

If, for reasons of space, the devices

need to be arranged as shown in

Figures 5 a and b, hexagon screws

must be used.

c

d

Fig. 5: Mounting options using a mounting bracket

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

7

Page 8

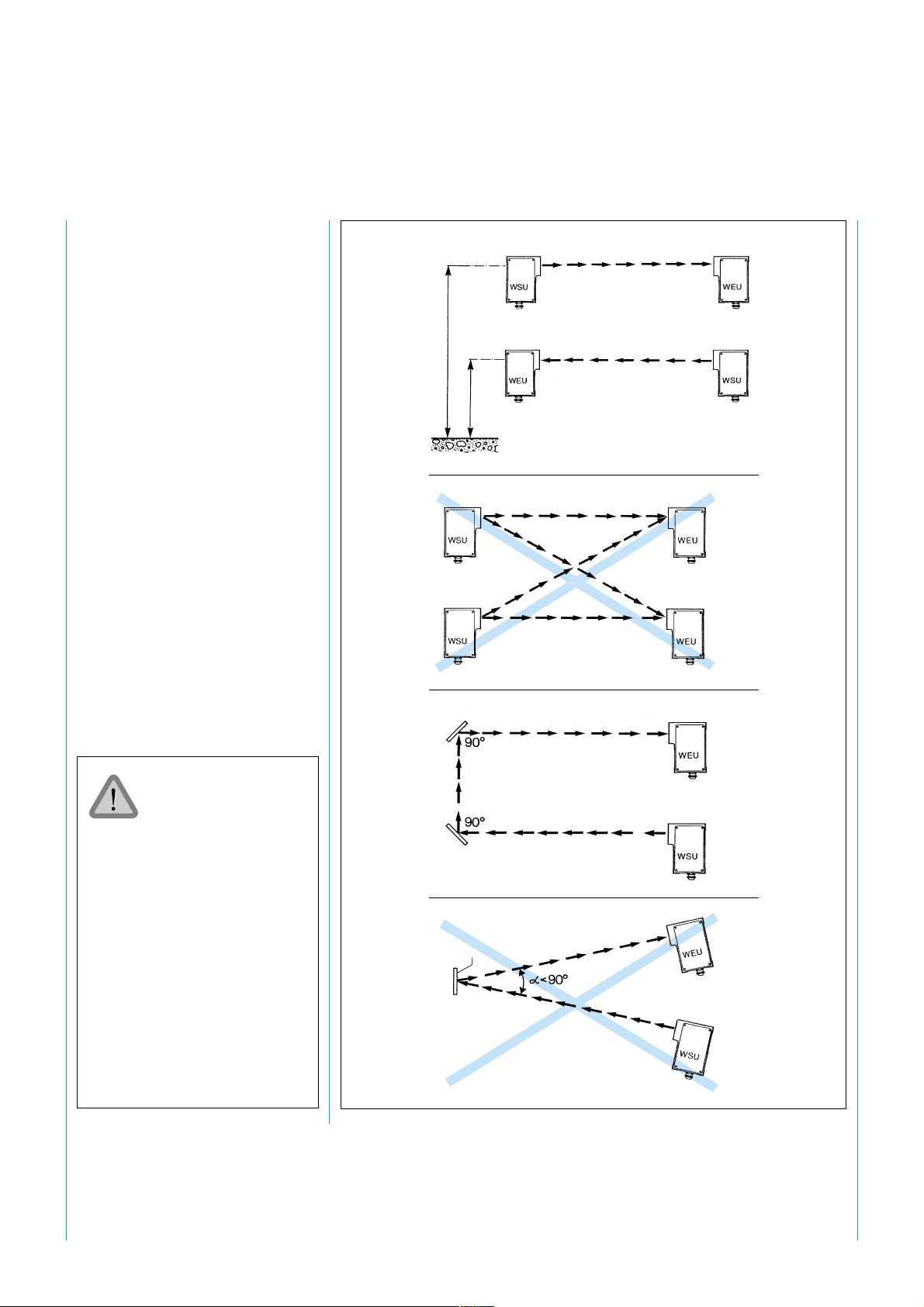

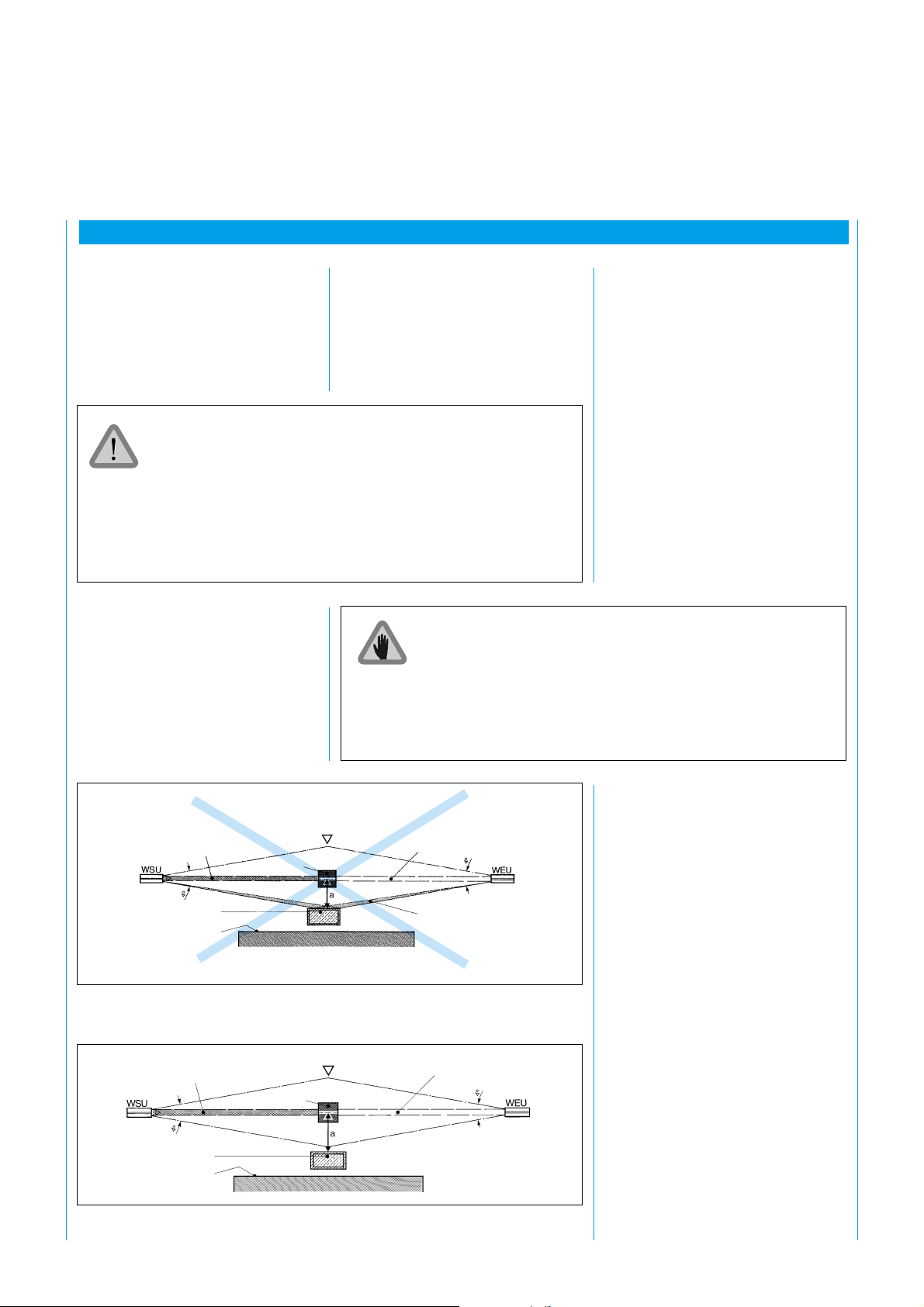

5.3 Multiple

Safeguarding

When using two WSU/WEU units

in a protective system, the

possibility of mutual interference

must be excluded. Since the light

beam of the WSU diverges, the

cross-section of the beam increases

as the distance between the WSU

and WEU grows. The following

conditions must therefore be met

when arranging the WSU/WEU:

SICK WSU 26/2 – WEU 26/2

approx. 900

approx. 400

5.3.1 Mutual Interference

The light beam of the WSU must

only be received by the

corresponding WEU. To prevent

mutual interference between

several WSU/WEU installations

arranged adjacent to or above each

other, the specified beam diameters

must be taken into account when

mounting the devices (Fig. 6).

There are two versions

of the WSU, for

operating ranges

0.5 ... 18 m and

15 ... 70 m. The WSU

must not be used for

operating ranges below

15 m. The operating

range is given on the

rating plate.

Mutual interference is possible

Corner mirror

Corner mirror

Corner mirror

Fig. 6: Safeguarding a hazardous area with WSU/WEU

8

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 9

SICK WSU 26/2 – WEU 26/2

WEU

WSU

WSU

WSU

WEU

WEU

Fig. 7: Mounting of two WSU/WEU units in series

WSU

WSU

WSU

WEU

WEU

WEU

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

9

Page 10

5.4 Corner mirrors

SICK WSU 26/2 – WEU 26/2

In conjunction with corner mirrors,

the WSU/WEU provides multisided, two-beam access protection

(Fig. 8 and 9).

Corner mirror

Hazardous area

Power-driven

machinery (PDM)

Corner mirror

Hazardous area

Power-driven

machinery

(PDM)

Corner mirror

The use of corner mirrors reduces the scanning range

of the WSU/WEU system as cited in the table.

Number of mirrors Reduced scanning range Reduced scanning range

0.5 ... 18 m WSU 15 ... 70 m WSU

1 17 m 67 m

2 15.5 m 61 m

3 13 m 51 m

4 11 m 42 m

Tab. 2: Reduction in scanning range when using corner mirrors

Corner mirror

Safety distance

Reflection

possible

KA

Fig. 8: Multi-sided protection of hazardous

areas

too small

Corner mirror

Fig. 9: Two-beam protection with a WSU/WEU 26 system

The use of more than 2 mirrors requires a very accurate

alignment.

10

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 11

SICK WSU 26/2 – WEU 26/2

6 Mounting

6.1 Mounting

Requirements

The devices should be mounted

and connected in accordance with

the on-site application conditions

and connections, taking account of

the following:

The scanning range is based on the width of the area being

protected. Bypassing or encircling must be prevented by suitable

(mechanical) means.

Where one or more WSU/WEU units are used, the height and

number of light beams must comply with the applicable

regulations.

There must be no reflective surfaces in the emitting or receiving

beam path.

The minimum distance must be maintained.

6 Mounting

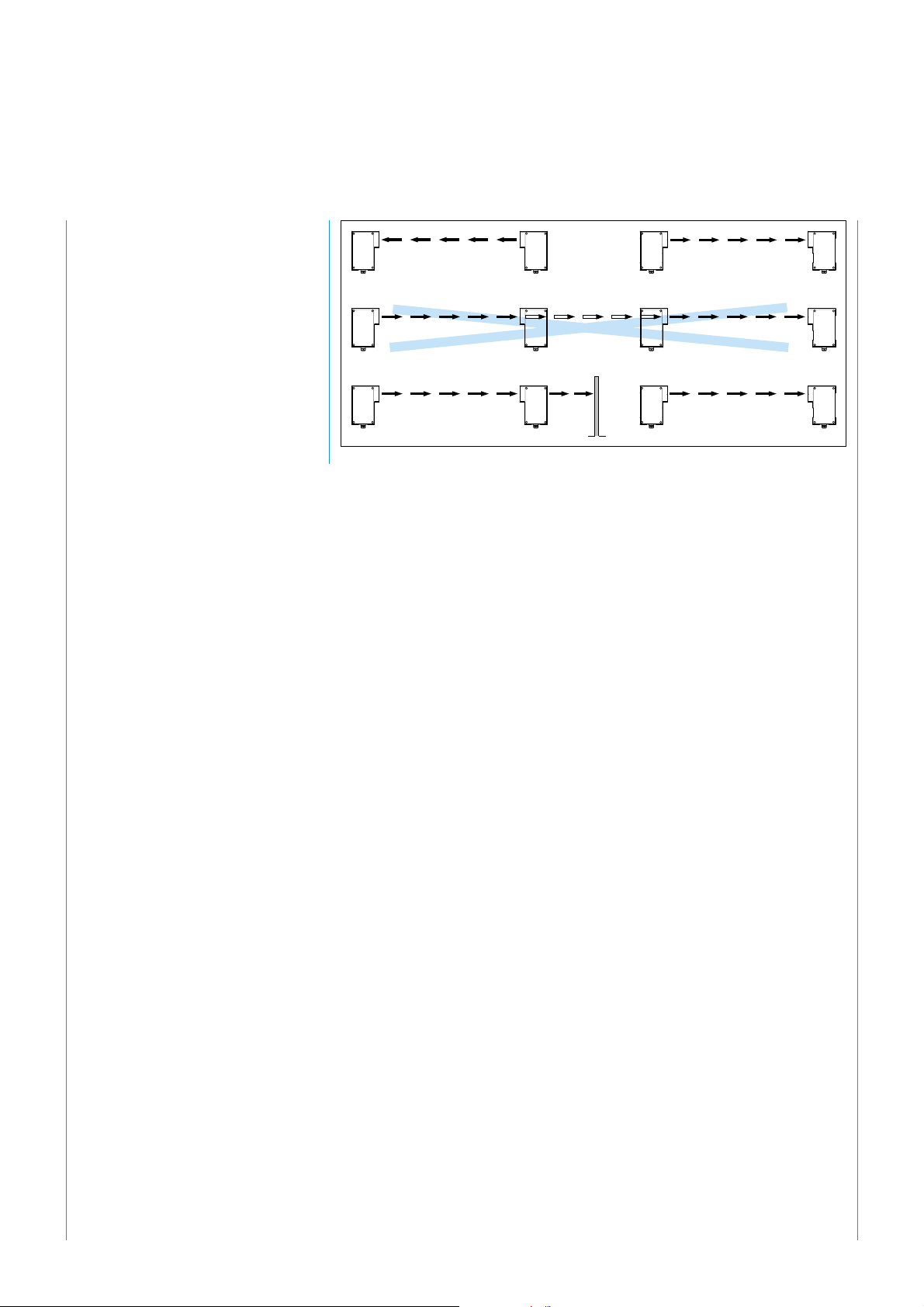

6.2 Detecting

Reflections

The light beam must not be

unintentionally reflected back to the

receiver by reflective surfaces.

Reflections can be detected as

follows:

Entry direction

Central beam

Reflective object

(e.g. material container)

Boundary

of point-ofoperation

Fig. 10: Incorrect mounting: reflective object in divergent light beam. No detection of the

obstacle due to reflection. No protection.

Entry direction

Central beam

Cover the light beam between the sender and receiver fully with

an obstacle (100 mm x 100 mm) and slowly move the obstacle

from the sender unit to the receiver unit.

While this is happening the green LED on the WEU must not

light up. If it lights up even just briefly during this check, reflection

is occurring.

See also 8. Commissioning.

Beam array

broken

Beam array

broken

Reflective object

(e.g. material container)

Boundary

of point-ofoperation

Fig. 11: Correct mounting, correctly aligned: reflective object outside divergent light beam.

No reflection. The obstacle is clearly detected.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

11

Page 12

a (mm)

SICK WSU 26/2 – WEU 26/2

2500

WSU WEU

2000

1500

1000

500

400

300

200

100

Fig. 12: Distance a as a function of scanning range SR

4°

3

10

a

a

6

20

30

a (70 m)

4°

a (18 m)

RW (m)

9

12

40

15

50

18

60

21

70

12

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 13

SICK WSU 26/2 – WEU 26/2

7 Electrical Connection

7 Electrical Connection

7.1 General Introduction

Depending on type, the WSU/WEU

26/2 photoelectric safety switch is

available for a supply voltage of

‡ 24 V DC

‡ 115 V AC or

‡ 230 V AC.

The rating plate gives details.

Before connection, check that the

supply voltage and mains frequency

on-site are consistent with the

specifications on the rating plate.

The cable is fed through the PG

connector and connected inside the

device, or connected to the

equipment plug. The wiring diagram

is depicted again on the housing

cover of the respective device.

The two system components must

be of the same voltage version and

the same scanning ranges.

Single- or fine-wire conductors up

to 1.5 mm

2

can be connected to

the screwless terminals (to VDE

0607). Stripping length: 11 mm.

The electrical connection of the WSU/WEU must only

be made or changed with the power disconnected.

Unscrew the housing cover to connect the WSU/WEU

with a PG connector.

Arc-suppression elements are essential under inductive load!

Arc-suppression elements must be connected in parallel with

the inductance. Connection in parallel with the output contact

is not permitted.

Diodes must not be used as arc-suppression elements.

At least two outputs must be

connected to the downstream

machine controller (Fig. 20/21).

Each of the two outputs (NO

contacts) must be assigned an

electromagnetic switching element.

Guide values for arc-suppression elements

The enclosure rating for the devices

can only be guaranteed when the

cable is properly clamped in the PG

connector and the housing seals fit

perfectly. Where long leads are

used, the cable cross-sections

should be chosen to ensure the

Operating

voltage

C

R

Contact

in WEU

Consumers,

contactor

Operating voltage Order no. R C

V ΩµF

115 ... 230 6 001 224 220 0.22

24 6 001 225 100 2.2

Plastic-encapsulated; connecting wires NYAF 0.5

dia. with cable lugs; mounting with adhesive tape

or cable tie.

devices are always supplied with

the required voltage (see Technical

Data).

Tab. 3: Overview for arc-suppression elements

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

13

Page 14

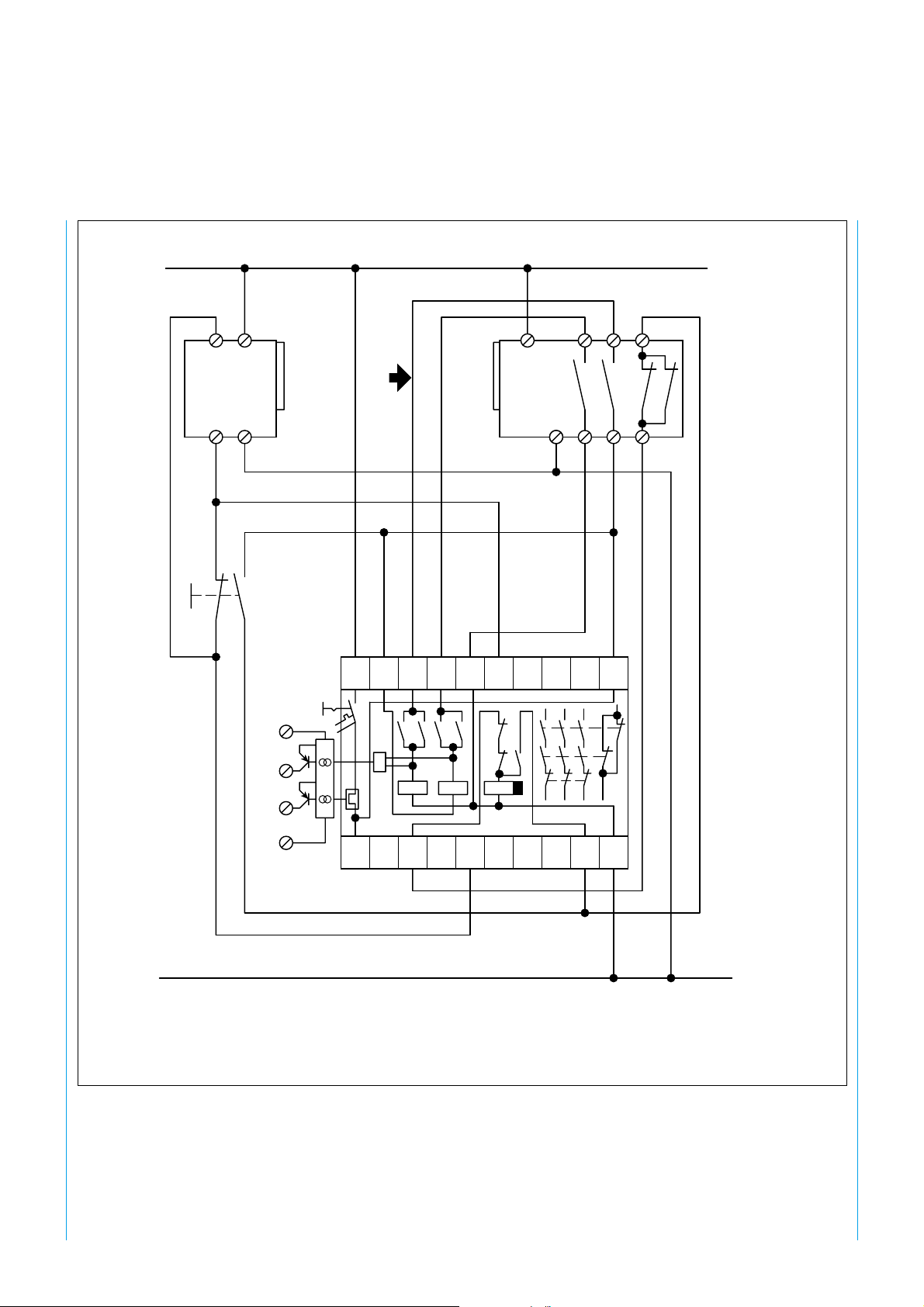

7.2 Wiring Diagram

SICK WSU 26/2 – WEU 26/2

31011

1/2

PE +24V

Fig. 13: Wiring diagram WSU/WEU for 24 V DC supply, with PG connector

0V 0V

31011

1/2

PE

1/2

+24V

1/2

456789

3

456789

3

PE

230V/

NN

115 V

Fig. 14: Wiring diagram WSU/WEU for AC supply, with PG connector

Connecting leads max. 1.5 mm

WSU

Test contact (10, 11)

Floating U 24 V DC

I 10 mA

Opening time t ≥ 50 ms

2

WEU

Outputs (4 - 9)

Umax. 250 V AC

Imax. 2 A per output

Imin. 0.02 A per output

PE

230V/

115 V

14

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 15

SICK WSU 26/2 – WEU 26/2

1/2

PE +24V

1/2

PE +24V

31011

1

2

0V

31011

5

6

0V

WSU 26/2 -131

231

1

B

A

2

G

F

3

3

4

Coded to

C

6

A or

D

5

E

4

Equipment plug

WSU 26/2 -133 WSU 26/2 -233

1

B

A

2

G

F

3

3

4

Equipment plug

Coded to

C

6

E or. 4

D

5

E

4

1

B

A

2

C

G

6

F

D

3

5

E

4

Equipment plug

Coded to

B or 1

3456789

1/2

3

2

1

PE +24V

0V

3456789

1/2

3

2

1

+24V 0V

PE

3456789

1/2

63

5

PE +24V 0V

WEU 26/2 -131

231

1

B

A

2

G

F

3

4

6

5

Coded to

C

6

D or 5

D

5

E

4

Equipment plug

WEU 26/2 -132

232

1

B

A

2

G

F

3

5

6

4

Coded to

C

6

E or 4

D

5

E

4

Equipment plug

WEU 26/2 -133

233

1

B

A

2

G

F

3

1

4

2

Equipment plug

Coded to

C

6

E or 4

D

5

E

4

Fig. 15: Wiring diagram WSU/WEU 26/2 for 24 V DC supply, interchangeable design

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

15

Page 16

SICK WSU 26/2 – WEU 26/2

PE

PE

1/2

230 V/

115 V

1/2

230 V/

115 V

1

5

31011

3

2

N

31011

3

6

N

WSU 26/2 -121

-221

-111

1

-211

B

A

2

C

G

6

Coded to

F

D

3

4

C or 6

5

E

4

Equipment plug

WSU 26/2 -113 WSU 26/2 -213

1

B

A

2

C

G

6

F

3

4

Coded to

D

A or

5

E

4

Equipment plug

WSU 26/2 -123

Equipment plug

1

B

A

2

G

F

D

3

E

4

Equipment plug

1

B

A

2

C

G

6

F

D

3

5

E

4

C

6

Coded to

G or 2

5

-223

Coded to

F or 3

3456789

1/2

3

2

1

N

PE

230 V/

115 V

1/2

3456789

3

6

5

PE

N

230 V/

115 V

3456789

1/2

3

2

1

PE 230/

N

115 V

WEU 26/2 -112

-122

-212

-222

1

B

A

2

C

G

6

6

4

F

3

5

Coded to

D

F or 3

5

E

4

Equipment plug

WEU 26/2 -113

-213

-123

-223

1

B

4

2

1

A

2

G

F

3

Coded to

C

6

A or

D

5

E

4

Equipment plug

WEU 26/2 -111

-211

1

B

A

2

C

G

6

4

6

5

F

3

Coded to

D

G or 2

5

E

4

Equipment plug

WEU 26/2 -121

-221

1

B

A

2

C

G

6

F

3

Equipment plug

Coded to

D

C or 6

5

E

4

Fig. 16: Wiring diagram WSU/WEU 26/2 for AC supply, interchangeable design

WSU 26/2 -114

B

C

A

+24V/L1 (1/2)

1

2

0V/N (3)

Test (10)

Test (11)

3

4

5

PE

(...) Terminals on electronic card (...) Terminals on electronic card

ABC

1 24 V n.c. Test

L 1

(1/2) (10)

2 0V n.c. Test

N

(3) (11)

3 n.c. n.c. n.c.

4 n.c. n.c. n.c.

5 n.c. n.c. n.c.

-214

-124

-224

-134

-234

WEU

B

C

A

1

+24V/L1 (1/2)

2

0V/N (3)

3

4

S1 (4)

S1 (5)

5

PE

ABC

1 24 V n.c. n.c.

L 1

(1/2)

2 0V n.c. n.c.

N

(3)

3 n.c. n.c. n.c.

4 S 1 Ö 1/2 S 2

(4) (6) (8)

5 S 1 Ö 1/2 S 2

(5) (7) (9)

26/2 -114

Ö1/2 (6)

S2 (8)

S2 (9)

Ö1/2 (7)

-214

-124

-224

-134

-234

Fig. 17: Pin assignment WSU/WEU 26/2, AC/DC version with equipment plug (15 + PE)

16

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 17

SICK WSU 26/2 – WEU 26/2

63

29.5

47

PG 13.5

For line dia. 6 ... 9 mm

Pay attention

to coding!

29,5

29.5

15.2

15,2

55,2

55.2

11

Plugs and sockets:

DIN 43651: 6 + PE

with crimp contacts

78

M 26 x 1.5

M 26x1,5

dia. 28

ø 28

straight

Order no. 6 006 612

Fig. 18: Cable receptacles 6 + PE

7,5

7.5

25,5

22.5

53

angled

Order no. 6 006 613

For line dia. 4 ... 11 mm

Important: Mark plug and socket

unambiguously! The WEU socket

must not be connected

to the WSU plug

In some cases no longer complies with

requirements for clearance and

creepage distances (VDE 0160 05/88

and VDE 0110); see selection table.

PG

16

54.5

54.5

Order no. 2 019 076

63

PG

13.5

29.5

29.5

47

Order no. 2 019 075

63

29.5

29.5

Fig. 19: Cable receptacles 15 + PE

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

17

Page 18

+24V

SICK WSU 26/2 – WEU 26/2

S1

2)

A1

A2PETo

C1 D1 PE C2 D2 PE T3 T4 C3 D3 PE C4 D4 14 24 32

PE T13 T14

X11 X12

WSU WEU

PE

1/2

10

11

3

PE

0V

+24V

Tes t

Tes t

+24V

0V

PE

1/2

4

8

9

5

3

PE

0 V

PE

Fig. 20: WSU/WEU 26/2 with Safety Interface LCU-X

k1

T21 T22

k2

X21 X22

K1

1)

x

y

k1

k2

x

13

23 31

y

z

k1

k2

z

K2

18

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 19

SICK WSU 26/2 – WEU 26/2

+24V

Start

10

WSU

1/2

311

+24V

Y32

Y35

1/2 4 8 6

WEU

3597

A1+ S52 S12 S22 S21 13 23 33 41 Y36

23

1

2

3

1

323

&

12 3

0V

0V

Outside switch cabinet separate line laying to receiver. Terminals 1, 3, 8 and 9 and 4, 5, 6 and 7 respectively in one plastic-sheathed

cable. Use PG 21 (order no. 5 305 978) and PG extension (order no. 5 306 052).

Fig. 21: WSU/WEU 26/2 with PNOZ 8 (Pilz); BIA-tested application no. 01131202933

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

S11 Y1 Y2 A3 14 24 34 42 Y37 A2

19

Page 20

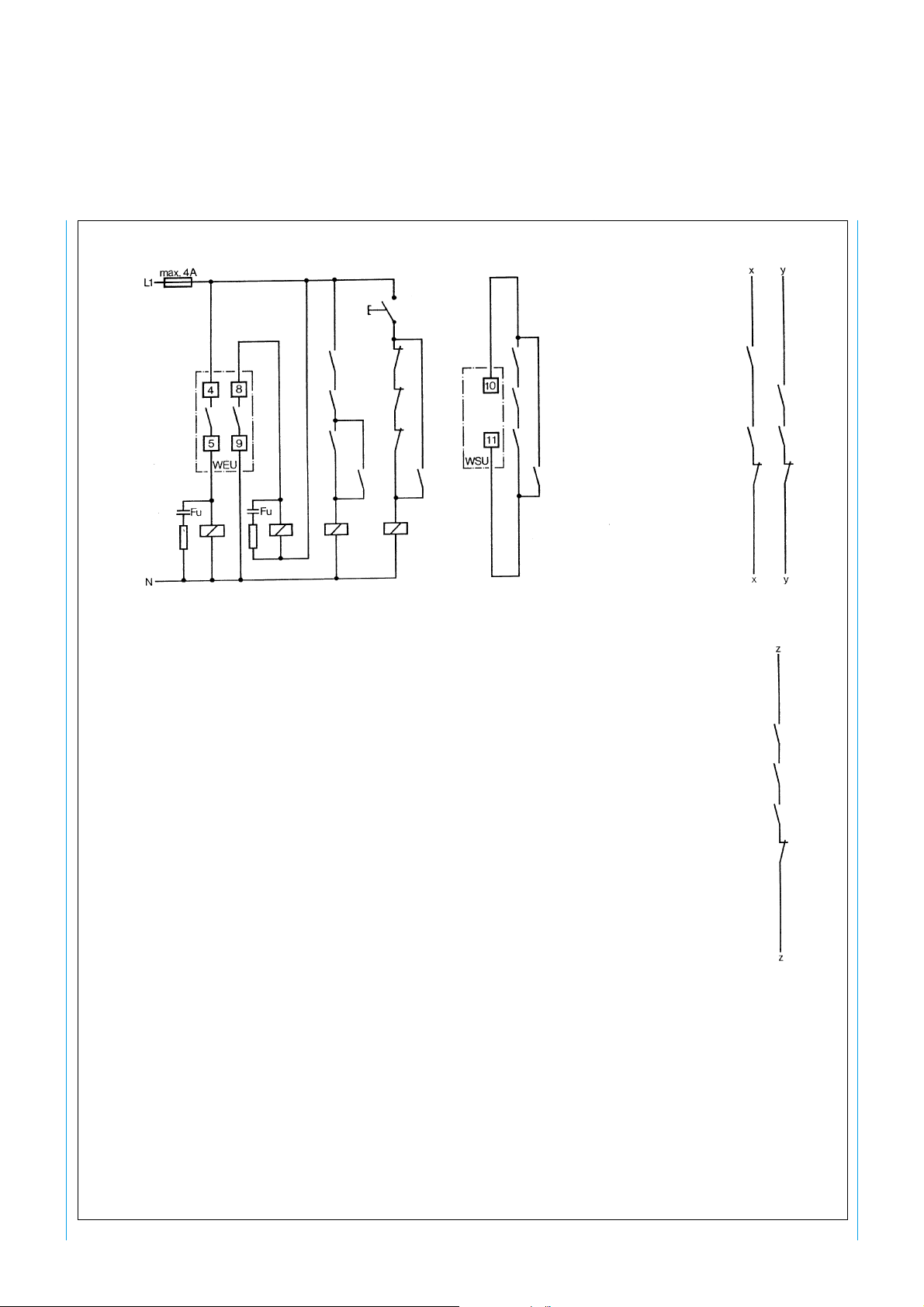

SICK WSU 26/2 – WEU 26/2

F

S

k 1

k 2

k 3

K 1 K 2 K 3 K 4

k 1

k 2

k 3

k 4

k 1

k 2

k 3

K1 to K4 Contactors or relays with positively-driven contacts

(not supplied)

Fu Arc-suppression, essential

S Command unit, e.g. pushbutton, key-operated switch etc.

Press button S to start, otherwise red LED on WEU remains lit.

x and y Insert in safe machine controller to interrupt the hazardous

movement. For safety reasons, the two contact rows (x and y)

must be inserted separately into the controller (two-channel).

z If, in exceptional cases, depending on the risk assessment, the

controller of the power-driven machinery is only of single-channel

design, contact row z can be used.

k 4

k 1

k 3

k 4

k 2

k 4

k 1

k 2

k 3

k 4

20

Fig. 22: Example of a connection with one WSU/WEU-26 system

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 21

SICK WSU 26/2 – WEU 26/2

F

k 1

k 1

k 2

k 2

k 3

k 3

k 4

k 4

k 5

k 5

k 6

k 6

K 1 K 2 K 3 K 4 K 5 K 6

K1 to K6 Contactors or relays with positively-driven contacts

(not supplied)

Fu Arc-suppression, essential

S Command unit, e.g. pushbutton, key-operated switch etc.

Press button S to start, otherwise red LED on WEU remains lit.

x and y Insert in safe machine controller to interrupt the hazardous

movement. For safety reasons, the two contact rows (x and y)

must be inserted separately into the controller (two-channel).

z If, in exceptional cases, depending on the risk assessment, the

controller of the power-driven machinery is only of single-channel

design, contact row z can be used.

k 1

k 3

k 5

k 6

k 2

k 4

k 5

k 6

k 1

k 3

k 5

k 6

k 2

k 4

k 5

k 6

k 1

k 2

k 3

k 4

k 5

Fig. 23: Example of a connection with two WSU/WEU-26 systems

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

k 6

21

Page 22

8 Commissioning

8 Commissioning

SICK WSU 26/2 – WEU 26/2

8.1 Alignment of WSU

and WEU

After checking the electrical

connections, loosen the fixing

screws on the WSU/WEU and

align the devices to each other

roughly using the alignment sight.

For further alignment keep pressing

button S or jumper terminals 10

and 11 on the WSU and switch on

the devices. When this is done the

LED on the WSU (yellow LED)

lights up (Fig. 24).

Align the devices to each other so

that the green and yellow LEDs on

the WEU light up.

For optimum alignment, ascertain

the limits of the emitting and

receiving ranges by swiveling the

WSU and WEU horizontally and

vertically one after the other. Just

before the limit of the optical range

the yellow LED on the WEU begins

to flash (Fig. 26). Beyond the

optical range the red LED on the

WEU lights up.

Then secure the WSU and WEU

respectively in the middle of the

resulting ranges. The yellow LED on

the WEU must be permanently lit.

8.3 Checking

Incorrect alignment may mean that

an obstacle is not detected or that

operational safety is not attained

investigate the diversion of the light

beam between the WSU and the

WEU (reflection may be occurring,

see 6.2 Detecting Reflections).

(Fig. 24).

The functional safety of the

photoelectric safety switch is

A function check of this kind must

be carried out

checked by breaking the light beam

continually and along its entire

length, from just in front of the

‡ daily prior to start of production,

‡ after any change in the WSU/

WEU back to the WSU (surface

area 100 mm x 100 mm). While

‡ after any servicing or

this check is being performed, the

red LED on the WEU must remain

continuously lit. If it does not,

Optical axis

Alignment sight

Fig. 24: Alignment with the aid of the alignment sight

WSU/WEU 26/2

Fixing screw M4 x 10

WEU configuration,

maintenance work on the

protective system.

8.2

Alignment of WSU

and WEU with

Alignment Aid AR 60

For precise alignment of the WSU

and WEU the alignment aid AR 60

is available.

The alignment aid is clamped in

front of the WSU and WEU

respectively on a bracket (Fig. 25),

which is mounted underneath the

optic and held in place by two

Adapter for

WSU/WEU 26/2

Alignment aid AR 60

screws.

The AR 60 emits a visible laser

beam which exactly marks the

optical axes of WSU and WEU if

they are correctly mounted.

22

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Fig. 25: Laser alignment aid AR 60 and WSU/WEU

Sender

optic

electronic

Receiver

Page 23

SICK WSU 26/2 – WEU 26/2

9 Maintenance

The front screens of the WSU and

WEU should be cleaned at regular

intervals, according to the site

conditions. The screens must only

be cleaned with a clean, soft cloth

or with cotton wool.

Use plastic cleaner as the cleaning

agent.

10 Commissioning

9 Maintenance

Since the WSU/WEU is a

protective system, it is

recommended that the system be

commissioned into operation by an

expert. Experts are deemed to be

only persons trained in the handling

of such safety equipment who are

11 Malfunctions

11.1 Diagnostic Elements

The LEDs on the WSU and WEU

indicate the following operating

states (Fig. 26):

‡ employees of SICK,

‡ employees of SICK subsidiaries

and representatives abroad,

WSU

yellow

Fig. 26: LEDs of the WSU and WEU

‡ employees of companies who

operate large quantities of SICK

safety equipment at their

premises, provided they have

been trained by SICK and have

been assigned by their

employers to perform such

duties.

WEU

green yellow red

Continuously lit yellow Operating voltage applied (test contact closed)

Off yellow No operating voltage applied or test active (For duration of test)

Continuously lit green Light beam of sender unit reaching receiver

yellow Sufficient light received

red Light beam broken, briefly during test

yellow + red Interference of another emitter element

Flashing yellow Insufficient light received, unit still functioning

Off green No operating voltage applied, light beam broken, test performed

yellow Light beam broken, testing performed, no operating voltage applied

red No operating voltage applied, light received from sender

Tab. 4: Functioning of the LEDs

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

23

Page 24

Simple malfunctions can be rectified

by referring to the chart below.

Before opening up the units clean

the housing thoroughly to prevent

dirt entering the interior.

SICK WSU 26/2 – WEU 26/2

Do not touch any electrical connections when the unit is open

and switched on.

Fault

LED on WSU not lit

LED on WSU lit,

none of the three LEDs

on the WEU lit

The red LED on the WEU

is permanently lit

(no light being received)

The yellow LED on the WEU flashes

(insufficient light being received)

The yellow and red LEDs

on the WEU are permanently lit

Cause

No power supply

Break between terminals 10 and 11

(test contact)

No power supply on WEU

Break at relay contact

Relay defective

Unit out of alignment

Front screen dirty

Test input (sender) interrupted

Receiver WEU defective

Sender WSU not emitting

Sender WSU defective

Units or corner mirrors out of alignment

Front screen of WSU/WEU or corner

mirror dirty

Electronics activated:

Interference of another emitter element

Electronic card defective

Testing and remedy

Check voltage

Check passage

Check voltage on WEU

Replace unit

Re-align WSU and WEU units

Clean front screens of WSU and WEU

Check testing

Replace unit

On WSU briefly switch power off and

on again (min. 1 s)

Replace unit

Adjust units or corner mirrors to

optimum alignment

Clean front screen or corner mirror

On WEU briefly switch power off and

on again (min. 1 s)

WEU must only respond to the

corresponding WSU

Replace unit

.

24

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 25

SICK WSU 26/2 – WEU 26/2

12 Technical Data WSU 26/2 / WEU 26/2

Dimensions

Protective field range 0.5 ... 18 m, 15 ... 70 m

Number of beams 1 beam

Light beam diameter 23 mm

Sender/receiver unit

Supply voltage (Uv) 24 V DC ± 20 %

230 V DC ± 10 % / - 15 %

115 V DC ± 10 % / - 15 %

Ripple Max. 5 % of U

Frequency 48 ... 62 Hz with AC version

Input, sender Test contact

Test time max. 150 ms

Min. opening time of NC

contact for test 75 ms

Power consumption (typical)

Voltage version 24 V 115 V 230 V

Sender unit 4 W 7 W 7 W

Receiver unit 6 W 10 VA 10 VA

Synchronization Optical

Outputs Relay max. operating frequency 0.2 Hz

(1 operation in 5 s)

Switching current (max./min.) 2 A / 0.02 A

Switching voltage (max./min.) 250 V AC / 24 V DC

Response time ≤ 22 ms

Connection cable: PG connector: IP 67

Connection plug: IP 65

Front screen heating As standard

Operating data

Protection class I

Enclosure rating IP 65 (connection plug)

IP 67 (PG connector)

Safety category Satisfies type 4 requirements

Requirements To pr EN 61496 Part I/Part II

Ambient operating

temperature – 25 ... + 55 °C

Storage temperature – 25 ... + 70 °C

Air humidity 15 ... 95 %

Vibrostability 5 g, 10 ... 55 Hz to IEC 68-2-6

Impact resistance 10 g, 16 ms to IEC 68-2-29

Weight Sender unit Approx. 0.9 ... 1.3 kg

Receiver unit Approx. 1.0 ... 1.4 kg

V

12 Technical Data

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

25

Page 26

13 Dimensional Drawing

13 Dimensional Drawing

SICK WSU 26/2 – WEU 26/2

50

65

156

65

14

PG13.5

Dimensional Drawing WSU 26/2-xx0 and WEU 26/2-xx0

34

17.5

128

15.5

116

65

95

96

26

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 27

SICK WSU 26/2 – WEU 26/2

156

65

65

14

50

34

128

15.5

65

95

96

116

81

50 mm

approx.

Dimensional Drawing WSU 26/2-xx4 and WEU 26/2-xx4

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

27

Page 28

SICK WSU 26/2 – WEU 26/2

156

65

65

14

50

34

128

15.5

65

95

96

116

100

50 mm

approx.

Dimensional Drawing WSU 26/2-xx1 and -xx3 and WEU 26/2-xx1, -xx2 and -xx3

28

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 29

SICK WSU 26/2 – WEU 26/2

6.5

65

51

82

65

51

6.5

6

64.5

64.5

20°

46.5

39.5

60°

67

124

149

38

14

96

100

Corner mirror PSK 1

Order number 1 005 229

9

9

Mounting bracket

Order number 2 007 900

160

177

ø 7

8.5

2.5

10

20

26

40

43

22

M6

16.5

M 8x30 SW 13

M 8x45 SW 13

33.5

63

Bracket for corner mirror PSK 1

Order number 2 009 292

+0.2_

7

44.5

14

30

12

_

+0.5

190

160 Mirror length

+0,1

Ø 20

58

71

M6

+0.5

_

40.5

+1

_

95

Mirror width

105

_

+0.2

135

+2

156

Corner mirror PNS 105-1

Order number 1 004 076

76

40

40.5

8.5

Corner mirror PSK 45

Order number 5 306 053

146.5

80

96.5

45˚

8.5

69.5

Center of

mirror surface

63

8.5

80

Mounting set for PSK 1

Order number 2 012 473

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

29

Page 30

50.5

SICK WSU 26/2 – WEU 26/2

119

4

Snow shield

65.5

65

12.3

7

3

Order number 1 003 619

50.5

65.565

73

4

11.8

140

Dust shield

Order number 1 003 556

30

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 31

SICK WSU 26/2 – WEU 26/2

14 At a glance: What is new about the WSU/WEU 26/2 in relation to the WSU/WEU 26?

Previously: WSU 26 / WEU 26

Now: WSU 26/2 / WEU 26/2

‡ The optical axis of the WSU/WEU

26/2 is shifted 6 mm toward the

device connection.

‡ There are two terminals for

connection of the power supply:

terminal 1/2 and terminal 3.

‡ Voltage versions

230 V AC

115 V AC

24 V DC

‡ A new adapter is required for

AR 60.

‡ No fiber-optic cable version is

available.

‡ An additional marking on the side

identifies the middle of the beam.

‡ The scanning ranges have changed:

WSU/WEU 26 WSU/WEU 26/2

0.5 ... 30 m 0.5 ... 18 m

30 ... 60 m 15 ... 70 m

For each range segment there is a

sender and a receiver.

‡ The beam diameter has changed:

WSU/WEU 26 WSU/WEU 26/2

33 mm 23 mm

‡ Connector version: the previous

connector no longer complies with

requirements for clearance and

creepage distances (VDE 0160 05/

88 and VDE 0110).

‡ New front screen: may only be

cleaned with plastic cleaner.

‡ The power consumption has

increased:

WSU/WEU 26 WSU/WEU 26/2 Version

5 VA / 7 VA 7 VA / 10 VA 115/230 V AC

3 W / 5 W 4 W / 6 W 24 V DC

‡ Response time

WSU/WEU 26: 20 ms

WSU/WEU 26/2: 22 ms

Components of the (new) WSU/

WEU 26/2 system cannot be

combined with components of the

(old) WSU/WEU 26 system. When

exchanging in the event of repair

please note that the following

combinations are not possible:

WSU 26 with WEU 26/2

WSU 26/2 with WEU 26

Exchange in pairs.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

31

Page 32

15 Selection Table

SICK WSU 26/2 – WEU 26/2

15 Selection Table WSU / WEU

Voltage Scanning Termination Sender unit Receiver unit

range type Type Order number Type Order number

230 V AC 0.5 ... 18 m PG WSU 26/2-110 1 015 615 WEU 26/2-110 1 015 616

Plug WSU 26/2-111 1 015 712 WEU 26/2-111 1 015 713

Plug *) WSU 26/2-113 1 015 715 WEU 26/2-113 1 015 715

Plug *) WEU 26/2-112 1 015 714

Plug 15 + PE*) WSU 26/2-114 1 015 834 WEU 26/2-114 1 015 835

15 ... 70 m PG WSU 26/2-210 1 015 731 WEU 26/2-210 1 015 743

Plug WSU 26/2-211 1 015 733 WEU 26/2-211 1 015 744

Plug *) WSU 26/2-213 1 015 736 WEU 26/2-213 1 015 748

Plug *) WEU 26/2-212 1 015 746

Plug 15 + PE*) WSU 26/2-214 1 015 840 WEU 26/2-214 1 015 841

115 V AC 0.5 ... 18 m PG WSU 26/2-120 1 015 717 WEU 26/2-120 1 015 718

Plug WSU 26/2-121 1 015 719 WEU 26/2-121 1 015 720

Plug *) WSU 26/2-123 1 015 723 WEU 26/2-123 1 015 722

Plug *) WEU 26/2-122 1 015 721

Plug 15 + PE*) WSU 26/2-124 1 015 836 WEU 26/2-124 1 015 837

15 ... 70 m PG WSU 26/2-220 1 015 738 WEU 26/2-220 1 015 749

Plug WSU 26/2-221 1 015 740 WEU 26/2-221 1 015 750

Plug *) WSU 26/2-223 1 015 737 WEU 26/2-223 1 015 505

WEU 26/2-222 1 015 751

Plug 15 + PE*) WSU 26/2-224 1 015 842 WEU 26/2-224 1 015 843

24 V DC 0.5 ... 18 m PG WSU 26/2-130 1 015 724 WEU 26/2-130 1 015 725

15 ... 70 m PG WSU 26/2-230 1 015 745 WEU 26/2-230 1 015 504

*) See electrical wiring diagram

Selection of plug variant,

WSU/WEU

Since 1989 VDE 0160 05/88 and

VDE 0110 have stipulated doubled

clearance and creepage distances. In

the following cases the necessary

clearance and creepage distances of

the 6-PE Hirschmann connecting

plug on the WEU are not met:

32

Plug WSU 26/2-131 1 015 726 WEU 26/2-131 1 015 727

Plug *) WSU 26/2-133 1 015 730 WEU 26/2-133 1 015 729

Plug *) WEU 26/2-132 1 015 728

Plug 15 + PE*) WSU 26/2-134 1 015 838 WEU 26/2-134 1 015 839

Plug WSU 26/2-231 1 015 747 WEU 26/2-231 1 015 753

Plug *) WSU 26/2-233 1 015 739 WEU 26/2-233 1 015 755

Plug *) WEU 26/2-232 1 015 754

Plug 15 + PE*) WSU 26/2-234 1 015 844 WEU 26/2-234 1 015 845

Supply voltage Voltage at WEU Remarks

WEU output relays

230 V AC 230 V AC Only in case of separated

circuits/phases (e.g. L1 to L2)

230 V AC 024 V DC –

024 V DC 230 V AC –

In order to meet the VDE requirements for clearance and creepage

distances in these cases, the square 15-pin + PE plug must be used.

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 33

SICK WSU 26/2 – WEU 26/2

14.1 Conversion List

WSU to be Nex type 26/2

replaced Scanning range 0.5 ... 18 m Scanning range 15 ... 70 m

WSU 26-110 WSU 26/2-110 1 015 615 WSU 26/2-210 1 015 731

WSU 26-111 WSU 26/2-111 1 015 712 WSU 26/2-211 1 015 733

WSU 26-112 WSU 26/2-113 1 015 716 WSU 26/2-213 1 015 736

WSU 26-120 WSU 26/2-120 1 015 717 WSU 26/2-220 1 015 738

WSU 26-121 WSU 26/2-121 1 015 719 WSU 26/2-221 1 015 740

WSU 26-130 WSU 26/2-130 1 015 724 WSU 26/2-230 1 015 745

WSU 26-131 WSU 26/2-131 1 015 726 WSU 26/2-231 1 015 747

WSU 26-132 WSU 26/2-133 1 015 730 WSU 26/2-233 1 015 739

WSU 26-210 WSU 26/2-210 1 015 731

WSU 26-211 WSU 26/2-211 1 015 733

WSU 26-212 WSU 26/2-213 1 015 736

WSU 26-220 WSU 26/2-220 1 015 738

WSU 26-221 WSU 26/2-221 1 015 740

WSU 26-230 WSU 26/2-230 1 015 745

WSU 26-231 WSU 26/2-231 1 015 747

WSU 26-232 WSU 26/2-233 1 015 739

old

WEU to be New type 26/2

replaced Scanning range 0.5 ... 18 m Scanning range 15 ... 70 m

WEU 26-710 WEU 26/2-110 1 015 616 WEU 26/2-210 1 015 743

WEU 26-712 WEU 26/2-112 1 015 713 WEU 26/2-211 1 015 744

WEU 26-713 WEU 26/2-113 1 015 715 WEU 26/2-213 1 015 748

WEU 26-720 WEU 26/2-120 1 015 718 WEU 26/2-220 1 015 749

WEU 26-730 WEU 26/2-130 1 015 725 WEU 26/2-230 1 015 504

WEU 26-731 WEU 26/2-131 1 015 727 WEU 26/2-231 1 015 753

WEU 26-732 WEU 26/2-132 1 015 728 WEU 26/2-232 1 015 754

WEU 26-733 WSU 26/2-133 1 015 729 WEU 26/2-233 1 015 755

old

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

33

Page 34

16 Selection Table, Accessories

16 Selection Table, Accessories

Description Order number

Alignment aid AR 60, complete 1 015 741

Adapter for alignment aid AR 60 4 031 156

Mounting bracket for WSU/WEU 2 007 900

Corner mirror PSK 1, for scanning range 0.5 ... 18 m 1 005 229

Mounting set for PSK 1 2 012 473

Hinged bracket for corner mirror PSK 1 (x 1) 2 009 292

Corner mirror PNS 105-1, for scanning range 15 ... 70 m 1 004 076

Corner mirror PSK 45 5 306 053

Cable receptacle, straight, 6 + PE (plastic) 6 006 612

Cable receptacle, angled, 6 + PE (plastic) 6 006 613

Cable receptacle, 15 + PE, lateral cable outlet, PG 16 2 019 076

Cable receptacle, 15 + PE, straight cable outlet, PG 13.5 2 019 075

Arc-suppression element 0.22 µF + 220 Ω (115 ... 230 V) 6 001 224

Arc-suppression element 2.2 µF + 100 Ω (24 V) 6 001 225

Switching amplifier LCU-X 24 V DC 1 013 410

Switching amplifier (PILZ)

Switching amplifier PST 1 24 V DC 6 010 808

230 V AC 6 010 809

SICK WSU 26/2 – WEU 26/2

Switching amplifier PST 3 24 V DC 6 008 424

Switching amplifier PNOZ 8 24 V DC 6 010 810

PG cable gland PG 21 5 305 978

for use of 2 cables with PNOZ 8

PG extension PG 13.5 to PG 21 5 306 052

for use of 2 cables with PNOZ 8

230 V AC 6 008 423

230 V AC 6 010 811

34

8 008 692/9-12-99 Technical Description · WSU/WEU 26-2 © SICK AG · Safety Systems · Germany · All rights reserved

Page 35

SICK AG · Safety Systems · P.O. Box 310 · D-79177 Waldkirch

Phone +49 76 81/2 02-0 · Fax +49 76 81/2 02-38 15 · http://www.sick.de

8 008 692/9-12-99 · KF · KF · Printed in Germany (1299)

·

Subject to change without prior notice

E 2.02

Your contacts:

Australia

Phone +61/3 94 97 4100

008/33 4802 – toll free

Fax +61/3 94 9711 87

Austria

Phone +43/2 23 66 2288-0

Fax +43/2 23 6622 88-5

Belgium/Luxembourg

Phone +32/24 66 55 66

Fax +32/24 66 6026

Brazil

Phone +55 11/55 61 2683

Fax +5511/5354153

China/Hong Kong

Phone +8 52/27 63 6966

Fax +8 52/27 6363 11

Czech Republik

Phone +42 /02 578 10561

Fax +42 /02 57810 559

Denmark

Phone +45/45 82 64 00

Fax +45/45 82 6401

Finland

Phone +3 58/9-728 85 00

Fax +3 58/9-72 88 50 55

France

Phone +33/1-64 62 35 00

Fax +33/1-64 62 3577

Germany

Phone +49 7681/2 02-0

Fax +49 76 81/2 02-3815

Great Britain

Phone +44/17 27-83 11 21

Fax +44/17 27-85 6767

Italy

Phone +3 90/2-92 14 20 62

Fax +3 90/2-92 14 20 67

Japan

Phone +8 13/33 58-13 41

Fax +8 13/33 58-05 86

Netherlands

Phone +31/30 229 25 44

Fax +31/30 229 39 94

Norway

Phone +47/67 56 75 00

Fax +47/67 56 6610

Poland

Phone +48/2 26 44 8345

Fax +48/2 26 4483 42

Singapore

Phone +65/7 44 37 32

Fax +65/8 41 7747

Spain

Phone +34/93 4 80 3100

Fax +34/93 4 7344 69

Sweden

Phone +46/8-6 80 64 50

Fax +46/8-7 10 1875

Switzerland

Phone +41/4 16 19 2939

Fax +41/4 16 1929 21

Taiwan

Phone +88 62/23 65 6292

Fax +88 62/23 6873 97

USA

Phone +16 12/9 41-67 80

Fax +16 12/9 41-9287

Representatives and agencies

in all major industrial nations.

Loading...

Loading...