Page 1

WI180C-EC

WI180C-EC EtherCAT coupler

O P E R A T I N G I N S T R U C T I O N

Page 2

Described product

2006/42/EC

NO

SAFETY

WI180C-EC

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Purpose of this document........................................................................ 5

1.2 Target group.............................................................................................. 5

1.3 Information depth..................................................................................... 5

1.4 Explanation of symbols............................................................................ 5

1.5 Product information.................................................................................. 6

1.6 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Correct use................................................................................................ 7

2.3 Forseeable misuse................................................................................... 7

3 Product description........................................................................... 8

3.1 Product characteristics............................................................................ 8

3.2 Setup and function................................................................................... 8

3.3 Interfaces.................................................................................................. 8

3.3.1 EtherCAT................................................................................... 8

3.3.2 Power supply............................................................................ 9

3.3.3 Grounding................................................................................. 9

4 Transport and storage....................................................................... 10

4.1 Transport................................................................................................... 10

4.2 Storage...................................................................................................... 10

5 Mounting............................................................................................. 11

5.1 Required materials................................................................................... 11

5.2 Preparing mounting location.................................................................... 11

5.3 Scope of delivery....................................................................................... 11

5.4 Mounting procedure................................................................................. 11

5.5 Connecting the device.............................................................................. 12

6 Commissioning.................................................................................. 13

6.1 Parameterization....................................................................................... 13

6.2 Switching on.............................................................................................. 13

7 Operation............................................................................................ 14

7.1 Safety......................................................................................................... 14

7.2 Daily thorough check................................................................................ 14

7.3 LED status indicators............................................................................... 14

7.4 Device slots and modules........................................................................ 15

7.5 Cyclic data (process data)........................................................................ 16

7.6 Acyclic data (service data)........................................................................ 17

7.7 Object library............................................................................................. 17

7.7.1 Standard objects..................................................................... 18

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

3

Page 4

CONTENTS

7.7.2 Module data............................................................................. 20

7.7.3 Coupler data............................................................................. 21

7.7.4 WLL180T.................................................................................. 23

7.7.5 KTL180..................................................................................... 25

7.7.6 OD1 on AOD1........................................................................... 27

7.7.7 OL1 on AOD1............................................................................ 31

8 Diagnosis............................................................................................ 35

9 Decommissioning............................................................................. 36

9.1 Dismantling............................................................................................... 36

9.2 Disposal..................................................................................................... 36

10 Technical data.................................................................................... 37

10.1 Dimensional drawings.............................................................................. 37

10.2 Technical data........................................................................................... 37

10.3 UL Satisfaction Ratings............................................................................ 39

10.4 Ordering information, accessories........................................................... 39

4

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Purpose of this document

These operating instructions contain information required during the life cycle of the

device.

These operating instructions must be made available to all those who work with the

device.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the device.

1.2 Target group

These operating instructions are intended for the following target groups: Project devel‐

opers (planners, developers, designers), installers, electricians, programmers, opera‐

tors and maintenance personnel.

The structure of these operating instructions is based on the life-cycle phases of the

device: Project planning, mounting, electrical installation, commissioning, operation,

maintenance and disposal.

ABOUT THIS DOCUMENT 1

1.3 Information depth

These operating instructions contain information about the following topics relating to

the device:

Product description

•

Mounting

•

Electrical installation

•

Commissioning and configuration

•

Furthermore, when planning and using sensors such as the device, technical expertise

is required, which is not covered in this document.

Official and legal regulations for operating the device volume measurement system

must always be complied with.

You can find further information on the Internet at www.sick.com.

1.4 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.5 Product information

Table 1: Product information

Product name WI180C-EC

Article number 6068089

Device version EtherCAT

Manufacturer SICK AG

1.6 Further information

www.sick.com

The following information is available on the Internet:

Other language versions

•

Data sheets and application examples

•

CAD data of drawings and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Current device files

•

6

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 General safety notes

The mounting, electrical installation and configuration of the device must be car‐

•

ried out by professionally qualified personnel only.

Before mounting, it is imperative that you familiarize yourself with the operating

•

instructions for the connected devices.

When mounting and electrical installation work is being carried out, always comply

•

with applicable health and safety and environmental regulations.

The device must not be used outdoors or in areas with flammable/explosive

•

atmospheres!

When installing the device, always consider the electrical connected loads.

•

Replace faulty or damaged cables and male connectors immediately.

•

Replace damaged or faulty couplers immediately.

•

When mounting the device, it is imperative that you use suitable mounting equip‐

•

ment and that you consider their specific requirements.

Ensure a constant power supply to the device within the set parameters.

•

Only operate the device within the set operating parameters.

•

Regularly check that the device is functioning properly.

•

Structural modifications to the device are not permitted.

•

The device is not designed as a safety product.

•

This device complies with the Radio Safety Requirements (EMC) for the industrial

•

sector (Radio Safety Class A). It may cause radio interference if used in a residen‐

tial area.

SAFETY INFORMATION 2

2.2 Correct use

Correct use requires that the device is used industrially indoors without any specific cli‐

matic and atmospheric requirements. Any use outside of the areas mentioned in each

case will be considered to be incorrect use and void any warranty claims against

SICK AG.

2.3 Forseeable misuse

Not taking account of the pin assignment or using an incorrect adapter cable may dam‐

age or destroy the connected EtherCAT coupler.

Connecting the EtherCAT coupler to signal or power cables that are too long may lead to

a loss of data and damage to the EtherCAT coupler.

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

7

Page 8

1

2

3

6

5

4

1

43

2

3 PRODUCT DESCRIPTION

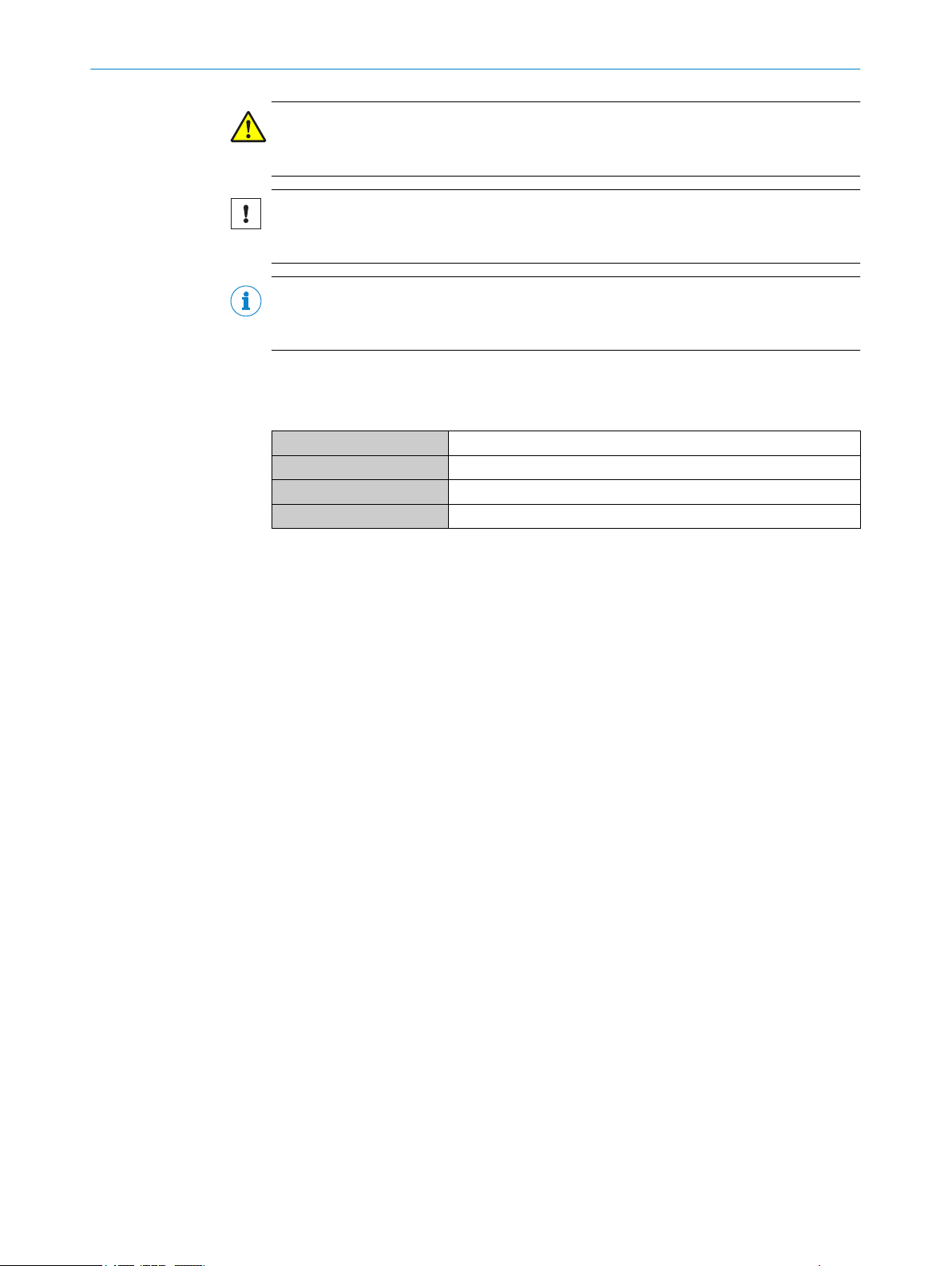

3 Product description

3.1 Product characteristics

The device is an interface coupler that can be used to connect connected devices (e.g.

WLL180T) to the EtherCAT network. The relevant devices are connected via a simple

plug system on the side of the coupler.

Normally the entire system is installed on a mounting rail near the application.

The coupler supports up to 16 connected devices, which are likewise connected to one

another via the plug system.

Further properties:

EtherCAT slave

•

Configuration via CoE protocol (CANopen over EtherCAT)

•

2 Ethernet connections with transmission rate of 100 Mbaud

•

Further specifications can be found in the technical data (see "Technical data",

page 37).

3.2 Setup and function

Bus male connector (system bus)

1

Service port

2

Power supply connection (M8), 4-pin

3

D-coded M12 connector, 4-pin, EtherCAT

4

D-coded M12 connector, 4-pin, EtherCAT

5

Status LEDs

6

3.3 Interfaces

3.3.1 EtherCAT

8

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Table 2: EtherCAT pin assignment

Pin Pin assignment

1 Tx+

2 Rx+

Subject to change without notice

Page 9

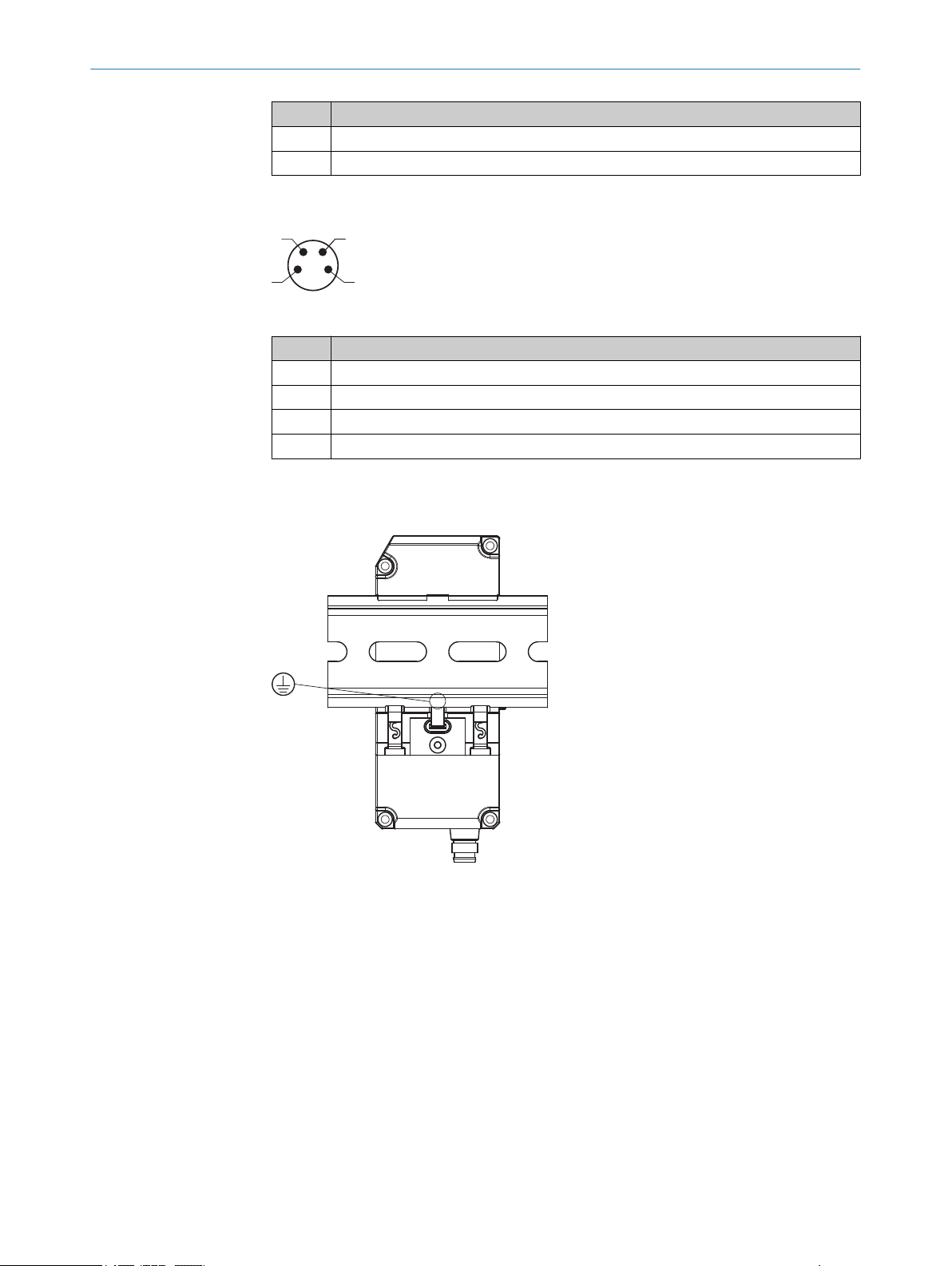

3.3.2 Power supply

2 4

1

3

3.3.3 Grounding

PRODUCT DESCRIPTION 3

Pin Pin assignment

3 Tx-

4 Rx-

Table 3: Power supply pin assignment

Pin Pin assignment

1 +12 – 24 VDC

2 Not assigned

3 GND

4 Not assigned

The device is grounded via the mounting rail by means of a spring contact:

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

9

Page 10

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

Either transport the device in the original packaging or use a padded transport con‐

tainer. Make sure that you comply with the maximum permitted environmental condi‐

tions (see "Technical data", page 37).

4.2 Storage

If you want to store the devicefor a relatively long time, pack it as you would for trans‐

port. Make sure that the storage location complies with the permitted environmental

conditions (see "Technical data", page 37).

10

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 11

5 Mounting

1

2

5.1 Required materials

You need the following additional materials to mount the device:

grounded mounting rail (pre-mounted)

•

pre-assembled cable (max. 30 m) with M8 female connector (see "Interfaces",

•

page 8)

pre-assembled cable for EtherCAT with M12 D-coded male connector (see "Inter‐

•

faces", page 8)

one or more signal sources (e.g. WLL180T)

•

small slotted screwdriver

•

MOUNTING 5

5.2

Preparing mounting location

1. Mount a grounded mounting rail in the same area as the application.

2. Lay the two pre-assembled cables so that they can easily be connected to the con‐

nections of the device. If necessary, use cable channels, cable ties and cable

grips.

5.3 Scope of delivery

WI180C-EC

•

Quick start instructions

•

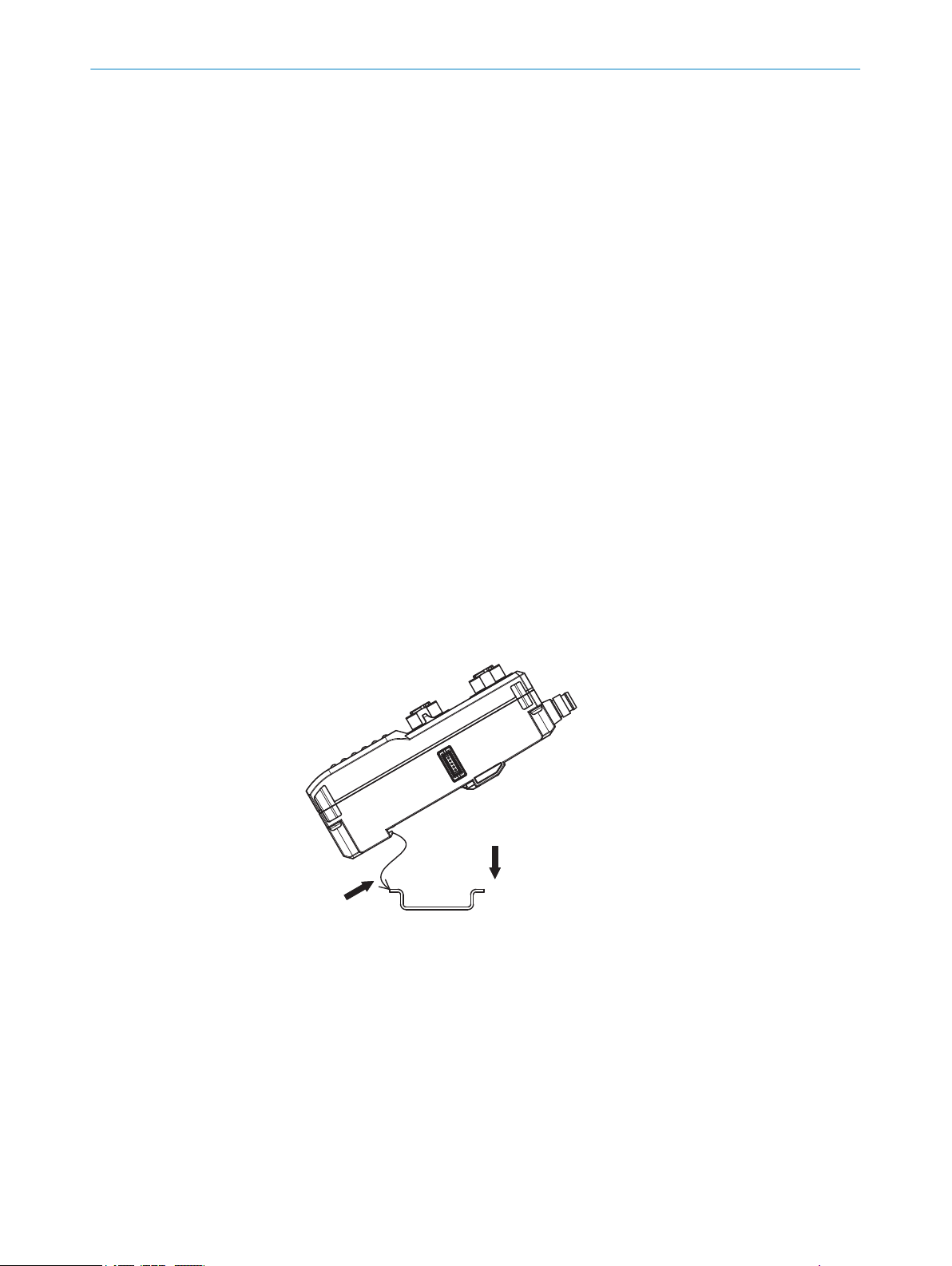

5.4 Mounting procedure

1. Carefully unpack the device.

2. Clamp the device onto the mounting rail, as shown in the image.

3. Clamp the series-connected devices onto the mounting rail as shown in their

mounting instructions.

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

11

Page 12

5 MOUNTING

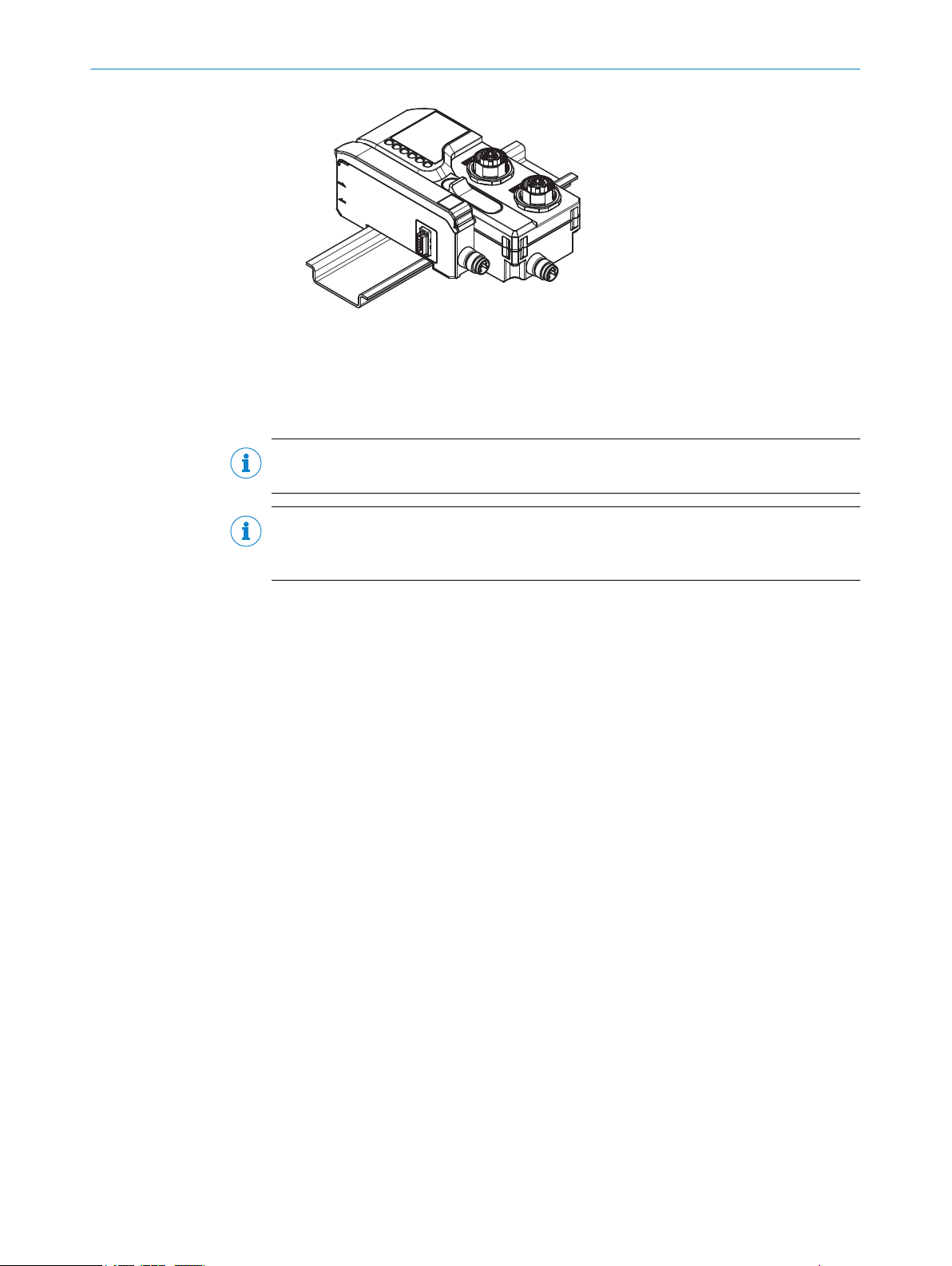

4. Push the series-connected devices onto the 5-pin connection on the left side of

the device. Make sure that the sequence is correct.

5. Fix the connected devices on the mounting rail without any spaces.

5.5 Connecting the device

NOTE

Switch off the voltage supply before you connect or replace the devices.

NOTE

Select the right EtherCAT connection for your network. Connection 1 has the function of

the “EtherCAT IN port”, connection 2 has the function of the “EtherCAT OUT port”.

1. Connect the D-coded M12 male connector for the EtherCAT network to the Ether‐

CAT connection on the device, and fasten it with the coupling nut.

2. Connect the M8 female connector to the voltage supply on the bottom of the

device and tighten the corresponding male connector.

1)

1)

see the operating instructions for the relevant device

12

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 13

6 Commissioning

6.1 Parameterization

The WI180C-EC can be integrated in a Beckhoff control system. An ESI file is loaded in

the system for this purpose. The ESI file for the WI180C-EC is available for download

from www.sick.de.

NOTE

All configuration information relates to controls manufactured by Beckhoff, which are

configured and diagnosed with the TwinCAT™ configuration tool.

1. Copy the ESI file in the TwinCAT™ directory into the TwinCAT\3.1\Config\IO\Ether‐

CAT folder.

2. Then restart the TwinCAT™ system manager.

3. Insert WI180C-EC into the device tree as a box.

4. For this purpose, select the WI180C-EC under SICK AG.

The WI180C-EC is shown in the device tree as box n.

5. Then switch the TwinCAT™ system manager to configuration mode.

You will be asked in sequence whether the TwinCAT system manager™ should be

switched to configuration mode, whether the data should be loaded from the I/O

device, and whether the system should be switched to Free Run operating mode.

6. Click OK or Yes in each instance.

The status display at the bottom right changes between Free Run in red and Config

Mode in blue. All object parameters can now be read out and configured on the

CoE - Online tab.

COMMISSIONING 6

6.2 Switching on

1. Switch on the power supply for the device.

2. Wait approximately two seconds until the device indicates that it is ready, see "LED

status indicators", page 14.

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

13

Page 14

1

2

3

4

5

6

7 OPERATION

7 Operation

7.1 Safety

A few guidelines must be followed to ensure the operational safety of the device:

Carry out a daily functional check (see "Daily thorough check", page 14).

•

If you want to connect devices to the device or remove devices, switch off the

•

power supply first.

Only operate the WI180C-EC under the specified operating conditions (see "Tech‐

•

nical data", page 37).

7.2 Daily thorough check

You should carry out the following functional checks once a day:

Check the function of the LED indicators.

•

Use appropriate status queries to check communication with each of the con‐

•

nected devices.

7.3 LED status indicators

14

Table 4: LED status indicators

LED Display Meaning

PWR Green

1

ERR (error) Red

2

RUN (operation) Green

3

STATUS Green

4

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

O

o

o

Single flash Local error in the device

Double flash Timeout in the device

O

Ö

o

O

Ö

o

O

Voltage supply on

Voltage supply off

No error

Application controller fault

Invalid configuration

Device initializes

Device has OPERATIONAL status

Device has PRE-OPERATIONAL status

Device not configured

Device is running

Subject to change without notice

Page 15

LED Display Meaning

1 2 3 16

L/A1 (Link/Activ‐

5

ity 1)

L/A2 (Link/Activ‐

6

ity 2)

7.4 Device slots and modules

WI180C-EC uses the EtherCAT “Modular Device Profile” (MDP) and every connected

device occupies one or more module slots.

The module slots 1 to 16 represent the connected devices, as shown in the figure

below.

Green

Green

o

O

Ö

o

O

Ö

OPERATION 7

No network connection at connection 1

Network connection at connection 1 avail‐

able, no communication

Network connection, communication

active

No network connection at connection 2

Network connection at connection 2 avail‐

able, no communication

Network connection, communication

active

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

The WI180C-EC supports up to 16 device modules. The following products are sup‐

ported:

Table 5: Supported products

Supported products Product description Note

WLL180T-L*

WLL180T-M*

WLL180T-E*

WLL180T-F*

Fiber amplifier basic device

Fiber amplifier expansion

module

The WLL180T basic device

•

can be installed only as

Module 1 (on the far out‐

side left of the mounting

rail)

No additional voltage supply

•

is required for the WLL180T

device

The WLL180T basic device

•

can be installed only as

Module 2 to Module 16

No additional voltage supply

•

is required for the WLL180T

device

15

Page 16

7 OPERATION

Supported products Product description Note

OD1 at one input of AOD1-M Displacement sensor

Evaluation unit basic device

OL1 at one input of AOD1-M Displacement sensor

Evaluation unit basic device

•

•

•

•

OD1 at one input of AOD1-S Displacement sensor

Evaluation unit expansion

module

OL1 at one input of AOD1-S Displacement sensor

Evaluation unit expansion

module

•

•

•

•

KTL180-ML*

KTL180-MM*

Fiber contrast sensor basic

device

•

•

KTL180-ME*

KTL180-MF*

Fiber contrast sensor expan‐

sion module

•

•

For each AOD1 unit con‐

nected, the number of plug‐

gable modules decreases

by one (max. 8 AOD1

devices possible)

If AOD1 and WLL180T are

used in combination with

WI180C-EC, all WLL180T

devices must be placed on

the left of AOD1

The AOD1-M basic device

can be installed only as

Module 1/2 (on the far out‐

side left of the mounting

rail)

Voltage supply required for

the AOD1-M device

For each AOD1 unit con‐

nected, the number of plug‐

gable modules decreases

by one (max. 8 AOD1

devices possible)

If AOD1 and WLL180T are

used in combination with

WI180C-EC, all WLL180T

devices must be placed on

the left of AOD1

The AOD1-S expansion

module can be installed

only as Module 3/4 to Mod‐

ule 15/16

Voltage supply required for

the AOD1-S device

The KTL180 basic device

can be installed only as

Module 1 (on the far out‐

side left of the mounting

rail)

No additional voltage supply

is required for the KTL180

device

The KTL180 expansion

module can be installed

only as Module 2 to Mod‐

ule 16

No additional voltage supply

is required for the KTL180

device

7.5 Cyclic data (process data)

WI180C-EC supports both “Transmit PDOs” (WI180C-EC to control) and “Receive PDOs"

(control to WI180C-EC). The PDOs are permanently implemented in the WI180C-EC and

it is not possible to map any other objects than the predefined objects. The minimum

PDO cycle time is 1000 µs.

16

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 17

7.6 Acyclic data (service data)

WI180C-EC supports the “CANopen over EtherCAT” (CoE) protocol for transmission of

service data. Service data objects (SDO) form the communication channel through

which device parameters are transmitted (e.g. programming switching thresholds).

Transmission of these parameters to SDOs is acyclic (i.e. takes place just once when

starting up the network). The objects of the object library (see "Object library",

page 17) can be accessed with the SDOs.

NOTE

It is possible to access the device parameters of every connected device via SDOs. The

specific addressing for each module depends on which modules were configured in the

control software.

7.7 Object library

The WI180C-EC device is structured according to the EtherCAT “Modular Device Profile”

(MDP). Objects are correspondingly available in the following address ranges:

Index range Use

0x1000 ...

0x1FFF

0x6000 ...

0x6FFF

0x7000 ...

0x7FFF

0x8000 ...

0x8FFF

0x9000 ...

0x9FFF

0xA000 ...

0xAFFF

0xF000 ...

0xFFFF

Standard communication objects

Input process data of connected modules

Output process data of connected modules

Configuration data of connected modules

Identification data of connected modules

Diagnostic data of connected modules

Data of the EtherCAT coupler WI180C-EC

OPERATION

7

NOTE

16 unique data record addresses are available for each module in the address ranges

0x6... / 0x7... / 0x8... / 0x9... / 0xA:

- Slot 1, sensor 1 (outside far left)

Data records

0x6000...0x600F / 0x7000...0x700F / 0x8000...0x800F / 0x9000...0x900F / 0xA000

...0xA00F

- Slot 2, sensor 2

Data records

0x6010...0x601F / 0x7010...0x701F / 0x8010...0x801F / 0x9010...0x901F / 0xA010

...0xA01F

- ...

- Slot 16, sensor 16

Data records

0x60F0...0x60FF / 0x70F0...0x70FF / 0x80F0...0x80FF / 0x90F0...0x90FF / 0xA0F0...

0xA0FF

The available objects are listed below. The following abbreviations apply:

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

17

Page 18

7 OPERATION

Abbreviation Meaning

R Read only access

R/W Read/write access

STRG String = a chain of characters of varying length

BOOL Boolean = logical value 0 or 1

ENUM Freely selectable values with a limited value range (e.g. BLACK, RED, BLUE,

YELLOW)

INT Signed Integer = whole number value with sign (e.g. INT-32 =

-2.147.483.648 ... 2.147.483.647)

UINT Unsigned Integer = whole number value (e.g. UINT-32 = 0 ...

4.294.967.295)

ARRAY Data sequence of a data type (e.g. Array UINT-8 = character string of the

data type UINT-8)

RECORD Sequence of data containing different data types (e.g. UINT-8, UINT-32,

UINT-32, UINT-16)

STRUCT Sequence of data containing different data types (e.g. UINT-8, UINT-32,

UINT-32, UINT-16)

7.7.1 Standard objects

Table 6: Standard objects

Detailed descrip‐

Object Function

tion

0x1000 Device type - R UINT-32 EtherCAT device type: 0x00001389, corre‐

0x1008 Device name - R STRG Type code

0x1009 Hardware version number - R STRG Hardware revision status

0x100A Software version number - R STRG Firmware revision status

0x1018 Identity Subindex, data

type

.00, UINT-8

.01, UINT-32

.02, UINT-32

.03, UINT-32

.04, UINT-32

0x10F3 Diagnostics history Subindex, data

type

.00, UINT-8

.01, UINT-8

.02, UINT-8

.03, UINT-8

.04, BOOL

.05, UINT-16

.06…xx, ARRAY

UINT-8

0x1600…

0x160F

Receive PDOs modules

(0x70n0)

Subindex, data

type

.00, UINT-8

.01, UINT-32

.02, UINT-32

Acc

ess Data type Content/meaning

sponding to Modular Device Profile

R RECORD EtherCAT identification values

Subindex 00 = Number of subindices

Subindex 01 = Vendor ID (SICK AG)

Subindex 02 = Product code

Subindex 03 = Revision number (Firmware

version)

Subindex 04 = Serial number

R RECORD Error history

Subindex 00 = Number of subindices

Subindex 01 = Max. number of stored

diagnostic messages (from subindex 06)

Subindex 02 = Subindex of the latest diag‐

nostic message

Subindex 03 = Latest confirmed diagnostic

message

Subindex 04 =New diagnostic message

present

Subindex 05 = Flags for transmission and

storage of diagnostic messages

Subindex 06...xx = Diagnostic messages

R RECORD Receive PDOs of the connected modules

Subindex 00 = Number of subindices

Subindex 01 = Object 0x70n0.01, Teach

Request

Subindex 02 = Object 0x70n0.02, Error

Clear

18

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 19

OPERATION 7

Object Function

0x16FF Receive PDO gateway

(0xF700)

0x1A00…

0x1A0F

Transmit PDOs modules

(0x60n0)

0x1AFF Transmit PDO gateway

(0xF600)

0x1C00 Sync manager communica‐

tion types

0x1C12 Sync Manager 2 (Rx) PDO

Assignment

Detailed descrip‐

tion

Subindex, data

type

.00, UINT-8

.01, UINT-32

.02, UINT-32

.03, UINT-32

Subindex, data

type

.00, UINT-8

.01, UINT-32

.02, UINT-32

.03, UINT-32

.04, UINT-32

.05, UINT-32

.06, UINT-32

Subindex, data

type

.00, UINT-8

.01, UINT-32

.02, UINT-32

.03, UINT-32

.04, UINT-32

.05, UINT-32

.06, UINT-32

Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

...

.10, UINT-16

.11, UINT-16

Acc

ess Data type Content/meaning

R RECORD Receive PDOs of the gateway

Subindex 00 = Number of subindices

Subindex 01 = Object 0xF700.01, Teach

Request, all modules

Subindex 02 = Object 0xF700.02, Error

Clear, all modules

Subindex 02 = Object 0xF700.03, Error

Clear Gateway

R RECORD Transmit PDOs of the connected modules

Subindex 00 = Number of subindices

Subindex 01 = Object 0x60n0.01, Output

1

Subindex 02 = Object 0x60n0.02, Output

2

Subindex 03 = Object 0x60n0.03, Output

3 / Ext. input

Subindex 04 = Object 0x60n0.04, Error

Status

Subindex 05 = Object 0x60n0.05, Quality

of run Alarm

Subindex 06 = Object 0x60n0.06, mea‐

sured value

R RECORD Transmit PDOs of the gateway

Subindex 00 = Number of subindices

Subindex 01 = Object 0xF600.01, Output

1, all modules

Subindex 02 = Object 0xF600.02, Output

2, all modules

Subindex 03 = Object 0xF600.03, Output

3 / Ext. input, all modules

Subindex 04 = Object 0xF600.04, Error

Status, all modules

Subindex 05 = Object 0xF600.05, Quality

of run Alarm, all modules

Subindex 06 = Object 0xF600.06, Error

Status Gateway

R ARRAY

UINT-8

Sync manager communication types

Subindex 00 = Number of subindices

Subindex 01 = Communication type sync

manager 0

Subindex 02 = Communication type sync

manager 1

Subindex 03 = Communication type sync

manager 2

Subindex 04 = Communication type sync

manager 3

R RECORD Sync Manager 2 PDO Assignment

Subindex 00 = Number of subindices

Subindex 01 = PDO 0x1600

Subindex 02 = PDO 0x1601

...

Subindex 10 = PDO 0x160F

Subindex 11 = PDO 0x16FF

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

19

Page 20

7 OPERATION

Object Function

0x1C13 Sync Manager 3 (Tx) PDO

Assignment

Detailed descrip‐

tion

Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

...

.10, UINT-16

Acc

ess Data type Content/meaning

R RECORD Sync Manager 3 PDO Assignment

Subindex 00 = Number of subindices

Subindex 01 = PDO 0x1A00

Subindex 02 = PDO 0x1A01

...

Subindex 10 = PDO 0x1A0F

Subindex 11 = PDO 0x1AFF

.11, UINT-16

7.7.2 Module data

Table 7: Module data

Object Function Detailed descrip‐

tion

0x60n0 Module Transmit PDO Subindex, data

type

.00, UINT-8

.01, UINT-8

.02, UINT-8

.03, UINT-8

.04, UINT-8

.05, UINT-8

.06, INT-16

0x70n0 Module Receive PDO Subindex, data

type

.00, UINT-8

.01, UINT-8

.02, UINT-8

0x80n0 Module Configuration R/W RECORD Configuration data of a module. See

0x90n0 Module Identification R RECORD Identification data of a module. See

Acc

Data type Content/meaning

ess

R RECORD Available input process data of a

module

Subindex 00 = Number of

subindices

Subindex 01 = Output 1. Output

state of first output (00 = Off, 01 =

On)

Subindex 02 = Output 2. Output

state of second output (00 = Off, 01

= On)

Subindex 03 = Output 3 / Ext. Input.

Output state of third output or exter‐

nal input (00 = Off, 01 = On)

Subindex 04 = Error Status. Error

status (00 = No error, 01 = Error)

Subindex 05 = Quality of run Alarm.

Validity of process data (00 = Data

valid, 01 = Data invalid)

Subindex 06 = Measured value of

module

R RECORD Available output process data of a

module

Subindex 00 = Number of

subindices

Subindex 01 = The subindex per‐

mits teach-in of the module switch‐

ing point(s). The first switching point

is taught at the change from 00 to

01 (or the teach-in process is

started in the case of dynamic

teach-in). The second switching

point is taught at the change from

01 to 00 (or the teach-in process is

ended in the case of dynamic teachin).

Subindex 02 = The subindex allows

an error message of the module to

be acknowledged (when the value

changes from 00 to 01)

following subchapters for details

following subchapters for details

20

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 21

OPERATION 7

Object Function Detailed descrip‐

tion

Acc

Data type Content/meaning

ess

0xA0n0 Module Diagnostics R RECORD Diagnostic data of a module. See

following subchapters for details

7.7.3 Coupler data

Table 8: Coupler data

Object Function Detailed descrip‐

tion

0xF000 Modular Device Profile Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

0xF030 Configured Module Ident List R/W ARRAY

0xF050 Detected Module Ident List R ARRAY

0xF100 Gateway Status Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

.03, UINT-16

0xF200 Gateway Control Subindex, data

type

.00, UINT-8

.01, UINT-16

Acc

Data type Content/meaning

ess

R RECORD Definition values of the profile

Subindex 00 = Number of

subindices

Subindex 01 = Index distance of

modules (16)

Subindex 02 = Max. number of mod‐

ules (16)

Configured module identification

UINT-32

numbers

Detected module identification num‐

UINT-32

bers

R RECORD Status of the gateway

Subindex 00 = Number of

subindices

Subindex 01 = Operating status (00

= Initialization, 01 = Idle, 02 = Run,

03 = In use by user)

Subindex 02 = Number of modules

present

Subindex 03 = Last error code

R/W RECORD Control of the gateway

Subindex 00 = Number of

subindices

Subindex 01 = Global diagnostics

(00 = Off, 01 = On)

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

21

Page 22

7 OPERATION

Object Function Detailed descrip‐

tion

0xF600 Gateway Transmit PDO Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

.03, UINT-16

.04, UINT-16

.05, UINT-16

.06, UINT-8

0xF700 Gateway Receive PDO Subindex, data

type

.00, UINT-8

.01, UINT-16

.02, UINT-16

.03, UINT-8

Acc

Data type Content/meaning

ess

R RECORD Available input process data of the

gateway

Subindex 00 = Number of

subindices

Subindex 01 = Output 1, all mod‐

ules. Output state of first output of

all modules (every bit 0 = Off, 1 =

On)

Subindex 02 = Output 2, all mod‐

ules. Output state of second output

of all modules (every bit 0 = Off, 1 =

On)

Subindex 03 = Output 3 / Ext. Input,

all modules. Output state of third

output or external input of all mod‐

ules (every bit 0 = Off, 1 = On)

Subindex 04 = Error Status, all mod‐

ules. Error status of all modules

(every bit 0 = No error, 1 = Error)

Subindex 05 = Quality of run Alarm,

all modules. Validity of process data

of all modules (every bit 0 = Data

valid, 1 = Data invalid)

Subindex 06 = Error Status Gateway.

Error status of the gateway (00 = No

error, 01 = Error)

R RECORD Available output process data of the

gateway

Subindex 00 = Number of

subindices

Subindex 01 = Teach Request, all

modules. Teach Request for all mod‐

ules (for bit coding, see object

0x70n0.1)

Subindex 02 = Error Clear, all mod‐

ules. Acknowledgment of error mes‐

sage for all modules (every bit 0 =

No action, 1 = Acknowledge error)

Subindex 03 = Error Clear Gateway.

Acknowledgment of gateway error

message (when value changes from

00 to 01)

22

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 23

OPERATION 7

Object Function Detailed descrip‐

tion

0xF800 Gateway Configuration Subindex, data

type

.00, UINT-8

.01, UINT-16 (R)

.02, UINT-16 (R)

.03, UINT-16 (R)

.04, UINT-16 (R)

.05, STRG (R)

.06, STRG (R)

.07, STRG (R)

.08, STRG (R/W)

.C8, UINT-16 (R)

.C9, UINT-16 (R)

.CA, UINT-16

(R/W)

.D4, UINT-16

(R/W)

Acc

Data type Content/meaning

ess

R(/W)RECORD Identification/parameterization of

the gateway

Subindex 00 = Number of

subindices (255)

Subindex 01 = Product series. Bits

15…12 = Manufacturer (1 = SICK),

Bits 11…8 = Categories (5 = Com‐

munication unit), Bit 7…0 = Family

(TBD)

Subindex 02 = Product type. TBD =

WI180C-EC

Subindex 03 = Firmware version

(01 h)

Subindex 04 = Product version

(01 h)

Subindex 05 = Vendor name (“SICK

AG”)

Subindex 06 = Product name

(“WI180C-EC”)

Subindex 07 = Product ID

(“6068089”)

Subindex 08 = User ID (max.

32 characters)

Subindex C8 = Firmware ID, applica‐

tion

Subindex C9 = Firmware ID, commu‐

nication

Subindex CA = Find me (00 = Stop,

01 = Initialization)

Subindex D4 = Reset to factory set‐

tings (03 = Execute)

7.7.4 WLL180T

Table 9: WLL180T

Detailed descrip‐

Object Function

tion

0x80n0.00 Number of module parame‐

ters

0x80n0.01 Display R/W UINT-16 0: Numeric display

0x80n0.03 Teach-in mode CH1 R/W UINT-16 0: 1-point

0x80n0.04 CH2 R/W UINT-16

0x80n0.05 Response speed R/W UINT-16 0: 16 us

0x80n0.06 Sender strength R/W UINT-16 0: low strength

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(155)

1: Bar graph

2: Percentage display

1: 2-point

2: Auto

3: Zone

4: Glass

1: 70 us

2: 250 us

3: 2 ms

4: 8 ms

1: medium strength

2: normal

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

23

Page 24

7 OPERATION

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.07 MF input R/W UINT-16 0: External teach-in

1: Test input

2: Synchronization

3: Reset counter

4: Master teach-in

5: No function

0x80n0.08 Key lock R/W UINT-16 0: cancel

1: Completely locked

2: Locked, but external teach-in

available

0x80n0.09 Operating mode CH1 R/W UINT-16 0: Light on

0x80n0.0A CH2 R/W UINT-16

1: Dark on

0x80n0.0B Threshold CH1 Lower limit R/W UINT-16 -999 ... 9,999 All values outside the

0x80n0.0C CH1 Upper limit R/W UINT-16

0x80n0.0D CH2 Lower limit R/W UINT-16

range

will be replaced by the nearest valid

values.

0x80n0.0E CH2 Upper limit R/W UINT-16

0x80n0.0F Counter setting CH1 R/W UINT-16 0: Delay off

0x80n0.10 CH2 R/W UINT-16

1: Single pulse

0x80n0.11 Delay time off CH1 R/W UINT-16 0 ... 9,999: 0 ... 9,999 ms

0x80n0.12 Delay time on CH1 R/W UINT-16

-1 … -9: 0.1 ... 0.9 ms

0x80n0.13 Delay time off CH2 R/W UINT-16

0x80n0.14 Delay time on CH2 R/W UINT-16

0x80n0.18 Hysteresis R/W UINT-16 1 ... 40

0x80n0.1A ASC (automated switching

threshold adjustment)

R/W UINT-16 0: Off

1: Normal

0x80n0.1B Eco Mode R/W UINT-16 0: Off

1: Display in energy-saving mode

0x80n0.1C Reverse display R/W UINT-16 0: normal

1: Display reversed

0x80n0.65 Save zero reset R/W UINT-16 Write any value to clear

zero reset

0x80n0.66 Cancel zero reset R/W UINT-16 Write any value to clear

zero reset

0x80n0.67 Teach-in 1-point R/W UINT-16 1: CH1 2: CH2

0x80n0.68 Teach-in 2-point R/W UINT-16 1: CH1 2: CH2

0x80n0.6F Reset R/W UINT-16 3: Execute

0x80n0.70 Return to start menu R/W UINT-16 Write any value to return to start

menu

0x80n0.71 Reset to factory settings R/W UINT-16 3: Execute

Object Function

90n0.00 h Number of module informa‐

tion elements

24

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(32)

Subject to change without notice

Page 25

OPERATION 7

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

90n0.01 h Product series - R UINT-16 0x1101 (model with 1 output)

- 0x1102 (model with 2 outputs)

b15–12 Manu‐

1: SICK

facturer

b11–8 Cate‐

1: Fiber amplifier

gories

b7–0 Family 1: WLL180T 1 output

- 2: WLL180T 2 outputs

90n0.02 h Product type R UINT-16 17: WLL180T

90n0.03 h Firmware version R UINT-16 0x0200 or higher

90n0.04 h Product version R UINT-16 1

90n0.06 h Vendor name R STRG “SICK AG”

90n0.07 h Product name R STRG Respective product type name

90n0.08 h Product ID R STRG Respective product type code

90n0.09 h User ID R/W STRG Reserved (max. 32 characters)

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

A0n0.00 h Number of module diagnoses R UINT-8 Number of parameters/subindices

(2)

A0n0.01 h Operating status R/W UINT-16 0 = Initialization

1: Idle

2: Execute

3: In use by user

A0n0.02 h Error code R/W UINT-16 Read: last error code

Write any value: delete last error

code

7.7.5 KTL180

Table 10: KTL180

Detailed descrip‐

Object Function

tion

0x80n0.00 Number of module parame‐

ters

0x80n0.01 Display R/W UINT-16 0: Numeric display

0x80n0.03 Teach-in mode CH1 R/W UINT-16 0: 1-point

0x80n0.04 CH2 R/W UINT-16

0x80n0.05 Response speed R/W UINT-16 0: 16 us

0x80n0.06 Receiver amplification R/W UINT-16 0: Low

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(155)

1: Bar graph

2: Percentage display

1: 2-point

2: Dynamic

1: 200 us

1: Standard

2: High

3: Auto

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

25

Page 26

7 OPERATION

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.07 MF input R/W UINT-16 0: External teach-in

1: Teach-in all

2: L/D selection

3: Blanking

4: No function

0x80n0.08 Key lock R/W UINT-16 0: cancel

1: Completely locked

2: Locked, but external teach-in

available

0x80n0.09 Operating mode CH1 R/W UINT-16 0 = Auto

0x80n0.0A CH2 R/W UINT-16

1: Light on

2: Dark on

0x80n0.0B Threshold CH1 Lower limit R/W UINT-16 -999 ... 9,999 All values outside the

0x80n0.0C CH1 Upper limit R/W UINT-16

0x80n0.0D CH2 Lower limit R/W UINT-16

range

will be replaced by the nearest valid

values.

0x80n0.0E CH2 Upper limit R/W UINT-16

0x80n0.0F Counter setting CH1 R/W UINT-16 0: Delay off

0x80n0.10 CH2 R/W UINT-16

1: Single pulse

0x80n0.11 Delay time off CH1 R/W UINT-16 0 ... 9,999: 0 ... 9,999 ms

0x80n0.12 Delay time on CH1 R/W UINT-16

-1 … -9: 0.1 ... 0.9 ms

0x80n0.13 Delay time off CH2 R/W UINT-16

0x80n0.14 Delay time on CH2 R/W UINT-16

0x80n0.16 Synchronization R/W UINT-16 0 = Asynchronous

1: Synchronous

0x80n0.18 Sensitivity R/W UINT-16 0: 10%

1: 20%

2: 50%

0x80n0.1A ASC (automated switching

threshold adjustment)

R/W UINT-16 0: Off

1: Normal

0x80n0.1B Eco Mode R/W UINT-16 0: Off

1: Display in energy-saving mode

0x80n0.1C Reverse display R/W UINT-16 0: normal

1: Display reversed

0x80n0.65 Save zero reset R/W UINT-16 Write any value to clear

zero reset

0x80n0.66 Cancel zero reset R/W UINT-16 Write any value to clear

zero reset

0x80n0.67 Teach-in 1-point R/W UINT-16 1: CH1 2: CH2

0x80n0.68 Teach-in 2-point R/W UINT-16 1: CH1 2: CH2

0x80n0.6F Reset R/W UINT-16 3: Execute

0x80n0.70 Return to start menu R/W UINT-16 Write any value to return to start

menu

0x80n0.71 Reset to factory settings R/W UINT-16 3: Execute

Object Function

90n0.00 h Number of module informa‐

tion elements

26

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(32)

Subject to change without notice

Page 27

OPERATION 7

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

90n0.01 h Product series - R UINT-16 1,111 h (model with 1 output)

- 1,112 h (model with 2 outputs)

b15–12 Manu‐

1: SICK

facturer

b11–8 Cate‐

1: Fiber amplifier

gories

b7–0 Family 11: KTL180 1 output

- 12: KTL180 2 outputs

90n0.02 h Product type R UINT-16 17: KTL180

90n0.03 h Firmware version R UINT-16 0100 h

90n0.04 h Product version R UINT-16 1

90n0.06 h Vendor name R STRG “SICK AG”

90n0.07 h Product name R STRG Respective product type name

90n0.08 h Product ID R STRG Respective product type code

90n0.09 h User ID R/W STRG Reserved (max. 32 characters)

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

A0n0.00 h Number of module diagnoses R UINT-8 Number of parameters/subindices

(2)

A0n0.01 h Operating status R/W UINT-16 0 = Initialization

1: Idle

2: Execute

3: In use by user

A0n0.02 h Error code R/W UINT-16 Read: last error code

Write any value: delete last error

code

7.7.6 OD1 on AOD1

Table 11: OD1 on AOD1

Detailed descrip‐

Object Function

tion

0x80n0.00 Number of module parame‐

ters

0x80n0.01 Threshold Near R/W UINT-16 -32,768 ... 32,767 (default: depend‐

0x80n0.02 Far R/W UINT-16 -32,768 ... 32,767 (default: depend‐

0x80n0.03 Output hysteresis R/W UINT-16 0 ... 32,767 (default: depending on

0x80n0.04 Calculation flags R/W UINT-16 0: No calculation

0x80n0.05 Calculation coefficient addi‐

tion

0x80n0.06 Calculation coefficient multi‐

plication

0x80n0.07 Calculation coefficient divi‐

sion

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(155)

ing on sensor type)

ing on sensor type)

sensor type)

1: Calculation

R/W UINT-16 -10,000 ... 10,000 (default: 0)

R/W UINT-16 -10,000 ... 10,000 (default: 1)

R/W UINT-16 1 ... 32,767 (default: 1)

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

27

Page 28

7 OPERATION

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.08 Monitor cumulative values R/W UINT-16 Field bus channel 2 data selection

(0: Head2,

1: Cumulative value)

0x80n0.09 Cumulative values Head1 R/W UINT-16 0: None

0x80n0.0A Head2 R/W UINT-16

0x80n0.0B Left unit Head1 R/W UINT-16

1: Add

2: Subtract

3: Difference

0x80n0.0C Left unit Head2 R/W UINT-16

0x80n0.0D I/O polarity R/W UINT-16 0: PNP (N/O / Normally open)

1: NPN (N/O / Normally open)

2: PNP (N/C / Normally closed)

3: NPN (N/C / Normally closed)

0x80n0.0E Output selection Out1 R/W UINT-16 0: Off

0x80n0.0F Out2 R/W UINT-16

0x80n0.10 Out3 R/W UINT-16

1: Calculated GO

2: Calculated LO

3: Calculated HI

4: Head 1 GO

5: Head 1 LO

6: Head 1 HI

7: Head 2 GO

8: Head 2 LO

9: Head 2 HI

0x80n0.11 Selection of external

input

R/W UINT-16 0: Off

1: Teach-in (rising: far, falling: near)

2: OBSB teach-in

3: Zero reset

4: Laser off

0x80n0.12 Selection of analog output R/W UINT-16 0: Off

1: Calculated

2: Head 1

3: Head 2

0x80n0.13 Analog scaling R/W UINT-16 0: Off

1: On

0x80n0.14 Analog scaling (max.) 10 V / 20 mA R/W UINT-16 -32,768 ... 32,767 (default: 10,000)

0x80n0.15 Analog scaling (min.) 0 V / 4 mA R/W UINT-16 -32,768 ... 32,767 (default:

-10,000)

0x80n0.16 Baud rate 0: No sensor head

1: 9.6 k

2: 19.2 k

3: 38.4 k

4: 57.6 k

5: 115.2 k

6: 230.4 k

7: 312.5 k

8: 460 k

9: 500 k

10: 625 k

11: 833 k

12: 921 k

13: 1,250 k (default: 9)

28

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 29

OPERATION 7

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.1F Switching point Near R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default:

-1,000)

OD1 35 mm: -2,249 ... 2,249

(default:

-300)

OD1 100 mm: -7,499 ... 7,499

(default:

-1,000)

0x80n0.20 Far R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default:

1,000)

OD1 35 mm: -2,249 ... 2,249

(default:

300)

OD1 100 mm: -7,499 ... 7,499

(default:

1,000)

0x80n0.21 Background

ObSB

R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default: 0)

OD1 35 mm: -2,249 ... 2,249

(default: 0)

OD1 100 mm: -7,499 ... 7,499

(default: 0)

0x80n0.22 Tolerance ObSB R/W UINT-16 OD1 15 mm: 0 ... 7,499 (default:

1,000)

OD1 35 mm: 0 ... 2,249 (default:

300)

OD1 100 mm: 0 ... 7,499 (default:

1,000)

0x80n0.23 Moving average R/W UINT-16 0: over one value

1: 8 values

2: 64 values

3: 512 values

0x80n0.24 Teach-in mode R/W UINT-16 0: 2-point

1: 1-point

2: ObSB

0x80n0.25 Sampling rate R/W UINT-16 0: 500 us

1: 1,000 us

2: 2,000 us

3: 4,000 us

4: Auto

0x80n0.26 Key lock R/W UINT-16 0: Unlocked

1: Locked

0x80n0.27 Switching behavior R/W UINT-16 0: Light ON

1: Dark ON

0x80n0.28 Calibration, near distance R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default:

-5,000)

OD1 35 mm: -2,249 ... 2,249

(default:

-1,500)

OD1 100 mm: -7,499 ... 7,499

(default:

-5,000)

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

29

Page 30

7 OPERATION

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.29 Calibration, far distance R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default:

5,000)

OD1 35 mm: -2,249 ... 2,249

(default:

1,500)

OD1 100 mm: -7,499 ... 7,499

(default:

5,000)

0x80n0.2A Error behavior R/W UINT-16 0: Clamp

1: Hold

0x80n0.2B Clamp holding time R/W UINT-16 0 ... 9,999 (default: 0)

0x80n0.2D Zeroing value R/W UINT-16 OD1 15 mm: -7,499 ... 7,499

(default: 0)

OD1 35 mm: -2,249 ... 2,249

(default: 0)

OD1 100 mm: -7,499 ... 7,499

(default: 0)

0x80n0.31 Barycenter R/W UINT-16 0: Max. light

1: Closest

2: 2nd point

3: 3rd point

4: 4th point

5: 5th point

0x80n0.34 Hysteresis value R/W UINT-16 OD1 15 mm: 0 ... 7,499 (default:

50)

OD1 35 mm: 0 ... 2,249 (default:

50)

OD1 100 mm: 0 ... 7,499 (default:

50)

0x80n0.35 Sensitivity R/W UINT-16 0: Auto adjust

1: Min. sense

2: 2nd sense

3: 3rd sense

4: 4th sense

5: 5th sense

6: Max. sense

0x80n0.36 Light threshold R/W UINT-16 0: Lowest

1: Lower

2: Middle

3: Upper

0x80n0.38 Key lock active R/W UINT-16 0: Display active if locked

1: Display inactive if locked

0x80n1.00 Number of module com‐

mands

R UINT-8 Number of parameters/subindices

(56)

0x80n1.01 Save zero reset R/W UINT-16

0x80n1.02 Cancel zero reset R/W UINT-16

0x80n1.03 Teach-in 1-point R/W UINT-16

0x80n1.04 Teach-in 2-point R/W UINT-16

0x80n1.05 Teach-in ObSB R/W UINT-16

0x80n1.0B Reset R/W UINT-16 3: Execute

0x80n1.0C Return to start menu R/W UINT-16 Write any value to return to start

menu

30

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 31

OPERATION 7

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n1.0D Reset to factory settings R/W UINT-16 3: Execute

Object Function

0x90n0.00 Number of module informa‐

tion elements

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(32)

0x90n0.01 Product series - R UINT-16 0x1301 (15 mm model)

- 0x1302 (35 mm model)

- 0x1303 (100 mm model)

b15–12 Manu‐

1: SICK

facturer

b11–8 Cate‐

3: Displacement

gories

b7–0 Family 1: OD1 15 mm

- 2: OD1 35 mm

- 3: OD1 100 mm

0x90n0.02 Product type R UINT-16 1: AOD1

0x90n0.03 Firmware version R UINT-16 0x0100

0x90n0.04 Product version R UINT-16 0

0x90n0.06 Vendor name R STRG “SICK AG”

0x90n0.07 Product name R STRG Respective product type name

0x90n0.08 Product ID R STRG Respective product type code

0x90n0.09 User ID R/W STRG Reserved (max. 32 characters)

0x90n0.0A Product series, amplifier b15–b0: Ampli‐

R UINT-16 0x1503

fier product

series

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0xA0n0.00 Number of module diagnoses R UINT-8 Number of parameters/subindices

(2)

0xA0n0.01 Operating status R/W UINT-16 0 = Initialization

1: Idle

2: Execute

3: In use by user

0xA0n0.02 Error code R/W UINT-16 Read: last error code

Write any value: delete last error

code

7.7.7 OL1 on AOD1

Detailed descrip‐

Object Function

tion

0x80n0.00 Number of module parame‐

ters

0x80n0.01 Threshold Near R/W UINT-16 -32,768 ... 32,767 (default: depend‐

0x80n0.02 Far R/W UINT-16 -32,768 ... 32,767 (default: depend‐

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(53)

ing on sensor type)

ing on sensor type)

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

31

Page 32

7 OPERATION

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.03 Output hysteresis R/W UINT-16 0 ... 32,767 (default: depending on

sensor type)

0x80n0.04 Calculation flags R/W UINT-16 0: No calculation

1: Calculation

0x80n0.05 Calculation coefficient addi‐

R/W UINT-16 -10,000 ... 10,000 (default: 0)

tion

0x80n0.06 Calculation coefficient multi‐

R/W UINT-16 -10,000 ... 10,000 (default: 1)

plication

0x80n0.07 Calculation coefficient divi‐

R/W UINT-16 1 ... 32,767 (default: 1)

sion

0x80n0.08 Monitor cumulative values R/W UINT-16 Field bus channel 2 data selection

(0: Head2, 1: cumulative

value)

0x80n0.09 Cumulative values Head1 R/W UINT-16 0: None

0x80n0.0A Head2 R/W UINT-16

0x80n0.0B Left unit Head1 R/W UINT-16

1: Add

2: Subtract

3: Difference

0x80n0.0C Left unit Head2 R/W UINT-16

0x80n0.0D I/O polarity R/W UINT-16 0: PNP (N/O / Normally open)

1: NPN (N/O / Normally open)

2: PNP (N/C / Normally closed)

3: NPN (N/C / Normally closed)

0x80n0.0E Output selection Out1 R/W UINT-16 0: Off

0x80n0.0F Out2 R/W UINT-16

0x80n0.10 Out3 R/W UINT-16

1: Calculated GO

2: Calculated LO

3: Calculated HI

4: Head 1 GO

5: Head 1 LO

6: Head 1 HI

7: Head 2 GO

8: Head 2 LO

9: Head 2 HI

0x80n0.11 Selection of external

input

R/W UINT-16 0: Off

1: Teach-in (rising: far, falling: near)

2: OBSB teach-in

3: Zero reset

4: Laser off

0x80n0.12 Selection of analog output R/W UINT-16 0: Off

1: Calculated

2: Head 1

3: Head 2

0x80n0.13 Analog scaling R/W UINT-16 0: Off

1: On

0x80n0.14 Analog scaling (max.) 10 V / 20 mA R/W UINT-16 -32,768 ... 32,767 (default: 10,000)

0x80n0.15 Analog scaling (min.) 0 V / 4 mA R/W UINT-16 -32,768 ... 32,767 (default:

-10,000)

32

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 33

OPERATION 7

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0x80n0.16 Baud rate 0: No sensor head

1: 9.6 k

2: 19.2 k

3: 38.4 k

4: 57.6 k

5: 115.2 k

6: 230.4 k

7: 312.5 k

8: 460 k

9: 500 k

10: 625 k

11: 833 k

12: 921 k

13: 1,250 k (default: 9)

0x80n0.23 Moving average R/W UINT-16 1 … 128 (scanning points)

0x80n0.24 Measurement type R/W UINT-16 0: Positive edge

1: Negative edge

2: Width

0x80n0.25 Sampling rate R/W UINT-16 0: 500 µs (fixed value)

0x80n0.2C Measurement direction R/W UINT-16 0: From top to bottom

1: From bottom to top

0x80n0.2D Zeroing value R/W UINT-16 -9,999 ... 5,000 (default: 0)

0x80n0.35 Sensitivity R/W UINT-16 0: Min. sense

1: 2nd sense

2: 3rd sense

3: 4th sense

4: Max. sense

5: Adjusted

0x80n1.00 Number of module com‐

mands

R UINT-8 Number of parameters/subindices

(13)

0x80n1.01 Save zero reset R/W UINT-16

0x80n1.02 Cancel zero reset R/W UINT-16

0x80n1.0D Reset to factory settings R/W UINT-16 3: Execute

Object Function

0x90n0.00 Number of module informa‐

tion elements

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

R UINT-8 Number of parameters/subindices

(32)

0x90n0.01 Product series - R UINT-16 0x1321

b15–12 Manu‐

1: SICK

facturer

b11–8 Cate‐

3: Displacement

gories

b7–0 Family 21: OL1

0x90n0.02 Product type R UINT-16 11: AOD1 / OL1

0x90n0.03 Firmware version R UINT-16 0x1011

0x90n0.04 Product version R UINT-16 0

0x90n0.06 Vendor name R STRG “SICK AG”

0x90n0.07 Product name R STRG Respective product type name

0x90n0.08 Product ID R STRG Respective product type code

0x90n0.09 User ID R/W STRG Reserved (max. 16 characters)

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

33

Page 34

7 OPERATION

Detailed descrip‐

Object Function

tion

0x90n0.0A Product series, amplifier b15–b0: Ampli‐

Acc

ess Data type Content/meaning

R UINT-16 0x1503

fier product

series

Object Function

Detailed descrip‐

tion

Acc

ess Data type Content/meaning

0xA0n0.00 Number of module diagnoses R UINT-8 Number of parameters/subindices

(1)

0xA0n0.01 Operating status R/W UINT-16 0 = Initialization

1: Idle

2: Execute

3: In use by user

34

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 35

8 Diagnosis

DIAGNOSIS 8

The device transmits error states in various ways. If a connected module detects a

fault, this is transmitted in the corresponding “Error status” process datum. Details

about the detected faults can be retrieved using the “Service Data Object” 0x1F03

(diagnosis history).

In addition, the gateway status object 0xF100 will report in subindex 3 the last occurred

error. The following table shows possible errors:

Diagnosis History (0x10F3) Last Gateway Error (0xF100:3) Description

Diag Code Diag Type

0x0006E0000x02 (Error) 0x0206 Number of connected modules

changed during run-time.

0x0007E0000x01 (Warn‐

ing)

0x0008E0000x01 (Warn‐

ing)

0x0107 An invalid module is connected

to the gateway.

0x0108 The order of connected modules

is wrong (see ch. 7.4).

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

35

Page 36

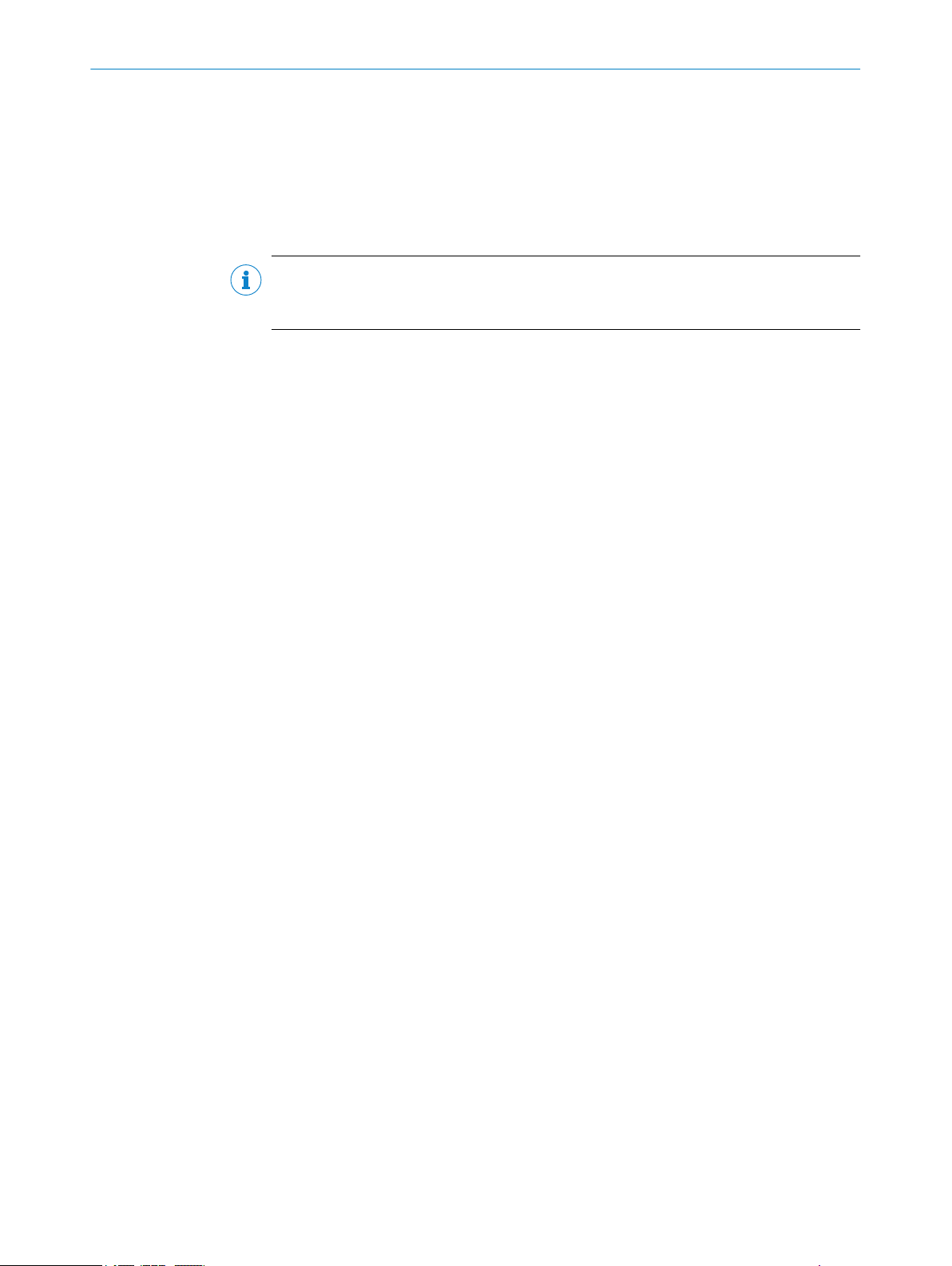

2

1

9 DECOMMISSIONING

9 Decommissioning

9.1 Dismantling

1. Switch off the power supply for the device.

2. Disconnect the male connector of the power supply and the EtherCAT male con‐

nector.

3. Detach the mountings for the connected devices.

4. Disconnect the connected devices from the bus male connector of the device.

5. Carefully push up the device until you can tip it forwards.

9.2 Disposal

6. Remove the device from the mounting rail.

At the end of its service life, the device must be disposed of correctly as waste electron‐

ics. Take the regulations in your country into account also.

36

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 37

10 Technical data

(37.9) (1.49)

33.2 (1.31)

39 (1.54)

(41.8) (1.65)

36.3 (1.43)

11 (0.43)

26 (1.02)

52 (2.05)

79 (3.11)

92 (3.62)

36.6 (1.44)

18.8

(0.74)

102.55 (4.04)

10.4 (0.41)

1

2

3

4

5

6

7

à

á

7

8

9

ß

â

10.1 Dimensional drawings

TECHNICAL DATA 10

1

2

3

4

5

6

7

8

9

ß

à

á

â

10.2 Technical data

Electrical system

Table 12: Electrical data

Description Value

Supply voltage 12 ... 24 VDC ± 10%

Power consumption (with‐

out connected devices)

Switch-on delay 1,000 ms

Switch-on delay (complete

system)

PWR-LED

BF/ERR/NS-LED

SF/RUN/MS-LED

STATUS-LED

L/A1-LED

L/A2-LED

Power supply connection M8, 4-pin

Bus male connection, 5-pin (system bus)

D-coded M12 connector, 4-pin, EtherCAT

D-coded M12 connector, 4-pin, EtherCAT

Factory reset button

Service port (USB, Micro-B)

M12 Connector Cap (accessory)

3 W

2,000 ms

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

37

Page 38

10 TECHNICAL DATA

Description Value

LEDs PWR, BF/ERR/NS, SF/RUN/MS, STATUS, L/A1, L/A2

Voltage supply M8 male connector, 4-pin

Other interfaces Bus male connector, 5-pin, internal system bus

2 x M12 male connector, 4-pin, D-coded, EtherCAT

EtherCAT

Table 13: EtherCAT data

Description Value

Maximum number of mod‐

ules that can be connected

Transmission rate 100 Mbit/s

Maximum distance

between nodes

Process data Depending on selected modules

Asynchronous data Service data objects (SDOs) over CANopen-over-EtherCAT (CoE).

Observed standard IEEE802.3u (100Base-Tx)

Ethernet connections 2

ESI file Available on www.sick.com

16

100 m

12 bytes input and 6 bytes output Gateway

8 bytes input and 3 bytes output per module

Minimum cycle time: TBD

EMC

Table 14: EMC data

Description Value

Noise immunity (length of

In accordance with EN 61000-6-2 / EN 61131-2

cable ≤ 30 m)

Emission In accordance with EN 55011, Class A

Product safety

Table 15: Product safety data

Description Value

Protection class 3

Short-circuit protection In accordance with VDE 0160

Mechanical system

Table 16: Mechanical data

Description Value

Enclosure rating IP54

Vibration resistance IEC 60068, 10 ... 55 Hz

Shock resistance IEC 60068, 500 m/s² (~50 g)

Housing material Polycarbonate

Dimensions (W x H x D) inmm39 x 102.55 x 36.3

1

38

1

Valid if WI180C-EC is connected to modules that comply with IP54 via internal system bus

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 39

Environmental parameters

Table 17: Environmental parameters

Description Value

Air humidity

(operation/storage)

Temperature range

(storage)

Temperature range

(operation, ≤ 3 connected

devices)

Temperature range

(operation, ≤ 8 connected

devices)

Temperature range

(operation, ≤ 16 connected

devices)

1

Temperature ranges apply if there is no output current at the connected devices

10.3 UL Satisfaction Ratings

35 ... 85% relative humidity

-40 ... +70 °C

-25 ... +55 °C

-25 ... +50 °C

-25 ... +45 °C

1

1

1

TECHNICAL DATA 10

The total control output current and ambient temperature will be retricted as follows

depends on the number of sensors (proximity switch) connected to the programmable

controller.

Up to 3 units:

Input 12 - 24 V dc, max. 1.02 A, Class 2

Output 12 - 24 V dc, max. 0.45 A, Class 2

Maximum surround air Temperature +55°C.

Up to 8 units:

Input 12 - 24 V dc, max. 1.02 A, Class 2

Output 12 - 24 V dc, max. 0.8 A, Class 2

Maximum surround air Temperature +50°C.

Up to 16 units:

Input 12 - 24 V dc, max. 1.02 A, Class 2

Output 12 - 24 V dc, max. 0.8 A, Class 2

Maximum surround air Temperature +45°C.

10.4 Ordering information, accessories

Table 18: Ordering information

Type Description Part number

YF8U14-020VA3XLEAX Female connector, M8, 4-pin,

2095888

straight, 2 m cable

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

39

Page 40

10 TECHNICAL DATA

Type Description Part number

YF8U14-050VA3XLEAX Female connector, M8, 4-pin,

2095889

straight, 5 m cable

YG8U14-020VA3XLEAX Female connector, M8, 4-pin, angled,

2095962

2 m cable

YG8U14-050VA3XLEAX Female connector, M8, 4-pin, angled,

2095963

5 m cable

SSL-1204-G02MZ90 Male connector, M12, 4-pin, straight,

6048241

D-coded, 2 m cable

40

O PE R AT I NG IN S TR U CT I ON | WI180C-EC 8024001/2019-05-27 | SICK

Subject to change without notice

Page 41

TECHNICAL DATA 10

8024001/2019-05-27 | SICK O P ER A TI N G I NS T RU C TI O N | WI180C-EC

Subject to change without notice

41

Page 42

Detailed addresses and further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 234 719 500

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 010

E-Mail info@sick.de

Greece

Phone +30 210 6825100

E-Mail office@sick.com.gr

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 97110 11

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mexico@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 10 060 0550

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail infokorea@sick.com

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail contact@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales

.gsg@sick.com

8024001/2019-05-27/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...