Page 1

WFZ

Fork sensors

O P E R A T I N G I N S T R U C T I O N S

Page 2

WFZ

Fork sensors

O P E R A T I N G I N S T R U C T I O N S

de

en

Page 3

Described product

2006/42/EC

NO

SAFETY

WFZ

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

8023382.14JZ | SICK

Subject to change without notice

3

Page 4

CONTENTS

Contents

1 General safety notes......................................................................... 5

2 Intended use...................................................................................... 5

3 Operating elements and status indicators.................................... 6

4 Mounting............................................................................................. 7

5 Electrical installation........................................................................ 7

5.1 DC.............................................................................................................. 8

6 Commissioning.................................................................................. 8

7 Troubleshooting................................................................................. 10

8 Disassembly and disposal............................................................... 11

9 Maintenance...................................................................................... 11

10 Technical data.................................................................................... 11

4

8023382.14JZ | SICK

Subject to change without notice

Page 5

1 General safety notes

2006/42/EC

NO

SAFETY

EN/IEC 60825-1:2014

IEC60825-1:2007

LASERKL ASSE 1

Laser

1

Maximum pulse power < 2,5 mW

Puls length: 4 µs

Wavelength: 650 - 670 nm

Complies with 21 CFR 1040.10

and 1040.11 except for deviations

pursuant to Laser Notice No. 50,

dated June 24, 2007

■

Read the operating instructions before commissioning.

■

Connection, mounting, and adjustment may only be performed by trained

specialists.

■

Not a safety component in accordance with the EU Machinery Directive.

■

When commissioning, protect the device from moisture and contamination.

■

These operating instructions contain information required during the life cycle of

the sensor.

■

The radiation of the emitted light must not be focused by additional optical

devices.

GENERAL SAFETY NOTES 1

2 Intended use

8023382.14JZ | SICK

Subject to change without notice

ATTENTION

WARNING: Interruption, manipulation or incorrect use can lead to hazardous exposure

due to laser radiation.

The WFZ through-beam photoelectric sensor consists of two opto-electronic sender and

receiver units. The respective sender and receiver units are arranged crosswise so that

objects in the center of the crossing point can be positioned using signals from both

switching outputs (Q1 + Q2). The WFZ is used for the optical, non-contact detection and

positioning of objects.

5

Page 6

4

4

2

3

6

5

7

4

1

3 OPERATING ELEMENTS AND STATUS INDICATORS

3 Operating elements and status indicators

Figure 1: Indicator LEDs

Cover side = upper side

1

Detection axis

2

Male connector, M12, 5-pin

3

Fixing hole Ø 5.4 mm

4

LED indicator green: supply voltage active

5

LED indicator yellow: Status of received light beam Q2

6

LED indicator yellow: Status of received light beam Q1

7

6

8023382.14JZ | SICK

Subject to change without notice

Page 7

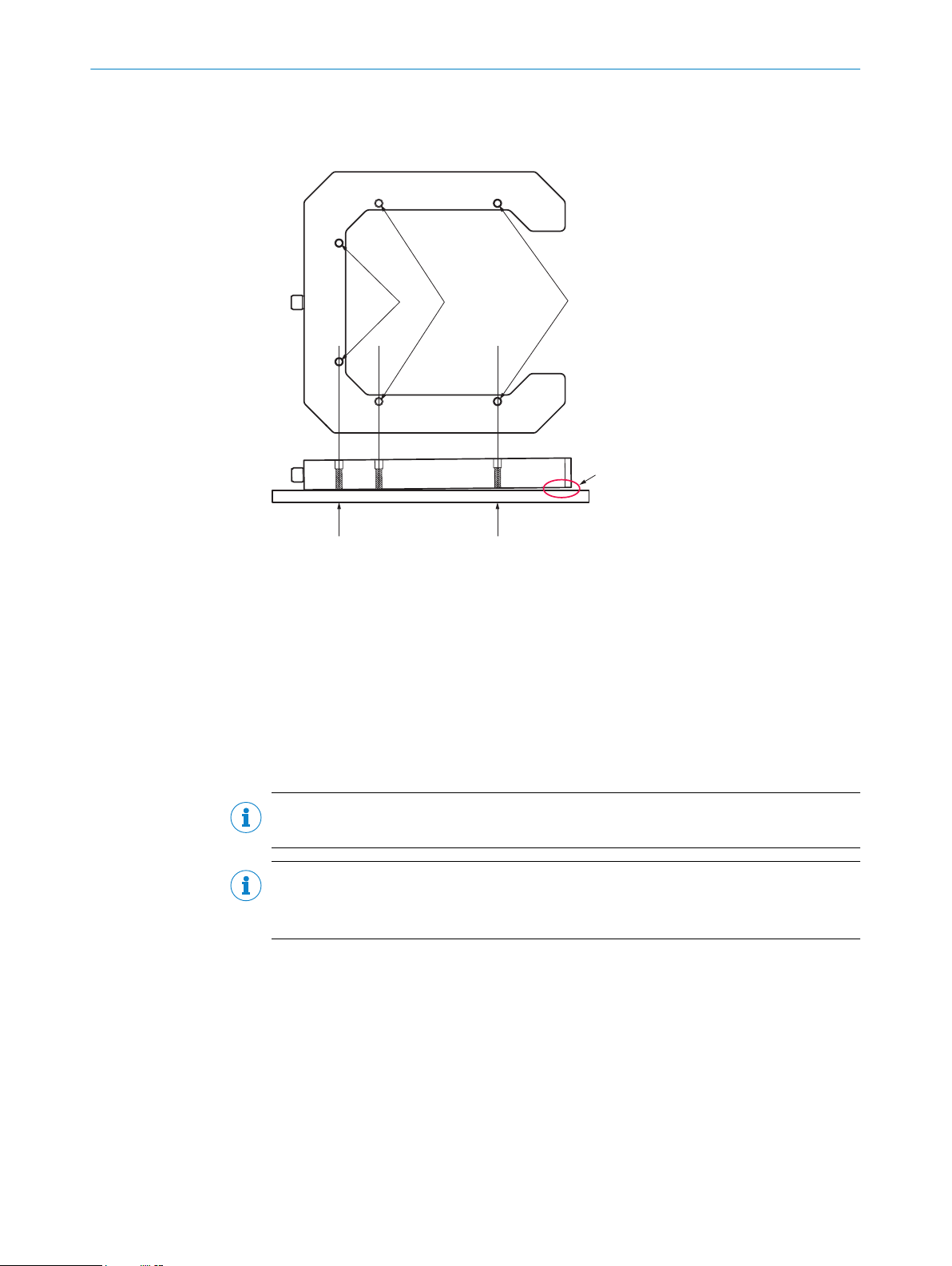

4 Mounting

1 2 3

6 5

4

MOUNTING 4

Figure 2: Mounting

Base screws

1

Optional base screws

2

Flank screws

3

No deformation!

4

Flank screws are loose

5

Base screws are tight

6

Normal mounting is recommended to be done with the base screws.

To obtain better stability the optional base screws can be used.

NOTE

It is important that the mounting surface is flat.

NOTE

To obtain full vibration resistance all 6 screws are to be used.

This requires an absolute flat mounting surface to avoid twisting of the sensor.

The reference points of the respective fixing holes to the crossed light beam can be

seen in the dimensional drawing, see figure 8.

5 Electrical installation

8023382.14JZ | SICK

Subject to change without notice

The sensors must be connected in a voltage-free state (UV = 0 V). The following informa‐

tion must be observed, depending on the connection type:

– Plug connection

Only apply voltage/switch on the voltage supply (UV > 0 V) once all electrical connec‐

tions have been established.

7

Page 8

1

2

5

4 3

3

1

2

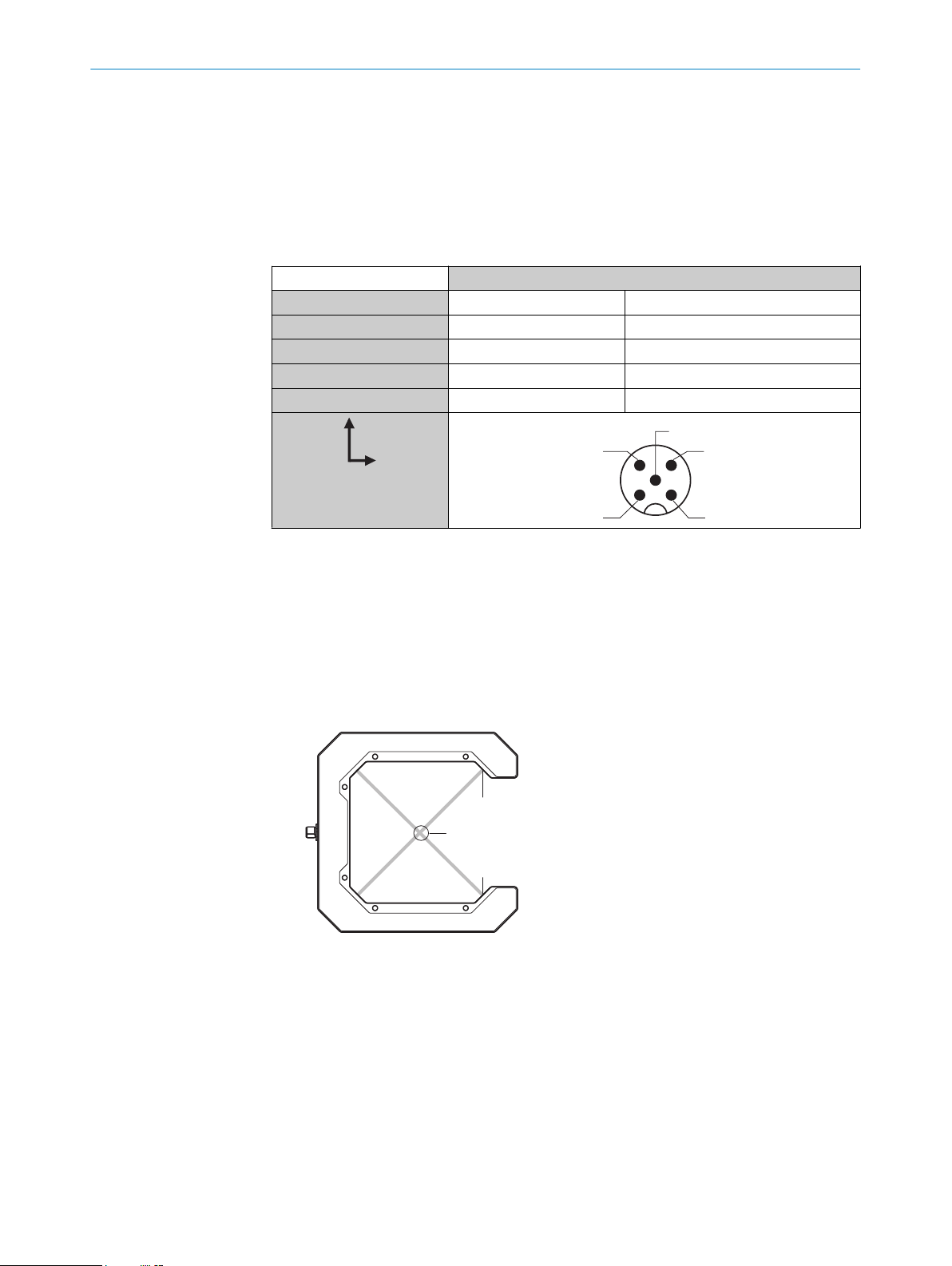

5 ELECTRICAL INSTALLATION

Explanations of the connection diagram (Tables 2–7):

Q = switching outputs

5.1 DC

DC: 10 V ... 30 V DC, see "Technical data", page 11

Table 1: DC

WFZ

1 BN + (L+)

2 WH Q2

3 BU - (M)

4 BK Q1

5 GY ET

6 Commissioning

1 Alignment: Positioning of objects in the crossed light beams

If one of the two crossed light beams is interrupted, this is signaled by the respective

switching behavior of Q1/Q2.

If light beam 1 is interrupted, switching output Q1 (pin 4) is deactivated.

If light beam 2 is interrupted, switching output Q2 (pin 2) is deactivated.

If an object covers both light beams, light beams 1+2 are interrupted and signaled by

switching outputs Q1 + Q2.

Figure 3: Switching outputs

1

2

3

Light beam 1, Q1

Light beam 2, Q2

Crossing point

8

8023382.14JZ | SICK

Subject to change without notice

Page 9

1.

2.

3.

1

2

3

COMMISSIONING

Figure 4: Reference points

The size of the object must be taken into account when positioning the switching point, see

figure 4.

The positioning procedure is carried out as follows:

Point determination

1. Move the tool into the WFZ until a switching output switches

2. Move the tool sideways until the second switching output switches

3. Move back to the central position and then move towards the center of the fork until

the crossing point is reached and both switching outputs switch

6

8023382.14JZ | SICK

Subject to change without notice

Figure 5: Point determination at the object tip

The alignment of the tool on the Z axis can also be ascertained by repositioning the tool on

the Z axis after point determination has been carried out (Step 4, 5 and 6).

9

Page 10

4

5

6

7 TROUBLESHOOTING

Figure 6: Second point determination

If two points on the tool’s Z axis lie within the WFZ’s crossing point, the tool is not only cen‐

trally aligned but also perpendicular to the WFZ.

Figure 7: Correct positioning in the crossing point, perpendicular to the WFZ

2 Teach-in function

Route pin 5 and gray cable to + (L+) for > 1 s. The yellow LEDs flash during the teach-in

procedure.

NOTE

For maximum accuracy, we recommend using the teach-in function before every measure‐

ment. At least, however:

•

•

•

3 PNP (Load → M): light path free, output (Q) high

7 Troubleshooting

The Troubleshooting table indicates measures to be taken if the sensor stops working.

10

after initial commissioning of the sensor

after cleaning

if the light beams display a weak signal, even though the light path is clear

8023382.14JZ | SICK

Subject to change without notice

Page 11

Table 2: Troubleshooting

LED indicator/fault pattern Cause Measures

Green LED does not light up or

flickers

Q-LED flashes yellow Sensor is still ready for opera‐

One of the two Q-LEDs do not

light up

8 Disassembly and disposal

The sensor must be disposed of according to the applicable country-specific regula‐

tions. Efforts should be made during the disposal process to recycle the constituent

materials (particularly precious metals).

No voltage or voltage below

the limit values

Voltage interruptions Ensure there is a stable power

Sensor is faulty If the power supply is OK,

tion, but the operating condi‐

tions are not ideal

The respective light beam is

interrupted

The optical surfaces are cont‐

aminated

Check the power supply,

check all electrical connec‐

tions (cables and plug connec‐

tions)

supply without interruptions

replace the sensor

Cleaning of the optical sur‐

faces. Perform teach-in again.

Remove object from light

beam

Cleaning of the optical sur‐

faces. Perform teach-in again.

NOTE

Disposal of batteries, electric and electronic devices

•

•

•

9 Maintenance

SICK sensors are maintenance-free.

We recommend doing the following regularly:

•

•

No modifications may be made to devices.

Subject to change without notice. Specified product properties and technical data are

not written guarantees.

According to international directives, batteries, accumulators and electrical or

electronic devices must not be disposed of in general waste.

The owner is obliged by law to return this devices at the end of their life to the

respective public collection points.

This symbol on the product, its package or in this document, indicates

that a product is subject to these regulations.

Clean the external lens surfaces

Check the screw connections and plug-in connections

10 Technical data

WFZ

Laser class I

8023382.14JZ | SICK

Subject to change without notice

11

Page 12

220 (8.66)

120 (4.72)

5.4 (0.21)

29.5

(1.16)

63 (2.48)

100 (3.94)

220 (8.66)

167 (6.57)

156 (6.14)

100 (3.94)

113 (4.45)

78 (3.07)

3

3

1

25 (0.98)

2

4

3

10 TECHNICAL DATA

WFZ

Wavelength 650 nm

Fork width 120 mm

Fork depth 185 mm

Smallest detectable object (MDO) 0.5 mm

Switching function Light switching

Supply voltage V

S

Current consumption < 100mA

Output current I

max.

Max. switching frequency 1,000 Hz

10 V DC ... 30 V DC

2)

100 mA

3)

Reproducibility ± 0.01 mm

Max. response time 0.5 ms

4)

Initialization time 50 ms

Enclosure rating IP67

Protection class III

Ambient operating temperature -10 °C ... +50 °C

Storage temperature -30 °C ... +65 °C

1)

Limit value; operation in short-circuit protection mains max. 8 A; residual ripple max. 5 V

2)

Without load.

3)

With light / dark ratio 1:1

4)

Signal transit time with resistive load

5)

Do not bend cables below 0 °C.

ss

1)

5)

Dimensional drawing

Figure 8: Dimensional drawing

Detection axes

1

Male connector, M12, 5-pin

2

12

8023382.14JZ | SICK

Subject to change without notice

Page 13

Fixing hole Ø 5.4 mm

3

LED indicator

4

TECHNICAL DATA 10

8023382.14JZ | SICK

Subject to change without notice

13

Page 14

WFZ

Gabelsensoren

B E T R I E B S A N L E I T U N G

de

en

Page 15

Beschriebenes Produkt

2006/42/EC

NO

SAFETY

WFZ

Hersteller

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Deutschland

Rechtliche Hinweise

Dieses Werk ist urheberrechtlich geschützt. Die dadurch begründeten Rechte bleiben

bei der Firma SICK AG. Die Vervielfältigung des Werks oder von Teilen dieses Werks ist

nur in den Grenzen der gesetzlichen Bestimmungen des Urheberrechtsgesetzes zuläs‐

sig. Jede Änderung, Kürzung oder Übersetzung des Werks ohne ausdrückliche schriftli‐

che Zustimmung der Firma SICK AG ist untersagt.

Die in diesem Dokument genannten Marken sind Eigentum ihrer jeweiligen Inhaber.

© SICK AG. Alle Rechte vorbehalten.

Originaldokument

Dieses Dokument ist ein Originaldokument der SICK AG.

8023382.14JZ | SICK

Subject to change without notice

15

Page 16

INHALT

Inhalt

11 Allgemeine Sicherheitshinweise..................................................... 17

12 Bestimmungsgemäße Verwendung............................................... 17

13 Bedien- und Anzeigeelemente........................................................ 18

14 Montage.............................................................................................. 19

15 Elektrische Installation..................................................................... 19

15.1 DC.............................................................................................................. 20

16 Inbetriebnahme................................................................................. 20

17 Störungsbehebung............................................................................ 22

18 Demontage und Entsorgung............................................................ 23

19 Wartung.............................................................................................. 23

20 Technische Daten.............................................................................. 24

16

8023382.14JZ | SICK

Subject to change without notice

Page 17

11 Allgemeine Sicherheitshinweise

2006/42/EC

NO

SAFETY

EN/IEC 60825-1:2014

IEC60825-1:2007

LASERKL ASSE 1

Laser

1

Maximale Pulsleistung: < 2,5 mW

Impulsdauer: 4 µs

Wellenlänge: 650 - 670 nm

Entspricht 21 CFR 1040.10

und 1040.11 mit Ausnahme von

Abweichungen nach

Laser-Hinweis 50, 24. Juni 2007

■

Vor der Inbetriebnahme die Betriebsanleitung lesen.

■

Anschluss, Montage und Einstellung nur durch Fachpersonal.

■

Kein Sicherheitsbauteil gemäß EU-Maschinenrichtlinie.

■

Gerät bei Inbetriebnahme vor Feuchte und Verunreinigung schützen.

■

Diese Betriebsanleitung enthält Informationen, die während des Lebenszyklus des

Sensors notwendig sind.

■

Die Strahlung des Sendelichtes darf nicht durch zusätzliche optische Bauteile

fokussiert werden.

ALLGEMEINE SICHERHEITSHINWEISE 11

12 Bestimmungsgemäße Verwendung

8023382.14JZ | SICK

Subject to change without notice

ACHTUNG

ACHTUNG: Eingriffe oder Manipulationen oder nicht bestimmungsgemäße Verwendung

kann zu gefährlicher Belastung durch Laser-Lichtstrahlung führen.

Das Einweg-Lichtschranken-System WFZ besteht aus zwei optoelektronischen Sendeund Empfangseinheiten. Die jeweiligen Sende- und Empfangseinheiten sind gekreuzt

angeordnet, sodass Objekte im Mittelpunkt des Kreuzungspunkts, durch Signalisierung

beider Schaltausgänge (Q1 + Q2) positioniert werden können. Das WFZ wird zum opti‐

schen, berührungslosen Erfassen und Positionieren von Objekten eingesetzt.

17

Page 18

4

4

2

3

6

5

7

4

1

13 BEDIEN- UND ANZEIGEELEMENTE

13 Bedien- und Anzeigeelemente

Abbildung 9: Anzeige LEDs

Deckelseite = obere Seite

1

Detektionsachse

2

Stecker M12, 5-polig

3

Befestigungsbohrung Ø 5,4 mm

4

Anzeige-LED grün: Betriebsspannung aktiv

5

Anzeige-LED gelb: Status Lichtempfang Q2

6

Anzeige-LED gelb: Status Lichtempfang Q1

7

18

8023382.14JZ | SICK

Subject to change without notice

Page 19

14 Montage

1 2 3

6 5

4

MONTAGE 14

Abbildung 10: Montage

1

2

3

4

5

6

Zur normalen Montage der WFZ wird empfohlen, die Basisschrauben zu verwenden.

Um eine bessere Stabilität zu erzielen, können die optionalen Basisschrauben verwen‐

det werden.

HINWEIS

Es ist wichtig, dass die Montageoberfläche eben ist.

HINWEIS

Um die maximale Vibrationsfestigkeit zu erreichen, müssen alle sechs Befestigungs‐

bohrungen verwendet werden.

Dies erfordert eine absolut ebene Montagefläche, um ein Verdrehen des Sensors zu

vermeiden.

Die Bezugspunkte der jeweiligen Befestigungsbohrungen zum gekreuzten Lichtstrahl

kann der Maßzeichnung entnommen werden, siehe Abbildung 16.

Basisschrauben

Optionale Basisschrauben

Gabelschrauben

Keine Verformung!

Gabelschrauben sind lose

Basisschrauben sind fest

15

8023382.14JZ | SICK

Subject to change without notice

Elektrische Installation

Anschluss der Sensoren muss spannungsfrei (UV = 0 V) erfolgen. Je nach Anschlussart

sind die folgenden Informationen zu beachten:

– Steckeranschluss

19

Page 20

1

2

5

4 3

3

1

2

15 ELEKTRISCHE INSTALLATION

Erst nach Anschluss aller elektrischen Verbindungen die Spannungsversorgung (UV > 0

V) anlegen bzw. einschalten.

Erläuterungen zum Anschlussschema (Tabellen 2-7):

Q = Schaltausgänge

15.1 DC

DC: 10 V ... 30 V DC, siehe "Technische Daten", Seite 24

Tabelle 3: DC

WFZ

1 BN + (L+)

2 WH Q2

3 BU - (M)

4 BK Q1

5 GY ET

16 Inbetriebnahme

1 Ausrichtung: Positionierung von Objekten in den gekreuzten Lichtstrahlen

Das Unterbrechen eines der beiden gekreuzten Lichtstrahlen wird durch das jeweilige

Schaltverhalten Q1 / Q2 signalisiert.

Wird der Lichtstrahl 1 unterbrochen, so wird der Schaltausgang Q1 (pin 4) deaktiviert.

Wird der Lichtstrahl 2 unterbrochen, so wird der Schaltausgang Q2 (pin 2) deaktiviert.

Deckt ein Objekt beide Lichtstrahlen ab, so werden die Lichtstrahlen 1 + 2 unterbrochen

und durch die Schaltausgänge Q1 + Q2 signalisiert.

Abbildung 11: Schaltausgänge

1

2

3

Lichtstrahl 1, Q1

Lichtstrahl 2, Q2

Kreuzungspunkt

20

8023382.14JZ | SICK

Subject to change without notice

Page 21

1.

2.

3.

1

2

3

INBETRIEBNAHME

Abbildung 12: Bezugspunkte

Bei der Schaltpunktpositionierung muss die Größe des Objektes berücksichtigt werden,

siehe Abbildung 12.

Der Positioniervorgang kann wie folgt vorgenommen werden:

Punktbestimmung

1. Mit dem Werkstück in das WFZ einfahren, bis ein Schaltausgang schaltet

2. Das Werkstück seitlich bewegen, bis der zweite Schaltausgang schaltet

3. Zurück zur mittleren Position bewegen und anschließend Richtung Gabelmitte bewe‐

gen bis der Kreuzungspunkt erreicht ist und beide Schaltausgänge schalten

16

8023382.14JZ | SICK

Subject to change without notice

Abbildung 13: Punktbestimmung an der Objektspitze

Die Ausrichtung des Werkstücks auf der Z-Achse kann zusätzlich ermittelt werden, indem

das Werkstück nach der Punktbestimmung auf der Z-Achse verschoben nochmals positio‐

niert wird (Schritt 4, 5 und 6).

21

Page 22

4

5

6

17 STÖRUNGSBEHEBUNG

Abbildung 14: Erneute Punktbestimmung

Wenn zwei Punkte auf der Z-Achse des Werkstücks im Kreuzungspunkt des WFZ liegen, ist

das Werkstück nicht nur mittig sondern auch senkrecht zum WFZ ausgerichtet.

Abbildung 15: Korrekte Positionierung im Kreuzungspunkt, senkrecht zum WFZ

2 Teach-in-Funktion

Pin 5 bzw. graue Leitung > 1 s auf + (L+) legen. Während des Teach-Vorgangs blinken die

gelben LED-Anzeigen.

HINWEIS

Es wird empfohlen, für die maximale Messgenauigkeit die Teach-in-Funktion vor jeder Mes‐

sung durchzuführen. Mindestens aber:

nach der Erstinbetriebnahme des Sensors

•

nach der Reinigung

•

wenn die Lichtstrahlen ein schwaches Signal anzeigen, obwohl der Lichtweg frei ist

•

3 PNP (Last → M): Lichtweg frei, Ausgang (Q) High

17 Störungsbehebung

Tabelle Störungsbehebung zeigt, welche Maßnahmen durchzuführen sind, wenn die

Funktion des Sensors nicht mehr gegeben ist.

22

8023382.14JZ | SICK

Subject to change without notice

Page 23

Tabelle 4: Störungsbehebung

Anzeige-LED / Fehlerbild Ursache Maßnahme

Grüne LED leuchtet nicht bzw.

flackert

Q-LED blinkt gelb Sensor ist noch betriebsbe‐

Eine der beiden Q-LEDs leuch‐

tet nicht

18 Demontage und Entsorgung

keine Spannung oder Span‐

nung unterhalb der Grenz‐

werte

Spannungsunterbrechungen Sicherstellen einer stabilen

Sensor ist defekt Wenn Spannungsversorgung

reit, aber die Betriebsbedin‐

gungen sind nicht optimal

Der entsprechende Lichtstrahl

ist unterbrochen

Die optischen Flächen sind

verschmutzt

Spannungsversorgung prüfen,

den gesamten elektrischen

Anschluss prüfen (Leitungen

und Steckerverbindungen)

Spannungsversorgung ohne

Unterbrechungen

in Ordnung ist, dann Sensor

austauschen

Reinigung der optischen Flä‐

chen. Teach-in erneut durch‐

führen.

Objekt aus Lichtstrahl entfer‐

nen

Reinigung der optischen Flä‐

chen. Teach-in erneut durch‐

führen.

19 Wartung

Die Lichtschranke muss entsprechend den geltenden länderspezifischen Vorschriften

entsorgt werden. Bei der Entsorgung sollte eine werkstoffliche Verwertung (insbeson‐

dere der Edelmetalle) angestrebt werden.

HINWEIS

Entsorgung von Batterien, Elektro- und Elektronikgeräten

Gemäß den internationalen Vorschriften dürfen Batterien, Akkus sowie Elektro-

•

und Elektronikgeräte nicht mit dem Hausmüll entsorgt werden.

Der Besitzer ist gesetzlich verpflichtet, diese Geräte am Ende ihrer Lebensdauer

•

bei den entsprechenden öffentlichen Sammelstellen abzugeben.

•

Dieses Symbol auf dem Produkt, dessen Verpackung oder im vorliegen‐

den Dokument gibt an, dass ein Produkt den genannten Vorschriften unterliegt.

SICK-Sensoren sind wartungsfrei.

Wir empfehlen, in regelmäßigen Abständen

die optischen Grenzflächen zu reinigen

•

Verschraubungen und Steckverbindungen zu überprüfen

•

Veränderungen an Geräten dürfen nicht vorgenommen werden.

8023382.14JZ | SICK

Subject to change without notice

Irrtümer und Änderungen vorbehalten. Angegebene Produkteigenschaften und techni‐

sche Daten stellen keine Garantieerklärung dar.

23

Page 24

20 TECHNISCHE DATEN

20 Technische Daten

WFZ

Laserklasse I

Wellenlänge 650 nm

Gabelweite 120 mm

Gabeltiefe 185 mm

Kleinstes detektierbares Objekt (MDO) 0,5 mm

Schaltfunktion Hellschaltend

Versorgungsspannung U

Stromaufnahme < 100mA

Ausgangsstrom I

Schaltfolge max. 1.000 Hz

Reproduzierbarkeit ± 0,01 mm

Ansprechzeit max. 0,5 ms

Initialisierungszeit 50 ms

Schutzart IP67

Schutzklasse III

Betriebsumgebungstemperatur -10 °C ... +50 °C

Lagertemperatur -30 °C ... +65 °C

1)

Grenzwerte; Betrieb im kurzschlussgeschützten Netz max. 8 A; Restwelligkeit max. 5 V

2)

Ohne Last.

3)

Mit Hell- / Dunkelverhältnis 1:1

4)

Signallaufzeit bei ohmscher Last

5)

Unter 0 °C Leitung nicht verformen.

max.

V

10 V DC ... 30 V DC

2)

1)

100 mA

3)

4)

5)

ss

24

8023382.14JZ | SICK

Subject to change without notice

Page 25

Maßzeichnung

220

120

5,4

29,5

63

100

220

167

156

100

113

78

3

3

1

25

2

4

3

TECHNISCHE DATEN 20

Abbildung 16: Maßzeichnung

Detektionsachsen

1

Stecker, M12, 5-polig

2

Befestigungsbohrung Ø 5,4 mm

3

Anzeige LED

4

8023382.14JZ | SICK

Subject to change without notice

25

Page 26

Detailed addresses and further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 234 719 500

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 010

E-Mail info@sick.de

Greece

Phone +30 210 6825100

E-Mail office@sick.com.gr

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 97110 11

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mexico@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 10 060 0550

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail infokorea@sick.com

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail contact@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales

.gsg@sick.com

SICK

26

Subject to change without notice

8023382.14JZ | SICK

Loading...

Loading...