Page 1

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

T

ECHNICAL D ESCRIPTION

Page 2

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

The information contained in

this document may be revised

or supplemented without prior

notice.

2

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 3

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Contents

Contents

1 Document Information .................................................................................................. 5

1.1 About this document ..................................................................................................... 5

1.2 Target group .......................................................................................................................5

1.3 Scope of information ....................................................................................................6

1.4 Symbols used in this document ............................................................................6

2 Safety....................................................................................................................................... 7

2.1 General safety advice and protective measures........................................ 7

2.2 Application areas ............................................................................................................. 8

2.3 Intended use of the device ...................................................................................... 9

2.4 Environmental compatibilty ....................................................................................... 9

3 Product Description..................................................................................................... 10

3.1 Characteristics................................................................................................................ 10

3.2 Device functionality..................................................................................................... 10

4 Mounting ............................................................................................................................ 11

4.1 Positioning the sensors ........................................................................................... 11

4.2 Safety distance.............................................................................................................. 11

4.3 Distance to reflective surfaces........................................................................... 13

4.4 Multiple safeguarding ................................................................................................ 15

4.4.1 Mutual interference ................................................................................................. 16

4.5 Mechanical mounting.................................................................................................. 16

4.5.1 Corner mirrors ............................................................................................................. 18

5 Electrical Installation................................................................................................. 19

5.1 Test instructions............................................................................................................ 20

5.2 Spark suppression....................................................................................................... 20

5.3 Short-circuit monitoring............................................................................................. 21

5.4 Overvoltage protection (fuse)............................................................................... 21

5.5 Wiring diagram ................................................................................................................ 22

5.6 Alignment of WSU and WEU ................................................................................... 30

5.6.1 Alignment of WSU and WEU with Alignment Aid AR 60.................... 31

6 Test Instructions ............................................................................................................ 32

6.1 Pre-commissioning tests ......................................................................................... 32

6.2 Regular testing of the safety device by competent personnel...... 32

6.3 Daily testing of the safety module by competent personnel .......... 33

7 Maintenance .................................................................................................................... 34

8 Diagnostic Elements ................................................................................................... 35

9 Technical Data ............................................................................................................... 36

9.1 Overview technical data ........................................................................................... 36

9.2 Dimensional drawings ................................................................................................ 38

10 At a glance: Comparison of old versus new devices............................ 42

11 Selection Table ............................................................................................................ 43

11.1 Conversion list ............................................................................................................. 44

12 Accessories Selection Table ............................................................................... 45

13 Checklist .......................................................................................................................... 46

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

3

Page 4

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

4

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 5

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Document Information

Abbreviations

Chapter 1

PDM

WSU

WEU

OSSD

AOPD

Power-driven machinery (machinery, plant)

Photoelectric Safety Switch: Sender unit

Photoelectric Safety Switch: Receiver unit

Output Signal Switching Device

Active Optoelectronic Protective Device

1 Document Information

1.1 About this document

This document provides instructions for the operation of the WSU/WEU

photoelectric safety switch. It contains information on

Application

Mounting

Electrical installation

Commissioning

Maintenance

Ordering

1.2 Target group

The target group of this document is those who install, commission and

use the WSU/WEU photoelectric safety switch.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

5

Page 6

Chapter 1

Document Information

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

1.3 Scope of information

This technical description contains information on how to install,

commission and operate the device. Official and legal regulations must

always be observed. It is not possible to provide comprehensive

information on all these requirements in this document. In Germany, for

example, the Trade Association Directives (ZH 1/597 and ZH 1/281) in

particular must be observed.

Further information on health and safety with respect to optoelectronic

guarding systems can be obtained directly from your local SICK

distributor, e. g. Safe Machines (SICK guidelines on the operation of

optoelectronic guarding systems).

1.4 Symbols used in this document

Some information in this document is highlighted to ease rapid access to

this information:

Note

Explanation

Recommendation

WARNING

A note provides information on special features of the device.

An explanation gives basic information.

A recommendation assists in deciding upon the best action.

Warning!

A warning indicates actual or potential hazards. This is to reduce the risk

of accidents.

Always read warning notices carefully and follow them closely.

6

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 7

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Safety

Chapter 2

2

Safety

WARNING

The devices can only perform their safety function if they are used

correctly and integrated into the process in a failsafe manner.

The WSU/WEU photoelectric safety switch meets the requirements of

Type 4 Safety Devices as stipulated in EN 61 496-1 and pr EN 50 100-2.

2.1 General safety advice and protective

measures

1 National and international regulations apply for the operation of non-

contact protection equipment as well as for commissioning and

regular maintenance checks, in particular

Machinery Safety Regulation 98/37 EC

Provision and Use of Work Equipment Regulations

89/665 EEC

Relevant safety regulations

Accident prevention regulations and safety guidelines

It is the responsibility of the manufacturers and operators of the

machine on which SICK protection equipment is used to discuss all

safety legislation, which may apply, with the responsible authorities

and to observe these rules and regulations.

2 Furthermore, our notes, in particular the Test Regulations (see

section ‘Tests’) in this Technical Description or the Operating

Instructions (such as use, assembly, installation or integration in the

machine control unit) must be observed.

3 The tests must be performed by qualified personell or by specially

authorised and instructed personnel and must be documented in

such a way as to be viewed and understood at any time.

4 These Operating Instructions shall be given to the employee

(operator) working with the machine on which SICK guarding systems

are installed. The employee shall be trained for their job and

operation of the equipment by a competent person.

5 The Test Protocol relating to use of the non-contact safety device is

printed at the end of these Technical Description. Acceptance testing

should be performed on the basis of that protocol.

6 Mounting and connection may only be done by qualified personnel.

Before commissioning, the mounting and connection must be

inspected by the operator’s responsible staff member, as is required

by the standards and directives of the specific country.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

7

Page 8

Chapter 2

Safety

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

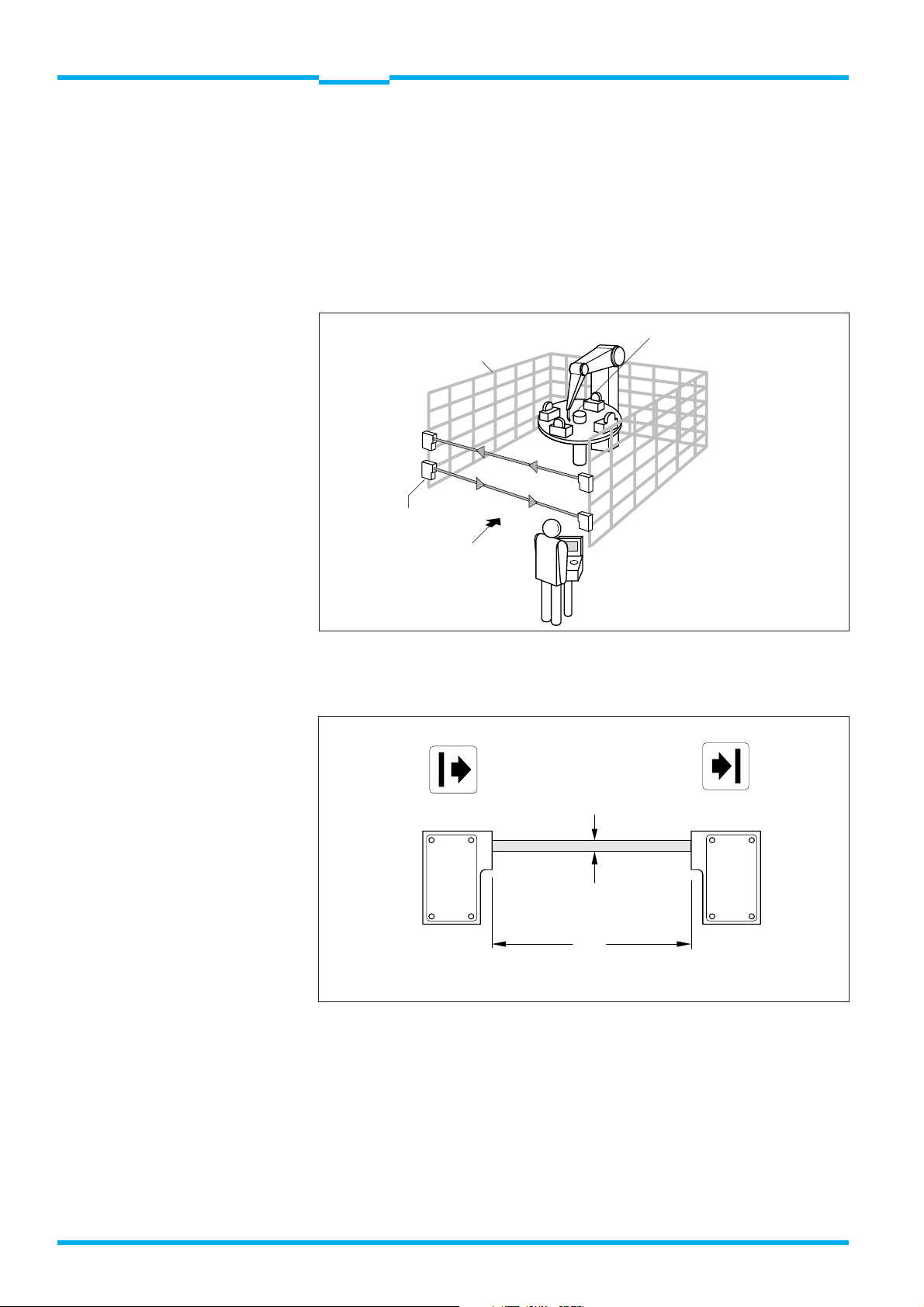

2.2 Application areas

The WSU/WEU 26/2 photoelectric safety switch is used as an access

safety system to hazardous areas around machinery or plant. The device

is securely mounted in the access area at a pre-determined safe

distance from the hazardous point. When the light beam is interrupted

the device transmits an emergency stop signal to the machinery or

plant.

Point-of-operation

Mechanical

mechanische

Absicherung

guarding

Gefahrstelle

Zugangssicherung

Entry/exit guarding

mit WSU/WEU

with WSU/WEU

Direction of entry

Eintrittsrichtung

into hazardous

in Gefahrbereich

area

Fig. 1: Entry/exit safeguarding using a WSU/WEU 26/2

The following key points are important for correct operation (Fig. 2):

Beam diameter

Lichtstrahldurchmesser

23 mm

WSU WEU

23 mm

RW

0.5 to 18 m

15 to 70 m

Fig. 2: System construction of the WSU/WEU 26/2

8

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 9

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Safety

Chapter 2

2.3 Intended use of the device

The WSU/WEU photoelectric safety switch may only be used as

specified in Section 2.2 Application areas. The device may be operated

only in accordance with its technical specifications. Any other use or

modification – including during mounting and installation – will

invalidate any guarantee and any claim against SICK AG.

2.4 Environmental compatibility

The WSU/WEU photoelectric safety switch is designed to have the

lowest possible impact on the environment. It neither emits nor

contains any environmentally damaging substances, and consumes

minimal quantities of energy and resources.

Disposal

Unusable systems or systems beyond repair must be disposed of in

accordance with the regulations on refuse disposal currently valid in the

respective country.

The aluminium housing should be recycled. If possible, remove the

plastic front panel.

All electronic components can be simply dismantled. They should be

disposed of as special waste. SICK AG will not accept back unusable

systems or systems beyond repair.

When dismantling and disposing of components, provisions relating to

occupational safety, the environment and disposal should be observed.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

9

Page 10

Chapter 3

Product Description

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

3

Product Description

3.1 Characteristics

Special characteristics of the WSU/WEU 26/2 photoelectric safety

switch are:

easy installation

universal functionality

solid construction

various connecton options

universal power supply

wide scanning range

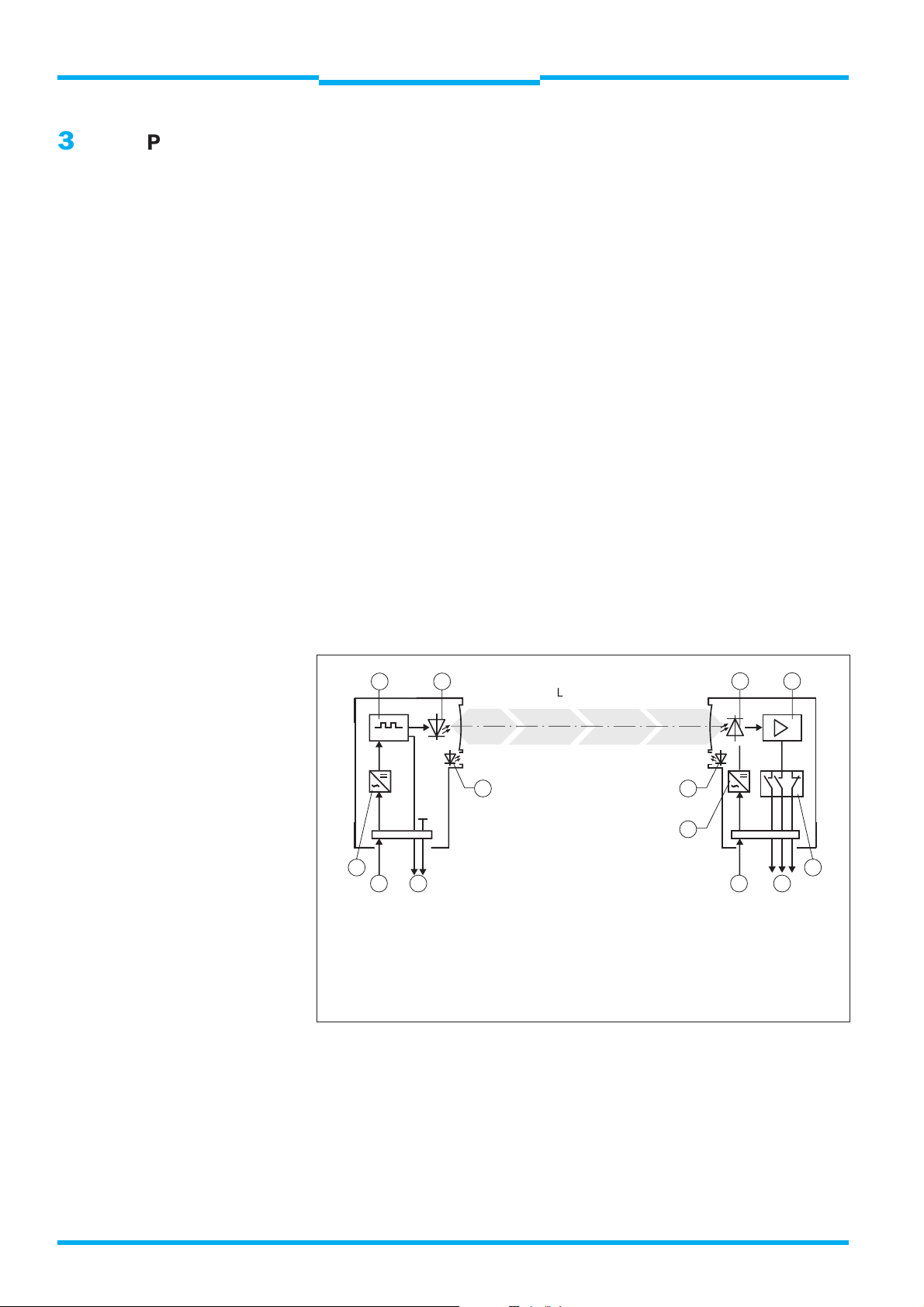

3.2 How the device functions

The housing of WSU/WEU consists of die-cast Aluminium. In the WSU,

an infrared sender diode emits pulse modulated light (Fig. 3).

If the light path is uninterrupted the output relays in the WEU are deenergized.

3 4

5 6

2

11 1 10

1

1 Connection for power supply

2 Power supply

3 Clock generator

4 Sender diode

5 LED, WSU

6 LED, WEU

Fig. 3: Principle of function of the WSU/WEU 26/2, AC version

Light beam

Lichtbündel

10 Outputs

11 Test contact

2

7 Photoelectric converter

8 Amplifier

9 Relay with positively-guided contacts

7 8

9

Diagnostic lights on the instruments signal the various operating

conditions (see 8 Diagnostic Elements). Their display, however, is not

safety related.

The diagnostic lights also serve as error diagnostics, see 8, Diagnostic

Elements.

10

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 11

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Mounting

Chapter 4

4

Mounting

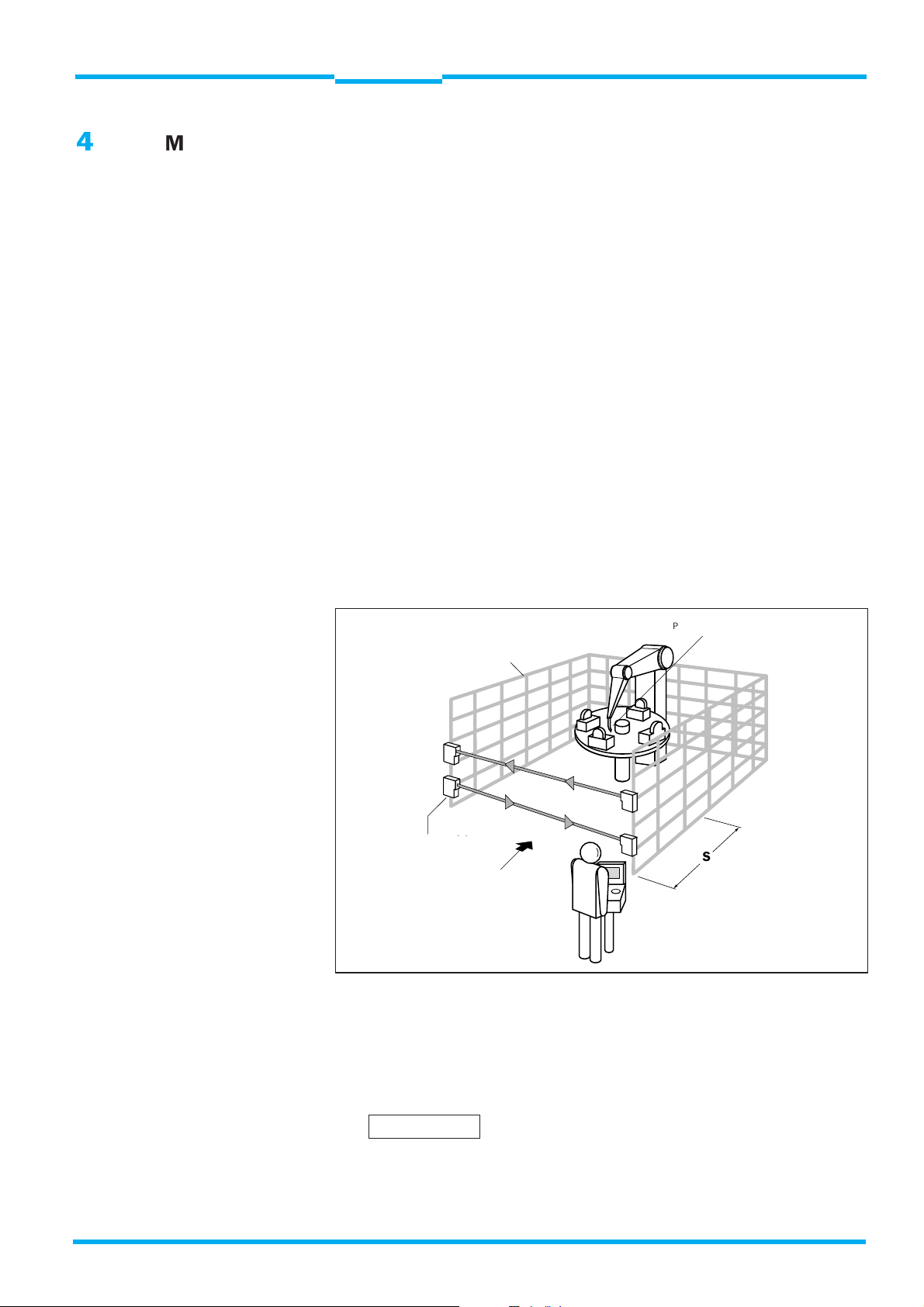

4.1 Positioning the sensors

The WSU/WEU can be operated in any position. Regulations regarding

safety distances must be observed as well as sufficient height of

beams above floor.

4.2 Safety distance

The WSU/WEU must be mounted such that, if the light beam is broken

during hazardous movement of the machinery, the point-of-operation can

only be reached when this hazardous movement has ceased. For this

purpose, a safety distance S must be maintained between the nearest

trapping point and the light beam (Fig. 4). The safety distance depends

on the machine stopping time and on the approach speed of the

personnel.

Point-of-operation

Mechanical

mechanische

guarding

Absicherung

Zugangssicherung

Entry/exit guarding

mit WSU/WEU

with WSU/WEU

Eintrittsrichtung

Direction of entry

in Gefahrbereich

into hazardous

area

Fig. 4: Safety distance S to light beam

Gefahrstelle

S

The machine stopping time must be determined by repeated measurements under practical conditions. 1.6 m/s is the recommended (by

EN 999) approach speed.

The safety distance is calculated as follows:

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

11

Page 12

Chapter 4

Mounting

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

S = K · T + C

S Safety distance (mm)

K Approach speed 1.6 m/s

T Machine stopping time (ms) + response time of WEU

(see Technical Data)

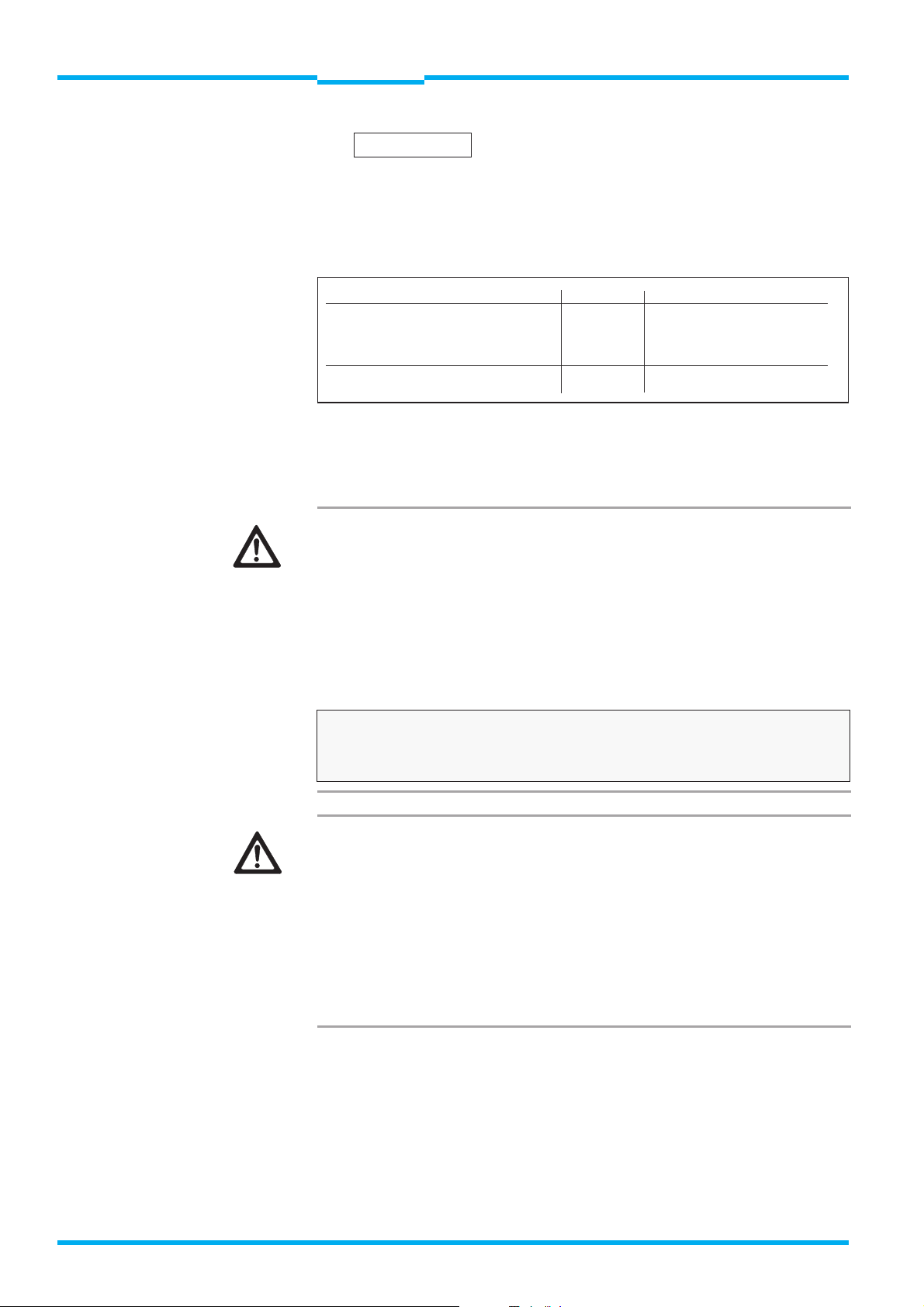

C Dependent on number of beams (1, 2, or 3), see Table 1

Table 1 shows which C value must be used for which application.

Number of beams 1 2 3

Height of beam(s) 750 400 300

above floor (mm) 900 700

C 1200 850 850

Tab 1: Height of beams above floor

1100

WARNING

WARNING

Maintain safety distance!

The WSU/WEU must be mounted such that, if the light beam is broken

during hazardous movement of the machinery, the point-of-operation can

only be reached when the power-driven machinery is no longer in a

hazardous state.

For this purpose, a safety distance must be maintained between the

light beam and the nearest boundary of the point-of-operation. This

safety distance is determined according to pr EN 999.

EN 999

Safety of machinery

Approach speed of body parts for arrangement of protective systems

Danger of non-detection

People within the hazardous area but outside the light beam are not

detected. It must, however, be ensured that any hazardous state can

only be initiated when there is no one in the hazardous area.

The WSU/WEU may not be utilised as a hand- and finger protection

system.

12

Use and mounting of the protective systems is subject to the relevant

official rules and regulations. These provisions differ depending on the

area of application.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 13

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Mounting

Chapter 4

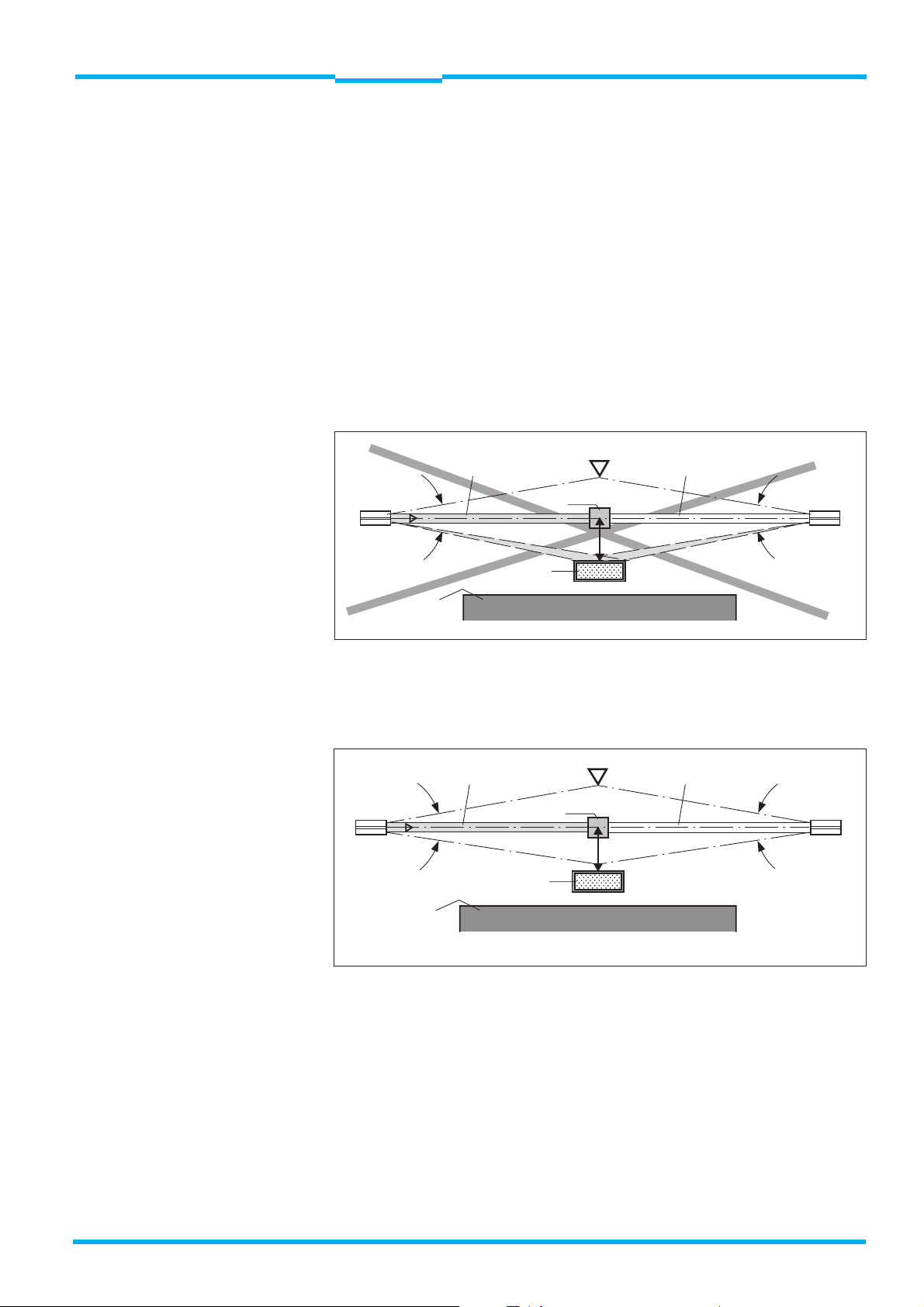

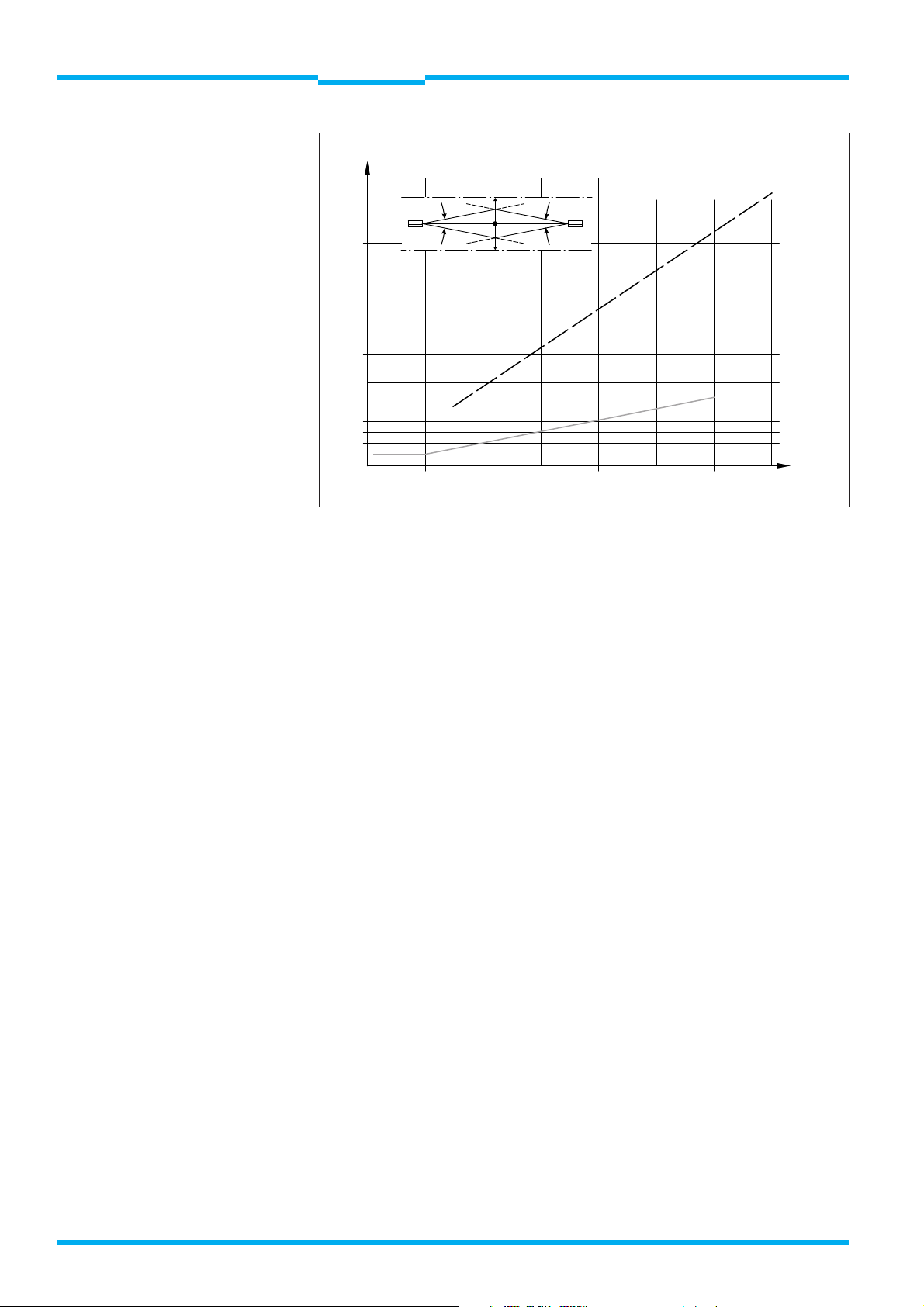

4.3 Distance to reflective surfaces

Reflective surfaces located (placed or fixed) within the sender and

receiver range, may cause reflection and thus prevent an obstacle from

being reliably detected (Fig. 5).

For this reason, a minimum distance “a” from reflective surfaces to

the optical axis (linear connection between transmitter and receiver)

must be maintained (Fig. 6). The distance “a” is dependent on the

distance between the sender and receiver (Fig. 7).

Testing for spurious reflection is described in Section 6 Test

Instructions.

Entry direction

Central beam

Obstacle

Beam array

broken

4

WSU WEU

4

Reflective object

(e. g. material container)

Boundary of

point-ofoperation

a

Deflection: “a” should be set higher

because of the reflection

Fig. 5: Incorrect mounting: reflective object in divergent light beam. No

detection of the obstacle due to reflection. No protection.

Entry direction

Central beam

WSU WEU

4˚

Reflective object

(e. g. material container)

Boundary of

point-ofoperation

Obstacle

a

Beam array

broken

4˚

Fig. 6: Correct mounting, correctly aligned: reflective object outside divergent

light beam. No reflection. The obstacle is clearly detected.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

13

Page 14

Chapter 4

Mounting

a (mm)

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

2500

2000

1500

1000

500

400

300

200

100

WSU WEU

4˚

3

10

20

a

30

4˚

9

12

40

15

50

a

6

Fig. 7: Distance “a” as a function of scanning range RW

a (18 m)

18

60

a (70 m)

21

70

RW (m)

RW I

RW II

14

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 15

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Mounting

Chapter 4

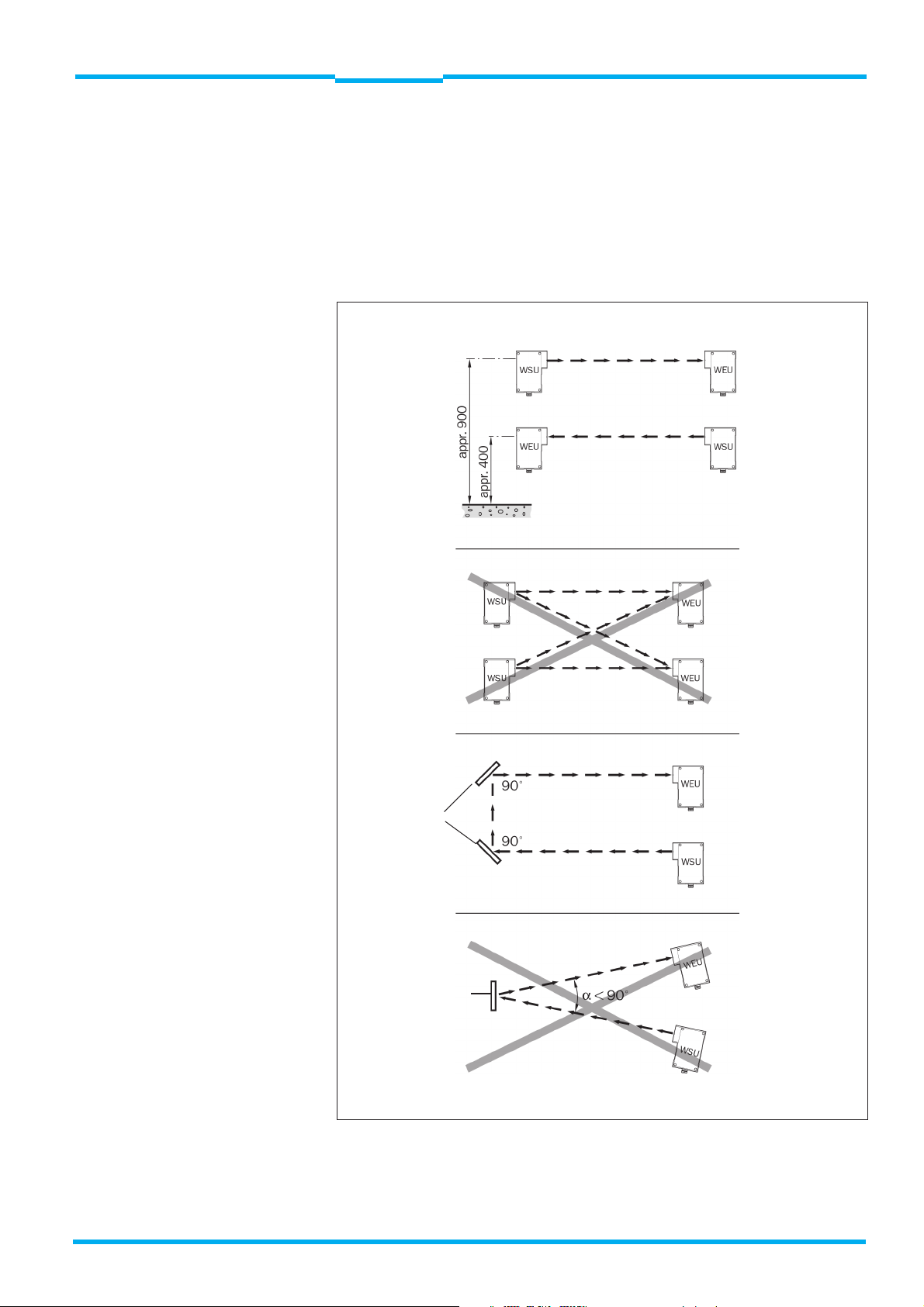

4.4 Multiple safeguarding

When using two WSU/WEU units in a protective system, the possibility

of mutual interference must be excluded. Since the light beam of the

WSU diverges, the cross-section of the beam increases as the distance

between the WSU and WEU increases. The following conditions must

therefore be met when arranging the WSU/WEU (Fig. 8).

Correct

Wrong

Correct

Corner mirror

Wrong

Corner mirror

Fig. 8: Safeguarding a hazardous area with WSU/WEU

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

15

Page 16

Chapter 4

Mounting

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

4.4.1 Mutual interference

The transmitted light beam of the WSU must only be received by the

corrsponding WEU. To prevent mutual interference between several

WSU/WEU installations arranged adjacent to or above each other, the

specified beam diameters must be taken into account when mounting

the devices (Fig. 9), see 9 Technical Data.

WARNING

WEU

WSU

WSU

WSU WSU

WEU

WEU

WSU

WSU

WEU

WEU

WEU

Fig. 9: Mounting of two WSU/WEU units in series

There are two versions of WSU ...

... for operating ranges 0.5 - 18 m and 15 - 70 m. The WSU for 15 - 70

m must not be used for operating ranges below 15 m. The operating

range is given on the information plate attached to the device.

4.5 Mechanical mounting

Note

WSU and WEU units can be mounted on one of the sides of their housing or using the mounting bracket, depending on site circumstances.

The mounting bracket greatly assists alignment. The devices can be

mounted in any operating orientation. However, the WSU and WEU

should be mounted such that the axis of the light beam emitted by the

WSU always matches the axis of the WEU optic (alignment sight).

The mounting brackets should be affixed so that all fixing screws are

easily accessible for alignment purposes. Fig. 10 shows examples. The

devices should be mounted such that the opposing device can be

aligned using the alignment sight.

16

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 17

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Mounting

Chapter 4

Do not use with

WSU/WEU 26/2-xx4

Do not use with

WSU/WEU 26/2-xx4

Note

plug version

Note

plug version

Mounting bracket

Part No. 2 007 900

Fig. 10: Mounting options using a mounting bracket

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

17

Page 18

Chapter 4

Mounting

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

4.5.1 Corner mirrors

In conjunction with corner mirrors the WSU/WEU provides multisided,

two-beam access protection (Fig. 11).

Note

Note

The use of corner mirrors reduces the scanning range of the WSU/WEU

system as indicated in the table.

The use of more than 2 mirrors (Fig. 12) requires a very accurate alignment. Use of alignment aid AR 60 is recommended.

Number of mirrors 0.5 ... 18 m WSU 15 ... 70 m WSU

1 17 m 68 m

2 15.5 m 61 m

3 13 m 51 m

4 11 m 42 m

Tab. 2: Reduction in scanning range when using corner mirrors with a = 90°

Corner mirror

Hazardous area

Corner mirror

Hazardous area

Reflection

possible

Power-driven

machinery (PDM)

Corner mirror

Power-driven

machinery

(PDM)

Safety

distance too

small

Umlenkspiegel

Corner mirror

Umlenkspiegel

Corner mirror

18

Fig. 11: Multi-sided protection of

hazardous areas

Fig. 12: Two-beam protection with a

WSU/WEU-26-system

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 19

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Electrical Installation

Chapter 5

5

Electrical Installation

Note

Depending on type, the WSU/WEU 26/2 photoelectric safety switch is

available for the following supply voltages:

24 V DC,

115 V AC or

230 V AC

The information plate gives details.

The two system components must be of the same voltage version and

the same scanning range.

Before connection, check that the supply voltage and mains frequency

on-site are consistent with the specifications on the information plate.

The cable is fed through the PG connector and connected inside the

device, or connected to the equipment plug. The wiring diagram is

depicted again on the housing cover of the respective device.

WARNING

WARNING

The enclosure rating of the devices can only be guaranteed when the

cable is properly clamped in the PG connector and the housing seals fit

correctly. Where long leads are used, the cable cross-sections should

be chosen to ensure the devices are always supplied with the required

voltage (see 9 Technical Data).

Single- or fine-wire conductors up to 1.5 mm2 can be connected to the

clamp terminals (to VDE 0607). Strip to length: 11 mm.

Switch off power!

The electrical connection of the WSU/WEU must only be made or

changed with the power disconnected.

Unscrew the housing cover to connect the WSU/WEU with a PG

connector.

Use both normally-open contacts!

At least two outputs must be connected to the control unit of the

machine being protected (Figs. 22/23). An electromagnetic contact

element (relay) must be connected to each of the two outputs

(normally-open contacts).

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

19

Page 20

Chapter 5

WARNING

Electrical Installation

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Use normally-open outputs!

In new installations, both normally-open outputs must be independently

supplied to two contact elements (e.g. contactors, relays). The normallyclosed output should be used only for functions that are not directly

safety-related.

Explanation

In general, the normally-open contacts

should be used. However, in older

installations a normally-open / normally-

456789

closed combination may have been selected.

This no longer conforms to presentday safety requirements. Should the

WSU/WEU be installed on existing installations,

K2

both normally-open contacts should

K1

be connected in series to the normallyclosed contact as a second channel.

Fig. 13: Installation in

old factories

5.1 Test instructions

The test function enables a check to be made on the connected

contactor mechanisms. In the process, the sender is switched off when

the normally-closed contact is opened. The testing functions is

triggered during a minimum opening time (see 9 Technical Data).

The testing function should be performed via the machinery control

system in the non-hazardous phase (e. g. during a non-hazardous

motion). If the test fails, the power-driven machinery — initiated via the

WEU – must receive a stop signal from the machinery control system.

20

Use the testing function as described!

The test input must be used exclusively as described.

WARNING

5.2 Spark suppression

Spark suppressors are required when using an inductive load ...

... and must be connected in parallel to the inductive load (Fig. 14).

WARNING

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Connections that are made in parallel to the output contact are not

permissible, and may result in unsafe operation.

Diodes must not be used as spark-suppression elements.

Page 21

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Electrical Installation

Contact

Kontakt

im

in

WEU

Supply

Betriebs-

spannung

voltage

Fig. 14: Wiring for inductive contact element

C

R

WEU

Verbraucher,

User

Schütz

relay

Chapter 5

WARNING

Supply voltage Part No. R C

V WmF

115 ... 230 6 001 224 22 0 0,22

2 4 6 001 225 100 2,2

Tab. 3: Summary of spark-suppressor values

Option: plastic encapsulated; connection wires

NYAF 0.5 mm Ø with spade

terminals; fixing with

adhesive pad or cable ties.

5.3 Short-circuit monitoring

The cables from the output contacts are not monitored by the WEU for

short circuits.

Suitable measures

Suitable steps should be taken for monitoring short circuits.

These could be

Short-circuit safe (protected) routing of cables from the WEU to the

contact elements

Screening output cables individually and connect screening to 0 V

Incorporating both contacts to differing voltage levels

Using relay(s) at the outputs where the pull in voltage must be greater

than UV /2.

5.4 Overvoltage protection (fuse)

A fuse must be provided for the control circuit. The fuse rating must

correspond to the maximum current drawn by the output relay.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

21

Page 22

Chapter 5

Electrical Installation

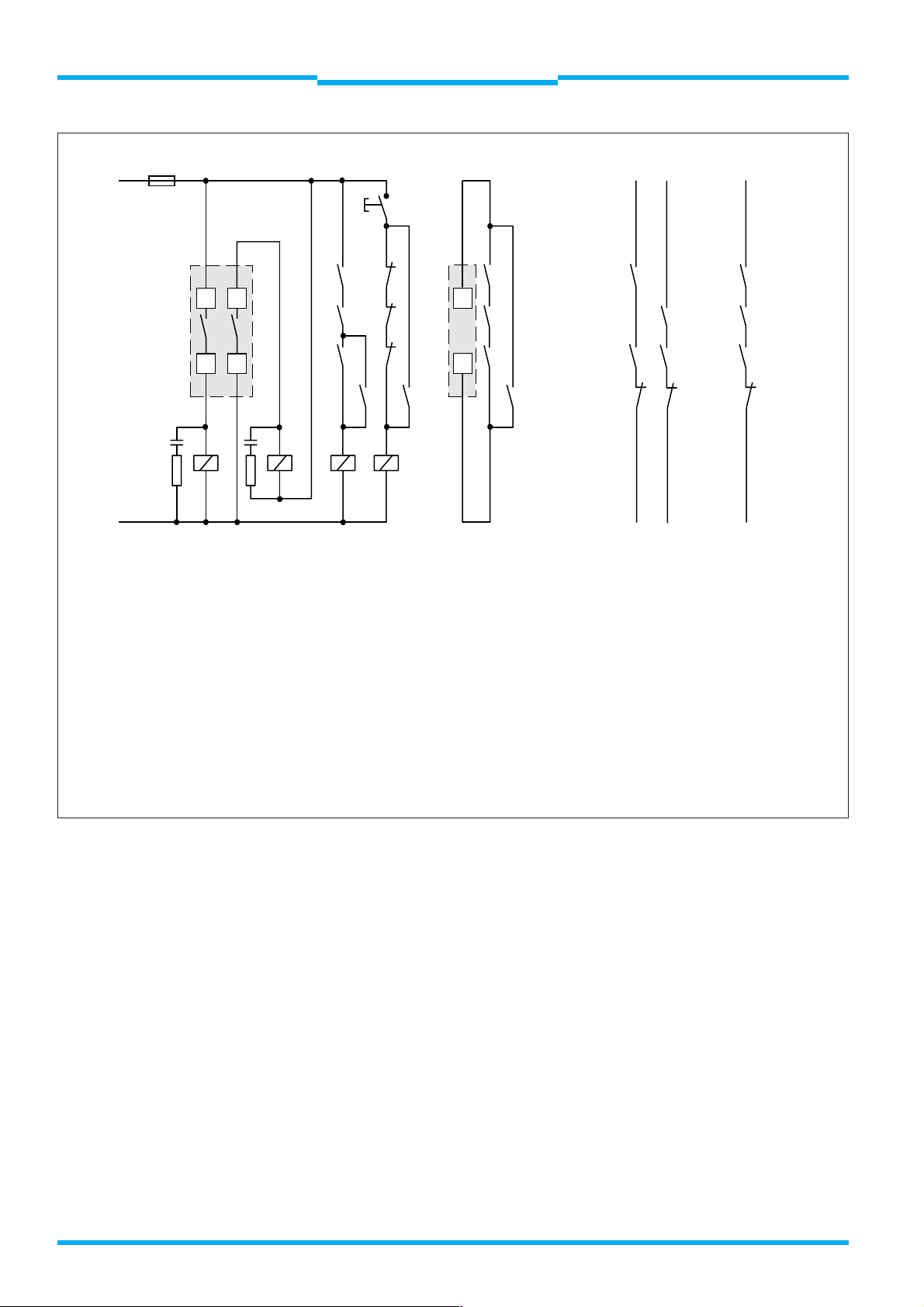

5.5 Wiring diagram

31011

1/2

PE

0 V

+ 24 V

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

3456789

1/2

0 V

PE

+24 V

Technical Description

K1

K2

Fig. 15: Wiring diagram WSU/WEU for 24 V DC supply, with PG connector

1/2

PE L1 N

31011

PE

3456789

1/2

N

L 1

K1

K2

22

Fig. 16: Wiring diagram WSU/WEU for AC supply, with PG connector

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 23

Technical Description

f

f

f

f

f

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Electrical Installation

Chapter 5

1/2

PE +24V

1/2

5

PE +24V

31011

1

2

0V

31011

6

3

0V

3

4

WSU 26/2 -133

4

Equipment plug

WSU 26/2 - 131

A

2

G

F

3

E

4

Gerätestecker

Equipment plug

1

B

A

2

C

G

F

3

Gerätestecker

Coded to

6

Codiert auf

E bzw. 4

D

E or 4

5

E

4

231

1

B

Coded to

C

6

Codiert au

A or

A bzw.

D

5

WSU 26/2 -233

Equipment plug

B

A

2

G

F

3

E

4

Gerätestecker

1

C

6

D

5

Coded to

Codiert au

B bzw. 1

B or 1

3456789

1/2

3

2

1

PE +24V

0V

3456789

1/2

3

2

1

+24V 0V

PE

3456789

1/2

63

5

PE +24V 0V

WEU 26/2- 131

-231

1

B

A

2

G

F

4

6

5

3

4

Gerätestecker

Equipment plug

Coded to

C

6

Codiert au

D or 5

D bzw. 5

D

5

E

WEU 26/2 -132

-232

1

B

A

2

G

F

5

6

4

3

4

Gerätestecker

Equipment plug

Coded to

C

6

Codiert au

E or 4

E bzw. 4

D

5

E

WEU 26/2 -133

-233

1

B

A

2

C

G

F

1

4

2

3

Gerätestecker

Equipment plug

Coded to

6

Codiert au

E bzw. 4

D

E or 4

5

E

4

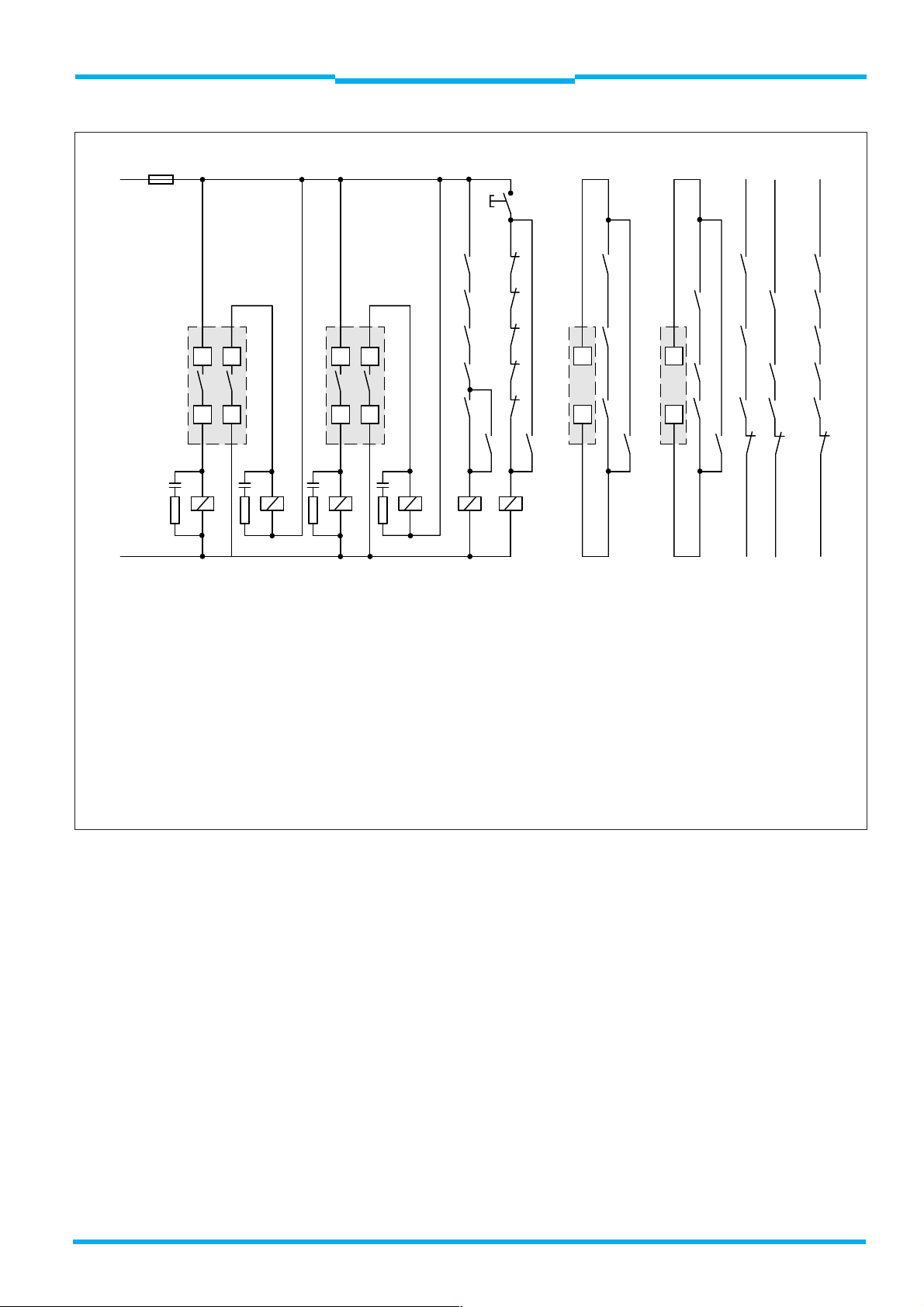

Fig. 17: Wiring diagram WSU/WEU for 24 V DC supply, interchangeable design

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

23

Page 24

f

f

f

Chapter 5

Electrical Installation

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

PE

1/2

1

L 1 NPE

1/2

5

L 1 N

31011

3

2

4

31011

3

6

4

WSU 26/2 -121

1

B

A

2

C

G

3

Gerätestecker

Equipment plug

2

G

F

3

Gerätestecker

Equipment plug

6

F

D

5

E

4

1

B

A

C

6

D

5

E

4

-221

-111

-211

Coded to

Codiert auf

C bzw. 6

C or 6

Coded

Codiert auf

to

A bzw.

A or

Equipment plug

Equipment plug

WSU 26/2 -213WSU 26/2-113

1

B

A

2

C

G

F

3

Gerätestecker

Coded to

6

Codiert auf

G bzw. 2

D

G or 2

5

E

4

WSU 26/2-123

-223

1

B

A

2

G

F

3

4

Gerätestecker

Coded to

C

6

Codiert au

F or 3

F bzw. 3

D

5

E

3456789

1/2

3

2

1

PE

L 1 N

1/2

3456789

3

6

5

PE 230/

N

115 V

3456789

1/2

3

2

1

PE 230/

N

115 V

WEU 26/2-122

-112

-212

-222

1

B

A

2

G

F

3

5

6

4

Gerätestecker

Equipment plug

Coded to

C

6

Codiert au

F bzw. 3

F or 3

D

5

E

4

WEU 26/2 -113

-213

-123

1

-223

B

A

2

C

G

6

Coded to

Codiert au

F

3

4

2

1

Gerätestecker

A bzw.

D

A or

5

E

4

Equipment plug

WEU 26/2 -111

-211

1

B

A

4

6

5

2

G

F

3

4

Equipment plug

Gerätestecker

Coded to

C

6

Codiert auf

G or 2

G bzw. 2

D

5

E

WEU 26/2 -121

221

1

B

A

2

G

F

3

4

Gerätestecker

Equipment plug

Coded to

C

6

Codiert auf

C or 6

C bzw. 6

D

5

E

Fig. 18: Wiring diagram WSU/WEU for AC supply, interchangeable design

24

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 25

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Electrical Installation

Chapter 5

ABC

WSU 26/2 -114

+24 V/L1 (1/2)

1

2

0 V/N (3)

Test (10)

Test (11)

3

4

5

PE

(...) Terminals on electronic card

ABC

1

24 V / L 1 n.c. Test

(1/2) (10)

2

0 V / N n.c. Test

(3) (11)

3

n.c. n.c. n.c.

4

n.c. n.c. n.c.

5

n.c. n.c. n.c.

-214

-124

-224

-134

-234

ABC

WEU 26/2 -114

+24 V/L1 (1/2)

1

2

3

4

5

0 V/N (3)

S 1 (4)

S 1 (5)

Ö 1/2 (6)

S 2 (8)

S 2 (9)

Ö1/2 (7)

PE

(...) Terminals on electronic card

ABC

1

24 V / L 1 n.c. n.c.

(1/2)

2

0 V / N n.c. n.c.

(3)

3

n.c. n.c. n.c.

4

S 1 Ö 1/2 S 2

(4) (6) (8)

5

S 1 Ö 1/2 S 2

(5) (7) (9)

-214

-124

-224

-134

-234

Fig. 19: Pin assignment WSU/WEU 26/2, AC/DC version with equipment plug 15 P + E

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

25

Page 26

Chapter 5

Electrical Installation

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

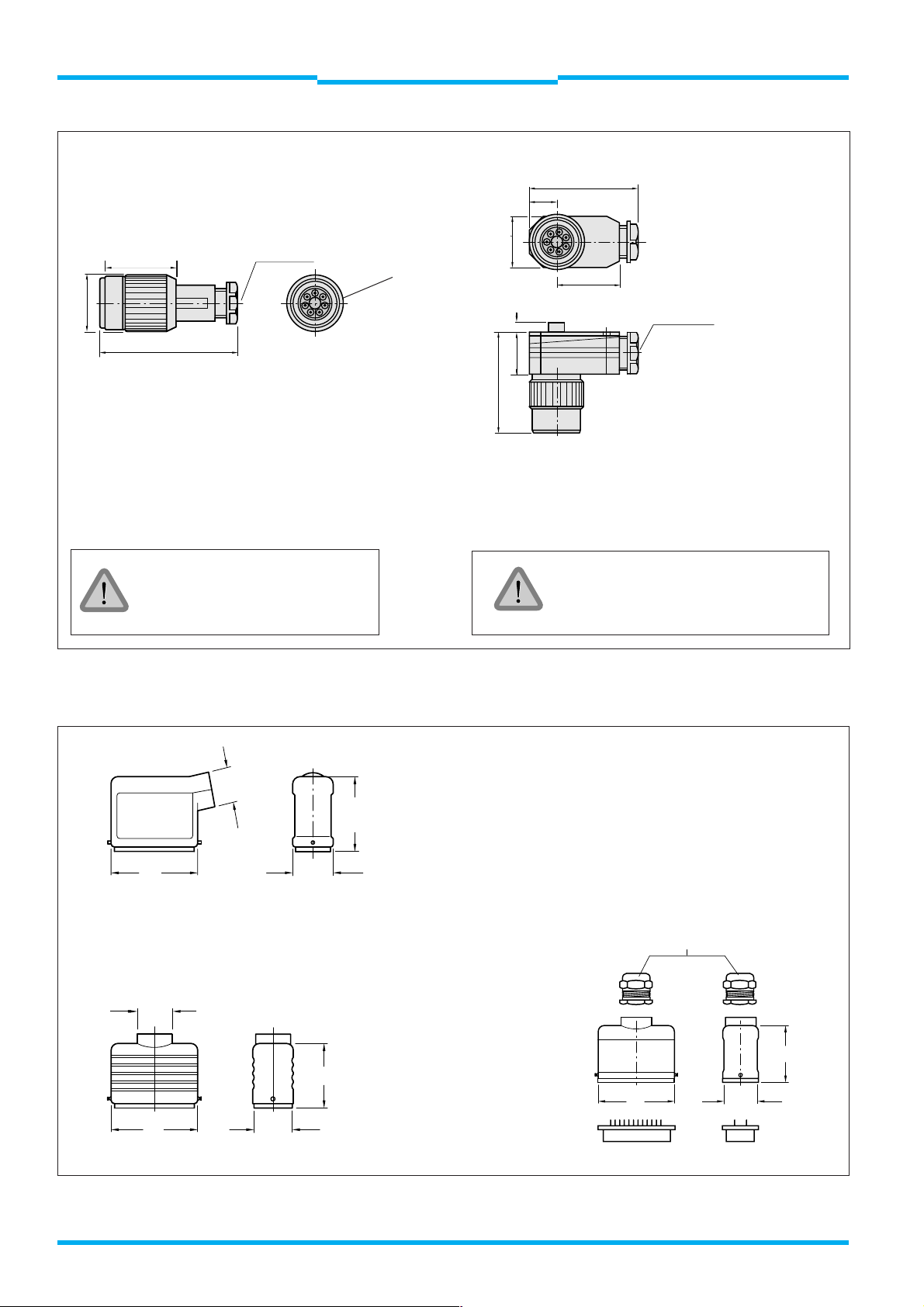

41

ø 28

78

straight

Part no. 6 006 612

Plugs and sockets must be correctly

keyed. The WEU socket must not be

connected to WSU plug.

PG 11

Pay attention to

coding!

66

15

29.5

29,5

40

7.5

7,5

25,5

25.5

53

angled

Part no. 6 006 613

In some cases no longer complies with

requirements for clearance and

creepage distances (pr EN 50 178 und

IEC 664); see selection table. Unsure of

the meaning of this statement!

Plugs and sockets:

DIN 43 651: 6 + PE

with crimp contacts

PG 11

Fig. 20: Cable receptacles 6 + PE

PG 16

63

PG 13.5

PG 13,5

63

29.5

29,5

29,5

47

54,5

54.5

Part no. 2 019 076

Part no. 2 019 075

63

PG 13.5

PG 13,5

29,5

29.5

47

Fig. 21: Cable receptacles 15 P + PE

26

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 27

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

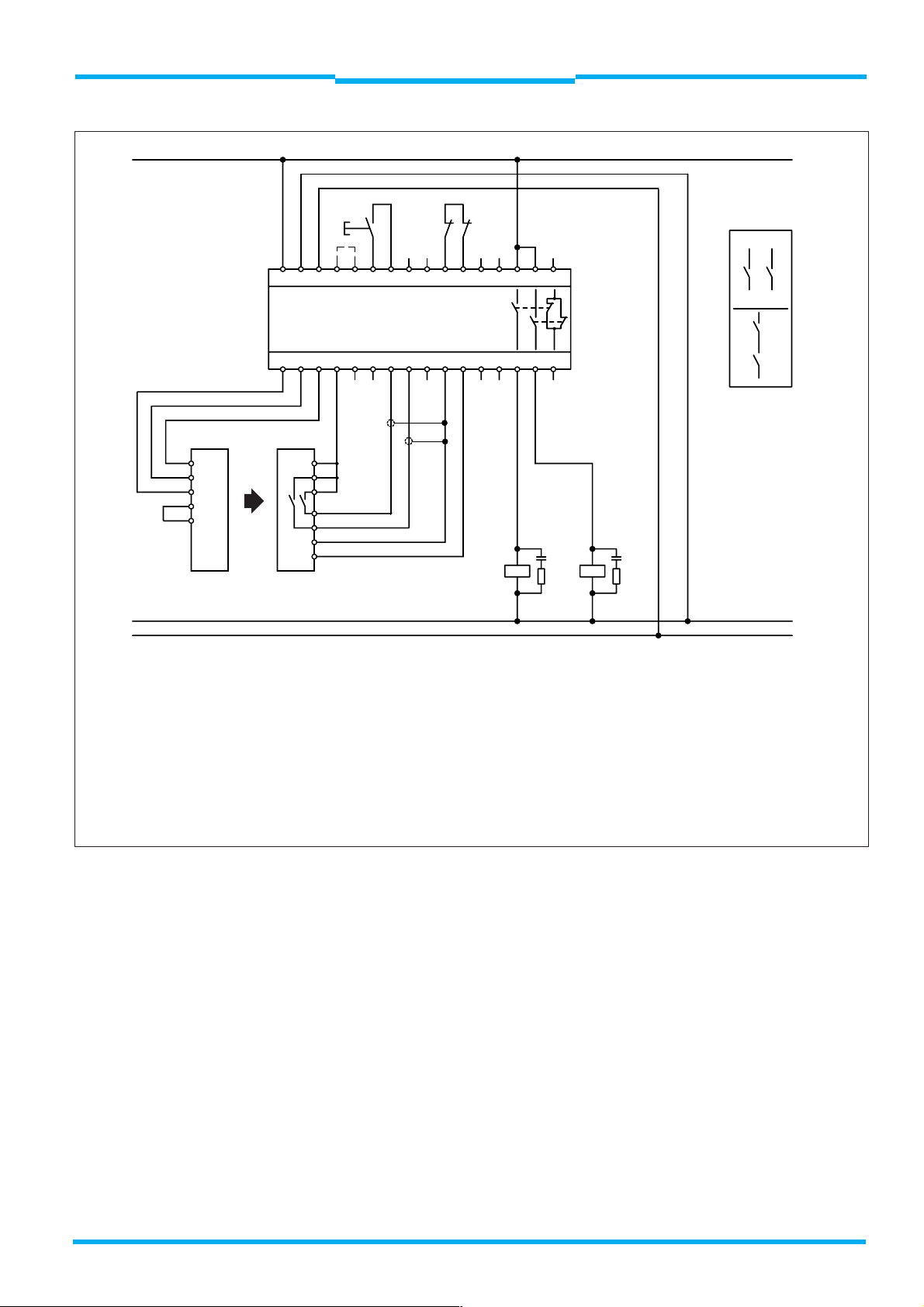

+24 V

Electrical Installation

S1

k1 k2

2

)

A1 A2 PE T0PE T13T14 X11 X12 T21 T22 X21

X22

13 2 3

N.O.

Chapter 5

XY

31

N.C.

N.O.

k1 k2

XY

WSU WEU

PE

PE

3

0V

1/2

+24V

10

Test

11

Test

LCU-X

C1 D1 PE C2 D2 PE T3 T4 C3 D3 PE C4 D4 14 24 32

1

)

1

)

1/2

+24V

4

8

9

5

3

0V

PE

PE

Z

k1

k2

Z

K2K1

0 V

PE

1

) The output contacts of the receiver must be separate and screened; screens must be connected to the negative potential, so that

any cross-connection of the cables on short circuit is detected (see 5.3 Short circuit monitoring).

2

) Potential compensation if power supply unit 0 V is not connnected with PE (VDE 0160)

x und y Connection to the machine controller to interrupt the hazardous movement. For safety reasons, the two

independent contacts

(x and y) must be inserted separately into the controller (two channel)

z If, in exceptional cases, depending on the risk assessment, the controller of the power-driven machinery is only of

a single-channel design, contact row z can be used

Fig. 22: WSU/WEU 26/2 with LCU-X safety interface

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

27

Page 28

Chapter 5

L1

F

max.4A

Electrical Installation

S

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

XY Z

WEU

k1

48

k2

k1

k2

WSU

10

k1

k2

k1

k2

k1

k2

1x

WSU/WEU26

59

Fu

K1

Fu

K2 K3 K4

N

K 1 to K 4 Contactors or relays with positively-driven contacts (not supplied)

Fu Spark-suppression, essential

S Command unit, e. g. pushbutton, key-operated switch etc.

Press button S to start, otherwise red LED on WEU remains lit

x und y Insert in safe machine controller to interrupt the hazardous movement. For safety reasons, the two contact rows

(x and y) must be inserted separately into the controller (two channel)

z If, in exceptional cases, depending on the risk assessment, the controller of the power-driven machinery is only

of single-channel design, contact row z can be used

k3

k3

11

k4 k4 k4

k3

k3

k3

k3

k4 k4 k4

XY Z

In this circuit example, short circuit monitoring is guaranteed by both relays K 1 (N-reference) and K 2 (L1-reference) being

connected at differing voltage levels.

An opened test contact (10 - 11 on WSU) ensures that the sender does not emit and the receiver is de-activated.

Fig. 23: Example connection with a single WSU/WEU-26/2 system

28

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 29

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

F

max.4A

L1

WEU

48

2 x

WSU/WEU 26

59

Electrical Installation

S

k1

k1

k2

k2

WEU WSU WSU

k3

k3

48

59

k4

k5

k4

k5

10

11

k1

k3

k5

10

11

XY Z

k1

k2

k3

k4

k5

k5

Chapter 5

k2

k4

k5

k1

k2

k3

k4

k5

k6 k6 k6

Fu

K1

N

K 1 to K 6 Contactors or relays with positively-guided contacts (not supplied)

Fu Spark-suppression required

S Reset unit, e. g. pushbutton, key-operated switch etc.

Press button S to start, otherwise red LED on WEU remains lit

x und y Connection to the machine controller to interrupt the hazardous movement. For safety reasons, the two contact

lines (x and y) must be inserted separately into the controller (two channel)

z If, in exceptional cases, depending on the risk assessment, the controller of the power-driven machinery is only

of a single-channel design, contact line z can be used

In this circuit example, short circuit monitoring is guaranteed by both relays K 1 (N-reference) and K 2 (L1-reference) being

connected at differing voltage levels.

An opened test contact (10 - 11 on WSU) ensures that the sender does not emit and the receiver is de-activated.

Fu Fu Fu

K2 K3 K4 K5 K6

k6 k6 k6 k6

XY Z

Fig. 24: Example connection with two WSU/WEU-26/2 systems

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

29

Page 30

Chapter 5

Electrical Installation

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

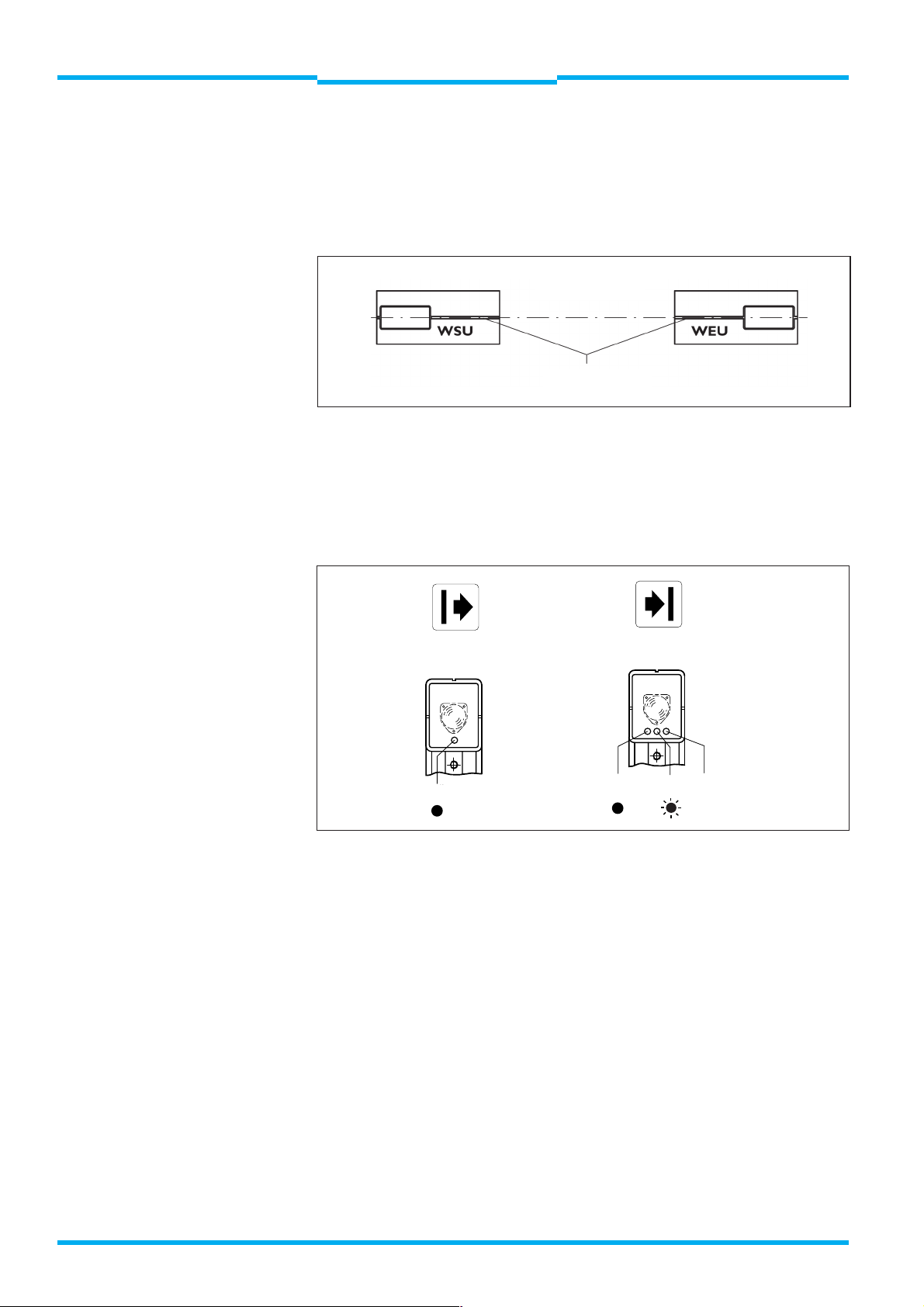

5.6 Alignment of WSU and WEU

After checking the electrical connections, lossen the fixing screws on

the WSU/WEU and roughly align the devices to each other using the

alignment sight (Fig. 25).

Optical axis

Alignment sight

Fig. 25: Alignment with the aid of the alignment sight

If the circuit example Fig. 23 or 24 is used: For further alignment keep

pressing button S or jumper terminals 10 and 11 on the WSU and switch

on the device. When this is done, the LED on the WSU (yellow LED)

lights up (Fig. 26).

Note

WSU

gelb

yellow

Fig. 26: LEDs of the WSU und WEU

WEU

grün gelb rot

green yellow red

Align the devices to each other so that the green LED on the WEU lights

up.

For optimum alignment, determine the limits of the transmission and

receiving range by pivoting the sender and receiver units horizontally

and vertically. When the device leaves its respective optical range, the

yellow LED on the WEU begins to flash. Then fix the sender and

receiver units in the middle of the determined optical range.

The yellow LED on the WEU must be permanently lit.

30

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 31

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Electrical Installation

Chapter 5

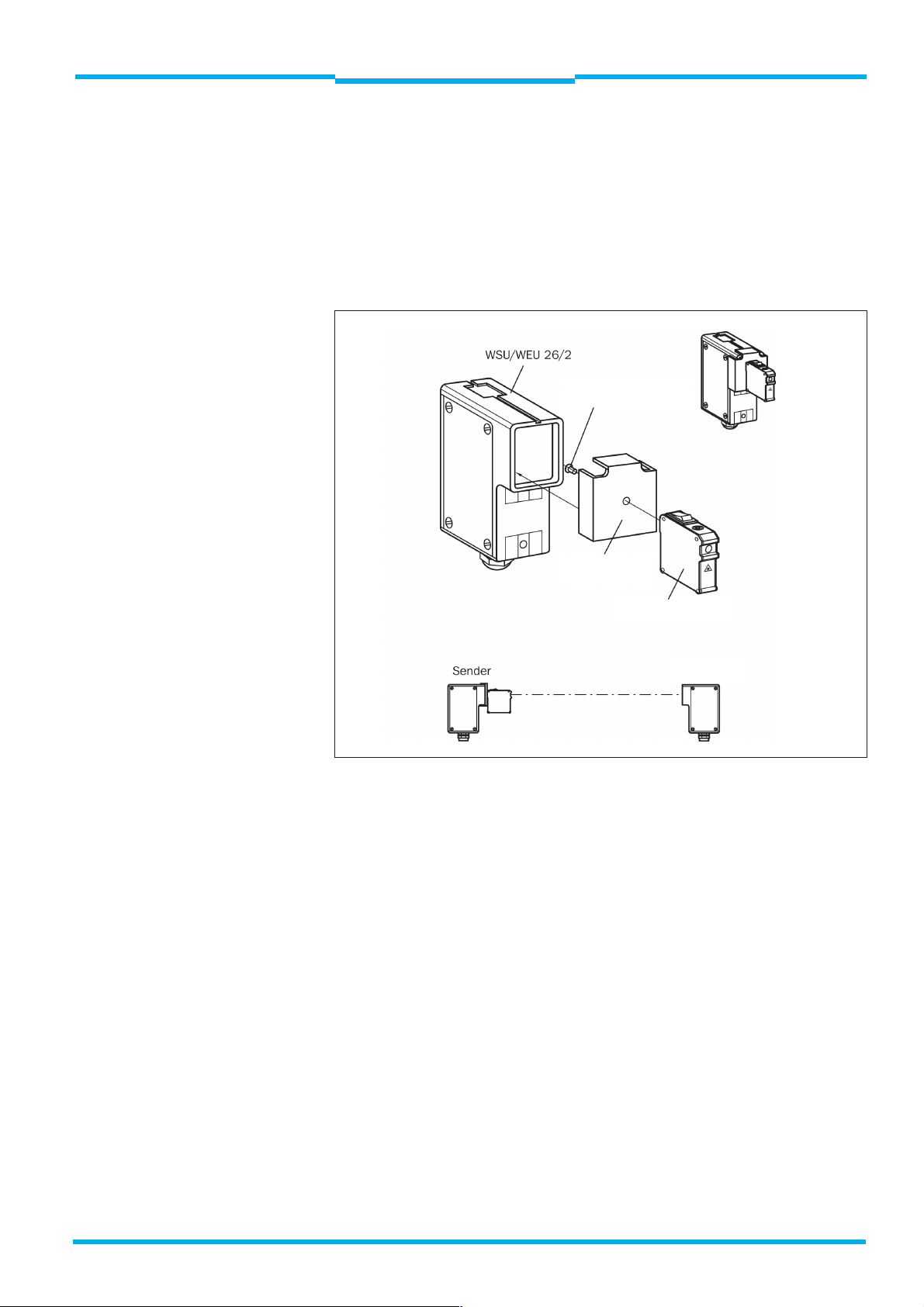

5.6.1 Alignment of WSU and WEU with alignment aid AR 60

For precise alignment of the WSU and WEU the alignment aid AR 60 is

available. The alignment aid is clamped on the front of the WSU and

WEU respectively on a bracket (Fig. 27).

The AR 60 emits a visible laser beam which exactly marks the optical

axes of WSU and WEU if they are correctly mounted.

Fixing screw

M4 x 10

Note

Adapter for

WSU/WEU 26/2

Alignment aid AR 60

Receiver

Fig. 27: Laser alignment aid AR 60 and WSU/WEU

Incorrect alignment may mean that an obstacle is not detected or that

operational safety is not achieved (Fig. 25).

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

31

Page 32

Chapter 6

Test Instructions

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

6

Test Instructions

6.1 Pre-commissioning tests

Inspection prior to commissioning is used to confirm compliance with

Inspection of the effectiveness of the protection equipment on the

Qualified personnel must, prior to starting work, instruct the personnel

Note

Incorrect alignment may mean that an obstacle is not detected or that

operational safety is not achieved (Fig. 25).

The light beam must not be unintentionally reflected by reflecting

surfaces. Reflections can be detected as follows:

the safety requirements specified in national or international

regulations, in particular the machinery safety regulations or the

provision and use of work equipment regulations.

machine in all the operating modes in which the machine can be

placed.

operating the machine protected by the safety device. Instruction is

the responsibility of the machine operating company.

Using an object (surface: 100 x 100 mm2), break the light beam

continuously and without any gaps, starting in front of the WEU and

moving up to the WSU. In the process, the red diode on the WEU must

illuminate continuously. If this is not the case, an inspection should be

made to establish the diversion path the beam takes from the WSU to

the WEU.

This type of functionality check must be performed:

daily before commencing production;

after modifying the WSU/WEU alignment;

after all maintenance and service work carried out on the protection

system.

6.2 Regular testing of the safety device by

competent personnel

Inspection should be carried out in accordance with valid national

regulations at the intervals defined in the regulations. The objective

of these inspections is to detect any changes or modifications to the

protection device since original commissioning.

Inspections should also be carried out whenever major modifications

are made to the machine or protection equipment, as well as after readjustment or repairs in the event of damage occurring to housing,

front lens, connecting cable, etc.

32

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 33

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

WARNING

Test Instructions

Chapter 6

6.3 Daily testing of the safety module by

authorised personnel

Daily testing provides assurance that an effective personnel protection

system is in place.

It is the duty of the operator’s staff to perform testing before each

working day.

Inspection by fully covering the light beam: the red diode on the

receiver unit must illuminate.

Inspection

If the green or yellow diodes illuminate on the WEU, then no more work

may be done using the machinery. It is recommended in this case to

check the system as specified in 6.1 Pre-commissioning tests.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

33

Page 34

Chapter 7

Maintenance

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

7

Maintenance

Note

The system requires no maintenance. However, if the exit window is very

dirty, a clean brush should be used to remove any dust deposits. The

exit window must then be cleaned using a soft, damp cloth.

The following cleaning agents are recommended:

· Non-corrosive window cleaners

· Anti-static plastic cleaners

Do not use any cleaning agents containing alcohol.

If the module has to be opened due to faulty operation, the housing

must be cleaned thoroughly before opening to prevent dirt ingress.

Switch the power off before doing this.

34

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 35

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Diagnostic Elements

Chapter 8

8

WSU

gelb

yellow green yellow red

Diagnostic Elements

WEU

grün gelb rot

Indicator lamp

WSU WEU Cause Inspection and rectification

yellow green yellow red

No voltage supply to WSU Check voltage

Break between terminals Check connection

10 and 11 (Test contact)

No voltage supply to WEU Check voltage on WEU

Break on relay contact, Exchange device

Relay defective

Device misaligned Re-align WSU and WEU devices

Front lens dirty Clean front lens of WSU

and WEU

WEU receiver defective Exchange device

WSU sender does not transmit Briefly switch off voltage

at WSU, then switch on (at least 1 s),

and if no function after this:

exchange WSU

Device or mirror misaligned Re-align device or

mirror

Front lens of WSU/WEU or Clean

mirror dirty

Electronics energize Switch off voltage

briefly and switch on (at least 1 s)

Spurious transmitters WEU may only respond to

WSU allocated to it

Defective electronics card Exchange device

LED off

LED illuminated

LED flashing LED no influence

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

35

Page 36

Technical DataChapter 9

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

9

Technical Data

9.1 Overview technical data

min. typ. max.

General system data

Protective field range 0,5 m 18 m

15 m 70 m

Number of beams 1

Synchronization optical, without separate synchronization

Light beam diameter in front of WSU 23 mm

divergence angle 4°

Wave length of sender 950 nm

Protection class 1

Enclosure rating IP 65 (connection plug)

IP 67 (PG connector)

Operating mode Guard only without start and restart inhibit

Supply voltage U

Frequency AC version 48 Hz 62 Hz

1

Ripple

Voltage if power fails (20 ms) 2) 18 V

On-transition time

Transmitter unit

Test output for floating switches

Test input

Power consumption

) 1.2 V

After applying the supply voltage

of sender and receiver 1.8 s

Output current 10 mA

Reaction time on test 50 ms 60 ms

Opening time of contact for test 75 ms

Test time 150 ms

Version 24 V DC 4 W

Version 115 V AC 7 VA

Version 230 V AC 7 VA

V

19.2 V DC 24 V DC 28.8 V DC

195.5 V AC 230 V AC 253 V AC

97.75 V AC 115 V AC 126 V AC

SS

Receiver unit

Outputs Relay max. operating frequency 0.2 Hz (1 operation in 5 s)

Response time 22 ms

Current 0.02 A 2 A

Voltage 24 V DC 250 V AC

Switch-on time

36

Power (DC/AC) 144 W / 1380 VA

Mech. life expectancy (lifetime) 10

Electr. life expectancy (lifetime)

DC at 2 A current 80 x 10

AC at 2 A current 50 x 10

Normally-open contacts 10 ms

Normally-closed contacts 9 ms

Reference point for measured values: equipment plug or terminals

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

7

3

3

Page 37

Technical Description

Technical Data

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

min. typ. max.

Power consumption

Version 24 V DC 6 W

Version 115 V AC 10 VA

Version 230 V AC 10 VA

Operating data

Connection Connecting cables (PG 13.5)

Connectors

Safety category Type 4

Tested to EN 61 496 part 1 and pr EN 50 100 part 2

Ambient operating temperature –25 °C +55 °C

Storage temperature –25 °C +70 °C

Air humidty (non-condensing) 15 % 95 %

Dimensions see Dimensional Drawings

Vibration resistance 5 g, 10 ... 55 Hz to IEC 68-2-6

Shock resistance 10 g, 16 ms to IEC 68-2-29

Weight

Sender unit 0.9 kg 1.3 kg

Receiver unit 1.0 kg 1.4 kg

Chapter 9

1

) The voltage must not exceed or fall below the limit values.

2

) In conformity with EN 60 204, external voltage supply for the devices must be capable of sustaining a short power

interruption of 20 ms. Suitable power supplies can be obtained from SICK as accessories (Siemens Series 6 EP 1).

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

37

Page 38

Chapter 9

Technical Data

9.2 Dimensional Drawings

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

50

34

65

156

65

14

PG 13.5

PG13,5

Fig. 28: Dimensional Drawing WSU 26/2-xx0 and WEU 26/2-xx0

50

M6 x 8

17.5

17,5

128

15.5

15,5

116

65

95

96

116

156

65

65

14

34

M6 x 8

128

15.5

15,5

65

95

96

81

Space

ca. 50

appr. 50

Freiraum

38

Fig. 29: Dimensional Drawing WSU 26/2-xx4 and WEU 26/2-xx4

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 39

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Technical Data

Chapter 9

156

65

65

14

50

34

M6 x 8

128

15,5

116

65

95

96

100

Space

min. 50

Freiraum

appr. 50

Fig. 30: Dimensional Drawing WSU 26/2-xx1 and -xx3 and WEU 26/2

-xx1, -xx2 and -xx3

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

39

Page 40

Chapter 9

64.5

46.5

39.5

64.5

Mounting bracket WSU/WEU

Part no. 2 007 900

Technical Data

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

M 8 x 30 SW 13

6.5

65

20˚

60˚

51

82

65

51

6

6.5

9

9

40

43

22

M 6

Bracket for corner mirror PSK 1

Part no. 2 009 292

20

26

16.5 33.5

63

ø 20

7

58

71

M 8 x 30 SW13

M 6

67

38

96

100

Corner mirror PSK 1

Part no. 1 005 229

124

14

149

40.5

95

8.5

160

177

2.5

ø 7

14

30

12

190

160 Miroor length

10

Mirror width

105

135

156

Corner mirror PNS 105-1

Part no. 1 004 076

80

96.5

Center of mirror

surface

76

40

40.5

8.5

45˚

146.5

Corner mirror PSK 45

Part no. 5 306 053

Fig. 31: Dimensional drawing accessories

40

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

69.5

8,5

8.5

63

Ø 5.5

80

Mounting set for PSK 1

Part no. 2 012 473

Page 41

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Technical Data

50.5

65.565

73

12.3

50.5

65.565

Chapter 9

119

4

Snow shield

Part no. 1 003 619

140

4

Dust shield

Part no. 1 003 556

7

3

11.8

Fig. 32: Dimensional drawing snow/dust shield

27

13

20

35

15

30

250

250

135

135

3.8

Spark-suppression element

110 - 220 V Part no. 6 001 224

3.8

6.3

Spark-suppression element

48 V Part no. 6 001 225

6.3

Fig. 33: Dimensional drawing spark-suppression element

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

41

Page 42

Chapter 10

At a glance: old versus new

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

10

At a glance: Comparison of old versus new devices

This has changed:

The optical axis of the WSU/WEU 26/2 is shifted 6 mm toward the

device connection

There are two terminals for connection of the power supply: terminal

1/2 and terminal 3

Voltage versions

230 V AC

115 V AC

24 V DC

A new adapter is required for AR 60

No fiber-optic cable version is available

An additional marking on the side identifies the middle of the beam

Die Reichweiten haben sich geändert (siehe unten)

For each range segement there is a sender and a receiver

The beam diameter has changed (see below)

Connector version: the previous connector no longer complies with

requirements for clearance and creepage distances (VDE 0160 05/88

and VDE 0110)

New front screen: may only be cleaned with plastic cleaner

The power consumption has increased (see below)

Note

Components of the (new) WSU/WEU 26/2 system cannot be combined

of the (old) WSU/WEU 26 system. When exchanging in the event of

repair please note that the following combinations are not possible:

WSU 26 with WEU 26/2

WSU 26/2 with WEU 26

Exchange in pairs.

WSU/WEU 26 WSU/WEU 26-2 Value

Scanning range 0.5 to 30 0.5 to 18 m

30 to 60 15 to 70 m

Beam diameter 33 23 m m

Power consumption

115/230 V AC 5 /7 7/10 VA

24 V DC 3/5 4/6 W

42

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 43

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Selection table

Chapter 11

11

Voltage Scanning Termination Sender unit Receiver unit

230 V AC 0.5 to 18 mPG WSU 26/2-110 1 015 615 WEU 26/2-110 1 015 616

115 V AC 0,5 to 18 mPG WSU 26/2-120 1 015 717 WEU 26/2-120 1 015 718

Selection Table

range type Type Part no. Type Part no.

Plug WSU 26/2-111 1 015 712 WEU 26/2-111 1 015 713

Plug *) WSU 26/2-113 1 015 716 WEU 26/2-113 1 015 715

Plug *) WEU 26/2-112 1 015 714

Plug 15 P + E *) WSU 26/2-114 1 015 834 WEU 26/2-114 1 015 835

15 to 70 m PG WSU 26/2-210 1 015 731 WEU 26/2-210 1 015 743

Plug WSU 26/2-211 1 015 733 WEU 26/2-211 1 015 744

Plug *) WSU 26/2-213 1 015 736 WEU 26/2-213 1 015 748

Plug *) WEU 26/2-212 1 015 746

Plug 15 P + E *) WSU 26/2-214 1 015 840 WEU 26/2-214 1 015 841

Plug WSU 26/2-121 1 015 719 WEU 26/2-121 1 015 720

Plug *) WSU 26/2-123 1 015 723 WEU 26/2-123 1 015 722

Plug *) WEU 26/2-122 1 015 721

Plug 15 P + E *) WSU 26/2-124 1 015 836 WEU 26/2-124 1 015 837

15 to 70 m PG WSU 26/2-220 1 015 738 WEU 26/2-220 1 015 749

Plug WSU 26/2-221 1 015 740 WEU 26/2-221 1 015 750

Plug *) WSU 26/2-223 1 015 737 WEU 26/2-223 1 015 505

WEU 26/2-222 1 015 751

Plug 15 P + E *) WSU 26/2-224 1 015 842 WEU 26/2-224 1 015 843

24 V DC 0,5 to 18 m PG WSU 26/2-130 1 015 724 WEU 26/2-130 1 015 725

Stecker WSU 26/2-131 1 015 726 WEU 26/2-131 1 015 727

Stecker *) WSU 26/2-133 1 015 730 WEU 26/2-133 1 015 729

Stecker *) WSU 26/2-231 1 015 747 WEU 26/2-231 1 015 753

Plug *) WSU 26/2-233 1 015 739 WEU 26/2-233 1 015 755

Plug *) WEU 26/2-232 1 015 754

Plug 15 P + E *) WSU 26/2-234 1 015 844 WEU 26/2-234 1 015 845

*) See electrical wiring diagram

Selection of plug variant WSU/WEU

Since 1989 VDE 0160 05/88 and VDE 0110 have stipulated doubled

WARNING

clearance and creepage distances. In the following cases the necessary

clearance and creepage distance of the 6 PE Hirschmann connecting

plug on the WEU are not met:

Supply voltage Voltage at WEU Remarks

WEU output relays

230 V AC 230 V AC Only in case of separated

circuits/phases

230 V AC 24 V DC –

24 V DC 230 V AC –

In order to meet the VDE requirements for clearance and creepage

distances in theses cases, the square 15-pin + PE plug must be used.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

43

Page 44

Chapter 11

Selection Table

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

11.1 Conversion list

WSU to be New type 26/2

replaced Scanning range 0.5 to 18 m Scanning range 15 to 70 m

WSU 26-110 WSU 26/2-110 1 015 615 WSU 26/2-210 1 015 731

WSU 26-111 WSU 26/2-111 1 015 712 WSU 26/2-211 1 015 733

WSU 26-112 WSU 26/2-113 1 015 716 WSU 26/2-213 1 015 736

WSU 26-120 WSU 26/2-120 1 015 717 WSU 26/2-220 1 015 738

WSU 26-121 WSU 26/2-121 1 015 719 WSU 26/2-221 1 015 740

WSU 26-130 WSU 26/2-130 1 015 724 WSU 26/2-230 1 015 745

old

WSU 26-131 WSU 26/2-131 1 015 726 WSU 26/2-231 1 015 747

WSU 26-132 WSU 26/2-133 1 015 730 WSU 26/2-233 1 015 739

WSU 26-210 WSU 26/2-210 1 015 731

WSU 26-211 WSU 26/2-211 1 015 733

WSU 26-212 WSU 26/2-213 1 015 736

WSU 26-220 WSU 26/2-220 1 015 738

WSU 26-221 WSU 26/2-221 1 015 740

WSU 26-230 WSU 26/2-230 1 015 745

WSU 26-231 WSU 26/2-231 1 015 747

WSU 26-232 WSU 26/2-233 1 015 739

Technical Description

WEU to be New type 26/2

replaced Scanning range 0.5 to 18 m Scanning range 15 to 70 m

WEU 26-710 WEU 26/2-110 1 015 616 WEU 26/2-210 1 015 743

WEU 26-712 WEU 26/2-112 1 015 713 WEU 26/2-211 1 015 744

WEU 26-713 WEU 26/2-113 1 015 715 WEU 26/2-213 1 015 748

WEU 26-720 WEU 26/2-120 1 015 718 WEU 26/2-220 1 015 749

WEU 26-730 WEU 26/2-130 1 015 725 WEU 26/2-230 1 015 504

old

WEU 26-731 WEU 26/2-131 1 015 727 WEU 26/2-231 1 015 753

WEU 26-732 WEU 26/2-132 1 015 728 WEU 26/2-232 1 015 754

WEU 26-733 WEU 26/2-133 1 015 729 WEU 26/2-233 1 015 755

44

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 45

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

Selection Table Accessories

Chapter 12

12

Selection Table Accessories

Description Part no.

Alignment aid AR 60, complete 1 015 741

Adapter for alignment aid AR 60 4 031 156

Mounting bracket for WSU/WEU 2 007 900

Corner mirror PSK 1, for scanning range 0.5 to 18 m 1 005 229

Mounting set for PSK 1 2 012 473

Hinged bracket for corner mirror PSK 1 (1 piece) 2 009 292

Corner mirror PNS 105-1,

for scanning range 15 to 70 m 1 004 076

Corner mirror PSK 45 5 306 053

Cable receptacle, straight, 6 + PE (plastic) 6 006 612

Cable receptacle, angled (plastic) 6 006 613

Cable receptacle 15 P + E, lateral cable outlet,

PG 16 2 019 076

Cable receptacle 15 P + E, lateral cable outlet,

PG 13.5 2 019 075

Spark-suppression element RC-A

0,22 mF + 220 W (115 to 230 V) 6 001 224

Spark-suppression element RC-AD

2,2 mF + 100 W (24 V) 6 001 225

Switching amplifier LCU-X 24 V DC 1 013 410

PG-cable gland PG 21 5 305 978

for use of 2 cables with PNOZ 8

PG extension PG 13.5 to PG 21 5 306 052

for use of 2 cables with PNOZ 8

Dust shield 1 003 556

Snow shield 1 003 619

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

45

Page 46

Chapter 13

Checklist

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

13

Maßbilder Spiegel

Checklist

Checklist for machine manufacturer/installer for the

installation of Electro Sensitive Protective Equipment (ESPE)

Dependent upon the application, the checks listed below are a minimum when placing an ESPE

into operation for the first time.

For reference purposes the list should be retained or stored with the machine documents.

1. Are the relevant safety standards incorporated into the machine build?

Will they satisfy the Regulations? Yes No

2. Are the standards listed in the Declaration of Conformity? Yes No

3. Is the ESPE the correct type and interfaced to the correct category? Yes No

4. Is access to the danger zone/point of danger only possible through

the ESPE? Yes No

5. Are measures in place to prevent standing between the ESPE and

the danger zone? If so, are these measures secured against removal? Yes l No

6. Has the overall machine stopping time been checked and

documented? Yes No

7. Is the resultant safety distance observed between the danger point

and the ESPE? Yes No

8. Is the ESPE correctly fixed and secured against movement after

setting in its fixed position? Yes No

9. Are the required protection measures against electric shock in place? Yes No

10. Is the re-set/re-start switch for the ESPE installed and fitted to the

correct standard? Yes No

11. Are the OSSDs of the ESPE connected in accordance with the machine

circuit diagram? Yes No

12. Have the protective functions been inspected in accordance with the

inspection instructions of this document? Yes No

13. Are the protective functions effective in every setting of the operating

mode switch? Yes No

14. Are the switching elements controlled by the ESPE, e. g. contactors,

valves monitored? Yes No

15. Is the ESPE effective during the entire hazardous state? Yes No

16. Is the hazardous state ended when the ESPE is switched on or off,

as well as upon changing operation modes or on switching over to

another protective device? Yes No

17. Is the Daily Check Requirement sign positioned in a place visible to

the operator? Yes No

46

This checklist does not replace the initial commissioning of regular inspections by qualified

personnel.

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Page 47

Technical Description

WSU 26/2 – WEU 26/2

Photoelectric Safety Switch

8 008 692/23-07-01 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

47

Page 48

8 008 692/23-07-01 · KW/KF · Printed in Germany (03.02)

·

Subject to change without prior notice GB 8.02 TB

SICK AG · Industrial Safety Systems · P.O. Box 310 · 79177 Waldkirch · Deutschland

Phone +49 76 81 2 02 0 · Fax +49 76 81 2 02 38 15 · www.sick.de

Your contacts:

A ustralia

Phone +61 3 94 9741 00

008 33 48 02 – toll free

Fax +61 3 94971187

A ustria

Phone +43 2 23 66 22 88-0

Fax +43 2 23 66 22 88-5

Belgium/Luxembourg

Phone +32 24 66 55 66

Fax +32 24 63 31 04

Brazil

Phone +55 11 55 6126 83

Fax +55 11 55 35 41 53

China/Hong Kong

Phone +8 52 27 63 69 66

Fax +8 52 2763 6311

Czech Republik

Phone +42 02 578 10 561

Fax +42 02 578 10 559

Denmark

Phone +45 45 82 64 00

Fax +45 45 82 64 01

Finland

Phone +3 58 9-728 85 00

Fax +3 58 9-72 88 5055

F rance

Phone +33 1 64 62 35 00

Fax +33 1 64 62 35 77

Germany

Phone +49 2 11 53 01 0

Fax +49 2 11 53 01 100

Great Britain

Phone +44 17 27-83 11 21

Fax +44 17 27-85 67 67

Italy

Phone +39 02 92 14 20 62

Fax +39 02 92 14 20 67

Japan

Phone +813 33 58 13 41

Fax +8 13 33 58 05 86

Netherlands

Phone +31 30 229 25 44

Fax +31 30 229 39 94

Norway

Phone +47 6756 7500

Fax +47 67 56 6610

Poland

Phone +48 22 8 3740 50

Fax +48 22 8 37 43 88

Singapore

Phone +65 7 44 37 32

Fax +65 8 417747

Spain

Phone +34 93 4 80 31 00

Fax +34 93 4 73 44 69

Sweden

Phone +46 8 6 80 64 50

Fax +46 8 7 10 18 75

Switzerland

Phone +41 4 16 19 29 39

Fax +41 4 16192921

Taiwan

Phone +88 62 23 65 62 92

Fax +88 62 23 68 73 97

USA

Phone +1(952) 9 41-67 80

Fax+1(952) 9 41-92 87

Representatives and agencies

in all major industrial nations.

Loading...

Loading...