SICK VSPM-6F2113, VSPM-6F2113S19, VSPM-6F2313, VSPM-6F2313S20, VSPM-6F2413 Reference Manual

...Page 1

Inspector PIM60 ver 2.0

Vision sensor

REFERENCE MANUAL

Page 2

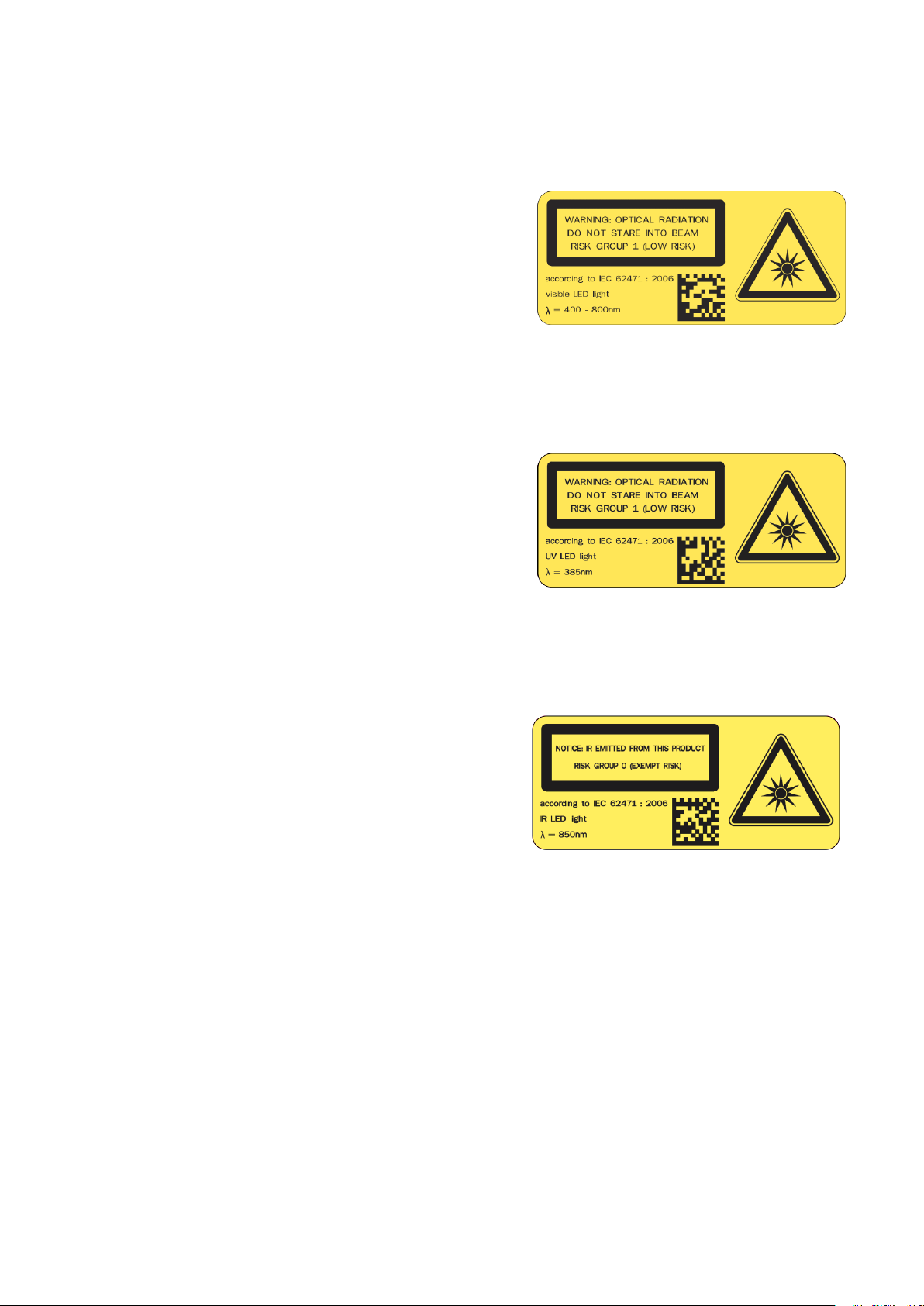

WARNING

VSPM-6F2113 (Inspector PIM60), VSPM-6B2113 (Inspector PIM60 Base)

The Inspector is equipped with a LED illumination

that must be considered as a lamp system of Risk

Group 1 (low risk) according to IEC 62471:2006

Accessible irradiance at distances > 200 mm:

LB<4 x 104W/(m2sr) within 100 s

LH<106W/(m2sr) within 10 s

WARNING: OPTICAL RADIATION DO NOT STARE INTO BEAM

RISK GROUP 1 (LOW RISK) according to IEC 62471:2006

Visible LED light λ = 400-800 nm

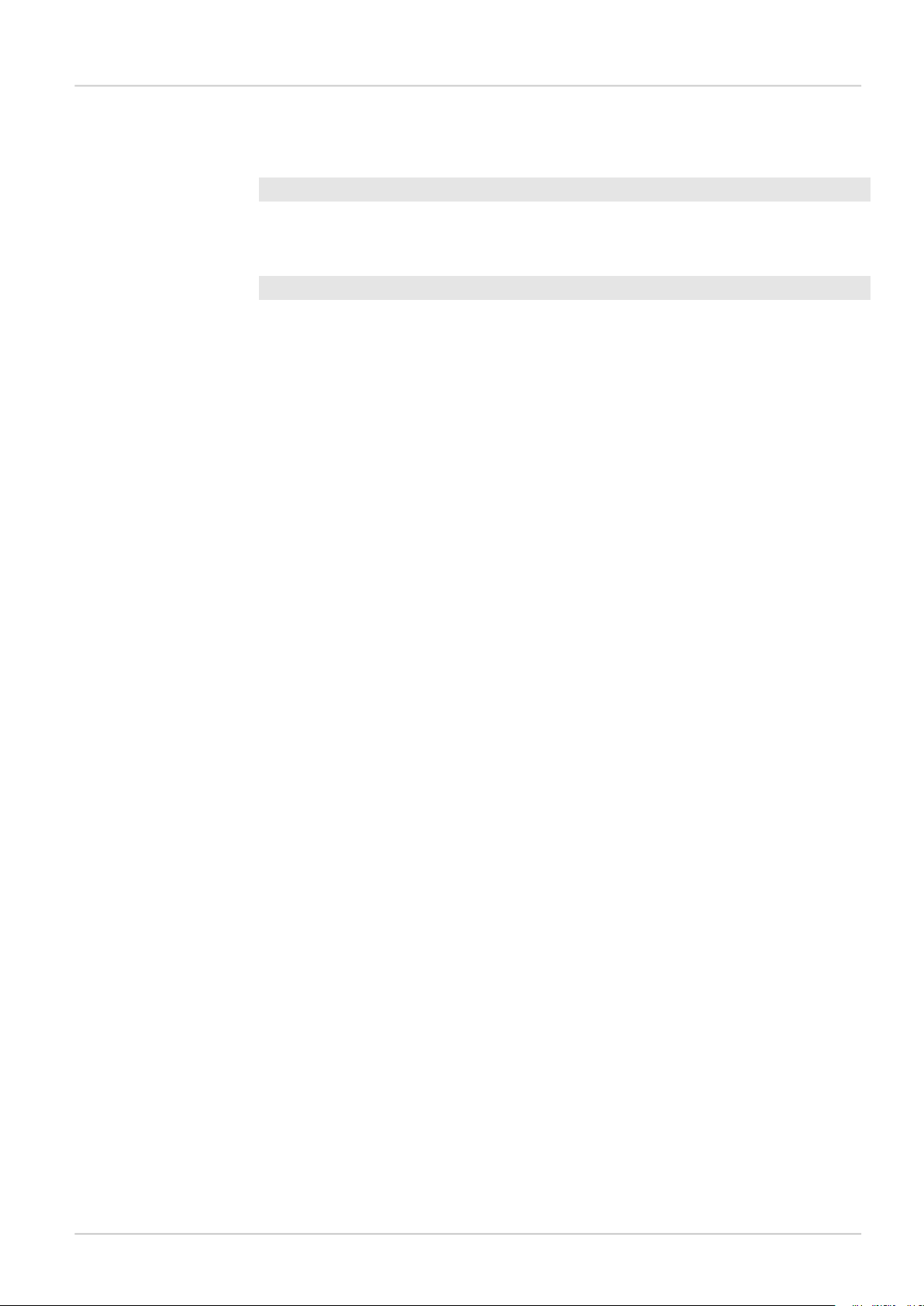

VSPM-6F2313 (Inspector PIM60-LUT)

The Inspector is equipped with a LED illumination

that must be considered as a lamp system of Risk

Group 1 (low risk) according to IEC 62471:2006

Accessible irradiance at distances > 200 mm:

ES< 3 x 10-3W/m2within 104s

E

< 33 W/m2within 300 s

UVA

LR< 7 x 106W/(m2sr) within 10 s

WARNING: OPTICAL RADIATION DO NOT STARE INTO BEAM

RISK GROUP 1 (LOW RISK) according to IEC 62471:2006

UV LED light λ = 385 nm

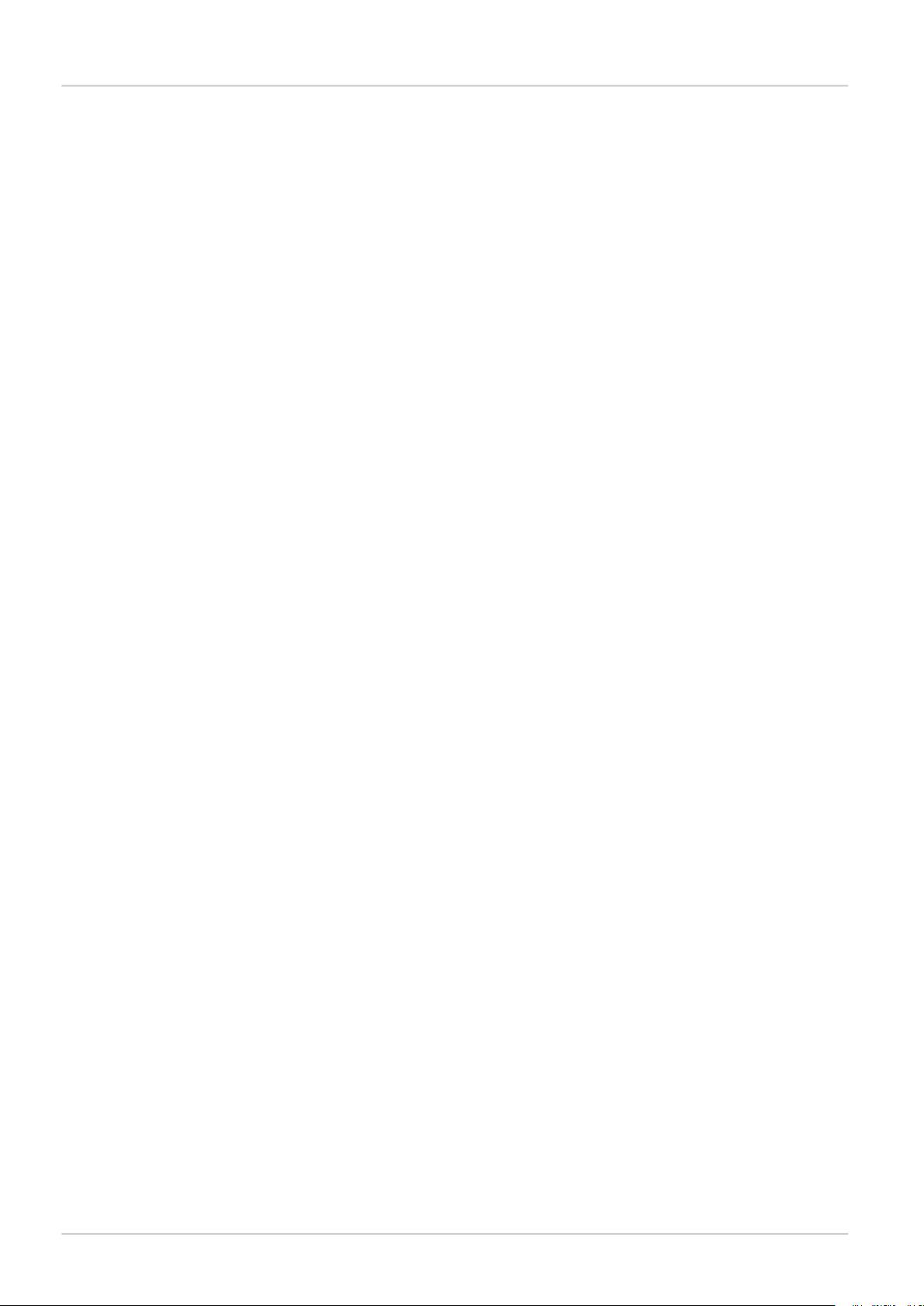

VSPM-6F2413 (Inspector PIM60-IR), VSPM-6B2413 (Inspector PIM60-IR Base)

The Inspector is equipped with an LED illumination that must be considered as a lamp system

of Risk Group 0 / Free Group (exempt risk) according to IEC 62471:2006

Accessible irradiance at distances > 200 mm:

EIR< 100 W/m2within 103s

LIR< 1.2 x 106W/(m2sr) within 103s

NOTICE: IR EMITTED FROM THIS PRODUCT

RISK GROUP 0 (EXEMPT RISK) according to IEC 62471:2006

IR LED light λ = 850 nm

DISCLAIMER

SICK uses standard IP technology for its products, e.g. IO Link, industrial PCs. The focus here is on providing availability of products and services. SICK always assumes that the integrity and confidentiality of data and rights involved

in the use of the above-mentioned products are ensured by customers themselves. In all cases, the appropriate

security measures, e.g. network separation, firewalls, antivirus protection, patch management, etc., are always implemented by customers themselves, according to the situation.

©SICK AG 2013-11-28

All rights reserved

8015726/2013-11

Subject to change without notice

0.1.0.105

Page 3

Reference Manual

Inspector PIM

Table of Contents

Inspector PIM60

Introduction 5

1 Introduction ................................................. ......................................... 6

1.1 Interfaces overview . .. .. .. .. .. .. .. .. .. ................................................. 6

1.2 Intended readers ....................................................................... 6

Interfaces 7

2 I/O extension box .................................................................................. 8

2.1 Physical network connection ........................................................ 8

2.2 Configuration of the IP address on the I/O extension box ................. 8

2.2.1 Basic configuration of the IP address ........ .. .. .. .. .. .. .. .. .. .. 9

2.3 Setup of the I/O extension box in the SOPAS Single Device applica-

tion .... .. .. .. .. .. .. .. .. .. .. .................................................................. 9

2.3.1 Enabling the I/O extension box ................................... 10

2.4 Input and output connections .................................................... 10

2.4.1 Special conditions during startup .. ............................. 10

2.4.2 Connection to the I/O extension box lost during opera-

tion ...................... .. .. .. .. .. .. .. .. .. .. .. ............................ 11

2.4.3 Object selection with I/O extension box ....................... 11

2.4.4 Timing issues ........................................ .. .. .. .. .. .. .. .. .. 11

2.4.5 Use of the digital outputs for logic .............................. 11

2.4.6 Change of Modules in the I/O extension box ................ 11

2.5 Troubleshooting ........ .. .. .. .. .. .. .. .. .. .. ........................................... 11

2.5.1 The I/O LED flashes 10 times .................................... 11

2.5.2 No contact with the I/O extension box ......................... 11

2.5.3 High number of unanswered requests to the I/O exten-

sion box . .. .. .. .. .. .. .. .. .. .. ............................................. 12

3 Web interface ............................................. ......................................... 13

3.1 Introduction ....................................................................... .. .. .. 13

3.2 Get results via Web API ...... .. .. .. .. .. .. .. .. .. .. ................................... 13

3.2.1 Live image ........... .. .. .. .. .. .. .. .. .. .. .. .............................. 13

3.2.2 Detailed results .................... .. .. .. .. .. .. .. .. .. .. ............... 13

3.2.3 Synchronize live image with result .............................. 14

3.2.4 Logged images ........................................................ 14

3.2.5 Statistics .. .. .. .. ......................................................... 15

3.3 Control the sensor via Web API ... .. .. .. .. .. .. .. .. ................................ 15

3.3.1 Basic principles ............................................ .. .... .. .. . 15

3.3.2 Command syntax ..................................................... 15

3.3.3 Current reference object ........................................... 16

3.3.4 Backup and restore configuration ............................... 16

3.4 Create custom web pages . .. ...................................................... 17

3.4.1 Example: Display live image .. .. .. ................................. 19

3.5 Handle the Web API ........................ .. .. .. .. .. .. .. .. .. ........................ 21

4 Ethernet Raw ................... ...................................................... ............. 22

4.1 Introduction ....................................................................... .. .. .. 22

4.1.1 Port interval ............................................................ 22

4.2 Get results via Ethernet Raw .. .. .. .. .. .. .. .. .. .................................... 22

4.2.1 TCP versus UDP . .. .. .. .. .............................................. 22

4.2.2 ASCII versus binary ................................................... 22

4.2.3 Attributes .................................... .. .. .. .. .. .. .. .. .. .. .. .. .... 23

4.2.4 Example formatting strings . .. .. ................................... 23

4.3 Control the sensor via Ethernet Raw ........................................... 26

4.3.1 Basic principles ............................................ .. .... .. .. . 26

4.3.2 Command syntax ..................................................... 26

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

3

Page 4

Inspector PIM60

Reference Manual

Inspector PIM

4.3.3 Select reference object .................................. .. .. .. .. .. . 27

4.3.4 Image triggering ....................................................... 27

4.3.5 Single port solution .................................................. 27

5 EtherNet/IP ............................. ........................................................... 28

5.1 Introduction ....................................................................... .. .. .. 28

5.2 Get results via EtherNet/IP ........................................................ 28

5.2.1 Attributes .................................... .. .. .. .. .. .. .. .. .. .. .. .. .... 28

5.2.2 Example formatting strings . .. .. ................................... 28

5.3 Control the sensor via EtherNet/IP . .. .. .. ...................................... 33

5.3.1 Basic principles ............................................ .. .... .. .. . 34

5.3.2 Command syntax ..................................................... 34

5.3.3 Select reference object .................................. .. .. .. .. .. . 34

5.3.4 Image triggering ....................................................... 35

5.3.5 Input assemblies, result channel . ............................... 35

5.3.6 Assemblies command channel ................................... 36

Appendix 38

A Result output formatting ...................................................................... 39

A.1 XML based formatting ............................................................... 39

A.2 XML formatting ........................................................................ 39

A.3 Container specific tags ............................................................ . 40

A.3.1 General tags . ........................................................... 48

A.3.2 Attributes . .. .. .. .. .. .. .. .. ............................................... 49

B Command channel ............................................................................... 52

B.1 Command syntax . .. .................................................................. 52

B.1.1 Commands ID numbers for EtherNet/IP ...................... 53

B.2 Command channel index handling .. ............................................ 54

B.2.1 Introduction ....................... .. .. .. .. .. .. .. .. .. .. .. ................ 54

B.2.2 Blob indexing ........................................................... 54

B.2.3 Polygon indexing . .. .. .. .. .. .. .. .. .. .. ................................. 54

B.2.4 Tools indexing .......................................................... 54

B.3 Command descriptions .. .. .. .. .. .. .. ............................................... 54

B.4 Error codes ... .. .. .. .. .. .. ............................................................... 72

B.5 Version information . ................................................................. 75

B.6 Command examples .. .. .. .. .. .. .. .. .. .. .. ........................................... 75

B.6.1 Command examples Ethernet Raw .. .. .. .. ..................... 75

C Restore configuration over Web API ......................................... ............. 77

C.1 Restore configuration ................................. .. .. .. .. .. .. .. .. .............. 77

C.2 Create session cookie .............................................. .. .. .. .. .. .. .. .. . 77

C.3 Login ................................................................................. .. .. . 77

C.4 Prepare restore mode ............................................................... 78

C.5 Transfer restore file to device ................................................ .. .. . 78

C.6 Device restart ........ .. .. .. .. .. .. .. .. .. .. .............................................. 78

Index ............................................................................................ .. .. .. .. .. .. .. .. 79

4

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 5

Introduction

Page 6

Introduction

Introduction

Reference Manual

Inspector PIM

1

Introduction

The Reference Manual is a complement to the Operating Instructions for Inspector PIM60

and covers the functionality of all product variants.

The Reference Manual contains detailed information about the interfaces including syntax

and available functionality. It focuses on Inspector PIM60 specific topics and does not describe

the basic technology behind each interface.

The details of the result output formatting and the contents and syntax of the command

channel are shared by several interfaces. They are described in an appendix valid for all relevant interfaces.

For instructions on configuring the interfaces, refer to the Operating Instructions.

1.1 Interfaces overview

The Reference Manual contains detailed information for the following interfaces:

• I/O Extension Box is used to increase the number of available input and output connections

• Web API interface is intended for integration with external HMI implementations, and for

customized web pages on the Inspector

• Ethernet Raw interface is intended for integration with external PLC equipment

• EtherNet/IP interface is intended for integration with external PLC equipment following the

EtherNet/IP communication standard

1.2 Intended readers

The intended readers of the Reference Manual are users working with integration between

the Inspector PIM60 and other equipment, for example PLC programmers and customized

human machineiInterface (HMI) developers.

The readers are assumed to have knowledge about the Inspector PIM60 product and features

as described in the Operating Instructions for Inspector PIM60. The readers are also assumed

to have knowledge about the basic functionality of the technology of the interfaces used for

the integration.

6

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 7

Interfaces

Page 8

Interfaces

I/O extension box

Reference Manual

Inspector PIM

2

I/O extension box

The Inspector PIM60 can be connected to an I/O extension box that increases the number

of digital inputs and outputs. The I/O Extension box is available as an accessory from SICK.

This section covers how the I/O extension box is connected to the Inspector, and how it is

configured.

The following basic steps are required to use the I/O extension box with the Inspector. Details

about the steps are found in the subsequent sections.

1. Connect the I/O extension box to the network.

2. Configure the IP address of the I/O extension box to match the settings of the network,

and the Inspector.

3. Enter the IP address of the I/O extension box in the SOPAS Single Device application.

4. Activate the inputs and/or outputs on the I/O extension box depending on the application.

Note

The SOPAS Single Device application should be closed or set to offline when the power to the

I/O box is disconnected. The I/O extension box needs to be restarted if the IP address is

changed or if the connections to the inputs and outputs on the box are changed.

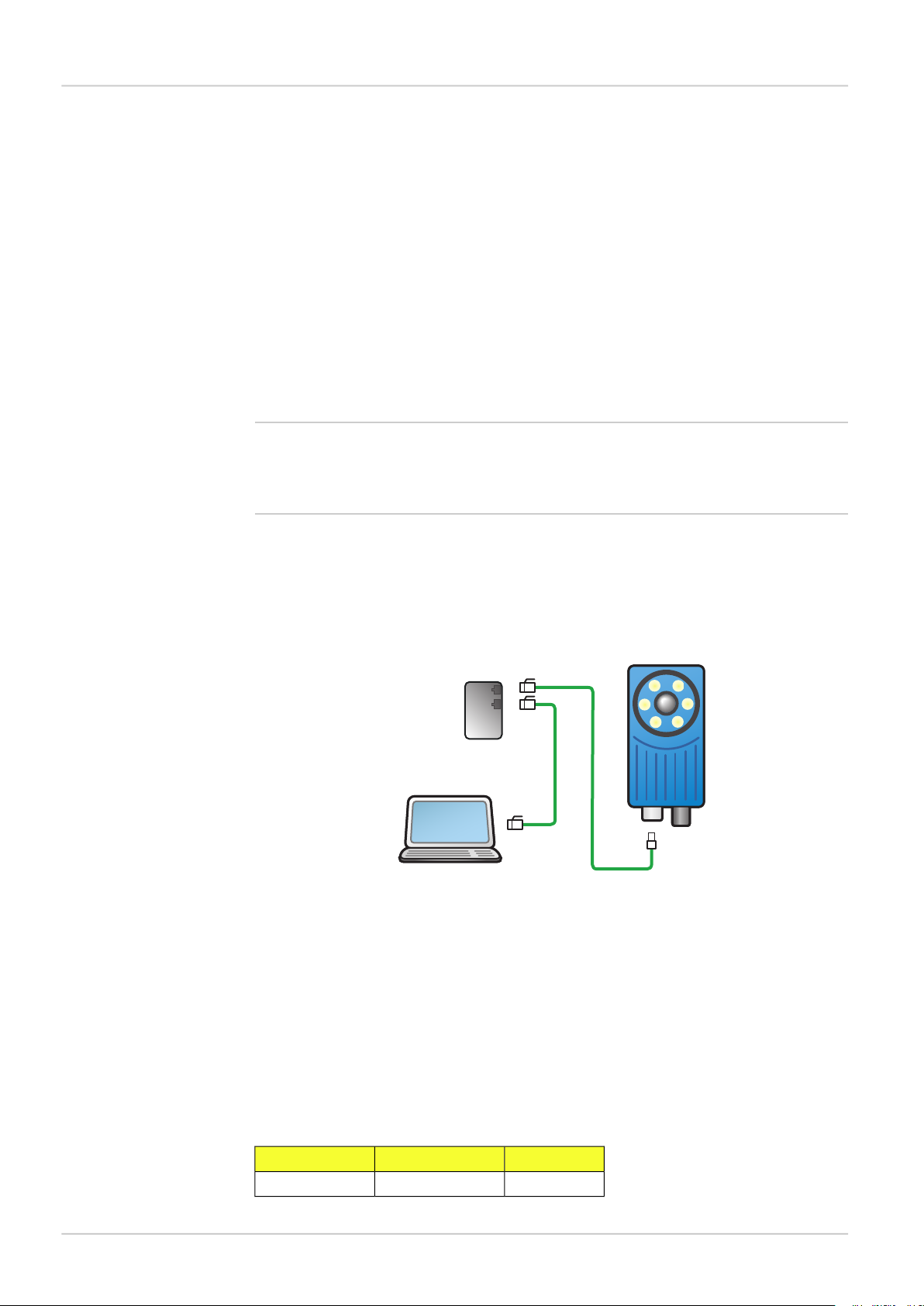

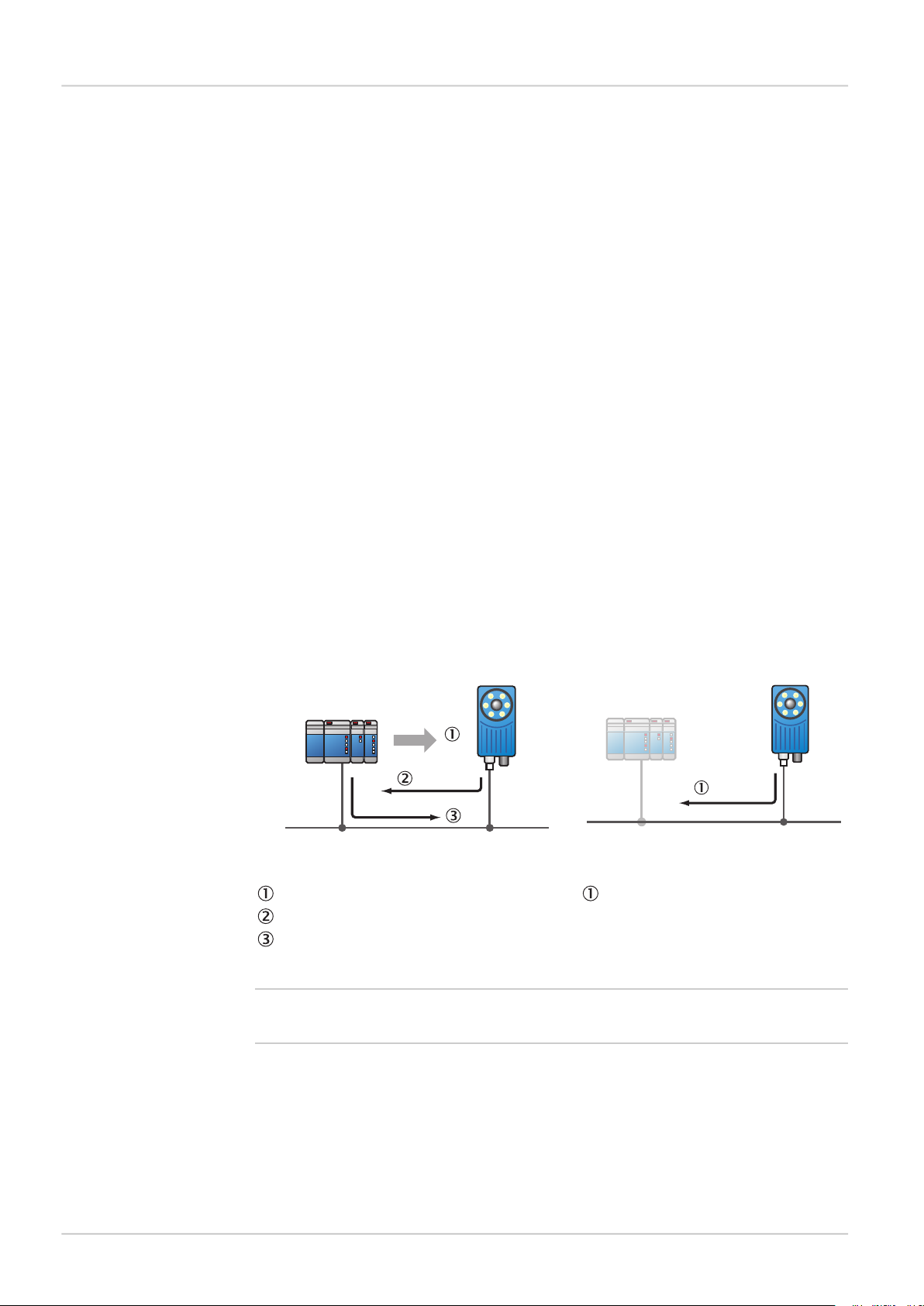

2.1 Physical network connection

To minimize network latency, it is recommended that the I/O extension box is connected

directly to the Inspector. The I/O box has a network switch so that a PC running SOPAS Single

Device can be connected via the I/O box.

InspectorI/O Extension box

PC with SOPAS

Single Device

Figure 2.1 Physical network connection

2.2 Configuration of the IP address on the I/O extension box

This section briefly describes how to configure the I/O extension box for operation with the

Inspector. For details, please refer to the user manual delivered with the I/O extension box.

The IP address of the I/O extension box must be compatible with the addresses of the Inspector and of the PC. For details of how to set and view the IP address of the Inspector, please

refer to the Operating Instructions for Inspector PIM60.

The following is an example of how the IP addresses can be configured for the Inspector, the

I/O box and the PC.

PCI/O Extension BoxInspector PIM60

192.168.1.30192.168.1.3192.168.1.110

8

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 9

Reference Manual

Inspector PIM

I/O extension box

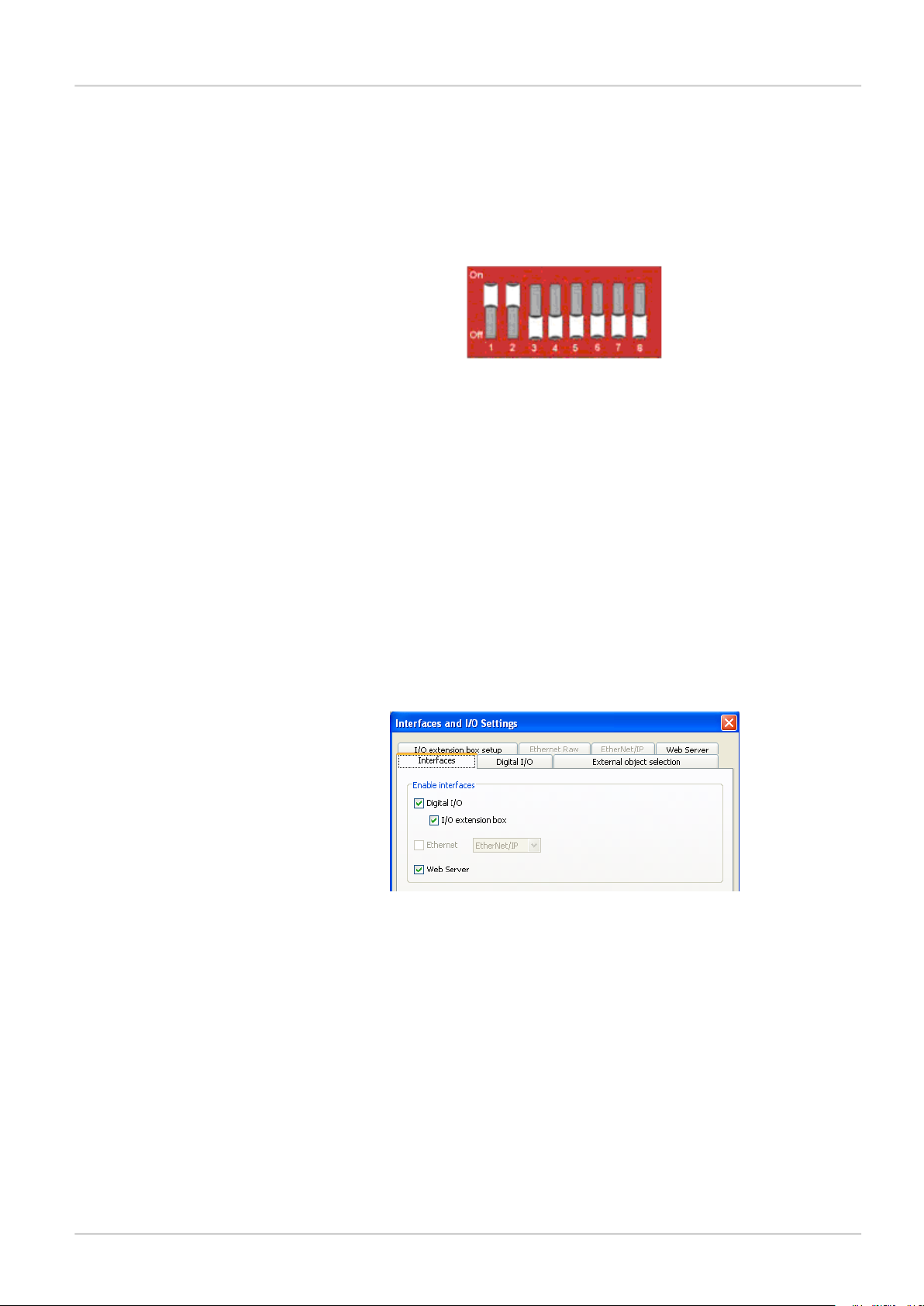

2.2.1 Basic configuration of the IP address

The address selection switch on the I/O extension box configures the host part of the IP address, that is, the last of the four parts of the IP address. By default, the first three parts of

the address (also known as the network address) are set to 192.168.1. If the switch is set

to a value other than 0 (all switches set to Off) or 255 (all switches set to On), the I/O extension

box will use the host part of the IP address assigned by the switch.

Figure 2.2 Example

The setting above configures the I/O extension box to have a host ID of 3 corresponding to

the binary value “00000011” where switch 1 is bit 0 (LSB) and switch 8 is bit 7 (MSB). The

I/O box will then have an IP address of 192.168.1.3.

Advanced configuration of the IP address

If the network part of the IP address must be changed from the default 192.168.1 for the

I/O extension box, the internal web server of the I/O extension box can be used. For details

please refer to the manual delivered with the I/O extension box.

Interfaces

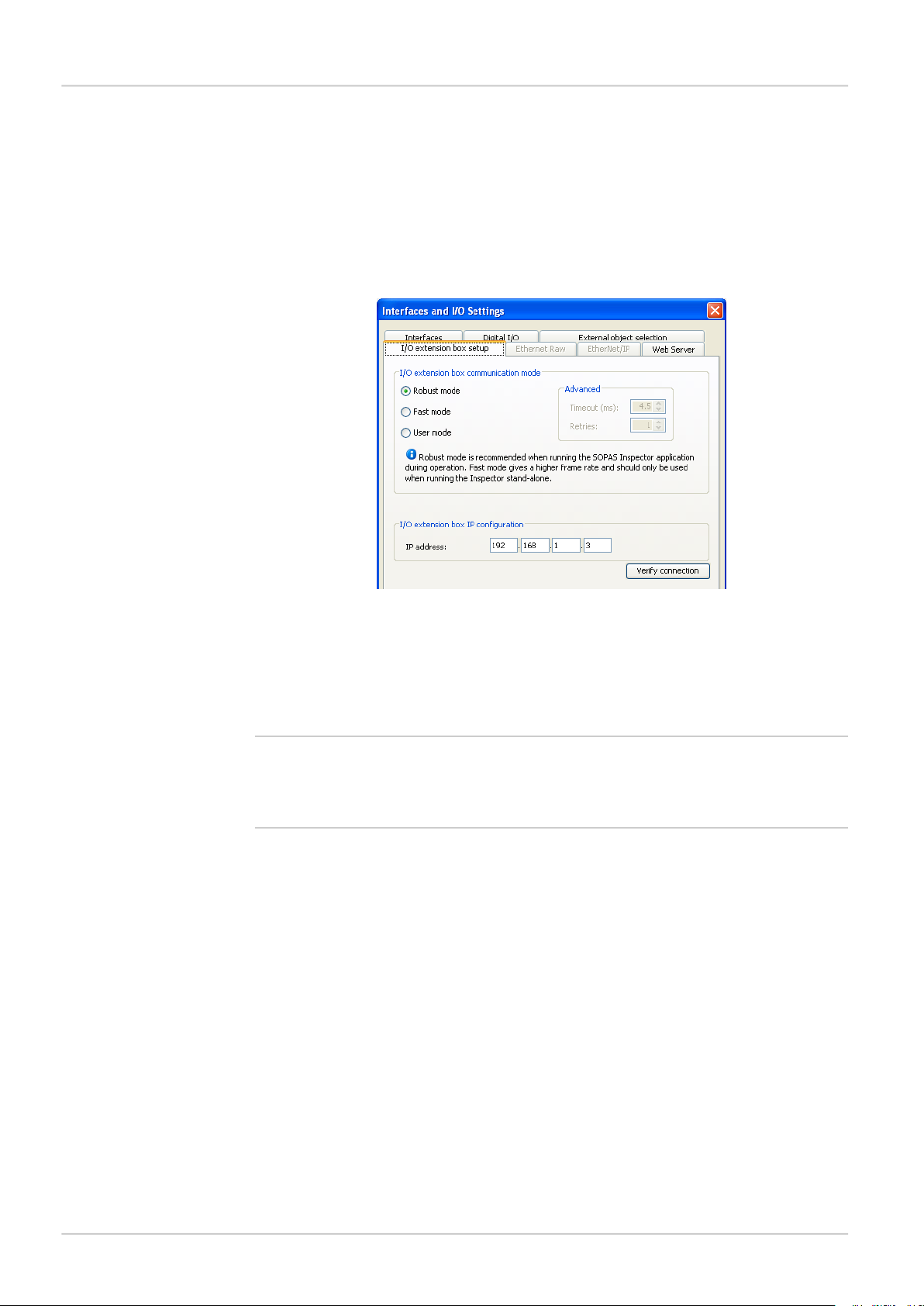

2.3 Setup of the I/O extension box in the SOPAS Single Device application

The communication with the I/O extension box is configured using the Interfacesand I/O Settings

dialog from the InspectorPIM60 menu. Check the Digital I/O and I/O extension boxes in the Inter-

faces tab. The I/O extension box is disabled if EtherNet/IP is selected in the same tab.

Figure 2.3 I/O Extension Box setup

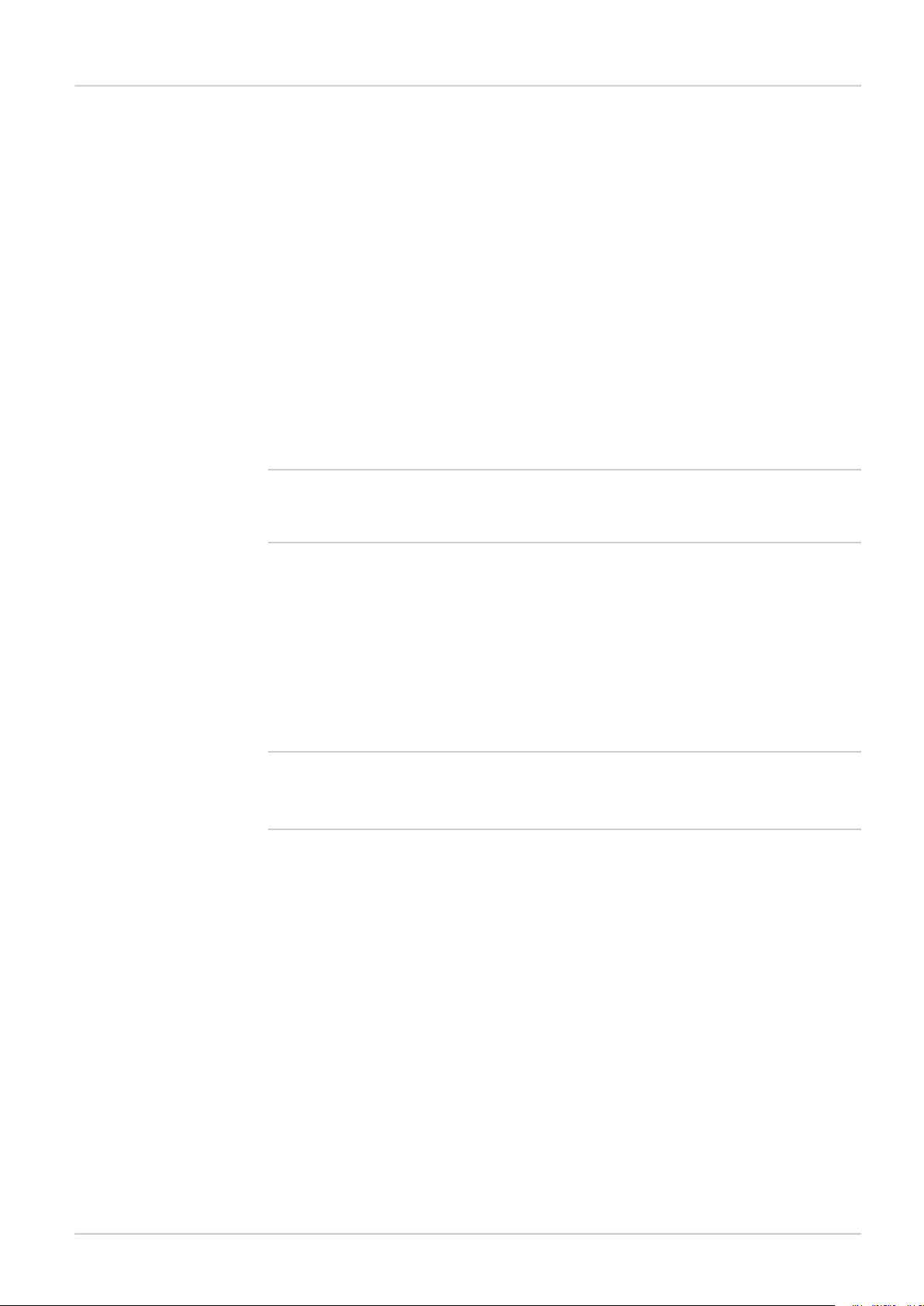

Communication mode

It is possible to adjust the way that the Inspector is communicating with the I/O extension

box. The settings are made in the I/O extension box setup tab in the Interfaces and I/O Settings

dialog from InspectorPIM60 menu. There are three modes available:

• Robust mode. This is the default communication mode, and it is the recommended one if

the Inspector is connected to the SOPAS Single Device application during operation.

• Fast mode. This mode allows the Inspector to operate at a higher frame rate but there is

a risk that some data in the communication with the I/O extension box is lost if there is

high load on the network. This mode shall not be used if the Inspector is connected to the

SOPAS Single Device application during operation.

• User mode. This is the advanced communication mode where it is possible to configure

the number of retries that the Inspector performs, and the timeout for each retry. The

timeout is the time (in milliseconds) that the Inspector is waiting for a reply from the I/O

extension box for a request to set outputs or read inputs.

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

9

Page 10

Interfaces

I/O extension box

Reference Manual

Inspector PIM

IP configuration

To be able to connect to the I/O extension box, the IP address of the I/O extension box must

be specified in the SOPAS Single Device application.

To specify the IP address of the I/O extension box:

1. Open the Interfaces and I/O Settings dialog from the InspectorPIM60 menu. Enter the selected

IP address of the I/O extension box setup tab in the four fields separated with dots.

2. Click Apply to store the settings.

Figure 2.4 Set up mode and IP address

Verify connection

It is possible to verify that the connection to the I/O extension box can be established by

clicking the Verify connection button. The SOPAS Single Device application will then try to connect

to the I/O extension box, and a message will be displayed informing if the I/O extension box

was found.

Note

It is possible to configure the Inspector for use with the I/O extension box even when the I/O

extension box is not available. As soon as the Inspector detects the I/O extension box on the

network, it will connect to it and start using it as configured.

2.3.1 Enabling the I/O extension box

The use of the inputs and outputs on the I/O extension box is enabled on the Digital I/O tab

of the Interface and I/O Settings dialog from the InspectorPIM60 menu.

2.4 Input and output connections

When delivered, the I/O extension box contains 4 digital inputs and 8 digital outputs. The

digital outputs can be expanded to 16, and the digital inputs of the Inspector PIM60 can be

extended to 5.

Please refer to the manual delivered with the I/O extension box for details on how to connect

the power supply to the box, and where to find the digital inputs and outputs.

10

2.4.1 Special conditions during startup

The following applies if the Inspector is configured to use the inputs of the I/O extension box

for object selection:

If the I/O extension box is not available when the Inspector starts up, the Inspector will use

the last reference object selected in the SOPASSingle Device application before saving to flash.

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 11

Reference Manual

Inspector PIM

I/O extension box

Interfaces

Once the I/O extension box is available, the Inspector will read the inputs of the box, and

select the corresponding reference object.

2.4.2 Connection to the I/O extension box lost during operation

If the connection to the I/O extension box is lost during operation, the last status of the inputs

on the box will be used until the connection is re-established.

2.4.3 Object selection with I/O extension box

The status of the inputs on the I/O extension box is checked in the end of each inspection

cycle. If the Inspector is configured to use external image trig, the status of the external inputs

will only be checked when an image trig signal has been received.

2.4.4 Timing issues

The digital outputs on the I/O extension box shall be read at minimum delay time as displayed

in the SOPAS Single Device application.

2.4.5 Use of the digital outputs for logic

The digital outputs on the I/O extension box are not guaranteed to be jitter-free. It is not recommended to use these outputs for direct control of other devices. The I/O extension box

shall be connected to a PLC for process control.

2.4.6 Change of Modules in the I/O extension box

The Inspector PIM60 supports I/O extension box configurations with up to 16 digital outputs

and 5 digital inputs (The standard configuration of the I/O extension box contains 8 digital

outputs and 4 digital inputs.). The configuration of an I/O extension box can be changed by

adding/removing I/O modules to/from the I/O extension box. I/O modules are available as

an accessory from SICK. For details about Accessories Ordering information see the Operating

Instructions for Inspector PIM60.

Perform the following steps to connect and use more I/O modules:

1. Close the SOPAS Single Device application.

2. Disconnect the power from the I/O extension box.

3. Connect the additional I/O modules (inputs and/or outputs) to the I/O extension box.

Please refer to the manual delivered with the I/O extension box for details.

4. Re-connect the power to the I/O extension box.

5. Re-start the SOPAS Single Device application.

The additional digital outputs are now be available in the SOPAS Single Device application.

2.5 Troubleshooting

2.5.1 The I/O LED flashes 10 times

If the power to the I/O extension box has been disconnected for a longer period of time, the

internal clock in the box will be reset. The I/O LED on the box will then flash 10 times in red.

This is not a serious error, and the I/O extension box can still be used together with the Inspector without any problems.

8015726/2013-11

2.5.2 No contact with the I/O extension box

Ensure that the network card on the PC has the same network address, for instance

192.168.1, as the I/O extension box. The host part of the IP address (that is the last number

in the IP address) must not be the same as for the I/O extension box or the Inspector.

There are two tools available in Windows to check the network connection and the IP settings:

• Ping. Open the command prompt, and type ping followed by the IP address of the I/O exten-

sion box. If the I/O extension box is available the following text will be displayed: Reply from

x.x.x.x (where x.x.x.x is the IP address of the I/O extension box). If the I/O extension box

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

11

Page 12

Interfaces

I/O extension box

Reference Manual

Inspector PIM

could not be found an error message is displayed, for instance Requesttimed out or Destination

host unreachable.

Example: ping 192.168.1.3

• Ipconfig. Open the command prompt and type ipconfig. The current status for the network

cards on the PC will then be displayed. Ensure that the network settings are corresponding

to the setting for the I/O extension box. The current IP address for the Inspector can be

viewed by selecting Device Info from the InspectorPIM60 menu.

The web browser on the PC must be configured not to use a proxy when communicating with

the web server in the I/O extension box.

2.5.3 High number of unanswered requests to the I/O extension box

The advanced communication mode, User mode, can be used to fine tune the communication

with the I/O extension box. It is recommended to try to increase the timeout as a first step,

and if this does not work, try to increase the number of retries. Increasing the number of retries

will reduce the inspection speed.

If the problem persists even if the timeout and the number of retries have been increased,

verify that the network topology does not block the use of UDP packets.

12

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 13

Reference Manual

Inspector PIM

Web interface

Interfaces

3

Web interface

3.1 Introduction

The Inspector PIM60's web interface can be used in two different ways:

• Users can use a web browser to open web pages served by the Inspector's built-in web

server.

The Inspector PIM60 is delivered with a set of web pages for handling the Inspector, but

you can also create custom web pages that can be accessed through the Inspector's builtin web server. When you create custom web pages, all functions available through the

Web API can be used.

• Custom applications running on separate systems can use the Web API to directly retrieve

images and results, and retrieve and set parameters on the Inspector.

Details on how to manage and access the web pages served by the Inspector is described

in the Operating Instructions for Inspector PIM60.

Note

All URLs on the Inspector are case sensitive. For example, trying to use /LiveImage.jpg to

retrieve the live image will not work.

3.2 Get results via Web API

3.2.1 Live image

The live image can be retrieved through the Web API by a live image request using the URL:

http://<IP-address>/LiveImage.jpg

The response to the request is a data buffer containing a JPEG image.

If the image is not available, an empty image is returned with a smaller size than a normal

image.

Note

The live image is not available when SOPAS is connected to the Inspector PIM60.

Live image response can be much slower when activating the Send to FTP feature.

Example URLs

Request a live image without overlay graphics:

http://192.168.1.110/LiveImage.jpg

The response to the request is a JPEG image.

Request a live image with overlay graphics:

http://192.168.1.110/LiveImage.jpg?ShowOverlay

Request a live image with simplified overlay graphics:

http://192.168.1.110/LiveImage.jpg?SimplifiedOverlay

3.2.2 Detailed results

The result string, containing the results from the last analyzed image, can be retrieved through

the Web API by a request using the URL:

http://<IP-address>/CmdChannel?gRES

The response is a string that has the following syntax:

rgRES <errorCode> <resultString>

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

13

Page 14

Interfaces

Web interface

Reference Manual

Inspector PIM

The result string is the string that is output over Ethernet, and which is defined in the Ethernet

Results Output dialog.

For example, if the current configuration has an object locator and an edge pixel counter,

and Ethernet Results Output uses the default example formatting string, the Inspector would

return the following string:

rgRES 0 194

Image_number: 9639

Object_locator.

Located: 1

Score: 99.00

Scale: 1.00

Position_(X,Y): (237.78,202.05)

Rotation: 20.05

------------------------Edge_pixel_counter_1

Decision: 1

Pixels: 724

The result is not synchronized with the live image. This means that in some situations, if you

retrieve a live image and after that a result string, that string may not contain the result for

the retrieved image, but for an image captured and analyzed later. See Section 3.2.3, “Syn-

chronize live image with result” (page 14) for a solution.

3.2.3 Synchronize live image with result

To synchronize the live image with the result, you need to assign an id to the image. The id

can be up to 16 characters long and can consist of numbers, letters, and special characters.

http://<IP-address>/LiveImage.jpg?id=<ID>

The result for the live image assigned to the <ID> can be listed using the following syntax:

http://<IP-address>/ImageResult?id=<ID>

Note

The image might not update if this method is used due to caching, see Section 3.4.1, “Example: Display live image” (page 19) for more information.

Example URLs

Request a live image without overlay graphics and assign an id to the image:

http://192.168.1.110/LiveImage.jpg?id=ID_ABC123

Request a live image with overlay graphics and assign an id to the image:

http://192.168.1.110/LiveImage.jpg?ShowOverlay&id=ID_ABC123

Request a live image with simplified overlay graphics and assign an id to the image:

http://192.168.1.110/LiveImage.jpg?SimplifiedOverlay&id=ID_ABC123

3.2.4 Logged images

Logged images can be retrieved using the URL:

http://<IP-address>/LogImage.jpg?00

where the argument "00" is the image number. The image number is two digits in the range

[00, 29]. The device keeps writing to the log and therefore the log first has to be locked to

be able to retrieve an image. This is done by using the URL http://<IP-address>/LockLog

The response to the request is a JPEG image. An empty image with a smaller size than a

normal image is returned if no log image is available for a certain position.

To start logging images again the log has to be unlocked first and this is done by using the

URL http://<IP-address>/LockLog?Unlock

14

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 15

Reference Manual

Inspector PIM

Web interface

Interfaces

Example URLs

http://192.168.1.110/LockLog

http://192.168.1.110/LockLog?Unlock

Retrieve a logged image without overlay graphics:

http://192.168.1.110/LogImage.jpg?00

Retrieve a logged image with overlay graphics:

http://192.168.1.110/LogImage.jpg?00&ShowOverlay

Retrieve a logged image with simplified overlay graphics:

http://192.168.1.110/LogImage.jpg?00&SimplifiedOverlay

3.2.5 Statistics

To retrieve statistics using the command channel, execute the following command:

gSTAT

Statistics can also be retrieved using the URL:

http://<IP-address>/CmdChannel?gSTAT

The response is rgSTAT 0 followed by an XML formatted string. To read the response in an

web browser, change the view in the web browser to reflect the source code.

Note

The statistic response is only for the active reference object.

3.3 Control the sensor via Web API

The Web API supports using the command channel for reading and updating parts of the

device configuration.

The Web API also supports the functionality to do a backup of the device configuration to a

file and to restore the configuration again. This is a convenient way to handle configurations

without installing and using SOPAS Single Device.

3.3.1 Basic principles

The command channel has a set of basic principles:

• Only one command at a time can be executed.

• Inspector PIM60 responds to each command with a response that includes the result of

the command as well as error codes.

• A specific task to control the Inspector PIM60 includes the command together with its

parameters, see list of command types and parameters in Appendix B, “Command chan-

nel” (page 52).

• Writing a parameter can typically only be done when the device is in Edit mode. Reading

a parameter can be done in both Edit and Run mode.

• It is possible to block configuration changes by deselecting Allow changes via Web Server in

the Web Ser ver tab in the dialog Interfaces and I/O Settings in InspectorPIM60 menu.

8015726/2013-11

3.3.2 Command syntax

The Web API command channel has the following syntax:

http://<IP-address>/CmdChannel?<command>_<identifier>_<argument 1>_<argument 2>..._<argument N>

The ACK message has the following syntax:

<ACK Command> <identifier> <errorCode> <returnValue1> <returnValue2> ...

<returnValueN> <errorMessage>

The command is sent as an ASCII string. The combination of a command with its parameters

will either change the device configuration or fetch information from the device. For more

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

15

Page 16

Interfaces

Web interface

Reference Manual

Inspector PIM

command examples see Section B.1, “Command syntax” (page 52) and Section B.6, “Command examples” (page 75).

Note

The command syntax differs from other interfaces where the initial part http://<IP-ad-

dress>/CmdChannel? is added and all space characters (" ") are replaced by an underscore

character ("_"). The ACK messages still contain spaces.

Example URL

The successful execution of the following command

http://192.168.1.110/CmdChannel?sINT_1_1

will perform the command (to select reference object with index 1) and then return the following string:

rsINT 1 0

while a failed command may return:

rsINT 1 8101 Ref bank index is not used.

3.3.3 Current reference object

The reference image of the current reference object can be retrieved using the URL:

http://<IP-address>/ActiveReferenceImage.jpg

The response to the request is a JPEG image.

The reference image of any reference object in the Inspector can be retrieved using the URL:

http://<IP-address>/getRefObject?0

where the argument "0" is the index of the reference object. The object index that corresponds

to each reference object can be found in the Reference object list in the Main view.

The response to the request is a JPEG image. An empty image with a smaller size than a

normal image is returned if no reference object is available for a certain position.

Example URL

http://192.168.1.110/ActiveReferenceImage.jpg

http://192.168.1.110/getRefObject?1

3.3.4 Backup and restore configuration

It is possible to backup and restore the device configuration through the Web API. This is the

same functionality also available through the standard web pages of the Web Server interface.

The backup data contains the device name and reference objects including corresponding

inspection and interface settings.

Note

The backup and restore functionality of the Web Server and the Web API corresponds to the

Export Sopas Parameter backup and Import Sopas Parameter backup in the InspectorPIM60 menu.

The backup data used by the Web API is saved as .sbp files, which can be imported to and

exported from SOPAS Single Device. The Web API can not use .sdv files.

Backup configuration

The URL to export a configuration is http://<IP-address>/backup_config?config1

Example URL:

http://192.168.1.110/backup_config?config1

The result of the request is an .spb file containing the device configuration. This file can be

stored in the file system of the receiving unit and used later in the restore procedure.

16

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 17

Reference Manual

Inspector PIM

Web interface

Interfaces

The Web Server standard web pages requires a login to perform a backup. A login is not required when doing a backup through the Web API.

Restore configuration

The restore operation takes a device configuration created with the backup functionality and

replaces the current configuration with the configuration in the backup file.

The operation is a multiple step procedure that requires a login. The details of the procedure

is described in Appendix C, “Restore configuration over Web API” (page 77).

The operation may take several minutes and the Inspector PIM60 is automatically restarted

after the configuration has been transferred to the Inspector PIM60.

Warning

During the restore operation the device is set in a special restore mode only expecting restore

operation requests. Operations and requests via other interfaces like field buses, SOPAS

Single Device, or other web browsers shall then be avoided since they may interfere with the

restore operation.

3.4 Create custom web pages

When creating customized web pages to be stored on and served by the Inspector, you use

the Web API to display images, retrieve results and settings, and change parameters in the

Inspector.

The functions that use the command channel (retrieving results, and getting and setting

parameters) returns the result in text strings, which you need to parse in order to extract the

information that you are interested in. To make this easier, the Inspector PIM60 provides a

JavaScript that you can use in your web pages, and that helps parsing the results.

You use the functions by including the script file inspector.js in your page, and then create

an Inspector object in your own script.

Note

The inspector.js script uses JQuery, so you need to also include the provided jquery.js

script. For more information on JQuery, see www.jquery.com.

<html>

<head>

<title>Custom page</title>

<script type="text/javascript" src="/jquery.js"></script>

<script type="text/javascript" src="/inspector.js"></script>

<script type="text/javascript">

//<!--

var inspector = new Inspector();

...

//-->

</script>

...

The Inspector object has methods that correspond to the commands that can be sent over

the command channel. The available methods are listed in Table 3.1, “Methods in inspector.js” (page 19). When using these methods, you pass the same arguments as when using

the "raw" command channel commands, as described in Appendix B, “Command chan-

nel” (page 52).

The Inspector object returns the (parsed) command response through a callback function.

To use the response, you define a function that takes a single argument – the response object

– and pass that function as an argument to the Inspector's method. In the function you can

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

17

Page 18

Interfaces

Web interface

Reference Manual

Inspector PIM

then check whether the command succeeded, and retrieve the information you are interested

in.

For example, to select the first reference object in the current configuration (with index 0),

you would call:

// First, define a callback function that handles the result

function setRefObjResponse(response) {

if (response.httpStatus != 200 || response.errorCode != 0) {

alert(response.errorMessage);

}

};

// Then, call the inspector object's setInt function

// with the arguments:

// identifier = 1 for "Set reference object"

// arg1 = 0, for reference object with index 0

function setRefObj() {

inspector.setInt(1, 0, setRefObjResponse );

};

Tip

As an experienced JavaScript developer, you would probably define your callback function

as an anonymous function directly in the call to the inspector methods:

inspector.setInt(1, 0, function(response) {

if (response.httpStatus != 200 || response.errorCode != 0) {

alert(response.errorMessage);

}

});

The content of the response object depends on the function that you called, as well as the

outcome of the command. The following attributes are common for all methods:

type The response type, which is basically the same as the command type.

See Table B.3, “Command ID numbers - for EtherNet/IP” (page 54).

errorCode If non-zero, the command failed for some reason. See Section B.4, “Error

codes” (page 72).

errorMessage A text message that describes the error. Exists only if the command failed.

httpStatus The HTTP status code. If this is not set to 200, the HTTP request failed

and the Inspector didn't return any result at all.

The following table lists the attributes that are specific to the called method:

18

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 19

Reference Manual

Inspector PIM

Web interface

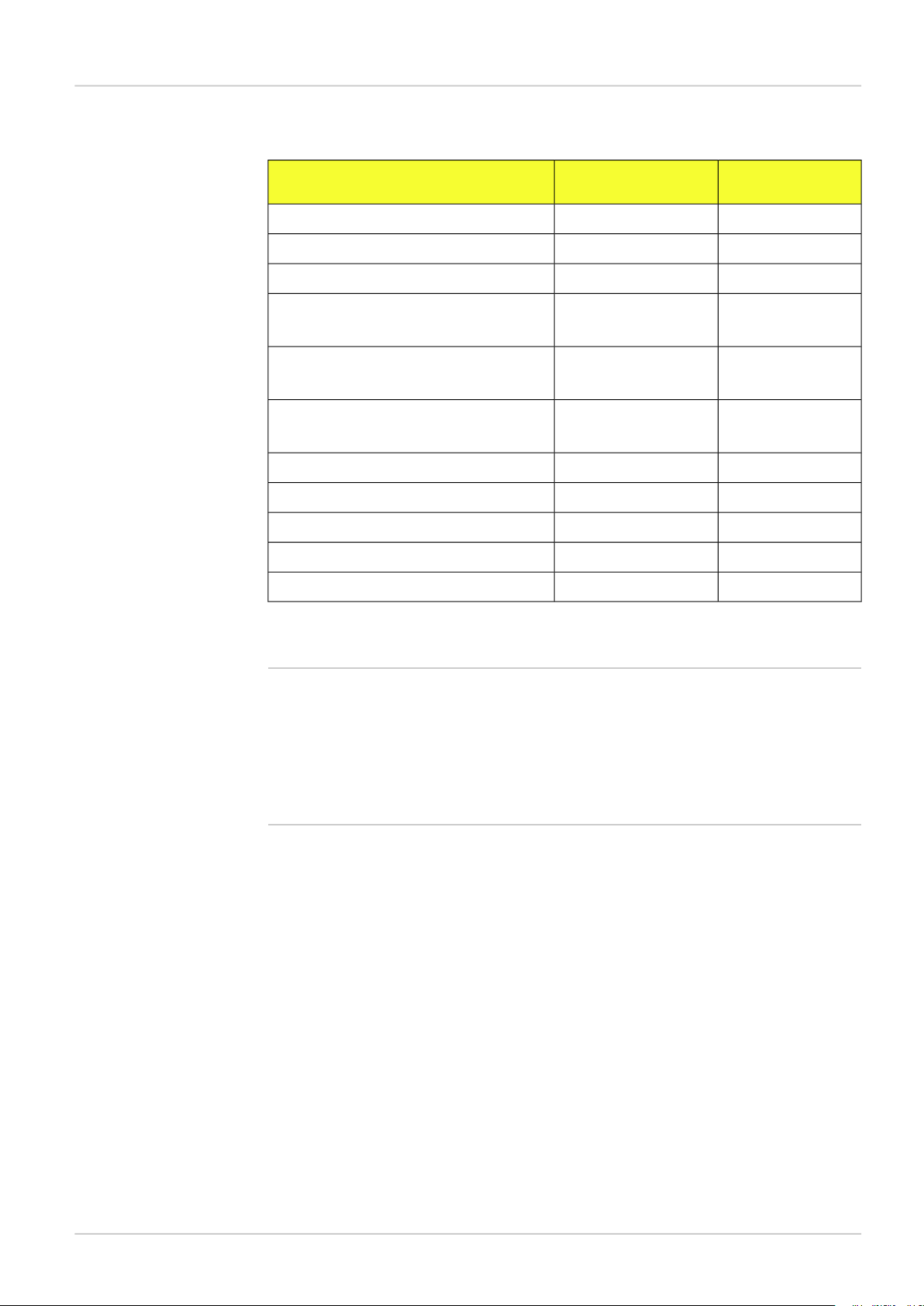

Table 3.1 Methods in inspector.js

Interfaces

Method

mand

gINTgetInt(identifier, arg1, ..., argn, callback)

sINTsetInt(identifier, arg1, ..., argn, callback)

gSTRgetString(identifier, arg1, ..., argn, callback)

Response attributesCorresponding com-

protocolVersiongVERgetVersion(callback)

modegMODgetMode(callback)

values[0]sMODsetMode(mode, callback)

identifier

values[0 ... n]

identifier

values[0 ... n]

identifier

value

identifieraACTperformAction(identifier, args, callback)

-TRIGtrig(callback)

resultStringgRESgetResult(callback)

-/LockLoglockLog(callback)

-/LockLog?UnlockunlockLog(callback)

The result string returned by the getResult() method is the same string that is output over

Ethernet, and which is defined in the Ethernet Results Output dialog.

Note

Do not make another call to the Inspector before the current call has returned a response.

If you do, the current command will be interrupted and will not return any response at all,

making it difficult to figure out whether or not the command was performed on the Inspector.

Normally, this is not a problem, but if you are using timed triggers, you should make sure

that the triggered functions don't interrupt any commands that may currently be performed

on the Inspector.

3.4.1 Example: Display live image

To display the current live image, simply include the image from /LiveImage.jpg on your

web page:

...

<image src="/LiveImage.jpg"/>

..

This image will not update automatically, so you could add some JavaScript that makes the

live image refresh with a certain interval.

...

<script type="text/javascript">

//<!--

function refreshLiveImage() {

var image = document.getElementById("liveImage");

image.src = "/LiveImage.jpg?ShowOverlay" + (new Date()).getTime() );

// The (new Date()...) is a trick to make the browser

// retrieve the image from the Inspector and not from cache

setTimeout(refreshLiveImage, 500);

};

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

19

Page 20

Interfaces

Web interface

Reference Manual

Inspector PIM

// Initiate the image and refresh when page is loaded

window.onload = function(){

refreshLiveImage();

};

//-->

</script>

...

</head>

<body>

<img id="liveImage" src="/LiveImage.jpg?ShowOverlay"/>

</body>

Alternatively, you can use the live image component that is used on the Inspector's default

Live image page, which has automatic refresh, setting for refresh interval, and magnifier.

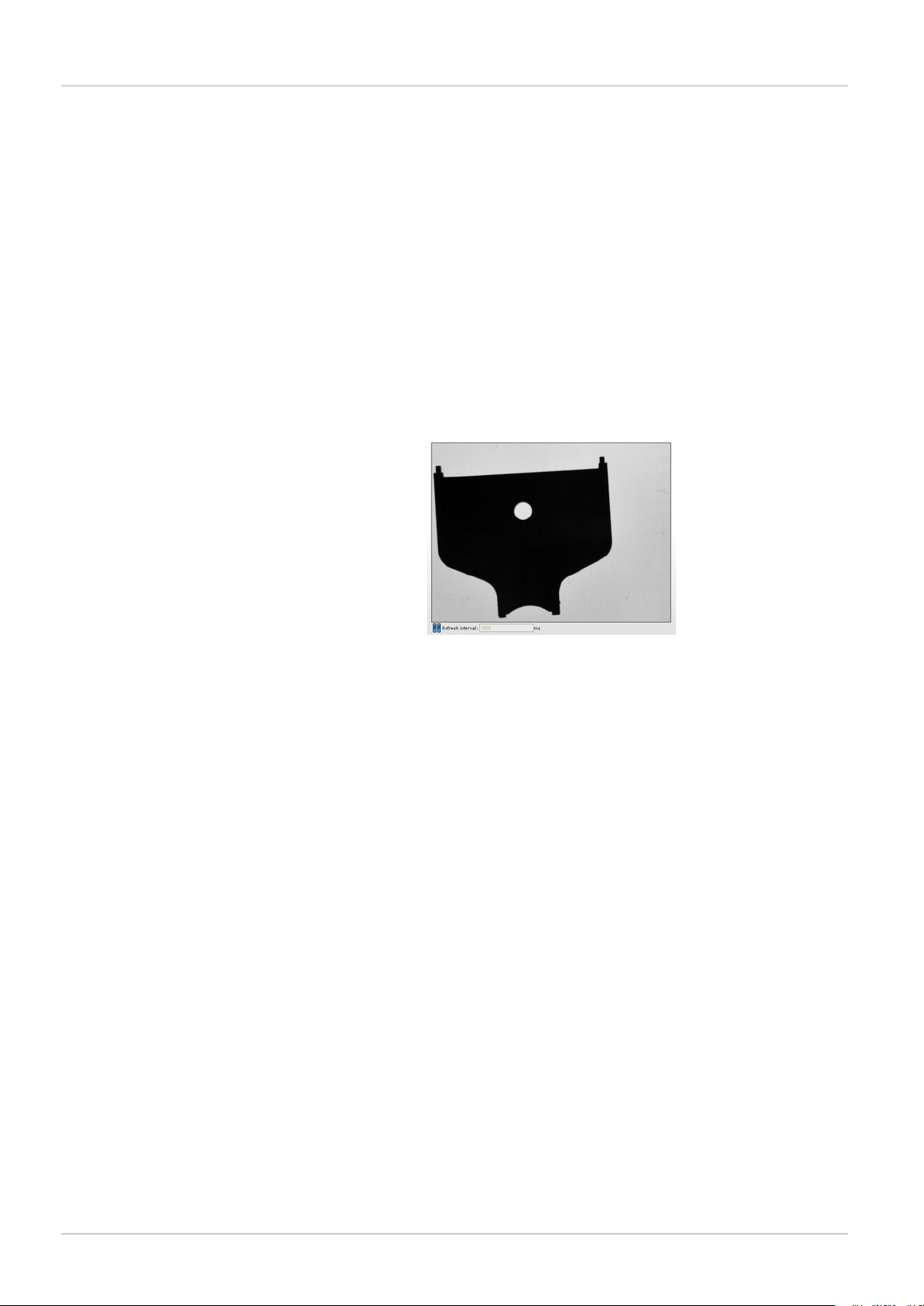

Figure 3.1 Inspector's default live image component

To use the default live image component, include the userliveimage.js script in your page,

and call the sickLiveImage() function as in the following example:

<html xmlns="http://www.w3.org/1999/xhtml">

<head>

<title>Live Image</title>

<script type="text/javascript" src="/jquery.js"></script>

<script type="text/javascript" src="/userliveimage.js"></script>

<script type="text/javascript">

//<!-$(document).ready(function () {

$("#liveImage").sickLiveImage({

width: 640,

height: 480,

nocache: true,

minInterval: 500,

refreshInterval: 1000,

magnifier: true,

imgUrl: "/LiveImage.jpg",

refreshText: "Refresh interval"

});

});

//-->

</script>

</head>

<body>

<div id="liveImage"></div>

</body>

</html>

20

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 21

Reference Manual

Inspector PIM

Web interface

Interfaces

More examples can be found on the installation CD, in the folder hmi_web_example inside

the documentation folder. A Custom Web Toolkit can be found on the support pages (visionsupport.sick.com) which provides a framework that simplifies the process of making an

HMI as well as additional templates and examples..

3.5 Handle the Web API

The Web Server and Web API interfaces can be activated or deactivated. When activated, it

is possible to select port number and to allow command channel changes. The same settings

apply both to the Web Server and to the Web API. The Web interfaces are configured in the

Interfaces and I/O settings dialog in the InspectorPIM60 menu.

The Web API is based on standard HTTP request and responses. Recommended request

timeout time is 3 seconds to allow for images to be transferred properly.

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

21

Page 22

Interfaces

Ethernet Raw

Reference Manual

Inspector PIM

4

Ethernet Raw

4.1 Introduction

To set up the connection and output results for Inspector PIM60 using Ethernet Raw see

Operating Instructions for Inspector PIM60.

4.1.1 Port interval

The default interval for the ports used by the communication channels is 2114-2116. This

interval can be changed, e.g. if the controlling device does not support the default interval.

The interval is controlled by the field Start port in the Ethernet Raw tab of the Interface and I/O

settings dialog.

The ports are assigned according to the following:

• Ethernet Result Output = start port (default 2114)

• Command channel = start port + 1

• Dedicated image trig = start port + 2

4.2 Get results via Ethernet Raw

The following settings are configured in the Ethernet Result Output dialog under InspectorPIM60

menu.

4.2.1 TCP versus UDP

The basic difference between these protocols, for the Ethernet result output function, is which

side initiates the connection to receive/send the data.

UDP:TCP:

PC/PLC initiates the connection Inspector sends results to the spe-

Inspector sends results to the PC/PLC

PC/PLC acknowledges that results are received (built into the TCP protocol)

Note

For TCP the default port number that the Inspector listens to is 2114.

cified IP address and port, without

knowing if it has been received

22

4.2.2 ASCII versus binary

The Inspector supports the possibility to choose whether the configured output is to be sent

in ASCII format or in a binary format. The parameters that should be transferred in binary

format are also defined in the XML based formatting, but some tags are not supported in the

binary format.

If such a parameter is added to the formatting it will be ignored by the Inspector. In binary

mode all added text and text formatting, for example <SPACE/>, are ignored. Only the values

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 23

Reference Manual

Inspector PIM

Ethernet Raw

Interfaces

of the parameters describing the results of inspected images or device information will be

sent. For details on which tags can be used in binary output see the tables in chapter Appendix A, “Result output formatting” (page 39).

4.2.3 Attributes

Attributes are used to control the formatting and identification of inspections. Some of them

can be controlled directly in the Ethernet Result Output dialog in the section Message settings. All

available attributes are listed in the table in section XML Formatting in Section A.3.2, “Attrib-

utes” (page 49).

Min number of digits Specifies the minimum number of digits (including decimal

point) to include in the result. If the value to be sent out has

fewer digits, the result is padded with leading zeros. The default setting is 0 which means the number of digits that will

be sent will differ depending on how many digits are needed.

The maximum number of digits is 9. Note: This attribute is

only applicable for ASCII

Number of decimals Specifies the number of digits to include after the decimal

point for values with decimals. The value will be rounded to

the specified number of decimals. Default value is 2. The

maximum number of decimals is 9. Note: This attribute is only

applicable for ASCII

Degrees/Radians Specifies the unit for the rotation of the object locator, angle

for blobs, angle for edges, and angle measurements.

Little/Big Endian This specifies the order of the bytes transferred from the

device on Ethernet. When using Little endian the least significant byte is transferred first and for Big endian the most

significant byte is transferred first. See the 2-byte example in

tables below. Note: Only applicable when using binary format.

Most significant

byte

Least significant

byte

0111000010000100Value to be sent

from device:

First transferred byteTransfer order

Second transferred

byte

1000010001110000Little endian

0111000010000100Big endian

Pixels/Millimeters Specifies whether position coordinates and distance meas-

urements should be expressed in pixels or millimeters. Note:

The device must be calibrated to be able to use millimeters

as unit of measurement.

4.2.4 Example formatting strings

The auto-generated example string will vary depending on the configuration in the selected

reference object. The intention with the example string is to give an idea of the available tags

and to be a good starting point for creating a suitable format.

Below follow some short descriptions of example strings for different configurations. For more

information about the XML formatting see Appendix A, “Result output formatting” (page 39).

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

23

Page 24

Interfaces

Ethernet Raw

Reference Manual

Inspector PIM

Example string for configuration with only an Object locator

<MESSAGE_SIZE/><NEWLINE/>

Image_number:<SPACE/><IMAGE_NUMBER/><NEWLINE/>

Object_locator.<NEWLINE/>

<OBJECT_LOC>

Located:<SPACE/><DECISION/><NEWLINE/>

Score:<SPACE/><SCORE/><NEWLINE/>

Scale:<SPACE/><SCALE/><NEWLINE/>

Position_(X,Y):<SPACE/>(<X/>,<Y/>)<NEWLINE/>

Rotation:<SPACE/><ROTATION/><NEWLINE/>

</OBJECT_LOC>

Size of the message, number of characters (ASCII) or bytes (binary)

Explanatory text and analyzed images number

Explanatory text

Start of container for object locator

Explanatory text and value for locator decision; 0=not found, 1=found

Explanatory text and locator score value, in percent how well of the object is found in

the object locator due to match settings

Explanatory text and locator scale value, factor of analyzed live image compared to

taught reference object

Explanatory text and x and y position of the reference point. This can be outside the

image and therefore negative. Shown in "pixels" or "mm"

Explanatory text and locator rotation, in degrees or radians depending on the configured

value in the Ethernet Result Output settings dialog

End of container for object locator

Result of validating output string with only an Object locator

The result of validating the example formatting output string with output format ASCII can

be as follows:

97

Image_number: 14471

Object_locator.

Located: 1

Score: 96.00

Scale: 1.00

Position_(X,Y): (291.52,238.55)

Rotation: 0.22

The result of validating the example formatting output string for only an object locator with

output format binary will be as follows:

Binary output OK. Number of bytes: 27

Part of example string for configuration with a Blob

Blob_tool.<NEWLINE/>

<BLOB index="0" name="Blob 1">

Found_blobs:<SPACE/><FOUND_BLOBS/><NEWLINE/>

-------------------------<NEWLINE/>

Blob_information:<NEWLINE/>

Position_(X,Y):<SPACE/>(<X/>,<SPACE/><Y/>)<NEWLINE/>

24

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 25

Reference Manual

Inspector PIM

Ethernet Raw

Area:<SPACE/><AREA/><NEWLINE/>

Angle:<SPACE/><ANGLE/><NEWLINE/>

Structure:<SPACE/><EDGE_PIXELS/><NEWLINE/>

Touches_ROI_border:<SPACE/><EDGE_FLAG/><NEWLINE/>

</BLOB>

Explanatory text

Start of container for the blob tool named "Blob 1" and instruction to fetch the first (index="0") blob in accordance with the Sort by criteria

Explanatory text and number of found blobs in analyzed image

Separator

Explanatory text

Explanatory text and information of blob with index="0" concerning position and center

of gravity (x and y position), in "pixels" or "mm"

Explanatory text and blob (index="0") area, in "pixels"

Explanatory text and blob (index="0") angle value, in degrees or radians depending on

the configured value in the Ethernet Result Output settings dialog

Explanatory text and blob (index="0") structure value, number of edge pixels inside the

blob

Explanatory text and blob (index="0") edge value, 0=blob fully within ROI, 1= blob touches

ROI border

End of container for blob tool

Interfaces

Result of validating output string with a Blob

The result of validating the example formatting output string with output format ASCII can

be as follows:

Blob_tool.

Found_blobs: 16

------------------------Blob_information:

Position_(X,Y): (177.00, 156.89)

Area: 75

Angle: 154.33

Structure: 0

Touches_ROI_border: 0

The result of validating the example formatting output string for a blob with output format

binary will be as follows:

Binary output OK. Number of bytes: 28

Part of example string for configuration with a Polygon

Polygon1<POLYGON name="Polygon1"><NEWLINE/>

Corners:<SPACE/><NUM_CORNERS/><NEWLINE/>

<CORNERS corners="all">(X,Y):<SPACE/>(<X/>,<Y/>)<NEWLINE/>

</CORNERS>

</POLYGON>

8015726/2013-11

Explanatory text and start of polygon container tag for the polygon tool named "Polygon

1"

Explanatory text and number of polygon corners

Start of container tag for polygon corners with instruction to loop over all polygon corners,

explanatory text, and corner position

End of container for polygon corners

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

25

Page 26

Interfaces

Ethernet Raw

Reference Manual

Inspector PIM

End of container for polygon

Result of validating output string with a Polygon

The result of validating the example formatting output string with output format ASCII will be

as follows:

Polygon_1

Corners: 4

(X,Y): (329.15,235.70)

(X,Y): (371.31,235.60)

(X,Y): (372.58,314.97)

(X,Y): (329.82,315.22)

The result of validating the example formatting output string for a polygon with output format

binary will be as follows:

Binary output OK. Number of bytes: 39

Example of a JSON formatted string

It is possible to get an example string in JSON1format. This is typically used in conjugation

with web based HMIs for easier result extraction.

{"MESSAGE": {

"IMAGE_NUMBER":"<IMAGE_NUMBER/>",<SPACE/>

"Pixel_counter_1": {<PIXEL_COUNTER name="Pixel counter 1">

"DECISION":"<DECISION/>",<SPACE/>

"PIXELS":"<PIXELS/>"

</PIXEL_COUNTER>

}}}

{"MESSAGE":{"IMAGE_NUMBER":"2975780", "Pixel_counter_1":{"DECISION":"1", "PIXELS":"5433"}}}

4.3 Control the sensor via Ethernet Raw

The Inspector has a command channel accessible via the Ethernet Raw interface. The command channel makes it possible to read and write a defined set of configuration parameters,

and to trigger image acquisition, via UDP or TCP. This section describes how to setup image

triggering and command channel settings in SOPAS Single Device, as well as the syntax of the

command channel.

4.3.1 Basic principles

The command channel has a set of basic principles:

• Only one command at a time can be executed.

• Each command is followed by a return message (ACK) that includes result of the command

as well as error codes.

• A specific task to control the Inspector PIM60 includes the command together with its

parameters, see list of command types and parameters in Appendix B, “Command chan-

nel” (page 52)).

• Writing a parameter can typically only be done when the device is in Edit mode. Reading

a parameter can be done in both Edit and Run mode.

• It is possible to block configuration changes by deselecting the setting Allow changes via

Ethernet Raw in the EthernetRaw tab in the dialog Interfaces and I/O Settings in the InspectorPIM60

menu.

26

4.3.2 Command syntax

The commands have the following syntax:

1

JSON (JavaScript Object Notation) in accordance with RFC 4627

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 27

Reference Manual

Inspector PIM

Ethernet Raw

<command> <identifier> <arg1> <arg2> ... <argN>

Interfaces

The ACK message has the following syntax:

<STX><ACK Command> <identifier> <errorCode> <returnValue1> <returnValue2>

... <returnValueN> <errorMessage><ETX>

where <STX> and <ETX> are the START OF TEXT and END OF TEXT characters (ASCII codes

2 and 3 respectively).

The command is sent as an ASCII string. The combination of a command with its parameters

will either change the device's configuration or fetch information from the device. For more

command examples see Section B.6, “Command examples” (page 75) and Section B.1,

“Command syntax” (page 52).

4.3.3 Select reference object

To enable reference object selection via Ethernet Raw do the following:

1. Choose Interface and I/O Settings from the InspectorPIM60 menu.

2. In the Interface tab choose Ethernet and Ethernet Raw in the listbox.

To select reference object via the command channel, use the command sINT 1 <object

index>. The object index that corresponds to each reference object is shown in the Reference

objects list in the Main view.

4.3.4 Image triggering

It is possible to trigger image acquisition via Ethernet. The communication runs on UDP or

TCP port 2116 (configurable). In order to use this function the triggering has to be enabled

in SOPAS Single Device. In the InspectorPIM60 menu and Interfaces and I/O settings dialog check

the Ethernet box and in the list Ethernet Raw in the Interfaces tab. For the selected reference

object, choose Triggered by Ethernet in the Image settings tab.

4.3.5 Single port solution

In real-time applications, the Inspector is controlled using three ports. However, it is possible

to use only the command port (default 2115) to control the sensor. The single port solution

is only recommended for applications where the cycle time is significantly larger than the

image analysis time. One reason for this is that the image acquisition has a lower priority on

the command port. Another reason is that the Ethernet Result string must be retrieved from

the sensor, therefore image trig and result handling cannot be performed in parallel when

using the single port solution.

This is how the Inspector is controlled by using only the command port:

• The image acquisition is performed by the TRIG command (with lower priority).

• The Ethernet Result Output string is retrieved explicitly by the controlling device, e.g. a PLC.

This is done by the command gRES. The sensor does not send the result automatically on

this port.

• All other commands on the command channel are available as in the standard three port

solution.

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

27

Page 28

Interfaces

EtherNet/IP

Reference Manual

Inspector PIM

5

EtherNet/IP

5.1 Introduction

The Inspector PIM60 can be controlled and results

retrieved using the EtherNet/IP™ standard, see

http://www.odva.org/.

To be able to use EtherNet/IP, the EtherNet/IP option has to be enabled and the connection

and output result setup has to be made, see the Operating Instructions for Inspector PIM60.

5.2 Get results via EtherNet/IP

The following settings are configured in the Ethernet Result Output dialog in the InspectorPIM60

menu.

5.2.1 Attributes

Attributes are used to control the formatting and identification of inspection results. Some

of them can be controlled directly in the Ethernet Result Output dialog in the section Message

settings. All available attributes are listed in the table in section XML Formatting in Section A.3.2, “Attributes” (page 49).

Degrees/Radians Choose unit for the rotation for object locator, angle for blobs,

angle for edges, and angle measurements.

Pixels/Millimeters Choose if position coordinates and distance measurements

should be sent in pixel or millimeter unit.

Note: The device must be calibrated for it to be possible to use

the “mm” attribute. An error message is given in the output string

if the device is not calibrated and mm is chosen.

5.2.2 Example formatting strings

The auto-generated example string will vary depending on the configuration in the selected

reference object. The intention with the example string is to give an idea of the available tags

and to be a good starting point for creating a suitable format.

Below follow some short descriptions of example strings for different configurations. For more

information about the XML formatting see Appendix A, “Result output formatting” (page 39).

Example string for configuration with only an Object locator

<IMAGE_NUMBER dataType="DINT" pos="0"/>

<OBJECT_LOC>

<DECISION dataType="SINT" pos="0"/>

<SCORE dataType="REAL" pos="0"/>

<SCALE dataType="REAL" pos="1"/>

<X dataType="REAL" pos="2"/>

<Y dataType="REAL" pos="3"/>

<ROTATION dataType="REAL" pos="4"/>

</OBJECT_LOC>

Analyzed image’s number

Start of container for object locator

Decisions reports whether the object was found (=1) or not found (=0)

28

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 29

Reference Manual

Inspector PIM

EtherNet/IP

Interfaces

Score expressed in percent how well the taught object is matched against the live image

Scale is the factor of analyzed live image compared to taught reference object

Position (x) of the reference point of the object locator

Position (y) of the reference point of the object locator

Rotation of the object locator, in degrees or radians depending on the configured value

in the Ethernet Result Output dialog

End of container for object locator

Attribute dataType Specifies the data type to use for this result. When using Ether-

Net/IP the attribute dataType specifies the dataType section in

the selected assembly. The attribute can be SINT, INT, DINT or

REAL. For more details about dataType and pos see table in

Section A.3.2, “Attributes” (page 49).

Attribute pos Used by EtherNet/IP to determine a position in the dataType

section in the selected assembly. The first position number of

the dataType section is 0. The range depends on which assembly

is used. For example if assembly 1 and dataType section SINT

is selected the range of position is [0, 7].

The combination of dataType and pos determine which parameter the result will be mapped

to. For more details about dataType and pos see table in Section A.3.2, “Attributes” (page 49).

Result of validating output string with only an Object locator

The validating in SOPAS Single Device will give the following result:

EtherNet/IP assembly string OK.

Result in PLC with only an Object locator

The table below describes how the Assembly 1's data structure will be populated when using

the configuration example above.

Position ref (pos)

from XML configuration

Offset byteData type

(dataType)

Variable from

example above

DECISION0SINT0

1SINT1

2SINT2

3SINT3

4SINT4

5SINT5

6SINT6

7SINT7

8INT0

10INT1

12INT2

14INT3

16INT4

18INT5

20INT6

22INT7

IMAGE_NUMBER24DINT0

28DINT1

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

29

Page 30

Interfaces

EtherNet/IP

Reference Manual

Inspector PIM

Position ref (pos)

from XML configuration

(dataType)

Offset byteData type

32DINT2

36DINT3

40DINT4

Example string for configuration with only a Blob

<IMAGE_NUMBER dataType="DINT" pos="0"/>

<BLOB index="0" name="Blob 1">

<FOUND_BLOBS dataType="SINT" pos="0"/>

<X dataType="REAL" pos="0"/>

<Y dataType="REAL" pos="1"/>

<AREA dataType="DINT" pos="1"/>

<ANGLE dataType="REAL" pos="2"/>

<EDGE_PIXELS dataType="DINT" pos="2"/>

<EDGE_FLAG dataType="SINT" pos="1"/>

</BLOB>

Variable from

example above

SCORE44REAL0

SCALE48REAL1

X52REAL2

Y56REAL3

ROTATION60REAL4

Analyzed image’s number, attributes dataType and pos

Start of container for blob, Index number of the found blob according to current blob

sorting order. Index 0 is the first blob. Name refers to the blob tool's name in the Tools

tab

Number of found blobs

Blob center of gravity (x position), "pixels" or "mm"

Blob center of gravity (y position), "pixels" or "mm"

Blob area in pixels

Angle of the blob, in degrees or radians depending on the configured value in the Ethernet

Result Output dialog

Structure value (number of edge pixels inside the blob)

Edge flag: 0= the blob is fully within the ROI, 1=the blob touches ROI border

End of container for Blob

Attribute dataType Casts to the specified datatype. When using EtherNet/IP the at-

tribute dataType specifies the dataType section in the selected

assembly. The attribute dataType can be SINT, INT, DINT or REAL.

For more details about dataType and pos see table in Section A.3.2, “Attributes” (page 49).

Attribute pos Used by EtherNet/IP to determine a position in the dataType

section in the selected assembly. The first position number of

the dataType section is 0. The range of the attribute pos depends

on which assembly is used. For example if assembly 1 and

dataType section SINT is selected the range of position is 8, i.e.

[0, 7]. For more details about dataType and pos see table in

Section A.3.2, “Attributes” (page 49).

30

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 31

Reference Manual

Inspector PIM

EtherNet/IP

Interfaces

Therefore the value of the attributes dataType and pos together specifies which parameter

in the assembly the result value should be mapped to.

Result of validating output string with only a Blob

The validating in SOPAS Single Device will give the following result:

EtherNet/IP assembly string OK.

Result in PLC with only a Blob

The table below describes how the Assembly 1's data structure will be populated when using

the configuration example above.

Position ref (pos)

from XML configuration

(dataType)

Offset byteData type

Variable from

example above

FOUND_BLOBS0SINT0

EDGE_FLAG1SINT1

2SINT2

3SINT3

4SINT4

5SINT5

6SINT6

7SINT7

8INT0

10INT1

12INT2

14INT3

16INT4

18INT5

20INT6

22INT7

IMAGE_NUMBER24DINT0

AREA28DINT1

EDGE_PIXELS32DINT2

36DINT3

40DINT4

X44REAL0

Y48REAL1

ANGLE52REAL2

56REAL3

60REAL4

8015726/2013-11

Part of default string for configuration with only a Polygon

<IMAGE_NUMBER dataType="DINT" pos="0"/>

<POLYGON name="Polygon 1">

<NUM_CORNERS dataType="SINT" pos="0"/>

<CORNERS corners="0">

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

31

Page 32

Interfaces

EtherNet/IP

Reference Manual

Inspector PIM

<X dataType="INT" pos="1"/>

<Y dataType="INT" pos="2"/>

</CORNERS>

</POLYGON>

Analyzed image’s number, attributes dataType and pos

Start of container for Polygon, Name refers to the Polygon tool's name in the Tools tab

Number of corners used for this Polygon tool

Number 0 to 15 gives the properties of a single corner. The index of this corner is the

order in which the polygon corner was added when the polygon was drawn

Polygon corner coordinate (x), "pixels" or "mm"

Polygon corner coordinate (y), "pixels" or "mm"

End of tag for corners

End of container for Polygon

Attribute dataType Casts to the specified datatype. When using EtherNet/IP the at-

tribute dataType specifies the dataType section in the selected

assembly. The attribute dataType can be SINT, INT, DINT or REAL.

For more details about dataType and pos see table in Section A.3.2, “Attributes” (page 49).

Attribute pos Used by EtherNet/IP to determine a position in the dataType

section in the selected assembly. The first position number of

the dataType section is 0. The range of the attribute pos depends

on which assembly is used. For example if assembly 1 and

dataType section SINT is selected the range of position is 8, i.e.

[0, 7]. For more details about dataType and pos see table in

Section A.3.2, “Attributes” (page 49).

Therefore the value of the attributes dataType and pos together specifies which parameter

in the assembly the result value should be mapped to.

Result of validating output string with only a Polygon

The validating in SOPAS Single Device will give the following result:

EtherNet/IP assembly string OK.

If the used assembly is too small the validating will give the following result:

EtherNet/IP assembly string not OK. Out of slots for data type INT

Use a larger assembly to solve this problem . Choose a larger assembly in the dialog Interfaces

and I/O settings in the InspectorPIM60 menu and the EtherNet/IP tab.

Result in PLC with only a Polygon

The table below describes how the Assembly 1's data structure will be populated when using

the configuration example above.

Position ref (pos)

from XML configuration

Offset byteData type

(dataType)

Variable from

example above

NUM_CORNERS0SINT0

1SINT1

2SINT2

3SINT3

4SINT4

5SINT5

32

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

8015726/2013-11

Page 33

Reference Manual

Inspector PIM

EtherNet/IP

Interfaces

Position ref (pos)

from XML configuration

(dataType)

Offset byteData type

Variable from

example above

6SINT6

7SINT7

X8INT0

Y10INT1

12INT2

14INT3

16INT4

18INT5

20INT6

22INT7

IMAGE_NUMBER24DINT0

28DINT1

32DINT2

36DINT3

40DINT4

44REAL0

48REAL1

52REAL2

56REAL3

60REAL4

5.3 Control the sensor via EtherNet/IP

The Inspector PIM60 has the following EtherNet/IP characteristics:

• Device type: Communication adapter

The Inspector relies on a Scanner device to set up the communication channel. The IP

address of the Inspector can be found by choosing Device Info from the InspectorPIM60

menu.

•

Slim command channel4100Output

Command channel result36101Input

Command channel32102Output

• Minimum RPI: > 16 ms.

When retrieving inspection results via EtherNet/IP, the time between two inspections

should be at least twice the RPI (Requested Packet Interval) specified for the communication

channel.

With the shortest possible RPI, the highest recommended inspection rate is therefore approximately 30 Hz.

Assembly no.CommentSize (bytes)Instance no.Assemblies

1Small result channel64103Input

2Medium result channel124105Input

3Large result channel248107Input

4Extra large result channel484109Input

8015726/2013-11

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Subject to change without notice

33

Page 34

Interfaces

EtherNet/IP

Reference Manual

Inspector PIM

The EDS file for the Inspector PIM60 can be found in the Documentation folder on the Inspector

CD.

The Inspector PIM60 has two Output assemblies that can be used for controlling the Inspector.

To do this the connection has to be set first, see Operating Instructions for Inspector PIM60.

The slim command channel assembly (instance no. 100) is used for controlling the Inspector

in the following ways:

• Select reference object

• Image trig

The command channel assembly (instance no. 102) is also used for controlling the Inspector.

With this assembly you have access to all functions in the command channel, see Section B.3,

“Command descriptions” (page 54).

The two output assemblies are described in detail, see Section 5.3.6, “Assemblies command

channel” (page 36).

5.3.1 Basic principles