Page 1

ring

customer-

0,8A/T

customer-

Scanning range in m (feet)

OPERATING INSTRUCTIONS

en

TiM35x

TiM36x

Detecting Laser Scanner

Short Range

Intended use

The TiM35x/TiM36x laser scanner (referred to as the TiM

below) is an intelligent sensor for invisibly detecting objects

in areas (elds) to be monitored. The device is designed for

portable or stationary use indoors or outdoors in standalone

operation, with a scanning range of up to 10 m. The combined control for the four switching inputs activates one of the

16 eld sets for eld monitoring. Each eld set provides three

congurable elds. The TiM indicates detected eld infringements in relation to the three elds through a combination of

three switching outputs.

The TiM can also evaluate the existence of a contour, which

has to be fully situated within the evaluation eld at all times.

This allows the TiM to detect, for example, that a door opens

outwards or that the position of the TiM has changed. It is

also possible to detect someone crawling beneath a vertical

evaluation eld or a laser beam deected in a mirror.

The TiM is available in both a PNP and an NPN variant. The

NPN variant is identied by S02 in the type code on the type

label.

The purpose of this instruction manual is to allow you to put

the TiM into operation quickly and easily using precongured

8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com TIM35X/TIM36X | SICK 1

eld sets and to obtain the rst detection results.

Further information on the mechanical and electrical

installation is available in the & Technical Information (no.

8014318). This information is available for download on the

TiM product page (www.sick.com/tim3xx).

The TiM is certied to IEC/EN/UL/CSA 61010-1:2007. These

operating instructions may contain passages of text in a

foreign language.

Safety information

• Read these instructions before commissioning the TiM

in order to familiarize yourself with the device and its

functions.

• The TiM corresponds to laser class 1 ( see “Laser radia-

tion!, page 4”).

• Mounting and electrical installation are to be performed

only by qualied technicians.

• Electrical connections between the TiM and other devices

may only be made when there is no power to the system.

Otherwise, the devices may be damaged.

• Wire cross-sections in the supply cable from the customer's power system should be designed in accordance with

the applicable standards. Protect the TiM with an external

0.8 A slow-blow fuse at the beginning of the supply cable.

• All circuits connected to the TiM must be designed as SELV

or PELV circuits. (SELV = Safety Extra Low Voltage, PELV =

Protective Extra Low Voltage).

• Use the device only under permitted environmental

conditions (e.g. temperature, grounding potential, see

“Technical data, page 4”).

• Protect the TiM against moisture and dust when the cover

to the USB socket is open. The black plastic cover must

be screwed ush in order to comply with enclosure rating

IP 67 in operation.

• Turn the swivel connector unit with the electrical connections max 180° from end position to end position.

• Opening the screws of the TiM housing will invalidate any

warranty claims against SICK AG.

• The TiM does not constitute personal protection equipment in accordance with the respective applicable safety

standards for machines.

Commissioning and conguration

Step 1: Electrical installation

1. Connect the communication interface of the TiM to the

PC (Ethernet or USB; recommended Ethernet, 4-pin M12

female connector).

> If using a USB, connect the TiM's Micro USB port (behind

the black plastic cover on the side) to a free USB port (type

A) on the PC using a suitable shielded high-speed USB

cable (e.g. no. 6036106, 2 m).

The USB cable must not exceed 3 m in length!

When operating the USB interface, be aware that ESD/

EMC inuences may break the USB connection. To re-establish the data transmission, remove the USB cable on

the TiM and plug it back into the contact. To re-establish

communication between TiM and PC in the SOPAS conguration software, select

CommuniCation > Go online.

2. Turn on and start the PC.

3. Provide power to the TiM (12-pin M12 male connector).

Using the power supply unit it must be ensured that the

supply voltage does not drop below 8 V for longer than

2 ms and never rises above 30 V.

Following successful initialization, the green LED lights up

▸" (device ready for operation).

"

Do not supply the switching inputs with current yet.

provided

OUT 1 OUT 3

OUT 4

OUT 2

Connection

delayaction

fuse

Electrical block diagram for commissioning PNP variant

delay-

action

fuse

0,8A/T

Electrical block diagram for commissioning NPN variant

...

IN 1 IN 4

DC 9 ... 28 V

OUT 1 OUT 3

OUT 2

Connection

IN 1 IN 4

DC 9 ... 28 V

box

provided

box

...

IN GND

OUT 4

IN

9 ... 28 V

“Power/I/O”

“Power/I/O”

“USB 2.0”

“USB 2.0”

TiMxS02

TiM

USBUSB

SOPASSOPAS

Configuration

Field monito

Diagnosis

USBUSB

SOPASSOPAS

Configuration

Field monitoring

Diagnosis

Step 2: Mounting and alignment

NOTE

During installation make sure there is no reective surface

behind the reference target see “Device layout, page

â.

3”, point

1. Optional: Mount the TiM to separately ordered mounting

accessories (mounting kit 2), see "Mounting" Chapter in

the & Technical Information (no. 8014318).

2. Otherwise, mount the two straight plates from the

enclosed mounting kit 1 on the TiM using two M3 screws.

Use the two blind-hole threads either on the underside or

back of the housing ( see “Device layout, page 3”). If

the straight plates are not used, screw the screws provided

by the customer max. 2.8 mm into the thread.

3. Mount the TiM on a prepared bracket.

The device should be as free from vibration as possible

during operation.

4. Align the 90° axis of the TiM's scanning angle with the

center of the area to be monitored. The

lid of the optical hood serves as a bearing alignment aid

( see “Device layout, page 3”).

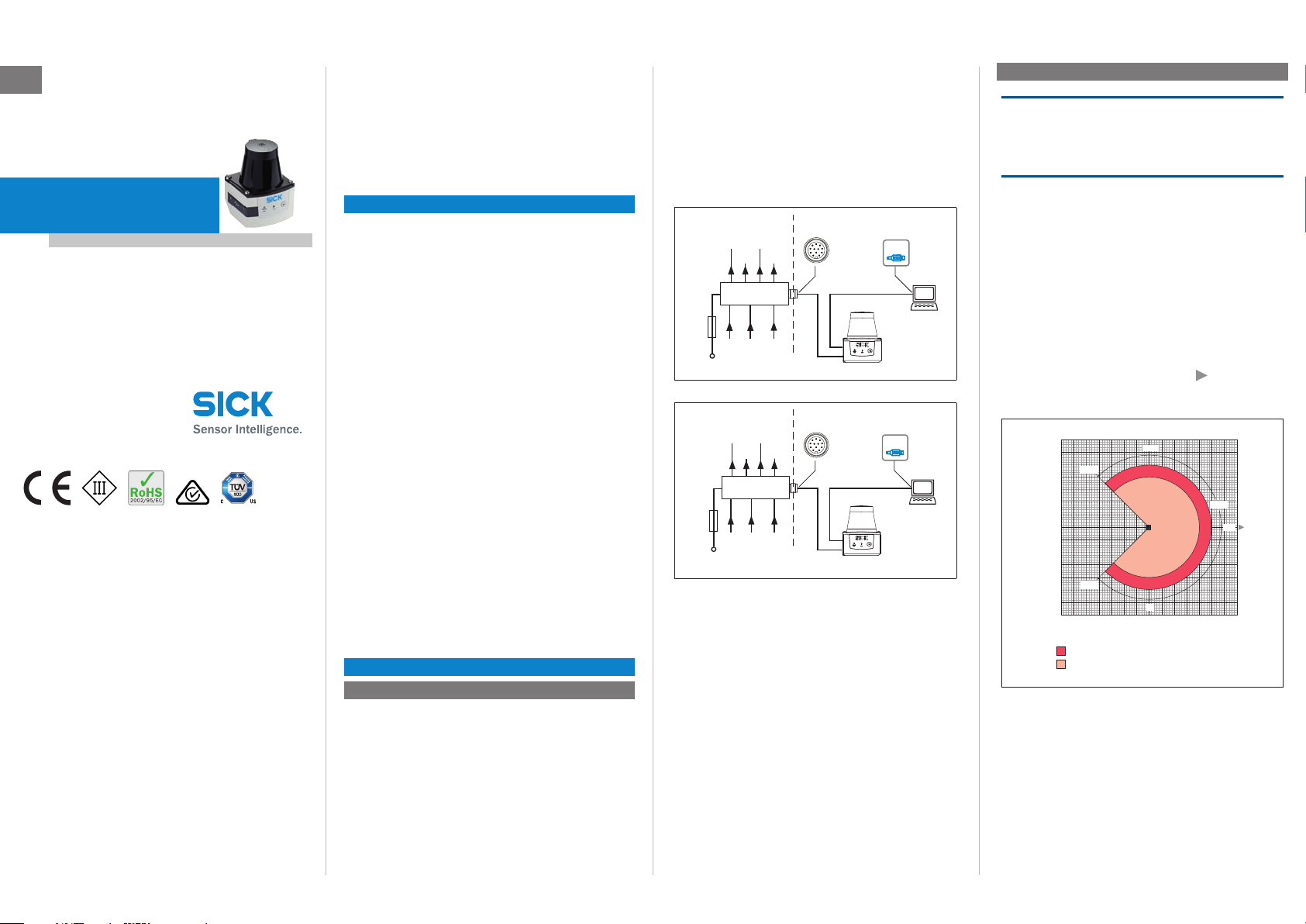

14

(45.93)

10

(32.81)

6

(19.69)

2

(6.56)

0

2

(6.56)

6

(19.69)

10

(32.81)

14

(45.93)

14

(45.93)10(32.81)

Scanning range max. 10 m (32.81 feet)

Scanning range typical 8 m (26.25 feet)

for objects up to 10 % remission

Range diagram for TiM

225°

‒45°

(19.69)

6

180°

0°

0

2

(6.56)2(6.56)

marking on the

270°

6

10

(19.69)14(45.93)

(32.81)

Scanning range in m (feet)

90°

Page 2

a. Conguration without PC

90°

Here, the TiM provides two options:

• Using one of 16 default eld sets, each with 3 predened

elds having the same eld shape, but different sizes

• Teach-in of the surrounding contour to automatically gener-

ate the outer eld with any shape, including more complex

shapes, and to deduce the two inner elds.

The eld sets are organized by groups into segmented eld

shapes. The shapes can be modied, with the default being a

rectangle. In the factory setting, the 3 origin-oriented elds of

a set are nested inside one another.

• The TiM stores the shortest value measured during the

teach-in phase as a eld limit for each angle.

• Note: A parameter upload is required in order to display

the newly taught-in eld contour in SOPAS.

> Start the eld contour teach-in.

3 seconds

= flashes slowly

2. Start the "Single Device" program option after completing

the installation.

Path: Start > Programs > SICK > SOPAS Engineering Tool >

SOPAS (Single Device).

SOPAS will automatically install the necessary USB driver

the rst time it detects a connected TiM. It may then be

necessary to restart the PC.

3. Establish a connection between SOPAS and TiM via the

wizard which opens automatically. Select the TiM from the

list of available devices.

SOPAS program window (single device)

Continuing the conguration process

Field 3

Field 2

Field 1

0°180°

Segmented,

free shape type

Structure of the elds of a eld set and possible eld shapes

Rectangle

Dimensions of the respective eld 1 and its shape in the

factory settings, as well as the required wiring of the switching

inputs for eld set selection see “Field set factory settings

– switching inputs, page 4”.

Preparing for teach-in

In general, the function button and both LEDs on the device

are used for teach-in.

• Remove all objects that will not permanently be in the eld

of view in monitoring mode later on.

• Distance yourself sufciently from the TiM during the

advance warning phase of the teach-in, so that you are not

detected as part of the eld contour.

Teaching-in the eld contour

The TiM uses eld set 1 (segmented, initial shape: rectangle)

to adjust the eld shape and size to the surrounding contour

that was detected. The switching inputs may not be supplied

with current during this process.

The TiM forms the outer eld 3 from the surrounding contour

with a negative offset of 100 mm, and deduces the limits

of the two inner elds from this, so that eld 2 = eld 1 plus

25% and eld 3 = eld 1 plus 52%.

• The eld shape to be formed can be dened by pacing out

the limits during the teach-in phase. Do not wear black

clothing during this process!

The behavior of the two LEDs indicates the progress of the

eld contour teach-in:

LED a

(red)

–

O O

–

–

O O

O = illuminated, = ashing

Status

LED b

(green)

Field contour teach-in – Start

LED ashes slowly (0.5 Hz)

Field contour teach-in – Advance warning

phase

LED ashes increasingly rapidly within 15 s

Field contour teach-in – Teach-in phase

60 seconds

Field contour teach-in – Completion of

advance warning phase

LED ashes increasingly rapidly within 15 s

Automatic return to monitoring mode

O

All elds free

Monitoring mode

In the event of eld infringement

The TiM stores the new eld set 1 permanently.

b. Conguration with PC

The SOPAS conguration software is used by default to adjust

the 3 elds of a eld set and other TiM parameters to the ap-

plication and to perform diagnostics in the event of an error.

If the eld shape of the eld set 1 has been taught in without

a PC using the function button, SOPAS is generally used to

continue the conguration.

This includes setting the eld shapes/sizes and any other

non-teachable eld sets based on the default setting, the

response time of the elds, the blanking size, and the holding

time of the assigned switching outputs OUT 1 ... OUT 3.

The blanking size is the smallest size from which an object

can be detected in a eld by the TiM and lead to a eld

infringement. All objects that are smaller than the minimum

size are blanked out. Like the response time and the holding

time, the blanking size applies to all eld sets and their elds.

Installing and launching the SOPAS conguration software

1. Download and install on the PC the software from the

website "www.sick.com/SOPAS_ET“. In this case, select

the "Complete" option as suggested by the install wizard.

Administrator rights may be required on the PC to install

the software.

Field monitor display window

• In the Field monitor window, SOPAS displays the eld

contour (scan line) currently seen by the device through

ambient reection in blue. If the 4 switching inputs are

not supplied with current, SOPAS also displays the three

evaluation elds (segmented rectangles) for the eld set

1 according to the TiM's default setting, or the eld shape

generated using the teach-in function along with its dimensions, the status of the switching inputs/outputs, and the

position of the mouse pointer.

• SOPAS displays the elds as green if no eld infringement

is present. If objects of a certain size ( see “Default set-

tings TiM, page 3”) are located for a certain duration

in the part of the visual range that is covered by elds,

the TiM will recognize this as a eld infringement. SOPAS

displays this separately in yellow for the individual elds.

> Try changing the orientation of the TiM in the room and ob-

serve the effects this has on detection in the eld monitor.

reset button to cause SOPAS to reset the switch-

Click the

ing output counters.

Field editor display window

The user can change parameters in the right part of the program window under

settinGs & deviCe status. SOPAS immedi-

ately transfers these changes to the TiM (default setting).

However, evaluation elds that have been changed in size and

shape must always be manually transferred to the TiM using

button. All changed parameters are only temporarily

the

stored in the device for the time being and are not stored in

the computer at all.

In order to optimize the dimensions of the monitoring elds:

1. Click the

evaluation Fields tab at the top of the program

window.

Field seleCtion on the right side of the window,

2. Under

select, for example, eld set 1.

3. Select the eld to be congured.

> You can optionally perform the following actions:

Shifting eld positions

1. Click the

button.

2. Click on the green marking rectangle of the desired eld

position in the outer eld.

The color of the marking rectangle changes to blue.

3. Re-click the rectangle and drag it to the desired position,

then release the pushbutton. SOPAS controls the available

positioning area during shifting.

Inserting additional eld positions

1. Click the

button.

2. Click on the desired position on the limits of the outer eld.

SOPAS inserts a new, green marking rectangle. This can

now also be shifted as already described.

Deleting eld positions

1. Click the

button.

2. Click on the green marking rectangle of the eld position to

be deleted in the outer eld.

The color of the marking rectangle changes to red.

3. Re-click the marking rectangle.

TIM35X/TIM36X | SICK 8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com2

Page 3

SOPAS removes the marking rectangle and instead con-

Cont

90°

51

(2.01)

nects the two nearest marking rectangles with a new line.

Rotating the eld pair around the central axis along with

the TiM

> In order to align the position of the eld pair in SOPAS to

the conditions on site from the user's perspective, enter

and conrm the desired angle of rotation in the 0.0° input

eld (negative sign "

–" means turn right).

Setting up the reference contour eld

In each eld set, any eld can be selected as a reference

contour eld. The reference contour eld is used to monitor

contours. This makes it possible to recognize when the

background is no longer detected in the required eld – for

example, as a result of covering or rotating the sensor.

The TiM uses the same evaluation strategy for all reference

contour elds (evaluation time and blanking size).

1. Select the required eld in the eld set.

2. Select the

seleCtion.

3. Delete the two eld positions closest to the sensor.

reFerenCe Contour Field check mark under Field

4. Mark the two remaining eld positions and shift them

outside of the required reference contour area.

5. Use the

button to switch to the conguration for the

reference contour eld start points. The eld starting

points must lie between the scan line and the scanner so

that the scan line passes between the start and end points

of the reference contour eld.

our as reference field

Field end point

Scan line

Field start point

Response time, blanking size and holding time

> Adjust the response time of the elds, the blanking size

of objects, and the holding time of the OUT 1 and OUT 4

switching outputs under

settinGs on the right side of the

program window. All three values are valid for both elds

and switching outputs.

When selecting the response time, note that the TiM's

internal reaction time must also be added (max. 67 ms).

> To test the effects of the changed settings, click on the

Field evaluation monitor tab at the top.

If the changed elds have been transferred to the TiM as

described, SOPAS will also display these in the monitor,

displaying the infringed elds in yellow. If you wish to

observe another eld set, it must rst be activated accord-

ingly using the switching inputs. If you wish to observe

another eld set, it must rst be activated accordingly

using the switching inputs.

The blanking size is the cross-section of the object after

which an object not previously in the viewing area of the TiM

leads to a eld infringement.

Completing the conguration process

> Permanently save the entire conguration:

Parameter set in: TiM click the

Conguration le on the PC: click the

button

button.

Default settings TiM

Parameter Value

Blanking size Cross-section 200 mm

Response time of the elds 335 ms (5 scans)

Holding time of the switching outputs 335 ms (5 scans)

Description of the device

Device layout

[Ø 4.3

(0.17)

]

44.79 (1.76)

33 (1.3)

(0.66)

16.79

27.3

(1.07)

8

(2.46)

62.46

[24.4

(0.31)

(0.96)]

85.75 (3.38)

7

0.7 (0.03)

60 (2.30)

[68.8 (2.71)]

[76.25

30°

(3.00)]

3

4

5

6

â

1

2

17.37

(0.68)

225°‒45°

101.12 (3.98)

8

Mounting set 1

61

(2.40)

46.71 (1.84)

74.39 (2.93)

2 x

9

ß

51 (2.01)

à

á

24.4

(0.96)

22

180°0°

TiM

6. Depending on the required shape of the reference contour

eld, create additional eld points between the sensor and

the reference contour eld. The distance between the start

ã

ä

All dimensions in mm (inch)

and end points of the reference contour eld should be

approximately 20 cm.

button can be used to switch between the start

> The

and end points of the reference contour eld for editing

purposes. The active points are highlighted in light green

while the deactivated points are dark green.

Some other useful functions

button: Display the elds in the polar coordinate

•

system

button: Change the view of the TiM/ elds from above

•

(TiM: black) to the view from below (TiM: blue)

or button: Switch off the display the full measur-

•

1 2 x straight plates with M3 x 4 mm screw (included in scope of

delivery)

2 M3 threaded mounting hole, 2.8 mm deep (blind hole thread)

3 Optical hood

4 Receiving range (light inlet)

5 Transmission range (light emission)

6 Function button for teach-in

7 Red and green LED (status displays)

8 Swivel connector unit with electrical connections and á

9 Micro USB port, behind the black plastic cover

('Aux interface' connection for conguration with PC)

"Power/inputs and outputs" connection, 12-pin M12 male connector

à Marking for the position of the light emission level

á Ethernet connection, 4-pin M12 female connector

â Area in which no reective surfaces are allowed for mounted devices

ã Bearing marking to support alignment (90° axis)

ä 270° aperture angle (visual range)

ing line or display a dotted measuring line.

8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com TIM35X/TIM36X | SICK 3

Page 4

a CAUTION

Laser radiation!

CLASS 1 LASER PRODUCT

The TiM corresponds to laser class 1 (eye-safe).

The laser beam is not visible to the human eye.

CAUTION – the use of controls, or adjustments or performance of procedures other than those specied herein may

result in hazardous radiation exposure.

> Do not open the housing (opening the housing will not

switch off the laser).

> Pay attention to the laser safety regulations as per

IEC 60825-1 (latest version).

a MISE EN GARDE

Rayonnement laser !

APPAREIL À LASER DE CLASSE 1

Le TiM est conforme à la classe laser 1 (sécurité des yeux).

Le rayon laser n’est pas visible pour l’oeil humain.

PRUDENCE – tout usage de commandes, réglages ou toute

application de procédures autres que ceux décrits dans ce

document peut entraîner une exposition dangereuse au

rayonnement.

Attention – L’utilisation des commandes ou réglages ou l’exécution des procédures autres que celles spéciées dans les

présentes exigences peuvent être la cause d’une exposition à

un rayonnement dangereux.

> Ne pas ouvrir le boîtier. (La diode laser n’est pas désac-

tivée en cas d’ouverture du boîtier)

> Se conformer aux dernières consignes de protection en

date contre le rayonnement laser IEC 60825-1 (dernière

version).

Additional information see “Technical data, page 4”.

Status indicators, functions

Status displays

LED a

(red)

LED b

(green)

–

O O

–

O O

–

– –

O = illuminated; = ashing

Status

Device ready/monitoring mode

O

Field infringement

Teach-in – Start

Teach-in – End of advance warning phase

60-second teach-in phase

Teach-in – End of teach-in phase

Errors

–

Device without supply voltage

Field set factory settings – switching inputs

Field

Switching inputs Field shape

set

IN 1 IN 2 IN 3 IN 4

1 0 0 0 0

2 1 0 0 0

3 0 1 0 0

4 1 1 0 0

5 0 0 1 0

6 1 0 1 0

7 0 1 1 0

8 1 1 1 0

9 0 0 0 1

10 1 0 0 1

11 0 1 0 1

12 1 1 0 1

13 0 0 1 1

14 1 0 1 1

15 0 1 1 1

16 1 1 1 1

L = length, W = width

1) Default setting, starting shape can be modied as required

Default size of eld 1

1)

Rectangle

, segmented

L: 1 m, W: 2 m

1)

, segmented

Rectangle

L: 1.25 m, B: 2 m

1)

Rectangle

, segmented

L: 1.5 m, B: 2 m

1)

Rectangle

, segmented

L: 1.75 m, B: 2 m

1)

Rectangle

, segmented

L: 1 m, W: 2 m

1)

, segmented

Rectangle

L: 1.25 m, B: 2 m

1)

Rectangle

, segmented

L: 1.5 m, B: 2 m

1)

Rectangle

, segmented

L: 1.75 m, B: 2 m

1)

Rectangle

, segmented

L: 1 m, W: 2 m

1)

, segmented

Rectangle

L: 1.25 m, B: 2 m

1)2)

Rectangle

L: 1.5 m, B: 2 m

Rectangle

L: 1.75 m, B: 2 m

Rectangle

L: 1 m, W: 2 m

Rectangle

L: 1.25 m, B: 2 m

Rectangle

L: 1.5 m, B: 2 m

Rectangle

L: 1.75 m, B: 2 m

, segmented

1)

, segmented

1)

, segmented

1)

, segmented

1)

, segmented

1)

, segmented

Input level

• PNP: Low (in resting position): ≤ 2 V, high (in working

position): ≥ 8 V

• NPN: Active low (in working position): ≤ (IN 9...28 V) – 8 V,

inactive high (in resting position) > (IN 9...28 V) – 2 V

Assignment of infringed elds - switching outputs

Fields of a eld set Switching outputs

OUT 1 OUT 2 OUT 3

Fields 1, 2, and 3 infringed Active

Fields 2 and 3 infringed

Field 3 infringed

All elds free

Field 1: inner, eld 2: center, eld 3: outer

Active: in working position; deactivated: in resting position

Deacti-

vated

Deacti-

vated

Deactivated

Active Active

Active Active

Deacti-

Active

vated

Deacti-

Deacti-

vated

vated

Output level

• PNP: The level of the switching outputs OUT 1 ... OUT 3 is

active low (in resting position: high, in working position: low

(eld infringed)).

• NPN: The level of the switching outputs OUT 1 ... OUT 3 is

active high (in resting position: low, in working position:

high (eld infringed)).

All elds of a eld set are also deemed to be infringed during

switching on, booting, in the event of an error, and when the

device is switched off.

The OUT 4 switching output works with the following levels:

Function Level PNP Level NPN

Device Ready High Low

Index signal (15 Hz), corresponds to

measurement at 90°

Errors Low High

Low-Peaks High-Peaks

Technical data

Model name TiM351-2134001 (Part no. 1067299)

Scanning range

Angular resolution

Scanning frequency

Response time

Scanning range

Remission

Physical Minimum

object size

(cross-section)

Measuring error

TIM361-2134101 (Part no. 1071399)

Radial, aperture angle 270°

TiM35x: 1°

TiM36x: 0.33°

15 Hz (15 scans/s)

Typical 67 ms (1 scan)

0.05 m to 10 m; typically 8 m at 10%

1)

remission

Typical 4% ... > 1,000% (reector)

213 mm (TiM35x) / 121 mm (TiM36x) for a

scanning range of 8 m,

112 mm (TiM35x) / 66 mm (TiM36x) for a

scanning range of 4 m,

61 mm (TiM35x) / 38 mm (TiM36x) for a

scanning range of 2 m and 10% remission

Statistical (1 s): ± 20 mm

Systematic: ± 60 mm

Temperature drift 0.5 mm/K

Model name TiM351-2134001 (Part no. 1067299)

Ambient light

immunity

Light source

Device laser class

Max. radiated

power

Max. pulse

duration

Field evaluation

Number of eld

sets

Aux interface

Ethernet interface Max. data rate: 10 Mbit and 100 Mbit, cable

Switching inputs PNP: 4 x IN (U

Switching outputs 4 x OUT (each I

Electrical connections

Function key Teach-in (eld set 1 eld contour)

Optical indicators 2 x LED

Supply voltage DC 9 ... 28 V, SELV an PELV acc. to

Power consumption

Housing Lower part : Die-cast aluminum

Weight

Electrical safety

Protection class

Enclosure rating

EMC

Vibration resistance

Shock resistance

Ambient temperature

Temperature

change

TIM361-2134101 (Part no. 1071399)

80,000 lx (indirect)

Laser diode, infrared (λ = 850 nm)

Laser class 1 according to EN 60825-1:

2)

2014

, eye-safe

2.0 W (TIM35x)

1.5 W (TIM36x)

5 ns

1 evaluation mode with 1 eld set (up to 3

detection elds), optional separate evaluation

for 1 reference contour eld

Field infringement signaling via a combination

of 3 switching outputs.

16, each with 3 exible, congurable elds,

one of which can be used as a reference

contour eld

USB 2.0 for conguration, connecting cable

max. 3 m.

length limited to max. 100 m

opto-decoupled, debouncing time approx.

10 ms

NPN: Common reference potential 9 ... 28 V

isolated from the supply voltage, short-circuit

protected/temperature protected

Congurable for OUT 1 .... OUT 3:

Response time (67 ms ... 30 s)

Holding time (0 ms ... 10 s)

1 x 12-pin M12 power male connector

1 x 4-pin. M12 Ethernet socket

1 x micro USB socket, type B (covered)

IEC 60364-4-41: 2005-12

4 W (with switching outputs without load)

16 W (with four loaded switching outputs)

Optics hood: Polycarbonate with scratch-proof

coating

Approx. 250 g without cables

According to According to IEC 61010-1 (ed.3)

III according to EN 61140: 2006-08

IEC 61010-1 (ed.3)

IP 67 (EN 60529: 1991-10/A2: 2000-02)

No specied enclosure rating for opened

"Aux interface" connection and/or plugged in

USB cable!

Radiated emission: Residential area according

to EN 61000-6-3: 2007-01

Electromagnetic immunity: Industrial environ-

ment according to

EN 61000-6-2: 2005-08

According to EN 60068-2-6: 2008-02

According to EN 60068-2-27: 2009-05

Commissioning/switching on: –10 ... +50 °C

Operation: –25 °C to +50 °C

Storage: –40 °C to +75 °C

According to EN 60068-2-14: 2009-07

= max. 28 V, Ie = max. 5 mA),

e

≤ 100 mA), not galvanically

a

3)

8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com TIM35X/TIM36X | SICK 4

Page 5

Model name TiM351-2134001 (Part no. 1067299)

“Power/switching inputs/outputs” connection

12-pin M12 plug on the cable

“Ethernet” connection

Damp heat

Air humidity

Installation height

Ambient conditions

1) T < -15 °C: typ. 7.5 m at 10% Remission

2) Complies with 21 CFR 1040.10 and 1014.11 except for the deviations pursuant to Laser Notice No. 50 of June 2007

3) The TiM has an internal, system-related delay time of 67 ms.

TIM361-2134101 (Part no. 1071399)

According to EN 60068-2-30: 2005-12

< 80%

< 5,000 m above sea level

According to EN 61010-1:2011-07, contamination level 3 outside housing

For further technical specications, see the Online data sheet

on the product website (www.sick.com/tim3xx).

a WARNING

Risk of potential equalization currents

The TiM is designed to be operated in a system with proper

grounding of all connected devices and mounting surfaces

to the same ground potential. If this condition is not met,

potential equalization currents may through along the cable

shields, causing the following hazards:

• Dangerous contact voltage on the metal housing

• Malfunction or destruction of the TiM

• Heating of the cables with possible spontaneous combustion.

> See the "Electrical installation“ chapter in the & Technical

Information (no. 8014318) on the product site on the web

(www.sick.com/tim3xx) for measures to eliminate hazards.

a ATTENTION

Risques liés à des courants d’équipotentialité

Le TiM a été conçu pour être utilisé dans une installation

prévoyant une mise à la terre correcte de tous les appareils

et surfaces de montage raccordés sur un même potentiel de

sol. Si cette condition n’est pas remplie, des courants d’équipotentialité risquent dans certaines conditions de passer par

les blindages des câbles et d’exposer aux risques suivants :

• tension de contact dangereuse sur le boitier en métal,

• comportement incorrect ou destruction du TiM.

• chauffe des câbles jusqu’à leur inammation spontanée.

> Pour des mesures de prévention de tels risques, voir le

chapitre « Installation électrique » de & l’Information tech-

nique (no. 8014318) ou sur la page produit sur internet

(www.mysick.com/en/tim3xx).

Pin assignment for rotary corners

Connection plug pin positions

6

5

7

1

GND

2

DC 9 ... 28 V

3

IN 1 (switching input)

4

IN 2 (switching input)

5

OUT 1 (switching output)

6

OUT 2 (switching output)

7

OUT 3 (switching output)

8

OUT 4 (switching output)

9

PNP: INGND

NPN: IN 9 ... 28 V (Reference potential for

10

switching inputs)

IN 3 (switching input)

11

IN 4 (switching input)

12

n.c.

8

9

1112

4

3

2

1

10

Ethernet connection (6034415)

4

1

M12 socket,

D-encoded

32

1

TD+

2

RD+

3

TD–

4

RD–

Maintenance and care

The TiM does not contain any components that require maintenance. Maintenance is not necessary to ensure compliance

with laser class 1.

> If it is dirty, carefully clean the infrared light-permeable,

black optical hood to ensure optimal detection perfor-

mance. Use a soft, damp cloth and a mild cleaning agent.

Transport and storage

The TiM must be transported and stored in its original pa-

ckaging with the USB protective cap plugged in. Do not store

outdoors. To ensure that any residual moisture present can

escape. Do not expose to aggressive media (e. g., solvents).

Storage conditions: dry, dust-free, no direct sunlight, as little

vibration as possible, storage temperature –40°C to +75°C,

relative air humidity max. 90% (non-condensing).

Repair

Repair work on TiM35x may only be performed by qualied

and authorized service personnel from SICK AG.

Removal and disposal

Any TiM35x which can no longer be used at the end of the

product life cycle must be disposed of in an environmentally

friendly manner in accordance with the respective applicable

country-specic waste disposal regulations.

The TiM35x is electronic waste and must under no circum-

stances be disposed of with general waste!

Sources for obtaining additional informat

Additional information about the TiM and its optional acces-

sories can be found in the following places:

Product web page for the TiM3xx

(www.sick.com/tim3xx)

• Technical Information (supplementary information on

mounting and electrical installation, an overview list, and

license texts for open-source software) in German (no.

8014317) and English (no. 8014318).

• These operating instructions in German (no. 8016902),

English (no. 8016903), and in other languages if required

• SOPAS conguration software with online help

• Ordering information in the detection and ranging solutions product catalog

• TiM3xx product information

• Detailed technical specications (online data sheet)

• Dimensional drawing and 3D CAD dimension models in

various electronic formats

• EC declaration of conformity

• SOPAS conguration software updates

Support is also available from your sales partner: www.sick.

com/worldwide.

Copyright notices for open-source programs

SICK uses open source software in its TiM sensors. This

software is licensed by the rights holders using the following

licenses among others: the free licenses GNU General Public

License (GPL Version2, GPL Version3) and GNU Lesser General Public License (LGPL), the MIT license, zLib license, and

the licenses derived from the BSD license.

This Program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty for merchantability or tness for a particular purpose.

See the GNU General Public License for more details.

View the complete license texts here: www.sick.com/licen-

setexts.

A printed copy of the license texts is also available on request.

TIM35X/TIM36X | SICK 8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com5

Page 6

8016903/ZP97/2017-07-27 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com TIM35X/TIM36X | SICK 6

8016903/ZP97/2017-07-27 ∙ 8M_DR ∙ Printed in Germany (2017-07) ∙ All rights reserved ∙ Subject to change without notice

Loading...

Loading...