Page 1

TiM361S

Safety-related 2D LiDAR sensor

OPERATING INSTRUCTIONS

Page 2

Product described

TiM361S

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal notes

This work is protected by copyright. The associated rights are reserved by SICK AG.

Reproduction of this document or parts of this document is only permissible within the

limits of the legal provisions of copyright law.

Any modification, abridgment, or translation of this document is prohibited without the

express written permission of SICK AG.

The trademarks mentioned in this document are the property of their respective

owners.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

2

Subject to change without notice

Page 3

CONTENTS

Contents

1 About this document ................................................................................ 5

1.1 Function ........................................................................................................... 5

1.2 Scope ............................................................................................................... 5

1.3 Target groups .................................................................................................. 5

2 Safety information .................................................................................... 7

2.1 Intended use .................................................................................................... 7

2.2 Application area .............................................................................................. 7

2.3 Requirements for the qualification of personnel ......................................... 8

2.4 Safety notes .................................................................................................... 9

2.5 Regulations and standards .......................................................................... 10

3 Product description ................................................................................. 11

3.1 Scope of delivery ........................................................................................... 11

3.2 Type label ...................................................................................................... 11

3.3 Device layout ................................................................................................. 12

3.4 Accessories .................................................................................................... 13

3.5 Safety characteristic values ......................................................................... 16

3.6 Safety-related detection capability .............................................................. 16

4 Mounting ................................................................................................... 17

4.1 Notes on mounting ....................................................................................... 17

4.2 Mutual interference ...................................................................................... 17

5 Commissioning and configuration ........................................................ 18

5.1 Notes on the electrical installation .............................................................. 18

5.2 Prerequisites for safe electrical operation .................................................. 18

5.3 Installation of SOPAS Engineering Tool ...................................................... 21

5.3.1 Installation process ..................................................................... 21

5.3.2 Installing the device driver ......................................................... 21

5.4 Configuration of the sensor .......................................................................... 22

5.4.1 Establishing the connection ....................................................... 22

5.4.2 Configure the device ................................................................... 22

5.4.3 Display of the current operational status.................................. 23

5.4.4 Changing parameters ................................................................. 23

5.4.5 Default configuration .................................................................. 23

5.4.6 Passwords ................................................................................... 27

5.5 Editing fields .................................................................................................. 27

5.5.1 Operating modes/operational statuses .................................... 28

5.5.2 Digital inputs/outputs ................................................................ 30

5.5.3 Function and status displays ..................................................... 33

6 Error behavior ........................................................................................... 34

6.1 General .......................................................................................................... 34

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

3

Page 4

CONTENTS

6.2 Detected errors ............................................................................................. 34

6.3 Undetected errors and faults ....................................................................... 34

6.4 Fault exclusions ............................................................................................ 35

6.5 Manipulation ................................................................................................. 35

7 Project planning ...................................................................................... 36

7.1 Manufacturer of the machine ...................................................................... 36

7.2 Operating entity of the machine .................................................................. 36

8 Regular thorough checks ....................................................................... 38

9 Working with the product ....................................................................... 39

9.1 Maintenance and care .................................................................................. 39

9.2 Transport and storage .................................................................................. 39

9.3 Repairs ........................................................................................................... 39

9.4 Disassembly and disposal ............................................................................ 39

10 Technical data .......................................................................................... 40

10.1 General technical data ................................................................................. 40

10.2 Safety-related technical data ....................................................................... 41

11 Declaration of conformity ...................................................................... 43

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

4

Subject to change without notice

Page 5

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Function

These operating instructions contain the information required during the life cycle of

the TiM361S safety-related 2D LiDAR sensor (2D laser scanner).

These operating instructions must be made available to everyone who works with this

sensor.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the sensor.

1.2 Scope

These operating instructions apply to the TiM361S safety-related laser scanner (also

referred to as TiM361S, device or sensor) with part number 1090608 and the

associated safety notes, part number 8018793.

The TiM361S comes with the conformity for use within the scope of application of the

Machinery Directive 2006/42/EC and the associated standards and regulations (see

also chapter 2.5).

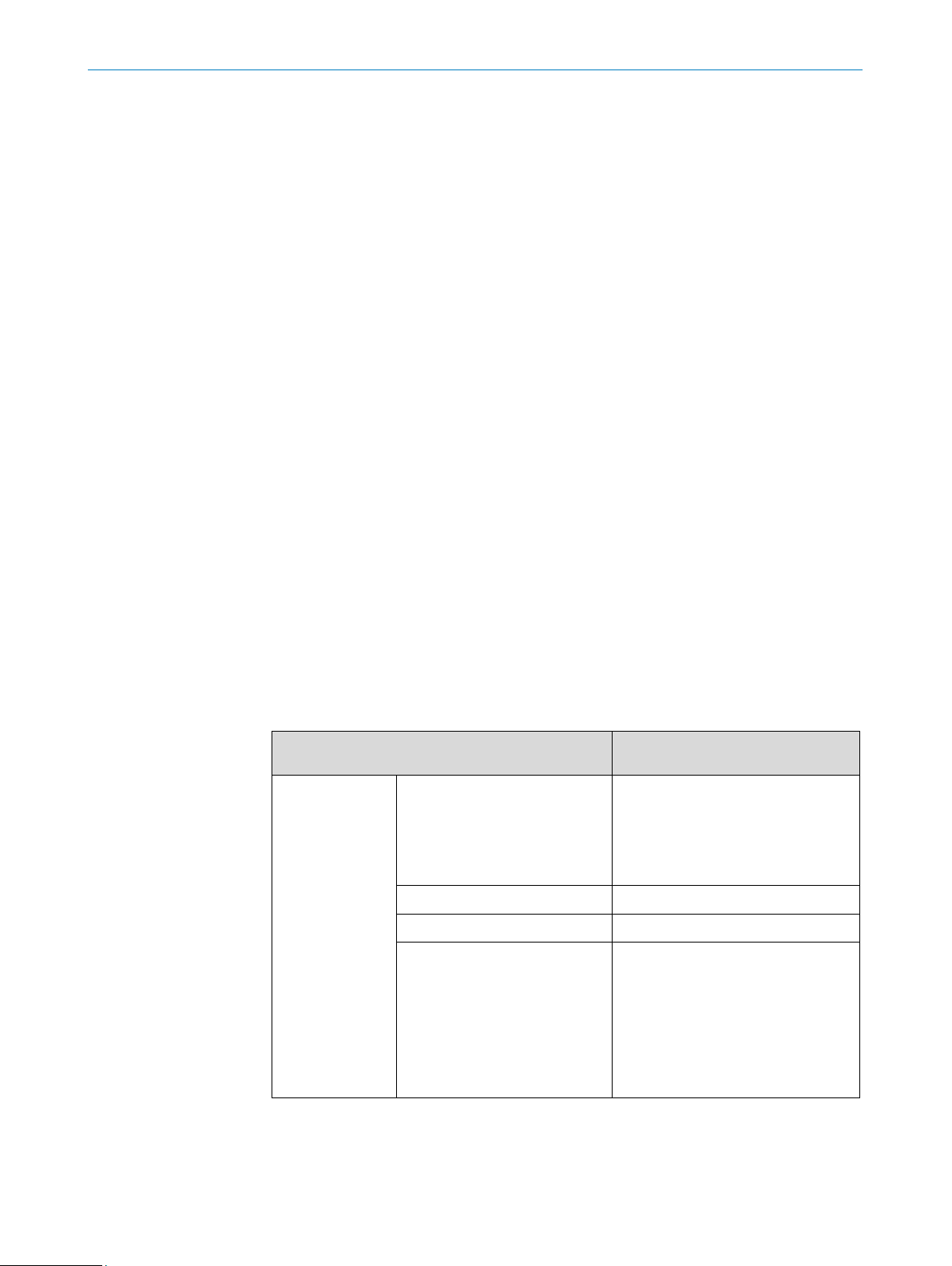

1.3 Target groups

These operating instructions are intended for the following target groups: project

developers (planners, developers, designers), installers, electricians, safety experts

(such as CE authorized representatives, compliance officers, people who test and

approve the application), operators, and maintenance personnel.

Commissioning, operation and maintenance.

In many applications, the target groups consist of the manufacturer and the operating

entity of the machine in which the TiM361S is integrated, as follows:

Manufacturer Project developers (planners,

Installers Mounting, page 17

Electricians Commissioning , page 18

Safety experts Project planning, page 8

Target group Specific chapters of these operating

instructions1

Project planning, page 8

developers, designers)

Configuration, page 8

Technical data, page 40

Accessories, page 13

Configuration, page 8

Commissioning , page 18

Regular thorough checks,

page 38

Technical data, page 40

1

Chapters not listed here are intended for all target groups. All target groups must comply with the safety notes in all of the operating

instructions!

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

5

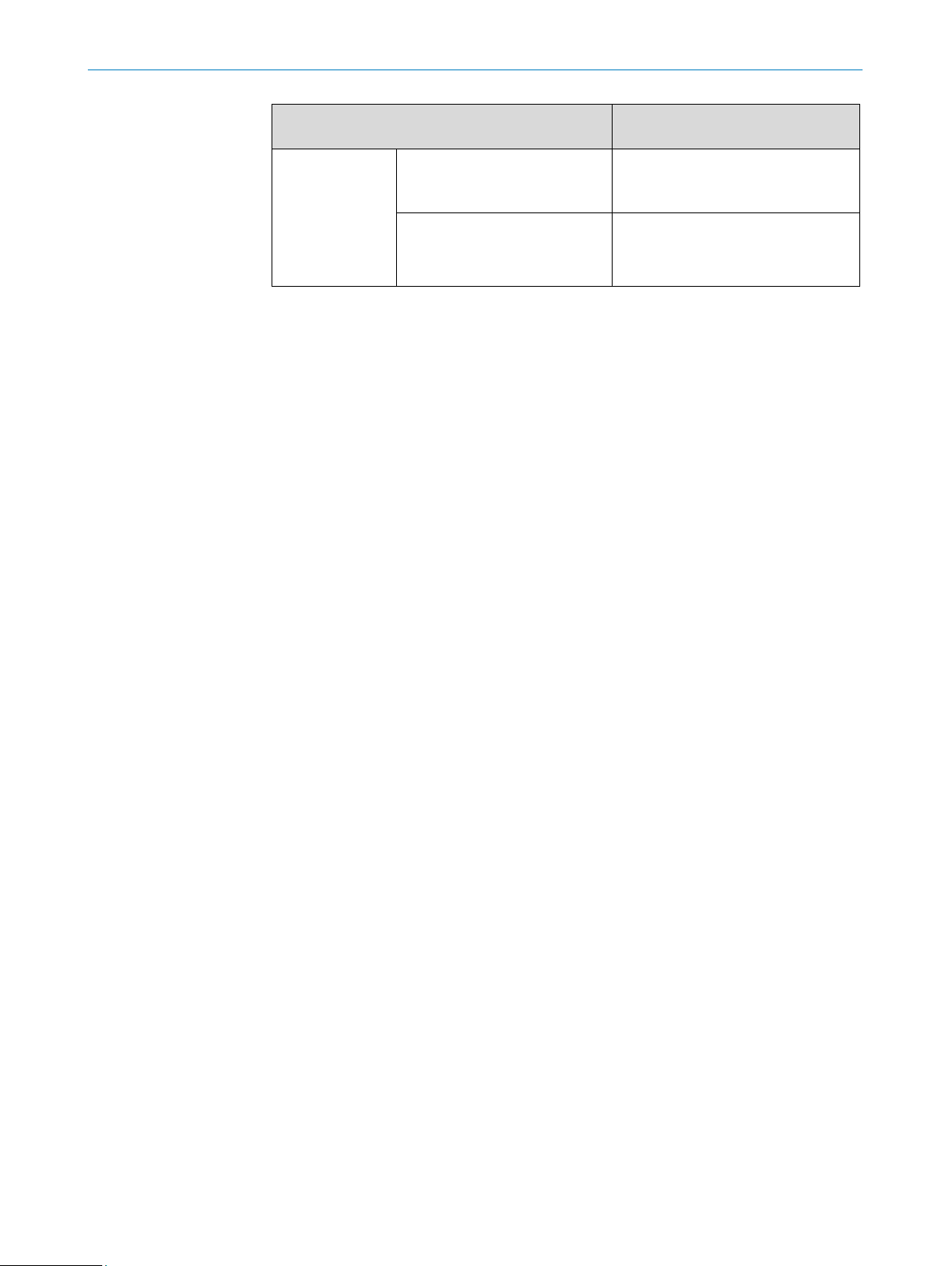

Page 6

1 ABOUT THIS DOCUMENT

Target group Specific chapters of these operating

instructions1

Operating entity Operator of the

device/person who performs

Configuration of the sensor,

page 22

device configuration

Maintenance personnel Regular thorough checks,

page 38

Accessories, page 13

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

6

Subject to change without notice

Page 7

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The TiM361S is a safety-related sensor suitable for the following applications:

Hazardous area protection

Hazardous point protection

Access protection

Mobile hazardous area protection (protection of mobile platforms)

The safety-related 2D LiDAR sensor must only be used within the limits of the

prescribed and specified technical data (see 10.2 Safety-related technical data,

page 41) and operating conditions at all times.

Use inconsistent with the intended use, operation beyond the technical limits, improper

modification of, or manipulation of the TiM361S, will invalidate any warranty from SICK;

in addition, any responsibility and liability of SICK AG for damage and consequential

damage caused by this is excluded.

Reasonably foreseeable misuse

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected may not recognized in case of nonobservance. The TiM361S works as an indirect protective measure and cannot provide

protection from pieces thrown from the application nor from emitted radiation. Objects

within the blind zone and outside of the safety-related detection zone as well as

transparent objects will not be detected.

You must only use the sensor as an indirect protective measure.

The TiM361S is not suitable for the following applications, among others:

Outdoors

Underwater

In explosion-hazardous areas

Use beyond the technical specifications

As a safety-related sensor, the TiM361S safety-related 2D LiDAR sensor with

performance level b (PL b), Category B, according to EN ISO 13849 is only intended to

perform part of the safety function (partial safety function). In its safety function, it

provides sensor information to a downstream logic unit for further processing.

The safety function arises only in context with the target application, e.g., machine

tools, a mobile platform or service robot.

Requirements and features of the application may differ from the features and

characteristic values of the product and must be evaluated within the scope of project

planning.

2.2 Application area

The TiM361S safety-related laser scanner is intended for use as a sensor in personal

protection equipment, in mobile applications on electrically operated autonomous

platforms in industrial environments, as well as in stationary applications for access

protection and presence monitoring in industrial environments.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

7

Page 8

2.3 Requirements for the qualification of personnel

The TiM361S safety-related laser scanner must be configured, installed, connected,

commissioned and serviced only by qualified safety personnel.

Project planning

For project planning, a person is considered qualified when he/she has expertise and

experience in the selection and use of protective devices on machines in the respective

area of application, and is familiar with the relevant technical rules and national work

safety regulations.

Mechanical mounting

For mechanical mounting, a person is considered qualified when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the use of

the protective device on machines in the respective area of application to be able to

assess whether it is in an operationally safe state.

Electrical installation

For electrical installation, a person is considered qualified when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the use of

the protective device on machines in the respective area of application to be able to

assess whether it is in an operationally safe state.

2 SAFETY INFORMATION

Configuration

For configuration, a person is considered qualified when he/she has the expertise and

experience in the relevant field and is sufficiently familiar with the use of the protective

device on machines in the respective area of application to be able to assess whether

it is in an operationally safe state.

Commissioning

For commissioning, a person is considered qualified when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the use of the

protective device on machines in the respective area of application to be able to

assess whether it is in an operationally safe state.

Regular thorough checks

For these regular thorough checks, a person is considered qualified when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

use of the protective device on machines in the respective area of application to be

able to assess whether it is in an operationally safe state.

Operation and maintenance

For operation and maintenance, a person is considered qualified when he/she has the

expertise and experience in the relevant field, is sufficiently familiar with the use of the

protective device on machines in the respective area of application, and has been

instructed by the operating entity of the machine in the details of operation.

An operator may clean the device and carry out specific thorough checks as instructed.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

8

Subject to change without notice

Page 9

2 SAFETY INFORMATION

2.4 Safety notes

The accessible radiation does not pose a danger when viewed directly for up to

100 seconds. It may pose a danger to the eyes and skin in the event of incorrect use.

Do not open the housing. Opening the housing will not switch off the laser.

Current national regulations regarding laser protection must be observed.

Electrical voltage can cause severe injury or death.

Work on electrical systems must only be performed by qualified electricians.

The power supply must be disconnected when attaching and detaching electrical

The product must only be connected to a voltage source as set out in the

National and regional regulations must be complied with.

Safety requirements relating to work on electrical systems must be complied with.

Caution

Optical radiation: Laser class 1!

Opening the housing may increase the level of risk.

Warning

Electrical voltage!

connections.

requirements in the operating instructions.

Warning

Dangerous equipotential bonding currents!

Improper grounding can lead to dangerous equipotential bonding currents, which may

in turn lead to dangerous voltages on metallic surfaces, such as the housing. Electrical

voltage can cause severe injury or death.

Work on electrical systems must only be performed by qualified electricians.

Follow the notes in the operating instructions.

Install the grounding for the product and the system in accordance with national

and regional regulations.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

9

Page 10

2.5 Regulations and standards

EN/IEC 60825-1:2014 - Laser safety standard

Complies with 21 CFR 1040.10 and 1040.11 except for the listed tolerances in

the document "Laser Notice No. 50" of June 24, 2007.

For safety-related parts of control systems

EN ISO 13849-1:2015

Safety of machinery – Safety-related parts of control systems – Part 1: General

principles for design

For mobile applications

EN ISO 13482:2014

Robots and robotic devices – Safety requirements for personal assistance robots

For stationary applications

DIN ISO 13855:2010

Safety of machinery – Positioning of protective devices with respect to the

approach speeds of parts of the human body

DIN CLC/TS 62046:2009

Safety of machinery – Application of protective equipment to detect the presence

of persons

2 SAFETY INFORMATION

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

10

Subject to change without notice

Page 11

3 PRODUCT DESCRIPTION

3 Product description

TiM361S safety-related laser scanner

Item description: TiM361S-2134101

Design: PNP

Part no. 1090608

Valid firmware version: 2.59 or higher

SOPAS configuration software

Item description: SOPAS ET

Valid software version: 3.3.3 or higher

3.1 Scope of delivery

TiM361S--2134101 including mounting kit 1

(two straight plates, 2 M3 x 4 mm screws)

Printed safety notes with reference to the operating instructions in German and

English; in other languages via the SICK AG website, if required

Other optional accessories (if these have been ordered)

3.2 Type label

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

11

Page 12

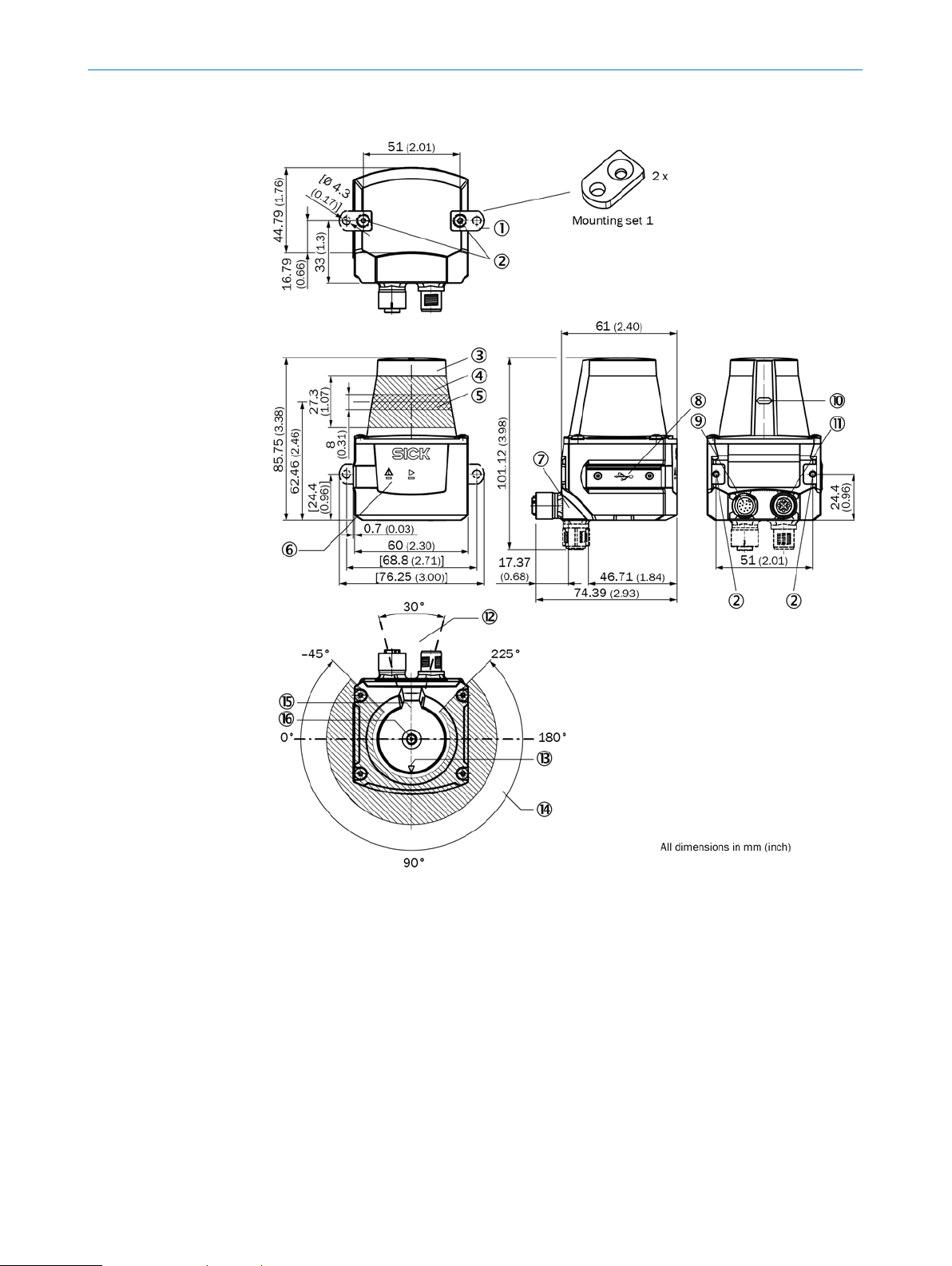

3.3 Device layout

3 PRODUCT DESCRIPTION

1 2 x straight plates with M3 x 4 mm screw (included in scope of delivery)

2 M3 threaded mounting hole, 2.8 mm deep (blind hole thread)

3 Optics cover

4 Receiving range (light inlet)

5 Transmission range (light emission)

6 Red and green LED (status displays)

7 Swivel connector unit with electrical connections

8 Micro USB port, behind the black plaster cover ("Aux interface" connection for

configuration with PC)

9 "Power/inputs and outputs" connection, 12-pin M12 male connector

10 Marking for the position of the light emission level

11 Connection (4-pin M12 female connector: not used)

12 Area in which no reflective surfaces are permitted when the device is mounted

13 Bearing marking to support alignment (90° axis)

14 270° aperture angle (visual range)

15 Internal reference target

16 Measurement origin

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

12

Subject to change without notice

Page 13

3 PRODUCT DESCRIPTION

Ø 4.3

2 x Ø 4.3

39.1

26.4

12.1

101.5

68.8

68.8

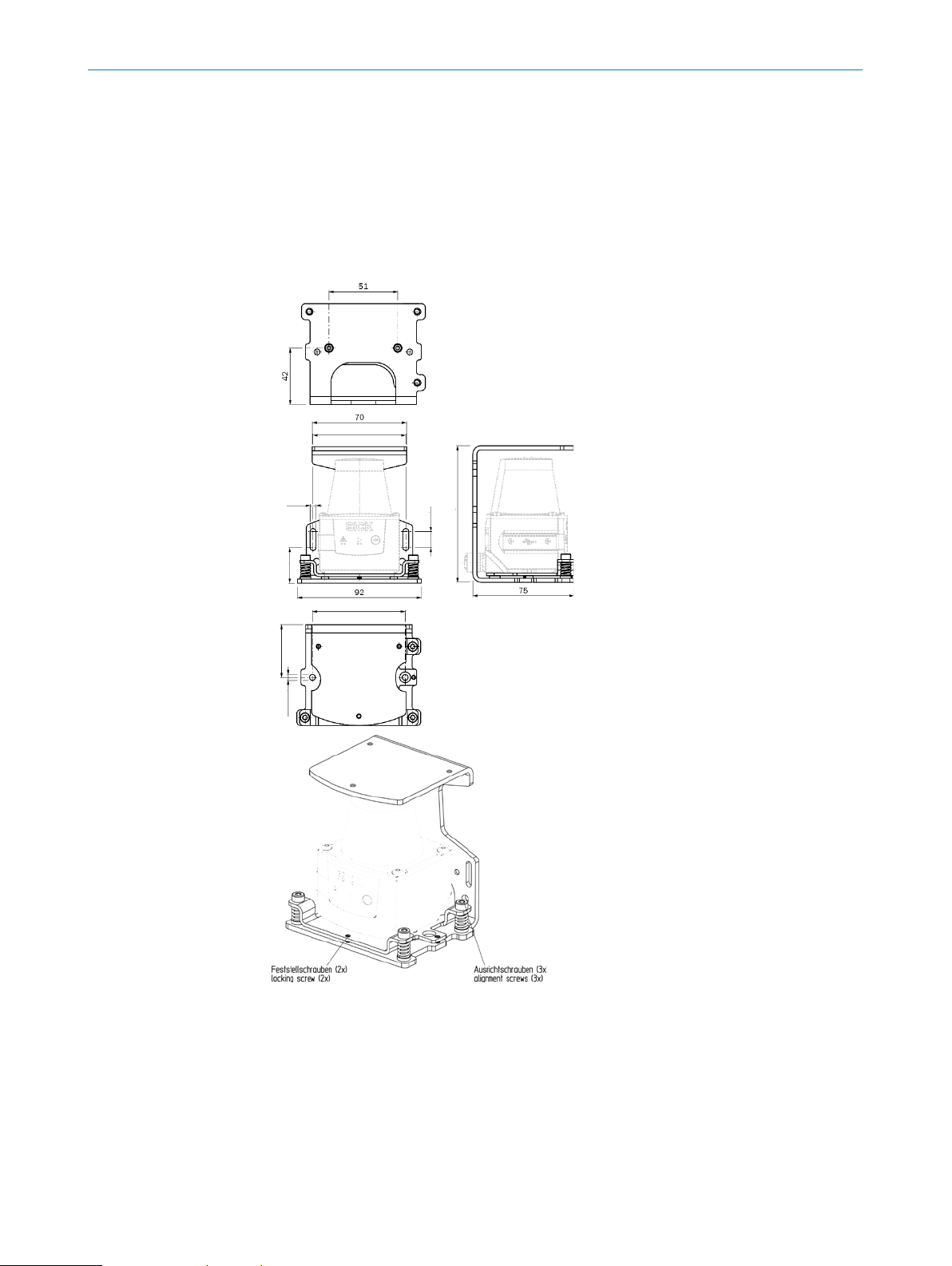

3.4 Accessories

The following accessories are permissible for safety-related use in connection with the

TiM361S.

Mounting kit with fine adjustment (2086761)

The mounting kit acts as a bracket, incl. the option of performing fine adjustment of the

scan level, and provides impact protection. The sensor can also be mounted directly on

the bracket without the adapter plate (mechanical collision protection only).

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

13

Page 14

3 PRODUCT DESCRIPTION

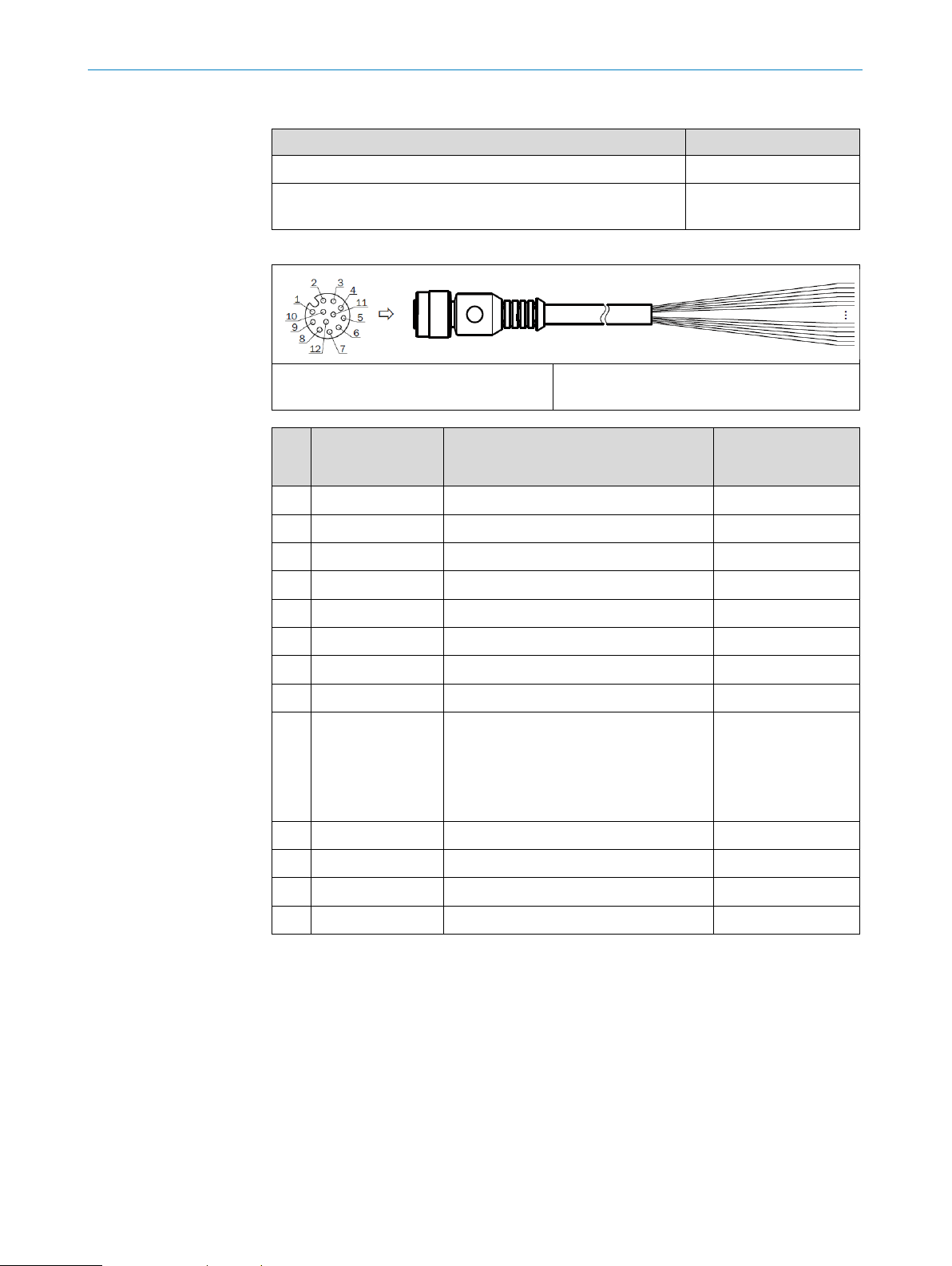

Cables

Designation Part number

USB – Guide for configuring the sensor 6036106

M12 female connector – open, 5 m, 12-wire, shielded,

6054974

PUR, halogen-free

Wire assignment, part number 6054974

M12 female connector, 12-pin,

A-coded (frontal view)

PIN Signal Function Wire color,

1 GND Ground Blue

2 DC 9 V … 28 V Supply voltage Brown

3 IN 1 Switching input 1 (field set selection) Red

4 IN 2 Switching input 2 (field set selection) Green

5 OUT 1 Switching output 1 (field breach) Pink

6 OUT 2 Switching output 2 (field breach) Yellow

Illustration may differ

connection

6054974 (5 m)

7 OUT 3 Switching output 3 (field breach) Black

8 OUT 4 Switching output 2 (index/error) Gray

9 PNP:

INGND

NPN:

IN DC 9 V … 28 V

PNP:

Common ground for all inputs

NPN:

Common reference potential of all

White

inputs

10 IN 3 Switching input 3 (field set selection) Violet

11 IN 4 Switching input 4 (field set selection) Gray-pink

12 N. c. - Red-blue

- - Shield

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

14

Subject to change without notice

Page 15

3 PRODUCT DESCRIPTION

Measurement principle

The TiM361S is an opto-electronic 2D LiDAR sensor that uses laser beams to scan the

outline of its surroundings on a plane. The TiM361S measures its surroundings in twodimensional polar coordinates, relative to its measurement origin in the middle of the

optics cover. The arrow visible on the optics cover marks the 90° angle as the middle

of the scanning range. If a laser beam strikes an object, the position of that object is

determined in terms of length (distance) and direction (angle).

The sensor uses a rotating mirror to deflect the emitted laser beams, thereby scanning

its surroundings in a circular pattern across a 270° segment. The measurements are

triggered internally by an encoder in regular angle increments.

The TiM361S works with a scanning frequency of 15 Hz (15 measurements per

second).

Safety function

The sensor is intended for use in personal protective equipment for detecting safetyrelated objects in mobile and stationary applications in industrial environments.

It additionally has a safety function (also see chapter 5.5.1 Operating modes/Statuses)

In its normal functioning (monitoring mode) the safety function is to report the

presence or penetration of detected objects in its active protective fields.

The TiM361S meets the requirements of performance level b (PL b), Category B, per

EN ISO 13849 and can be used within its area of application for risk reduction

according to its features.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

15

Page 16

3.5 Safety characteristic values

The TiM361S safety-related laser scanner has the following safety characteristic values

per EN ISO 13849-1:2015:

Performance level (PL): b

Category (Cat.): B

3 PRODUCT DESCRIPTION

Mean Time To Dangerous Failure (MTTF

(at 25° ambient temperature)

Mission Time (MT) (period of use): 10 years

3.6 Safety-related detection capability

With the TiM361S safety-related laser scanner, with its emission wavelength, the

following objects can be reliably and safely detected up to a relative speed of 1.6 m/s

and at min. 5% remission:

Objects 50 mm in diameter and 400 mm in length (standing up) at a distance of

0.05 m up to max. 1.5 m with a horizontal protective field

Objects 70 mm in diameter and 400 mm in length (standing up) at a distance of

0.05 m up to max. 2 m with a horizontal protective field

Objects 200 mm in diameter and 600 mm in length in or penetrating a vertical

protective field and those lying on the ground with a horizontal protective field, at

a distance of 0.05 m up to max. 4 m

Restrictions

The safety-related detection capability (determined by the measurement procedure)

can be impaired for measurement of objects with edges and/or corners and/or those

moving too quickly. This can result in incorrect distance values, causing impairment,

reduction or complete loss of detection capability, and the device no longer being able

to perform its function.

Blind zone

): 100 years

D

No objects will be detected within a range of 0.05 m from the measurement origin,

across the entire scanning range of the TIM361S!

NOTE

Due to the necessary system reserve of the TiM361S, its detection range and/or

system range is greater than the assured distances for safety-related detection.

This system reserve must not be used for safety-related analysis!

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

16

Subject to change without notice

Page 17

4 MOUNTING

4 Mounting

4.1 Notes on mounting

Mount the TiM361S safety-related laser scanner using the optionally available

mounting accessories (see chapter 3.4 "Accessories").

Mount the TiM361S on a prepared bracket. The sensor should be mounted and

operated as free from shock and vibration as possible.

The TiM361S can be mounted in any position depending on the application

purpose.

Mount the TiM361S so that it is not exposed to direct sunlight (window, skylight)

or other sources of heat. This prevents the temperature inside the device from

increasing unacceptably as well as the reduction or loss of detection capability.

During mounting, make sure there is no reflective surface behind the internal

reference target (see chapter 3.3 "Device Structure").

In general, the mounting position of the sensor should be chosen such that in the

sensor’s rear range (behind the internal reference target, see chapter 3.3

Structure"), dazzle due to other light sources is excluded, in order to prevent

reduction or loss of detection capability.

"Device

4.2 Mutual interference

The TiM361S safety-related laser scanner has been designed to minimize the

probability of mutual interference with sensors of the same type as the TiM361S. To

rule out even the slightest effects on the measurement accuracy, the devices should be

arranged such the laser beams are not received by another device.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

17

Page 18

5 Commissioning and configuration

Electrical block diagram for commissioning:

TiM361S-2134101

5.1 Notes on the electrical installation

Requirements for the IP 65/IP 67 enclosure rating: the black rubber plate (USB

female connector) must be flush-mounted on the housing.

Protect the TiM361S against moisture and dust when the cover to the USB female

connector is open.

Electrical connections between the sensor and other devices may only be made or

separated in a voltage-free state. Otherwise, the devices may be damaged.

Wire cross-sections in the supply cable from the customer’s power system should

be chosen in accordance with the applicable standards.

All electrical circuits connected to the sensor must be configured as SELV or PELV

circuits (SELV = Safety Extra Low Voltage, PELV = Protective Extra Low Voltage).

The supply voltage of the TiM361S must be secured accordingly.

Only switch on the supply voltage to the sensor when the connection tasks have

been completed and the wiring has been thoroughly checked.

5 COMMISSIONING AND CONFIGURATION

5.2 Prerequisites for safe electrical operation

The sensor is designed and tested for electrical safety in accordance with

IEC 61010-1:2010-06.

It is connected to the peripheral devices (voltage supply, control, actuators) via

shielded cables. The cable shield – for the supply cable, for example – rests against

the metal housing of the TiM361S. The device can either be grounded through the

cable shield or through both fastening latches.

If the peripheral devices have metal housings and if the cable shields also lie on their

housings, it is assumed that all devices involved in the installation have the same

ground potential.

This is achieved by complying with the following conditions, among others:

Mounting the devices on conductive metal surfaces

Correct grounding of the devices/metal surfaces in the system

Low-impedance and current-carrying equipotential bonding between areas with

different ground potentials, if necessary.

If these conditions are not met, e.g., on devices in a widely distributed system over

several buildings, potential equalization currents may, due to different ground

potentials, flow along the cable shields between the devices and create hazards or

malfunctions.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

18

Subject to change without notice

Page 19

5 COMMISSIONING AND CONFIGURATION

Control for

TiM361S

Voltage

supply

Closed current loop with

equalizing currents via cable

shield.

Grounding point

Ground potential

Grounding point

= Metal housing

= Shielded electrical cable

switching inputs

Actuators for

switching outputs

Due to insufficient ground potential equalization, voltage differences arise between

grounding points 1 and 2. The current loop closes via the shielded cables and metal

housing.

DANGER

Risk of injury/risk of damage due to electrical current!

Potential equalization currents between the TiM361S and other grounded devices in

the system can have the following effects:

Dangerous voltages on the metal housing

Incorrect function or irreparable damage to the devices

Damage/irreparable damage of the cable shield due to heating and cable fires

Where local conditions are unfavorable and thus do not meet conditions for a safe

earthing method (same ground potential at all grounding points), take measures

in accordance with the following formats.

Remedial measures

The most common solution to prevent potential equalization currents on cable shields

is to ensure low-impedance and current carrying equipotential bonding. If this is not

possible, the following solution approaches serve as a suggestion.

Important! We expressly advise against opening up the cable shields. This would mean

that the EMC limit values can no longer be guaranteed.

Measures for widely distributed system installations

On widely distributed system installations with correspondingly large potential

differences, we recommend setting up local islands and connecting them using

commercially available electro-optical signal isolators. This measure achieves a high

degree of resistance to electromagnetic interference.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

19

Page 20

5 COMMISSIONING AND CONFIGURATION

Control for

Electro-

isolator

Electro-

TiM361S

Grounding point 1

Grounding point 2

= Metal housing

= Shielded electrical cable

= Optical fiber

Control for

TiM361S

Voltage

Grounding point 1

Grounding point 2

Grounding point 3

= Metal housing

= Shielded electrical

Insulated mounting

Ground potential differential

switching inputs

Actuators for

switching outputs

optical

Ground potential differential

optical

isolator

The ground loop is isolated by using the electro-optical signal isolator between the

islands. Within the islands, stable equipotential bonding prevents equalizing currents

on the cable shields.

Measures for small system installations

For smaller installations with only slight potential differences, insulated mounting of the

sensor and of peripheral devices may be a sufficient solution.

switching inputs

Actuators for

switching outputs

supply

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

20

Subject to change without notice

cable

Even in the event of large differences in the ground potential, ground loops are

effectively prevented. As a result, equalizing currents can no longer flow via the cable

shields and metal housing.

Important! The voltage supply of the TiM361S safety-related laser scanner and of the

connected peripheral devices must also guarantee the required insulation level. Under

certain circumstances, a tangible potential can develop between the insulated metal

housings and the local ground potential.

Page 21

5 COMMISSIONING AND CONFIGURATION

5.3 Installation of SOPAS Engineering Tool

System requirements for SOPAS ET, version 3.3.3

System Minimum requirement

Processor Standard Intel Pentium PC or compatible, at minimum

Pentium III 500 MHz

Frequency and working

memory

Interface USB 2.0 or compatible

Operating system Windows XP, Vista, Windows 7 or Windows 8 (32/64 bit)

Minimum resolution 1024 x 768 px

Memory At least 450 MB

5.3.1 Installation process

When selecting between "installation" and "portable version," always choose the

"installation" version. This ensures that all SOPAS ET functions and drivers are

available. For installation, it may also be necessary to have administrator

authorizations.

1. Select the installation language.

This selection only determines the language of the installation wizard. Regardless

of the selected installation language, all SOPAS ET languages can be selected

subsequently.

2. Chose whether you want to have an icon on the desktop or on the Start Menu bar,

and click Next >.

3. Select the installation location for SOPAS ET.

It is recommended not to change the suggested location.

Min. 1 GHz / 1 GB RAM

4. Click Next>.

The installation process starts. Please wait until it is fully complete and the next page

appears. The checkbox Run SOPAS Engineering Tool is preselected.

5. Use the Close button to complete the installation and launch SOPAS ET.

5.3.2 Installing the device driver

Installing the device driver for the TiM36S device occurs automatically the first time a

connection is established between SOPAS ET and the device.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

21

Page 22

5.4 Configuration of the sensor

Configuration of the sensor is done with SOPAS ET PC software.

DANGER

Risk of ineffectiveness of the protective device

Before establishing a connection between SOPAS ET and the TiM361S safety-

related laser scanner and before beginning configuration, ensure that the

machine, plant or application in which the TiM361S is involved as part of a safety

function is in a safe state.

5.4.1 Establishing the connection

Before launching SOPAS ET, a suitable cable (see chapter 3.4 "Accessories") must be

used to establish a USB connection between the configuration interface of the

TiM361S and the PC.

Double-click the program icon to start SOPAS ET – a new project is opened.

A quick search for connected devices is performed.

5 COMMISSIONING AND CONFIGURATION

The progress bar shows how far the process has progressed. The x symbol to the

right of the progress bar enables you to end the search process prematurely.

Found devices are listed in the search results window. If the TiM361S was

previously connected to the PC via USB, it will appear in the search results.

Found devices can be inserted into the project from the search results area via drag &

drop, double-click, the Enter key, or the Add icon. They will remain in the search results

but are displayed in gray.

Devices can only be configured and observed if they are inserted into the project.

No actions can be performed on the device in the search results window.

A device driver must be installed before establishing a connection with the TiM361S for

the first time. Follow the instructions provided by SOPAS ET. When selecting the source

for the driver installation, choose the option "Upload from device."

5.4.2 Configure the device

To configure a device, double-click on the desired device.

This opens the device window which displays all the device parameters. You can

configure the device, download parameters to and from the device, or observe

parameter values in this window.

The parameter values then also remain in the project after you close the device

window.

Only when the main window is closed will you be informed that parameters must be

permanently saved in the device and parameter values will be lost if the project has not

been saved.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

22

Subject to change without notice

Page 23

5 COMMISSIONING AND CONFIGURATION

5.4.3 Display of the current operational status

The "Monitor field analysis" page (in the navigation area of the device window, below

the "monitor" node) displays the current operational status consisting of measurement

data, status of the individual fields as well as status of the switching inputs and

outputs.

The field monitor, which is placed in the middle of the page, displays measurement

data as blue points and/or a blue line. Penetrated fields are shown in yellow; free fields

appear in green.

5.4.4 Changing parameters

DANGER

Risk of injury/risk of damage due to incorrect parameters!

Parameter changes are transferred to the device and take effect immediately

after being edited. Permanent saving (in the non-volatile memory of the device)

does not occur, however, until the "Save permanently" button is clicked.

After parameter changes, the effectiveness of the protective device in the

application must be reviewed and documented.

Before beginning configuration ensure that the machine, plant or application in

which the TiM361S is involved as part of a safety function is in a safe state.

Please note:

The individual parameters of the device can be changed on the pages below the

"Parameters" node in the navigation area.

The TiM361S must be configured using the SOPAS configuration software.

5.4.5 Default configuration

The product is delivered with the following default configuration, which prevents

unintentional or unaware sensor activation.

DANGER

Risk of ineffectiveness of the protective device

After configuring the product or after making parameter changes, the

effectiveness of the protective device in the application must be reviewed and

documented.

For a safety-related use of the TiM361S, the configuration and commissioning must

only be performed by appropriately qualified personnel (see also Qualification).

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

23

Page 24

5 COMMISSIONING AND CONFIGURATION

Particle filter

Default: Particle filter is "deactivated"

The particle filter should be deactivated, since otherwise objects that appear

sporadically and for a short time will not be detected and/or filtered out. Similarly, the

particle filter also delays the functioning of the switching outputs.

Teach button

Default: TeachIn (SOPAS) is deactivated ("TeachIn disabled")

The TeachIn function (including via switching input) is deactivated in order to prevent

unintentional configuration.

Duration time for the outputs

Default: Maximum (Duration Time) on the outputs

The sensor automatically releases its protective field outputs when no more objects are

detected. The maximum output delay (duration time) therefore prevents immediate

restart.

Important! Continuous restart interlock with reset function must be implemented by

the user in the application.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

24

Subject to change without notice

Page 25

5 COMMISSIONING AND CONFIGURATION

Response time for object detection

Default: Minimum Response Time for object detection

The shortest configurable response time is preset to 67 ms and represents the most

rapid object detection.

Object sensitivity

Default: Maximum "sensitivity" (Blanking Size) for object detection

The smallest configurable blanking size of 10 mm represents the greatest degree of

object detection (i.e., the smallest detectable object).

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

25

Page 26

5 COMMISSIONING AND CONFIGURATION

Switching outputs/Index signal

Default: Set all outputs to "active low" in PNP version

With its PNP switching outputs, the TiM361S safety-related laser scanner applies the

principle of energy release as an active status by using the "active low" logic.

Index Signal

Default: Index Signal is "active"

The index signal can be used as a "live signal" for the TiM361S safety-related laser

scanner by a downstream controller.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

26

Subject to change without notice

Page 27

5 COMMISSIONING AND CONFIGURATION

Protective fields

Default: No protective fields are configured, i.e., all field points, segments of a

protective field are deleted (no entries).

For all fields in all field sets, the reference contour (Contour as Reference) is

"deactivated".

Deleting the field points means that the corresponding outputs for signaling protective

field infringements are active (active low) until they are actively changed.

When the field points are deleted, the field editor will not display any protective fields!

5.4.6 Passwords

Software access to the TiM361S is protected by various passwords. After configuring

the device successfully, the respective password must be changed so that it can fulfill

its protective function.

The "Maintenance" user level enables parameter changes to be saved, among other

things.

The "Authorized client" user level allows for general sensor configuration.

5.5 Editing fields

Fields can be created and edited on the "Analysis fields" page (below the "Parameters"

node).

User level Password factory settings

Maintenance sicksafe98

Authorized client sicksafe99

Before editing a field, first select the desired field set itself and the desired field within

the field set.

Field set no. 1 and Field no. 1 are preset.

Different from all other parameters, changes to fields (adding, moving or removing

individual field points or entire fields) are not transferred to the device until the

"Download all fields to device" button is clicked.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

27

Page 28

5.5.1 Operating modes/operational statuses

The TiM361S safety-related laser scanner has the following operating modes and

operational statuses:

Power On and boot phase

Begins after connecting and/or interruption of the supply voltage, and ends with

operational readiness or fault/error

Operational readiness

Begins after Power On and boot phase, and ends 1 min or more after connection of the

supply voltage. Operational readiness is indicated optically by the "green" LED on the

device.

Operational status (monitoring mode)

(See also Normal functioning)

The TiM361S automatically enters this status after reaching operational readiness and

after the output "Device Ready" (OUT4) has changed to the "high" status. To do so, the

TiM361S must not be in configuration mode. (See Configuration mode)

Configuration mode

5 COMMISSIONING AND CONFIGURATION

Once the sensor is connected to the SOPAS configuration software via the USB

interface, the sensor can be configured.

The output "Device Ready" remains unchanged until write access to the device is

initiated by SOPAS (e.g., changing a parameter, downloading field data, or accessing

the "Save permanently" function), then the output "Device Ready" (OUT4) enters the

status "low" for a period of approx. 1 s.

Fault/error

The TiM361S automatically enters this status when it detects an internal error. If there

is an internal error, the output "Device Ready" (OUT4) is deactivated and enters the

"low" status. This status is shown optically on the device.

Safety function

The TiM361S safety-related laser scanner has a safety function.

The safety function is detecting the presence or penetration of an object in a defined

detection field (protective field).

When the safety function is requested, the Defined status is entered within max.

134 ms (max. 2 scans) and the safety-related output signals (OUT1-3) assigned

according to the detection field are switched off. (deactivated status)

Example:

When a mobile platform approaches a person, a protective field can trigger an optical

or acoustic signal. If the person does not respond and the mobile platform continues to

approach, the infringement of an additional protective field by the person can be used

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

28

Subject to change without notice

Page 29

5 COMMISSIONING AND CONFIGURATION

to stop the mobile platform via the associated safety outputs, before it reaches the

person.

Defined statuses

The TiM361S has three defined statuses.

When the safety function is requested, defined Status 1 is to switch off (deactivated

status) the safety-related output signal (OUT1, OUT2, OUT3) assigned according to the

detection field.

Defined Status 2 is the status in which one or more of the safety-related output signals

(OUT1, OUT2, OUT3) has entered the switched off (deactivated) status while the safety

function was not requested.

Defined Status 3 is the status in which the safety-related output signal "Device Ready"

(OUT4) has entered the switched off (deactivated) status for more than 67 ms.

Response times for defined statuses

Upon request of the safety function, the sensor enters defined status 1 with a

response time of 134 ms or less (max. 2 scans).

It enters defined status 2 with a response time of 3,000 ms or less (15 scans) and

defined status 3 with a response time of 3,000ms or less (15 scans).

Protective field analysis

In its normal functioning (monitoring mode), the TiM361S reports, with an angular

resolution of 0.33° in its detection field (detection range), the presence or penetration

of detected objects in its active protective fields.

Protective fields

The TiM361S can simultaneously analyze 3 independent protective fields (detection

fields). Each protective field is assigned to a digital output OUT1, OUT2, OUT3 which is

activated upon infringement of the protective field (active low). The 3 independent

protective fields are configured in a field set in the TiM361S and saved.

If a field set change occurs, the sensor activates analysis of the new protective fields

with a response time of 134 ms or less (max. 2 scans).

Field sets

The sensor has 16 independent field sets. Selection of the active field set, and

therefore also of the active protective fields, is performed via inputs IN1, IN2, IN3, IN4.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

29

Page 30

5.5.2 Digital inputs/outputs

The TiM361S has the following safety-related interfaces, the statuses of which only

become valid after operational readiness is reached (see also Operating

modes/operational statuses):

Digital inputs

The sensor has 4 digital PNP switching inputs (IN 1-4), which by means of selecting the

corresponding binary combination (see table, below), activate one of the 16 available

field data sets, and therefore the active protective fields.

5 COMMISSIONING AND CONFIGURATION

Field set factory settings – switching inputs:

Field set Switching inputs

IN 1 IN 2 IN 3 IN 4

1 0 0 0 0

2 1 0 0 0

3 0 1 0 0

4 1 1 0 0

5 0 0 1 0

6 1 0 1 0

7 0 1 1 0

8 1 1 1 0

9 0 0 0 1

10 1 0 0 1

11 0 1 0 1

12 1 1 0 1

13 0 0 1 1

14 1 0 1 1

15 0 1 1 1

16 1 1 1 1

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

30

Subject to change without notice

Page 31

5 COMMISSIONING AND CONFIGURATION

Input level:

PNP: Low (in resting position): ≤ 2 V, high (in working position): ≥ 8 V

Characteristic data of the switching inputs:

The characteristic data is identical for of all switching inputs.

Switching behavior Current to the input starts the assigned function in the

Properties Opto-decoupled

PNP electrical values Low: Ue ≤ 2 V, Ie ≤ 0.3 mA

device. Default: active high level, debounce 10 ms

Switchable with an electronic switch (PNP output) or

mechanical switch

High: 8 V ≤ U

≤ 32 V, 0.7 mA ≤ Ie ≤ 5 mA

e

Digital outputs

Infringement of the respective protective field is displayed in the active field data set by

means of 3 available digital PNP switching outputs (OUT1 … OUT3).

The factory setting for the digital outputs is the status "Field 1, 2, and 3 infringed."

Assignment of infringed fields – switching outputs:

Fields of a field set Switching outputs

OUT 1 OUT 2 OUT 3

Fields 1, 2, and 3

Active Active Active

infringed

Fields 2 and 3

Disabled Active Active

infringed

Field 3 infringed Disabled Disabled Active

All fields free Disabled Disabled Disabled

Field 1 inside, Field 2 middle, Field 3 outside

Active: in working position; deactivated: in resting position

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

31

Page 32

5 COMMISSIONING AND CONFIGURATION

Initial level:

The level of the PNP switching outputs OUT 1 … OUT 3 is active low (deactivated status,

resting position: high, in working position: low (field infringed)).

All fields of a field set are considered infringed upon switching on, booting, in the event

of an error and when the device is switched off.

PNP switching output 4 works with the following levels:

Function Level

Device ready High

Index signal (15 Hz),

Low peaks

corresponds to

measurement at 90°

Error Low

Characteristic data of the switching outputs:

PNP switching

behavior

Properties Short-circuit protected and temperature protected

PNP electrical

values

Important! Longer connecting cables at the switching outputs of the device should be

avoided due to the resulting fall in voltage. This is calculated as follows:

PNP switching to supply voltage Uv.

OUT1 … OUT3:

resting level: high (no field infringement),

working level: low (field infringement)

response time 134 ms … 30 s (configurable via SOPAS ET ),

Duration time: 0 ms … 10 s (configurable via SOPAS ET)

OUT4:

resting level: high (Device Ready),

working level: low (error), low-impulse (15 Hz, index,

corresponds to measurement at 90°)

Not electrically isolated from supply voltage U

v

0 V ≤ Ua ≤ UV

– 1,5 V) ≤ Ua ≤ UV where Ia ≤ 100 mA

(U

V

ΔU = 2 x length x current / conductance value x cross-section

2

Conductance value for copper 56 m/Ω mm

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

32

Subject to change without notice

Page 33

5 COMMISSIONING AND CONFIGURATION

5.5.3 Function and status displays

LED a (red) LED b (green)

Status

- Lights up Device ready/monitoring mode

Lights up Lights up Field infringement

Flashing - Error

- - Device without supply voltage

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

33

Page 34

6 Error behavior

6.1 General

A non-hazardous failure of the laser scanner occurs:

• When the laser scanner switches to defined status 2 and/or 3 without request of

the safety function.

• When the laser scanner switches to defined status 2 and/or 3 in the event of a

detected internal error.

A hazardous undetected failure occurs:

• When the laser scanner fails to switch to defined status 1, defined status 2 and/or

defined status 3 upon request of the safety function.

6.2 Detected errors

The TiM361S detects some internal errors merely to improve its availability and

support troubleshooting in the event of a fault.

The sensor has diagnostic coverage (DC) of zero in accordance with EN ISO 13849-1

PL b. The internal errors detected by the sensor cannot be used to increase the DCs

within the meaning of this standard! (See also Error codes of the 2D LiDAR sensor)

6 ERROR BEHAVIOR

6.3 Undetected errors and faults

The TiM361S will not detect the following errors and faults, among others:

• Digital inputs:

wire break, short-circuit, cross-circuit to the digital inputs for field set selection (IN1,

IN2, IN3, IN4), making it possible to select an incorrect field set.

• Digital outputs:

wire break, short-circuit, cross-circuit to the digital outputs for field set infringement

(OUT1, OUT2, OUT3) and Device Ready (OUT4), with the effect that the defined

statuses can no longer be detected by the downstream controller.

• Status indicators:

Failure of the status indicators for field set status, with the result that infringement

of the protective field is not correctly displayed optically on the device.

• Contamination:

Contamination of the optics and/or the front screen, causing impairment, reduction

or complete loss of detection capability, and the device no longer being able to

perform the safety function.

• Ambient light:

Malfunctions due to faults of other scanners and light sources within the level of the

scan field, causing impairment, reduction or complete loss of detection capability,

and the device no longer being able to perform its function.

• Incorrect measurements:

Measurement of objects with edges and/or corners and/or which are moving too

quickly (determined by the measurement procedure) can result in incorrect distance

values, causing impairment, reduction or complete loss of detection capability, and

the device no longer being able to perform the safety function.

• Blind zone:

Objects, especially covering objects, located within the blind zone extending f

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

34

Subject to change without notice

Page 35

6 ERROR BEHAVIOR

0.05 m from the measurement origin of the TIM361S, causing impairment,

reduction or complete loss of detection capability, and the device no longer being

able to perform the safety function.

Undetected errors and faults of the TiM361S can cause impairment, reduction or

complete loss of detection capability, such that the device is no longer able to perform

the safety function.

NOTE

As per EN ISO 13849-1 PL b, the sensor has diagnostic coverage (DC) of zero, i.e., it

must not detect errors and if they occur, can result in loss of the safety functions.

Testing and diagnostic measures can identify errors, such as those of the downstream

controller.

6.4 Fault exclusions

DANGER

Risk of ineffectiveness of the protective device

No fault exclusions have been specified for the sensor. The occurrence of faults can

result in the loss of the safety function.

6.5 Manipulation

The device does not have any protective measures against manipulation, especially

none that relate to the optical system. Objects, especially covering objects on the optics

cover and/or in the blind zone, are not detected by the TiM361S, causing impairment,

reduction or complete loss of detection capability, and the device no longer being able

to perform the safety function.

Manipulations with effects similar to undetected faults (see chapter 6.3 "Undetected

errors and faults") are also not detected.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

35

Page 36

7 Project planning

7.1 Manufacturer of the machine

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected may not recognized in case of nonobservance.

Use of the sensor requires a risk assessment. Check whether additional protective

measures are required.

Comply with the applicable national regulations derived from the application (e.g.,

work safety regulations, safety rules, or other relevant safety guidelines).

Apart from the procedures described in this document, the components of the

device must not be opened.

The TiM361S must not be tampered with or changed.

Improper repair of the device can lead to loss of the safety function. The protective

device must only be repaired by the manufacturer or by someone authorized by

the manufacturer.

7 PROJECT PLANNING

7.2 Operating entity of the machine

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected may not recognized in case of nonobservance.

Changes to the electrical integration of the sensor in the control of a machine and

changes to the mechanical mounting of the TiM361S safety-related laser scanner

necessitate a new risk assessment. The results of this risk assessment may

require the entity operating the machine to meet the obligations of a

manufacturer.

Changes to the device’s configuration may impair the safety function of the

TiM361S safety-related laser scanner. Therefore the device’s safety function and

the effectiveness of the protective device must be checked after any change in

configuration. The person carrying out the change is responsible for maintaining

the safety function of the device and the protective device.

The TiM361S must not be tampered with or changed.

Improper repair of the device can lead to loss of the safety function. The protective

device must only be repaired by the manufacturer or by someone authorized by

the manufacturer.

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

36

Subject to change without notice

Page 37

7 PROJECT PLANNING

DANGER

Danger due to optical and electromagnetic ambient conditions

Optical and electromagnetic ambient conditions can impair the functioning of the

TiM361S.

This can result in loss of the safety function. Please note the following:

Avoid having strong electric fields in the vicinity of the laser scanner. These may

be caused by nearby welding or induction cables, for example.

Prevent condensation on and/or contamination of the optics cover. To ensure the

continuing, reliable safety function of the device, the optics cover must be cleaned

regularly.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

37

Page 38

8 Regular thorough checks

At regular intervals the user must demonstrate that the measures taken still fulfill the

protective purpose, and that the protective device still functions correctly in the

application during the service life.

Thorough checks and tests are required in this regard:

• Upon commissioning (e.g., initial commissioning, recommissioning)

• After changes and extraordinary events (e.g., conversion, change of parameters,

modification, retrofitting and equipment, damage, repair, ...)

• And at regular intervals (e.g., recurring thorough checks intended to ensure that a

safety function and/or safety function still functions correctly in the application)

These thorough checks must be documented clearly and comprehensibly.

Determination of the time intervals for thorough checks at regular intervals must be

decided and established by the manufacturer of the machine and/or by the operating

entity depending on the specific application, place of application and influencing

factors prevailing there. (e.g., dirt, demand rate, EMC, …).

Example: thorough check of the effectiveness of protective fields

The effectiveness of protective fields can be demonstrated, for example, by positioning

a suitable test object with the diameter and remission of the desired detection

capability at multiple points along the effective protective range, and having the sensor

detect them.

8 REGULAR THOROUGH CHECKS

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

38

Subject to change without notice

Page 39

9 WORKING WITH THE PRODUCT

9 Working with the product

9.1 Maintenance and care

The TiM361S safety-related laser scanner does not contain any components that

require maintenance. The device must not be opened. Maintenance is not necessary to

ensure compliance with laser class 1, either.

The black, infrared-transparent optics cover should be cleaned, at regular

intervals and in the event of contamination, with a lint-free lens cloth

(part no. 4003353) and plastic cleaning agent (part no. 5600006). In this regard,

the cleaning interval essentially depends on the ambient conditions.

9.2 Transport and storage

The TiM361S safety-related laser scanner must be transported and stored in its

original packaging with the USB protective cap plugged in. Do not store outdoors. To

ensure that any residual moisture present can escape, do not store the device in

airtight containers. Do not expose to aggressive media (e.g. solvents).

Storage conditions: Dry, dust-free, no direct sunlight, as little vibration as possible,

storage temperature –40 to +75 °C, relative humidity max. 90% (non-condensing).

9.3 Repairs

Repair work on the TiM361S safety-related laser scanner may only be performed by

qualified and authorized service personnel from SICK AG.

9.4 Disassembly and disposal

Any TiM361S safety-related laser scanner which can no longer be used at the end of

the product life cycle must be disposed of in an environmentally-friendly manner in

accordance with the country-specific waste disposal regulations that are applicable at

the time.

The TiM361S safety-related laser scanner is electronic waste and must under no

circumstances be disposed of with general waste.

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

39

Page 40

10 Technical data

10.1 General technical data

Characteristic Values

Field of view Radial, aperture angle 270°

Angular resolution 0.33°

Scanning frequency 15 Hz (15 scans/s)

10 TECHNICAL DATA

Detection range/system

distances

0.05 m … 4 m; at 5% remission

0.05 m … 8 m; at 10% remission

0.05 … 10 m, at > 50% remission

Minimum physical object

sizes

(cross-section)

121 mm at a distance of 8 m,

66 mm at a distance of 4 m,

38 mm at a distance of 2 m,

at respective remission

Light source Laser diode, infrared (λ = 850 nm +/- 10 nm)

Laser class Laser class 1 according to EN 60825-1 (eye-safe)

Max. radiated power 1.5 W

Max. pulse duration 5 ns

Configuration interface USB 2.0 for configuration, connecting cable max. 3 m

Electrical connections 1 x 12-pin M12 power male connector

1 x micro USB female connector, type B (covered)

Optical indicators 2 x LED

Supply voltage DC 9 … 28 V, SELV and PELV

according to IEC 60364-4-41

Power consumption Typical power consumption of 4 W with unloaded

switching outputs

Max. power consumption 16 W with max. four loaded

switching outputs

Protection The supply voltage must be protected with a max.

0.8 A slow-blow fuse (take into account the cable

cross-section of the wiring!)

Housing Lower part: aluminum die cast

Optics cover: polycarbonate with scratch-resistant

coating

Weight Approx. 250 g without cables

Electrical safety According to IEC 61010-1 (ed.3)

Protection class III, acc. to EN 61140: IEC 60010-1 (ed. 3)

Ambient light immunity 60,000 lx (indirect)

Ambient Temperature –10°…50 °C

Temperature change Thorough check N according to EN 60068-2-14

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

40

Subject to change without notice

Page 41

10 TECHNICAL DATA

Characteristic Values

Damp heat According to EN 60068-2-30

Air humidity < 80% (non-condensing)

Enclosure rating IP67

Altitude max. 2,900 m ASL

EMC Residential area according to EN 61000-6-3

Industrial area according to EN 61000-6-2

Vibration resistance (according to EN 60068-2-6)

Shock resistance (in accordance with EN 60068-2-27)

Contamination Contamination level 1, EN 61010-1 outside housing

Contamination level 3, EN 61010-1 outside housing,

with sealed USB connection

(All specifications regarding contamination do not

apply to the optics)

For further technical specifications, see the Online data sheet on the product page on

the web (www.sick.com/tim3xx).

10.2 Safety-related technical data

Characteristic Values

Performance level (PL) PL b according to EN ISO 13849-1:2015

Category (Cat.) Cat. B according to EN ISO 13849-1:2015

Mean Time To Dangerous

Failure (MTTF

Mission Time (service life) 10 years

Safety-related detection

range

Safety-related detection

capability

Blind zone No objects are detected across the entire radial visual

)

D

100 years according to EN ISO 13849-1:2015

(at 25° ambient temperature)

0.05 m … 4 m; at 5 % remission

Objects 50 mm in diameter at a distance of 0.05 m

up to max. 1.5 m or

objects 70 mm in diameter at a distance of 0.05 m

up to max. 2 m or

objects 200 mm in diameter at a distance of 0.05 m

up to max. 4 m,

up to a relative speed of 1.6 m/s and at min. 5%

remission.

range (scanning range of 270°) from the

measurement origin up to a distance of 0.05 m

Response time Response of the switching outputs upon detection of

an object

Max. 134 ms (2 scans); typically 67 ms (1 scan)

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

41

Page 42

10 TECHNICAL DATA

Characteristic Values

Protective field/Field

analysis

1 analysis case with 1 field set and up to

3 independent protective fields, signaling of field

infringements via a combination of 3 PNP switching

outputs (OUT1 … OUT3)

Protective field tolerance +100 mm; 0.66° acc. To DIN CLC/TS 62046:2009 at

5% remission

Temperature drift: 1.5 mm/Kelvin

Number of field sets 16 field sets with 3 independently configurable

protective fields each

Switching inputs PNP inputs: 4 x IN, IN1 … IN4,

= max. 28 V, Ie = max. 5 mA), opto-decoupled,

(U

e

debounce approx. 10 ms

Switching outputs PNP outputs: 4 x OUT, OUT1 … OUT4, (each Ia max.

100 mA), not electrically isolated from supply voltage,

short-circuit protected/ temperature protected

Configurable for OUT 1 … OUT 3:

Response time (67 ms … 30 s)

2

Duration time (0 ms … 10 s)

For further technical specifications, see the online data sheet on the product page on

the web (www.sick.com/tim3xx).

NOTE

The product is intended for use in industrial environments, under indoor conditions. It

is not suitable for use in special surroundings (e.g., radiation and sparks from welding

systems, strong sources of infrared, thermal convection, fluorescent and stroboscopic

light sources, snow, rain, contamination) or must yet be made suitable, if applicable.

2

The TiM has an internal, system-related time delay of 67 ms

SAFETY-RELATED 2D LIDAR SENSOR | TIM361S 8022483/108R/2018-07-09 | SICK

42

Subject to change without notice

Page 43

11 DECLARATION OF CONFORMITY

11 Declaration of conformity

EU declaration of conformity

The undersigned, who represents the manufacturer below, hereby declares that the

product complies with the regulations of the EU directive(s) below (including all relevant

changes), and that it is based on the relevant standards and/or technical

specifications.

Complete EU declaration of conformity for download

You can call up the EU declaration of conformity and the current operating instructions

for the product by entering the part number in the search field at www.sick.com.

(Part number: see the type label entry in the "P/N" field).

8022483/108R/2018-07-09 | SICK SAFETY-RELATED 2D LIDAR SENSOR | TIM361S

Subject to change without notice

43

Page 44

8022483

Australia

Phone +61 (0)3 9457 0600

1800 334 802 – toll free E-Mail

sales@sick.com.au

Austria

Phone +43 22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 2 466 55 66

/108R/en/2018-07-09

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 1444

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 (0)45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 (0)1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 211 5301-301

E-Mail info@sick.de

Hong Kong

Phone +852 (0)2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 (0)1 371 2680

E-Mail office@sick.hu

India

Phone +91 (0)22 6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 4 6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 (0)2 27 43 41

E-Mail info@sick.it

Japan

Phone +81 (0)3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +6 03 8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 (0)30 2044 000

E-Mail info@sick.nl

New Zealand

Phone +64 (0)9 415 0459

0800 222 278 – tollfree E-Mail sales@sick.co.nz

Norway

Phone +47 (0)67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 (0)22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 (0)356 171 120

E-Mail office@sick.ro

Russia

Phone +7 495 775 05 30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 788 49

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 (0)2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 (0)93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 (0)10,110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 (0)2645 0009

E-Mail Ronnie.Lim@sick.com

Turkey

Phone +90 (0)216 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 8865 878

E-Mail info@sick.ae

United Kingdom

Phone +44 (0)1727 831121

E-Mail info@sick.co.uk

USA

Phone +1 800 325 7425

E-Mail info@sick.com

Vietnam

Phone +84 945452999

E-Mail

Ngo.Duy.Linh@sick.com

Further locations at www.sick.com

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...