Page 1

TIM310-1030000S01

RANGING AND DETECTING LASER SCANNER

Mounting, electrical installation and license texts

TECHNICAL INFORMATION

Page 2

Technical Information

TiM310-1030000S01 ranging and detecting laser scanner

Described product

TiM3xx

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch,

Germany

Copyright

This work is protected by copyright. Any rights derived from the copyright shall be reserved

for SICK AG. Reproduction of this document or parts of this document is only permissible

within the limits of the legal determination of Copyright Law. Any modification, expurgation

or translation of this document is prohibited without the express written permission of SICK

AG.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

The TiM is certified to IEC/EN/UL/CSA 61010-1:2007. These operating instructions may

contain passages of text in a foreign language.

2 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 3

Technical Information Chapter 1

NOTICE

WARNING

TiM310-1030000S01

About this document

1 About this document

This document summarizes supplementary information on mounting and electrical instal-

lation, measured value output fomat of the TiM310-1030000S01 as well as license texts.

It is aimed at sufficiently qualified personnel for the purposes of installation, commissioning

and further data processing.

Notes on commissioning, configuration and maintenance can be found in the TiM3101030000S01 operating instructions.

Information on the TiM310-1030000S01 can be found on the Internet on the TiM3xx product page at www.mysick.com/en/tim3xx:

Technical specifications in the online data sheet (PDF)

Dimensional drawing and 3D CAD dimension models in various electronic formats

Range diagram (PDF)

EC Declaration of Conformity (PDF)

Configuration software SOPAS ET

Product information with overview of available accessories (PDF)

TiM3xx operation instructions (PDF) in additional languages where applicable

This technical information (PDF)

Support is also available from your sales partner, see www.sick.com/worldwide.

Important The TiM310-1030000S01 is simply referred as TiM3xx in this technical information.

Symbols used

Certain information in this documentation is emphasized as follows to enable faster access

to the information:

Notice!

A notice indicates potentially damaging hazards or functional impairments to the TiM3xx or

its connected devices.

Warning!

A warning indicates specific or potential dangers to the user's physical integrity. It is intended to protect the user against accidents.

The safety symbol to the left of the warning indicates the type of accident hazard e.g. due

to electricity. Increasing warning levels (CAUTION, WARNING, DANGER) indicate the severity

of the possible hazard.

Always reading warnings carefully and obey them meticulously.

Important This important notice informs you about special aspects.

This symbol refers to supplementary technical documentation.

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 3

Page 4

Chapter 1 Technical Information

About this document

TiM310-1030000S01 ranging and detecting laser scanner

Safety information

Read the notes on mounting and electrical installation before carrying out these tasks.

Read additionally the TiM310-1030000S01 operating instructions to familiarize your-

self with the device and its functions.

The TiM310-1030000S01 complies with laser class 1, for laser warnings see the oper-

ating instructions.

Only use the device in permissible ambient conditions (e.g. temperature, ground poten-

tial). Any applicable legal regulations or regulations of other authorities will have to be

observed during operation.

Opening the screws of the TiM3xx housing will invalidate any warranty claims against

SICK AG.

Repairs may only be performed on the TiM3xx by trained and authorized SICK AG ser-

vice personnel.

The TiM3xx does not constitute personal protection equipment in sense of the respec-

tive applicable safety standards for machines.

4 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 5

Technical Information

TiM310-1030000S01

Contents

Table of contents

1 About this document..................................................................................................... 3

2 Operating principle of the TiM3xx ............................................................................... 6

2.1 Distance measurement ............................................................................................6

2.2 Direction measurement ............................................................................................6

3 Mounting......................................................................................................................... 8

3.1 Notes on mounting .................................................................................................... 8

3.2 Optional accessories ...............................................................................................10

4 Electrical installation .................................................................................................. 12

4.1 Overview of all interfaces .......................................................................................12

4.2 Pin and wire color assignments .............................................................................13

4.3 Notes on electrical installation ...............................................................................15

4.4 Prerequisites for safe operation of the TiM3xx in a system .................................15

4.5 Installation steps .....................................................................................................19

5 Measured value output...............................................................................................21

5.1 Telegrams ................................................................................................................21

5.2 Request measured values ......................................................................................22

5.3 Measured value output fomat ................................................................................24

6 License texts ................................................................................................................30

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 5

Page 6

Chapter 2 Technical Information

Operating principle of the TiM3xx

TiM310-1030000S01 ranging and detecting laser scanner

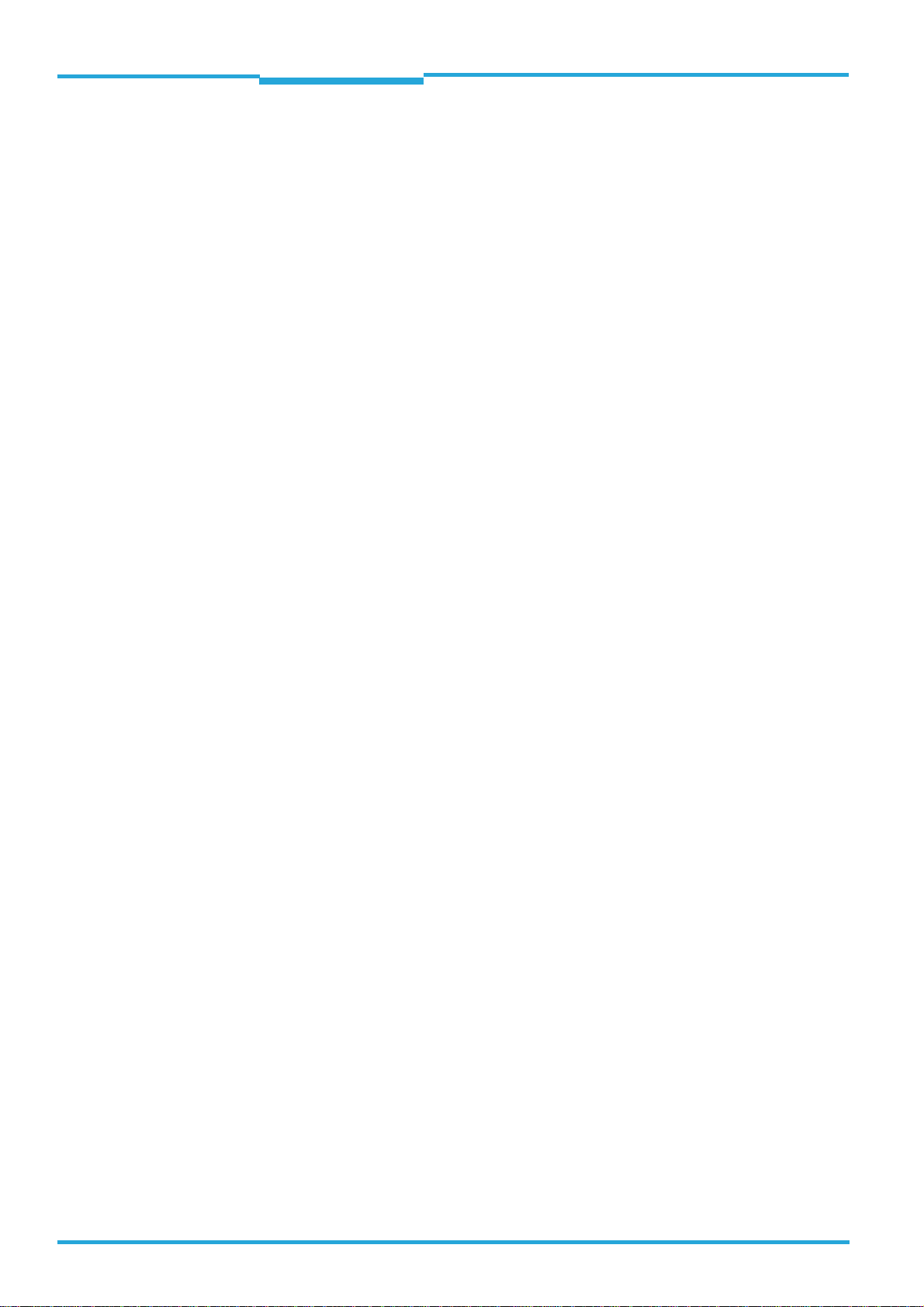

2 Operating principle of the TiM3xx

The TiM3xx is an opto-electronic laser scanner that electro-sensitively scans the perimeter

of its surroundings at a single plane with the aid of laser beams. The TiM3xx measures its

surroundings using two-dimensional polar coordinates based on its measurement origin.

This is marked on the hood in the centre using a circular indentation. If a laser beam hits

an object, its position in terms of distance and direction is determined.

Scanning is performed across a 270° sector. The maximum range of the TiM3xx is 4 m

(13.12 ft) on light, natural surfaces with an object reflectivity > 50 % (e. g. a white house

wall).

2.1 Distance measurement

The TiM3xx emits pulsed laser beams using a laser diode. If one of these laser pulses hits

an object or a person, this is reflected at its surface. The reflection is detected in the

TiM3xx's receiver by a photodiode. The TiM3xx uses HDDM technology (High Definition

Distance Measurement), a SICK own-development. Using this measurement method, a

measured value is formed by the average value for several individual pulses. The TiM3xx

calculates the distance to the object from the transit time required by the light from emission of the beam to receipt of the reflection. This principle of "time-of-flight measurement"

is used by radar systems in a similar manner.

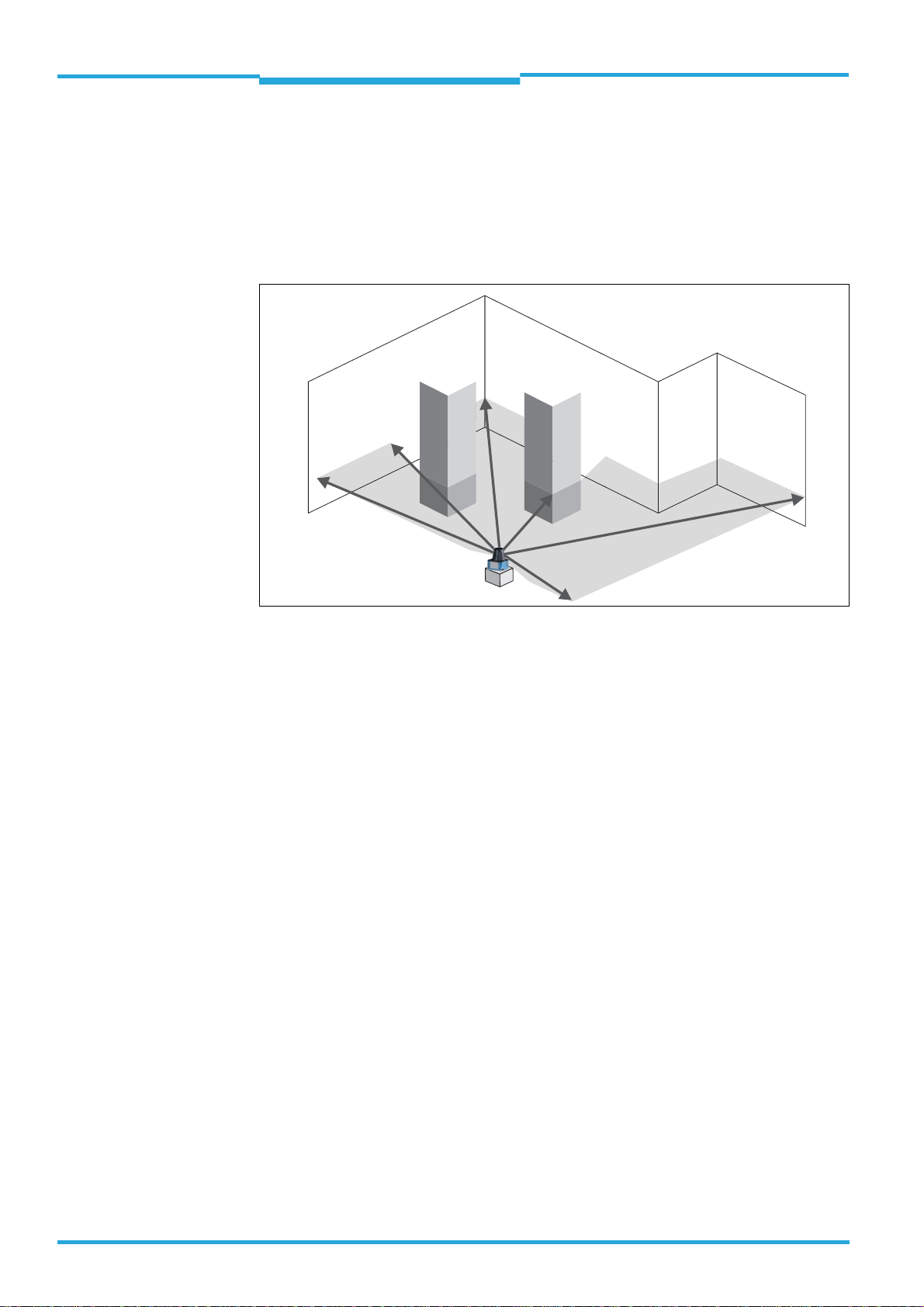

2.2 Direction measurement

The emitted laser beams are deflected by the TiM3xx using a rotating mirror and its surroundings scanned in a circular form. The measurements are triggered internally at regular

angle increments using an angular encoder. One complete rotation represents one measuring process (scan).

The TiM3xx works at a scanning frequency of 15 Hz, i.e. it performs 15 measuring processes

per second and makes the measurement results continuously available in real time via the

USB interface.

The measurement method forms an average value from several pulses to determine individual measured values. At an angle resolution of 1°, a measuring point is formed from the

average of 84 measurements. The spot geometry of the submeasuring points is virtually circular whereas a measuring point has the form of a narrow rectangle due to overlapping.

6 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 7

Technical Information Chapter 2

Operating principle of the TiM3xx

TiM310-1030000S01

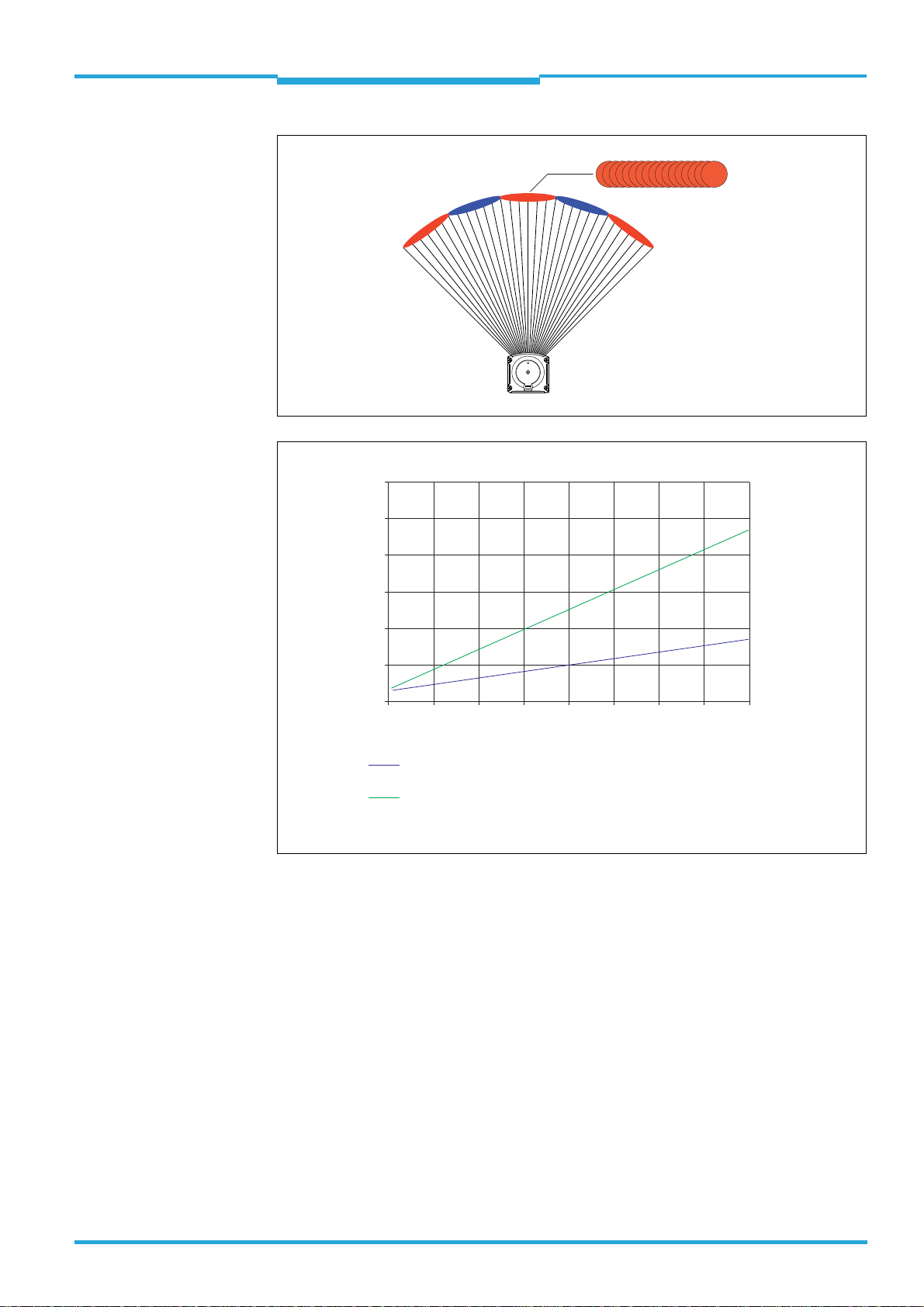

84 submeasuring points

TiM3xx

Spot diameter (mm/in)

120

4.73

100

3.94

80

3.15

60

2.36

40

1.58

20

0.79

0

0 0.5 1 1.5 2.5 3.5234

1.64 3.28 4.92 8.20 11.486.56 9.84 13.12

Range (m/ft)

Spot diameter of a submeasuring point.

Divergence 7 mrad, spot diameter on the front screen 6 mm (0.24 in)

Elongation of the 84 overlayed submeasuring points in direction

of deflection at angle step 1°.

Divergence 22 mrad, spot diameter on the front screen 6.5 mm (0.26 in)

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 7

Page 8

Chapter 3 Technical Information

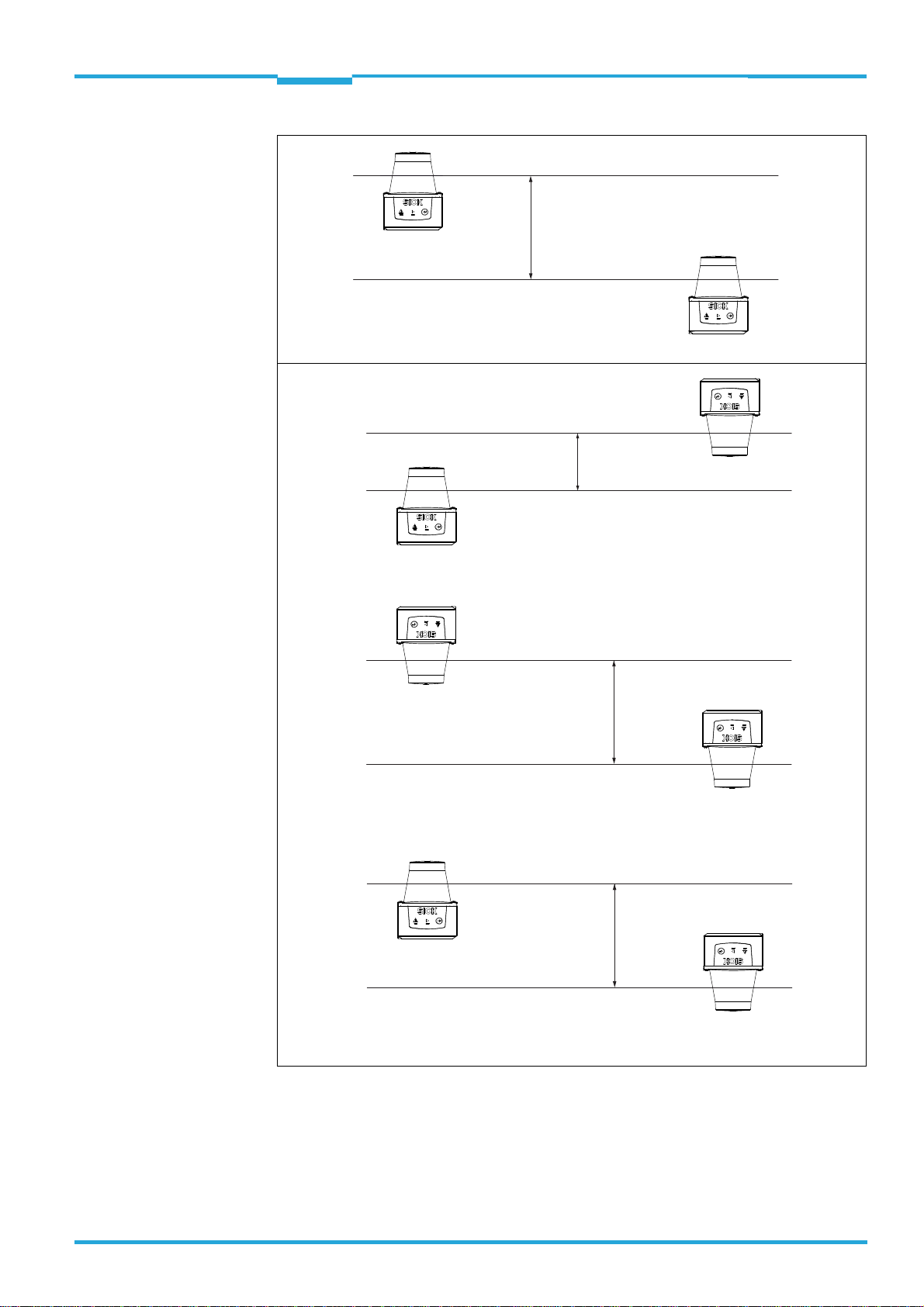

Crosswise placement of two TiM3xx

Placement of two TiM3xx opposed to each other

Mounting

TiM310-1030000S01 ranging and detecting laser scanner

3 Mounting

3.1 Notes on mounting

The TiM3xx can, depending on the application purpose, be mounted in any position.

Install the TiM3xx so it as unaffected by shocks and vibrations as possible.

Install the TiM3xx so it is not exposed to any direct sunlight (window, skylight) or any

other heat sources. This prevents impermissible temperature increases inside the

device.

During mounting, make sure there is no reflective surface behind the reference target

(see Figure ).

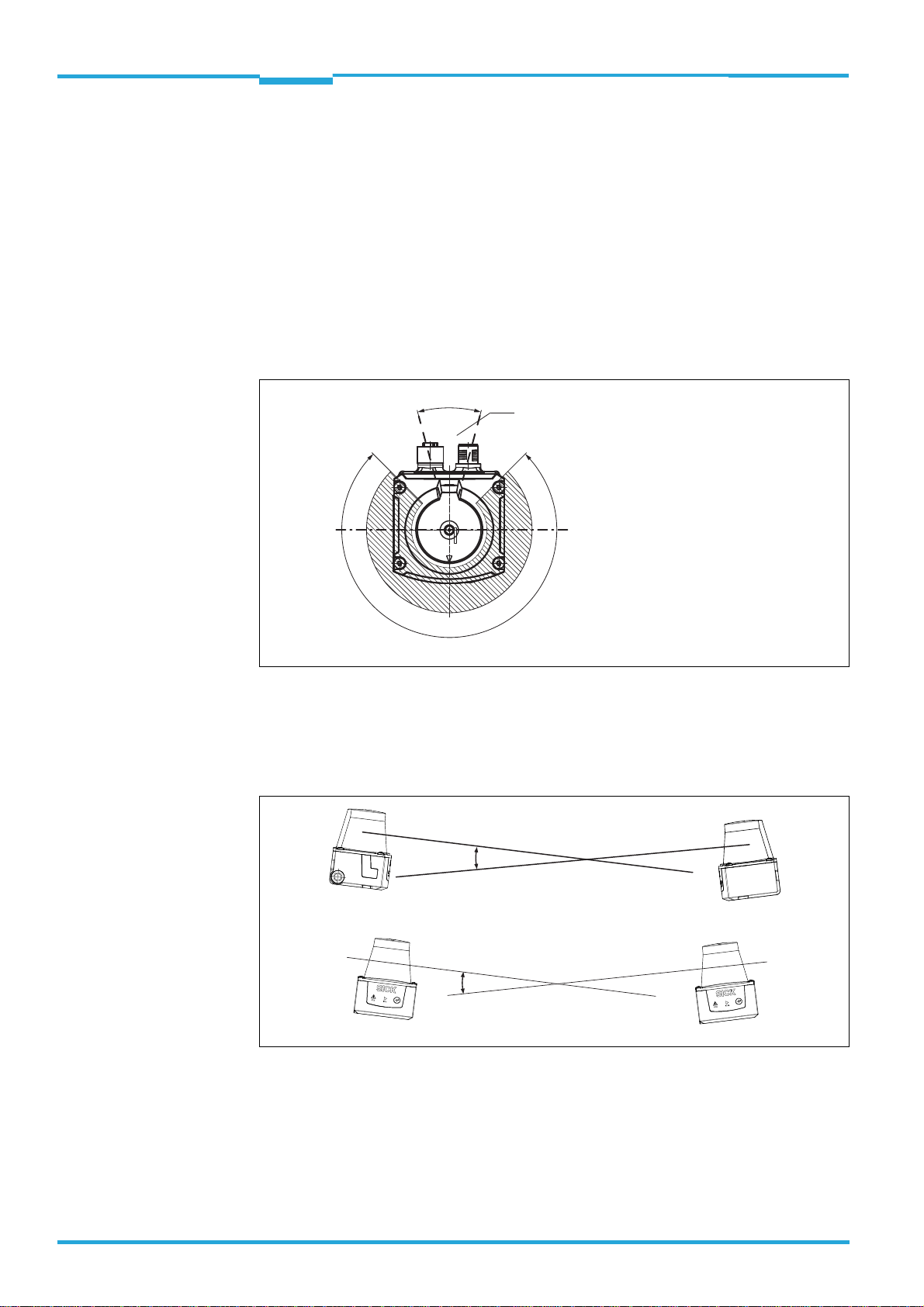

30°

‒45°

90°

1

225°

180°0°

Using several TiM3xx

The TiM3xx is designed so that mutual interference of the same types of sensors is very unlikely. To preclude even the slightest of influences on the measuring accuracy, we recommend installing the TiM3xx as in the examples below.

8 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 9

Technical Information Chapter 3

Placement of two TiM3xx with parallel offset

TiM310-1030000S01

Mounting

Placement of two TiM3xx with parallel offset, one of these upside down

Placement of two TiM3xx upside down, parallel offset

Placement of two TiM3xx with parallel offset, one of these upside down

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 9

Page 10

Chapter 3 Technical Information

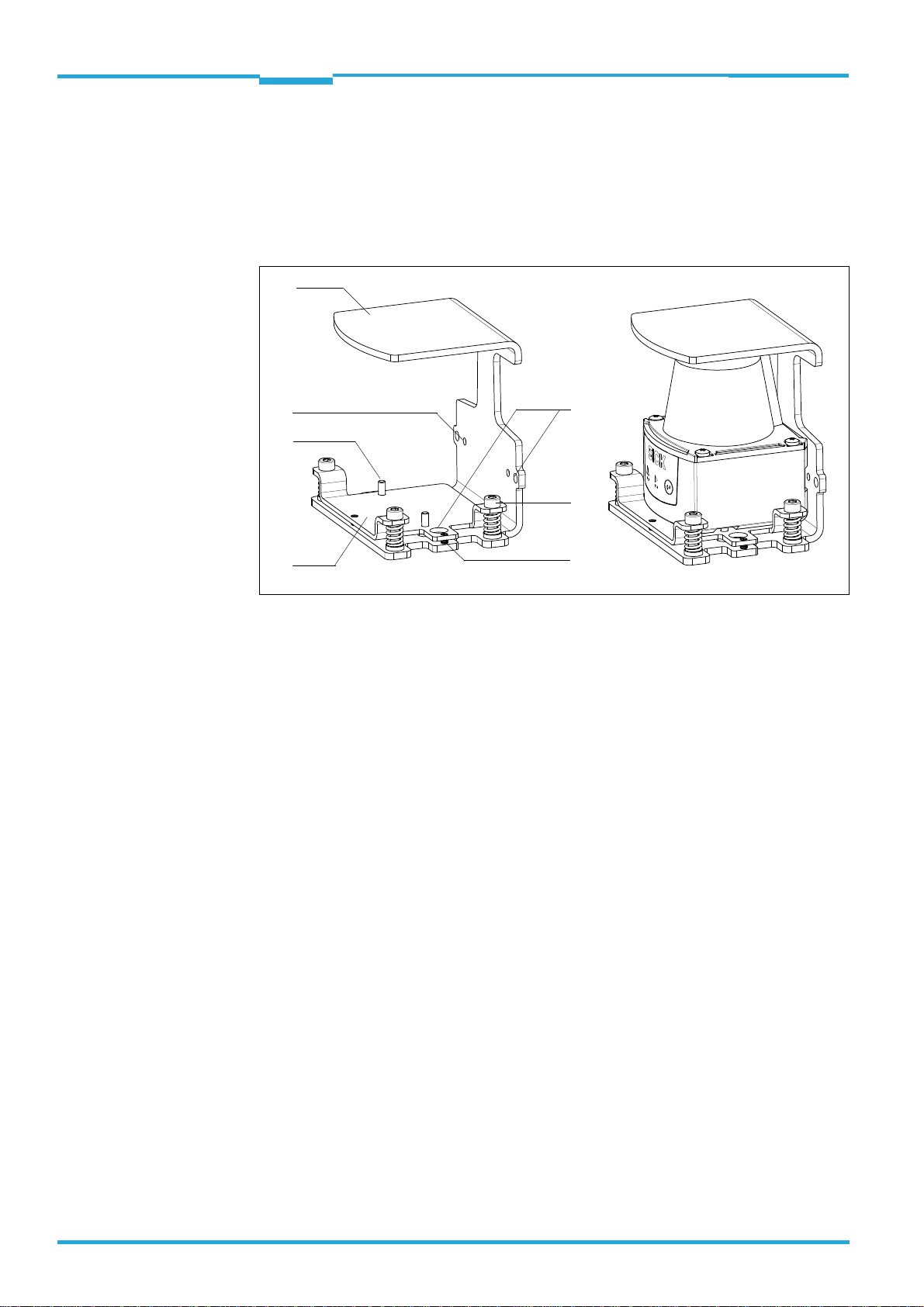

1

2

7

6

5

3

4

Mounting

TiM310-1030000S01 ranging and detecting laser scanner

3.2 Optional accessories

3.2.1 Install mounting set 2 (part no. 2061776) on the TiM3xx

The hanger-shaped mounting set 2 is used as skirting protection and as a bracket for making fine adjustments on the scan plane. The TiM3xx can also be fastened directly onto the

bracket without the adapter plate (skirting protection only).

1 Mounting bracket

2 4.3 mm (0.17 in) diameter hole for mounting the mounting bracket horizontally or vertically on a

surface, 2 x 2

3 Cheese-head screw M4 x 16 (hexagon socket) and compression spring for aligning the TiM3xx,

3 x

4 Set screw for locking the adapter plate after alignment, 2 x

5 Adapter plate

6 Cheese-head screw M3 x 8 in a 3.2 mm (0.13 in) diameter hole for mounting the TiM3xx to the

adapter plate, 2 x

7 3.2 mm (0.13 in) diameter hole for mounting the TiM3xx directly on the mounting bracket, 2 x

(alternatively, without option for making adjustments on the scan plane)

10 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 11

Technical Information Chapter 3

All measures of length in mm

68

89.4

70

51

92

68.8

26.4 4238.5

68.8

Ø 4.3 (2 x)

Ø 4.3 (2 x)

mm

4.3

26.4

38.5

42.0

51.0

68.0

68.8

70.0

89.4

92.0

inch

0.17

1.04

1.51

1.65

2.00

2.68

2.71

2.76

3.52

3.62

Mounting

TiM310-1030000S01

Procedure for mounting the TiM3xx

1. Mount the TiM3xx to the adapter plate using the two screws M3 x 8 supplied. For this

purpose, insert the screws from below through the hole in the mounting bracket and

the hole in the adapter plate.

2. Align the scan plane of the TiM3xx using the three cheese-head screws

3. After alignment, lock the adapter plate against the mounting bracket using both set

screws

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 11

4.

3.

Page 12

Chapter 4 Technical Information

SOPASSOPAS

“Power/Out”

“USB 2.0”

Configuration

Diagnosis

TiM3xx

Connection

box

USBUSB

Driver for request of

measurement values

and further data

processing

customer-provided

OUT 4

“Device

Ready”

DC 9 ... 28 V

delayaction

fuse

0,8A/T

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

4 Electrical installation

4.1 Overview of all interfaces

Measuring mode

Field monitoring

customer-provided

Field monitoring

OUT 1 OUT 2

delayaction

fuse

0,8A/T

DC 9 ... 28 V

Connection

box

OUT 4

“Device

Ready”

“Power/Out”

“USB 2.0”

TiM3xx

USBUSB

SOPASSOPAS

Configuration

Diagnosis

Tem porar y

field monitoring

12 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 13

Technical Information Chapter 4

TiM310-1030000S01

Electrical installation

4.2 Pin and wire color assignments

15-pin D-Sub HD plug on the cable

6

1

11

Pin Signal Color of wire Function

1 DC 9 ...28 V red Supply voltage

2n.c. purple –

3n.c. yellow –

4 OUT 4 red + black Switching output 4 (Device ready/index/error)

5GND black Ground

6 n.c. light blue –

7n.c. dark blue –

8 reserved turquoise or light gray –

9 reserved green –

10 reserved gray –

11 reserved pink –

12 OUT 1 brown Switching output 1 (field infringement)

13 OUT 2 orange Switching output 2 (field infringement)

14 reserved white –

15 reserved white + black –

– – metal Shield

Do not connect reserved pins!

5

15

10

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 13

Page 14

Chapter 4 Technical Information

D Sub socket,

front view

110

15611

5

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

Connecting cable no. 2043413 with 15-pin D-Sub-HD socket and open end

(optional accessory)

Pin Signal Color of wire Function

1 DC 9 ...28 V red Supply voltage

2n.c. purple –

3 n.c. yellow –

4 OUT 4 red + black Switching output 4 Device Ready/index/error)

5GND black Ground

6 n.c. light blue –

7n.c. dark blue –

8 reserved turquoise or light gray –

9 reserved green –

10 reserved gray –

11 reserved pink –

12 OUT 1 brown Switching output 1 (field infringement)

13 OUT 2 orange Switching output 2 (field infringement)

14 reserved white –

15 reserved white + black –

– – metal Shield

14 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 15

Technical Information Chapter 4

TiM310-1030000S01

Electrical installation

4.3 Notes on electrical installation

When the cover of the USB socket is open or the USB cable is connected, the TiM3xx

must not come into contact with moisture and dust. In this status, the TiM3xx does not

correspond to any specified IP enclosure rating.

Use the supplied seal for the USB connection to prevent contact with moisture and dirt.

When operating the USB interface, ESD/EMC interferences can lead to an interruption

of the USB connection. To continue with the data transfer, disconnect the USB cable

from the TiM3xx and reattach it to establish contact. To re-establish communication

between TiM3xx and PC, select C

software.

Electrical connections between the TiM3xx and other devices may only be connected

or disconnected when the system is not live, otherwise the devices may be damaged.

All connection cables on the TiM3xx may not exceed a length of 3 m (9.84 ft) in order

to ensure that it conforms with the CE.

Conducting cross sections of the supply cable from the customer's power system

should be selected and perform in accordance with the applicable standards.

Protected the TiM3xx with an external 0.8 A delay-action fuse at the start of the supply

cable from the point of view of the power supply. The connection module already has a

suitable fuse.

All electrical circuits connected to the TiM3xx must be designed as SELV or as PELV

electric circuits (SELV = Safety Extra Low Voltage, PELV = Protective Extra Low Voltage).

When constructing a connection box with 15-pin D-sub HD socket do not use the re-

served pins of the socket (e.g. as solder post)!

Do not switch on the supply voltage for the TiM3xx until the connection work has been

completed and wiring work has been checked carefully.

OMMUNICATION > GO ONLINE in the SOPAS configuration

4.4 Prerequisites for safe operation of the TiM3xx in a system

The TiM3xx is designed and tested for electrical safety according to the standard EN 609501 (2006-04)/A11 (2009-03):

It is connected to peripheral devices (power supply, control, actuators) via shielded cables.

The cable shield e.g. of the supply line is therefore flush with the metal housing of the

TiM3xx. The device can either be grounded via the cable shield or via the two straight plates.

If the peripheral devices also have metal housing and if the cable shields also flush with

their housing, it is assumed that all devices involved in installation have the same ground

potential.

This is achieved by observing the following conditions for instance:

mounting of devices on conducting metal surfaces

professional grounding of devices/metal surfaces in the system

low-impedance and current-conducting equipotential bonding between areas with dif-

ferent ground potentials if necessary.

If these conditions are not met, e.g. on devices in a widely distributed system across several

buildings, equipotential bonding currents may, due to different ground potentials, flow via

the cable shields between the devices, which can lead to dangers.

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 15

Page 16

Chapter 4 Technical Information

DANGER

DANGER

closed current loop

with equalizing currents

via cable shields

grounding point 2

grounding point 1

grounding potential difference

Actuators for

switching outputs

Power

supply unit

I

U

= metal housing

= shielded electrical cable

TiM310-

1030000S01

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

Insufficient ground potential equalization leads to voltage differences arising between

grounding points 1 and 2. The current loop closes via the shielded cables/metal housing.

Risk of injury/risk of damage due to electrical current!

Equipotential bonding currents between the TiM3xx and other grounded devices in the system may have the following effects:

dangerous currents on the metal housing e.g. of the TiM3xx

incorrect functioning or irreparable damage to the devices

Damage/irreparable damage of the cable shield due to heating and cable fires

Where local conditions are unfavorable and thus do not meet conditions for a safe

earthing method (same ground potential at all grounding points), carry out the measures below.

Risque de blessure ou d’endommagement dû au courant électrique !

Des courants d’équipotentialité entre le TiM3xx et les autres appareils mis à la terre de

l’installation peuvent avoir les effets suivants :

tensions dangereuses sur le boîtier métallique du TiM3xx par ex.

comportement défectueux ou destruction des appareils

endommagement ou destruction du blindage des câbles par échauffement et par

combustion des câbles

Prendre des mesures selon les indications suivantes là où les caractéristiques locales

sont défavorables et ne permettent pas un concept de mise à la terre sûr (même

potentiel de terre dans tous les points de mise à la terre).

16 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 17

Technical Information Chapter 4

Actuators for

switching outputs

grounding point 1

Electro-

optical

signal

isolators

Electro-

optical

signal

isolators

grounding point 2

= metal housing

= shielded electrical cable

= fiber optic cable

grounding potential difference

U

TiM310-

1030000S01

Electrical installation

TiM310-1030000S01

Remedial measures

The primary solution for avoiding equipotential bonding currents on the cable shields is to

guarantee low-impedance and current-conducting potential equalization. If this is not possible, the following two solution approaches are intended as suggestions.

Important It is not advisable to open up the cable shields. This can cause compliance with EMC limit

values for the devices to be no longer guaranteed.

a) Measures for widely distributed system installations

On widely distributed system installations with correspondingly large potential differences,

we recommend setting up local islands and connecting them using commercially available

electro-optical signal isolators. This will attain maximum resistance to electromagnetic interference, while observing all requirements of EN 60950-1 at the same time.

The ground loop is isolated by using the electro-optical signal isolator between the islands.

Equalization currents are prevented on the cable shields within the islands by conductible

equipotential bonding.

b) Measures for small system installations

For smaller installations with only slight potential differences, insulated installation of the

TiM3xx and of peripheral devices may be a sufficient solution.

Actuators for

switching outputs

grounding point 1

grounding potential difference

U

TiM310-

1030000S01

electrically

insulated

grounding point 2 grounding point 3

= metal housing

= shielded electrical cable

Power

supply unit

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 17

Page 18

Chapter 4 Technical Information

Important The power supply for the TiM3xx and the connected peripheral devices must also guarantee

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

Ground loops are, even in the event of large differences in ground potential, effectively prevented. This prevents any equalization currents flowing via the cable shields or metal housings.

the required level of insulation.

Under certain circumstances, a tangible potential can develop between the insulated metal

housings and the local ground potential.

18 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 19

Technical Information Chapter 4

TiM310-1030000S01

Electrical installation

Special national regulations for Sweden and Norway

Varning och atjarder

Utrustning som ar kopplad till skyddsjord via jordat vagguttag och/eller via annan utrustning

och samtidigt ar kopplad till kabel-TV nat kan i vissa fall medfora risk for brand.

For att undvika detta skall vid anslutning av utrustningen till kabel-TV nat galvanisk iso-

lator finnas mellan utrustningen och kabel-TV natet.

Advarsel og tiltaker

Utstyr som er koplet til beskyttelsesjord via nettplugg og/eller via annet jordtilkoplet utstyr

- og er tilkoplet et kabel - TV nett, kan forarsake brannfare.

For a unnga dette skal det ved tilkopling av utstyret til kabel-TV nettet installeres en gal-

vanisk isolator mellom utstyret og kabel-TV nettet.

Corresponding English translation

Devices which are connected to the electrical system PE of the building via a mains connection or other devices with a connection to the PE, and which are connected to a cable distribution system with coaxial cables, can under certain circumstances cause a risk of fire.

Connections to a cable distribution system must therefore be made such that electrical

insulation is offered below a certain frequency range (galvanic separating link).

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 19

Page 20

Chapter 4 Technical Information

DANGER

DANGER

TiM310-1030000S01xx

V

S

= DC 9 ... 28 V

OUT 1

Structure and wiring principle of output OUT 2 (pin 13)

and OUT 4 (pin 4) same as output OUT 1

12

5

GND

V

out

Quenching circuit:

Install an anti-surge

diode directly at the

load!

For inductive load:

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

4.5 Installation steps

4.5.1 Supply voltage connection

The TiM3xx requires a supply voltage between DC 9 and 28 V (stabilized protective extralow voltage [SELV or PELV] as per the IEC 60364-4-41 standard) .

The electricity source must be able to provide a power of 5 W at minimum.

Risk of injury due to electrical current!

If the supply voltage is generated by extracting and converting current from the alternating

current network using a stabilized power supply unit, insufficient electrical separation between the input and output circuit may lead to an electric shock.

Only use a power supply unit whose output circuit has reliable electrical separation due

to double insulation and a safety transformer as per IEC 742.

Risque de blessure dû au courant électrique !

Une séparation électrique insuffisante entre les circuits d’entrée et de sortie peut provoquer une électrocution si la tension d’alimentation est générée par le prélèvement et la

conversion de courant du réseau alternatif à l’aide d’un bloc d’alimentation stabilisé.

N’utiliser qu’un seul bloc d’alimentation dont le circuit de sortie, à l’opposé du circuit

d’entrée, possède une séparation électrique sécurisée par une double isolation et un

transformateur de sécurité selon CEI 742 (VDE 0551).

4.5.2 Wiring of switching outputs OUT 1, OUT 2 and OUT 4

Switching outputs OUT 1 and OUT 2 signal in combination infringement of the both fields.

Output OUT 4 is used to output the Device Ready signal, an error and a regular index pulse.

20 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Characteristic data of all switching outputs is identical.

Page 21

Technical Information Chapter 4

Electrical installation

TiM310-1030000S01

Switching behavior PNP-switching against supply voltage VS.

OUT 1 and OUT 2:

Idle level: High (no field infringement),

Working level: Low (field infringement)

Response time: 134 ms to 30 s (adjustable via SOPAS)

Duration time: 0 ms to 10 s (adjustable via SOPAS)

OUT 4:

Idle level: High (Device Ready),

Working level: Low (error), low pulse (15 Hz, index, corresponds to

measurement at 90°)

Properties – Short-circuit resistant and temperature-protected

– Not electrically isolated from the supply voltage V

Electrical values 0 V V

Guaranteed: (VS – 1.5 V)V

out

V

S

VS at I

out

100 mA

out

S

Important Longer connecting cables at the switching outputs of the TiM3xx should be avoided due to

the resultant voltage drop. This is calculated as follows:

2 x length x current

D V = -------------------------------------------------------------

Conductance value x cross section

Conductance value for copper: 56 m/W mm

2

.

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 21

Page 22

Chapter 4 Technical Information

Electrical installation

TiM310-1030000S01 ranging and detecting laser scanner

22 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 23

Technical Information Chapter 5

TiM310-1030000S01

Measured value output

5 Measured value output

5.1 Telegrams

Notation

The individual sections in the syntax of the telegrams from the TiM3xx are each separated

by a space (ASCII code 32, 20h) as also neccessary in the request to the TiM3xx.

The TiM3xx sends measured values conditioned as followed:

Values with a leading “+” or “–” as a decimal value (ASCII notation).

Values without a leading “+” or “–” as a hexadecimal value (ASCII notation).

The different notations can be mixed within the telegram.

All following telegram examples refer to the CoLa-A protocol

Variable types

The variable types are the given in the syntax of the measuring data output telegram.

The following variable types are possible:

Variable type Length (byte) Value range Sign

uint_8 1 0 … 255 No

uint_16 2 0 … 65,535 No

uint_32 4 0 … 4,294,967,295 No

int_32 4 –2,147,483, 648 … +2,147,483, 647 Yes

float_32 4

string Context-dependent Important: strings are not terminated by zeroes

–10

–44.85

... +10

38.53

Yes

Important The information in the “Length” column of the table refers to the binary transfer of the

numeric parameters.

The information in the “Value range” column in the table refers to the value range math-

ematically possible for the variable type. The actual value ranges for the parameters

may be different see also Chapter 5.3 Measured value output fomat, Page 26.

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 23

Page 24

Chapter 5 Technical Information

Measured value request

Output of one measured value telegram

Measured value output

TiM310-1030000S01 ranging and detecting laser scanner

5.2 Request measured values

After switching on the supply voltage, the TiM3xx initializes and the green LED will light up

to indicate its readiness for operation.

The TiM3xx begins its readiness to measure automatically. It continuously scans the surrounding contour in its field of vision at a frequency of 15 Hz. It continuously saves the values determined in each measuring process (scan) in its measured value memory by

overwriting the previous values.

5.2.1 Single measured value output

If the data from a measuring process are required, the TiM3xx sends the measured values

from the most recent scan.

Example of single measured value output

Request:

<STX>sRN LMDscandata<ETX>

Answer of TiM3xx:

<STX>sRA LMDscandata (contents see Chapter 5.3 Measured value output fomat,

Page 26) <ETX>

Telegram structure: sRN LMDscandata

Telegram part Description Variable type Length (byte) Value range

Type of command Request (SOPAS read by name) string 3 sRN

Command Data request string 11 LMDscandata

24 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 25

Technical Information Chapter 5

Measured value request

Output of the measured value telegrams

Stop the output

TiM310-1030000S01

Measured value output

5.2.2 Continuous measured value output

If the data from ongoing measuring processes are required, the TiM3xx sends measured

values from successive scans until the output of measured values is stopped again using

the same telegram.

Example of continuous measured value output

1. Start measured value output

Request:

<STX>sEN LMDscandata 1<ETX>

Answer of TiM3xx (acknowledgement of request):

<STX>sEA LMDscandata 1<ETX>

Answer of TiM3xx (measured value output):

<STX>sSN LMDscandata (contents see Chapter 5.3 Measured value output fomat,

Page 26) <ETX>

2. Stop measured value output

Request:

<STX>sEN LMDscandata 0<ETX>

Answer of TiM3xx (acknowledgement of request):

<STX>sEA LMDscandata 0<ETX>

Telegram structure: sEN LMDscandata MeasurementStartStop

Telegram part Description Variable type Length (byte) Value range

Type of command Request (SOPAS event by name) string 3 sEN

Command Data request string 11 LMDscandata

MeasurementStartStop Enum8 1 0 Stop measured value output

1 Start measured value output

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 25

Page 26

Chapter 5 Technical Information

Measured value output

TiM310-1030000S01 ranging and detecting laser scanner

5.3 Measured value output fomat

Important Information that is grayed out in the following table is not output by the TiM3xx.

Telegram part Description Variable type Length (byte) Value range

Type of command Request (SOPAS read

answer/SOPAS sent event)

Command Data request string 11 LMDscandata

Version number Firmware version information uint_16 2 0000h ... FFFFh

Device number Device ID as configured in

SOPAS ET

Serial number Factory serial number uint_32 4 00000000h ... FFFFFFFFh

Device status Status of the TiM3xx uint_x 2 x 1 00 00h Device OK

Device information

Telegram counter Counter, starting at the first

measured value telegram

(cyclic data) after confirmation of the measured value

request.

When the upper limit is

reached, the counter starts

again at 0 (= 1st telegram).

Scan counter Counter, starting with the first

scan after confirmation of the

measured value request.

When the upper limit is

reached, the counter starts

again at 0 (= 1. scan).

Time since startup Time since the TiM3xx was

switched on and the end

point of the scan in micro

seconds (μs)

Time of transmission Time since the TiM3xx was

Status information

Input status The least significant byte

Output status The least significant byte

Reserved byte A Reserved uint_16 2 –

switched on and the transfer

of the measured values in

micro seconds (μs)

reflects the state of the digital

switching inputs by bit.

The least significant bit corresponds to input 1.

reflects the state of the digital

switching outputs by bit.

The least significant bit corresponds to output 1.

string 3 sRA/sSN

uint_16 2 0000h ... FFFFh

00 01h Device error

uint_16 2 0000h 0

FFFFFh 65,535

uint_16 2 0000h 0

FFFFFh 65,535

uint_32 4 00000000h 0

FFFFFFFFFh 4,294,967,295

uint_32 4 00000000h 0

FFFFFFFFFh 4,294,967,295

uint_x 2 x 1 00 00h all switching inputs inactive

uint_x 2 x 1 00 00h all switching outputs inactive

00 0Bh all switching outputs active

26 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 27

Technical Information Chapter 5

TiM310-1030000S01

Telegram part Description Variable type Length (byte) Value range

Scanning frequency Information in 1/100 Hz uint_32 4 1500 15 Hz

Measurement

frequency

Measurement parameters

Number of encoders Defines the number of encod-

Encoder position Information in ticks uint_32 4 00000000h ... FFFFFFFFh

Encoder speed Information in mm/s uint_16 2 0000h ... FFFFh

Encoder

Number of 16 bit channels Defines the number of 16-bit

Measured data contents

Scaling factor Multiplier for the values in the

Scaling offset For the TiM3xx always 0 float_32 4 00000000h ... FFFFFFFFh

Starting angle Information 1/10,000 degree Int_32 4 –450,000 ... + 2,250,000

Angular step width Information 1/10,000 degree uint_16 2 10,000 (1 degree)

Number of data Defines the number mea-

Data_1 ... Data_n Output of the measured val-

Output channels 1 ... 4 (16 bit)

Measured value output

Frequency between two separate measurements in 100 Hz

ers from which data are output

output channels on which the

TiM3xx outputs measured

data.

If “0 output channels” are

selected, no data is output.

The telegram part defines the

contents of the output channel.

telegram parts Data_1 to

Data_n

sured values the TiM3xx outputs

ues 1 to n. The contents and

the unit depend on the telegram part “Measured data

contents”. DIST in mm

uint_32 4 00000000h ... FFFFFFFFh

uint_16 2 0 No encoder data

(can not be changed)

uint_16 2 1 The TiM3xx sends the distance

data as 16 bit value via one

channel

string 5 DIST1 Radial distance for the first echo

float_32 4 00000000h ... FFFFFFFFh

uint_16 2 271

uint_16 2 0000h ... FFFFh

(contd.)

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 27

Page 28

Chapter 5 Technical Information

Telegram part Description Variable type Length (byte) Value range

Number of 8 bit channels Defines the number of 8-bit

Measured data contents

Scaling factor Multiplier for the values in the

Scaling offset For the TiM3xx always 0 float_32 4 00000000h ... FFFFFFFFh

Starting angle Information 1/10,000 degree Int_32 4 –450,000 ... + 2,250,000

Angular step width Information 1/10,000 degree uint_16 2 10.000 (1 degree)

Number of data Defines the number mea-

Output channels 1 ... 4 (8 bit)

Data_1 ... Data_n Output of the measured val-

Position Defines the output of position

X position XN coordinate of the sensor in

Y position YN coordinate of the sensor in

Z position ZN coordinate of the sensor in

X rotation XN rotation of the sensor in a

Y rotation YN rotation of the sensor in a

Z rotation ZN rotation of the sensor in a

Position information

Type of rotation Kind of rotation Enum8 1 0 No rotation

Measured value output

output channels on which the

TiM3xx outputs measured

data.

If “0 output channels” are

selected, no data is output.

The telegram part defines the

contents of the output channel.

telegram parts Data_1 to

Data_n

sured values the TiM3xx outputs

ues 1 to n. The contents and

the unit depend on the telegram part “Measured data

contents”. RSSI in digits

data

a coordinate system

a coordinate system

a coordinate system

coordinate system

coordinate system

coordinate system

TiM310-1030000S01 ranging and detecting laser scanner

uint_16 2 1 The TiM3xx sends the RSSI data

as 8 bit value via one channel

string 5 RSSI1 Received power for the first

echo

float_32 4 00000000h ... FFFFFFFFh

uint_16 2 271

uint_8 1 00h ... FFh

uint_16 2 0 No position data

(can not be changed)

Real 4 00000000h ... FFFFFFFFh

Real 4 00000000h ... FFFFFFFFh

Real 4 00000000h ... FFFFFFFFh

Real 4 00000000h ... FFFFFFFFh

Real 4 00000000h ... FFFFFFFFh

Real 4 00000000h ... FFFFFFFFh

1 Pitching

2 Rolling

3 Free rotation

Name Defines whether the TiM3xx

outputs the device name configured with SOPAS ET

Device name Flexible range from 0 to

16 characters (20h … FFh)

Comment Defines whether the TiM3xx

outputs the comment configured with SOPAS ET

Contents of comment Configured comment string 0 ... 128 ..........

RSSI = Received Signal Strength Indicator

(contd.)

uint_16 2 0 No device name

(can not be changed))

string 0 ... 16 ..........

uint_16 2 0 No comment

(can not be changed)

28 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 29

Technical Information Chapter 5

TiM310-1030000S01

Telegram part Description Variable type Length (byte) Value range

Time information Defines whether the TiM3xx

Year Year (4 digits) uint_16 2 0000h ... 270Fh

Month Month from 1 to 12 uint_8 1 00h ... 0Ch

Day Day of the month from 1 to 31uint_8 1 00h ... 1Fh

Hour Hour from 0 to 23 uint_8 1 00h ... 17h

Minute Minute from 0 to 59 uint_8 1 00h ... 3Bh

Second Second from 0 to 59 uint_8 1 00h ... 3Bh

Time information

Micro second Micro seconds from 0 to

Event information Defines whether the TiM3xx

Type of event Fast digital input event string 4 FDIN

Encoder position Encoder position at the time

Event time Time since the TiM3xx was

Angular position Angular position of the

Event information

(contd.)

Measured value output

outputs time information

999,999

outputs event information

of the event.

Information in ticks

switched on up to the time of

the event in micro second

(μs)

TiM3xx at the time of the

event.

Information in 1/10,000

degree

uint_16 2 0 No time information

(can not be changed)

uint_32 4 00000000h ... 000F423Fh

unit_16 2 0 No event information

(can not be changed)

uint_32 4 00000000h ... FFFFFFFFh

uint_32 4 00000000h 0

FFFFFFFFFh 68,719,476,735

int_32 4 –450,000 ... + 2,250,000

8014884/YK97/2015-04-27 © SICK AG · Germany · All rights reserved · Subject to change without notice 29

Page 30

Chapter 6 Technical Information

License texts

TiM310-1030000S01 ranging and detecting laser scanner

6 License texts

SICK uses open source software in its TiM sensors. This software is licensed by the rights

holders using the following licenses among others: the free licenses GNU General Public License (GPL Version2, GPL Version3) and GNU Lesser General Public License (LGPL), the MIT

license, zLib license, and the licenses derived from the BSD license.

This Program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY;

without even the implied warranty for merchantability or fitness for a particular purpose.

See the GNU General Public License for more details.

View the complete license texts here: www.sick.com/licensetexts.

A printed copy of the license texts is also available on request.

30 © SICK AG · Germany · All rights reserved · Subject to change without notice 8014884/YK97/2015-04-27

Page 31

Page 32

8014884/YK97/2015-04-27 ∙ SH_8M/ITL (2015-04) ∙ A4 4c int43

Australia

Phone +61 3 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Belgium/Luxembourg

Phone +32 (0)2 466 55 66

E-Mail info@sick.be

Brasil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Česká republika

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

China

Phone +86 4000 121 000

E-Mail info.china@sick.net.cn

Phone +852-2153 6300

E-Mail ghk@sick.com.hk

Danmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Deutschland

Phone +49 211 5301-301

E-Mail info@sick.de

España

Phone +34 93 480 31 00

E-Mail info@sick.es

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Great Britain

Phone +44 (0)1727 831121

E-Mail info@sick.co.uk

India

Phone +91–22–4033 8333

E-Mail info@sick-india.com

Israel

Phone +972-4-6881000

E-Mail info@sick-sensors.com

Italia

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 (0)3 5309 2112

E-Mail support@sick.jp

Magyarország

Phone +36 1 371 2680

E-Mail office@sick.hu

Nederland

Phone +31 (0)30 229 25 44

E-Mail info@sick.nl

Norge

Phone +47 67 81 50 00

E-Mail sick@sick.no

Österreich

Phone +43 (0)22 36 62 28 8-0

E-Mail office@sick.at

Polska

Phone +48 22 837 40 50

E-Mail info@sick.pl

România

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7-495-775-05-30

E-Mail info@sick.ru

Schweiz

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovenija

Phone +386 (0)1-47 69 990

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail info@sickkorea.net

Suomi

Phone +358-9-25 15 800

E-Mail sick@sick.fi

Sverige

Phone +46 10 110 10 00

E-Mail info@sick.se

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Türkiye

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail info@sick.ae

USA/México

Phone +1(952) 941-6780

1 (800) 325-7425 – tollfree

E-Mail info@sickusa.com

More representatives and agencies

at www.sick.com

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...