Page 1

8024118/2019-03

SICK AG

Erwin -Sick-Straße 1

D-79183 Waldkirch

www.sick.com

USER INSTRUCTIONS en

All rights reserved. Subject to change without notice.

Conditioning of Instrument Air

for analyzer solutions

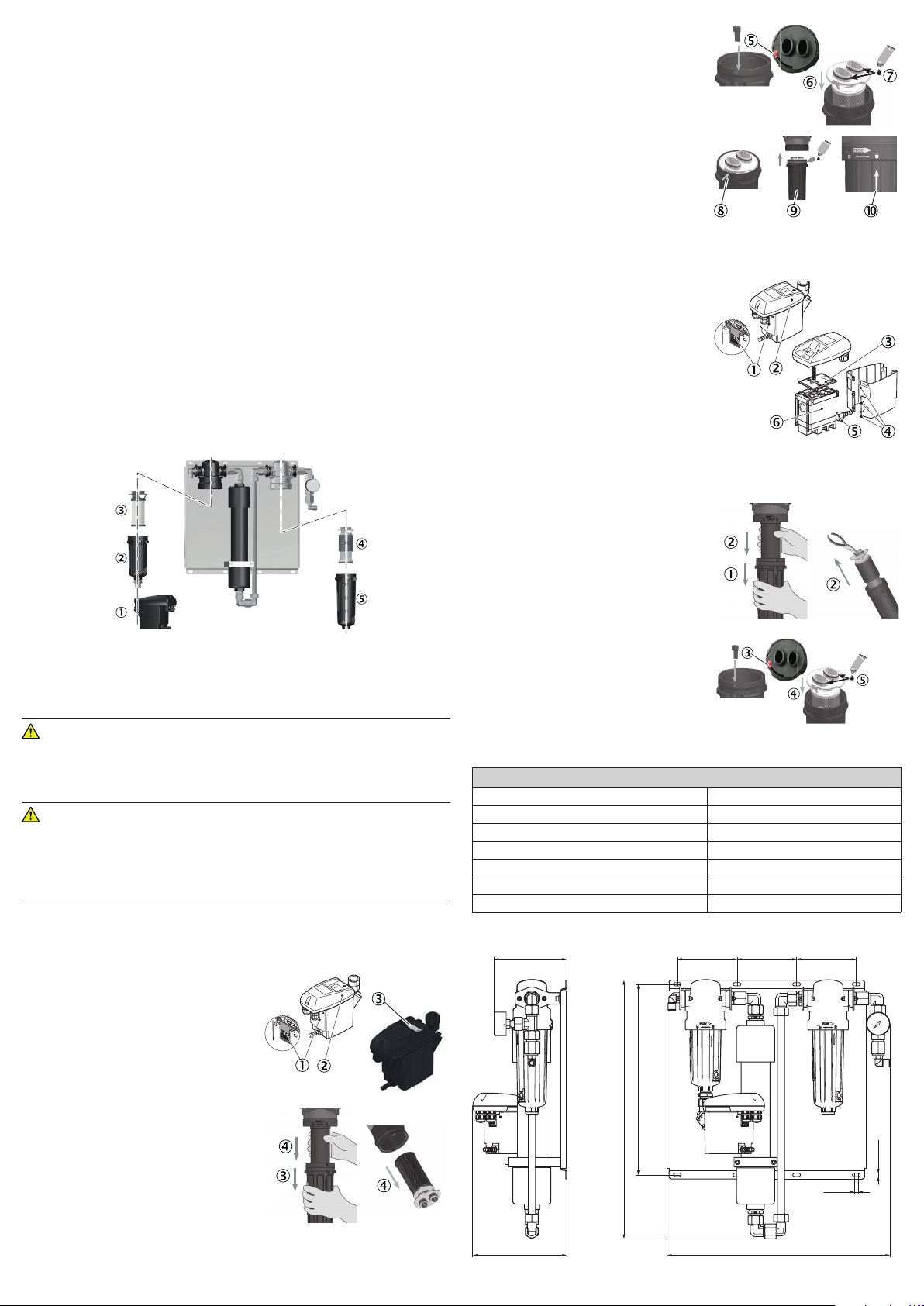

5. Electrical installation

The instrument air conditioning unit has to be fed with a

power supply of 95 … 240 V AC/±10% (50 … 60 Hz) or

100 … 125 V DC/±10%; refer to the user manual for Ultramat

UFM-D05.

Warning: Risk of death by electric shock

Risk of electric shock when working on electrical parts while

the unit is switched on.

b Before any action step ensure that the unit is turned o.

b A voltage separator (e. g. power plug or switch) must be pro-

vided close-by to separate all current carrying conductors.

5.1 Connections

Connect power supply

1. Check the supply voltage on the type plate of the condensate

separator UFM-D05 (left side; 1) to ensure the correct specications.

2. Loosen the screws (2) and remove the upper cover (3).

3. Unscrew the right threaded cable gland (4) and, if available

remove the plug and put through the cable (5).

4. Connect the power supply cable wires (5) to the terminal X1.

1. Intended use

The intended use of the Instrument Air Conditioning Unit, part No.

6070177, is to supply a measuring device with clean, ltered and

conditioned instrument air, see “Specications”.

2. About this document

This user instruction describes the the installation, connections

and maintenance work.

3. Supplementary documents

Refer to the documents from Donaldson on the enclosed data

volume. You can download additional documents from www.sick.

com. Enter the part number in the search eld.

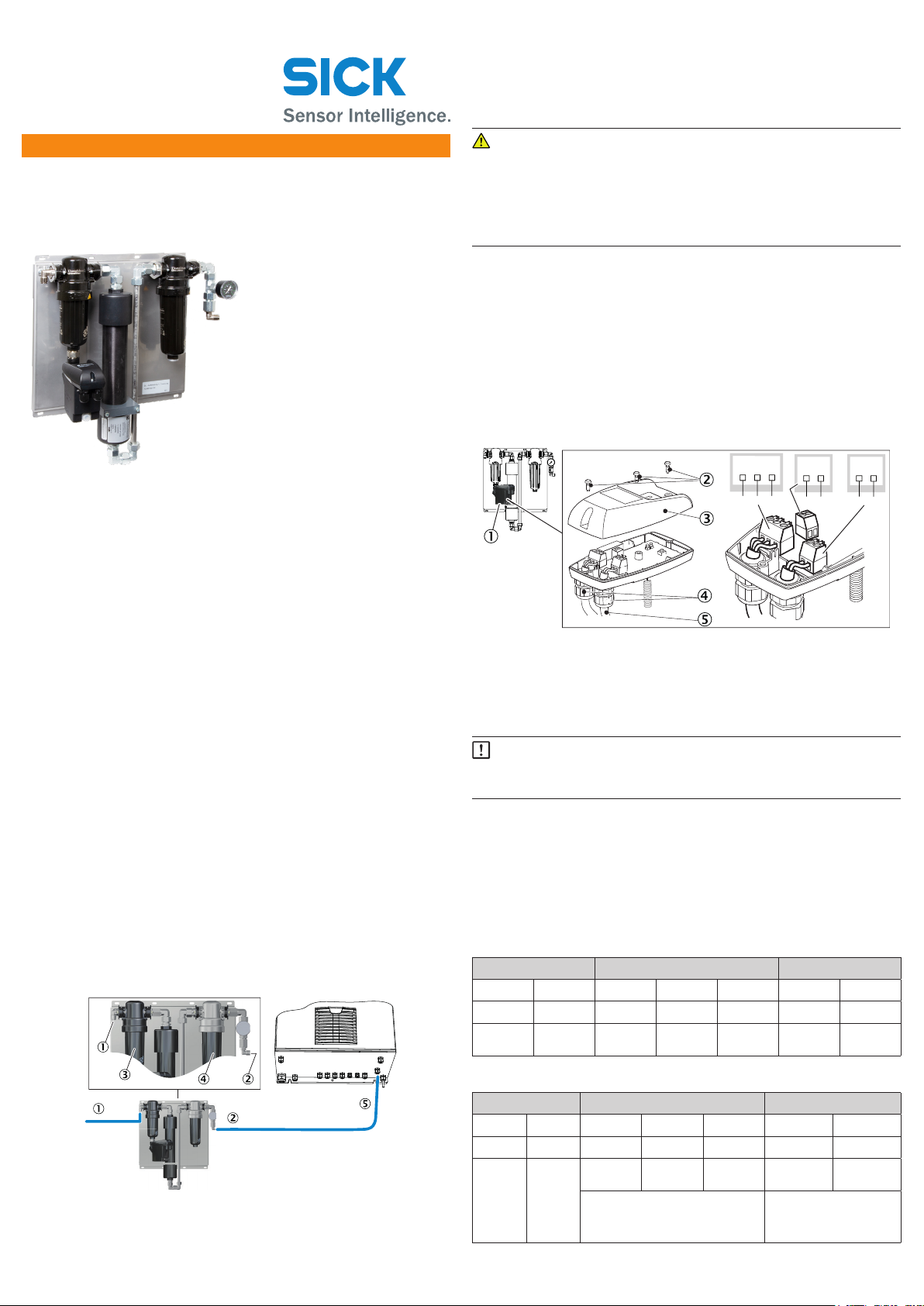

4. Hardware installation

The instrument air conditioning unit includes a stainless steel

ground plate, compressed air lters, automatic condensate separator and a membrane air dryer.

Steps

1. Place and attach the ground plate close to the measuring de-

vice using 8 dened xing holes, see “Dimensional Drawing”.

2. Connect the instrument air tube (10 mm) to the instrument air

inlet (1).

3. Connect the instrument air tube (10 mm) from the measuring

device (5) to the instrument air outlet (2).

X2

nc

noco

X2.3

X2.1X2.2

1. Condensate separator UFM-D05

2. Screw

3. Upper cover

Fig. 2: Electrical connections; see also terminal assignment

4. Cable gland

5. Cable

X3

In1

321

1

gnd

X3.2X3.1

X1

N(–)

1

2

Connect fault indication and external test

Notice:

b Ensure a sucient clearance to other parts of the unit, or

suitable insulation.

5. Unscrew the left threaded cable gland (4) and, if available

remove the plug and put through the cable (5).

6. Connect the cable wires (5) to the terminal X2 and/or X3.

7. Tighten the threaded cable gland (4) slightly.

8. Put on the upper cover (3) and tighten the screws (2).

Terminal assignment

Terminal assignment for supply voltage (operating voltage)

Terminal X1 Terminal X2 Terminal X3

X1.1 X1.2 X2.1 X2.2 X2.3 X3.1 X3.2

L1 (+) N (–) NO CO NC IN1 GND

Phase Neutral Normally

open

Common Normally

closed

External

test

GND

L(+)

X1.1X1.2

2

1. Instrument air inlet

2. Instrument air outlet

3. Filter DFM-S 0070 OS

Fig. 1: Connection overview: conditioning of instrument air

4. Filter DF-T 0050 OS

5. Measuring device:

instrument air inlet

Terminal assignment for potential-free contact and external test

Terminal X1 Terminal X2 Terminal X3

X1.1 X1.2 X2.1 X2.2 X2.3 X3.1 X3.2

L1 (+) N (–) NO CO NC IN1 GND

Power Neutral Normally

open

n.c.: Malfunction or power failure

n.o.: Normal operation

Potential-free contacts

Common Normally

closed

Instrument Air Conditioning Unit | SICK8024118/ V1-0/2019 -03/en 1

External test GND

Contacts closed: test active

Contacts open: test inactive, no pot.-free contacts

Page 2

151 (5.94)

125 (4.92) 125 (4.92)125 (4.92)

6. Commissioning

b Before connecting the instrument air, blow the instrument air

into the environment for a few minutes. Check dryness with a

paper towel.

b Slowly apply pressure to the instrument air inlet. For the maxi-

mum limit value refer to “Specications”.

b Make sure that no pressure peaks occur. See manufacturer’s

documents attached.

7. Maintenance

7.1 Yearly maintenance work

Only the replacement of the lter elements of the maintenance

kit has to be carried out once a year.

Requirements: maintenance kit, part No. 5339994.

The maintenance kit consists of the components:

• Filter element DFM-S 0070 and housing sealing

• Maintenance kit for condensate separator UFM-D05 and

sealing

• Filter element DF-T 0050 and housing sealing

Overview of maintenance kits elements

6. Insert the new lter element (6)

to the marking (5) on the lter

bowl.

7. Grease the sealing rings at the

lter element (7) as shown.

8. Check marker at the lter top (8).

9. Grease the new lter bowl o-ring

on the lter top (9) and attach

the UFM-D05 housing.

10. Check that the nal position of

the lter housing is locked (ß).

7.3 Replacing the UFM-D05 maintenance kit

1. Remove UFM-D05 (2) by pressing

the arresting hook (1).

2. Unfasten UFM-D05 from the

outlet (5) and remove the design

shell (4).

3. Detach the maintenance unit (6)

from the tubing at the inlet by

removing the union nut.

4. Install the new maintenance unit

(6) in reverse order.

Grease

Grease

1. Condensate separator UFM-D05

2. Filter DFM-S 0070 OS

3. Filter element DFM-S 0070 OS

Fig. 3: Disassembly/assembly of maintenance kits components

4. Filter element DF-T 0050 OS

5. Filter DF-T 0050 OS

Warning: Risk of death by electric shock

Risk of electric shock when working on electrical parts while

the unit is switched on.

b Before any action step ensure that the unit is turned o.

Caution: Risk of injury due to high pressure

When working on parts under pressure, it is possible that

parts come o unexpectedly or compressed air escapes.

b Before working on the unit, ensure an appropriate decom-

pression within the instrument air tubes.

7.2 Replacing the lter element DFM-S 0070 OU

1. Slowly reduce and stop the pressure supply at the instrument

air inlet.

2. Remove the UFM-D05 (2) by

pressing the arresting hook (1).

3. Reset UFM-D05: press the TEST

button (3) below the LED, hold it

for at least 5 sec. and switch o

the voltage supply.

4. Loosen and remove the lower part

(bowl) of the lter housing (3).

5. Remove the lter element (4).

7.4 Replacing the lter element DF-T 0050 OS

1. Loosen and remove lower part

(bowl) of the lter housing (1).

2. Remove the lter element (2).

3. Insert the new lter element (4)

to the marking (3) on the lter

Grease

bowl.

4. Grease the sealing rings at the

lter element (5) as shown.

8. Specications

Instrument air specications

Particle (class 6/ISO 8573:2010) ≤ 100.000 solid particle [1 ... 5 µm]

Water vapor (class 4/ ISO 8573:2010) ≤ +3 °C pressure dew point (steam)

Total oil portion (class X/ ISO 8573:2010) ≤ 10 mg total oil (liquid, aerosol, fog)

Flow rate 1.3 Nm3/h

Pressure 12.5 bar

Operating temperature 1 ... 60 °C

Volume 1.5 l

8.1 Dimensional drawing

400 (15.75)

543 (21.38)

9 (0.35)

7 (0.28)

196 (7.72)

465 (18.31)

Instrument Air Conditioning Unit | SICK8024118/ V1-0/2019 -03/en 2

Loading...

Loading...