Page 1

TELEMATIC DATA COLLECTOR

Gateway systems

OPERATING INSTRUCTIONS

Page 2

2

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Product described

Product name: Telematic Data Collector

Document identification

Title: Telematic Data Collector operating instructions

Status: 2017-11-27

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

only used here for identification purposes.

Original documents

The German version 8021803 of this document is an original document of

In case of doubt, contact SICK AG or your local dealer.

Legal notes

Subject to change without notice

© SICK AG. All rights reserved

Part number: 8021804

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be trademarks and are

SICK AG.

SICK AG does not assume liability for the correctness of a non-authorized

translation.

Page 3

3

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Contents

ABOUT THESE OPERATING INSTRUCTIONS 1

1 About these operating instructions ................................................................................ 6

1.1 Described software versions ............................................................................... 6

1.2 Purpose of this document .................................................................................... 6

1.3 Target group ......................................................................................................... 6

1.4 Information depth ................................................................................................ 7

1.5 Abbreviations used............................................................................................... 7

1.6 Symbols used ....................................................................................................... 8

2 Safety ................................................................................................................................. 9

2.1 Qualified personnel .............................................................................................. 9

2.2 Applications of the system ................................................................................... 9

2.3 Intended use ......................................................................................................... 9

2.4 General safety notes and protective measures .............................................. 10

2.4.1 Safety notes and symbols ................................................................. 10

2.4.2 General safety notes .......................................................................... 11

2.4.3 Potential sources of danger .............................................................. 12

2.5 Protecting the environment .............................................................................. 13

3 System description ........................................................................................................ 14

3.1 Scope of delivery ............................................................................................... 14

3.2 System components.......................................................................................... 18

3.2.1 TDC devices – collecting and transmitting sensor data .................. 18

3.2.1.1 The TDC device as a receiver ........................................... 18

3.2.1.2 The TDC device as a sender ............................................. 19

3.2.2 Processing and visualizing sensor data on the SICK online

portal ................................................................................................... 21

3.2.2.1 Components of the SICK online portal ............................. 21

3.2.2.2 Multi-client capability and access rights .......................... 21

3.2.2.3 Visualization and monitoring ............................................ 22

3.3 Interfaces for integration into customer applications ..................................... 23

3.4 Status indicators for the TDC devices .............................................................. 25

3.4.1 TDC-B100/TDC-B200 ........................................................................ 25

3.4.2 TDC-M100 .......................................................................................... 26

4 Mounting ........................................................................................................................ 27

4.1 Inserting the SIM card (not EU countries or for MQTT operation) .................. 27

4.2 Mounting the TDC-B100/200 .......................................................................... 30

4.3 Mounting the TDC-M100 .................................................................................. 30

5 Electrical installation .................................................................................................... 31

5.1 Connecting TDC devices ................................................................................... 31

5.1.1 Connectors on the TDC devices ........................................................ 31

5.1.2 Connecting the TDC device to the voltage supply ............................ 32

5.1.3 Connecting the TDC device to the ignition system ........................... 34

5.1.4 Connecting the TDC device to SICK sensors .................................... 35

5.1.5 Connecting fuel level sensors ........................................................... 38

5.2 Screwing on the GSM antenna ......................................................................... 39

5.3 Connecting the GPS antenna ........................................................................... 39

6 Commissioning .............................................................................................................. 40

6.1 Launching the TDC devices .............................................................................. 40

6.2 Preparing the configuration PC ........................................................................ 40

Page 4

1 ABOUT THESE OPERATING INSTRUCTIONS

4

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

6.3 General notes .....................................................................................................40

6.3.1 Establishing a connection with the configuration PC .......................41

6.3.2 Installing TDC Configurator ................................................................42

6.4 Connecting to the TDC device ...........................................................................43

6.4.1 Launching the configuration software ...............................................43

6.4.2 Establishing a connection to the TDC device ....................................44

6.5 Adjusting the standard parameters and configuring the interfaces ...............46

6.5.1 General settings ..................................................................................46

6.5.1.1 General ...............................................................................46

6.5.1.2 GPRS connection data .......................................................48

6.5.1.3 Tracking ..............................................................................51

6.5.2 Configuring the interfaces ..................................................................53

6.5.2.1 What are telemetry elements? ..........................................53

6.5.2.2 Configuring a telemetry element for a digital signal ........55

6.5.2.3 Copying a telemetry element.............................................60

6.5.2.4 Configuring a telemetry element for a motor signal ........61

6.5.2.5 Configuring a telemetry element for a fuel level sensor ..62

6.5.3 Configuring the internal sensors ........................................................63

6.5.4 Transferring the configuration to the TDC device .............................64

6.5.5 Saving the configuration on the PC ...................................................64

6.5.6 Recording ............................................................................................64

6.5.7 Displaying system information ...........................................................65

7 Monitoring .......................................................................................................................66

7.1 Setting up a customer account for the SICK online portal ..............................66

7.1.1 Applying for a customer account .......................................................66

7.1.2 Notification about your customer account ........................................70

7.2 Configuring the TDC Management System.......................................................71

7.2.1 Logging in to the TDC Management System .....................................71

7.2.2 Registering additional TDC devices ...................................................72

7.2.3 Configuring a dashboard ....................................................................73

7.2.3.1 Creating a dashboard ........................................................73

7.2.3.2 Defining the structure for displaying telemetry

elements on the dashboard ..............................................74

7.2.4 Visualizing key figures using widgets on the dashboard ..................76

7.2.4.1 Adding key figures for sensor data ...................................76

7.2.4.2 Adding key figures for alarms ............................................78

7.2.4.3 Adding diagrams ................................................................79

7.2.5 Analyzing sensor data in detail ..........................................................81

7.2.6 Administering the management platform .........................................82

7.3 Working with fleet management .......................................................................83

7.3.1 Position display ...................................................................................83

7.3.2 Displaying the vehicle list with detailed information ........................84

7.3.3 Displaying current vehicle fuel levels ................................................84

7.3.4 Accessing information about a specific vehicle ................................85

7.3.5 Accessing fuel consumption information ..........................................88

7.3.6 Analyzing the kilometers covered ......................................................90

7.4 Transferring data to a customer application using an API interface ..............92

7.4.1 Input parameter ..................................................................................92

7.4.2 Example for API call ............................................................................93

7.5 Accessing data from the TDC device via the MQTT interface ..........................94

7.5.1 Description of the MQTT interface structure .....................................94

7.5.2 Description of the MQTT protocol ......................................................95

Page 5

ABOUT THESE OPERATING INSTRUCTIONS 1

5

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

8 Maintenance .................................................................................................................. 97

8.1 Maintenance during operation ......................................................................... 97

8.1.1 Visual inspection ................................................................................ 97

8.1.2 Cleaning .............................................................................................. 98

8.2 Replacing components ................................................................................... 100

8.2.1 Basic procedure ............................................................................... 100

8.2.2 Replacing the GPS antenna ............................................................ 100

8.2.3 Replacing the TDC device overcurrent protection device .............. 101

8.2.4 Replacing the TDC device ................................................................ 102

9 Annex ............................................................................................................................ 103

9.1 Technical data ................................................................................................. 103

9.1.1 TDC-B100 data sheet ...................................................................... 103

9.1.2 TDC-B200 data sheet ...................................................................... 105

9.1.3 TDC-M100 data sheet ..................................................................... 108

9.2 Dimensional drawings ..................................................................................... 110

9.2.1 TDC-B100 dimensional drawing...................................................... 110

9.2.2 TDC-B200 dimensional drawing...................................................... 110

9.2.3 TDC-M100 dimensional drawing ..................................................... 110

10 Figures and tables ....................................................................................................... 111

10.1 List of tables .................................................................................................... 111

10.2 List of figures ................................................................................................... 112

Page 6

1 ABOUT THESE OPERATING INSTRUCTIONS

6

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Software

Function

Status

TDC Configurator

Configuring the TDC devices

≥ V 1.0-0-0

Target group

Tasks

Entity operating the customer system

System user

Operating the system:

The system user reports faults to the system manager.

System manager

Mounting, electrical installation, maintenance, and replacement

The system manager submits support requests to SICK.

SICK

SICK service technician

Commissioning, configuration, and support.

1 About these operating instructions

Please read this chapter carefully before you begin working with this documentation and

the Telematic Data Collector (TDC for short) gateway system.

1.1 Described software versions

Tab. 1: Software versions

1.2 Purpose of this document

These operating instructions are designed to give technical personnel instructions on

the safe mounting, configuration, electrical installation, commissioning, operation, and

maintenance of the gateway system as well as on the connection and configuration of

the sensors.

These operating instructions do not provide information on operating vehicles or

machines into which the individual devices of the gateway system have been or are going

to be integrated. Additional information on this can be found in the customer

documentation.

1.3 Target group

These operating instructions are intended for people integrating the devices of the

gateway system into a vehicle or machine and performing initial commissioning,

operation, and maintenance.

They are also intended for the planners and integrators of the customer system, as well

as the operating entity with responsibility for it.

Tab. 2: Target group

of system components:

Page 7

7

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

1.4 Information depth

ABOUT THESE OPERATING INSTRUCTIONS 1

Note

These operating instructions contain information about the following topics related to the

profiling system:

• System description

• Mounting

• Electrical installation

• Commissioning

• Operation

• Maintenance and care

• Fault diagnosis and troubleshooting

• Technical data and dimensional drawings

When planning and using the gateway system, technical skills are also required that are

not covered by this document.

The official and legal regulations for operating the system must always be complied with.

Further information about the device components used in the gateway system can be

found in the respective operating instructions.

1.5 Abbreviations used

API

APN

CAN bus

GSM

GPRS

GPS

MQTT

SIM

TDC

Application programming interface

Access point name = access point of the network operator in the GPRS data network

Controller area network = serial bus system

Global system for mobile communications = technical wireless standard for digital

wireless telephony

General packet radio service = the name given to the packet-based service for

transmitting data within GSM networks

Global positioning system = global satellite navigation system for position determination

Message queue telemetry transport = open messaging protocol for transmitting telemetry

data between devices in the form of messages

Subscriber identity module = chip card for cell phones

Telematic Data Collector = system used to collect and transmit telemetry data

Page 8

1 ABOUT THESE OPERATING INSTRUCTIONS

8

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

1.6 Symbols used

Recommendation

Note

1. / 2. ...

Step by step

Action

Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or technical measure.

Notes provide information about the features of a device, application tips, or other useful

information.

Instructions that must be carried out in the described order are referred to as step-by-step

instructions and are indicated by numbered lists. Carefully read and follow the

instructions for taking action.

Instructions for taking action are indicated by an arrow. Carefully read and follow the

instructions for taking action.

Page 9

9

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

2 Safety

This chapter concerns your own safety and the safety of the system operator.

Please read this chapter carefully before you begin working with the gateway system.

▸

2.1 Qualified personnel

The gateway system must only be commissioned and maintained by properly qualified

personnel.

A qualified person

• has sufficient skills in the field of the respective equipment based on their technical

training and experience and

• has been instructed by the manufacturer in system operation and all applicable safety

guidelines and

• is familiar with all relevant country-specific occupational safety regulations, work safety

regulations, guidelines, and generally accepted technical rules and standards

(e.g., DIN standards, VDE regulations, country-specific rules) to such an extent that

they are able to evaluate the safe condition of the power-driven machinery, and

• has access to and has read the operating instructions.

2.2 Applications of the system

SAFETY 2

The Telematic Data Collector (TDC) gateway system is a system used to receive and

transmit telemetry data on a cloud server. It is, for example, ideal for sensor-controlled

monitoring tasks, vehicle tracking, working hours management, and access control as

well as for remote measurement.

The gateway system uses one or more TDC devices to collect data. The TDC devices

feature all of the standard interfaces that are required to integrate sensors and other

devices.

The sensor data received is transmitted to the cloud via the mobile network through either

the SICK online portal or a customer server.

The SICK online portal is a platform that can be used to visualize sensor data on a webbased user interface, allowing for convenient monitoring.

The TDC gateway system also supports the integration of recorded sensor data into all

leading business applications. Integration is an option when using either the SICK online

portal or a cloud-based customer server via an API included as part of the scope of

delivery or via the MQTT protocol in a defined topic structure.

2.3 Intended use

The gateway system may only be used by qualified personnel in the environment in which

it was mounted and initially commissioned by qualified personnel in accordance with

these operating instructions.

Note

If used in any other way or if alterations are made to the gateway system – including

in the context of mounting and installation – this will render void any warranty claims

directed to SICK AG.

Page 10

2 SAFETY

10

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

HAZARD

WARNING

WARNING

NOTE

2.4 General safety notes and protective measures

2.4.1 Safety notes and symbols

The following safety and hazard notes concern your own safety, the safety of third parties,

and the safety of the devices. You must therefore observe these symbols at all times.

Denotes an immediate hazard that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from electrical current).

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of damage to the eye by laser beams).

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

Denotes a potential risk of damage or functional impairment of the device or the devices

connected to it.

This symbol refers to supplementary technical documentation.

Page 11

11

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

2.4.2 General safety notes

WARNING

The gateway system has been designed such that it can be operated safely. Protective

devices reduce potential risks to the maximum possible extent. However, a certain level

of risk will always remain.

Awareness of potential sources of danger in the system will help you to work in a safer

manner and thus prevent accidents.

To avoid risks, please also observe the special warnings in each of the individual

chapters.

Safety notes

Observe the following to ensure the safe use of the gateway system as intended.

• The notes in these operating instructions (e.g., regarding use, mounting, or installation)

must be observed.

• All official and statutory regulations governing the operation of the gateway system

must be complied with.

• National and international legal specifications apply to the installation and use of the

system, to its commissioning, and to recurring technical inspections, in particular:

- Work safety regulations and safety rules

- Any other relevant safety provisions

• All checks must be carried out by qualified personnel or specially authorized and

commissioned personnel, and must be recorded and documented to ensure that they

can be reconstructed and retraced at any time.

• These operating instructions must be made available to the operator of the system

in which the components of the gateway system are used.

• The operator of the gateway system must be instructed by qualified personnel and

must read the operating instructions.

SAFETY 2

Page 12

2 SAFETY

12

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

HAZARD

WARNING

NOTE

WARNING

2.4.3 Potential sources of danger

Electrical current

Risk of injury and damage caused by electrical current

Improper handling of live devices may lead to severe personal injury or death by electric

shock.

Electrical installation and maintenance work must only be carried out by personnel

▸

authorized to do so.

The power supply must be disconnected when attaching and detaching electrical

▸

connections.

Select and implement wire cross-sections and their correct fuse protection in accordance

▸

with the applicable standards.

Do not touch any live parts.

▸

In the event of danger, immediately disconnect the device from the grid.

▸

Always use original fuses with the specified current rating.

▸

Report any damaged cables to the maintenance team without delay.

▸

Observe the up-to-date safety regulations when working on electrical systems.

▸

Commissioning/operation/maintenance

Risk resulting from incorrect commissioning and configuration

Do not commission until a thorough check has been performed by qualified personnel.

Before carrying out initial commissioning of the devices of the gateway system, you must

have the system checked and approved by qualified personnel.

Claims under the warranty rendered void

The housings of the devices must not be opened. The devices are sealed.

If the device is opened, any warranty claims against SICK AG will be void.

Risk resulting from faults

Cease operation if the cause of the malfunction has not been clearly identified.

Immediately deactivate the TDC device if you cannot clearly identify the fault and if you

▸

cannot safely remedy the problem.

Page 13

13

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

2.5 Protecting the environment

The components of the gateway system have been designed to minimize their impact on

the environment. They consume only little energy.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information regarding disposal.

Disposal after final decommissioning

Always dispose of unusable or irreparable devices in accordance with the applicable

▸

waste disposal regulations specific to your country.

Remove the plastic parts and recycle the aluminum housing of the TDC device.

▸

Dispose of all electronic assemblies as hazardous waste. The electronic assemblies are

▸

easy to dismantle.

Note

SICK AG does not take back devices that are unusable or irreparable.

SAFETY 2

Page 14

3 SYSTEM DESCRIPTION

14

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

3 System description

This chapter describes the layout and operating principle of the gateway system, in

particular the interaction of the different components.

Note

3.1 Scope of delivery

Always read this chapter before you mount, install, and commission the components of

the gateway system.

Depending on the installation conditions and number of interfaces required, the gateway

system uses the TDC-B100, TDC-B200 or TDC-M100 device variants. The different TDC

devices are suitable for different installation conditions and numbers of interfaces.

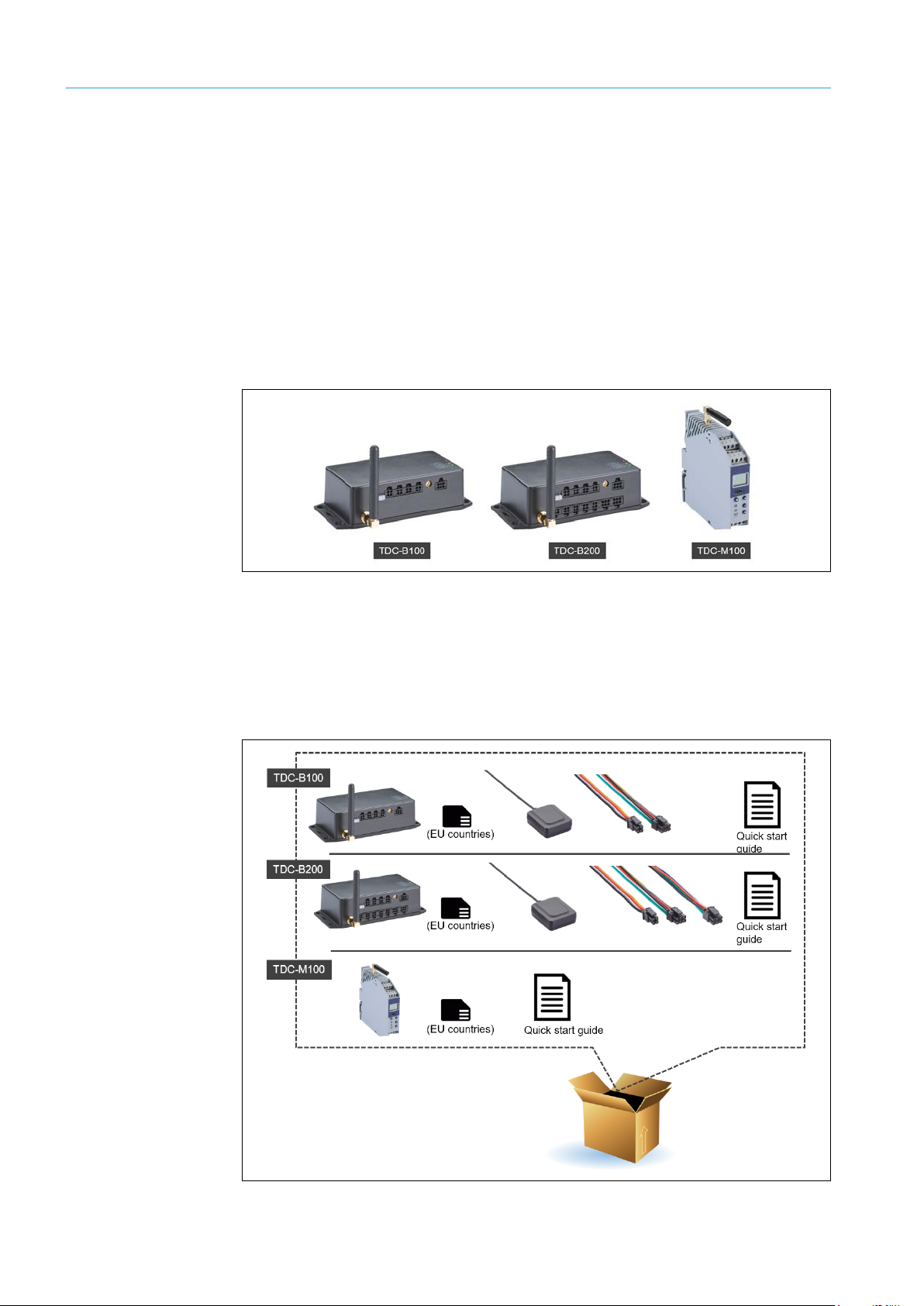

Fig. 1: TDC gateway system device variants

All TDC devices come with a GSM antenna, installed overcurrent protection device, and

SIM card inserted for operation in EU countries.

The scope of delivery for TDC devices in the B series also includes a GPS antenna, a

voltage supply cable, and cables for connecting sensors. Additional cables can be ordered

as accessories.

Fig. 2: TDC gateway system scope of delivery

Page 15

SYSTEM DESCRIPTION 3

15

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

NOTE

Number

Part No.

Description

1 TDC gateway system consisting of:

n

6064656

TDC-B100 with GSM antenna and installed overcurrent protection

TDC Configurator configuration software

n

6067023

GPS antenna

n

6067024

3-A back-up overcurrent protection device

n

6067018

RS485 connecting cable (4-pin)

and/or

n

6064657

TDC-B200 with GSM antenna and installed overcurrent protection

configuration software

n

6067023

GPS antenna

n

6067024

3-A back-up overcurrent protection device

n

6067019

INPUT cable (6-pin)

A quick start guide is also included as part of the scope of delivery to provide assistance

at the initial commissioning stage. The quick start guide also includes a download link

for the operating instructions, system documentation, interface specifications, and TDC

Configurator configuration software.

Fig. 3: Quick start guide including download link for the documentation and configuration

Basic inspection for completeness and damage

It is recommended that you carefully check for and report transport damage of any kind

as soon as possible after receiving the system.

Also verify that the delivery includes all components listed on the delivery note.

▸

▸

software

Report any incomplete or damaged deliveries to Customer Service.

Always document the damage by taking photographs.

device

SIM card inserted for operation in EU countries

Quick start guide including a download link for the operating

instructions, system documentation, interface specifications, and

1 cable set consisting of:

Cable for the voltage supply and connection of a peripheral device

to two digital inputs (6-pin)

device

SIM card inserted for operation in EU countries

Download link for the operating instructions, system

documentation, interface specifications, and TDC Configurator

1 cable set consisting of:

Cable for the voltage supply and connection of a peripheral device

to two digital inputs (6-pin)

RS485 connecting cable (4-pin)

Page 16

3 SYSTEM DESCRIPTION

16

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Number

Part No.

Description

and/or

n

6065413

TDC-M100 with GSM antenna and installed overcurrent protection

TDC Configurator configuration software

n

6067024

3-A back-up overcurrent protection device

Part No.

Description

TDC-B100 / TDC-B200

6066259

Cable for connecting the TDC-B100 to a configuration PC, Micro-Fit USB

Drivers are included in the configuration software

TDC-M100

6066258

Cable for connecting the TDC-M100 to a configuration PC, Micro-Fit USB

Drivers are included in the configuration software

Tab. 3: TDC gateway system scope of delivery

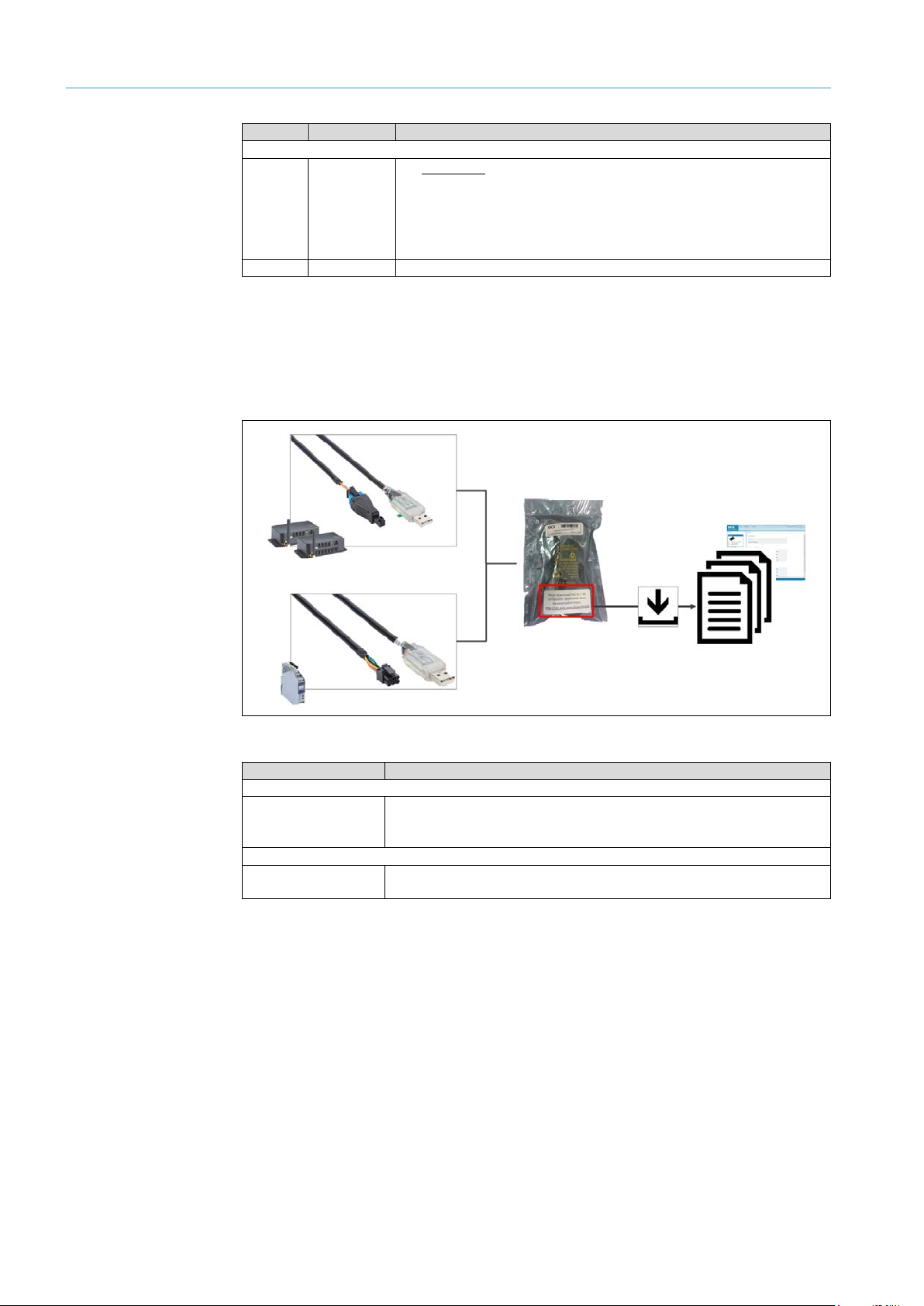

Configuration cables (optional)

There is an optional configuration cable available for all device types that can be used to

connect the TDC device to a configuration PC. The label on the packaging also includes

the link with the access data for the documentation and configuration software.

device

SIM card inserted for operation in EU countries

Quick start guide including a download link for the operating

instructions, system documentation, interface specifications, and

Fig. 4: Configuration cables (optional)

(6-pin)

Tab. 4: Configuration cables (optional) – part numbers

Page 17

SYSTEM DESCRIPTION 3

17

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Part No.

Description

TDC-B100

6067018

1 cable set consisting of:

(included in delivery)

6067022

1 cable set with 3 cables (UART/USB, CAN1, DIAG)

TDC-B200

1 cable set consisting of:

(included in delivery)

6066260

1 cable set with 9 cables (UART, CAN1, DIAG, RS-232, OUTPUTS,

1Wire, USB, CAN2, FULL RS-232)

Part No.

Description

6066264

LLS30160-700mm-RS232/485 fuel level sensor with mounting kits,

connecting cable, and quick start guide.

Part No.

Description

5337537

SIM card (for operation in EU countries)

6067024

MINI ATO overcurrent protection device, 32 V, 3 A, 0297003. L

5337536

EAD PST2100SMA RA GSM antenna, penta band

6067023

GPS antenna (only TDC-B100/TDC-B200)

Additional cables (optional)

Preconfigured cables can be obtained for connecting sensors and devices to TDC devices

in the B series.

TDC PWR+2IN – 90 cm, Micro-Fit 4-pin, open ends

TDC RS485 – 30 cm, Micro-Fit 4-pin, open ends

TDC PWR+2IN – 90 cm, Micro-Fit 4-pin, open ends

TDC RS485 – 30 cm, Micro-Fit 4-pin, open ends

TDC INPUTS – 30 cm, Micro-Fit 6-pin, open ends

Tab. 5: Additional connecting cables (optional) – part numbers

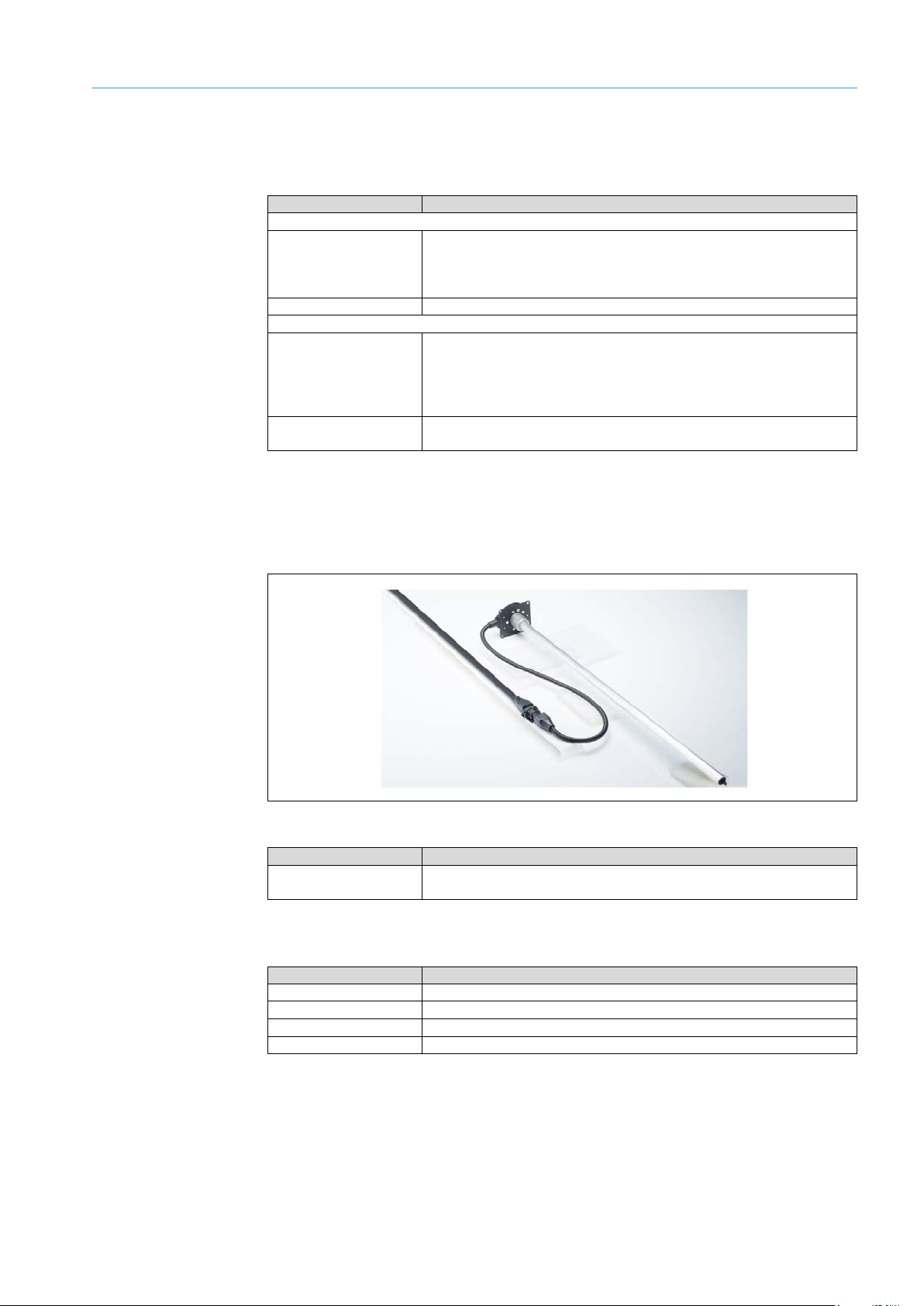

Fuel level sensor for TDC-B200 (optional)

A fuel level sensor manufactured by Omnicomm is available as an optional accessory for

the TDC-B200 device.

Fig. 5: Fuel level sensor (optional)

Tab. 6: Fuel level sensor (optional) – part number

Spare parts

Tab. 7: Spare parts – part numbers

Page 18

3 SYSTEM DESCRIPTION

18

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

3.2 System components

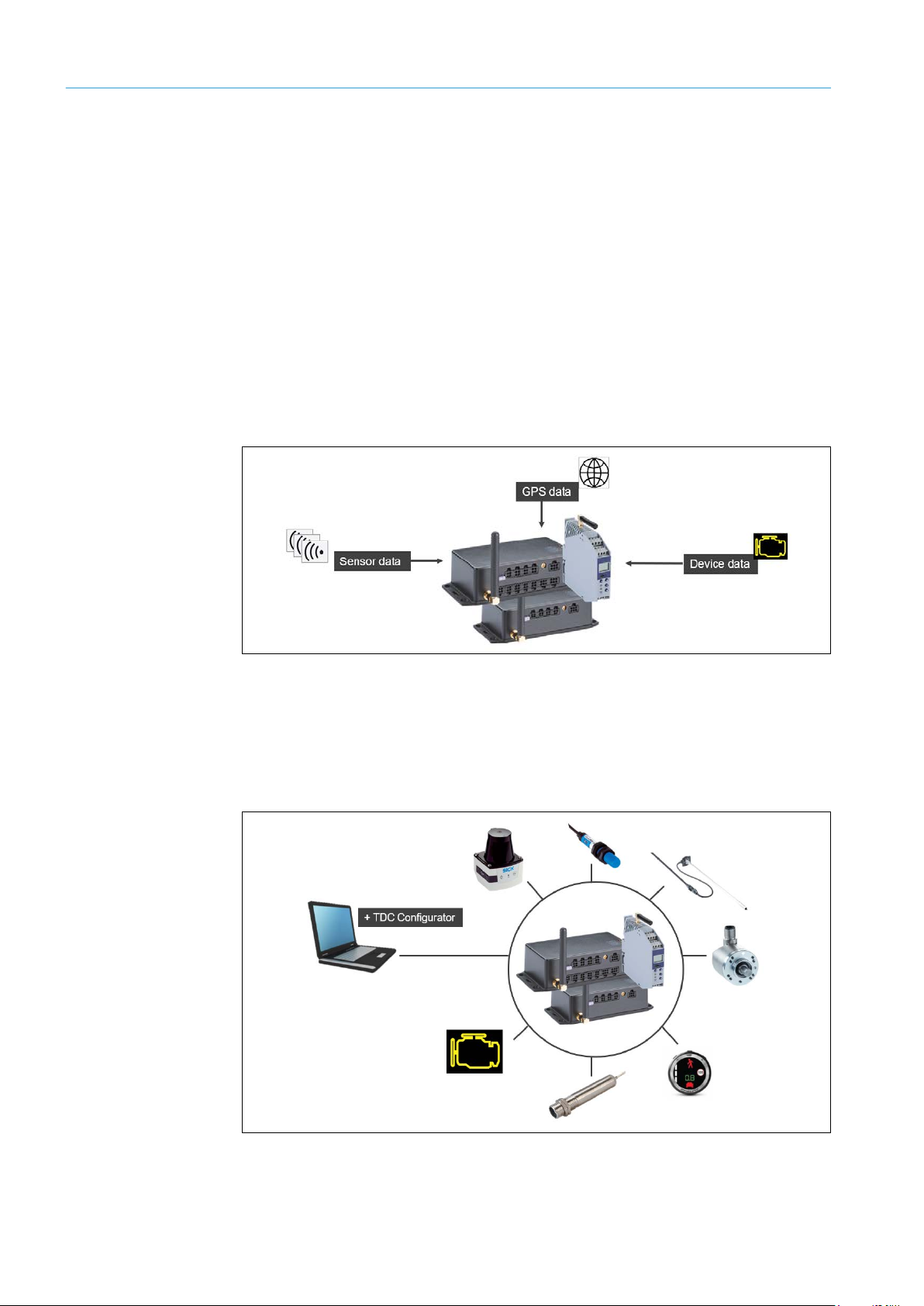

3.2.1 TDC devices – collecting and transmitting sensor data

The gateway system uses TDC devices to receive and transmit sensor data.

• As a receiver, the TDC device collects data from connected sensors and devices.

• As a sender, the TDC device transmits the sensor data received to the cloud via the

mobile network.

3.2.1.1 The TDC device as a receiver

A TDC device will generally receive sensor data from a vehicle or a machine. For this to

happen, the sensors are connected to the TDC device via appropriate interfaces.

The TDC device also has built-in sensors that are used to detect the movement of the

vehicle. This movement data can be output along with GPS data (this only applies to TDC

devices of the B series). A GPS antenna is included in the scope of delivery for these

devices.

Fig. 6: The TDC device as a sensor data receiver

Which sensors and devices can be integrated?

The TDC device features all of the standard interfaces that are required to integrate

sensors and other devices. Digital, analog, and CAN bus-based signals can be processed.

The interfaces are configured via the TDC Configurator configuration software included in

the scope of delivery.

Fig. 7: TDC device interfaces for the integration of sensors

Page 19

19

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

• SICK sensors of the TiM series detect the presence of an object within a specified area

(detection). They are ideally suited for monitoring the area around a vehicle, for

instance. If an object is detected in the monitored area, the result is output via the

digital output.

• Capacitive level sensors (such as those from the company Omnicomm) are used for

the level measurement of fuels and oils. When using a capacitive measuring method,

an insulated measurement electrode forms an electric capacitor with the medium

surrounding it. As the level and in turn the capacitance decreases, the latter is analyzed

by electronics and communicated by an electrical signal.

• Capacitive proximity sensors, such as SICK sensors of the CM series, can detect all

kinds of materials beyond a surface. This allows a minimum level to be detected, for

example.

• A TDC device can also process signals from other devices or motors. Vehicle activities

can be traced upon connection to the ignition system.

3.2.1.2 The TDC device as a sender

When using the SICK online platform, the TDC device transmits the sensor data received

to the SICK cloud server in real time. This happens automatically via the mobile network

using the SIM card inserted into the TDC device.

If a cloud-based customer server is used instead of the SICK online portal, it is not

possible to transmit the sensor data directly. However, there is the option to access the

data on the customer server using the MQTT interface of the device in question.

The TDC device alarm management system can be configured and used to trigger a realtime alarm in the form of SMS messages via input signals.

SYSTEM DESCRIPTION 3

Fig. 8: The TDC device as a sensor data sender

Page 20

3 SYSTEM DESCRIPTION

20

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Permanent data transmission in online mode

The TDC device is connected to a voltage supply and permanently supplied with voltage.

It is also always connected to the mobile network via the SIM card. The GPRS access data

for the SICK online portal is shared with the device through the TDC Configurator

configuration software.

This means that the TDC device is always online, regardless of whether the vehicle or

machine into which the TDC is installed has been started up or not. Sensor data is

therefore always transmitted in real time – even when the motor is not running. Given an

appropriate connection to the TDC device, starting up a motor or machine would therefore

constitute a signal in itself, which could then be transmitted and analyzed.

Data storage in offline mode

If there is no mobile signal, the data received from the connected sensors is stored on the

internal device memory. No matter how many sensors are connected, sensor data can be

stored for up to one month.

Note

If the device is not connected to a voltage supply, it will not be possible to save sensor data.

The TDC device will be back online as soon as a connection to the mobile network is

reestablished, and at this point the sensor data that has been saved will be transmitted

automatically to the SICK online portal. When using an internal customer server, it will be

possible to access data again once the connection has been restored.

Fig. 9: Data storage on the TDC device in offline mode

If the connection to the mobile network is interrupted for longer than one month, the data

stored on the internal device memory will be overwritten in line with the FIFO (first in, first

out) principle. What this means is that the data that was stored first will be the first to be

overwritten.

This principle ensures that the data from the last four weeks is always available – even

when the connection to the mobile network is interrupted for a prolonged period of time.

Device logging

TDC device activity, such as when a voltage supply is connected or the mobile network is

accessed, is reported to the SICK online portal.

Using the notification management system, the SICK online portal can issue a message

in the event of a mains voltage failure or a failure of the mobile network (for further

information on this, please also refer to Chapter 3.2.2.3 Visualization and monitoring).

Page 21

21

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

3.2.2 Processing and visualizing sensor data on the SICK online portal

The SICK online portal is a standard cloud solution. It is the central platform used for

processing and visualizing the delivered sensor data.

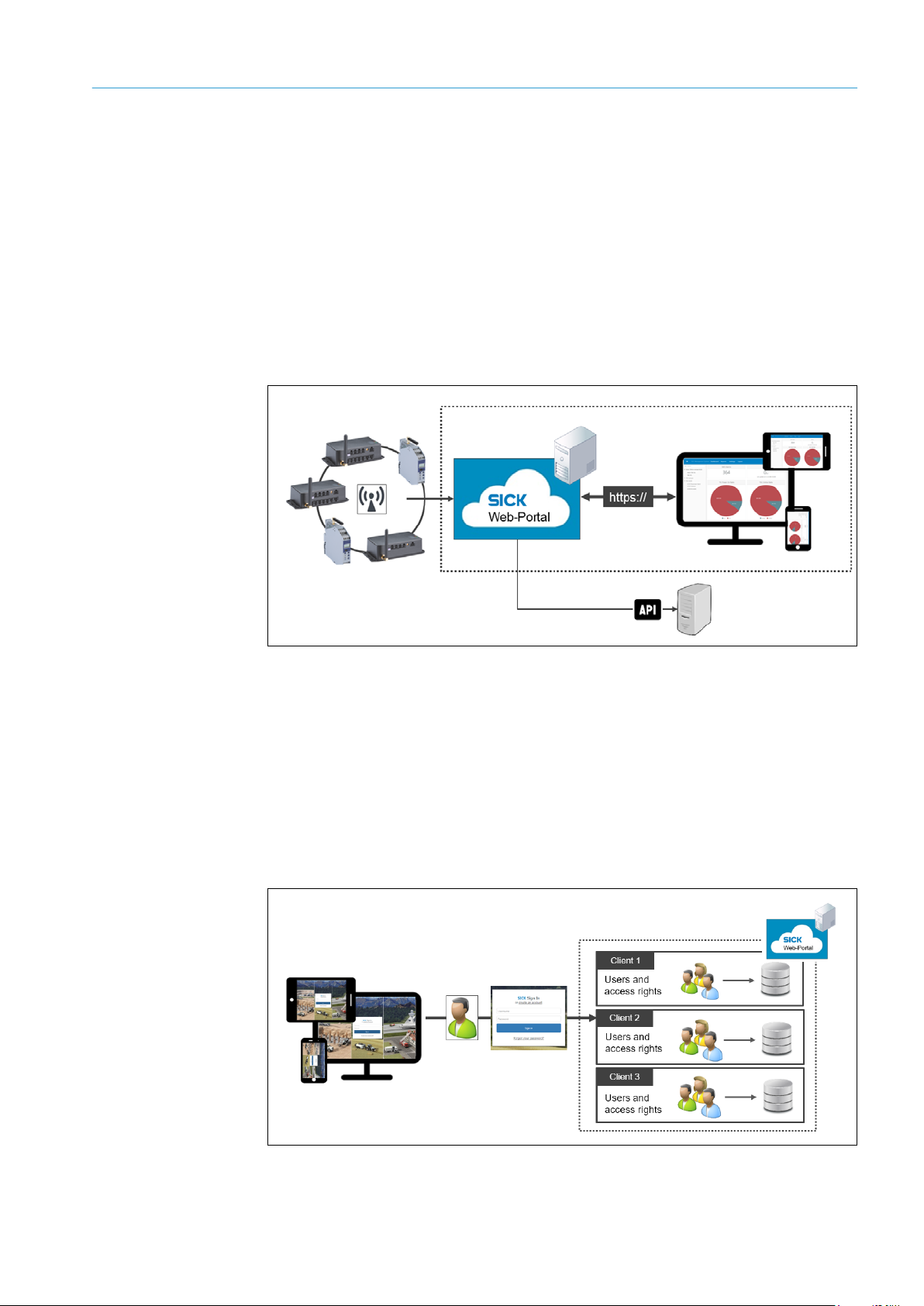

3.2.2.1 Components of the SICK online portal

The cloud server receives and stores the sensor data transmitted by an individual TDC

device.

The data can be visualized in real time on a web-based user interface. Sensor data can be

accessed from any computer or mobile device by logging in to the portal site. All common

web browsers are supported.

Sensor data can then be transferred to a customer application using an API interface.

SYSTEM DESCRIPTION 3

Fig. 10: Components of the SICK online portal

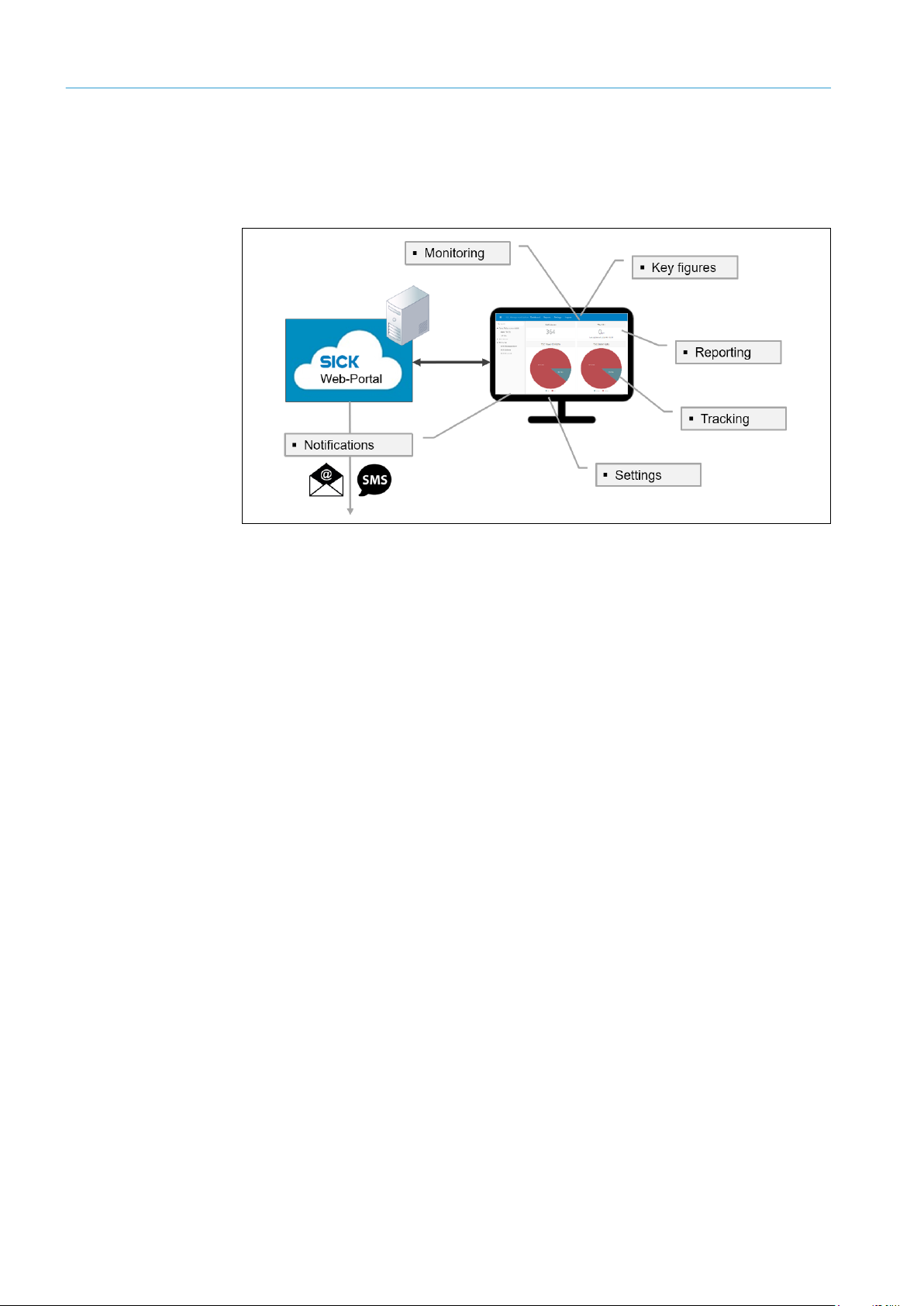

3.2.2.2 Multi-client capability and access rights

The cloud solution has multi-client capability, which allows the SICK online portal to be

used by multiple clients on the same server, with each client only being able to view and

edit their own data.

The SICK online portal is accessed from a browser using the URL of the cloud server.

Users must log in using a user name and password.

At the client level, the SICK online portal also supports various user levels with

corresponding access rights as far as sensor data and program functions are concerned.

Fig. 11: Multi-client capability and access rights on the SICK online portal

Page 22

3 SYSTEM DESCRIPTION

22

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

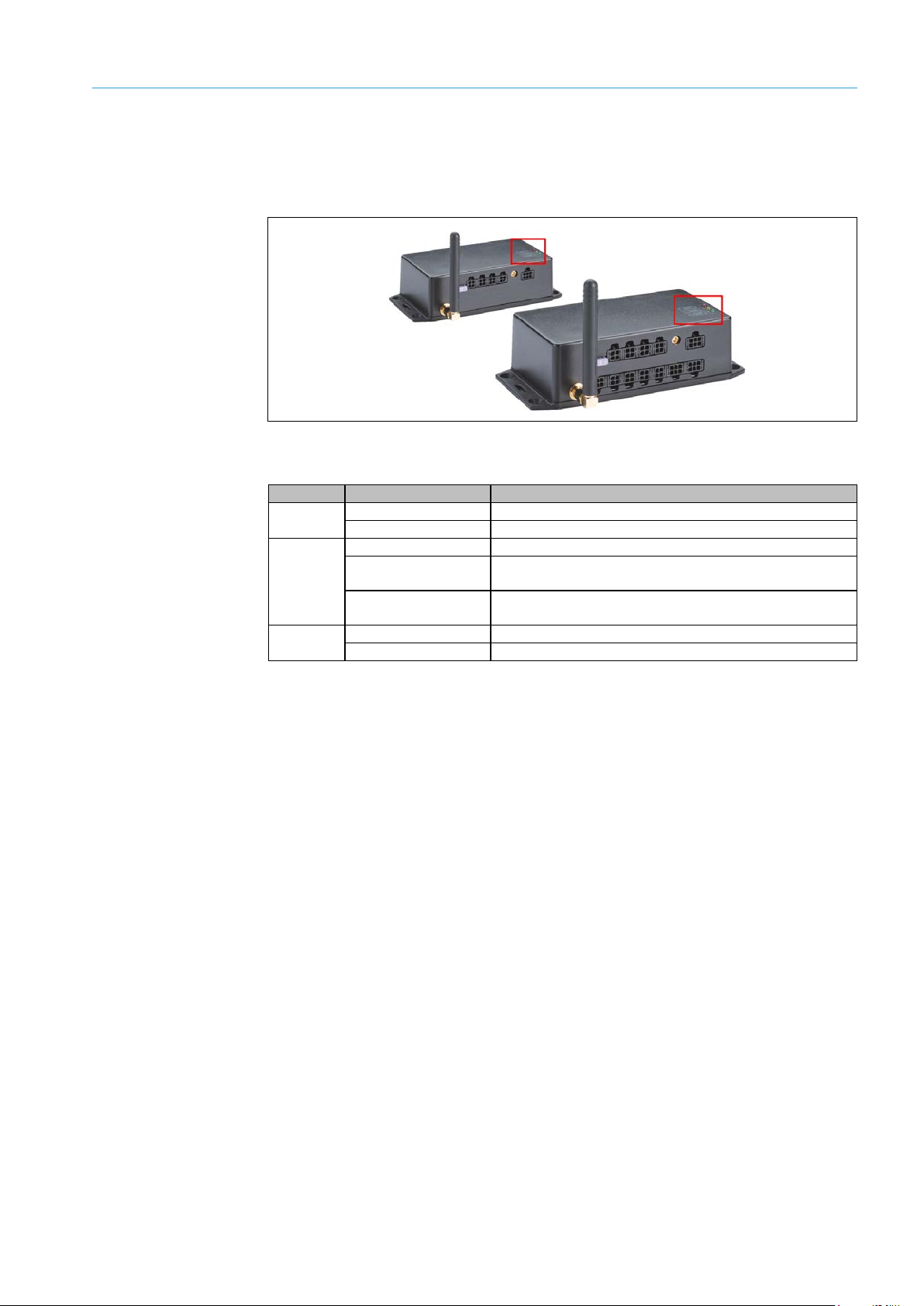

3.2.2.3 Visualization and monitoring

Viewing a graphical overview of the data on the SICK online portal allows for vehicle

activity, fuel levels, and even suspicious movements or potential collision hazards in the

vicinity of vehicles and machines to be monitored effectively.

Fig. 12: Visualization of sensor data and monitoring on the SICK online portal

Information is condensed in the form of key figures for the purposes of aiding the

decision-making process, controlling and monitoring measures, or running comparisons

within a company or across multiple companies.

Comprehensive reporting helps in the analysis and assessment of sensor data – even

over a prolonged period. Custom reports can be defined.

In addition to the alarm management system specific to the TDC device, the SICK online

portal also has its own notification system that issues messages in line with rules that

can be freely defined and displays them in the portal message center based on the user

and/or user group.

The automated notifications issued by the system can also be sent in e-mail or SMS

format via the integrated e-mail server for the SICK online portal.

Page 23

23

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

3.3 Interfaces for integration into customer applications

The system solution supports the integration of recorded sensor data into all leading

business applications (ERP, CRM OMD, BI, etc.).

There are two options available for integration, which is possible regardless of whether

the SICK online portal or a cloud-based customer server is used.

Transferring data from the SICK cloud via an API

If the SICK online portal is used to process and visualize the sensor data, the data can

be transferred directly from the SICK online portal to a customer application. The data is

transferred via a programming interface (API) included in the scope of delivery.

This programming interface grants access to the software logic of the SICK online portal,

allowing files and content to be processed further among different programs.

Communication with the API uses the REST standard protocol in XML data format.

SYSTEM DESCRIPTION 3

Note

Fig. 13: Transferring data from the SICK cloud to a customer application via an API

For further information on the methods used with the API, refer to Chapter 7.4

Transferring data to a customer application using an API interface.

Accessing data from the TDC device via MQTT

If a customer's own server is used instead of the SICK online portal, it is not possible to

transmit the sensor data directly from the TDC device to the server. Data can only be

accessed using the MQTT interface.

MQTT is a special publish-subscribe-based messaging protocol. Here topics are set up by

the user, which are then used by clients (in the role of a publisher) to prepare messages

and by other clients (in the role of a subscriber) to receive messages.

On the basis of this principle, communication takes place via a central hub known as the

MQTT message broker. Each message sent by a client includes a topic with the data.

Every MQTT client that wants to receive messages for the topic must subscribe to them

through the message broker.

Whenever there are new messages, interested clients will be notified by the broker,

ensuring efficient communication with the subscribers. However, the individual clients are

only familiar with the message broker and not the other subscribers.

Page 24

3 SYSTEM DESCRIPTION

24

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Within the system, the TDC device takes on the role of the publisher. It sends topics

with sensor data to the mobile network in a defined structure via the MQTT protocol.

The customer server subscribes to this data. Messages can be accessed and further

processed by this server using the defined topic structure.

Fig. 14: Accessing data from the TDC device via MQTT

Note

For more information on the topic structure of the MQTT interface, refer to Chapter 7.5

Accessing data from the TDC device via the MQTT interface.

Page 25

25

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

3.4 Status indicators for the TDC devices

LED

Color

Meaning

Red (permanent)

No valid GPS signal found or no GPS antenna connected.

Red (periodical)

GPS signal found.

Yellow (permanent)

Device not connected to the mobile network.

Yellow (periodical

with a pulse)

Device connecting to the mobile network.

Yellow (periodical

with two pulses)

Device connected to the mobile network.

OFF

Device switched off or booting.

Green (permanent)

Device switched on.

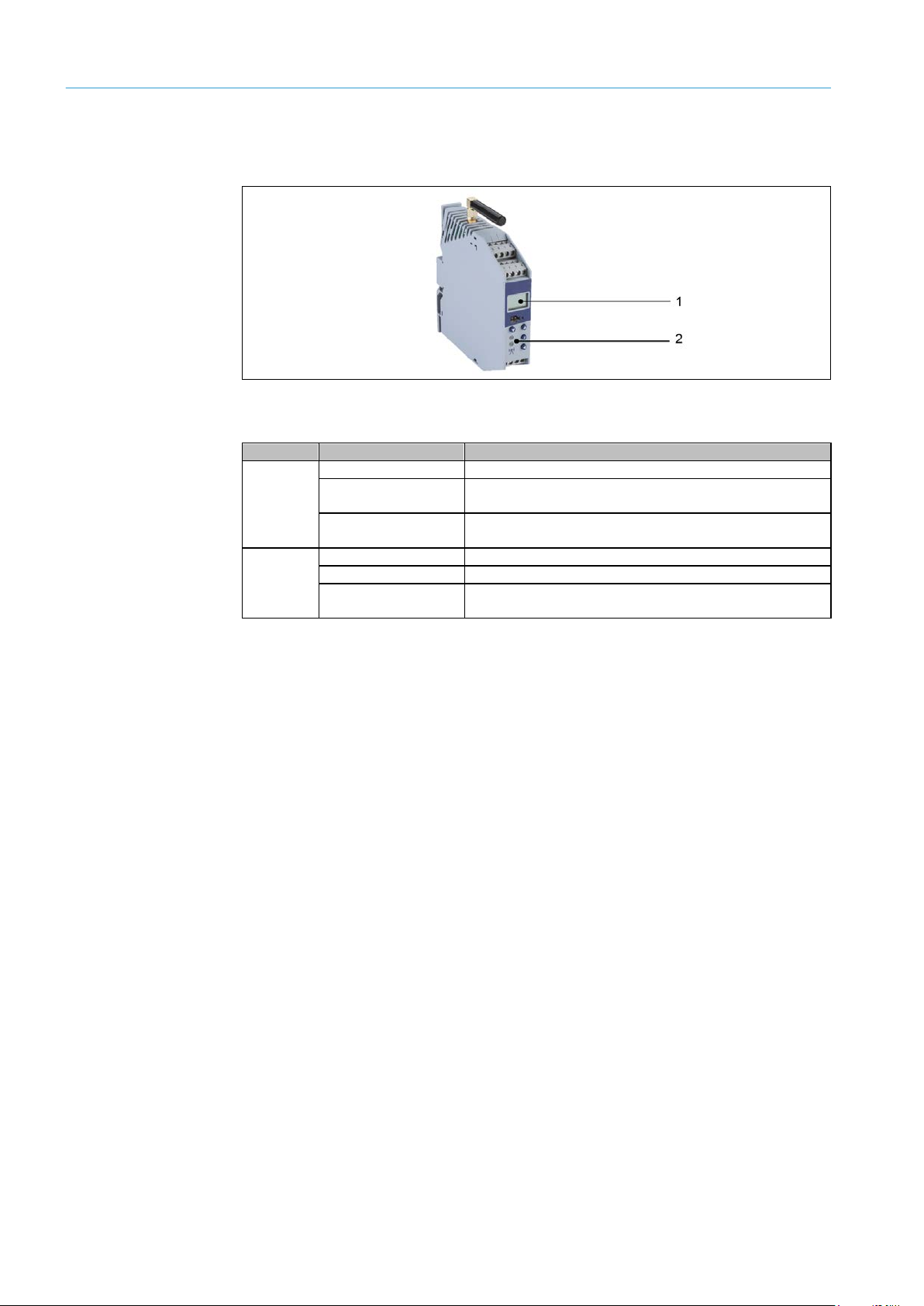

3.4.1 TDC-B100/TDC-B200

The TDC-B100 and TDC-B200 devices each have three status LEDs.

Fig. 15: TDC-B100/TDC-B200 status indicators

The LEDs have the following meanings:

SYSTEM DESCRIPTION 3

GPS

COM

PWR

Tab. 8: TDC-B100 / TDC-B200 status indicators

Page 26

3 SYSTEM DESCRIPTION

26

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

LED

Color

Meaning

Yellow (permanent)

Device not connected to the mobile network.

Yellow (periodical

with a pulse)

Device connecting to the mobile network.

Yellow (periodical

with two pulses)

Device connected to the mobile network.

Off

Device switched off or booting.

Red (permanent)

Counter has no reference.

Red/green

(alternating)

Counter reference OK.

3.4.2 TDC-M100

The TDC-M100 device has a 7- and 16-segment display (1) and two LEDs (2).

Fig. 16: TDC-M100 status indicators

The LEDs have the following meanings:

LED 1

Note

LED 2

Tab. 9: TDC-M100 status indicators

Manual operation and configuration of the TDC device using the four pushbuttons on the

front of the device is visualized on the two-line display.

Page 27

27

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

4 Mounting

WARNING

WARNING

Note

MOUNTING 4

The TDC device should be mounted as close as possible to the battery for connection to

the voltage supply or close to the electrical installation for the connection of peripherals.

A SIM card for operation in EU countries and a 3-A fuse are already included in the TDC

devices.

Be sure to closely observe the following notes during mounting:

Mount the TDC device so that it is protected from dirt and mechanical damage.

Use a cover plate where possible.

We recommend installing the device in a connection box with PG connectors to ensure

compliance with protection class IP65.

4.1 Inserting the SIM card (not EU countries or for MQTT operation)

If the TDC device is being operated in an EU country in conjunction with the SICK cloud,

the SIM card inserted at the factory can be used for data transmission.

If the device is being operated in a country outside of the EU, the customer will have to

insert a SIM card from their telecommunications provider.

Note

Only use M2M SIM cards.

Ensure the device is switched off before inserting a SIM card.

Page 28

4 MOUNTING

28

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

TDC-B100/TDC-B200

1. Loosen and remove the four screws on the bottom of the device.

2. Push the SIM card holder to release the catch and fold it up. Follow the red arrows.

3. Remove the SIM card that was inserted for operation within the EU at the factory and

insert a SIM card from your telecommunications provider into the SIM card holder with

the contacts facing down.

4. Close the fixing plate to hold the SIM card in place in the SIM card holder (follow the

arrows).

5. Fold the SIM card holder down to close it, pushing it down firmly to activate the catch.

Follow the red arrows.

Page 29

29

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Note

MOUNTING 4

TDC-M100

1. Remove the plastic cover with the display and navigation buttons.

Be aware of the two spacers between the plastic covers.

2. Open the device by pulling the two sides of the plastic housing out of the plastic

brackets and separating them from one another.

3. Remove the whole PCB.

4. Lift up the SIM card holder a little.

Remove the SIM card that was inserted for operation within the EU at the factory and

insert a SIM card from your telecommunications provider into the SIM card holder with

the contacts facing down.

5. Fold the SIM card holder down to close it, pushing it down firmly to lock it.

6. Insert the PCB back into the housing.

7. Reassemble the two sides of the plastic housing..

8. Insert the spacers and mount the plastic cover with the display.

Page 30

4 MOUNTING

30

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

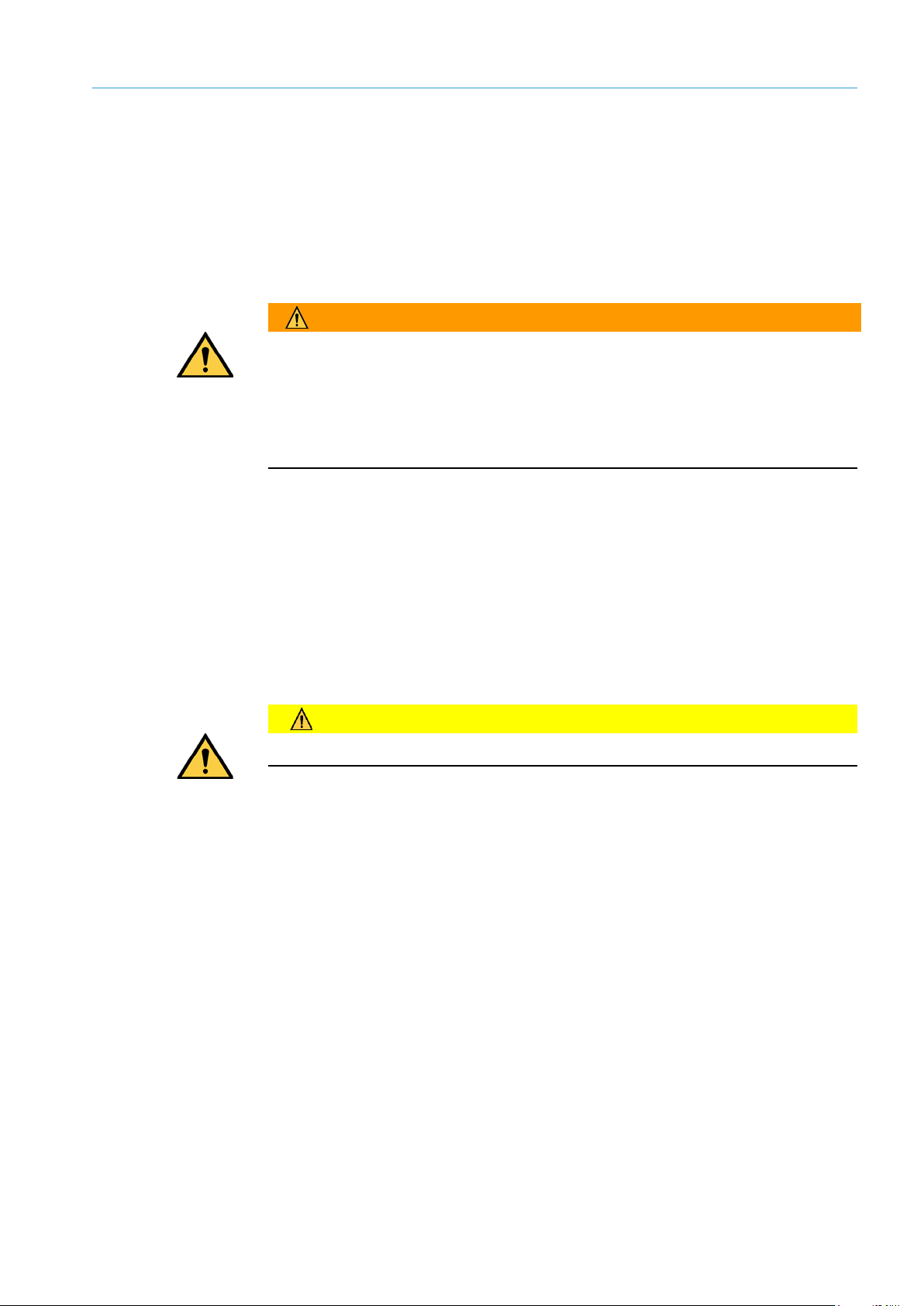

4.2 Mounting the TDC-B100/200

Use the mounting holes on the bottom of the device for the mounting process.

Fig. 17: Mounting the TDC-B100 /TDC-B200

Mounting on a plate

Mount the device using four M4 pan-head screws.

▸

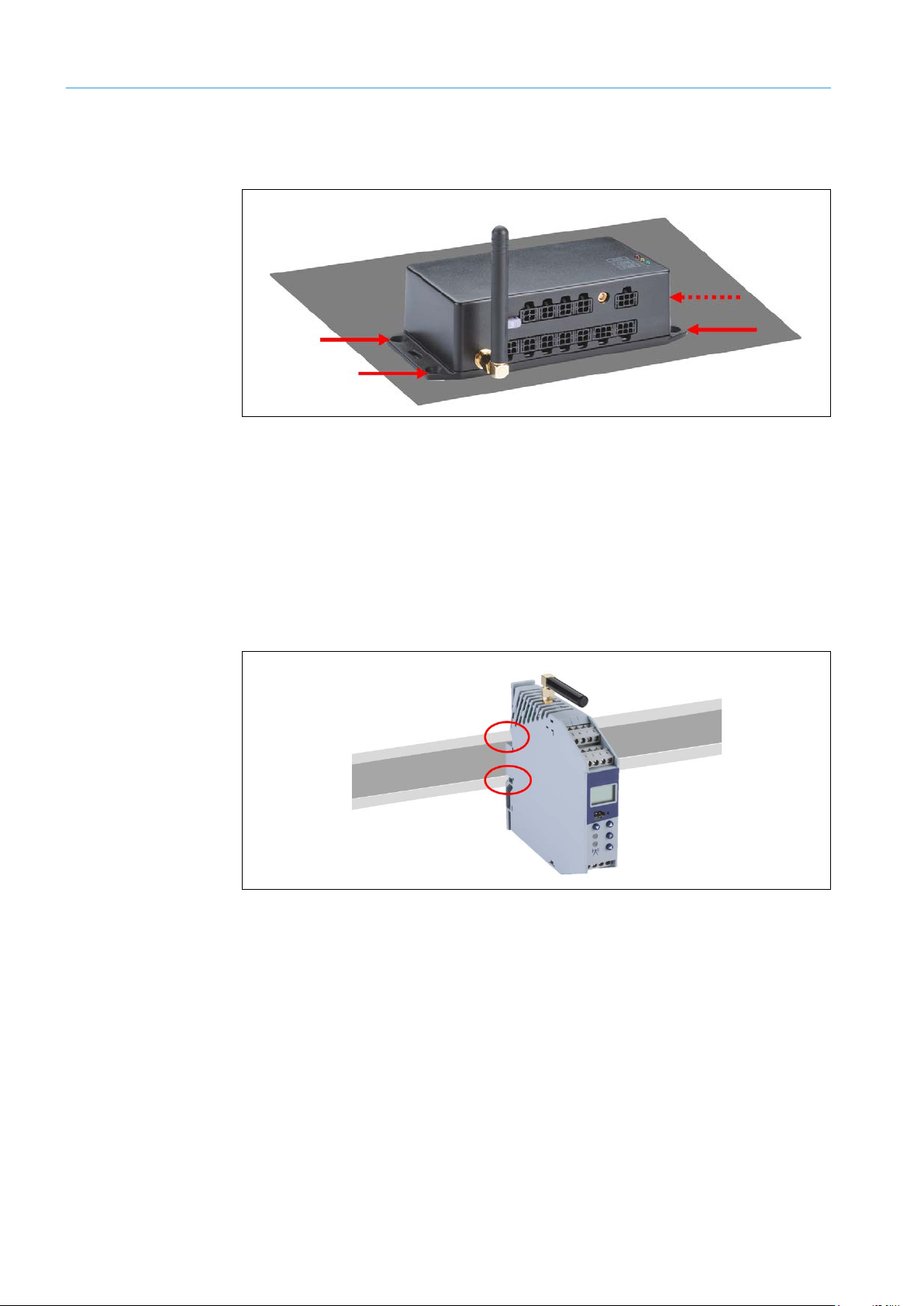

4.3 Mounting the TDC-M100

The TDC-M100 device is designed to be mounted in a control cabinet. This device variant

is mounted on a mounting rail. Any mounting orientation will be suitable.

Fig. 18: Mounting the TDC-M100

Mounting on a mounting rail

1. Position the device from above with the bracket on the mounting rail.

2. At the same time, push on the front of the device in the direction of the mounting rail

until you hear the device click into place.

Page 31

31

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

5 Electrical installation

5.1 Connecting TDC devices

5.1.1 Connectors on the TDC devices

Depending on the device variant, the TDC devices have clamp or plug connectors with

four or six pins.

ELECTRICAL INSTALLATION 5

Fig. 19: Connections to the TDC devices (overview)

For details about the pin assignments, please refer to the operating instructions for the

specific devices concerned.

Page 32

5 ELECTRICAL INSTALLATION

32

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

PWR

Pin

Wire color

Connection

3

Black

GND

4

Red

DC-IN

5.1.2 Connecting the TDC device to the voltage supply

A TDC device is connected to the vehicle battery to guarantee that it is permanently

supplied with voltage.

A 4-wire connecting cable is used for the connection. Two wires here help with the

connection to the voltage supply, while the two other wires are used to also connect

a sensor and/or to connect the TDC device to the motor ignition system (see below).

Connecting the TDC-B100 / TDC-B200 to the voltage supply

The 4-wire connecting cable has a Micro-Fit plug connector on one side for the connection

to the device and open ends on the other side for the connection to the voltage supply.

Fig. 20: Connecting the TDC-B100 / TDC-B200 to the voltage supply

1. Plug the Micro-Fit male connector on the connecting cable for the TDC device into the

PWR female connector.

2. Use the red and black wires of the connecting cable to connect the TDC device to the

voltage supply:

Tab. 10: Connecting the TDC-B100 /TDC-B200 to the voltage supply

Page 33

ELECTRICAL INSTALLATION 5

33

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Pin

Wire color

Connection

13

Red

DC-IN

14

Black

GND

Connecting the TDC-M100 to the voltage supply

The 4-wire connecting cable has open ends on both sides.

Fig. 21: Connecting the TDC-M100 to the voltage supply

Use the red and black wires of the connecting cable to connect the TDC device to the

▸

voltage supply:

Tab. 11: Connecting the TDC-M100 to the voltage supply

Page 34

5 ELECTRICAL INSTALLATION

34

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

PWR

Pin

Wire color

Connection

2

Yellow

IN A/IGN

Pin

Wire color

Connection

15/16

Yellow

Digital input

5.1.3 Connecting the TDC device to the ignition system

If you want to find out whether or not the vehicle motor is running, connect the TDC device

to the ignition system. The motor signal is processed by the TDC device via a digital input.

A wire of the connecting cable for the voltage supply is used for the connection.

Connecting the TDC-B100/TDC-B200 to the ignition system

Fig. 22: Connecting the TDC-B100 /TDC-B200 to the ignition system

1. If you have not already done so, plug the Micro-Fit male connector on the connecting

cable for the TDC device voltage supply into the PWR female connector.

2. Use the yellow wire to connect the TDC device to the ignition system.

Tab. 12: Connecting the TDC-B100 /TDC-B200 to the ignition system

Connecting the TDC-M100 to the ignition system

Fig. 23: Connecting the TDC-M100 to the ignition system

Use the yellow connecting cable to connect the TDC device to either the IN-E or IN-F

▸

input.

Tab. 13: Connecting the TDC-M100 to the ignition system

Page 35

35

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

5.1.4 Connecting the TDC device to SICK sensors

Pin

Wire color

Connection

1

Blue

IN C 2 Pink

IN D

3

Gray

IN D 4 Violet

IN F

5

White

IN G 6 Brown

IN H

SICK sensors are usually connected to the TDC device via two digital inputs. Depending on

how many sensors are connected to the TDC device, use the two wires of the connecting

cable for the voltage supply (TDC devices in the B series only) or a suitable INPUT cable

for the connection.

The wires are to be connected by the customer to the connecting cable of the relevant

sensor via a compatible Micro-Fit adapter (4- or 6-pin).

Voltage can be supplied to the sensor via the voltage supply to the CAN bus or the RS485

bus.

Note

The TDC devices also feature interfaces that can be used to connect sensors from thirdparty providers.

For additional information on the connection, please see the operating instructions for the

relevant TDC device or sensor.

Connecting the TDC-B100/TDC-B200 to a sensor

ELECTRICAL INSTALLATION 5

Fig. 24: Connecting the TDC-B100 /TDC-B200 to SICK sensors

1. Plug the Micro-Fit male connector on the connecting cable for the TDC device into the

Input female connector.

2. For each sensor, connect two wires to the connecting cable of the corresponding

sensor via an adapter.

Inputs

Tab. 14: Connecting the TDC-B100 /TDC-B200 to SICK sensors

Page 36

5 ELECTRICAL INSTALLATION

36

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

CAN1

Pin

Wire color

Connection

CAN2

RS485

PWR

Pin

Wire color

Connection

1

White

IN B

2

Yellow

IN A/IGN

CAN1

Pin

Wire color

Connection

CAN2

RS485

3. Plug the male connector on the CAN/RS485 connecting cable for the TDC device into

the RS485, CAN1, or CAN2 female connector.

4. For each sensor, connect pin 4 of the cable to the connecting cable of the corresponding

sensor via an adapter. Voltage will then be supplied to the sensor.

4 Blue DOUT CAN1

4 Blue DOUT CAN2 (TDC-B200 only)

Note

4 Blue DOUT RS485

Tab. 15: Connecting the TDC-B100 /TDC-B200 to SICK sensors (voltage supply)

For the TDC-B200, the yellow and white wires of the connecting cable for the voltage

supply can also be used for signal transmission for one sensor. For the TDC-B100, this

is the only possible variant.

In addition, the sensor needs to be connected to an output for the voltage supply as

described.

4 Blue DOUT CAN1

4 Blue DOUT CAN2 (TDC-B200 only)

4 Blue DOUT RS485

Tab. 16: Connecting the TDC-B100 /TDC-B200 to one SICK sensor via the cable for the voltage

supply

Page 37

37

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Pin

Connection

9/10

Configured as digital inputs for signal transmission

5/1

Voltage supply output for connected sensors

Pin

Connection

15

IN-E digital input

16

IN-F digital input

5/1

Voltage supply output for connected sensors

Note

ELECTRICAL INSTALLATION 5

Connecting the TDC-M100 to a SICK sensor

Fig. 25: Connecting the TDC-M100 to SICK sensors

1. Connect the two wires of the connecting cable for the TDC device to two digital inputs.

If you use the I/O connections, you must ensure that they have been configured as

inputs.

2. Connect one wire of the connecting cable for the TDC device to the DOUT CAN1 or

DOUT RS485 input. Voltage will then be supplied to the sensor.

3. Connect the wires to the connecting cable of the sensor via an adapter.

Note

11/12

Tab. 17: Connecting the TDC-M100 to SICK sensors

The yellow and white wires of the connecting cable for the voltage supply can also

be used for signal transmission for one sensor. In addition, the sensor needs to be

connected to an output for the voltage supply as described.

Tab. 18: Connecting the TDC-M100 to one SICK sensor via the cable for the voltage supply

Page 38

5 ELECTRICAL INSTALLATION

38

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

RS485

Pin

Wire color

Connection

1/2

Blue

RS485 A / RS485 B

3

White

GND

4

Brown

PWR-OUT

5.1.5 Connecting fuel level sensors

Fuel level sensors manufactured by Omnicomm are connected to the TDC device via

the RS485 interface. The device is supplied with all the required connecting cables.

Note

On the basis that TDC-M100 TDC devices cannot supply GPS information revealing the

vehicle location, it is recommend that the fuel level sensor is only operated with TDCB100 /TDC-B200 TDC devices. Otherwise, the signal from the fuel level sensor for the

TDC-M100 will only be supplied with a time stamp and no position determination.

Use the connecting cable included in the delivery.

▸

Fig. 26: Connecting the TDC-B100 /TDC-B200 to fuel level sensors

1. Plug the Micro-Fit male connector on the connecting cable for the TDC device into the

RS485 female connector.

2. Connect the wires of the connecting cable to the fuel level sensor via an adapter as

follows:

Tab. 19: Connecting the TDC-B100 /TDC-B200 to fuel level sensors

Page 39

39

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

5.2 Screwing on the GSM antenna

The GSM antenna is not installed at the factory. It needs to be screwed on before the

devices are commissioned.

Fig. 27: Screwing on the GSM antenna

1. Hold the device in place with one hand.

2. Place the GSM antenna on the antenna connector on the TDC device.

3. Screw the GSM antenna clockwise onto the antenna connector on the device.

ELECTRICAL INSTALLATION 5

5.3 Connecting the GPS antenna

The GPS antenna is usually installed in the driver's cab with clear visibility upward or in

the vehicle roof area.

Have an expert install the connecting cable in the vehicle depending on where exactly the

antenna is being installed and connect this to the TDC-B100/TDC-B200 device via the

Cinch male connector.

Note

The TDC-M100 device cannot supply any GPS information, as there is no connector for

a GPS antenna.

Connecting the GPS antenna to the TDC-B100 /TDC-B200

Fig. 28: Connecting the GPS antenna to the TDC-B100 /TDC-B200

Plug the Cinch male connector on the connecting cable for the TDC-B100/TDC-B200

▸

device into the GPS female connector.

Page 40

6 COMMISSIONING

40

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

HAZARD

HAZARD

6 Commissioning

6.1 Launching the TDC devices

Establish the voltage supply for the TDC devices. All sensors connected to the TDC device

will then also be supplied with voltage.

Operational readiness after 60 seconds

The TDC device is ready for operation after approximately 60 seconds.

Check the operational status of the TDC device by looking at the status indicators.

▸

6.2 Preparing the configuration PC

6.3 General notes

Disconnecting the power to the system

Make sure that all the components of the gateway system are disconnected from the

▸

power supply during the electrical installation work.

Risk of injury due to electrical current

Standard safety requirements must be met when working on electrical systems.

▸

The power supply must be disconnected when attaching and detaching electrical

▸

connections.

Page 41

41

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

6.3.1 Establishing a connection with the configuration PC

Part No.

Description

6066259

TDC-B100 /TDC-B200 configuration cable

6066258

TDC-M100 configuration cable

The TDC device is configured via a configuration PC with the TDC Configurator

configuration software installed on it.

Fig. 29: Connecting the TDC device and the configuration PC

Connecting the configuration PC

The configuration PC is connected to the TDC device using the configuration cable, which

can be procured separately as an accessory.

The configuration cable has a device-specific Micro-Fit plug connector for the connection

to the TDC device and a USB connector for the connection to the configuration PC.

COMMISSIONING 6

TDC-M100 connection

1. Plug the device-specific Micro-Fit male connector on the configuration cable into the

DIAG female connector on the TDC device.

2. Connect the cable to a free USB port on the configuration PC.

Page 42

6 COMMISSIONING

42

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

6.3.2 Installing TDC Configurator

Install the TDC Configurator configuration software. Download the configuration software

from the SICK website in the form of a zipped folder that also contains the system

documentation and interface files. The link with the access data for the download can be

found in the quick start guide and on the packaging for the configuration cable.

Installing TDC Configurator

1. Unpack the zipped folder in a temporary directory on the configuration PC.

2. Start the installation by double-clicking on the Setup.exe file.

The installation wizard will open. A note will appear to point out that the drivers for the

configuration cable will also be installed when the configuration software is installed for

the first time.

3. Start the installation by clicking on Install.

4. Follow the instructions in the installation wizard.

5. Once the configuration software has been installed, the drivers for the configuration

cable will also be installed. These drivers will be installed in the corresponding directory

of the operating system.

6. Complete the installation.

The configuration PC will then have to be restarted.

Depending on the configuration, a program group is created and an icon is placed on the

desktop.

Page 43

43

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

6.4 Connecting to the TDC device

6.4.1 Launching the configuration software

Launch the configuration software and log in to TDC Configurator at the Service user

level.

Logging in

1. To log in, click on the program icon in the Windows start menu or on the desktop.

The login window will open.

2. Under Access, select the Service user level.

3. Enter servicelevel as the password.

4. Click OK to confirm.

The configuration software will open.

The TDC Configurator configuration interface

The TDC Configurator configuration interface is divided into several sections.

COMMISSIONING 6

• A number of functions can be found in the menu bar. This is where the connection to

the TDC device is established and where parameters can be written onto the device

or loaded into the configuration software from the device. A configuration can also be

stored on a local data card.

• In the top left-hand corner, you can see the Device box for the connected TDC device.

No information about the device is currently being displayed in this box because the

connection is yet to be established.

• In the bottom left-hand corner, you can see the TDC device configuration. This is where

the connection settings are saved and the sensor interfaces are configured.

• The right-hand side is used for entries depending on the current processing context.

Page 44

6 COMMISSIONING

44

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

6.4.2 Establishing a connection to the TDC device

Start with establishing a connection to the connected TDC device. To do this, select the

COM port that has been used to connect the TDC device to the configuration PC.

Selecting the COM port in TDC Configurator

1. Open the Select communication port window via Device

Connect.

Note

2. Select the COM port that has been used to connect the TDC device to the configuration

PC.

If you are not sure which port has been used to connect to the configuration PC,

open up the device manager on the operating system in order to check the COM port

allocation.

3. Click OK to confirm.

Device data

As soon as the connection to the TDC device has been established, the device will appear

in the Device box along with details such as its IMEI and firmware version.

The connection status of the device will then be Connected.

Page 45

45

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Note

COMMISSIONING 6

Loading the standard parameters

At the initial commissioning stage, the standard parameters included on the connected

device as the factory settings will be automatically downloaded and transferred over to

the configuration software.

The standard parameters can then be adapted to the requirements of the individual

application. The bottom left-hand corner of the programming interface is now activated

and entries can be made.

Fig. 30: Loading the standard parameters

A note will appear in the status bar when the configuration has been loaded successfully.

Page 46

6 COMMISSIONING

46

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

6.5 Adjusting the standard parameters and configuring the interfaces

Parameters can be entered under the two tabs Settings and Telemetry Elements.

• The Settings tab is mainly used to configure the connection settings and movement

monitoring.

• The Telemetry Elements tab is used to configure the interfaces for peripheral devices

and to process the input signals.

6.5.1 General settings

It is recommended to edit the standard parameters under the Settings tab from the top

down.

The parameters are displayed in a tree structure, which offers the user guidance for the

configuration process.

6.5.1.1 General

The General section contains information about the TDC device. This makes it easier to

identify and manage each individual TDC device when multiple devices are in use. This is

also where phone numbers are entered for SMS alerts.

Last edited

From the Last edited section, it is possible to find out which user was last to edit the

parameters and when. The name of the user logged on to the operating system at the

time of processing is displayed here..

Note

The last time the parameters were edited and the corresponding user are shown for all

of the parameters under the Settings tab.

Page 47

47

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

Note

Note

COMMISSIONING 6

General

Enter a meaningful name for the device in the Device name field (e.g., the installation

▸

location).

A short name for the device can be stored in the Device identification field. Do not

▸

select the vehicle registration number as the short name, as these are subject to

change and cannot be used as a way to clearly identify the device.

Enter the phone number of the contact person responsible for the TDC device in the

▸

Admin phone num. field.

If the Daily reset enabled checkbox is checked, the device's memory will be deleted

▸

every day.

Hovering the cursor over an input field will bring up a short description.

Alerting

Up to five phone numbers can be saved in the Alerting section. If a real-time alarm is

triggered, the TDC device will send SMS messages to these numbers.

The specific sensors that should trigger an alarm under specific input conditions can be

defined via corresponding telemetry elements (for further information on this, refer to the

next chapter).

Page 48

6 COMMISSIONING

48

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

6.5.1.2 GPRS connection data

In the Connectivity section, specify how the SIM card should connect to the SICK or

customer server.

Note

GPRS data for applications in EU countries

If the TDC device is being used in an EU country, the GPRS access data for the SICK

server is automatically stored when the standard parameters are uploaded. The Access

Point Name is preset in the APN Name field in the Connectivity / GPRS section. The

user name and password for the access point are not displayed, however.

There is an explanatory text on the right-hand side of the input fields pointing out that

there is no input required here if the device is being used in an EU country.

The content in the fields must not be changed.

The Reset to defaults option restores the access data for the SICK cloud.

Page 49

COMMISSIONING 6

49

8021804/2017-11-27|SICK

Subject to change without notice

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telematic Data Collector

GPRS data for applications in countries outside of the EU

If the TDC device is being used in a country outside of the EU, the user-inserted SIM card

from the telecommunications provider in the respective country will need to be configured.

After the standard parameters have been uploaded, the fields in the Connectivity / GPRS

section will be left empty.

The telecommunications provider in the respective country will need some information in

advance, which can be found in the checklist to the right of the input field. The details that

need to be passed on to them include – among others - the IP address of the SICK server.

In return, the telecommunications provider will provide the APN (Access Point Name)

along with the user name and password.

Fig. 31: Requesting GPRS connection data for applications in countries outside of the EU

Insert the information provided by the telecommunications provider in the

▸

corresponding fields in the Connectivity / GPRS section.

Page 50

6 COMMISSIONING

50

8021804/2017-11-27|SICK

TRANSLATION O F THE ORIGINAL IN STRUCTIONS | Telem atic Data Collector

Subject to change without notice

Saving MQTT access data from the customer server