Page 1

STR1

Draft 2016-10-19

Safety switch

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

Draft 2016-10-19

STR1

Manufacturer

SICK A

G

Erwin-Sick

-Str. 1

79183 Waldkirch

Germany

Legal information

This work is prot

ected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an or

iginal document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 3

Contents

Draft 2016-10-19

CONTENTS

1 About this document........................................................................ 5

1.1 Function of this document....................................................................... 5

1.2 Scope......................................................................................................... 5

1.3 Target groups and structure of these operating instructions................ 5

1.4 Additional information.............................................................................. 5

1.5 Symbols and document conventions...................................................... 6

2 Safety information............................................................................ 8

2.1 General safety notes................................................................................. 8

2.2 Intended use............................................................................................. 8

2.3 Requirements for the qualification of personnel.................................... 8

3 Product description........................................................................... 10

3.1 Setup and function................................................................................... 10

3.2 Product characteristics............................................................................. 10

4 Project planning................................................................................ 12

4.1 Manufacturer of the machine.................................................................. 12

4.2 Operating entity of the machine.............................................................. 12

4.3 Design........................................................................................................ 13

4.4 Integration into the electrical control...................................................... 13

4.5 Thorough check concept.......................................................................... 17

5 Mounting............................................................................................. 18

5.1 Safety......................................................................................................... 18

5.2 Unpacking.................................................................................................. 18

5.3 Possible mounting types.......................................................................... 18

5.4 Mounting................................................................................................... 20

6 Electrical installation........................................................................ 22

6.1 Safety......................................................................................................... 22

6.2 Notes on cULus......................................................................................... 23

6.3 Device connection (flying leads).............................................................. 24

6.4 Device connection (M12, 5-pin).............................................................. 24

6.5 Device connection (M12, 8-pin).............................................................. 24

6.6 Connecting a cascade.............................................................................. 25

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

7 Commissioning.................................................................................. 28

7.1 Safety......................................................................................................... 28

7.2 Switching on.............................................................................................. 28

7.3 Teach-in..................................................................................................... 28

7.4 Thorough check........................................................................................ 29

8 Troubleshooting................................................................................. 30

8.1 Safety......................................................................................................... 30

3

Page 4

CONTENTS

Draft 2016-10-19

8.2 Diagnostic LEDs........................................................................................ 30

9 Maintenance...................................................................................... 33

9.1 Cleaning..................................................................................................... 33

9.2 Regular thorough check........................................................................... 33

10 Decommissioning............................................................................. 34

10.1 Protection of the environment................................................................. 34

10.2 Disposal..................................................................................................... 34

11 Technical data.................................................................................... 35

11.1 Technical data........................................................................................... 35

11.2 Dimensional drawings.............................................................................. 38

11.3 Response time and enable time in cascade.......................................... 39

12 Ordering information........................................................................ 40

12.1 Scope of delivery...................................................................................... 40

12.2 STR1 ordering information....................................................................... 40

13 Spare parts......................................................................................... 42

13.1 Actuator..................................................................................................... 42

13.2 Sensors..................................................................................................... 42

14 Accessories........................................................................................ 43

14.1 Connectivity............................................................................................... 43

15 Annex.................................................................................................. 45

15.1 Compliance with EU directives................................................................. 45

15.2 FCC and IC radio approval........................................................................ 46

16 List of figures..................................................................................... 47

17 List of tables....................................................................................... 48

4

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 5

1 About this document

Draft 2016-10-19

1.1 Function of this document

These operating instructions contain the information needed during the life cycle of the

safety switch.

ABOUT THIS DOCUMENT 1

They mus

t be made available to all people who work with the safety switch.

1.2 Scope

The operating instructions only apply to the STR1 safety switch with the following infor‐

mation on t

he product packaging: Oper

ating Instructions 8018074.

These operating instructions are included with SICK part number 8018074 (all availa‐

ble languages of this document).

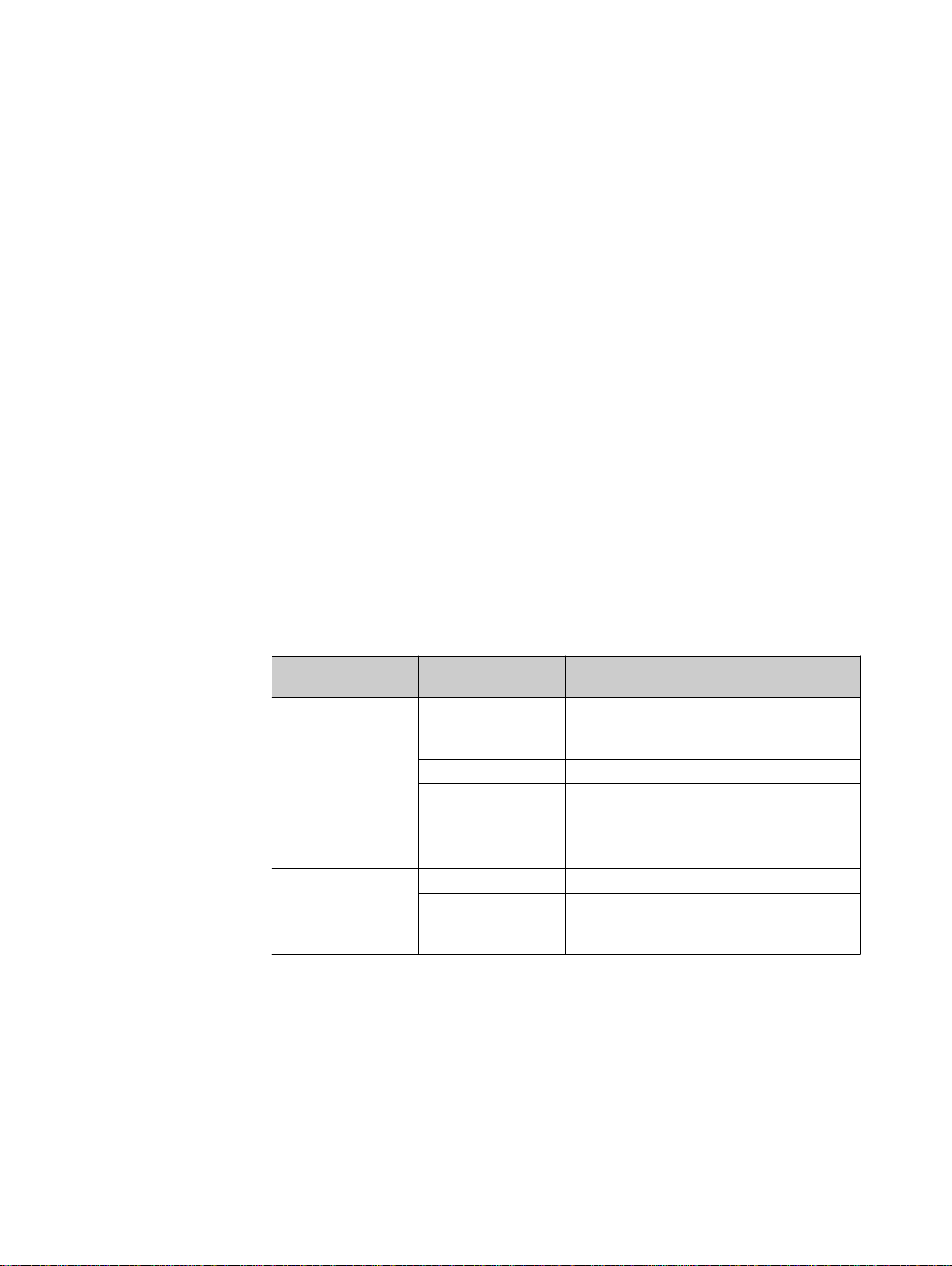

1.3 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: project devel‐

oper

s (planner

CE authorized representatives, compliance officers, people who test and approve the

application), operators, and maintenance personnel.

The structure of these operating instructions is based on the life cycle phases of the

safety switch: project planning, mounting, electrical installation, commissioning, opera‐

tion, and maintenance.

In many applications, the target groups consist of the manufacturer and the operating

entity of the machine in which the safety switch is integrated:

Area of responsibility Target group Special chapters of these operating instruc‐

Manufacturer Project developers

Operating entity Operators Troubleshooting, pag

s, developer

(planners, developers,

designer

Installers Mounting, pag

Electricians Electrical inst

Safety experts Project planning, page 12

Maintenance person‐

nel

s, designers), installers, electricians, safety experts (such as

1)

tions

Project planning, page 12

Technical data, page 35

s)

Accessories, page 43

Commissioning, page 28

echnical data, page 35

T

Maint

enance, page 33

Troubleshooting, page 30

Ordering information, page 40

e 18

allation, page 22

e 30

1.4 Additional information

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

1)

Chapters not listed here are intended for all target groups. All target groups must follow all of the safety

and warning instructions in all c

hapters of the operating instructions!

In other applications, the operating organization is also the manufacturer of the equip‐

ment with the corresponding allocation of t

he target groups.

www.sick.com

The following information is a

vailable on the Internet:

5

Page 6

1 AB

Draft 2016-10-19

OUT THIS DOCUMENT

versions in other languag

•

data sheets and application examples

•

CAD data of drawings and dimensional drawings

•

certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery (Six steps to a safe machine)

•

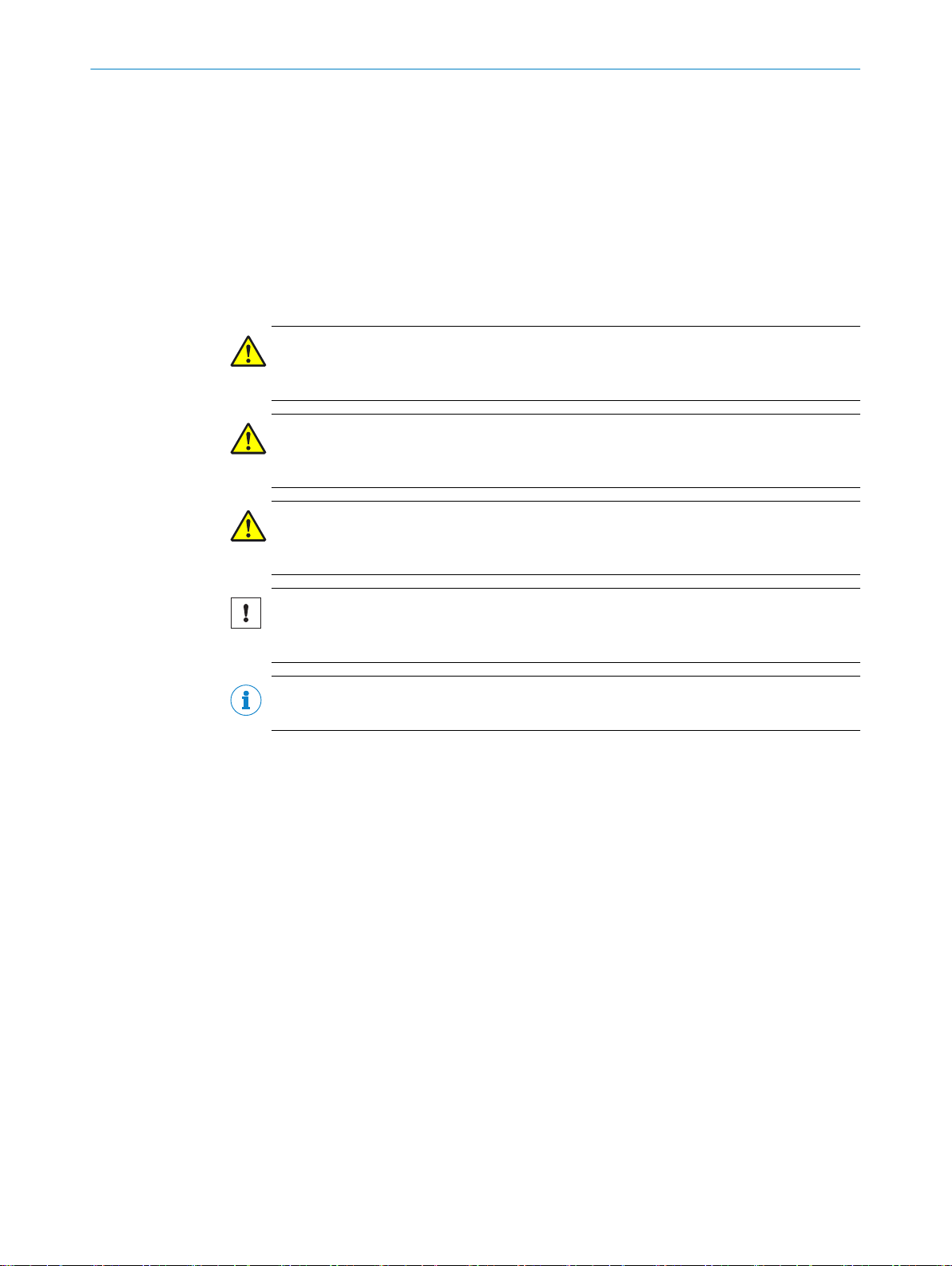

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, whic

injuries if not prevented.

WARNING

Indicat

es a situation pr

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, whic

injuries if not prevented.

esenting possible danger, whic

es

h will lead to death or serious

h may lead to death or serious

h may lead to moderate or minor

NOTICE

Indicates a situation presenting possible danger, whic

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions for action

The arrow denot

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes a result of an instruction for action.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

The LED is flashing.

The LED is illuminated continuously.

Terminology

erous state

Dang

es instructions for action.

h may lead to property damage if

6

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

A dang

erous state is a status of the machine or facility, where people may be injured.

Protective devices prevent this risk if the machine is operated within its intended use.

The figures in this document always show the dangerous state of the machine as move‐

ment of a machine part. In practice, there are different dangerous states, such as:

Subject to change without notice

Page 7

Machine movements

Draft 2016-10-19

•

Electrical par

•

Visible and invisible beam

•

A combination of multiple hazards

•

ts

ABOUT THIS DOCUMENT 1

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

Draft 2016-10-19

2 Safety information

2.1 General safety notes

This chapter contains general safety information about the safety switch.

Further infor

chapters.

DANGER

Hazar

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

b

b

Incorrect installation or manipulation can lead to severe injuries.

2.2 Intended use

The safety switch is a transponder safety switch that is switched in a non-contact man‐

ner by means of actuators, and is suitable f

•

The safety switch must only be used within the limits of the prescribed and specified

technical data and operating conditions at all times.

Incorrect use, improper modification, or manipulation of the safety switch will invalidate

any warranty from SICK AG; in addition, any responsibility and liability of SICK AG for

damage and secondary damage caused by this is excluded.

mation about specific product use situations can be found in the relevant

o lac

d due t

Read this document carefully and ensure that you have fully understood the con‐

tents before you work with the device.

Pay particular attention to all safety notes in this document.

Movable physical guards

f

ectiveness of the protective device

k of ef

or the following applications:

The safety switch is not suitable for certain ambient conditions, including:

Radioactivity (with the exception of natural radioactivity)

•

Vacuum or high pressure

•

High UV exposure

•

In the vicinity of low-frequency RFIDs

•

In the vicinity of magnetic fields

•

The following can impair the function of the safety switch:

Metal subsurfaces or metal in the immediate vicinity (see "Design", page 13)

•

Flying metal chips

•

2.3 Requirements for the qualification of personnel

The safety switch must be configured, mounted, connected, commissioned, and serv‐

iced by qualified safe

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

ty personnel only.

8

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 9

SAFETY INFORMATION 2

Draft 2016-10-19

Mechanical mounting, electrical installation, and commissioning

For the task, a per

rience in the relevant field and is sufficiently familiar with the application of the protec‐

tive device on the machine to be able to assess whether it is in an operationally safe

state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

son is considered qualified when he/she has the expertise and expe‐

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

9

Page 10

3 PRODUCT DESCRIPTION

Draft 2016-10-19

3 Product description

3.1 Setup and function

The safety switch consists of two components:

Sensor

•

The sensor is mounted on the fixed part of the protective device.

Actuator (transponder)

•

The actuator is mount

When the protective device is closed, the actuator is guided to the sensor. When the

switch on distance is reached, the sensor detects the actuator code. If the sensor

detects a taught-in code (valid actuator), it sets safety outputs OSSD 1 and OSSD 2

(semiconductor outputs) to High and application diagnostic output Aux to Low.

When the protective device is opened, the actuator is removed from the response range

of the sensor. The sensor sets safety outputs OSSD 1 and OSSD 2 to Low and applica‐

tion diagnostic output Aux to High.

3.2 Product characteristics

ed on the moving part of the protective device.

3.2.1 Product variants

The safety switch is delivered in different variants. You will find an overview of impor‐

t

ant distinguishing features of t

Universally coded, unique coded, and permanently coded safety switches

•

Actuator design: “Standard”, “Flat”, or “Mini”

•

Cable with M12 plug connector (5-pin or 8-pin) or flying leads (3 m or 10 m)

•

Complete overview of all variants: see "STR1 ordering information", page 40.

Coding

Universally coded

•

All actuator

Unique coded

•

An actuator must be taught in dur

taught in one after the o

Previously taught-in actuators can no longer be used.

Permanently coded

•

An actuator mus

performed once. It is not possible t

3.2.2 Active sensor surfaces

The sensor has 3 active sensor surfaces:

Front: black sur

•

2 x sides: yellow surface with long black edge

•

he variants in the following.

s are accepted. No teach-in is required.

ing commissioning. Up to 8 actuators may be

ther. Only the most recently taught-in actuator is valid.

t be taught in during commissioning. Teach-in only needs to be

o teach in any further actuators.

face

3.2.3 Fault detection

10

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Faults that arise, including internal device faults, are detected no later than the next

r

equirement to close t

switch then switches to the safe state. If a fault is detected, the safety circuit is

switched off and the DIAG and STATE light emitting diodes display the fault (see

table 10).

he safety contacts (e.g., when the machine starts). The safety

Subject to change without notice

Page 11

3.2.4 Cascading

Draft 2016-10-19

PRODUCT DESCRIPTION 3

In the case of cascading, up to 30 safety switches are connected in series.

F

or more information, see "Cascading",

page 25

3.2.5 State indicators

The STATE light emitting diode (red/green) and the DIAG light emitting diode (yellow)

signal t

Complete overview of the light emitting diode states and their meanings: see "Diagnos‐

tic LEDs", page 30.

3.2.6 Protective functions

The safety switch has the following internal protective functions:

•

•

•

•

page 16 and see "Connecting a cascade",

he operational state of the safety switch.

Short-circuit protection at all outputs

Cross-circuit monitoring at OSSDs

Overload protection at OSSDs

Reverse polarity protection for the supply voltage

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

11

Page 12

4 PROJECT PLANNING

Draft 2016-10-19

4 Project planning

4.1 Manufacturer of the machine

DANGER

Failure to compl

Hazard due to lack of effectiveness of the protective device

Perform a risk assessment before using the safety switch.

b

Do not manipulate, open, or modify components of the safety switch.

b

Do not repair defective devices; replace them instead.

b

Make sure the switch-on commands that cause the machine to enter a dangerous

b

state only take effect when the protective device is closed.

Make sure a stop command is triggered when the protective device is opened in a

b

hazardous machine state.

Safety switches must not be bypassed (i.e., the contacts jumpered), swiveled out

b

of the way, removed, or rendered ineffective in any other way. If necessary, take

measures to reduce the possibility of bypassing.

If multiple devices are connected in series (cascaded) and the simplified procedure

according to ISO 13849 is used to det

drop.

y with manufacturer’s obligations

ermine the performance level (PL), the PL may

As the number of safety switches in a cascade increases, so too does the response

time.

4.2 Operating entity of the machine

DANGER

Failure to compl

Hazard due to lack of effectiveness of the protective device

Modifications to the machine and modifications to the mechanical mounting of

b

the safety switch necessitate a new risk assessment. The results of this risk

assessment may require the operating entity of the machine to fulfill the manufac‐

turer’s obligations.

Apart from during the procedures described in this document, the components of

b

the safety switch must not be opened or modified.

Do not perform repair work on the components. Improper repair of the safety

b

switch can lead to a loss of the protective function.

Make sure that bypassing is not carried out by substitute actuators. Restrict

b

access to actuators for unlocking.

y with operating entity’s obligations

12

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 13

4.3 Design

Draft 2016-10-19

PROJECT PLANNING 4

DANGER

Bypassing the protectiv

Hazard due to lack of effectiveness of the protective device

Prevent incentives to manipulate the safety switch by taking at least one of the fol‐

b

lowing measures:

Universally coded variant only:

Co

°

°

Mounting location

ver the sensor and the actuat

against access.

If possible, use non-detachable mounting methods for actuators (such as

welding, gluing, safety screws, or rivets).

e device

or with additional equipment or protect them

When the protectiv

b

other at the safe switch on distance of Sao or closer (see table 3).

Select a mounting location that allows the sensor and actuator to be accessed for

b

maintenance work and protects them against damage.

If possible, mount the sensor and actuator on non-ferrous subsurfaces and at a

b

distance from metallic parts in order to avoid affecting the sensing range. If this is

not possible, the effect on the safe switch on distance Sao and the safe switch off

distance Sar must be checked.

Make sure that there is no possibility of hazards arising when the protective device

b

is opened, even if the actuator has not yet reached the safe switch off distance

Sar.

If the actuator is approaching the sensor in a parallel position, observe the mini‐

b

mum distances (see table 3).

If necessary, attach an additional stop for the moving protective device.

b

Distance

If multiple saf

minimum distance in relation to one another; see "Mounting", page 20.

Alignment

The sensor can be mounted in any alignment see "Mounting", page 20, see "Possible

mounting types", page 18.

ety switches are mounted on the machine, they must be mounted with a

e device is closed, the sensor and actuator must face each

4.4 Integration into the electrical control

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

Actuating direction

The actuator may approach the front or the long side of the sensor.

NOTE

he actuat

If t

closed, but instead approaches it in a parallel position, the specified minimum distance

must be adhered to. This prevents the sensor from enabling the safety outputs despite

the protective device not being fully closed.

Switch-on commands that cause the machine to enter a dangerous state may only take

effect when the pro

ous state, a stop command must be triggered if the protective device opens. Depending

on the safety concept, the signal is analyzed by, e.g., safety relays or a safety controller.

or does no

t mo

e directly onto the sensor when the protective device is

v

tective device is closed. In cases where the machine is in a danger‐

13

Page 14

4 PROJECT PLANNING

Draft 2016-10-19

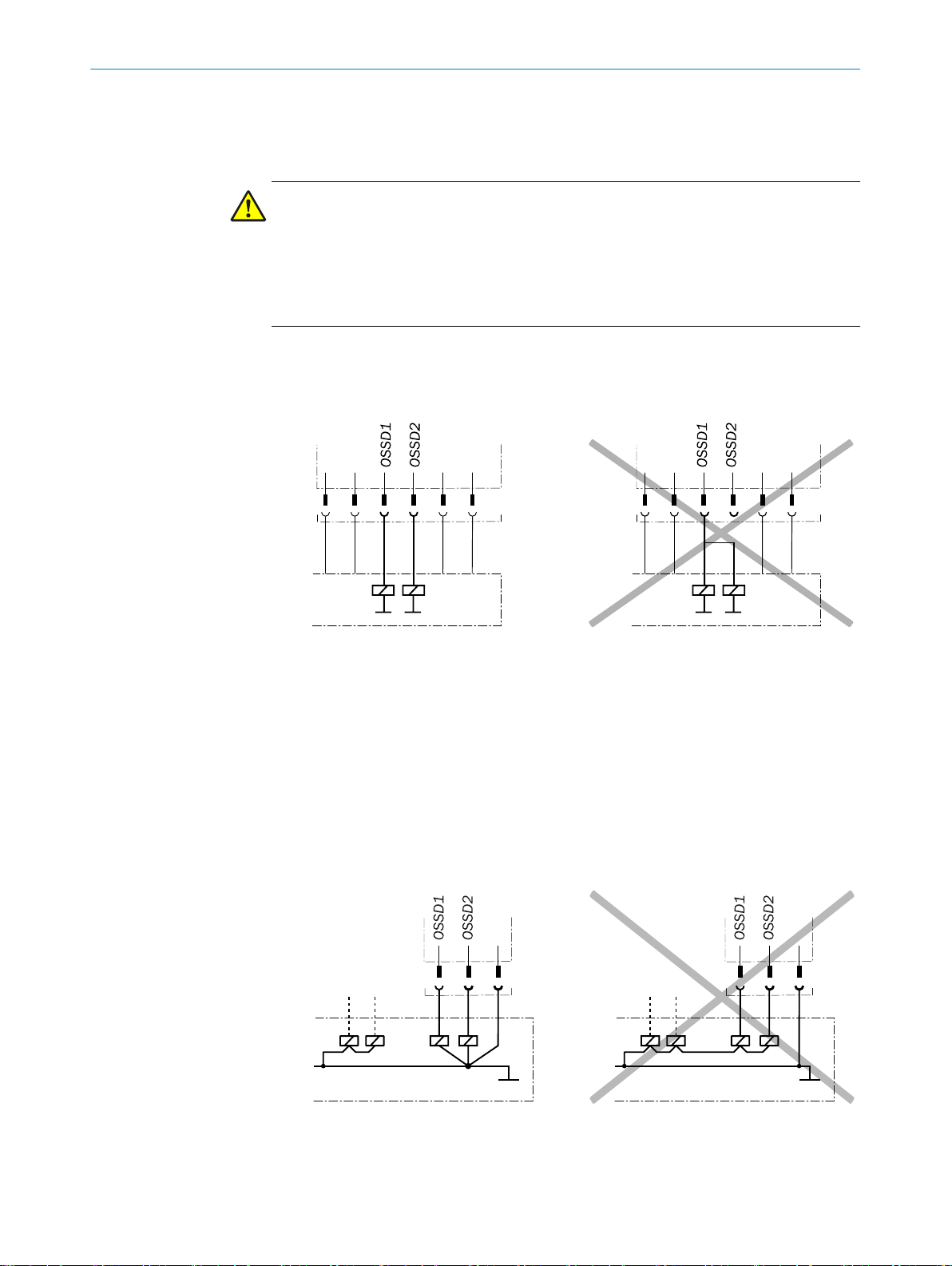

4.4.1 OSSDs

Safety switches with local inputs and outputs can be directly integrated into the

mac

hine controller.

DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so the

b

protective function can be fulfilled.

The output signals from an OSSD pair must not be connected to each other.

•

In the machine controller, both signals from an OSSD pair must be processed sep‐

•

arately.

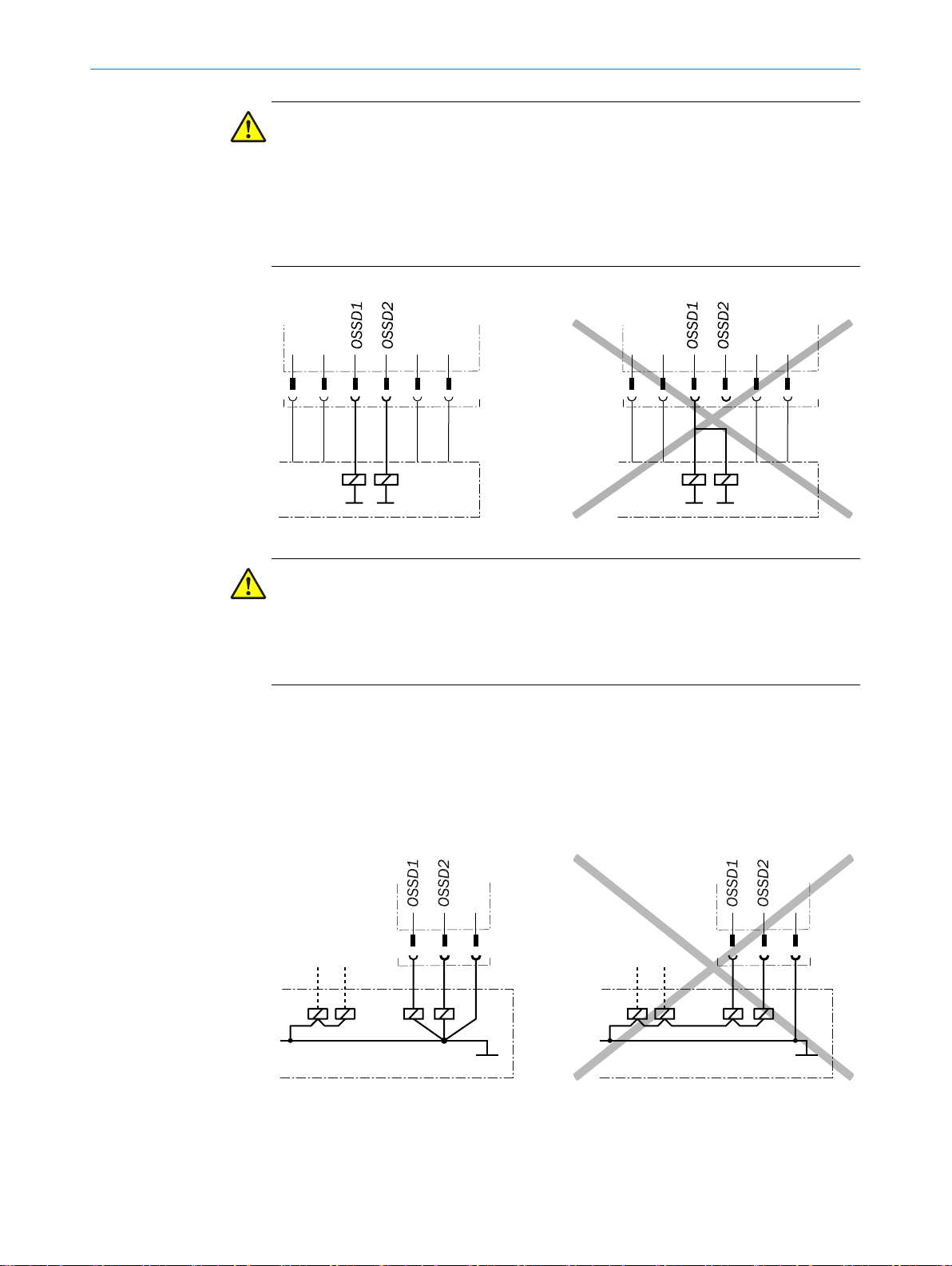

Figure 1: Dual-channel and isolated connection of OSSD 1 and OSSD 2

The machine must switch to t

•

OSSD pair switches to the OFF state.

Prevent the formation of a potential difference between the load and the protec‐

•

tive device. If you connect loads to the OSSDs (safety outputs) that then also

switch if controlled with negative voltage (e.g., electro-mechanical contactor with‐

out reverse polarity protection diode), you must connect the 0 V connections of

these loads and those of the corresponding protective device individually and

directly to the same 0 V terminal strip. In the event of a fault, this is the only way to

ensure that there can be no potential difference between the 0 V connections of

the loads and those of the corresponding protective device.

he safe state at any time if at least one OSSD in an

14

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Figure 2: No potential difference between load and protective device

Subject to change without notice

Page 15

PROJECT PLANNING 4

Draft 2016-10-19

DANGER

Hazard due to lack of eff

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Downstream contactors must be positively guided and monitored depending on appli‐

cable national regulations or required reliability of the safety function.

Make sure that downstream contactors are monitored (external device monitoring,

b

EDM).

Requirements for the electrical control of the machine

ectiveness of the protective device

he contr

Use t

•

The safety switch tests the OSSDs at regular intervals. To do this, it switches each

•

OSSD briefly (for max. 1 ms) to the OFF state and checks whether this channel is

voltage-free during this time.

Make sure that the machine’s control does not react to these test pulses and the

machine does not switch off.

The in

•

The OSSDs are short-circuit protected to 24 V DC and 0 V. When the actuator is in the

sensor’s response range, the OSSDs signal the ON state with the HIGH signal level

(non-isolated). If the actuator is removed from the sensor’s response range or there is a

device fault, the OSSDs signal the OFF state with the LOW signal level.

The safety switch complies with the regulations for electromagnetic compatibility (EMC)

for the industrial sector (Radio Safety Class A). Radio interference cannot be ruled out

when used in residential areas.

DANGER

Hazar

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

b

puts of a connect

two outputs of the safety switch send a level of the supply voltage in the switchedon state.

o lac

d due t

Make sure that the following control and electrical requirements are met so the

safety switch can fulfill its protective function.

hout t

ol wit

f

ectiveness of the protective device

k of ef

t pulses. The safety switch is self-testing.

es

ed evaluation unit mus

t be positive-switching (PNP), as the

4.4.2 Application diagnostic output

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

The exter

•

power failures of 20 ms as specified in IEC 60204-1.

The power supply unit must provide safe isolation according to IEC 61140 (SELV/

•

PELV). Suitable power supply units are available as accessories from SICK.

The application diagnostic output signal changes as soon as the actuator is moved into

or leaves the response r

moving protective device is opened and closed. This is not a safety output.

Actuator Application diagnostic output

Actuator not in response range. ON

Actuator in response range. OFF

Table 1: Application diagnostic output switching behavior

nal v

olt

age supply of the safety switch must be capable of buffering brief

ange of the safety switch. In other words, it does so when the

15

Page 16

1 1 1 1 1 2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

4 PROJECT PLANNING

Draft 2016-10-19

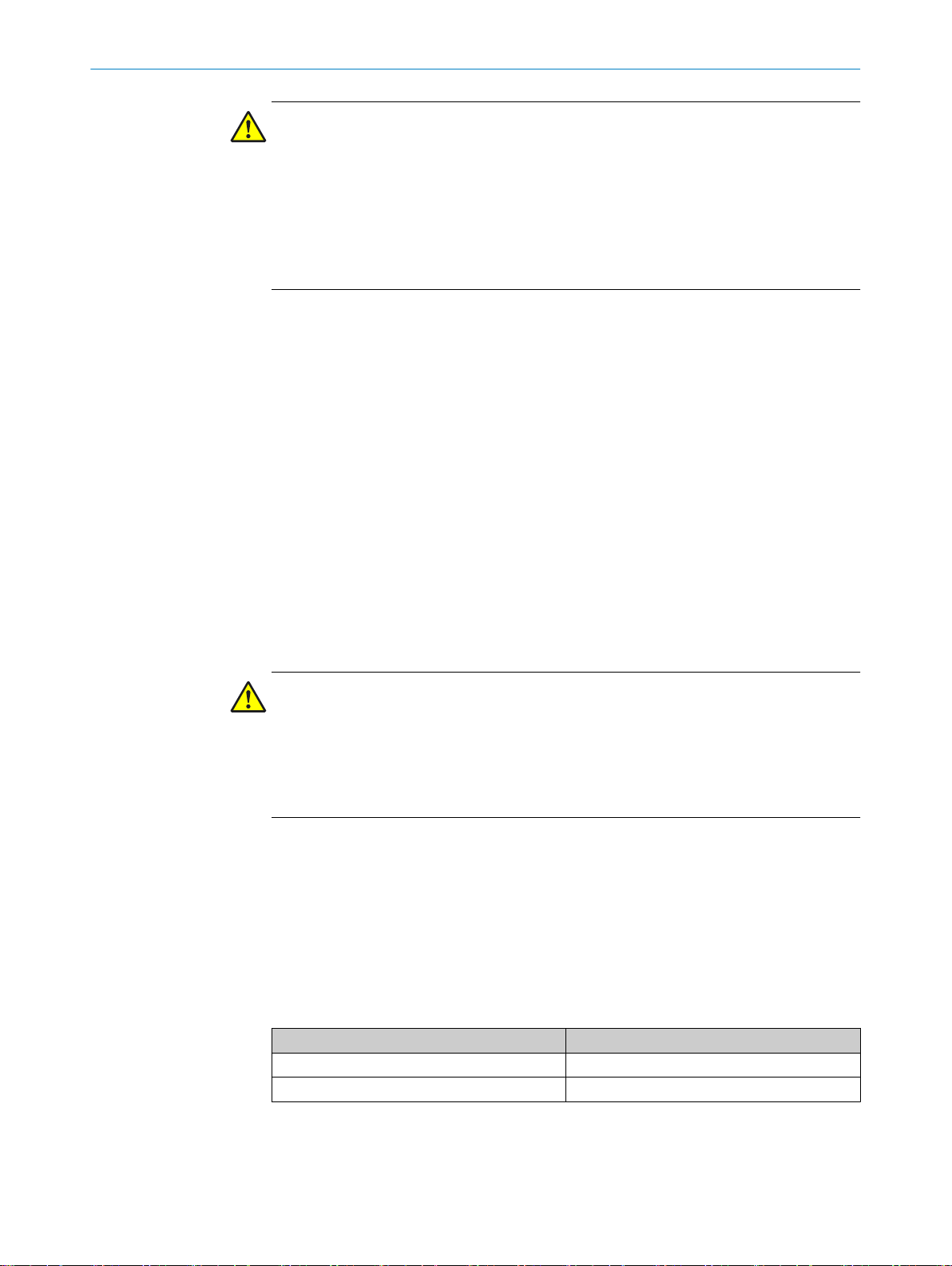

4.4.3 Cascading

Cascading makes it possible to connect multiple safety switches. The connected devi‐

ces act lik

e a single device. Cascading is only possible wit

h the variant that includes the

8-pin M12 male connector.

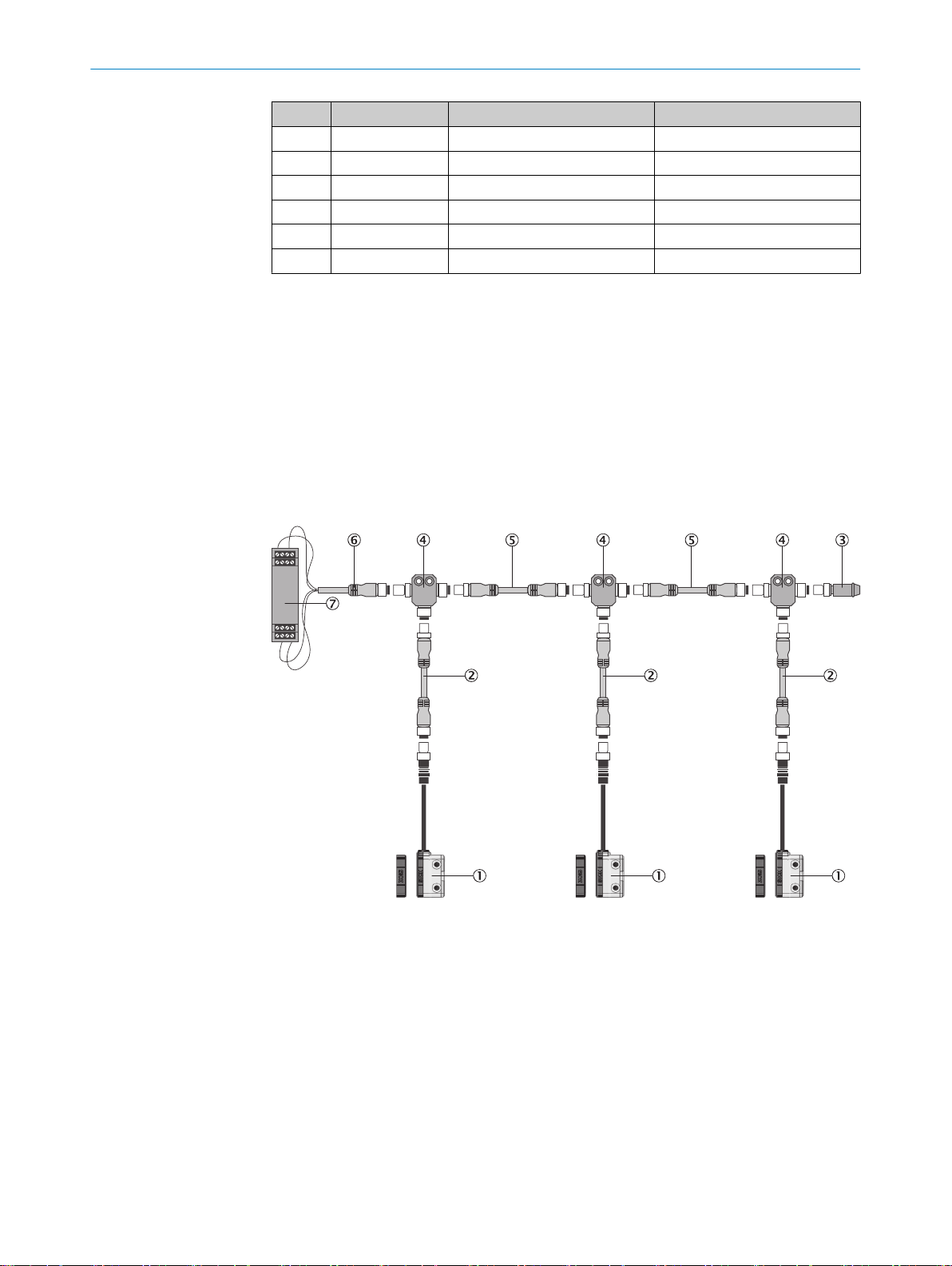

Figure 3: Circuit with 5 cascaded safety switches

Safety switch

Safe evaluation unit

It is not possible to use more than 30 safety switches in a cascade.

The maximum number of safety switches depends on the f

Applied supply voltage

•

Length of cables used

•

Cross-section of cables used

•

ollowing factors:

The voltage drop in the cascade must be checked to ensure that the defined minimum

voltage is still present at the last safety switch.

In the case of connection cables with a length of 2 m and a cable cross-section of

0.25 mm², the maximum number of cascadable safety switches is relative to the volt‐

age, as explained below:

Voltage Connection cables,

the same kind for the

entire cascade

24 V Length: 2 m

26.8 V 19.2 V 30

Table 2: Maximum number of cascadable safety switches relative to the voltage

Cable cross-section:

0.25 mm²

In

put voltage at 30th

safety switch

17.8 V 24

Maximum number of

cascadable safety

switches

The number of safety switches in a cascade affects the response time of the system

(see "Response time and enable time in cascade", page 39).

The cascade can be created using special T-pieces and an end connector (see "Con‐

necting a cascade", page 25).

NOTE

he case of safety switc

In t

16

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

ate the application diagnostic output.

hes cascaded using T

-connectors, it is not possible to evalu‐

Subject to change without notice

Page 17

4.5 Thorough check concept

Draft 2016-10-19

Thorough checks must be performed on the safety switch by appropriately qualified

ety personnel during commissioning, af

saf

see "Thorough check", page 29

Regular thorough checks serve to investigate the effectiveness of the safety switch and

discover defects resulting from modifications or external influences (such as damage or

manipulation).

The manufacturer and operating entity must define the type and frequency of the thor‐

ough checks on the machine on the basis of the application conditions and the risk

assessment. The process of defining the thorough checks must be documented in a

traceable manner.

4.5.1 Minimum requirements for regular thorough checks

The following thorough checks must be carried out at least once a year:

PROJECT PLANNING 4

ter modifications, and at regular intervals.

Thorough check of the pr

•

Thorough check of the safe sensing range S

•

Thorough check for damage on the switch housing

•

Thorough check for damage on the switch cables

•

Thorough check for signs of misuse or manipulation on the safety switch

•

incipal protective function of the safety switch

ar

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

17

Page 18

5 MOUNTING

Draft 2016-10-19

5 Mounting

5.1 Safety

DANGER

Hazard due to unexpected s

Death or severe injury

Make sure that the dangerous state of the machine is and remains switched off.

b

DANGER

Bypassing the protectiv

Hazard due to lack of effectiveness of the protective device

Prevent incentives to manipulate the safety switch by taking at least one of the fol‐

b

lowing measures:

Universally coded variant only: Attach safety switches with a cover or with

°

shielding, or ensure they are out of reach.

If possible, use non-detachable mounting methods for actuators (such as

°

welding, gluing, non-removable screws, or rivets).

tarting of the machine

e device

NOTICE

Incorrect mounting and unsuitable ambient conditions may damage the safety switch.

Arrange the sensor and actuator in a way that prevents damage from foreseeable

b

external influences.

Do not use the sensor and actuator as a stop.

b

The holder and mounting method for the sensor and actuator must be stable

b

enough to ensure that correct operation can take place.

Always use reliable mounting elements that can only be removed using tools.

b

If misalignment results in an opening on the physical guard, this must not impair

b

the protection that is provided.

5.2 Unpacking

Check the components for com

b

of delivery", page 40.

Please contact your respective SICK subsidiary should you have any complaints.

b

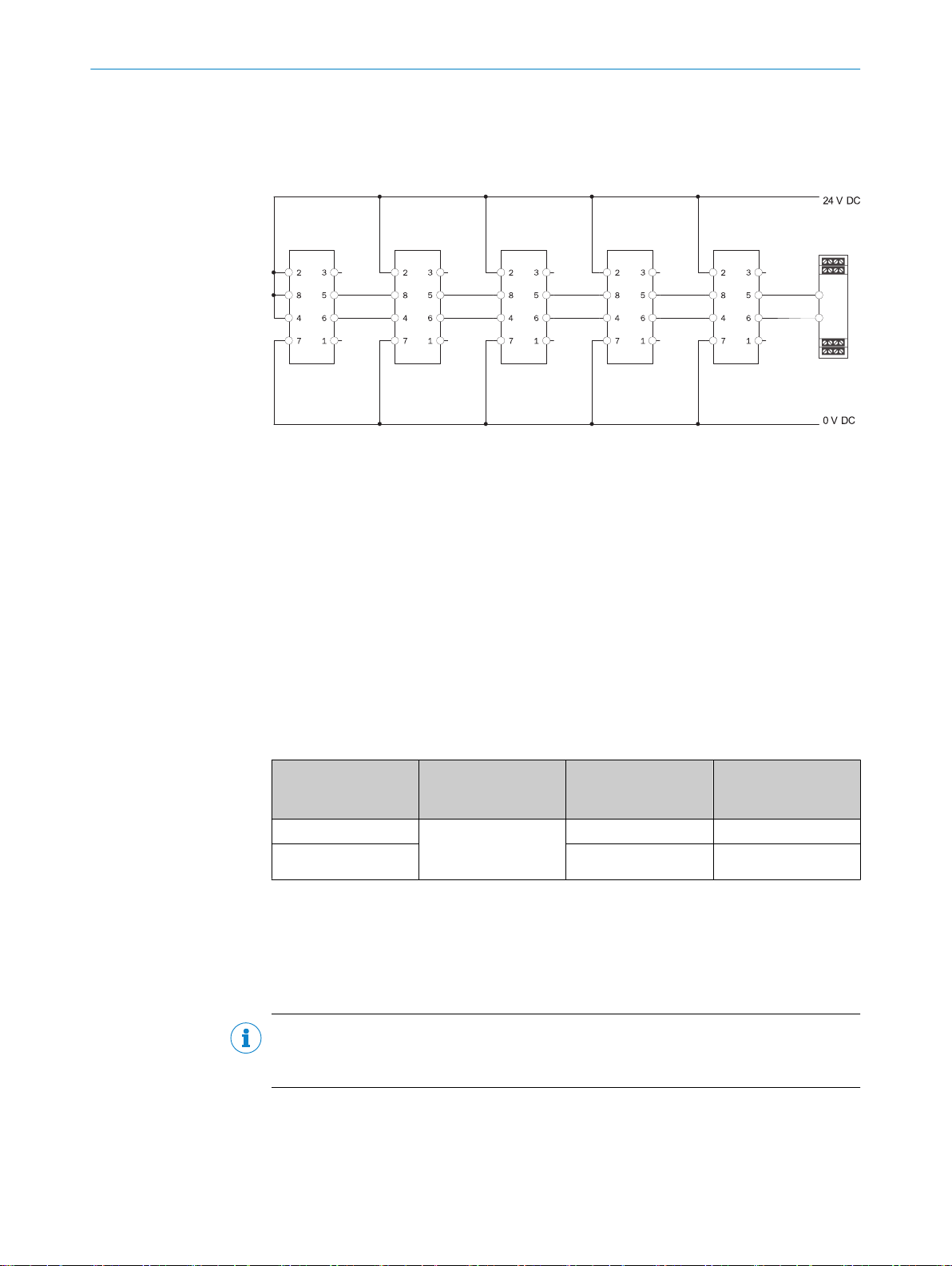

5.3 Possible mounting types

“Standard” actuator

pleteness and the integrity of all parts, see "Scope

Front actuation Side actuation

18

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Safe switch on distance S

Safe switch off distance S

Table 3: Safe switch-on range based on actuator, alignment, and approach direction

≤ 10 mm ≤ 6 mm

ao

≤ 25 mm

ar

Subject to change without notice

Page 19

Switch-on behavior with

–40

–20

2

0

40

0

0 4 8 12 16 20

[mm]

–40

–20

2

0

40

0

0 4 8 12 16 20

[mm]

–40

–20

20

40

0

0 4 8 12 16 20

[mm]

–40

–20

20

40

0

0 4 8 12 16 20

[mm]

Draft 2016-10-19

“Standard” actuator relativ

direction of approach

MOUNTING 5

Front actuation Side actuation

e to

“Flat” actuator

Safe switch on distance S

Safe switch off distance S

ao

ar

“Mini” actuator

Safe switch on distance S

Safe switch off distance S

ao

ar

Switch-on behavior with “Flat”

or “Mini” actuator relative to

dir

ection of approach

Peripheral zones with parallel

approach. Minimum distance:

6 mm

No peripheral zones. No mini‐

mum distance with parallel

oach

appr

≤ 14 mm ≤ 9 mm

≤ 28 mm

≤ 14 mm ≤ 9 mm

≤ 28 mm

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

Peripheral zones with parallel

approach. Minimum distance:

10 mm

Peripheral zones with parallel

approach. Minimum distance:

4 mm

able 3: Safe switch-on range based on actuator, alignment, and approach direction

T

19

Page 20

5 MOUNTING

Draft 2016-10-19

5.4 Mounting

NOTE

If the actuator does not mov

closed, but instead approaches it in a parallel position, the specified minimum distance

must be adhered to. This prevents the sensor from enabling the safety outputs despite

the protective device not being fully closed.

Selecting the mounting location

e directly onto the sensor when the protective device is

he machine documentation does not specify t

If t

fully:

When the protective device is closed, the sensor and actuator must face each

b

other at the safe switch on distance of Sao or closer (see table 3).

Select a mounting location that allows the sensor and actuator to be accessed for

b

maintenance work and protects them against damage.

If possible, mount the sensor and actuator on non-ferrous subsurfaces and at a

b

distance from metallic parts in order to avoid affecting the sensing range. If this is

not possible, the effect on the safe switch on distance Sao and the safe switch off

distance Sar must be checked.

Make sure that there is no possibility of hazards arising when the protective device

b

is opened, even if the actuator has not yet reached the safe switch off distance

Sar.

If the actuator is approaching the sensor in a parallel position, observe the mini‐

b

mum distances (see table 3).

If necessary, attach an additional stop for the moving protective device.

b

Mounting the sensor

Mount the sensor on the fixed part of the protective device.

1.

2. Take account of the tightening torque for the fixing screws: 1 Nm

Mounting the actuator

1. Align the actuator using the marking notches on the sensor.

he mounting location, select one care‐

20

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Figure 4: Aligning the actuator on the sensor

2. If you are mounting using fixing screws, take account of the tightening torque for

the screws:

“Standard” and “Flat” actuators: 1 Nm

°

“Mini” actuator: 0.7 Nm

°

Subject to change without notice

Page 21

Mounting multiple safety switches

³ 140

³ 100

³ 100

³ 200

Draft 2016-10-19

MOUNTING 5

1. When mounting multiple safety switches, adher

e to the specified minimum dis‐

tance between the individual systems in order to avoid mutual interference.

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

Figure 5: Minimum distances relative to the alignment of the safety switches

21

Page 22

6 ELECTRICAL INSTALLA

Draft 2016-10-19

TION

6 Electrical installation

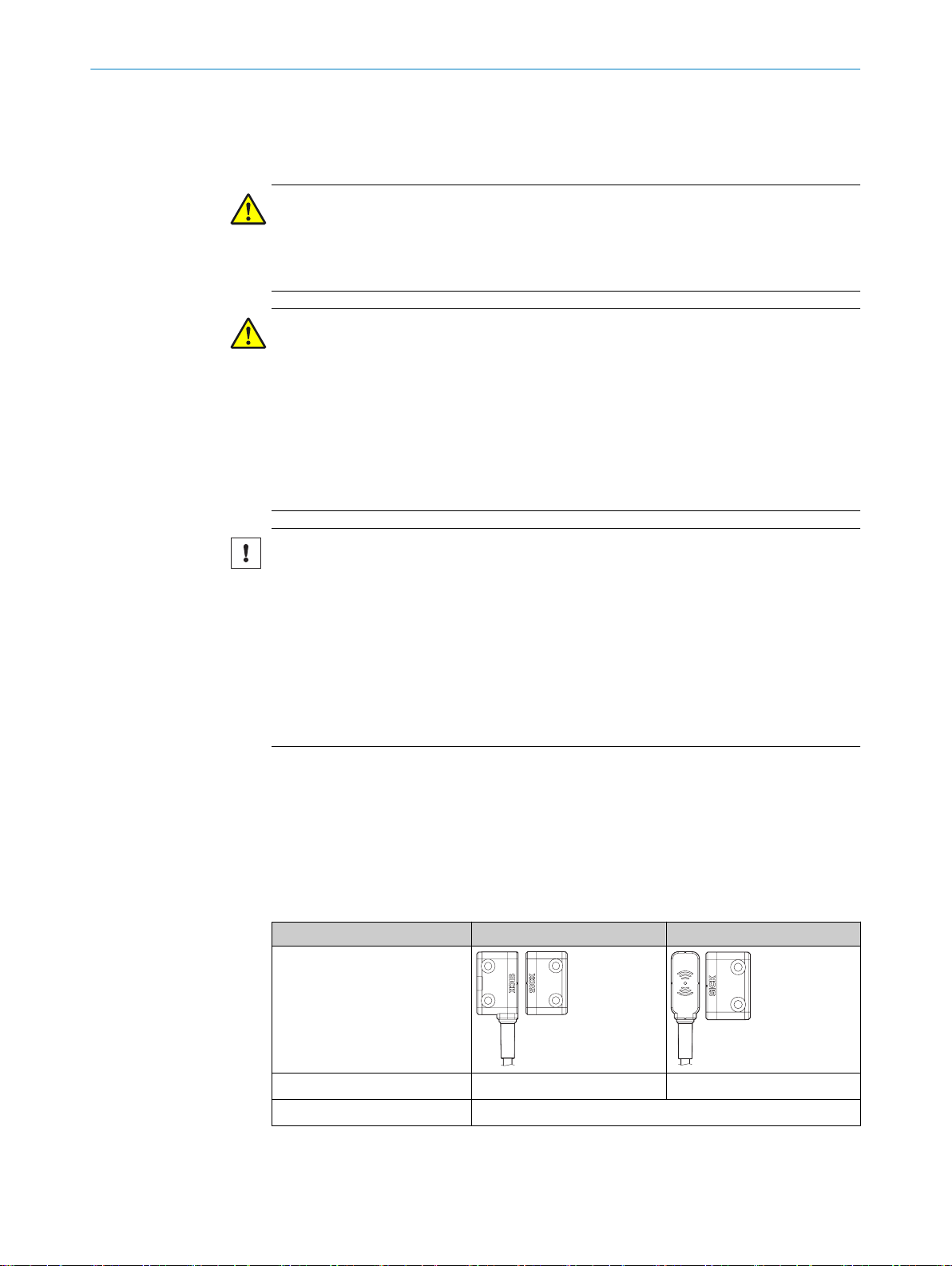

6.1 Safety

DANGER

Hazard due to electrical volt

Hazard due to unexpected starting of the machine

Make sure that the machine is and remains disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is and remains switched off

b

during electrical installation.

Make sure that the outputs of the safety switch have no effect on the machine

b

during electrical installation.

DANGER

Incorrect safety switc

Loss of safety function

When using insulation material or stranded connection wires, make sure they

b

demonstrate the required temperature resistance and mechanical load capability.

Use only safe contacts for safety functions.

b

age

h connection

Use a suitable voltage suppl

b

PELV (IEC 60204-1) for all devices that are electrically connected to the safety

switch.

All devices that are electrically connected to the safety switch must have the same

b

voltage supply.

Use protected cable routing to eliminate cross-circuits and short-circuits.

b

Power devices (such as motors) that represent a strong source of interference

b

must be kept isolated from circuits for signal processing. Route the cables for the

safety circuits as far away as possible from the power circuit cables.

Make sure that 1 A fuse protection is provided for safety switches.

b

Make sure that all electrical outputs have an adequate suppressor to accommo‐

b

date inductive loads. For this purpose, the outputs must be protected with an

appropriate suppressor such as a freewheeling diode, a varistor, or an RC element.

DANGER

Hazard due to lack of effectiveness of the protective device

The dangerous state may not be stopped in the event of non-compliance.

Operate safety switches within the specifications. If you operate them outside the

b

specifications, this may result in the sensor temperature increasing and in a loss

of the safety function.

Make sure that a current of no more than 100 mA is flowing at safety outputs

b

OSSD 1 and OSSD 2. Otherwise, it is no longer possible to guarantee the safety

function.

y. Voltage must be supplied in accordance with SELV/

22

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 23

ELECTRICAL INSTALLATION 6

Draft 2016-10-19

DANGER

Hazard due to lack of eff

The dangerous state may not be stopped in the event of non-compliance.

Always connect the two OSSDs separately. The two OSSDs must not be connected

b

to each other.

Connect the OSSDs such that the machine controller processes both signals sepa‐

b

rately.

ectiveness of the protective device

DANGER

Hazard due to lack of eff

The dangerous state may not be stopped in the event of non-compliance.

Prevent the formation of a potential difference between the load and the protec‐

b

tive device.

If you connect loads to the OSSDs (safe

b

led with negative voltage (e.g., electro-mechanical contactor without reverse polar‐

ity protection diode), you must connect the 0 V connections of these loads and

those of the corresponding protective device individually and directly to the same

0 V terminal strip. In the event of a fault, this is the only way to ensure that there

can be no potential difference between the 0 V connections of the loads and

those of the corresponding protective device.

ectiveness of the protective device

ty outputs) that then also switch if control‐

6.2 Notes on cULus

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

The following conditions must also be fulfilled in order to use and apply the equipment

in accordance with UL 508 requirements:

23

Page 24

12

3 4

5

3

4

8

5

6

1

7

2

6 ELECTRICAL INSTALLATION

Draft 2016-10-19

The voltage supply mus

•

Connections In 1 and In 2 must conform to Class 2 according to UL 508.

•

The device must have 1 A fuse protection.

•

6.3 Device connection (flying leads)

Wire color Designation Description

Brown +24 V DC 24 V DC voltage supply

White OSSD 1 Output OSSD 1

Blue 0 V 0 V DC voltage supply

Black OSSD 2 Output OSSD 2

Gray Aux Application diagnostic output

Table 4: Device connection cable assignment

6.4 Device connection (M12, 5-pin)

t conform to Class 2 according to UL 508.

(not safe)

Figure 6: Device connection (male connector, M12, 5-pin, A-coded)

Pin Wire color

1 Brown +24 V DC 24 V DC voltage supply

2 White OSSD 1 Output OSSD 1

3 Blue 0 V 0 V DC voltage supply

4 Black OSSD 2 Output OSSD 2

5 Gray Aux Application diagnostic output

Table 5: Device connection pin assignment (male connector, M12, 5-pin, A-coded)

1)

Applies to the extension cables recommended as accessories.

e t

Ensur

b

1)

he plug connect

6.5 Device connection (M12, 8-pin)

Figure 7: Device connection (male connector, M12, 8-pin, A-coded)

Designation Description

(not safe)

or is tightl

y connect

ed.

24

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Pin Wire color

1 White Aux Application diagnostic output

2 Bro

Table 6: Device connection pin assignment (male connector, M12, 8-pin, A-coded)

1)

wn +24 V DC 24 V DC voltage supply

Designation Description

(not safe)

Subject to change without notice

Page 25

ELECTRICAL INSTALLATION 6

Draft 2016-10-19

Pin Wire color

3 Green N.C. Not connected

4 Yellow In 2 Input OSSD 2

5 Gray OSSD 1 Output OSSD 1

6 Pink OSSD 2 Output OSSD 2

7 Blue 0 V 0 V DC voltage supply

8 Red In 1 Input OSSD 1

Table 6: Device connection pin assignment (male connector, M12, 8-pin, A-coded)

1)

Applies to the extension cables recommended as accessories.

2)

When used as a single safety switch or as the first safety switch in a cascade: apply 24 V DC (see "Con‐

necting a cascade", page 25).

Ensure the plug connector is tightly connect

b

6.6 Connecting a cascade

Structure of a cascade

The cascade can be created using special T-connector

"Accessories", page 43).

1)

Designation Description

2)

2)

ed.

s and an end connector (see

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

Figure 8: Cascading multiple safety switches

STR1 safety switch

M12 connection cable, 8-pin

End connector

T-piece

M12 connection cable, 4-pin

M12 connecting cable, 4-pin

Safe evaluation unit

25

Page 26

5

4

3

2

1

55

44

33

2

2

1

1

5

6 7

8

4

3

21

12

3 4

5

6 ELECTRICAL INSTALLATION

Draft 2016-10-19

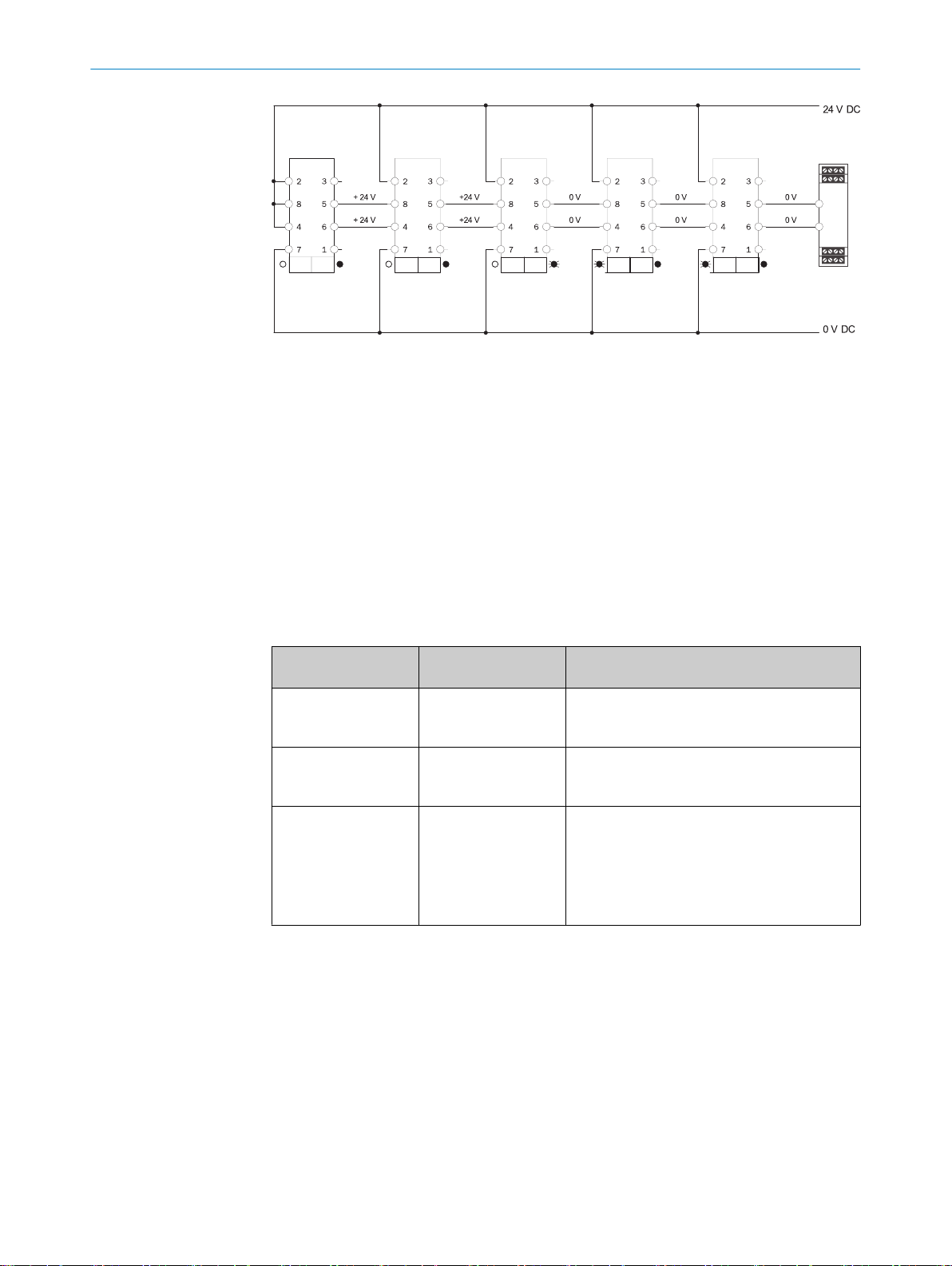

Figure 9: Internal circuitry: end connector for cascade

Figure 10: Internal circuitry: T-piece for cascade

DANGER

Bypassing the protectiv

e device

The dangerous state may not be stopped in the event of non-compliance.

If the cascade is created using T-pieces, install the connecting cables in a way that pre‐

vents a single T-piece (and therefore a safety switch) from simply being jumpered.

NOTE

In the case of safety switches cascaded using T

-connectors, it is not possible to evalu‐

ate the application diagnostic output.

NOTE

If special T-pieces and end connectors are no

t being used to create the cascade, make

sure that inputs In 1 and In 2 are connected to a constant 24 V DC at the first safety

switch in the cascade.

Cascade connection (M12, 5-pin)

The 5-pin male connect

or of t

he las

t T

-piece bef

ore the safe evaluation unit is the inter‐

face between the cascade and the safe evaluation unit.

26

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Figure 11: Cascade connection (M12, 5-pin, A-coded, male connector)

Subject to change without notice

Page 27

ELECTRICAL INSTALLATION 6

Draft 2016-10-19

Pin Wire color

1)

Designation Description

1 Brown +24 V DC 24 V DC voltage supply

2 White OSSD 1 Output OSSD 1

3 Blue 0 V 0 V DC voltage supply

4 Black OSSD 2 Output OSSD 2

5 Gray N.C. Not connected

Table 7: Cascade connection pin assignment (male connector, M12, 5-pin, A-coded)

1)

Applies to the extension cables recommended as accessories.

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

27

Page 28

7 COMMISSIONING

Draft 2016-10-19

7 Commissioning

7.1 Safety

DANGER

Hazard due to lack of eff

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

1. Have qualified safety personnel perform a thorough check on the machine and

approve it before commissioning.

2. Make sure that the time for the safety requirement (closing the protective device

again) is longer than the risk time.

7.2 Switching on

The device initializes after switching on. During this process, the OSSDs are switched

off and the light emitting diodes light up alternately in the color sequence green, red,

and yellow. For unique coded and permanently coded safety switches only: If any actua‐

tors have already been taught in, the STATE light emitting diode will flash once after ini‐

tialization for each taught-in actuator.

ectiveness of the protective device

7.3 Teach-in

DANGER

Bypassing the protectiv

The dangerous state may not be stopped in the event of non-compliance.

If an actuator is taught in, document this

b

During regular thorough checks, make sure that the taught-in actuator is still being

b

used.

Variant for universally coded actuators

No teach-in is req

Variant for unique coded actuators

An actuator must be taught in during commissioning. Up to 8 actuators may be taught

in one after the other. Only the most recently taught-in actuator is valid. Previously

taught-in actuators cannot be taught in again.

Variant for permanently coded actuators

An actuator must be taught in during commissioning. It is not possible to teach in any

further actuators.

Teaching in an actuator

e device

uired.

28

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

1. Open the physical guard.

2. Connect the safety switch to the voltage supply (see "Electrical installation",

page 22).

✓

The start sequence is performed. The LEDs light up alternately in the color

sequence green, red, and yellow.

3. Close the physical guard.

✓

When the guard is closed and the actuator has reached the appropriate position,

the safety switch will automatically start the teach-in sequence. The LEDs will dis‐

Subject to change without notice

Page 29

4. Within 5 minutes of successfully teaching in the actuator, connect and restore the

Draft 2016-10-19

✓

NOTE

Actuators can only be taught in at cascaded safety switches if voltage is present at

inputs In 1 and In 2. For this purpose, the actuators must be taught in individually in a

specific order. Viewed from the evaluation unit, teach-in starts at the last safety switch

in the cascade (STATE light emitting diode lights up red, DIAG light emitting diode is off).

Then the actuator is taught in at the second-to-last safety switch in the cascade, and so

on.

7.4 Thorough check

COMMISSIONING 7

play the individual steps.

STATE light emitting

diode (red/green)

green yellow

green yellow

Table 8: Displays for teach-in sequences

voltage supply f

Once the taught-in actuator is in the response range, both OSSDs switch to the ON

state and the STATE light emitting diode lights up green.

DIAG light emitting

diode (y

or the safety switch.

ellow)

Step

A

ctuator is being taught in

A

ctuator has been taught in

Requirements for the thorough check during commissioning and in certain situations

The protective de

situations:

Before commissioning

•

After changes to the configuration or the safety function

•

After changes to the mounting, the alignment, or the electrical connection

•

After exceptional events, such as after a manipulation has been detected, after

•

modification of the machine, or after replacing components

The thorough check ensures the following:

Compliance with all relevant regulations and effectiveness of the protective device

•

for all of the machine’s operating modes.

The documentation corresponds to the state of the machine, including the protec‐

•

tive device

The thorough checks must be carried out by qualified safety personnel or specially

qualified and authorized personnel and must be documented in a traceable manner.

1. Check whether the protective device of the machine is effective in all operating

modes in whic

Make sure that the operating personnel have been instructed in the function of

2.

the protective device before starting work on the machine. The instruction is the

responsibility of the machine operator and must be carried out by qualified per‐

sonnel.

vice and its application must be thoroughly checked in the following

h t

he mac

hine can be se

t.

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

29

Page 30

8 TR

Draft 2016-10-19

OUBLESHOOTING

8 Troubleshooting

8.1 Safety

DANGER

Hazard due to lack of eff

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Immediately put the machine out of operation if the behavior of the machine can‐

b

not be clearly identified.

Immediately put the machine out of operation if you cannot clearly identify or allo‐

b

cate the fault and if you cannot safely remedy the fault.

Secure the machine such that it cannot be switched on unintentionally.

b

DANGER

Hazard due to unexpected s

When any work is taking place, use the protective device to secure the machine or

b

to ensure that the machine is not switched on unintentionally.

ectiveness of the protective device

tarting of the machine

DANGER

Hazard due to lack of eff

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

b

b

b

NOTE

If you cannot remedy the f

please contact your respective SICK subsidiary.

8.2 Diagnostic LEDs

8.2.1 Switching on

STATE light emitting diode

(red/green)

green

red

yellow

green

T

able 9: LED displays dur

1)

For unique coded and permanently coded safety switches only: If any actuators have already been taught

in, t

ectiveness of the protective device

Do not carry out any repairs on the device components.

Do not make any modifications to or manipulate the device components.

Apart from during the procedures described in this document, the device compo‐

nents must not be opened.

ault with the help of the information provided in this chapter,

el‐

Duration

500 ms

500 ms

500 ms

1)

TE light emitting diode will f

he STA

DIAG light emitting diode (y

low)

ing initialization

lash once after initialization for each taught-in actuator.

30

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 31

8.2.2 State display

Draft 2016-10-19

8.2.3 Fault displays

STATE light emitting diode

(red/green)

red

green

ed yellow

r

DIAG light emitting diode (y

low)

TROUBLESHOOTING 8

el‐

Meaning

No voltage supply

No valid actuator in r

range. OSSD pair in OFF stat

Actuator in response r

OSSD pair in ON state

Signal at OSSD in

In 2 invalid or not present.

OSSD pair in OFF s

puts In 1 and

tate

esponse

e

ange.

STATE light emitting

diode (red/green)

red yellow

r

ed

Table 10: Fault displays

DIAG light emitting

diode (y

ellow)

Possible cause Corrective measure

No voltage supply Check voltage supply.

If the light emitting

diodes do not light up

oltage sup‐

k OSSD 1

Chec

and OSSD 2 for

short-circuit

do

wnstream of

0 V or 24 V DC,

or between one

another

Check cabling

for damage.

There must be a

dual-channel

configuration.

he faulty

e t

Isolat

sensor and

chec

k it sepa‐

rately

Check wiring for

cross-circuits

and short-cir‐

cuits.

Switch the volt‐

age supply off

and on.

If the fault still

occurs after this,

the sensor is

defective.

Replace sensor.

Ext

ernal fault

Internal fault

even if a v

ply is present, replace

the safety switch.

•

•

•

•

•

•

8.2.4 Fault displays in cascading

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

If a fault affects a device in a cascade, the device in question displays the fault and

switc

hes off the OSSDs (ST

ATE light emitting diode flashes red). All downstream devices

switch off their OSSDs (STATE light emitting diode lights up red, DIAG light emitting

diode flashes yellow).

31

Page 32

1

DIAGSTATE

2 3 4 5

DIAGSTATE

DIAG

STATE

DIAGSTATE

DIAG

STATE

6

6 7

8 8

!

8 TROUBLESHOOTING

Draft 2016-10-19

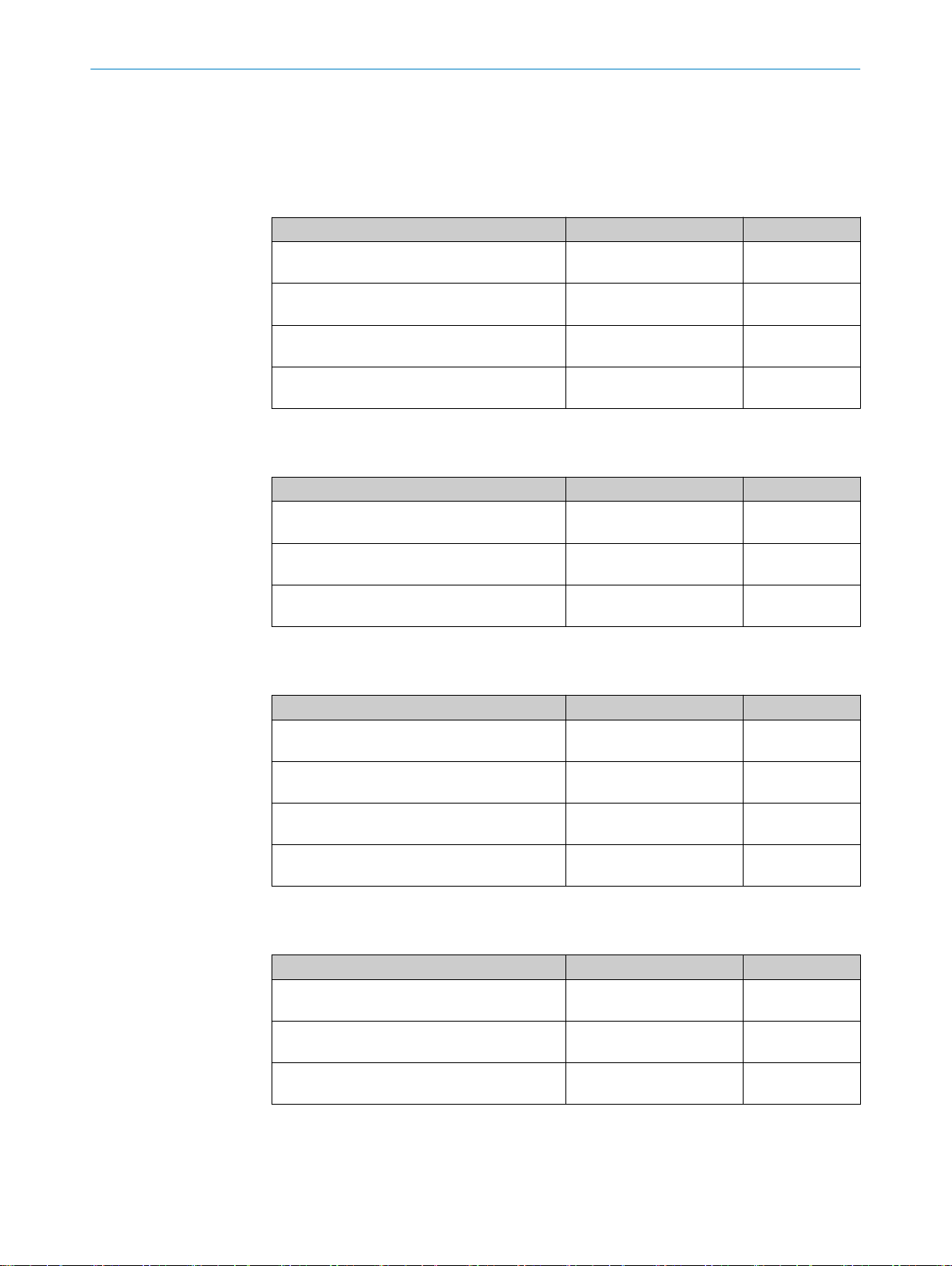

Figure 12: Fault displays on cascaded safety switches. The example shows an internal fault at

safety switch 3

Safety switch

–

Light emitting diode lights up green

Light emitting diode flashes red

Light emitting diode lights up red

What to do in the event of a fault affecting cascaded safety switches:

e the faulty sensor and chec

Isolat

•

Check wiring for cross-circuits and short-circuits.

•

Switch the voltage supply off and on. If the fault still occurs after this, the sensor is

•

defective. Replace sensor.

8.2.5 Fault displays during teach-in

STATE light emitting

ed/green)

diode (r

red/green yellow

red/green yellow

red/green

Table 11: Fault displays during teach-in

Fault displays are repeated until the equipment is reset.

S

ATE light emitting

T

diode (yellow)

k it separately.

Cause

The maximum number of actuat

taught in. It is not possible to carr

teach-in process.

An actuat

needs to be taught in again. This is not possi‐

ble.

Teach-in sequence f

again. Possible fault:

•

•

or that has already been taught in

ailed. Teach in the actuator

ctuator removed from response range

A

too early.

Voltage supply not isolated in a timely

manner.

ors has been

y out another

32

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

To perform a r

b

eset, disconnect the voltage supply for at least 3 s.

Subject to change without notice

Page 33

9 Maintenance

Draft 2016-10-19

9.1 Cleaning

NOTICE

Do not use aggressive cleaning ag

b

Do not use any substances that hinder the wetting properties of lacquers.

b

We recommend anti-static cleaning agents.

b

9.2 Regular thorough check

The safety switch must be thoroughly checked regularly. The type and frequency of thor‐

ough checks are def

see "Thorough check concept", page 17

Regular thorough checks serve to investigate the effectiveness of the safety switch and

detect any ineffectiveness due to modifications or external influences (such as damage

or manipulation).

1. Carry out the thorough checks according to the instructions from the manufacturer

and the operating entity of the machine.

MAINTEN

ents.

ined by the manufacturer and the operating entity of the machine;

ANCE 9

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

33

Page 34

10 DECOMMISSIONING

Draft 2016-10-19

10 Decommissioning

10.1 Protection of the environment

The safety switch has been designed to minimize its impact on the environment. It uses

a minimum of energy and resources.

ys act in an environmentally responsible manner at work. For this reason,

Alwa

b

please note the following information regarding disposal.

10.2 Disposal

Always dispose of serviceableness devices in compliance with local/national rules and

egulations with respect to w

r

NOTE

We would be pleased to be of assistance on the disposal of this device. Contact us.

aste disposal.

34

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 35

11 Technical data

Draft 2016-10-19

11.1 Technical data

Features

e switch on distance Sao (IEC 60947 5-3)

Saf

Front actuation

Side actuation

Typical switch on distance

Front actuation

Side actuation

Safe switch off distance S

Max. actuation frequency 0.5 Hz

Cascading ≤ 30 safety switches

Table 12: Features

TECHNICAL DATA 11

“Standard”

actuator

10 mm

6 mm

14 mm

8 mm

ar

25 mm 28 mm 28 mm

“Flat” actuator “Mini” actua‐

tor

14 mm

9 mm

19 mm

12 mm

14 mm

9 mm

19 mm

12 mm

Safety-related parameters

Performance level PL e (EN ISO 13849-1)

Category 4 (EN ISO 13849)

Safety integrity level SIL 3 (EN 61508)

SIL claim limit SILCL 3 (EN 62061)

PFHd (mean probability of a dangerous failure

per hour)

5.21 × 10–9 at 40 °C and mean sea level

14 x 10–9 at 40 °C and 2,000 m

TM (mission time) 20 years (EN ISO 13849-1)

R

esponse time (removal from response range) ≤ 40 ms

Enable time (reaction time when approaching

esponse range)

r

Risk time

Lengt

Minimum distance be

1)2)

h of cable

3)

tween 2 safety switches Dependent on alignment see "Mounting",

≤ 100 ms

≤ 80 ms

≤ 200 m

page 20

Type Type 4 (EN ISO 14119)

Coding level

Universally coded

Unique coded

Permanentl

y coded

Low coding level (EN ISO 14119)

High coding le

vel (EN ISO 14119)

High coding level (EN ISO 14119)

Safe state when a fault occurs At least one OSSD is in the OFF state

Table 13: Safety-related parameters

1)

At least one of the two OSSD outputs is safely switched off within the reaction time.

2)

The risk time is the fault detection time in the case of internal or external faults. External faults affect the

OSSDs (shor

is safely switched off within the risk time.

3)

The length of cable and the cable cross-section change the voltage drop according to the output current

(R

max

t-circuit to an OSSD or cross-cir

= 14.5 Ω).

cuit between the two OSSDs). At least one of the two OSSDs

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

35

Page 36

11 TECHNICAL DATA

Draft 2016-10-19

Interfaces

System connection

Voltage supply

Local inputs and outputs

Male connector, M12, 5-pin, A-coded (common

male connect

or

Male connector, M12, 8 pin, A-coded (common

male connector for voltage supply and inputs

and outputs) or

Flying leads

Length of connecting cable 3 m or 10 m

Table 14: Interfaces

Electrical data

OSSD pairs 1

Rated impulse withstand voltage U

imp

Pollution degree 3 (ext

1,500 V

ernal, according to EN 60947-1)

Power-up delay (after supply voltage is applied)1)2.5 s

or for voltage supply and outputs)

Supply voltage V

s

24 V DC (19.2 V ... 28.8 V)

Rated insulation voltage Ui 32 V DC

Cable capacitance 400 nF (for Out A and Out B)

or Out A

vice fuse pr

De

tection 1 A

o

2 μF (f

ux)

Current consumption (without load) 50 mA

Protection class III (EN 61140/IEC 61140)

Table 15: Electrical data

1)

Once the supply voltage is switched on, the OSSDs and the application diagnostic output will be in the

OFF state during t

0.1 s is added for each sensor. In the case of unique coded and permanently coded sensors, an addi‐

tional 0.5 s must be added per taught-in actuator.

he time delay before availability. The specified time applies to one sensor; in a cascade,

Mechanical data

Dimensions (W x H x D)

Safety switch

“Standard” actuator

“Flat” actuator

“Mini” actuat

or

40 mm x 18 mm x 26 mm

figure 15

see

see figure 16

see figure 17

Material

®

al

Sensor

ctuator

A

Vist

V

istal

®

Weight

Safety switch

“Standard” actuator

“Flat” actuator

“Mini” actuat

or

63 g ... 436 g (depending on variant)

26 g

13 g

6 g

Table 16: Mechanical data

36

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Inputs

Rated voltage 24 V DC (19,2 V ... 28,8 V)

Table 17: Inputs

Subject to change without notice

Page 37

TECHNICAL DATA 11

Draft 2016-10-19

Inputs

Switching current

ON state

OFF state

Switching v

ON state

OFF state

Table 17: In

Outputs

2 OSSDs (Out 1 and Out 2) 2 x PNP, 100 mA max., short-circuit protected

Application diagnos

Switching current

ON state

OFF state

Switching v

ON state

OFF state

Table 18: Outputs

oltage

puts

tic output (Aux) 50 mA max., short-circuit protected

oltage

≤ 5 mA

0 mA

21 V DC ... 24 V DC

≤ 2 V DC

and overload-proof

≤ 100 mA

< 500 µA

21 V DC ... 24 V DC

0 V DC ... 2 V DC

Ambient data

Enclosure rating IP 67 (IEC 60529)

Ambient operating temperature –10 °C … +70 °C

Storage temperature –25 °C … +70 °C

Vibration resistance 1 mm/10 Hz ... 55 Hz (IEC 60068-2-6)

Shock resistance 30 g, 11 ms (IEC 60068-2-27)

EMC According to IEC/EN 61326-3-1, IEC/

EN 60947-5-2, and IEC/EN 60947-5-3

Table 19: Ambient data

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

37

Page 38

18

14

M12 x 1

13,5

Ø 5,5

19

26,2

40

25175

3

5

Ø 8,5

22

18

14 13,5

Ø 5,5

19

26,2

40

25L

3

5

Ø 8,5

22

18

Ø 4,5

19

22

26,2

5

Ø 8,5

11 TECHNICAL DATA

Draft 2016-10-19

11.2 Dimensional drawings

Sensor

Figure 13: Dimensional drawing for STR1 sensor

with M12 male connector

Actuat

or

Figure 14: Dimensional drawing for STR1 sensor

with flying leads

Figure 15: STR1 dimensional drawing, “Standard” actuator

38

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 39

18 9

24

Ø 4,5

Ø 8,51

5

Figure 16: STR1 dimensional drawing, “Flat” actuator

9 7

23

Ø 3,4

Ø 6,5

4

Draft 2016-10-19

TECHNICAL DATA 11

Figure 17: STR1 dimensional drawing, “Mini” actuator

11.3 Response time and enable time in cascade

The reaction times are subject to the following parameters:

esponse time or enable time

R

•

Number of cascaded devices

•

Response time (r

Response time for cascade: 40 ms + 80 ms * number of safety switc

Enable time (actuator approaching response range)

Enable time for cascade: 100 ms + 80 ms * number of safety switches in cascade

emoval of actuator from response range)

hes in cascade

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

39

Page 40

12 ORDERING INFORMATION

Draft 2016-10-19

12 Ordering information

12.1 Scope of delivery

Sensor

•

Actuator

•

Safety no

•

Operating instructions for download: www.sick.com

•

12.2 STR1 ordering information

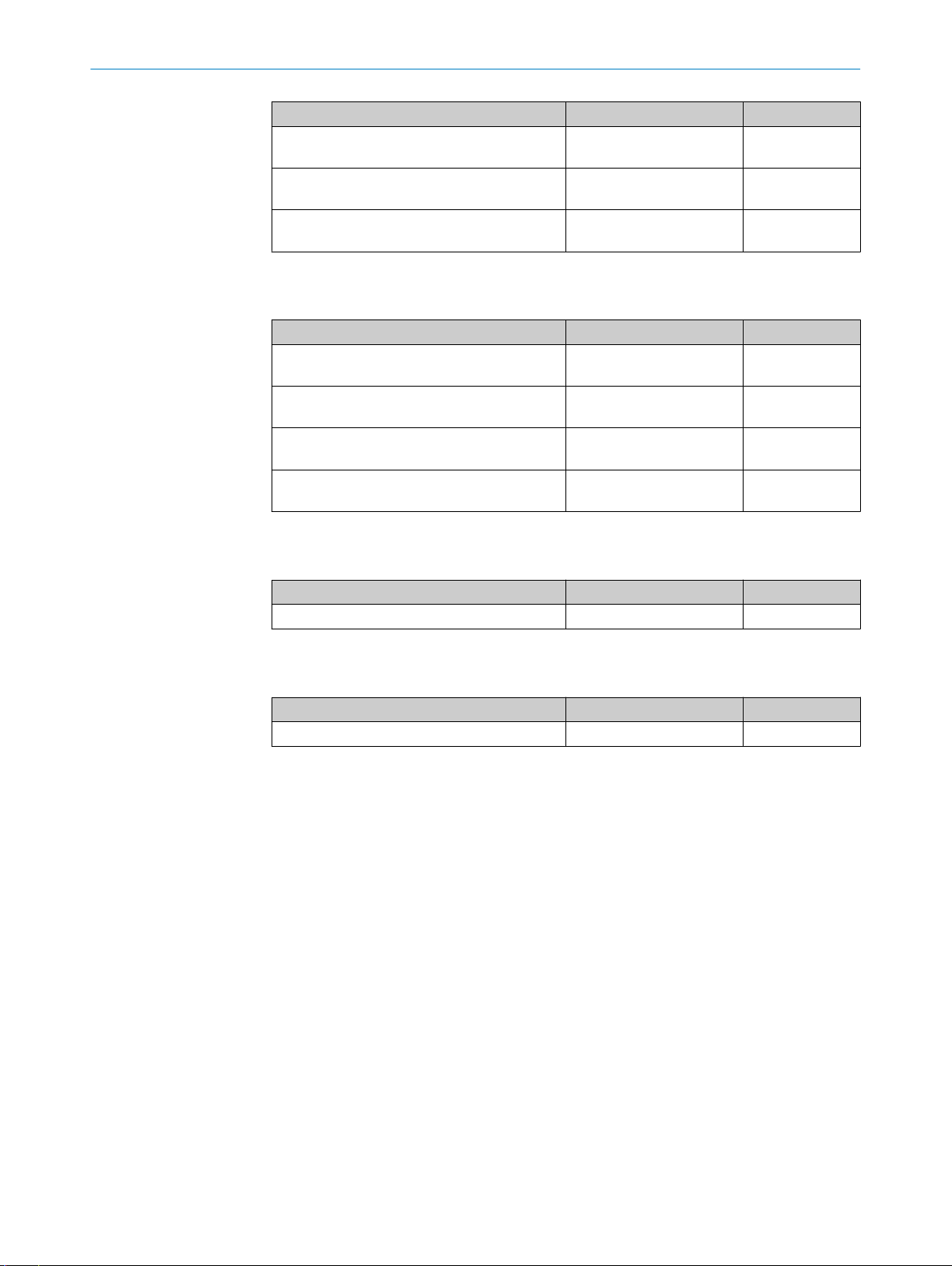

Actuator Sensor connection type Type code Part number

Flat Cable with male connector,

Standard Cable with male connector,

Mini Cable with male connector,

Table 20: STR1 ordering information, universally coded

te

STR1-SAFM0AC5 1069565

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAFM03P5 1069567

Cable, 5-wire, 10 m STR1-SAFM10P5 1069568

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SASM03P5 1069562

Cable, 5-wire, 10 m STR1-SASM10P5 1069563

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAMM03P5 1069572

Cable, 5-wire, 10 m STR1-SAMM10P5 1069573

STR1-SAFM0AC8 1069566

STR1-SASM0AC5 1069560

STR1-SASM0AC8 1069561

STR1-SAMM0AC5 1069570

STR1-SAMM0AC8 1069571

40

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Actuator Sensor connection type Type code Part number

Flat Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAFU03P5 1069577

Cable, 5-wire, 10 m STR1-SAFU10P5 1072707

Standard Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SASU03P5 1072711

Cable, 5-wire, 10 m STR1-SASU10P5 1072712

Table 21: STR1 ordering information, unique coded

STR1-SAFU0AC5 1069575

STR1-SAFU0AC8 1069576

STR1-SASU0AC5 1072709

STR1-SASU0AC8 1072710

Subject to change without notice

Page 41

ORDERING INFORMATION 12

Draft 2016-10-19

Actuator Sensor connection type Type code Part number

Mini Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAMU03P5 1073201

Cable, 5-wire, 10 m STR1-SAMU10P5 1073203

Table 21: STR1 ordering information, unique coded

Actuator Sensor connection type Type code Part number

Flat Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAFF03P5 1073208

Cable, 5-wire, 10 m STR1-SAFF10P5 1073209

Standard Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SASF03P5 1073213

Cable, 5-wire, 10 m STR1-SASF10P5 1073214

Mini Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-SAMF03P5 1073218

Cable, 5-wire, 10 m STR1-SAMF10P5 1073219

Table 22: STR1 ordering information, permanently coded

STR1-SAMU0AC5 1073205

STR1-SAMU0AC8 1073204

STR1-SAFF0AC5 1073206

STR1-SAFF0AC8 1073207

STR1-SASF0AC5 1073211

STR1-SASF0AC8 1073212

STR1-SAMF0AC5 1073216

STR1-SAMF0AC8 1073217

8018754/2016-xx-xx | SICK OP E RA T IN G I N ST R UC T IO N S | STR1

Subject to change without notice

41

Page 42

13 SPARE PARTS

Draft 2016-10-19

13 Spare parts

13.1 Actuator

Type Type code Part number

Flat STR1-XAF 1073221

Standard STR1-XAS 1073223

Mini STR1-XAM 1073222

Table 23: Actuator

13.2 Sensors

Coding Connection type Type code Part number

Universally coded Cable with male connector,

Unique coded Cable with male connector,

Permanently

coded

Table 24: Sensors

STR1-XDAM0AC5 1073224

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-XDAM03P5 1073226

Cable, 5-wire, 10 m STR1-XDAM10P5 1073227

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-XDAU03P5 1073231

Cable, 5-wire, 10 m STR1-XDAU10P5 1073232

Cable with male connector,

M12, 5-pin

Cable with male connector,

M12, 8-pin

Cable, 5-wire, 3 m STR1-XDAF03P5 1073235

Cable, 5-wire, 10 m STR1-XDAF10P5 1073236

STR1-XDAM0AC8 1073225

STR1-XDAU0AC5 1073228

STR1-XDAU0AC8 1073230

STR1-XDAF0AC5 1073233

STR1-XDAF0AC8 1073234

42

O PE R AT I NG IN S TR U CT I ON S | STR1 8018754/2016-xx-xx | SICK

Subject to change without notice

Page 43

14 Accessories

Draft 2016-10-19

14.1 Connectivity

Connecting cable, M12, 4-pin (0.34 mm2)

Part Type code Part number

Female connector straight, 5 m cable, open

end

Female connector straight, 10 m cable, open

end

Female connector straight, 15 m cable, open

end

Female connector straight, 20 m cable, open

end

Table 25: Ordering information for M12 connecting cable, 4-pin (0.34 mm2)

Connecting cable, M12, 5-pin (0.34 mm2)

Part Type code Part number

Female connector straight, 2 m cable, open

end

Female connector straight, 5 m cable, open

end

Female connector straight, 10 m cable, open

end

Table 26: Ordering information for M12 connecting cable, 5-pin (0.34 mm2)

ACCESSORIES 14

DOL-1204-G05MC 6025901

DOL-1204-G10MC 6025902

DOL-1204-G15MC 6034749

DOL-1204-G20MC 6034750

)

1

DOL-1205-G02MC 6025906

DOL-1205-G05MC 6025907

DOL-1205-G10MC 6025908

1)

Connection cable, M12, 8-pin (0.25 mm2)

Part Type code Part number

Female connector straight, 5 m cable, open

DOL-1208-G05MA 6020993

end

Female connector straight, 10 m cable, open

DOL-1208-G10MA 6022152

end

Female connector straight, 15 m cable, open

DOL-1208-G15MA 6022153

end

Female connector straight, 30 m cable, open

DOL-1208-G30MA 6022242

end

Table 27: Ordering information for M12 connecting cable, 8-pin (0.25 mm2)

1)

Connection cable, M12, 4-pin (0.25 mm2)

Part Type code Part number