Page 1

SIM1000 FXA

Sensor Integration Machine

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

SIM1000 FXA

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

1.4 SICK service.............................................................................................. 6

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Internet protocol (IP) technology.............................................................. 8

2.5 Limitation of liability................................................................................. 8

2.6 Modifications and conversions................................................................ 8

2.7 Requirements for skilled persons and operating personnel.................. 9

2.8 Operational safety and particular hazards.............................................. 9

3 Product description........................................................................... 11

3.1 Device view................................................................................................ 11

3.2 Functionality.............................................................................................. 11

3.3 SICK AppSpace......................................................................................... 11

3.4 Preset ETHERNET interfaces................................................................... 12

4 Transport and storage....................................................................... 13

4.1 Transport................................................................................................... 13

4.2 Transport inspection................................................................................. 13

4.3 Storage...................................................................................................... 13

5 Mounting............................................................................................. 14

5.1 Overview of mounting procedure............................................................. 14

5.2 Scope of delivery....................................................................................... 14

5.3 Mounting the device................................................................................. 14

6 Electrical installation........................................................................ 16

6.1 Important notes........................................................................................ 16

6.2 Preparing the electrical installation......................................................... 17

6.3 Assembling the cables (optional)............................................................ 18

6.4 Overview of connections.......................................................................... 18

6.5 Pin allocation of the connections............................................................ 19

6.5.1 Terminal block 1 and 2............................................................ 19

6.5.2 Terminal block 3 and 4............................................................ 20

6.5.3 Ethernet connections.............................................................. 20

6.6 Connecting peripheral devices................................................................ 21

6.7 Connecting voltage supply....................................................................... 21

7 Commissioning.................................................................................. 22

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

3

Page 4

CONTENTS

7.1 Preparatory commissioning..................................................................... 22

8 Operation............................................................................................ 23

8.1 Status LEDs............................................................................................... 23

8.1.1 Situation and function of the LEDs......................................... 23

9 Maintenance...................................................................................... 25

9.1 Maintenance schedule............................................................................. 25

9.2 Cleaning..................................................................................................... 25

10 Decommissioning............................................................................. 26

10.1 Removing the module............................................................................... 26

10.2 Disposal..................................................................................................... 26

11 Technical data.................................................................................... 27

11.1 Features.................................................................................................... 27

11.2 Interfaces.................................................................................................. 27

11.3 Mechanics and electronics...................................................................... 28

11.4 Ambient data............................................................................................. 28

12 Annex.................................................................................................. 29

12.1 Dimensional drawings.............................................................................. 29

12.2 Licenses.................................................................................................... 29

4

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied.

•

Compliance with local work safety regulations and general safety regulations for

•

device applications

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully to familiarize yourself with the device and its

functions before commencing any work.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

ABOUT THIS DOCUMENT 1

These operating instructions do not provide information on operating the machine or

system in which the device is integrated. For information about this, refer to the operat‐

ing instructions of the specific machine.

1.2 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1.3 Further information

NOTE

Further documentation for the device can be found on the online product page at:

www.sick.com/SIM10xx

•

There, additional information has been provided depending on the product, such as:

Model-specific online data sheets for device variants, containing technical data,

•

dimensional drawing, and specification diagrams

EU declarations of conformity for the product family

•

Dimensional drawings and 3D CAD dimension models in various electronic for‐

•

mats

This documentation, in English and German and other languages if applicable

•

Other publications related to the devices described here

•

Publications dealing with accessories

•

1.4 SICK service

If you require any technical information, our SICK Service will be happy to help. To find

your agency, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.,

to ensure faster processing.

6

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 General safety notes

The following safety notes must always be observed regardless of specific application

conditions:

The device must only be mounted, commissioned, operated, and maintained by

•

professionally qualified safety personnel.

Electrical connections with peripheral devices must only be made when the volt‐

•

age supply is disconnected.

The device is only to be operated when mounted in a fixed position.

•

The device voltage supply must be protected in accordance with the specifications.

•

The specified ambient conditions must be observed at all times.

•

The electrical connections to peripheral devices must be screwed on correctly.

•

The pin assignment of pre-assembled cables must be checked and adjusted if

•

necessary.

These operating instructions must be made available to the operating personnel

•

and kept ready to hand.

2.2 Intended use

SAFETY INFORMATION 2

The device is a programmable control and evaluation unit for sensors. The device also

acts as a link between system and plant controls, and the connected terminal devices.

The device is mainly used in an industrial environment in production, testing, and con‐

trol. Other applications are possible depending on the device-specific properties. When

using the device in a mobile application, make sure the floor is flat and smooth and

avoid door sills.

The device is programmed on a PC by using the development environment software

SICK AppSpace. Depending on the application, a browser-based, graphical user inter‐

face (HMI) can be created, which provides opportunities defined by the application

developer to influence an application at operator level. The device is connected to

peripherals via Ethernet interfaces and other interfaces.

The device offers various interfaces for controlling, programming, and operating pur‐

poses, which can be activated as necessary via development environments, control sys‐

tems (programmable logic controllers), or applications. However, configuration, pro‐

gramming, and control requires various technical skills, depending on how the device is

connected and used.

2.3 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

•

•

•

The device does not constitute a safety component in accordance with the respec‐

tive applicable safety standards for machines.

The device must not be used in explosion-hazardous areas, in corrosive environ‐

ments or under extreme environmental conditions.

Any use of accessories not specifically approved by SICK AG is at your own risk.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

Device should be used only in accordance with its intended use.

■

All information in these operating instructions must be strictly observed.

2.4 Internet protocol (IP) technology

NOTE

SICK uses standard IP technology in its products. The emphasis is placed on availability

of products and services.

SICK always assumes the following prerequisites:

The customer ensures the integrity and confidentiality of the data and rights

•

affected by its own use of the aforementioned products.

In all cases, the customer implements the appropriate security measures, such as

•

network separation, firewalls, virus protection, and patch management.

2.5 Limitation of liability

Relevant standards and regulations, the latest technological developments, and our

many years of knowledge and experience have all been taken into account when com‐

piling the data and information contained in these operating instructions. The manufac‐

turer accepts no liability for damage caused by:

■

Non-adherence to the product documentation (e.g., operating instructions)

■

Incorrect use

■

Use of untrained staff

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

NOTE

The product is a programmable device. The respective programmer is therefore respon‐

sible for his/her programming work and the resultant operation of the device. The liabil‐

ity and warranty of SICK AG is limited to the device specification (hardware functionality

and any programming interfaces) according to the agreed conditions. SICK AG will

therefore not be liable, among other things, for any damages resulting from the pro‐

gramming of the product by the customer or third parties.

2.6 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dangers.

Interrupting or modifying the device or SICK software will invalidate any warranty claims

against SICK AG. This applies in particular to opening the housing, even as part of

mounting and electrical installation.

8

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 9

2.7 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

This product documentation refers to the following qualification requirements for the

various activities associated with the device:

■

Instructed personnel have been briefed by the operator about the tasks assigned

to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g. Master Electrician). Other relevant regulations applicable in other

countries must be observed.

SAFETY INFORMATION 2

The following qualifications are required for various activities:

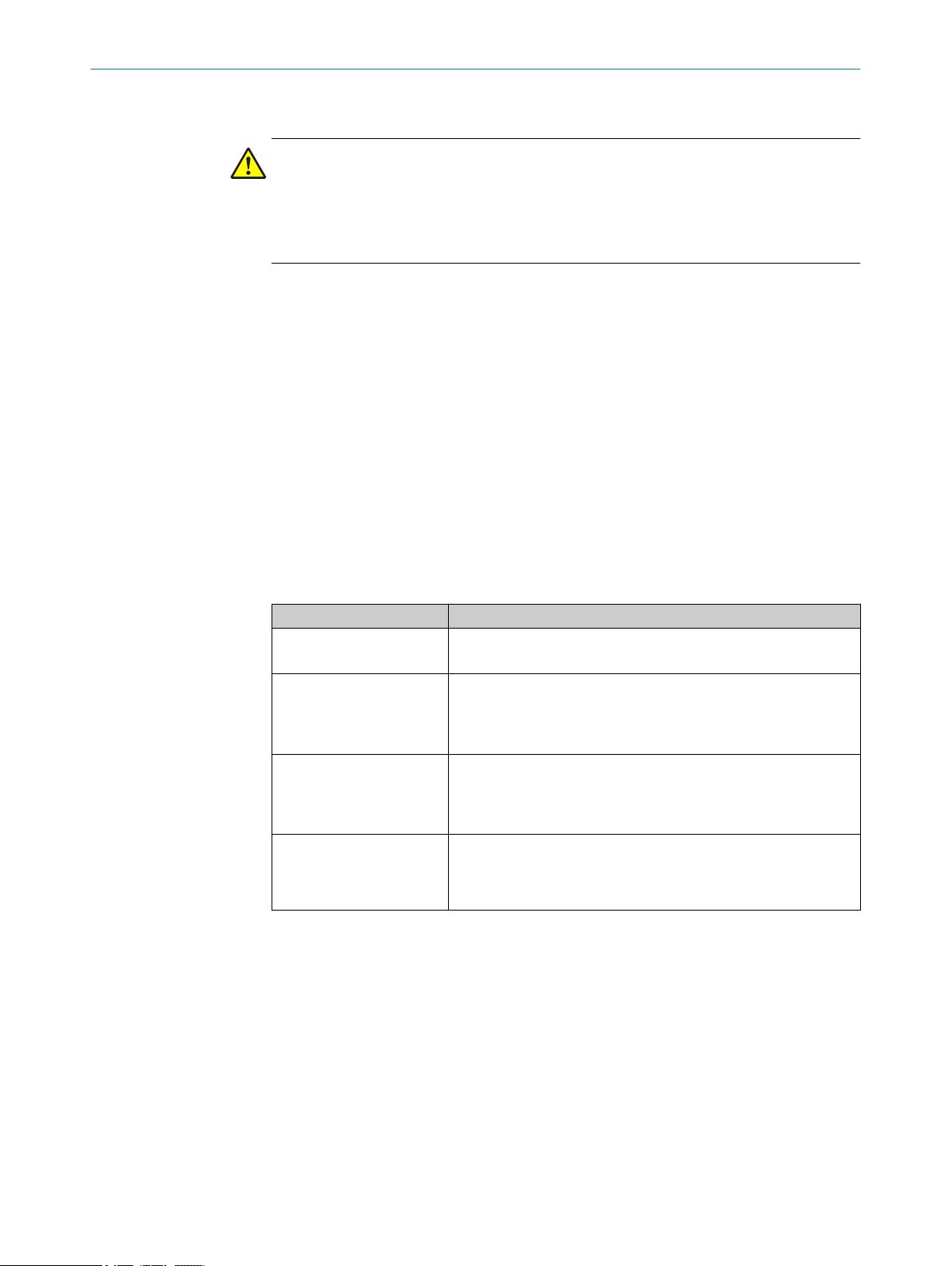

Table 1: Activities and technical requirements

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in their

■

particular application

Commissioning, configura‐

tion

Basic knowledge of the WindowsTM operating system in use

■

Basic knowledge of the design and setup of the described con‐

■

nections and interfaces

Basic knowledge of data transmission

■

Operation of the device for

the particular application

Knowledge of the operation and control of the devices in their

■

particular application

Knowledge of the software and hardware environment for the

■

particular application

2.8 Operational safety and particular hazards

Please observe the safety notes and the warnings listed here and in other chapters of

this product documentation to reduce the possibility of risks to health and avoid dan‐

gerous situations.

The product is fitted with LEDs in risk group 0. The accessible radiation from these

LEDs does not pose a danger to the eyes or skin.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

WARNING

Electrical voltage!

Electrical voltage can cause severe injury or death.

■

■

■

■

■

WARNING

Risk of injury and damage caused by potential equalization currents!

Improper grounding can lead to dangerous equipotential bonding currents, which may

in turn lead to dangerous voltages on metallic surfaces, such as the housing. Electrical

voltage can cause severe injury or death.

■

■

■

Work on electrical systems must only be performed by qualified electricians.

The power supply must be disconnected when attaching and detaching electrical

connections.

The product must only be connected to a voltage supply as set out in the require‐

ments in the operating instructions.

National and regional regulations must be complied with.

Safety requirements relating to work on electrical systems must be complied with.

Work on electrical systems must only be performed by qualified electricians.

Follow the notes in the operating instructions.

Install the grounding for the product and the system in accordance with national

and regional regulations.

10

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 11

3 Product description

1

2

3

3.1 Device view

PRODUCT DESCRIPTION 3

1

2

3

3.2 Functionality

The SIM1000 FXA Sensor Integration Machine – part of the SICK AppSpace ecosystem

– is opening up new possibilities for application solutions.

It can read, evaluate, archive, and transmit data from a number of different sensors.

The Ethernet interfaces with OPC UA and MQTT provide preprocessed data (edge com‐

puting) for cloud computing.

The HMI and data visualization features can be provided on any browser-enabled note‐

book, PC, or tablet. The app is developed in SICK AppStudio .

3.3

SICK AppSpace

Detailed instructions on the SICK AppStudio as well as programming the device can be

found at supportportal.sick.com.

Connections for switching input/output, IO-Link, CAN, and voltage supply

Serial connections

Ethernet connections

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

11

Page 12

3 PRODUCT DESCRIPTION

3.4 Preset ETHERNET interfaces

NOTE

Preset IP addresses of the ETHERNET interfaces:

Port 1: 192.168.0.1

•

Port 2: 192.168.1.1

•

Port 3: 192.168.2.1

•

Port 4: 192.168.3.1

•

When expanding the GigE interfaces with one or more Ethernet switches, it is essential

to use only jumbo-frame compatible GigE switches. Switches limited to just 100 MB do

not support the data packet mode used by cameras and can cause transmission

errors.

Changing the IP addresses

The individual IP addresses can be changed using the SICK SOPAS ET PC tool. This is

described in detail in the “SIM Getting Started Guide”, which is available for download

from the SICK AppSpace area of the SICK Support Portal. This guide also includes fur‐

ther notes on how to connect SICK sensors and the SICK picoCam and midiCam cam‐

eras to the Ethernet interfaces.

12

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 13

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

TRANSPORT AND STORAGE 4

4.2

Transport inspection

4.3 Storage

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 27.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

13

Page 14

5 MOUNTING

5 Mounting

5.1 Overview of mounting procedure

NOTICE

Damage to device through improper mounting.

Mount the device in an environment corresponding to enclosure rating IP54

(EN 60529), e.g., inside a control cabinet with enclosure rating IP54.

NOTE

The mounting procedure described here for the device meets the requirements for use

in the target system.

Additional or different requirements may become necessary in the laboratory and dur‐

ing preparation, and should be taken into account as necessary, see "Commissioning",

page 22. If you have any questions or anything remains unclear in this regard, please

contact our service team.

Mounting the device.

•

Connect the cables.

•

Connecting peripheral devices.

•

Connecting the voltage supply.

•

5.2 Scope of delivery

SIM1000 FXA

•

Safety note

•

Optional: ordered accessories

•

5.3 Mounting the device

Mount the device in accordance with EN 50274.

•

Ensure suitable ESD protective measures during mounting.

•

Implement suitable measures to prevent any foreign bodies from entering the con‐

•

nector openings or ventilation slots.

The module is housed in a 67.5 mm wide housing for standard 35 mm rails in

•

accordance with EN 60715 (mounting rail).

Install the module in the control cabinet in such a way that the minimum distance

•

to the control cabinet is adhered to. This distance is 50 mm above and below the

module, and 25 mm to the front and back.

Mount the module vertically. The ventilation slots must be positioned at the top

•

and bottom.

Mount the module in such a way as to allow vertical air circulation.

•

14

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 15

MOUNTING

Figure 1: Mounting the device, illustration only

Mounting rail

1

Grounding clip

2

Direction of engagement with the mounting rail

3

1. Make sure that the voltage supply is switched off.

2. Hook the device onto the DIN mounting rail.

3. The grounding clip must sit flush against the mounting rail so that it is secure and

can conduct electricity effectively.

4. Snap the module into place on the mounting rail by applying a slight pressure in

the direction of the arrow.

5. Mount the end pieces on the left and right side of the module.

5

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

15

Page 16

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Important notes

DANGER

Danger from electrical voltage.

Danger posed by the machine starting up unexpectedly.

Disconnect the power for the entire system/machine.

•

Prevent the system from starting unexpectedly while you are connecting the

•

devices!

WARNING

Risk of injury and damage caused by electrical current!

Due to equipotential bonding currents, incorrect earthing can lead to the following dan‐

gers and faults: Voltage is applied to the metal housing, cable fires due to cable shields

heating up, the product and other devices become damaged.

■

Generate the same ground potential at all grounding points.

NOTICE

Device damage due to improper supply voltage!

■

Only operate the device with the specified supply voltage.

■

The voltage supply and all connected signals must meet the requirements for

extra-low voltages with safe separation (SELV, PELV) as specified in EN 60664 and

EN 50178 (Electronic equipment for use in power installations).

Carry out the electrical installation work in conformity with EN 60204-1.

•

The external voltage supply for the devices must be capable of bridging short-term

•

power outages of 20 ms as specified in EN 60204-1, for example.

Make sure the device and the voltage supplies are all connected to the same

•

ground.

Connect the shielding of all data lines (Ethernet, CAN, serial) directly to the func‐

•

tional earth (FE) at the control cabinet entry point.

NOTE

Layout of data cables

■

Use screened data cables with twisted-pair wires.

■

Implement the screening design correctly and completely.

■

To avoid interference, e.g. from switching power supplies, motors, clocked drives,

and contactors, always use cables and layouts that are suitable for EMC.

■

Do not lay cables over long distances in parallel with power supply cables and

motor cables in cable channels.

16

EMC measures

Electromagnetic influences can interfere with signal transmissions and interrupt com‐

munications. To minimize electromagnetic influences, it is necessary to implement the

following measures:

Connect the mounting rail to functional earth (FE).

•

Ensure sufficient equipotential bonding of the connection points for the shielding.

•

Ensure compliance with the applicable standards and directives.

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 17

1

2

3

ELECTRICAL INSTALLATION 6

Connect all inactive metal parts (doors and housing of the control cabinet, DIN

•

mounting rails, etc.) to the ground potential.

Always connect the cable shielding to the ground connection across a large area

•

at both ends.

Use suitable cable clamps to connect the shielding of the shielded cables to the

•

ground potential directly at the access to the system (control cabinet, frame, DIN

mounting rail). The cable clamps must reach all the way around the cable shield‐

ing.

Use suitable cable clamps to connect the cable shielding to the ground potential,

•

once again as close as possible to the main module (e.g., on the DIN mounting

rail). The cable clamps must reach all the way around the cable shielding.

Keep the cable ends from which the insulation has been stripped as short as pos‐

•

sible.

Insulate the end of the shielding braid, for example using a suitable heat-shrink‐

•

able sleeve.

Figure 2: Connecting the cable shielding to the mounting rail, example

Mounting rail

1

Cable

2

Heat-shrinkable sleeve

3

6.2 Preparing the electrical installation

To carry out the electrical installation, you will need:

Connection cables for the peripheral devices, including the corresponding data

•

sheets

Voltage supply cable

•

If customers assemble the cables: crimping tool, ferrules, soldering iron, and other

•

installation material

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

17

Page 18

6 ELECTRICAL INSTALLATION

6.3 Assembling the cables (optional)

NOTE

For a list of cables suitable for use with the device, visit supportportal.sick.com or

www.sick.com. Customer assembly of the cables is only necessary in special cases.

Ensure a sufficient length of cable is provided, e.g. for strain-relief clamps.

NOTICE

Risk of damage/malfunction due to incorrect PIN assignment

Incorrect wiring of the male connectors/female connectors can lead to damage to or

malfunctions in the system.

■

Observe data sheets provided by the cable manufacturer.

■

Observe the pin assignment.

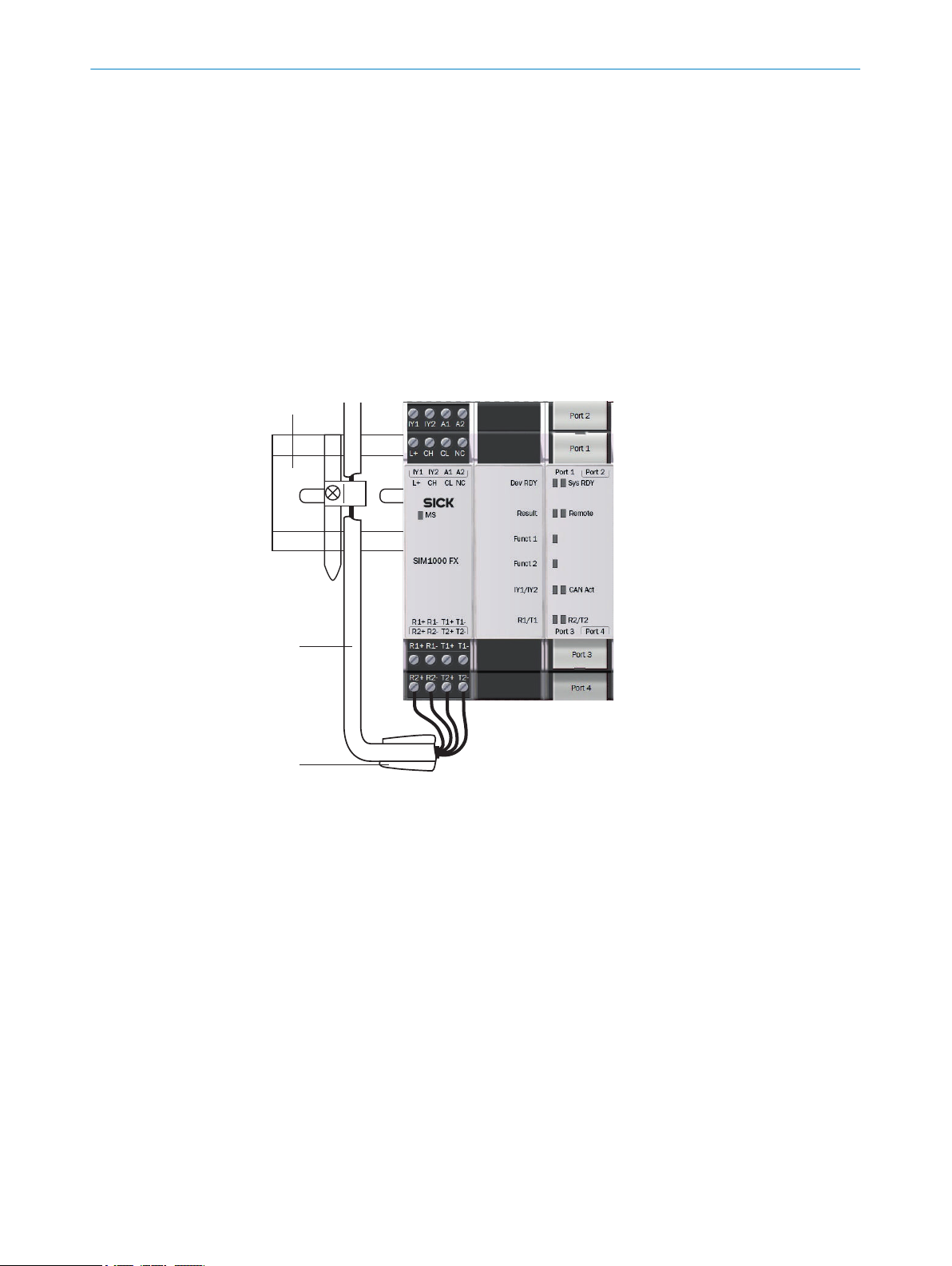

6.4 Overview of connections

18

Figure 3: Overview of connections

Terminal block 1 and 2

1

Terminal block 3 and 4

2

Ethernet connections

3

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 19

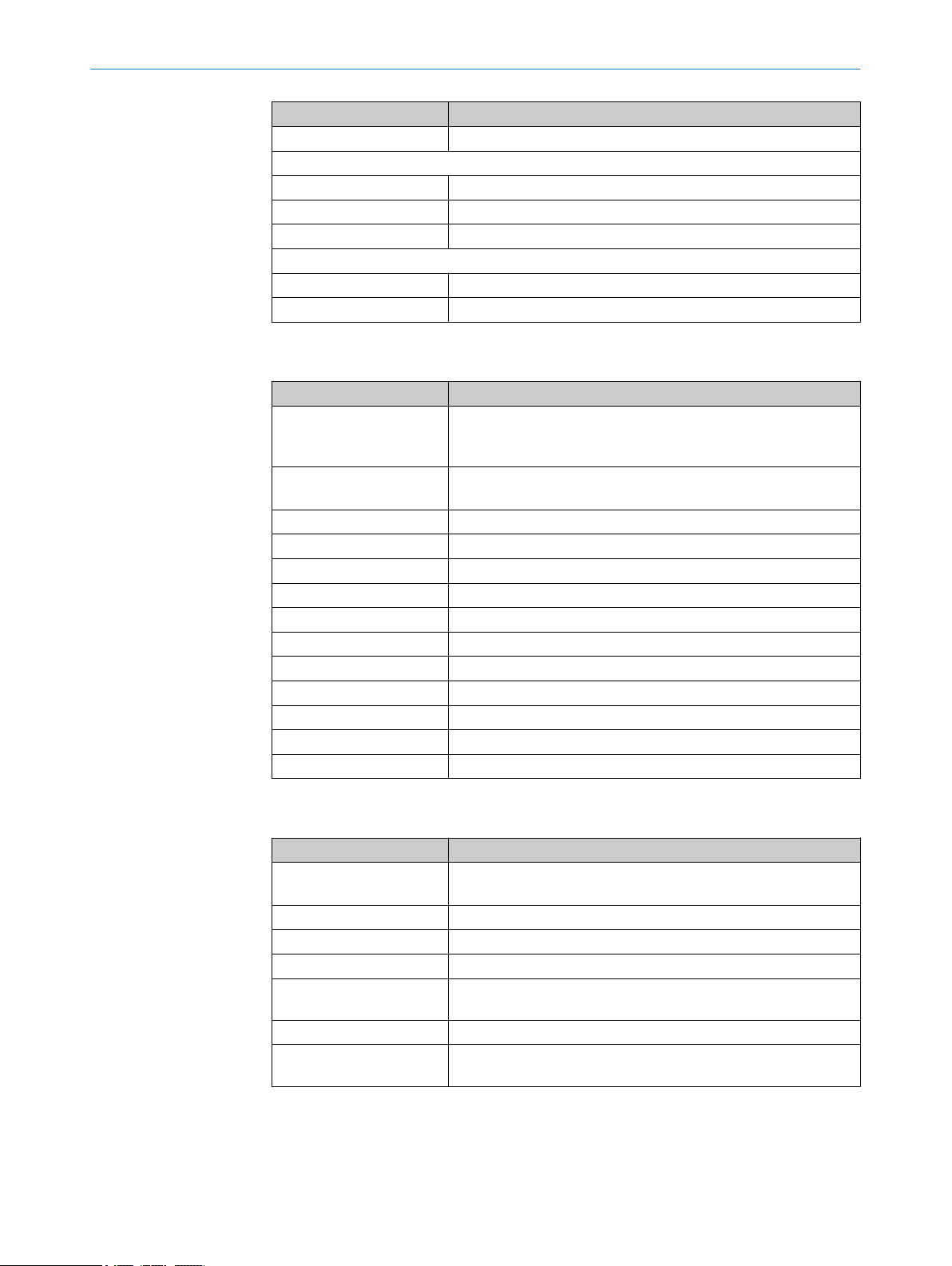

6.5 Pin allocation of the connections

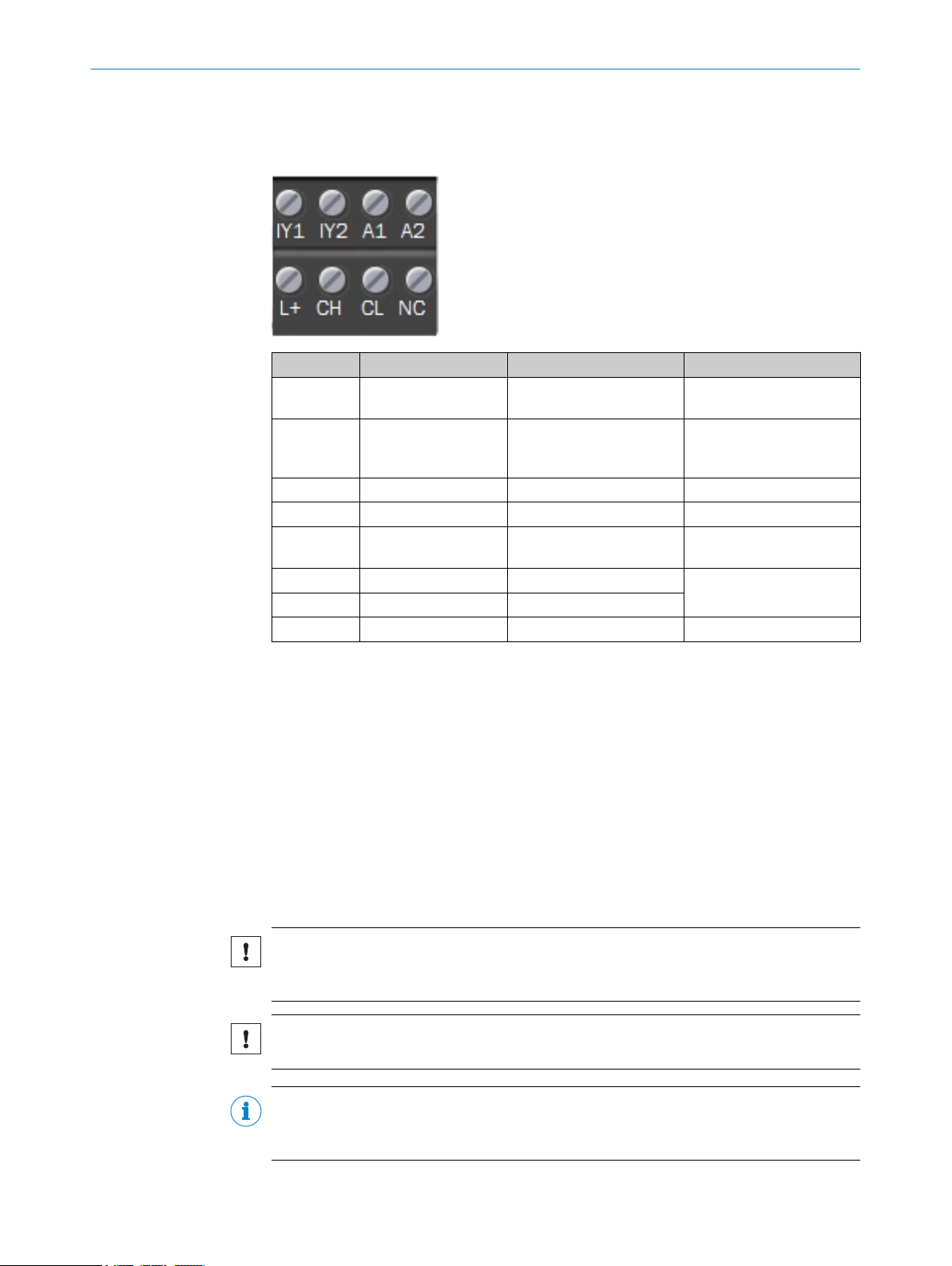

6.5.1 Terminal block 1 and 2

Designation Signal Function Factory settings

IY1 Input 2 Switching input (not iso‐

IY2 C/Q or Input 1 / Out‐

put 1

A1 +24 V Supply voltage IN -

A2 GND Ground -

L+ +24 V Supply voltage for peripher‐

CH CAN_H CAN high Termination deactivated*

CL CAN_L CAN low

NC - Not connected

ELECTRICAL INSTALLATION 6

lated)

C/Q IO-link or configurable

switching input/output (not

isolated)

als, configurable

-

Configured as input

Deactivated

*Termination controllable via app

Additional notes

Switching output

Max. output current: 100 mA

•

Min. high output logic level: VCC – 3 V

•

Max. low output logic level: 3 V

•

Push/pull, NPN, PNP configurable

•

Switching inputs

Min. high input logic level: 12 V

•

Max. low input logic level: 4 V

•

Supply voltage, peripherals L +

Output current: 200 mA

•

NOTICE

Shielded CAN cables must be used. The shielding of the CAN cables must be connected

to functional earth.

NOTICE

IO-Link ground and CAN ground of the sensor must be connected to system ground A2.

NOTE

The SIM1000 FXA device is supplied with power from an external power supply unit via

the pins A1 and A2.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

19

Page 20

ELECTRICAL INSTALLATION

6

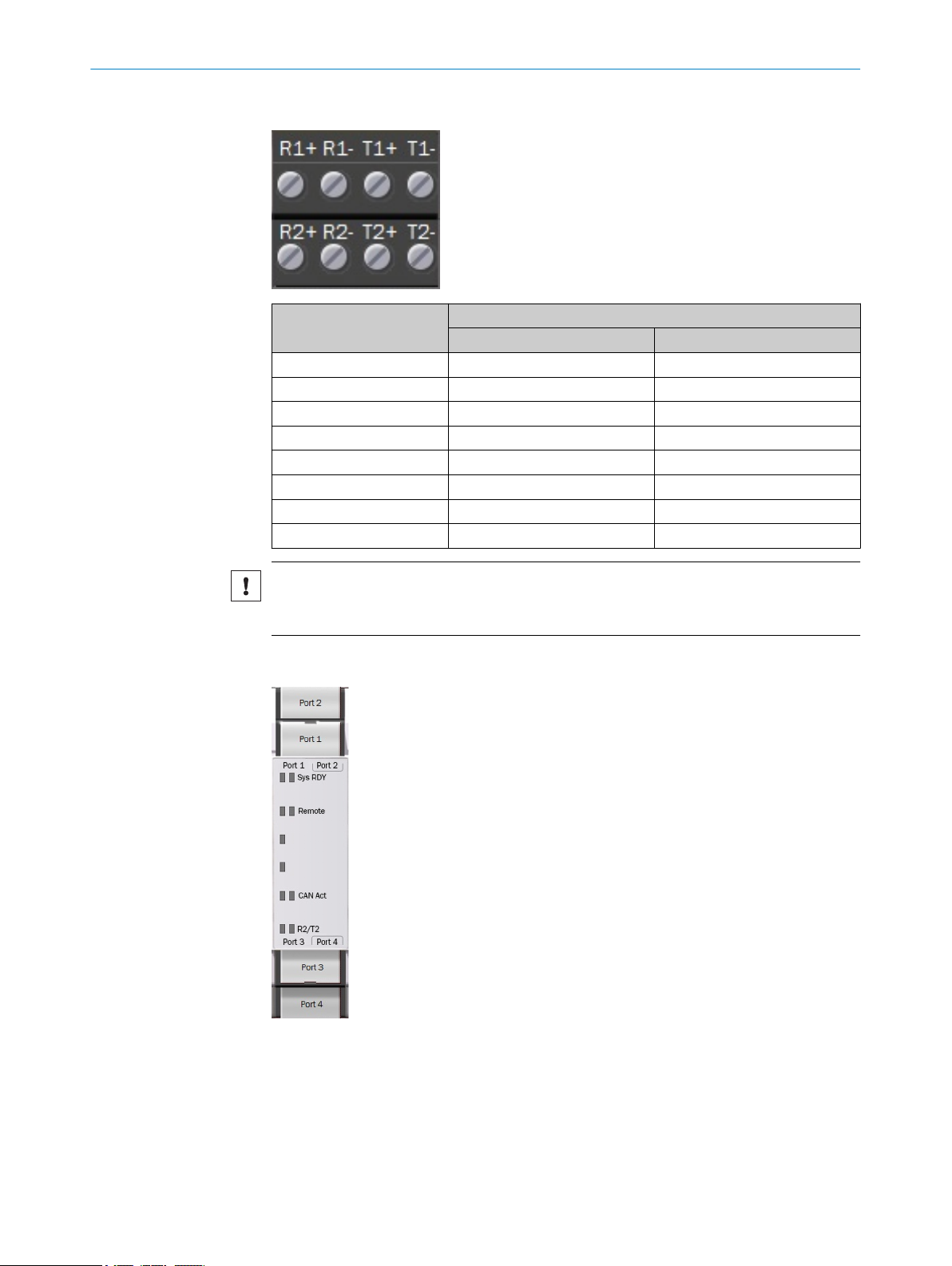

6.5.2 Terminal block 3 and 4

Designation Mode

R1+ R1+ -

R1- R1- -

T1+ T1+ Rx1+/Tx1+

T1- T1- Rx1-/Tx1-

R2+ R2+ -

R2- R2- -

T2+ T2+ Rx2+/Tx2+

T2- T2- Rx2-/Tx2-

RS-422 RS-485

NOTICE

Shielded cables must be used. The shielding of the cables must be connected to func‐

tional earth.

6.5.3 Ethernet connections

20

Port 1: 100 MBit/s

Port 2: 1 GBit/s

Port 3: 100 MBit/s

Port 4: 1 GBit/s

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 21

NOTICE

Shielded Ethernet cables must be used. The shielding of the Ethernet cables must be

connected to functional earth.

6.6 Connecting peripheral devices

The device can be connected to a wide range of sensors and cameras.

The required pin assignments can be found in the data sheets for the peripherals to be

connected as well as in the relevant connection descriptions, see "Pin allocation of the

connections", page 19.

1. Connect the cables to peripheral devices.

2. Route the cables to the device using installation materials (cable channels, cable

ties, etc.). When doing so, pay attention to cable strain relief.

3. Connect cables to the relevant device connections and screw together tightly.

6.7 Connecting voltage supply

NOTICE

Risk of damage to peripheral devices!

If peripheral devices are connected when the voltage supply is also applied, these

devices can become damaged.

■

Only connect peripheral devices when the voltage supply is disconnected.

ELECTRICAL INSTALLATION 6

1. Ensure that the voltage has been disconnected by the user.

2. Connect the voltage supply cable(s) to the device.

3. Lay the cable(s) with strain relief.

4. Have the user connect the voltage supply.

5. Have the user activate the voltage.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

21

Page 22

7 COMMISSIONING

7 Commissioning

7.1 Preparatory commissioning

Commissioning for preparatory purposes and under laboratory conditions differs in

some respects from commissioning in the target system.

In general, all safety and hazard warnings applicable to mounting (see "Mounting",

page 14) and electrical installation see "Important notes", page 16 must also be

observed under laboratory conditions. In addition, further notes must be taken into con‐

sideration to guarantee the most effective preparation possible:

Only connect those devices to the product that you want to configure or program.

•

Operate the connected device in a controlled and contained network environment

•

for the time being to check network communication if necessary.

Note the company standards that apply to the use of checking and testing devices.

•

For initial programming, use ideal conditions for sensor or camera recognition.

•

Use the largest possible deviations from these ideal conditions to check the pro‐

•

gramming with respect to its error tolerance and reliability, and to determine error

limit values.

Procedure

1. Place the device on a non-slip base.

2. Connect the required peripheral devices, see "Connecting peripheral devices",

page 21.

3. Connect the network connection.

4. Connect the voltage supply.

5. Switch on the voltage supply.

22

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 23

8 Operation

8.1 Status LEDs

OPERATION 8

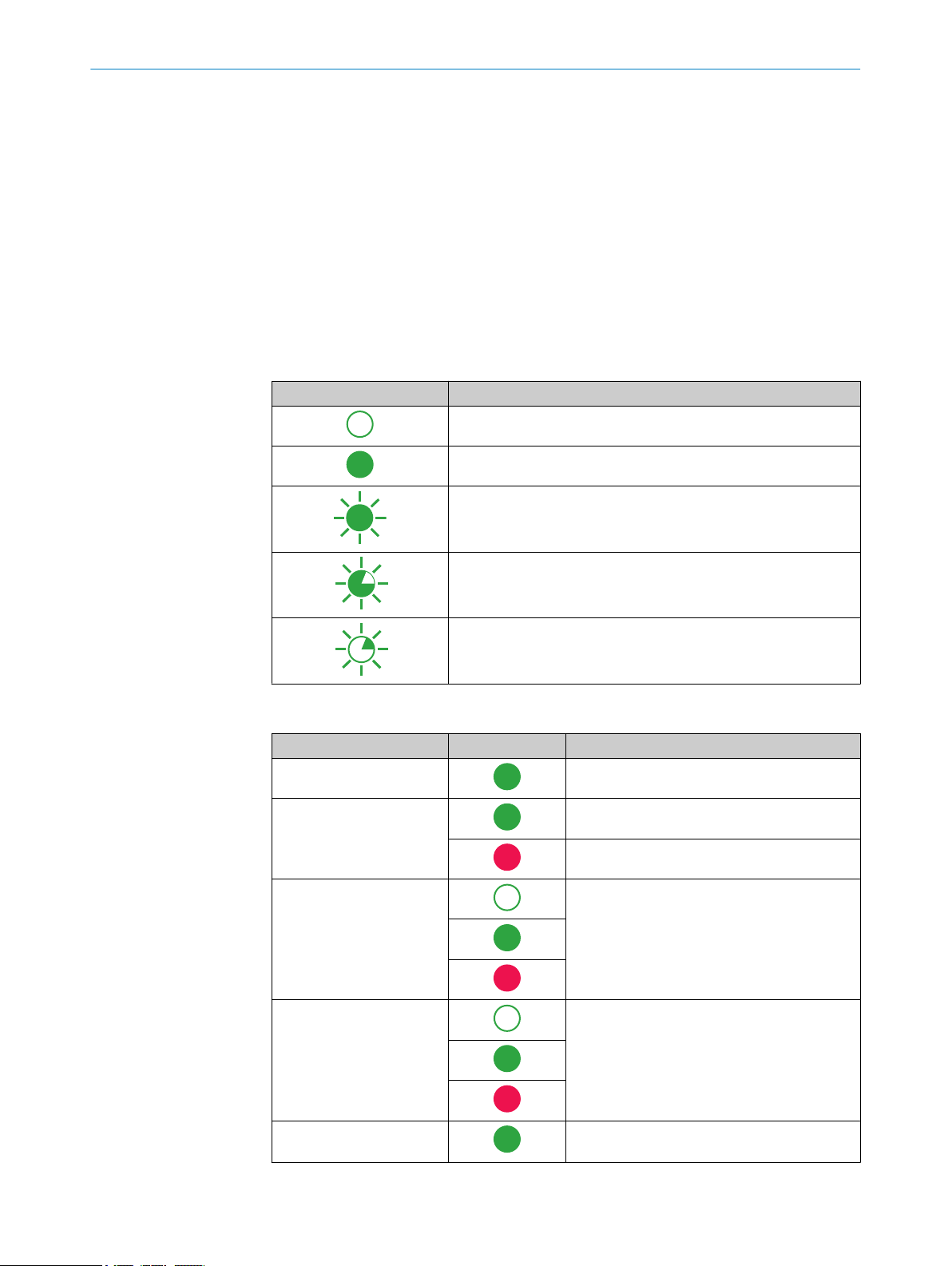

When the device is operating, the operational status of the connections is indicated

visually by status LEDs.

Using these status indicators, the operator can find out quickly and easily whether the

device and the peripherals are working properly or whether any faults or errors have

occurred.

Monitoring the visual indicators is part of the routine inspection carried out on the

device and the machine/plant area into which the device is incorporated.

Meaning of symbols

Symbol Meaning

LED off

LED on

LED flashes

8.1.1 Situation and function of the LEDs

Designation LED behavior Description

*)

MS

Dev RDY Runlevel READY, no errors detected.*

Sys RDY User-defined, configurable using SICK App‐

Result User-defined, configurable using SICK App‐

LED goes out briefly

LED lights up briefly

Voltage connected.

Runlevel READY, boot process error.

Space.

Space.

Remote Remote maintenance active, not currently sup‐

ported.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

23

Page 24

8 OPERATION

Designation LED behavior Description

Funct 1 User-defined, configurable using SICK App‐

Space.

Funct 2 User-defined, configurable using SICK App‐

Space.

IY1 / IY2

Voltage not applied to the connection.

CAN Act

R1 / T1

R2 / T2

Voltage applied.

No signal activity.

Voltage applied.

Signal activity.

Voltage not applied to the connection.

Signal activity.

Link Connection not established with Ethernet.

Connection established with Ethernet.

Act No activity.

Data transmission via Ethernet.

*Time delay before availability due to boot process (approx. 20 s)

*) Module status

24

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 25

9 Maintenance

9.1 Maintenance schedule

During operation, the device works maintenance-free.

9.2 Cleaning

NOTICE

Equipment damage due to improper cleaning.

Improper cleaning may result in equipment damage.

■

Only use recommended cleaning agents.

■

Never use sharp objects for cleaning.

The device must be cleaned regularly from the outside to guarantee heat dissipa‐

b

tion and therefore operation. Clean using a dry towel or an industrial vacuum

cleaner. Do not use cleaning agents.

MAINTENANCE 9

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

25

Page 26

10 DECOMMISSIONING

10 Decommissioning

10.1 Removing the module

Remove the plug-in terminals along with the wiring and the end pieces.

•

Push the module down at the back (1). With the module still pushed down, move it

•

in the direction of the arrow to remove it from the mounting rail (2).

10.2 Disposal

Figure 4: Removing the module, example

CAUTION

Risk of injury due to hot device surface.

The surface of the device can become hot during operation.

■

Before commencing disassembly, switch off the device and allow it to cool down

as necessary.

If a device can no longer be used, dispose of it in an environmentally friendly manner in

accordance with the applicable country-specific waste disposal regulations. Do not dis‐

pose of the product along with household waste.

NOTICE

Danger to the environment due to improper disposal of the device.

Disposing of devices improperly may cause damage to the environment.

Therefore, observe the following information:

■

Always observe the valid regulations on environmental protection.

■

Separate the recyclable materials by type and place them in recycling containers.

26

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

Subject to change without notice

Page 27

11 Technical data

NOTE

The relevant online data sheet for your product, including technical data, dimensional

drawing, and connection diagrams can be downloaded, saved, and printed from the

Internet:

www.sick.com/SIM10xx

•

11.1 Features

Feature Parameter

Task Data recording, evaluation, and archiving

Supported devices

(excerpt)

Technology Embedded hardware architecture:

Random Access Memory 1 GB

Flash memory 256 MB in total, 30 MB of which available for applications

Memory card, integrated Industrial-grade MicroSD memory card, 1 GB

Programming software SICK AppStudio

Sensor data processing According to SICK Algorithm API

TECHNICAL DATA 11

Encoders, code readers, RFID read/write devices, SICK LiDAR

scanners, SICK picoCam and midiCam

Dual-core ARM Cortex-A9 CPU with NEON accelerator

•

FPGA for I/O handling

•

Software:

Can be programmed within the SICK AppSpace environment

•

SICK Algorithm API

•

11.2 Interfaces

Feature Parameter

Data storage and retrieval Image and data logging via microSD memory card, internal RAM,

and external FTP

SERIAL (RS-422 / RS-485)

Number 2

Function RS-422 / RS-485

Maximum data transmis‐

sion rate

ETHERNET

Number 4

Function Host, image transmission

Data transmission rate Port 1, 3: 100 Mbit/s

Protocol TCP/IP, FTP (image transmission)

CAN

Number 1

Function SICK CAN sensor network (master/slave, multiplexer/server), ter‐

Data transmission rate 20 kbit/s ... 1 Mbit/s

RS-422: 2 MBaud

RS-485: 2 MBaud

Port 2, 4: 1 Gbit/s

mination controllable via app

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

27

Page 28

11 TECHNICAL DATA

Feature Parameter

Protocol CSN (SICK CAN sensor network)

IO-Link

Number 1

Function IO-Link Master V1.1

Data transmission rate max. 230 kBaud

Digital switching inputs/outputs

IYI: Switching input, max. frequency: 30 kHz

IY2: Switching input/output (configurable), max. frequency: 30 kHz

11.3 Mechanics and electronics

Feature Parameter

Optical indicators 7 x status indicators, front membrane, red/green

Electrical connection Terminal block 1 - 4: spring terminals

Supply voltage 24 V DC, -30% / +25%

Operating current Must be limited by external power supply unit to max. 2 A

Power consumption Max. 10.5 W, without connected sensors

Power output Max. 9 W total (all connections)

Output current IY2 Max. 100 mA

Output current L+ 200 mA (400 mA briefly when switched on)

Housing material Polycarbonate

Housing color Light gray (RAL 7035)

Protection class III (EN 61140:2016-05)

Weight 430 g (with spring terminals)

Dimensions (W x D x H) 67.5 mm x 96.5 mm x 120.6 mm

4 x status indicators, front membrane, green

4 x status indicators, Ethernet, orange/green

Ethernet connections: RJ - 45

11.4 Ambient data

Feature Parameter

Electromagnetic compati‐

bility (EMC)

Vibration resistance EN 60068-2-6:2008-02, EN 61131-2:2007-09

Shock resistance EN 60068-2-27:2009-05, EN 61131-2:2007-09

Enclosure rating IP20 as per EN 60529:1991-10 + A1:2000-02 + A2:2013-10

Ambient operating temper‐

ature

Storage temperature -25 °C ... +70 °C

Permissible relative humid‐

ity

28

O PE R AT I NG IN S TR U CT I ON S | SIM1000 FX A 8023299//2019-03-13 | SICK

EN 61000-6-2:2005-08

EN 61000-6-4:2007 + A1:2011

-25 °C ... +55 °C

90%, non-condensing

Subject to change without notice

Page 29

12 Annex

67.5 (2.66)

120.6 (4.75)

114.3 (4.5)

75.3 (2.96)

93.7 (3.69)

109 (4.29)

14.8 (0.58)

14.8 (0.58)

20

(0.79)20(0.79)

22.5

(0.89)

22.5

(0.89)

15.8 (0.62)

96.5 (3.80)

93.3 (3.67)

58 (2.28)

78 (3.07)

5.1

(0.20)

5.1

(0.20)

12.1 Dimensional drawings

Dimensions without accessories

All measurements in mm.

ANNEX 12

12.2 Licenses

SICK uses open-source software. This software is licensed by the rights holders using

the following licenses among others: the free licenses GNU General Public License (GPL

Version2, GPL Version3) and GNU Lesser General Public License (LGPL), the MIT

license, zLib license, and the licenses derived from the BSD license.

This program is provided for general use, but WITHOUT ANY WARRANTY OF ANY KIND.

This warranty disclaimer also extends to the implicit assurance of marketability or suit‐

ability of the program for a particular purpose.

More details can be found in the GNU General Public License. View the complete

license texts here: www.sick.com/licensetexts. Printed copies of the license texts are

also available on request.

8023299//2019-03-13 | SICK OP E RA T IN G I N ST R UC T IO N S | SIM1000 FXA

Subject to change without notice

29

Page 30

Further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 01

E-Mail info@sick.de

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972-4-6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 (0)11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail info@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

8023299//2019-03-13/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...