Page 1

SFU

Gas Sampling Unit

with Weatherproof Enclosure

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

SFU (gas sampling unit) with higher protection class

These Operating Instructions refer to the gas sampling unit of the SFU-BF NI GL in the

weatherproof enclosure.

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Function of this document....................................................................... 5

1.2 Target group.............................................................................................. 5

1.3 Symbols and document conventions...................................................... 5

1.3.1 Warning symbols...................................................................... 5

1.3.2 Warning levels / signal words................................................. 6

1.3.3 Information symbols................................................................ 6

2 Safety information............................................................................ 7

2.1 Basic safety information........................................................................... 7

2.2 Warnings on the device............................................................................ 7

2.3 Intended use............................................................................................. 8

2.4 Qualification of the operator.................................................................... 8

3 Product description........................................................................... 9

3.1 Product identification............................................................................... 9

3.2 Product description.................................................................................. 10

3.3 Design........................................................................................................ 11

3.3.1 Gas sampling tube................................................................... 11

4 Installation and start-up................................................................... 12

4.1 Important information.............................................................................. 12

4.2 Weatherproof enclosure........................................................................... 13

4.3 Preparing the connection bundle............................................................ 14

4.4 Mounting................................................................................................... 15

4.4.1 Installing the welding neck flange.......................................... 15

4.4.2 Connection of sample gas line............................................... 17

4.4.3 Connection of the pneumatic lines........................................ 18

4.5 Electrical installation................................................................................ 19

4.6 Installing the gas sampling tube on the gas sampling unit................... 20

4.7 Installing the SFU on the welding neck flange........................................ 20

5 Maintenance...................................................................................... 22

5.1 Important Information.............................................................................. 22

5.2 Maintenance plan..................................................................................... 22

5.3 Spare parts............................................................................................... 23

5.4 Replacing the sintered metal filter element........................................... 23

5.5 Replacing the glass fiber filter element.................................................. 26

5.6 Retrofitting the filter element................................................................... 29

5.7 Checking for correct operation................................................................ 32

6 Troubleshooting................................................................................. 33

6.1 Troubleshooting........................................................................................ 33

7 Disposal.............................................................................................. 34

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

3

Page 4

CONTENTS

8 Technical data.................................................................................... 35

8.1 Compliances and Standards.................................................................... 35

8.2 Dimensions............................................................................................... 35

8.3 Operating data.......................................................................................... 35

4

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Function of this document

These Operating Instructions describe:

Device components

•

Installation

•

Operation

•

Maintenance work required for reliable operation

•

1.2 Target group

This document is addressed to technicians (persons with technical understanding)

installing, operating and maintaining the measuring system.

Responsibility of the operator

Use the device only as described in these Operating Instructions. The manufac‐

•

turer assumes no responsibility for any other use.

Maintenance work should be performed as prescribed in this Manual.

•

Do not remove, add or change any components in or on the device unless such

•

changes are officially allowed and specified by the manufacturer.

Otherwise the manufacturer's warranty becomes void.

°

Otherwise the device can become dangerous.

°

Observe special local conditions.

•

Follow all local laws, regulations, and company policies applicable at the

°

installation location.

Retain documents. These Operating Instructions:

•

Must be kept available for reference.

°

Must be passed on to new owners.

°

ABOUT THIS DOCUMENT 1

Requirements on the maintenance personnel

The technician must be familiar with the exhaust gas technology of the operator's

•

plant (overpressure, toxic and hot flue gases) and be able to avoid hazards when

working on gas ducts.

The technician must be familiar with handling compressed gas cylinders (span

•

gases).

The technician must be able to avoid hazards caused by noxious span gases.

•

The technician must be familiar with gas lines (PTFE lines) and their screw fittings

•

(be able to ensure gas-tight connections).

Only electricians are permitted to work on the electrical system or electrical sub‐

•

assemblies.

1.3 Symbols and document conventions

1.3.1 Warning symbols

Symbol Significance

Hazard (general)

Hazard by voltage

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

Symbol Significance

1.3.2 Warning levels / signal words

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

Hazard by acidic substances

Hazards by noxious substances

Hazard by high temperature

Hazard for the environment/nature/organic life

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

Note

Hints.

1.3.3 Information symbols

Symbol Significance

Important technical information for this product

Important information on electric or electronic functions

6

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 Basic safety information

WARNING

Health risk through dangerous sample gas

If dangerous sample gas is applied to the SFU:

The operator is responsible for safe handling of sample gas.

b

WARNING

Risk of explosion in potentially explosive atmospheres

Do not operate the SFU in potentially explosive atmospheres.

b

WARNING

Hazard through explosive or ignitable gases

Do not use the SFU for measuring explosive or combustible gases.

b

SAFETY INFORMATION 2

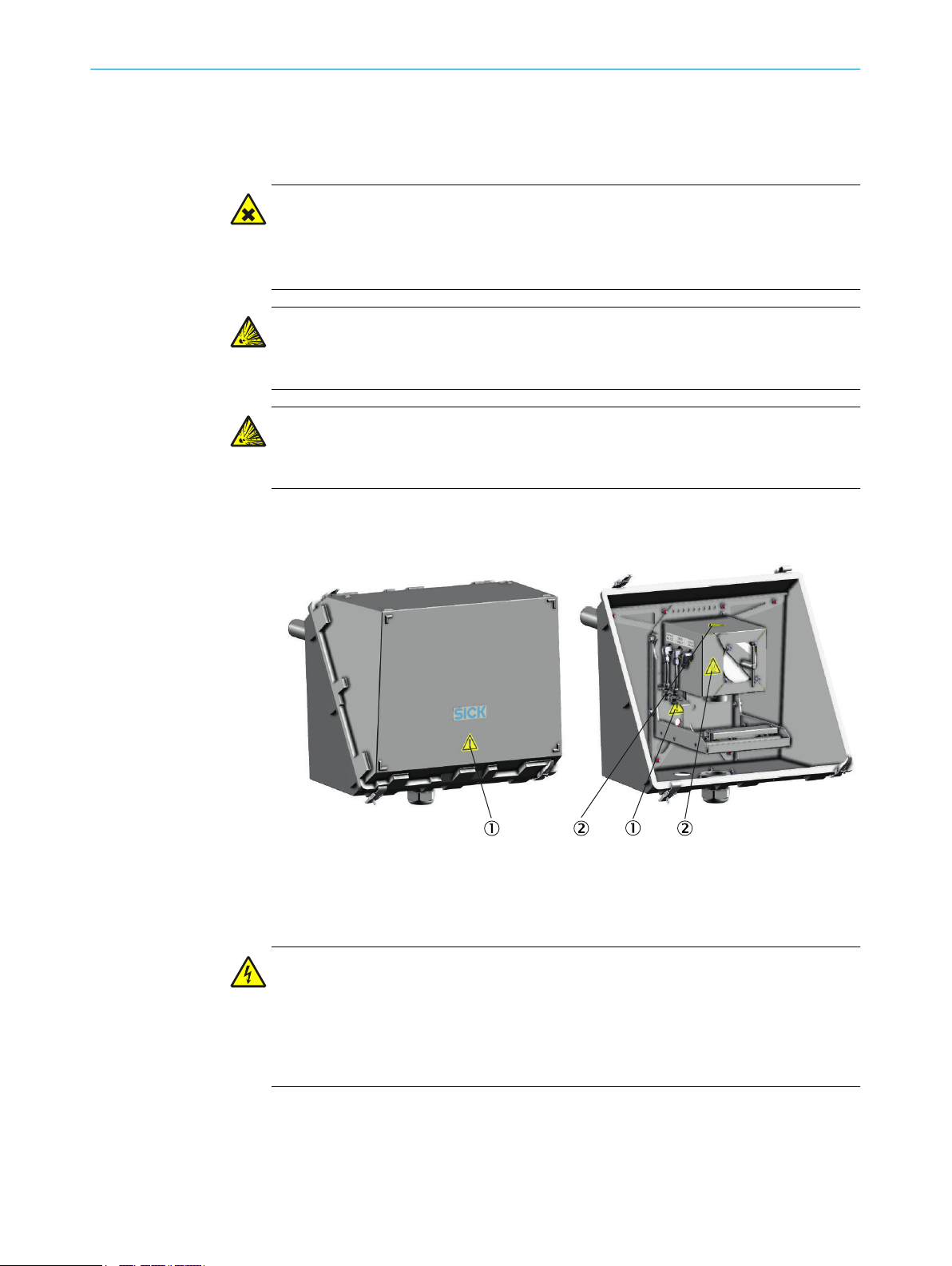

2.2 Warnings on the device

Figure 1: Location of the warning signs on the device

Warning sign "Caution!"

1

Warning sign "Hot surface!"

2

DANGER

Hazard by voltage

Only authorized electricians may perform work on electrical components.

b

Do not touch live components.

b

Disconnect the device from the power supply before working on electrical compo‐

b

nents (e.g. by switching off the measuring system).

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

WARNING

Risk of burns on hot surfaces

Avoid contact with hot surfaces or wear protective clothing (e.g. protective gloves).

b

Lay hot parts on fireproof supports only.

b

2.3 Intended use

The gas sampling unit is used for extracting a partial stream of a gas mixture (usually

flue gas) from a line, stack or similar and for retaining particles that are contained in

the gas stream.

2.4 Qualification of the operator

The SFU may only be maintained by persons properly instructed on the tasks assigned,

possible risks and protective measures.

8

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 9

3 Product description

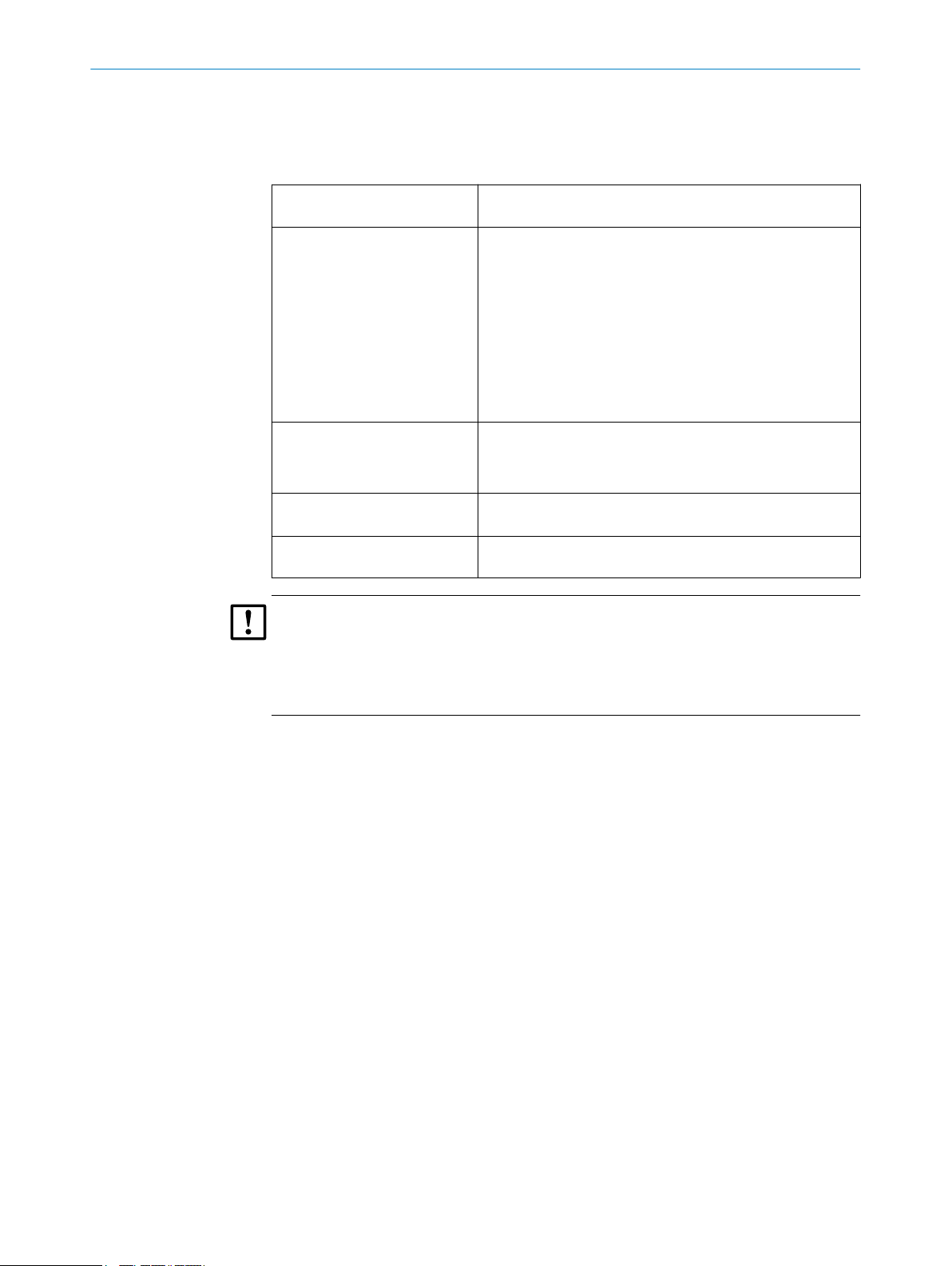

3.1 Product identification

Product name SFU-BF NI GL

Accessories:

Name of the pre-assembled set:

Consisting of:

Manufacturer SICK AG

Type plate The type plate is located on the underside of the gas sam‐

PRODUCT DESCRIPTION 3

The exact type designation can be found on the type plate.

0.5 m unheated maritime gas sampling tube

•

0.8 m unheated maritime gas sampling tube

•

0.5 m heated gas sampling tube

•

0.8 m heated gas sampling tube

•

1.0 m heated gas sampling tube

•

1.5 m heated gas sampling tube

•

2.0 m heated gas sampling tube

•

IP54 enclosure

•

Can already be ordered pre-assembled in combination

with the maritime gas sampling unit SFU-BF NI GL

SFU-BF NI GL in IP54 enclosure (PN 2098126)

SFU-BF NI GL

•

IP54 enclosure for SFU

•

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

pling unit.

NOTICE

It is possible that your SFU has a different configuration to that described in this Man‐

ual.

Refer to the System Documentation delivered with your SFU for the individual con‐

•

figuration of your system.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

9

Page 10

3 PRODUCT DESCRIPTION

3.2 Product description

Figure 2: Example configuration of a set consisting of weatherproof enclosure and SFU

Weatherproof enclosure

1

Gas sampling tube

2

SFU filter housing

3

Flange

4

Silicone press ring seal (gas sampling tube seal)

5

The gas sampling unit consists of filter housing, gas sampling tube, weatherproof enclo‐

sure and optional pre-filter.

Application area

The gas sampling unit SFU is used for flue gas extraction and filtering for analysis in a

measuring system.

The flue gas is taken via a gas sampling tube and fed to a measuring system after filtra‐

tion.

The gas sampling tube is optionally available in various lengths.

As an option, the gas sampling tube contains a pre-filter at the probe tip.

For maritime applications, unheated gas sampling tubes without pre-filters are used.

Measuring system

The gas sampling unit is operated on a SICK measuring system. Thus, only this operat‐

ing mode is described in this Manual.

Applications with customer-owned peripheral devices are not planned.

10

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 11

3.3 Design

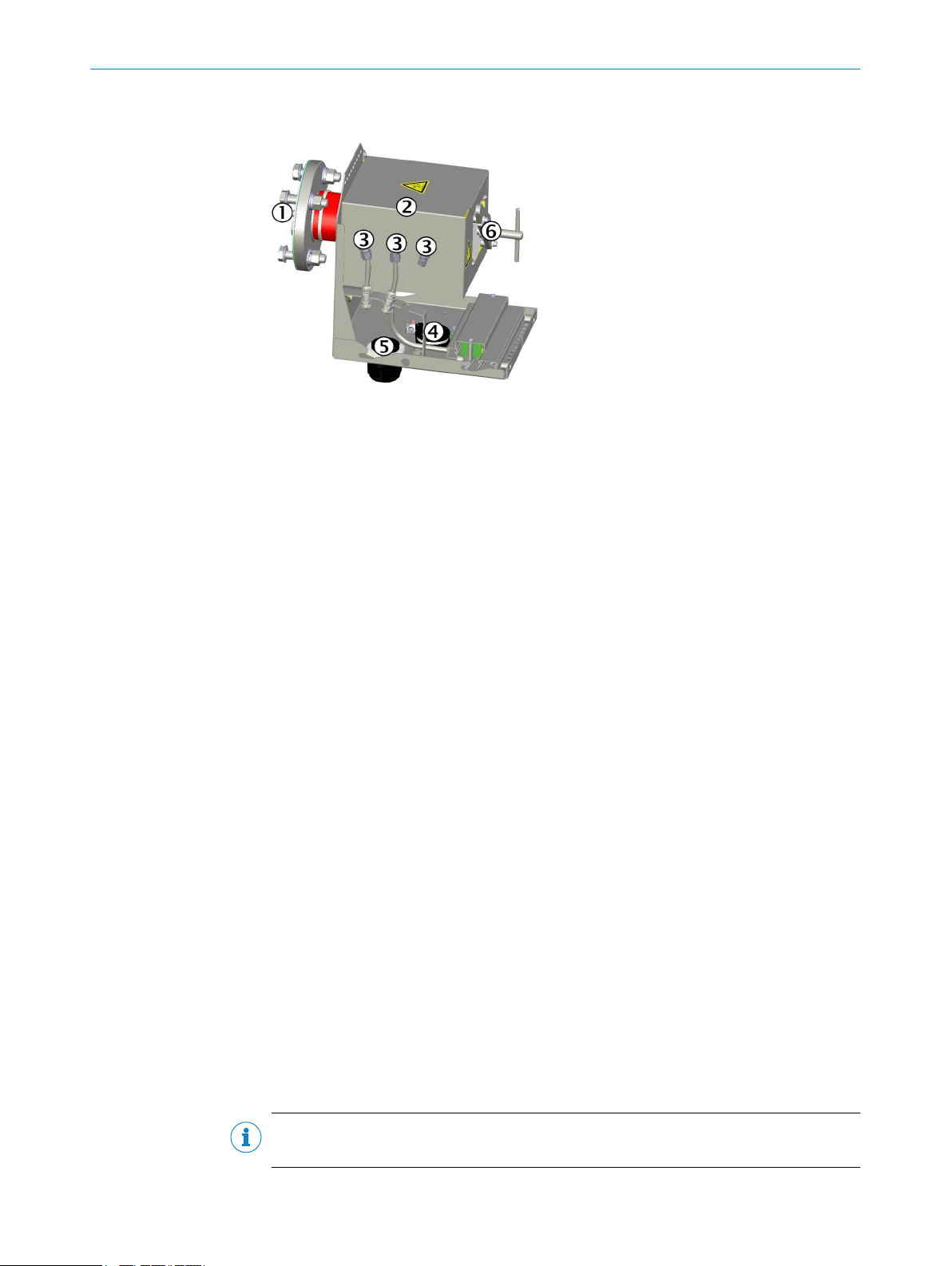

Figure 3: SFU-BF NI GL

Gas sampling tube

1

Filter housing

2

3 pneumatic lines (backflush, activa‐

3

tion of main valve, zero gas)

Output sample gas line

4

Input connection bundle (electrical

5

and pneumatic lines)

Filter element with rotary handle

6

PRODUCT DESCRIPTION 3

The gas sampling unit consists of the following subassemblies:

•

•

The electrically heated filter housing is made of coated aluminum. The filter housing is

insulated by an aluminum housing lined with polyimide.

The weatherproof enclosure is made of glass fiber reinforced plastic (GRP).

Thermostatic control

The gas sampling unit is thermostatically controlled.

•

•

3.3.1 Gas sampling tube

The length of the gas sampling tube depends on the conditions at the sampling point.

The gas sampling tube is available for maritime applications in an unheated version.

Type and length of the gas sampling tube are described in the supplied system docu‐

mentation.

Gas sampling tube:

Heated gas sampling tube:

°

Unheated maritime gas sampling tube

°

Optional: Pre-filter at the tip of the gas sampling tube

°

SFU in IP54 enclosure:

Heated filter housing with filter element

°

Weatherproof enclosure

°

Heating control with Pt100 sensor and external heating control

Limit value monitoring in the controller of the measuring system

NOTE

The gas sampling tube is supplied pre-assembled.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

11

Page 12

4 INSTALLATION AND START-UP

4 Installation and start-up

4.1 Important information

WARNING

Risk of injury by a heavy load

The weatherproof enclosure including the sampling system with flange weighs

approx. 30 kg.

Use proper lifting techniques to lift or move the device.

b

Lift the unit by the enclosure. If necessary, remove the cover in order to grip the

b

device better and reduce the weight.

Always work in pairs.

b

WARNING

Health risk through dangerous sample gas

If dangerous sample gas is applied to the SFU: The operator is responsible for safe han‐

dling of sample gas.

In addition to these Operating Instructions, observe all local laws, technical rules,

b

and company-internal instructions valid at the site where the SFU is installed.

Operate the SFU only in rooms with adequate installation OR install suitable gas

b

monitoring equipment.

Channel sample gas off safely.

b

WARNING

Hazard through sample gas pressure

The stacks can have underpressure or overpressure.

Observe information from the plant operator.

b

WARNING

Risk of burns on hot surfaces

Filter housing, flanges and sample gas line can be hot.

Allow the surface of the device parts to cool down to body temperature or wear

b

suitable protective gloves.

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system.

b

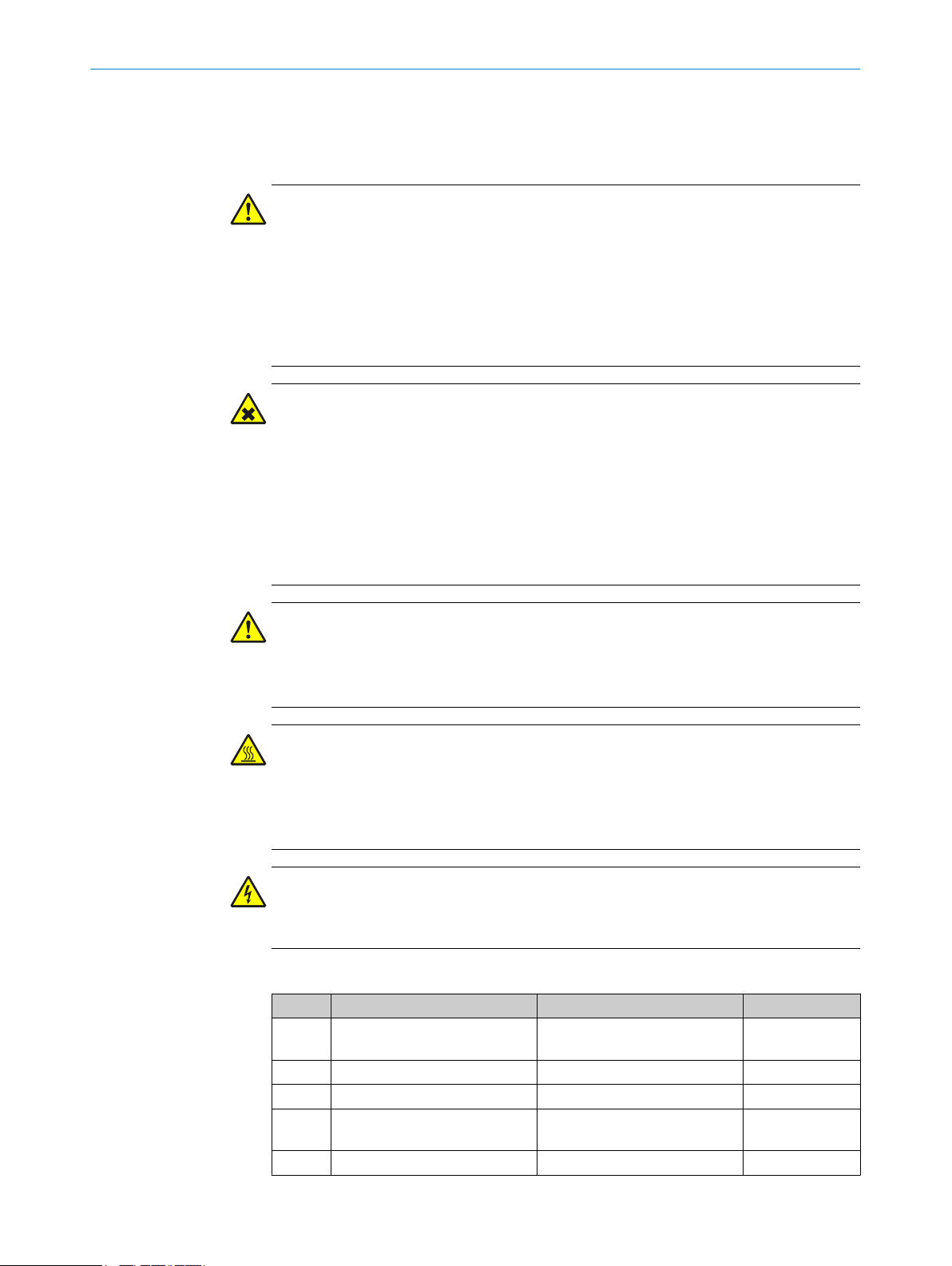

The assembly of the gas sampling unit contains the following work steps:

Step Work step Special features Side

1 Install the welding neck flange Has to be performed by the

operator beforehand

2 Connect the sample gas line page 17

3 Connect the hoses for valves page 18

4 Connect the electrical connec‐

tions

5 Install the gas sampling tube page 20

page 15

page 19

12

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 13

Step Work step Special features Side

6 Attach the SFU to the welding

neck flange

4.2 Weatherproof enclosure

INSTALLATION AND START-UP 4

Observe preheating period page 20

Figure 4: SFU-BF NI GL in weatherproof enclosure (closed left and open right)

Enclosure cover

1

Enclosure base

2

Tension locks

3

Filter housing

4

Gas sampling tube

5

Ventilation membrane

6

DANGER

Hazard by voltage

Live parts are accessible after the weatherproof enclosure has been opened.

Disconnect the gas sampling unit from the power supply before opening the enclo‐

b

sure (for example by switching off the measuring system).

CAUTION

Risk of burns on hot surfaces

You can perform the work while the filter is hot.

Wear suitable gloves.

b

Removing the enclosure cover

1 Unlock the tension locks.

2 Pull the enclosure cover away from the gas sampling tube and lift.

Fitting the enclosure cover

1 Fit the enclosure cover in the direction of the gas sampling tube.

2 Lock the tension locks.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

13

Page 14

4 INSTALLATION AND START-UP

4.3 Preparing the connection bundle

Figure 5: Standard connection bundle

Standard hose bundle cable (systemspecific example) with:

- Power supply

- Grounding conductor yellow/green

- Signal lines

- Tube, gray: Zero gas/span gas

- Tube, black: Main valve

- Tube, blue: Backflush

14

Figure 6: DNV GL approved connection bundle:

DNV GL approved connection bundle:

- Power supply

- Grounding conductor yellow/green

- Signal lines

- Tube, gray: Zero gas/span gas

- Tube, black: Main valve

- Tube, blue: Backflush

Halogen-reduced for use on passenger

ships

Additionally improved protection against

fire

The connection bundle (option) connects the SFU with the measuring system.

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 15

Preparation of the connection bundle

NOTE

Leave a sufficient length for pulling the gas sampling unit out of the stack (approx. 2

m).

1 Strip the connection bundle and shorten the hoses and lines to the required

length.

Cut the hoses at right angles. Avoid damaging the lines and hose lines.

2 Cut the flexible wires to the required length. Press the crimp lead end sleeves onto

the ends of the flexible wires.

4.4 Mounting

4.4.1 Installing the welding neck flange

WARNING

Risk of burns by hot flanges.

The flanges can reach high temperatures.

Before starting any work on the flanges, allow the flanges to cool down to body

b

temperature or wear appropriate protective gloves.

INSTALLATION AND START-UP 4

DANGER

Health risk through hot or toxic gases/dusts in the measuring duct

The measuring duct can contain hot or toxic gases or dust deposits which can escape

when opening the duct-side flange. Even if the measuring duct is out of operation dur‐

ing the installation, escaping gases can lead to severe damage to health.

Always put the measuring duct out of operation for the duration of the installation.

b

If required, purge the measuring duct with ambient air before starting installation

b

work.

During installation work, always wear protective clothing which is suitable or speci‐

b

fied by the operating company.

The operator is responsible for installing the welding neck flange.

The specifications of the flange connection are described in the System Documentation

delivered.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

15

Page 16

min.70

10°

~

~30

1

2

3 4

a

4 INSTALLATION AND START-UP

Figure 7: Installation requirements for welding neck flange

Gas sampling tube

1

Stack wall

2

Welding neck flange

3

Probe filter

4

Attach the flange with a tilt of approx. 10°.

b

The minimum distance a behind welding neck flange must be min. the length

b

specified in the following table in order to maintain and dismantle the gas sam‐

pling unit.

Table 1: Minimum distance behind welding neck flange

Length of gas sampling tube Minimum distance a

0.5 m 915 mm

0.8 m 1215 mm

1.0 m 1415 mm

1.5 m 1915 mm

2.0 m 2415 mm

16

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 17

4.4.2 Connection of sample gas line

Figure 8: Sample gas connection SFU-BF NI

GL in weatherproof enclosure

Insulating shell

1

Clamping ring screw connection

2

Sample gas line

3

Cable gland with cap nut, small

4

Cable gland with cap nut, large

5

INSTALLATION AND START-UP 4

NOTE

If you lay the heated sample gas line before installing the gas sampling unit: Observe

the installation of the sample gas line:

Start laying at the measuring system:

b

The end with electrical connection is connected to the measuring system.

°

The end without electrical connection is connected to the gas sampling unit.

°

Roll up excess length at the gas sampling unit.

Leave enough length for pulling out the gas sampling unit (approx. 2 m).

Protect the line from damage (chafing through vibration, mechanical and thermal

b

load).

Observe a minimum bending radius of 300 mm.

b

1. Remove the enclosure cover (see "Weatherproof enclosure", page 13).

2. Unscrew the large cap nut and slide it onto the sample gas line.

3. Unscrew the insulation half-shell.

4. Feed the sample gas line through the large cable gland of the weatherproof enclo‐

sure and then through the installation plate and the hose clamp.

5. Screw the sample gas line tight on the clamping ring screw connection.

For first screwing (clamping ring still loose): 1¼ turn to "hand-tight".

°

For further screwing: (clamping ring tight) ¼ turn to "hand-tight".

°

6. Fasten the sample gas line using a hose clamp. The screw head can be reached

via an opening in the chamfer of the installation plate.

7. Screw the insulation half-shell back on again.

8. Tighten the cap nut hand-tight.

9. Check hose connections for leaks:

The leak tightness check is performed via the connected measuring system: See

the Operating Instructions of the measuring system.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

17

Page 18

4 INSTALLATION AND START-UP

4.4.3 Connection of the pneumatic lines

NOTICE

Risk of damaging the measuring system.

Ensure correct assignment of the pneumatic connections.

•

Ensure leak tightness of the system.

•

Connection for SFU-BF NI GL

Figure 9: Connection of SFU-BF NI GL pneu‐

matic lines

Backflush

1

Main valve

2

Zero gas

3

Installation plate

4

1. Push the cap nut onto the connection bundle.

2. Feed the connection bundle through the cable gland of the weatherproof enclo‐

sure and then through the installation plate.

3. Connect the 3 hoses with the 3 hose fittings on the filter housing and ensure cor‐

rect layout.

4. Push the hoses flush over the hose connections of the hose fitting.

5. Hose for the zero gas: Use clamping ring screw connection with support sleeve.

6. Tighten the cap nut by hand.

7. Screw the cable gland tight.

4.4.3.1 Adapter for inch thread (option)

If you want to connect pneumatic lines with inch thread: There is an adapter set with 4

clamping ring screw fittings.

Part No. "Adapter set inch thread": 2083838

18

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 19

INSTALLATION AND START-UP 4

Figure 10: Adapter set

Installation

1. Wrap the thread with 2 - 2.5 layers of Teflon tape.

2. Tighten the adapter with an open-end wrench until a distinct increase in strength

is felt.

Then tighten by approx. 1/8 to 1/4 turn.

4.5 Electrical installation

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system.

b

WARNING

Risk of short-circuit due to condensate.

Allow the electronics to acclimatize sufficiently before connecting.

b

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

19

Page 20

4 INSTALLATION AND START-UP

Figure 11: Terminal diagram for 230 V and 115 V

The electrical connection of the gas sampling unit is made via the connection terminals

on the installation plate.

Observe the terminal diagram on the SFU.

The temperature sensors and the heating cartridges are wired ex factory.

Remove the enclosure.

b

Perform electrical connections.

b

4.6

Installing the gas sampling tube on the gas sampling unit

Installing the gas sampling tube

The gas sampling unit with gas sampling tube is supplied pre-assembled.

Installing the pre-filter

The pre-filter can be screwed to the gas sampling tube.

1 Wrap the thread with Teflon tape.

2 Screw the pre-filter onto the tip of the gas sampling tube. Tighten by hand with a

wrench.

4.7 Installing the SFU on the welding neck flange

NOTICE

Risk of contamination of the gas sampling unit

Do not install a cold gas sampling unit on the stack.

Allow the gas sampling unit to warm up before installing it on the welding neck

b

flange.

Warm-up time: Approx. 1.5 h at 25 °C ambient temperature

b

20

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 21

1

2

3

4

INSTALLATION AND START-UP 4

Figure 12: Installation of gas sampling tube on welding neck flange

Gas sampling tube

1

Welding neck flange

2

Filter housing flange

3

Filter housing

4

WARNING

Risk of burns on hot surfaces

The gas sampling tube and the gas sampling unit become hot during operation.

Wear suitable protective clothing, e.g. heat-resistant gloves.

b

1. Push the seal over the gas sampling tube.

2. Push the gas sampling unit with probe tube into the welding neck flange.

The hose outputs of the gas sampling unit have to point downwards.

3. Screw the filter housing flange of the gas sampling unit to the welding neck flange.

4. Fit the weatherproof enclosure: see "Weatherproof enclosure", page 13

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

21

Page 22

5 MAINTENANCE

5 Maintenance

5.1 Important Information

WARNING

Risk of injury by a heavy load

The weatherproof enclosure including the sampling system with flange weighs

approx. 30 kg.

Use proper lifting techniques to lift or move the device.

b

Lift the unit by the enclosure. If necessary, remove the cover in order to grip the

b

device better and reduce the weight.

Always work in pairs.

b

WARNING

Health risk through dangerous sample gas

If dangerous sample gas is applied to the SFU: The operator is responsible for safe han‐

dling of sample gas.

In addition to these Operating Instructions, observe all local laws, technical rules,

b

and company-internal instructions valid at the site where the SFU is installed.

Operate the SFU only in rooms with adequate installation OR install suitable gas

b

monitoring equipment.

Channel sample gas off safely.

b

WARNING

Hazard through sample gas pressure

The stacks can have underpressure or overpressure.

Observe information from the plant operator.

b

WARNING

Risk of burns on hot surfaces

Filter housing, flanges and sample gas line can be hot.

Allow the surface of the device parts to cool down to body temperature or wear

b

suitable protective gloves.

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system.

b

5.2 Maintenance plan

No. Maintenance work Reference Interval

W1

W2

W3 Check gas connections

1

3M = every 3 months

Replace sintered metal filter element

and seals

Replace glass fiber filter element

and seals

see "Replacing the sintered metal

filter element", page 23

see "Replacing the glass fiber filter

element", page 26

see "Checking for correct operation",

page 32

3M

3M

3M

1

1

1

22

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 23

5.3 Spare parts

MAINTENANCE 5

No. Conversion Reference Interval

U1 Change from sintered metal to glass

fiber filter element

Required spare parts for W1 and W2 Part number Quantity required Picture

Service kit (contains: 1*2 μm sin‐

tered metal filter element, 2*flat

seals, 1*O-ring)

2039002 1

see "Retrofitting the filter element",

page 29

-

Service kit (contains 1*0.1µm glass

fiber filter element, 1*flat seal, 1*Oring)

Required spare parts for U1 Part number Quantity required Picture

Glass fiber filter element with holder

(contains 1*0.1µm glass fiber filter

element, adapter, 1*flat seal, 1*Oring

2043616 1

2024972 1

NOTE

Further spare parts can be found in the individual System Description provided with the

gas sampling unit.

5.4 Replacing the sintered metal filter element

You can perform the work while the filter element is hot.

Pay attention to the warning about hot surfaces.

The filter element may be hot inside.

WARNING

Risk of burns on hot surfaces

The filter element can reach high temperatures in operation.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

WARNING

Hazard by toxic substances

Filter elements can contain toxic substances depending on the sample gas composi‐

tion.

Observe the relevant safety regulations.

b

Dispose of the filter elements in an environmentally compatible manner.

b

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

23

Page 24

MAINTENANCE

5

Procedure

1. Switch off the fuse of the gas sampling unit in the measuring system.

The position of the fuse is described in the System Documentation enclosed with

the measuring system.

2. Remove the enclosure:see "Weatherproof enclosure", page 13.

3. Check all gas connections:

Optical condition

°

Tight seat

°

Leak tightness:

°

The leak tightness check is performed via the connected measuring system:

See the Operating Instructions of the measuring system.

Changing the sintered metal filter element

1. Loosen the rotary handle counterclockwise.

Rotary handle

1

Mounting bracket

2

Pressure disk (covered)

3

2. Swing the mounting bracket to the right.

WARNING

Risk of burns on hot surfaces

The inner parts of the gas sampling filter can be especially hot.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

CAUTION

Risk of injury due to high weight

Do not drop the filter cover.

b

3. Pull the filter cover out using the rotary handle.

4. If the filter cover is hot: Place the filter cover on a heat-resistant mat.

5. Remove the sintered metal filter element.

24

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 25

Sintered metal filter element

1

Filter housing

2

6. Pull out the bottom flat seal with a hook.

7. Insert new bottom flat seal.

MAINTENANCE 5

Bottom flat seal

1

8. Replace O-ring and flat seal of the filter cover.

O-ring

1

Flat seal

2

9. Insert new or cleaned filter element.

If one side of the filter element has a groove: The groove must point in the direc‐

tion of the filter cover.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

25

Page 26

5 MAINTENANCE

10. Fit the filter cover.

11. Swing back the mounting bracket. Make sure that the pressure disk is behind the

mounting bracket.

Rotary handle

1

Pressure disk

2

Mounting bracket

3

12. Tighten the rotary handle clockwise.

13. Fit the enclosure again: see "Weatherproof enclosure", page 13.

5.5 Replacing the glass fiber filter element

You can perform the work while the filter element is hot.

Pay attention to the warning about hot surfaces.

The filter can have an internal temperature of 185 °C.

WARNING

Risk of burns on hot surfaces

The filter element can reach high temperatures in operation.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

WARNING

Hazard by toxic substances

Filter elements can contain toxic substances depending on the sample gas composi‐

tion.

Observe the relevant safety regulations.

b

Dispose of the filter elements in an environmentally compatible manner.

b

Replacing fine filter cartridge

1. Loosen the rotary handle counterclockwise.

26

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 27

Rotary handle

1

Mounting bracket

2

Pressure disk (covered)

3

2. Swing the mounting bracket to the right.

MAINTENANCE

5

WARNING

Risk of burns on hot surfaces

The filter element can reach high temperatures in operation.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

CAUTION

Risk of injury due to high weight

Do not drop the filter cover.

b

Filter housing

1

Filter cover

2

Mounting bracket

3

Pressure disk

4

3. Pull out the filter cover with glass fiber filter element using the rotary handle.

4. If the filter cover is hot: Place the filter cover on a heat-resistant mat.

5. Pull out the bottom flat seal with a hook.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

27

Page 28

MAINTENANCE

5

Bottom flat seal

1

6. Loosen the glass fiber filter element from the filter handle by opening the spiral

thread.

O-ring

1

Glass fiber filter element

2

Rotary handle

3

7. Insert new bottom flat seal.

8. Renew the O-ring in the filter cover.

9. Fit new or cleaned glass fiber filter element on the filter cover. Tighten the spiral

thread.

If one side of the filter element has a groove: The groove must point in the direc‐

tion of the filter cover.

10. Replace the filter cover.

Rotary handle

1

Pressure disk

2

Mounting bracket

3

28

11. Swing back the mounting bracket. Make sure that the pressure disk is behind the

mounting bracket.

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 29

12. Tighten the rotary handle clockwise.

13. Fit the housing again: see "Weatherproof enclosure", page 13.

5.6 Retrofitting the filter element

You can perform the work while the filter element is hot.

Pay attention to the warning about hot surfaces.

The filter can have an internal temperature of 185 °C.

WARNING

Risk of burns on hot surfaces

The filter element can reach high temperatures in operation.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

WARNING

Hazard by toxic substances

Filter elements can contain toxic substances depending on the sample gas composi‐

tion.

MAINTENANCE 5

Observe the relevant safety regulations.

b

Dispose of the filter elements in an environmentally compatible manner.

b

Procedure

1. Switch off the fuse of the gas sampling unit in the measuring system.

The position of the fuse is described in the System Documentation enclosed with

the measuring system.

2. Remove the enclosure:see "Weatherproof enclosure", page 13.

3. Check all gas connections:

Optical condition

°

Tight seat

°

Leak tightness:

°

The leak tightness check is performed via the connected measuring system:

See the Operating Instructions of the measuring system.

Retrofitting the sintered metal filter element to a glass fiber filter element

1. Loosen the rotary handle counterclockwise.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

29

Page 30

MAINTENANCE

5

Rotary handle

1

Mounting bracket

2

Pressure disk (covered)

3

2. Swing the mounting bracket to the right.

WARNING

Risk of burns on hot surfaces

The filter element can reach high temperatures in operation.

Wear suitable gloves.

b

Provide a heat-resistant support.

b

CAUTION

Risk of injury due to high weight

Do not drop the filter cover.

b

3. Pull the filter cover out using the rotary handle.

4. If the filter cover is hot: Place the filter cover on a heat-resistant mat.

5. Remove the sintered metal filter element.

30

Sintered metal filter element

1

Filter housing

2

6. Pull out the bottom flat seal with a hook.

7. Insert new bottom flat seal.

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 31

Bottom flat seal

1

8. Replace O-ring and flat seal of the filter cover.

MAINTENANCE

5

O-ring

1

Position of flat seal

2

9. Fit the glass fiber filter element on the filter cover. Tighten with the spiral thread.

If one side of the glass fiber filter element has a groove: The groove must point in

the direction of the filter cover.

O-ring

1

Glass fiber filter element

2

Rotary handle

3

10. Replace the filter cover.

11. Swing back the mounting bracket. Make sure that the pressure disk is behind the

mounting bracket.

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

31

Page 32

5 MAINTENANCE

Rotary handle

1

Pressure disk

2

Mounting bracket

3

12. Tighten the rotary handle clockwise.

13. Fit the enclosure again: see "Weatherproof enclosure", page 13

5.7 Checking for correct operation

Check all fastening screws of the housing for tight seat.

•

Check the sample gas line for damage.

•

Check all hose fittings for tight seat.

•

Check gas sampling unit for cleanness, dryness and freedom from corrosion.

•

Check all electric connections for freedom from corrosion and tight seat.

•

Check grounding conductors are free from corrosion.

•

Perform a leak tightness check:

•

The leak tightness check is performed via the connected measuring system: See

the Operating Instructions of the measuring system.

32

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 33

6 Troubleshooting

6.1 Troubleshooting

Fault Possible cause Correction

Gas throughput decreases Pre-filter contaminated Clean or replace

Heating failed Heating cartridge or tempera‐

Contaminated or corroded gas

paths

Leaky non-return valves Contaminated instrument air Replace

Leaky main valve Valve seating contaminated or

TROUBLESHOOTING 6

Filter element contaminated

If necessary, replace seal or

ture sensor defective

Defective seal Replace seal

Defective or missing pre-filter Replace

damaged

Metal bellow leaky Replace the metal bellow

defective component

Check the purity of the instru‐

ment air

Replace the valve cone

Replace the filter housing

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

33

Page 34

7 DISPOSAL

7 Disposal

The device can easily be disassembled into its components which can then be sent to

the respective raw material recycling facilities.

WARNING

Filters and lines with sample gas contact can contain toxic substances.

Observe the relevant safety regulations.

Depending on their components, filters and lines with sample gas contact must be

b

disposed of according to the legal regulations. If required, they must be treated as

hazardous waste.

34

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 35

8 Technical data

8.1 Compliances and Standards

Compliance

The technical version of device SFU-BF NI GL complies with the following EU directives

and EN standards:

EC Directive: LVD (Low Voltage Directive)

•

EN 61010-1: Safety requirements for electrical equipment for measurement, con‐

trol and laboratory use

Further standards: See Declaration of Conformity provided with the device

Additional standards for SFU-BF NI GL

MARPOL Annex VI and NTC 2008 - MEPC.177(58)

•

Guidelines for exhaust gas cleaning systems - MEPC.184(59)

•

DNV GL Rules for Classification and Construction, Part VI Additional Rules and

•

Guidelines Chapter 7, Guidelines for the Performance of Type Approvals, Test

Requirements for Electrical / Electronic Equipment and Systems (2012)

TECHNICAL DATA 8

8.2 Dimensions

Figure 13: SFU-BF NI GL in weatherproof enclosure

8.3 Operating data

Ambient conditions SFU-BF NI GL in weatherproof enclosure

Ambient temperature -35 … +55 °C (-31 ... +131 °F)

Storage temperature –40 … +60 °C (-40 ... 140 °F)

Relative humidity Max. 95%

Degree of protection IP54

Installation SFU-BF NI GL in weatherproof enclosure

Tubing SFU-BF NI GL

Main valve

•

Zero gas

•

Backflush

•

Sample gas line

•

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

Dimensions:

8 mm

•

6 mm

•

8 mm

•

6 mm

•

35

Page 36

8 TECHNICAL DATA

Installation SFU-BF NI GL in weatherproof enclosure

Compressed air

Main valve

•

Zero gas

•

Backflush

•

Flange

NW = Rated width

ND = Rated pressure

Fitting position Horizontally with an inclination of approx. 10° (see "Installing

Power input SFU-BF NI GL in weatherproof enclosure

probe filter 115/230 V, 50-60 Hz, max. 450 VA

Device characteristics SFU-BF NI GL in weatherproof enclosure

Materials

Gas sampling tube

•

IP54 enclosure

•

Locks

•

Seals

•

Weight Approx. 30 kg (SFU in IP54 enclosure with flange and gas

Gas temperature in sampling

system

Gas temperature in stack Unheated gas sampling tube: Max. 1300°C (2400°F)

Heating temperature of the SFU Max. 200°C (392°F)

Temperature control External, Pt100

Limit monitoring External heating controller

Purge gas flow Approx.12 l/min

Backpurge flow rate Approx.80 l/min

Sample gas throughput 300 ... 1000 l/h

Heating up time Approx. 1,5 h (from room temperature to 200 °C)

Pressure:

5 - 6 bar (500 - 600 kPascal)

•

2.5 - 3 bar (250 - 300 kPascal)

•

5 - 6 bar (500 - 600 kPascal)

•

NW 65 ND 6

the welding neck flange", page 15)

Materials

Application-dependent;maritime unheated gas sampling

•

tubes: 1.4547/254 SMO

GRP enclosure (glass fiber reinforced plastic)

•

Tension locks:Stainless steel

•

EPDM/silicone

•

sampling tube)

Max. 250°C (482°F)

Heated gas sampling tube: Max. 200°C (392°F)

36

Standard lengths of unheated maritime gas sampling tubes [mm]; Material 1.4547/254 SMO

500 800

Standard lengths of heated gas sampling tubes [mm]; Material 1.4404

500 800 1000 1500 2000

O PE R AT I NG IN S TR U CT I ON S | SFU 8023849/14SF/V1-1/2019-07 | SICK

Subject to change without notice

Page 37

TECHNICAL DATA 8

8023849/14SF/V1-1/2019-07 | SICK O P ER A TI N G I NS T RU C TI O NS | SFU

Subject to change without notice

37

Page 38

Detailed addresses and further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 234 719 500

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 010

E-Mail info@sick.de

Greece

Phone +30 210 6825100

E-Mail office@sick.com.gr

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 97110 11

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mexico@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 10 060 0550

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail infokorea@sick.com

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail contact@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales

.gsg@sick.com

8023849/14SF/V1-1/2019-07/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...