Page 1

Safe Entry Exit

Safety System

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

S

afe Entry Exit

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Purpose of this document........................................................................ 6

1.2 Scope......................................................................................................... 6

1.3 Target groups and structure of these operating instructions................ 7

1.4 Symbols and document conventions...................................................... 7

1.5 Further information................................................................................... 8

2 Safety information............................................................................ 9

2.1 General safety note.................................................................................. 9

2.2 Intended use............................................................................................. 9

2.3 Requirements for the qualification of personnel.................................... 9

2.4 Safe state.................................................................................................. 10

3 Product description........................................................................... 11

3.1 Product identification............................................................................... 11

3.2 Application description............................................................................. 11

3.3 Components of the safety system........................................................... 11

3.4 Components required............................................................................... 11

3.4.1 Requirements for hold to run device...................................... 12

3.4.2 Reset pushbutton requirements............................................. 12

3.4.3 Requirements for Flexi Soft safety controller........................ 12

3.4.4 Requirements for the higher-level control.............................. 13

3.4.5 Requirements for the electro-sensitive protective device..... 13

3.5 Construction and function........................................................................ 14

3.6 Limits of the safety system...................................................................... 14

3.7 Functions................................................................................................... 15

4 Project planning................................................................................ 16

4.1 Manufacturer of the machine.................................................................. 16

4.1.1 Calculation of the performance level..................................... 16

4.2 Operating entity of the machine.............................................................. 17

4.3 Safety Functions....................................................................................... 17

4.3.1 Identifying hazards.................................................................. 17

4.3.2 Enabling material throughput................................................. 17

4.4 Design........................................................................................................ 17

4.4.1 Type 4 electro-sensitive protective device.............................. 17

4.4.2 Minimum distance between the Type 4 electro-sensitive

otective device and the hazardous point............................ 18

pr

4.4.3 Design of the material opening............................................... 18

4.4.4 Conveyor speed........................................................................ 19

4.4.5 Calculating response times and stopping times................... 19

4.5 Integrating the equipment into the electrical control............................. 20

4.5.1 Circuit diagram......................................................................... 20

4.5.2 Testing plan.............................................................................. 21

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

3

Page 4

CONTENTS

5 Mounting............................................................................................. 22

5.1 Mounting conditions for the electro-sensitive protective device........... 22

6 Electrical installation........................................................................ 23

6.1 General requirements.............................................................................. 23

6.2 Safety controller pin assignment............................................................. 23

6.3 Interfaces and signals.............................................................................. 24

7 Configuration..................................................................................... 26

7.1 Requirements on software and firmware................................................ 26

7.2 Pre-configured project files...................................................................... 26

7.2.1 Checking the checksums of the project files......................... 26

7.2.2 Standard values for timing sets.............................................. 27

7.3 Opening project file................................................................................... 28

7.4 Configuring logics for Flexi Soft CPU....................................................... 28

7.4.1 Creating or deleting links......................................................... 28

7.5 Transfer configuration.............................................................................. 28

7.6 Adjust configuration.................................................................................. 29

7.6.1 Configuration of S

7.6.2 Configuration of Time monitoring............................................... 31

7.6.3 Configuration of PLC monitoring & override................................ 35

equence monitoring....................................... 29

8 Commissioning.................................................................................. 37

8.1 Safety......................................................................................................... 37

8.2 Thorough check........................................................................................ 37

9 Maintenance...................................................................................... 38

10 Troubleshooting................................................................................. 39

11 Operation............................................................................................ 40

11.1 Description of signals............................................................................... 40

11.2 Muting function......................................................................................... 40

11.3 Time Extension Function.......................................................................... 41

11.4 Hold to run device..................................................................................... 42

11.5 1 of n timing sets...................................................................................... 43

12 Technical data.................................................................................... 44

12.1 Data sheet................................................................................................. 44

13 Ordering information........................................................................ 45

13.1 Scope of delivery....................................................................................... 45

13.2 Safe Entry Exit ordering data................................................................... 45

13.3 Ordering data for Safe Entry Exit components....................................... 46

14 Spare parts......................................................................................... 47

14.1 Safe Entry Exit spare parts....................................................................... 47

4

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 5

CONTENTS

15 Annex.................................................................................................. 48

15.1 Checklist for initial commissioning and commissioning........................ 48

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Purpose of this document

These operating instructions contain the information required during the life cycle of the

afety system. This document describes:

s

The individual components

•

The project planning

•

The mounting and electrical installation, insofar as special measures are neces‐

•

sary for the safety system

The configuration

•

The necessary thorough checks

•

The commissioning

•

The maintenance

•

The troubleshooting

•

1.2 Scope

These operating instructions contain information regarding the Safe Entry Exit safety

ystem.

s

NOTICE

he operating instructions of the components also apply. In the event of contradictions

T

between the operating instructions, the information specified in the operating instruc‐

tions for the safety system applies.

The relevant information must be made available to the employees for all work per‐

formed on the safety system.

The following documents contain information about the possible components of the

S

afe Entry Exit:

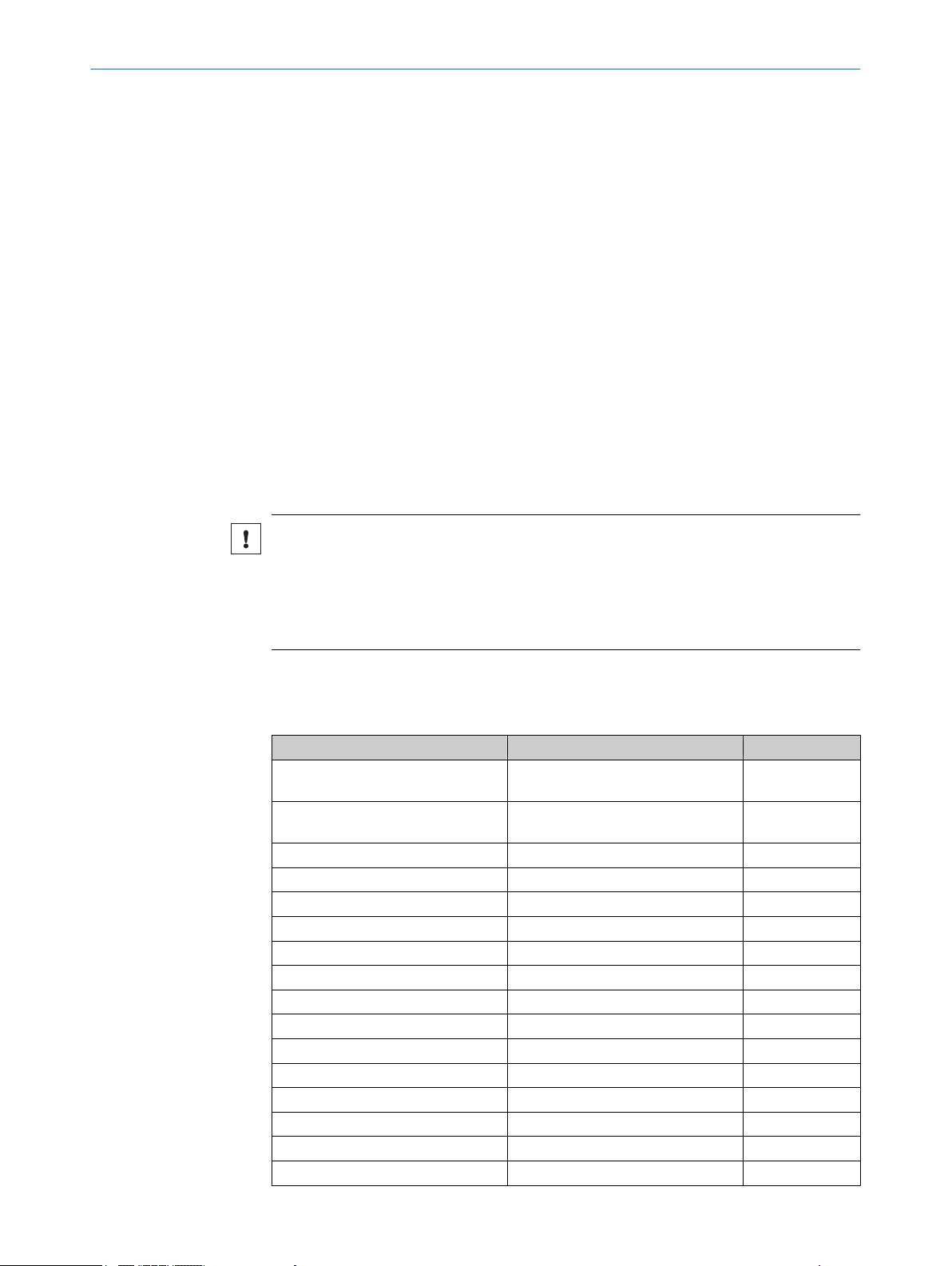

Table 1: Available documents

Document type Title Part number

Operating instructions Flexi Soft Modular Safety Controller

ardware

H

Operating instructions Flexi Soft in the Flexi Soft Designer

tware

sof

Operating instructions deTec4 Prime 8017724

Operating instructions deTec4 Core 8014251

Operating instructions miniTwin4 8012731

Operating instructions C4000 Standard 8009855

Operating instructions C4000 Standard ATEX II 3G/3D 8013551

Operating instructions C4000 Advanced 8009855

Operating instructions C4000 Advanced Ex 8017105

Operating instructions C4000 Advanced ATEX II 3G/3D 8013551

Operating instructions C4000 Select 8012198

Operating instructions C4000 Select Ex 8017106

Operating instructions M4000 Advanced Curtain 8010794

Operating instructions deTec4 Core IP69K 8021546

Operating instructions deTec4 Core Ex 8017107

Operating instructions deTem4 Core 8020445

8012999

8012998

6

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 7

ABOUT THIS DOCUMENT 1

Document type Title Part number

Operating instructions M4000 Standard 8011190

Operating instructions M4000 Standard A/P 8011190

Supplement to operating instructions M4000 Standard A/P in IP69K

Housin

g

Operating instructions M4000 Advanced 8010794

Operating instructions M4000 Advanced A/P 8010794

Operating instructions M4000 area 8010794

Operating instructions deTem4 Core IP69K 8021557

This document is included with the following SICK part numbers (this document in all

vailable language versions):

a

8021672

1.3 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: project devel‐

oper

s (planners, developers, designers), installers, electricians, operators, and mainte‐

nance personnel.

8014815

These operating instructions are organized by the life phases of the safety system:

project planning, mounting, electrical installation, commissioning, operation and main‐

tenance.

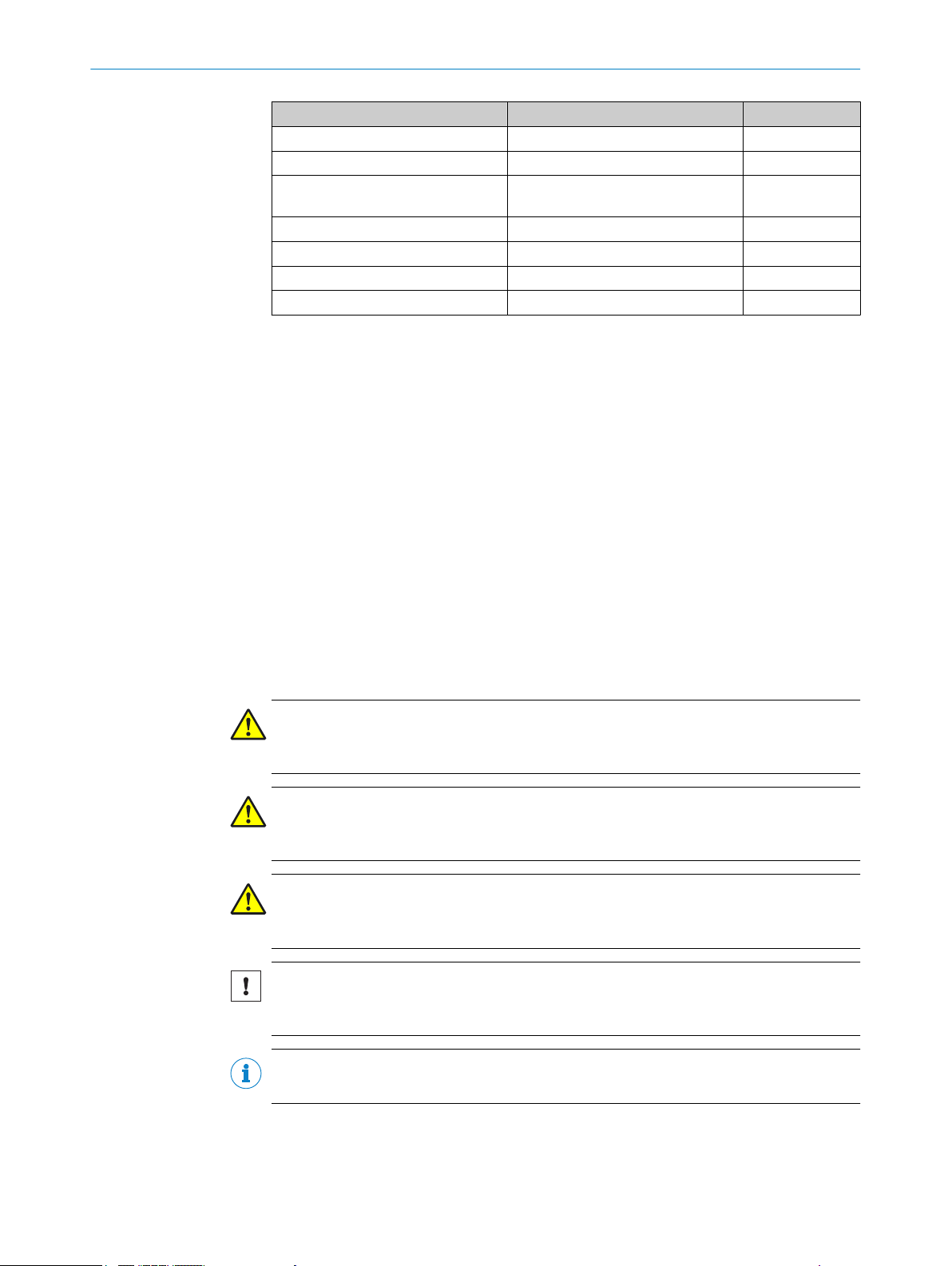

1.4 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

ates a situation presenting imminent danger, which will lead to death or serious

Indic

injuries if not prevented.

WARNING

Indic

ates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indic

ates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

ates a situation presenting possible danger, which may lead to property damage if

Indic

not prevented.

NOTE

ates useful tips and recommendations.

Indic

Instructions to action

The arrow denotes instructions to action.

b

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

7

Page 8

1 A

BOUT THIS DOCUMENT

1. The sequence of instructions for action is numbered.

2.

Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

1.5 Further information

www.sick.com

T

he following information is available via the Internet:

■

This document in other languages

■

Operating instructions and mounting instructions of SICK components suitable for

the safety system

■

The Flexi Soft Designer configuration software

■

Other configuration tools (e.g. Excel tool)

■

Pre-configured project file for Flexi Soft Designer for this safety system

■

Export file of the pre-configured project file for use in various Flexi Soft CPU mod‐

ules

■

Complete subsystems for SISTEMA for this safety system

■

Circuit diagram for the safety system (ePLAN)

■

■

Guide for Safe Machinery (“Six steps to a safe machine”)

8

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 9

2 Safety information

2.1 General safety note

The information and tools will not fulfill the safety requirements for your application

ithout further adjustments being made. The project planning provided by way of exam‐

w

ple is intended to serve as the basis to allow you to perform your own project planning

and programming in line with your specific requirements. What this means is that the

information and tools merely provide an example to demonstrate how a safety function

can be taken care of.

When it comes to your own project planning and programming, you will need to rely on

qualified staff given that it is your responsibility to ensure that the following require‐

ments are complied with at the very least:

Carrying out a risk assessment

b

Taking into account applicable standards

b

Verifying and validating the safety function

b

2.2 Intended use

The Safe Entry Exit safety system is used in hazardous areas with material transporta‐

t

ion via a conveyor (e.g., conveyor belt), e.g., a robot cell. Safe Entry Exit reduces the

risk of personal injury caused by passing through the machine’s material transporta‐

tion. Safe Entry Exit can be used both at the entry area as well as the exit area of the

material transportation.

SAFETY INFORMATION 2

Safe Entry Exit is suitable for applications with the following properties:

The material is moved by a conveyor into the hazardous area.

•

The conveyor moves at a defined speed (maximum of 4 different speeds) during

•

the transportation of the material.

The material is at least 500 mm long.

•

The length of the material is always identical or can be determined automatically

•

(e.g. via a combination of existing process signals).

2.3 Requirements for the qualification of personnel

The protective device must be configured, installed, connected, commissioned, and ser‐

iced by qualified safety personnel only.

v

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting, electrical installation, and commissioning

For the task, a person is considered qualified when he/she has the expertise and expe‐

rience in the relevant field and is sufficiently familiar with the application of the protec‐

tive device on the machine to be able to assess whether it is in an operationally safe

state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

9

Page 10

2 S

AFETY INFORMATION

2.4 Safe state

In the safe state, the accordingly configured safe switching outputs are in the OFF state.

he safe state is initiated in the following cases:

T

The muting function is not correctly terminated because the detected object is too

•

short or too long.

The muting function is not correctly initiated.

•

Deviation from preset timing detected.

•

Deviation from preset sequence detected.

•

When the muting function is active, the connection between the higher-level con‐

•

trol and the safety controller is interrupted.

When the muting function is inactive, the connection between the higher-level con‐

•

trol and the Type 4 electro-sensitive protective device is interrupted.

When the muting function is inactive, the Type 4 electro-sensitive protective device

•

detects an object.

The voltage supply of the higher-level control, the Type 4 electro-sensitive protec‐

•

tive device or the safety controller is interrupted.

Internal fault detected in the Type 4 electro-sensitive protective device.

•

Internal fault detected in the safety controller or one of its components.

•

When the safety system initiates the safe state, the machine manufacturer and user

t ensure that the safe switching outputs are evaluated appropriately and that the

mus

hazard is rectified.

10

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 11

3 Product description

3.1 Product identification

The part number of the safety system is located on the packaging.

Further topics

dering information", page 45

"Or

•

3.2 Application description

The Safe Entry Exit safety system is used on machines in which it is not possible to

ent

er the hazardous area as long as the machine is in a dangerous state. Appropriate

protective devices (e.g., fixed guards) prevent access to the hazardous area. The haz‐

ardous area can only be accessed via an opening that enables the material to pass

through via the conveyor.

Safe Entry Exit is used to monitor the opening provided for material transport and to

place the machine in the safe state if anything other than the expected material passes

through the opening. To accomplish this, the safety system monitors the time it takes

for the expected material to pass through the Type 4 electro-sensitive protective device,

but not the height of the material, see "Construction and function", page 14.

PRODUCT DESCRIPTION 3

3.3 Components of the safety system

Safe Entry Exit components (hardware and software)

F

lexi Soft safety controller main module

•

Flexi Soft safety controller expansion module – I/O module (8 inputs, 4 outputs)

•

Optional, if the conveyor is going to switch between different speeds: Flexi Soft

•

safety controller, expansion module – I/O module (8 inputs)

Memory Plug (MLP)

•

Type 4 electro-sensitive protective device

•

Higher-level control

•

Hold to run device

•

Pushbutton for reset function

•

Configuration file for the Flexi Soft safety controller

•

Implementing all the safety functions for the application requires a complete system

consisting of sensors, a controller, actuators, and control switches. This safety system

comprises sensors and a controller only and is therefore only a subsystem. The user is

responsible for the safe design of the complete system and all safety functions.

3.4 Components required

The following components are essential for using the Safe Entry Exit safety system in an

applic

ation:

Type 4 electro-sensitive protective device

•

Flexi Soft safety controller main module

•

Flexi Soft safety controller expansion module

•

Higher-level control

•

Hold to run device

•

Pushbutton for reset function

•

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

11

Page 12

RODUCT DESCRIPTION

3 P

NOTE

All nece

to safety technology. The components must therefore have a MTTFd value that is suit‐

able for the entire application and satisfies the necessary performance level. The nec‐

essary performance level results from the risk assessment. For evaluating the perfor‐

mance level achieved, subsystems for SISTEMA are available under:

www.sick.com

3.4.1 Requirements for hold to run device

The pushbutton must be installed outside of the hazardous area. From the position of

t

he pushbutton, there must be a complete view of the hazardous area. It must not be

possible for a person to enter the hazardous area while activating the pushbutton.

The pushbutton must be designed according to the following standard:

•

NOTICE

T

sure to prevent unauthorized use is a key-operated spring-back pushbutton.

ssary components influence the parameters of the entire application that relate

EN 60204

he pushbutton should only be operable by authorized personnel. An example of a mea‐

The hold to run device is supplied via test output X2 of the XTIO module, which it is con‐

ted to. Test output X2 of this module must not be used for other devices.

nec

3.4.2 Reset pushbutton requirements

Reset pushbutton requirements

T

he pushbutton must be installed outside of the hazardous area. From the position of

the pushbutton, there must be a complete view of the hazardous area. Activating the

pushbutton must not initiate any movement of the machine.

The reset pushbutton must be designed in accordance with the following standard:

EN 60204

•

Complementary information

he reset pushbutton resets the muting function of the safety system. If the reset push‐

T

button is also to be used to reset the machine, the risk assessment must show that

there is no possibility of this causing a hazard.

3.4.3 Requirements for Flexi Soft safety controller

The Flexi Soft safety controller must be installed in a control cabinet with an enclosure

r

ating of IP 54.

Please note the following for installation:

Continuous equipotential bonding via conductive connections between machine

•

parts and systems

Physically separate supply unit (voltage supply/actuator systems/inverter)

•

Do not use the shielding to conduct equipotential bonding current

•

Keep the shielding short and use the full surface

•

Use every existing or available functional earth (FE)

•

Carefully connect all available communications cables. Twisted lines are often nec‐

•

essary for fault-free data transmission (fieldbus).

12

The voltage supply for the main module and each expansion module for input and out‐

put mus

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

t be limited to a maximum of 4 A, either by the power supply unit or by a fuse.

Subject to change without notice

Page 13

3.4.4 Requirements for the higher-level control

The signals of the higher-level control are part of the initiation of the muting function.

T

he higher-level control can be a standard programmable logic controller that controls

the machine process or an existing safety controller.

The control requires information about the position and speed of the material on the

conveyor. If material with different sizes is transported, the size of the current material

must also be available.

This information must be processed such that the programmable logic controller can

change the status of the signals according to the sequence. Moreover, this information

must also originate from a source that is difficult to manipulate.

Recommended sources are, for example:

Code reader

•

Process information

•

...

•

The entire chain of signal generation must exhibit at least a MTTFd value of three years.

According to EN ISO 13849-1, a MTTFd value of ten years must be assumed for the indi‐

vidual components of the chain if no manufacturer information is available and simple

determination according to appendix C and D is not possible.

PRODUCT DESCRIPTION 3

Examples:

Example 1: In a chain of three non-safe components with an assumed MTTFd value of

10 years, this results in a total MTTFdvalue of 3.3 years. Such a chain is permitted.

Example 2: In a chain of four non-safe components with an assumed MTTFd value of

10 years, this results in a total MTTFdvalue of 2.5 years. Such a chain is not permitted.

If PL e is required, the higher-level control and signal source must also correspond to

PL e and have a MTTFd value of at least 100 a.

Measures must be taken with regard to the voltage supply for the higher-level control so

as to prevent voltage drops, voltage fluctuations, as well as overcurrent and undercur‐

rent.

The wiring of the signals SR (Muting Request) and TE (Time Extension) influences the

safety application and must be validated at the time of commissioning.

3.4.5 Requirements for the electro-sensitive protective device

The Type 4 electro-sensitive protective device must meet the requirements of EN ISO

61496-1 and ha

out in accordance with EN ISO 13855.

If the Type 4 electro-sensitive protective device has additional functions that affect the

direct relationship between the status of the output signal switching devices and the

interruption of the protective field by the material being conveyed, these must be deac‐

tivated.

ve an MTTFd value of at least 100 a. The positioning must be carried

Such functions are, for example, integrated reset functions.

This does not apply to functions – for example a blanking function – that ignore contin‐

uously interrupted signal pathways.

The following must also be taken into account:

The penetration distance required to calculate the minimum distance depends on

•

the resolution of the Type 4 electro-sensitive protective device.

The approach speed of the material depends on the speed of the conveyor.

•

If it is possible to step onto the conveyor, the speed at which a person is moving

•

must be considered in the calculation.

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

13

Page 14

1

3

2

7

4 5

6

3 PRODUCT DESCRIPTION

NOTE

his safety system only covers the positioning of a Type 4 electro-sensitive protective

T

device for monitoring an opening for material transport. The positioning of other equip‐

ment, such as safety fences, is not covered.

3.5 Construction and function

Functionality

he Type 4 electro-sensitive protective device monitors the material opening. When a

T

light beam is unexpectedly interrupted, the safety controller outputs a dual-channel sig‐

nal to place the machine in the safe state.

When material on the conveyor approaches the opening, the material is identified (e.g.

via a combination of existing process signals) or is known to the higher-level control

because of process information. Based on the type of material and speed of the con‐

veyor, an exact time window is determined during which the material will pass through

the opening and therefore also pass by the Type 4 electro-sensitive protective device.

The higher-level control sends the safety controller a signal to request the muting func‐

tion. When the muting function is active, an interruption of the Type 4 electro-sensitive

protective device does not cause the machine to stop. While the material is passing

through the opening, the safety controller continues to monitor the signals from the

Type 4 electro-sensitive protective device. If the actual duration of the interruption dif‐

fers from the expected duration, the machine is placed in the safe state.

Error-free ending of the muting function is performed by the Type 4 electro-sensitive

protective device being released along with the respective signal change of the higherlevel control.

Complementary information

W

hen the muting function is requested, the safety controller expects an interruption of

the Type 4 electro-sensitive protective device. This interruption must take place within

the initialization time window, otherwise this is seen as an error and the muting func‐

tion is not started (see "Conveyor speed", page 19 ).

3.6 Limits of the safety system

The safety system ends at all inputs and outputs that are not used to wire the compo‐

nent

s of the safety system.

For detailed information about the interfaces see "Electrical installation", page 23.

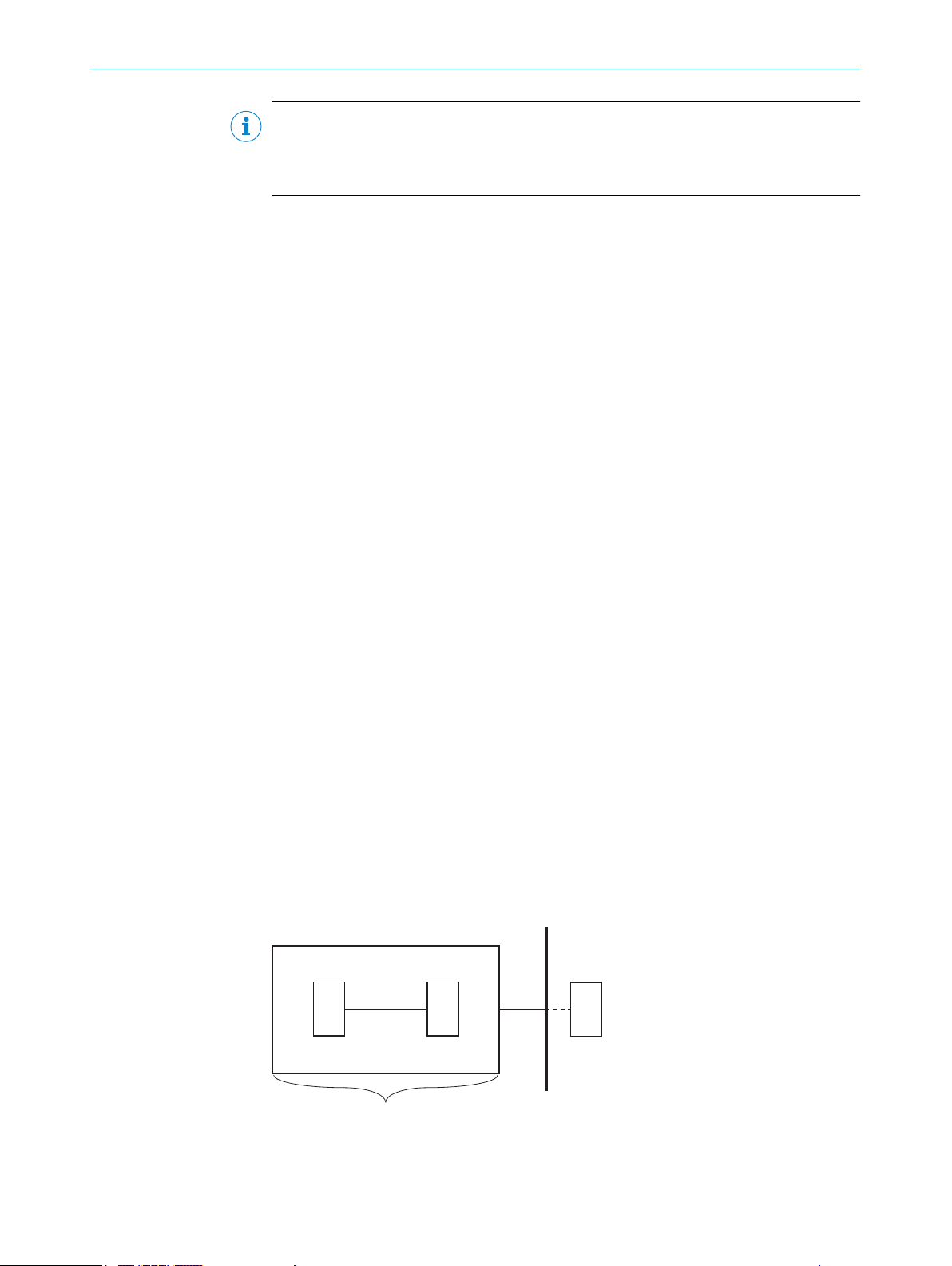

The limits of the safety system are presented in abstract and general terms in the figure

below:

14

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Figure 1: Limits of the safety system

Sensors

1

Subject to change without notice

Page 15

3.7 Functions

PRODUCT DESCRIPTION 3

Logic (safety relay or safety controller)

2

Sub-safety function

3

Wiring between sensors and logic

4

Wiring between safety system components and components outside the safety system

5

Limit of the safety system

6

Components outside the safety system, e.g., actuators, safety capable input devices, or

7

gher-level controller

hi

The Safe Entry Exit safety system offers the following functions:

ing function

Mut

•

The safety controller monitors the signal change from requesting the muting

°

function and from the output signal switching devices of the Type 4 electrosensitive protective device and if necessary, switches to the safe state, see

"Muting function", page 40.

Time Extension Function

•

After a correct initiation sequence of the muting function, the maximum dura‐

°

tion of the muting function can be extended, see "Time Extension Function",

page 41.

Hold to run device

•

When the safety system has switched to the safe state, the hold to run device

°

is used to place the conveyor in motion while the material is blocking the pro‐

tective field of the Type 4 electro-sensitive protective device. see "Hold to run

device", page 42.

1 of n timing sets

•

This function makes it possible to select different transport speeds and mate‐

°

rial lengths, see "1 of n timing sets", page 43.

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

15

Page 16

4 P

ROJECT PLANNING

4 Project planning

4.1 Manufacturer of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Use of the safety system requires a risk assessment. Check whether additional

b

protective measures are required.

Comply with the applicable national regulations derived from the application (e.g.,

b

work safety regulations, safety rules, or other relevant safety guidelines).

The safety system was developed under consideration of typical application cases. A

tial safety function can be implemented with the safety system in these application

par

cases. The manufacturer must check whether the safety system is suitable for its spe‐

cific application case (risk assessment).

If the thorough check shows that the safety system is not suitable for the specific appli‐

cation case, the safety system can be used as a basis for an individualized develop‐

ment suitable for the specific application case. This case will not be considered further

in this document.

In any event, additional work is necessary for the safety system to be used, e.g. subse‐

quent configuration of the safety controller.

The manufacturer has the following duties:

Executing a risk assessment.

b

Verifying and validating the safety functions.

b

Integrating the individual components in accordance with the appropriate stan‐

b

dards.

Please note that C standards have priority compared to statements about this

b

safety system.

4.1.1 Calculation of the performance level

Complete subsystems for SISTEMA available on the internet for this safety system can

be used t

Three subsystems are available:

•

•

•

WARNING

C

ertain indicators for the individual components were used as the basis for calculating

the values for the subsystems. Accordingly, the subsystems are only valid if the selected

components of the safety system meet all requirements, see "Components required",

page 11.

o calculate the achieved performance level.

Safe Entry Exit with a standard control as a higher-level control (requirements see

"Requirements for the higher-level control", page 13)

Safe Entry Exit with a safety controller as a higher-level control (requirements see

"Requirements for the higher-level control", page 13)

A separate subsystem for the hold to run device

16

During the development of the safety system, certain measures against common-cause

aults were implemented or defined. Some of these measures must be taken into

f

account during implementation, see "General requirements", page 23.

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 17

4.2 Operating entity of the machine

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Changes to the electrical integration of the safety system in the machine control

b

and changes to the mechanical mounting of the safety system necessitate a new

risk assessment. The results of this risk assessment may require the entity operat‐

ing the machine to meet the obligations of a manufacturer.

Changes to the safety system’s configuration may impair the protective function.

b

The effectiveness of the safety system must be checked after any change to the

configuration. The person carrying out the change is also responsible for maintain‐

ing the protective function of the safety system.

4.3 Safety Functions

4.3.1 Identifying hazards

This document exclusively considers the monitoring of material transport in or out of

ha

zardous areas and the associated risks.

PROJECT PLANNING 4

Other residual risks, e.g., due to small parts being thrown about, are not considered

and must be considered in detail in the risk analysis, see "Manufacturer of the

machine", page 16.

4.3.2 Enabling material throughput

To move materials into or out of hazardous areas, specific features of the conveyed

ma

terials are used for material detection or to automatically differentiate between

material and people. The protective device is then not actuated during material trans‐

port; however, people are still detected.

4.4 Design

This chapter contains information about implementing the design of the safety system.

An

y design-related contents of the relevant operating instructions also apply.

4.4.1 Type 4 electro-sensitive protective device

P

osition Type 4 electro-sensitive protective device according to EN ISO 13855.

b

If possible, mount the Type 4 electro-sensitive protective device such that the pal‐

b

let for transporting the material on the conveyor does not trigger the Type 4 elec‐

tro-sensitive protective device.

The Type 4 electro-sensitive protective device should only be triggered by the

terial on the pallet. The lowest beam of the Type 4 electro-sensitive protective

ma

device should run just above the surface of the pallet. If this is not practical, the

Type 4 electro-sensitive protective device can also be aligned to the pallet. In this

case, the possibility of persons being situated in an empty pallet must be consid‐

ered in the risk assessment and, if applicable, measures must be taken to prevent

climbing onto an empty pallet. The height of the lowest beam of the Type 4 electrosensitive protective device must be chosen such that it is not possible for persons

to end up in the hazardous area by passing underneath the beam.

Mount t

b

enter the hazardous area by moving past the material.

he Type 4 electro-sensitive protective device such that persons cannot

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

17

Page 18

4 P

ROJECT PLANNING

The distance to the opening should be a maximum of 200 mm on each side,

unle

ss otherwise determined in the risk assessment.

If needed the operating entity of the machine must take additional security mea‐

sures, such as mounting electronically monitored swinging flaps.

The type 4 electro-sensitive protective device must only be mounted with the original

accessories of the manufacturer and connected according to the instructions of the

manufacturer. For more notes, see the operating instructions for the Type 4 electro-sen‐

sitive protective device.

4.4.2 Minimum distance between the Type 4 electro-sensitive protective device and the hazardous point

Calculation of minimum distance

T

he minimum distance between the Type 4 electro-sensitive protective device and the

hazardous point is calculated in accordance with EN ISO 13855 as follows:

S = K × T + C + Z

S= K × T + C +700 mm

Formula symbols Description

S Minimum distance

K Approach speed

T Overall system stopping time

C Penetration distance

Z Application-specific supplement

he application-specific supplement is 700 mm. This supplement

T

is made up of 500 mm for differentiating between people and

materials and 200 mm of monitored conveying distance that is

usually the result of the delay time T

tance other than 200 mm is configured, the application-specific

supplement must be adapted accordingly.

. If a conveying dis‐

Clearance

The risk assessment must determine to what degree people can misuse a process sig‐

ended for transport goods in order to activate the muting function themselves (by

nal int

interrupting the Type 4 electro-sensitive protective device). This possibility must be

taken into account in particular with transport goods which can be taken off the con‐

veyor by hand.

A person who activates the muting function will be detected at the latest because the

muting period is too short. However, the person is already in the hazardous area at this

point.

The application-specific supplement Z is not needed if the risk assessment concludes

that it is not possible for people to be on the conveyor or AGV/AGC.

4.4.3 Design of the material opening

The material transportation opening should be designed so as to provide free space of

ma

ximum 200 mm next to the material when the material is passing through. If the risk

assessment concludes that even with a larger free space it is still impossible for per‐

sons to end up in the hazardous area by passing next to the material, the free space

can be adjusted accordingly.

If the free space next to the material is larger than 200 mm, it should be at least

500 mm to prevent the crushing of persons between the material and the Type 4 elec‐

tro-sensitive protective device or other machine parts. In this case, additional protective

measures must be taken, e.g., installation of electrically monitored swing doors.

18

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 19

It must be clarified during the risk assessment whether it is possible for persons to be

1

1

on t

taken, such as preventing the possibility of climbing onto the transported material or

monitoring the maximum transport material height.

1

4.4.4 Conveyor speed

The speed at which the material is transported on the conveyor must be calculated in

t

PROJECT PLANNING 4

op of the material being transported. If this is the case, suitable measures must be

200 mm maximum

he previously determined sequence.

If different conveyor speeds are used, up to four different timing sets can be set in the

safety controller. The currently valid timing set must be selected via signals from the

higher-level control, see "1 of n timing sets", page 43.

The maximum possible speed of the conveyor depends on the drive as well as the mea‐

surement accuracy of the muting function request. The muting function request must

be sent when the material is a maximum of 200 mm from the Type 4 electro-sensitive

protective device. If the risk assessment concludes that persons in front of the material

definitely need more than 200 mm, the distance can be adjusted accordingly.

4.4.5 Calculating response times and stopping times

Response time of the safety system

T

he response time of the safety system when the muting function is deactivated is cal‐

culated as follows:

T

Safety System

T

Safety System

Formula symbols Description

T

afety System

S

T

SPE

E

T

CPU cycle time

= T

= T

+6.5 ms +2 × T

ESPE

+2 × T

ESPE

CPU cycle time

Response time of the safety system

Response time of the Type 4 electro-sensitive protective device

that is in use (see the relevant operating instructions).

Cycle time of the Flexi Soft safety controller

CPU cycle time

+11 ms

+4.5 ms

The additional 11 ms correspond to the response time of the digital inputs and outputs

he Flexi Soft safety controller.

of t

Stopping time of the application

T = T

Safety System

Formula symbols Description

T Stopping time of the application

T

S

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

afety System

+ T

deceleration

+ T

others

Response time of the safety system

19

Page 20

ESPE Type 4

Independent Control System

Process

sensor

Control unit

(e. g. PLC)

Signal MR

Muting request

Signal TE

Time extension

OSSD

Safety System

Safety Controller Flexi Soft

Safety Outputs

Inputs

Outputs

CPU

Logic

4 PROJECT PLANNING

Formula symbols Description

T

dece

leration

T

thers

o

4.5 Integrating the equipment into the electrical control

NOTE

veral safety functions are generally necessary in order to ensure a safe design for the

Se

entire application. This requires additional components that are not part of the safety

system, such as switches, fuses, and contactors. The circuit diagrams contain informa‐

tion on wiring the safety system with additional components within an application.

4.5.1 Circuit diagram

A more detailed circuit diagram for Safe Entry Exit is available online:

www

.sick.com/Safe_Entry_Exit

The components of Safe Entry Exit are interconnected per the following diagram:

Machine stopping time

Other application-specific variables, such as the response time of

the contactors

20

Figure 2: Block diagram for Safe Entry Exit

T

able 2: Block diagram terminology

ESPE Type 4 The electro-sensitive protective device must conform to Type 4 and

c

an be a safety light curtain, for example.

Independent Control Sys‐

tem

The signals of the higher-level control are part of the initiation of

the muting function. The combination of process sensor and con‐

trol unit is an example. The higher-level control is not part of the

safety system.

Process Sensor The process sensor forwards information about transported mate‐

rials to the control unit. It must not be easy to manipulate this

information, e.g., by modifying it.

Control unit The control unit is a functional unit of the process that controls the

command pr

ocessing sequence. It can be a standard programma‐

ble logic controller, for example.

OSSD Safety output of the Type 4 electro-sensitive protective device con‐

nected in pairs and subject to dual-channel evaluation.

Signal MR - Muting request This signal requests the muting function.

Signal TE - Time extension This signal is used to request the time extension function.

Safety Controller The safety controller monitors the signal change and switches

cordingly.

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Inputs Safety controller inputs

ac

Subject to change without notice

Page 21

PROJECT PLANNING 4

CPU Logic The CPU logic is used to set the timing and sequence of the sig‐

nals

.

Outputs Safety controller outputs

4.5.2 Testing plan

For the detailed pin assignment of the safety controller, see "S

afety controller pin

assignment", page 23.

The safety system must be thoroughly checked by appropriately qualified safety person‐

ne

l during commissioning, after changes at regular intervals.

The regular thorough checks serve to assess the effectiveness of the safety system and

to identify defects as a result of changes or other influences (e.g., damage or manipula‐

tion).

The manufacturer and user must define the type and frequency of the thorough checks

on the basis of the application conditions and the risk assessment. Determination of

the thorough checks must be documented in a traceable manner.

A thorough check must be carried out during commissioning and following modifi‐

•

cations.

The regular thorough checks of the safety system must fulfill certain minimum

•

requirements. The minimum requirements for the thorough check of the safety

system comply at least with the sum of the minimum requirements for the thor‐

ough check of the components of the safety system (see operating instructions of

the components).

In many cases, depending on the application conditions, the risk assessment can

•

determine that further thorough checks are required.

Further chapters

T

horough check, see "Commissioning", page 37

•

Checklist for initial commissioning and commissioning, see "Annex", page 48

•

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

21

Page 22

5 MOUN

TING

5 Mounting

NOTE

Inf

ormation is included in the operating instructions for the components.

5.1 Mounting conditions for the electro-sensitive protective device

For mounting conditions see "T

ype 4 electro-sensitive protective device", page 17.

22

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 23

6 Electrical installation

NOTE

Inf

ormation is included in the operating instructions for the components.

6.1 General requirements

The following measures to prevent common-cause failures must be considered during

lectrical installation:

e

Separation of the signal pathways for the safety system signals, e.g. by laying sep‐

•

arate cables or shielding the signal paths separately.

Protection against overvoltage, overcurrent, etc. according to the manufacturer’s

•

instructions for the individual components.

Mechanical fastening of the wiring of the pushbutton for the manual muting

•

device, e.g. with cable ties.

Measures for controlling the consequences of voltage failure, voltage fluctuations,

•

overvoltage and undervoltage in the voltage supply of the process controller.

6.2 Safety controller pin assignment

ELECTRICAL INSTALLATION 6

Figure 3: Safety controller setup

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

23

Page 24

6 ELE

CTRICAL INSTALLATION

Table 3: Modules of the safety controller

Module 1 Main module FX3-CPUx

Module 2 I/O module FX3-XTIO

Module 3 (optional) I/O module FX3-XTDI

Module 2: Input configuration for FX3-XTIO module

T

able 4: Function of the connections

Connection Function

l1/l2 B100.1 Type 4 electro-sensitive protective device

l3 B100.2 Muting function request

l4 B100.2 Time extension

l5 S300 Pushbutton for the reset function

l6 S200 Hold to run device (connected to test output X2)

Module 2: Output configuration for FX3-XTIO module

T

able 5: Function of the connections

Connection Function

Q1/Q2 Q100 Safety release

Q3 P100 Safe Entry Exit Status

Q4 P101 Hold to run device status

X2 Test output for supply of S200 hold to run device

Module 3: Input configuration for FX3-XTDI module

T

his module is optional and is only required if timings need to be set for different con‐

veyor speeds or different material sizes.

Table 6: Function of the connections

Connection Function

l1 S301.1 Timing 1

l2 S301.2 Timing 2

l3 S301.3 Timing 3

l4 S301.4 Timing 4

6.3 Interfaces and signals

Signals for triggering the muting function

T

his safety system requires two digital 24 V signals from a higher-level control to trigger

the muting function. These signals are part of the initiation sequence for the muting

function.

The first signal for requesting the muting function, MR (Muting Request – in the Flexi

Soft project file also: PLC_Request), detects approaching material with a rising edge

and remains at logical high while an interruption of the Type 4 electro-sensitive protec‐

tive device is expected.

The second signal, TE (Time Extension), changes its status in the opposite direction

from the MR signal.

24

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 25

ELECTRICAL INSTALLATION 6

This opposite behavior is monitored by the safety controller. When the muting function

is ac

tive, the TE signal can be used to extend the maximum duration of the muting func‐

tion, such as if the conveyor has to be stopped while the protective field of the Type 4

electro-sensitive protective device is occupied by material.

The following four signal combinations are possible:

Table 7: Possible signal combinations

MR signal TE signal Meaning

High Low Muting function request

Low High No muting function request

High High Time extension for muting function required

Low Low Error

1)

This signal combination is only valid following successful initiation of the muting function. Otherwise a

fault is output.

Signals for timing set selection

U

p to four optional signals can be used by the higher-level control to select different

timing sets for multiple conveyor speeds or different material sizes. These signals must

be coded as 1 of n.

1)

For more information see "1 of n timing sets", page 43.

Up to four timing sets can be configured and selected accordingly via signals. The fol‐

lowing table describes the signals required to select the sets, depending on the number

of configured timing sets. Configuring only one set is equivalent to deactivating the Tim‐

ing Set selection function.

The value 1 means logical High (24 V signal) and the value 0 means logical Low.

“-” means that this signal is not required.

Table 8: Relationships between configured sets

Number of con‐

figured timing

sets

1 Timing Set configured

Timing Set 1 - - - -

2 Timing Sets configured

Timing Set 1 1 0 - -

Timing Set 2 0 1 - -

3 Timing Sets configured

Timing Set 1 1 0 0 -

Timing Set 2 0 1 0 -

Timing Set 3 0 0 1 -

4 Timing Sets configured

Timing Set 1 1 0 0 0

Timing Set 2 0 1 0 0

Timing Set 3 0 0 1 0

Timing Set 4 0 0 0 1

Signal Timing Set1Signal Timing Set2Signal Timing Set3Signal Timing Set

4

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

25

Page 26

7 CONFIGURATION

7 Configuration

7.1 Requirements on software and firmware

Configuration of the safety system requires at least the following versions of the soft‐

are or firmware:

w

Table 9: Minimum versions

Software and firmware Minimum version

Flexi Soft Designer 1.8.0 SP1

Firmware FX3-CPUx 4.0

Firmware FX3-XTIO 3.0

Process software requirements

T

he software source code for the higher-level controller influences the safety applica‐

tion. This relates to the generation and timing of the MR and TE signals for requesting

the muting function. The corresponding section of source code must therefore be vali‐

dated during commissioning.

7.2 Pre-configured project files

Reference source

Pr

e-configured project files for the safety system are available under the following link:

www.sick.com/Safe_Entry_Exit

Export file

In addit

ion to the project files provided, an export file is available on the Internet. This

corresponds to the hardware configuration and logic of the project file with an activated

Timing Set Selection function, but it can be imported into any Flexi Soft CPU module

(firmware version ≥ 4.00).

CPU3 module only:

1. Check CPU cycle times and clock generators.

2. If necessary, adjust the settings to optimize the CPU cycle time.

7.2.1 Checking the checksums of the project files

Approach

1.

Open the required project file in the configuration software or import the required

export file.

2. Click on Hardware configuration.

3. In the Info selection window, click on info.

4. Make sure that the checksum that is displayed corresponds to one of the following

checksums:

Table 10: Checksums

Description Checksum

Project file with activated Timing Set Selection function 0xF3E6EDD7

Project file with deactivated Timing Set Selection function 0xA1EC4147

Checksums of the export file in combination with the relevant Flexi Soft CPU

CPU0 0xF3E6EDD7

CPU1 0x330BBBC5

26

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 27

Description Checksum

CPU2 0x330BBBC5

CPU3 0x54476CD3

Complementary information

ging the configuration logic or the hardware configuration changes the checksum.

Chan

7.2.2 Standard values for timing sets

Important information

WARNING

he indicated application values do not correspond with the values of the target appli‐

If t

cation, the standard values for the timing sets must be adjusted accordingly.

Standard values for timing sets

T

able 11: Standard values for timing sets

T

Init

iation

T

arance

Cle

T

ermination

T

T

Min

T

x

Ma

CONFIGURATION 7

Timing Set 1 Timing Set 2 Timing Set 3 Timing Set 3

2,000 ms 660 ms 400 ms 280 ms

2,000 ms 660 ms 400 ms 280 ms

2,000 ms 660 ms 400 ms 280 ms

131 (=13 s) 45 (=4.4 s) 27 (=2.6 s) 20 (=1.9 s)

141 (=14 s) 47 (=4.6 s) 29 (=2.8 s) 21 (=2 s)

The four different timing sets can be selected sequentially using the Timing Set Selec‐

ion function. In the project file with a deactivated Timing Set Selection function, Timing

t

Set 1 is selected as standard.

Assumed application values

The standard values of the timing sets were calculated using the following application

values:

Material length: 1,200 mm

•

Conveyor speeds:

•

Timing Set 1: 0.1 m/s

°

Timing Set 2: 0.3 m/s

°

Timing Set 3: 0.5 m/s

°

Timing Set 4: 0.7 m/s

°

Clock generator 0:

•

Clock period: 25 (= 100 ms)

°

Pulse time: 5 (= 20 ms)

°

Clock generator 2:

•

Clock period: 1,500 (= 6 s)

°

Pulse time: 25 (= 100 ms)

°

All the data relate to a CPU cycle time of 4 ms. If the CPU cycle time is longer, the set‐

tings of the clock generators must be adjusted accordingly.

Complementary information

ging the standard values of the timing sets changes the checksum.

Chan

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

27

Page 28

ONFIGURATION

7 C

Further topics

"C

onfiguration of PLC monitoring & override", page 35

•

7.3 Opening project file

1. Start Flexi Soft Designer.

2.

Click on Project.

3. Click on Open.

4. Select the project file.

5. Click on Open.

✓

The project file opens. The Hardware configuration view appears.

In the Configuration area, the entire hardware configuration of the Flexi Soft safety con‐

troller and the connected devices is displayed graphically.

7.4 Configuring logics for Flexi Soft CPU

1. Move the mouse cursor to the L

2. Click on Logic editor.

✓

The Logic editor view opens. The Sequence monitoring page appears.

7.4.1 Creating or deleting links

The logics in the Flexi Soft Designer mainly consist of the following elements:

afety controller inputs

S

•

Safety controller outputs

•

Function blocks with inputs and outputs

•

Links connect these elements. Links are represented as lines. Every element contains

blue anchor points which represent the inputs and outputs of the elements. A link can

only be created between the anchor point on the right side of an element and the

anchor point on the left side of another element.

Creating link

1.

Click and hold the blue anchor point on the right side of an element.

2. Move and release the mouse cursor on the blue anchor point on the left side of an

element.

✓

A link is created between 2 elements.

Deleting link

1. Click on the link between 2 elements.

2. Press the Del pushbutton.

3. In the Delete page dialog box, click on the Yes button.

✓

The link is deleted.

ogic editor button.

7.5 Transfer configuration

T

ransmit configuration to the Flexi Soft main module (see operating instructions

b

8012998).

28

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 29

7.6 Adjust configuration

Important information

WARNING

he safety-related application software is expanded and used for other safety func‐

If t

tions, the additional function blocks must be strictly separated, on separate logic

pages, from the Safe Entry Exit function blocks.

The logic pages for Safe Entry Exit may only be changed as described in this document.

Any other changes can impair the safety of the system.

NOTE

C

onfigured time values are subject to a tolerance during evaluation. This depends on

the function blocks used and CPU cycle time, among other things.

For detailed information on the time evaluation in Flexi Soft logic, see the Flexi Soft

operating instructions in the Flexi Soft Designer software (part number 8012998).

Adjust configuration

T

he configuration must be adjusted on the following logic pages:

CONFIGURATION 7

•

•

•

All user-defined function blocks in the safety-related application software are locked

and do not have to be configured.

Data relating to the speed of the conveyor and the size of the material being trans‐

ported are needed for the settings of the Timer and Event counter function blocks.

Complementary information

An Ex

Excel tool can help with calculating the settings for the function blocks.

7.6.1 Configuration of S

“Initiation” network

Sequence monitoring

Time monitoring

PLC monitoring & override

cel tool is included in the download archive, together with the project file. This

equence monitoring

Figure 4: “Initiation” network

his network contains an Adjustable off-delay timer function block. Up to four different

T

times can be configured for different conveyor speeds, depending on the application.

These times can be selected using the optional Timing Set Selection, see "Interfaces

and signals", page 24. If this function is not used, only the Off delay time 1 parameter

needs to be configured.

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

29

Page 30

7 C

ONFIGURATION

The time set here is the initialization time window between the request from the higherle

vel controller and the interruption of the Type 4 electro-sensitive protective device. By

configuring a suitable initialization time window, it is possible to ensure that people in

front of the material being transported are detected.

Configuration instructions:

The delay times to be configured correspond to the time required for a 200 mm convey‐

ing line at the respective conveyor speed. It is forbidden to set this value above 4 s.

T

initiation

=

0.2m

V

conveyor

A shorter delay time can be set if the accuracy of the signals from the higher-level con‐

rol is precise enough to ensure the availability of the system.

t

WARNING

ious injury may occur due to unreliable presence detection.

Ser

Monitoring the 200 mm conveying distance between requesting the Safe Entry Exit

function and the time at which the protective field of the Type 4 electro-sensitive protec‐

tive device is interrupted ensures that people in front of the material being transported

will be detected.

The calculation of T

is safety-related.

initiation

If the risk assessment concludes that people in front of the material definitely need

more than 200 mm of space, the distance can be adjusted accordingly.

“Termination” network

Figure 5: “Termination” network

T

his network includes the two Adjustable on-delay timer function blocks. Up to four differ‐

ent times can be configured for different conveyor speeds, depending on the applica‐

tion. These times can be selected using the optional Timing Set Selection, see "Inter‐

faces and signals", page 24. If this function is not used, only the On delay time 1 parame‐

ter needs to be configured.

The switch-on delay time set in the upper function block is the time needed for the pro‐

tective field of the Type 4 electro-sensitive protective device to be released again after

the muting function has ended.

30

The switch-on delay time configured in the above function block also correlates to the

size tolerance for gaps between the conveyed materials.

The switch-on delay time configured in the lower function block refers to the time after

which the muting function is ended, following the end of the request from the higherlevel control.

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 31

CONFIGURATION 7

Configuration instructions:

T

he delay times to be configured correspond to the time required for a 200 mm convey‐

ing line at the respective conveyor speed. It is forbidden to set this value above 4 s.

T

clearance

T

=

termination

Tclearance corresponds to the specified delay time after the protective device has been

released and until the muting function is ended.

The delay time for the lower function block can be reduced or even deactivated (config‐

ured time = 0) if a quicker response is required to the end of the request from the

higher-level control system.

WARNING

ious injury may occur due to unreliable presence detection.

Ser

Monitoring the 200 mm conveying distance after unlocking the protective field of the

Type 4 electro-sensitive protective device ensures that a gap larger than 200 mm

between the conveyed material will not be tolerated. Monitoring a 200 mm line after

the end of the request for the muting function ensures that people located between or

behind the material being transported will be detected.

The calculation of T

clearance

=

0.2m

V

conveyor

and T

termination

is safety-related.

7.6.2 Configuration of T

“Time monitoring general” network

Figure 6: “Time monitoring general” network

T

his network includes two Clock generator function blocks, which must be configured.

The configuration of both clock generator function blocks depends on the CPU cycle

time of the respective project. The basic CPU cycle time of a project with an FX3-CPU0

module is 4 ms, but this can rise if additional function blocks or other FX3-CPUx mod‐

ules are used.

ime monitoring

Configuration instructions:

T

he settings for the upper Clock generator function block only have to be configured if the

CPU cycle time of the finished project file does not equal 4 ms. If the cycle time is not

4 ms, the value of the clock period must be changed so that the resulting clock period

equals 6 s. The values for the most common cycle times are set out in the table below:

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

31

Page 32

7 C

ONFIGURATION

Table 12: Values for common cycle times

CPU cycle time Value for the clock period setting

4 ms 1,500

8 ms 750

12 ms 500

When configuring the lower c

lock generator function block, it is only necessary to set the

clock period. The resulting clock period depends on the CPU cycle time. If changes in

the safety-related application software affect the CPU cycle time, the settings for this

function block must be adjusted accordingly.

The resulting clock period defines the increments at which the minimum and maximum

duration of the muting function can be set and is therefore important for calculating

and configuring these times.

In the calculation formulas for the following two networks, the cycle time of this Clock

generator function block is referred to as T

clock period

. We recommend setting the cycle

time to around 100 ms.

“Min time monitoring” network

32

Figure 7: “Min time monitoring” network

his network includes four Event Counter (up) function blocks that must be configured. Up

T

to four different timings for the different conveyor speeds or different material sizes can

be configured.

Each of the four Event Counter (up) function blocks corresponds to one of the timings that

can be selected using the Timing Set Selection function. The uppermost Event Counter

(up) function block defines Timing 1, while the lowest, in accordance with the ascending

order, defines Timing 4.

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 33

CONFIGURATION 7

The value set in this function block determines the minimum duration of the muting

f

unction. If the muting function ends before this time has elapsed, an error is output.

Configuration instructions:

The configuration of the minimum time in this network is based on the counting of peri‐

ods at a defined clock with a defined overflow value.

The defined clock periods are set in the Time monitoring general network, see "Configura‐

tion of Time monitoring", page 31.

The overflow values for the various timings must be set in the Event Counter (up) function

blocks in this network. If the Timing Set Selection function is not used, only the upper‐

most Event Counter (up) function block has to be configured. The time required until the

overflow value for the respective Event Counter (up) function block is reached with the pre‐

set clock determines the minimum duration of the muting function.

The minimum duration of the muting function is calculated using the following formula.

The material length l

To calculate the minimum duration of the muting function, a material length l

less than 500 mm is not permitted.

T

Min

= (l

– tolerance) / V

goods

Recommended value for tolerance: 0.1 m

and conveyor speed V

goods

+ T

Conveyor

Clearance

conveyor

= T

are needed for this.

clock period

× ( a

overflow

–1)

goods

of

If l

- tolerance is less than 0.5 m, the value must be rounded up to 0.5 m.

goods

We recommend that you define the clock period Tclock period first. The overflow value

to be set for the respective function block can then be calculated using the following

formula.

a

overflow

= (l

goods

– t

olerance

) / (V

Conveyor

× T

clock period

) + (T

Clearance

/ T

clock period

) +1

8021675/ZV26/2019-05-13 | SICK OP E RA T IN G I N ST R UC T IO N S | Safe Entry Exit

Subject to change without notice

33

Page 34

7 C

ONFIGURATION

“Max time monitoring” network

Figure 8: “Max time monitoring” network

T

his network includes four Event Counter (up) function blocks that must be configured. Up

to four different timings for the different conveyor speeds or different material lengths

can be configured.

Each of the four Event Counter (up) function blocks corresponds to one of the timings that

can be selected using the Timing Set function. The uppermost Event Counter (up) function

block defines the timing with the index 1, while the lowest, in accordance with the

ascending order, defines Timing 4.

The value set in this function block determines the maximum duration of the muting

function. If the Type 4 electro-sensitive protective device is still interrupted after this

period has elapsed, an error is output.

Configuration instructions:

T

he configuration of the maximum time in this network is based on the counting of peri‐

ods in a defined clock with a defined overflow value.

The defined clock periods are set in the Time monitoring general network, see "Configura‐

tion of Time monitoring", page 31.

The overflow values for the various timings must be set in the Event Counter (up) function

blocks in this network. If the Timing Set Selection function is not used, only the upper‐

most Event Counter (up) function block has to be configured. The time required until the

overflow value for the respective Event Counter (up) function block is reached with the pre‐

set clock determines the maximum duration of the muting function.

34

The maximum duration of the muting function is calculated using the following formula.

The material length l

and conveyor speed V

goods

are needed for this. T

conveyor

Interruption ESPE

corresponds to the expected muting period of the protective device. It is forbidden to

set this value above 10 min.

O PE R AT I NG IN S TR U CT I ON S | Safe Entry Exit 8021675/ZV26/2019-05-13 | SICK

Subject to change without notice

Page 35

CONFIGURATION 7

T

= T

Ma

x

Interruption ESPE

T

Max

= (l

goods

/ V

It is recommended to first define the clock period T

set for the respective function block can then be calculated using the following formula.

a

= l

overflow

goods

Complementary information

T

able 13: Timing errors

Timing errors Description

End of the maximum duration

he muting function

of t

End of the minimum duration

of the muting function

Conveyor)

/ (V

+ T

+ T

Conveyor

Clearance

Clearance

× T

clock period

= T

clock period

) + (T