SICK S30A-6111DP, S30A-4111DP, S30A-6111CP, S30A-7111CP, S30A-7111DP Operating Instructions Manual

...Page 1

ADDENDUM OPERATING INSTRUCTIONS

S3000 PROFINET IO and

S3000 PROFINET IOOF

Safety laser scanner

en

Page 2

Addendum Operating Instructions

S3000 PROFINET IO/IOOF

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 3

Addendum Operating Instructions

S3000 PROFINET IO/IOOF

Contents

Contents

1 About this document.........................................................................................................5

On safety.............................................................................................................................6

2

2.1 Applications of the device.....................................................................................6

2.2 General safety notes and protective measures ..................................................6

Product description........................................................................................................... 7

3

3.1 Special features ....................................................................................................7

3.2 Operating principle of the devices .......................................................................7

3.3 Input signals .......................................................................................................... 8

3.3.1 Reset signals ....................................................................................... 8

3.3.2 Control signals for switching monitoring cases................................. 8

3.3.3 Stand-by............................................................................................... 9

3.3.4 Initialising ............................................................................................ 9

4 Mounting ..........................................................................................................................10

5 Electrical installation......................................................................................................11

5.1 System connection..............................................................................................11

5.1.1 Voltage supply ...................................................................................12

5.1.2 Network connection with RJ845-push-pull plug ...............................13

5.1.3 Network connection with SCRJ-push-pull plug (optical fiber) .........14

5.1.4 Local configuration connection........................................................14

6 Configuration ...................................................................................................................15

6.1 Configuration PROFINET IO.................................................................................16

6.1.1 Reading the generic station description (GSDML) ..........................16

6.1.2 Configuring users ..............................................................................17

6.2 Configuration PROFIsafe.....................................................................................18

6.2.1 Setting the PROFIsafe address on the

S3000 PROFINET IO/IO8OF...............................................................20

6.2.2 Passivation and reintegration of the

S3000 PROFINET IO/IO8OF...............................................................21

6.3 Configuration of the S3000 PROFINET IO/IO8OF...............................................22

7 Diagnostics ......................................................................................................................23

7.1 Meaning of the status indicators .......................................................................23

7.1.1 Meaning of the LEDs.........................................................................23

7.1.2 Meaning of the 78segment display...................................................23

7.2 CDS (Configuration & Diagnostic Software) ......................................................26

7.3 Alarms..................................................................................................................27

7.3.1 I&M function (Identification & Maintenance function) ...................27

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Page 4

Contents

S3000 PROFINET IO/IOOF

8 Technical specifications ................................................................................................ 28

8.1 Process image S3000 PROFINET IO/IO8OF Advanced .....................................28

8.1.1 INPUT................................................................................................. 28

.1.2 OUTPUT..............................................................................................29

8

8.2 Process image S3000 PROFINET IO/IO8OF Professional ................................. 31

8.2.1 INPUT................................................................................................. 31

8.2.2 OUTPUT..............................................................................................32

8.3 PROFINET diagnostic messages........................................................................ 34

8.4 Response times .................................................................................................. 35

8.5 Data sheet........................................................................................................... 36

8.6 Services supported............................................................................................. 37

8.7 Dimensional drawing S3000 PROFINET IO/IO8OF............................................ 38

9 Ordering information ......................................................................................................39

9.1 Items supplied .................................................................................................... 39

9.2 Systems available............................................................................................... 39

9.2.1 S3000 PROFINET IO with RJ-45 sockets......................................... 39

9.2.2 S3000 PROFINET IO8OF with SCRJ sockets (optical fiber) ............. 39

9.3 Accessories/spare parts .................................................................................... 40

10 Annex................................................................................................................................ 41

10.1 Compliance with EU directives........................................................................... 41

10.2 List of tables .......................................................................................................42

10.3 List of illustrations ..............................................................................................42

Addendum Operating Instructions

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 5

Addendum Operating Instructions Chapter 1

S3000 PROFINET IO/IOOF

About this document

1 About this document

his document is an original document.

T

This addendum is applicable for the S3000 PROFINET IO and S3000 PROFINET IO8OF safe-

ty laser scanners, in the following summarized as S3000 PROFINET IO/IO8OF. As far as the

connection variants differ, the respective product variant is named.

This addendum is applicable to the S3000 PROFINET IO/IO8OF safety laser scanner with

one of the following entries on the type label in the field Operating Instructions:

8013289

8013289/TL59

8013289/US26

8013289/YAX9

8013289/YKY7

8013289/YY95

This document is part of SICK part number 8013289 (addendum operating instructions

“Safety Laser Scanner S3000 PROFINET IO and S3000 PROFINET IO8OF” in all available

languages).

Note

This addendum only applies in conjunction with the original operating instructions

“S3000 Safety Laser Scanner” (SICK part number 8009791).

If not otherwise revised in this document, the information in the original operating

instructions applies, which relate to the S3000 Advanced or Professional safety laser

scanner.

For the configuration and diagnostics of these devices you require CDS (Configuration &

Diagnostic Software) version 3.6.4 or higher.

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

Page 6

Chapter 2 Addendum Operating Instructions

On safety

S3000 PROFINET IO/IOOF

2 On safety

2.1 Applications of the device

The S3000 PROFINET IO/IO8OF safety laser scanner is used to protect persons and plant.

Stationary applications, e.g. for access or hazardous area protection, can be realised.

The safety level of the S3000 PROFINET IO/IO8OF corresponds to category 3 PL d

according to EN ISO 1384981 and SIL2 according to IEC 61508.

2.2 General safety notes and protective measures

Safety notes

WARNING

This addendum must be made available to the operator of the system, machine or the

vehicle where the S3000 PROFINET IO/IO8OF safety laser scanner is used, together with

the original operating instructions. The operator is to be instructed by qualified safety

personnel and is to read and follow the addendum; the operating instructions must also be

followed.

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 7

Addendum Operating Instructions Chapter 3

S3000 PROFINET IO/IOOF

Product description

3 Product description

his chapter provides information on the special features and properties of the

T

S3000 PROFINET IO/IO8OF safety laser scanner. It also describes the properties and

functions that differ from the S3000 Advanced or Professional.

Please read this chapter before mounting, installing and commissioning the device.

3.1 Special features

protective field range 4 m, 5.5 m or 7 m

warning field range 49 m (20 m at 20% remission)

S3000 PROFINET IO/IO8OF Advanced with 4 protective fields/warning fields (field sets)

S3000 PROFINET IO/IO8OF Professional with 8 protective/warning fields (field sets)

simultaneous protective fields with separate output information and separate feature

for resetting (see section 8.1 on page 28 or 8.1.2 on page 29)

direct fail-safe integration into PROFINET IO networks

supply connector with integrated configuration memory

connection types:

– S3000 PROFINET IO: RJ845 sockets for RJ845 push-pull plug

– S3000 PROFINET IOOF: SCRJ sockets for VARIOSUB push-pull SCRJ8plug

The S3000 PROFINET IO/IO8OF does not have any local inputs or outputs except the

interfaces for setting the parameters. All communication is via the PROFINET IO network.

3.2 Operating principle of the devices

PROFINET IO device

The PROFINET IO device is a remotely connected field device for installation in close proximity to the process. It expects the configuration from an IO controller/supervisor and

cyclically transmits its process data to the IO controller.

PROFIsafe for PROFINET

PROFIsafe defines how fail-safe devices (e.g. S3000 PROFINET IO/IO8OF) communicate

over a network with safety controllers (e.g. FPLC). It realises the safe communication via a

profile, i.e. using a special data format and a special protocol.

Device role

The S3000 PROFINET IO/IO8OF is an IO device.

It expects the configuration from an IO controller and cyclically transmits its process data

to the IO controller.

Device model

The S3000 PROFINET IO/IO8OF is available as a compact device.

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

Page 8

Chapter 3 Addendum Operating Instructions

Tab.1:

Logical state 0 of the

Tab.2:

Logical state 1 of the

Product description

Services supported

PROFINET IO with Conformance Class B

LLDP according to IEEE 802.1 AB

SNMP

MIB-II

cyclic IO communication

acyclic read/write services for communication via TCI interface

diagnostics alarms

TCP/IP communication via port 9000

support for MRP client

S3000 PROFINET IO/IOOF

3.3 Input signals

3.3.1 Reset signals

If the safety laser scanner is operated using the “With restart interlock” function, then

after a protective field interruption and the subsequent clearing of the protective field, the

S3000 PROFINET IO/IO8OF requests a reset signal from the control system (Reset Re-

quired). The safety laser scanner reacts to an edge change on the reset signal from low to

high (not to the level).

WARNING

Note

control inputs in the process

image

control inputs in the process

image

The reset signal must be fail-safe (single failure proof)!

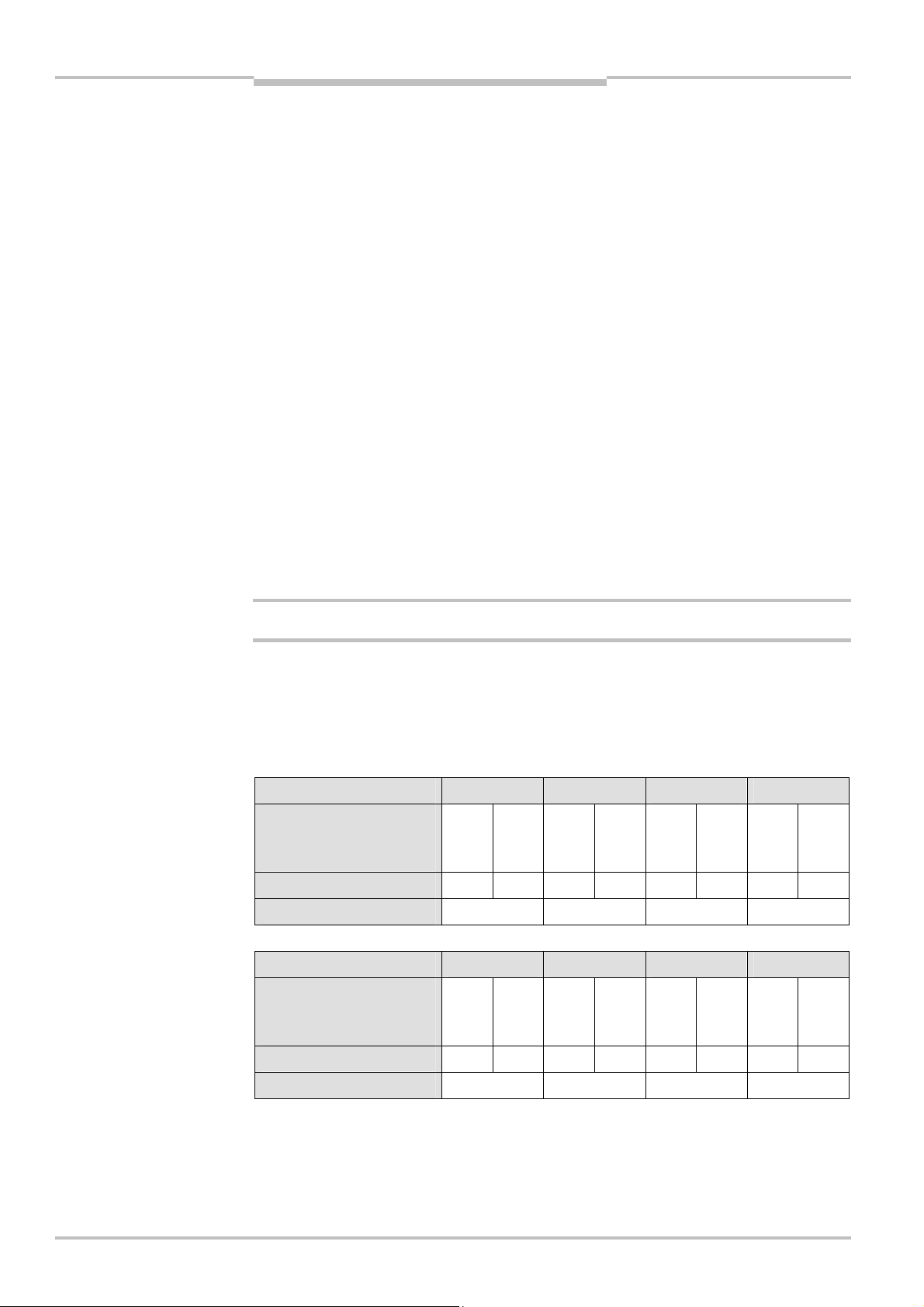

3.3.2 Control signals for switching monitoring cases

You can switch between protective fields by switching monitoring cases.

The related control inputs A, B, C, D on theS3000 PROFINET IO/IO8OF Professional or A, B

on the S3000 PROFINET IO/IO8OF Advanced expect complementary signals.

Control input A B C D

Bits of the output byte 0 in

the process image (see

Tab. 10 on page 32)

Value of the bit 1 0 1 0 1 0 1 0

Logical state 0 0 0 0

Control input A B C D

Bits in output byte 0 in the

process image (see

Tab. 10 on page 32)

Value of the bit 0 1 0 1 0 1 0 1

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Logical state 1 1 1 1

Examples:

01011010 = valid value: A = 1, B = 1, C = 0, D = 0

11011010 = invalid value, input A is not set complementarily

Subject to change without notice

Page 9

Addendum Operating Instructions Chapter 3

S3000 PROFINET IO/IOOF

Product description

3.3.3 Stand-by

The protective field and warning field outputs are deactivated by operating the

S3000 PROFINET IO/IO8OF in stand-by. The S3000 PROFINET IO/IO8OF remains in the

tand-by mode as long as the related input information is present (active high) (see

s

Tab. 10 on page 32).

3.3.4 Initialising

If the S3000 PROFINET IO/IO8OF is in the lock-out status, e.g. due to invalid values on the

inputs, the safety laser scanner can be initialised. During initialisation the device runs

through the boot sequence, similar to a warm start.

Once the cause of the error has been rectified, the device then starts to operate normally.

The safety laser scanner reacts to an edge change on the signal from low to high (not to

the level).

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

Page 10

Chapter 4 Addendum Operating Instructions

Mounting

S3000 PROFINET IO/IOOF

4 Mounting

o calculate the safety distance and the size of the protective field when operated

T

horizontally or vertically in stationary or mobile applications, read the chapter “Mounting”

in the original operating instructions “S3000 Safety Laser Scanner” (SICK part number

009791). Also pay attention to the dimensional drawings in section 8.7 on page 38.

8

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 11

Addendum Operating Instructions Chapter 5

Fig.1:

System connection

RJ 45

sockets

Supply connector

SCRJ

sockets

S3000 PROFINET IO/IOOF

Electrical installation

5 Electrical installation

witch the power supply off!

S

WARNING

The machine/system could inadvertently start up while you are connecting the devices.

Ensure that the entire machine/system is disconnected during the electrical

nstallation.

i

5.1 System connection

The S3000 PROFINET IO/IO8OF is installed electrically using the supply connector and

using the two RJ845 ord SCRJ sockets.

Note

Port 2 Port 1

System connection for RJ 45 System connection for SCRJ (Optical Fiber)

With the push-pull plug connected the connection complies with enclosure rating IP 65.

– RJ-45: e.g. Phoenix VS-PPC-C1-RJ45-MNNA-PG9-4Q5, material no. 1608100

– SCRJ: e.g. Phoenix VS-PPC-C1-SCRJ-MNNA-PG9-A4D-C, material no. 1608032

With the provided cover the connection complies with enclosure rating IP 54.

Port 2 Port 1

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Page 12

Chapter 5 Addendum Operating Instructions

Fig.2:

Terminals on the

Tab.3:

Terminal assign

-

Fig.3:

Pre-assembl

ed supply

Fig.4:

Pre-assembled cable

Voltage supply

S3000

Part No.: 2049857 (on request)

Part no.: 2049575

Electrical installation

S3000 PROFINET IO/IOOF

5.1.1 Voltage supply

The power is supplied via the supply connector. Lay the connecting cables through the

cable entry into the connector housing.

supply connector

ments on the supply

connector

connector

with Y-piece

Note

Terminal Signal Function Wire colour (for the flying leads)

1 +24 V DC Supply voltage Brown

2 – Do not use –

3 0 V DC Supply voltage Blue

The external 24 V supply voltage may not exceed 40 V (SELV or PELV). This must be

ensured during the electrical installation.

As an option a pre-assembled supply connector with flying leads is available.

Additionally a pre-assembled supply connector with cable and external Y-piece is available.

This corresponds to a standardized push-pull power connector (industry standard).

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 13

Addendum Operating Instructions Chapter 5

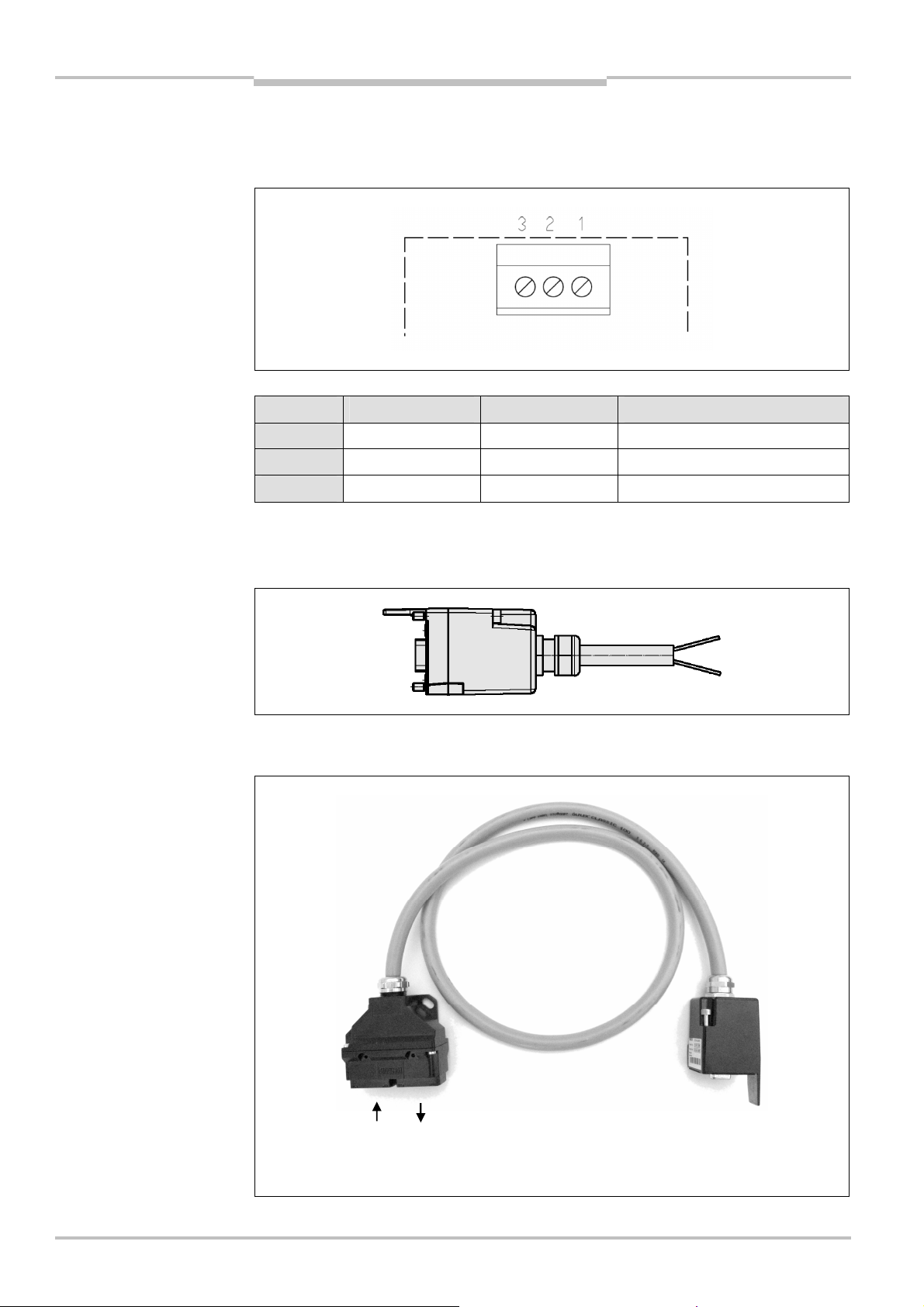

Fig.5:

RJ 45

-

push-pull plug

Tab.4:

Pin assignment on

S3000 PROFINET IO/IOOF

Electrical installation

5.1.2 Network connection with RJ45-push-pull plug

(not included)

the RJ 45 sockets

Notes

For the connection to the network you must use the push-pull plugs with a metal hous-

ing. With the push-pull plug connected the connection complies with enclosure rating

P 65 (e.g. Phoenix VS8PPC8C18RJ45-MNNA-PG9-4Q5, material no. 1608100).

I

With the provided cover the connection complies with enclosure rating IP 54.

If the network is not connected to a following bus device, then a connection using a plug

is sufficient. It does not matter which of the two sockets is used. The unused socket

must always be protected with the provided cover (see Fig. 1).

Pin Signal PROFINET IO colours

1 TX+ Yellow

2 TX– Orange

3 RX+ White

4 – Do not use

5 – Do not use

6 RX– Blue

7 – Do not use

8 – Do not use

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Page 14

Chapter 5 Addendum Operating Instructions

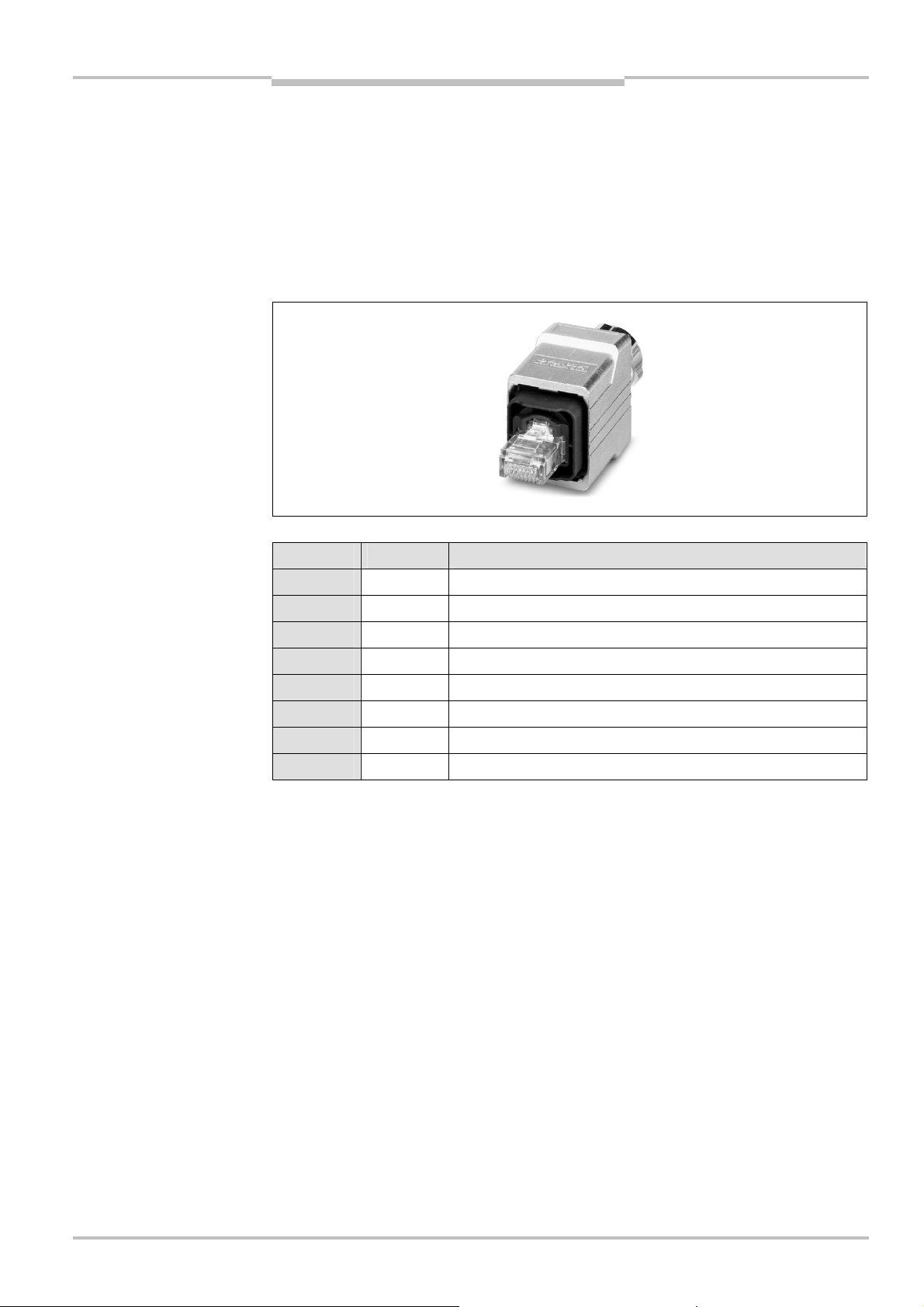

Fig.6:

SCRJ-push-pull plug

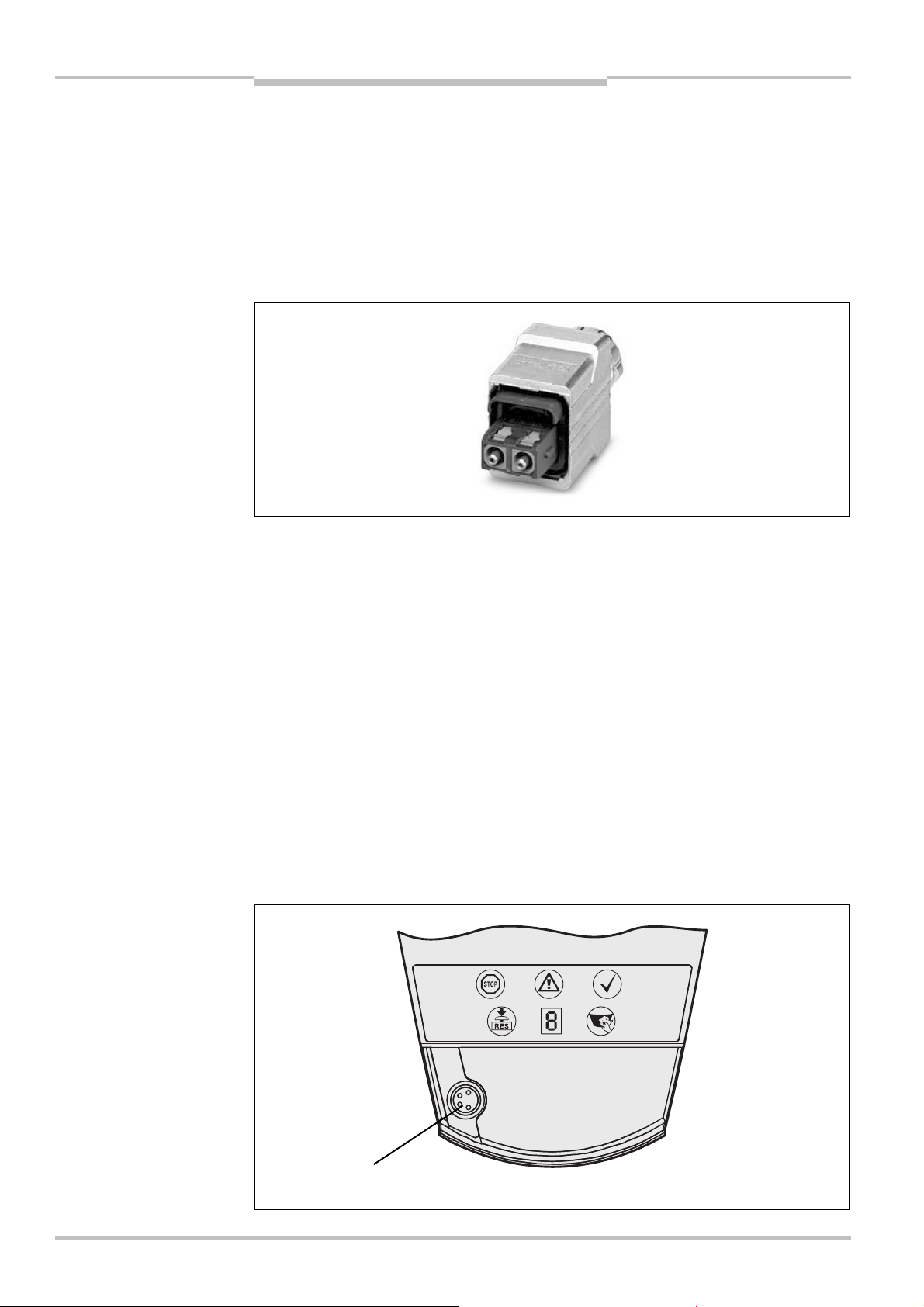

Fig.7:

Local configurati

on

Local configuration connection

Electrical installation

S3000 PROFINET IO/IOOF

5.1.3 Network connection with SCRJ-push-pull plug (optical fiber)

(not included)

Notes

Notes

For the connection to the network you must use the push-pull plugs with a metal hous-

ing. With the push-pull plug connected the connection complies with enclosure rating

P 65 (e.g. Phoenix VS8PPC8C18SCRJ-MNNA-PG9-A4D-C, material no. 1608032).

I

With the provided cover the connection complies with enclosure rating IP 54.

If the network is not connected to a following bus device, then a connection using a

single plug is sufficient. It does not matter which of the two sockets is used. The unused

socket must always be protected with the provided cover (see Fig. 1).

Without the usage of optical adapter plugs the maximum allowed cable length to the

next device is 50 m.

The maximum allowed line attenuation for the transmission link is 12 dB.

Pay attention to the mounting and wiring instructions of the manufacturer of the con-

nectors and cables, in particular with regard to the number of bending radiuses.

Minimize the number of connectors in a connection cable, ideally to only two: one at the

S3000 PROFINET IO/IO8OF and another one at the FPLC.

Once the electrical installation is completed, determine the signal reserve of the con-

nection cable using the CDS diagnostic function.

Use cables and connectors with low attenuation in order to obtain a signal reserve of

> 4 dB.

5.1.4 Local configuration connection

As a rule configuration is performed via PROFINET IO. A local RS8232 configuration connection is available on the S3000 PROFINET IO/IO8 OF for configuration and diagnostics

directly at the device.

connection

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 15

Addendum Operating Instructions Chapter 6

S3000 PROFINET IO/IOOF

Configuration

6 Configuration

PROFINET IO network

Note

An MRP domain and a NameOfStation must be named as per the PNO specification V2.3.

For this reason take into account the following naming convention during the configuration

of your PROFINET IO network:

The identifier comprises one or more words.

These words are separated using a [.].

The total length of the identifier is 1 to 240 characters.

The word length is 1 to 63 characters.

The identifier uses the following syntax:

– Words comprise [a-z0-9-].

– Words do not start with [-].

– Words do not end with [-].

– The first word must not have the form port-xyz or port-xyz-abcde

(a, b, c, d, e and x, y, z = 0 … 9).

– Identifiers must not have the form n.n.n.n (n = 0 … 999).

Also take into account on naming an MRP domain:

The total length of the identifier must be 3, 7, 11, 15, 19, … characters.

S3000 PROFINET IO/IOOF

The configuration is performed in 3 steps:

1. Configuration PROFINET IO

2. Configuration PROFIsafe

3. Configuration of the S3000 PROFINET IO/IO8OF

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Subject to change without notice

Page 16

Chapter 6 Addendum Operating Instructions

Fig.8:

Configuration

S3000 PROFINET IO/IOOF

6.1 Configuration PROFINET IO

ou can find an application and programming example for the configuration of the

Note

Y

S3000 PROFINET IO/IO8OF and an FPLC under the respective part number in the download

area on www.mysick.com.

.1.1 Reading the generic station description (GSDML)

6

S3000 PROFINET IO/IO OF in

the hardware catalogue

Before you can configure PROFINET IO for the first time for the S3000 PROFINET IO/IO8OF,

ou must add the generic station description (GSDML

y

1)

for the S3000 PROFINET IO/IO8OF

)

to the hardware catalogue in the network engineering tool, e.g. the SIMATIC Manager

(Siemens) for PROFINET IO.

Insert the DVD “CDS — Configuration & Diagnostic Software” contained in the package

into the DVD drive of the Notebook/PC, on which you have installed the network engineering tool of your FPLC.

The generic station description for the S3000 PROFINET IO/IO8OF can be found on the

DVD in the S3000 directory.

Follow the instructions of the online help or in the user manual of the network engi-

neering tool for loading the generic station description.

Then the S3000 PROFINET IO/IO8OF appears in the hardware catalogue in the network

engineering tool under PROFINET IO > Additional Field Devices > Sensors > SICK.

1)

GSDML = Generic station description based on XML.

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 17

Addendum Operating Instructions Chapter 6

Fig.9:

Properties of the

S3000 PROFINET IO/IOOF

Configuration

6.1.2 Configuring users

Every PROFINET IO field device, e.g. the S3000 PROFINET IO/IO8OF has a dedicated MAC

address. You will find the MAC address for the S3000 PROFINET IO/IO8OF on the sticker on

he rear of the I/O module (e.g. 00:06:77:02:00:A7).

t

In addition a PROFINET IO field device requires a unique system-specific device name. The

device name is used by the IO controller to define the IP address for the field device. The

IP address is defined in two steps:

1. You use the device name assigned to the S3000 PROFINET IO/IO8OF by the network

engineering tool, or you configure a unique system-specific device name with the aid of

the network engineering tool (e.g. SIEMENS SIMATIC Manager).

2. The IO controller assigns the IP address based on the device name.

How to define the name of the S3000 PROFINET IO/IOOF if necessary:

Double-click the symbol for S3000 PROFINET IO/IO8OF in the network engineering tool.

The Properties dialog box will open.

Select the General tab.

Enter the the device name for the S3000 PROFINET IO/IO8OF there.

Assign a new IP address.

Note

Device name and IP address must match the settings in the CDS.

S3000 PROFINET IO/IO OF

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Subject to change without notice

Page 18

Chapter 6 Addendum Operating Instructions

Fig.10:

Configuration

Fig.11:

Configuration

Configuration

S3000 PROFINET IO/IOOF

6.2 Configuration PROFIsafe

In slots in the network engineering tool, choose the command Object properties on the

context menu.

PROFIsafe, step 1

PROFIsafe, step 2

Note

On the PROFIsafe tab configure the parameters for the S3000 PROFINET IO/IO8OF.

See Tab. 5 for the parameters to be entered.

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 19

Addendum Operating Instructions Chapter 6

Tab.5:

PROFIsafe

S3000 PROFINET IO/IOOF

Configuration

parameters for the

S3000 PROFINET IO/IO OF

Parameter Meaning Setting

F_SIL Safety integrity level (NoSIL, SIL1 or SIL2) of

the S3000 PROFINET IO/IO8OF

F_CRC_Length Anticipated length of the CRC checksum in

Depending on

application

3 Byte CRC

the PROFIsafe telegram

F_Block_ID The value 1 in the parameter indicates that

he data set for the value of F_iPar_CRC is

t

0

extended by 4 bytes. You are not allowed to

change the parameter.

F_Par_Version Implemented PROFIsafe version. You cannot

1

change this parameter.

F_Source_Add PROFIsafe source address. Must be unique in

1 to 65534

combination with the PROFIsafe destination

address and is assigned automatically.

F_Dest_Add PROFIsafe destination address. Must be

1 to 65534

unique in combination with the PROFIsafe

source address and is assigned

automatically.

Notes:

The PROFIsafe address for the

S3000 PROFINET IO/IO8OF must match

this value (see section 6.2.1 on page 20).

You must enter the default value for the

parameter F_Dest_Add using CDS (see

Fig. 12 on page 20).

F_WD_Time Monitoring time (“Watchdog time”) for the

cyclic service. If no valid PROFIsafe telegram

is exchanged between the

Depending on the

application from

1 to 65535 ms

S3000 PROFINET IO/IO8OF and the FPLC

within the set monitoring time, both will

proceed to the safe status, i.e. they assign

themselves failsafe values.

The monitoring time should be sufficiently

long to tolerate minor delays in communica-

tion. In the event of an error however, it must

not unnecessarily delay the system response

of the S3000 PROFINET IO/IO8OF or that of

the FPLC.

2)

2)

Cannot be changed.

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Subject to change without notice

Page 20

Chapter 6 Addendum Operating Instructions

Fig.12:

Corresponding

parameter in the CDS

Configuration

S3000 PROFINET IO/IOOF

6.2.1 Setting the PROFIsafe address on the S3000 PROFINET IO/IOOF

In order for you to operate the S3000 PROFINET IO/IO8OF as a PROFIsafe user, this must

have a PROFIsafe address. The PROFIsafe address must correspond to the appropriate

etting in the FPLC network engineering tool.

s

For this purpose, in the network engineering tool in the PROFIBUS configuration for the bus

node, read the value of the parameter F_Dest_Add and use the value read as the

PROFIsafe address in the configuration for the S3000 with the aid of the CDS.

CDS, device symbol S3000 PROFINET IO, context menu Configuration draft, Edit, file

card General, option PROFIsafe address(F_Dest_Add).

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 21

Addendum Operating Instructions Chapter 6

S3000 PROFINET IO/IOOF

Configuration

6.2.2 Passivation and reintegration of the S3000 PROFINET IO/IOOF

Passivation

After establishing the communication link from the S3000 PROFINET IO/IO8OF to the fail-

safe control, the S3000 PROFINET IO/IO8OF is in the passive state. The safety laser scanner is also placed in this state after the following events:

in case of errors in the safety-related communication (communication error) between

F8CPU and S3000 PROFINET IO/IO8OF via the safety protocol as per PROFIsafe,

in case of F peripheral/channel errors (e.g. wire break, short-circuit),

if the F peripheral has been rendered passive in the fail-safe control.

If the S3000 PROFINET IO/IO8OF is in the passive state, it must be reintegrated.

Reintegration of the S3000 PROFINET IO/IOOF

The reintegration of a S3000 PROFINET IO/IO8OF into the fail-safe control system, i.e. the

provision of process values, is generally automatic. Depending on the cycle time for the

F process group and the PROFINET IO, the reintegration may take a few cycles of the

F process group in certain circumstances.

If the establishment of the communication between F8CPU and F peripheral takes longer

than the monitoring time set, automatic reintegration is not performed.

In this case the reintegration must be undertaken in the F program in accordance with the

information from the manufacturer of the control. For this purpose refer to the operating

instructions for the fail-safe control system.

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Subject to change without notice

Page 22

Chapter 6 Addendum Operating Instructions

Fig.13:

Example of opening

Configuration

S3000 PROFINET IO/IOOF

6.3 Configuration of the S3000 PROFINET IO/IOOF

or information on the configuration of the basic functions, refer to the original operating

F

instructions “S3000 safety laser scanner” (SICK part number 8009791). Using the CDS

(Configuration & Diagnostic Software) you can configure all available parameters and

define the field geometries for the protective fields and warning fields.

The connection is made to the device via …

the local device connection.

The connection to the local configuration and diagnostics connection is made using an

RS8232 cable available as an accessory.

the network.

Configuration via the network is only possible after the PROFINET configuration. The

CDS is opened using TCI in the hardware configuration in the network engineering tool.

the CDS using TCI

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 23

Addendum Operating Instructions Chapter 7

Tab.6:

Error displays of the

S3000 PROFINET IO/IOOF

Diagnostics

7 Diagnostics

he diagnostics are undertaken using …

T

the messages on the 7-segment display and LED displays,

the CDS (Configuration & Diagnostic Software),

alarms (PROFINET diagnostics messages).

7.1 Meaning of the status indicators

In normal, fault-free operation, the green LED illuminates and the dot on the 7-segment

display flashes.

7.1.1 Meaning of the LEDs

Contrary to the meaning of the status indicators described in the original operating

instructions “S3000 safety laser scanner”, the LEDs have the following function:

LED illuminated = PROFIsafe communication active, no fault

LED flashing at 0.5 Hertz = Operator acknowledge requested by the FPLC

7 segment display

LED illuminated = Device passive or has a fault

Reset required

LED off = Warning field(s) unoccupied

LED illuminated = Warning field(s) infringed

LED illuminated = Contamination

7.1.2 Meaning of the 7segment display

Display Possible cause Remedying the error

, , ,,

, , ,

PROFINET IO commu-

Stand-by mode active,

Object in protective

Object in the simulta-

Power-up cycle — all

segments are activated sequentially

nication in progress

the laser is switched

off

field

neous protective field

or the contour as reference function has

triggered

No error

No error

No error

No error. Status indication eases system

testing on the use of simultaneous protective

fields

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Subject to change without notice

Page 24

Chapter 7 Addendum Operating Instructions

Diagnostics

Display Possible cause Remedying the error

Initialisation of the

device

The display goes out automatically when

the S3000 PROFINET IO/IO8OF is initialised.

If the display does not go out:

Check the system configuration with the aid

of the CDS. Transfer the corrected configu-

ration to the S3000 PROFINET IO/IO8OF

again.

S3000 PROFINET IO/IOOF

Waiting for valid input

signals

Waiting for configura-

tion or configuration

not completed

Sensor head faulty Send the sensor head to the manufacturer

I/O module faulty Send the I/O module to the manufacturer

Configuration memory

in the system plug

faulty

The display goes out automatically when an

input signal is present that corresponds to

a configured monitoring case.

If the display does not go out:

Check the system configuration.

The display goes out automatically once the

configuration has been successfully trans-

ferred.

If the display does not go out:

Check the configuration of the system using

the CDS (Configuration & Diagnostic Soft-

ware). Transfer the corrected configuration

to the S3000 PROFINET IO/IO8OF again.

for repair.

for repair.

Send the system plug to the manufacturer

for repair.

The S3000 PROFINET

IO/IO8OF is receiving

no measured values

within a range of at

least 90° (measuring

range maximum

49 m), it thus is not

detecting any obsta-

cles such as e.g.

building walls.

PROFINET IO module

identification (is initiated by the FPLC)

Device is dazzled Check whether the S3000 PROFINET

For the correct function of the safety laser

scanner, always ensure that measured

values are received within a range of 90°;

this range can be moved as required within

the scan range.

No error

IO/IO8OF is being dazzled by an external

light source, e.g. headlight, infrared light

source, stroboscopic light, sun etc.

If necessary, re-mount the device.

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 25

Addendum Operating Instructions Chapter 7

S3000 PROFINET IO/IOOF

Diagnostics

Display Possible cause Remedying the error

Temperature error. The

operating temperature

Check whether the S3000 is operated as

per the permissible ambient conditions.

of the S 3000 has ex-

ceeded the permissible range.

Input signal for an

undefined monitoring

case

Incorrect sequence on

switching the moni-

toring cases

Incorrect operation of

the control inputs

With

field switching

Without

field switching

No PROFINET IO

communication, no

PROFIsafe active

With

field switching

(with

flashing point)

Without

field switching

PROFINET IO commu-

nication active, no

PROFIsafe active

(with

flashing point)

Check the operating process of the moni-

tored machine or system.

If necessary, check the configuration of the

monitoring cases with the aid of the CDS.

Check the operation of the control inputs.

Check the configuration of the PROFINET IO

(see section 6.1 on page 15) and the confi-

guration of the safety laser scanner (see

operating instructions “S3000 safety laser

scanner” (SICK part number 8009791)).

Check the PROFIsafe configuration (see

section 6.2 on page 18).

Read the device diagnostics in the safety

laser scanner using the network engineer-

ing tool or using the CDS. Typical PROFIsafe

configuration errors are indicated.

If there are no more diagnostics messages,

the S3000 PROFINET IO/IO8OF is waiting for

reintegration by the fail-safe control (see

section 6.2.2 on page 21). If this action

cannot be performed, check the monitoring

time (F_WD_Time) for the S3000 PROFINET

IO/IO8OF and the cycle with which the fail-

safe program is started (see table 5

F_WD_Time e.g. on SIMATIC).

… Channel 1 to 6 of the

Clean the front screen.

contamination mea-

surement contaminated

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Subject to change without notice

Page 26

Chapter 7 Addendum Operating Instructions

Fig.14:

Diagnostics via

Diagnostics

Diagnostics

Diagnostics

Display Possible cause Remedying the error

No front screen fitted

or dazzling of the contamination measure-

ment

Re-fit the new front screen (then perform

front screen calibration).

If at the time of the error a front screen was

fitted:

S3000 PROFINET IO/IOOF

Check whether the S3000 PROFINET

IO/IO8OF is being dazzled by an external

light source, e.g. headlight, infrared light

source, stroboscopic light, sun etc.

network or locally on the

device

Internal error of the

Internal error on the

I/O module/sensor

Traceability data incorrect or front screen

calibration failed

sensor head

I/O module

head device combi-

Carry out a front screen calibration or re-

place the S3000 PROFINET IO/IO8OF, if

necessary.

Replace the sensor head of the

S3000 PROFINET IO/IO8OF.

Replace the I/O module of the

S3000 PROFINET IO/IO8OF.

Check whether the correct I/O module has

been used and replace if necessary.

nation invalid

7.2 CDS (Configuration & Diagnostic Software)

Detailled diagnostics can be undertaken using CDS locally (RS8232 on the front) as well as

via the network or the higher level FPLC (TCI integration of the diagnostic device in the

FPLC).

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

locally on the device

via network

Subject to change without notice

Page 27

Addendum Operating Instructions Chapter 7

Fig.15:

I&M function in the

S3000 PROFINET IO/IOOF

Diagnostics

7.3 Alarms

larms can be output acyclically. As soon as an error occurs in the

A

S3000 PROFINET IO/IO8OF, the safety laser scanner passes it on to the network.

The device-specific help can be read using the IO controller. The help is saved in the

GSDML

7.3.1 I&M function (Identification & Maintenance function)

The following data are loaded and displayed during the online device diagnostics from e.g.

Step 7.

IM0 = device identification (serial number, version number, order no., manufacturer

IM1 = user can enter system code and location code

IM2 = Installation date

IM3 = Description of the function

IM4 = Signature (Config CRC)

CDS

3)

for the S3000 PROFINET IO/IO8OF.

etc.)

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

See “PROFIBUS Profile Guidelines Part1: I&M Functions V1.1.1”.

3)

GSDML = Generic station description based on XML

Page 28

Chapter 8 Addendum Operating Instructions

Tab.7:

Process image

Technical specifications

S3000 PROFINET IO/IOOF

8 Technical specifications

8.1 Process image S3000 PROFINET IO/IOOF Advanced

The process contains data on four monitoring cases and four field sets.

8.1.1 INPUT

S3000 PROFINET IO/IO OF

Advanced INPUT

Bit Description

0.0 Protective field unoccupied

0.1 Warning field unoccupied

0.2 Simultaneous protective field unoccupied

0.3 Simultaneous warning field unoccupied

0.4 Reset required (protective field)

Byte 0

0.5 Reserved

0.6 Reset required (simultaneous protective field)

0.7 Reserved

1.0 Contamination

1.1 Monitoring case valid

1.2 Monitoring case number – Bit 0

1.3 Monitoring case number – Bit 1

1.4 Reserved

Byte 1

1.5 Reserved

1.6 Reserved

1.7 Reserved

2.0 Reserved

2.1 Reserved

2.2 Reserved

2.3 Reserved

2.4 Reserved

Byte 2

2.5 Reserved

2.6 Reserved

2.7 Reserved

3.0 Reserved

3.1 Reserved

3.2 Reserved

3.3 Reserved

3.4 Reserved

Byte 3

3.5 Reserved

3.6 Reserved

3.7 Reserved

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 29

Addendum Operating Instructions Chapter 8

Tab.8:

Process image

S3000 PROFINET IO/IOOF

Technical specifications

Bit Description

4.0 Reserved

4.1 Reserved

4.2 Reserved

4.3 Reserved

4.4 Reserved

Byte 4

4.5 Reserved

4.6 Reserved

4.7 Reserved

5.0 Reserved

5.1 Reserved

5.2 Reserved

5.3 Reserved

5.4 Reserved

Byte 5

5.5 Reserved

S3000 PROFINET IO/IO OF

Advanced OUTPUT

5.6 Reserved

5.7 Reserved

8.1.2 OUTPUT

Bit Description

0.0 Monitoring case switching A1

0.1 Monitoring case switching A2

0.2 Monitoring case switching B1

0.3 Monitoring case switching B2

0.4 Reserved

Byte 0

0.5 Reserved

0.6 Reserved

0.7 Reserved

1.0 Reset the protective field

1.1 Reserved

1.2 Reset the simultaneous protective field

1.3 Reserved

1.4 Stand8by

Byte 1

1.5 Initialising

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Subject to change without notice

1.6 Reserved

1.7 Reserved

Page 30

Chapter 8 Addendum Operating Instructions

Technical specifications

S3000 PROFINET IO/IOOF

Bit Description

2.0 Reserved

2.1 Reserved

2.2 Reserved

2.3 Reserved

2.4 Reserved

Byte 2

2.5 Reserved

2.6 Reserved

2.7 Reserved

3.0 Reserved

3.1 Reserved

3.2 Reserved

3.3 Reserved

3.4 Reserved

Byte 3

3.5 Reserved

3.6 Reserved

3.7 Reserved

4.0 Reserved

4.1 Reserved

4.2 Reserved

4.3 Reserved

4.4 Reserved

Byte 4

4.5 Reserved

4.6 Reserved

4.7 Reserved

5.0 Reserved

5.1 Reserved

5.2 Reserved

5.3 Reserved

5.4 Reserved

Byte 5

5.5 Reserved

5.6 Reserved

5.7 Reserved

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 31

Addendum Operating Instructions Chapter 8

Tab.9:

Process image

S3000 PROFINET IO/IOOF

Technical specifications

8.2 Process image S3000 PROFINET IO/IOOF Professional

he process contains data on eight monitoring cases and eight field sets.

T

8.2.1 INPUT

S3000 PROFINET IO/IO OF

Professional INPUT

Bit Description

0.0 Protective field unoccupied

0.1 Warning field unoccupied

.2 Simultaneous protective field unoccupied

0

0.3 Simultaneous warning field unoccupied

0.4 Reset required (protective field)

Byte 0

0.5 Reserved

0.6 Reset required (simultaneous protective field)

0.7 Reserved

1.0 Contamination

1.1 Monitoring case valid

1.2 Monitoring case number – Bit 0

1.3 Monitoring case number – Bit 1

1.4 Monitoring case number – Bit 2

Byte 1

1.5 Monitoring case number – Bit 3

1.6 Reserved

1.7 Reserved

2.0 Reserved

2.1 Reserved

2.2 Reserved

2.3 Reserved

2.4 Reserved

Byte 2

2.5 Reserved

2.6 Reserved

2.7 Reserved

3.0 Reserved

3.1 Reserved

3.2 Reserved

3.3 Reserved

3.4 Reserved

Byte 3

3.5 Reserved

3.6 Reserved

3.7 Reserved

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Subject to change without notice

Page 32

Chapter 8 Addendum Operating Instructions

Tab.10:

Process image

Technical specifications

S3000 PROFINET IO/IOOF

Bit Description

4.0 Reserved

4.1 Reserved

4.2 Reserved

4.3 Reserved

4.4 Reserved

Byte 4

4.5 Reserved

4.6 Reserved

4.7 Reserved

5.0 Reserved

5.1 Reserved

5.2 Reserved

5.3 Reserved

5.4 Reserved

Byte 5

5.5 Reserved

S3000 PROFINET IO/IO OF

Professional OUTPUT

5.6 Reserved

5.7 Reserved

8.2.2 OUTPUT

Bit Description

0.0 Monitoring case switching A1

0.1 Monitoring case switching A2

0.2 Monitoring case switching B1

0.3 Monitoring case switching B2

0.4 Monitoring case switching C1

Byte 0

0.5 Monitoring case switching C2

0.6 Monitoring case switching D1

0.7 Monitoring case switching D2

1.0 Reset the protective field

1.1 Reserved

1.2 Reset the simultaneous protective field

1.3 Reserved

1.4 Stand8by

Byte 1

1.5 Initialising

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

1.6 Reserved

1.7 Reserved

Subject to change without notice

Page 33

Addendum Operating Instructions Chapter 8

S3000 PROFINET IO/IOOF

Technical specifications

Bit Description

2.0 Reserved

2.1 Reserved

2.2 Reserved

2.3 Reserved

2.4 Reserved

Byte 2

2.5 Reserved

2.6 Reserved

2.7 Reserved

3.0 Reserved

3.1 Reserved

3.2 Reserved

3.3 Reserved

3.4 Reserved

Byte 3

3.5 Reserved

3.6 Reserved

3.7 Reserved

4.0 Reserved

4.1 Reserved

4.2 Reserved

4.3 Reserved

4.4 Reserved

Byte 4

4.5 Reserved

4.6 Reserved

4.7 Reserved

5.0 Reserved

5.1 Reserved

5.2 Reserved

5.3 Reserved

5.4 Reserved

Byte 5

5.5 Reserved

5.6 Reserved

5.7 Reserved

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Subject to change without notice

Page 34

Chapter 8 Addendum Operating Instructions

Technical specifications

S3000 PROFINET IO/IOOF

8.3 PROFINET diagnostic messages

perating states:

O

waiting for configuration

lock-out

device error

error in the sensor head

error in the I/O module

error in the system plug

measured value error in a 90° segment

dazzle

temperature error

undefined monitoring case

sequence error field set switching

invalid input state

contamination error or contamination measurement

PROFIsafe communication error

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 35

Addendum Operating Instructions Chapter 8

S3000 PROFINET IO/IOOF

Technical specifications

8.4 Response times

he total response time of your application is dependent on …

T

the basic response time of the S3000 for the related resolution (0.5°/0.25°), please

refer to the original operating instructions “S3000 safety laser scanner” for this

information,

the supplement for the response time for the multiple sampling set,

the response time of the I/O module,

the transfer and cycle time for the bus information,

the response time of the control system and actuators.

Response time on protective field or warning field infringement:

S3000 basic response time

+ resulting response time supplement due to multiple sampling

+ response time of the I/O module (8 ms)

+ response time of the FPLC

Example:

60

+ 90

+ 8

= 158 ms (+ response time of the FPLC)

Reaction to input information:

In the case of monitoring case switching pay attention to the advancement of the timing of

the switching. The response time of the safety laser scanner to input information

comprises:

S3000 basic response time

+ configured input delay

+ response time of the I/O module (2 × 8 ms = 16 ms)

+ response time of the FPLC

ms Basic response time (resolution = 0.5°)

ms (multiple sampling = 5)

ms

Example:

60

ms Basic response time (resolution = 0.5°)

+ 30 ms (configured input delay)

+ 16

= 106 ms (+ response time of the FPLC)

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 35

Subject to change without notice

ms

Page 36

Chapter 8 Addendum Operating Instructions

Tab.11:

Data sheet

Technical specifications

S3000 PROFINET IO/IOOF

8.5 Data sheet

ontrary to the technical data described in the original operating instructions “S3000

C

safety laser scanner”, described in the following are the technical data that are different or

additional to the technical data for the safety laser scanners in the S3000 family.

S3000 PROFINET IO/IO OF

Minimum Typical Maximum

General data

PFHd (T

= 25 °C)

amb

80 × 10

–9

(mean probability of a dangerous

failure per hour)

Protective field range

Short Range

Medium Range

Long Range

Range of performance

Advanced

Professional

4.00 m

5.50 m

7.00 m

4 protective and warning fields (field sets)

8 protective and warning fields (field sets)

Electrical data

Electrical protection class III (VDE 0106, EN 60950)

Bus connection 2 standard PROFINET IO sockets for push-pull plug

connectors with metal housing (RJ845 or SCRJ)

Supply connection Plug-in device connection plug with …

cable gland for cable diameter of 5–10 mm

screw type terminal connection for max. wire

cross-section 1.5 mm

2

integrated configuration memory

Levels for input information:

Restart4)

Initialising

Stand-by

Monitoring case switching4)

Activated on low-high transition

Activated on low-high transition

Activated on permanently high

Static (complementary)

Optical fiber

Wave length of the transmitter

650 nm

(EN 72471)

Diameter of the fiber-optic cable of

980 µm 1000 µm

the POF cables

Cable length 50 m

Line attenuation5) 12 dB

4)

Fail-safe input signals are required.

5)

Pay attention to the mounting and wiring instructions of the manufacturer of the connectors and cables, in

particular with regard to the number of bending radiuses.

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 37

Addendum Operating Instructions Chapter 8

S3000 PROFINET IO/IOOF

Technical specifications

8.6 Services supported

PROFINET IO with Conformance Class B

LLDP according to IEEE 802.1 AB

SNMP

MIB-II

cyclic IO communication

acyclic read/write services for communication via TCI interface

diagnostics alarms

TCP/IP communication via port 9000

support for MRP client

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 37

Subject to change without notice

Page 38

Chapter 8 Addendum Operating Instructions

Fig.16:

Dimensional drawing

63

4× M6

×

8

4 × reference points for mounting

147

136.8

53.2

120

224

202

78.5

155

77

13.5

4× M8

×9

31.65

159

Technical specifications

S3000 PROFINET IO/IOOF

8.7 Dimensional drawing S3000 PROFINET IO/IOOF

S3000 PROFINET IO/IO OF

(mm)

38 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 39

Addendum Operating Instructions Chapter 9

Tab.12:

Part numbers,

Tab.13:

Part numbers,

S3000 PROFINET IO/IOOF

Ordering information

9 Ordering information

9.1 Items supplied

S3000 PROFINET IO/IO8OF

operating instructions and CDS (Configuration & Diagnostic Software) on DVD

adhesive label “Important information”

9.2 Systems available

9.2.1 S3000 PROFINET IO with RJ-45 sockets

S3000 PROFINET IO with

RJ 45 sockets

S3000 PROFINET IO OF with

SCRL sockets (optical fiber)

Device type Part Part number

S30A-4111CP S3000 PROFINET IO Advanced

with short-range sensor head (4 m)

S30A-4111DP S3000 PROFINET IO Professional

with short-range sensor head (4 m)

S30A-6111CP S3000 PROFINET IO Advanced

with medium-range sensor head (5.5 m)

S30A-6111DP S3000 PROFINET IO Professional

with medium-range sensor head (5.5 m)

S30A-7111CP S3000 PROFINET IO Advanced

with long-range sensor head (7 m)

S30A-7111DP S3000 PROFINET IO Professional

with long-range sensor head (7 m)

9.2.2 S3000 PROFINET IOOF with SCRJ sockets (optical fiber)

Device type Part Part number

S30A-4111CL S3000 PROFINET IO8OF Advanced

with short-range sensor head (4 m)

S30A-4111DL S3000 PROFINET IO8OF Professional

with short-range sensor head (4 m)

1045650

1045651

1045652

1045653

1045654

1045655

1052591

1052592

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 39

Subject to change without notice

S30A-6111CL S3000 PROFINET IO8OF Advanced

with medium-range sensor head (5.5 m)

S30A-6111DL S3000 PROFINET IO8OF Professional

with medium-range sensor head (5.5 m)

S30A-7111CL S3000 PROFINET IO8OF Advanced

with long-range sensor head (7 m)

S30A-7111DL S3000 PROFINET IO8OF Professional

with long-range sensor head (7 m)

1052593

1052594

1052595

1052596

Page 40

Chapter 9 Addendum Operating Instructions

Tab.14:

Part

numbers

Ordering information

S3000 PROFINET IO/IOOF

9.3 Accessories/spare parts

accessories/spare parts

Recommendation

Notes

Device type Part Part number

S30A-xxxxCP I/O module S3000 PROFINET IO Advanced 2047737

S30A-xxxxDP I/O module S3000 PROFINET IO Professional 2047169

S30A-xxxxCL I/O module S3000 PROFINET IO8OF Advanced 2057800

S30A-xxxxDL I/O module S3000 PROFINET IO8OF Professional 2057801

30A-411 Sensor head 4 m 2049566

S

S30A-611 Sensor head 5,5 m 2049567

S30A-711 Sensor head 7 m 2049568

Sx1A-A0000L Supply connector 2047286

Sx1A-B0201L Supply connector with 1 m cable 2049575

SX1A-B0201M Power Y-distribution with supply connector

(available on request)

For further device accessories, e.g. mounting kits, see operating instructions “S3000

safety laser scanner”.

For further accessories related to PROFINET connector technology, e.g. RJ845 push-pull

connection plugs, see www.phoenixcontact.com.

2049857

40 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 41

Addendum Operating Instructions Chapter 10

S3000 PROFINET IO/IOOF

Annex

10 Annex

10.1 Compliance with EU directives

EU declaration of conformity (excerpt)

The undersigned, representing the following manufacturer herewith declares that the

product is in conformity with the provisions of the following EU directive(s) (including all

applicable amendments), and that the respective standards and/or technical specifications are taken as the basis.

Complete EU declaration of conformity for download: www.sick.com

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 41

Subject to change without notice

Page 42

Chapter 10 Addendum Operating Instructions

Annex

S3000 PROFINET IO/IOOF

10.2 List of tables

ab. 1: Logical state 0 of the control inputs in the process image .................................... 8

T

ab. 2: Logical state 1 of the control inputs in the process image .................................... 8

T

Tab. 3: Terminal assignments on the supply connector ................................................... 12

Tab. 4: Pin assignment on the RJ845 sockets.................................................................... 13

Tab. 5: PROFIsafe parameters for the S3000 PROFINET IO/IO8OF ..................................19

Tab. 6: Error displays of the 78segment display.................................................................23

Tab. 7: Process image S3000 PROFINET IO/IO8OF Advanced INPUT............................... 28

Tab. 8: Process image S3000 PROFINET IO/IO8OF Advanced OUTPUT ........................... 29

Tab. 9: Process image S3000 PROFINET IO/IO8OF Professional INPUT ..........................31

Tab. 10: Process image S3000 PROFINET IO/IO8OF Professional OUTPUT ....................... 32

Tab. 11: Data sheet S3000 PROFINET IO/IO8OF ................................................................. 36

Tab. 12: Part numbers, S3000 PROFINET IO with RJ-45 sockets ......................................39

Tab. 13: Part numbers, S3000 PROFINET IO8OF with SCRL sockets (optical fiber) ..........39

Tab. 14: Part numbers accessories/spare parts ................................................................. 40

10.3 List of illustrations

Fig. 1: System connection.................................................................................................. 11

Fig. 2: Terminals on the supply connector........................................................................ 12

Fig. 3: Pre-assembled supply connector ........................................................................... 12

Fig. 4: Pre-assembled cable with Y-piece.......................................................................... 12

Fig. 5: RJ845-push-pull plug ...............................................................................................13

Fig. 6: SCRJ-push-pull plug ................................................................................................ 14

Fig. 7: Local configuration connection .............................................................................. 14

Fig. 8: S3000 PROFINET IO/IO8OF in the hardware catalogue........................................ 16

Fig. 9: Properties of the S3000 PROFINET IO/IO8OF........................................................ 17

Fig. 10: Configuration PROFIsafe, step 1 ............................................................................ 18

Fig. 11: Configuration PROFIsafe, step 2 ............................................................................ 18

Fig. 12: Corresponding parameter in the CDS .................................................................... 20

Fig. 13: Example of opening the CDS using TCI.................................................................. 22

Fig. 14: Diagnostics via network or locally on the device................................................... 26

Fig. 15: I&M function in the CDS .........................................................................................27

Fig. 16: Dimensional drawing S3000 PROFINET IO/IO8OF (mm)....................................... 38

42 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8013291/YY95/2016-02-05

Subject to change without notice

Page 43

Addendum Operating Instructions Chapter 10

S3000 PROFINET IO/IOOF

Annex

8013291/YY95/2016-02-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 43

Subject to change without notice

Page 44

8013291/YY95/2016-02-05 ∙ REIPA/XX (2016-03) ∙ A4 sw int44

Australia

+61 3 9457 0600

Phone

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0)22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0)2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 4000 121 000

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Gemany

Phone +49 211 5301-301

E-Mail info@sick.de

Great Britain

Phone +44 (0)1727 831121

E-Mail info@sick.co.uk

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail office@sick.hu

India

Phone +91–22–4033 8333

E-Mail info@sick-india.com

Israel

Phone +972-4-6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 (0)3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603 808070425

E-Mail enquiry.my@sick.com

Netherlands

Phone +31 (0)30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 837 40 50

E-Mail info@sick.pl

Romania

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7-495-775-05-30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 (0)1-47 69 990

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2645 0009

E-Mail tawiwat@sicksgp.com.sg

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail info@sick.ae

USA/Mexico

Phone +1(952) 941-6780

1 (800) 325-7425 – tollfree

E-Mail info@sick.com

Vietnam

Phone +84 8 62920204

E-Mail Ngo.Duy.Linh@sicksgp.com.sg

More representatives and agencies

at www.sick.com

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...