Page 1

MLG-2 Pro

Measuring automation light grid

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

MLG-2 Pro

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Purpose of this document........................................................................ 7

1.2 Scope......................................................................................................... 7

1.3 Target group.............................................................................................. 7

1.4 Information depth..................................................................................... 7

1.5 Symbols used............................................................................................ 7

1.6 Abbreviations used................................................................................... 8

2 Safety information............................................................................ 9

2.1 Requirements for the qualification of personnel.................................... 9

2.2 Correct use................................................................................................ 9

2.3 General safety notes................................................................................. 10

3 Product description........................................................................... 11

3.1 Type labels of the MLG-2 Pro................................................................... 11

3.2 MLG-2 Pro type code................................................................................ 11

3.2.1 Monitoring height..................................................................... 12

3.2.2 Combinations of MLG-2 Pro inputs and outputs................... 13

3.2.3 Optical properties.................................................................... 13

3.2.4 MLG-2 Pro preconfigurations.................................................. 13

3.3 MLG-2 product properties........................................................................ 15

3.4 Setup and function................................................................................... 15

3.4.1 MLG-2 Pro device components............................................... 15

3.4.2 Measurement principle........................................................... 16

3.4.3 Synchronizing the MLG-2........................................................ 16

3.4.4 Beam separations and monitoring height............................. 16

3.4.5 Teach-in.................................................................................... 17

3.4.6 Beam blanking......................................................................... 18

3.4.7 Sensing ranges........................................................................ 19

3.5 Scan time.................................................................................................. 19

3.5.1 Response time, minimum presence time and reproducibil‐

ity of the MLG-2........................................................................ 20

3.5.2 Scan time with cross-beam function...................................... 20

3.5.3 Scan time with high-speed scan on the MLG-2..................... 21

3.6 Beam separation and minimum detectable object................................ 22

3.6.1 Minimum detectable object with parallel-beam function..... 22

3.6.2 Minimum detectable object length......................................... 23

3.6.3 Minimum detectable object with cross-beam function ........ 24

3.6.4 Minimum detectable object with high measurement accu‐

racy from the MLG-2................................................................ 25

3.7 Operating reserve..................................................................................... 26

3.7.1 Operating reserves on the MLG-2........................................... 26

3.8 MLG-2 operating modes........................................................................... 26

3.8.1 Standard operating mode....................................................... 27

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

3

Page 4

CONTENTS

3.8.2 Transparent operating mode.................................................. 27

3.8.3 Dust- and sunlight-resistant operating mode........................ 27

3.9 Interfaces ................................................................................................. 28

3.9.1 Output of measurement data (raw data)............................... 28

3.9.2 Preliminary evaluation............................................................. 29

3.9.3 Configurable applications of the MLG-2 Pro.......................... 29

3.10 Display and operating elements.............................................................. 31

3.10.1 Sender...................................................................................... 31

3.10.2 Receiver.................................................................................... 31

3.11 Inputs......................................................................................................... 33

3.11.1 Switching inputs on the MLG-2 Pro receiver.......................... 33

3.11.2 Test input on the sender......................................................... 33

3.12 Application examples............................................................................... 33

3.12.1 Application examples for the MLG2....................................... 33

4 Mounting............................................................................................. 35

4.1 Scope of delivery...................................................................................... 35

4.2 Recommended mounting arrangements................................................ 35

4.2.1 Mounting with light in opposite directions............................. 35

4.2.2 Mounting with light in the same direction.............................. 36

4.2.3 Placement of two light grids at right angles........................... 38

4.2.4 Minimum distance from reflective surfaces.......................... 39

4.3 Mounting procedure................................................................................. 40

4.3.1 Mounting the QuickFix bracket............................................... 40

4.3.2 Mounting the FlexFix bracket.................................................. 41

5 Electrical installation........................................................................ 43

5.1 MLG2 Pro electrical installation............................................................... 43

5.1.1 T-distributor for MLG2 Pro connection................................... 46

6 Commissioning.................................................................................. 50

6.1 Mechanical alignment of sender and receiver....................................... 50

6.2 Alignment and teach-in............................................................................ 51

6.2.1 MLG-2 Pro................................................................................. 51

7 Configuration with SOPAS ET.......................................................... 53

7.1 Preparation............................................................................................... 53

7.1.1 Installing the software............................................................. 53

7.1.2 Device selection....................................................................... 53

7.2 SOPAS ET interface................................................................................... 54

7.2.1 System boundaries, status, and interfaces........................... 55

7.2.2 Basic functions and status of the output............................... 58

7.2.3 Representation of the detection area.................................... 59

7.2.4 Expandable menus.................................................................. 62

7.3 System settings......................................................................................... 64

7.3.1 System settings for the user levels EASY and EXPERT......... 64

4

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 5

CONTENTS

7.3.2 System settings for the EXPERT user level............................ 65

7.4 Measuring and diagnostic functions for switching outputs................... 66

7.4.1 Height classification................................................................ 67

7.4.2 Object recognition.................................................................... 69

7.4.3 Object detection/object width................................................ 71

7.4.4 Hole detection/hole size......................................................... 73

7.4.5 Outside/inside dimension....................................................... 75

7.4.6 Classification of an object position........................................ 77

7.4.7 Classification of a hole position.............................................. 78

7.4.8 Diagnostics............................................................................... 80

7.5 Measuring and diagnostic functions for analog outputs....................... 80

7.5.1 Object height measurement .................................................. 81

7.5.2 Hole detection ......................................................................... 81

7.5.3 Object detection....................................................................... 82

7.5.4 Measuring the outer or inner dimension .............................. 82

7.5.5 Measurement of the object position ..................................... 83

7.5.6 Measurement of the hole position ........................................ 83

7.5.7 Diagnostic functions ............................................................... 83

7.6 Advanced settings for the outputs........................................................... 84

7.7 Zones......................................................................................................... 85

7.7.1 “Zone measuring” function..................................................... 85

7.8 Data output via the interfaces................................................................. 87

7.8.1 RS485 – Data transmission format....................................... 87

7.8.2 RS485 – Transmission mode................................................. 88

7.8.3 RS485 and IO-Link – Data transmission content................. 88

7.9 Teach-in..................................................................................................... 90

7.10 Performance options................................................................................ 93

7.10.1 “Cross beam” function............................................................ 96

7.10.2 Energy options (only in the EXPERT user level)..................... 99

7.11 Beam evaluation....................................................................................... 99

7.11.1 “Blocked Beams Hold (BBH)” evaluation mode.................... 99

7.11.2 “Lost Beams Hold (LBH)” evaluation mode........................... 101

7.12 Simulation................................................................................................. 102

7.13 Beam monitor (only in the EXPERT user level)....................................... 103

7.14 Function programming (in the EXPERT user level)................................. 104

7.14.1 Beam functions........................................................................ 107

7.15 MLG-2 configuration with the internal web server................................. 108

8 IO-Link................................................................................................. 110

8.1 Configuration via acyclic service data..................................................... 110

8.2 Data storage (IO-Link)............................................................................... 110

8.3 Output of process data from the MLG-2 Pro........................................... 110

9 RS-485................................................................................................ 112

9.1 Payload...................................................................................................... 112

9.2 Data volume for the beam functions....................................................... 113

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

5

Page 6

CONTENTS

9.3 Data volume for the separators............................................................... 113

9.4 Transmitting the beam status.................................................................. 114

9.5 Calculation examples for the total data volume..................................... 114

10 Servicing............................................................................................. 115

11 Troubleshooting................................................................................. 116

11.1 Response to faults.................................................................................... 116

11.2 SICK support............................................................................................. 116

11.3 LED indicators and error indicators......................................................... 116

11.3.1 .................................................................................................. 117

11.4 Advanced diagnostics on the MLG-2....................................................... 117

12 Decommissioning............................................................................. 118

12.1 Disposal..................................................................................................... 118

12.2 Returns...................................................................................................... 118

13 Technical data....................................................................................119

13.1 Data sheet................................................................................................. 119

13.2 Diagrams................................................................................................... 122

13.2.1 Response time and minimum presence time without high-

speed scan............................................................................... 122

13.2.2 Response time and minimum presence time during high-

speed scan with 2,5 mm resolution....................................... 123

13.2.3 Response time and minimum presence time during high-

speed scan with up to 3.5 m sensing range.......................... 123

13.2.4 Response time and minimum presence time during high-

speed scan with up to 8.5 m sensing range.......................... 124

13.2.5 Minimum detectable absorption............................................ 124

13.3 Dimensional drawings.............................................................................. 126

13.3.1 MLG-2 Pro dimensional drawing............................................. 126

13.3.2 Measurement tables............................................................... 127

14 Ordering information........................................................................ 128

15 Accessories........................................................................................ 129

15.1 Accessories............................................................................................... 129

16 Annex.................................................................................................. 132

16.1 Compliance with EU directive................................................................... 132

17 List of figures..................................................................................... 133

18 List of tables....................................................................................... 136

6

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 7

1 About this document

1.1 Purpose of this document

These operating instructions are for giving technical personnel of the machine manu‐

facturer or operator instructions on the mounting, configuration, electrical installation,

commissioning, operation, and maintenance of the MLG-2 measuring automation light

grid.

These operating instructions do not provide information on operating the machine into

which a measuring automation light grid is integrated. For information about this, refer

to the operating instructions of the particular machine.

ABOUT THIS DOCUMENT 1

1.2

Scope

These operating instructions apply to the MLG-2 Pro measuring automation light grid.

1.3 Target group

These operating instructions are intended for planning engineers, developers, and

operators of plants and systems into which one or more MLG-2 measuring automation

light grids are to be integrated. They are also intended for people who integrate the

MLG-2 into a machine, carry out its commissioning, or who are in charge of mainte‐

nance.

1.4 Information depth

These operating instructions contain information about the MLG-2 measuring automa‐

tion light grid on the following topics:

Mounting

•

Electrical installation

•

Commissioning and configuration

•

Care

•

When planning and using a measuring automation light grid such as the MLG-2, techni‐

cal skills are required that are not covered by this document.

The official and legal regulations for operating the MLG-2 must always be complied

with.

Fault diagnosis

•

Part numbers

•

Conformity and approval

•

NOTE

Please also refer to the SICK AG website: www.sick.de.

1.5 Symbols used

Recommendation

Recommendations are designed to assist you in the decision-making process with

respect to the use of a certain function or a technical measure.

NOTE

Notes inform you about special aspects of the device.

O, Ö, o

LED symbols describe the status of a diagnostics LED. Examples:

O

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

The LED is illuminated continuously.

7

Page 8

1 ABOUT THIS DOCUMENT

Ö

ôKõ

o

Take action ...

b

Instructions for taking action are indicated by an arrow. Carefully read and follow the

instructions for action.

CAUTION

Warning!

A warning indicates a specific or potential hazard. This is intended to protect you

against accidents.

Read carefully and follow the warnings!

s r Sender and receiver

In figures and connection diagrams, the symbol s indicates the sender and r indi‐

cates the receiver.

1.6 Abbreviations used

BNB Beam Number (x) Blocked

BNM Beam Number (x) Made

CBB Central Beam Blocked

CBM Central Beam Made

FBB First Beam Blocked

FBM First Beam Made

IDI Inner Dimension

LBB Last Beam Blocked

LBM Last Beam Made

MDA Minimum Detectable Absorption

MDO Minimum Detectable Object

MLG-2 Measuring automation light grid 2

MOL Minimum Detectable Object Length

MSB Most Significant Bit

NBB Number of Beams Blocked

NBM Number of Beams Made

NCBB Number of Consecutive Beams Blocked

NCBM Number of Consecutive Beams Made

ODI Outer Dimension

RLC Run-length code

SDD SOPAS Device Description

PLC Programmable logic controller

The LED flashes evenly.

The LED flashes briefly.

The LED is off.

8

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 9

2 Safety information

2.1 Requirements for the qualification of personnel

The MLG-2 measuring automation light grid must only be mounted, commissioned, and

maintained by authorized personnel.

NOTE

Repair work on the MLG-2 may only be performed by qualified and authorized service

personnel from SICK AG.

The following qualifications are necessary for the various tasks:

Task Qualification

Mounting

Electrical installation and

device replacement

Commissioning, operation, and

configuration

Table 1: Authorized personnel

Basic practical technical training

•

Knowledge of the current safety regulations in the work‐

•

place

Practical electrical training

•

Knowledge of current electrical safety regulations

•

Knowledge of the operation and control of the devices

•

in their particular application (e. g., industrial robots,

storage and conveyor systems)

Knowledge of the current safety regulations and of the

•

operation and control of the devices in their particular

application

Knowledge of automation systems

•

Knowledge of how to use automation software

•

SAFETY INFORMATION 2

2.2 Correct use

The MLG-2 measuring automation light grid is a measuring device which is manufac‐

tured according to the recognized industrial regulations and which meets the quality

requirements stipulated in ISO 9001:2008 as well as those relating to environmental

management systems as defined in ISO 14001:2009.

The measuring automation light grids are solely intended for the optical and non-con‐

tact detection of objects, animals, and persons.

A measuring automation light grid is designed for mounting and may only be operated

according to its intended function. For this reason, it is not equipped with direct safety

devices.

The system designer must provide measures to ensure the safety of persons and sys‐

tems in accordance with the legal guidelines.

In the event of any other usage or modification to the MLG-2 measuring automation

light grid (e.g., due to opening the housing during mounting and electrical installation)

or in the event of changes made to the SICK software, any claims against SICK AG

under the warranty will be rendered void.

Foreseeable misuse

The MLG-2 is not suitable for the following applications, among others:

As a safety device to protect persons, their hands, or other body parts

•

Under water

•

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

In explosive environments

•

Outdoors, without additional protection

•

2.3 General safety notes

CAUTION

Observe the following to ensure the safe use of the MLG-2 as intended.

The measuring automation light grid must be installed and maintained by trained,

qualified personnel with knowledge of electronics, precision engineering, and

control programming. The relevant technical safety standards must be observed.

All persons entrusted with the installation, operation, or maintenance of the devices

must follow the safety guidelines:

The operating instructions must always be available and must be followed.

•

Unqualified personnel must stay away from the system during installation and

•

maintenance.

The system must be installed in accordance with the applicable safety regulations

•

and mounting instructions.

The work safety regulations of the employers' liability insurance associations and

•

trade associations in the respective country must be observed during installation.

Failure to observe the relevant work safety regulations may lead to physical injury

•

or cause damage to the system.

10

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 11

3 Product description

2

5

1

34

1110

4

7

6

5

9

3

2

1

8

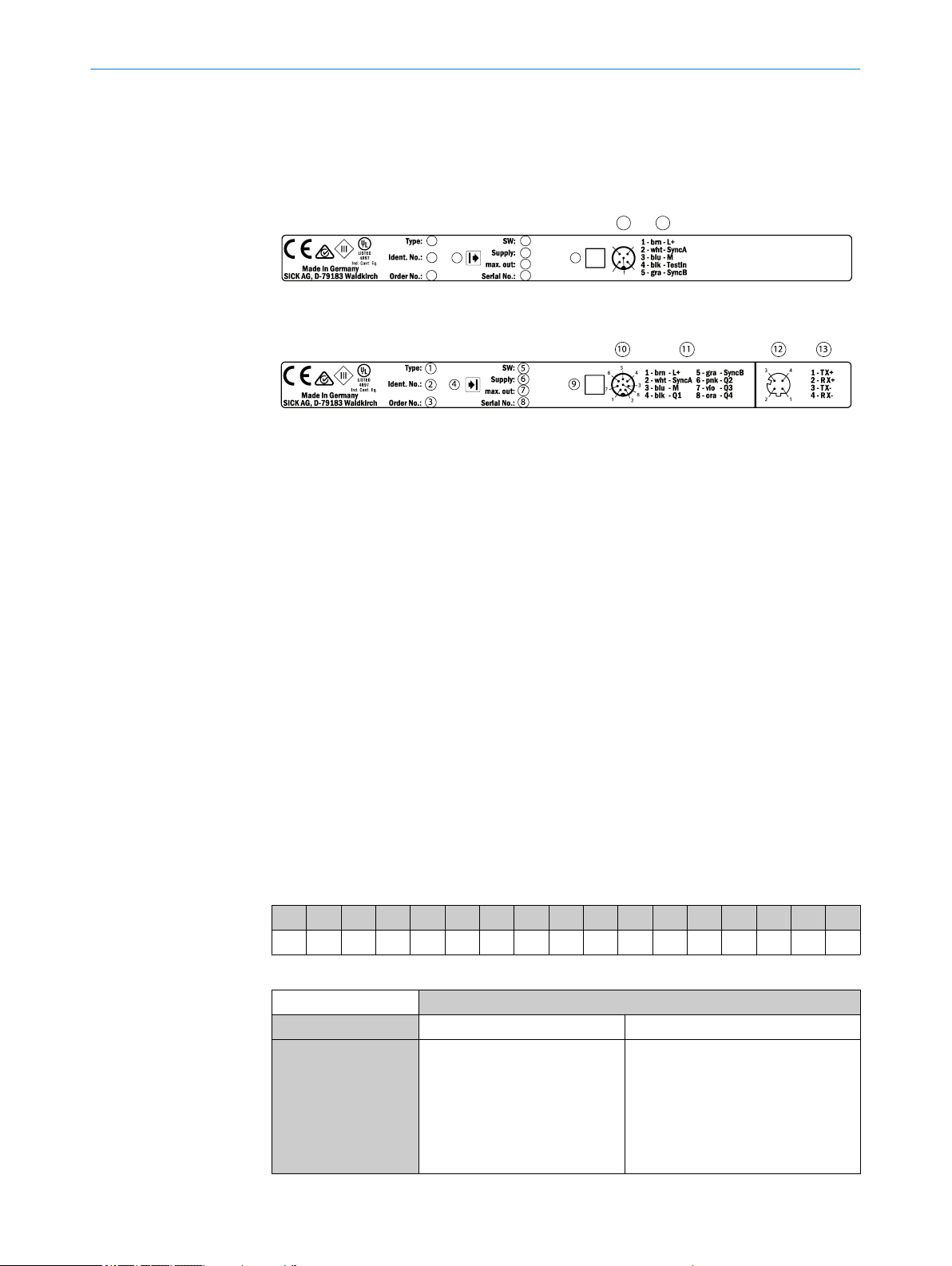

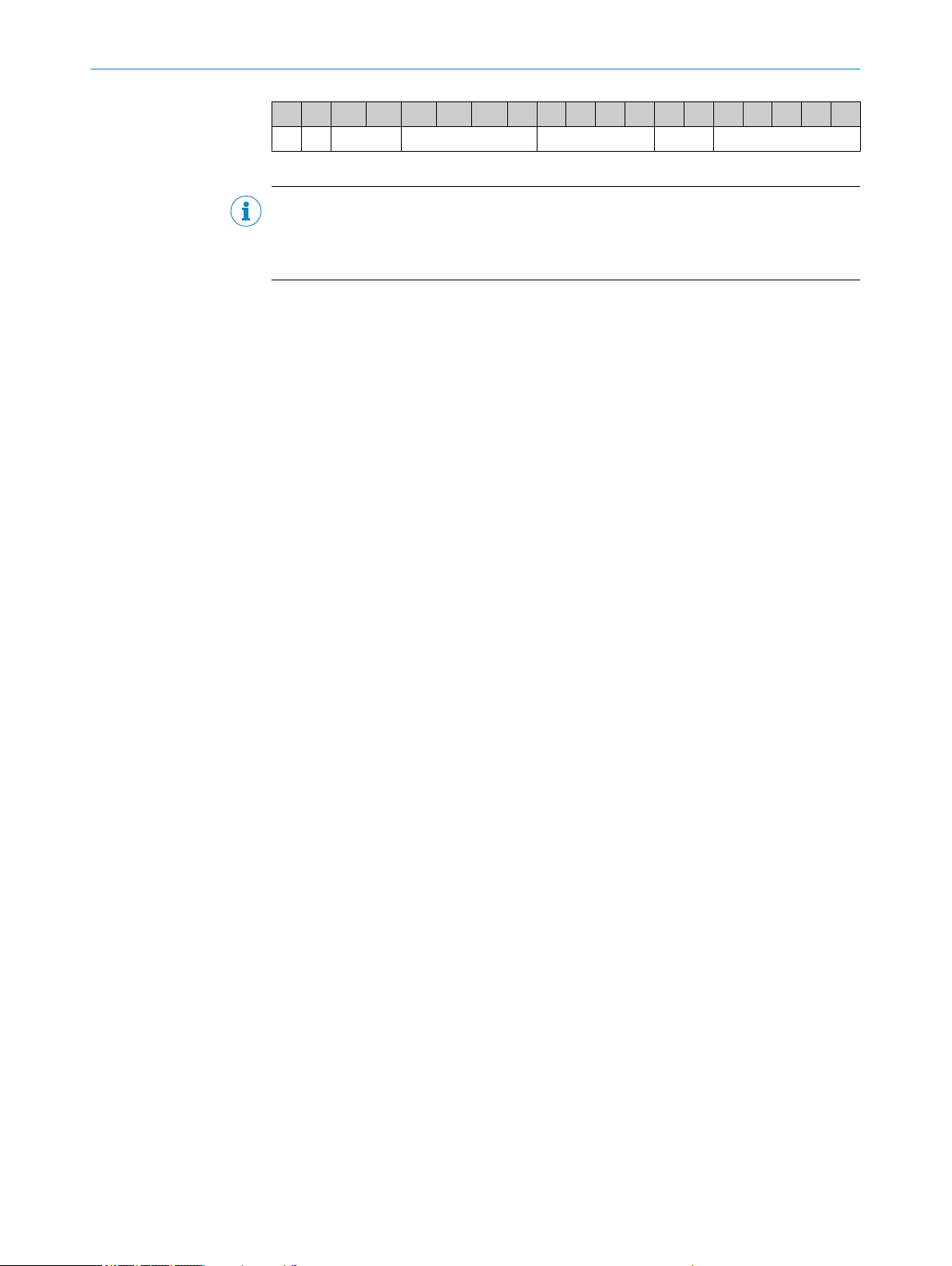

3.1 Type labels of the MLG-2 Pro

The MLG-2 Pro senders and receivers each have a type label.

Figure 1: Type label of sender

Figure 2: Type label of receiver

Type code

1

Part number for the individual sender or receiver

2

Part number of the entire MLG-2

3

Symbol for sender or receiver

4

Firmware version

5

Required power supply

6

Maximum output current

7

Serial number

8

2D matrix code, contains the order numbers of the sender/receiver, the order number of

9

the MLG-2, and the serial number

Diagram of the M12/5-pin or M12/8-pin male connector

ß

Pin assignment of the M12/5-pin or M12/8-pin male connector

à

Diagram of the M12/4-pin female connector

á

Pin assignment of the M12/4-pin female connector

â

PRODUCT DESCRIPTION 3

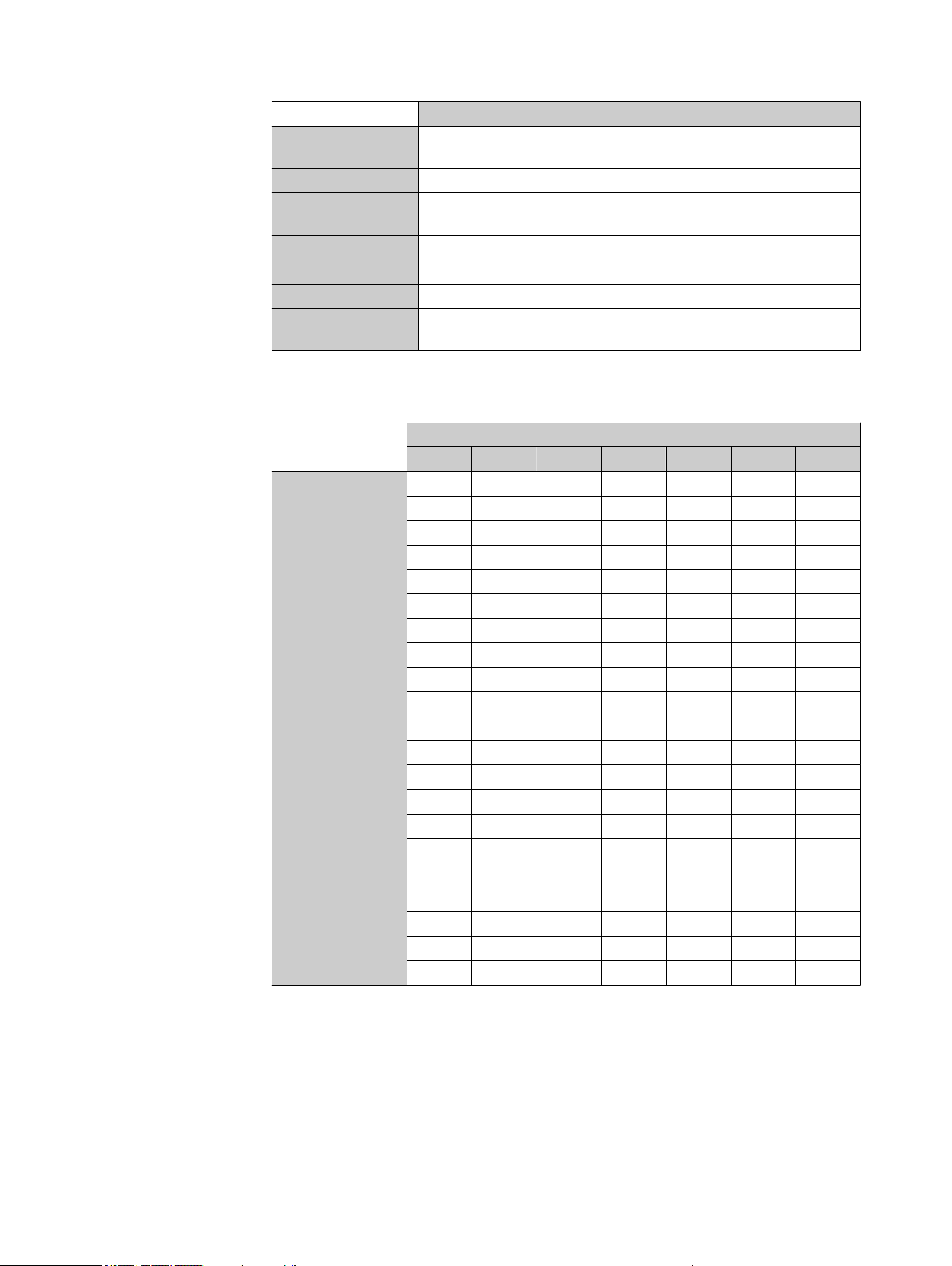

3.2 MLG-2 Pro type code

Example

MLG-2 with 5 mm beam separation, type Pro, detection height 145 mm, 1 input, 1

switching output and 2 analog outputs, no options, 5 m sensing range and pre-configu‐

ration for NBB,LBB,object detection and teach-in.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

M L G 0 5 A - 0 1 4 5 B 1 0 5 0 1

Table 2: Example of an MLG-2 Pro type code

Position Meaning

1 … 3 Product family MLG

4 and 5 Beam separation 02 = 2.5 mm

05 = 5 mm

10 = 10 mm

20 = 20 mm

25 = 25 mm

30 = 30 mm

50 = 50 mm

Table 3: Meaning of the positions in the type code

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

11

Page 12

3 PRODUCT DESCRIPTION

Position Meaning

6 Type 0 = Special type

7 Hyphen –

8 … 11 Detection height 0000 = Special detection height

12 Interfaces, I/O see table 5, page 13

13 Options 1 = none

14 and 15 Optical properties see table 6, page 13

16 and 17 Preconfiguration of the I/O con‐

Table 3: Meaning of the positions in the type code

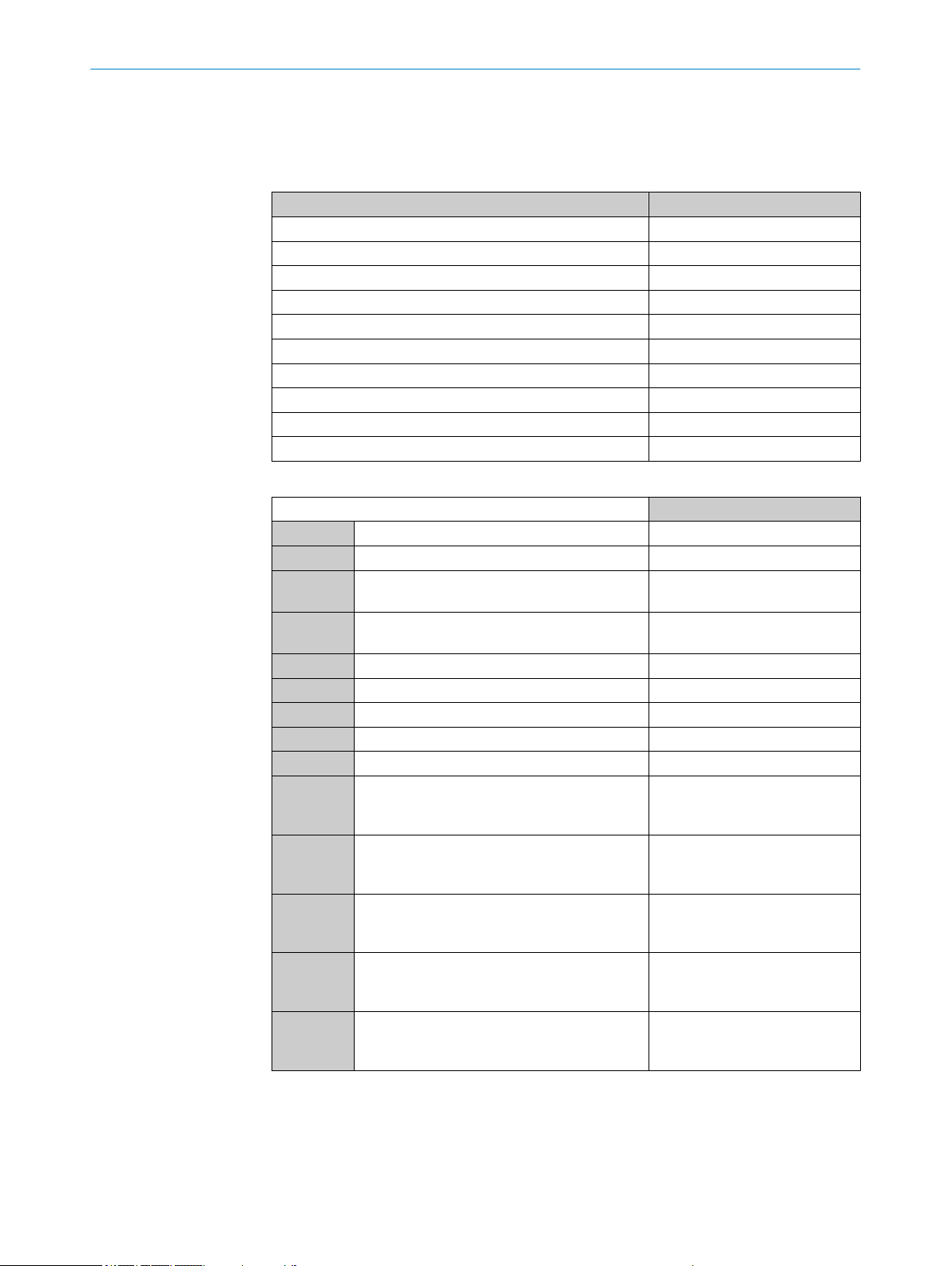

3.2.1 Monitoring height

Monitoring height

Table 4: Monitoring height [mm]

[mm]

A = Pro

see table 4, page 12

see "MLG-2 Pro preconfigurations",

nections and the software

page 13

Type

MLG02… MLG05… MLG10… MLG20... MLG25… MLG30... MLG50…

145 145 140 140 – – –

295 295 290 280 275 270 250

445 445 440 440 425 420 400

595 595 590 580 575 570 550

745 745 740 740 725 720 700

895 895 890 880 875 870 850

1045 1045 1040 1040 1025 1020 1000

1195 1195 1190 1180 1175 1170 1150

– 1345 1340 1340 1325 1320 1300

– 1495 1490 1480 1475 1470 1450

– 1645 1640 1640 1625 1620 1600

– 1795 1790 1780 1775 1770 1750

– 1945 1940 1940 1925 1920 1900

– 2095 2090 2080 2075 2070 2050

– 2245 2240 2240 2225 2220 2200

– 2395 2390 2380 2375 2370 2350

– 2545 2540 2540 2525 2520 2500

– – 2690 2680 2675 2670 2650

– – 2840 2840 2825 2820 2800

– – 2990 2980 2975 2970 2950

– – 3140 3140 3125 3120 3100

12

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 13

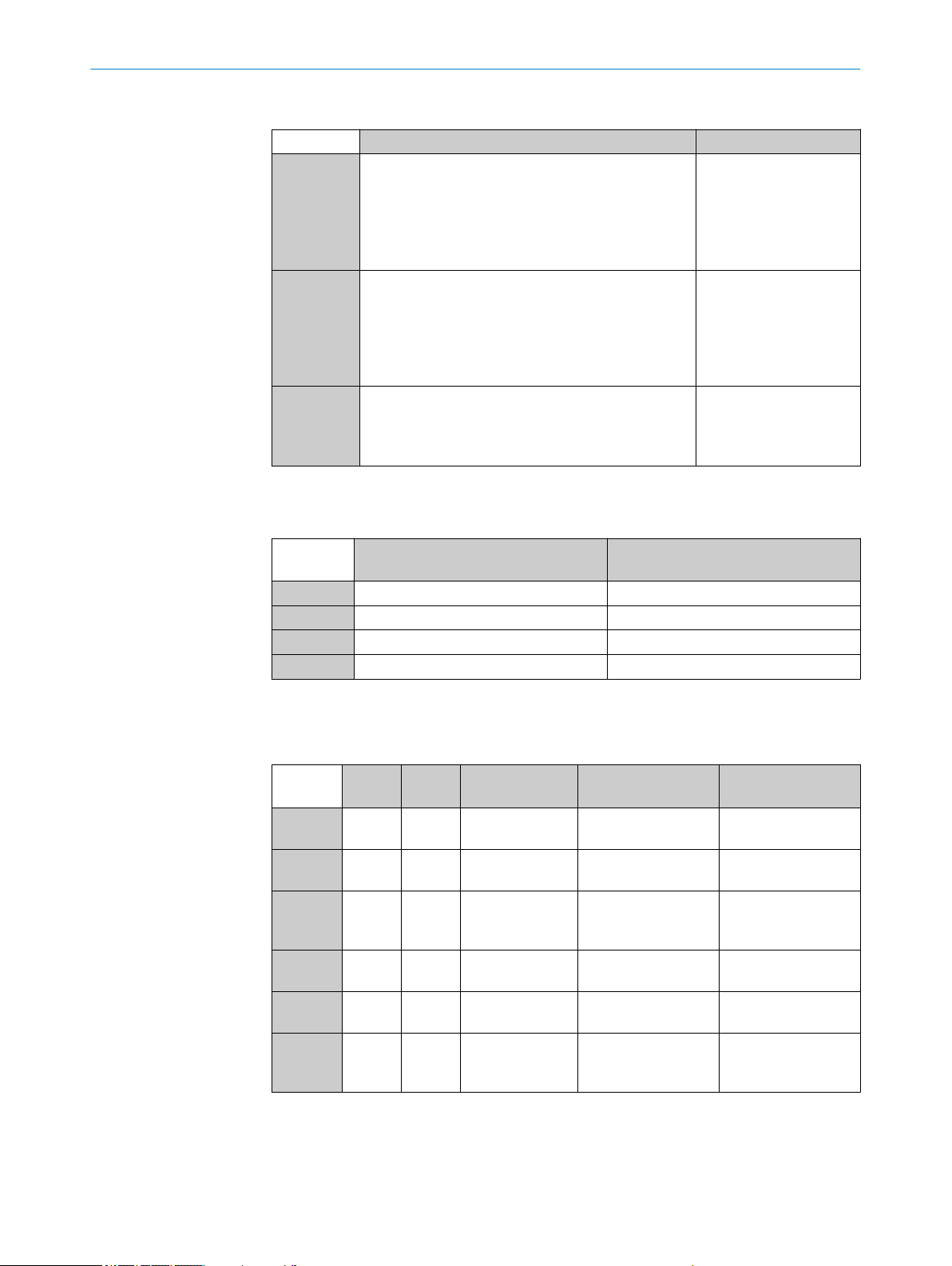

3.2.2 Combinations of MLG-2 Pro inputs and outputs

Position 12 Inputs and outputs, data interface Connection type

B 2 × switching output (Q) and

2 × analog output (QA)

or

1 × input (IN) and

1 × switching output (Q) and

2 × analog output (QA)

I 2 × switching output (Q) and

1 × RS-485 interface

or

1 × input (IN) and

1 × switching output (Q) and

1 × RS-485 interface

R 4 × switching output (Q)

or

2 × input (IN) and

2 × switching output (Q)

Table 5: Possible combinations of MLG-2 Pro inputs and outputs

PRODUCT DESCRIPTION 3

M12/8-pin, A-coded

M12/8-pin, A-coded

M12/8-pin, A-coded

3.2.3 Optical properties

Position

14 and 15

00 Special Special

32 2 m 2.5 mm

05 5 m 5 mm

08 8.5 m 5 mm

Table 6: Sensing range and minimum detectable object length

Sensing range Minimum detectable object length

3.2.4 MLG-2 Pro preconfigurations

Position

16, 17

01 NBB LBB Object detection Teach-in Standard operating

02 NBB LBB Object detection Object detection

03 NBB LBB Object detection Object detection

04 NBB FBB Object detection Teach-in Standard operating

05 NBB FBB Object detection Object detection

06 NBB FBB Object detection Object detection

Table 7: Preconfiguration of MLG-2 Pro with I/O combination B (see table 5, page 13)

QA1 QA2 Q1/C Q2/IN1 Teach-in

(inverted)

(inverted)

(inverted)

(inverted)

mode

Standard operating

mode

Standard & cross

beam operating

mode

mode

Standard operating

mode

Standard & cross

beam operating

mode

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

13

Page 14

3 PRODUCT DESCRIPTION

Position

16, 17

RS-485

Output

RS-485

Data transmis‐

Q1/C Q2/IN1 Teach-in

sion rate

01 System status

States of the

9600 baud Object detec‐

tion

Teach-in Standard

switching outputs

NBB

LBB

FBB

ODI

IDI

02 System status

States of the

9600 baud Object detec‐

tion

Teach-in Standard

switching outputs

Beam status

03 System status

States of the

9600 baud Object detec‐

tion

Object detec‐

tion (inverted)

switching outputs

Beam status

04 System status

States of the

9600 baud Object detec‐

tion

Teach-in Standard

switching outputs

RLC

05 System status

States of the

9600 baud Object detec‐

tion

Object detec‐

tion (inverted)

switching outputs

RLC

Table 8: Preconfiguration of MLG-2 Pro with I/O combination I (see table 5, page 13)

operating

mode

operating

mode

Standard

operating

mode

operating

mode

Standard

operating

mode

Position

Q1/C Q2/IN1 Q3 Q4/IN2 Teach-in

16, 17

01 Object detection Teach-in Object detec‐

tion

Object detec‐

tion

Standard

operating

mode

02 Object detection Teach-in Object detec‐

tion (inverted)

Object detec‐

tion

Standard

operating

mode

03 Object detection Teach-in Object detec‐

tion

Object detec‐

tion

Standard &

cross beam

operating

mode

04 Object detection Object detection Object detec‐

tion

Object detec‐

tion

Standard

operating

mode

05 Object detection Object detection

(inverted)

Object detec‐

tion (inverted)

Object detec‐

tion (inverted)

Standard

operating

mode

06 Object detection Object detection Object detec‐

tion

Object detec‐

tion (inverted)

Standard &

cross beam

operating

mode

Table 9: Preconfiguration of MLG-2 Pro with I/O combination R (see table 5, page 13)

14

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 15

3.3 MLG-2 product properties

Different beam separations from 2.5 mm to 50 mm

•

Monitoring heights from 130 to 3,140 mm

•

Operating range up to 2 m, 5 m or 8.5 m

•

Quick response time

•

Convenient configuration using the SOPAS ET software interface

•

Detection of transparent objects

•

Dust- and sunlight-resistant

•

Integrated applications including object detection, height classification, etc.

•

3.4 Setup and function

The MLG-2 is an optical light grid. It comprises a sender and a receiver.

The sender consists of sender optics, several sender elements (LEDs), and actuation

electronics. The receiver consists of receiver optics, several receiver elements (photodi‐

odes) and evaluation electronics.

3.4.1 MLG-2 Pro device components

PRODUCT DESCRIPTION

3

Figure 3: MLG-2 Pro

Receiver

r

Sender

s

Receiver connection

1

Ethernet configuration interface on the receiver

2

Sender connection

3

The receiver has a connection for the power supply, for inputs and outputs, and for syn‐

chronization. It also has an Ethernet connection for configuration via TCP/IP.

The sender has a connection for the power supply, for synchronization, and for a test

input.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

15

Page 16

3 PRODUCT DESCRIPTION

3.4.2 Measurement principle

Provided no object is located between the sender and receiver elements, the light

beams from the sender elements will hit the receiver elements.

If an object is located between the sender and receiver elements, the light beams will

be blocked, depending on the size of the object.

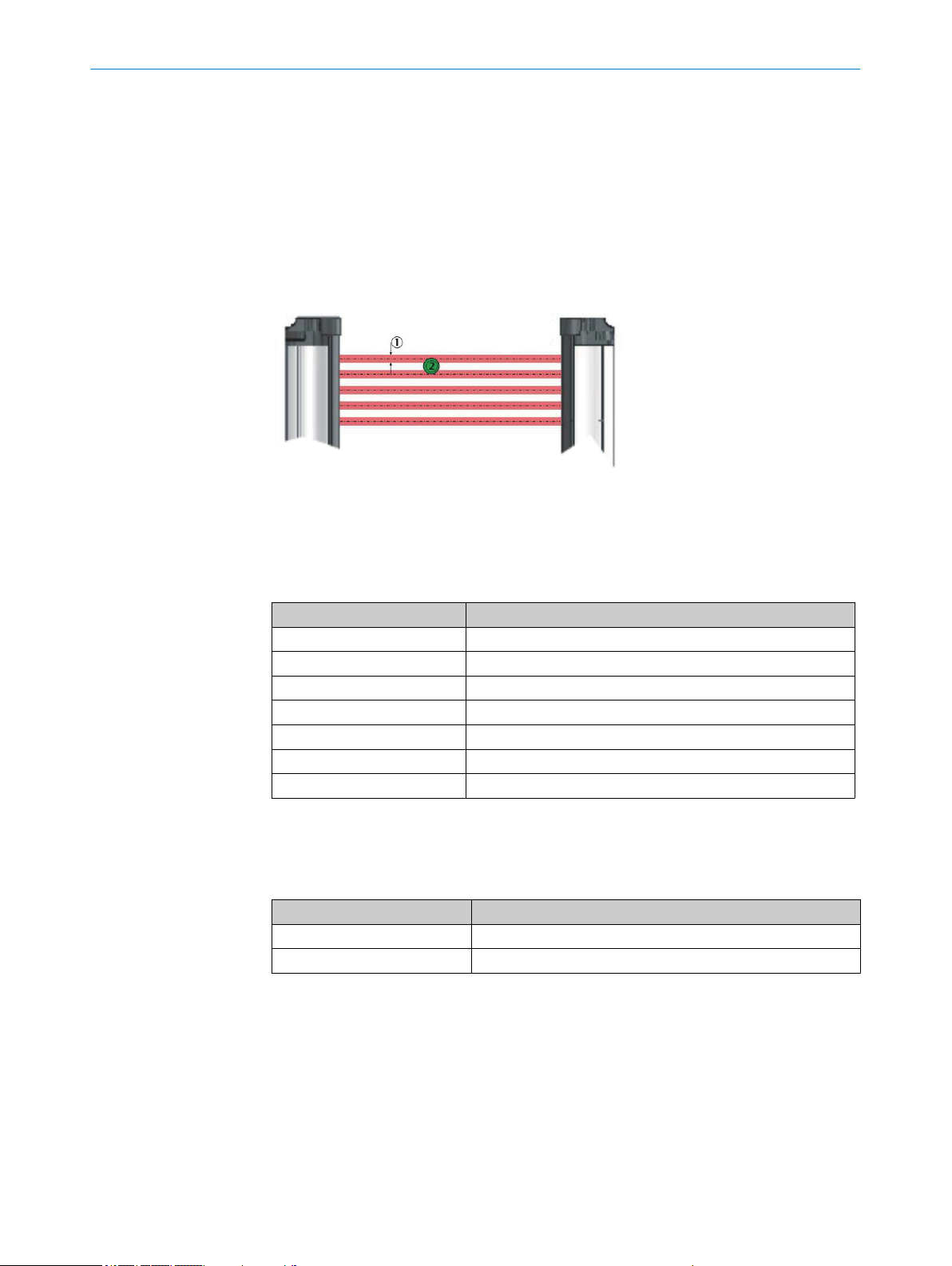

Detection area

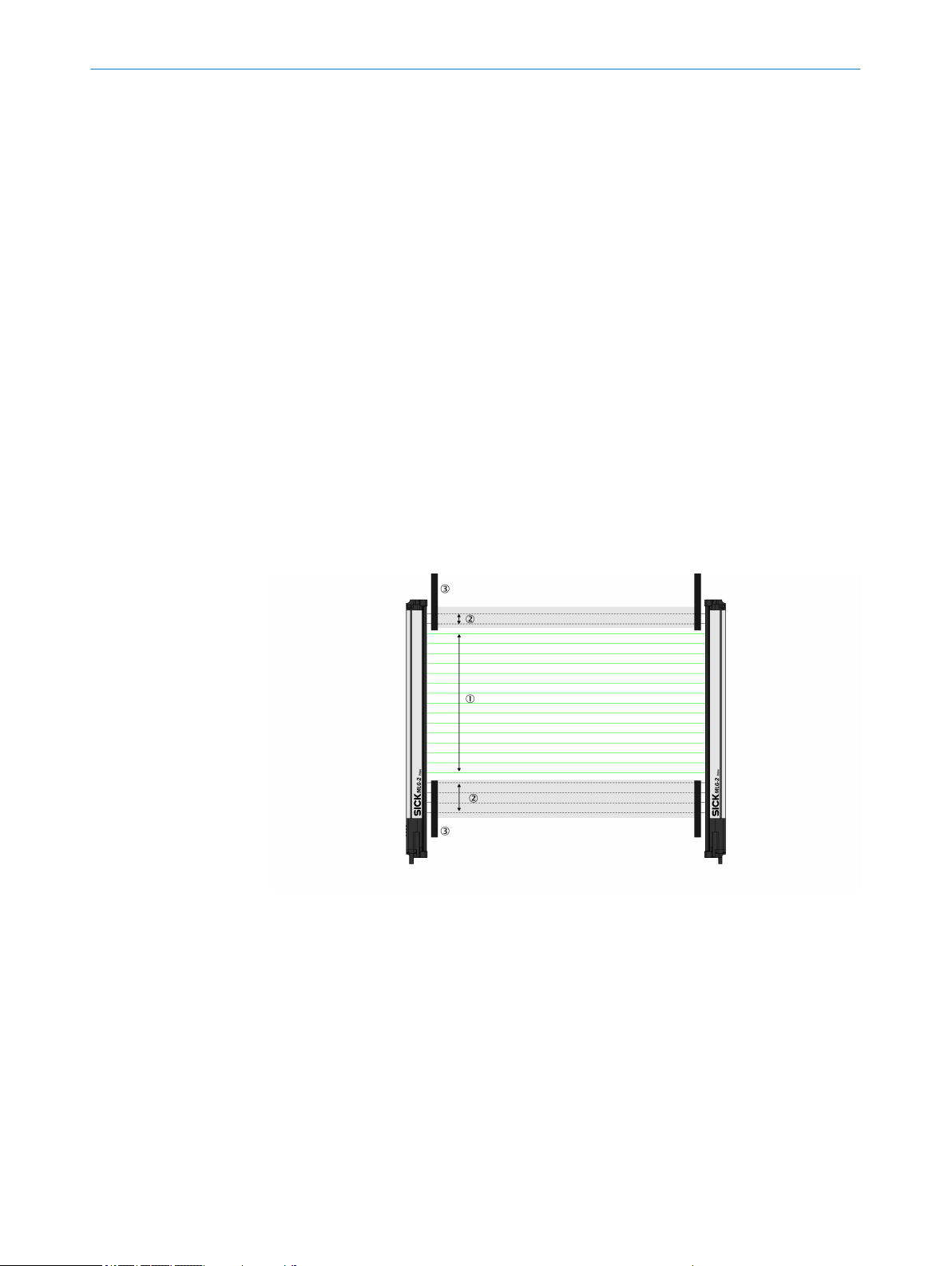

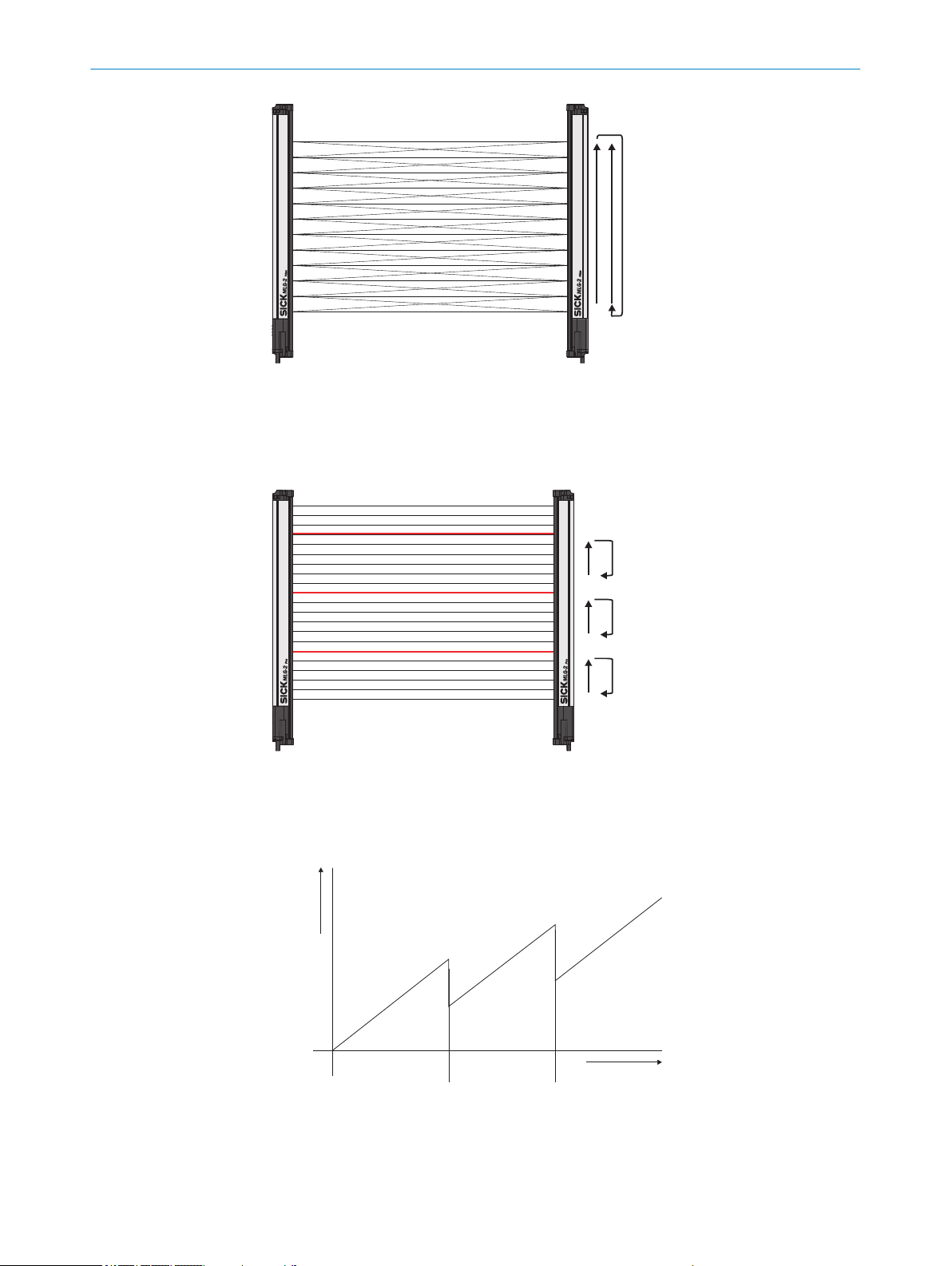

Figure 4: Detection area of the MLG-2

Monitoring height

1

Beam separation

2

Sensing range

3

The detection area is determined by the monitoring height and the sensing range of the

light grid. The monitoring height is determined by the beam separation and the number

of beams. The sensing range of the light grid is the distance between sender and

receiver.

3.4.3 Synchronizing the MLG-2

The sender and receiver synchronize with each other electronically, thus one electrical

connection between the sender and receiver is necessary.

3.4.4 Beam separations and monitoring height

Beam separations

In order to achieve different levels of measurement accuracy, the MLG-2 is available

with different beam separations.

16

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 17

PRODUCT DESCRIPTION 3

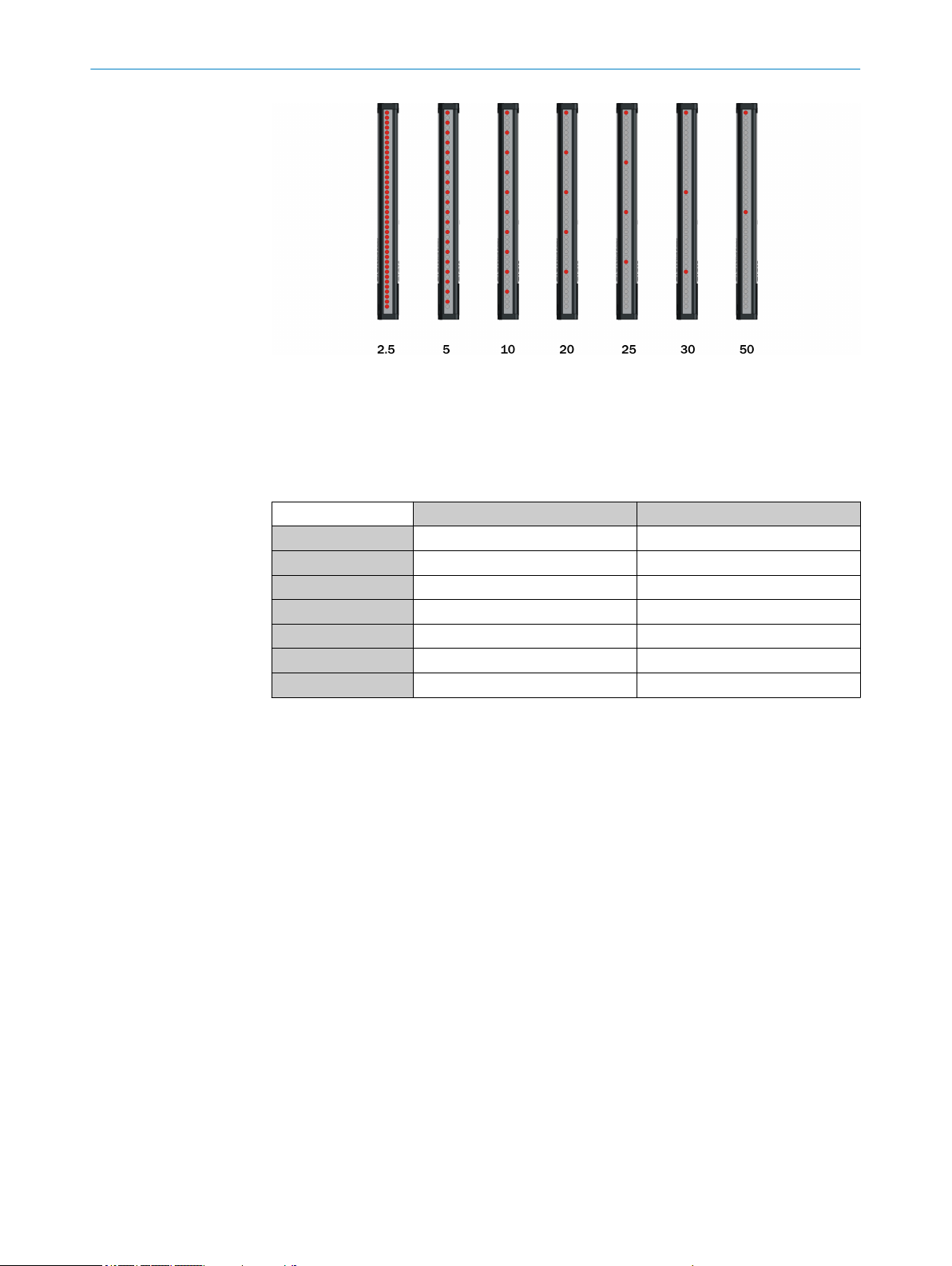

Figure 5: Schematic depiction of available beam separations (mm)

Maximum and minimum monitoring height

The number of LEDs is limited to 510. This results in different maximum monitoring

heights depending on the beam separation. The minimum monitoring height is deter‐

mined by the beam separation and the smallest module size for this beam separation.

3.4.5 Teach-in

Beam separation Maximum monitoring height Minimum monitoring height

2.5 mm 1195 mm 145 mm

5 mm 2,545 mm 145 mm

10 mm 3,140 mm 140 mm

20 mm 3,130 mm 130 mm

25 mm 3,125 mm 275 mm

30 mm 3,1320 mm 270 mm

50 mm 3,100 mm 250 mm

Table 10: Maximum monitoring heights

During the teach-in process, the switching thresholds for all beams are individually

adjusted for the sensing range and the ambient conditions.

After teach-in has been completed, it must be ensured that the setup is no longer

changed otherwise another teach-in will have to be carried out.

The MLG-2 Pro provides the following options for carrying out a teach-in:

Pressing the teach-in button

•

Automatic teach-in (when switching on)

•

Signal at a switching input

•

SOPAS ET

•

IO-Link

•

Webserver

•

Teach-in quality

The teach-in quality indicates the quality after the teach-in process. The MLG-2 calcu‐

lates this value based on the quality of the light level received. The teach-in quality

depends on the alignment of the MLG-2 and the cleanliness of the front screens.

The value remains constant until another teach-in process is carried out.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

17

Page 18

3 PRODUCT DESCRIPTION

Process quality

The process quality indicates the quality of the light level currently being received. The

MLG-2 analyzes the light level received when the light path is unblocked and compares

this to the values after the last teach-in process.

If the received values are getting worse, the process quality drops.

Possible causes of a drop in process quality include:

•

•

•

Retrieving teach-in quality and process quality data

The quality performance indicators can be retrieved in various ways:

•

•

•

•

•

•

Contamination or fogging of the front screen of the sender and/or receiver

Misalignment

Continuous partial blocking of a light beam or several light beams

SOPAS ET

RS485

IO-Link

Integrated web server

switching outputs

Analog outputs

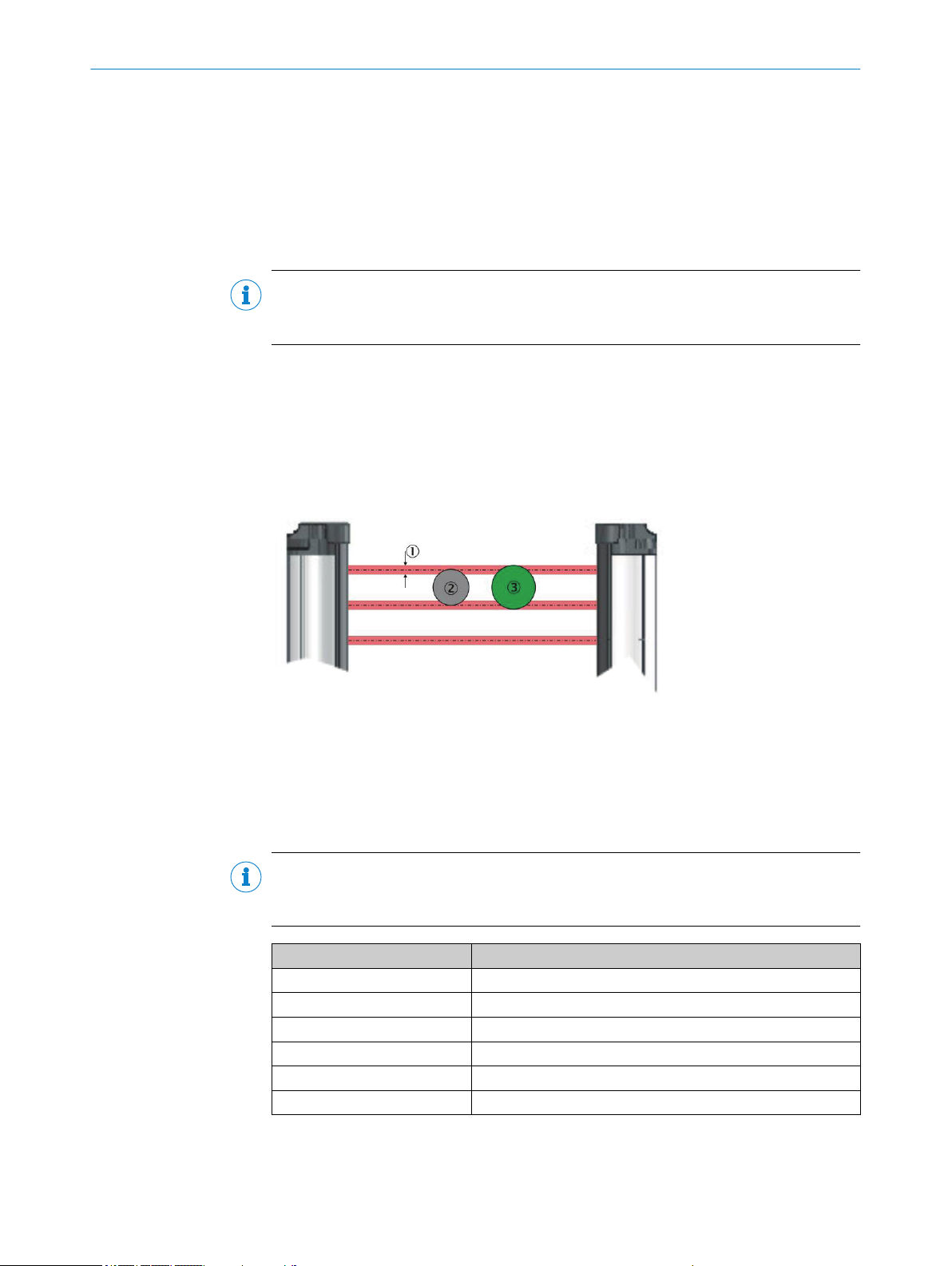

3.4.6 Beam blanking

Individual beams can be blanked.

Figure 6: Detection area with beams blanked

1

2

3

Included beams

Blanked beams

Structural restrictions on the detection area

18

The MLG-2 Pro offers various options for blanking light beams (see "Teach-in",

page 90).

One-off blanking

•

The blocked beams are blanked.

Beam blanking for each teach-in

•

The blocked beams are blanked in every teach-in process.

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 19

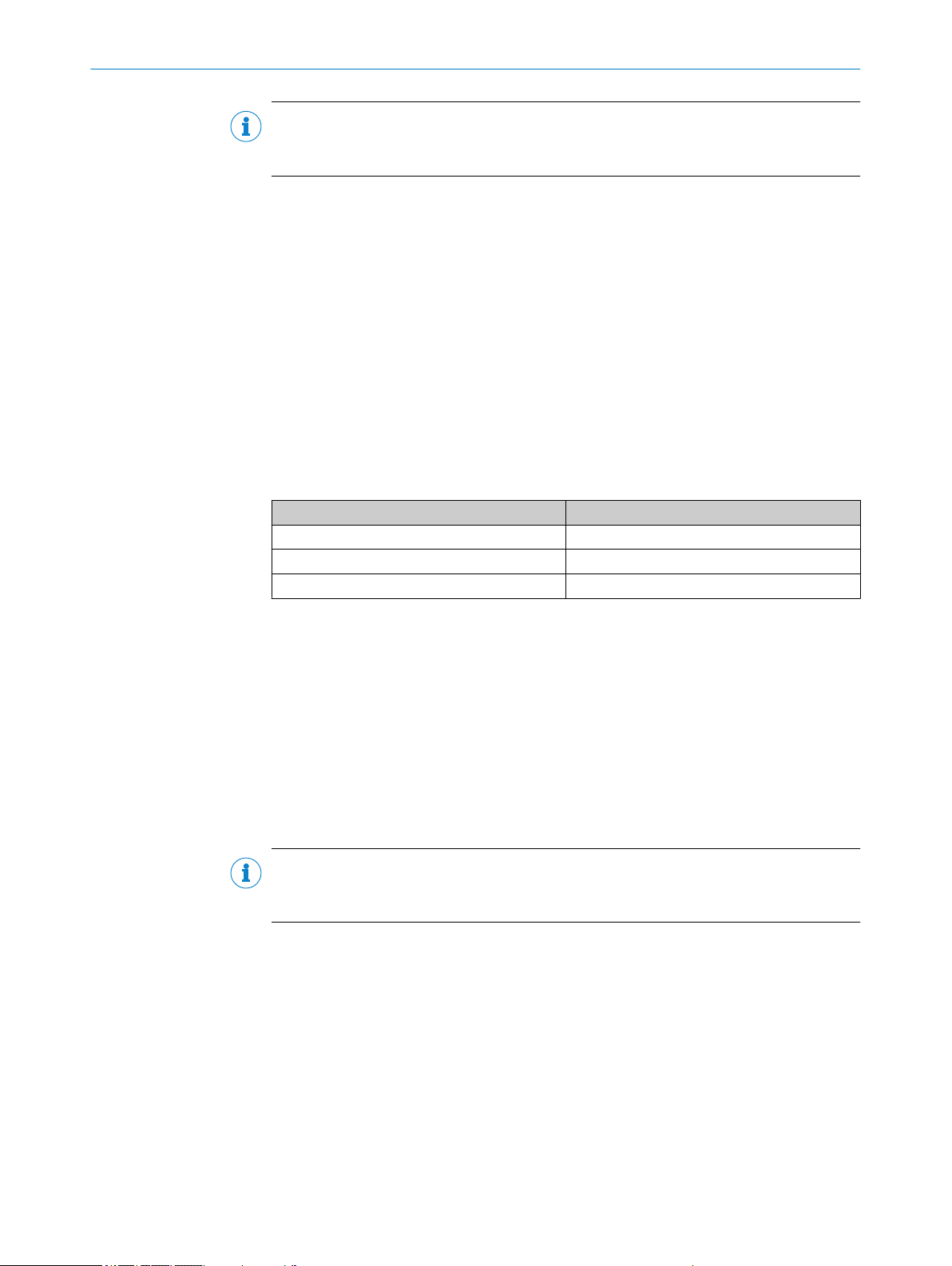

NOTE

If this option is selected and an object is located in the detection area during the teachin process, this will not be identified as an error.

3.4.7 Sensing ranges

Operating range

Light grids are generally available with a 2 m range, 5 m range or 8.5 m sensing range.

This is referred to as the operating range, which includes an operating reserve.

Limiting range

It is also possible to operate the MLG-2 up to its limiting range, which goes beyond the

operating range.

Table 11: Limiting range

PRODUCT DESCRIPTION 3

Manual blanking

•

Light beams can be individually selected and blanked using the interface in

SOPAS ET and via IO-Link (see "Representation of the detection area", page 59).

The beams are not taken into account in the measurement, even if they are made

at the time of the teach-in process.

Operating range Limiting range

2 m 2.8 m

5 m 7 m

8.5 m 12 m

3.5 Scan time

Operation within the limiting range requires the following conditions:

Clean ambient conditions

•

Front screens are cleaned regularly

•

Regular teach-in

•

The following functions cannot be provided when operating within the limiting range:

High level of operating reserves

•

High measurement accuracy

•

Transparent operating mode

•

Dust- and sunlight-resistant operating mode

•

NOTE

The sensing range of the MLG-2 Pro is reduced in certain operating modes (see "MLG-2

operating modes", page 26).

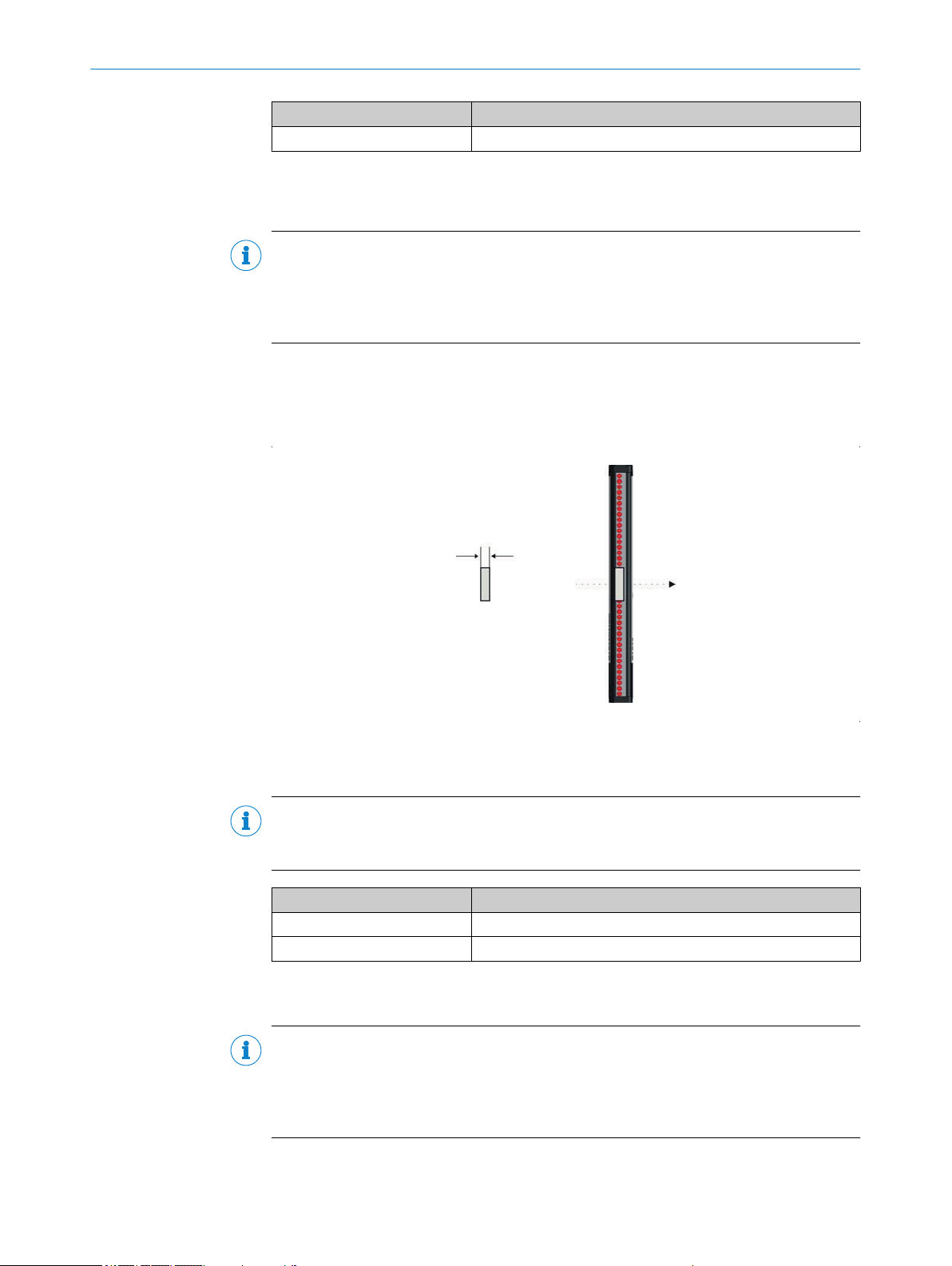

In the MLG-2, not all light beams are active at the same time, instead one light beam is

activated after the other starting from the bottom.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

19

Page 20

Number of beams

Scan time

3 PRODUCT DESCRIPTION

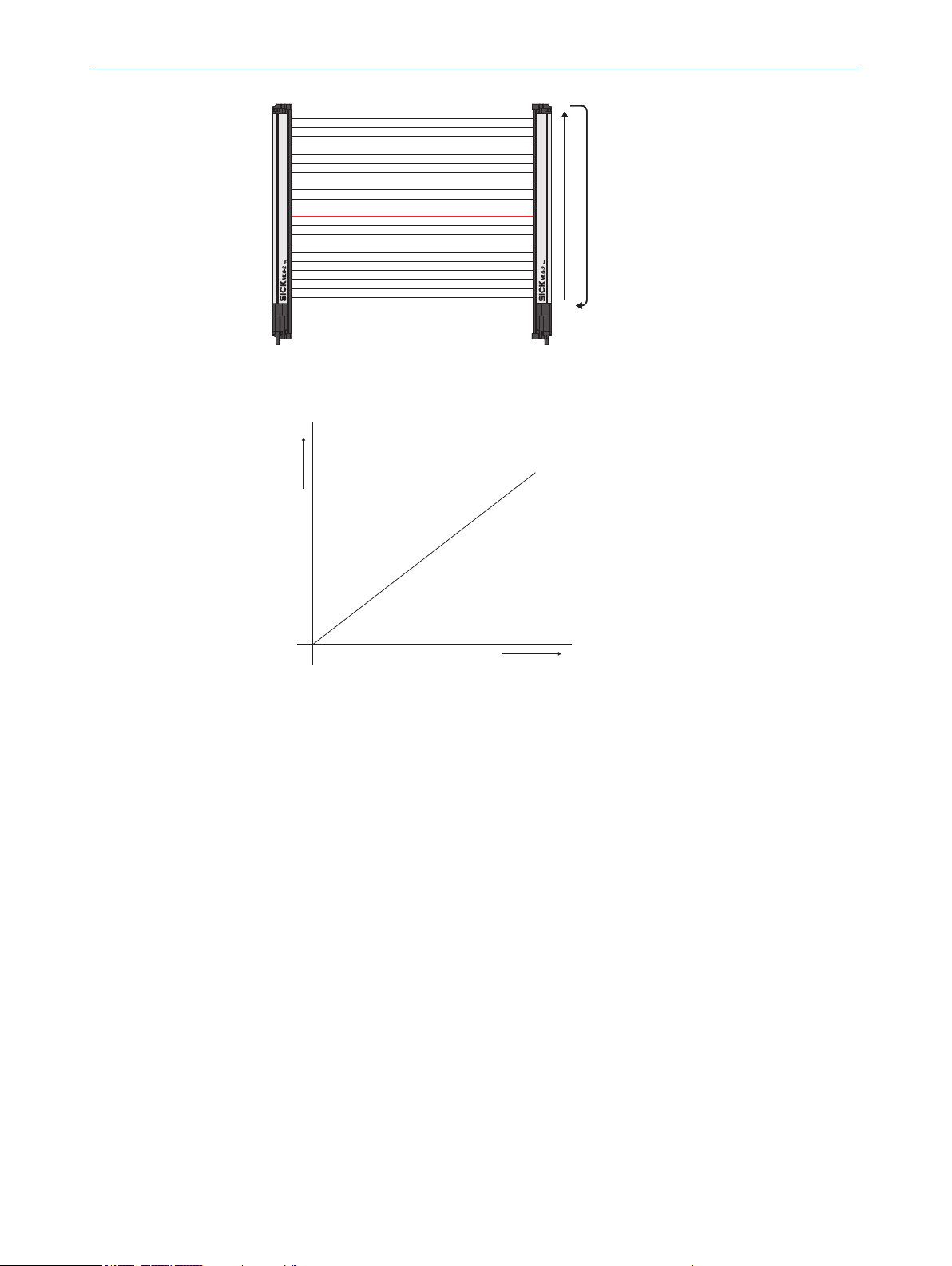

Figure 7: Standard scan method

The scan time increases according to the number of beams of an MLG-2.

Figure 8: Scan time in relation to the number of beams

The scan time is used to determine the response times of the outputs, the minimum

presence time of an object and the repeat accuracy of a measurement result (reprodu‐

cibility).

The response time is the time it takes for an output to react following the detec‐

•

tion of an object/gap. The maximum response time is 3 × the scan time plus the

transmission time to the outputs.

The minimum presence time is the time an object or a gap has to be in the detec‐

•

tion area for it to be detected. The minimum presence time is max. 2 × the scan

time.

The repeat accuracy of a measurement result (reproducibility) is the amount of

•

time by which an object detection can differ from a previous or subsequent detec‐

tion. The reproducibility time is 1 × the scan time.

3.5.1 Response time, minimum presence time and reproducibility of the MLG-2

On the MLG-2, the response time, minimum presence time, and reproducibility are dis‐

played via SOPAS ET. Response time and minimum dwell time can be read off in the

diagramsee figure 129, page 122.

3.5.2 Scan time with cross-beam function

When the cross-beam function is enabled, the light beam from a sender LED is

received by three receiver diodes in two scans. This doubles the scan time.

20

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 21

Figure 9: Cross-beam function

Number of beams

Scan time

1 2

3.5.3 Scan time with high-speed scan on the MLG-2

With high-speed scan, several beams are active in each cycle. This reduces the scan

time by a variable factor.

PRODUCT DESCRIPTION 3

Figure 10: High-speed scan

The scan time is also dependent on the number of beams. Beyond a certain number of

beams, the scan time is reduced because it is possible to use the high-speed scan.

Figure 11: Scan time in relation to the number of beams when using the high-speed scan

High-speed scan with 2 beams active simultaneously

1

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

21

Page 22

3 PRODUCT DESCRIPTION

High-speed scan with 3 beams active simultaneously

2

The number of beams that can be activated at the same time depends on the size of

the detection area (sensing range, beam separation, and number of beams). On the

MLG-2, the response time, minimum presence time, and reproducibility are displayed

via SOPAS ET. You can also find the response time and minimum presence time when

using the high-speed scan in the diagrams in these operating instructions (see "Dia‐

grams", page 122).

NOTE

With a beam separation of 2.5 mm, the high-speed scan can only be adjusted in combi‐

nation with the high measurement accuracy function.

3.6 Beam separation and minimum detectable object

The measurement accuracy achieved by the MLG-2 depends on the beam separation.

3.6.1 Minimum detectable object with parallel-beam function

In order for an object to be detected continuously, it must completely cover at least one

beam. This is referred to as the minimum detectable object, or MDO.

Figure 12: Minimum detectable object

Beam diameter

1

Object is not completely reliably detected

2

Object is reliably detected (meets requirements of minimum detectable object size)

3

NOTE

For moving objects, the minimum detectable object depends on the speed of the

object.

Beam separation Minimum detectable object (stationary object)

2.5 mm 3.5 mm

5 mm 9 mm

10 mm 14 mm

20 mm 24 mm

25 mm 29 mm

30 mm 34 mm

Table 12: Minimum detectable object in relation to the beam separation of the MLG-2

12

22

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 23

1

PRODUCT DESCRIPTION 3

Beam separation Minimum detectable object (stationary object)

50 mm 54 mm

Table 12: Minimum detectable object in relation to the beam separation of the MLG-2

1

Only if the object also meets the minimum detectable object length requirements.

2

All the values are typical values and can be found in the respective setting modes.

NOTE

The minimum detectable object size is also dependent on the other performance

options, such as the configured response time and operating reserve. The precise mini‐

mum detectable object size is displayed in SOPAS ET on the MLG-2 (see "SOPAS ET

interface", page 54).

3.6.2 Minimum detectable object length

When an object moves through the detection area, it must have a certain length.

12

Figure 13: Minimum detectable object length

Minimum detectable object

1

NOTE

For moving objects, the minimum detectable object length also depends on the speed

of the object.

Beam separation Minimum detectable object length (stationary object)

2.5 mm 2.5 mm

5 … 50 mm 5 mm

Table 13: Minimum detectable object length with the MLG-2

1

Only if the object also meets the minimum detectable object requirements.

1

NOTE

The minimum detectable object length is also dependent on the other performance

options, such as the configured response time and operating reserve. The precise mini‐

mum detectable object length is displayed in SOPAS ET on the MLG-2 (see "SOPAS ET

interface", page 54).

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

23

Page 24

3 PRODUCT DESCRIPTION

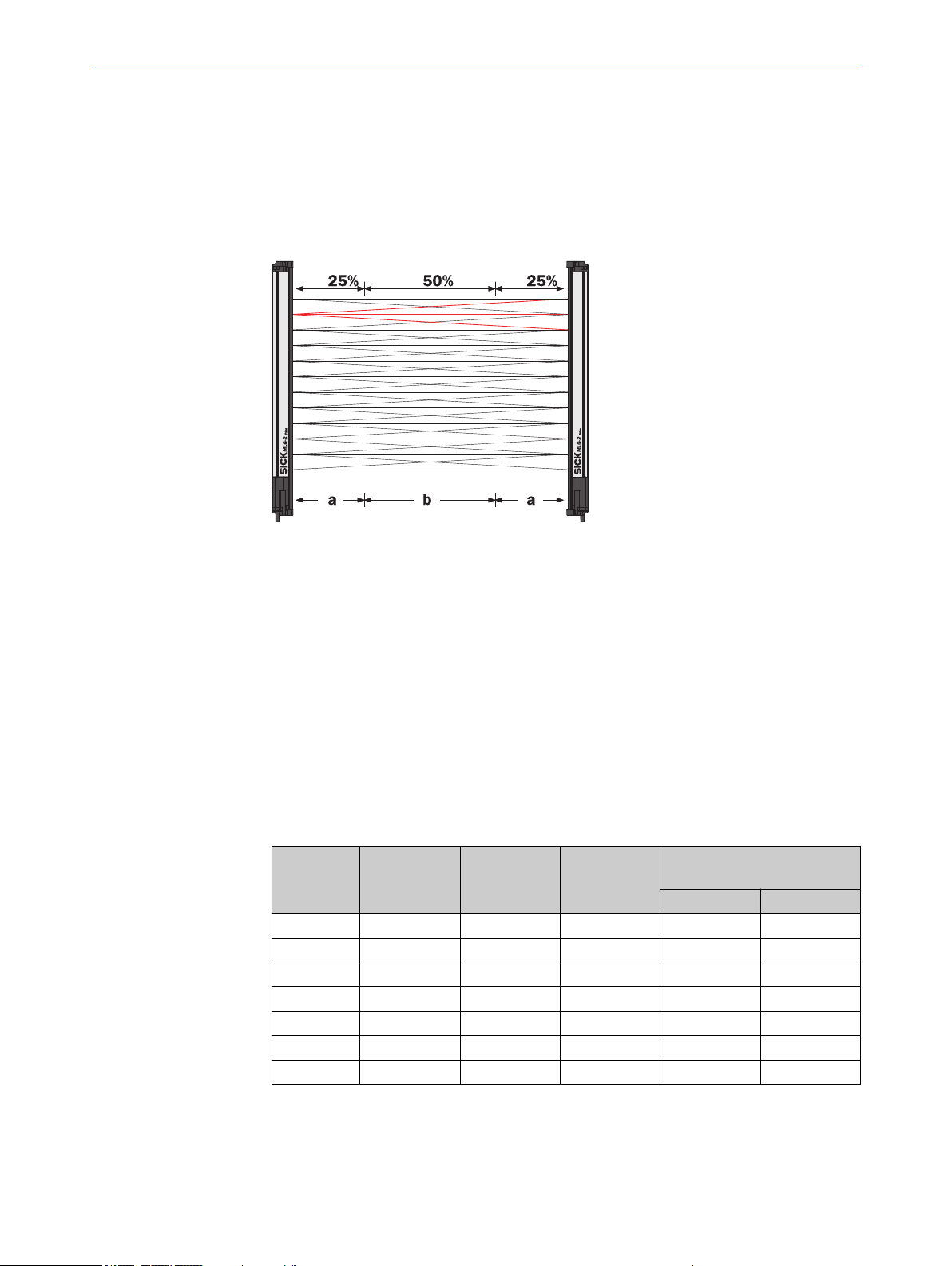

3.6.3 Minimum detectable object with cross-beam function

The parallel-beam function is used for measuring by default. With the parallel-beam

function, each light beam is received only by the receiver element situated directly

opposite.

With the cross-beam function, a sender LED projects beams to several receiver diodes.

The cross-beam function increases the measurement accuracy and enables the detec‐

tion of smaller objects.

Figure 14: Cross-beam function

A minimum distance between the sender and the receiver is required for the crossbeam function. The minimum detectable object size depends on the position of the

object within the detection area. Detection of the smaller minimum detectable object

size is therefore only possible in the central area (b) of the detection area.

The cross-beam function is only useful for object detection (NBB ≤ 1). For other

•

applications (height classification, object recognition, etc.), the results of the paral‐

lel-beam function are used.

Use of the cross-beam function increases the response time.

•

With the cross-beam function, a minimum distance needs to be maintained

•

between sender and receiver. The minimum distance depends on the aperture

angle of the light grid.

For moving objects for the cross-beam function, the minimum detectable object

•

depends on the speed of the object.

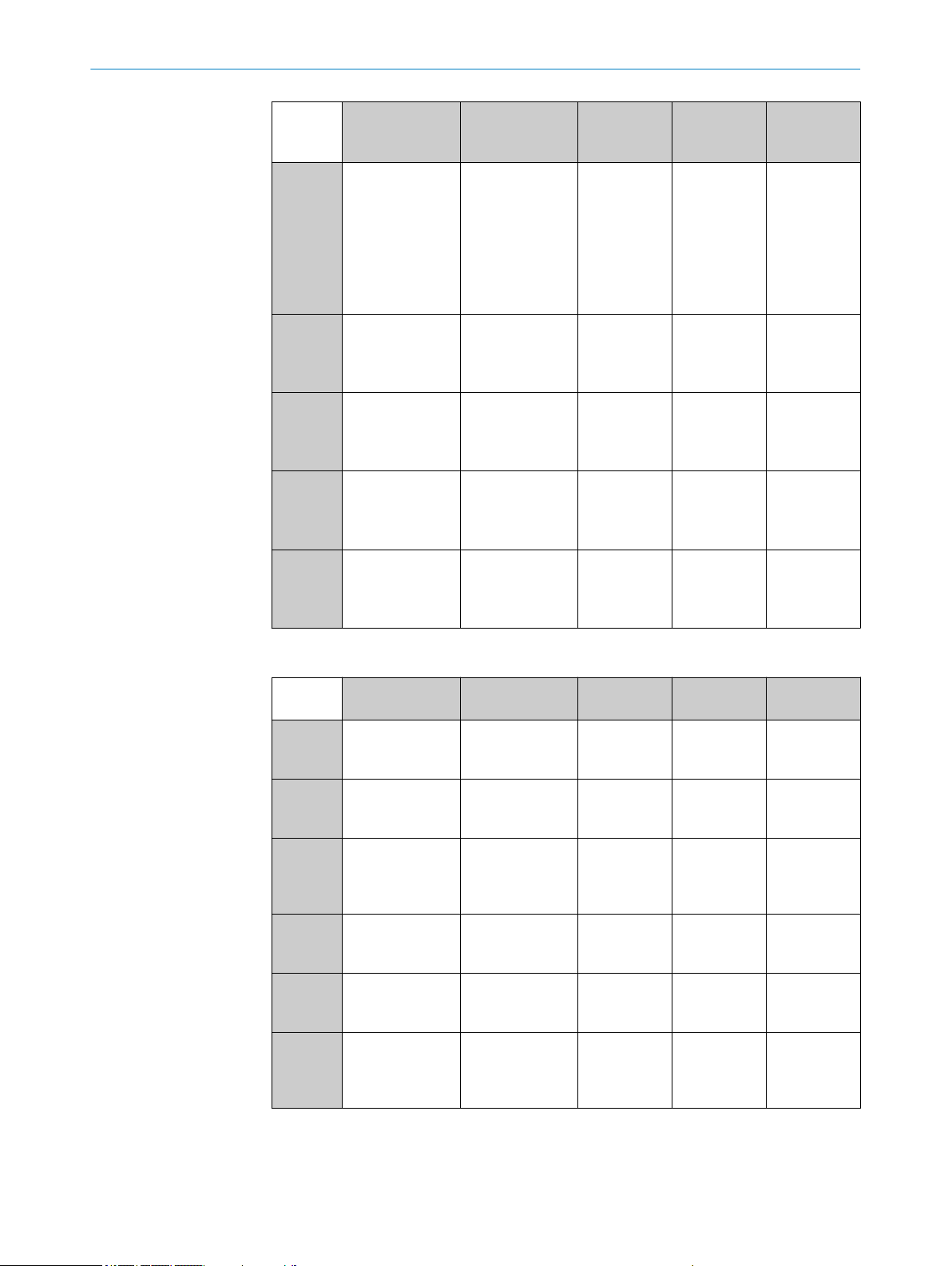

Beam sepa‐

ration

2.5 mm 200 mm – – 2.5 mm 4 mm

5 mm – 110 mm 120 mm 6.5 mm 9 mm

10 mm – 220 mm 240 mm 9 mm 14 mm

20 mm – 440 mm 480 mm 14 mm 24 mm

25 mm – 550 mm 600 mm 16.5 mm 29 mm

30 mm – 660 mm 720 mm 19 mm 34 mm

50 mm – 1110 mm 1200 mm 29 mm 54 mm

Table 14: Minimum detectable object with cross-beam function on the MLG-2

Minimum dis‐

tance

2 m variant

Minimum dis‐

tance

5 m variant

Minimum dis‐

tance

8.5 m variant

Minimum detectable object

(stationary object)

In area B In area A

24

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 25

PRODUCT DESCRIPTION 3

High-speed scan is not possible.

•

The minimum detectable object size with cross-beam function is also dependent

•

on the other performance options, such as the configured response time and

operating reserve. The precise minimum detectable object size is displayed in

SOPAS ET on the MLG-2 (see "SOPAS ET interface", page 54).

3.6.4 Minimum detectable object with high measurement accuracy from the MLG-2

On the MLG-2, the measurement accuracy can be increased in SOPAS ET (see "Per‐

formance options", page 93). This means that an object can be detected even if it

only covers half of a beam.

Figure 15: Minimum detectable object size with high measurement accuracy

Beam diameter

1

Object is reliably detected (meets requirements of minimum detectable object size)

2

Beam separation Minimum detectable object (stationary object)

1

2.5 mm 2.5 mm

5 mm 5 mm

10 mm 10 mm

20 mm 20 mm

25 mm 25 mm

30 mm 30 mm

50 mm 50 mm

Table 15: Minimum detectable object size with high measurement accuracy

1

Only if the object also meets the minimum detectable length requirements see table 13, page 23).

Minimum detectable object length

Beam separation Minimum detectable object length (stationary object)

2.5 mm 1 mm

5 … 50 mm 2 mm

Table 16: Minimum detectable object length with high measurement accuracy

1

Only if the object also meets the minimum detectable length requirements (see table 12, page 22).

1

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

25

Page 26

3 PRODUCT DESCRIPTION

When using high measurement accuracy to detect moving objects, the minimum

•

detectable object length also depends on the speed of the object and the other

performance options, such as the configured response time and operating

reserve. The precise minimum detectable object length is displayed in SOPAS ET

on the MLG-2 (see "SOPAS ET interface", page 54).

Sensing ranges larger than the operating range are not possible when using high

•

measurement accuracy.

High measurement accuracy can cause the operating reserve to decrease in the

•

event of large sensing ranges and imperfect alignment.

3.7 Operating reserve

The operating reserve defines the operational safety before contamination, vibrations,

misalignment, temperature fluctuations, etc. cause the MLG-2 to produce incorrect

measurements.

The MLG-2 is subject to a certain level of contamination depending on its environment

and application. In principle, the MLG-2 must be cleaned regularly and a teach-in

should be carried out after cleaning.

3.7.1 Operating reserves on the MLG-2

On the MLG-2, the operating reserve can be adjusted according to the operating mode.

Standard operating reserve

The standard setting for the operating reserve is the best setting for most applications.

High level of operating reserves

Setting the operating reserve high makes the MLG-2 very resistant to contamination.

However, it is not possible to activate high measurement accuracy in this case.

NOTE

In order to achieve a high operating reserve, the input sensitivity must be increased.

This increases the risk of reflection. If there are reflective surfaces near the detection

area, the light beams from the LEDs may reflect off these surfaces and reach the

receiver, even though there is an object in the detection area.

The high input sensitivity means that only opaque objects can be detected. Transparent

or semi-transparent objects are not detected.

Low operating reserve

Setting the measurement accuracy high reduces the operating reserve. When the oper‐

ating reserve is low, the MLG-2 must be cleaned more frequently and a teach-in proc‐

ess must be carried out.

3.8 MLG-2 operating modes

The MLG-2 has the operating modes Standard, Transparent and Dust and SunlightResistant.

Within the operating modes, the performance options can be used to modify the

response time, minimum detectable object size, minimum detectable absorption (in

Transparent operating mode), and operating reserve.

The configurable performance options depend on the operating mode selected.

•

When the operating mode is changed, a new teach-in process must be performed.

•

26

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 27

3.8.1 Standard operating mode

Standard operating mode is the mode in which most measuring applications can be

carried out.

Only opaque objects can be detected.

•

There must not be a high level of constant light irradiation.

•

3.8.2 Transparent operating mode

Transparent operating mode enables the detection of transparent objects, such as

those made of glass, PET, etc.

Transparent objects do not completely cover the light beam. In order to detect these

objects, they must have what is known as a minimum detectable absorption (MDA).

NOTE

It is not possible to use the cross-beam function, high operating reserve or high-speed

scan in the Transparent operating mode.

Minimum detectable absorption

In order to detect a transparent object, it must absorb a certain percentage of the

energy from the light beam. Depending on the objects being measured, an object can

be detected with 30% absorption, 15% absorption, or 10% absorption.

PRODUCT DESCRIPTION 3

NOTE

The minimum detectable absorption that an object needs in order to be detected

increases with the sensing range (see "Minimum detectable absorption", page 124).

Examples of the signal attenuation of transparent objects1):

Approx. 10% signal attenuation:

•

Clean PET bottles, clear glass, thin and clear films (e.g., cellophane), household

plastic film, plastic wrapping

Approx. 15% signal attenuation:

•

Clean clear glass bottles, thick films, film and wrapping folded multiple times

Approx. 30% signal attenuation:

•

Green and brown glass, colored glass bottles

The following prerequisites must be met:

The sender and receiver must be aligned precisely with one another.

•

The sender and receiver elements must be kept clean at all times.

•

AutoAdapt

The AutoAdapt function is active in the Transparent operating mode. AutoAdapt adjusts

the switching threshold at which objects are detected in accordance with the level of

contamination on the MLG-2. As a result, the MLG-2 thus becomes less sensitive as the

level of contamination increases.

3.8.3 Dust- and sunlight-resistant operating mode

Dust and sunlight-resistant operating mode is intended for applications when there is a

large amount of dust in the environment or a high level of solar radiation.

Dust and sunlight-resistant operating mode reduces the maximum sensing range

•

1)

Examples are for illustrative purposes only. The signal attenuation and the minimum detectable absorption to be configured must be

determined for each individual application.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

27

Page 28

3 PRODUCT DESCRIPTION

•

3.9 Interfaces

The MLG-2 can be used to evaluate the measurements in different ways. The MLG-2

provides various interfaces for data output.

•

•

•

•

The MLG-2 can output the raw data via the interfaces in the form of the beam status or

run-length code, so the user can evaluate the data him/herself.

The MLG-2 can also preprocess the raw data (beam function, e.g., NBB – number of

beams blocked) and output the data via bus or analog interfaces.

The preprocessed data can be assigned directly to the switching outputs via a program‐

mable function logic or via predefined applications.

– To 1.2 m for devices with a 2 m operating range

– To 3 m for devices with a 5 m operating range

– To 5 m for devices with an 8.5 m operating range

This operating mode can only be configured on an MLG-2 with fewer than

240 beams.

Switching outputs (Push-Pull)

Analog outputs

RS-485 interface

IO-Link interface

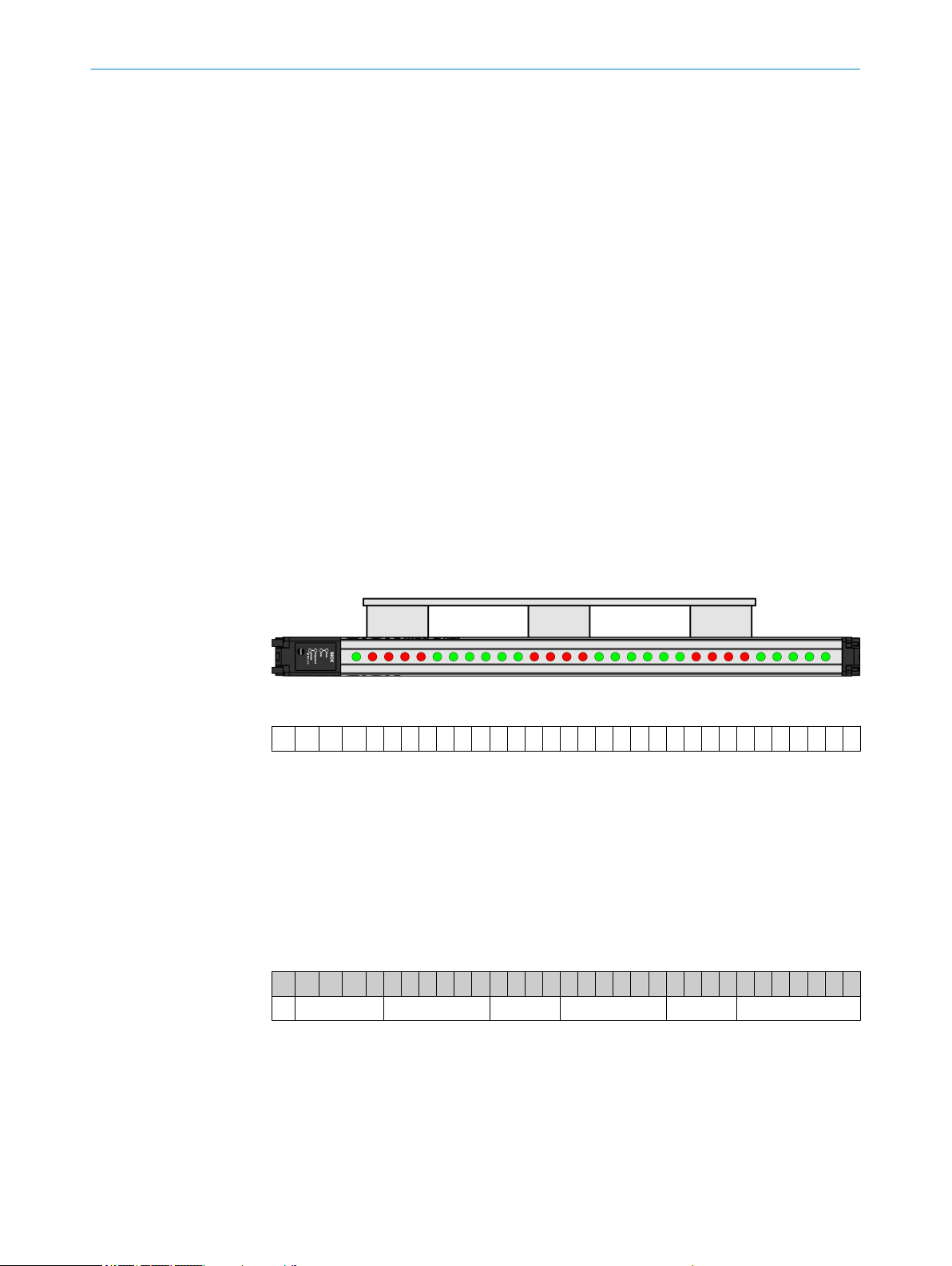

3.9.1 Output of measurement data (raw data)

The MLG-2 provides the status of all beams at its data interface using a data message.

Figure 16: Status of the beams

0 1 1 1 1 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 0 0

Table 17: Example status for an MLG-2 with 32 beams

0

Beam clear

1

Beam blocked

The data message can be output continuously or in response to particular events.

Run-length code

In order to reduce the volume of data, the run-length code can be output instead of the

complete status of all beams. This code only contains the status change of the beams.

The run-length code indicates how many beams currently have the same status.

0 1 1 1 1 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 0 0

1 4 6 4 6 4 7

Table 18: Example status for the run-length code of an MLG-2 with 32 beams

28

RLC = 1464645

The example shows: 1 beam made, 4 beams blocked, 6 beams made, 4 beams

blocked, 6 beams made, 4 beams blocked, 5 beams made.

The first value always indicates the number of unblocked beams. If the first beam is

blocked, the first value will therefore be zero. The second value indicates how many

beams are blocked; in the example in table 19, this value = 1.

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 29

1 0 0 1 1 1 1 0 0 0 0 1 1 0 0 0 0 0

0 1 2 4 4 2 5

Table 19: Example run-length code with the first beam blocked

NOTE

The run-length code can contain a maximum of 16 values; i.e., 15 status changes. It is

therefore only useful for measuring objects with a small number of parts, e.g., a pallet.

Objects such as pallet cages are not suitable as they involve too many status changes.

3.9.2 Preliminary evaluation

Beam functions for preliminary evaluation

The MLG-2 creates a preliminary evaluation on the basis of the beam status, e.g.:

NBB – Number of Beams Blocked

•

NBM – Number of Beams Made

•

LBB – Last Beam Blocked

•

FBB – First Beam Blocked

•

see table 33, page 107: Table shows all available functions.

The results of the preliminary evaluation can be output via the data interfaces and

processed further externally. Alternatively, they can first be processed in a function pro‐

gramming option in the MLG-2.

PRODUCT DESCRIPTION 3

Function programming for the MLG-2 Pro

Function programming can be used to carry out complex applications with variables,

operands, and functions in SOPAS ET.

1st option:

The beam functions are directly linked with the outputs.

Example:

Q1 = Total number of beams made (NBM) ≥ 30

The output Q1 switches when the total number of beams made is greater than or

equal to 30.

2nd option:

The MLG-2's beam functions are used to define beam function variables first.

Example:

BFVar 1: Total number of beams made (NBM) ≥ 30

BFVar 2: Number of consecutive beams blocked (NCBB) = 5

These can be linked to logical variables.

Example:

LogVar1 = BFVar 1 OR BFVar 2

The logical variables can be linked in turn to the outputs (Q).

Example:

Q1 = LogVar1 = true

The output Q1 switches when the total number of beams made is greater than or

equal to 30 or when the number of consecutive beams blocked equals 5.

3.9.3 Configurable applications of the MLG-2 Pro

The MLG-2 provides predefined applications which are assigned to the outputs. The fol‐

lowing options are available for configuring the applications:

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

29

Page 30

3 PRODUCT DESCRIPTION

– Via SOPAS ET (see "Configuration with SOPAS ET", page 53)

– Using the integrated web server (see "MLG-2 configuration with the internal web

– Using IO-Link (see "IO-Link", page 110)

Application MLG-2 Pro

Height classification

Object detection/object width

Contamination warning

Object recognition

Hole detection/hole size

Outer/inner dimension

Classification of the object position

Classification of the hole position

Zones

Diagnostics

Table 20: Configurable applications for switching outputs

Application MLG-2 Pro

NBB Object detection

NBM Hole detection

LBB Object height measurement (last beam

FBB Object height measurement (first beam

ODI Measurement of the outer dimension

IDI Measurement of the inner dimension

CBB Measurement of the object position

CBM Measurement of the hole position

– Diagnostics

NBB Zone X

(X = 1, 2, 3

or 4)

NCBB Zone

X (X = 1, 2,

3 or 4)

FBB Zone X

(X = 1, 2, 3

or 4)

LBB Zone X

(X = 1, 2, 3

or 4)

CBB Zone X

(X = 1, 2, 3

or 4)

Table 21: Configurable applications for analog outputs

server", page 108)

blocked)

blocked)

Object detection system within a zone

Object width within a zone

Object height measurement (first beam

blocked) within a zone

Object height measurement (last beam

blocked) within a zone

Object position within a zone

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

30

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 31

3.10 Display and operating elements

1

2

3

3.10.1 Sender

The sender has three LEDs on its front. The LEDs are located on the connection side.

The section LED indicators and error indicators on page 116 explains the meaning of

the LED indicators.

PRODUCT DESCRIPTION 3

3.10.2 Receiver

Figure 17: LEDs on the sender

Yellow

1

Red

2

Green

3

LEDs

The receiver has three LEDs on its front and a control panel with LEDs and membrane

keys on its rear. The LEDs and the control panel are located on the connection side.

The section LED indicators and error indicators on page 116 explains the meaning of

the LED indicators.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

31

Page 32

1

4

2

3

3 PRODUCT DESCRIPTION

Figure 18: LEDs on the front side

Yellow

1

Red

2

Green

3

LEDs on the control panel

4

Control panel

Figure 19: Control panel of the MLG-2 Pro

The teach-in process for the MLG-2 can be started by pressing the Teach button.

The MLG-2 control panel can be locked to prevent incorrect operation. The lock can be

activated and deactivated via SOPAS ET, IO-Link, or via the pushbuttons on the control

panel.

32

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 33

Locking the control panel

Press the Teach (Set) pushbutton for 15 s.

b

✓

The control panel is locked; the configuration cannot be changed.

Disabling the lock

On the MLG-2 Pro, press the Teach button for 15 s.

b

✓

The lock is disabled again.

3.11 Inputs

3.11.1 Switching inputs on the MLG-2 Pro receiver

On the MLG-2 Pro, the switching inputs can be used for the following functions (see

"System settings for the EXPERT user level", page 65):

Teach-in

•

Standby

•

Activating or deactivating digital or analog outputs

•

Triggering RS485 data output

•

3.11.2 Test input on the sender

PRODUCT DESCRIPTION 3

The test input can be used to switch off the sender. This simulates a complete blocking

of the beams. This makes it possible to test the behavior of the switching or analog out‐

puts that have been configured accordingly.

3.12 Application examples

3.12.1 Application examples for the MLG2

The MLG-2 is suitable for complex applications including e. g. start and end detection,

detection of small or transparent objects, traffic applications, volume measurement, or

contour measurement.

Figure 20: Start and end detection Figure 21: Detection of transparent objects

Table 22: Application examples for the MLG-2

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

33

Page 34

3 PRODUCT DESCRIPTION

Figure 22: Detection of small objects Figure 23: Traffic applications

Figure 24: Volume measurement Figure 25: Contour measurement

Table 22: Application examples for the MLG-2

34

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 35

4 Mounting

4.1 Scope of delivery

1 × sender

1 × receiver

4/4 x QuickFix brackets

1 × Quick Start Guide

4.2 Recommended mounting arrangements

When several MLG-2s are mounted close to one another, there is a risk of mutual inter‐

ference. This is particularly likely if there are shiny surfaces nearby or if the objects

being detected are shiny.

Therefore, when mounting two MLG-2s close to one another, their light beams should

be oriented in opposite directions.

4.2.1 Mounting with light in opposite directions

2)

MOUNTING 4

Figure 26: Placement with light in opposite directions

Two MLG-2s, one behind the other

1

Two MLG-2s, one above the other

2

Two MLG-2s, one next to the other

3

2)

6 x QuickFix brackets for detection heights above 2 m.

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

35

Page 36

4 MOUNTING

NOTE

When two MLG-2s are placed opposite one another and their light beams are in oppo‐

site directions,1 reflections may occur from sender 1 to receiver 2 in the case of shiny

objects.

4.2.2 Mounting with light in the same direction

When several MLG-2s are mounted with their light beams oriented in the same direc‐

tion, a minimum distance must be maintained between the MLG-2s. The minimum dis‐

tance increases as the distance between the sender and receiver increases and is

dependent on the operating range.

Figure 27: Distances when light is in the same direction

X Operating range

Y Minimum distance of the MLG-2

Z Minimum distance of the MLG-2

36

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 37

MLG-2 with 2 m sensing range

0 mm

200 mm

400 mm

600 mm

800 mm

0.0 m 2.0 m 4.0 m 6.0 m 8.0 m

Y

XOperating range

Minimum distance

MLG-2 with 5 m and 8.5 m sensing range

MOUNTING

4

Figure 28: Graph, distances when light is in the same direction

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

37

Page 38

MLG-2 with 2 m sensing range

0 mm

0.0 m 2.0 m 4.0 m 6.0 m 8.0 m

Z

XOperating range

Minimum distance

MLG-2 with 5 m and 8.5 m sensing range

200 mm

400 mm

600 mm

800 mm

4 MOUNTING

Figure 29: Graph, distances when light is in the same direction (XZ)

4.2.3 Placement of two light grids at right angles

Light grids are placed at right angles for volume detection or operator guidance, for

example.

Figure 30: Placement of two light grids at right angles

38

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 39

Standby solution

MLG-2 with 2 m sensing range

2)

MLG-2 with 5 m sensing rangev

3)

MLG-2 with 8,5 m sensing range

3)

1)

Applies to reflective surfaces parallel to the housings.

2)

Applies to reflective surfaces perpendicular to the housings.

3)

Applies to reflective surfaces perpendicular and parallel to the housings.

MLG-2 with 2 m sensing range

1)

0 mm

0.0 m 2.0 m 4.0 m 6.0 m 8.0 m

X

Operating range

Minimum distance

200 mm

400 mm

500 mm

100 mm

300 mm

Y

Select the Standby function for both light grids (this function is set under the energysaving options in SOPAS ET). You should only ever activate one light grid at a time via

the relevant inputs.

Test inputs solution

Activate the test inputs of both senders alternately. The beams will be switched off in

each case for as long as the test input is active.

Mounting solution

Mount the two MLG-2 as far apart as possible.

4.2.4 Minimum distance from reflective surfaces

Reflective surfaces between the sender and receiver may result in disruptive reflections

and beams being deflected and, hence, result in a failure to detect objects.

In the case of reflective surfaces, a minimum distance must be maintained between

the reflective surface and the light beams to ensure reliable operation.

This minimum distance depends on the distance between sender and receiver and on

the operating range.

MOUNTING

4

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

Figure 31: Graph, minimum distance from reflective surfaces

39

Page 40

4 MOUNTING

This distance also applies to reflective surfaces located next to the light grid (parallel to

the sending/receiving axis).

4.3 Mounting procedure

Mount the sender and receiver at the same height. For minor adjustments when

b

aligning, the sender and receiver can be adjusted in the brackets.

If possible, mount the top bracket at a height such that the offset in the housing of

b

the MLG-2 sits on the bracket. This prevents the MLG-2 from sliding down.

Figure 32: The sender and receiver are aligned incorrectly

The end with the cable connection must point in the same direction for both devices.

Sender and receiver must not be installed at 180° rotated relative to each other.

Tighten the screws used to mount the bracket to a torque of 5 to 6 Nm. Tighten the

screws used to secure the MLG-2 in the bracket to a torque of 2.5 to 3 Nm. Higher tor‐

ques can damage the bracket while lower torques do not provide adequate fixation to

prevent the MLG-2 from moving in the event of vibrations.

When mounting, make sure that sender and receiver are aligned correctly. The optical

lens systems of sender and receiver must be located opposite one another. If neces‐

sary, use a water level to check the components are parallel.

4.3.1 Mounting the QuickFix bracket

QuickFix brackets can be mounted in two ways:

On the side

•

On the back

•

The two mounting surfaces for the brackets of the sender or receiver must not be

angled more than ±2° to each other. If this is not possible, use the optional FlexFix

bracket.

Mounting the QuickFix bracket on the side of a machine or profile frame

Up to a monitoring height of 2 m, the sender and receiver are mounted with two Quick‐

Fix brackets each.

40

For a monitoring height of more than 2 m, the sender and receiver are mounted with

three QuickFix brackets each.

O PE R AT I NG IN S TR U CT I ON S | MLG-2 Pro 8017460.ZIK1/2017-02-13 | SICK

Subject to change without notice

Page 41

MOUNTING 4

The QuickFix bracket consists of two parts, which are pushed into each other. An M5

screw is used to join both parts and to clamp the housing (sender or receiver).

Mounting can be carried out in two ways:

With the M5 screw through the QuickFix bracket to the machine or profile frame. A

•

screw nut or threaded hole is required on the machine or profile frame.

With the M5 screw through the machine or profile frame to the QuickFix bracket. A

•

screw nut is required for each QuickFix bracket.

When choosing the length of the M5 screw (hexagon head or cylinder head screw), con‐

sider the QuickFix bracket and the machine or profile frame.

CAUTION

Risk of injury from protruding screw thread!

When mounting through the machine or profile frame to the QuickFix bracket, the M5

screw can present an injury risk if too long.

Select an appropriate screw length to prevent any risk of injury from an overrun.

b

Figure 33: Mount QuickFix bracket to a profile frame

Mount QuickFix bracket to the back of a device column

NOTE

The QuickFix bracket has cable routing. Depending on the installation, the cable routing

can make mounting easier.

The sender and receiver are each mounted with two QuickFix brackets.

The QuickFix bracket consists of two parts, which are pushed into each other. An M5

screw is used to join both parts and to clamp the housing (sender or receiver).

You need two M5 screws per bracket if mounting them on the back.

Choose the length of the M5 screw such that it is possible to clamp the housing

b

(sender or receiver) in the QuickFix bracket.

4.3.2 Mounting the FlexFix bracket

In the FlexFix bracket, sender and receiver can be flexibly rotated by ±15°.

FlexFix brackets can be mounted in two ways:

On the side

•

On the back

•

8017460.ZIK1/2017-02-13 | SICK O P ER A TI N G I NS T RU C TI O NS | MLG-2 Pro

Subject to change without notice

41

Page 42

MOUNTING

4

Mounting the FlexFix bracket on a profile frame

The sender and receiver are mounted at the designated points using two FlexFix brack‐

ets in each case.

M5 screws are inserted through the FlexFix bracket and into the machine or profile

frame for mounting. A screw nut or threaded hole is required on the machine or profile

frame.

Figure 34: Mounting the FlexFix bracket on a profile frame

Screwing the sender or receiver into the FlexFix brackets

After mounting the FlexFix brackets, screw the sender or receiver into the FlexFix brack‐

ets from the front. Then align the sender and receiver.

NOTE

The MLG-2 can only be screwed in when both FlexFix brackets are in alignment. If nec‐

essary, use a water level to check the components are parallel.

42

Figure 35: Inserting the MLG-2 in the FlexFix brackets

Use an M5 screw to fix the position of the sender and receiver in the FlexFix

b

bracket.