Page 1

MLG-2

SICK Smart Sensors / IO-Link

Device configuration – Advanced operating instructions

T E C H N I C A L I N F O R M A T I O N

Page 2

Product described

IO Link – MLG2

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be reserved for SICK AG. Reproduc‐

tion of this document or parts of this document is only permissible within the limits of the legal determination of

Copyright Law. Any modification, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Purpose of this document........................................................................ 5

1.2 Intended use............................................................................................. 5

1.3 Symbols..................................................................................................... 5

2 Description of IO-Link....................................................................... 6

3 Accessories for visualization, configuration, and integration..... 7

4 Data repository.................................................................................. 8

5 Physical layer..................................................................................... 9

6 Process data...................................................................................... 10

6.1 PD in.......................................................................................................... 10

6.1.1 System and Q status + run length code (RLC)....................... 10

6.1.2 System and Q status + beam status...................................... 10

6.1.3 User-defined process data content........................................ 10

6.1.4 System status and output status............................................ 11

6.2 PD out........................................................................................................ 11

7 Service data....................................................................................... 12

7.1 Device identification................................................................................. 12

7.1.1 Product name and manufacturer name................................. 12

7.1.2 Product text and serial number.............................................. 12

7.1.3 Definable names..................................................................... 12

7.1.4 Hardware and firmware version.............................................. 13

7.1.5 Find me..................................................................................... 13

7.2 Teach-in / detection settings for MLG-2 devices.................................... 13

7.2.1 Teach-in and beam blanking via teach-in............................... 13

7.2.2 Beam blanking mask............................................................... 14

7.2.3 Definition of zones................................................................... 15

7.3 Performance options................................................................................ 15

7.4 Process data setting................................................................................. 17

7.5 Beam hold functions................................................................................ 19

7.6 Configuring outputs Q1 – Q4................................................................... 21

7.7 System settings......................................................................................... 22

7.8 Installation / Diagnostics......................................................................... 23

7.8.1 Process quality and teach quality........................................... 23

7.8.2 Device alignment..................................................................... 23

7.8.3 Device properties..................................................................... 24

7.8.4 Diagnostics............................................................................... 24

8 Events.................................................................................................. 25

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

3

Page 4

CONTENTS

9 Use cases............................................................................................ 26

10 List of abbreviations.......................................................................... 30

11 Index.................................................................................................... 31

4

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 5

ABOUT THIS DOCUMENT 1

1 About this document

1.1 Purpose of this document

The ISDU descriptions in this document apply to IO-Link-enabled photoelectric sensors (Smart Sensors) with the

following principle of operation: MLG-2.

In some cases, functions may be described in this document which are not supported by individual sensors. The

functions in question are marked accordingly (see "Symbols", page 5).

The specific functional scope of an individual sensor is described in full in the Supplement to operating instructions on

the relevant product page under www.sick.com.

1.2 Intended use

Use IO-Link only as described in this documentation.

1.3 Symbols

NOTICE

This symbol indicates important information.

NOTE

This symbol provides additional information, e.g., dependencies / interactions between the described function and

other functions, or when individual functions are not supported by every sensor.

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

5

Page 6

DESCRIPTION OF IO-LINK

2

2 Description of IO-Link

IO-Link and control integration

IO-Link is a non-proprietary internationally standardized communication technology, which makes it possible to

communicate with sensors and actuators in industrial environments (IEC 61131-9).

IO-Link devices communicate with higher-level control systems via an IO-Link master. The IO-Link devices (slaves)

are connected to these via a point-to-point connection.

Different variants of IO-Link master are available. In most cases, they are remote fieldbus gateways or input cards

for the backplane bus of the control used.

To make it possible for an IO-Link sensor to communicate with the control, both the IO-Link master and the

IO-Link sensor must be integrated in the hardware configuration in the control manufacturer’s Engineering Tool.

To simplify the integration process, SICK provides sensor-specific device description files (IODD = IO-Link Device

Description) for IO-Link devices.

You can download these device description files free of charge: www.sick.com/[device-part number].

Not all control system manufacturers support the use of IODDs. If third-party IO-Link masters are used, it is possi‐

ble to integrate the IO-Link sensor by manually entering the relevant sensor parameters directly during the hard‐

ware configuration.

To ensure that the IO-Link sensor can be easily integrated into the control program, SICK also provides function

blocks for many control systems. These function blocks make it easier to read and write the individual

sensor parameters, for example, and provide support when it comes to interpreting the process data supplied by

the IO-Link sensor. You can also download them free of charge from the homepage: www.sick.com/[device-part

number].

On SICK’s YouTube channel, you can find some tutorials, which will help you to integrate SICK IO-Link masters:

www.youtube.com/SICKSensors.

If you have any questions, SICK’s Technical Support is available to help all over the world.

6

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 7

ACCESSORIES FOR VISUALIZATION, CONFIGURATION, AND INTEGRATION 3

3 Accessories for visualization, configuration, and integration

Using the , you can easily connect IO-Link sensors from SICK to a PC or a laptop via USB. You can then quickly and

easily test or configure the connected sensors using the SOPAS ET program (SICK Engineering Tool with graphic

user navigation and convenient visualization).

The corresponding visualization files (SDD = SOPAS Device Description) are available for many devices so that you

can operate the IO-Link sensors using SOPAS ET.

You can download SOPAS ET and the device-specific SDDs directly and free of charge from the SICK homepage:

www.sick.com.

Various IO-Link masters are available from SICK for integrating IO-Link masters using fieldbus. For more details,

see: www.sick.com.

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

7

Page 8

4 DATA REPOSITORY

4 Data repository

When the current IO-Link standard V1.1 was introduced, the automatic data repository (Data Storage) was added

to IO-Link’s range of functions. The data repository allows the machine operator to replace defective IO-Link

devices with corresponding replacement devices without having to reconfigure these manually.

When the data repository is activated, the IO-Link 1.1 master always saves the last valid setting parameters of all

connected IO-Link 1.1 devices in its local memory. If you replace one of the connected IO-Link devices with

another device which is compatible with the function, the IO-Link master will transfer the last valid parameter set

of the previous sensor to the new sensor automatically.

The data repository therefore means that devices can be replaced in a plug-and-play manner within a matter of

seconds – without complex reconfiguration, special hardware or software tools, and specific specialist knowledge.

NOTE

To use the data repository, you must activate it in the IO-Link master.

•

When the conversion of one or several sensor parameters is initiated via the control, then the control must

•

activate the Data Storage Upload Request-Flag as the final command in the sensor. Only this initiates the data

repository.

Uploading / downloading sensor parameters using the data repository function can take between a few hun‐

•

dred milliseconds and three seconds depending on the volume of data and the IO-Link master used (typical

values; values can differ in practice).

For details on using the data repository, see IO-Link Interface and System Specification, V1.1.2, chapter 10.4

•

Data Storage (DS) at www.io-link.com, Downloads menu item.

8

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 9

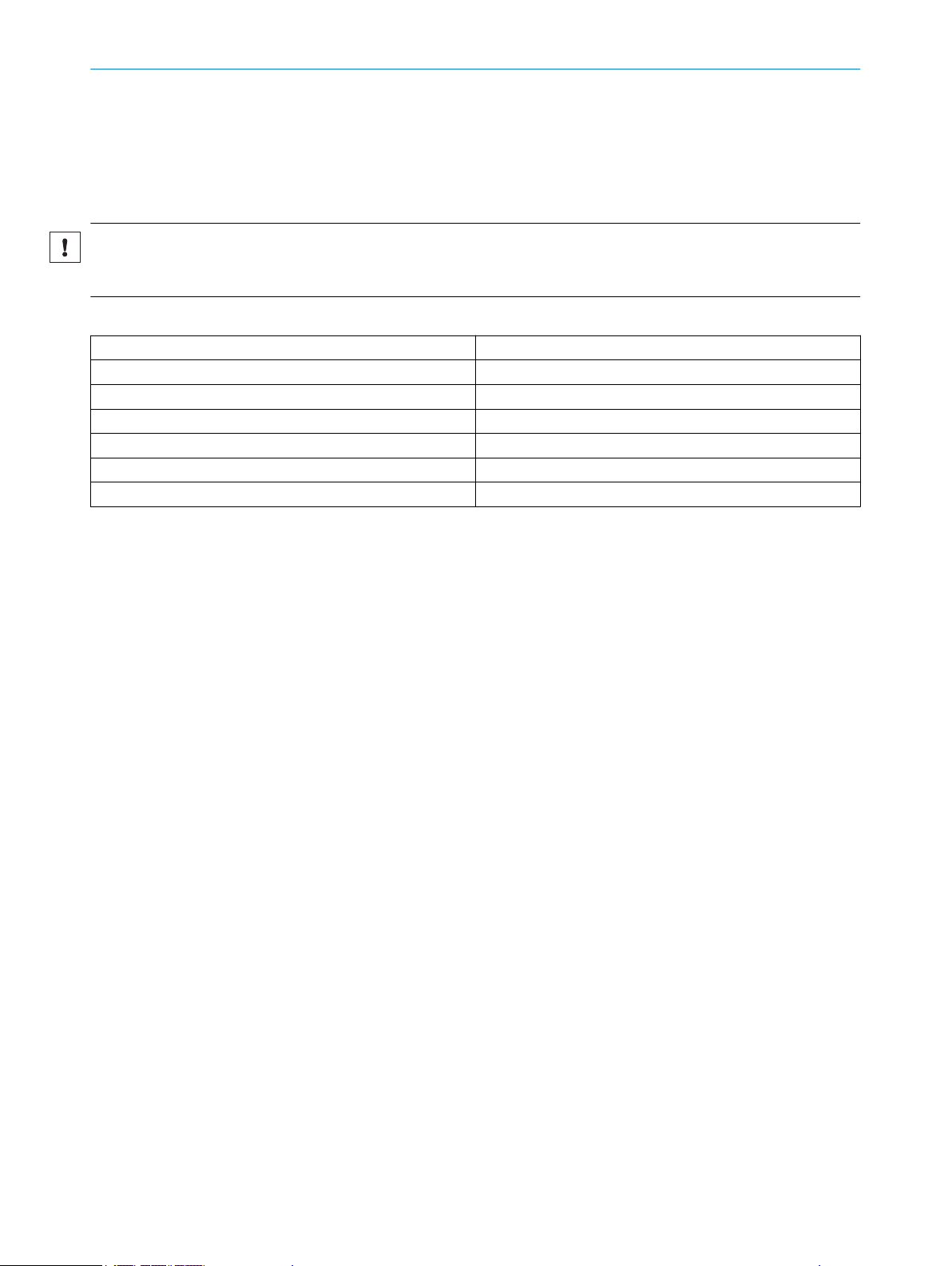

PHYSICAL LAYER 5

5 Physical layer

The physical layer describes the basic IO-Link device data (see table below). The device data is automatically

shared with the IO-Link master. It is important to ensure that the used IO-Link master supports this performance

data.

NOTICE

The maximum current consumption of the IO-Link sensor (including load at the outputs) must not exceed the per‐

missible output current of the relevant port on the IO-Link master.

Table 1: Physical layer – IO-Link device data

SIO mode Yes

Min. cycle time 3 ms

Baud rate COM 3 (230.4 kbit/s)

Process data length PD in (from device to master) 32 bytes

Process data length PD out (from master to device) 1 byte

IODD version V1.0.1

Supported IO-Link version IO-Link V1.1

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

9

Page 10

6 PROCESS DATA

6 Process data

Process data is transmitted cyclically. There is no confirmation of receipt.

The master determines the cycle time; however, this must not be less than the minimum cycle time of the sensor

(see table 1, page 9).

Note: The service data (acyclic data) does not influence the cycle time.

There is PD-in and PD-out data:

PD in

•

Data from the IO-Link sensor to the IO-Link master – the current status of the sensor is displayed as quickly

as possible (incoming process data).

PD out

•

Commands from the IO-Link master to the IO-Link sensor – for the quickest possible transmission of system

commands (outgoing process data).

6.1

PD in

The PD-in process data, which is transmitted cyclically from the MLG-2 to the IO-Link master, can be configured

depending on the application. 3 different types of data content can be selected using ISDU 120.

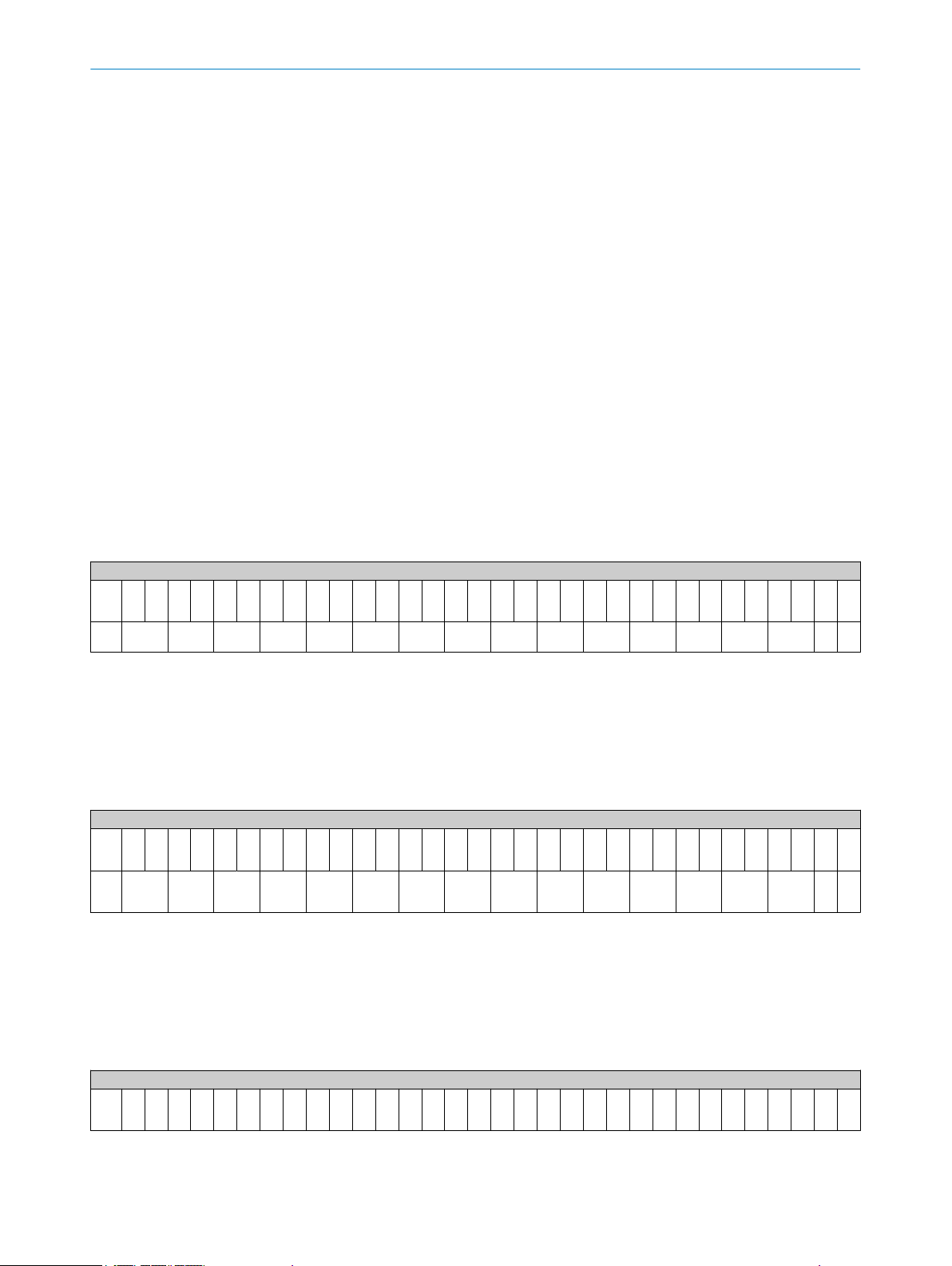

6.1.1 System and Q status + run length code (RLC)

Table 2: Process data selection, can be set using ISDU 120; value 0

System and Q status + run length code (RLC)

Byte

Off‐

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

set

RLC 15 RLC 14 RLC 13 RLC 12 RLC 11 RLC 10 RLC 9 RLC 8 RLC 7 RLC 6 RLC 5 RLC 4 RLC 3 RLC 2 RLC 1

1

SS = system status (description: see table 5)

2

AS = output status (description: see table 5)

SS1AS

6.1.2 System and Q status + beam status

Process data selection, can be set using ISDU 120; value 1

Table 3: Process data selection, can be set using ISDU 120; value 1

System and Q status + beam status

Byte

off‐

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

set

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

beam

225 ...

209 ...

224

193 ...

240

1

SS = system status (description: see table 5)

2

AS = output status (description: see table 5)

208

177

192

161 ...

176

145 ...

160

129 ...

144

113 ...

128

97 ...

112

81 ...

96

65 ...

80

49 ...

64

33 ...

48

17 ...

32

1 ...

16

SS1AS

2

2

6.1.3 User-defined process data content

Process data selection, can be set using ISDU 120; value 2

Table 4: Process data selection, can be set using ISDU 120; value 2

User-defined process data

Byte

off‐

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

set

10

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 11

PROCESS DATA 6

User-defined process data

pre‐

no func‐

no func‐

no func‐

no func‐

no func‐

no func‐

no func‐

no func‐

no func‐

set‐

tion

tion

tion

ting

1

SS = system status (description: see table 5)

2

AS = output status (description: see table 5)

tion

tion

tion

tion

tion

tion

no func‐

tion

IDI ODI FBB LBB NBB

6.1.4 System status and output status

Table 5: Description of system status and output status

System status (HIGH byte) Output status (LOW byte)

Bit

offset

1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Hard‐

Sync

error

Teach

fail

Contami‐

ware

error

0 = False, 1 = True 0 = OFF, 1 = ON

nation

alarm

Teach

active

Q1 ... Q4 outputs can be configured using ISDU 183 ... 186

Over-

tempera‐

ture

Process

data

invalid

Q

short-cir‐

not used not used not used not used Q4 Q3 Q2 Q1

cuit

1

6.2 PD out

Using the PD-out process data, control commands can be sent cyclically from the IO-Link master to the MLG-2.

Outgoing process data, control byte

Bit

offset

7 6 5 4 3 2 1 0

Test Teach-in BBH Reserved STANDBY Reserved

SS1AS

2

TEST Switch off all sender LEDs.

Used to force a reaction from the receiver and therefore test for correct functionality.

Teach-in Used primarily to set the transmitting power and switching threshold for all light beams to the cur‐

rent installation situation / sensing range. Same functionality as for service data -see "PD out",

page 11.

BBH Block beams hold: All blocked beams are held.

This function is only effective if the BBH function has been activated via the service data - see

"Beam hold functions", page 19.

STANDBY

Switches the MLG-2 into the energy-saving sleep mode. Same as ISDU 75 - see "Performance

options", page 15.

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

11

Page 12

7 SERVICE DATA

7 Service data

Service data is only exchanged between the control and IO-Link sensor via the IO-Link master on request by the

control (acyclically). The service data is designated as ISDUs. Using an ISDU, you can change the configuration or

read out information about the status of the sensor.

The respective counterpart confirms receipt of the data.

If the sensor does not answer within five seconds, the master reports a communication error.

7.1 Device identification

7.1.1 Product name and manufacturer name

Table 6: Device identification

ISDU

DEC HEX

16

10

18

12 Product name - 18 bytes

219

DB

1)

ro = Read only

rw = Read/write

wo = Write only

Name Data type

Subindex

Vendor name

-

1 Product ID system

2 Product ID receiver - 7 bytes 2xxxxxx Order no. Receiver

String

Record

Data reposi‐

tory

- 32 bytes

- 7 bytes 1xxxxxx

Length Access

ro

Default

value

SICK AG

MLGXXAXXXXXXXXX

1)

Value/rangeIndex

Order no. System, consisting of system &

receiver

The Product ID is also the part number of the connected IO-Link device.

To make it possible to provide a family IODD for a device family, the Product ID can be found under Device identifica‐

tion (ISDU 219) for SICK IO-Link devices.

Furthermore, the part numbers for the components associated with the system are filed in sub-index 2…x for sen‐

sors (e.g., a light grid).

7.1.2 Product text and serial number

Table 7: Device identification – Product text / serial number

ISDU

Name Data type

Sub-

DEC HEX

20

21

index

14

15 Serial number 8 bytes

Product text

-

String -

Data reposi‐

tory

Length Access

64 bytes

ro

Default

value

MLG-2 Pro

Value/rangeIndex

Format of the serial number:

YYWWnnnn (Y = year, W = week, n = sequential numbering)

7.1.3 Definable names

Table 8: Device identification – Specific tag / name

ISDU

Name Data type

Sub-

DEC HEX

24

64

index

18 - Application-specific tag

40 - Device-specific name no

String

Data reposi‐

tory

yes

Length Access

32 bytes rw

Default

value

Value/rangeIndex

In Application-specific tag, you can write any text with a maximum of 32 characters. This can be useful for describing

the exact position or task of the sensor in the overall machine. The Application-specific tag is saved via the Data repos‐

itory.

In Device-specific name, you can also write any text with a maximum of 32 characters. This name is NOT saved via

the Data repository and is therefore available for information which is valid temporarily or for information which is

only applicable to this sensor.

12

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 13

SERVICE DATA 7

7.1.4 Hardware and firmware version

Table 9: Device identification – Version

ISDU

Name Data type

Sub-

DEC HEX

22

23

index

16

17 Firmware version 12 bytes Vxxx.xxx.xxx

-

Hardware version

String -

This ISDU indicates the hardware and software versions.

7.1.5 Find me

Table 10: Device identification – Find me

ISDU

Name Data type

Sub-

DEC HEX

204

index

CC - Find me UInt no 8 bits rw 0

The sensor can be uniquely identified using Find me. For machines with several identical sensors, it is therefore

possible to uniquely identify the device with which communication is currently taking place.

When Find me is activated, the yellow indicator LED of the sensor flashes at 1 Hz.

Data reposi‐

tory

Data reposi‐

tory

Length Access

4 bytes

Length Access

ro

Default

value

xxxx

Default

value

Value/rangeIndex

Value/rangeIndex

0 = Find me deactivated

1 = Find me activated

To identify the switching output (pin 2) in the control cabinet, you can also activate or deactivate the digital output

at pin 2 by writing the value 16.

NOTICE

Observe the effect of the output activation and deactivation on the connected system.

7.2 Teach-in / detection settings for MLG-2 devices

7.2.1 Teach-in and beam blanking via teach-in

Table 11: Teach-in / detection – Teach-in

ISDU

DEC HEX

2

02

98

62

70

46

188

BC

189

BD

Subindex

-

Name

System

command

Teach

result

Blanking

teach

enable

Blank all

currently

blocked

beams

Blank all

currently

made

beams

Data

type

UInt

Data

reposi‐

tory

-

yes

-

Acc-

Length

8 bits

Default

ess

value

wo 160 = Teach-in

ro

0

rw

wo 1 = Execute

wo 1 = Execute

Value/rangeIndex

Bit no.

7 6 5 4 3 2 1 0

AutoTeach

not possi‐

ble

0 = False

1 = True

0 = Blanking teach inactive

1 = Blanking teach active

Teach-in

failure,

beam

blanking

Highspeed

mode not

possible

Teach-in

failure,

crossbeam

mode

Warning,

beam sig‐

nal over‐

drive

Teach-in

failure,

low beam

signal

Teach-in

failure,

parallel

beam

mode

Teach-in

failure,

general

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

13

Page 14

SERVICE DATA

7

2 Setting the command value 160 triggers a teach-in.

As a result, the relevant switching thresholds are assigned to all light

beams and with senders, the appropriate transmitting power for the sens‐

ing range is set.

For a successful teach-in, the light path for all light beams must be free

(exception: Blank teach-in active).

For further options, see ISDU 70.

98 For diagnostic purposes, it is possible to read out whether the teach-in

was successful in this ISDU.

In addition, the bits indicate the causes of a possible error during the

teach-in.

70 This ISDU specifies whether blocked light beams are blanked by the light

grid during teach-in via the system command with value 160 (see above).

This is then useful, for example, when machine parts permanently project

into the detection zone.

Note:

When this function is active, teach-in errors can no longer be signaled. If,

for example, a detection object has been unintentionally left in the beam

path during a teach-in, all light beams blocked by this are blanked without

warning as a result.

188 With this ISDU, the currently blocked beams can be blanked immediately;

the set switching thresholds remain unchanged.

Unlike the Blank teach-in option, this happens directly – without a teach-in

system command – and just once in ISDU 70.

189 With this ISDU, the currently free beams can be blanked immediately; the

set switching thresholds remain unchanged.

Unlike the Blank teach-in option, this happens directly – without a teach-in

system command – and just once in ISDU 70.

7.2.2 Beam blanking mask

Table 12: Teach-in / detection – Beam blanking mask

ISDU

Name Data type

Sub-

48 -

index

Beam blanking mask

Beam 1 … 32

Beam 33 ... 64

Beam 65 ... 96 416 bits FFFFFFFF

Beam 97 ... 128 384 bits FFFFFFFF

Beam 129 ... 160 352 bits FFFFFFFF

Beam 161 ... 192 320 bits FFFFFFFF

Beam 193 ... 224 288 bits FFFFFFFF

Beam 225 ... 256 256 bits FFFFFFFF

Beam 257 ... 288 224 bits FFFFFFFF

Beam 289 ... 320 192 bits FFFFFFFF

Beam 321 ... 352 160 bits FFFFFFFF

Beam 353 ... 384 128 bits FFFFFFFF

Beam 385 ... 416 96 bits FFFFFFFF

Beam 417 ... 448 64 bits FFFFFFFF

Beam 449 ... 480 32 bits FFFFFFFF

Beam 481 ... 512 0 bits FFFFFFFF

1)

DEC HEX

72

1)

Freely adjustable bit mask for blanking light beams

Record yes 64 bytes rw

Offset -

Data reposi‐

tory

Length Access Default value Value/rangeIndex

480 bits

448 bits FFFFFFFF

FFFFFFFF

0 = Beam inactive

1 = Beam active

Using the beam blanking mask, you can manually blank any light beams (without teach-in).

This is done using binary-coded beam masks.

The beam mask contains a unique 64-byte string 0xFF FF FF FF ... by default, i.e., all light beams are active.

The actual number of beams of the MLG-2 must be observed.

14

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 15

7.2.3 Definition of zones

Table 13: Teach-in / detection – Definition of zones

ISDU

Name Data type

Sub-

DEC HEX

207

208

209

210

index

0CF Zone 1 Record

1

Lower limit

2 Upper limit 1 … 510 = Upper limit zone 1

0D0 Zone 2 Record 32 bits

1 Lower limit

2 Upper limit 1 … 510 = Upper limit zone 2

0D1 Zone 3 Record 32 bits

1 Lower limit

2 Upper limit 1 … 510 = Upper limit zone 3

0D2 Zone 4 Record 32 bits

1 Lower limit

2 Upper limit 1 … 510 = Upper limit zone 4

Data reposi‐

tory

yes

Length Access

32 bits

16 bits 1

16 bits 1

16 bits 1

16 bits 1

207 – 210 These ISDUs allow you to define 4 zones within the MLG-2.

Every zone can be individually assigned with beam functions (see ISDU 67).

For each zone, the upper and lower limit must be specified in beam numbers.

SERVICE DATA 7

Default

value

rw

Value/rangeIndex

1 … 510 = Lower limit zone 1

1 … 510 = Lower limit zone 2

1 … 510 = Lower limit zone 3

1 … 510 = Lower limit zone 4

7.3 Performance options

Table 14: Performance options

ISDU

Name Data type

Sub-

DEC HEX

65

66

68

75

206

index

41

42 Performance options

44 Transparent mode

4B Standby 0

CE Cross-beam measuring 1 bit False

Device mode

-

Data reposi‐

tory

UInt yes

Length Access

8 bits

rw

Default

value

0

Value/rangeIndex

0 = Standard mode

1 = Transparent mode

2 = Sunlight-resistant mode

0 = Standard resolution

1 = High resolution

2 = High operating reserve

3 = Cross-beam mode

4 = Cross-beam mode with high operating

reserve

5 = High-speed scan

6 = High-speed scan with high resolution

7 = High-speed scan with high operating

reserve

0 = Attenuation 30%

1 = Attenuation 15%

2 = Attenuation 10%

0 = Standby inactive

1 = Standby active

False = Cross-beam measuring inactive

True = Cross-beam measuring active

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

15

Page 16

7 SERVICE DATA

65 MLG-2 operating mode selection:

Standard mode Reliable operating mode with normal operating reserve.

Suitable for most applications.

Transparent mode Suitable for detecting transparent objects. The required minimum attenuation

of the object to be recorded can be set via ISDU 68.

In Transparent mode, process quality (ISDU 225) is not available.

Transparent mode is only available together with Standard measurement accuracy

(ISDU 66, value 0).

Sunlight-resistant mode Operating mode to prevent faults due to sunlight shining directly into the

receiver.

Dust and sunlight-resistant operating mode reduces the maximum sensing

range.

– To 1.2 m for devices with a 2 m operating range

– To 3 m for devices with a 5 m operating range

– To 5 m for devices with an 8.5 m operating range

This operating mode can only be configured on an MLG-2 with fewer than 240

beams.

66 It is possible to choose between different beam analysis methods for the “Normal” and “Sunlight-resis‐

tant” operating modes via the performance options:

Standard measurement accu‐

racy

High measurement accuracy For applications in a clean environment.

High operating reserve Maximum transmitting power.

Cross-beam mode The cross-beam function increases the measurement accuracy and enables

High-speed scan The High-speed scan reduces the scan time by a variable factor.

68 Selection of the suitable setting for objects with different transparency.

Only effective in conjunction with the “Transparent” operating mode.

The object to be detected must dim the infrared light of the MLG-2 by at least the specified percentage in

order to be detected.

In addition, observe the dependency of the minimum attenuation via the sensing range. See operating

instructions, chapter 13.2.5.

75 Standby mode is suitable for longer operating breaks.

The MLG-2 is in the energy-saving sleep mode here.

No measurements are possible in this mode.

Alternatively, Standby mode can also be controlled via an external input.

206 Only effective in the middle position between the sender and receiver. Cross-beam measuring is suitable

for measurement functions, such as height measurement.

With this function, a group of crossed beams is combined into a single virtual beam. The real and virtual

beams are renumbered and, as a result, the number of beams is nearly doubled.

This function is only effective if Cross-beam mode is active (see ISDU 66).

The response time of the MLG-2 doubles.

Reliable operating mode.

Requires 3/4 beam coverage to detect a beam as blocked.

Process quality not available.

Requires 1/2 beam coverage to detect a beam as blocked.

For applications in a dirty environment or for applications in which semi-trans‐

parent films (with short sensing range) need to be penetrated.

Requires full beam coverage to detect a beam as blocked.

the detection of smaller objects.

A sender LED projects beams to several receiver diodes. For further details,

see operating instructions, chapter 3.6.3.

Several light beams are active in each cycle. Operating mode is only effective

after teach-in via system command or teach key.

For further details, see operating instructions, chapter 3.5.3.

16

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 17

SERVICE DATA 7

7.4 Process data setting

In the following section, the process data, which is required for the application and is described under chapter 6.1,

can be set.

Table 15: Process data

ISDU

Index Sub-

DEC HEX

120

67

inde

x

78

43

-

Name

Process data select UInt

Process data user def‐

inition

User-defined output

function 1

User-defined output

function 2

User-defined output

function 3

User-defined output

function 4

User-defined output

function 5

User-defined output

function 6

User-defined output

function 7

User-defined output

function 8

User-defined output

function 9

User-defined output

function 10

User-defined output

function 11

User-defined output

function 12

User-defined output

function 13

User-defined output

function 14

User-defined output

function 15

User-defined output

function 16

Data

type

Record

Offset

Data

repo

Length

sitor

y

8 bits

yes

16 byt

es

120 bi

ts

112 bi

ts

104 bi

ts

96 bits 20

88 bits 28

80 bits 29

72 bits 0

64 bits 0

56 bits 0

48 bits 0

40 bits 0

32 bits 0

24 bits 0

16 bits 0

8 bits 0

0 bits 0

Acce

ss

rw

Defa

ult

Value/range

valu

e

0 = System status, Q status, and run length code

0

1 = System status, Q status, and beam status (for value 1 max. no. of beams = 240)

2 = User-defined process data

0 = No function

20

1 = RLC 1 – 1st value of the run length code

2 = RLC 2 – 2nd value of the run length code

18

3 = RLC 3 – 3rd value of the run length code

4 = RLC 4 – 4th value of the run length code

22

5 = RLC 5 – 5th value of the run length code

6 = RLC 6 – 6th value of the run length code

7 = RLC 7 – 7th value of the run length code

8 = RLC 8 – 8th value of the run length code

9 = RLC 9 – 9th value of the run length code

10 = RLC 10 – 10th value of the run length code

11 = RLC 11 – 11th value of the run length code

12 = RLC 12 – 12th value of the run length code

13 = RLC 13 – 13th value of the run length code

14 = RLC 14 – 14th value of the run length code

15 = RLC 15 – 15th value of the run length code

16 = RLC 16 – 16th value of the run length code

17 = System status (high byte) and Q status (low

byte)

18 = Number of beams blocked

19 = Number of beams made

20 = First beam blocked

21 = First beam made

22 = Last beam blocked

23 = Last beam made

24 = Number of consecutive beams blocked

25 = Number of consecutive beams made

26 = Central beam blocked

27 = Central beam made

28 = Outside dimension

29 = Inside dimension

30 = Virtual outputs (VQs)

31 = Teach quality

32 = Process quality

33 = Data update counter

Selection of beam functions, zone 1

34 = NBB Z1 – Number of beams blocked,

zone 1

35 = FBB Z1 – First beam blocked, zone 1

36 = LBB Z1 – Last beam blocked, zone 1

37 = NCBB Z1 – Number of consecutive

beams blocked, zone 1

38 = CBB Z1 – Central beam blocked, zone 1

Selection of beam functions, zone 2

39 = NBB Z2 – Number of beams blocked,

zone 2

40 = FBB Z2 – First beam blocked, zone 2

41 = LBB Z2 – Last beam blocked, zone 2

42 = NCBB Z2 – Number of consecutive

beams blocked, zone 2

43 = CBB Z2 – Central beam blocked, zone 2

Selection of beam functions, zone 3

44 = NBB Z3 – Number of beams blocked,

zone 3

45 = FBB Z3 – First beam blocked, zone 3

46 = LBB Z3 – Last beam blocked, zone 3

47 = NCBB Z3 – Number of consecutive

beams blocked, zone 3

48 = CBB Z3 – Central beam blocked, zone 3

Selection of beam functions, zone 4

49 = NBB Z4 – Number of beams blocked,

zone 4

50 = FBB Z4 – First beam blocked, zone 4

51 = LBB Z4 – Last beam blocked, zone 4

52 = NCBB Z4 – Number of consecutive

beams blocked, zone 4

53 = CBB Z4 – Central beam blocked, zone 4

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

17

Page 18

7 SERVICE DATA

120 The 32-byte process data of the MLG-2 can be assigned different functions in

accordance with the application.

You can choose between fixed pre-assignment (value 0 or 1) or individual selec‐

tion (see ISDU 67).

Value 0 System status, Q status and Run length code:

Pre-assignment with RLC for flexible applications.

For further details, see operating instructions, chapter 3.9.1.

Example: see "Use cases", page 26.

Value 1 System status, Q status and Beam status:

Binary-coded output of the beam status:

0 = Beam made

1 = Beam blocked

This function is limited to 240 beams.

Value 3 Freely defined process data:

Individual selection from all available functions.

You must make the selection using ISDU 67.

67 The content of the freely definable process data is determined using this ISDU.

Each selectable function is 2 bytes in size.

16 different functions can be mapped on the process data via sub-index 1 ... 16.

18

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 19

7.5 Beam hold functions

Table 16: Beam functions

ISDU

Name

Sub-

DEC HEX

272

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

index

110

100 Beam hold function – NBB

101 Beam hold function – NBM

102 Beam hold function – FBB

103 Beam hold function – FBM

104 Beam hold function – LBB

105 Beam hold function – LBM

106 Beam hold function – NCBB & CBB

107

108 Beam hold function – ODI

109 Beam hold function – IDI

10A Beam hold function – RLC

10B Beam hold function – BS

10C

10D Beam hold selection for zone – FBB Record 8 bits

10E Beam hold selection for zone – LBB Record 8 bits

10F

Selection for beams hold mode

-

Beam hold function – NCBM &

CBM

Beam hold selection for zone –

NBB

1 Beam hold function zone 1 – NBB

2 Beam hold function zone 2 – NBB Activation for zone 2

3 Beam hold function zone 3 – NBB Activation for zone 3

4 Beam hold function zone 4 – NBB Activation for zone 4

1 Beam hold function zone 1 – FBB

2 Beam hold function zone 2 – FBB Activation for zone 2

3 Beam hold function zone 3 – FBB Activation for zone 3

4 Beam hold function zone 4 – FBB Activation for zone 4

1 Beam hold function zone 1 – LBB

2 Beam hold function zone 2 – LBB Activation for zone 2

3 Beam hold function zone 3 – LBB Activation for zone 3

4 Beam hold function zone 4 – LBB Activation for zone 4

Beam hold selection for zone –

NCBB/CBB

Beam hold function zone 1 –

1

NCBB/CBB

Beam hold function zone 2 –

2

NCBB/CBB

Beam hold function zone 3 –

3

NCBB/CBB

Beam hold function zone 4 –

4

NCBB/CBB

Data

type

UInt

Bool 1 bit False

Record

Record 8 bits

SERVICE DATA 7

Data

repo

sitor

y

yes

AccessDefault

Length

8 bits

8 bits Number of beams blocked for zones

rw

1 bit False

1 bit False

1 bit False

1 bit False

Value/range MeaningIndex

value

0 = None

0

1 = Blocked beams hold BBH

2 = Lost beams hold LBH

False = Inactive

True = Active

False = Inactive

True = Active

False = Inactive

True = Active

False = Inactive

True = Active

False = Inactive

True = Active

Selection for 2 different beam hold func‐

tions BBH = trigger via control byte (PD

out)

Activation for NBB = Number of beams

blocked

Activation for NBM = Number of beams

made

Activation for FBB = First beams blocked

Activation for FBM = First beams made

Activation for LBB = Last beams blocked

Activation for LBM = Last beams made

Activation for NCBB & CBB = Number of

consecutive beams blocked & central

beams blocked

Activation for NCBM & CBM = Number of

consecutive beams made & central

beams made

Activation for ODI = Outside dimension

Activation for IDI = Inside dimension

Activation for RLC = Run length code

Activation for BS = Beam status

Activation for zone 1

First beam blocked for zones

Activation for zone 1

Last beam blocked for zones

Activation for zone 1

Number of consecutive beams blocked

and central beam blocked for zones

Activation for zone 1

Activation for zone 2

Activation for zone 3

Activation for zone 4

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

19

Page 20

7 SERVICE DATA

272 The MLG-2 can save the state of blocked beams. The following two hold func‐

tions can be selected:

BBH BBH (Blocked beams hold) can be used to measure the height of items

which pass through the light grid, for example.

For this, BBH is started before the detection item enters (via input or

PD out).

Once the detection item has passed through, the corresponding func‐

tion (for height measurement, e.g., LBB) is read out and BBH is deacti‐

vated again.

All blocked beams are held.

This function can be started and ended in 2 ways.

Either via an external input – assigned with BBH function

•

Or via the PD-out control byte by setting / resetting bit 5 (see PD

•

out).

The functions, on which BBH is to work, must be defined in ISDUs 256

to 267.

Furthermore, you can specify the zones (see Definition of zones) for

which BBH is to work (ISDUs 268 to 271).

For further details, see operating instructions, chapter 7.11.1.

LBH The LBH (Lost beams hold) function works by holding the last beam

when an object leaves the last / the only remaining active light beam.

As a result, the last blocked beam is always marked as blocked until a

new beam is blocked.

Unlike BBH, the LBH function is effective globally on all beam func‐

tions. Example: see "Use cases", page 26.

256 –

267

268 –

271

Selection of the beam function on which the BBH function is to work.

Selection of the zones on which the BBH function is to work.

20

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 21

7.6 Configuring outputs Q1 – Q4

Table 17: Configuring the outputs

ISDU

Name

Sub-

DEC HEX

183

184

185

186

160

161

162

163

164

index

B7 Output 1 (Q1) configuration Record

1 Operand 1

2 Operator 16 bits

3 Operand 2 0 bits 0 ... 510

B8 Output 2 (Q2) configuration Record

1 Operand 1

2 Operator 16 bits

3 Operand 2 0 bits 0 … 510

B9 Output 3 (Q3) configuration Record

1 Operand 1

2 Operator 16 bits

3 Operand 2 0 bits 0 … 510

BA Output 4 (Q4) configuration Record

1 Operand 1

2 Operator 16 bits

3 Operand 2 0 bits 0 … 510

A0 Q1 – Minimum pulse width

A1 Q2 – Minimum pulse width

A2 Q3 – Minimum pulse width

A3 Q4 – Minimum pulse width

A4

Q5 ... Q16 – Minimum

pulse width

Data

Data

repo

type

Offset

Offset

Offset

Offset

UInt 16 bits rw 0 0 ms … 65535 ms

Length

sitor

y

4 byte

s

24 bits

4 byte

s

24 bits 0 … 32 equal to Q1 configuration

Yes

4 byte

s

24 bits 0 … 32 equal to Q1 configuration

4 byte

s

24 bits 0 … 32 equal to Q1 configuration

AccessDefault

value

rw

rw

1

rw

rw

SERVICE DATA 7

Value/rangeIndex

0 = NBB – Number of beams blocked

1 = NBM – Number of beams made

2 = FBB – First beam blocked

3 = FBM – First beam made

4 = LBB – Last beam blocked

5 = LBM – Last beam made

6 = NCBB – Number of consecutive beams blocked

7 = NCBM – Number of consecutive beams made

8 = CBB – Central beam blocked

9 = CBM – Central beam made

10 = ODI – Outside dimension

11 = IDI – Inside dimension

12 = BNB – Beam n blocked

13 = BNM – Beam n made

14 = ALARM – As configured by SOPAS

15 = Process quality

16 = Teach quality

17 … 32 = RLC 1 … 16 = 1st to 16th value of the run length code

0 = == (equal)

1 = >= (greater or equal)

2 = <= (less or equal)

3 = != (not equal)

0 = == (equal)

1 = >= (greater or equal)

2 = <= (less or equal)

3 = != (not equal)

0 = == (equal)

1 = >= (greater or equal)

2 = <= (less or equal)

3 = != (not equal)

0 = == (equal)

1 = >= (greater or equal)

2 = <= (less or equal)

3 = != (not equal)

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

21

Page 22

7 SERVICE DATA

183 –

186

160 –

164

7.7 System settings

Table 18: System settings

ISDU

Name Data type

Sub-

DEC HEX

81

74

2

12

121

122

index

51

4A Beam numeration

02 System command

0C Data Storage lock

79 PIN2 configuration

7A PIN5 configuration

Key lock

-

These ISDUs configure switching outputs Q1 to Q4. Each switching output is

set depending on a beam function, which is to be selected and which is com‐

pared to an operator and a reference value.

For each switching output, the identical beam functions and comparison oper‐

ators are available.

If a switching output is to switch in the event of a certain beam being blocked

(BNB function), the operator selection will not play any role. The “Equal” con‐

nection is always used.

This also applies to the BNM function.

If the switching signal is too short to be registered by a programmable logic

controller:

A pulse extension can be assigned to every switching output (including virtual

outputs Q5 to Q16, which can only be configured using the SOPAS ET soft‐

ware).

The pulse extension only works when the object detection is shorter than the

set minimum pulse width.

Data reposi‐

tory

Bool yes

UInt

Bool

UInt - 8 bits

- wo 130 = Restore factory settings

yes 16 bits

Length Access

8 bits

rw 0

rw

Default

value

0

1

Value/rangeIndex

0 = Released

1 = Locked

0 = Beam number 1 begins at the male con‐

nector

1 = Beam number 1 begins at the head

0 = Access free

2 = Access locked

0 = Deactivated

1 = Active

81 Key lock: The teach-in button on the MLG-2 receiver can be locked or released.

74 This ISDU makes it possible to reverse the beam numeration of the MLG-2, with beam 1 beginning at

the male connector or head.

This can be useful when the MLG-2 has to be rotated by 180° (e.g., with connection facing upward)

when it is installed; however, the beam function used previously must remain unchanged (e.g., once

with the connection facing upward and once with the connection facing downward during a height mea‐

surement).

2 Setting the system command with the value 130 resets all parameters to the MLG-2’s factory settings.

12 You can lock the Data Storage functionality using this ISDU.

When Data Storage is locked, the sensor rejects Data Storage write requests from the IO-Link master

with an error message (see "Data repository", page 8).

121 – 122 Pins 2 and 5 can be deactivated (high impedance). This is designed to prevent short-circuits if one of

the two pins is pulled to 0 V by the IO-Link master used.

22

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 23

7.8 Installation / Diagnostics

7.8.1 Process quality and teach quality

Table 19: Installation / Diagnostics – Process quality and teach quality

ISDU

Name Data type

Sub-

DEC HEX

225

224

1)

Process quality in %

2)

Teach-in quality in %

index

E1

E0 Teach quality

Process quality

-

1)

UInt yes 8 bits ro

2)

225 Assessment of the signal quality of all light beams based on the last teach-in.

100% All beams have a sufficient received signal – no signal loss compared to

50% Half of all beams have a significantly lower received signal than during the

224 Two statuses are defined for the MLG-2:

100% Successful teach-in with sufficient signal strength.

0% Teach-in failed.

Data reposi‐

tory

Length Access

Default

value

Value/rangeIndex

0 … 100

100 = Best quality

Lower value = Poor quality

0 = Teach-in failed

100 = Teach-in successful

the last teach-in.

last teach-in.

Corrective measures:

Clean the front screen. If necessary, check the alignment and perform a

new teach-in.

The reason for the teach-in error can be read out from ISDU 98.

SERVICE DATA 7

7.8.2 Device alignment

Table 20: Installation / Diagnostics – Alignment

ISDU

DEC HEX

69

45

71

65

Name Data type

Subindex

Alignment help enable UInt

-

Alignment help

Signal strength of the first

1

beam at connector side in

%

Signal strength of the first

2

beam at the endcap side in

%

Signal strength of the weak‐

3

est beam in %

Record

Offset

Data reposi‐

tory

yes

Length Access

8 bits rw 1

3 bytes ro

16 bits

8 bits

0 bits

Default

value

Value/rangeIndex

0 = Alignment help inactive

1 = Alignment help active

69 The alignment aid ensures that the MLG-2 is aligned as effectively as possible, particularly during initial

commissioning.

Note:

When the alignment aid is active, the process data is invalid.

The analog outputs and switching outputs are deactivated.

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

23

Page 24

7 SERVICE DATA

71 To optimize the alignment, three different signal strengths are issued in this ISDU.

The alignment aid (see ISDU 69) must be active.

For a successful teach-in and optimum operation, all three values must reach the highest possible per‐

centages. They do not have to reach 100% each time.

When the alignment aid is activated, the levels for the first, last, and weakest light beams are dis‐

played.

Attention:

The displayed value can change as soon as a teach-in has been performed, as various transmitting

powers are used for different sensing ranges.

The 100% value is reached for short sensing ranges with the factory settings, for example. This is the

maximum value for optimum alignment.

7.8.3 Device properties

Table 21: Installation / Diagnostics – Device properties

ISDU

Name Data type

Sub-

DEC HEX

83

index

53 Device properties Record 10 bytes ro

1 Number of beams

2 Beam separation in mm 48 bits

3 Reproducibility 32 bits

4 Minimum presence time 16 bits

5 Response time 0 bits

Offset

Data reposi‐

tory

Length Access

64 bits

Default

value

Value/rangeIndex

Shows the value, which matches the used

MLG model

83 The MLG-2 is a modular system.

As a result, the device properties depend on the model in question and its current configuration.

In this ISDU, the key data from the connected device can be read out.

7.8.4 Diagnostics

Table 22: Installation / Diagnostics – Diagnostics

ISDU

Name

Sub-

DEC HEX

100

36

153

1)

2)

index

64

24

99

System

1)

status

-

Device sta‐

tus

Tempera‐

2)

ture

Status of all important warning and error statuses

Temperature in degrees Celsius

Data

type

UInt

Int

Data

reposi‐

tory

Length

8 bits

Access

ro

100 The system status provides information about the current status of the MLG-2

and is also issued cyclically via process data (see "PD in", page 10).

Both errors and information (e.g., invalid process data due to an active teachin process) are issued.

153 The temperature refers to the internal temperature of the device.

This is typically approx. 10 K above the ambient temperature. If the tempera‐

ture is too high, bit 2 is set in the system status and an event is generated (see

"Events", page 25).

Default

Value/rangeIndex

value

Bit no.

7 6 5 4 3 2 1 0

0

Sync error Teach fail

0 = False

1 = True

1 0 = Device is OK

1 = Maintenance required

2 = Out of specification

3 = Functional check

4 = Failure

-127 … +127

Hardware

error

Contami‐

nation

alarm

Teach

active

Over-tem‐

perature

Process

data

invalid

Q shortcircuit

24

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 25

EVENTS 8

8 Events

IO-Link communication is a master-slave communication system.

With “Events”, an IO-Link device reports events to the master (without being prompted by the master). Device-spe‐

cific events are classified as follows:

Table 23: Device-specific events

Notification For information purposes only; system is not restricted.

Warning System is still functional, but is impaired in some way. You must rectify this with suitable mea‐

sures as soon as possible.

Error System is no longer functional. Depending on the cause of the error, it may be possible to

restore functionality.

An event issues an event code, which contains the cause of the occurrence of the event.

NOTE

Not all IO-Link masters support the event mechanism.

You can deactivate the generation of events on the device side in ISDU 227 Notification handling.

The following events are supported:

Table 24: Events

Code

Dec Hex

6144 1800

6145 1801 Teach-in failure Error

6146 1802 Contamination Warning

6147 1803 Hardware error Error Sensor is defective. Replace the sensor.

6148 1804

6149 1805

6151 1807

Name Type Comment Action

Teach-in success‐

ful

Short-circuit on

outputs

Device tempera‐

ture over-run

Synchronization

error

Notification

Warning

Warning

Error

Triggered after a successful

teach-in.

Triggered after a failed teach-in.

The received signal was too low

during teach-in.

Triggered in the event of contami‐

nation.

The received signal is signifi‐

cantly lower than during the last

teach-in.

Triggered in the event of a shortcircuit on at least one switching

output.

Overcurrent detection.

Triggered if the critical tempera‐

ture is exceeded in the device.

Triggered if the sync connection

is interrupted in the connection

cable between the sender and

receiver.

Details on the teach-in result can

be read out from ISDU 98.

Realign the MLG-2 and perform a

new teach-in.

Clean the MLG-2 and perform a

new teach-in.

Alternatively, check the alignment

and perform a new teach-in after

any corrections.

Check the cabling.

Check the sensor environment and

remove the heat source.

Check the cabling. Ensure a short

connection between the sender

and receiver.

Lay the cables in such a way that

they are separate from power

cables (e.g., drives, frequency con‐

verters).

Use a T-connector (accessories).

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

25

Page 26

Blank teach-in.

ISDU 70.

Value = 1

then teach-in.

Blank immediately.

ISDU 188.

Value = 1.

Blank immediately.

ISDU 189.

Value = 1.

Set the beam mask.

ISDU 72.

Value = bit pattern.

Beam blanking

Example 2

Example 1

Example 3

Example 4

Blanking.

Within object

immediately.

Blanking.

Outside object

immediately.

Beam blanking

in accordance with beam mask.

111000111...

Blanking within object.

During next teach-in.

9 USE CASES

9 Use cases

1. Beam blanking

There are several options for beam blanking.

Figure 1: Beam blanking

Example 1 An object projects into the monitored area. The object or the associated light beams are

blanked during the next teach-in.

26

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 27

Auswahl

Prozessdaten.

ISDU 120 Wert = 2.

Frei definierte

Prozessdaten.

Höhenmessung

Beispiel 2

Höhenmessung.

Von unten nach oben.

Beispiel 1

Höhenmessung.

Von oben nach unten.

Beispiel 4Beispiel 3

20 Strahlen = 200 mm40 Strahlen = 200 mm

Einstellungen Prozessdaten.

ISDU 67.

Wert = 20.

FBB = erster unterbr.

Strahl.

Einstellungen Prozessdaten.

ISDU 67.

Wert = 22.

LBB = letzter unterbr.

Strahl.

Einstellung Betriebsart.

ISDU 66.

Wert 3.

Kreuzstrahl-Modus

aktiv.

Einstellung Mess-Modus.

ISDU 206.

Wert = 1.

Kreuzstrahl messend.

Einstellungen Prozessdaten.

ISDU 67.

Wert = 20.

FBB = erster unterbr.

Strahl.

Einstellungen Prozessdaten.

ISDU 67.

Wert = 22.

LBB = letzter unterbr.

Strahl.

USE CASES 9

Example 2 As in example 1 but with immediate blanking without teach-in.

Example 3 An object, which marks the entire monitored area, is brought into the beam path. Then all

light beams outside the object are blanked.

Example 4 All light beams are blanked, regardless of whether an object is located in the detection

area.

2. Standard height measurement or with cross-beam mode and high resolution

You can find several examples for height measurement below. For the sample calculation, an MLG-2 with a 10 mm

beam grid is used as a basis. The counting direction always starts at the male connector. Using the “Cross-beam

measuring” function, it is possible to improve the beam resolution by observing the crossed beams during the

measurement.

Figure 2: Height measurement

Example 1 Object moves from the head to the male connector,

e.g., measurement result FBB = 20 corresponds to 200 mm from the uppermost light beam

for an MLG-2 with 10 mm beam separation.

Example 2 Object moves from the male connector to the head,

e.g., measurement result LBB = 20 corresponds to 200 mm from the lowermost light beam.

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

27

Page 28

Paket 1 Paket 2

RLC 1

Auswahl Prozessdaten.

ISDU 120.

Wert = 0.

Einstellung Prozessdaten auf

RLC = Werkseinstellung.

Paketposition

Paketlücke

RLC 2 RLC 5RLC 3 RLC 4

Einstellung Strahl-Speicher-Fuktion.

ISDU 272.

Wert = 2.

Aktivierung LBH

Lost Beam Hold.

Fadenposition

mit

Lost Beam Hold

Auswahl Prozessdaten.

ISDU 120 Wert = 2.

Frei definierte

Prozessdaten.

Einstellung Mess-Modus.

ISDU 66.

Wert = 1.

Hohe Messgenauigkeit.

Einstellung Prozessdaten.

ISDU 67.

Wert = 20.

FBB = erster

unterbrochener Strahl.

9 USE CASES

Example 3 As in example 1, but with double beam resolution. Object moves from the head to the male

connector,

e.g., measurement result FBB = 40 corresponds to 200 mm from uppermost light beam.

Example 4 As in example 2, but with double beam resolution. Object moves from the male connector

to the head,

e.g., measurement result LBB = 40 corresponds to 200 mm from the lowermost light beam.

3. Parcel flow with RLC

To control the parcel flow, the position of the parcels must be determined continuously. For the sample calculation,

an MLG-2 with a 10 mm beam grid is used as a basis. By evaluating the RLC values, it is possible to determine the

parcel position and the gap between the parcels. 15 RLC values are issued via the process data in the factory

settings (see "PD in", page 10). RLC = Change between free and blocked beams as in figure 3, e.g., the first 12

beams free, then 13 beams blocked, etc.:

The number of parcels,

•

e.g., 2 parcels, when RLC 5 > 0

The width of the parcels,

•

e.g., parcel 1 = RLC 2 x 10 mm

The gap between the parcels,

•

e.g., gap between parcel 1 and parcel 2 = RLC 3 x 10 mm

The position of the parcels,

•

e.g., distance to front beam from parcel 2 = RLC 5 x 10 mm

Figure 3: Parcel flow

4. Controlling a coil winder with LBH

When a coil is being wound up, the wire position must be continuously detected as a controlled variable. The wire

diameter is smaller than the MLG-2’s beam grid so that the threads between the beams cannot be detected. The

“LBH” function is used to prevent the measured value from being interrupted.

28

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 29

FBB oder LBB

Drahtposition.

Strahl wird so lange gehalten, bis

der nächste unterbrochen wird.

Figure 4: Coil winder

Please note the following with regard to the wire diameter:

Wire diameter > beam diameter = Standard measurement accuracy

Wire diameter < beam diameter = High measurement accuracy required

(Minimum diameter is > half of the beam diameter)

Reliable beam blocking depends on the operating mode (see "Performance options", page 15).

USE CASES 9

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

29

Page 30

10 LIST OF ABBREVIATIONS

10 List of abbreviations

Table 25: List of abbreviations

IODD IO Device Description Device description file of an IO-Link device

ISDU Indexed Service Data Unit Service data object in IO-Link

COM 1

– 3

SDCI Single-drop digital interface Official (specification) name for IO-Link technology

SDD SOPAS ET Device Description

SDCI communication mode

1 = 4.8 kbit/s

2 = 38.4 kbit/s

3 = 230.4 kbit/s

Device description file / driver for SICK SOPAS ET

software

30

T EC H NI C AL IN F OR M AT I ON | MLG-2 8022573/2018-01-19 | SICK

Subject to change without notice

Page 31

11 Index

INDEX 11

I

ISDU

100 System status........................................................................ 24

120 Process data select.............................................................. 17

121 PIN2 configuration................................................................ 22

122 PIN5 configuration................................................................ 22

12 Data Storage lock.................................................................... 22

153 Temperature.......................................................................... 24

160 Q1 – Minimum pulse width.................................................. 21

161 Q2 – Minimum pulse width.................................................. 21

162 Q3 – Minimum pulse width.................................................. 21

163 Q4 – Minimum pulse width.................................................. 21

164 Q5 ... Q16 – Minimum pulse width...................................... 21

16 Vendor name........................................................................... 12

183 Output 1 (Q1) configuration................................................. 21

184 Output 2 (Q2) configuration................................................. 21

185 Output 3 (Q3) configuration................................................. 21

186 Output 4 (Q4) configuration................................................. 21

188 Blank all currently blocked beams...................................... 13

189 Blank all currently made beams.......................................... 13

18 Product name.......................................................................... 12

204 Find me.................................................................................. 13

206 Cross-beam measuring........................................................ 15

207 Zone 1.................................................................................... 15

208 Zone 2.................................................................................... 15

209 Zone 3.................................................................................... 15

20 Product text............................................................................. 12

210 Zone 4.................................................................................... 15

219 Product ID.............................................................................. 12

21 Serial number.......................................................................... 12

224 Teach quality......................................................................... 23

225 Process quality...................................................................... 23

22 Hardware version.................................................................... 13

23 Firmware version..................................................................... 13

24 Application-specific tag........................................................... 12

256 Beam hold function – NBB.................................................. 19

257 Beam hold function – NBM.................................................. 19

258 Beam hold function – FBB................................................... 19

259 Beam hold function – FBM.................................................. 19

260 Beam hold function – LBB................................................... 19

261 Beam hold function – LBM.................................................. 19

262 Beam hold function – NCBB & CBB.................................... 19

263 Beam hold function – NCBM & CBM................................... 19

264 Beam hold function – ODI.................................................... 19

265 Beam hold function – IDI..................................................... 19

266 Beam hold function – RLC................................................... 19

267 Beam hold function – BS..................................................... 19

268 Beam hold selection for zone – NBB................................... 19

269 Beam hold selection for zone – FBB................................... 19

270 Beam hold selection for zone – LBB................................... 19

271 Beam hold selection for zone – NCBB/CBB....................... 19

272 Selection for beams hold mode........................................... 19

2 System command............................................................... 13, 22

36 Device status........................................................................... 24

64 Device-specific name.............................................................. 12

65 Device mode............................................................................ 15

66 Performance options.............................................................. 15

67 Process data user definition.................................................. 17

68 Transparent mode................................................................... 15

69 Alignment help enable............................................................ 23

70 Blanking teach enable............................................................ 13

71 Alignment help........................................................................ 23

72 Beam blanking mask.............................................................. 14

74 Beam numeration................................................................... 22

75 Standby.................................................................................... 15

81 Key lock.................................................................................... 22

83 Device properties.................................................................... 24

98 Teach result............................................................................. 13

8022573/2018-01-19 | SICK T E CH N IC A L I NF O RM A TI O N | MLG-2

Subject to change without notice

31

Page 32

Further locations at www.sick.com

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 22 36 62 28 8-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail marketing@sick.com.br

Canada

Phone +1 905 771 14 44

E-Mail information@sick.com

Czech Republic

Phone +420 2 57 91 18 50

E-Mail sick@sick.cz

Chile

Phone +56 2 2274 7430

E-Mail info@schadler.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-2515 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 211 5301-301

E-Mail info@sick.de

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail office@sick.hu

India

Phone +91 22 6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 4 6881000

E-Mail info@sick-sensors.com

Italy

Phone +39 02 274341

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +6 03 8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mario.garcia@sick.com

Netherlands

Phone +31 30 2044 000

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356 171 120

E-Mail office@sick.ro

Russia

Phone +7 495 775 05 30

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 788 49

E-Mail office@sick.si

South Africa

Phone +27 11 472 3733

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321

E-Mail info@sickkorea.net

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886 2 2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2645 0009

E-Mail Ronnie.Lim@sick.com

Turkey

Phone +90 216 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 4 88 65 878

E-Mail info@sick.ae

United Kingdom

Phone +44 1727 831121

E-Mail info@sick.co.uk

USA

Phone +1 800 325 7425

E-Mail info@sick.com

Vietnam

Phone +84 945452999

E-Mail Ngo.Duy.Linh@sick.com

8022573/2018-01-19/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...