Page 1

miniTwin4

Safety light curtain

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

mini

Twin4

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

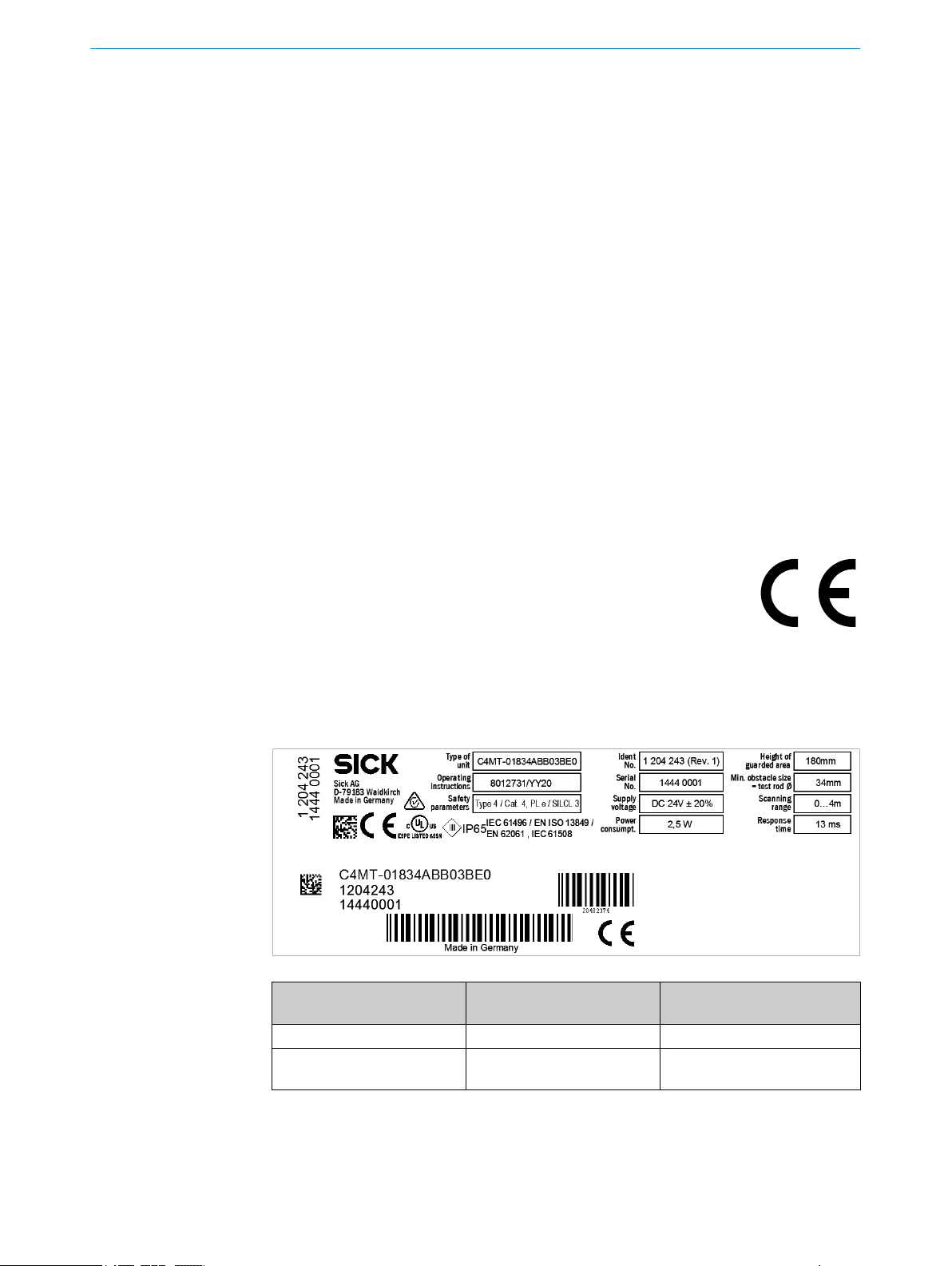

Change history of the device

T

he table below describes the technical changes made to the device in the course of

product maintenance. The change history of the device can be seen on the type label in

the Ident No. field with the additional change number “(Rev. #)”.

Change number in Ident No.

f

ield

No change number Initial device version

(Rev. 1) Addition to the Cross-circuit

Change Additional information

see "Structure and function",

monit

oring field

page 11

2

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Scope......................................................................................................... 6

1.2 Target groups and structure of these operating instructions................ 6

1.3 Additional information.............................................................................. 7

1.4 Symbols and document conventions...................................................... 7

2 Safety information............................................................................ 9

2.1 General safety notes................................................................................ 9

2.2 Intended use............................................................................................. 9

2.3 Requirements for the qualification of personnel.................................... 10

3 Product description........................................................................... 11

3.1 Structure and function............................................................................. 11

3.2 Product characteristics............................................................................ 13

3.2.1 Device overview....................................................................... 13

3.2.2 Absence of blind zones........................................................... 14

3.2.3 Beam coding............................................................................ 14

3.2.4 Restart interlock...................................................................... 14

3.2.5 External device monitoring (EDM).......................................... 14

3.2.6 Cascading................................................................................. 15

3.2.7 System plug.............................................................................. 15

3.2.8 Flexible control cabinet cabling and status indication on

th sides................................................................................. 16

bo

3.2.9 Status indicators...................................................................... 17

3.3 Example applications............................................................................... 19

4 Project planning................................................................................ 21

4.1 Manufacturer of the machine.................................................................. 21

4.2 Operator of the machine.......................................................................... 21

4.3 Design........................................................................................................ 21

4.3.1 Scanning range and protective field width............................. 22

4.3.2 Minimum distance from the hazardous point....................... 23

4.3.3 Minimum distance from reflective surfaces.......................... 25

4.3.4 Minimum distance for cascaded systems............................. 26

4.3.5 Protection against interference from systems in close prox‐

imity to each other................................................................... 28

4.4 Integrating the equipment into the electrical control............................. 29

4.4.1 Protective operation without reset and/or without EDM...... 31

4.4.2 Restart interlock...................................................................... 32

4.4.3 External device monitoring (EDM).......................................... 34

4.4.4 Cascading................................................................................. 35

4.4.5 Connection diagrams.............................................................. 38

4.5 Testing plan............................................................................................... 40

4.5.1 Test rod check.......................................................................... 41

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

3

Page 4

CONTENTS

4.5.2 Visual check of the machine and the protective device........ 43

5 Mounting............................................................................................. 44

5.1 Safety......................................................................................................... 44

5.2 Unpacking.................................................................................................. 44

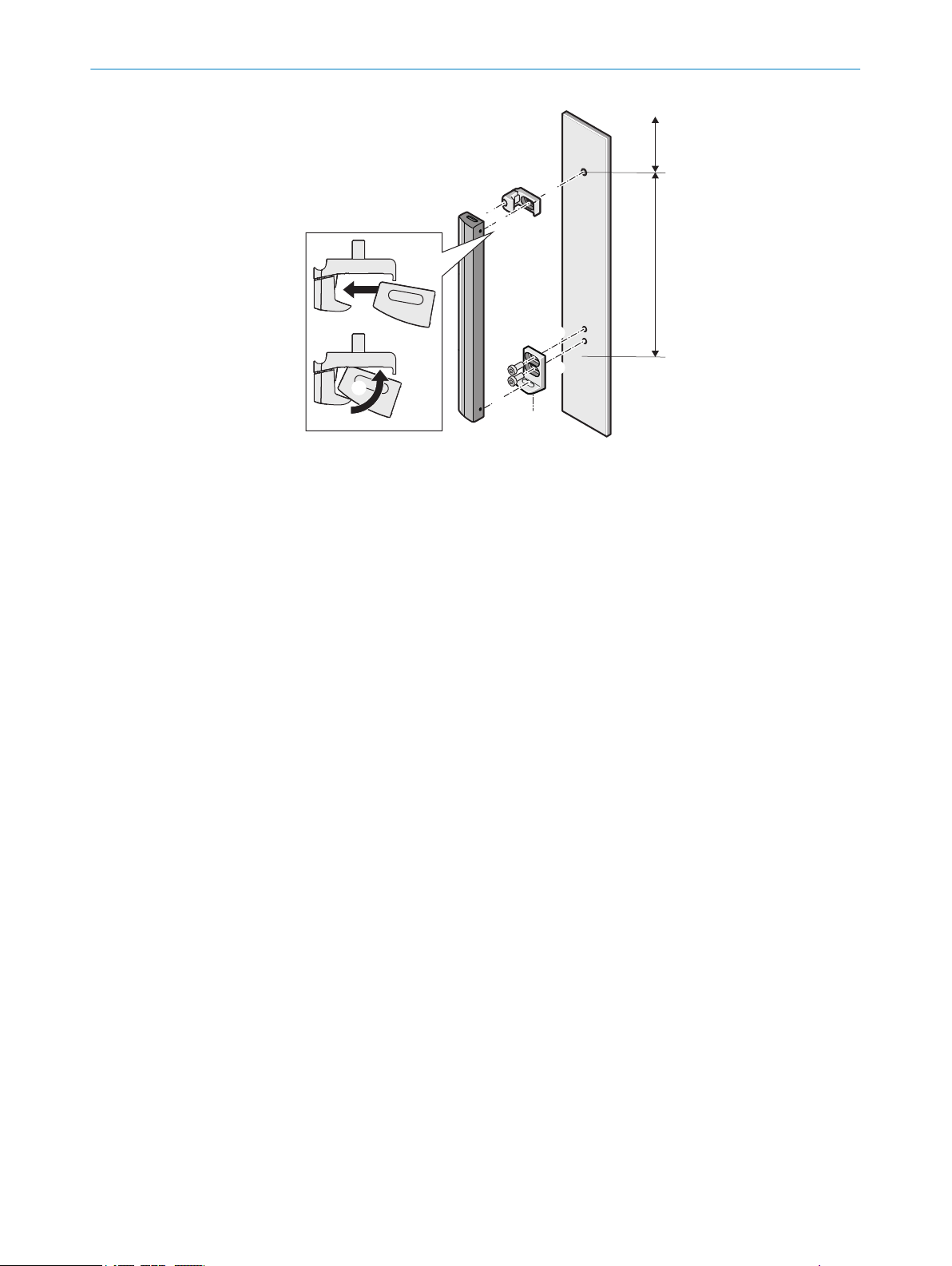

5.3 Mounting the system plug........................................................................ 45

5.4 Mounting................................................................................................... 47

5.4.1 Mounting direction of the twin stick....................................... 49

5.4.2 Mounting options..................................................................... 49

5.4.3 Mounting with O-Fix bracket................................................... 50

5.4.4 Mounting with C-Fix bracket.................................................... 52

5.4.5 Mounting with L-Fix bracket..................................................... 53

5.4.6 Mounting with C-Fix bracket and L-Fix bracket...................... 55

5.4.7 Mounting with C-Fix-Flex bracket............................................ 56

5.5 Resolution at the end of the twin sticks.................................................. 58

6 Electrical installation........................................................................ 60

6.1 Safety......................................................................................................... 60

6.2 System connection................................................................................... 62

7 Configuration..................................................................................... 63

7.1 Factory settings......................................................................................... 63

7.1.1 Changing the configuration later............................................ 63

7.2 Configuring beam coding......................................................................... 63

7.3 Reset and external device monitoring (EDM)......................................... 64

7.3.1 Configuring reset..................................................................... 64

7.3.2 Configuring external device monitoring (EDM)...................... 65

7.3.3 Deactivating reset and EDM................................................... 66

7.4 Cascading.................................................................................................. 68

7.4.1 Cascading new devices........................................................... 71

7.4.2 Connecting a new device in an existing cascade.................. 71

7.4.3 Cascading pre-configured devices.......................................... 72

7.5 Status indication on both sides............................................................... 72

8 Commissioning.................................................................................. 73

8.1 Safety......................................................................................................... 73

8.2 Overview.................................................................................................... 73

8.3 When it is switched on.............................................................................. 74

8.4 Alignment of the twin stick....................................................................... 74

8.4.1 Aligning the twin sticks to one another.................................. 75

8.4.2 Indication of the alignment quality......................................... 77

8.5 Check during commissioning and modifications.................................... 77

9 Operation............................................................................................ 78

9.1 Safety......................................................................................................... 78

9.2 Regular thorough check........................................................................... 78

9.3 LEDs........................................................................................................... 79

4

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 5

CONTENTS

10 Maintenance...................................................................................... 81

10.1 Safety......................................................................................................... 81

10.2 Regular cleaning....................................................................................... 81

10.3 Regular thorough check........................................................................... 82

11 Troubleshooting................................................................................. 83

11.1 Safety......................................................................................................... 83

11.2 Diagnostic LEDs........................................................................................ 83

11.2.1 Indications when switching on................................................ 83

11.2.2 Status indicator........................................................................ 85

11.2.3 Fault indicators........................................................................ 86

12 Decommissioning............................................................................. 88

12.1 Protection of the environment................................................................. 88

12.2 Disposal..................................................................................................... 88

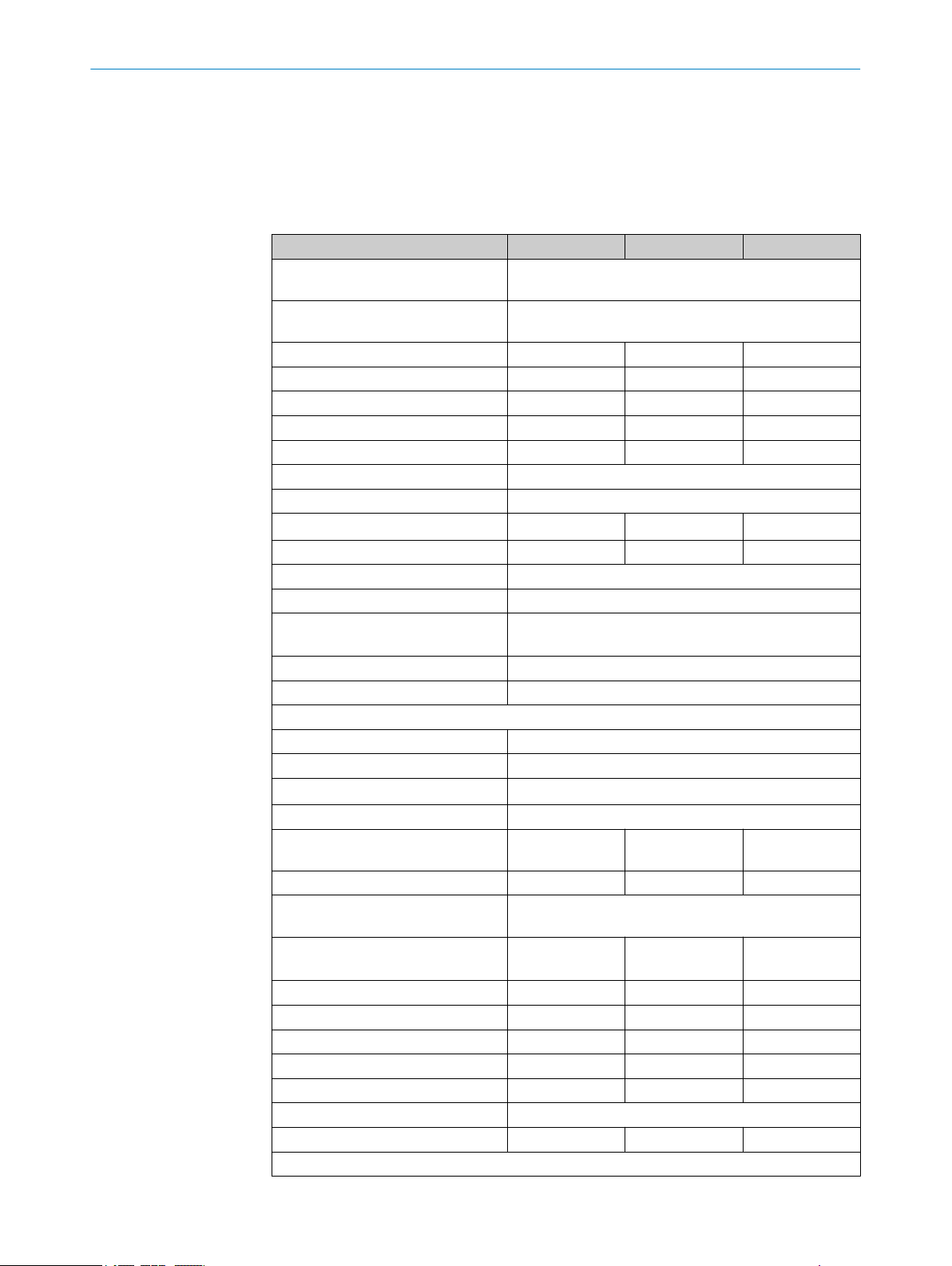

13 Technical data.................................................................................... 89

13.1 Data sheet................................................................................................. 89

13.2 Response time.......................................................................................... 91

13.3 Power consumption.................................................................................. 92

13.4 Table of weights........................................................................................ 92

13.5 Dimensional drawings.............................................................................. 94

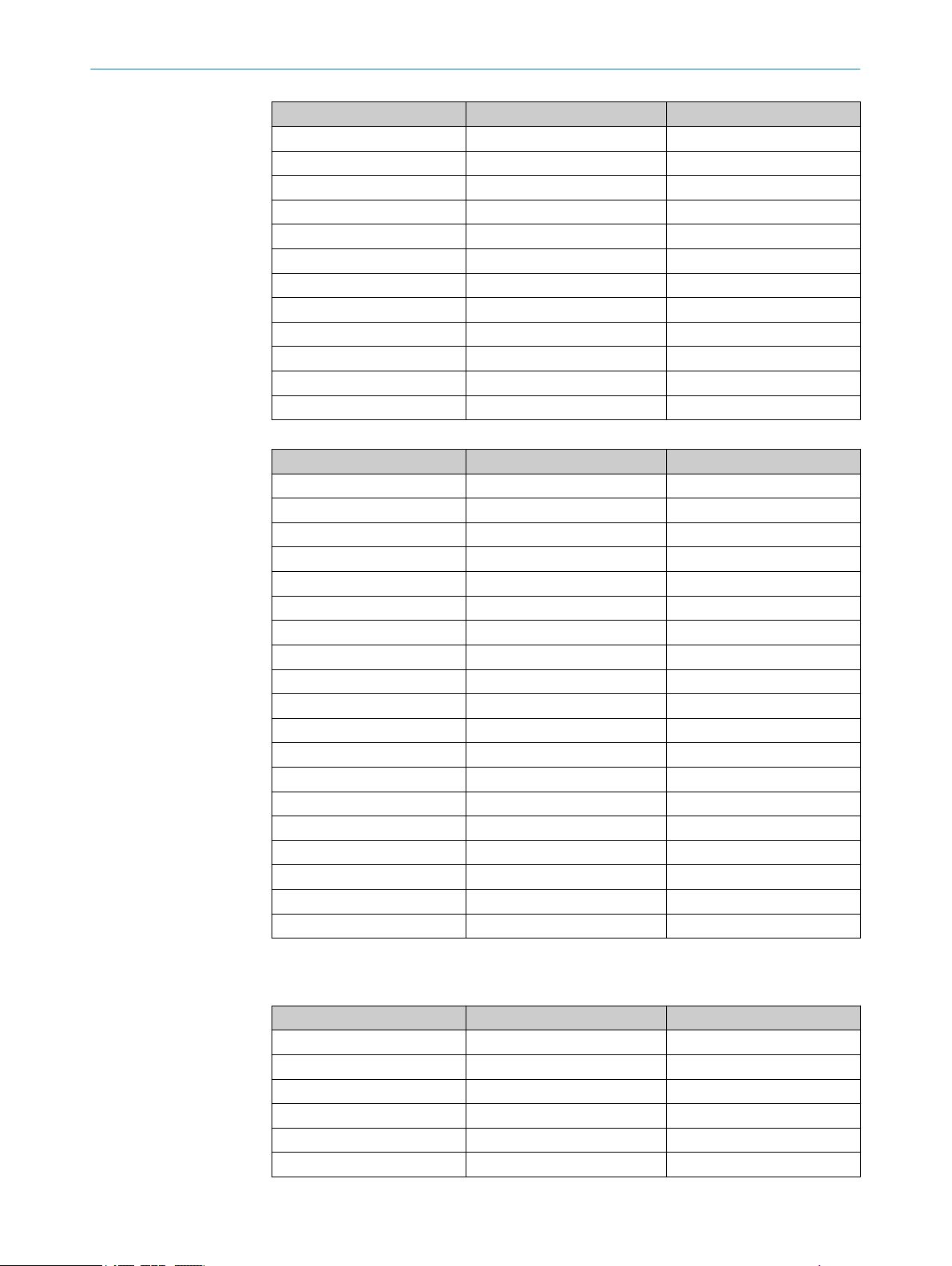

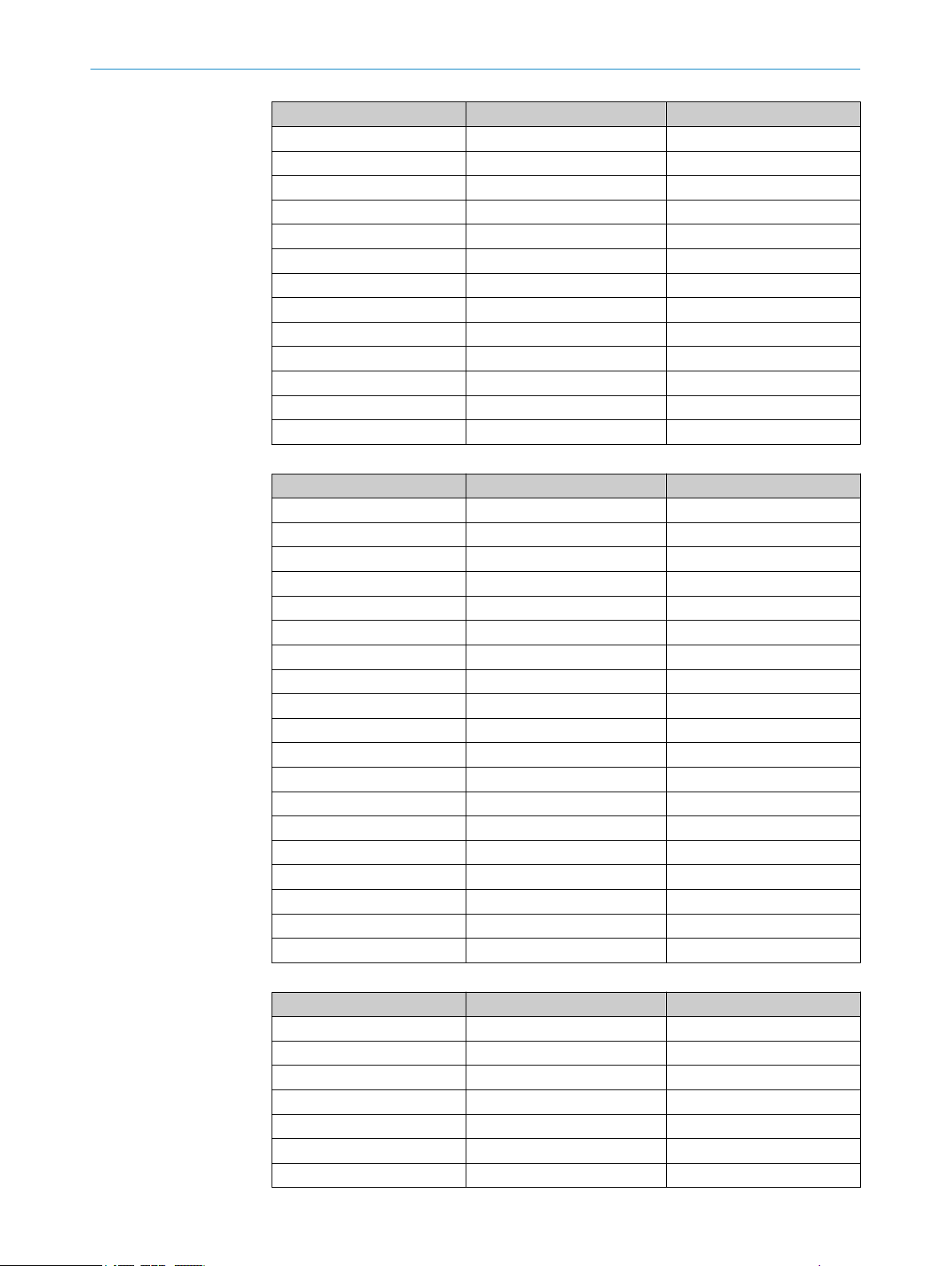

14 Ordering information........................................................................ 95

14.1 Scope of delivery....................................................................................... 95

14.2 Ordering information miniTwin4............................................................... 95

14.3 Weld spark guard...................................................................................... 99

14.4 Alignment aid............................................................................................ 100

15 Accessories........................................................................................ 101

15.1 Brackets.................................................................................................... 101

15.2 Connectivity............................................................................................... 102

15.3 Deflector mirrors....................................................................................... 104

15.3.1 Change in scanning range using deflector mirrors................ 104

15.3.2 PNS75 deflector mirror........................................................... 104

15.3.3 PNS125 deflector mirror......................................................... 105

16 Annex.................................................................................................. 106

16.1 Compliance with EU directives................................................................. 106

16.2 Checklist for initial commissioning and commissioning........................ 107

17 List of figures..................................................................................... 108

18 List of tables....................................................................................... 110

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

These operating instructions contain information required during the life cycle of the

afety light curtain.

s

These operating instructions are available to all those who work with the safety light

curtain.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the safety light curtain.

1.1 Scope

These operating instructions only apply to the miniTwin4 safety light curtain with one of

t

he following type label entries in the “Operating Instructions” field:

8012731

•

8012731/V114

•

8012731/YY20

•

8012731/YT85

•

This document is included with the following SICK part numbers (this document in all

available language versions):

8012731

1.2 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: Project devel‐

oper

s (planners, developers, designers), installers, electricians, safety experts (e.g., CE

authorized representatives, compliance officers, persons who test and approve the

application), operators, and maintenance personnel.

The structure of these operating instructions is based on the life cycle phases of the

safety light curtain: Project planning, mounting, electrical installation, commissioning,

operation, and maintenance.

In many applications, the target groups are assigned as follows to the manufacturer

and the organization operating the machine in which the safety light curtain is inte‐

grated:

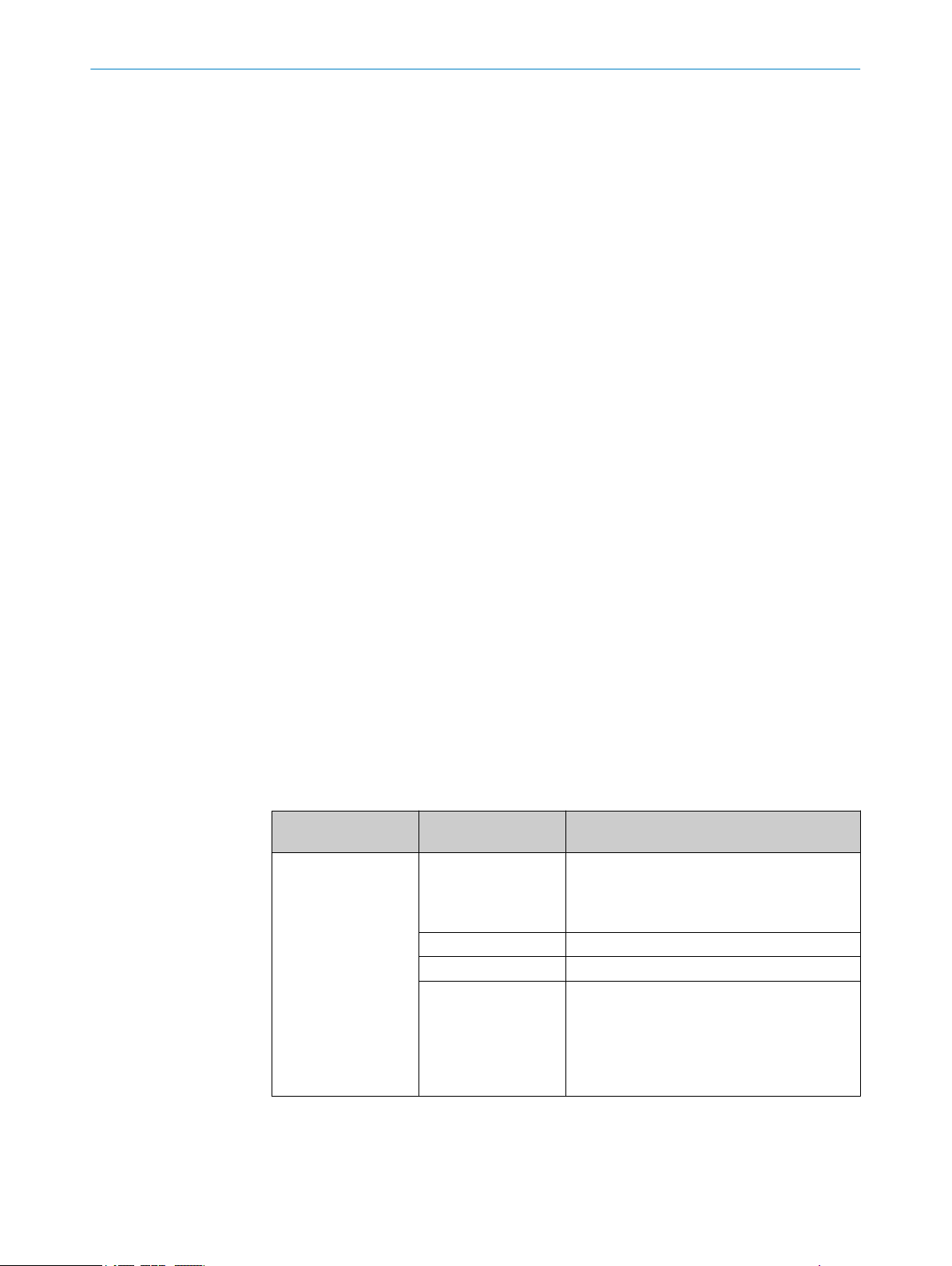

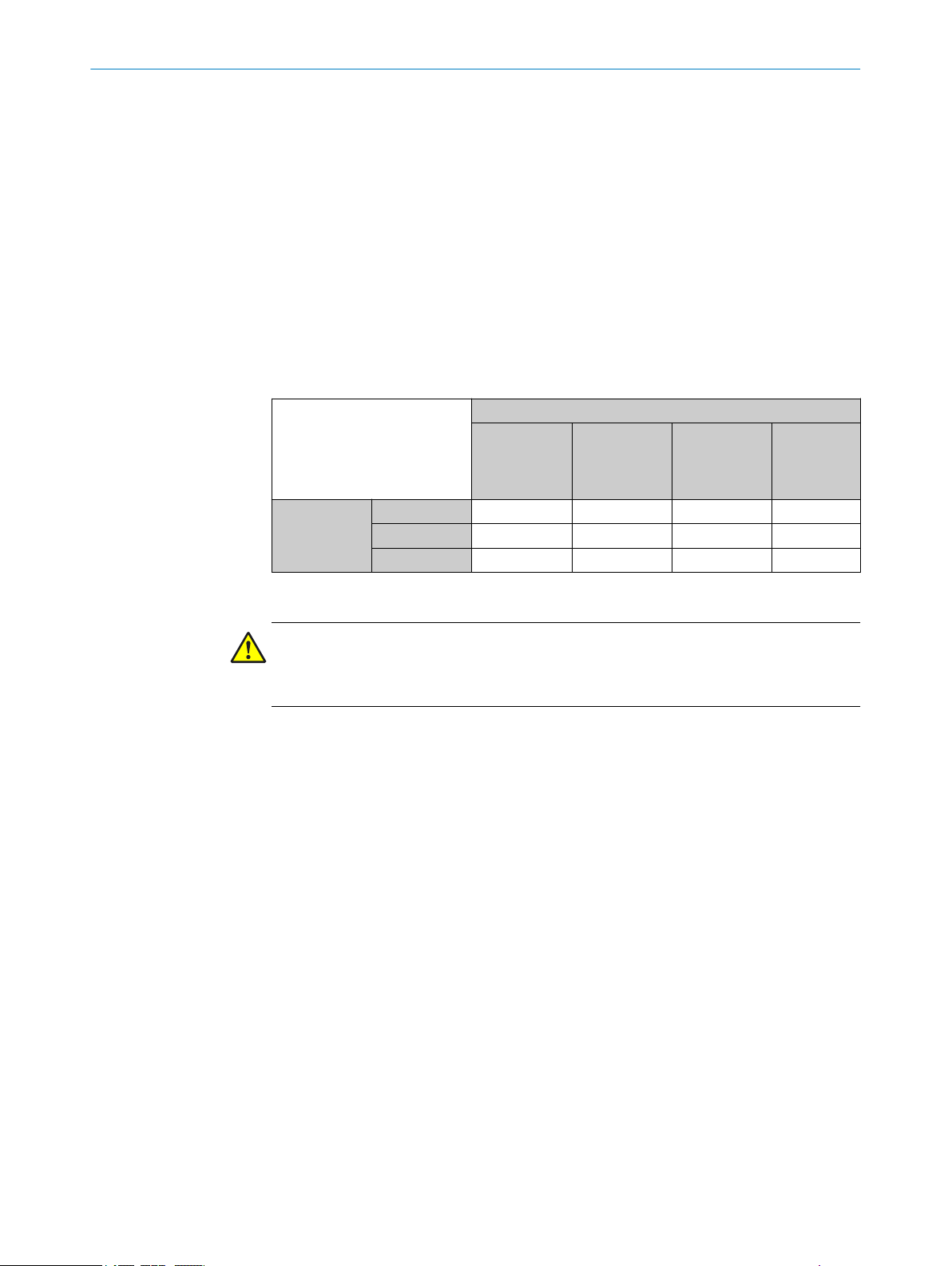

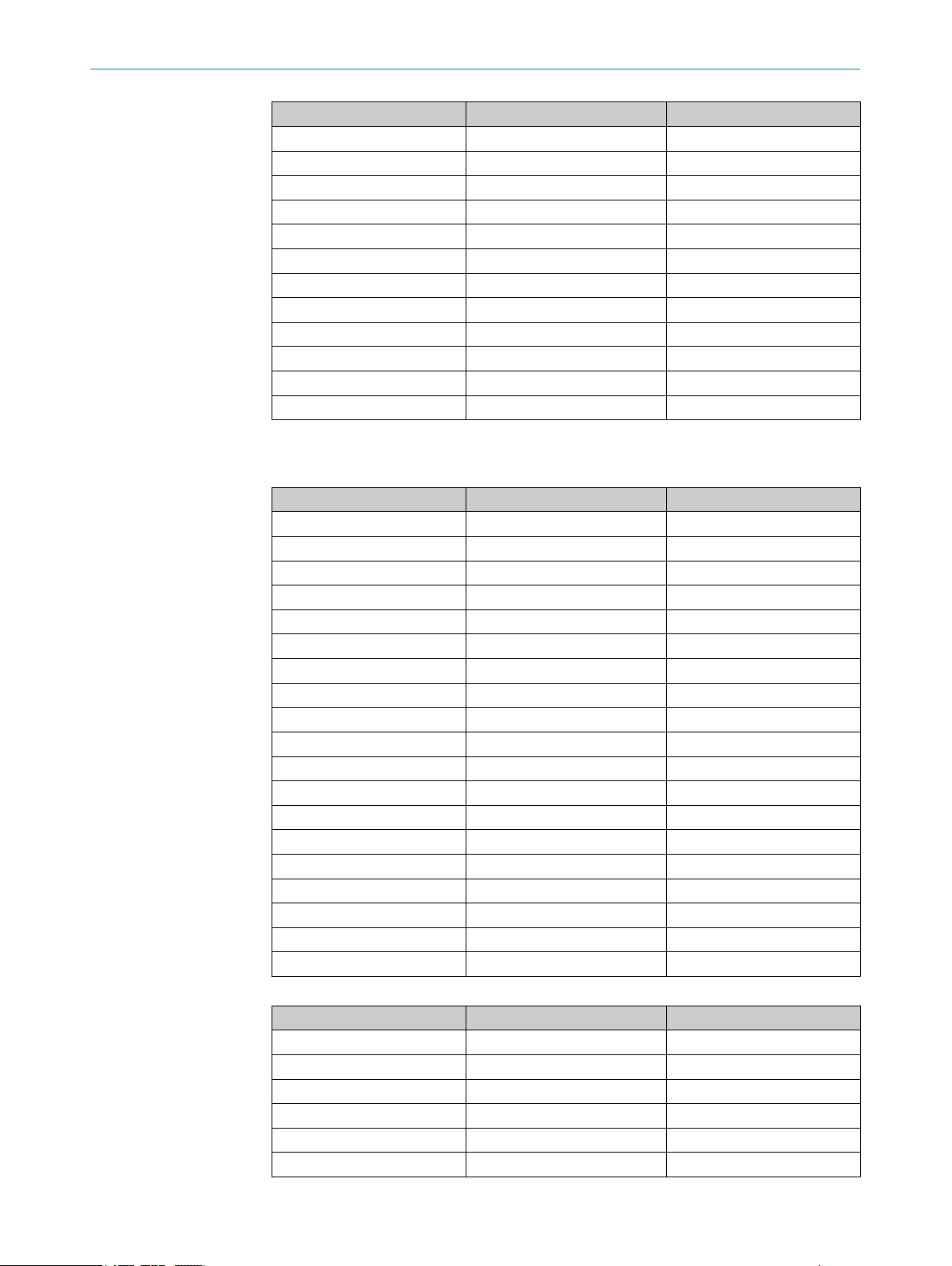

Area of responsibility Target group Specific chapters of these operating instruc‐

Manufacturer Project developers

(planners, developers,

designers)

Installers "Mounting", page 44

Electricians "Electrical installation", page 60

Safety experts "Project planning", page 21

1)

tions

"Project planning", page 21

"Configuration", page 63

"Technical data", page 89

"Accessories", page 101

onfiguration", page 63

"C

"Commissioning", page 73

"Technical data", page 89

"Checklist for initial commissioning and com‐

missioning", page 107

6

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 7

ABOUT THIS DOCUMENT 1

Area of responsibility Target group Specific chapters of these operating instruc‐

Operating entity Operators "Operation", page 78

1)

Chapters not listed here are intended for all target groups. All target groups must follow all of the safety

and w

arning instructions in all chapters of the operating instructions!

In other applications, the operating organization is also the manufacturer of the equip‐

ment w

ith the corresponding allocation of the target groups.

1.3 Additional information

www.sick.com

T

he following information is available on the Internet:

This document in other languages

•

Data sheets and application examples

•

CAD data of drawings and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery Six steps to a safe machine

•

Maintenance person‐

l

ne

1)

t

ions

"Troubleshooting", page 83

"Maintenance", page 81

"Troubleshooting", page 83

"Ordering information", page 95

1.4 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indic

ates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

ates a situation presenting possible danger, which may lead to death or serious

Indic

injuries if not prevented.

CAUTION

ates a situation presenting possible danger, which may lead to moderate or minor

Indic

injuries if not prevented.

NOTICE

Indic

ates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

T

he arrow denotes instructions to action.

b

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

7

Page 8

1 A

BOUT THIS DOCUMENT

1. The sequence of instructions for action is numbered.

2.

Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

Sender and receiver

T

hese symbols indicate the sender and receiver of the device:

The symbol indicates the sender.

s

The symbol indicates the receiver.

r

8

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 9

2 Safety information

This chapter contains information on general safety for the safety light curtain.

e safety information about specific usage situations of the safety light curtain is

Mor

available in the respective chapters.

2.1 General safety notes

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Please read this document carefully and make sure that you understand the con‐

b

tent fully before working with the device.

Follow all safety notes in this document.

b

2.2 Intended use

SAFETY INFORMATION 2

Overview

he miniTwin4 safety light curtain is an electro-sensitive protective device (ESPE) and is

T

suitable for the following applications:

Hazardous point protection

•

Access protection

•

Hazardous area protection

•

The miniTwin4 safety light curtain must only be used within the limits of the prescribed

pecified technical data and operating conditions at all times.

and s

Any instance of improper use, incorrect modification, or manipulation of the miniTwin4

safety light curtain shall void any warranty provided by SICK AG; furthermore, SICK AG

shall not accept any responsibility or liability for any resulting damage and consequen‐

tial damage.

Important information

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The safety light curtain works as an indirect protective measure and cannot provide pro‐

tection from parts thrown out nor from emitted radiation. Transparent objects are not

detected.

Only use the safety light curtain as an indirect protective measure.

b

Reasonably foreseeable misuse

g others, the miniTwin4 safety light curtain is not suitable for the following appli‐

Amon

cations:

Outdoors

•

Underwater

•

In explosion-hazardous areas

•

In environments with increased levels of ionizing radiation

•

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

9

Page 10

AFETY INFORMATION

2 S

2.3 Requirements for the qualification of personnel

The safety light curtain must be configured, installed, connected, commissioned and

viced only by qualified safety personnel.

ser

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting

For mechanical mounting, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Electrical installation

For electrical installation, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Configuration

For configuration, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its work safety aspects.

Commissioning

For commissioning, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its operational safety sta‐

tus.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

An operator may clean the safety light curtain and carry out specific checks as

instructed.

Further topics

"Operation", page 78

•

"Regular cleaning", page 81

•

10

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 11

3 Product description

s

s

r

r

! !

This chapter provides information on the operation of the safety light curtain and shows

xamples of its range of use.

e

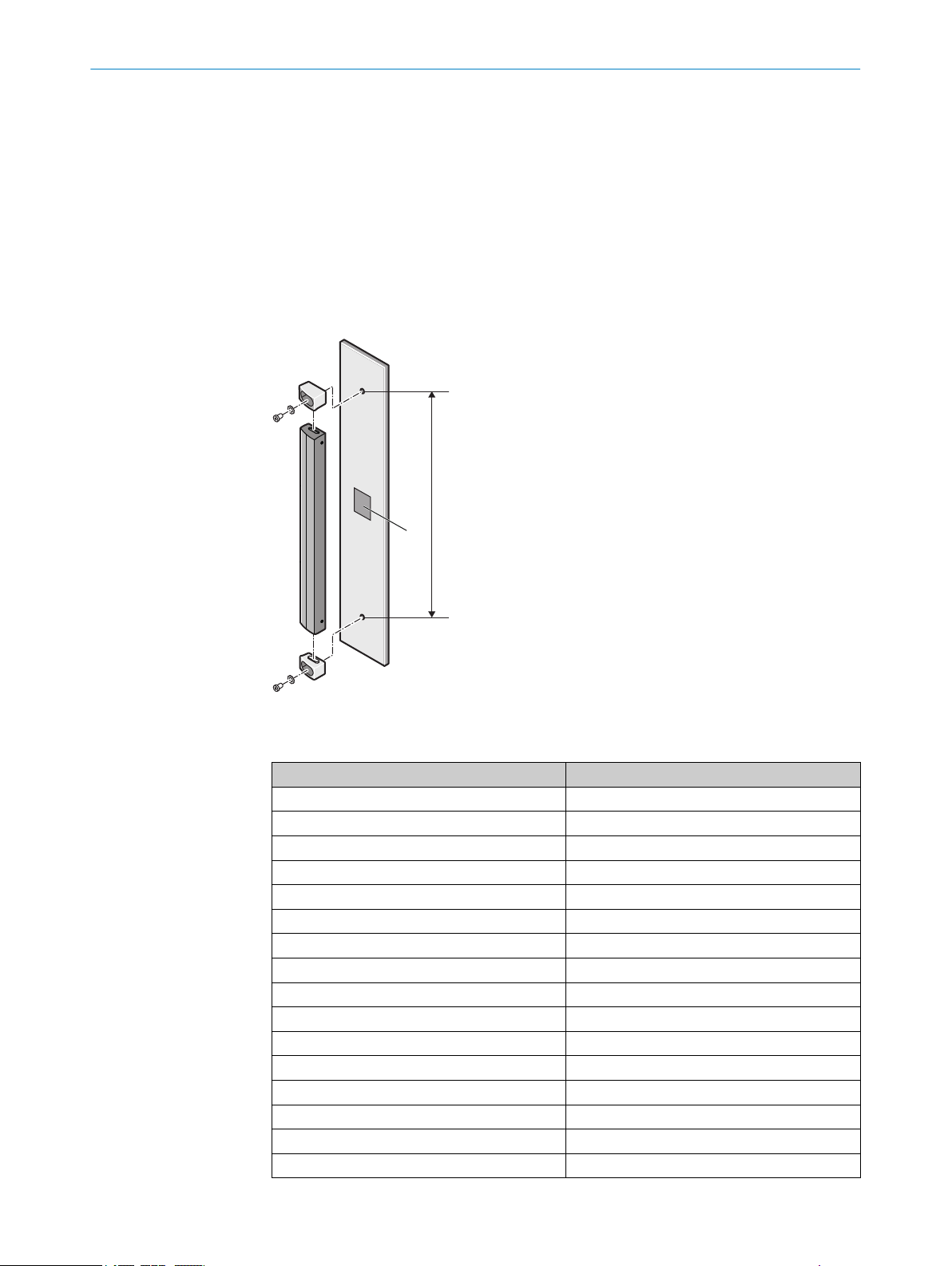

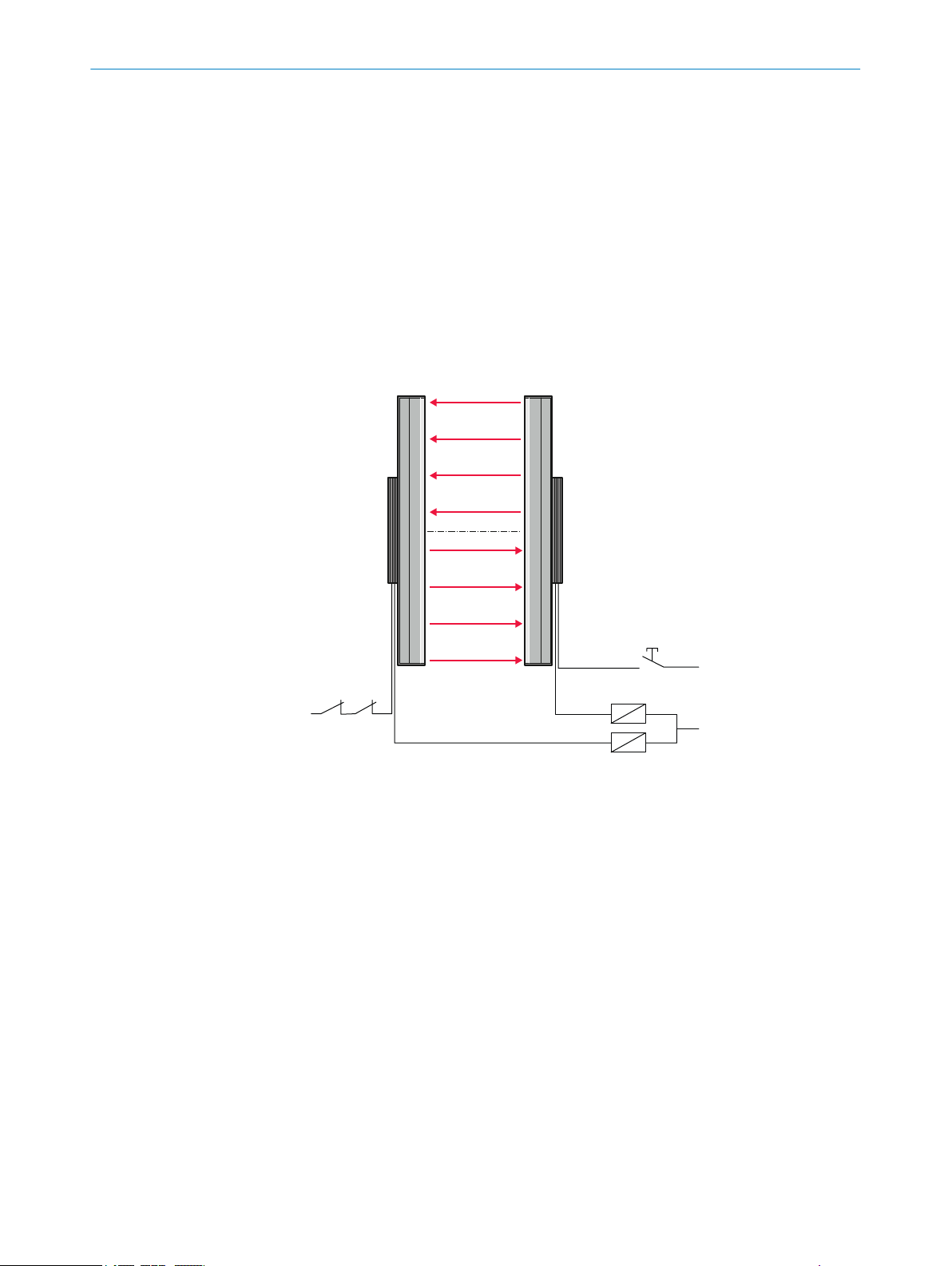

3.1 Structure and function

Overview

T

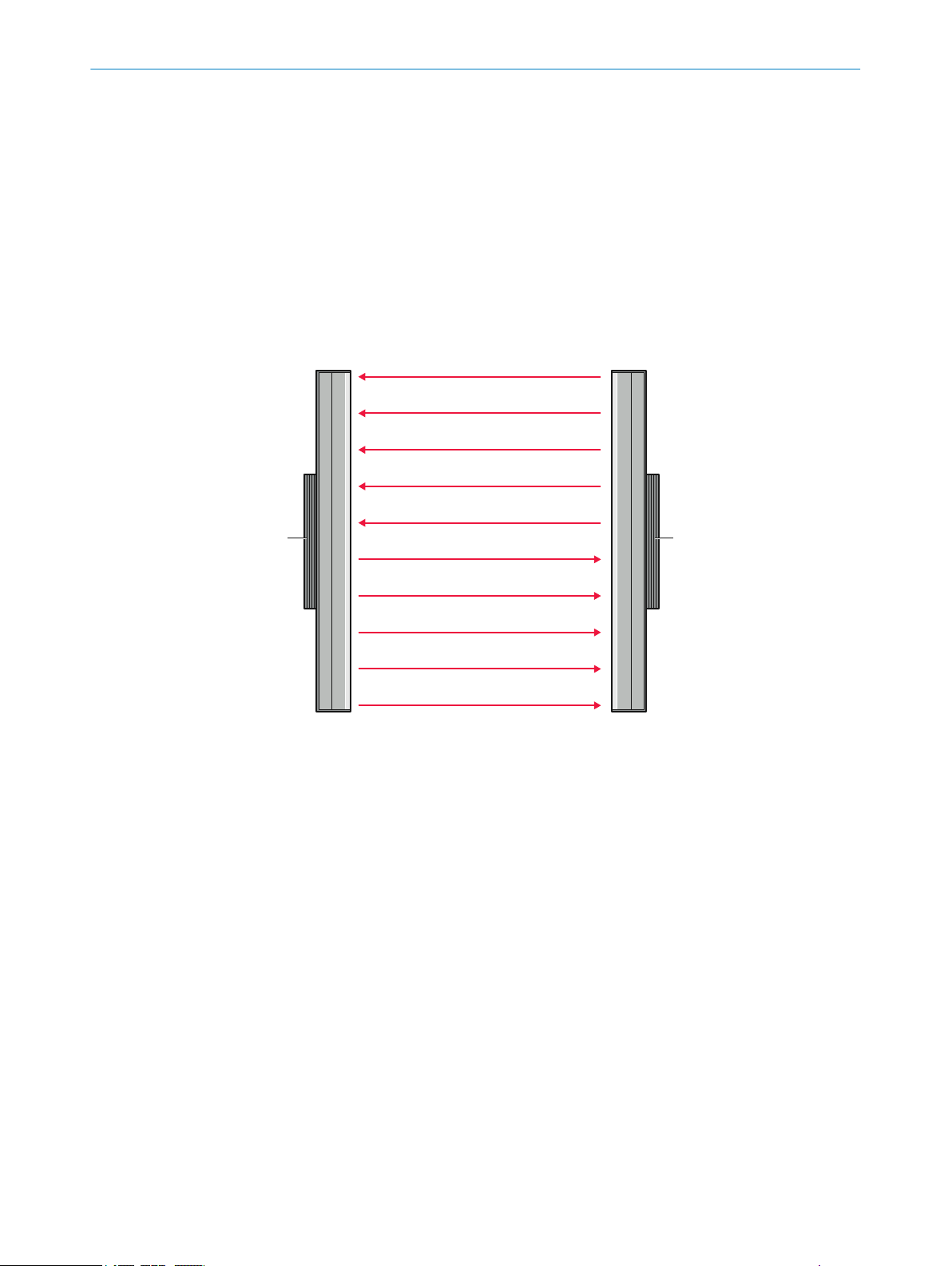

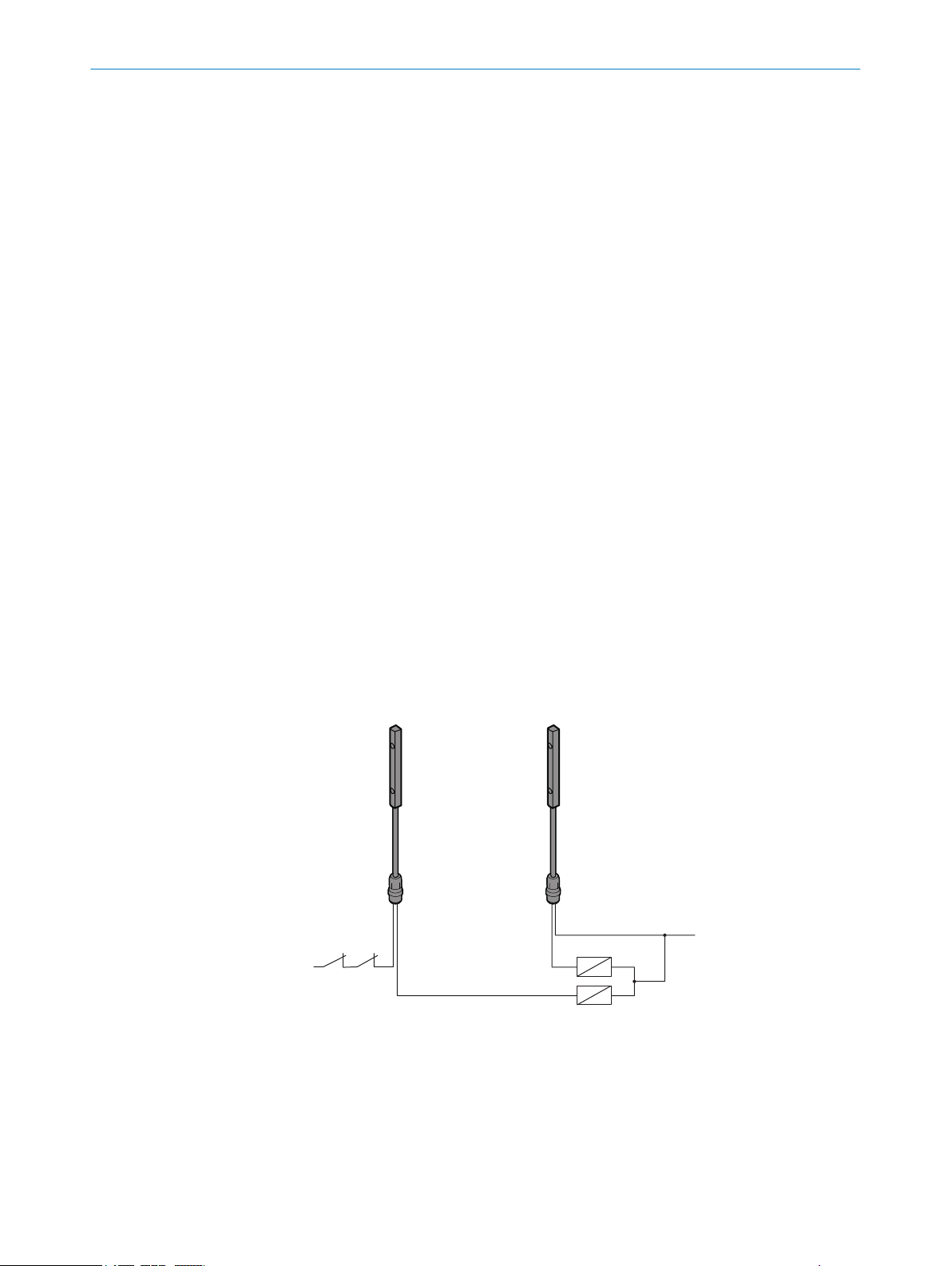

he miniTwin4 safety light curtain consists of 2 identical twin sticks. Each twin stick

contains both the sender as well as the receiver unit, see figure 1, page 11. The two

twin sticks are installed so that each sender and receiver unit are located opposite one

another.

PRODUCT DESCRIPTION 3

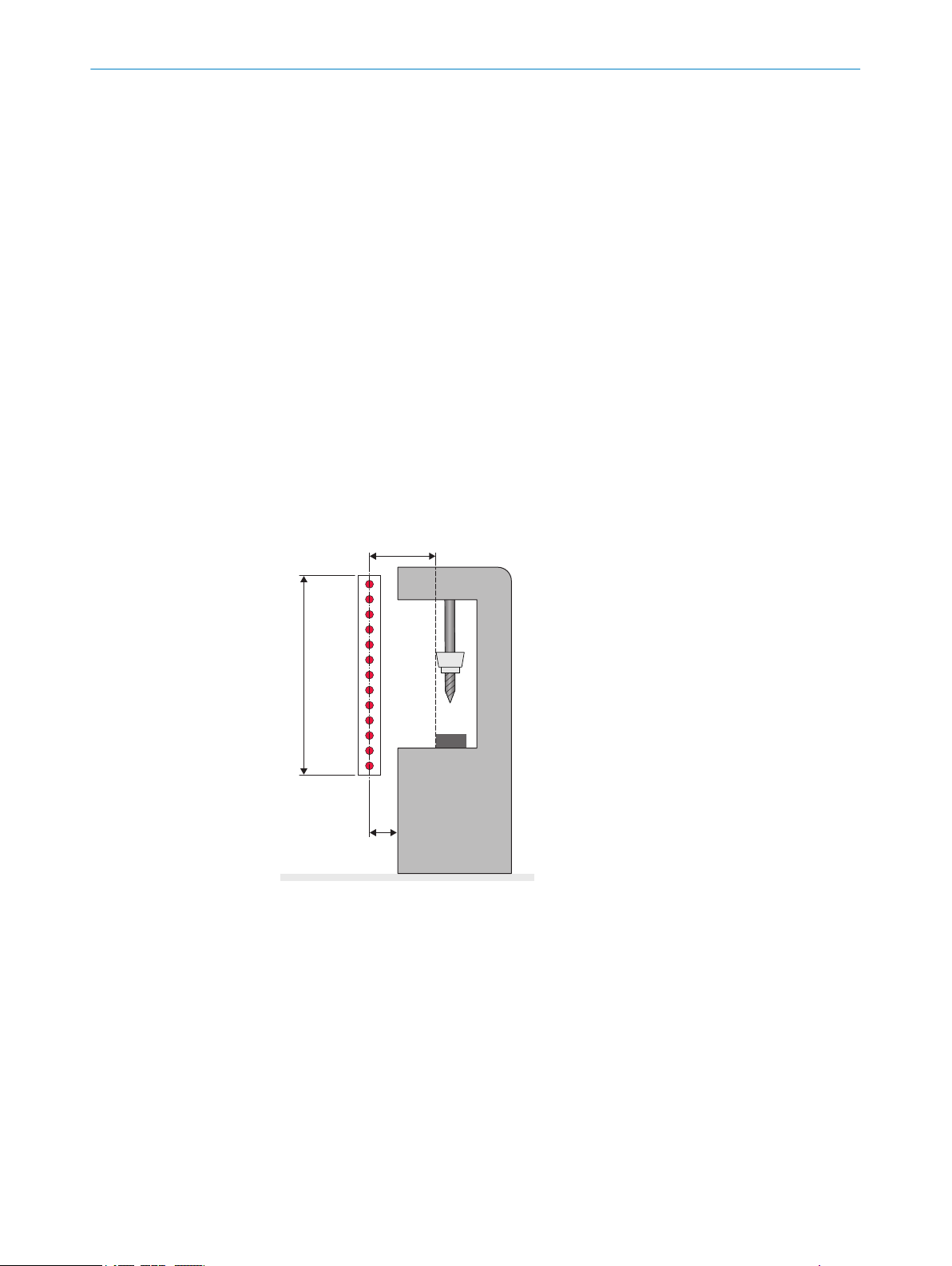

Figure 1: Device components of the safety light curtain

Twin stick

!

Safety light curtain principle

he protective field is between the two twin sticks and is defined by the protective field

T

height and the protective field width.

The two twin sticks automatically synchronize themselves optically. Each twin stick pro‐

vides an OSSD and a so-called multifunctional connection. The OSSDs are integrated

into the machine controller. Either a reset button or an EDM can be connected to the

multifunctional connections.

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

11

Page 12

O

SSD2

O

SSD1

§

$

!

"

3 P

RODUCT DESCRIPTION

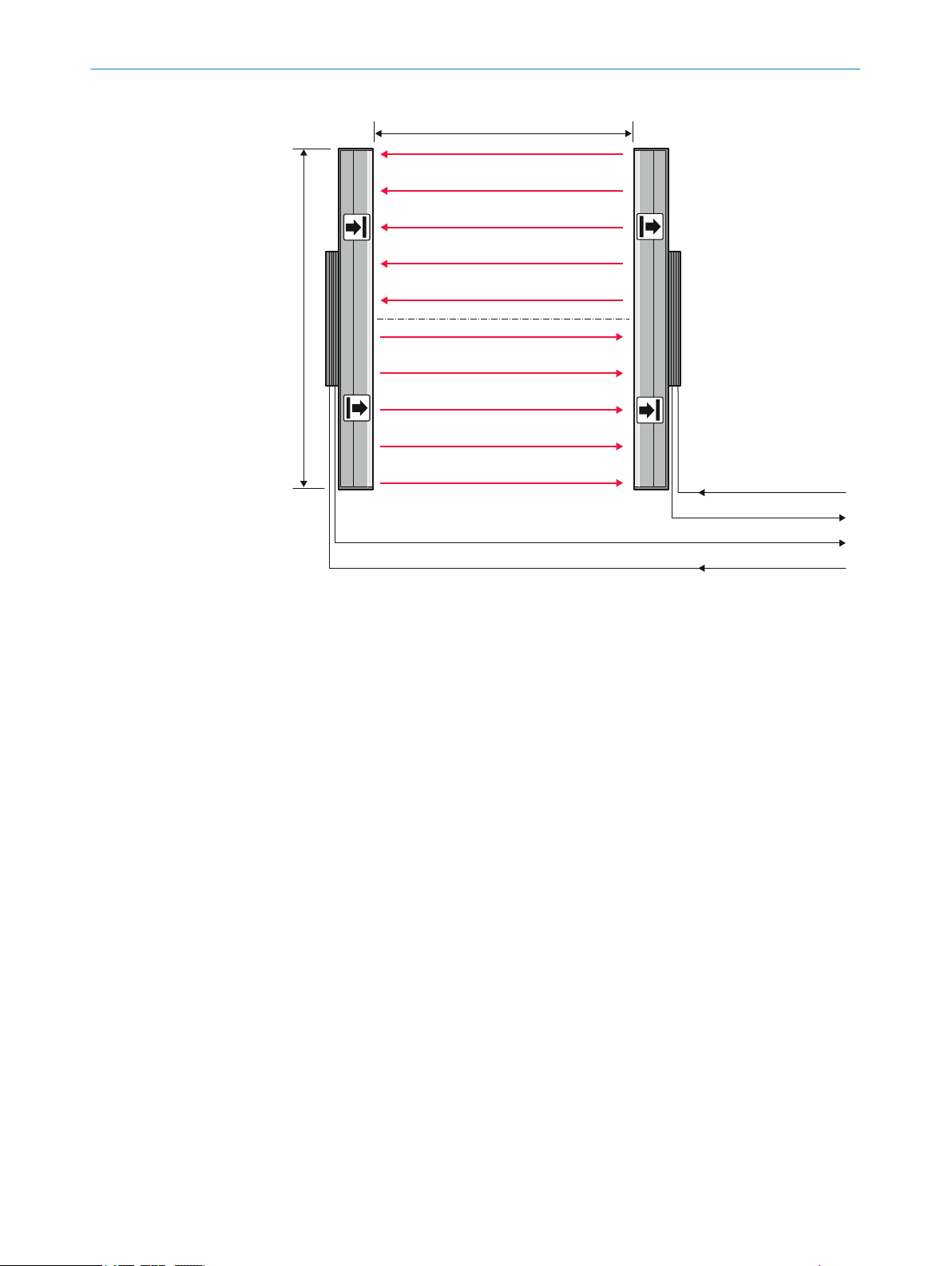

Figure 2: Safety light curtain principle

Protective field width

!

Protective field height

"

E.g. reset button

§

E.g. EDM

$

Protective field height

T

he protective field height indicates the range within which the test rod belonging to the

safety light curtain is reliably detected.

The size of the safety light curtain determines the protective field height.

Protective field width

T

he protective field width is the dimension of the light path between the twin sticks. The

maximum protective field width is limited by the scanning range.

Resolution

The resolution describes the size of the smallest object detected by the safety light cur‐

tain in the protective field. The resolution corresponds to the diameter of the test rod

belonging to the safety light curtain.

With the appropriate resolution, the safety light curtain provides finger and hand protec‐

tion.

12

Scanning range

The scanning range is the maximum protective field width. It is subject to the resolution

variant (14 mm or 30 mm).

The scanning range is reduced by the use of deflector mirrors and/or a weld spark

guard.

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 13

!

"

§

PRODUCT DESCRIPTION 3

Cross-circuit monitoring

T

he following prerequisites apply for cross-circuit monitoring:

Cross-circuit monitoring is only done for devices which have a supplementary

•

change number “(Rev. no.)” on the type label in the Ident No. field.

When combining several devices, all devices must have a supplementary change

•

number “(Rev. no.)” on the type label in the Ident No. field, otherwise cross-circuit

monitoring is not provided.

Prerequisites for the protective function of the safety light curtain miniTwin4

he miniTwin4 safety light curtain can only fulfill its protective function when the follow‐

T

ing requirements are satisfied:

It must be possible to electrically influence the control of the machine.

•

It must be possible to change the dangerous state of the machine into a safe

•

state.

The miniTwin4 safety light curtain must be arranged so that objects are reliably

•

detected upon entry into the hazardous area.

The reset button must be mounted outside of the hazardous area so that it cannot

•

be actuated by a person who is inside the hazardous area. In addition, the opera‐

tor must have a complete overview of the hazardous area when actuating the reset

button.

When setting up and using the devices, the applicable statutory and regulatory

•

requirements must be observed.

Further topics

ata sheet", page 89

"D

•

"Deflector mirrors", page 104

•

"Weld spark guard", page 99

•

"Technical data", page 89

•

"Dimensional drawings", page 94

•

3.2 Product characteristics

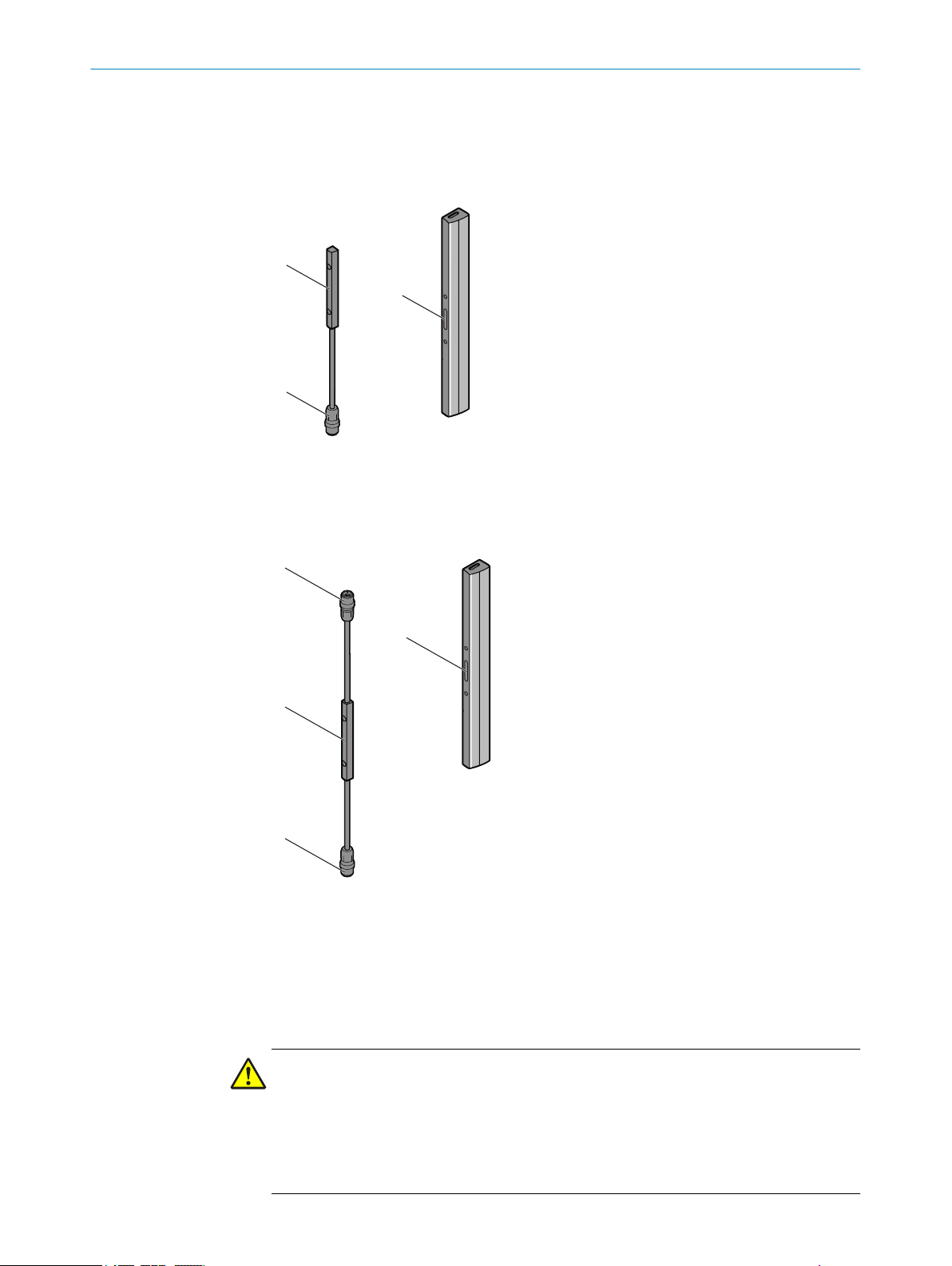

3.2.1 Device overview

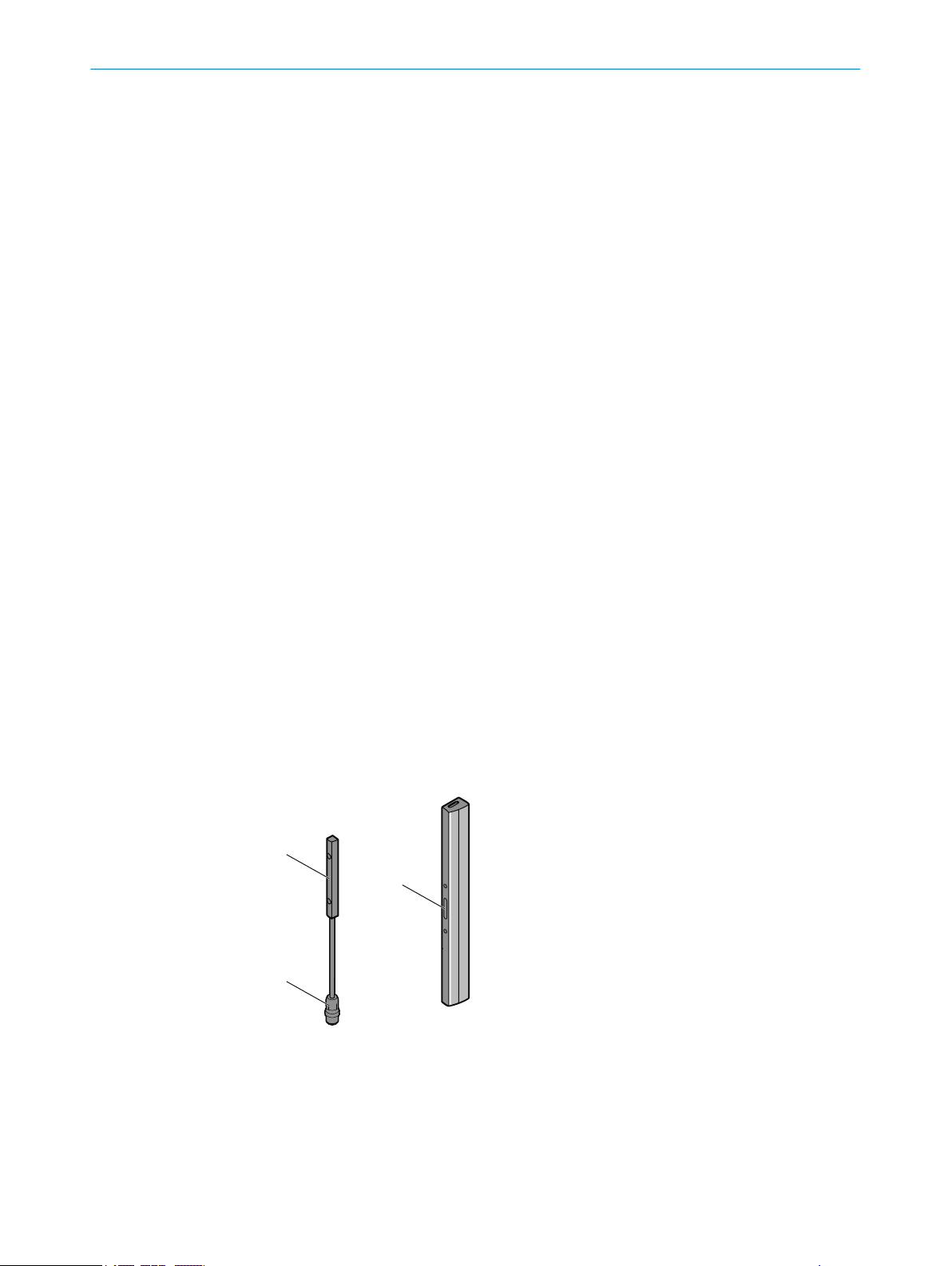

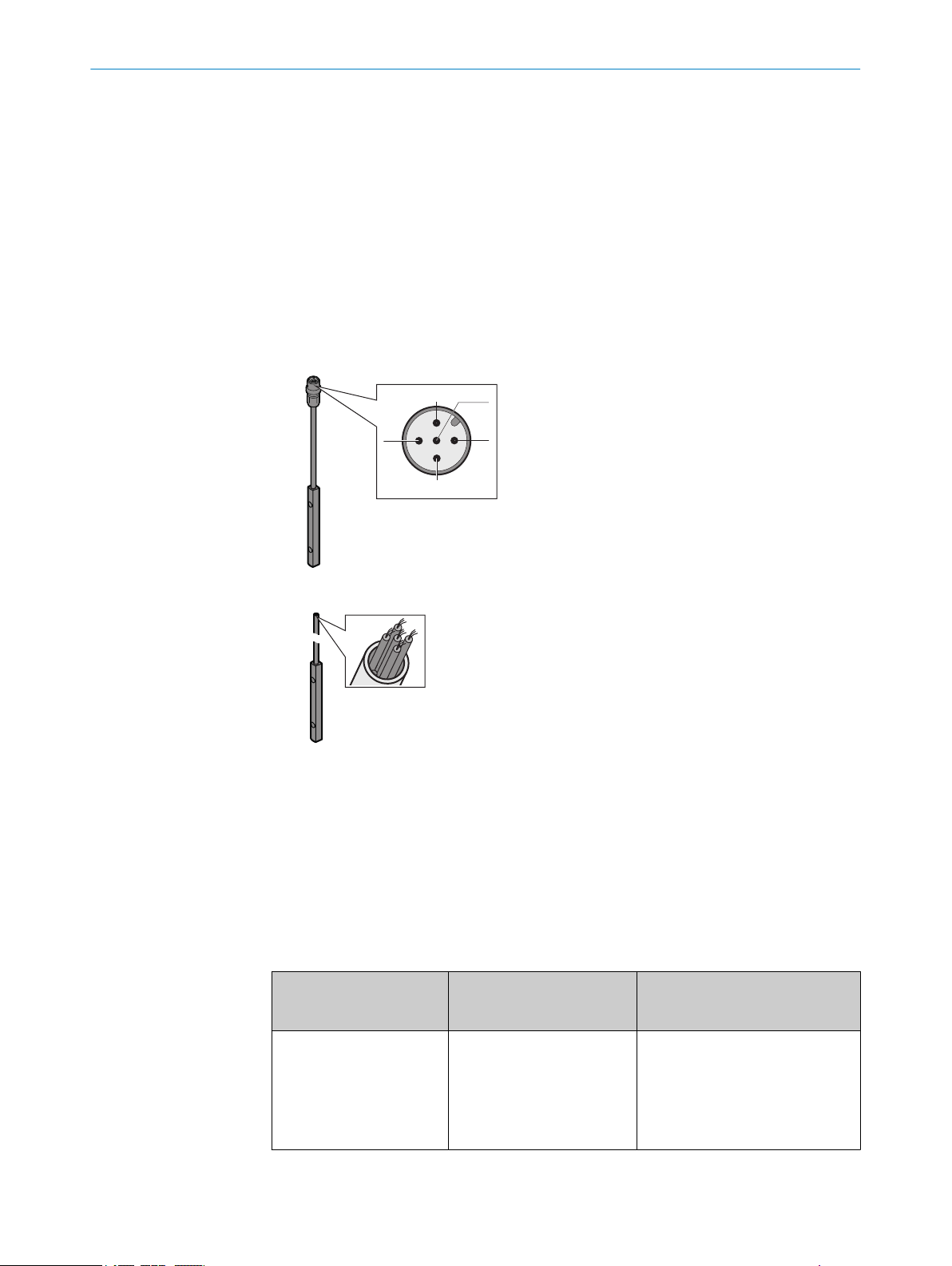

Figure 3: Device with system plug and system connection

System plug

!

System connection

"

Device connection

§

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

13

Page 14

!

$

"

§

3 P

RODUCT DESCRIPTION

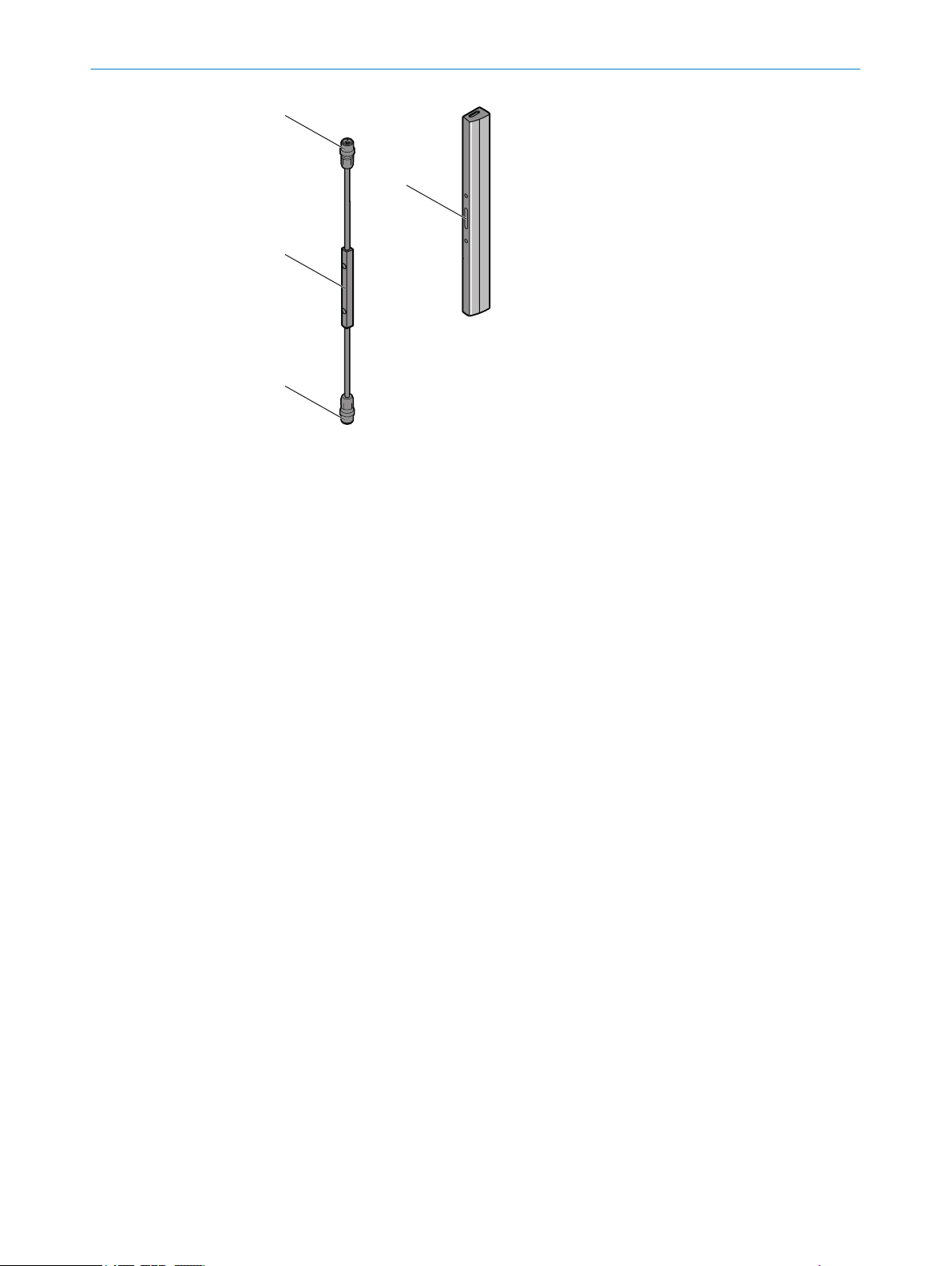

Figure 4: Device with system plug and system connection and one extension connection

Extension connection

!

System plug

"

System connection

§

Device connection

$

3.2.2 Absence of blind zones

The design and construction of the safety light curtain extends the protective function

t

o the end of the housing without any blind spots. The absence of blind zones reduces

the space requirement when integrated in the machine.

3.2.3 Beam coding

Depending on its configuration, the safety light curtain operates with 1 of 2 beam cod‐

in

gs: code 1 or code 2. In order to avoid mutual interference between 2 neighboring

safety light curtains, one can be operated with code 1 and the other with code 2.

3.2.4 Restart interlock

The safety light curtain has an integrated restart interlock. The function can be config‐

ur

ed during commissioning.

A restart interlock prevents the machine from starting again once the protective device

has been triggered. First, the operator must press a reset pushbutton to return the pro‐

tective device to monitoring status. Then, in a second step, the operator can restart the

machine.

The reset pushbutton can be connected locally to the extension connection or in the

control cabinet.

3.2.5 External device monitoring (EDM)

The safety light curtain has integrated external device monitoring. The function can be

c

onfigured during commissioning.

14

The external device monitoring (EDM) monitors the status of downstream contactors.

In order to use the external device monitoring, positively guided contactors must be

used to switch off the machine. If the auxiliary contacts of the positively guided contac‐

tors are connected to the external device monitoring, the external device monitoring

checks whether the contactors drop off when the OSSDs are switched off.

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 15

3.2.6 Cascading

FE

2

3

1

4

PRODUCT DESCRIPTION 3

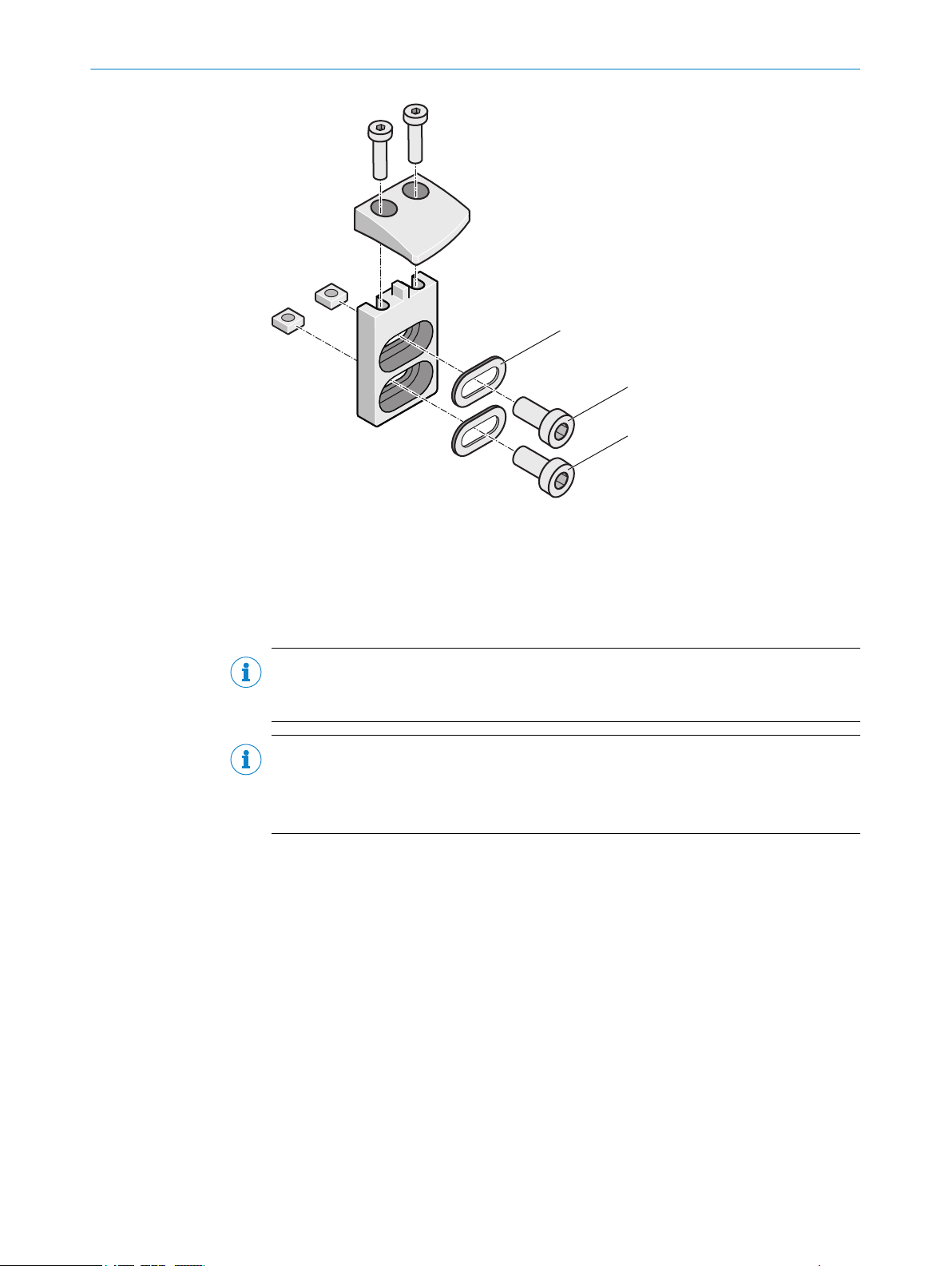

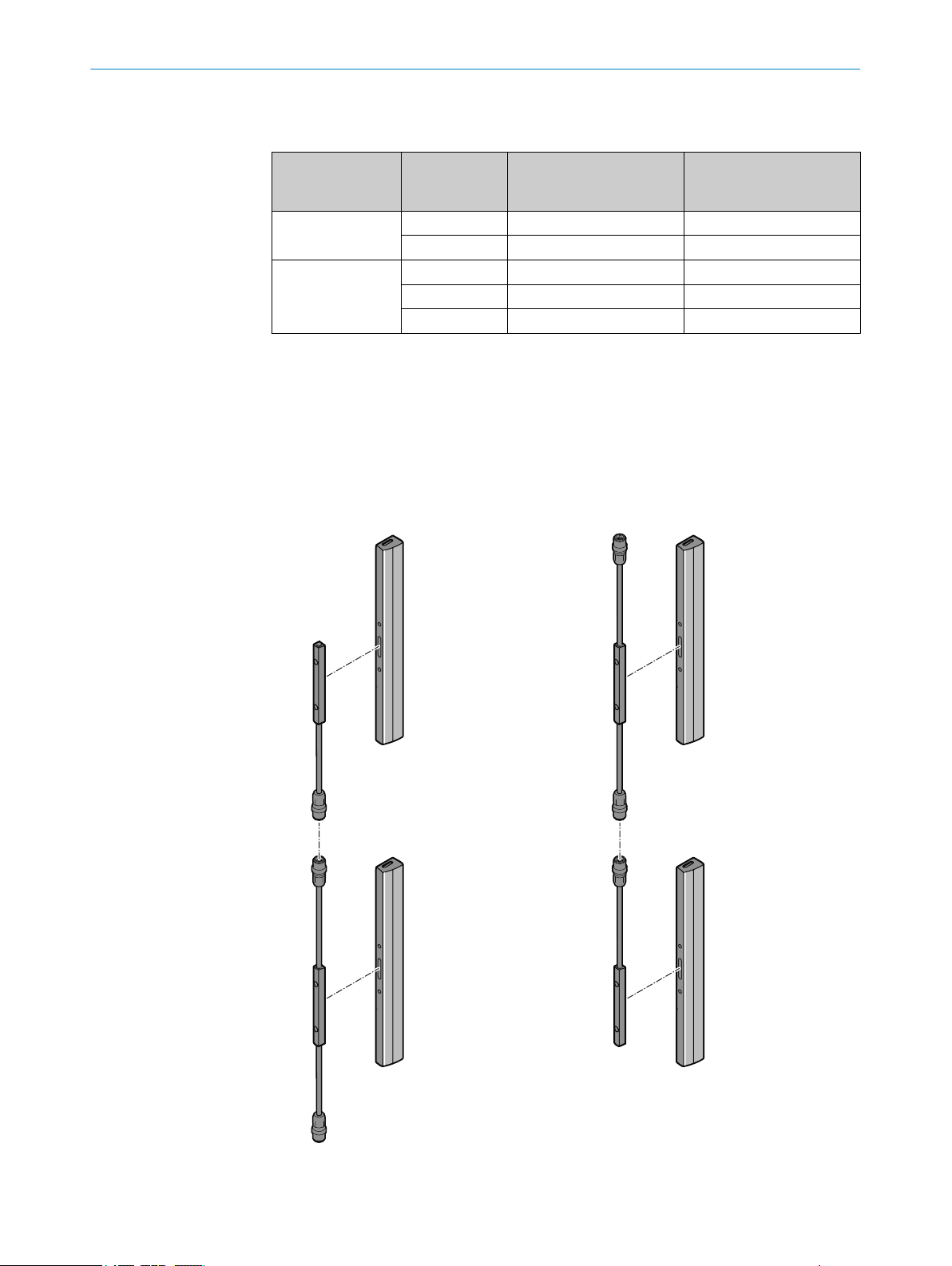

3.2.7 System plug

Cascading allows up to 3 safety light curtains to be connected in series, e.g. f

or reliable

presence detection. The device connected to the control cabinet is the host device. The

subsequent sensors are called guest 1 and guest 2.

Overview

T

he safety light curtain requires a system plug.

The system plug is available in the following variants:

System plug with 5-pin system connection (M12×4 + FE male connector)

•

System plug with one 5-pin system connection (M12×4 + FE male connector) and

•

one 5-pin extension connection (M12×4 + FE female connector)

Figure 5: System connection pin assignment

Figure 6: System connection wires

Pre-assembled cables with open ends are available for connecting applications.

Functions of the safety light curtain

he following functions are available depending on the system plug used:

T

Restart interlock

•

External device monitoring (EDM)

•

Cascading

•

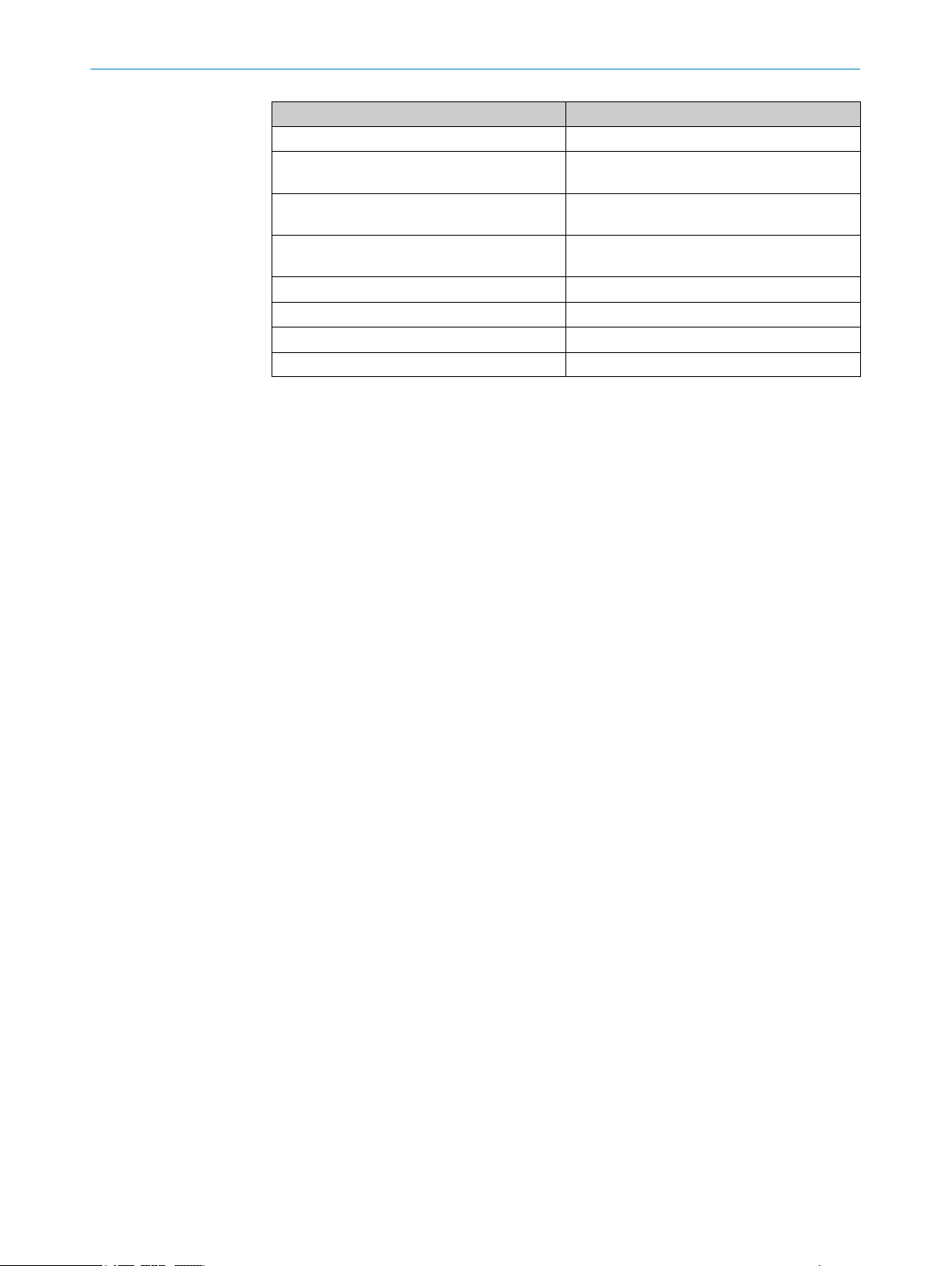

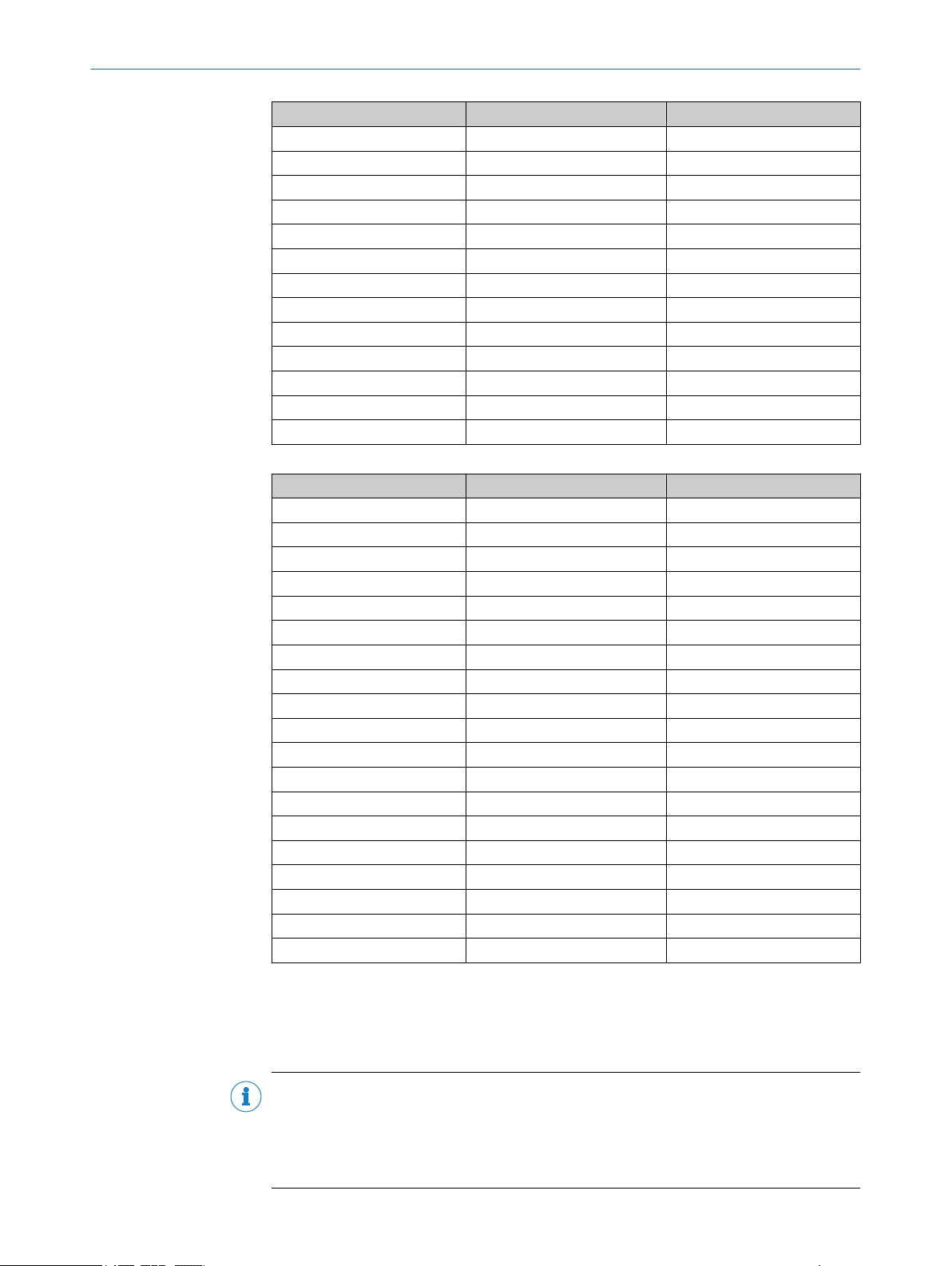

Table 1: Use of system plugs in a single system and in a cascade

System plug with 5-pin sys‐

em connection

t

Single system

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

✓

w

ithout additional func‐

•

tion

RES or EDM can option‐

•

ally be configured on a

twin stick

System plug with 5-pin system

connection and 5-pin extension

connection

–

15

Page 16

3 P

RODUCT DESCRIPTION

System plug with 5-pin sys‐

t

em connection

Host of a cascade –

First guest of a cascade

for cascade with 2 guest

(

devices)

Last guest of a cascade

✓

System plug suitable.

–

System plug not suitable.

–

✓

no addit

•

on the device

ional function

Further topics

"R

estart interlock", page 14

•

"External device monitoring (EDM)", page 14

•

"Cascading", page 15

•

"Connectivity", page 102

•

"Test rod check", page 41

•

3.2.8 Flexible control cabinet cabling and status indication on both sides

System plug with 5-pin system

connection and 5-pin extension

connection

✓

R

ES or EDM can optionally be

•

configured on a twin stick

✓

–

•

no addit

device

ional function on the

The safety light curtain can be connected to the control cabinet via separate connec‐

t

ion cables for each twin stick.

In a cascade, only the twin sticks of the host are connected to the control cabinet.

The OSSD status and the status of the protective field are indicated via LEDs, if applica‐

ble, the configured RES or EDM additional function is as well.

Further topics

"C

onnection diagrams", page 38

•

16

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 17

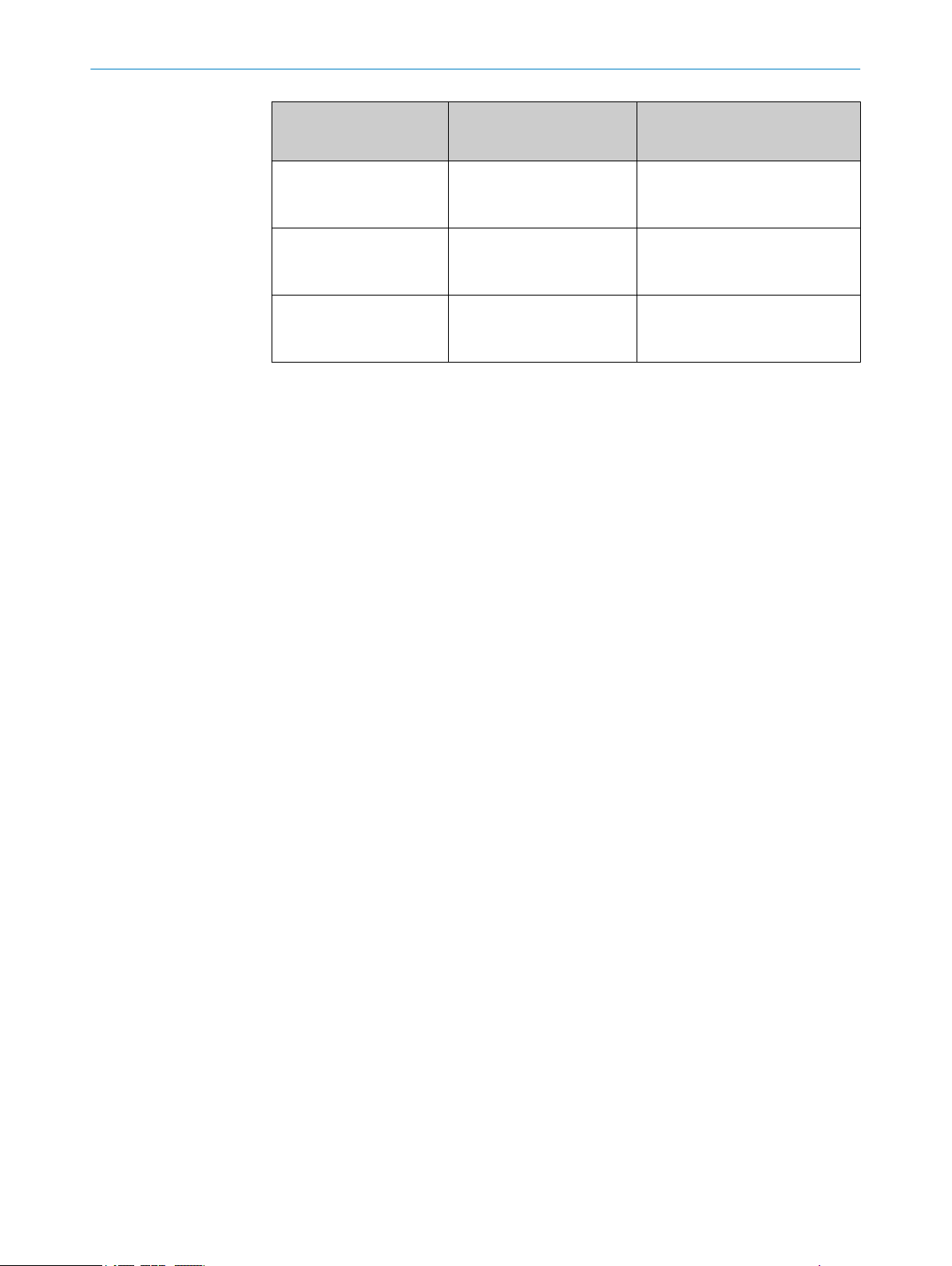

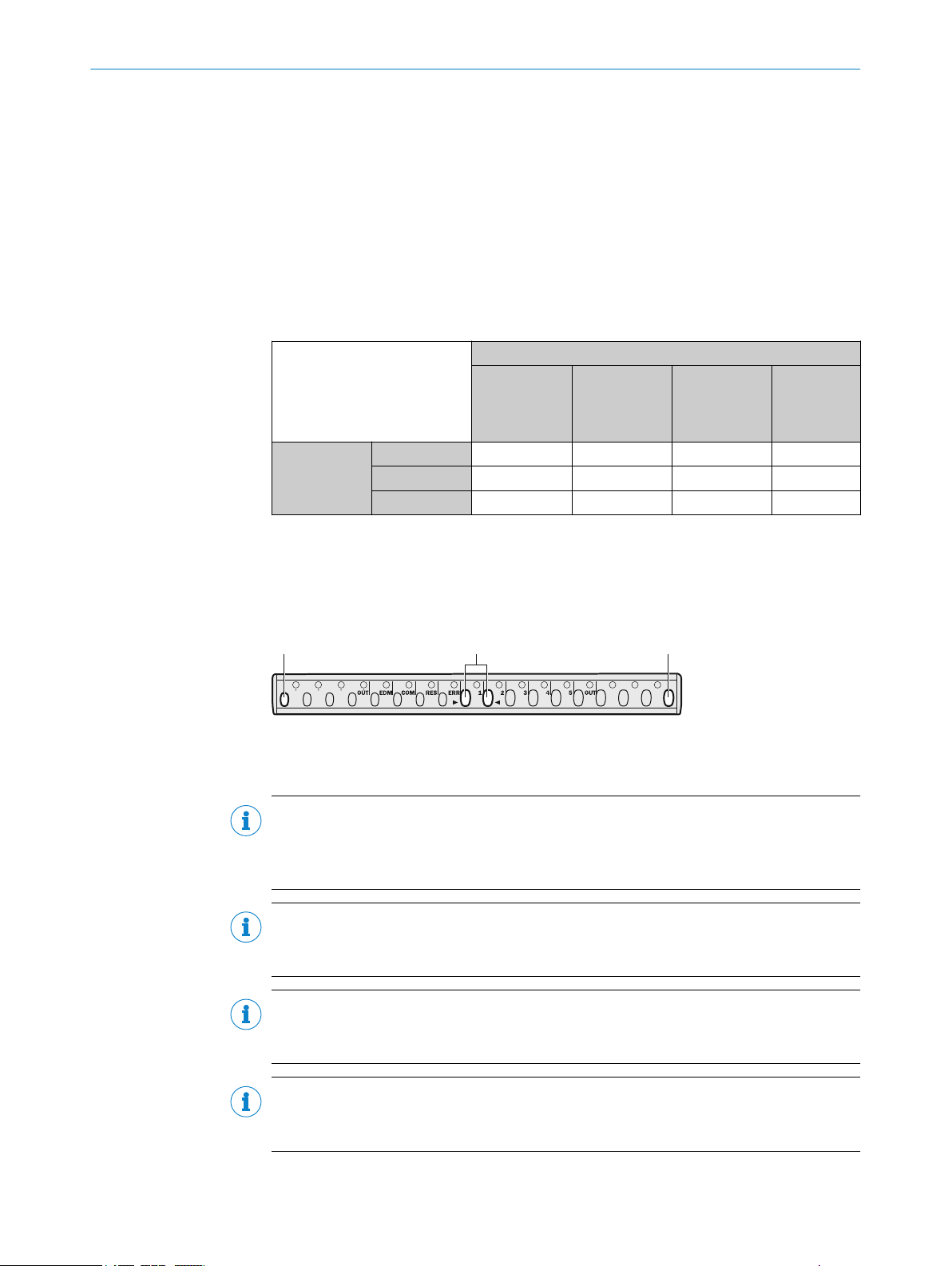

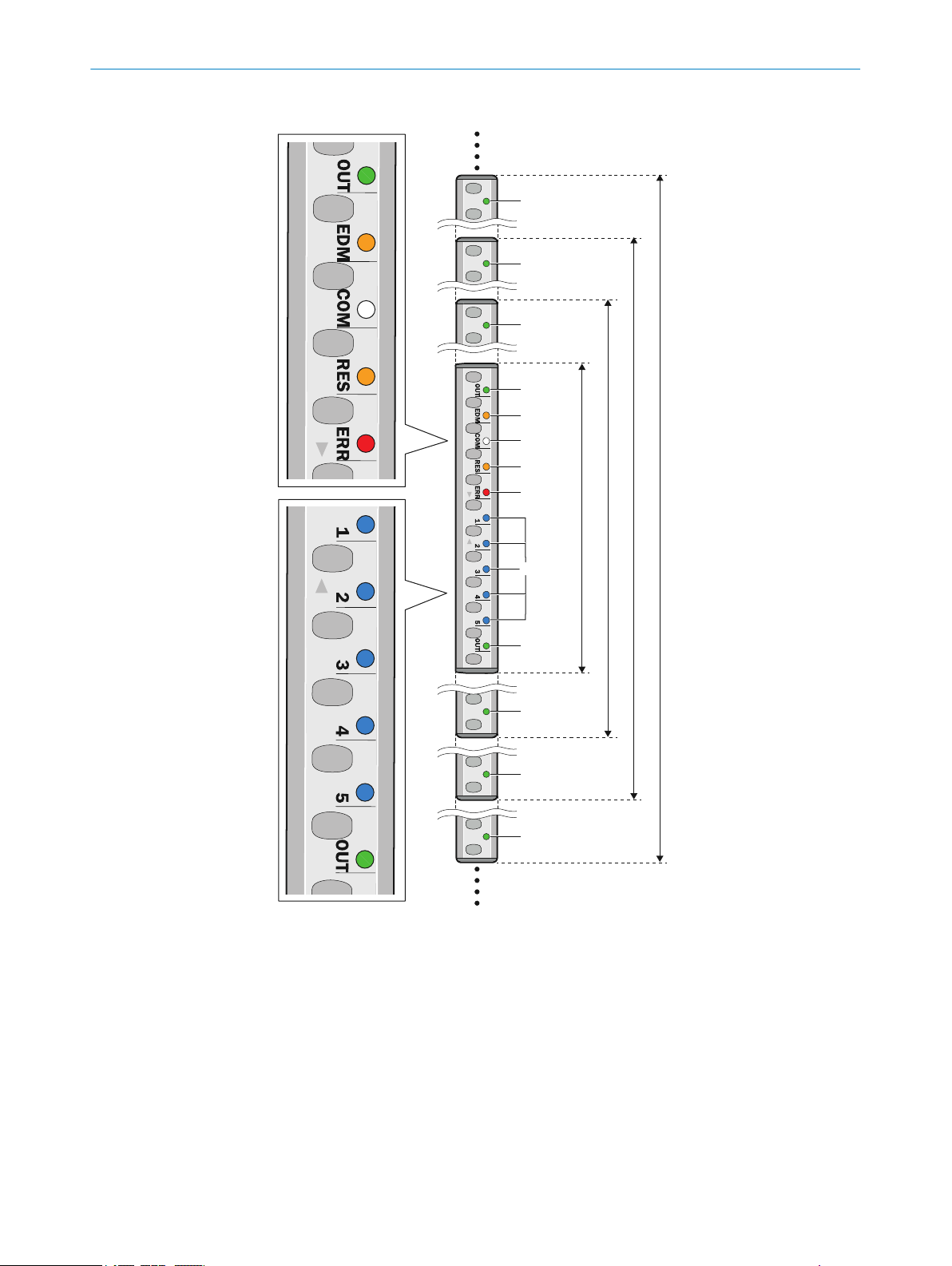

3.2.9 Status indicators

!

!

!

!

!

!

!

!

180 mm

300 mm

120 mm

240 mm

&

"

§

$

%

PRODUCT DESCRIPTION 3

Figure 7: LEDs on the twin sticks

!

"

§

$

%

&

OUT

EDM

COM

RES

ERR

1, 2, 3, 4, 5

figure 7 sho

ular intervals above a protective field height of 180 mm and can light up red or green. It

is only labeled OUT in two locations on the safety light curtain.

ws the LEDs of the safety light curtain. The OUT LED (!) is mounted at reg‐

Lit up LEDs indicate a specific status of the safety light curtain. Flashing LEDs demand

action.

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

17

Page 18

3 P

RODUCT DESCRIPTION

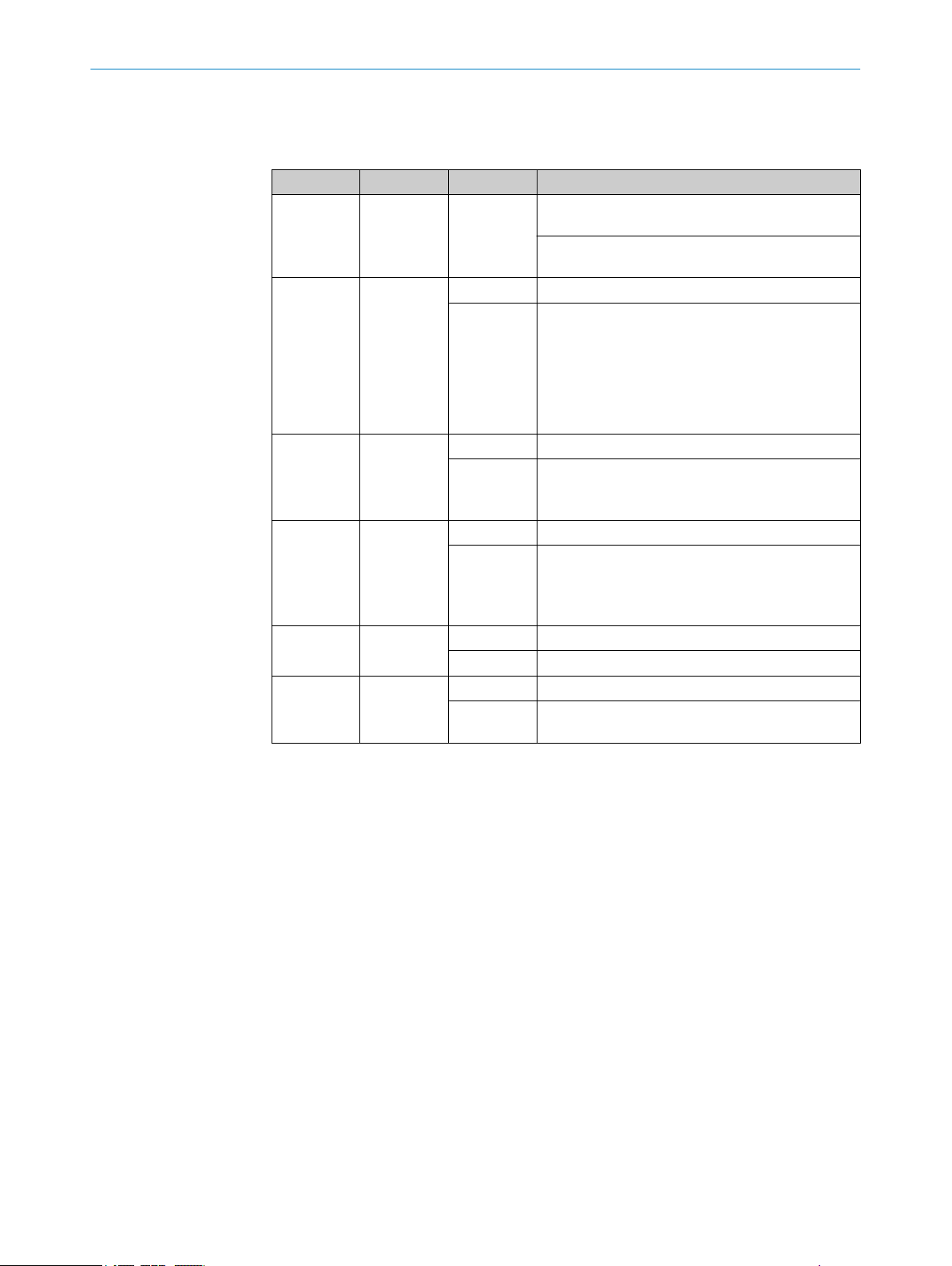

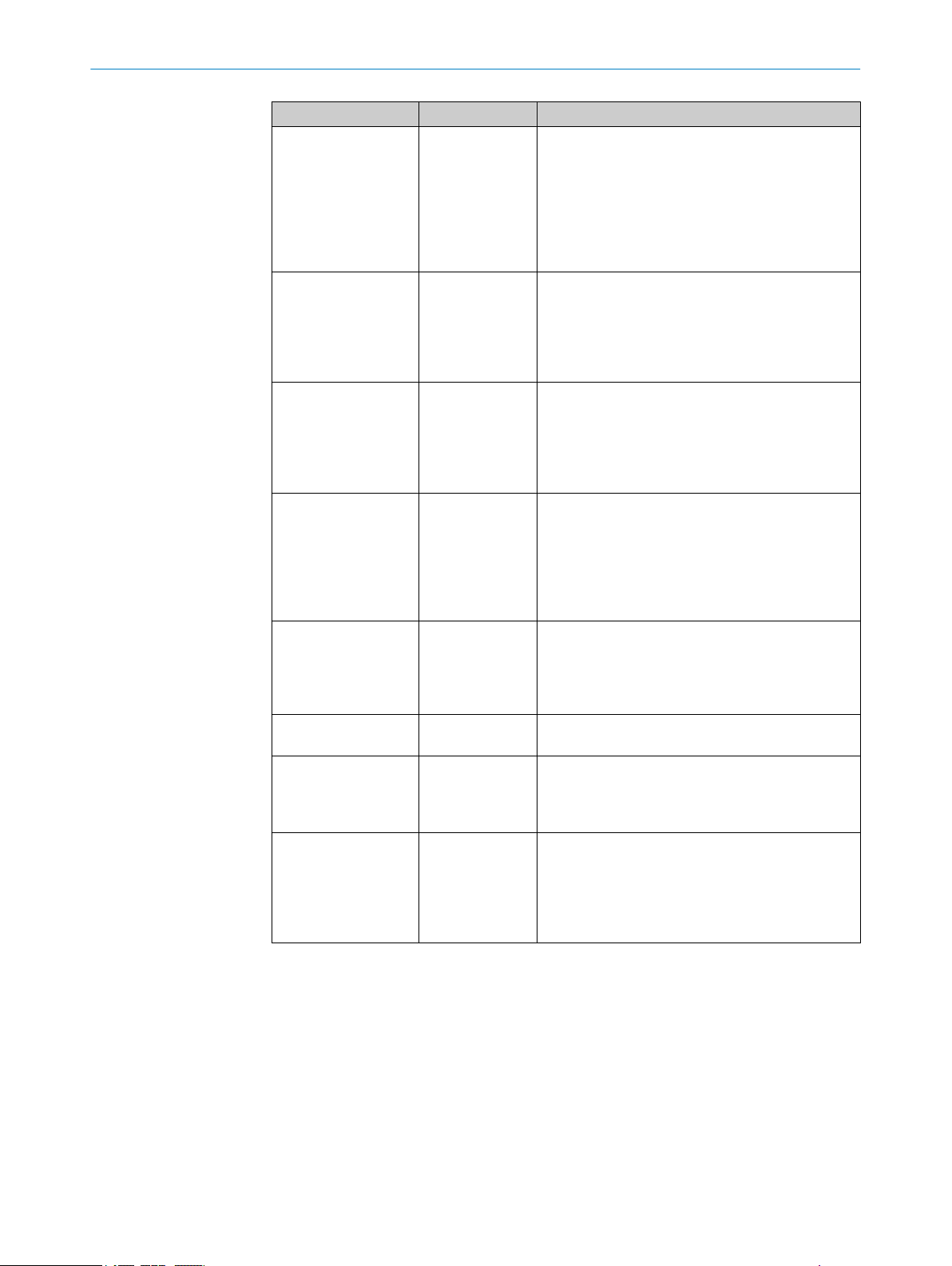

Table 2: Meaning of LEDs

Position LED Display Comment

!

"

§

$

%

&

OUT

EDM

COM

RES

ERR

1, 2, 3, 4, 5

O Gr

een

O Red

O Or

ange

Ö Or

ange

hite

O W

Ö W

hite

O Or

ange

Ö Or

ange

O Red

Ö R

ed

O Blue

Ö Blue In combination with ERR-LED Ö r

LED lights up green when protective field is free

SSD on).

(O

LED lights up red when protective field is inter‐

rupted (OSSD off).

External device monitoring configured.

For the configuration of EDM at the first OSSD sta‐

us change, the safety light curtain expects the

t

change from 24 V to 0 V at the multifunctional

input.

Or:

In combination with the ERR-LED Ö red: External

device monitoring reports defective contactor

External communication active (e.g. for service)

No optical communication to another twin stick .

Or:

eedback when deactivating configuration.

F

Reset configured.

Reset configured.

Or:

In combina

Ö orange: error with configuration or cabling.

Protective field interrupted.

Error.

Indication of the alignment quality.

error.

tion with ERR-LED Ö red and EDM-LED

ed: display of an

o LED of

f. Ö LED flashes. O LED illuminates.

Further topics

"Dia

•

•

•

gnostic LEDs", page 83

"Status indicators", page 17

"Aligning the twin sticks to one another", page 75

18

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 19

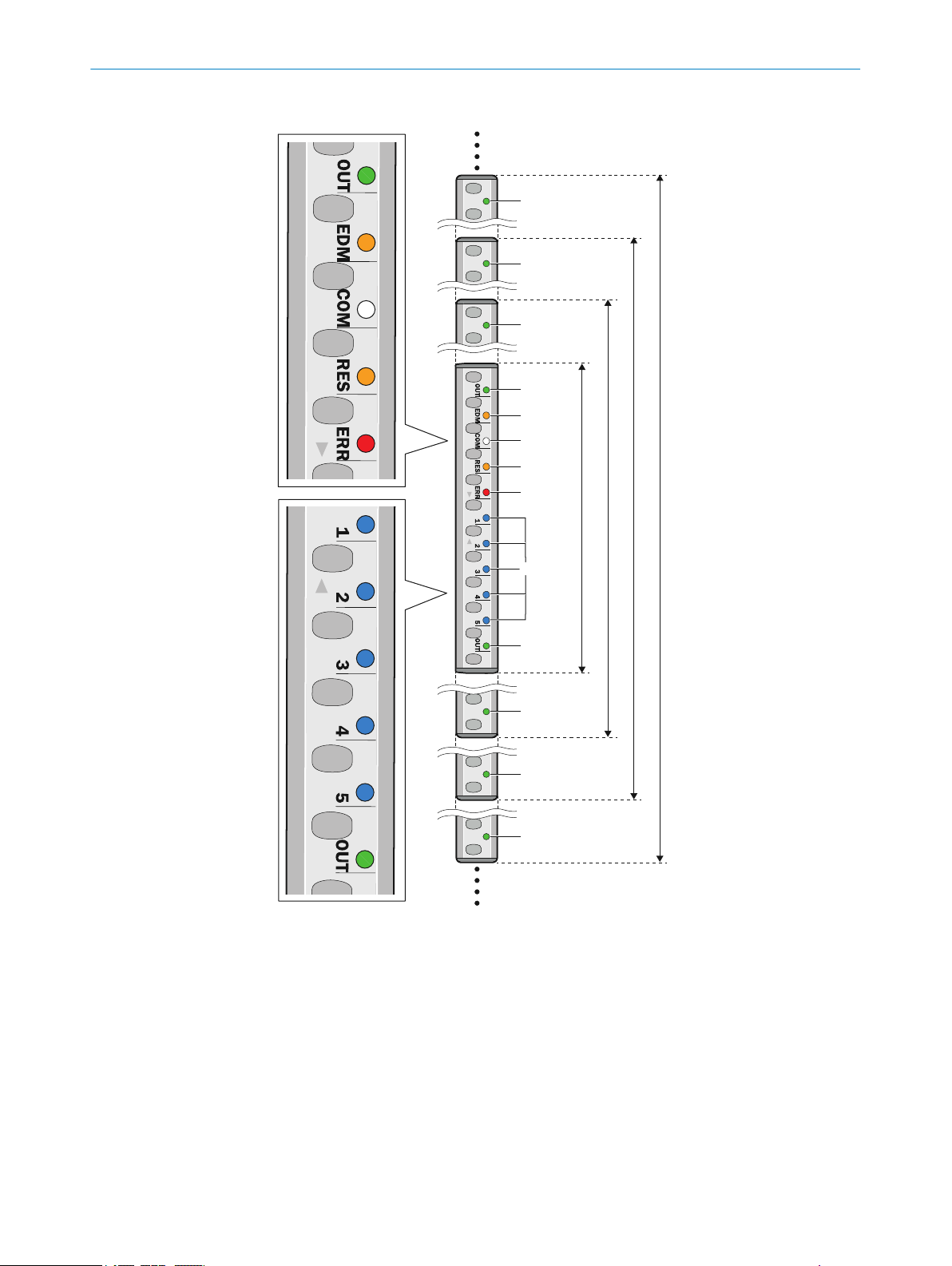

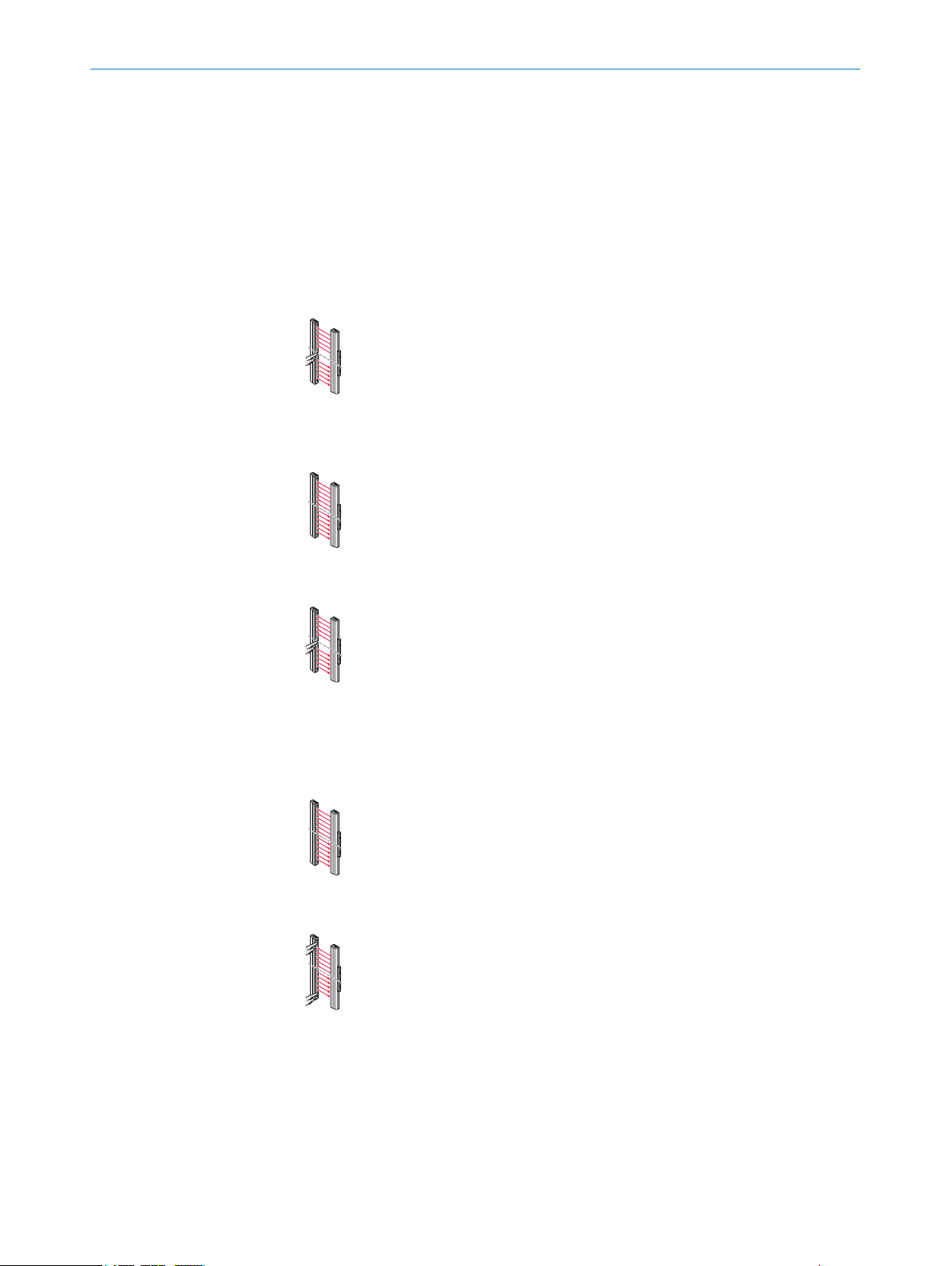

3.3 Example applications

PRODUCT DESCRIPTION 3

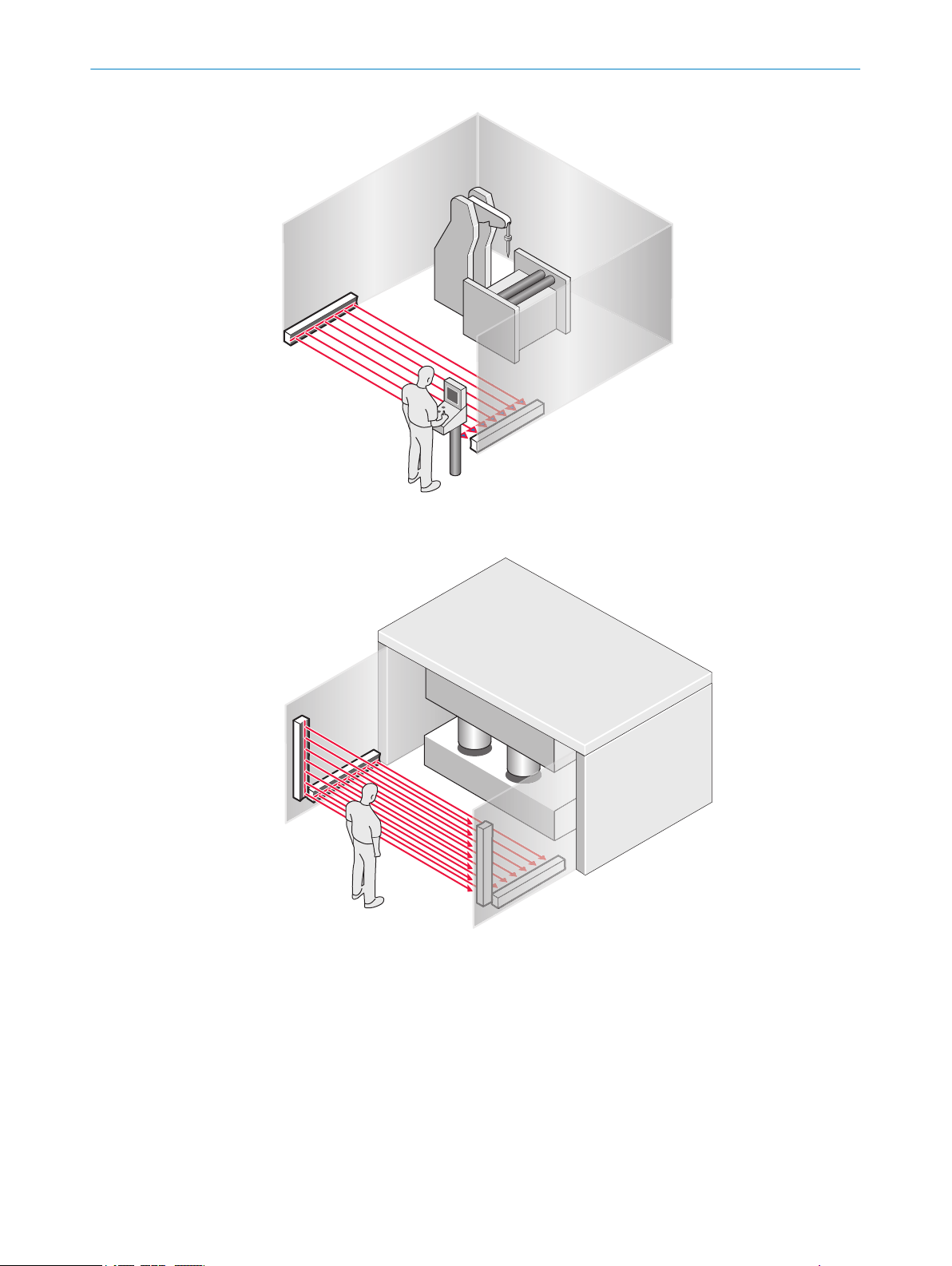

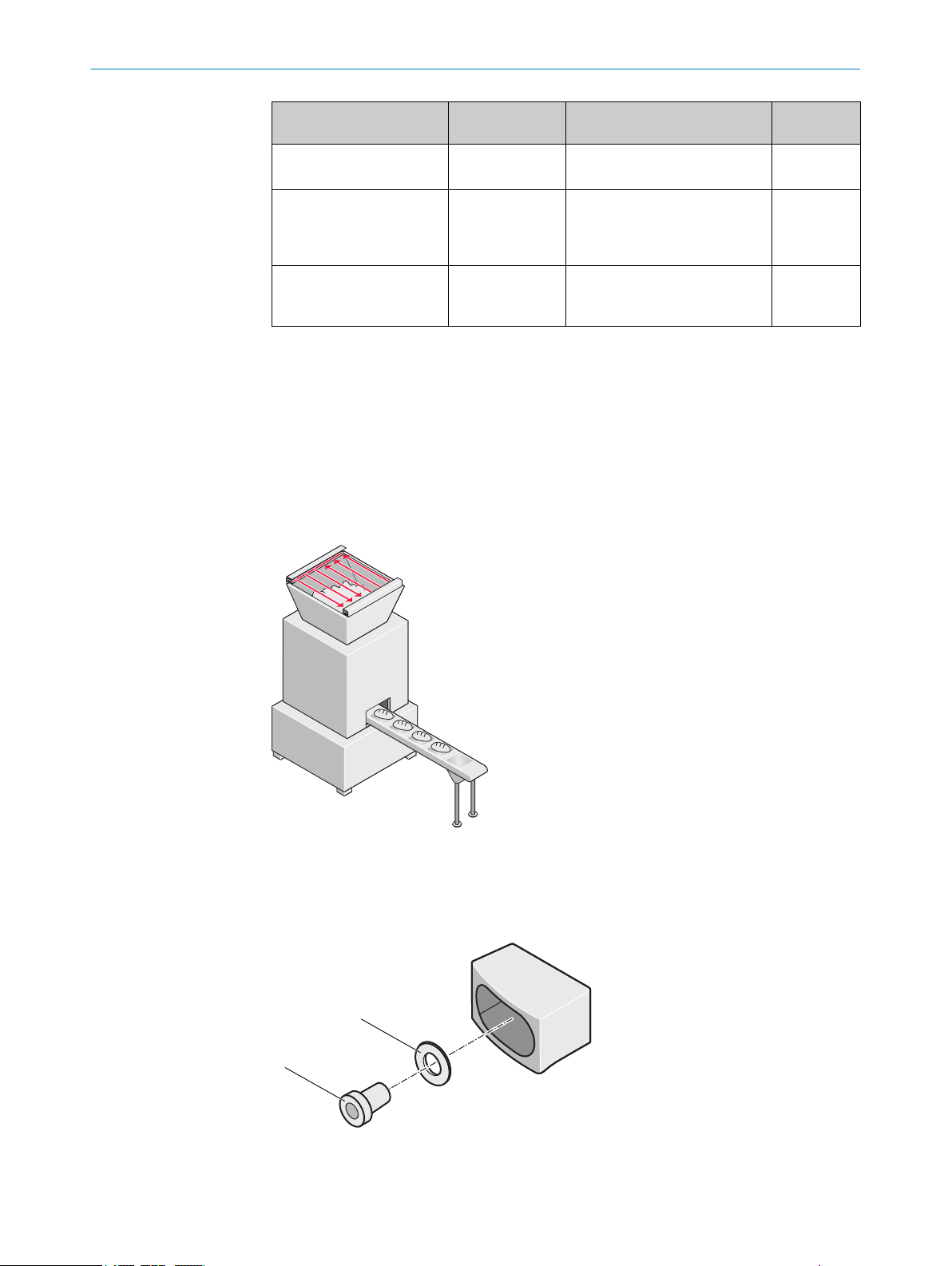

Figure 8: Hazardous point protection

Figure 9: Access protection

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

19

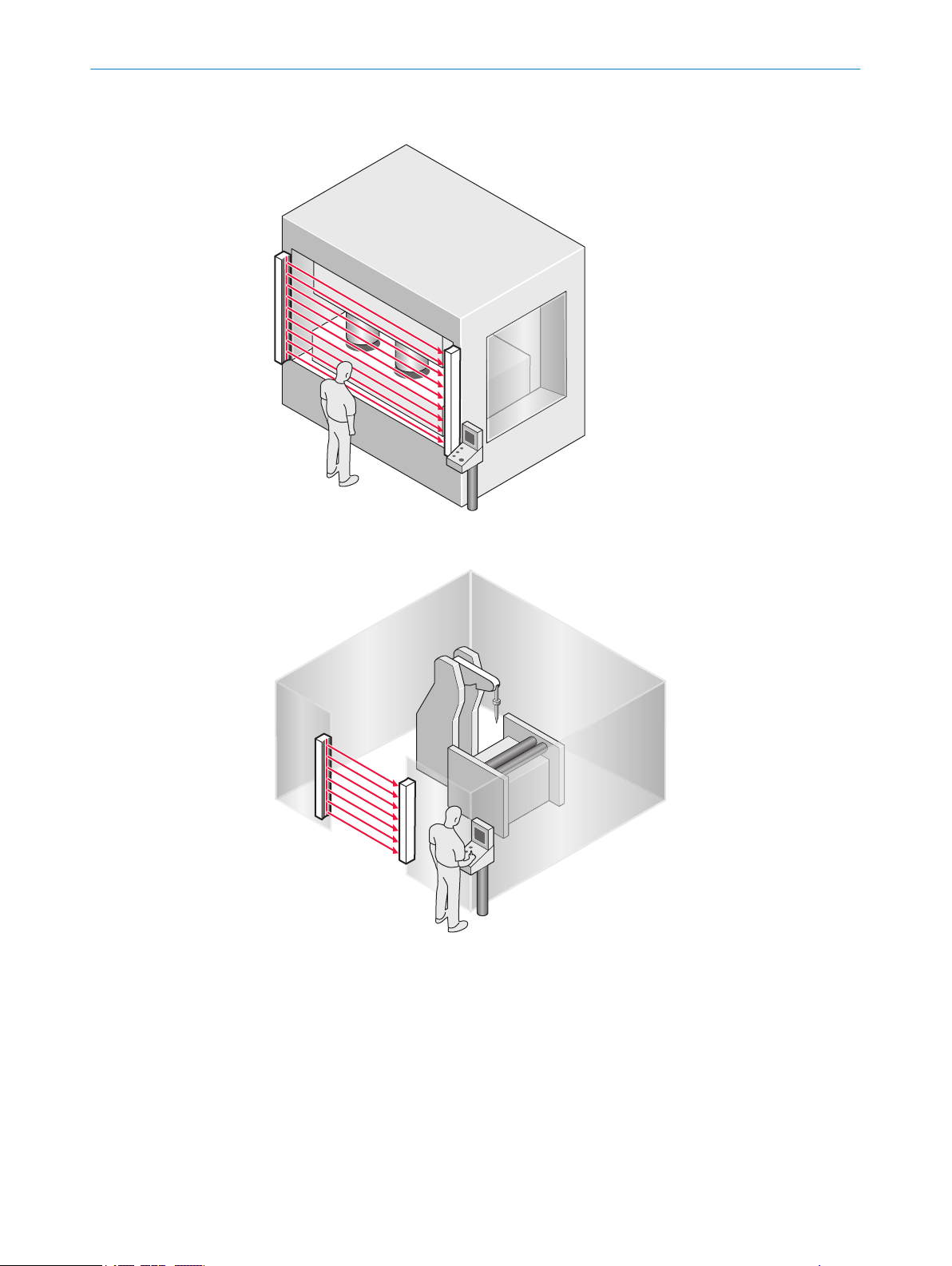

Page 20

3 PRODUCT DESCRIPTION

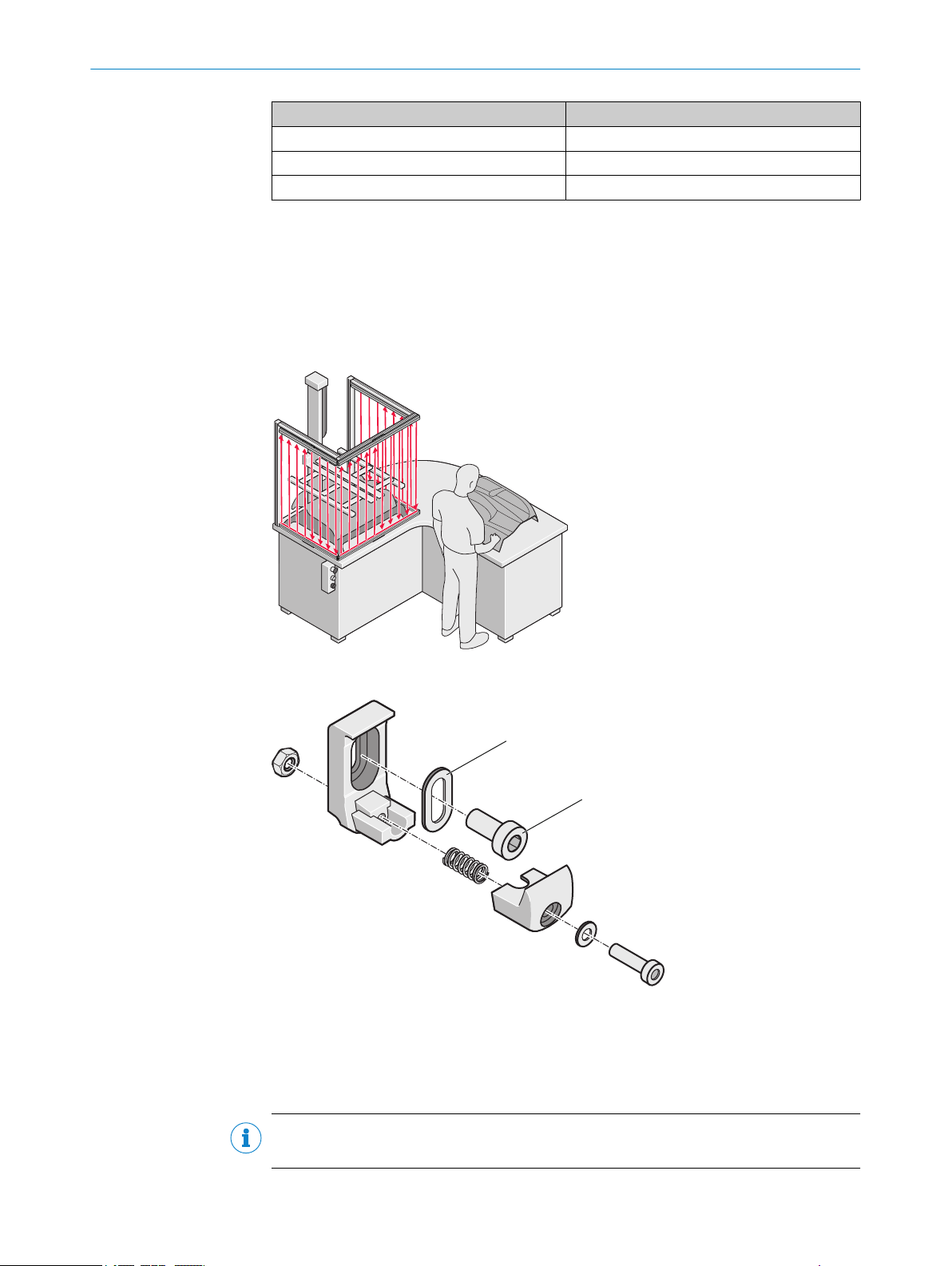

Figure 10: Hazardous area protection

Figure 11: Access protection with presence detection, implemented by cascade

20

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 21

4 Project planning

This chapter includes important information about the proper integration of the safety

ght curtain in machines for planners, developers and designers.

li

4.1 Manufacturer of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Conduct a risk assessment and check whether additional protective measures are

b

required.

Comply with the applicable national regulations derived from the application (e.g.,

b

work safety regulations, safety rules, or other relevant safety guidelines).

Do not combine the components of the safety light curtain with components from

b

other safety light curtains.

Apart from for the procedures described in this document, the components of the

b

safety light curtain must not be opened.

The components of the safety light curtain must not be tampered with or changed.

b

Do not carry out any repairs on the device components. Improper repair of the pro‐

b

tective device can lead to a loss of the protective function.

PROJECT PLANNING 4

4.2 Operator of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Changes to the electrical integration of the safety light curtain in the machine con‐

b

trol and changes to the mechanical installation of the safety light curtain require

another risk assessment. The results of this risk assessment may require the

operator of the machine to meet the obligations of a manufacturer.

Apart from the procedures described in this document, the components of the

b

safety light curtain must not be opened.

The components of the safety light curtain must not be tampered with or changed.

b

Do not carry out any repairs on the device components. Improper repair of the pro‐

b

tective device can lead to a loss of the protective function.

4.3 Design

Overview

T

his chapter contains important information about the design.

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

21

Page 22

4 PROJECT PLANNING

Important information

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Make sure that the following construction requirements are met so that the safety

b

light curtain can fulfill its protective function.

Twin sticks must be arranged such that persons or parts of the body are reli‐

°

ably detected when they enter the hazardous area.

Reaching under, over, and around as well as moving the safety light curtain

°

must be prevented.

Check whether additional safety measures (e.g. restart interlock) are neces‐

°

sary when it is possible for people to be located between the protective

device and the danger point without being detected.

DANGER

H

azard due to lack of effectiveness of the protective device

Certain types of light radiation can influence the protective device, e.g., light radiation

from fluorescent lamps with electronic ballast installed in the path of the beam, or

beams from laser pointers directed at the receiver unit of a twin stick.

If this type of light radiation is present in the environment of the protective device,

b

take additional measures to ensure that the protective device does not become

dangerous.

Further topics

"Mount

•

4.3.1 Scanning range and protective field width

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The safety light curtain can only be mounted on machines on which the protective

b

field width does not change when the safety light curtain is switched on.

Scanning range

he scanning range limits the maximum protective field width.

T

The scanning range is reduced by the use of deflector mirrors and/or a weld spark

guard.

ing", page 44

22

Protective field width

T

he protective field width is the dimension of the light path between the twin sticks of a

system.

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 23

Further topics

"T

echnical data", page 89

•

"Deflector mirrors", page 104

•

"Weld spark guard", page 99

•

4.3.2 Minimum distance from the hazardous point

Overview

PROJECT PLANNING 4

A minimum dis

ardous point. This distance is required to prevent a person or part of their body from

reaching the hazardous point before the end of the machine’s dangerous state.

Calculating the minimum distance according to ISO 13855

The calculation of the minimum distance is based on international or national stan‐

dards and statutory requirements applicable at the place of installation of the machine.

If the minimum distance is calculated according to ISO 13855, it depends on the fol‐

lowing points:

Machine stopping time (time interval between triggering the sensor function and

•

the end of the machine’s dangerous state)

Response time of the protective device

•

Reach or approach speed of the person

•

Resolution (detection capability) of the safety light curtain

•

Type of approach: orthogonal (at right angles) or parallel

•

Parameters specified based on the application

•

For the USA (scope of OSHA and ANSI), different regulations may apply, e.g.:

a) Laws: Code of Federal Regulations, Title 29 (CFR 29), Part 1910.217

b) Standards: ANSI B11.19

Complementary information

A

dditional information is available in the ISO 13855 standard and in the Guide for Safe

Machinery.

tance must be maintained between the safety light curtain and the haz‐

SICK offers a stopping/run-down time measurement service in many countries.

Further topics

"R

esponse time", page 91

•

4.3.2.1 Calculating minimum distance from the hazardous point

Important information

DANGER

Minimum distance from the hazardous point is too small

The dangerous state of the machine may not be stopped or not be stopped in a timely

manner due to a minimum distance that is too small.

Calculate the minimum distances for the machine in which the safety light curtain

b

is integrated.

When mounting the safety light curtain, observe the minimum distance.

b

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

23

Page 24

!

"

§

S

4 P

ROJECT PLANNING

Approach

T

he example shows the calculation of the minimum distance in accordance with ISO

13855 for an orthogonal (right-angled) approach to the protective field. A different cal‐

culation may be required depending on the application and the ambient conditions

(e.g., for a protective field parallel to or at any angle to the direction of approach or an

indirect approach).

1. First calculate S with the following formula:

S = 2,000 mm/s × T + 8 ×(d – 14 mm)

where:

S = minimum dis

°

T = machine stopping time + response time of the protective device after

°

interruption in the light path in seconds (s)

d = resolution of the safety light curtain in millimeters (mm)

°

The reach or approach speed is already included in the formula.

tance in millimeters (mm)

2. If the result S is ≤ 500 mm, then use the determined value as the minimum dis‐

ance.

t

3. If the result S is > 500 mm, then recalculate S as follows:

S = 1,600 mm/s × T + 8 ×(d – 14 mm)

4. If the new value S is > 500 mm, then use the newly determined value as the mini‐

mum distance.

5. If the new value S is ≤ 500 mm, then use 500 mm.

24

Figure 12: Minimum distance to hazardous point for orthogonal (right-angled) approach to pro‐

t

ective field

Protective field height

!

Hazardous point

"

Depending on the application and distance, persons must be prevented from standing

§

behind the protective device.

Example calculation

Mac

hine stopping time = 290 ms

Response time after interruption of the light path = 30 ms

Resolution of the safety light curtain = 14 mm

T = 290 ms + 30 ms = 320 ms = 0.32 s

S = 2,000 mm/s × 0.32 s + 8 × (14 mm – 14 mm) = 640 mm

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 25

S > 500 mm, therefore:

rs

D

a

S = 1,600 mm/s × 0.32 s + 8 × (14 mm – 14 mm) = 512 mm

4.3.2.2 Taking reach over into account

In accordance with ISO 13855, it must not be possible to defeat the ESPE. If access to

t

he hazardous area by reaching over a protective field cannot be prevented, the height

of the protective field and minimum distance of the ESPE must be determined. This is

done by comparing the calculated values based on the possible detection of limbs or

body parts with the values resulting from reaching over the protective field. The greater

value resulting from this comparison must be used.

PROJECT PLANNING 4

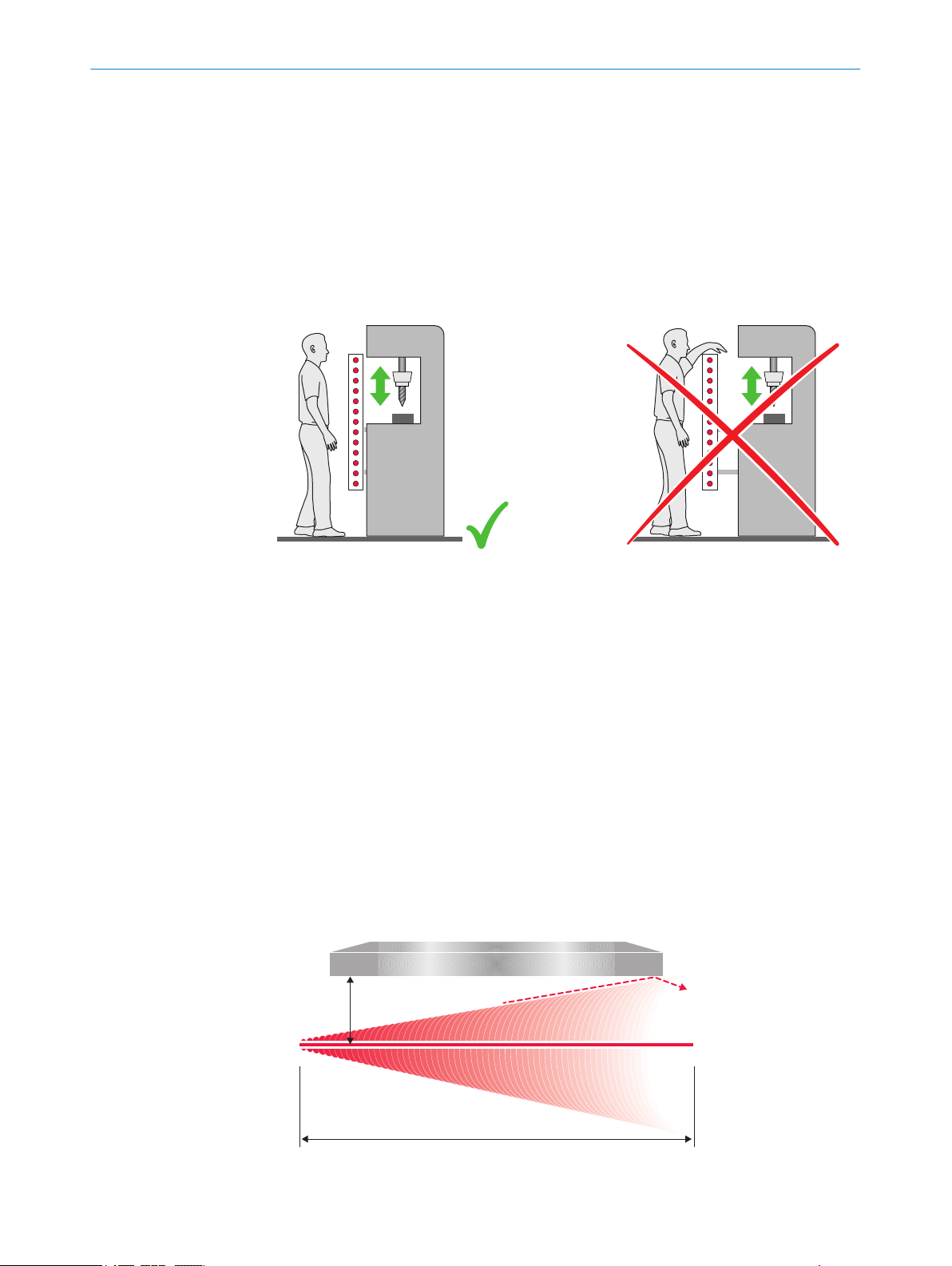

Figure 13: Representation of the accessibility of electro-sensitive protective device by reaching

ver. Left: Protective field that cannot be reached over. Right: Protective field that can be reached

o

over.

4.3.3 Minimum distance from reflective surfaces

Overview

T

he light beams from the sender unit may be deflected by reflective surfaces and dis‐

persive media. This can prevent an object from being detected.

Therefore, all reflective surfaces and objects (e.g. material bins, machine table, etc.)

must maintain a minimum distance (a) from the protective field. This minimum dis‐

tance (a) must be maintained on all sides of the protective field. This applies in horizon‐

tal, vertical and diagonal directions as well as at the end of the safety light curtain. The

same area must be free of dispersive media (e.g., dust, fog, or smoke).

The minimum distance (a) depends on the distance (D) between the twin sticks (protec‐

tive field width).

The weld spark guard can influence the optical properties of the safety light curtain,

meaning that reflective surfaces have to observe a larger minimum distance.

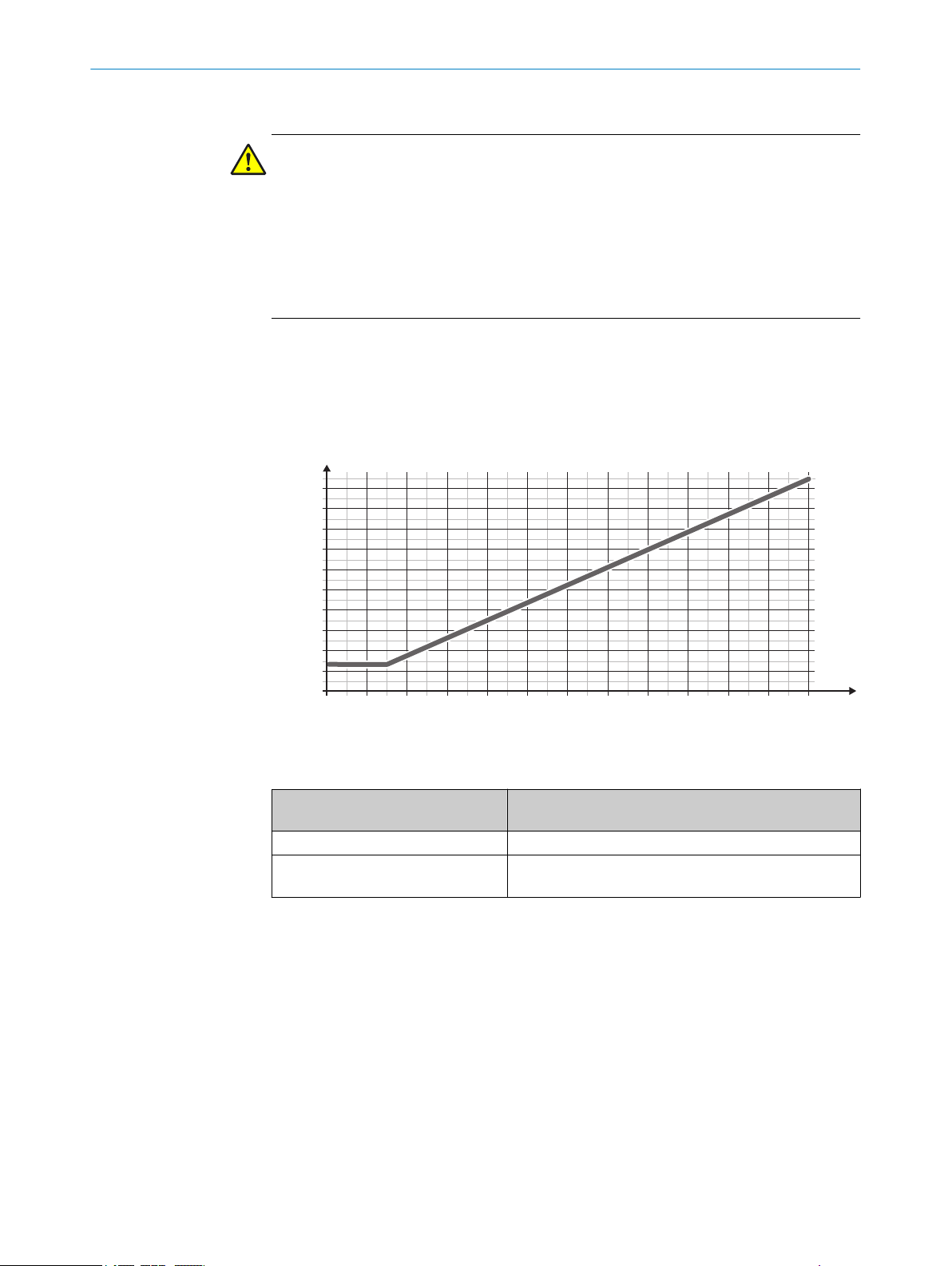

Figure 14: Minimum distance from reflective surfaces

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

25

Page 26

1000

900

800

700

600

14 16 18 20 22 242 4 6 8 10 12

500

400

300

200

100

0

0

D/m

a/mm

4 P

ROJECT PLANNING

Important information

DANGER

azard due to lack of effectiveness of the protective device

H

Reflective surfaces and dispersive media can prevent persons or parts of the body to

be protected from being properly reflected and, therefore, remain undetected.

Make sure that all reflective surfaces and objects maintain a minimum distance

b

from the protective field.

Make sure that no dispersive media (e.g., dust, fog, or smoke) are within the calcu‐

b

lated minimum distance from the protective field.

Determining minimum distance to reflective surfaces

T

he minimum distance can be determined as follows:

Determine the distance between the twin sticks D in meters (m).

b

Read the minimum distance a in millimeters (mm) in the graph or calculate it

b

based on the respective formula table 3:

Figure 15: Graph of minimum distance from reflective surfaces

T

able 3: Formula for calculating the minimum distance from reflective surfaces

Distance D between twin sticks in m Calculation of the minimum distance (a) from reflective

faces in mm

sur

D ≤ 3 m a = 131 mm

D > 3 m a = tan (2.5°) × 1000 mm/m × D = 43.66 × 1 mm/m ×

D

Further topics

eld spark guard", page 99

"W

•

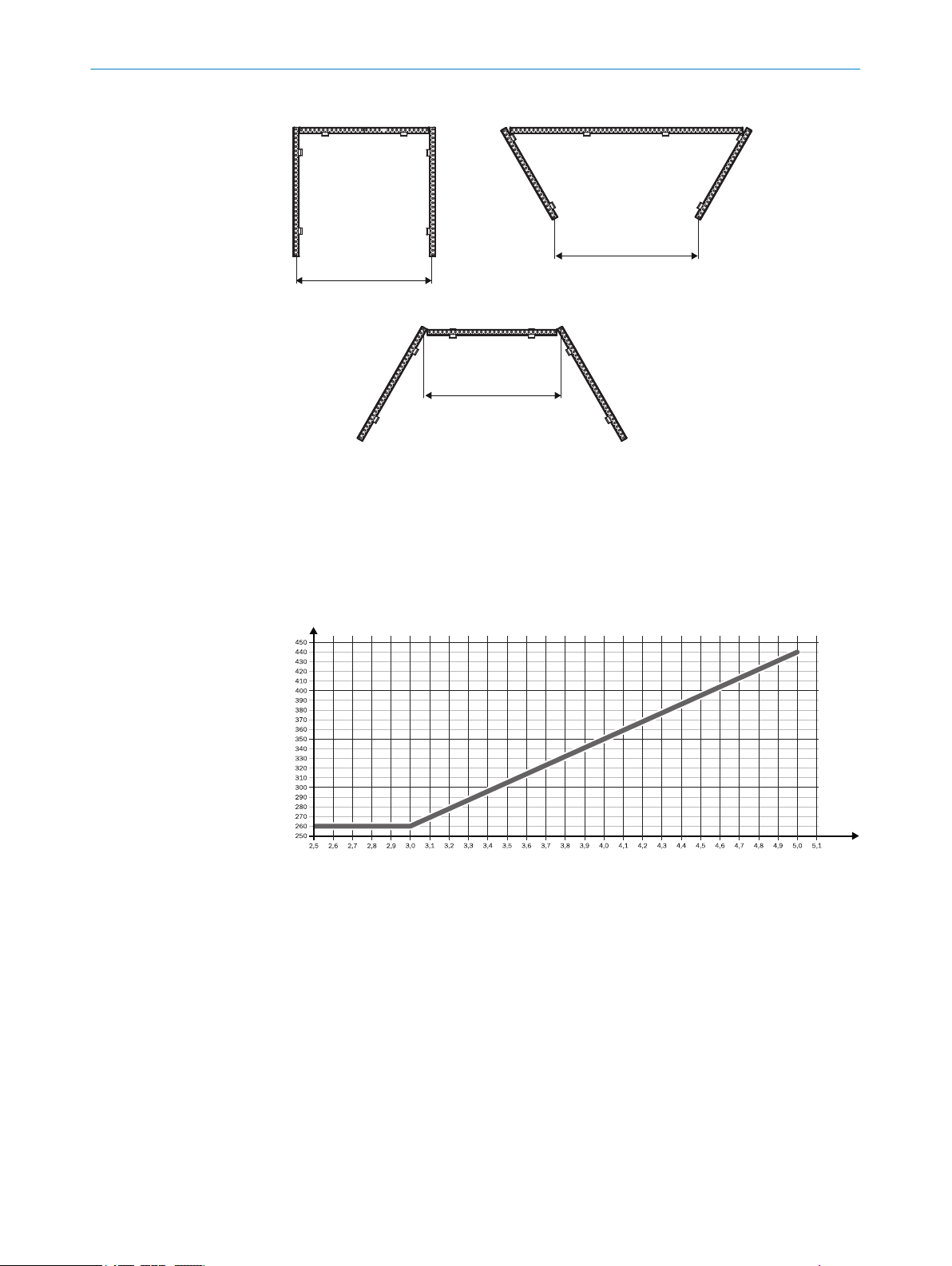

4.3.4 Minimum distance for cascaded systems

Overview

In a c

ascade, the codes of the individual participants are automatically set to code 1 or

code 2 in alternation.

In a cascaded system with a protective field width of up to 3 m, a minimum distance of

262 mm between the host and guest 2 must be upheld during mounting.

26

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 27

a min. 262

a min. 262

a min. 262

!

!

!

"

"

"

§ §

§

Figure 16: Minimum distance between host and guest 2 (mm)

a/mm

D/m

Guest 1

!

Guest 2

"

Host

§

PROJECT PLANNING 4

F

or protective field widths over 3 m, minimum distance a [mm] can be read in the

b

diagram:

Figure 17: Diagram minimum distance between host and guest 2

Or:

F

rom a 3 m protective field width, calculate the minimum distance with the follow‐

b

ing formula

a [mm] = tan 5° × D [m] × 1000

Example:

a = tan 5° × 4 m × 1000

a = 349.28 mm ~ 350 mm

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

27

Page 28

s

rs

r

!

"

4 P

ROJECT PLANNING

4.3.5 Protection against interference from systems in close proximity to each other

Overview

!

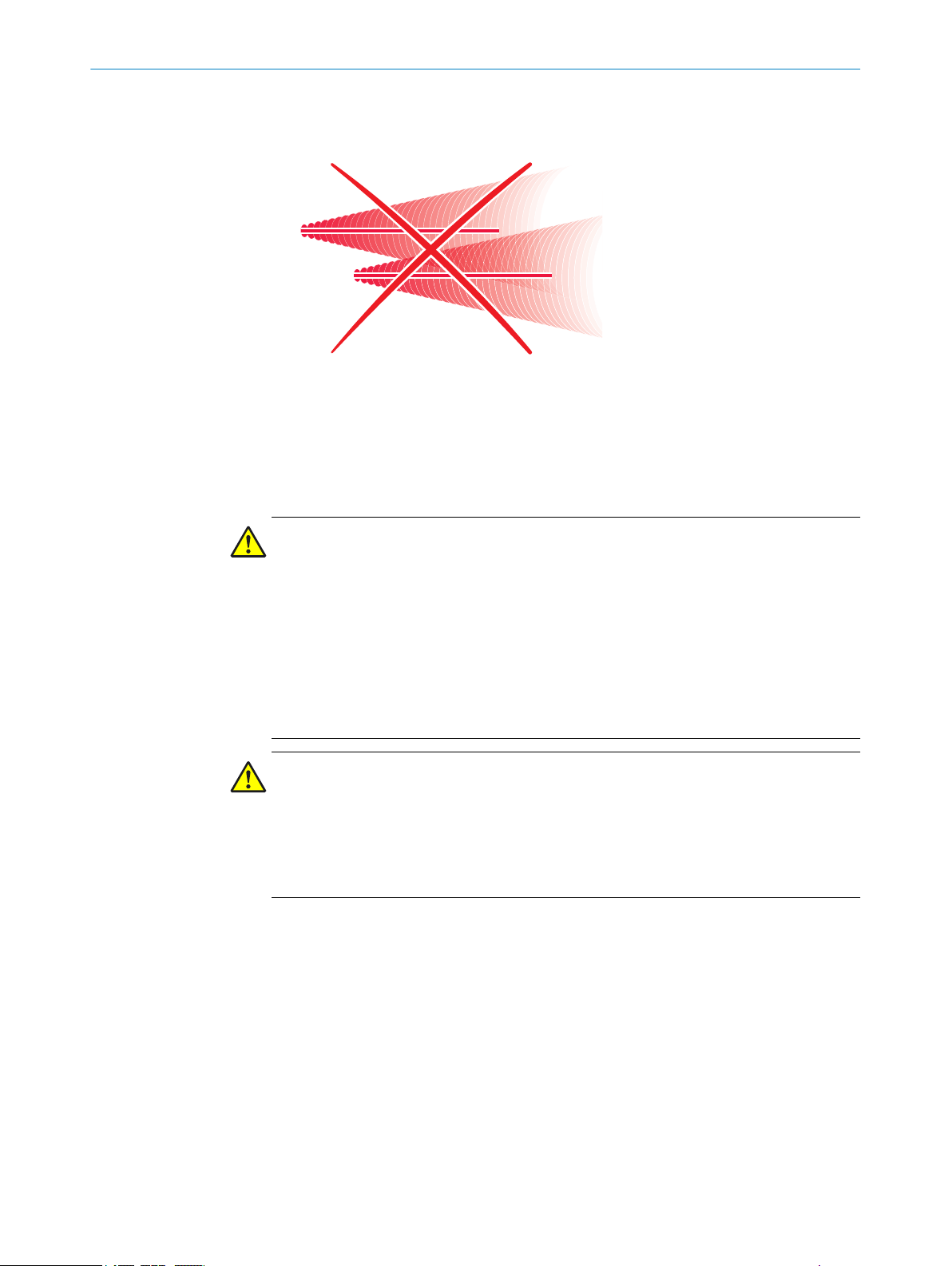

Figure 18: Preventing mutual interference from system

The infrared light beams of the sender unit of system ! can interfere with the receiver

unit of system ". This can disrupt the protective function of system ". This would

mean that the operator is at risk.

Important information

and system

"

DANGER

H

azard due to lack of effectiveness of the protective device

The external laser alignment aid may influence the receiver unit of a safety light curtain

in close proximity. In such cases, the neighboring safety light curtain may not detect

persons or parts of the body that require protection.

Perform an alignment or take other measures to ensure that the laser beam only

b

hits the front screen of the relevant twin stick. An external twin stick is a twin stick

that is not part of the same safety light curtain or same cascade.

During alignment in particular, make sure that the laser beam does not hit any

b

external twin stick.

DANGER

H

azard due to lack of effectiveness of the protective device

Systems of safety light curtains that operate in close proximity to each other can inter‐

fere with each other.

Use appropriate measures to prevent systems in close proximity from interfering

b

with each other.

Preventing interference between systems in close proximity to each other

he following measures prevent interference from systems in close proximity:

T

Different beam coding for neighboring systems

•

Optically opaque partitions

•

28

Further topics

"Using beam coding", page 29

•

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 29

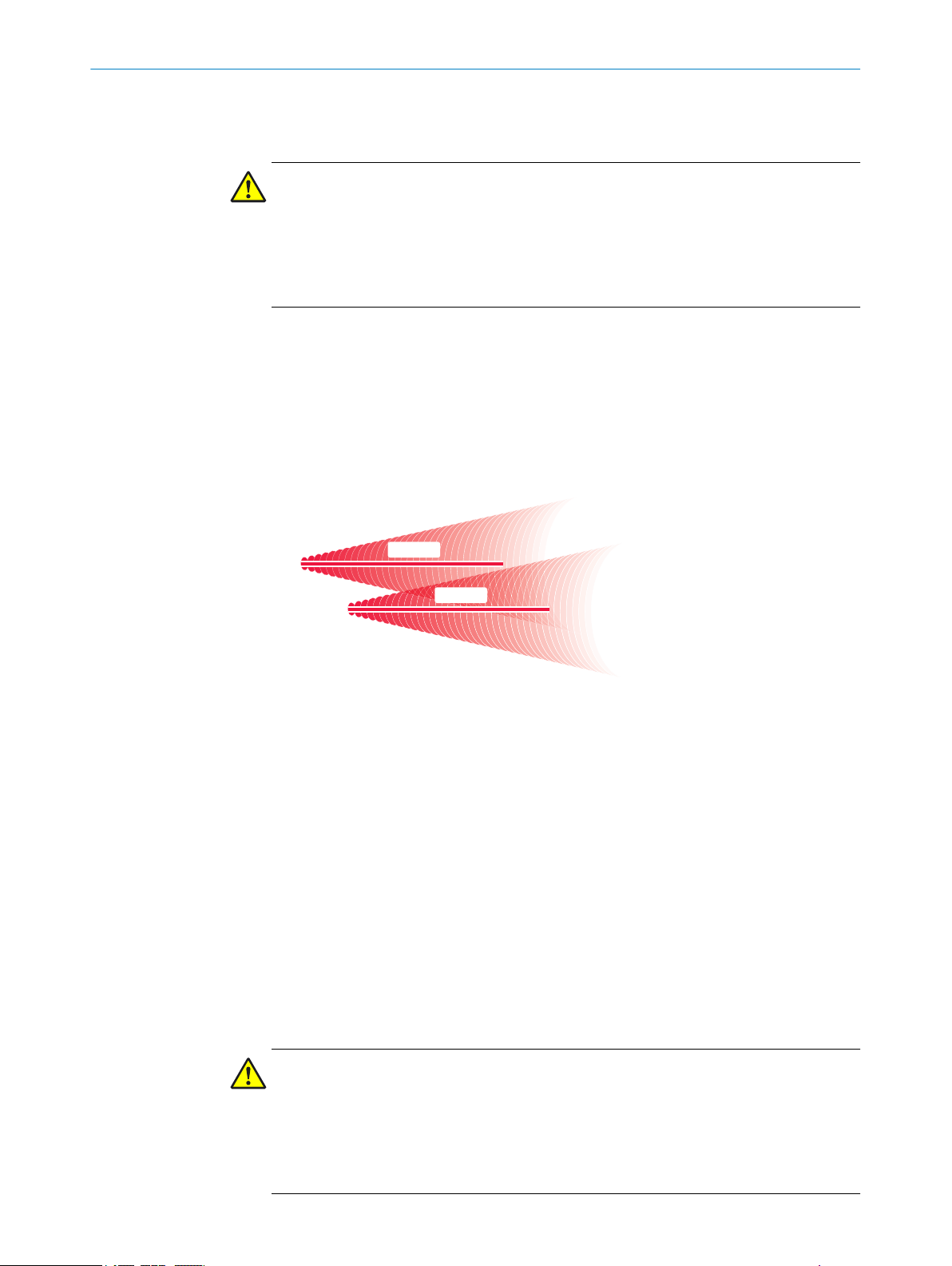

4.3.5.1 Using beam coding

s

Code 1

r

s

Code 2

r

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Different beam codings only prevent mutual interference if both safety light curtains are

of type miniTwin4.

b

Using beam coding

PROJECT PLANNING 4

In the case of systems in close proximity that are of a different type, take different

measures to prevent mutual interference.

Use suit

b

The system automatically performs the coding. As soon as a system is influenced by

another system with an identical code, a fault occurs. During the next power-up, the

code is converted and operation is no longer possible.

Figure 19: Trouble-free operation due to beam coding

In t

The system with code 2 is not affected by the beams of the system with code 1.

able beam codings to prevent mutual interference from neighboring systems.

Configure one safety light curtain with code 1 and the other safety light curtain

with code 2.

he figure, the beam coding of systems in close proximity to each other is different.

4.4 Integrating the equipment into the electrical control

Overview

T

his chapter contains important information about integration in the electrical control.

Information about the individual steps for electrical installation of the device: see "Elec‐

trical installation", page 60.

Requirements for use

The output signals of the protective device must be analyzed by downstream controllers

in such a way that the dangerous state of the machine is ended safely. Depending on

the safety concept, the signal is analyzed by safety relays or a safety controller, for

example.

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so that

b

the safety light curtain can fulfill its protective function.

29

Page 30

OSSD1

OSSD2

OSSD1

OSSD2

O

S

SD

0 V

OSSD

0 V

4 PROJECT PLANNING

t be possible to electrically influence the control of the machine

It mus

•

The electrical control of the machine must meet the requirements of IEC 60204-1

•

When using a safety controller, different signal levels of both OSSDs must be

•

detected depending on applicable national regulations or required reliability of the

safety function. The maximum discrepancy time tolerated by the control must be

selected according to the application.

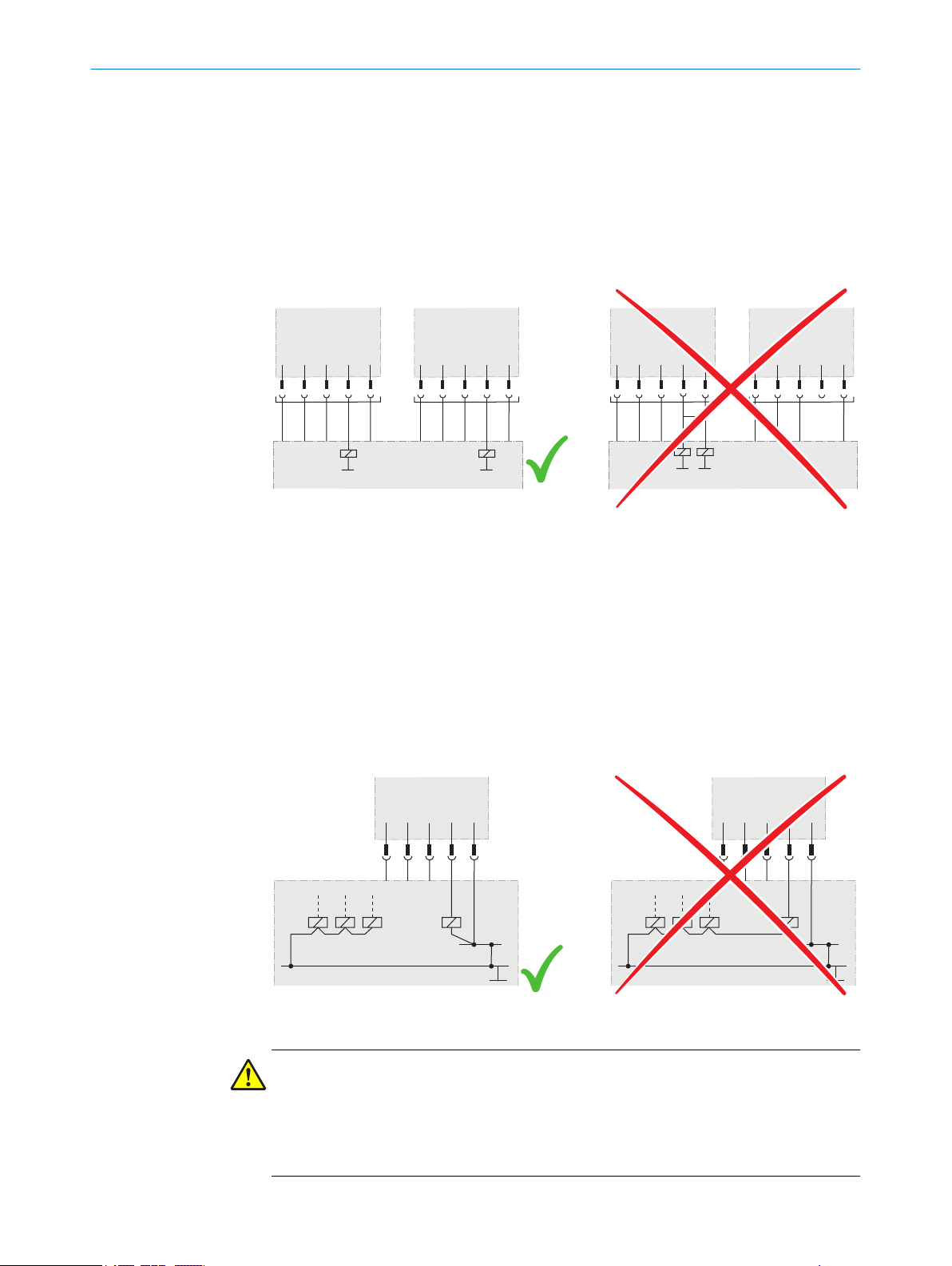

The OSSD1 and OSSD2 output signals must not be connected to each other

•

In the machine controller, the signals of both OSSDs must be processed sepa‐

•

rately

Figure 20: Dual-channel and isolated connection of OSSD1 and OSSD2

he machine must switch to the safe state at any time if at least one of the two

T

•

OSSDs switches to the OFF state

Prevent the formation of a potential difference between the load and the protec‐

•

tive device. If loads are connected to the OSSDs (switching outputs) that then also

switch if controlled with negative voltage (e.g., electro-mechanical contactor with‐

out reverse polarity protection diode), the 0 V connections of these loads and

those of the corresponding protective device must be connected individually and

directly to the same 0 V terminal strip. In the event of a fault, this is the only way to

ensure that there can be no potential difference between the 0 V connections of

the loads and those of the corresponding protective device.

30

Figure 21: No potential difference between load and protective device

DANGER

azard due to unexpected starting of the machine

H

A restart interlock must be implemented depending on applicable national regulations

or required reliability of the safety function.

Make sure that a restart interlock is implemented.

b

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 31

PROJECT PLANNING 4

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Downstream contactors must be positively guided and monitored depending on applic‐

able national regulations or required reliability of the safety function.

Make sure that downstream contactors are monitored (external device monitoring,

b

EDM).

Requirements for the electrical control of the machine

th outputs are short-circuit protected to 24 V DC and 0 V. When the protective field is

Bo

clear, the OSSDs are in the ON state. When a switch-off condition is present (e.g., inter‐

ruption in the light path), the OSSDs are in the OFF state. In the event of a device fault,

at least one OSSD is in the OFF state.

The safety light curtain complies with the rules for electromagnetic compatibility (EMC)

for the industrial sector (Radio Safety Class A).

Radio interference cannot be ruled out when used in residential areas.

NOTE

Usin

g the device in residential areas may cause radio interference. The operating entity

is responsible for taking appropriate measures (e.g., shielding).

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so that

b

the safety light curtain can fulfill its protective function.

T

he external voltage supply of the safety light curtain must be capable of jumper‐

•

ing a brief power failure of 20 ms as specified in IEC 60204-1.

The power supply unit must ensure safe isolation according to IEC 61140

•

(SELV/PELV). Suitable power supply units are available as accessories from SICK,

see "Accessories", page 101.

4.4.1 Protective operation without reset and/or without EDM

If the miniTwin4 safety light curtain is configured in protective operation without reset

and/or EDM, t

he respective multifunctional connection or both multifunctional connec‐

tions must be routed to 0 V.

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

31

Page 32

Pi

n

2

Pi

n

4

Pi

n

4

Pi

n

2

K1

K2

0 V DC

0 V DC

4 P

ROJECT PLANNING

Figure 22: Connection of multifunctional connections in protective operation without reset

and/or w

ithout EDM

4.4.2 Restart interlock

Overview

T

he safety light curtain has an internal restart interlock.

Depending on the regulations which apply at the place of installation, a restart interlock

may be required.

The restart interlock prevents the machine from automatically starting up, for example

after a protective device has responded while the machine is operating or after chang‐

ing the machine’s operating mode.

Important information

DANGER

azard due to unexpected starting of the machine

H

The machine may not restart if the OSSDs switch to the ON state once the reset push‐

button has been pressed. The control must ensure that the machine only restarts if the

machine start button is also pressed after the reset pushbutton.

b

Operating principle

T

he restart interlock prevents the machine from automatically starting up, for example

after a protective device has responded while the machine is operating or after chang‐

ing the machine’s operating mode.

Make sure that the machine can only restart once the reset pushbutton and start

button have been pressed in the specified order.

Before the machine can be restarted, the operator must reset the restart interlock.

32

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 33

!

§" $

Pi

n

4

Pi

n

2

+24 V DC

0 V DC

K1

K2

Pi

n

2

Pi

n

4

PROJECT PLANNING 4

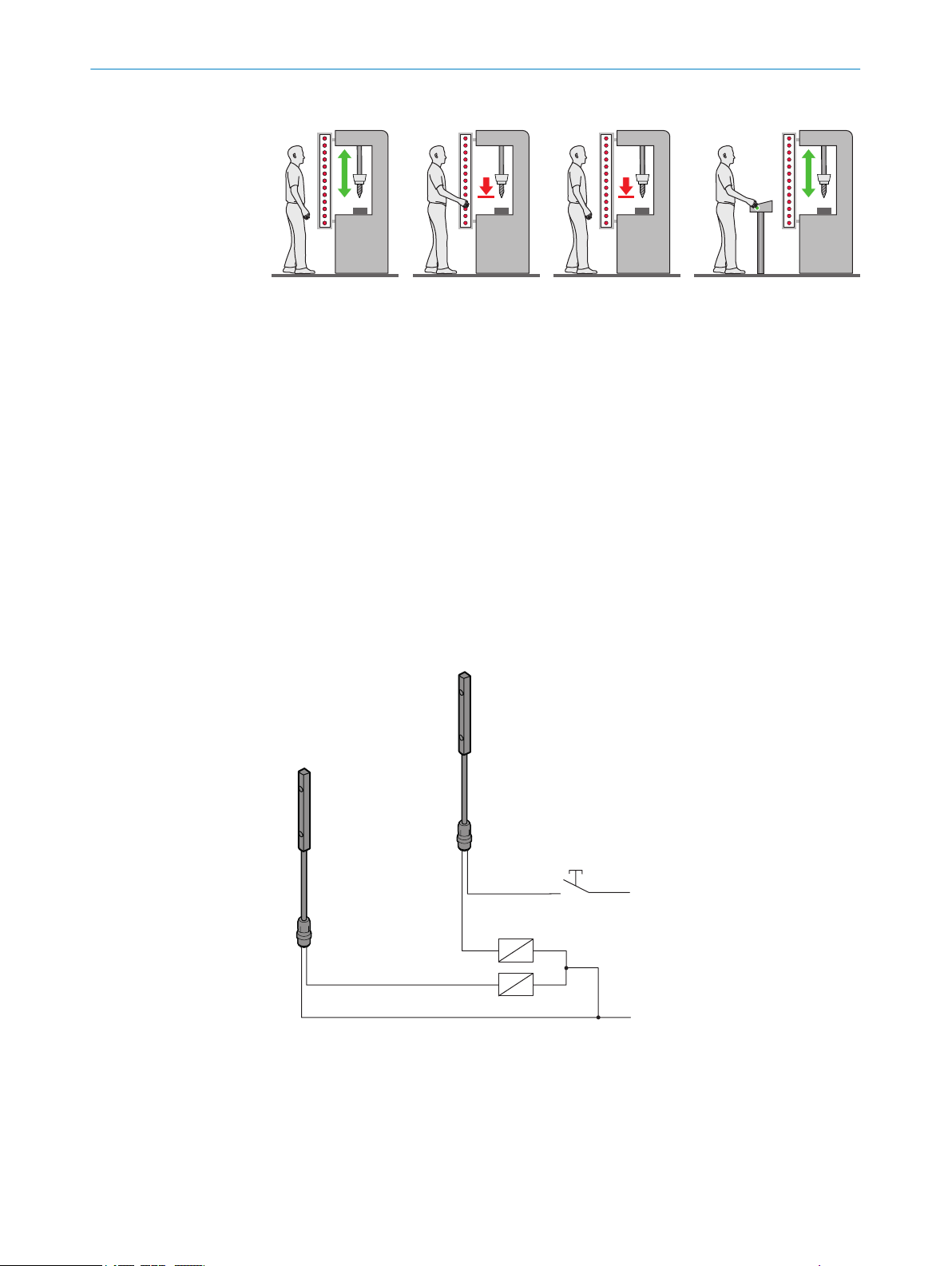

Figure 23: Schematic representation of operation with restart interlock

he dangerous state of the machine (!) is brought to an end if the light path is inter‐

T

rupted (") and is not re-enabled (§) until the operator presses the reset pushbutton

located outside the hazardous area ($). The machine can then be restarted.

Depending on applicable national regulations, a restart interlock must be available if it

is possible to stand behind the protective field. Observe IEC 60204-1.

The following applies to the restart interlock:

If the protective field is clear once the machine has been switched on or following

•

an interruption, the OSSDs do not switch to the ON state

If someone presses the reset pushbutton and then lets go of it when the protec‐

•

tive field is clear, the OSSDs switch to the ON state

The machine may not restart yet. The operator must also press the machine start

•

button after having pressed the reset pushbutton.

Internal restart interlock and reset

A r

eset device (e.g., a reset pushbutton) must be connected to allow the restart inter‐

lock to be used.

Figure 24: Electrical diagram of the reset device

he restart interlock is configured once the reset pushbutton has been connected.

T

Only one reset pushbutton may be connected to a single safety light curtain. A total of

just one reset pushbutton may be connected to a cascade comprising 2 or 3 safety

light curtains.

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

33

Page 34

Pi

n

4

Pi

n

2

Pi

n

2

Pi

n

4

K1

k1

k2

K2

0 V DC

24 V DC

ROJECT PLANNING

4 P

For a single system, the reset pushbutton can be connected to the 5-pin system con‐

nec

tion.

In a cascade, the reset pushbutton can be connected to the 5-pin system connection of

the host twin stick.

When the restart interlock is configured, the RES LED signals when the reset pushbut‐

ton needs to be pressed.

Further topics

"C

onfiguring reset", page 64

•

4.4.3 External device monitoring (EDM)

Overview

T

he safety light curtain has internal external device monitoring.

The external switching elements (external device monitoring, EDM) must be inspected

in line with the regulations which apply at the place of installation or the required relia‐

bility of the safety function.

The external device monitoring (EDM) monitors the status of downstream contactors.

Prerequisites

Use posit

•

Connect the auxiliary contacts of the positively guided contactors to the external

•

ively guided contactors for shutting down the machine.

device monitoring (EDM).

Operating principle

If e

xternal device monitoring is configured, the safety light curtain then checks the con‐

tactors after every interruption to the light path and before the machine restarts. Exter‐

nal device monitoring is then able to detect if one of the contactor’s contacts is welded,

for instance. In this case, the OSSDs remain in the OFF state.

Figure 25: Electrical diagram of external device monitoring (EDM)

T

he external device monitoring must be implemented electrically so that the two N/Cs

(k1, k2) close in a positively guided manner when the contactors (K1, K2) reach their

de-energized position once the protective device has responded. 24 V are then present

at the input of external device monitoring. If 24 V are not present once the protective

device has responded, one of the contactors is defective and external device monitor‐

34

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

ing prevents the machine from restarting.

Subject to change without notice

Page 35

4.4.4 Cascading

PROJECT PLANNING 4

Important information

DANGER

Risk of ineffectiveness of the protective device

The length of cable between 2 cascaded systems must not exceed 3 m.

Use the shortest possible cables between the devices of a cascaded system.

b

Protect the cascaded system from manipulation with an optimized length of cable

b

or with cable routing under a cover.

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Maintenance work, alignment work, fault diagnoses, and any changes to the inte‐

b

gration of the protective device in the machine must only be carried out by quali‐

fied personnel.

The effectiveness of the protective device must be checked following such work.

b

NOTE

hen 2 or 3 safety light curtains are used in a cascade and the connecting cables are

W

later interchanged, if may be necessary to deactivate any guest configurations and

manually re-teach the restart interlock.

Integrating a safety light curtain in a cascade

C

ascading allows up to 3 safety light curtains to be connected, e.g. for reliable pres‐

ence detection. The connected devices act like a long safety light curtain. Only one

device, the host, is connected to the control cabinet. The second device, guest 1, is

connected to the host. The 3rd guest 2, is connected to guest 1.

Advantages of cascading:

Rapid connection, no additional external circuitry required

•

No optical mutual interference between the protective fields within a cascade.

•

Host and guests are operated automatically and without configuration with the

alternating beam coding.

Resolution and protective field heights of the individual systems may be different

•

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

35

Page 36

!

"

§

4 P

ROJECT PLANNING

Figure 26: Cascading

Host

!

Guest 1

"

Guest 2

§

The following system plugs are available for cascading:

S

ystem plug for single systems with an M12×4 + FE system connection (male con‐

•

nector)

System plug for cascaded systems with an M12×4 + FE system connection (male

•

connector) and an M12×4 + FE extension connection (female connector)

A cascaded system with several safety light curtains is configured solely through the

selection of the system plug (single system or cascade) and its cabling. No other action

is necessary.

The individual safety light curtains can be used as single systems after disconnecting

them from the cascaded systems if they are connected via a system plug for single sys‐

tems.

36

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 37

PROJECT PLANNING 4

Use of system plugs in a cascade

R

equirements: extension connection at the host. 5-pin system connection at the

•

guest devices.

Additional requirement for cascades with 2 guest devices: Extension connection at

•

the devices of the first guest system

Restart interlock and external device monitoring (EDM) can be configured in the

•

host

Table 4: Use of system plugs in a cascade

System plug with system

connection and extension

connection

✓

–

✓

✓

–

Cascade with one

guest

Cascade with two

st devices

gue

✓

System plug suitable.

–

System plug not suitable.

Device type System plug with system

onnection

c

Host –

Guest 1

Host –

Guest 1 –

Guest 2

✓

✓

Complementary information

If a de

vice which may already have been configured is used to extend a cascade or

replace a (defective) device in a cascade, see table 9, page 66.

Further topics

"Deactivating reset and EDM", Seite 66

•

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

37

Page 38

+24 V

S1

0 V

K1

B1

B2

Y1

13

23

A2

UE10-2FG

Y2

14

24

K1

K2

K2

1

+24 V

OSSD

0 V

Mtfkp

FE

+24 V

OSSD

0 V

M

tfkp

FE

4

3

2

5

1

4

3

2

5

PELV

4 P

ROJECT PLANNING

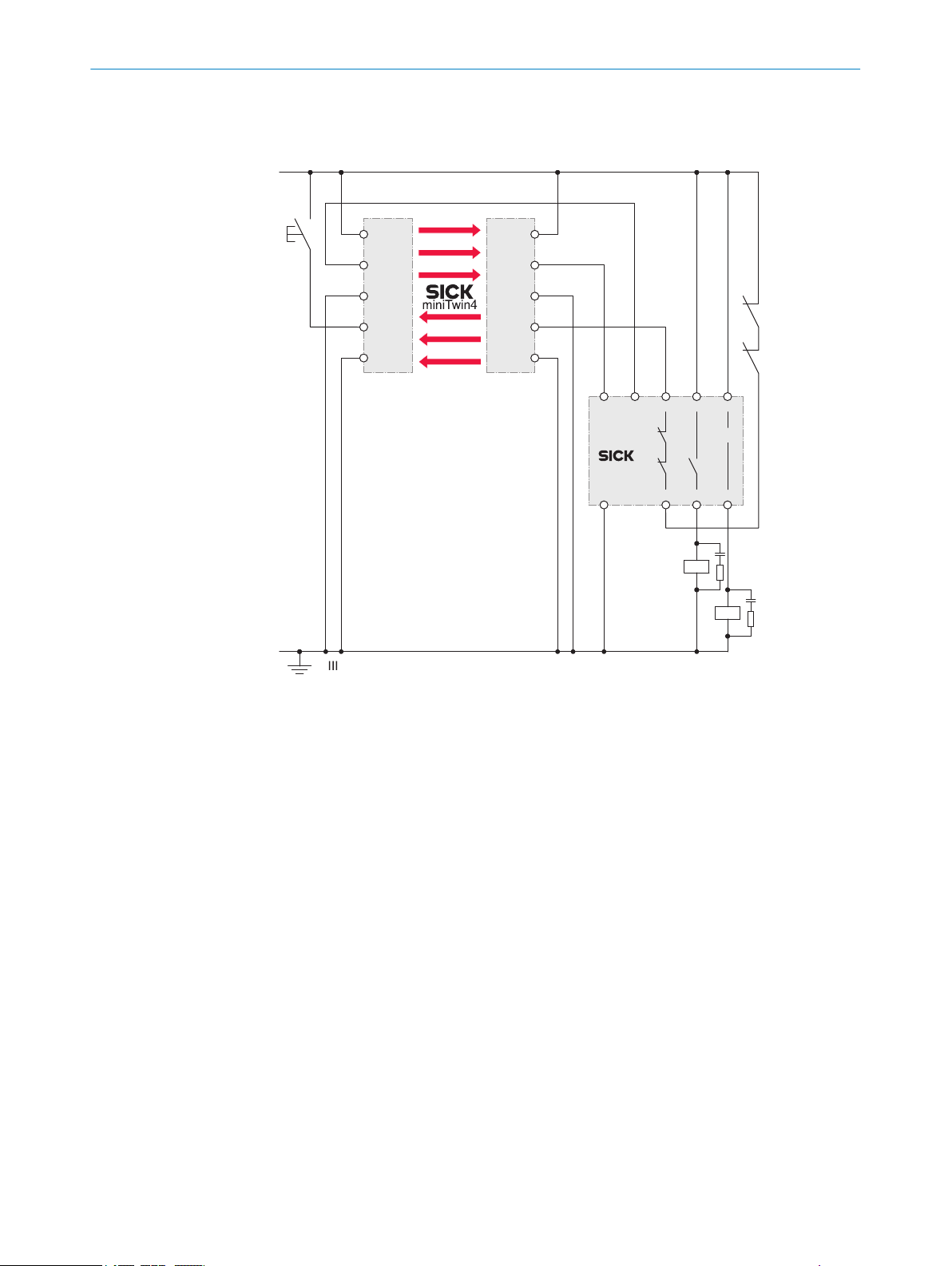

4.4.5 Connection diagrams

UE10-2FG

Figure 27: miniTwin4 in connection with UE10-2FG

38

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 39

UE10-3OS

+24 V

S1

0 V

PELV

1

+24 V

OSSD

0 V

Mtfkp

FE

+24 V

OSSD

0 V

M

tfk

p

FE

K1

K1

K2

B1

UE10-3 OS

B3

Y1

13

23

33

41

B2

B4

Y2

14

24

34

42

K2

4

3

2

5

1

4

3

2

5

+24 V

S1

0 V

K1

K1

K2

l

1

l

2

A1

X1

X2

S1

S2

S3

l

3

l

4

A2

Q1

Q2

Q3

Q4

F

unct

ion

EN

FE

K2

PELV

1

+24 V

OSSD

0 V

Mtfkp

FE

+24 V

OSSD

0 V

Mtfkp

FE

4

3

2

5

1

4

3

2

5

PROJECT PLANNING 4

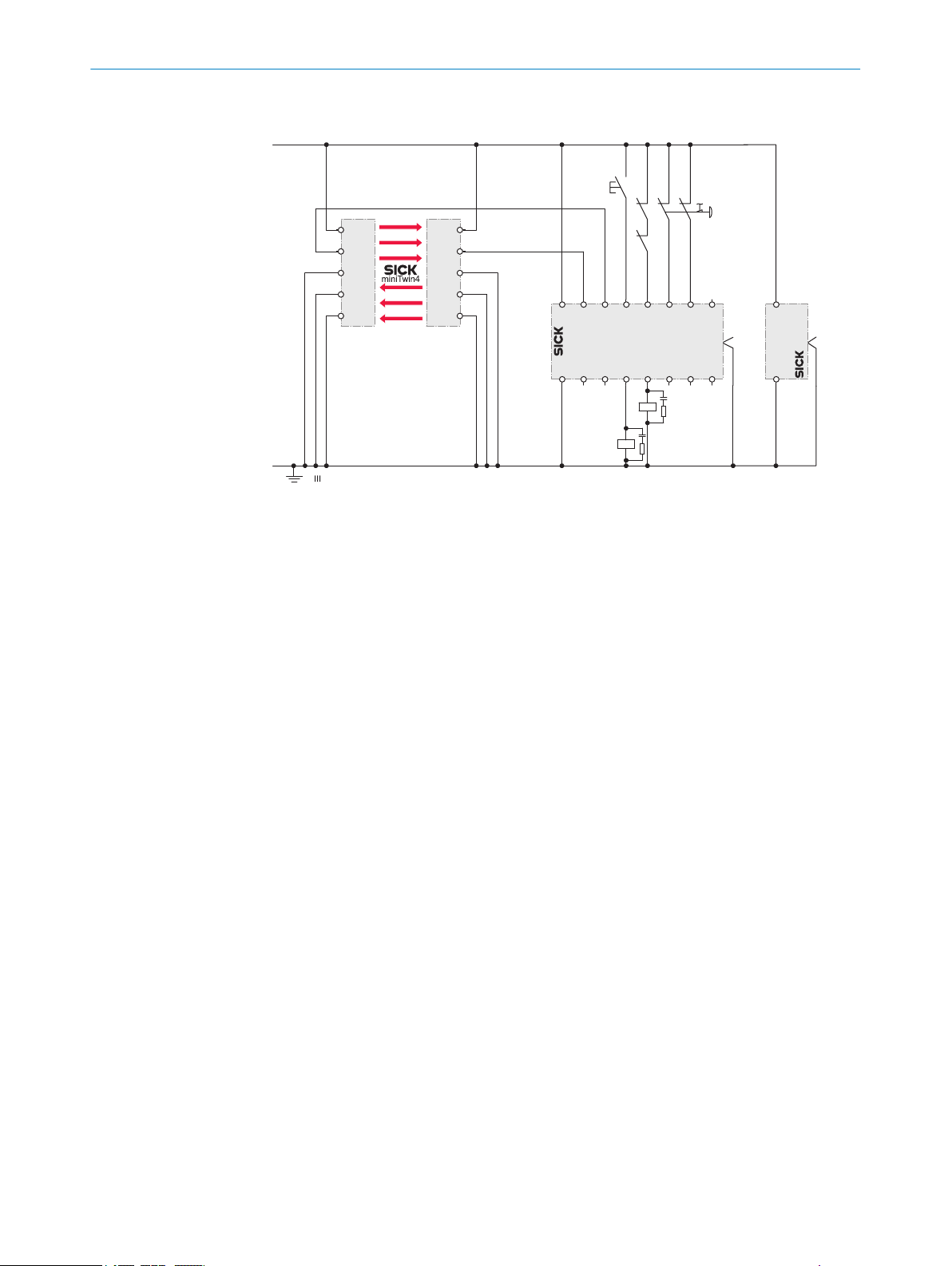

Figure 28: miniTwin4 in connection with UE10-3OS

Flexi Classic

Figure 29: miniTwin4 with Flexi Classic safety controller

8012624/10OM/2018-08-09 | SICK O PE R AT I NG IN S TR U CT I ON S | miniTwin4

Subject to change without notice

39

Page 40

+24 V

0

V

PELV

1

+24 V

OSSD

0 V

Mtfkp

FE

+24 V

OSSD

0 V

Mtfkp

FE

4

3

2

5

1

4

3

2

5

K1

K1

S1

K2

K2

A1

I1

I

2

I3

I

4

I5

I6

X1

FE

FE

A2

A1

A2

I7

I

8

Q1

Q2

Q3

Q4

X2

Fl

e

xi

Soft XTIO

FLEXI

s

oft

CPU

4 P

ROJECT PLANNING

Flexi Soft

Figure 30: miniTwin4 with Flexi Soft safety controller

4.5 Testing plan

The manufacturer of the machine and the operator must define all required checks.

T

he definition must be based on the application conditions and the risk assessment

and must be documented in a traceable manner.

When defining the check, please note the following:

b

Define the type and execution of the check.

°

Define the frequency of the check.

°

Notify the machine operators of the check and instruct them accordingly.

°

The following checks are often defined in connection with a protective device:

Check during commissioning and modifications

•

Regular thorough check

•

Check during commissioning and modifications

The check must detect if it is possible to enter the hazardous area without being

detected.

The following points are often helpful for the definition of the check:

Does the check have to be completed by qualified safety personnel?

•

Can the check be completed by personnel specially qualified and authorized to do

•

so?

Does the check have to be documented in a traceable manner?

•

Can the check be carried out according to a check list?

•

Do the machine operators know the function of the protective device?

•

Have the machine operators been trained to work on the machine?

•

Have the machine operators been notified about modifications to the machine?

•

Does the hazardous area being secured have to be checked with a test rod?

•

Define all guidelines for the check.

b

40

O PE R AT I NG IN S TR U CT I ON S | miniTwin4 8012624/10OM/2018-08-09 | SICK

Subject to change without notice

Page 41

4.5.1 Test rod check

PROJECT PLANNING 4

Regular thorough check

T

he check must detect if it is possible to enter the hazardous area without being

detected. Such possibilities may exist due to modifications, manipulations or external

influences.

The following points are often helpful for the definition of the check:

Which check must be carried out and how is it carried out?

•

Test rod check

°

Visual check of the machine and the protective device

°

How often does the check have to be carried out?

•

Do the machine operators have to be notified of the check and do they need to be

•

instructed accordingly?

Define all guidelines for the check.

b

Further topics

"Chec

•

•

•

klist for initial commissioning and commissioning", page 107

"Test rod check", page 41

"Visual check of the machine and the protective device", page 43

Overview

T

he rod test check is used to check whether the hazardous point is only accessible via

the protective field of the safety light curtain and whether the protective device is able

to identify each time the hazardous point is approached.

The test is carried out with an opaque test rod whose diameter corresponds to the reso‐

lution of the safety light curtain.