Page 1

microScan3 – EtherNet/IP™

Safety laser scanner

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

micr

oScan3 – EtherNet/IP™

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

OD

•

•

•

•

VA is a trademark of ODVA, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

CIP is a trademark of ODVA, Inc.

CIP Safety is a trademark of ODVA, Inc.

Original document

his document is an original document of SICK AG.

T

2

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 8

1.1 Function of this document....................................................................... 8

1.2 Scope......................................................................................................... 8

1.3 Target groups and structure of these operating instructions................ 8

1.4 Further information................................................................................... 9

1.5 Symbols and document conventions...................................................... 9

2 Safety information............................................................................ 10

2.1 General safety notes................................................................................ 10

2.2 Correct use................................................................................................ 11

2.3 Requirements for personnel qualifications............................................. 11

3 Product description........................................................................... 13

3.1 Setup and function................................................................................... 13

3.2 Product characteristics............................................................................ 15

3.2.1 Device overview....................................................................... 15

3.2.2 Variants.................................................................................... 16

3.2.3 Status indicators...................................................................... 16

3.2.4 Connections............................................................................. 17

3.2.5 System plug.............................................................................. 17

3.2.6 Field types................................................................................ 17

3.2.7 Field set.................................................................................... 20

3.2.8 Monitoring case....................................................................... 21

3.2.9 Simultaneous monitoring........................................................ 22

3.3 Example applications............................................................................... 22

4 Project planning................................................................................ 25

4.1 Manufacturer of the machine.................................................................. 25

4.2 Operator of the machine.......................................................................... 25

4.3 Assembly................................................................................................... 25

4.3.1 Protection against interference from systems in close prox‐

y to each other................................................................... 27

imit

4.3.2 Preventing unprotected areas................................................. 28

4.3.3 Response time of the safety laser scanner........................... 30

4.3.4 Reference contour monitoring................................................ 30

4.3.5 Monitoring case switching time.............................................. 32

4.3.6 Hazardous area protection...................................................... 34

4.3.7 Hazardous point protection..................................................... 40

4.3.8 Access protection.................................................................... 43

4.3.9 Mobile hazardous area protection.......................................... 45

4.4 Integrating the equipment into the electrical control............................. 51

4.4.1 Voltage supply.......................................................................... 52

4.4.2 USB connection....................................................................... 52

4.4.3 Control inputs........................................................................... 53

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

3

Page 4

CONTENTS

4.4.4 EtherNet/IP.............................................................................. 54

4.4.5 Restart interlock...................................................................... 54

4.5 Integration into the network of the control............................................. 57

4.5.1 Network topology..................................................................... 57

4.5.2 Integration of the safety laser scanner into the network...... 57

4.5.3 Configuring control.................................................................. 58

4.5.4 Available data........................................................................... 61

4.5.5 Assemblies............................................................................... 62

4.6 Testing plan............................................................................................... 64

4.6.1 Minimum requirements for the regular thorough check....... 64

4.6.2 Recommendations for further thorough checks.................... 64

4.6.3 Carrying out thorough checks................................................. 65

5 Mounting............................................................................................. 67

5.1 Safety......................................................................................................... 67

5.2 Unpacking.................................................................................................. 67

5.3 Mounting procedure................................................................................. 67

5.3.1 Changing position of the system plug.................................... 69

5.3.2 Direct mounting....................................................................... 71

5.3.3 Mounting using mounting kit 1............................................... 72

5.3.4 Mounting using mounting kit 2............................................... 72

6 Electrical installation........................................................................ 75

6.1 Safety......................................................................................................... 75

6.2 Connection overview................................................................................ 75

6.2.1 microScan3 – EtherNet/IP™................................................... 76

6.3 Pin assignment......................................................................................... 76

6.3.1 Voltage supply (XD1)................................................................ 76

6.3.2 Ethernet for EtherNet/IP – CIP Safety, data output, config‐

ur

ation, and diagnostics (XF1, XF2)....................................... 76

7 Configuration..................................................................................... 78

7.1 General requirements.............................................................................. 78

7.1.1 Delivery state........................................................................... 78

7.2 Safety Designer......................................................................................... 78

7.2.1 Installation assistant............................................................... 78

7.2.2 Projects..................................................................................... 78

7.2.3 User interface.......................................................................... 79

7.2.4 User groups.............................................................................. 80

7.2.5 Settings.................................................................................... 80

7.2.6 Configuration............................................................................ 81

7.3 Overview.................................................................................................... 83

7.3.1 Functional scope...................................................................... 84

7.4 Addressing................................................................................................. 85

7.5 Reading configuration.............................................................................. 86

7.6 Identification............................................................................................. 87

4

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 5

CONTENTS

7.7 Application................................................................................................ 88

7.8 Monitoring plane....................................................................................... 89

7.8.1 Parameters for the monitoring plane..................................... 90

7.8.2 Parameters for the safety laser scanner................................ 92

7.9 Reference contour field............................................................................ 93

7.10 Fields......................................................................................................... 95

7.10.1 Using the field editor............................................................... 95

7.10.2 Creating field-set templates.................................................... 98

7.10.3 Importing and exporting field sets and fields........................ 99

7.10.4 Background image................................................................... 99

7.10.5 Settings for the field editor..................................................... 100

7.10.6 Editing fields using coordinates.............................................. 101

7.10.7 Drawing in points that cannot be monitored......................... 102

7.10.8 Enable propose field................................................................ 102

7.11 Inputs and outputs................................................................................... 104

7.12 Monitoring cases...................................................................................... 105

7.12.1 Settings for monitoring case tables........................................ 106

7.12.2 Settings for monitoring cases................................................. 107

7.12.3 Input conditions....................................................................... 108

7.12.4 Cut-off paths............................................................................ 108

7.12.5 Assigning field sets.................................................................. 108

7.13 Simulation................................................................................................. 109

7.14 Data output............................................................................................... 110

7.15 Transfer..................................................................................................... 111

7.16 Starting and stopping safety function..................................................... 112

7.17 EtherNet/IP overview................................................................................ 113

7.18 Reports...................................................................................................... 113

7.19 Service....................................................................................................... 114

7.19.1 Device restart........................................................................... 114

7.19.2 EtherNet/IP.............................................................................. 115

7.19.3 Factory settings........................................................................ 115

7.19.4 Managing passwords............................................................... 115

7.19.5 Optics cover calibration........................................................... 116

8 Commissioning.................................................................................. 117

8.1 Safety......................................................................................................... 117

8.2 Alignment.................................................................................................. 117

8.3 Switching on.............................................................................................. 118

8.4 Thorough check........................................................................................ 119

9 Operation............................................................................................ 121

9.1 Safety......................................................................................................... 121

9.2 Regular thorough check........................................................................... 121

9.3 LEDs........................................................................................................... 121

9.4 Buttons and display.................................................................................. 122

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

5

Page 6

CONTENTS

10 Maintenance...................................................................................... 127

10.1 Safety......................................................................................................... 127

10.2 Regular cleaning....................................................................................... 127

10.3 Replacing the optics cover....................................................................... 128

10.4 Replacing the safety laser scanner......................................................... 131

10.4.1 Replacing the safety laser scanner without system plug...... 131

10.4.2 Completely replacing the safety laser scanner...................... 132

10.5 Replacing the system plug....................................................................... 132

10.6 Regular thorough check........................................................................... 133

11 Troubleshooting................................................................................. 135

11.1 Safety......................................................................................................... 135

11.2 Diagnostic LEDs........................................................................................ 135

11.2.1 Status LEDs.............................................................................. 135

11.2.2 Network light emitting diodes................................................. 136

11.3 Diagnostics using the display.................................................................. 138

11.3.1 Status display........................................................................... 138

11.3.2 Detailed diagnostics................................................................ 140

11.3.3 Fault display............................................................................. 142

11.4 Diagnostics using Safety Designer.......................................................... 144

11.4.1 Data recorder........................................................................... 145

11.4.2 Event history............................................................................. 146

11.4.3 Message history....................................................................... 148

11.4.4 Inputs and outputs.................................................................. 148

11.5 Diagnostics using the control................................................................... 148

12 Decommissioning............................................................................. 149

12.1 Protection of the environment................................................................. 149

12.2 Disposal..................................................................................................... 149

13 Technical data....................................................................................150

13.1 Variant overview........................................................................................ 150

13.2 Version numbers and functional scope.................................................. 150

13.3 Data sheet................................................................................................. 151

13.3.1 microScan3 – EtherNet/IP™................................................... 151

13.4 Response times........................................................................................ 155

13.5 Sensing range........................................................................................... 156

13.6 Data exchange in the network................................................................. 158

13.6.1 Standard objects (open objects)............................................ 158

13.6.2 Manufacturer-specific objects (vendor-specific objects)...... 163

13.6.3 Assemblies............................................................................... 167

13.7 Dimensional drawings.............................................................................. 174

14 Ordering information........................................................................ 175

14.1 Scope of delivery....................................................................................... 175

14.2 microScan3 ordering information............................................................ 175

6

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 7

CONTENTS

15 Spare parts......................................................................................... 176

15.1 microScan3 without system plug............................................................. 176

15.2 System plug............................................................................................... 176

15.3 Additional spare parts.............................................................................. 176

16 Accessories........................................................................................ 177

16.1 Brackets.................................................................................................... 177

16.2 Connection technology............................................................................. 179

16.3 Alignment aid............................................................................................ 181

16.4 Cleaning agent.......................................................................................... 181

16.5 Additional accessories............................................................................. 181

17 Glossary.............................................................................................. 182

18 Annex.................................................................................................. 186

18.1 Compliance with EU directives................................................................. 186

18.2 Note on specified standards.................................................................... 187

18.3 Checklist for initial commissioning and commissioning........................ 188

18.4 Mounting methods for protection from interference from systems in

lose proximity.......................................................................................... 189

c

19 List of figures..................................................................................... 192

20 List of tables....................................................................................... 195

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

7

Page 8

1 A

BOUT THIS DOCUMENT

1 About this document

1.1 Function of this document

These operating instructions contain the information needed during the life cycle of the

afety laser scanner.

s

Operating instructions of the safety laser scanner must be made available to all people

who work with the device.

Read the operating instructions carefully and ensure that you have understood the con‐

tents completely before you work with the safety laser scanner.

1.2 Scope

The operating instructions apply to the microScan3 safety laser scanner with the follow‐

in

g type label entry in the Operating Instructions field:

8020198

•

This document is included with the following SICK part numbers (this document in all

available language versions):

8020198

•

1.3 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: project devel‐

oper

s (planners, developers, designers), installers, electricians, safety experts (such as

CE authorized representatives, compliance officers, people who test and approve the

application), operators, and maintenance personnel.

The structure of these operating instructions is based on the life cycle phases of the

safety laser scanner: project planning, mounting, electrical installation, configuration,

commissioning, operation, and maintenance.

In many applications, the target groups consist of the manufacturer and the operator of

the machine in which the safety laser scanner is integrated:

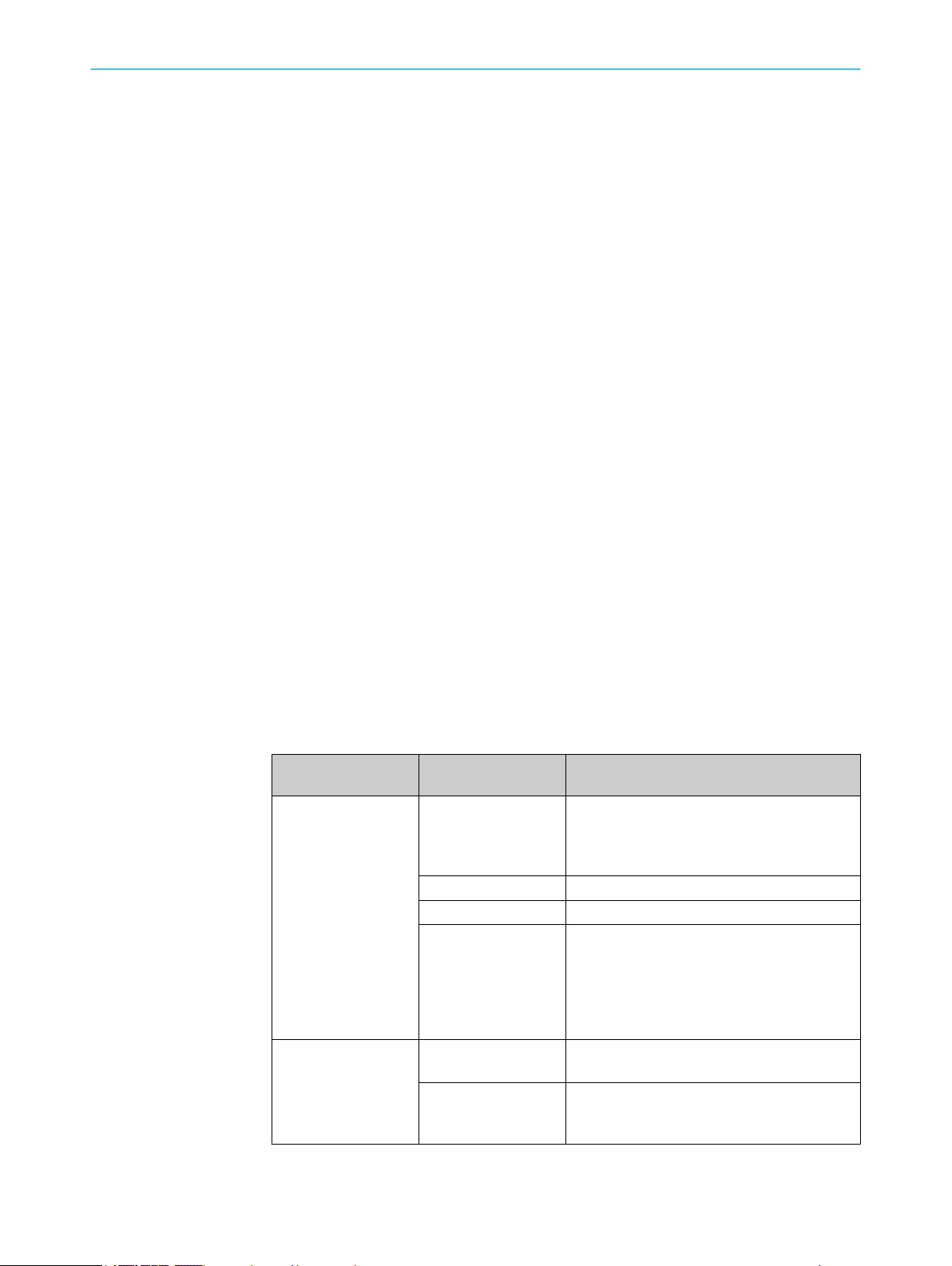

Area of responsibility Target group Special chapters of these operating instruc‐

Manufacturer Project developers

(planners, developers,

designers)

Installers Mounting, pa

Electricians Electrical installation, pa

Safety experts Project planning, page 25

User Operator Operation, pa

Maintenance person‐

l

ne

1

Chapters not listed here are intended for all target groups. All target groups must understand the safety

inf

ormation in all of the operating instructions!

1

t

ions

Project planning, page 25

Configuration, page 78

Technical data, page 150

Accessories, page 177

Configuration, page 78

Commissioning, page 117

Technical data, page 150

Checklist for initial commissioning and com‐

missioning, page 188

Troubleshooting, page 135

Maintenance, page 127

Troubleshooting, page 135

Accessories, page 177

ge 67

ge 75

ge 121

8

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 9

In other applications, the operating organization is also the manufacturer of the equip‐

ment w

ith the corresponding allocation of the target groups.

1.4 Further information

www.sick.com

T

he following information is available via the Internet:

Further language versions of these operating instructions

•

Data sheets and application examples

•

CAD data of drawings and dimensional drawings

•

Certificates (such as the EU declaration of conformity)

•

Guide for Safe Machinery (six steps to a safe machine)

•

Safety Designer (software for configuring the safety laser scanner and further

•

safety solutions)

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

ABOUT THIS DOCUMENT 1

DANGER

Indic

ates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

ates a situation presenting possible danger, which may lead to moderate or minor

Indic

injuries if not prevented.

NOTICE

Indic

ates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

he arrow denotes instructions to action.

T

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

9

Page 10

IEC 60825-1:2007 & 2014

Complies with 21 CFR

1040.10 and 1040.11

except for deviations

pursuant to Laser Notice

No. 50, June 2007

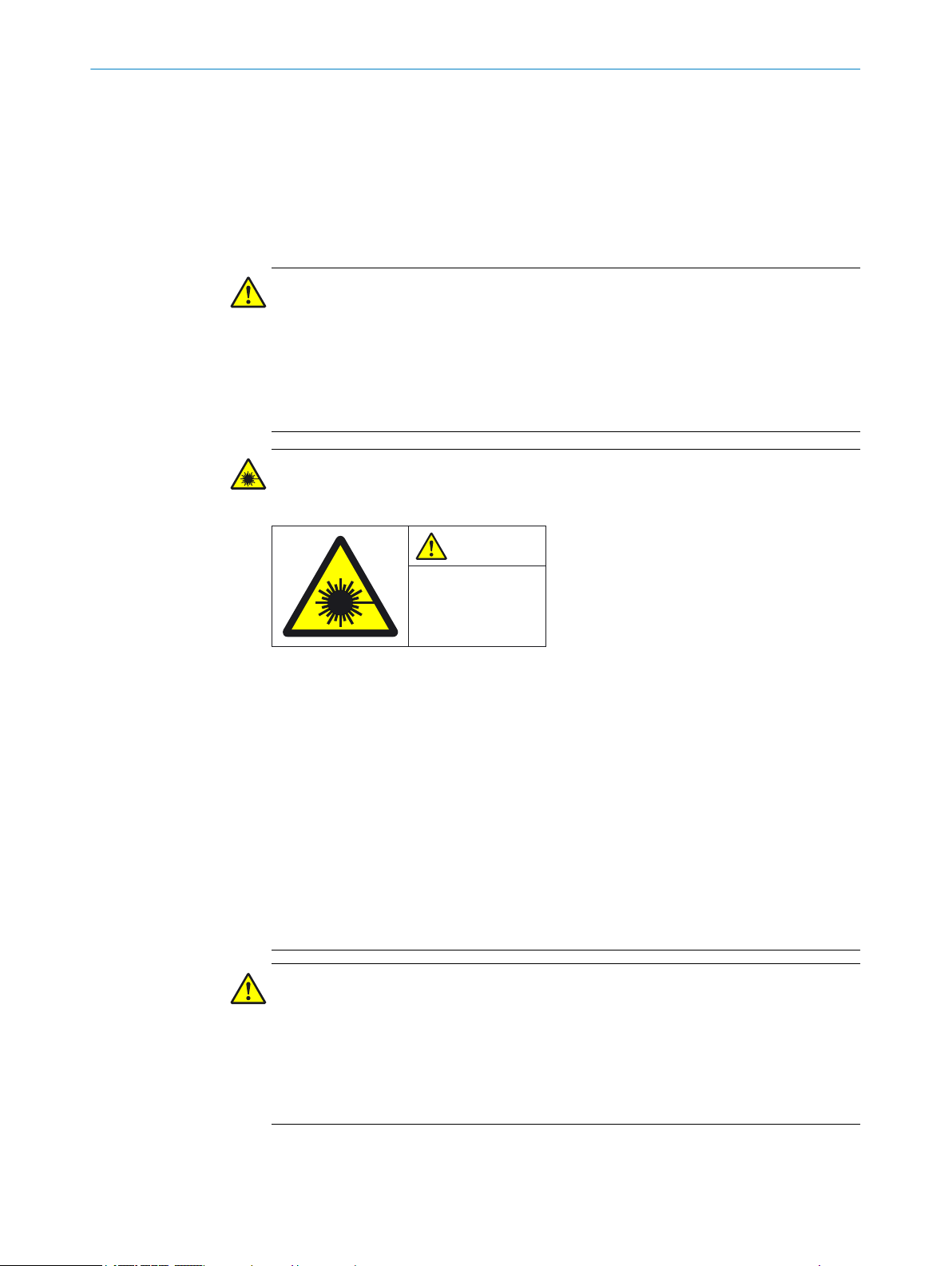

CAUTION

LASER

1M

2 SAFETY INFORMATION

2 Safety information

2.1 General safety notes

This chapter contains general safety information about the safety laser scanner.

urther information about specific product use situations can be found in the relevant

F

chapters.

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Please read this document carefully and make sure that you understand the con‐

b

tent fully before working with the device.

Follow all safety notes in this document.

b

WARNING

In

visible laser radiation

Laser class 1M

Figure 1: Laser class 1M

T

his device complies with the following standards:

IEC 60825-1:2007/EN 60825-1:2007

•

IEC 60825-1:2014/EN 60825-1:2014

•

21 CFR 1040.10 and 1040.11, except for changes due to Laser Notice No. 50 of

•

24/06/2007

The safety laser scanner’s accessible laser is not hazardous as long as the beam cross

section is not reduced by optical instruments, such as magnifying glasses, lenses, tele‐

scopes.

The curved part of the optics cover is the outlet for the laser radiation.

The laser marking is located on the underside of the safety laser scanner.

You must comply with the latest version of the applicable laser safety regulations.

b

CAUTION

y operating or adjusting devices other than those specified in this document are

If an

used or other methods are employed, this can lead to dangerous exposure to radiation.

Only use the operating or adjusting devices specified in this document.

b

Only follow the methods specified in this document.

b

Do not open the housing, except for the purposes of the installation and mainte‐

b

nance work specified in these operating instructions.

10

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 11

2.2 Correct use

SAFETY INFORMATION 2

CAUTION

serving the safety laser scanner through optical instruments (such as magnifying

Ob

glasses, lenses, telescopes) may be hazardous for the eyes.

Do not look directly at the laser beam source using optical instruments.

b

The safety laser scanner is an electro-sensitive protective device (ESPE) and is suitable

or the following applications:

f

Hazardous area protection

•

Hazardous point protection

•

Access protection

•

Mobile hazardous area protection (protection of automated guided vehicles)

•

The safety laser scanner must only be used within the limits of the prescribed and

pecified technical data and operating conditions at all times.

s

Incorrect use, improper modification of or tampering with the safety laser scanner will

invalidate any warranty from SICK; in addition, any responsibility and liability of SICK for

damage and secondary damage caused by this is excluded.

Foreseeable misuse

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The safety laser scanner works as an indirect protective measure and cannot provide

protection from pieces thrown from application nor from emitted radiation. Transparent

objects are not detected.

You must only use the safety laser scanner as an indirect protective measure.

b

The safety laser scanner is no

Outdoors

•

Underwater

•

In explosive environments

•

t suitable for the following applications, among others:

2.3 Requirements for personnel qualifications

The safety laser scanner must only be configured, installed, connected, commissioned

and ser

Project planning

viced by qualified safety personnel.

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting

For mechanical mounting, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

11

Page 12

AFETY INFORMATION

2 S

Electrical installation

F

or electrical installation, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Configuration

For configuration, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its work safety aspects.

Commissioning

For commissioning, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its operational safety sta‐

tus.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

An operator may clean the safety laser scanner and carry out specific thorough checks

following instruction. More information for the operator of the machine: see "Regular

cleaning", page 127, see "Operation", page 121.

12

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 13

3 Product description

t

t

∆t

3.1 Setup and function

The safety laser scanner is an electro-sensitive protective device (ESPE), which twodimensionall

The safety laser scanner forms a protective field using the invisible laser beams. This

protective field protects the hazardous area and enables hazardous point protection,

access protection or hazardous area protection. As soon as an object is situated in the

protective field, the safety laser scanner signals the detection by means of a signal

change at the safety output (OSSD for example). The machine or its control must safely

analyze the signals (for example using a safe control or safety relays) and stop the dan‐

gerous state.

The safety laser scanner operates on the principle of time-of-flight measurement. It

emits light pulses in regular, very short intervals. If the light strikes an object, it is

reflected. The safety laser scanner receives the reflected light. The safety laser scanner

calculates the distance to the object based on the time interval between the moment of

transmission and moment of receipt (∆t).

PRODUCT DESCRIPTION 3

y scans its environment with infrared laser beams.

Figure 2: Principle of time-of-flight measurement

Transmitted light pulse

1

Reflected light pulse

2

A rotating mirror is situated in the safety laser scanner. The mirror deflects the light

pulse

s so that they scan a fan-shaped area.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

13

Page 14

227,5°

0°

90°

-47,5°

3 P

RODUCT DESCRIPTION

Figure 3: Light pulses scan an area

Angular resolution: the angular distance (in degrees) between 2 distance measurements

1

Scan cycle time and resolution

T

he time that the mirror requires for one rotation is called the scan cycle time. The

number of light pulses per unit time is constant. A change in the scan cycle time also

changes the number of light pulses per mirror rotation. This results in different angular

resolutions. The range for a given object resolution changes with the angular resolution.

The object resolution indicates the minimum size that an object must be to allow it to

be detected safely. Also, different response times result from a change to the scan

cycle time.

Slightly different scan cycle times can be used to minimize mutual interference in

neighboring safety laser scanners.

The resolution in protective fields can be set between 30 mm and 200 mm, according

to the intended purpose.

Geometry of the scan plane

T

he laser beams emitted cover a sector of a circle, so an object can be detected in an

area of up to 275°.

The sector of a circle covered ranges from –47.5° to 227.5°, where 90° denotes the

axis of the safety laser scanner from the back to the front. When viewing the safety

laser scanner from above, the direction of rotation of the mirror and the deflected light

pulses is counterclockwise, see figure 3.

14

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 15

3.2 Product characteristics

3.2.1 Device overview

PRODUCT DESCRIPTION 3

Figure 4: microScan3 – overview

Optics cover

1

Display

2

Keypad

3

USB port

4

Status LEDs

5

Additional LEDs

6

Network LEDs

7

Safety laser scanner without system plug

8

System plug

9

Cover plate

ß

Different variants of the safety laser scanner are available, see "V

ariants", page 16.

Further information about the variants see "Variant overview", page 150.

All variants have an optics cover and the rotating mirror is located below the optics

cover. The light pulses are emitted and the reflected light pulses are received through

the optics cover.

The display with 4 pushbuttons is located below the optics cover. The safety laser scan‐

ner also has a number of light emitting diodes, see "Status indicators", page 16, see

"Buttons and display", page 122.

Information about connections: see "Connections", page 17.

The safety laser scanner can be mounted and operated in any alignment. In this docu‐

ment, position and direction information is used as follows with respect to the safety

laser scanner, as long as different usage is not indicated separately:

The top is the side of the safety laser scanner on which the optics cover is located.

•

The bottom is the side of the safety laser scanner opposite the optics cover.

•

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

15

Page 16

1 2 3 4

3 PRODUCT DESCRIPTION

•

•

3.2.2 Variants

The safety laser scanner is delivered in different variants. You will find an overview of

im

portant distinguishing features of the variants in the following. Further information

about the variants see "Variant overview", page 150.

The following properties differ in the variants:

•

•

Performance package

T

he Core and Pro performance packages feature a number of configurable fields and a

number of safety switching functions.

•

•

he front is the side of the safety laser scanner on which the display is located.

T

The 90° angle of the sector of a circle scanned by the safety laser scanner points

in this direction.

The back is the side of the safety laser scanner opposite the display. The sector of

a circle not scanned by the safety laser scanner lies in this direction.

Performance package

Maximum protective field range

microScan3 Core – EtherNet/IP™: 8 fields, 4 safety outputs via network

microScan3 Pro – EtherNet/IP™: 128 fields, 8 safety outputs via network

Integration in the control

he safety laser scanner communicates with the machine controller as follows:

T

•

Protective field range

here are two variants with different maximum protective field range:

T

•

•

3.2.3 Status indicators

The safety laser scanner outputs important status information using a number of light

emit

additional information.

4 status light emitting diodes are located directly above the display.

EtherNet/IP™ – CIP Safety™

4.0 m

5.5 m

ting diodes. The safety laser scanner has a graphical display and 4 pushbuttons for

16

Figure 5: Status LEDs

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 17

PRODUCT DESCRIPTION 3

Table 1: Status LEDs

Number Function Color Meaning

1

2

3

4

The OFF state and ON state light emitting diodes can be found in multiple locations on

t

he safety laser scanner. 3 additional sets are arranged in pairs on the base of the

optics cover. So the light emitting diodes can also be seen in many cases when it is not

possible to see the display, e.g. due to the mounting situation or because it is hidden

from the operator’s position.

The device has different light emitting diodes for every network interface. These net‐

work light emitting diodes are located below the display.

OFF state Red Lights up red when at least one

s

afety output is in the OFF state.

ON state Green Lights up green when at least one

safety output is in the ON state.

Warning field Yellow Shines yellow if at least one warning

field is interrupted.

Restart interlock Yellow Setup with reset: Flashes if the

estart interlock has been triggered.

r

Configuration with automated restart

after a time: Lights up while the con‐

figured time to restart expires.

3.2.4 Connections

3.2.5 System plug

More information about the meaning of the light emitting diodes see "Diagnostic LEDs",

page 135.

Depending on the configuration, the display shows current information about the safety

laser scanner’s status, see "Buttons and display", page 122.

1 x male connec

•

2 × female connector, M12, D-coding for Ethernet (EtherNet/IP – CIP Safety, data

•

tor, M12, A-coding for voltage supply

output, configuration, and diagnostics)

1 × female connector, USB 2.0 Mini-B for configuration and diagnosis

•

1)

A system plug is required to operate the safety laser scanner.

he metal plate with the connections is the system plug (see figure 4, page 15). The

T

system plug can either be mounted on the rear side or the underside.

The safety laser scanner’s internal configuration memory is integrated in the system

plug. The system plug and all connecting cables can remain at the installation site

when the safety laser scanner is replaced. The system plug is detached from the defec‐

tive safety laser scanner and connected to the new safety laser scanner. The new

safety laser scanner reads the configuration from the configuration memory when

switching on.

3.2.6 Field types

During operation, the safety laser scanner uses its laser beams continuously to check

whe

ther people or objects are present in one or more areas. The areas to be checked

are called fields. A distinction is made between the following field types, depending on

how the safety laser scanner is used:

Protective field

•

Reference contour field

•

1)

he USB connection may only be used temporarily and only for configuration and diagnostics.

T

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

17

Page 18

3 P

RODUCT DESCRIPTION

ontour detection field

C

•

Warning field

•

Table 2: Field types and their function

Protective field Reference con‐

Safe switch off

cording to ISO

(ac

13849-1)

Max. sensing

range of

microScan3

Purpose Detection and

Yes (PL d) Yes (PL d) Yes (PL d) No

4.0 m or 5.5 m

(depends on vari‐

ant)

protection of peo‐

ple

t

our field

4.0 m or 5.5 m

(depends on vari‐

ant)

Tamper protec‐

tion

Contour detec‐

tion field

4.0 m or 5.5 m

(depends on vari‐

ant)

e.g. door monitor‐

ing

Warning field

40 m

Functional use

(no safety-rele‐

vant use)

Protective field

T

he protective field protects the hazardous area of a machine or vehicle. As soon as the

electro-sensitive protective device detects an object in the protective field, it switches

the associated safety outputs to the OFF state. This signal can be passed to controllers

resulting in the dangerous state coming to an end, e.g. to stop the machine or the vehi‐

cle.

18

Figure 6: Protective field, shown in red in this document

Reference contour field

T

he reference contour field monitors a contour of the environment. The safety laser

scanner switches all safety outputs to the OFF state if a contour does not match the set

parameters, because, for example, the mounting situation of the safety laser scanner

were changed.

National and international standards require or recommend that a reference contour is

monitored, if the safety laser scanner is used in vertical operation for hazardous point

protection or for access protection.

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 19

PRODUCT DESCRIPTION 3

The reference contour field detects unintentional and intentional changes to the posi‐

t

ion or alignment of the safety laser scanner. Unintentional changes may be caused by

vibrations for example. An example of an intentional change is deliberate tampering to

disable the safety laser scanner’s functionality.

Figure 7: Reference contour field, shown in blue-green in this document

Contour detection field

T

he contour detection field monitors a contour of the environment. The safety laser

scanner switches the associated safety outputs to the OFF state if a contour does not

match the set parameters, because, for example, a door or flap is open.

The contour detection field is used for detecting changes in the environment and only

switches the outputs in the current monitoring case. By contrast, the reference contour

field is used for detecting changes at the safety laser scanner and switches all safety

outputs.

Warning field

T

he warning field monitors larger areas than the protective field. Simple switching func‐

tions can be triggered with the warning field, e.g. a warning light or an acoustic signal

can be triggered if a person approaches, even before the person enters the protective

field.

The warning field must not be used for safety-relevant tasks.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

19

Page 20

RODUCT DESCRIPTION

3 P

Figure 8: Warning field, shown in yellow or orange in this document

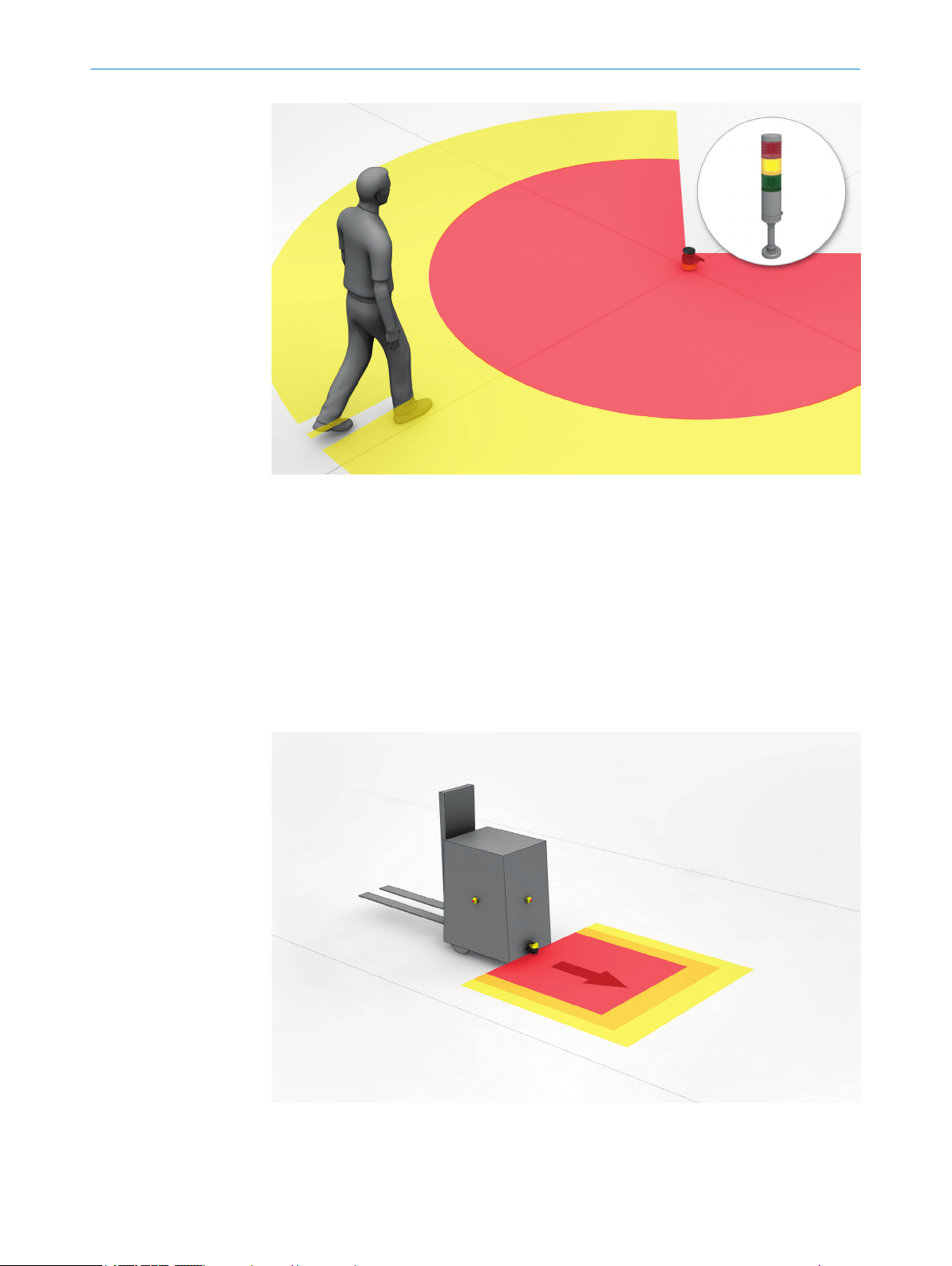

3.2.7 Field set

A field set consists of one or more fields. The fields in a field set are monitored simulta‐

neousl

y.

A field set can contain various types of field.

A typical application is the use of a protective field with one or more warning fields: if a

vehicle approaches a person, a warning field triggers an optical or acoustic signal. If the

person does not react to this and the vehicle continues to approach, the safety laser

scanner detects an object in the protective field and switches the associated safety out‐

puts to the OFF state. The vehicle stops before it reaches the person.

20

Figure 9: Field set, consisting of one protective field (red) and 2 warning fields (orange and yel‐

lo

w)

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 21

3.2.8 Monitoring case

A monitoring case signals the machine status to the safety laser scanner. The safety

la

therefore a particular machine status.

If a machine, e.g., has various operational statuses, a monitoring case can be assigned

to each operational status. The safety laser scanner receives a defined signal for the

current operational status via the safety-related network. If there is a change of signal,

the safety laser scanner switches from one monitoring case to the monitoring case that

is assigned to the new signal (as well as the new operational status). Generally, one

field set is assigned to each monitoring case.

PRODUCT DESCRIPTION 3

ser scanner activates the field set, which is assigned to the monitoring case and

Figure 10: Monitoring case 1 with field set 1

Figure 11: Monitoring case 2 with field set 2

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

21

Page 22

3 P

RODUCT DESCRIPTION

3.2.9 Simultaneous monitoring

The safety laser scanner can monitor several field sets in one monitoring case (e.g. haz‐

ar

dous area to the left and hazardous area to the right). The field sets can affect differ‐

ent safety outputs in variants with several safety outputs.

For example, they can protect 2 machines with only one safety laser scanner.

In order to configure simultaneous monitoring, assign several field sets to a monitoring

case in Safety Designer, see "Assigning field sets", page 108.

Figure 12: Simultaneous monitoring

3.3 Example applications

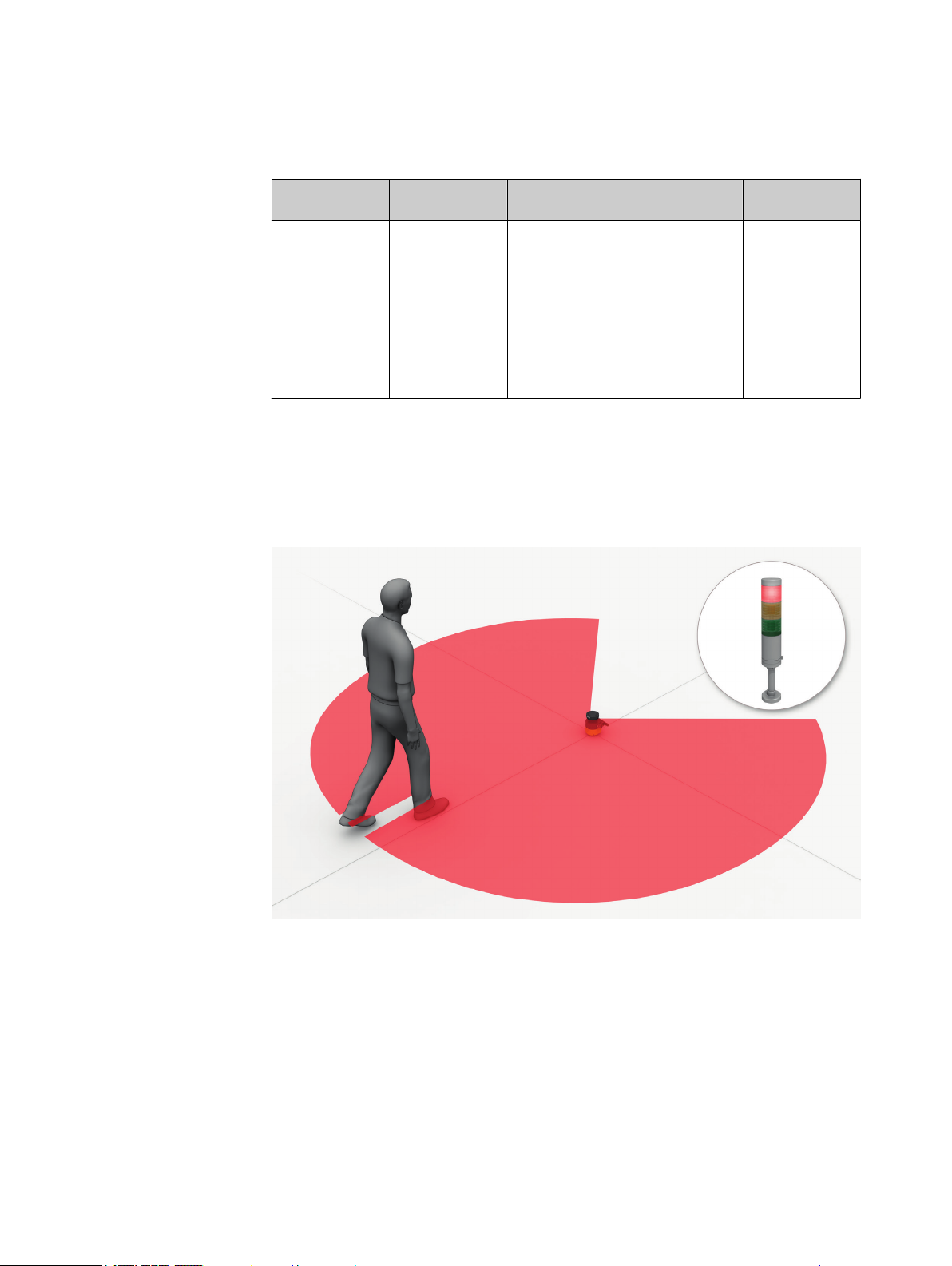

Hazardous area protection

In ha

zardous area protection, people are detected if they stay in a defined area.

This type of protective device is suitable for machines, where it is possible to see a haz‐

ardous area completely from the reset pushbutton. When the hazardous area is

entered, a stop signal is triggered and starting is prevented.

22

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 23

PRODUCT DESCRIPTION 3

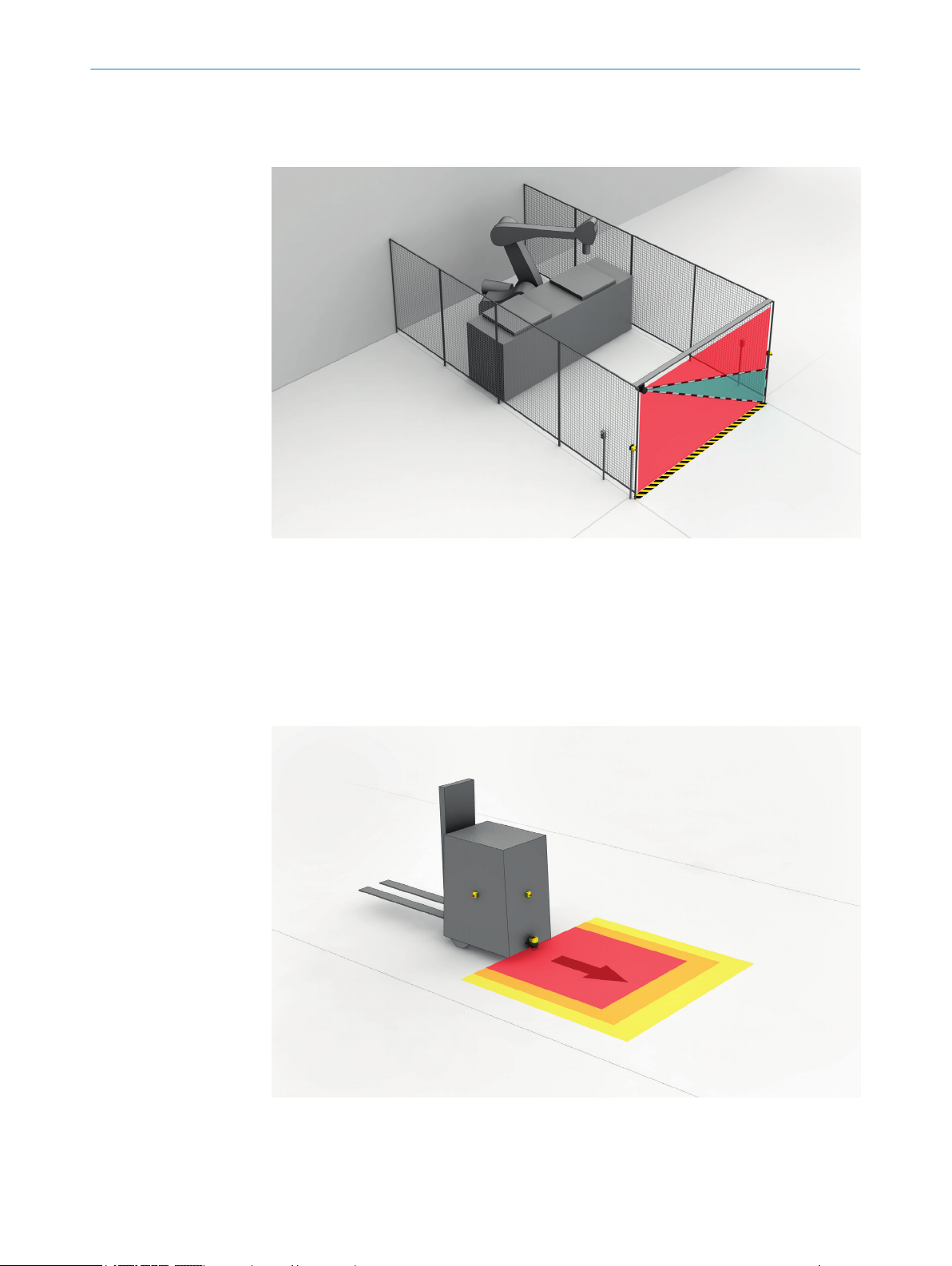

Figure 13: Hazardous area protection: detection of the presence of a person in the hazardous

ar

ea

Hazardous point protection

In hazardous point protection, the approach is detected very close to the hazardous

point.

The advantage of this type of protective device is that it is possible to have a short mini‐

mum distance and the operator can work more ergonomically.

Figure 14: Hazardous point protection: hand detection

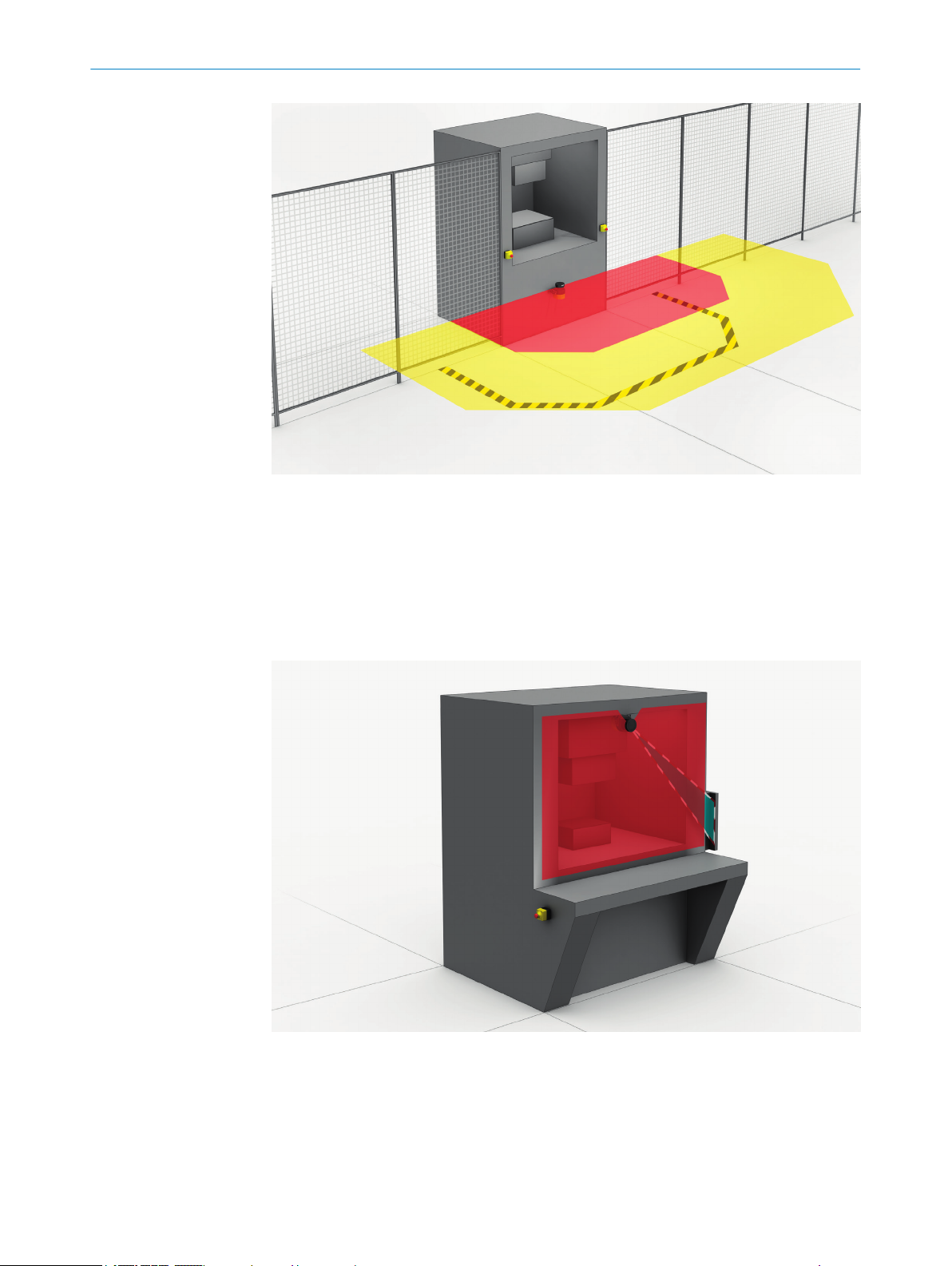

Access protection

In ac

cess protection, people are detected if their whole body passes through the protec‐

tive field.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

23

Page 24

3 P

RODUCT DESCRIPTION

This type of protective device is used for the protection of access to hazardous areas.

W

hen the hazardous area is entered, a stop signal is triggered. A person standing

behind the protective device will not be detected by the ESPE.

Figure 15: Access protection: detection of a person when accessing a hazardous area

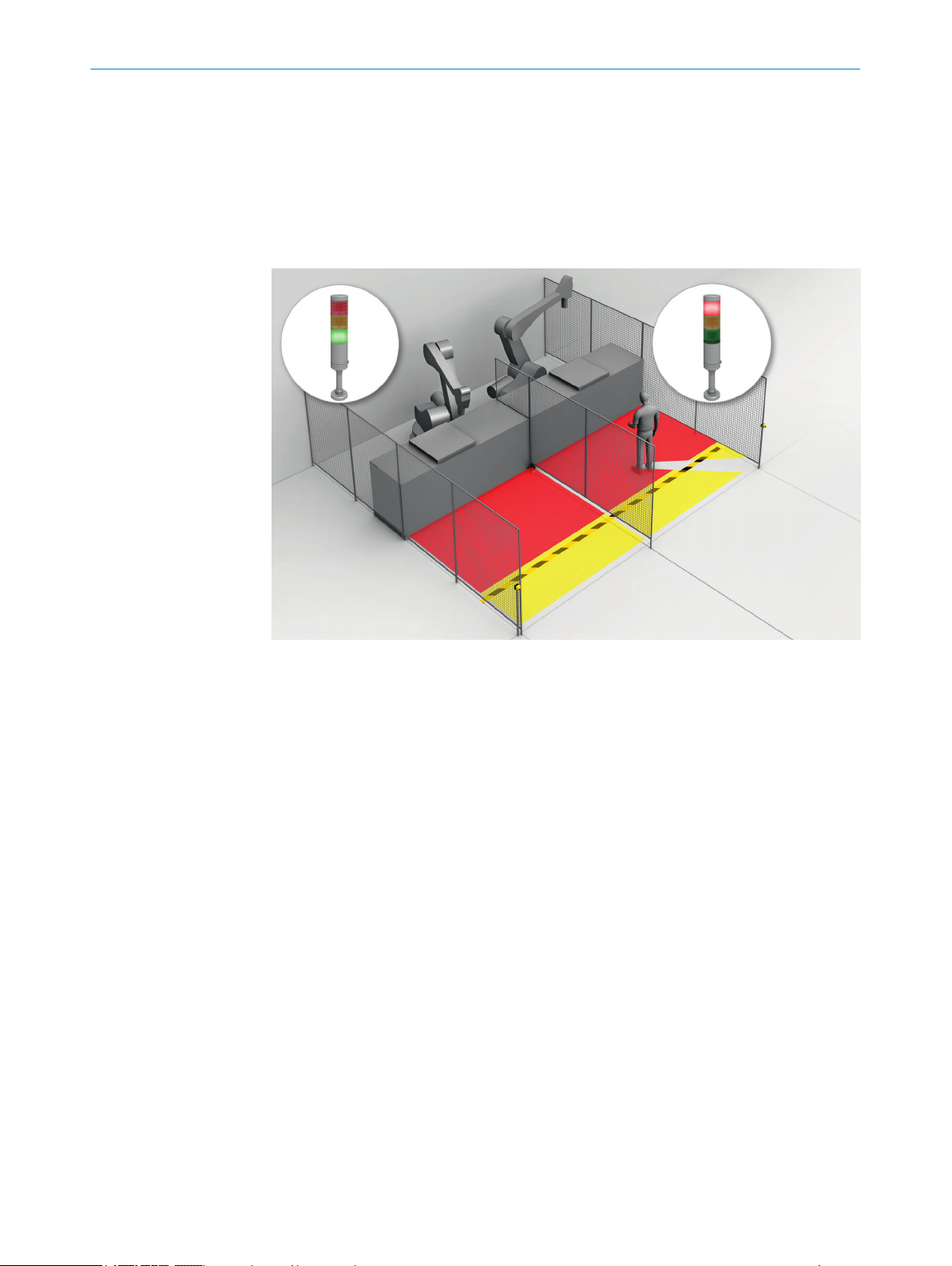

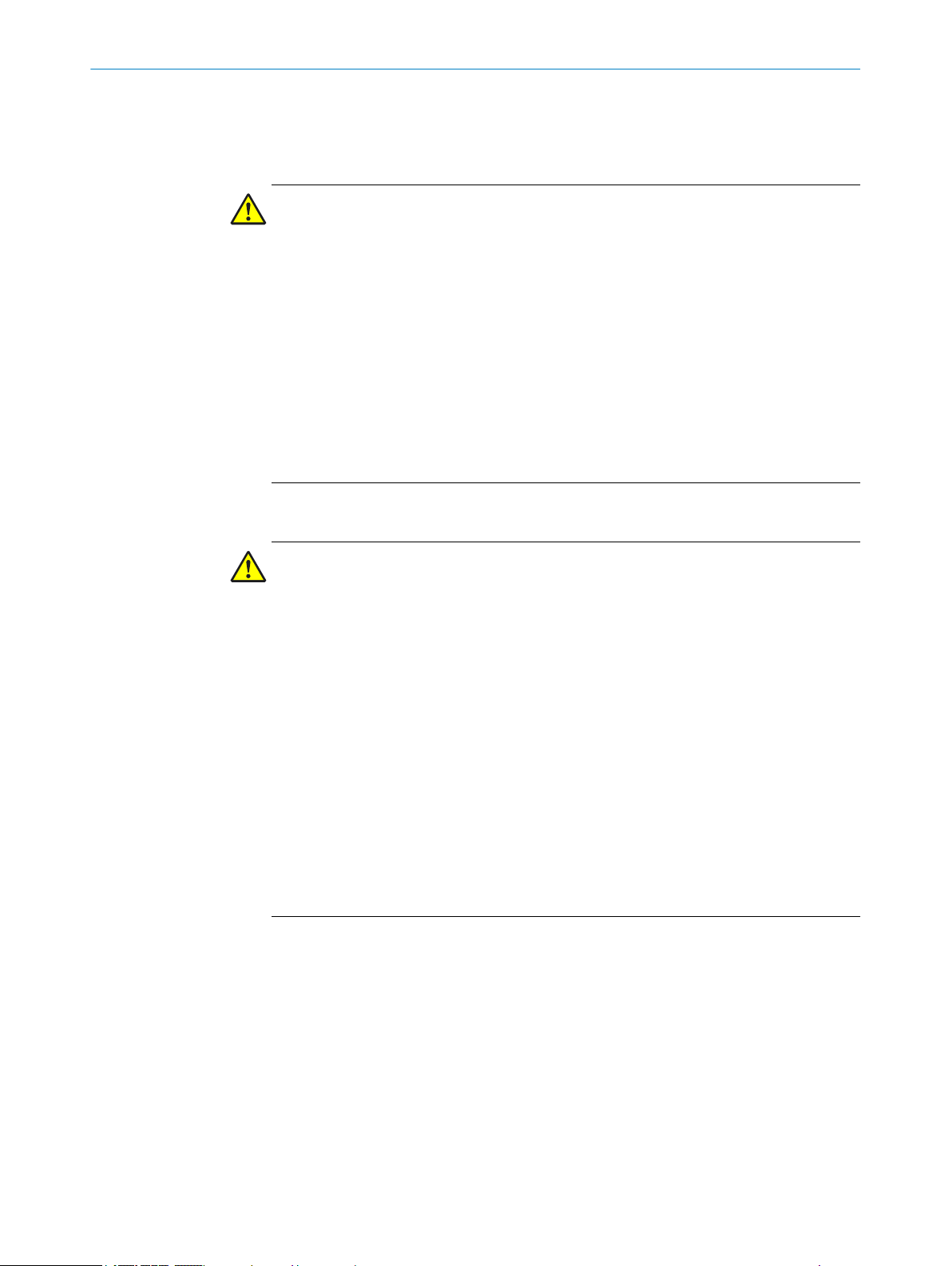

Mobile hazardous area protection

Mobile ha

zardous area protection is suitable for AGVs (automated guided vehicles),

cranes and forklifts, to protect people when vehicles are moving or docking at a fixed

station.

The safety laser scanner monitors the area in the direction of travel and stops the vehi‐

cle as soon as an object is located in the protective field.

24

Figure 16: Mobile hazardous area protection: detection of a person when a vehicle approaches

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 25

4 Project planning

4.1 Manufacturer of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Use of the safety laser scanner requires a risk assessment. Check whether addi‐

b

tional protective measures are required.

Comply with the applicable national regulations derived from the application (e.g.,

b

work safety regulations, safety rules, or other relevant safety guidelines).

Apart from the procedures described in this document, the components of the

b

safety laser scanner must not be opened.

The safety laser scanner must not be tampered with or changed.

b

Improper repair of the protective device can lead to a loss of the protective func‐

b

tion. The protective device must only be repaired by the manufacturer or by some‐

one authorized by the manufacturer.

PROJECT PLANNING 4

4.2 Operator of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Changes to the electrical integration of the safety laser scanner in the machine

b

control and changes to the mechanical mounting of the safety laser scanner

necessitate a new risk assessment. The results of this risk assessment may

require the operator of the machine to meet a manufacturer’s obligations.

Changes to the device’s configuration may impair the protective function. The

b

effectiveness of the protective device must be checked after any change to the

configuration. The person carrying out the change is also responsible for maintain‐

ing the protective function of the device.

Apart from the procedures described in this document, the components of the

b

safety laser scanner must not be opened.

The safety laser scanner must not be tampered with or changed.

b

Improper repair of the protective device can lead to a loss of the protective func‐

b

tion. The protective device must only be repaired by the manufacturer or by some‐

one authorized by the manufacturer.

4.3 Assembly

This chapter contains important information about the design.

Information about the individual steps for mounting the device: see "Mounting",

page 67.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

25

Page 26

4 P

ROJECT PLANNING

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Make sure that the following design requirements are met so that the safety laser

b

scanner can fulfill its protective function.

he safety laser scanner must be affixed so that people or parts of the body are

T

•

reliably detected upon entry into the hazardous area.

The safety laser scanner must be affixed so that no mirrors or other exceedingly

•

reflective objects are in the protective field.

The safety laser scanner must be affixed so that no small objects (e.g. cables) are

•

in the protective field, even if the safety outputs do not switch to the OFF state as a

result.

The safety laser scanner must be affixed so that no obstacles disrupt the safety

•

laser scanner’s field of view. Take additional protective measures if a risk arises

due to unavoidable obstacles.

If people can stay between the protective device and the hazardous point without

•

being detected, check if additional protective measures (e.g. restart interlock) are

required.

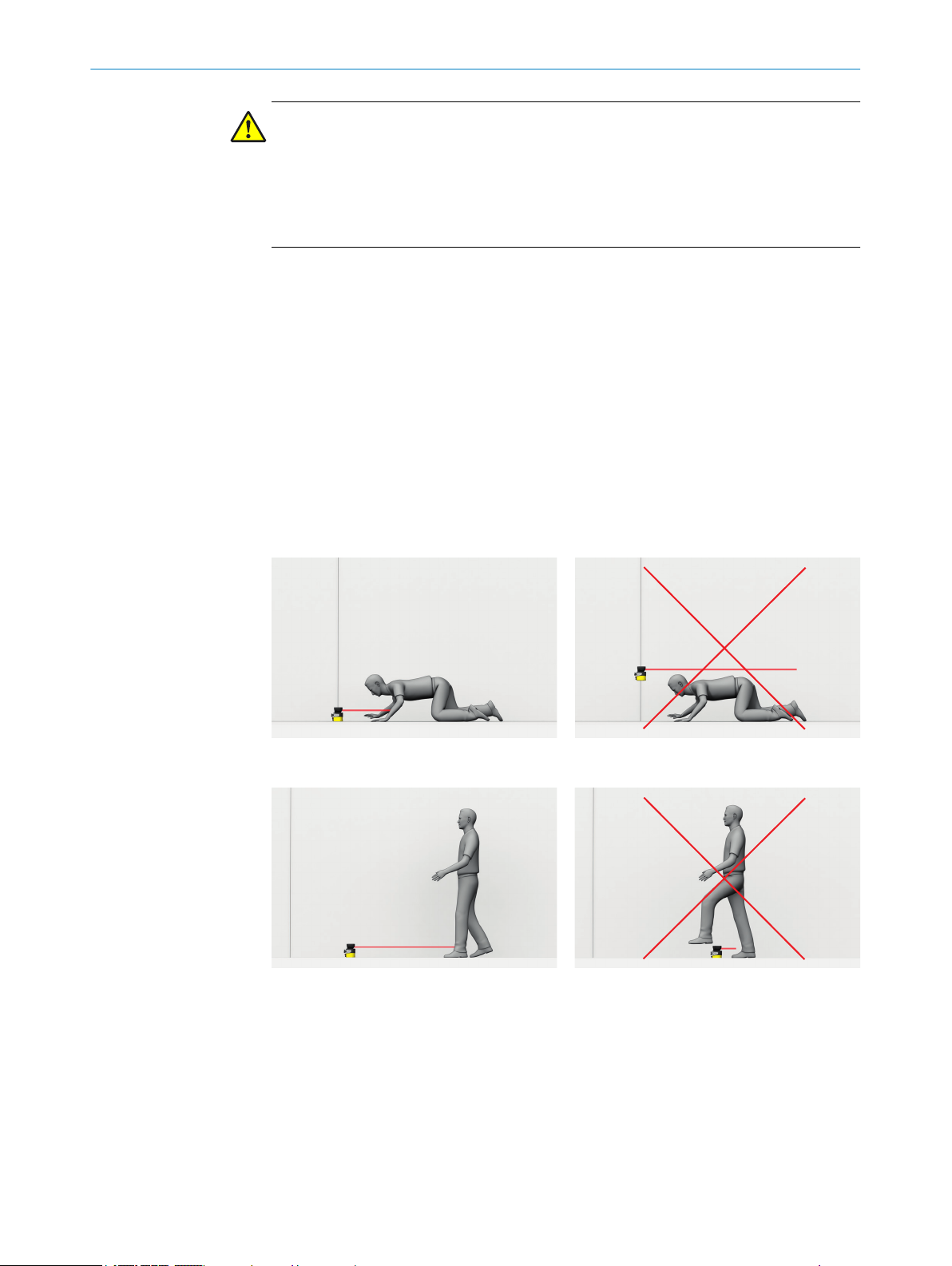

Reaching under, over and around, crawling beneath and stepping over the safety

•

laser scanner, as well as moving it, must be prevented.

Figure 17: Prevent crawling beneath

Figure 18: Prevent stepping over

26

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 27

PROJECT PLANNING 4

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

The optical beam path must not be disrupted, e.g. if the system is incorporated into

paneling.

Do not attach an additional front screen.

b

If a viewing slit is required, make sure that its size is sufficient, see "Dimensional

b

drawings", page 174.

NOTE

ertain optical and electromagnetic ambient conditions can affect the safety laser

C

scanner. This may impair the machine’s availability. That is to say, the safety laser scan‐

ner switches the machine off, although no people are located in the protective field.

Take note of the following for a high level of availability:

Avoid having strong electric fields in the vicinity of the safety laser scanner. These

b

may be caused by nearby welding or induction cables, for example.

Prevent condensation forming on the optics cover.

b

4.3.1 Protection against interference from systems in close proximity to each other

A safety laser scanner can be influenced by the beams from a different laser source in

close proximity to it, e.g. by another laser scanner. This may impair the machine’s avail‐

ability. That is to say, the affected safety laser scanner switches the machine off,

although no people are situated in the protective field.

You can use the following measures to increase the availability:

The safety laser scanner has a function for interference protection. The scan cycle

•

time is adjusted in small increments. You can increase the availability by choosing

different modes for interference protection in adjacent safety laser scanners, see

"Additional interference protection", page 93.

Higher multiple sampling reduces the likelihood of a laser source influencing the

•

safety laser scanner. You can increase the availability by setting multiple sampling

to the highest value permitted in your application, while taking minimum distances

into account, see "Multiple sampling", page 91.

You can further increase the availability by choosing a suitable mounting method,

•

see "Mounting methods for protection from interference from systems in close

proximity", page 189.

You can check the safety laser scanner’s beam path using the Scanfinder LS-80L (part

no. 6020756).

NOTE

Y

ou must comply with the standard ISO 13855 when choosing the mounting method.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

27

Page 28

4 P

ROJECT PLANNING

4.3.2 Preventing unprotected areas

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Mount the safety laser scanner so that people cannot enter unsecured areas. Take one

or more of the measures described below as required:

Attach deflector plates to prevent anyone standing behind.

b

Mount the safety laser scanner in an undercut.

b

Mount the safety laser scanner in the paneling of the machine or vehicle.

b

Mount a frame to prevent access to the area.

b

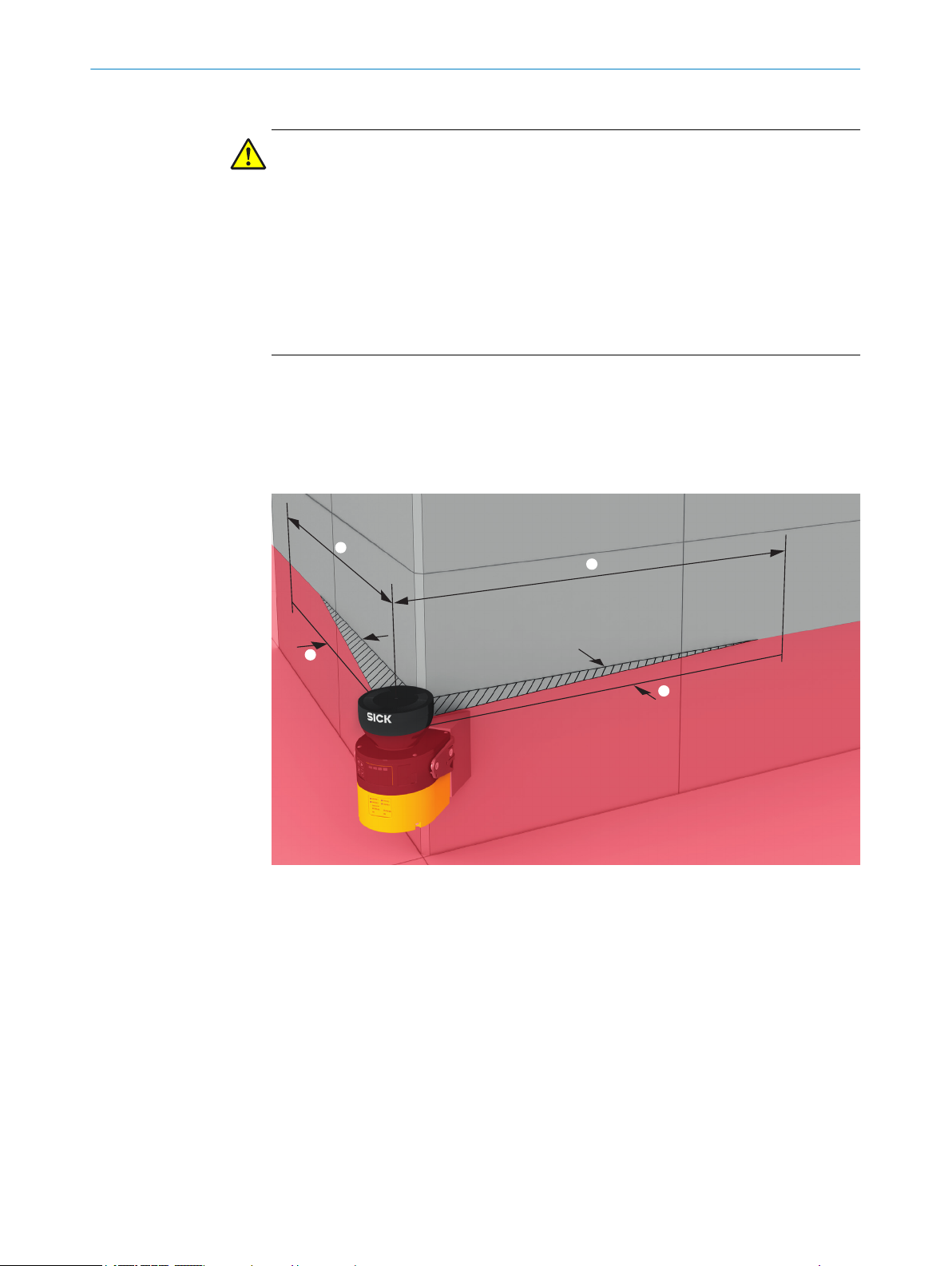

Unsecured areas behind the safety laser scanner

epending on the mounting situation, areas may result, which cannot be detected by

D

the safety laser scanner.

The undetected areas become larger if the safety laser scanner is mounted using a

mounting kit.

28

Figure 19: Unsecured areas

Length of the unsecured area

1

Width of the unsecured area

2

Area where detection capability is restricted

lose proximity (50 mm wide area in front of the optics cover), the detection capabil‐

In c

ity of the safety laser scanner may be restricted. If required, this area must be secured

using an undercut or frame, for example.

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 29

Mounting with deflector plates

PROJECT PLANNING 4

Figure 20: Mounting with deflector plates (example)

b Attach the deflector plates 1 so that it is not possible to step into unsecured

areas.

Attach the deflector plates so that they lie outside the scan plane.

b

Mounting in an undercut

Figure 21: Mounting in an undercut (example)

b

Mount t

he safety laser scanner in an undercut so that no-one can enter the unse‐

cured areas.

b Make the undercut at least deep enough 1, that it covers the unsecured areas

completely and no one can enter the unsecured areas.

b Prevent crawling beneath the undercut. Design the undercut to be so low 2, that

no one can crawl into it.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

29

Page 30

4 P

ROJECT PLANNING

Mounting in the machine or vehicle’s paneling

Figure 22: Mounting in vehicle paneling (example)

If a v

b

iewing slit is required, make sure that its size is sufficient, see "Dimensional

drawings", page 174.

4.3.3 Response time of the safety laser scanner

The safety laser scanner’s response time must be taken into account, among other

t

hings, so that the safety laser scanner can be positioned in a suitable location and the

protective fields can be sized correctly.

The response times are specified in the technical data, see "Response times",

page 155.

The response time of the safety laser scanner resulting from current settings is shown

in Safety Designer.

4.3.4 Reference contour monitoring

Reference contour field

T

he reference contour field monitors a contour of the environment. The safety laser

scanner switches all safety outputs to the OFF state if a contour does not match the set

parameters, because, for example, the mounting situation of the safety laser scanner

were changed.

National and international standards require or recommend that a reference contour is

monitored, if the safety laser scanner is used in vertical operation for hazardous point

protection or for access protection.

30

The reference contour field detects unintentional and intentional changes to the posi‐

tion or alignment of the safety laser scanner. Unintentional changes may be caused by

vibrations for example. An example of an intentional change is deliberate tampering to

disable the safety laser scanner’s functionality.

Vertical operation

N

ational and international standards require or recommend that a reference contour is

monitored, if the angle between access direction and scan plane exceeds +30°.

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 31

PROJECT PLANNING 4

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Use a contour from the environment as a reference to protect the protective device

b

from inadvertent adjustment or tampering.

Configuring the reference contour field during vertical operation

N

ote the following points in particular when configuring the reference contour field:

In many cases, it makes sense to use lateral vertical passage boundaries (e.g.

•

door frames) and the floor as a reference.

The reference contour field has a tolerance band, which can be set, around the

•

contour. If the safety laser scanner does not detect the contour within the toler‐

ance band, all safety outputs switch to the OFF state.

For high availability, it is recommended to set the tolerance band to 65 mm

°

positive tolerance (far) and 65 mm negative tolerance (near).

Make sure that the tolerance band is not too wide. The reference contour

°

field must detect a change in the position or alignment of the safety laser

scanner before a dangerous gap is created between the protective field and

mechanical limit.

The following requirements apply to the protective field with respect to the refer‐

•

ence contour field:

Access protection:

°

°

You can define a number of contours in the reference contour field and so monitor

•

various areas in the environment.

If the reference contour represents the edge of the protected opening,

•

the distance between the edge of the protected opening and the protec‐

tive field must be no more than 100 mm wide. A distance of 65 mm is

recommended for high availability and sufficient protection.

If the reference contour does not represent the edge of the protected

•

opening, the protective field must be larger than the protected opening.

The required overrun (o) is calculated using the same formula as for haz‐

ardous point protection.

Hazardous point protection: the protective field must be larger than the pro‐

tected opening. The required overrun (o) is calculated using the following for‐

mula:

o ≥ 130 mm – d

where:

verrun of the protective field over the opening

o = o

•

d = set resolution

•

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

31

Page 32

1 2

3

1

2

ROJECT PLANNING

4 P

Figure 23: Tolerance band of the reference contour field (protective field within the protected

openin

g, edge of the protected opening = reference contour)

TZ = tolerance band of the reference contour field

1

Distance of the protective field from the contour, to ensure availability

2

Figure 24: Overrun of the protective field in front of an opening

TZ = tolerance band of the reference contour field

1

Distance of the protective field from the contour, to ensure availability

2

o = overrun of the protective field over the opening

3

4.3.5 Monitoring case switching time

When switching between monitoring cases, it is possible that a person may already be

in t

he newly activated protective field when switching takes place. Only switching in time

(namely before the danger arises for the person at this location) ensures protection.

32

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 33

PROJECT PLANNING 4

DANGER

azard due to lack of effectiveness of the protective device

H

Switching of the monitoring case should be timed so that the safety laser scanner

b

detects a person in the protective field with a sufficient minimum distance, before

the dangerous state occurs.

DANGER

H

azard due to lack of effectiveness of the protective device

Persons or parts of the body to be protected may not be recognized or not recognized in

time in case of non-observance.

In addition to the parameters considered below, the switching signal’s propagation

delay time up to the protective device also influences the switching duration. These

include the network cycle time and the processing time of a control, for example.

Take account of the switching signal’s propagation delay time up to the protective

b

device.

In some cases, the process of switching between monitoring cases takes so long that

t

he new monitoring case is not available inside the response time provided. This means

that it may not be possible to detect a person in the protective field in time. In cases

like this, you must start switching between monitoring cases earlier.

The following parameters influence the duration of the process:

The set input delay (see "Input delay ", page 106).

•

The processing time for the chosen input.

•

You calculate when to switch between monitoring cases as follows

First calculate how long it takes to switch between monitoring cases:

1.

t

= tID + t

CSR

I

where:

t

= time required for switching between monitoring cases in milliseconds

C

SR

°

(ms)

tID = input delay for the control inputs in milliseconds (ms) (only for Assembly

°

100)

tI = processing time for the selected switching type in milliseconds (ms)

°

Switching signal via network: tI = 28 ms

•

2. Then calculate how much time is available in the response time for switching

between monitoring cases:

= (n – nCS) × t

t

SA

C

S

where:

t

= time available for switching between monitoring cases in milliseconds

C

SA

°

(ms)

n = set multiple sampling (default: n = 2)

°

nCS = multiple sampling after switching between monitoring cases (with set‐

°

ting Fast (presetting): nCS = 1, with setting Reliable: nCS = n – 1, with setting

User-defined: nCS ≤ n – 1)

tS = scan cycle time (poss. incl. supplement due to interference protection) in

°

milliseconds (ms)

3. Then check whether there is enough time available for switching between monitor‐

ing cases:

If t

≥ t

: earlier start is not necessary.

CSR

< t

: you must start switching between monitoring cases earlier. The

CSR

required is: t

CSP

CSP

= t

CSR

– t

CSA

If t

CSA

CSA

°

°

time advance t

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

33

Page 34

S

S

4 P

ROJECT PLANNING

NOTE

In some c

ases, it is not possible to define when to switch (for example because pro‐

cessing times of the machine vary) or the time advance means that the monitoring of

an area finishes too early. Follow one of the following recommendations in these cases:

Allow the two protective fields to partially overlap.

b

Temporarily monitor both hazardous areas simultaneously.

b

4.3.6 Hazardous area protection

The safety laser scanner is mounted with a horizontal scan plane in a stationary appli‐

c

ation, for example on a machine where the hazardous area is not completely sur‐

rounded by a physical guard. During hazardous area protection, the safety laser scan‐

ner detects a person’s legs. The protective field is parallel to the person’s direction of

approach.

34

Figure 25: Stationary application with horizontal scan plane for hazardous area protection

NOTE

k the outline of the protective field boundaries on the floor after you have worked

Mar

out the protective field size. By doing this, you allow machine operators to see the pro‐

tective field boundaries and make it easier to thoroughly check the protective function

at a later date.

Protective field

T

he protective field must be designed so that it detects a person at a minimum dis‐

tance from the hazardous point. This distance is required to prevent a person or part of

their body from reaching the hazardous area before the end of the machine’s danger‐

ous state.

In hazardous area protection, the minimum distance typically defines the protective

field size required.

If you define a number of monitoring cases with different protective fields, you must cal‐

culate the protective field size separately for each protective field used.

In many cases, a resolution of 50 mm or 70 mm is suitable for hazardous area protec‐

tion.

O PE R AT I NG IN S TR U CT I ON S | microScan3 – EtherNet/IP™ 8020200/ZU95/2018-02-05 | SICK

Subject to change without notice

Page 35

PROJECT PLANNING 4

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

1. Calculate the required minimum distance for your machine using the following for‐

mulas and examples.

2. Take this calculation and the specifications in these instructions into account

when mounting the safety laser scanner.

3. Take this calculation and the specifications in these instructions into account

when configuring the safety laser scanner.

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Body parts to be protected may not be detected under coarse resolution.

Use a resolution of 70 mm or finer for hazardous area protection.

b

For hazardous area protection with a resolution of 70 mm: make sure that it is

b

possible to detect a human leg.

For hazardous area protection with a resolution of 70 mm: mount the safety laser

b

scanner at a height of at least 300 mm (height of the scan plane).

If it is not possible to mount the safety laser scanner at a height of at least

b

300 mm, use a resolution of 50 mm.

NOTE

he protective field needs to be as small as possible, you may have to calculate the

If t

minimum distance multiple times with different scan cycle times (iterative calculation)

because of various dependencies.

2)

Always take the actual response time into account when calculating the minimum dis‐

tance, see "Response times", page 155.

1. First calculate the minimum distance on the basis of the response time for a scan

cycle time of 30 ms.

2. If the calculated minimum distance is larger than the resulting protective field

range (see "Protective field range", page 156), recalculate the minimum distance

on the basis of the response time for a scan cycle time of 40 ms.

Calculating minimum distance

T

he calculation of the minimum distance is based on international or national stan‐

dards and statutory requirements applicable at the place of installation of the machine.

If the minimum distance is calculated according to ISO 13855, then it depends on the

following points:

Machine stopping time (time interval between triggering the sensor function and

•

the end of the machine’s dangerous state, including signal propagation times in

the network and processing time in the control)

Response time of the protective device, see "Response times", page 155

•

Reach or approach speed of the person

•

Resolution (detection capability) of the safety laser scanner

•

Type of approach: parallel

•

Parameters specified based on the application

•

2)

he required minimum distance depends on the response time, among other things, and therefore on the scan cycle time. The protective

T

field range likewise depends on the scan cycle time: the protective field range is shorter for a faster scan cycle time.

8020200/ZU95/2018-02-05 | SICK O P ER A TI N G I NS T RU C TI O NS | microScan3 – EtherNet/IP™

Subject to change without notice

35

Page 36

4 PROJECT PLANNING

Supplement

•

Supplement to protect against reaching over

•

Height of the scan plane

•

Switching time between monitoring cases

•

NOTE

e information is available in the ISO 13855 standard and in the Guide for Safe

Mor

Machinery.

NOTE

SIC

K offers a stopping/run-down time measurement service in many countries.

Calculation example of the minimum distance S according to ISO 13855

he example shows the calculation of the minimum distance for parallel approach to

T

the protective field. Depending on the application and the ambient conditions a differ‐

ent calculation may be required. (e.g., a protective field or at an arbitrary angle to the

direction of approach or an indirect approach)

Calculate S using the following formula:

b

S = 1600 mm/s × T + 65 mm + ZR + C

where:

°

°

°

°

The reach/approach speed is already included in the formula.

s for general and, possibly, reflection-based measurement errors

S = minimum dis