Page 1

Title Page

MCS300P

Multicomponent Analysis System

Operating for Service Technicians

Technical Details

TECHNICAL INFORMATION

These Instructions are intended exclusively

for trained personnel.

Unauthorized intervention voids the manufacturer's warranty.

Page 2

Document Information

Described Product

Product name MCS300P, MCS300P-Ex

Document Identification

Title: Technical Information MCS300P

Part No.: 8013265

Version: 1-2

Release: 2013-08

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: info.pa@sick.de

Original document

The English edition 8013265 of this document is an original document of SICK AG.

SICK AG assumes no liability for the correctness of an unauthorized translation.

In case of doubt, contact SICK AG or your local representative.

Legal information

Subject to change without notice.

© SICK AG. All rights reserved.

2 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Page 3

Warning Symbols

Information Symbols

Hazard (general)

Hazard by voltage

Hazard by explosive substances/mixtures

Hazard by corrosive substances

Hazard by toxic substances

Hazard by unhealthy substances

Hazard by high temperature or hot surface

Warning Levels / Signal Words

DANGER

Risk or hazardous situation which will result in severe personal

injury or death.

Important technical information for this device

Important information on electric or electronic functions

Supplementary information

Link to information at another place

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or

minor injuries and/or property damage.

NOTICE

Hazard which could result in property damage.

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 3

Page 4

Contents

Contents

1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Responsibility of user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Designated users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Special local conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 SOPAS ET (PC program). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.1 Modbus-TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2 OPC (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 SOPAS ET (Description) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.1 Changing the user level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.2 Grayed out fields - input not possible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.3 Using menus with assignments and calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Menu tree (in SOPAS ET). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Measuring Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Measuring Screen 1 .. x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1.1 Scaling the Measuring Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1 Control value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1.1 Zero drift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1.2 Reference energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1.3 Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.2 Sensor values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.2.1 Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.2.2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.3 Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3.1 Measuring signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3.2 Digital signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3.3 Analog signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3.4 Real values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3.5 Integer and filtered values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.4 Logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.5 System status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.6 System information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Page 5

Contents

3.5 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.1 Measuring components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.1.1 Global definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.1.2 Definition measuring components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.2 Measuring screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5.2.1 Measuring box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.2.2 Bargraph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.2.3 Line writer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.3 I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5.3.1 Addressing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5.3.2 Hardware map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5.3.3 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5.4 Variables and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5.4.1 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5.4.2 Cyclic trigger (CTi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5.5 Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.5.6 Temperature control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.7 Logbook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.8 Instrument display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.5.9 System parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.5.10 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.6 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.6.1 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6.1.1 Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6.1.2 Adjustment factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6.1.3 Start times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6.2 Manual adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.6.3 Automatic adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.7 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.7.1 Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.7.2

Operating states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.7.3 Hardware reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.7.4 Reset messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.7.5 Service log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.8 Tags (identifiers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 5

Page 6

Contents

6 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Page 7

Important Information

MCS300P

1 Important Information

Main hazards

Main instructions for operation

Own responsibility

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 7

Page 8

1.1 Validity

This Manual is valid for the MCS300P and MCS300P-Ex.

It is only valid in combination with the "Operating Instructions MCS300P" or

"Operating Instructions MCS300P-Ex".

1.2 Responsibility of user

1.2.1 Designated users

This Technical Information is aimed at qualified persons familiar with the MCS300P and

who, based on their device-specific training and knowledge of the device as well as knowledge of the relevant regulations, can assess the tasks given and recognize the dangers

involved.

1.2.2 Special local conditions

Follow all local laws, regulations and company-internal operating directives applicable at

the respective installation location of the equipment.

Important Information

8 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 9

Product Description

MCS300P

2 Product Description

Functional principle

Characteristics

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 9

Page 10

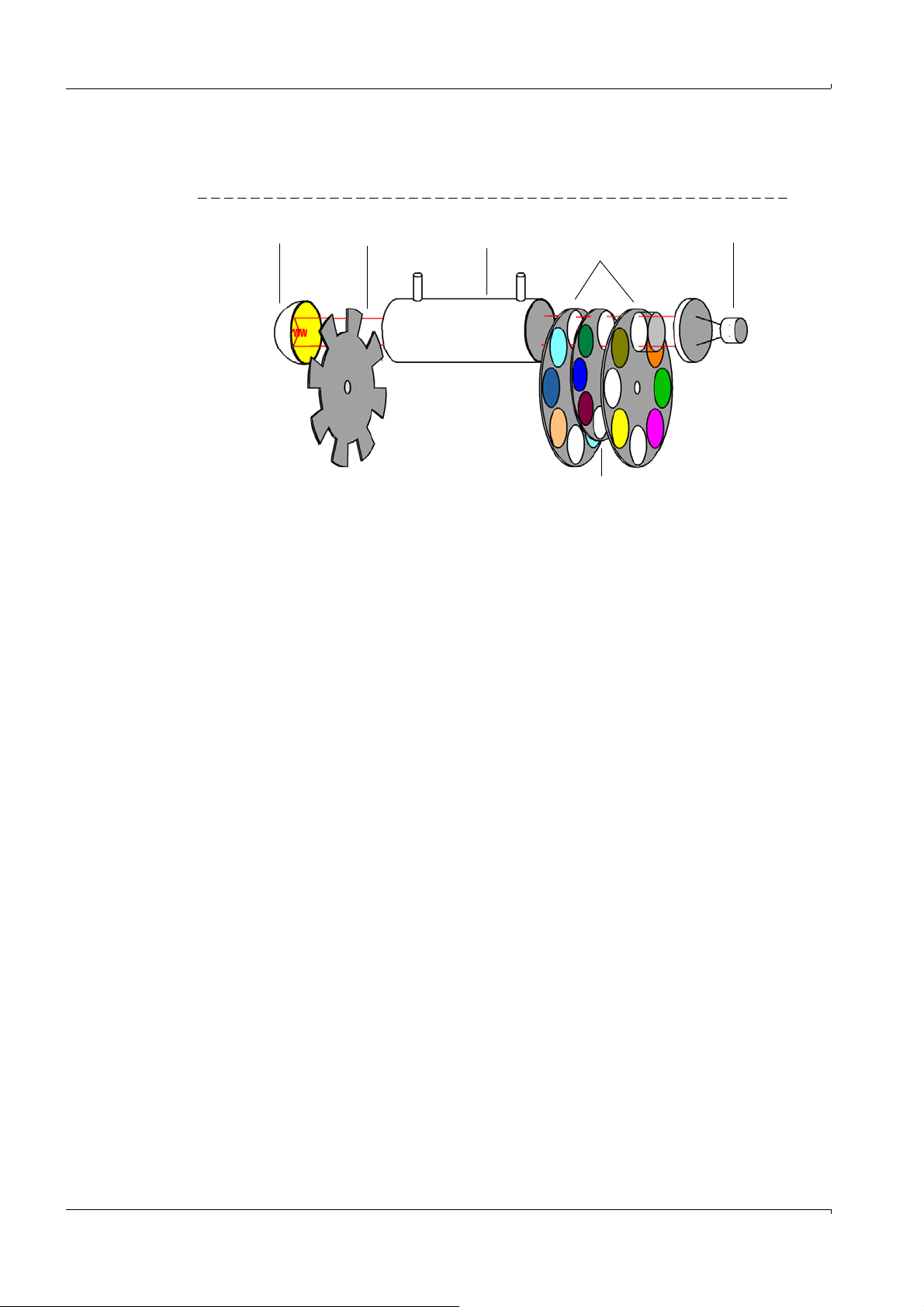

2.1 Functional principle

Source Chopper Cell Filter wheels with

measuring filters

Detector

Filter wheel with

adjustment standard

MCS300P is a non-dispersive process photometer.

Fig. 1 Beam path

Product Description

● Depending on the device type, the radiation source used is an IR or VIS radiator.

● The measuring beam goes through the sample cell and is specifically absorbed

depending on the sample gas composition.

● Interference and gas filters swiveled into the beam path on filter wheels select the

measurement wavelength.

● The detector receives the successive measurement and reference radiation.

– With the measuring filter swiveled in, the signal depends on the sample gas compo-

sition.

– With the reference filter swiveled in, a concentration-independent signal is gener-

ated.

By computation of both signals, the MCS300P determines the measured variable

"absorption” which is then, to a wide extent, independent from the changes of the optical characteristics of the photometer.

After correction of possible disturbance variables, the determined absorption is converted to the concentration value via the linearization function.

● As an option, a filter wheel with an internal adjustment standard is available which simulates a test with a test medium.

10 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 11

Product Description

2.2 SOPAS ET (PC program)

SOPAS ET can be used to set the MCS300P parameters and provides access to the

MCS300P logbook.

SOPAS ET runs on an external PC connected via the Ethernet interface to the MCS300P

( MCS300P Operating Instructions).

2.2.1 Modbus-TCP

Modbus® is a communication standard for digital controls to connect a »Master« device

with several »Slave« devices. The Modbus protocol defines the communication commands

only but not their electronic transfer; therefore it can be used with different digital interfaces (for MCS300P: Ethernet).

Configuration: → p. 30, § 3.5.3.3

2.2.2 OPC (option)

OPC is a standardized software interface that allows to exchange data between different

applications.

The SICK OPC server (part of SOPAS ET) is required.

System bus: Ethernet.

Configuration: → p. 30, § 3.5.3.3

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 11

Page 12

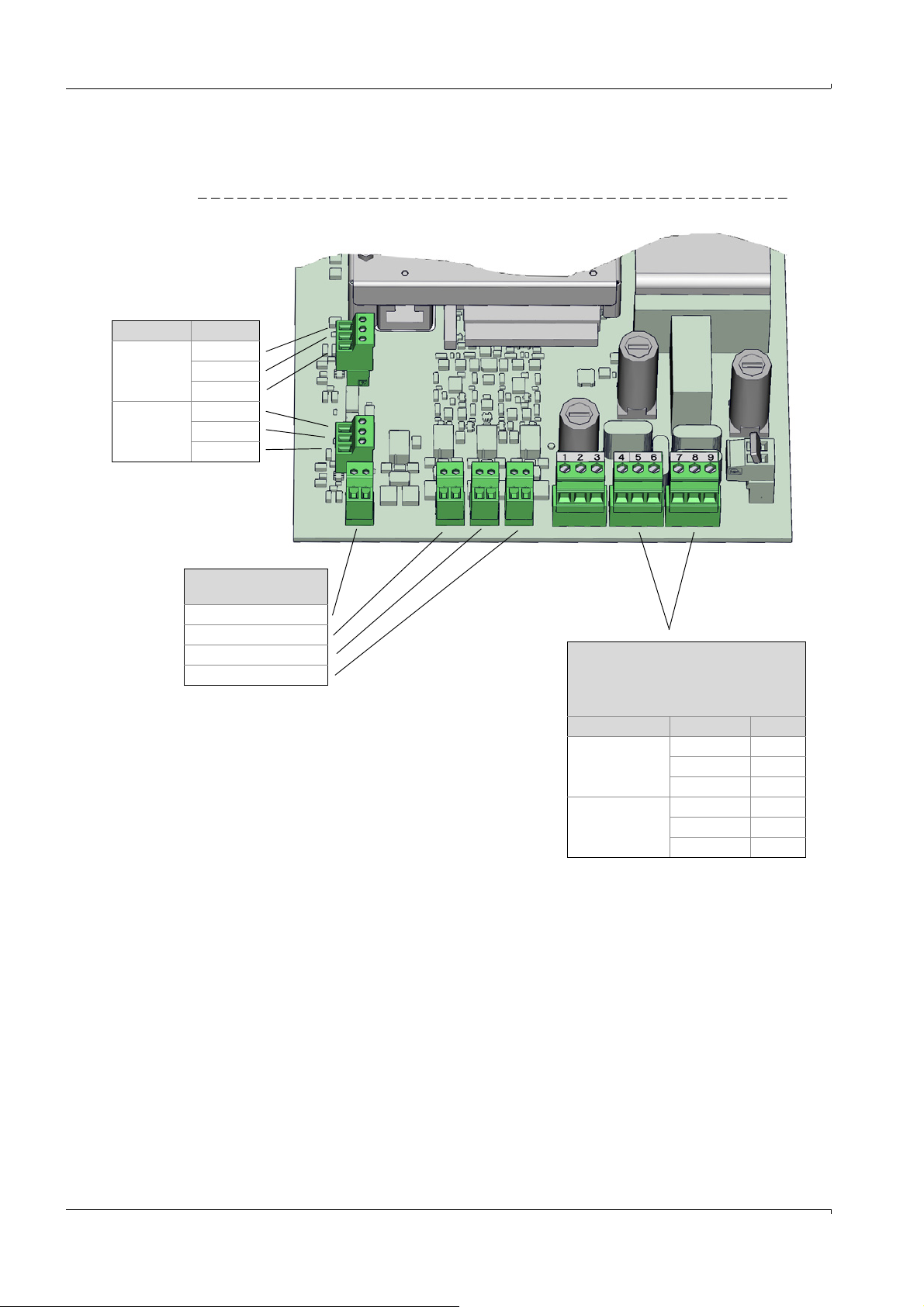

2.3 Circuit board

Pt100

Line: AWG26-15

Controller 2 limiter

Controller 1 limiter

Controller 2

Controller 1 (cell)

Heaters

Output voltage as mains voltage

Capacity: Max. 550 VA (per output)

Line: AWG24-12

Heater Line Pin

Heater 1

(cell)

L1 4

N5

PE 6

Heater 2 L1 7

N8

PE 9

CAN Line

CAN1

(internal)

ISOGND

LOW

HIGH

CAN2

External I/O

ISOGND

LOW

HIGH

Electrical connections on the circuit board in the sender unit

Fig. 2 Electrical connections in the sender unit

Product Description

12 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 13

Operation

MCS300P

3 Operation

Configuration

Advanced operation

Adjustments

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 13

Page 14

3.1 SOPAS ET (Description)

SOPAS ET is on the CD-ROM enclosed with the MCS300P.

Operator menus and measured value displays are also available on an external PC via Ethernet for user comfort (with the engineering tool SOPAS ET).

The SICK Open Portal for Applications and Systems (SOPAS) is an engineering tool for communication with analyzers and sensors.

SOPAS is based on the following techniques:

● Device communication via Ethernet (TCP/IP).

● A common engineering tool for the various product lines.

● Universal device description file as the data source for all relevant device data and

parameters required for communication and display.

3.1.1 Changing the user level

In SOPAS ET

1 Click: Authorized Operator in the dialog window in SOPAS ET

2 Enter the password.

Operation

User level Password

Authorized operator HIDE

[1] Upper case mandatory

3.1.2 Grayed out fields - input not possible

[1]

Displays in grayed out fields cannot be changed.

3.1.3 Using menus with assignments and calculations

Example: Menu: MCS300P/Parameterization/I/O/Data/Digital outputs

Entry field Significance

Save Store current entries

Mark Create group

▸

Click "Mark" and then click the desired lines.

▸

To cancel "Mark":

Click "Mark" again and then click on an empty line.

Edit For editable menus: Call up the Settings menu for the line

▸

Click the desired line. Then click "Edit".

Show For non-editable menus: display settings for the line.

▸

Click the desired line. Then click "Show".

Copy Copy marked lines

Replace Insert copied lines before a marked line.

Next Call up the "Next function group".

(The bottom lines of the example depend on the menu)

Subject to change w ithout notice

14 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Page 15

Operation

3.2 Menu tree (in SOPAS ET)

Menu Reference

Measuring screen → p. 17, §3.3

Measuring Screen xx

Diagnosis → p. 20, §3.4

Control values → p. 20, §3.4.1

Zero drift

Reference display

Intensity

Sensor values → p. 21, § 3.4.2

Temperatures

Hardware

Signals → p. 22, §3.4.3

Measuring signals

Digital signals

Analog signals

Real values

Integer and filtered values

Logbook → p. 23, §3.4.4

System status → p. 24, §3.4.5

System information → p. 24, §3.4.6

Parameterization → p. 25, §3.5

Measuring components → p. 25, §3.5.1

Global definitions

Definition measured value components

Measuring component xx

Measuring screen → p. 26, §3.5.2

Measured value xx

I/O → p. 29, §3.5.3

Hardware map

CAN Bus address 0..3 (N1 .. N2)

Data

OPC outputs (OPCOi)

Modbus outputs (MBOi)

Modbus inputs (MBIi)

Digital inputs (DIi)

Digital outputs (DOi)

Analog inputs (AIi)

Analog outputs (AOi)

Variables and Functions → p. 32, §3.5.4

Timer

Stop watches (SWi)

Cyclic trigger (CTi)

Limit values (LIi)

Real values (RVi)

Real constants (RCi)

Integer values (IVi)

Boolean values (BVi)

Filtered values (FVi)

Formulas → p. 35, §3.5.5

Temperature control → p. 35, §3.5.6

Logbook → p. 35, §3.5.7

Instrument display → p. 36, §3.5.8

System parameter → p. 36, §3.5.9

Subject to change w ithout notice

Modbus → p. 37, §3.5.10

Adjustment → p. 38, §3.6

Parameter → p. 38, §3.6.1

Concentration

Adjustment factors

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 15

Page 16

Menu Reference

Start times

Manual adjustment → p. 39, §3.6.2

Automatic adjustment → p. 39, §3.6.3

Maintenance → p. 40, §3.7

Tes ts → p. 40, §3.7.1

Digital inputs

Digital outputs

Analog inputs

Analog outputs

Operating states → p. 40, §3.7.2

Hardware Reset → p. 41, §3.7.3

Reset messages → p. 41, § 3.7.4

Service log → p. 41, §3.7.5

Operation

16 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 17

Operation

Only the Measuring Screens are shown for which parameters have

been set.

▸

Double-click the desired Measuring Screen.

Component

Unit

Measured value

Component Measured value Unit

3.3 Measuring Screen

Menu: Measuring

Parameter settings of Measuring Screens: → p. 26, §3.5.2

Scaling of Measuring Screens: → p. 19, §3.3.1.1

3.3.1 Measuring Screen 1 .. x

Menu: Measuring/Measuring Screen 1 .. x

Depending on the parameters set, the Measuring Screen is shown as measuring box, bar

graph or line writer.

Measuring box

The measured values are shown numerically in the measuring box.

Bar graph

The measured values are shown as a graphic bar in the bar graph.

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 17

Page 18

Line writer and data storage

Measuring box

Line writer

The measured values that

have been activated are

shown (→ p. 19, § 3.3.1.1).

The line writer starts with the

representation only when the

display is called up for the

first time.

Changing the user level

deletes the history of the line

display.

The measured values are shown numerically as measuring box and as time diagram in the

line writer.

Operation

Data memory functions

▸

Start:

Start data storage.

The data for which parameters have been set are saved (independent from the graphic

representation) (→ p. 28, §3.5.2.3).

Max. 65536 entries per curve are saved in a file, afterwards a new file (with ascending

index) is automatically created.

▸

A dialog field to enter a target file (.txt) is displayed

The following is shown above the line diagram:

▸

Stop:

Stop recording.

▸

View:

View the recorded data.

A dialog field to select the file with the saved values is shown.

The following is then shown above the line diagram:

▸

Reset:

Delete all shown lines (no effect on data storage).

Subject to change w ithout notice

18 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Page 19

Operation

▸

Font color (The colors of the line writer are predefined)

▸

Precision of Measuring Screen

Example:

-2: 123.45

-1: 1234.5

0

: 12345

1 : 123450

▸

Scale start value

▸

Scale end value

(line diagram: for y-axis)

▸

Display of lines active / not active

(for line writer)

3.3.1.1 Scaling the Measuring Screen

Touch the screen to display a scaling screen:

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 19

Page 20

3.4 Diagnosis

The zero drift since the last "Reset” of the zero

drift (e.g., during maintenance) is shown and

reset in this menu.

The zero drift is recalculated during each zero

adjustment and displayed in Absorption.

This value can be used for system diagnosis.

Typical cause: Decrease in lamp energy, contami-

nation of cell windows.

▸

Reset the zero drift

The current reference energy (in percent) is

shown and reset in this menu.

This value is monitored automatically. If the value

is below a limit value (default: 60%), the

MCS300P switches to the "Maintenance request”

classification.

Typical cause: Contamination of the cell windows.

▸

Reset the reference energy

3.4.1 Control value

3.4.1.1 Zero drift

Menu: Diagnosis/Control values/Zero drift

3.4.1.2 Reference energy

Menu: Diagnosis/Control values/Reference energy

Operation

3.4.1.3 Intensity

Menu: Diagnosis/Control values/Intensity

The intensities (energies) and amplification levels of the measured components are shown

in this menu.

Leave the evaluation of this information to SICK Customer Service.

20 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 21

Operation

3.4.2 Sensor values

3.4.2.1 Temperatures

Menu: Diagnosis/Sensor values/Temperatures

Temperatures are shown in this menu.

3.4.2.2 Hardware

Menu: Diagnosis/Sensor values/Hardware

Operational parameters are shown in this menu.

Leave the evaluation of these parameters to SICK Customer Service.

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 21

Page 22

3.4.3 Signals

The current states of the digital signals (DIi,

DOi, limit values) are shown in this menu.

Digital values:

. = off (0)

I = on (1)

For limit values:

. = within the limit value

I = outside the limit value

The current values of the analog signals

(AIi, AOi) are shown in this menu

The current real values (RVi) are shown in

this menu.

The current integer values (IVi) and filtered

values (FVi) are shown in this menu.

3.4.3.1 Measuring signals

Menu: Diagnosis/Signals/Measuring signals

Measuring signals are shown in this menu.

Leave the evaluation of these signals to SICK Customer Service.

3.4.3.2 Digital signals

Parameter settings of the signals listed below: → p. 29, § 3.5.3 and the following

pages.

Menu: Diagnosis/Signals/Digital signals

Operation

3.4.3.3 Analog signals

Menu: Diagnosis/Signals/Analog signals

3.4.3.4 Real values

Menu: Diagnosis/Signals/Real values

3.4.3.5 Integer and filtered values

Menu: Diagnosis/Signals/Integer and filtered values

22 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 23

Operation

3.4.4 Logbook

Menu: Diagnosis/Logbook

Max. number of entries: 6000.

(Representation: Uncompressed data storage)

Designation Remark

Fill level of logbook in %.

When the characters are red: The logbook is full.

Warning mode: Further entries are not accepted.

Circular buffer mode: Oldest entries are overwritten.

Data storage:

Symbol not crossed out: Compressed.

Symbol crossed out: Uncompressed.

Significance and default: → p. 35, §3.5.7

Circular buffer mode

Warning mode

Significance and default: → p. 35, §3.5.7

Entries Number of entries of selected filter.

Filter for messages Only the filtered messages are shown.

- Failure (active)

- Failure (all)

- Maintenance request (active)

- Maintenance request (all)

- Uncertain (active)

- Uncertain (all)

- Others (active)

- Others (all)

- All active messages

- All messages

Delete all entries. Caution: All logbook entries in the MCS300P are deleted.

Export All entries selected via the filter ( further back in this Table) are saved on the

PC in C:\My Documents as .log file.

Format: CSV (comma-separated list). Can be read in EXCEL, for example.

Refresh To refresh the display: Click.

Up Scroll to older entries

Down Scroll to newer entries

Consecutive message number.

Red LED: Message still pending.

Green LED: Message no longer pending.

Device Activating element: System, measured value identifier (sample gas component),

subassembly, Evaluation module

[1]

Entries

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 23

Text Logbook message (error messages Operating Instructions MCS300P).

Number of times errors have occurred.

Significance and default value: (→ p. 35, § 3.5.7)

Page 24

Designation Remark

LEDs according to operator panel

Current sampling point

For sampling point switching:

Time remaining until sampling

point switching

Time remaining of current

sequence program

Name of current sequence program

Classification F = Failure

Date Start Format: yy-mm-dd

Time Start Format: hh:mm:ss

Date stop Format: yy-mm-dd

Time stop Format: hh:mm:ss

[1]Only for compressed data storage

3.4.5 System status

Menu: Diagnosis/System status

Operation

M = Maintenance request

C = Check

U = Uncertain

X = Extended message

For "Uncompressed": Occurrence of message.

For "Compressed": Last occurrence of message.

For "Uncompressed": Occurrence of message.

For "Compressed": Last occurrence of message.

For "Uncompressed": Clearing of message.

For "Compressed": Last clearing of message.

For "Uncompressed": Clearing of message.

For "Compressed": Last clearing of message.

3.4.6 System information

Menu: Diagnosis/System information

System information (e.g.: Serial number, software version, cell length, window material) is

shown in this menu.

24 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 25

Operation

Value above/below alarm Alarm value [in calibrated unit]

3.5 Parameterization

3.5.1 Measuring components

3.5.1.1 Global definitions

Menu: Parameterization/Measuring components/Global definitions

Global system information (e.g.: number of filter wheels, number of activated components)

is shown in this menu.

3.5.1.2 Definition measuring components

Menu: Parameterization/Measuring components/Definition measuring components

The setting of the individual measuring components is shown in this menu.

The following settings can be changed:

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 25

Page 26

3.5.2 Measuring screen

Selection of desired Measuring Screen

No display of measured values

1 measuring box

4 measuring boxes

16 measuring boxes (example → p. 27, §3.5.2.1)

2 large, 8 small measuring boxes

6 bargraphs (example → p. 27, §3.5.2.2)

3 bars + 2 measuring boxes

3 bars + 8 measuring boxes

(hidden)

Selected Measuring Screen

After changes: Click "Save”

Line writer (example → p. 28, §3.5.2.3)

Menu: Parameterization/Measuring screen

8 Measuring Screens can be parameterized and displayed:

Double-click a Measuring Screen to open the screen to set the parameters for the Measuring Screen.

Operation

26 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 27

Operation

Example: Measuring Screen 1 with

Layout III (16 measuring boxes)

▸

Enter the desired identifiers (tags ).

Tags MCS300P: → p. 42, §3.8

Scaling of measuring box: → p. 19, § 3.3.1.1

The Measuring Screen then has the following

appearance:

The component names and units come, for

example, from the factory settings (e.g., RVi),

from a filter source (e.g., FVi) or from the analyzer.

Example: Measuring Screen 1 with bargraph I (6 bars)

▸

Enter the desired identifiers (tags ).

Scaling of measuring box: → p. 19, §3.3.1.1

The Measuring Screen then has the following

appearance:

3.5.2.1 Measuring box

3.5.2.2 Bargraph

Subject to change w ithout notice

MCS300P · Technical Information · 8013265 V1-2 · © SICK AG 27

Page 28

3.5.2.3 Line writer

▸

Enter the desired identifiers (tags).

Scaling of measuring box: → p. 19, § 3.3.1.1

▸

Scaling of time axis

[Sec, Min or Hour]

Scaling of y-axis: → p. 19, §3.3.1.1

The Measuring Screen then has the following

appearance:

Measuring box

Line writer

Operation

28 MCS300P · Technical Information · 8013265 V1-2 · © SICK AG

Subject to change w ithout notice

Page 29

Operation

CAN bus gateway 1

Node N1

CAN bus address 0