Page 1

Title Page

MCS100E

IR Analyzer

Commissioning

Operation

Maintenance

OPERATING INSTRUCTIONS

Page 2

Document Information

Described Product

Product name: MCS100E

Document ID

Title: Operating Instructions MCS100E

Part No.: 8009504

Version: YWA7/V3-1

Release: 2018-01

Publisher

SICK AG

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Tel.: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: info.pa@sick.de

Trademarks

MS-DOS is a Microsoft Corporation trademark.

Other product names used in this document may also be

trademarks and are only used for identification purposes.

Original Documents

The English version 8009504 of this document is an original

document from SICK AG.

SICK AG assumes no liability for the correctness of an

unauthorized translation.

Contacts

Guarantee Information

Specified product characteristics and technical data do not serve

as guarantee declarations.

© SICK AG. All rights reserved.

2 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 3

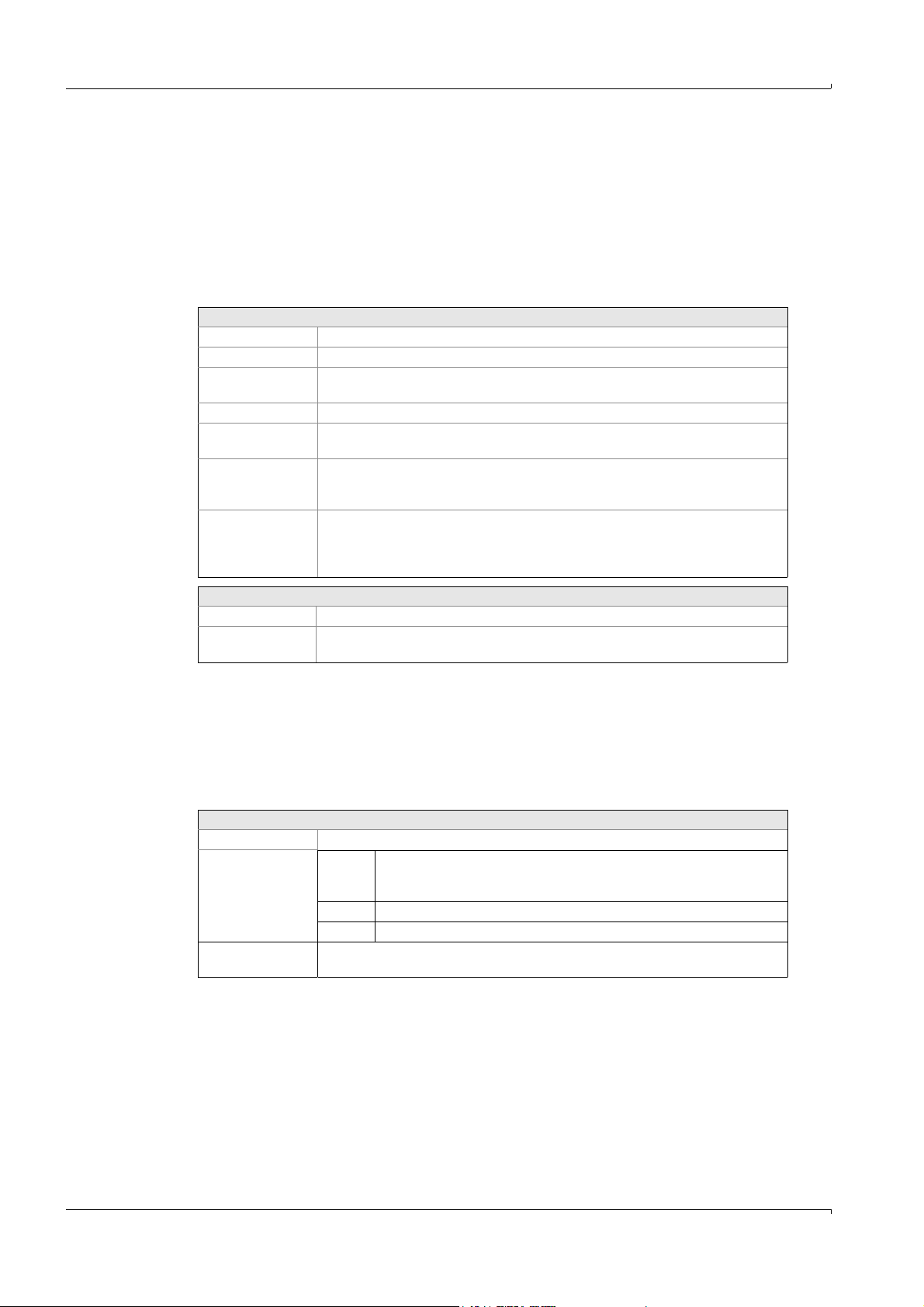

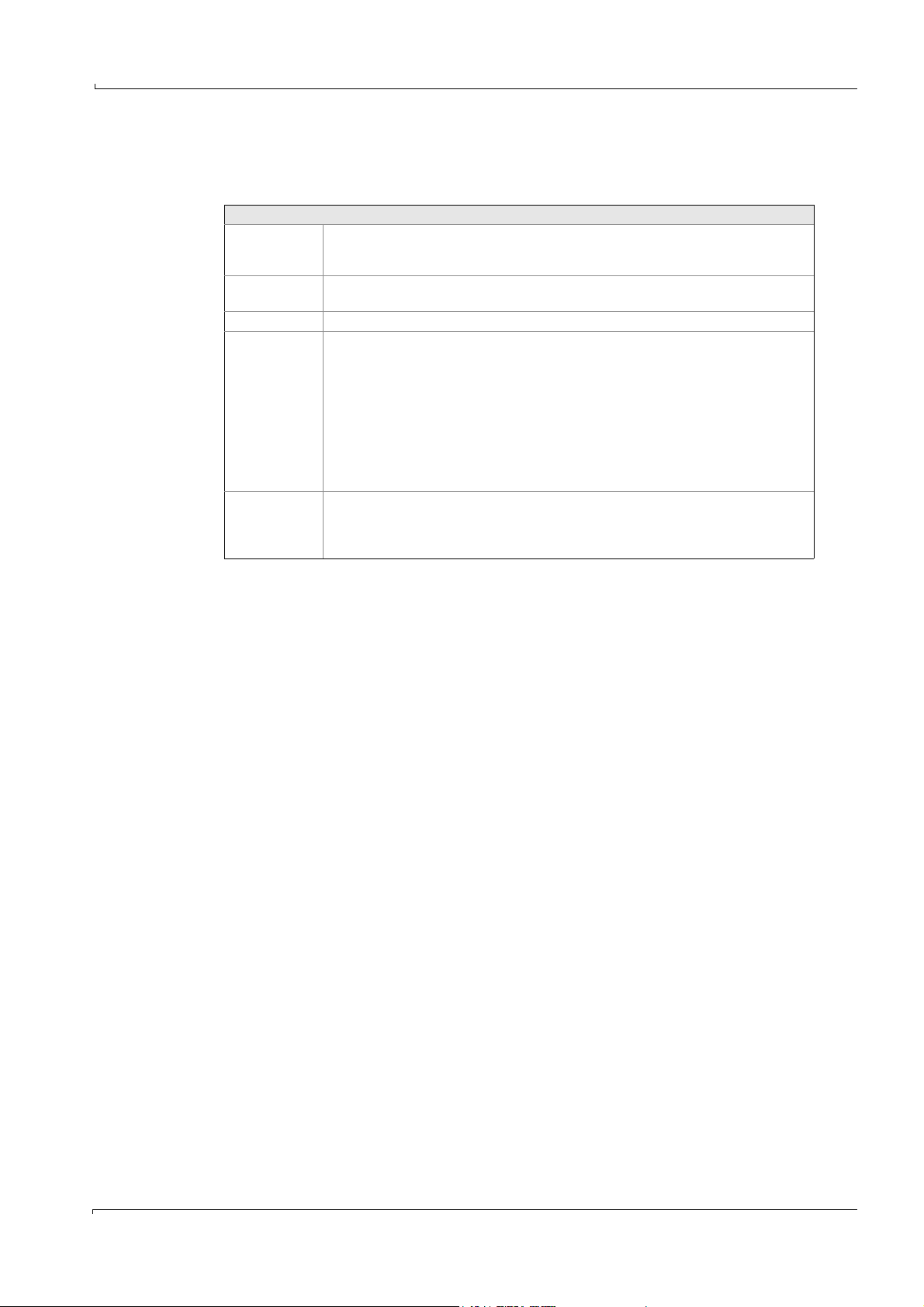

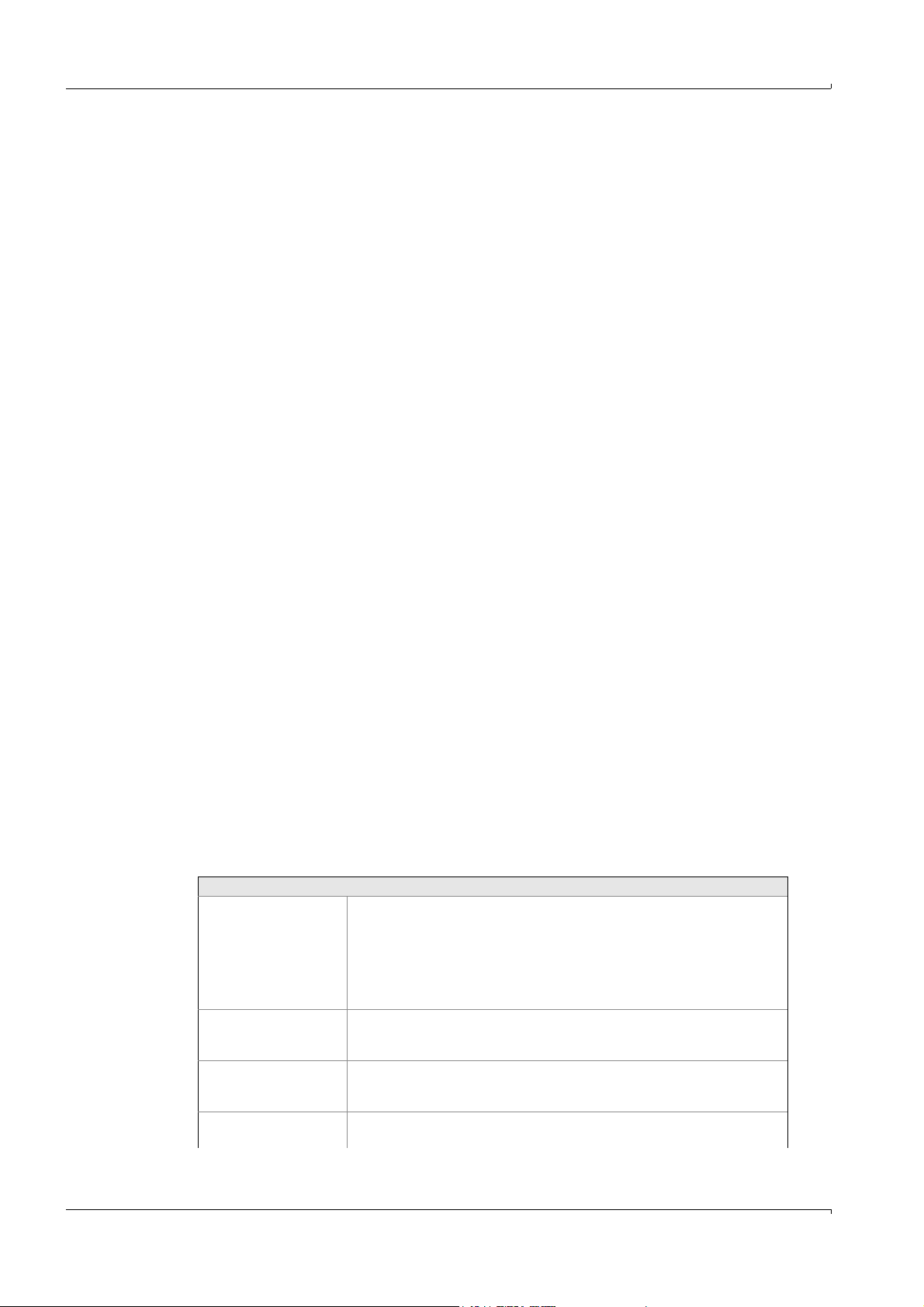

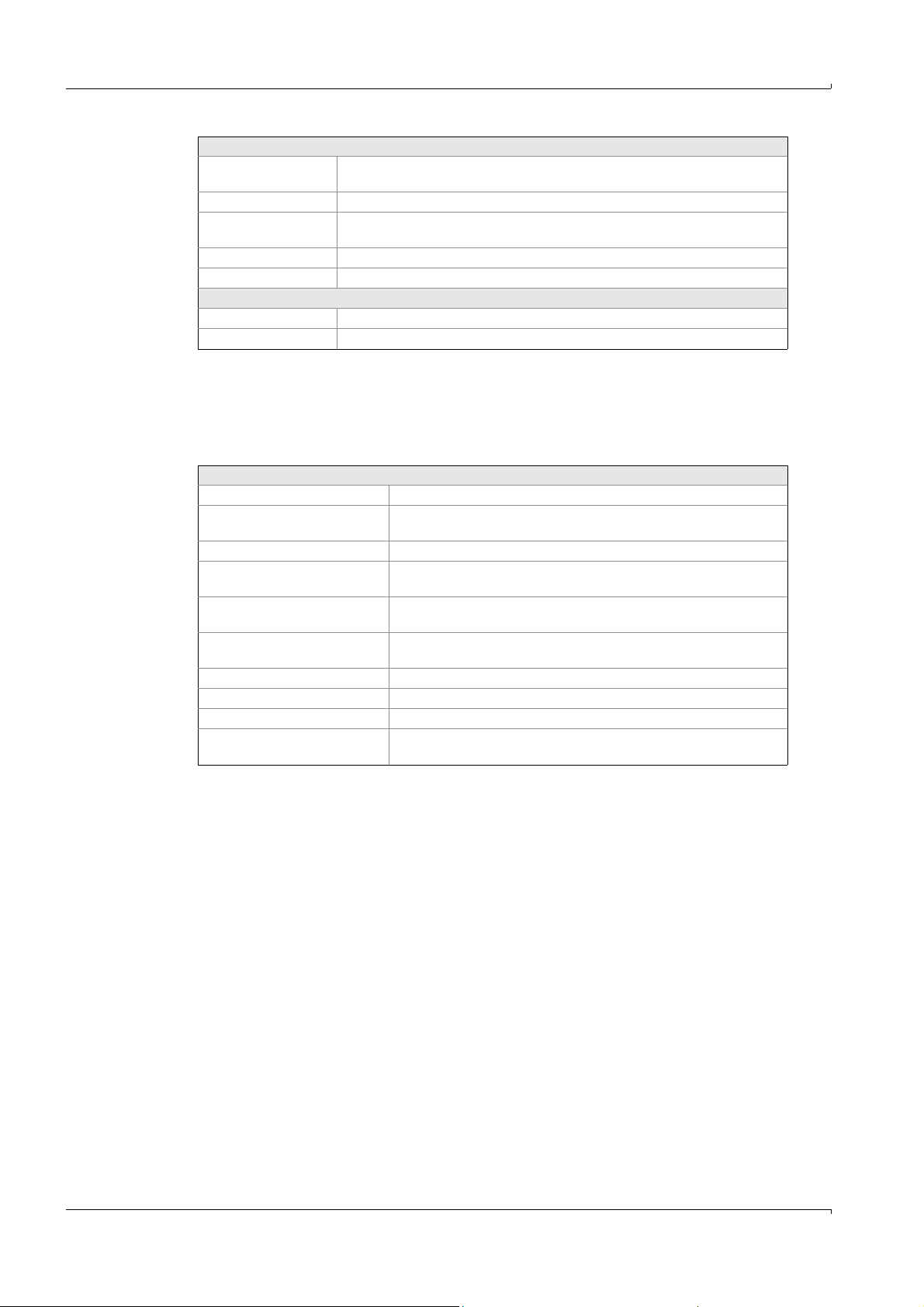

Warning Symbols

Information Symbols

Hazard (general)

Hazard by voltage

Hazard in potentially explosive atmospheres

Hazard by explosive substances/mixtures

Hazard by corrosive substances

Hazard by poisonous substances

Hazard by unhealthy substances

Hazard by high temperature or hot surface

Important technical information for this device

Important information on electric or electronic

functions

Supplementary information

Link to information at another place

Hazard for the environment/nature/organic life

Warning Levels / Signal Words

DANGER

Risk or hazardous situation which will result in severe personal

injury or death.

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or

minor injuries and/or property damage.

NOTICE

Hazard which could result in property damage.

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 3

Page 4

Contents

Contents

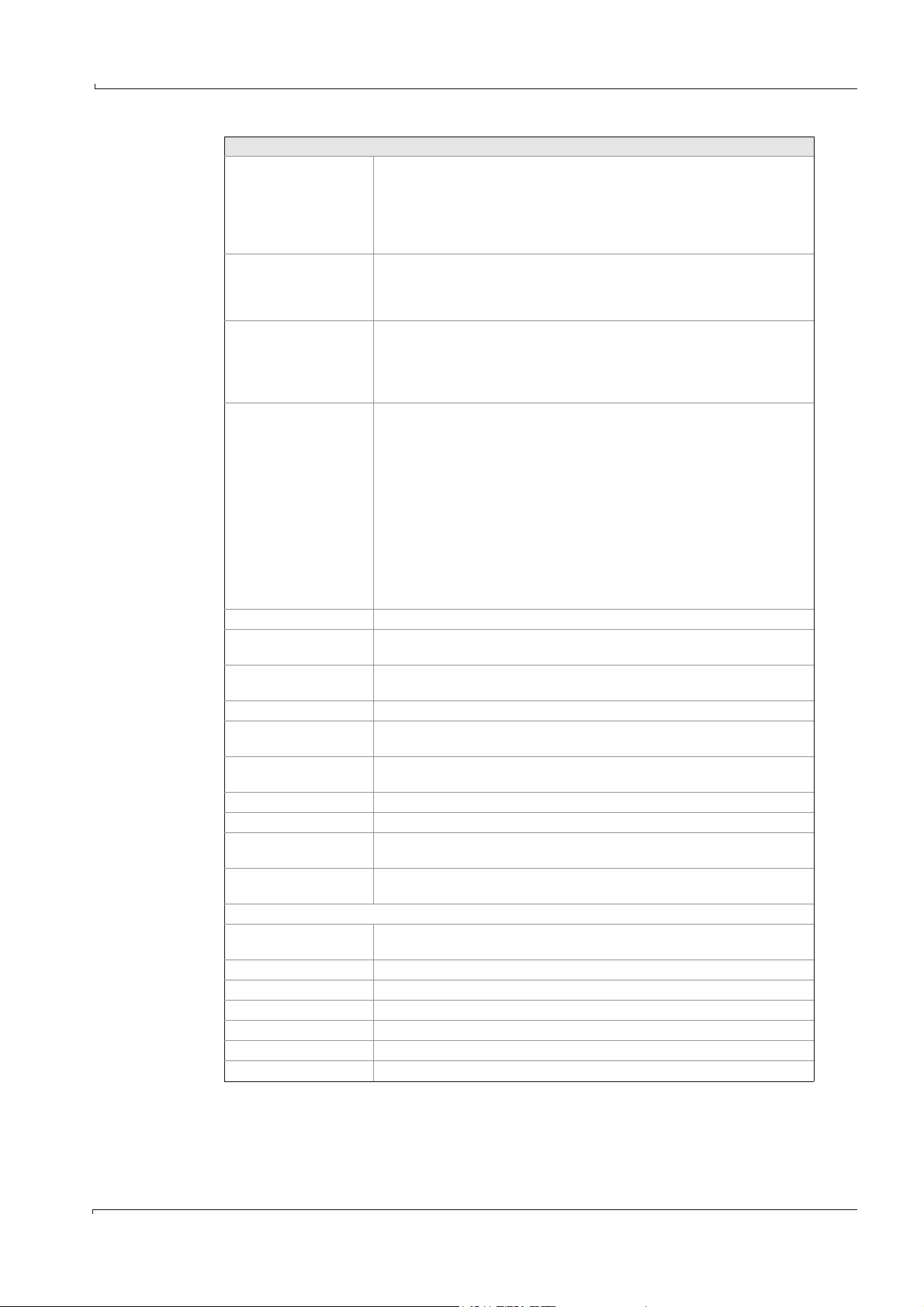

1 Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Main hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1 Purpose of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.2 Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 Responsibility of user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Additional documentation/information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Product identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.1 Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.2 Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.2.1 Correction of spectral interferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.3 Thermostatic control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.4 Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.5 Flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.6 O

2.2.7 Barometric pressure compensation (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.8 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

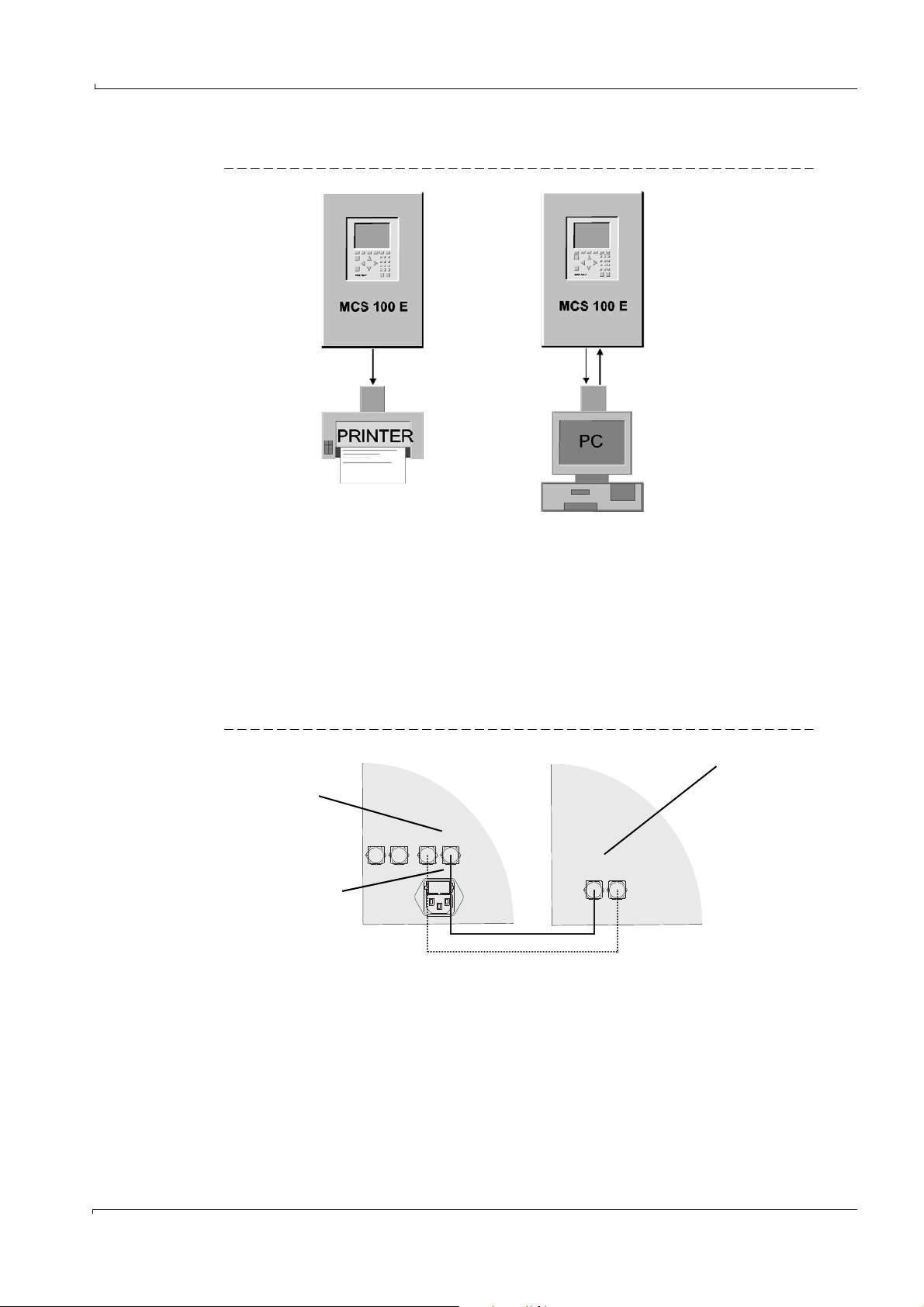

2.5 Data transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.1 Data transmission with MCS100E program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.2 File transfer with modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6 Communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7 QAL3 (DIN EN 14181) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7.1 Evaluation of zero and reference point data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7.2 Use of the calibration filter option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

sensor (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2

4 MCS100E Operating Instructions 8009504/V YWA7/V3-1/2018-01 © SICK AG

Page 5

Contents

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Installation and initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.2.1 Preparing the place of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.2 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.2.1 Sample gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.2.3 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.2.3.1 Optical interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

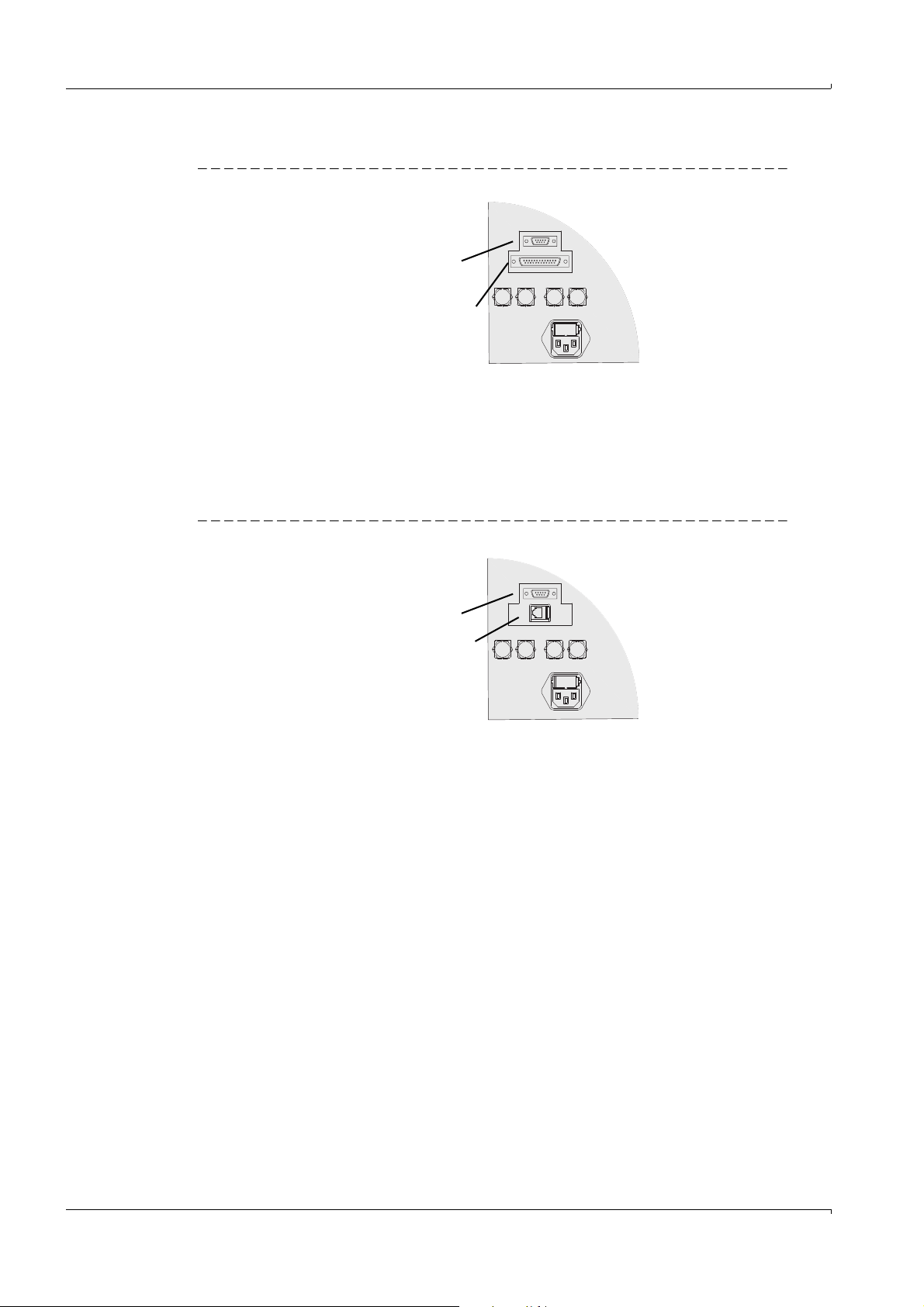

3.2.3.2 Electric serial and parallel interface (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.2.3.3 Electric serial and Ethernet interface (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.3 Remote control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1 Ethernet with TINY program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1.1 Connection on MCS100E side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1.2 Connection on PC side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.3.1.3 Program start on MCS100E side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1.4 Program start on PC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3.1.5 Special characters, e.g. on a German keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.2 Modem with the NetOP program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.2.1 Connection on MCS100E side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.2.2 Connection on PC side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.3.2.3 Program start on MCS100E side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.2.4 Program start on PC side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.2.5 Terminating the transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 Data transfer to/from external PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.4.1 Data transfer via fiber optical cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.2 File transfer via modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 Modbus communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.6 Hardware requirements for external PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.7 Hardware requirements for printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.8 Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.8.1 Power voltage adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.8.1.1 Adjusting the bridge for power voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.8.1.2 Power fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2 External keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.1 Country-specific assignment of keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3 Language selection of the MCS program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.4 Display setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 5

Page 6

Contents

5Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.1 Significance of keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.1.1 Entering alphanumerical characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Data and program storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.1 Structure of directories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.2 Data files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.3 Program files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3 Starting the measurement program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.1 Automatic start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.2 Starting from the DOS level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.3 Aborting the start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4 Stopping and starting measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4.1 STOP, START measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4.2 Quitting the measurement program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5 Status bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.6 Using the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.1 In Menu fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.2 In Entry menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.3 In file selection lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.4 Safety prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6 MCS100E Operating Instructions 8009504/V YWA7/V3-1/2018-01 © SICK AG

Page 7

Contents

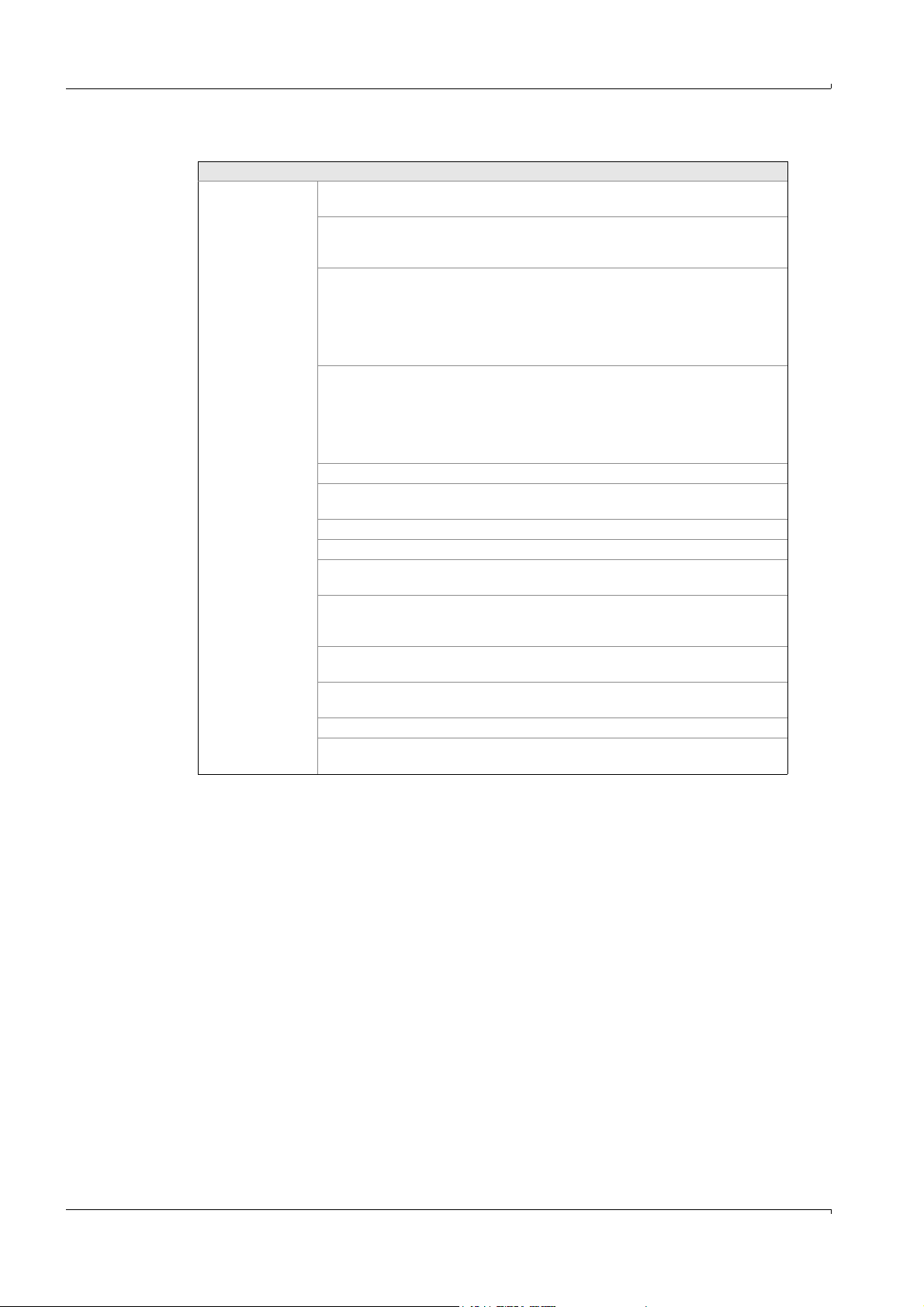

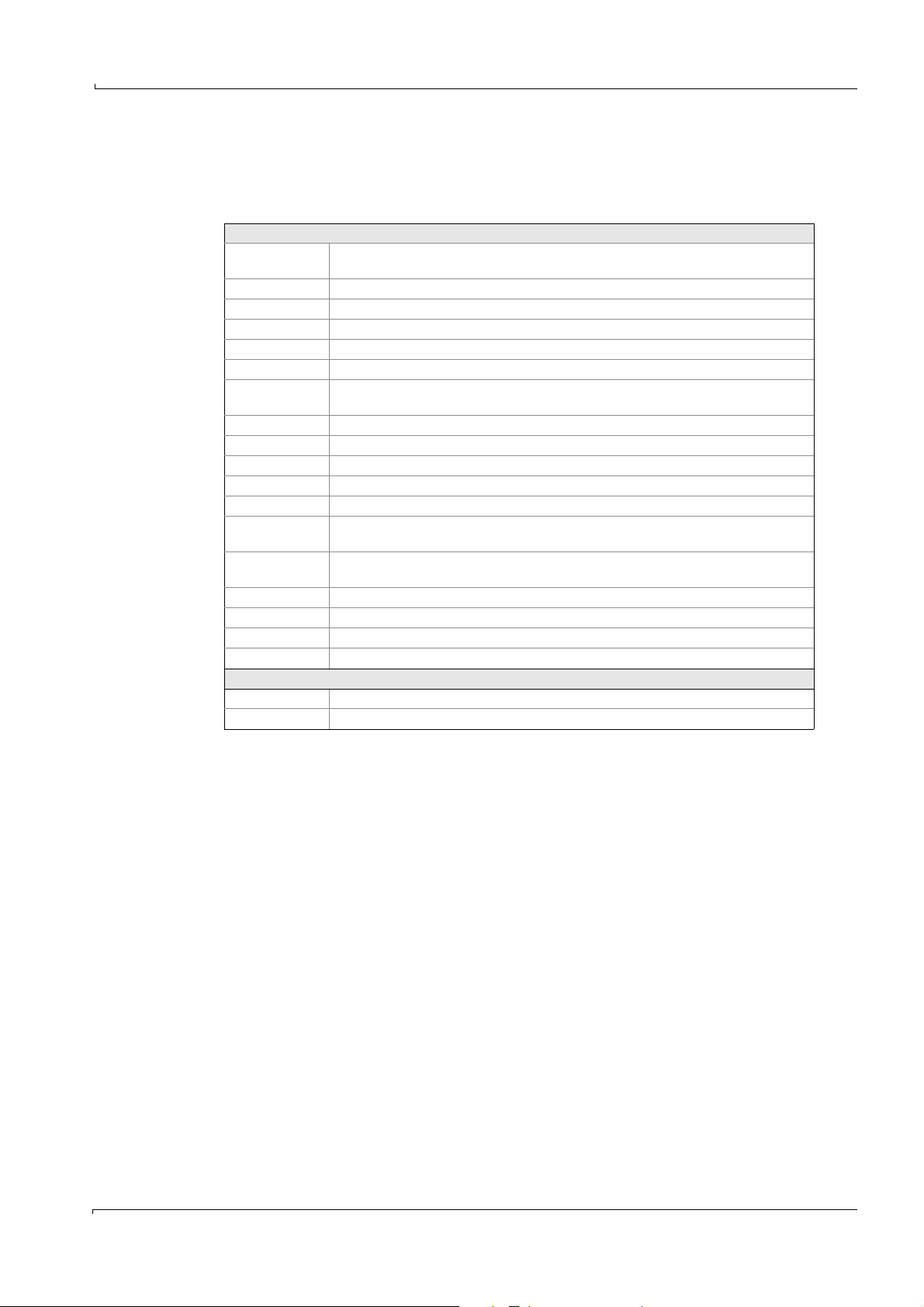

5.7 Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

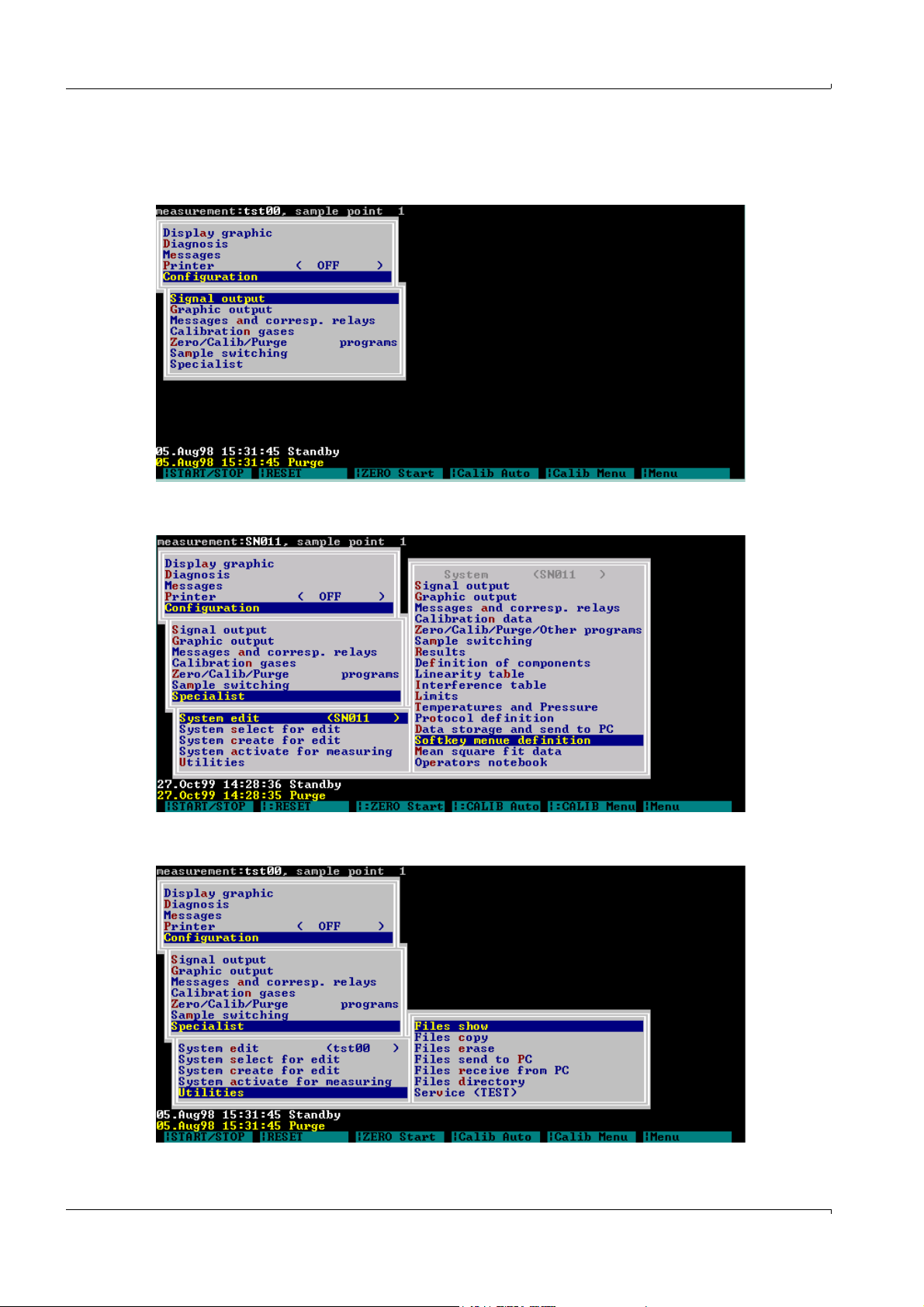

5.7.1 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.7.2 Specialist: System edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.7.3 Specialist: Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

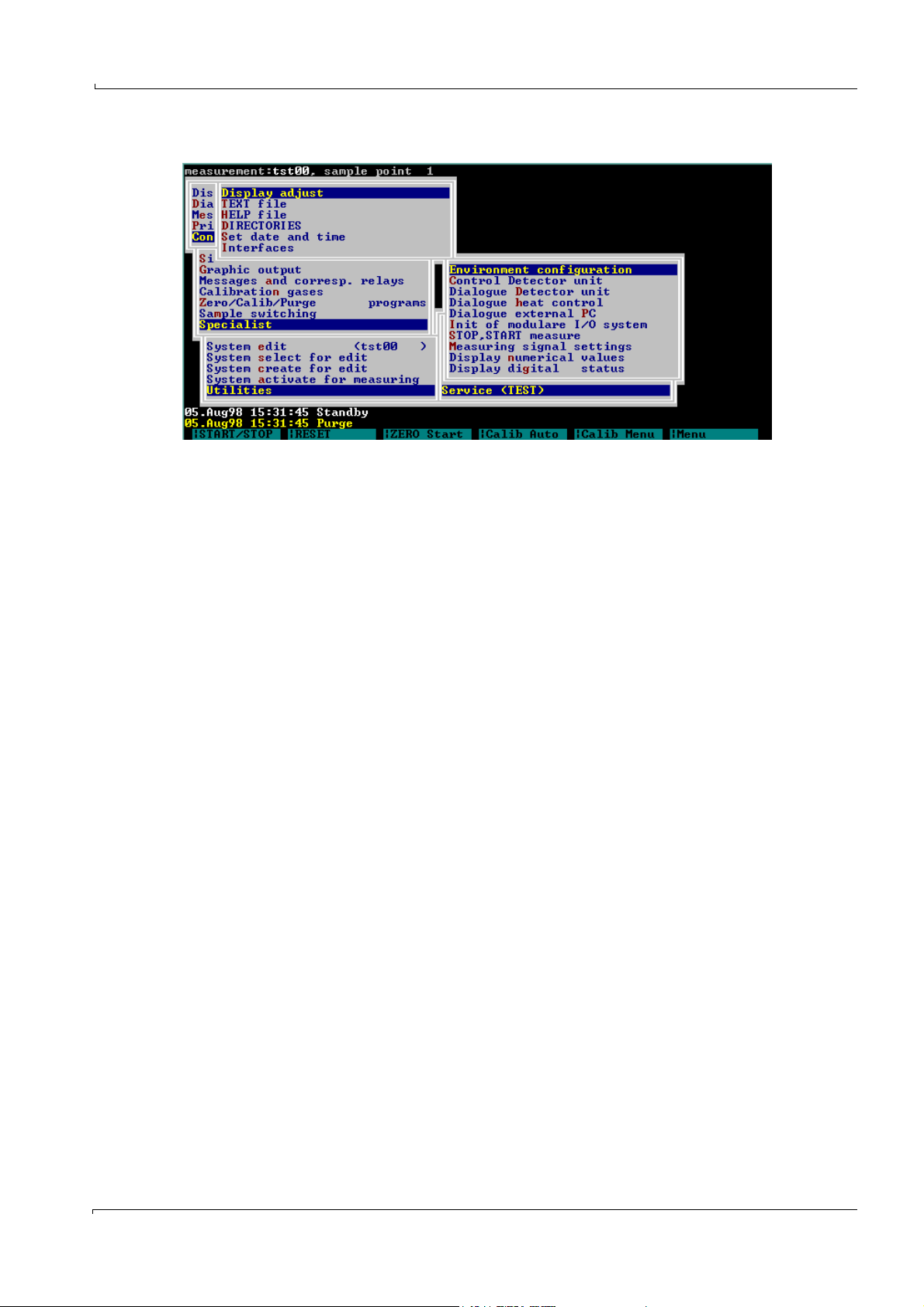

5.7.4 Specialist: Utilities: Service: Environment configuration . . . . . . . . . . . . . . . . . . . . . . . 51

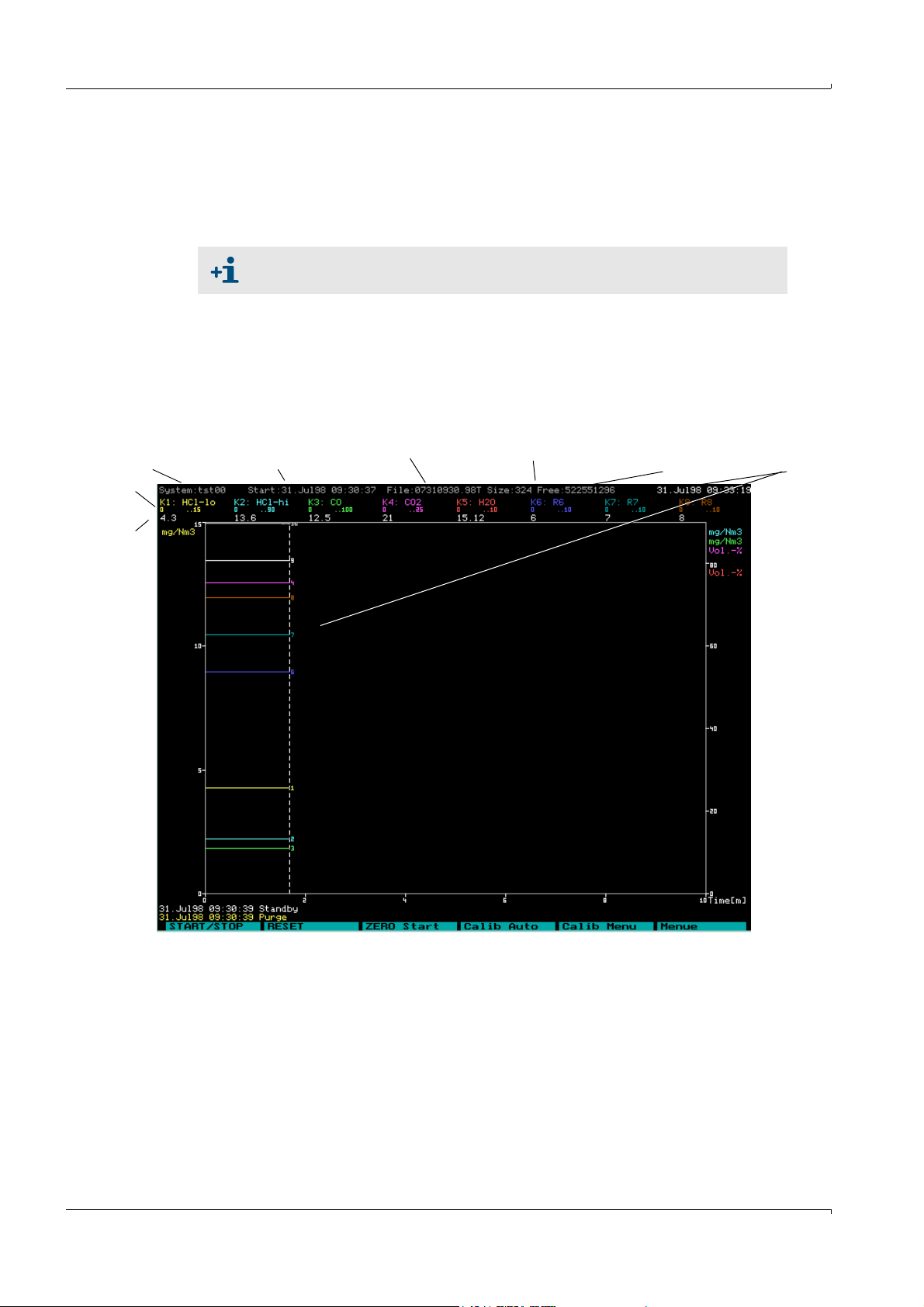

5.7.5 Display graphic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.5.1 Graphic output: Time history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.7.5.2 Graphic output: Bar graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

5.7.5.3 Archive Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7.6 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5.7.7 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.7.8 Print (On/Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.7.8.1 Print on-line (On/Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.7.8.2 Print Archive (Name) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.7.8.3 Start and end. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.7.8.4 Protocol Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.7.8.5 Protocol Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.7.8.6 Print diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.8.7 Print Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.8.8 Print System data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.9 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7.9.1 Password for the configuration level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7.9.2 Signal output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7.9.3 Graphic output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.7.9.4 Messages and corresp. relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.7.9.5 Calibration gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.7.9.6 Zero/Calib/Purge programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.7.9.7 Sample switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.7.10 Specialist menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.7.10.1 Password for the specialist level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.7.11 System edit (Name) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.7.11.1 Signal output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.7.11.2 Graphic output

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7.11.3 Messages and corresp. relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7.11.4 Calibration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.7.11.5 Zero/Calib/Purge programs/other programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.7.11.6 Sample switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.7.11.7 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.7.11.8 Definition of Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.7.11.9 Linearization tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.11.10 Interference table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.7.11.11 Limit values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.7.11.12 Temperatures and Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

5.7.11.13 Protocol Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.7.11.14 Data storage and send to PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.7.11.15 Softkey menu definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.7.11.16 Mean square fit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.7.11.17 Operator's Notebook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.7.12 System, select for editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.7.13 System, create for editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.7.14 System, activate for measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

5.7.15 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.7.15.1 Show files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 7

Page 8

Contents

5.7.15.2 Copy files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.7.15.3 Erase files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.7.15.4 Send files to an external PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.7.15.5 Receive files from PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.7.15.6 Files directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.7.15.7 Service (TEST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.7.15.8 Display, digital status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.1 Switch off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.1 Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.2 Visual check of the MCS100E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.3 Check sample gas flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4 Check/replace the filter pad in the fan of the analyzer . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.5 Span gas feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.6 Programming the Measurement Sequence (Overview) . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.6.1 Concentration Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.6.2 Definition of Components and Calibrating a System . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.6.3 Addresses and Assignment of the Input Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.7 Parameters at Program Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.8 Watchdogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.8.1 CPU watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.8.2 Watchdog for Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.9 Load Program from external PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.1 Adjust the monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2 Flow too low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.3 MCS100E becomes too hot (excess temperature) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4 MCS100E does not start operation upon power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.5 Excess temperature switch-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.6 Cell and photometer are not heated properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.7 No contact with printer/PC resp. I/O module boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.8 Fuses, jumpers and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.8.1 Internal voltage control (LPM40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.8.2 Heating controller (LPM42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.9 Error messages on the screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.9.1 Message: CAUTION! MOD-IO boxes changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8 MCS100E Operating Instructions 8009504/V YWA7/V3-1/2018-01 © SICK AG

Page 9

Contents

9 Utility programs and protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

9.1 MCSCONF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

9.1.1 Start of the configuration program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

9.1.2 Terminating the configuration program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

9.1.3 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

9.1.3.1 Runtime Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

9.1.3.2 Text Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.1.3.3 Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.1.3.4 Directories and files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.2 ACQINIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

9.3 Modbus protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

10 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.1 Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

10.1.1 Electrical protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

10.2.1 Dimension drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

10.2.2 Operating data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 9

Page 10

Contents

10 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 11

Important information

MCS100E

1 Important information

Main hazards

Main instructions for operation

Intended use

Own responsibility

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 11

Page 12

1.1 Main hazards

Important safety information in abbreviated form.

Always observe the complete safety information (see cross-references).

WARNING: Noxious and irritating sample gas

When the sample gas contains noxious or irritating substances:

Channel sample gas off safely (→p. 24, §3.2.2.1)

WARNING: Danger to life/health risks caused by leaks in the gas path

If noxious gases are channeled into the MCS100E: A leak in the gas path can

create acute danger for persons.

Ensure suitable safety measures.

WARNING: Hazards by explosive or combustible gases

⊗ Do not use the MCS100E for measuring explosive or combustible gases

WARNING: Hazard in potentially explosive atmospheres

⊗ Do not use the MCS100E in potentially explosive atmospheres.

Important information

1.2 Intended use

1.2.1 Purpose of the device

The MCS100E measuring device is used for continuous and selective measurement of

emissions (e.g.: HCl, NH

3

The MCS100E is normally located in the SICK MCS100E system cabinets.

Application limitations

The MCS100E only measures the gas composition correctly for which it was calibrated

(

→ System Documentation). A change of the gas matrix can result in incorrect measured

values.

NOTICE: Risk of contamination of the gas path

If the sample gas does not have the composition for which the MCS100E was

designed (

1.2.2 Installation site

→ System Documentation):

Ensure that the MCS100E cannot draw in sample gas.

Flush the gas path of the MCS100E with inert gas.

The MCS100E gas analyzer is designed for operation in rooms or system cabinets.

, H2O, CO, SO2, NOx, O2) in the stack gases of incineration plants.

12 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 13

Important information

1.3 Responsibility of user

Designated users

The MCS100E may be operated by competent persons only who, based on their devicespecific training and knowledge of the device as well as knowledge of the relevant

regulations, can assess the tasks given and recognize the dangers involved.

The Specialist level of the MCS100E may be operated only by skilled technicians who,

based on their technical training and knowledge as well as knowledge of the relevant

regulations, can assess the tasks given and recognize the hazards involved.

Correct use

Use the MCS100E only as described in these Operating Instructions. The manufacturer

bears no responsibility for any other use.

Perform the specified maintenance work.

Do not remove, add or modify any components to or on the device unless described and

specified in the official manufacturer information. Otherwise

– the device could become dangerous

– the manufacturer’s warranty becomes void

Special local conditions

In addition to these Operating Instructions, follow all local laws, technical rules and

company-internal operating directives applicable at the respective installation site of

the equipment.

Retention of documents

These Operating Instructions and the System Documentation:

Must be available for reference.

Must be passed on to new owners.

1.4 Additional documentation/information

System documentation

Individualized versions of MCS100E with adapted internal or peripheral equipment exist.

For the relevant information, see the delivered separate documentation, for example:

• Operating Instructions of additional components

Pay attention to the supplied documents.

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 13

Page 14

Important information

14 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 15

Product description

MCS100E

2 Product description

Product identification

Functional principle

Characteristics

Variants

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 15

Page 16

2.1 Product identification

Product name: MCS100E

Manufacturer:

SICK AG · Rengoldshauser Str. 17A

88662 Überlingen · Germany

The type plate is located on the top of the right side of the housing.

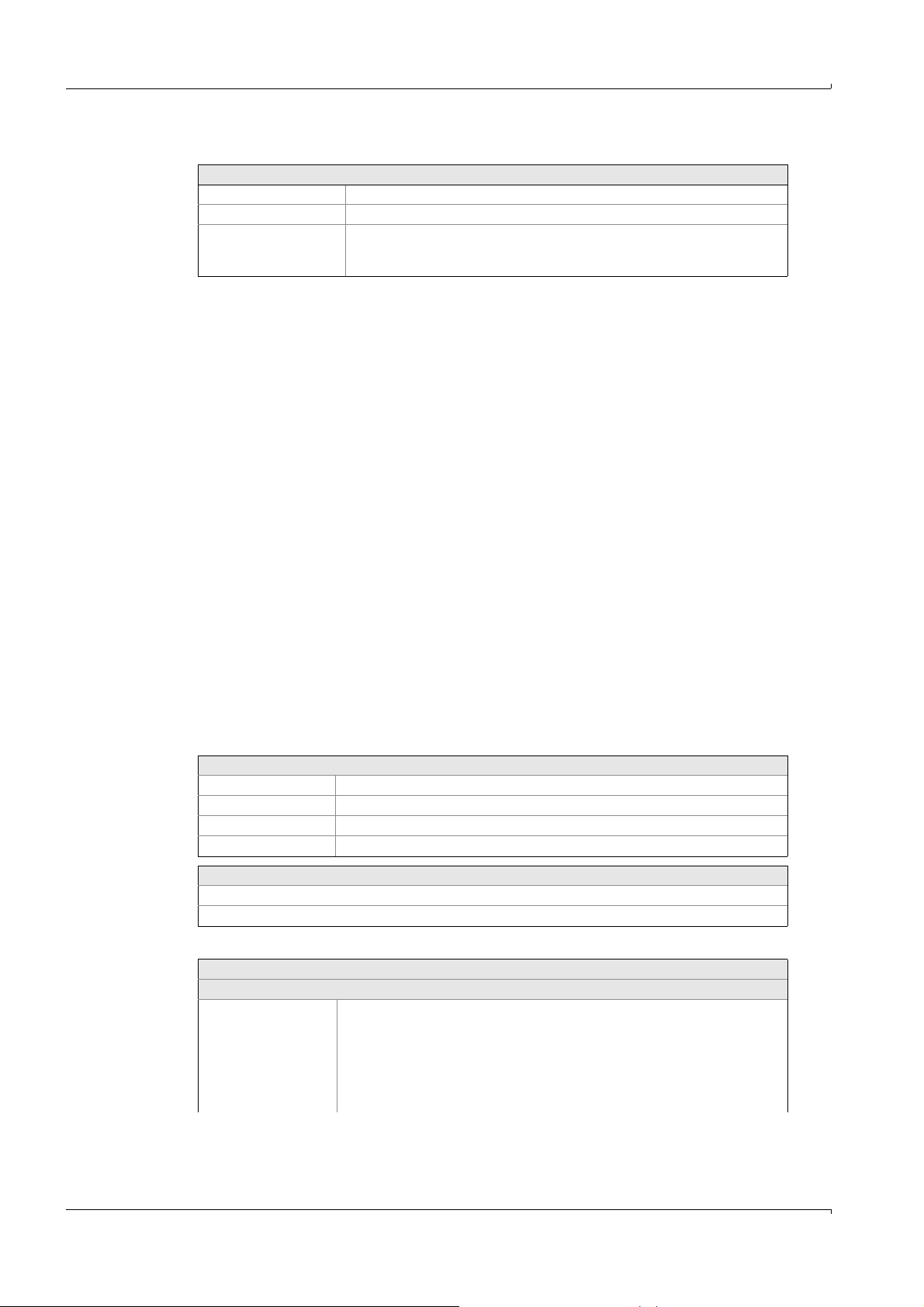

2.2 Description

The MCS100E measuring device is used for extractive continuous and selective

measurement of emissions (e.g.: HCl, NH

MCS100E can measure quasi-simultaneously up to 8 components (plus optionally O

max. 12 sample points.

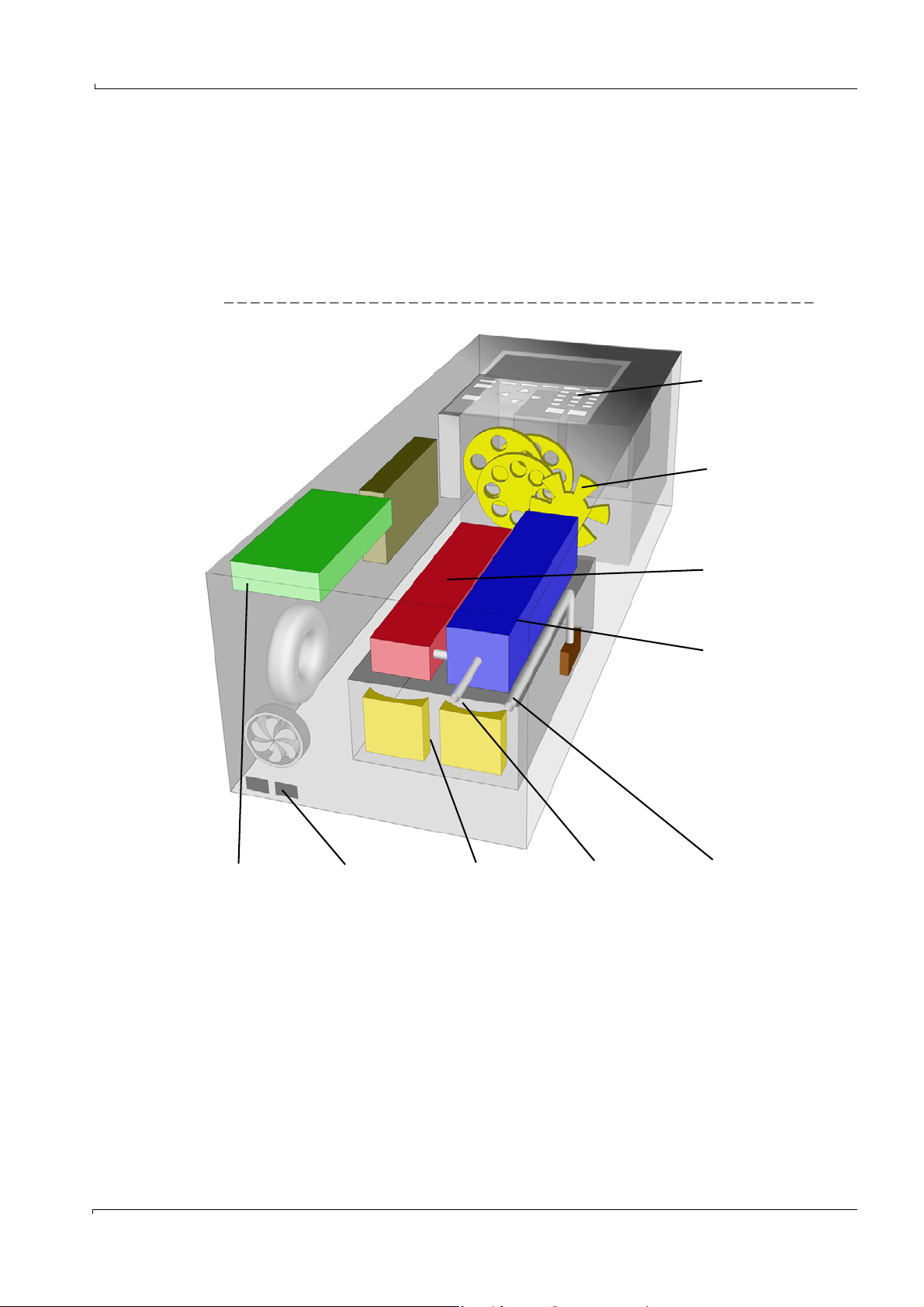

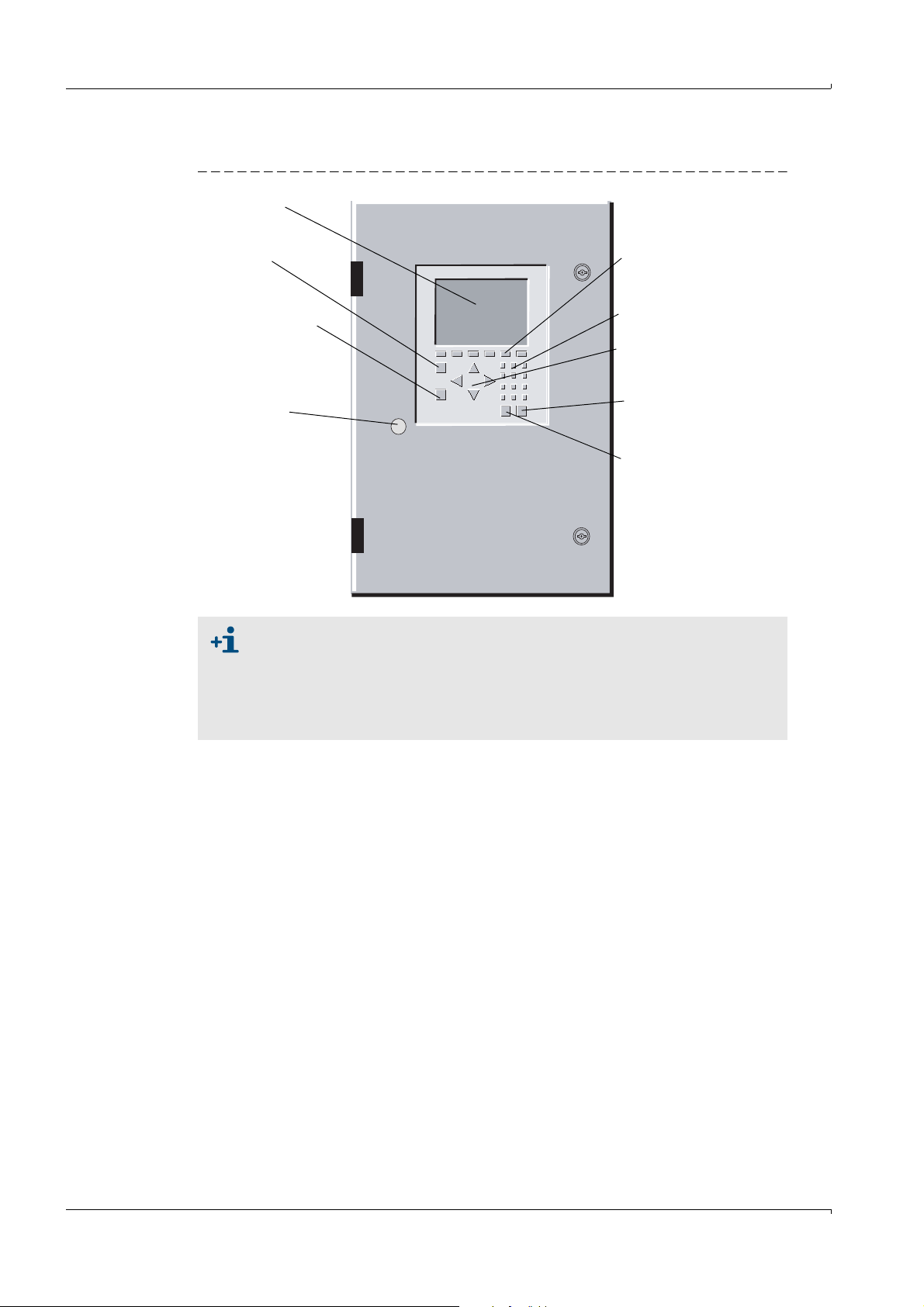

Figure 1 MCS100E

, H2O, CO, SO2, NOx) of incineration plants.

3

Product description

) at

2

16 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 17

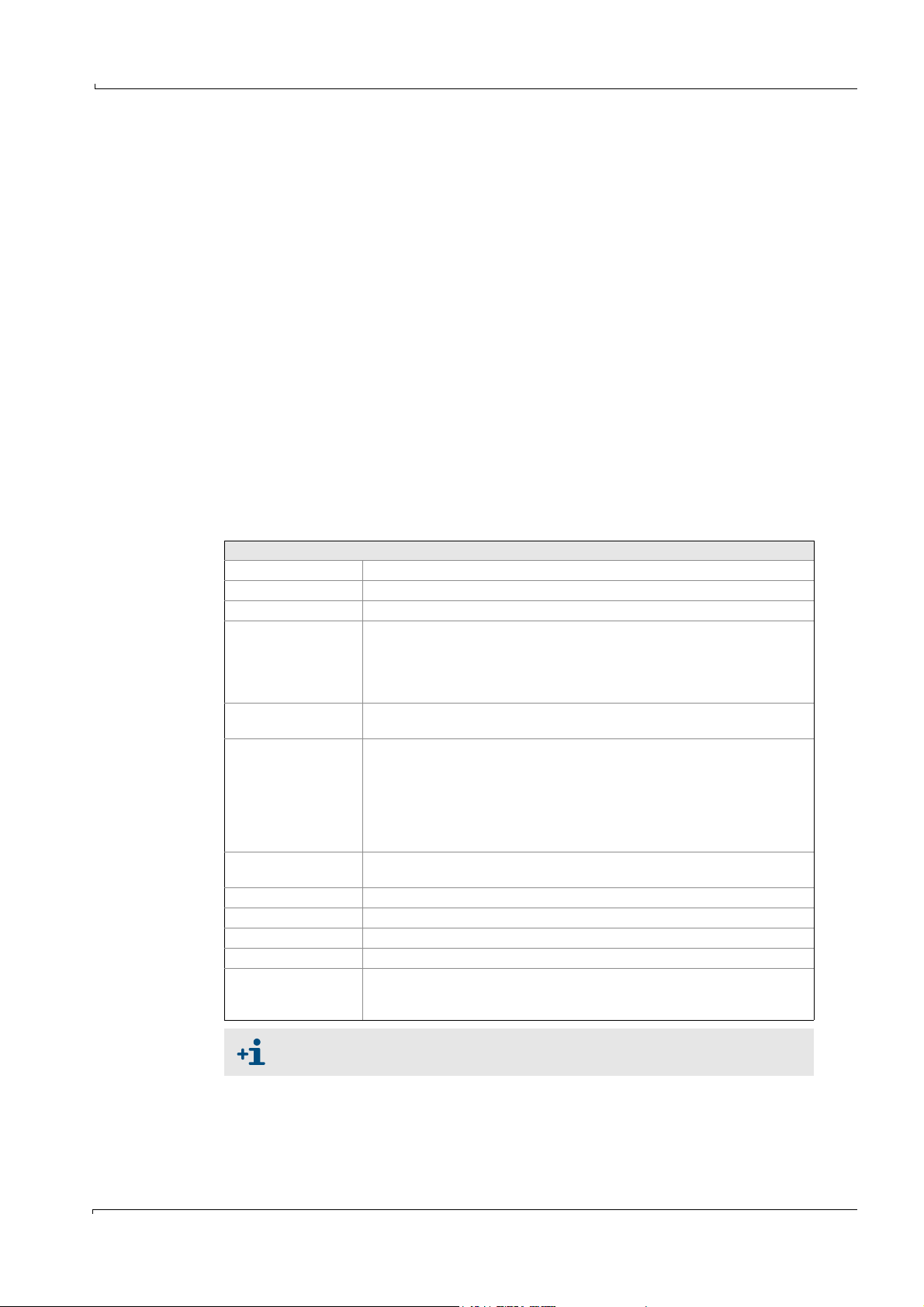

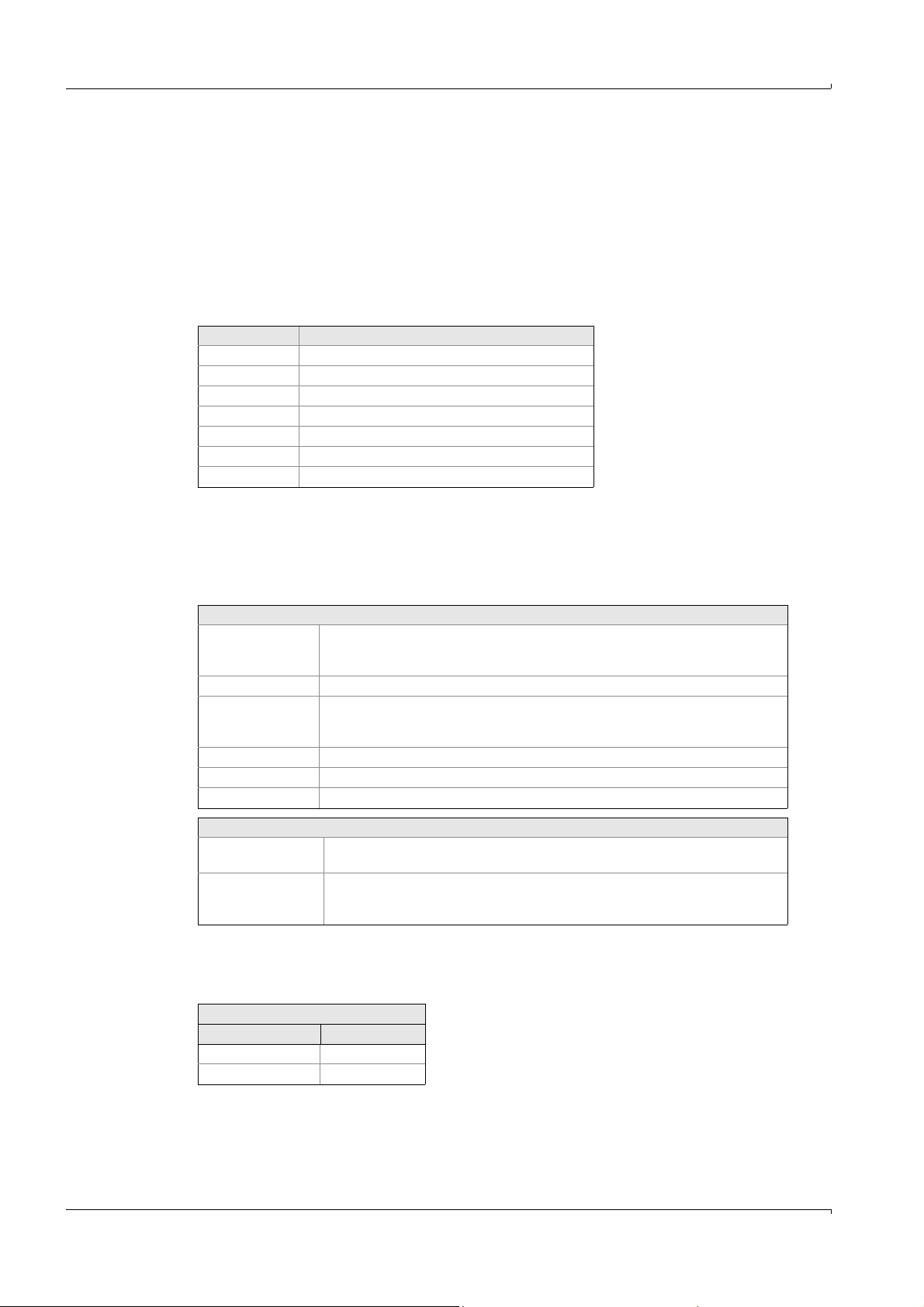

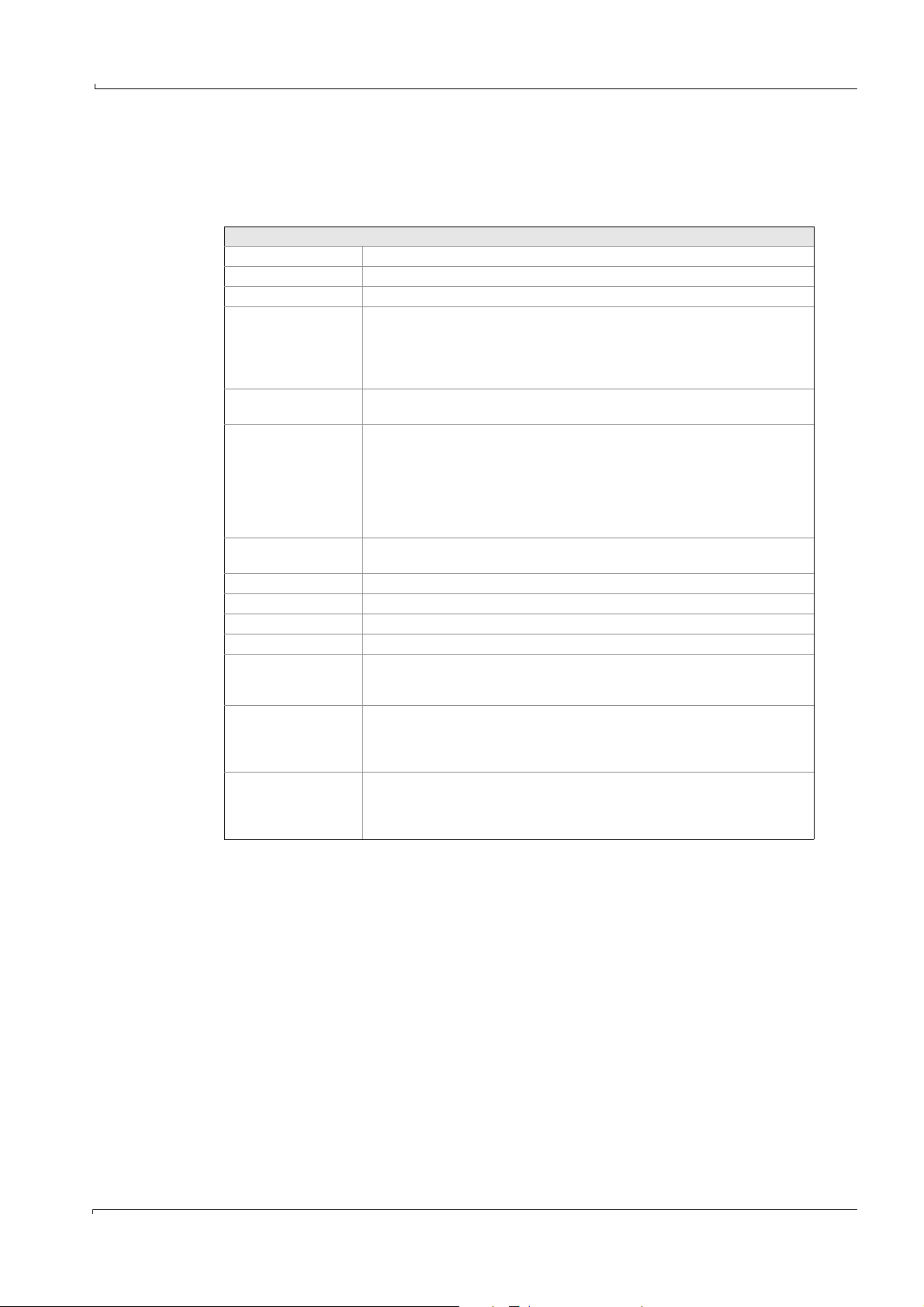

Product description

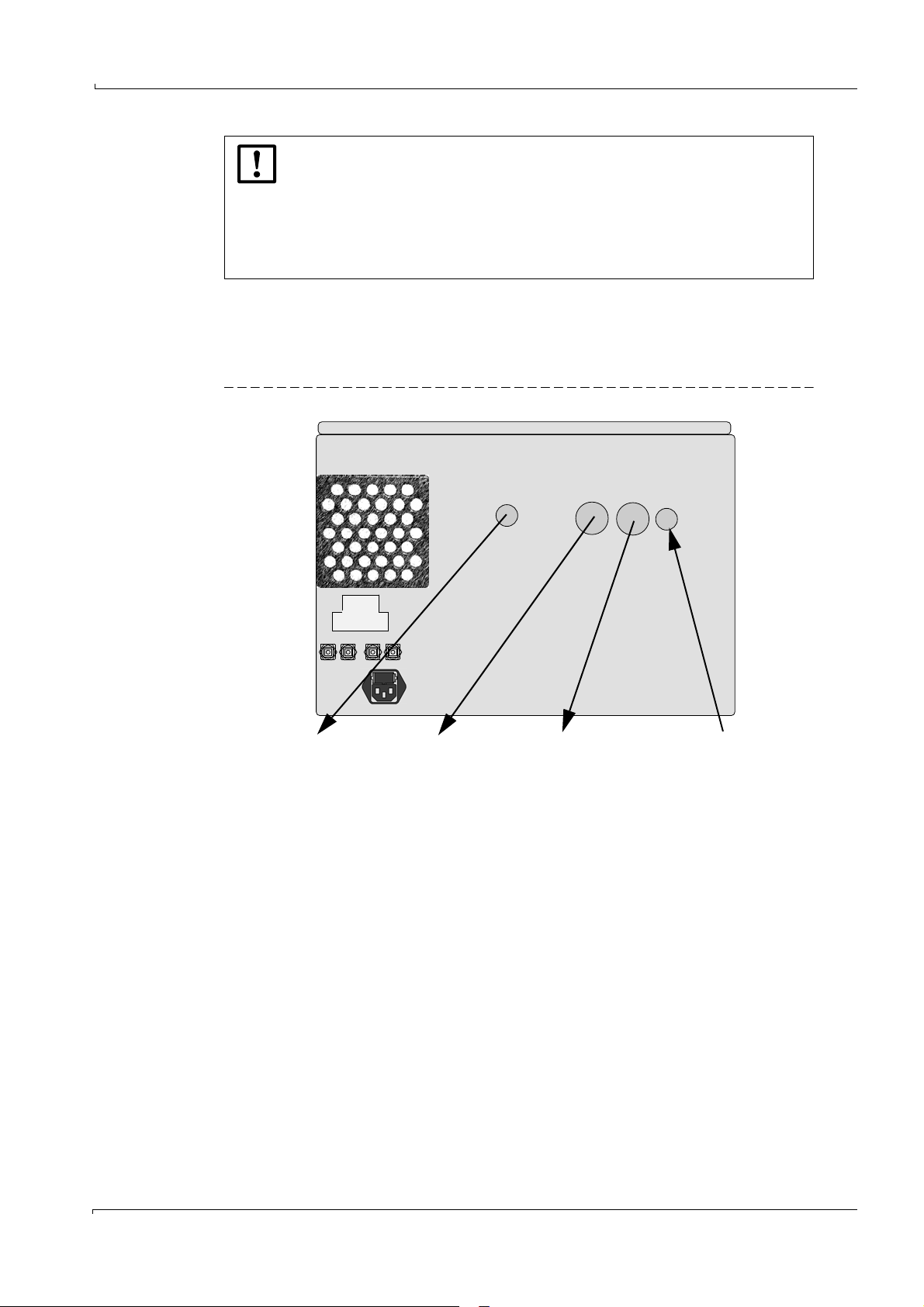

Computer

Flow meter

Photometer

User interface

Interfaces

Cell

Sample gas outlet

Sample gas inlet

O

2

sensor

(optional)

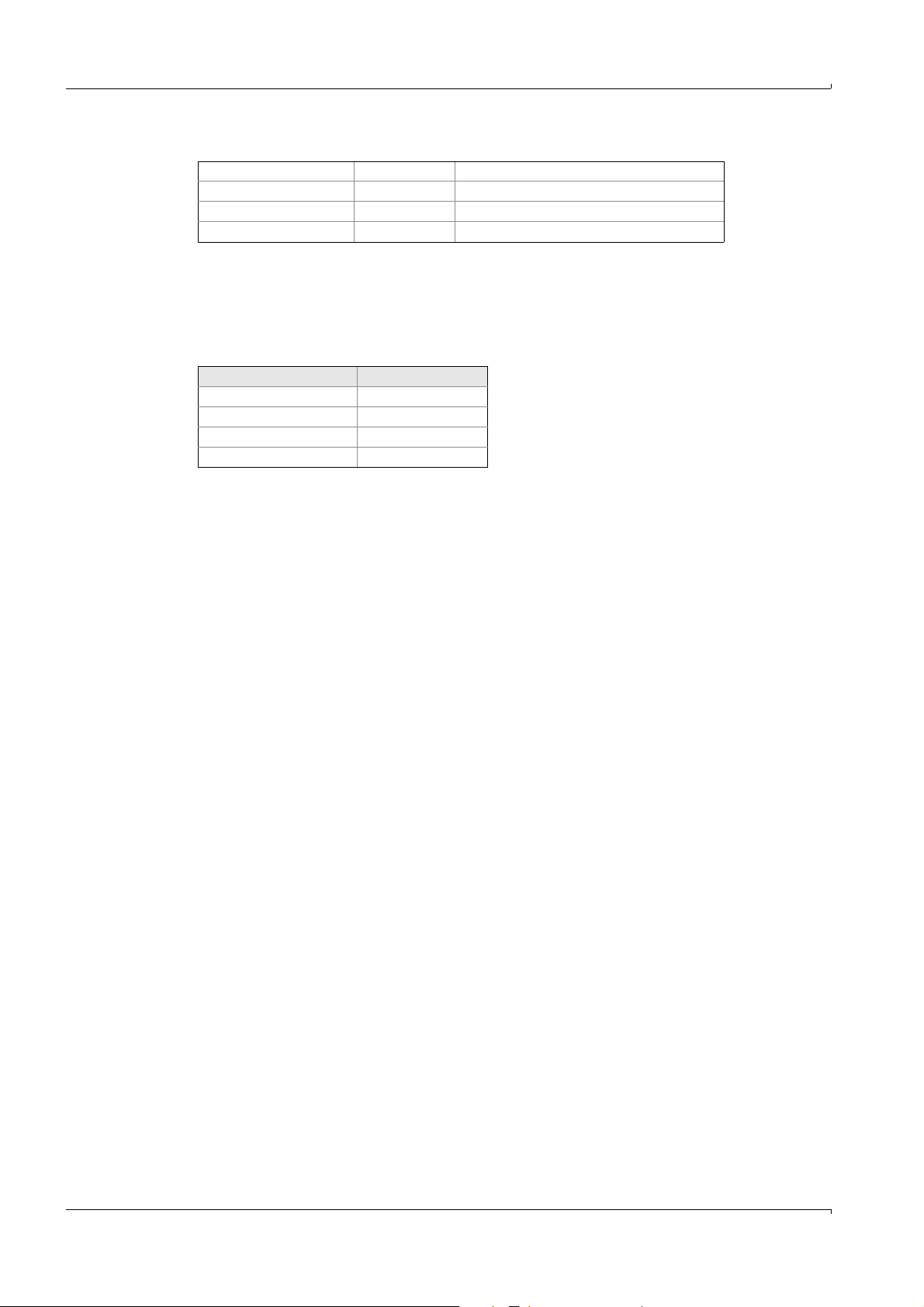

2.2.1 Design

MCS100E consists of the following main assemblies:

• Photometer with filter wheels (design dependent on application)

• Cell (optical path length dependent on application)

• Flow meter

•O

• Computer and electronics

Figure 2 MCS100E setup

sensor (optional)

2

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 17

Page 18

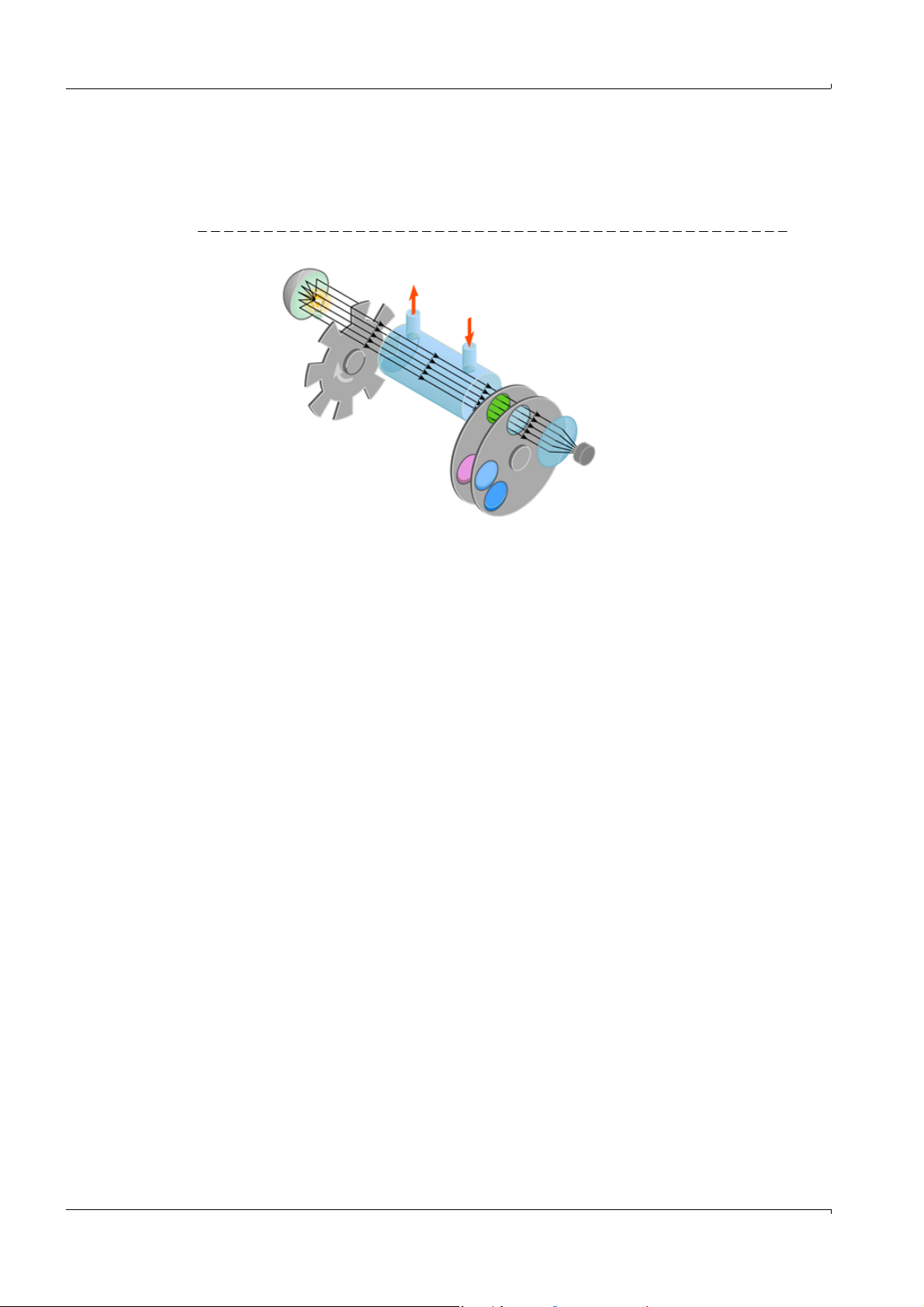

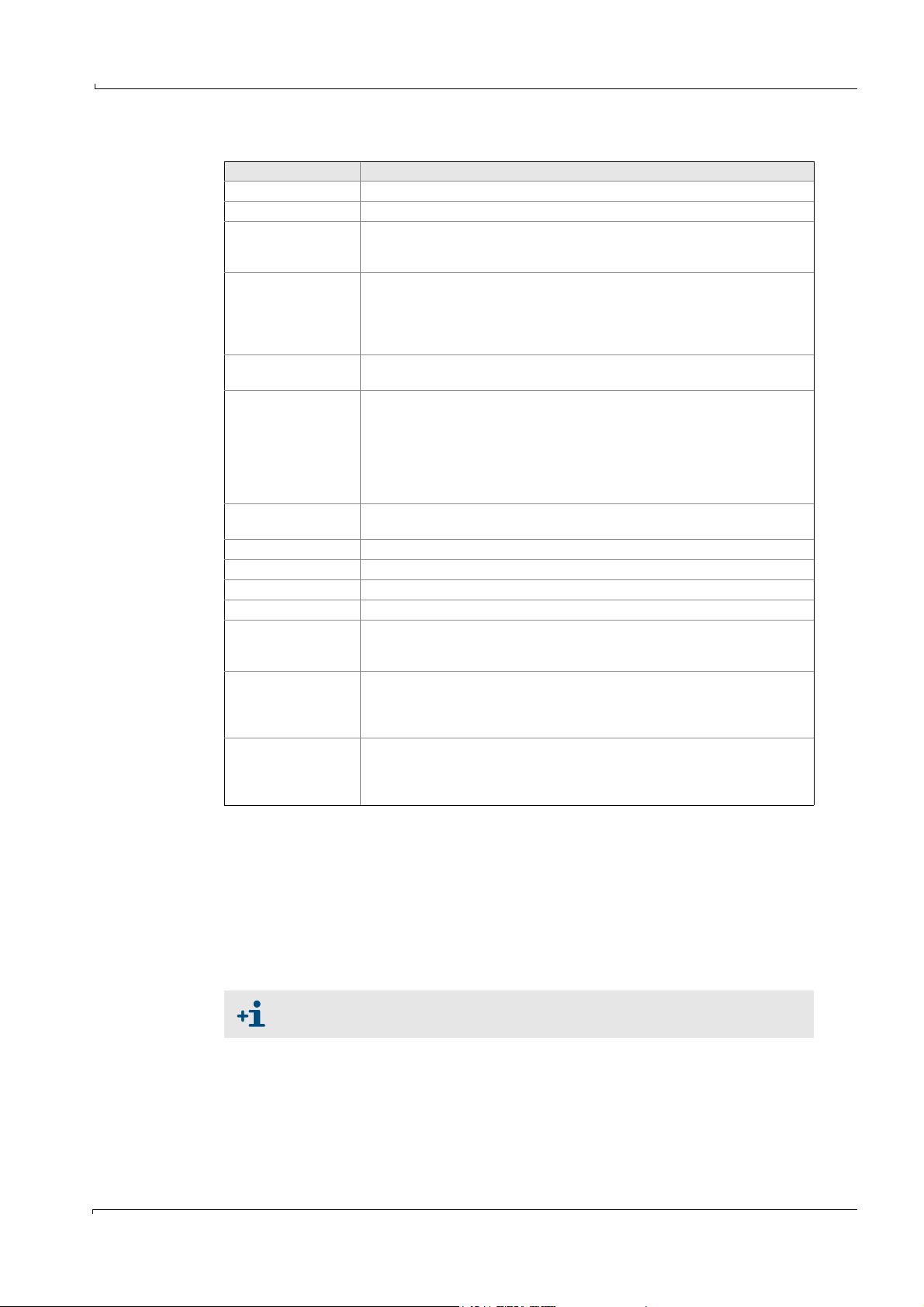

2.2.2 Measuring principle

Light source

Cell

Interference filter

Detector

MCS100E is a single-beam infrared photometer that works on the basis of the transmitted

light measuring technique applying the single-beam dual-wavelength method and the gas

filter correlation method.

Figure 3 Measuring principle

Product description

2.2.2.1

Correction of spectral interferences

In order to achieve greater measuring accuracy, interference sensitivities can be detected

and compensated (depending on application).

Additive (spectral superposition) and multiplicative (dilution effects) effects are considered.

Moreover, external digital and analog signals can be read in and processed (option).

2.2.3 Thermostatic control

MCS100E is equipped with a self-resetting thermal circuit breaker that protects the

instrument against thermal damage.

2.2.4 Cell

Sample gas filter

A sintered metal filter in the gas inlet of the cell serves as protective filter.

Beam path

The beam path corresponds to the principle of the White Cell with the beam being folded by

mirrors. The mirrors are mill-cut in the end plates. Thus the optical path length of the cell is

invariable (depending on the application).

Thermostatic control

The cell is thermostatic-controlled (temperature control

2.2.5 Flow meter

The flow meter functions on the resistance anemometer principle. It comprises two

temperature-dependent, heated resistors, one of which is positioned in the gas stream

begin measured while the other does not have gas flowing over it. The difference in the

resistances is a measure of the flow rate.

→

p. 83, §5.7.11.12).

Subject to change without notice

18 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 19

Product description

2.2.6 O

sensor (option)

2

O2 measurement is carried out by means of a circonium dioxide sensor.

The sample gas flows past the O

sensor, the gas exchange inside the sensor takes place

2

by turbulence. Ambient air which reaches the cell by diffusion is used as reference gas.

2.2.7 Barometric pressure compensation (option)

Barometric pressure compensation for the MCS100E is available as an option.

2.2.8 Interfaces

Fiber optics interfaces

• 2 optical interfaces (fiber optics) for connection of:

– I/O module boxes (containing the digital and analog interfaces) or HC8X heating

controller (

–Printer or PC (

→

p. 26)

→

p. 27)

Electrical interfaces (option)

• 1 serial and 1 parallel interface for connection of:

–PC or MODEM and printer (

→

p. 28, §3.2.3.2)

OR

• 1 serial and 1 Ethernet interface for connection of

–PC and Ethernet (

→

p. 28, §3.2.3.3)

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 19

Page 20

2.3 Data storage

• Storage of measured values (→p. 44, §5.2).

• Storage of status messages (

• Storage of results or signal outputs: (

2.4 Remote control

→

p. 44, §5.2).

→

p. 86, §5.7.11.14).

In remote control, MCS100E is operated via an external PC.

Screen contents and keyboard commands are transmitted.

• Ethernet (program TINY) (

•Modem (program NetOP) at serial interface (

2.5 Data transmission

2.5.1 Data transmission with MCS100E program

→

p. 29, §3.3.1).

→

The MCS100E program must be installed on the external PC.

File transfer is carried out via the MCS100E menus (

§5.7.15.5).

Connection of external PC:

• Optical (fiber optics) (

• Serial interface (

→

p. 27).

→

p. 28, §3.2.3.2).

p. 31, §3.3.2).

→

Product description

p. 90, §5.7.15.4 and →p. 91,

2.5.2 File transfer with modem

• At DOS level (program NetOP) at the serial interface (→p. 31, §3.3.2).

2.6 Communication protocol

• Communication protocol: Modbus RTU (→p. 126, §9.3).

• Interface: Serial interface (

→

p. 28, §3.2.3.2).

20 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 21

Product description

2.7 QAL3 (DIN EN 14181)

The procedure described in the following is TÜV-tested for MCS100E in the

MCS100E HW emission measuring system.

2.7.1 Evaluation of zero and reference point data

In regular intervals – at the latest within the maintenance intervals as specified in the

aptitude test - an internal readjustment of the measuring device is performed either

automatically or manually at certain

time intervals by either automatic or manual sampling of reference gases for zero point and

reference

point. As an option, the readjustment of the reference point can be performed by swiveling

in an optical calibration filter (

→

§2.7.2).

If the limit for readjustment is reached (usually a deviation > 6% off the

preceding calibration), an error is indicated.

Zero point

The value for the zero point is determined by sampling zero gas (usually dry instrument air)

and

reading the instrument display resp. determining the corresponding analog signal. In

practice, the

same zero gas that is used for internal readjustment can also be used for this procedure.

Reference point

The value for the reference point is determined by sampling a reference gas of known gas

concentration and reading the instrument display resp. determining the corresponding

analog signal. In practice, the

same reference gas that is used for internal readjustment can also be used for this

procedure.

2.7.2 Use of the calibration filter option

As an option, the MCS100E HW measuring device can be equipped with a third filter wheel

which allows to swivel-in so-called calibration filters (

This function can either be started program-controlled or manually using the MCS100E

standard software.

Zero point

As described above

Reference point, conventional method

As described above

Reference point, alternative method with calibration filter

The value for the reference point is determined by sampling zero gas and swiveling-in the

calibration

filters one after the other by selecting the corresponding menu functions. Then the value is

displayed

resp. the corresponding analog signal is given for each component.

The set reference value corresponds to the value of the calibration filter.

→

p. 17, Figure 2).

Subject to change without notice

During gas calibration, the last measured deviation of the calibration filter

values is overwritten and set

to zero until the next gas calibration is performed.

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 21

Page 22

Product description

22 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 23

Installation

MCS100E

3 Installation

Project planning

Transport

Setup

Installation

Initial commissioning

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 23

Page 24

3.1 Transport

WARNING: Risk of injury by a heavy load

The MCS100E weighs approx. 70 kg.

Improper lifting can cause painful and sometimes permanent back injury.

Use proper lifting techniques or auxiliary equipment to lift or move the

MCS100E.

• Protect MCS100E from shock and vibrations.

3.2 Installation and initial commissioning

Only qualified personnel trained on the instrument may perform installation

and initial commissioning of the MCS100E.

Please contact SICK Customer Service as required.

3.2.1 Preparing the place of installation

Make sure that the bearing capacity of the mounting location is appropriate.

3.2.2 Mechanical installation

MCS100E:

Must be mounted in a vertical position.

Use the existing mounting holes.

Use appropriate mounting material only.

Ensure sufficient heat dissipation, take care that instrument space is minimum 5 cm.

Installation

3.2.2.1 Sample gas connections

• Sample gas lines:

– Sample gas inlet: 6 mm fitting with ferrule

– Sample gas outlet: 10 mm fitting with ferrule

WARNING: Hot surface - risk of burns

The surface of the cell insulation is hot.

Allow hot components to cool down.

WARNING: Noxious and irritating sample gas

Depending on the sample gas composition, it is possible that the sample gas

contains noxious or irritating components.

Discharge the gas outlets into the open or to an extractor.

Observe information from the plant operator.

NOTICE: Condensate is formed at the sample gas outlet

When the sample gas cools down, it is possible that condensate is formed at

the sample gas outlet.

Lay the sample gas outlet running downwards so that no condensate is

accumulated.

If necessary, provide for a suitable condensate collecting device and

adequate ventilation.

Protect the measuring gas outlet from frost.

Subject to change without notice

24 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 25

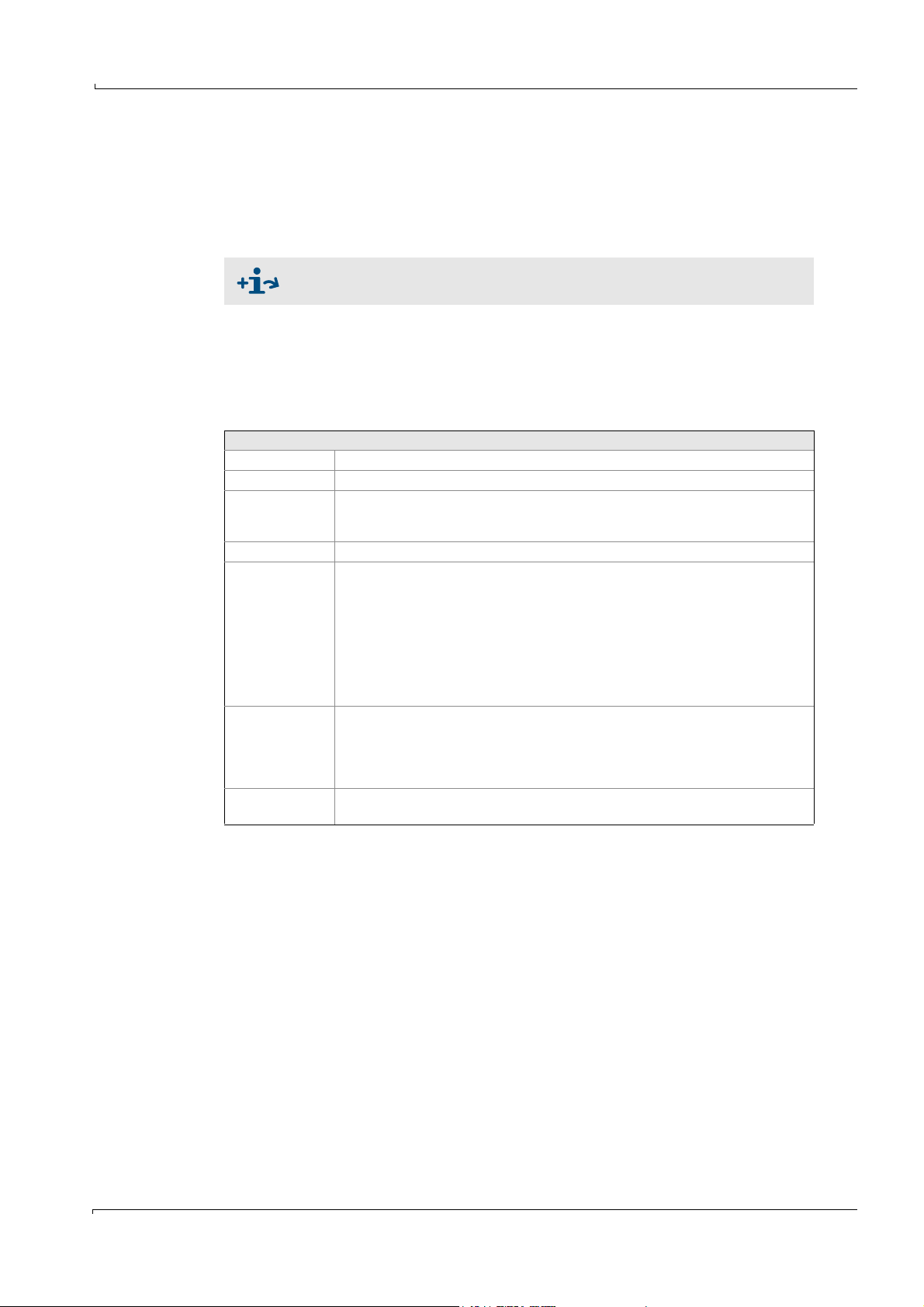

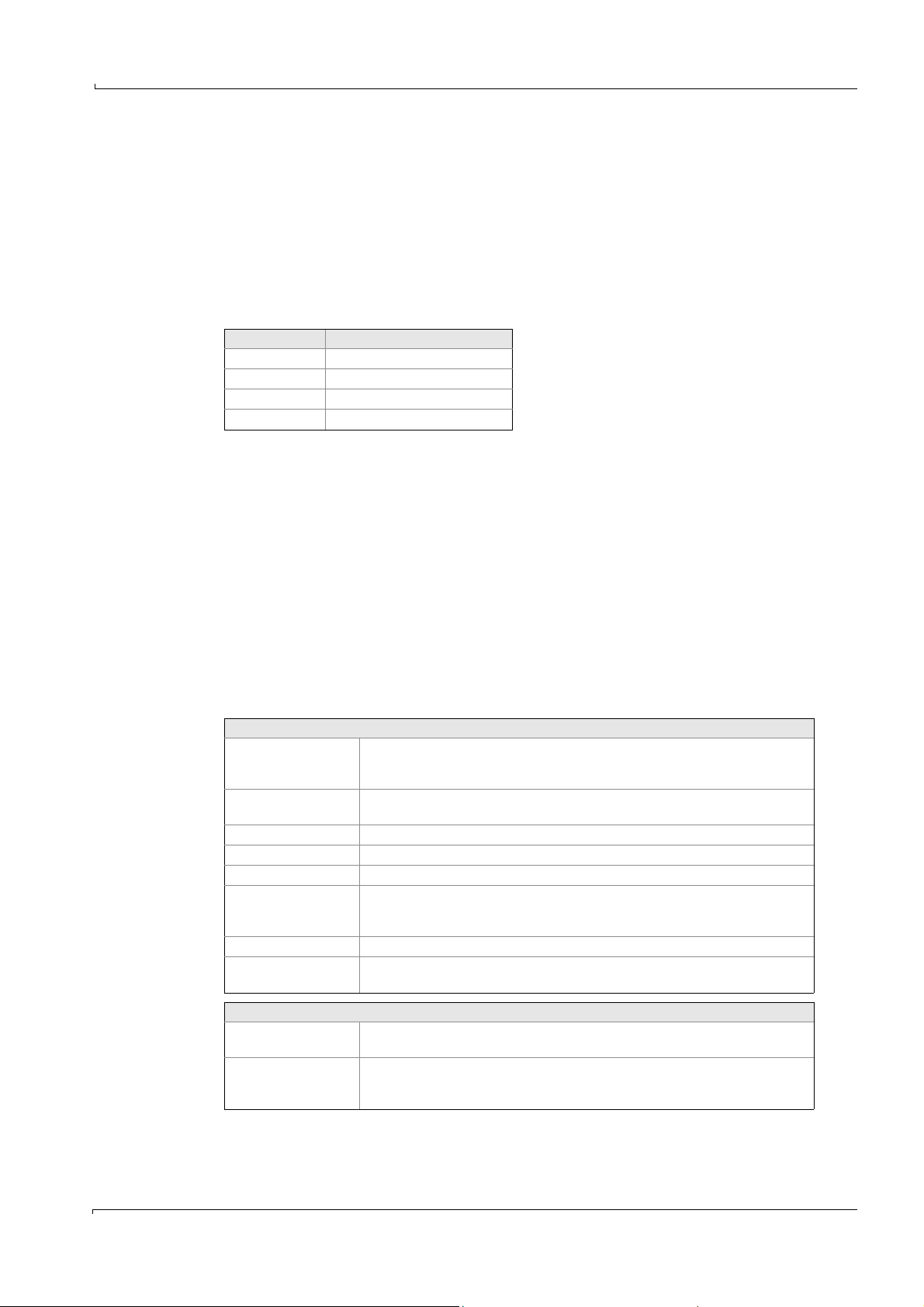

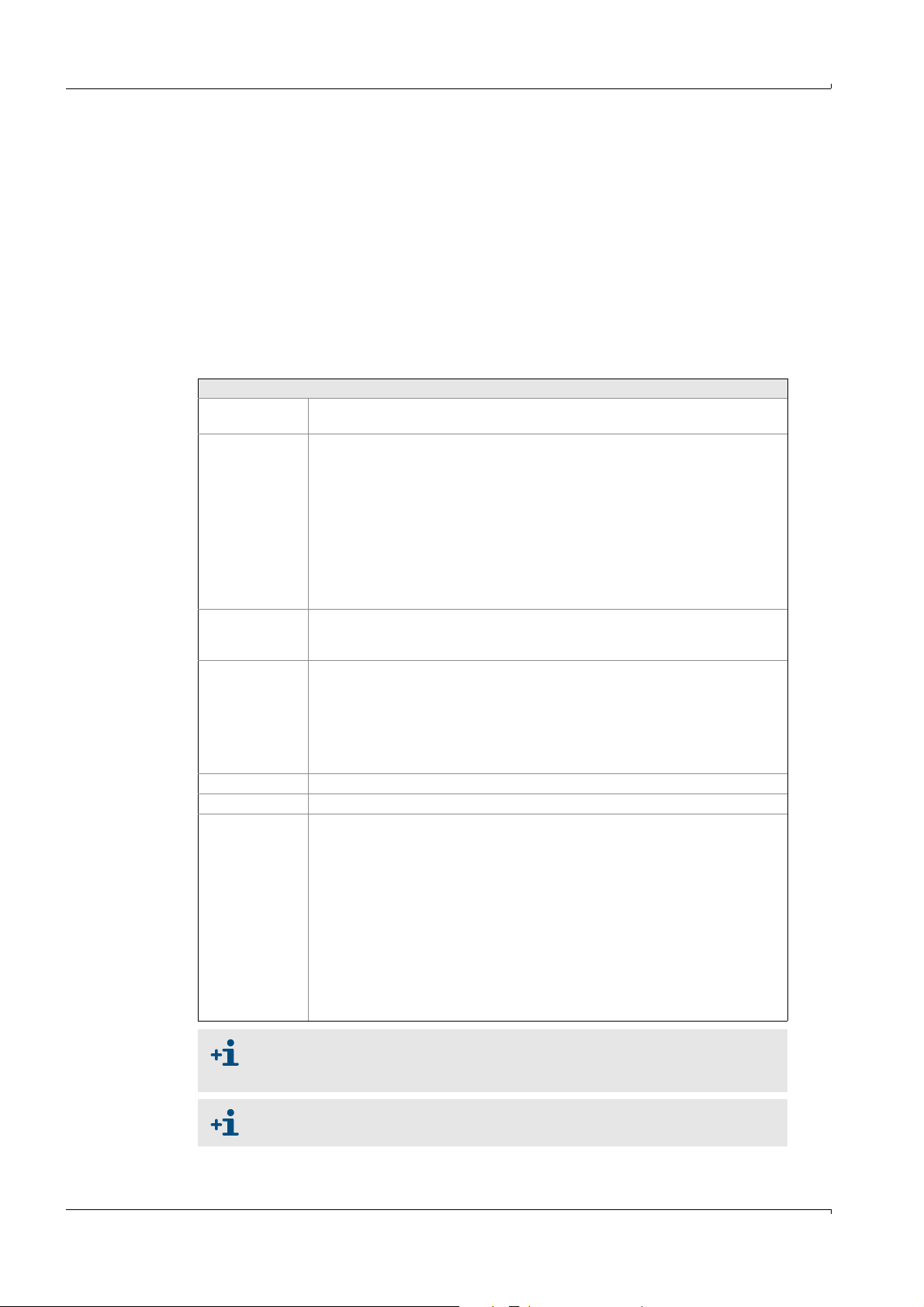

Installation

Sample gas outlet

If:

- No O

2

sensor

- No external FID

Sample gas outlet

If:

- O2 sensor

AND/OR

- External FID

Branch current to external

FID

If external FID:

- Branch current to external

FID

Sample gas inlet

Procedure

1 Unscrew the cell cover screws.

2 Remove the cell cover.

3 Connect the sample gas lines.

Figure 4 Sample gas connections

NOTICE: Lay the pipes properly

Blocked pipes can falsify measured values and possibly damage the measuring

device.

⊗ The sample gas outlet may not increase the intended working pressure

(must be open to the ambient pressure).

⊗ Do not bend or crimp the pipes.

Use temperature-resistant pipes.

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 25

4 Place cell cover in position and tighten screws.

5 Check sample gas lines for leaks.

Page 26

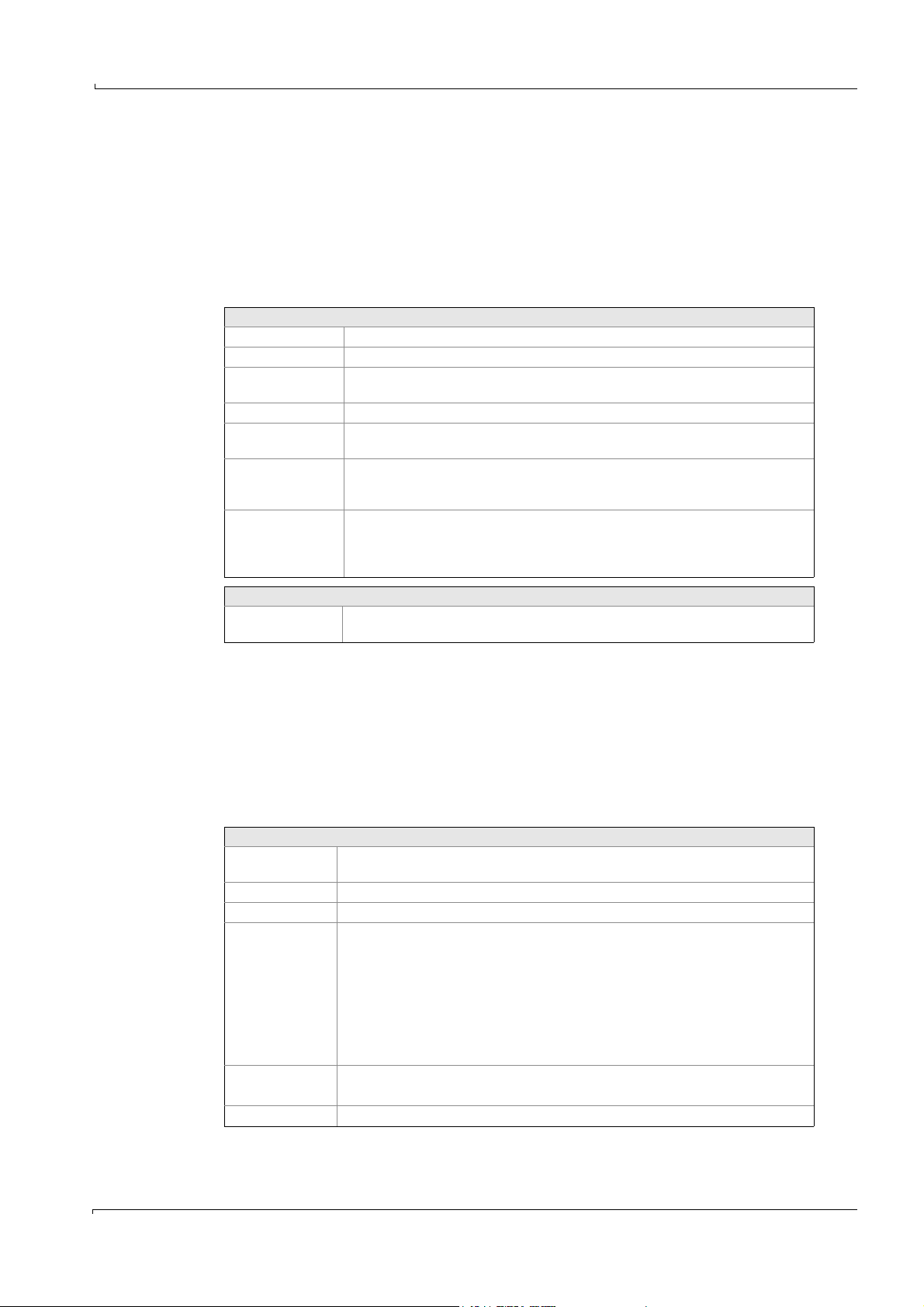

3.2.3 Interfaces

MA SL MA SL

E E S S

E S E S

I/O module box or HC8X

“MA” interfaces

MCS100E

“Module box” interfaces

3.2.3.1 Optical interfaces

The optical connections are located at the bottom of MCS100E.

Connecting the fiber optical cables:

⊗ Do not sharply bend the fiber optical cables.

• Minimum bending radius: 3 cm.

• The direction of the fiber optical cable can be as desired.

• The connectors can be plugged into the sockets in any 90° angle.

Press connector into socket until you hear that it is locked.

To remove the fiber optical cables, pull at the connector only (not at the cable).

Optical interface “module box“

I/O module boxes (digital and analog input/output units) or HC8X heating controllers are

connected to the interface to the “module box”.

• Max. length of recommended fiber optical cables: 50 m (for further information, refer to

Technical Data).

• Designation of the connections:

– At the MCS100E: Module box “E” or “S”

– At the module box:“MA E” or “MA S”

(MA = Master, E = Receiver, S = Sender)

Installation

Figure 5 Connection of “module box” interface

26 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 27

Installation

1 fiber optical

cable

2 fiber optical

cables

Converter to V24

Converter*

*Plug-in board or converter with inherent power supply

E S

E S E S

MCS100E

“PC/printer” interface

Only this 1 fiber optical cable

for the V24 converter for

printer

Converter

Interface

Optical interface “PC/printer“

Figure 6 Optical interface“PC/printer”

• The following equipment can be connected to the “Printer/PC” interface:

–Printer or PC

• Designation of the connections on the MCS100E:

“Printer/PC” “E” or “S” (E = receiver, S = sender)

• Maximum length of fiber optical cables: 50 m (unless required differently by the

receiver)

• An appropriate converter is used for connection of the fiber optical cables to the

electrical input of the terminal equipment.

Figure 7 Connection of “PC/Printer” interface

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 27

Page 28

3.2.3.2 Electric serial and parallel interface (option)

RS232 interface

- PC

- Modem

Parallel interface

- Printer

Serial interface

- PC

Ethernet interface

- Ethernet

Figure 8 Connection to serial and parallel interface

• Serial line for PC or modem

• Parallel (“DOS-Interlink” cable 11-core) interface cable for printer.

• Use sufficiently screened cables.

• Max. cable length: Approx. 10 m

3.2.3.3 Electric serial and Ethernet interface (option)

Installation

Figure 9 Connection to serial and Ethernet interface

• Serial interface (→§3.2.3.2).

• Ethernet interface

–Type: Ethernet

–Protocol: UDP

– Connector: RJ 45

– Cable: Cross-over on PC, 1:1 on hub

– Data format: 10 MBit half-duplex

– Addresses (preset):

- IPADDRESS:192.168.0.x (see label on Ethernet interface)

- SUBNETMASK:255.255.255.0

28 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 29

Installation

MCS100E

Ethernet

PC

Ethernet

line

Ethernet

line

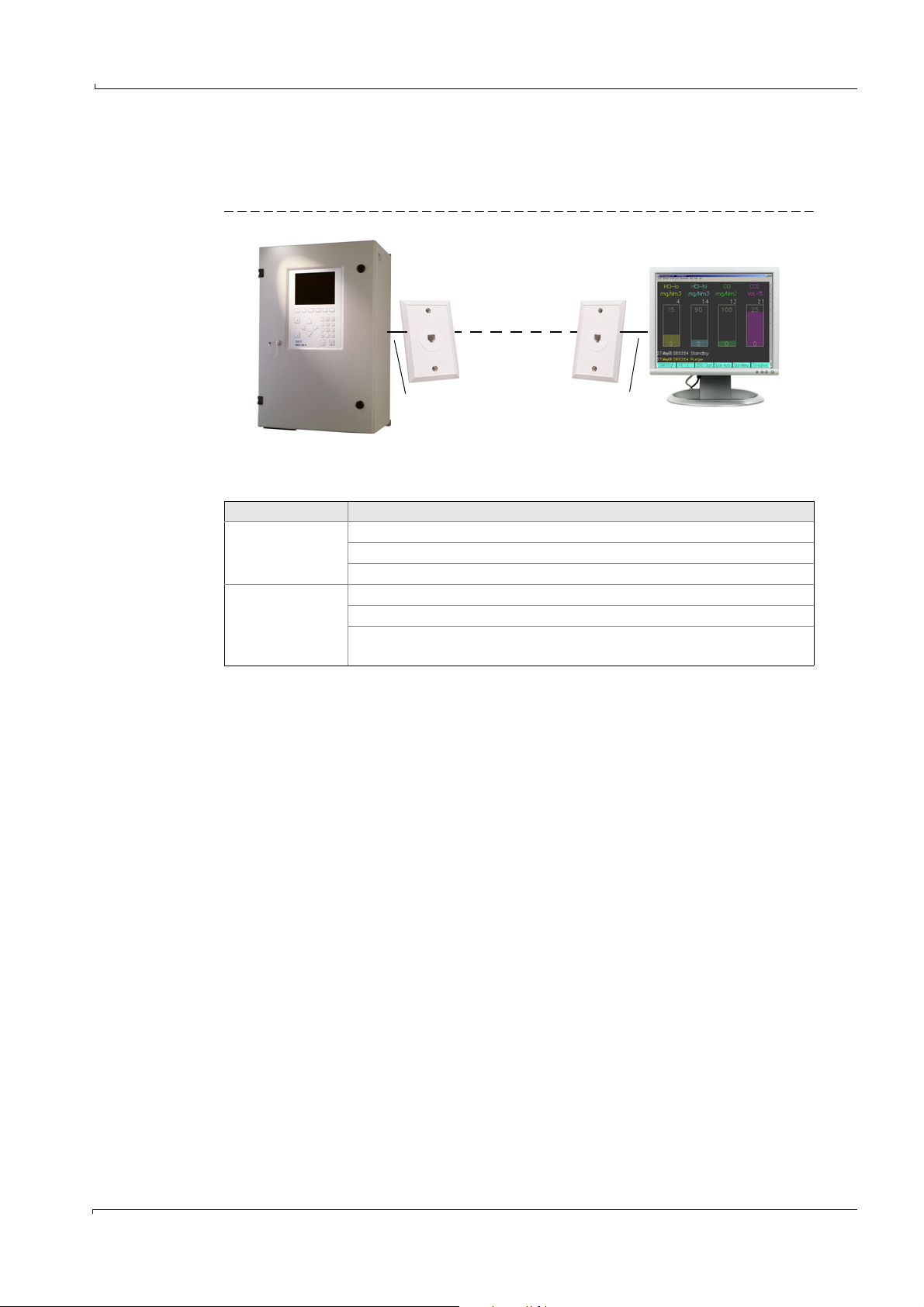

3.3 Remote control

3.3.1 Ethernet with TINY program

Figure 10 Remote control via Ethernet

Equipment

Control unit Equipment

MCS100E side

PC side

Ethernet interface RJ45 for MCS100E (Part No. 2043636)

Software package “TINY” (Part No. 2040228) (CD-ROM) (pre-installed)

Ethernet connection RJ45

Ethernet connection

Software package “TINY” (Part No. 2040228) (CD-ROM)

PC with Java (JDK or JRE) (Java JDK is included in the “TINY” software

package)

3.3.1.1 Connection on MCS100E side

Connect the MCS100E to the Ethernet.

3.3.1.2 Connection on PC side

Connect the PC to the Ethernet.

3.3.1.3 Program start on MCS100E side

First-time start:

1 The MCS100E starts.

2 Exit the MCS100E program (

→

p. 46, §5.4.2).

You are at DOS level.

3 Switch off the watchdogs (

→

p. 109, §7.8).

4 Call up: TSETUP <IP_ADDRESS> <IP_NETMASK> <IP_ROUTER>

The addresses depend on the customer network

Example:

- IP_ADDRESS : 192.168.0.x (x = 0 .. 9)

- IP_NETMASK: 255.255.255.0

- IP_ROUTER: 192.168.0.1

Call-up: TSETUP 192.168.0.1 255.255.255.0 192.168.0.1

Is it OK? [y,n] : <y> <ENTER> (saved in “C:\NOVELL\CLIENT32\NET.CFG”).

Subject to change without notice

5 Switch off the MCS100E.

Then automatic start when the MCS100E is switched on.

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 29

Page 30

3.3.1.4 Program start on PC side

First-time start:

1 Install Java JDK or Java JRE on the PC.

Installation file: In the “JAVAinst” directory on the CD.

2 Copy the “TINYclient” directory from the CD to the PC.

3 Using a text editor, enter the IP address of MCS100E in the “ts.bat” file.

Example:

- IP address of MCS100E: 192.168.0.1

java.exe -jar TinyClient.jar /Xde.kcf /D100 /K50 /R 192.168.0.1 password

4 If you want to call up the command line version of TINY:

- Connect with MCS100E.

- Call up “ts.bat”.

The DOS and the TINY windows are displayed on your PC.

OR

4 If you only want to view the TINY window:

- Start the Windows version of Java.

- Using a text editor, enter the IP address of MCS100E and display the path of the

“javaw” program to your Java installation in “Properties” of “Link”.

Example:

C:\Programms\Java\jdk1.5.0\bin\javaw.exe -jar TinyClient.jar /Xde.kcf /D100 /

K50 /R 192.168.0.1 password

Automatic start

1 - Call up “ts.bat”.

OR

1 If you only want to view the TINY window:

Double-click “Link” “ts”.

Installation

For further information, see the “xxxx_install.txt” file on your CD.

3.3.1.5 Special characters, e.g. on a German keyboard

Popup menu

Input of special characters in the MCS100E menus:

– Open a popup menu by clicking the window with the right mouse button.

– Click “Send Keystroke” “Custom Keys”.

If the required keys or characters are not shown in the popup menu: Define the keys in

a text file and call up the program with “/X<file name>” (

If the program is started in version “Call in DOS” (

codes are shown in a window.

For more information, see file “de.kcf” (open with a text editor) on your CD.

→

§3.3.1.4).

→

§3.3.1.4) with the “/C” option: The

Subject to change without notice

30 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 31

Installation

MCS100E

RS232

RS232

Telephone line

Telephone line

PC

Modem ModemTelephone connection Telephone connection

3.3.2 Modem with the NetOP program

Figure 11 Remote control via modem

Equipment

Control unit Equipment

RS232 interface for MCS100E ((Part No. 2023049)

Modem (Part No. 6029430)

MCS100E side

Power supply unit 100 - 240 V, 24 V) (Part No. 6029654)

NetOP software (pre-installed)

Telephone connection (analog)

Telephone connection (analog)

PC side

Modem

NetOP software (Part No. 6029452).

3.3.2.1 Connection on MCS100E side

1 Connect the RS232C interface of MCS100E (

→

p. 28, Figure 8) to the modem.

The modem setting cannot be changed.

2 Connect the modem to the telephone network (analog).

3.3.2.2 Connection on PC side

1 Connect the modem to the telephone network (analog).

– If an external modem is used (this means: No modem PC card):

Connection of modem exclusively to a “real” COM port of the PC

- No USB ports

- No USB-to-COM ports

2 Set the modem corresponding to the PC.

3.3.2.3 Program start on MCS100E side

If NetOP has not been installed:

Leave the installation of NetOP to an expert.

1 Start MCS100E.

2 If NetOP has not been pre-installed:

– Copy directory \ndial to the root directory of MCS100E

– Check BIOS settings:

Subject to change without notice

- COM port: COM 4 or AUTO

- COM port may not be occupied already.

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 31

Page 32

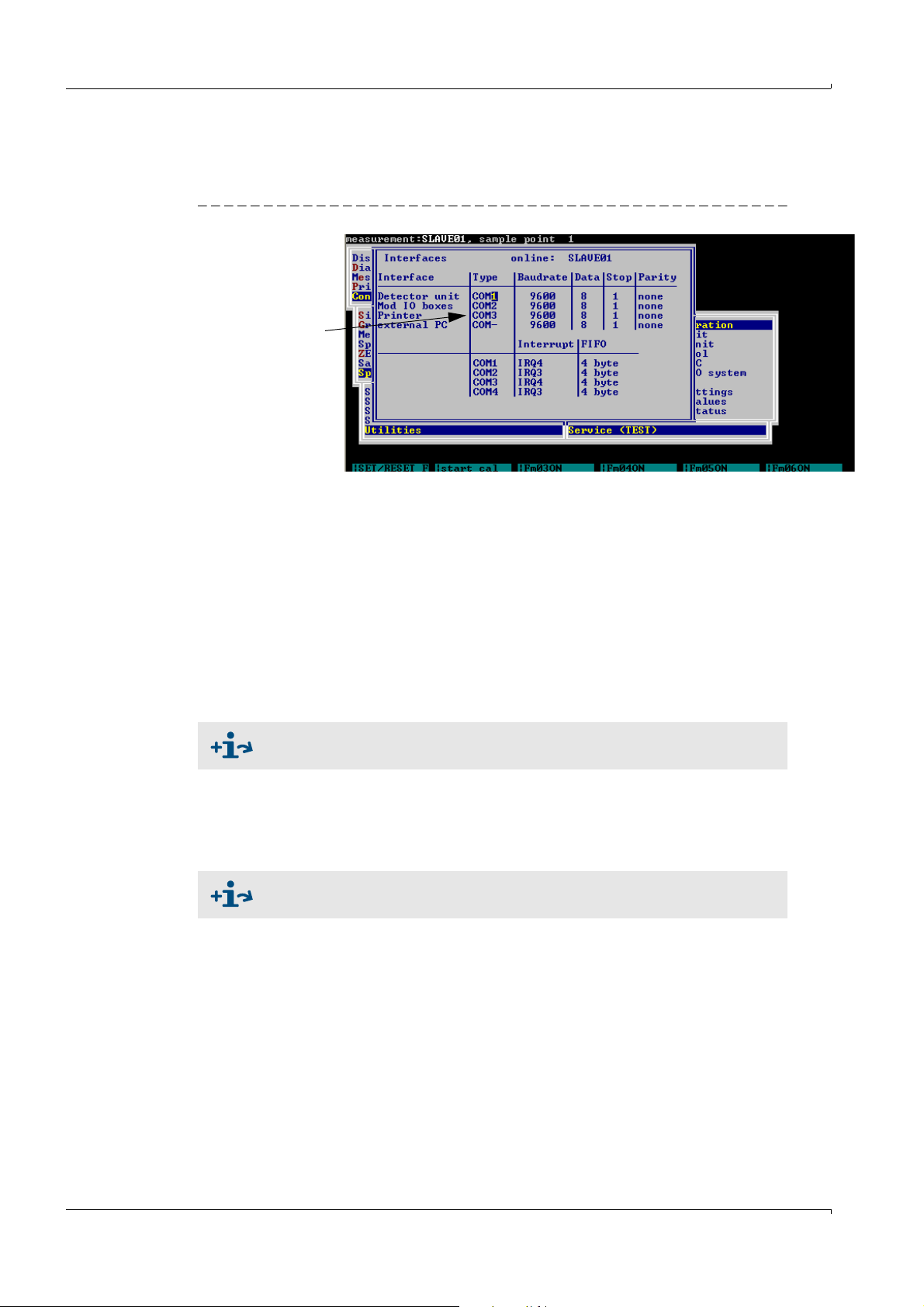

–In the Specialist menu: Utilities: Service: Environment Configuration: Interfaces

In this block

there may be no COM4

(

→

p. 93):

The “Interfaces” must not be assigned to any COM4. Example:

Figure 12 Settings

– Restart MCS100E.

3.3.2.4 Program start on PC side

1 Install NetOP on PC.

2 Start the NDGUEST.EXE program.

– At the first call-up: Set the parameters for NDGUEST according to the customer

network

Procedure:

→ documentation supplied with the delivery.

– “Quick DIAL”

Specify the telephone number of the MCS100E telephone connection (comma for

“Wait time”)

– The screen content of the MCS100E is shown.

Installation

File transfer via modem →p. 33, §3.4.2

3.3.2.5 Terminating the transfer

1 Switch to the NDGUEST user interface with <ALT-X>.

2 “Remote Control“- “Hang up”

3 “File” - “Exit”

For more information on NetOP → documentation supplied with the delivery.

Subject to change without notice

32 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 33

Installation

3.4 Data transfer to/from external PC

3.4.1 Data transfer via fiber optical cable

1 Install the fiber optical cable connection (→p. 27, Figure 6).

2 The MCS100E measurement program must be installed and running on the PC (1.bat).

3 Start the desired data transfer on the MCS100E (for example

§5.7.15.4,

3.4.2 File transfer via modem

→

p. 91, §5.7.15.5).

For file transfer via modem, the running measuring operation must be

interrupted.

1 Install the modem connection (→p. 31, §3.3.2).

2 Exit the MCS program (

→

p. 46, §5.4.2).

3 Enter at DOS level:

a) wdog disable <ENTER>

b) cd\ndial <ENTER>

c) ndtrans <ENTER>

A transfer message is shown.

→

p. 86, § 5.7.11.14, →p. 90,

MCS100E is now at DOS level.

Use only the specified commands.

Otherwise, it is possible that the connection is interrupted; MCS100E

“hangs” at DOS level and can be restarted locally only.

d) Ctrl-Alt-x (call up NETOP).

e) Alt-T: Determine transfer direction and directories.

f) Start

Data transfer is running.

g) After the transfer, reply to the “Close file transfer window” prompt with “Yes”.

h) Change to the MCS100E screen with Alt-z.

i) Exit the transfer program with ESC.

j) Restart the MCS100E with “1”.

k) Change to NETOP again with Ctrl-Alt-x

4 Terminate the connection (

→

p. 31, §3.3.2)

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 33

Page 34

3.5 Modbus communication protocol

Communication protocol: Modbus RTU →p. 126, §9.3

3.6 Hardware requirements for external PC

• If you want to install the operator menu on an external PC, the minimum requirements

are:

– IBM-compatible computer with 386 CPU

–1 MB DRAM

– 2 MB disk for internal programs

– 2 MB memory extension (required for data saving))

3.7 Hardware requirements for printer

•V24 interface

•IBM-compatible.

Installation

34 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 35

Installation

Bridge and LED

115 V

Bridge closed between pins 1 and 2.

The red LED is on if power is switched on.

230 V

Bridge open between pins 1 and 2.

The red LED is off if power is switched on.

3.8 Electrical installation

As soon as the power plug is connected to line power, MCS100E automatically starts

operation (

→

p. 38, § 4.1). Before connecting the power plug to the line power, ensure that all

necessary installation work has been done.

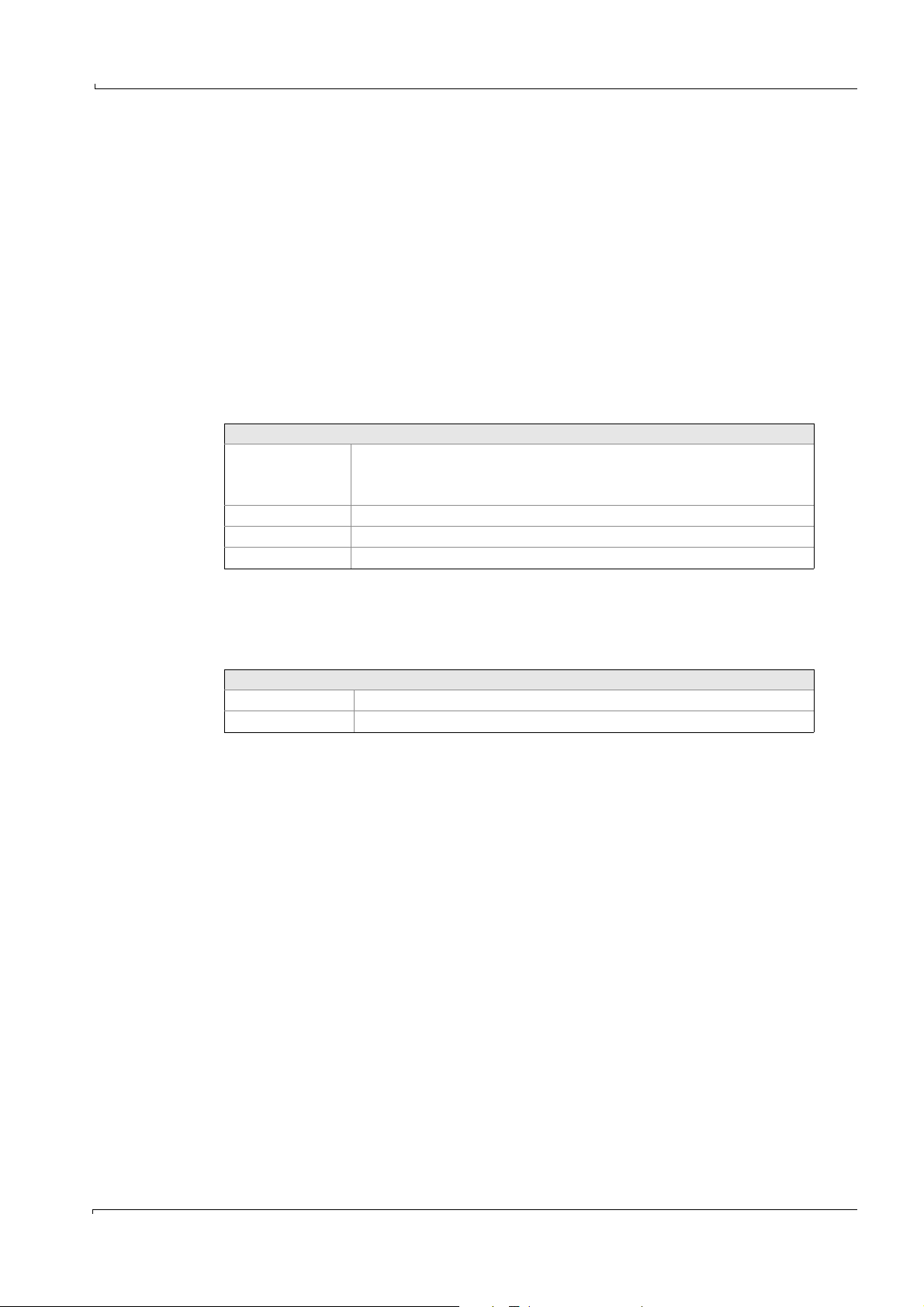

3.8.1 Power voltage adjustment

To adjust the power voltage:

Adjust bridge according to the requested power voltage (see below).

Use a backup with the current rating that corresponds to the power voltage (→p. 36,

§3.8.1.2).

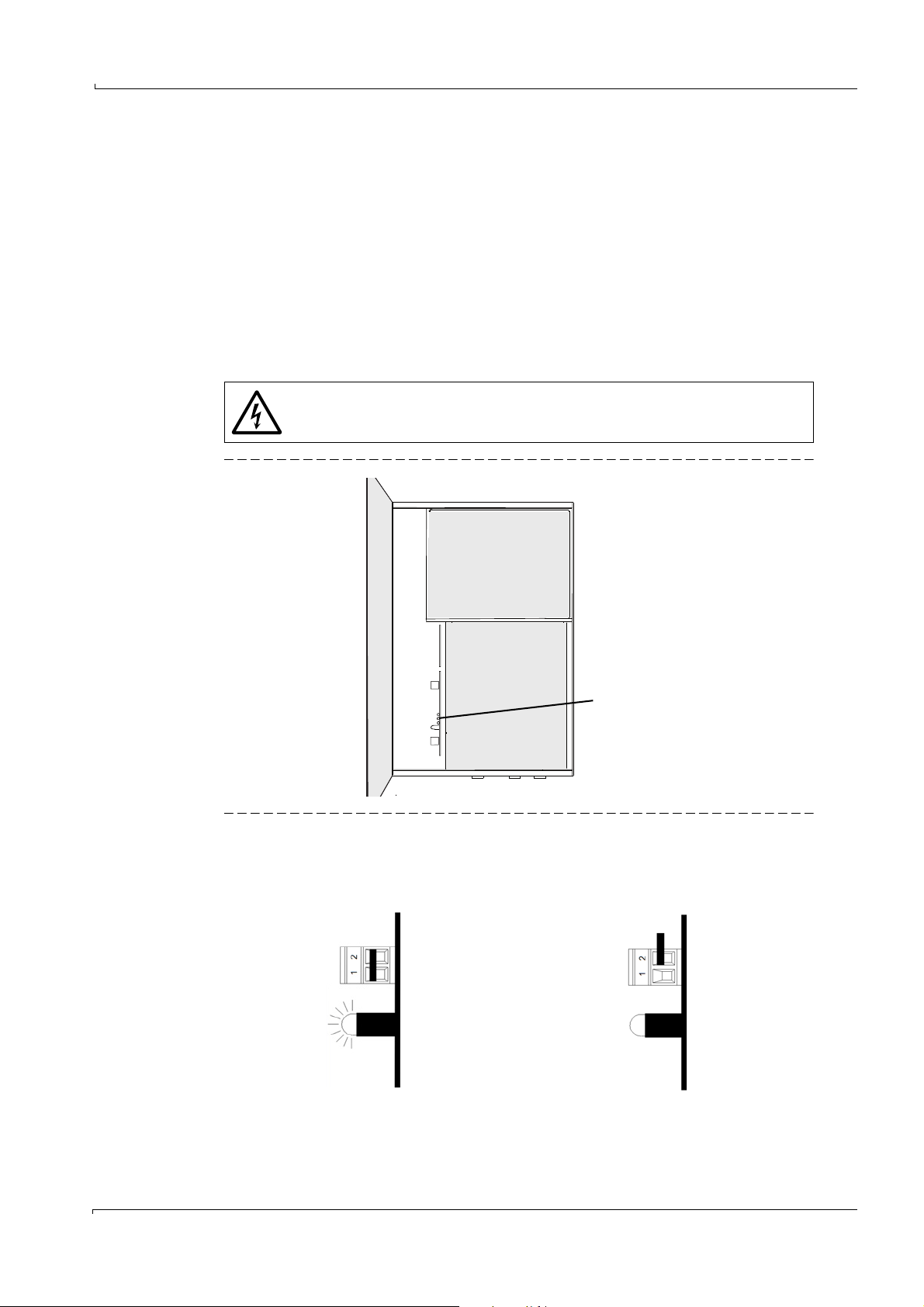

3.8.1.1 Adjusting the bridge for power voltage

The current values of the power fuses are voltage-dependent.

Use different fuses if the power voltage changes (→§3.8.1.2).

Figure 13 Position of LED (red) and bridge for power voltage adjustment

Figure 14 Bridge and LED for adjustment of 115 V or 230 V

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 35

Page 36

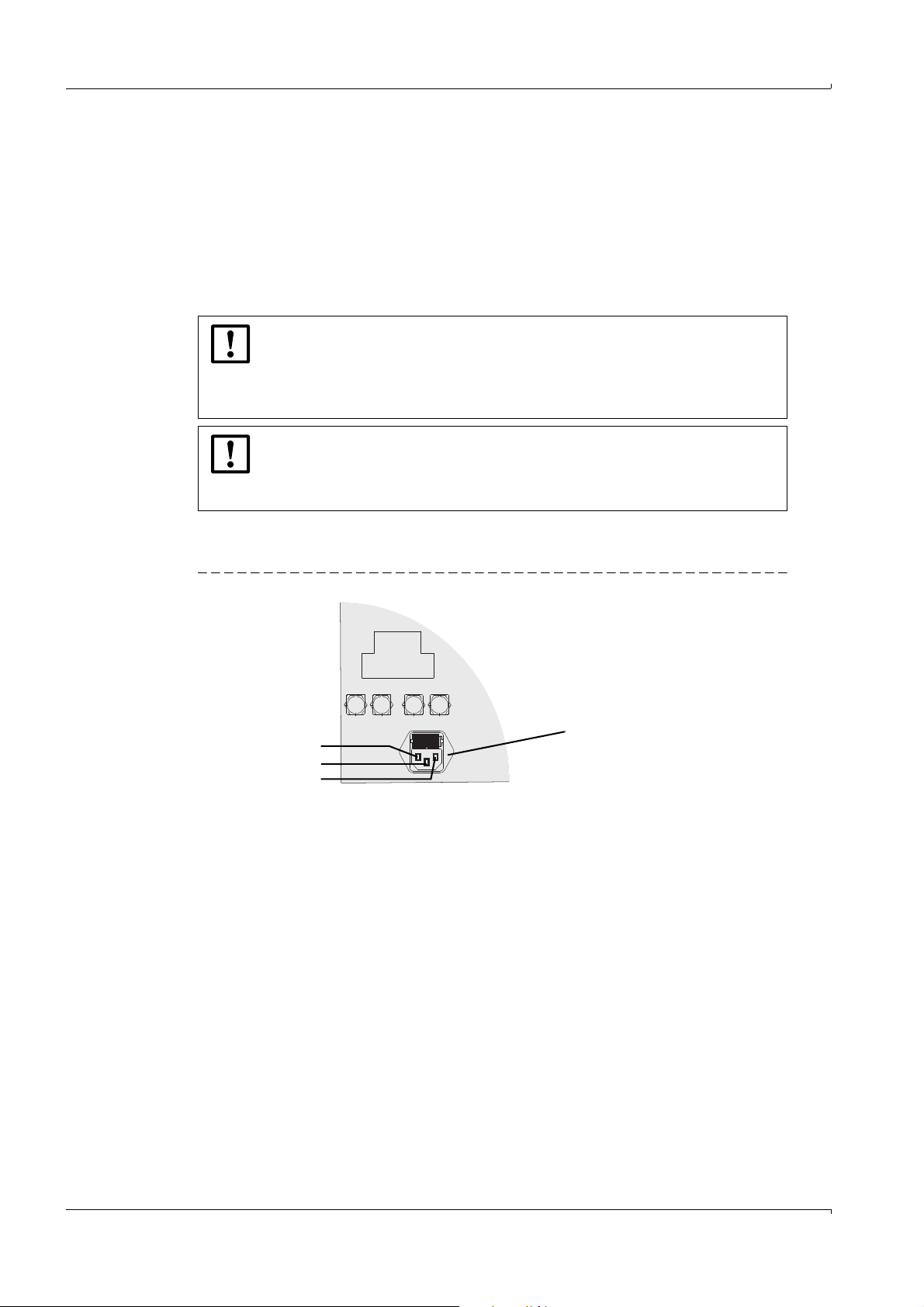

3.8.1.2 Power fuses

Fuse holder

1 Put MCS100E out of operation (

2 Remove power plug (otherwise the fuse holder cannot be opened)

• The fuse holder is inside the power plug housing.

Figure 15 Fuse holder

3 To remove the fuse holder, press the two notches at the sides and pull out.

→

p. 100, §6.1)

WARNING: Hazard caused by incorrect fuses.

The fuses are dependent on the power voltage.

Use only fuses with the required current rating and of the specified type for

replacement.

⊗ Do not use makeshift fuses.

⊗ Do not short-circuit the fuse holder.

Installation

•Fuse types

– 230 V: 5 AT (slo-blo) (2 each)

– 115 V: 10 AT (slo-blo) (2 each)

4 Put in fuses (2 fuses) of the correct rating.

5 Press fuse holder back into position.

6 Reconnect power plug.

Subject to change without notice

36 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 37

Commissioning

MCS100E

4 Commissioning

Preparation

Power-on procedure

Function test

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 37

Page 38

4.1 Commissioning

Power connection

L

N

PE

As soon as connected to line power (power plug connected), MCS100E automatically starts

operation.

In particular, check before power-on:

– Power voltage adjustment (

– Fuse ratings (depend on voltage) (

– Correct connection of the sample gas lines (

– Correct connection of the fiber optical cables (

NOTICE:

If a cold instrument is installed in a warm environment, there is a risk of

condensation inside the instrument.

Allow the instrument to stand for approx. 24 h to adopt ambient

temperature before switching on the supply voltage.

NOTICE:

The heating-up time of MCS100E is approx. 4 h.

Do not apply condensing gas to the instrument before the end of the

heating-up time.

For connection to line power, a grounded cord connector is used (the MCS100E does

not have a power switch).

→

p. 35, §3.8.1).

→

p. 36, §3.8.1.2).

→

p. 24, §3.2.2.1).

→

p. 26, §3.2.3.1).

Commissioning

Figure 16 Power connection at the bottom of MCS100E

The MCS100E is supplied with all parameters set.

It will start operating immediately after power-on.

Subject to change without notice

38 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 39

Commissioning

4.2 External keyboard

To ease the entry of rather large volumes of data a standard type external keyboard can be

attached to the keyboard connector (DIN-connector with 5 poles) at the door.

4.2.1 Country-specific assignment of keys

Depending on the type of external keyboard attached, it may be necessary to adjust the

country-specific assignment of keys.

1 Switch MCS100E off and then on again.

2 Abort automatic start after query <Start Program Y/N> (

3 If you want to remain at DOS level for more than 4 minutes: Disable the watchdogs

(

→

p. 109, §7.8).

4 Start the “Norton Commander” at DOS level with: <c:\nc>

Note: Switch MCS100E off and on again before selecting the “Norton Commander”.

5 In the “Autoexec.bat” file (<F4>):

–Insert “rem(blank)” before the line with the previous language and

– delete “rem” before the line with the desired language.

Example: After switching from German (gr) to English (us):

– rem C:\dos\keyb gr,,c:\dos\keyboard.sys

– C:\dos\keyb\ us,,c:\dos\keyboard.sys

6 If required, enable watchdogs again (

7 Exit the “Norton Commander”.

8 Start the measurement program with 1.bat (

→

p. 109, §7.8).

→

→

p. 45, §5.3.2).

p. 45, §5.3.3)

To enable the display of country-specific characters on the screen, countryspecific code pages must be loaded. This task should only be carried out by a

specialist who is well-acquainted with MS-DOS.

4.3 Language selection of the MCS program

The language of the MCS program is set:

• In the MCSCONF configuration program “Directories and Files”

• In the measurement sequence program in menu option Specialist: Utilities: Service:

Environment Configuration: Text file.

4.4 Display setup

• Setting in the measurement program: (→p. 92, §5.7.15.7.1)

• Setting via external keyboard:

– CTRL ALT +

– CTRL ALT –

The settings are not saved.

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 39

Page 40

Commissioning

40 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 41

Operation

MCS100E

5 Operation

Operation

Status messages

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 41

Page 42

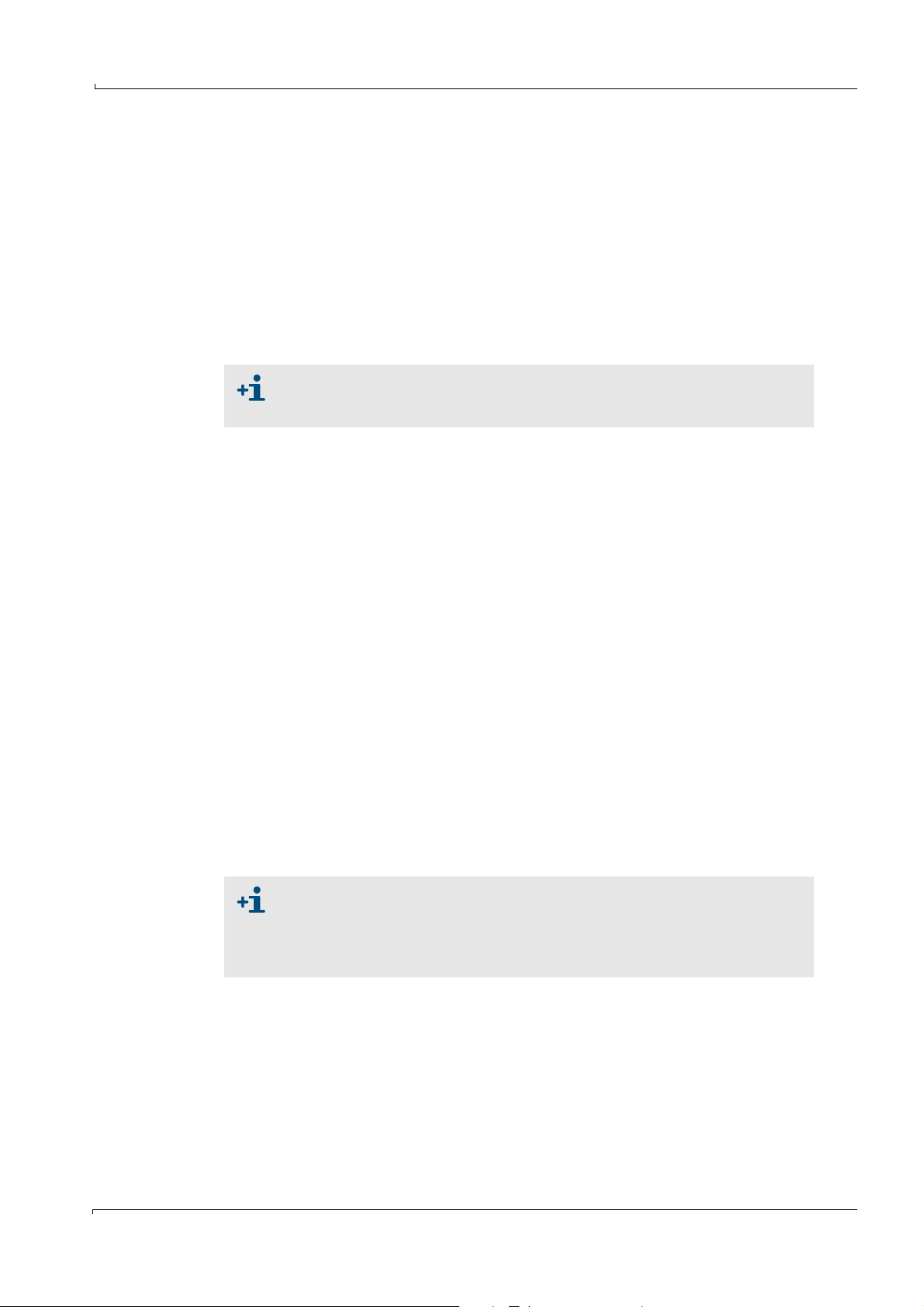

5.1 User interface

MCS 100 E

Key F1

Help

Monitor

Function keys

F3 ... F8

Numeric

keys

Cursor keys

Key

<ENTER>

Key

<ESC>

Key F2

Measured value

display

5-pole DIN

connector

for external

keyboard

Figure 17 Front of MCS100E with controls

Operation

Screen saver

The screen is automatically switched off after approx. 4 h if no key was pressed

during this period.

Press any key to switch the screen on again.

Normally, the “Digital Input 1” is designed for a corresponding external pin

switch (pre-set).

MCS100E is operated

• In measuring mode via the membrane keyboard.

• For setting parameters it is suitable to use an external keyboard (

5.1.1 Significance of keys

Arrow keys

Within the menus you can move up and down, resp. left and right using the arrow keys.

Numerical keys

Enter the appropriate characters into those lines where you are expected to enter figures

only. (Please use an external keyboard, if letters must be entered.)

<ESC> key

The <ESC> key is used to quit the menus, to terminate the program, to cancel a command,

etc. If modifications were entered you will be prompted whether to save or not.

<ENTER> key

The <ENTER> key is used to open a menu, to confirm entries, etc.

→

p. 39, §4.2).

Subject to change without notice

42 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 43

Operation

F1 key (question mark)

The F1 key is used to go to a help menu. You will get help information on the actually used

menu. The help information is related to the highlighted line, resp. the field where the entry

mark is actually positioned. Use ESC to proceed within and/or quit the help menu.

From a menu field F1 displays:

• The revision number of the software

• The memory available on the flash disk

• The actually free main memory

• The assignment of the graphic buffers

• The addresses of the I/O module boxes connected

• General help

F2 key (measurement icon)

By means of the F2 key you quit the menu actually in use and return to the measured value

display. Any changes made beforehand in the menu will be ignored.

Function keys F3 ... F8 (softkeys)

Different actions can be initiated with the function keys F3 ... F8 (softkeys), depending on

the menu. The respective significance of the function key is shown at the bottom edge of

the screen above the respective key.

5.1.1.1 Entering alphanumerical characters

1 Highlight the line in question.

2 Keep pressing function key F8 until the required character is displayed in the function

key fields.

3 Press the function key which is positioned below the required character.

It is best to use an external keyboard for entering characters (→p. 39, §4.2).

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 43

Page 44

5.2 Data and program storage

5.2.1 Structure of directories

The MCS100E software is located in a directory of its own,

containing:

• The configuration program

•The measurement program (1.bat) itself

• The text and help files (.txt and .hlp)

• Some other files associated with the program

The call-in .bat files (1.bat and mcsconf.bat) are in the directory C:\BAT\

Each “System” (

→

p. 68, §5.7.11) created in the measurement program automatically

creates an own subdirectory containing the system's default settings as well as the

measured values and the messages of the message lines. The name of this directory is

identical to the system's name.

Automatically and intermediately saved files are stored on drive d: (default setting).

The structure of the directories has to be entered in the configuration program (

§9.1.3.4) in Directories and Files.

5.2.2 Data files

The data files contain the measured values or status messages.

The name of the data files contains date and time of file creation, the last letter identifying

the type of file.

File name: MMtthhmm.jjx

→

p. 123,

Operation

MM: Month

tt: Day

hh: Hours

mm: Minutes

jj: Year

x: x = 1: Messages from status bar 1

x = 2: Messages from status bar 2

x = d: Measured values stored

Example: 01230856.09d: The file was created on January 23

contains measured values.

When 100 status messages are reached, a new file is automatically created (max. 5 files

per status bar, the oldest file is overwritten).

Memory required for measured values

Per component with a cycle time of 60 seconds => approx. 10 Kbyte memory required per

day.

The memory available is displayed in the main menu:

•Via function key F1

• In the graphics at the upper edge of the screen (when storage is “active”).

5.2.3 Program files

Files with names identical to their associated directory contain the measuring sequence

(=system).

rd

, 2009 at 08.56 and

Subject to change without notice

44 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 45

Operation

5.3 Starting the measurement program

MCS100E starts the measurement program and thus measurement:

• Automatically when MCS100E (

• AT DOS level by means of the 1.bat program (

After the start of the measurements, the measured value display is shown.

To go to the main menu: Press <ESC>.

Which system (= measuring system) is started depends on the MCSCONF

(

→

p. 123, §9.1.3.4 Directories and Files).

If you wish another system to be started automatically, the entries in the

MCSCONF must be modified accordingly.

If you wish another system to be activated temporarily: Menu: Specialist:

System, activate for measurement.

5.3.1 Automatic start

Upon start, several prompts are displayed with which the automatic program start can be

aborted.

If there are no entries, the program starts automatically.

→

§5.3.1) is switched on.

→

§5.3.2).

5.3.2 Starting from the DOS level

Enter: 1 <ENTER>

Parameters for the 1.bat program

5.3.3 Aborting the start

To go to the DOS level: Answer within 2 seconds to <Start Program Y/N> with <N>.

If required, disable the watchdogs (→p. 109, §7.8).

→

p. 109, §7.7

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 45

Page 46

5.4 Stopping and starting measurement

5.4.1 STOP, START measurement

Menu: Specialist: Utilities: Service: STOP, START measurement

• Upon measurement “STOP”, all interfaces (e.g. I/O module boxes) are inactivated.

• Upon measurement “START”, all interfaces are initialized anew and measurement is

started.

5.4.2 Quitting the measurement program

1 To quit the measurement program: Enter <ESC> repeatedly until a screen prompt for

exiting the measurement program is displayed.

2 A password must be entered.

The password input is not displayed on the screen.

Definition of password: →p. 121, §9.1.3.1

The password is identical with the password at “Specialist level”.

3 You are then at DOS level.

4 If required, disable the watchdogs (

→

p. 109, §7.8).

To be sure that - after having quit the program - MCS100E is in the basic

condition (important e.g. for configuration of the I/O module boxes):

Boot the MCS100E (<CTRL-ALT-DEL> or switch off/on).

Operation

46 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 47

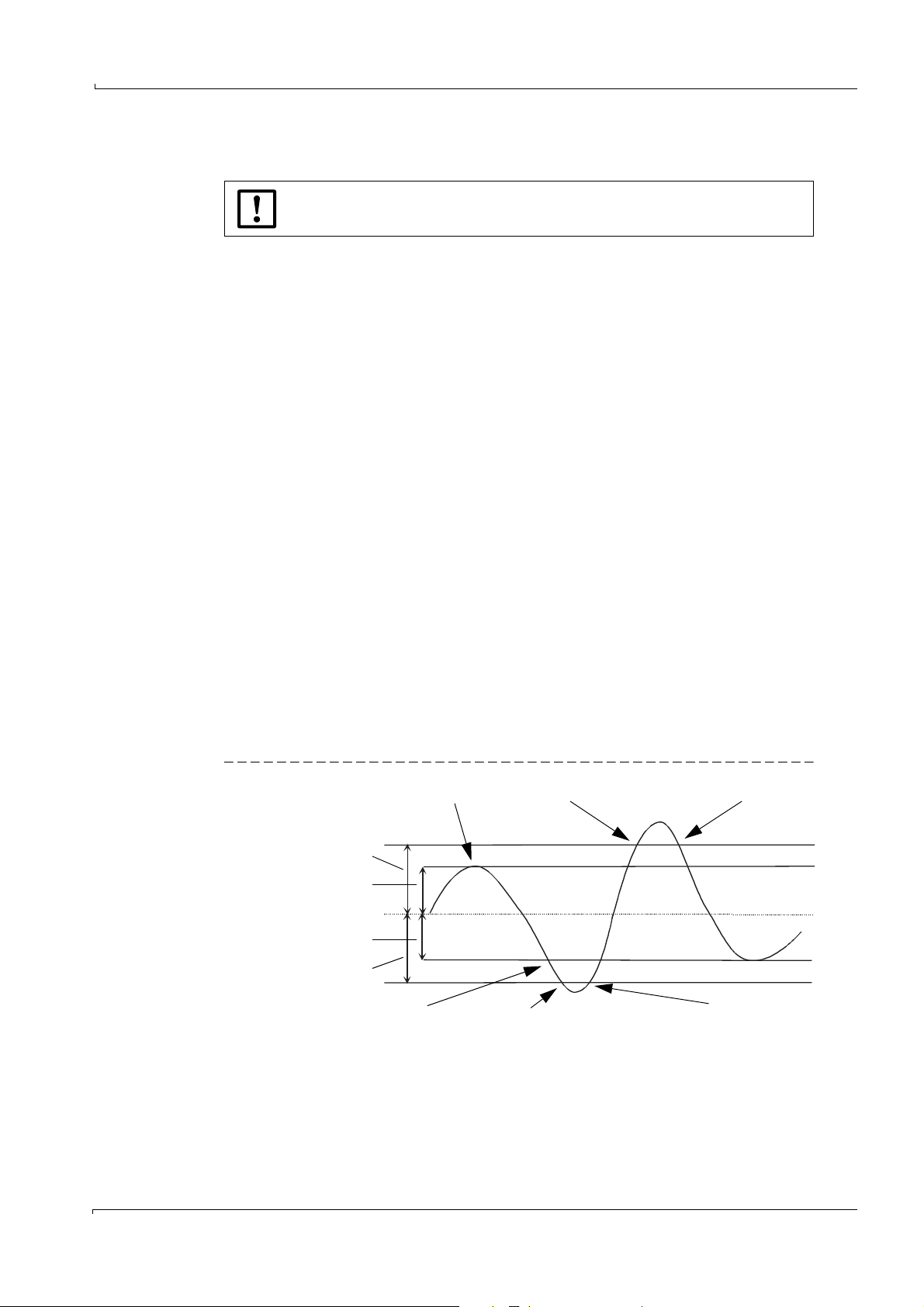

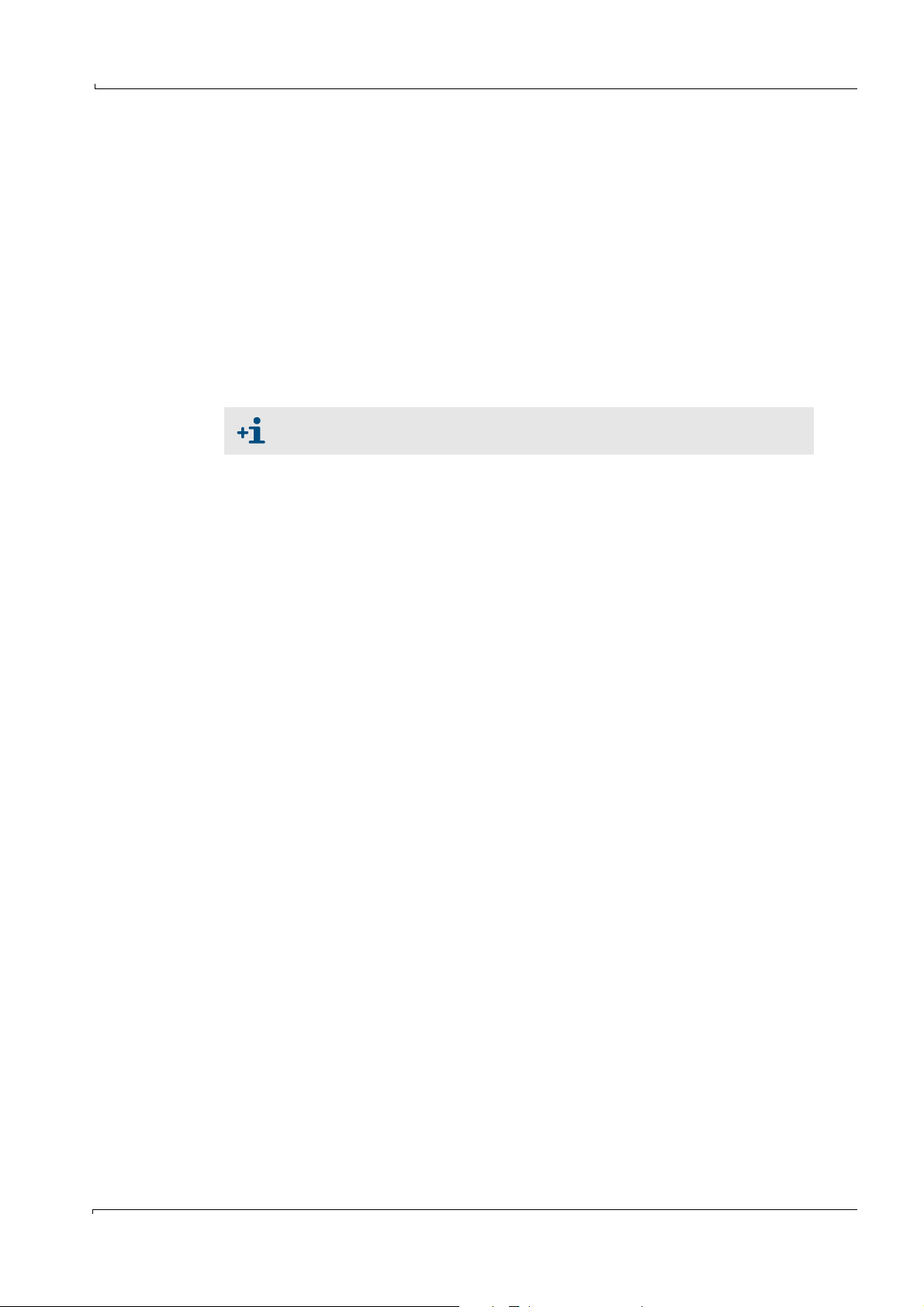

Operation

Status bar 2

Status bar 1

Measurement sequence

(= system)

Sample point

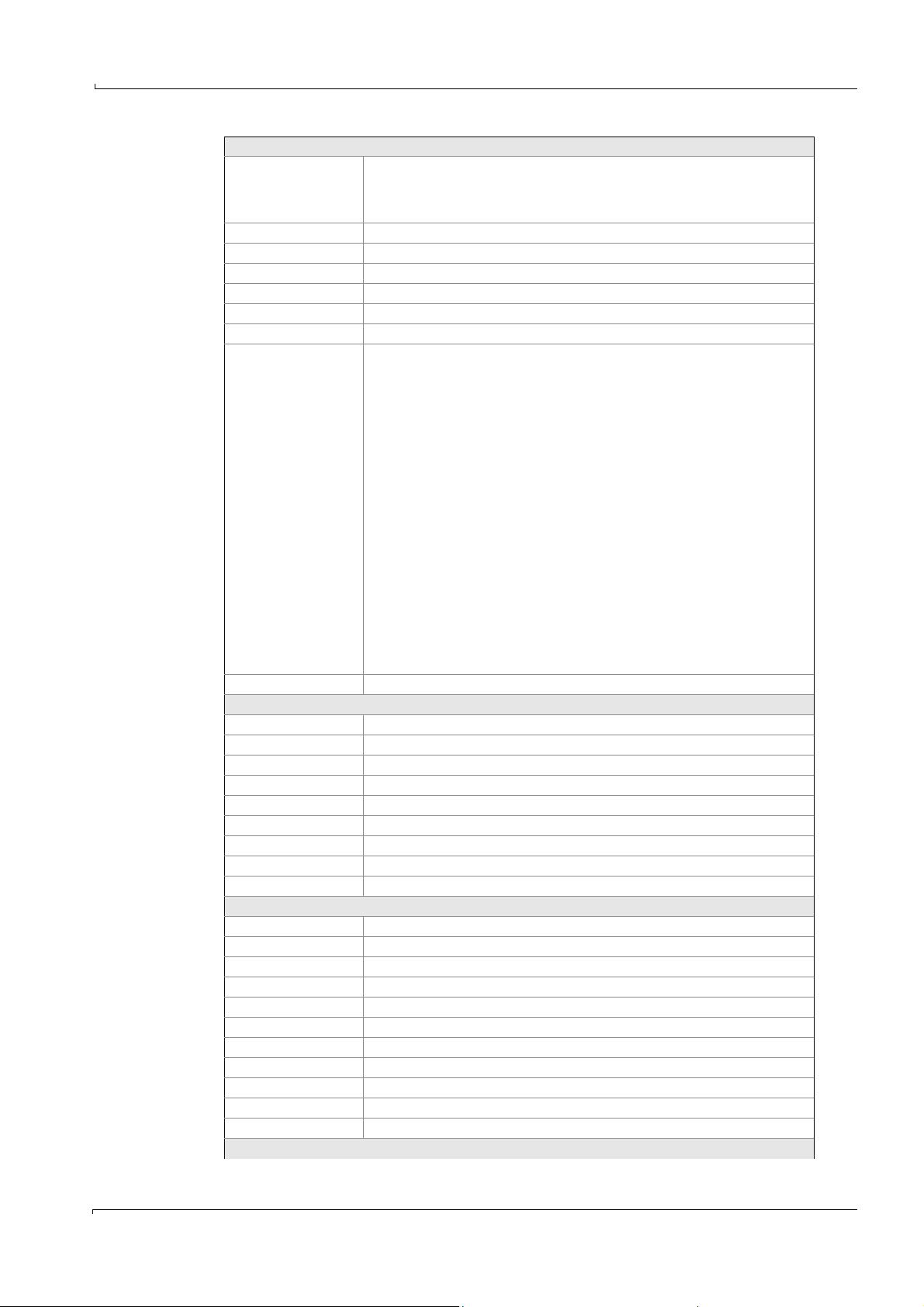

5.5 Status bars

Figure 18 Status bars

Up to 3 status bars are displayed:

• At the top screen margin one information line with information on the current

measurement.

This line is not archived.

• Two status bars at the bottom screen margin:

– Upper line (status bar 2): Fix, contains the operational state.

– Lower line (status bar 1): Flashing, contains warnings and messages.

– If no status bar is displayed, there is no active status.

– Status bars 1 and 2 are saved in files (

→

p. 44, §5.2)

– Status bar 1 is output to the printer (if the on-line protocol Main Menu: Printer: Print

on-line: Protocol Start is active).

– If there are several active status messages, they are displayed successively (each

message for approx. 4 seconds).

– The texts associated to the status bars are programmed in the menu Specialist:

System edit: Message and corresp. relays.

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 47

Page 48

5.6 Using the menus

5.6.1 In Menu fields

Selection of a sub-menu Arrow keys, then <ENTER>

Quit menus/graphics <ESC> (you are prompted whether or not to save

Selection from a list Arrow keys, then <ENTER>

Counting upwards in the numbering of lists <ENTER>

Counting downwards in the numbering of lists <–> (Minus key)

Entry of numbers Numerical keys

Entry of texts Alphanumerical keys

Switching from insertion to overwrite <INS (EINFG)>

Accept prompt <ENTER>

Reject prompt <ESC>

Interrupt printing <ESC>

5.6.2 In Entry menus

De-/Activate components ( )<ENTER>

Toggle (e.g. 0/4 .. 20 mA, decimals) <ENTER>

Activate an entry line <ENTER>

Entry of numbers (e.g. measurement ranges) Numerical keys

Entry of texts (e.g. messages) Alphanumerical keys

Copy text lines <Shift–F3>

Display list of names <Shift–F6>

Termination of entries:

Accept modifications performed

Reject modifications performed

Quit menus <ESC> (you are prompted whether or not to save

Operation

any modifications)

<ENTER>

<ESC>

any modifications)

You are not allowed to make entries in the fields that are automatically skipped. Entries in

these fields can only be made in the relevant menus (of the same name) in the specialist

level.

5.6.3 In file selection lists

Change sorting algorithms <–> or <+>

Go to top margin line <> (arrow key left)

Tag files <Space key>

Edit tagged files <ENTER>

Reject entries <ESC>

Subject to change without notice

48 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Page 49

Operation

5.6.4 Safety prompts

Before saving changes in some menus you will be prompted whether or not the changes

should be accepted.

Yes The changes performed are accepted and saved.

No The changes performed are ignored.

In some menus you will be prompted additionally, whether or not the changes performed

should be accepted for the current measurement sequence.

Yes The changes performed are immediately applied to the current measurement sequence.

No The changes performed are saved and only applied after starting the next measurement

Function of keys

Accept safety prompt <J> (Y) or <ENTER> on Yes field

Reject safety prompt <N> on Yes field or <ENTER> on No/Cancel field

Ignore safety prompt <ESC>

1

Starting from the “Yes” field, the No/Cancel field will only be displayed when pressing “once the

arrow key, right”.

If the safety prompt is not answered within 120 seconds, then it will automatically be

answered “No”.

sequence.

1

Subject to change without notice

MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG 49

Page 50

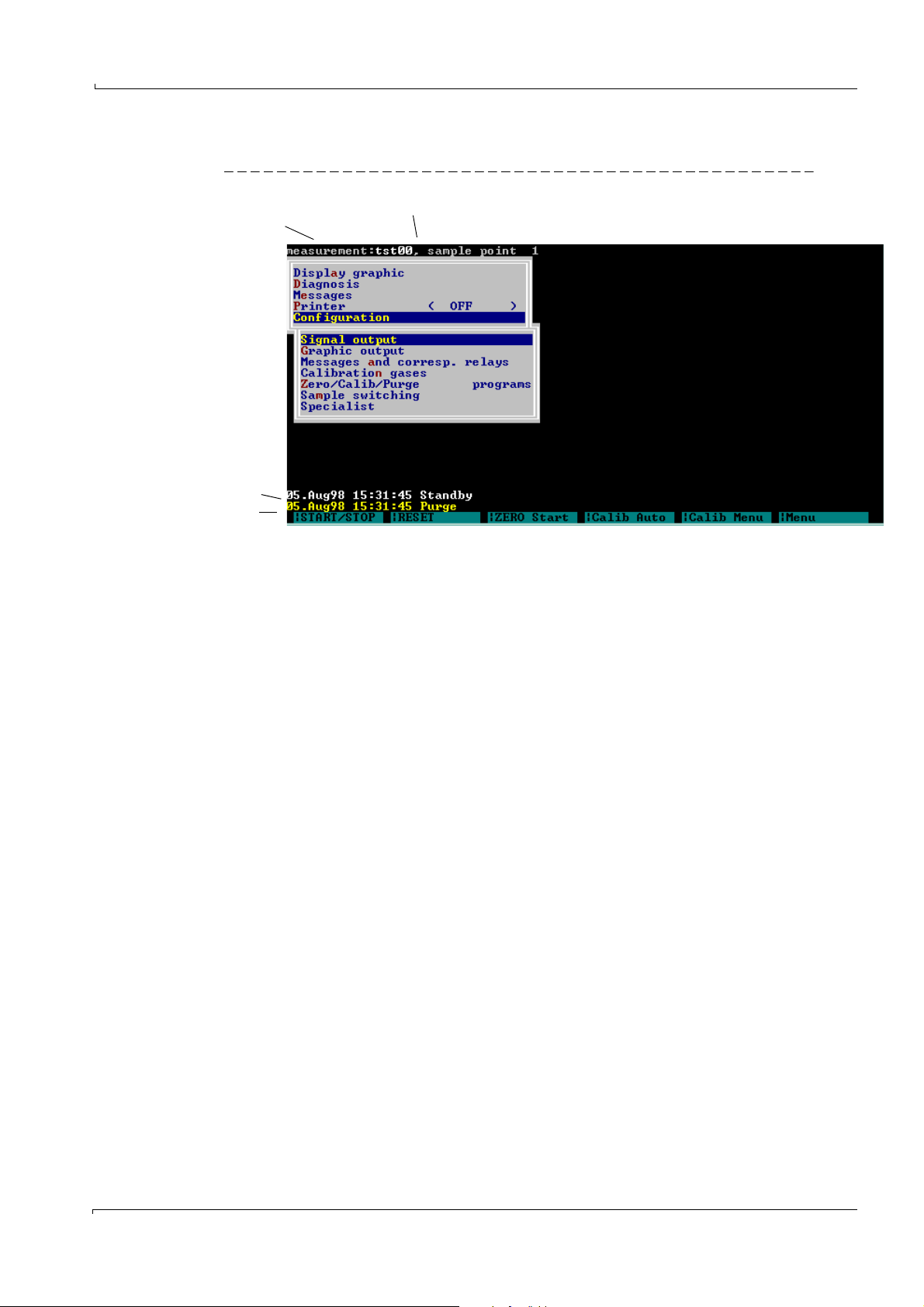

5.7 Menus

5.7.1 Main menu

5.7.2 Specialist: System edit

Operation

5.7.3 Specialist: Utilities

50 MCS100E Operating Instructions 8009504/VYWA7/V3-1/2018-01 © SICK AG

Subject to change without notice

Page 51

Operation

5.7.4 Specialist: Utilities: Service: Environment configuration

Subject to change without notice