Page 1

O P E R A T I N G I N S T R U C T I O N S

MAX

Linear encoder

Page 2

Product described

MAX linear encoder

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 3

Contents

1 About this document........................................................................ 6

1.1 Purpose of this document........................................................................ 6

1.2 Target audience........................................................................................ 6

1.3 Further information................................................................................... 6

1.4 Symbols and document conventions...................................................... 6

1.4.1 Warning levels and signal words............................................. 6

1.4.2 Information symbols................................................................ 6

2 Safety information............................................................................ 7

2.1 General notes............................................................................................ 7

2.2 Intended use............................................................................................. 7

2.2.1 Purpose of the device.............................................................. 7

2.3 Responsibility of user............................................................................... 7

3 Product description........................................................................... 9

3.1 Device variants......................................................................................... 9

3.2 Product identification............................................................................... 9

3.3 Construction and function........................................................................ 10

4 Mounting............................................................................................. 12

4.1 Preparation before installing the encoder.............................................. 12

4.1.1 Installation cavity for the linear encoder................................ 12

4.1.2 Installation cavity for the piston and piston rod.................... 13

4.1.3 Insertion chamfer.................................................................... 14

4.1.4 Bore hole for the retaining screw............................................ 14

4.1.5 Bore hole for the electrical connection.................................. 15

4.1.6 Installation cavity for the position magnet............................. 17

4.2 Installing the position magnet................................................................. 17

4.3 Installing the encoder............................................................................... 18

4.3.1 Positioning the O-ring and support ring................................. 18

4.3.2 Insertion in the cylinder........................................................... 19

4.3.3 Installation with an M12 connector system........................... 20

4.3.4 Installation with a cable connector and cable gland............. 21

4.4 Install the retaining screw........................................................................ 22

4.5 Cylinder handling after encoder installation........................................... 22

4.5.1 Washing and drying the cylinder............................................. 22

4.5.2 Electrostatic painting of the cylinder...................................... 23

4.5.3 Mounting the cylinder on mobile hydraulic machines.......... 23

4.5.4 Electrical and electrostatic interference................................ 23

5 Electrical installation........................................................................ 25

5.1 Electrical connection................................................................................ 25

5.1.1 Connection diagram, pin assignment for 4-pin M12 male

connector................................................................................. 25

CONTENTS

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

3

Subject to change without notice

Page 4

5.1.2 Cable connection diagram...................................................... 25

5.1.3 Connection diagram, pin assignment for 5-pin M12 male

connector................................................................................. 25

5.1.4 Connection sequence.............................................................. 26

5.2 Connection diagram for vehicle electronics............................................ 26

6 Commissioning.................................................................................. 27

6.1 Putting the encoder into operation.......................................................... 27

6.2 Select a suitable fuse............................................................................... 27

6.3 Set up the filter wiring - analog................................................................ 27

6.4 Power-up and output signal in the event of a fault................................. 27

6.5 Bus termination - digital........................................................................... 28

6.6 Tolerance considerations for the set point............................................. 28

6.7 CAN bus protocols.................................................................................... 29

6.8 Communication objects........................................................................... 30

6.8.1 CANopen................................................................................... 30

6.8.2 SAE J1939................................................................................ 31

6.9 Configuration and system startup........................................................... 31

6.9.1 Configuring CANopen.............................................................. 31

6.9.2 Configuring SAE J1939........................................................... 33

6.9.3 System startup for CANopen................................................... 34

6.9.4 System startup for SAE J1939................................................ 34

6.9.5 Setting CANopen operating parameters................................ 34

6.9.6 Setting SAE J1939 operating parameters............................. 36

6.9.7 CANopen encoder data during operation............................... 36

6.9.8 SAE J1939 encoder data during operation............................ 36

6.9.9 CANopen error messages....................................................... 36

6.9.10 SAE J1939 error messages.................................................... 37

7 Maintenance...................................................................................... 38

7.1 Error table................................................................................................. 38

7.2 Checking the functioning of the encoder................................................ 38

7.3 Repairs...................................................................................................... 39

7.4 Testing and programming........................................................................ 40

8 Transport and storage....................................................................... 41

8.1 Transport and storage conditions............................................................ 41

9 Decommissioning............................................................................. 42

9.1 Dismantling............................................................................................... 42

9.2 Disposal..................................................................................................... 42

10 Technical data.................................................................................... 43

10.1 MAX Analog/PWM..................................................................................... 43

10.2 MAX Digital CANopen / SAE J1939......................................................... 46

10.3 Encoder dimensions................................................................................. 48

10.4 Position magnet dimensions.................................................................... 49

CONTENTS

4

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 5

10.5 M12 flange dimensions........................................................................... 50

11 Annex.................................................................................................. 51

11.1 Accessories............................................................................................... 51

11.2 Spare parts............................................................................................... 53

11.3 CE Declaration of Conformity................................................................... 55

CONTENTS

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

5

Subject to change without notice

Page 6

1 About this document

1.1 Purpose of this document

In the following instructions, the MAX linear encoder is referred to simply as “encoder”

or “device”.

These operating instructions describe:

•

Device components

•

Mechanical preparation of the device

•

Electrical preparation of the device

•

Necessary maintenance work for safe operation

1.2 Target audience

This document is intended for technicians (persons with technical expertise) tasked

with installing and maintaining the device.

These technicians must be trained on the device.

Only trained electricians are permitted to carry out work on the electrical system or

electrical assemblies.

1.3 Further information

•

MAX quickstart

•

Technical information - interface description

MAX product pages

•

www.sick.com/MAX48

•

www.sick.com/MAX30

1.4 Symbols and document conventions

1.4.1 Warning levels and signal words

Important

Hazard which could result in property damage.

Note

Tips

1.4.2 Information symbols

Table 1: Information symbols

Icon Meaning

Important technical information for this product

Important information about electrical or electronic functions

1 ABOUT THIS DOCUMENT

6

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 General notes

Should persons be placed at risk, or operating equipment potentially be damaged in

the event of a malfunction or failure of the device, this must be prevented by means of

suitable protective devices, e. g., emergency shutdown systems.

If the device is not functioning correctly, it must be taken out of operation and secured

against unauthorized operation.

To guarantee proper operation of the device, please observe the following:

•

Protect the device against mechanical stress during installation

•

Do not open the device

•

Connect the device with the correct polarity, supply voltage, and control pulses

•

Observe the permissible operating and ambient conditions for the device

•

Regularly check the device for correct operation and document the results

2.2 Intended use

2.2.1 Purpose of the device

The MAX linear encoder is designed for position measurements in mobile hydraulic

applications and therefore can be used to control the hydraulic components of con‐

struction machinery; e.g., in hydraulic cylinders. The rugged housing offers optimum

protection against dust, climatic influences, vibrations, surrounding media, as well as

electrical and magnetic fields.

The device is an accessory and must be connected to a suitable electronic control unit.

2.3 Responsibility of user

Designated users

see "Target audience", page 6.

Correct project planning

•

This document assumes that appropriate project planning has been carried out

before delivery of the device (e.g., based on the SICK application questionnaire),

and the device is in the required delivery state based on that planning (see sup‐

plied system documentation).

w

If you are not certain whether the device corresponds to the state defined

during project planning or in the supplied system documentation, please con‐

tact SICK Customer Service.

Special local conditions

In addition to the instructions in this Technical Information, follow all local laws, techni‐

cal rules and company-internal operating directives applicable at the respective device

installation location.

Read the operating instructions

b

Read and follow the operating instructions in this document

b

Follow all safety notes

b

If there is anything you do not understand, please contact SICK Customer Service

SAFETY INFORMATION 2

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

7

Subject to change without notice

Page 8

Retention of documents

These operating instructions:

b

Must be made available for reference.

b

Must be conveyed to new owners.

2 SAFETY INFORMATION

8

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 9

3 Product description

3.1 Device variants

The device is available in the following variants:

•

M12 male connector (4-pin or 5-pin) or 3-wire PUR cable

Output signals

•

Analog (current, voltage)

•

PWM

•

Digital (CANopen, SAE J1939)

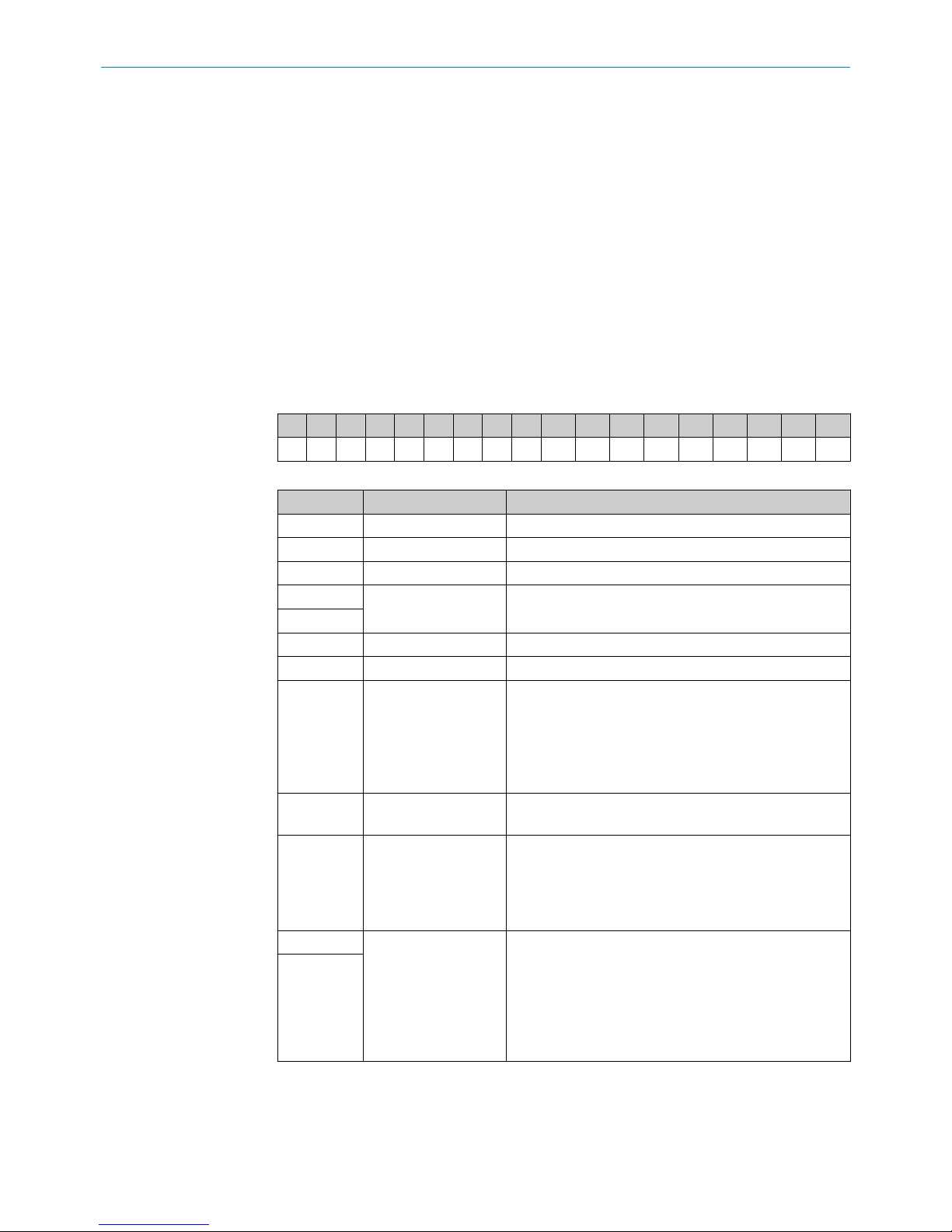

3.2 Product identification

Type code

Table 2: Type code (example)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

M T X 4 8 N - 1 1 R 1 0 T T

Table 3: Type code Explanation

Position Meaning Description

1 Series M = Mobile

2 Technology A = Magnetostrictive

3 Installation type X = Integrated (hydraulic cylinder)

4 Size 48 = MAX48 diameter

30 = MAX30 diameter

5

6 Version N = Non-Safety

7 Place holder -

8 Diameter

Pressure pipe

1 = 10 mm / 30 mm damping

2 = 10 mm / 36 mm damping

3 = 10 mm / 63 mm damping

7 = 7 mm / 30 mm damping

8 = 7 mm / 36 mm damping

9 = 7 mm / 63 mm damping

9 Voltage supply 1 = 12 VDC

2 = 24 VDC

10 Electrical

Interface

V = Voltage

A = Current

C = Digital CANopen (250 kbit)

J = Digital SAE J1939 (250 kbit)

P = pulse-width modulation, 5 V signal

11 Signal output 10 = current (4 ... 20 mA)

10 = voltage (0.50 ... 4.50 V)

21 = voltage (4.75 ... 0.25 V)

7F = CANopen (node ID 7F Hex)

JD = SAE J1939 (source address JD Hex)

B = pulse width (10 ... 90%)

D = frequency (250 Hz)

12

PRODUCT DESCRIPTION 3

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

9

Subject to change without notice

Page 10

Position Meaning Description

13 Connection type A = M12 4-pin analog / PWM

(1 = VDC; 2 = n.c.; 3 = GND; 4 = SIG)

B = M12 4-pin analog / PWM

(1 = VDC; 2 = SIG; 3 = GND; 4 = n.c.)

M= M12 4-pin analog

(1 = n.c.; 2 = VDC; 3 = GND; 4 = SIG)

K = analog cable connection / PWM 3-wire cable

C = M12 5-pin digital

(1 = n.c.; 2 = VDC; 3 = GND; 4 = CAN_HI; 5 = CAN_LO)

D = M12 5-pin digital

(1 = VDC; 2 = n.c.; 3 = GND; 4 = CAN_HI; 5 = CAN_LO)

14 Connector length A = 60 mm M12

E = 100 mm M12

15 Measuring range

Position measurement

in 1 mm steps

e.g., 0300 = 50 ... 300 mm

16

17

18

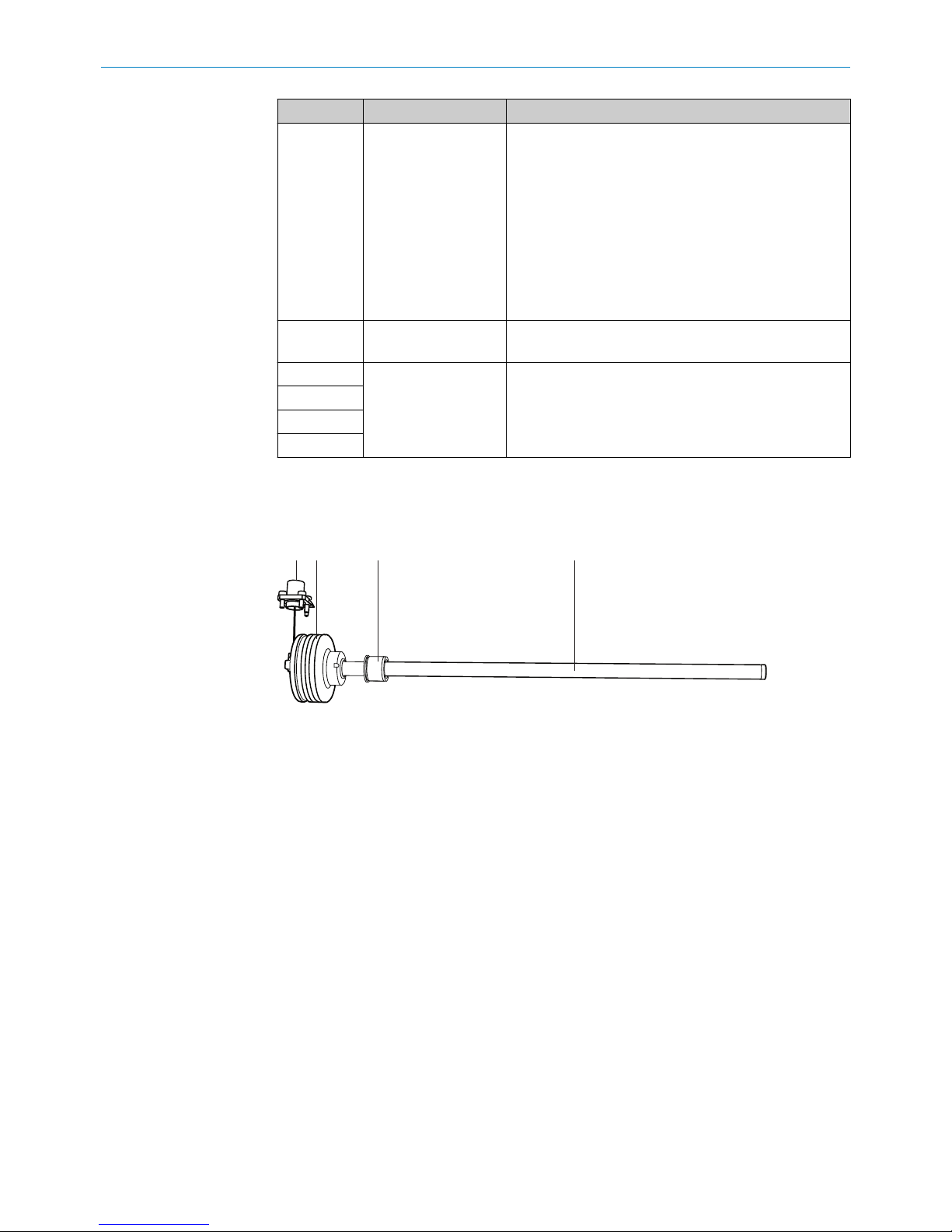

3.3 Construction and function

Construction of the device

1

2 3 4

Figure 1: MAX design

1

M12 connector system

2

Protective housing (electronics)

3

Position magnet

4

Pressure pipe

Connector system:

The M12 connector system requires very little time to attach. It is suitable for applica‐

tions in harsh environments up to IP69K (when using a suitable mating connector).

Protective housing (electronics):

The housing is designed to be installed in a hydraulic cylinder and protects the electron‐

ics against external influences.

Position magnet:

The position magnet is the only moving component in the measuring device when

installed in the piston. The position magnet is located inside the piston and moves over

the pressure pipe without contacting it. The magnet field that is produced during this

process defines the current position of the piston.

Pressure pipe:

The pressure pipe is a pressure-resistant structure that is immersed into the cylinder

piston rod. It contains the hermetically protected magnetostrictive sensing element.

3

PRODUCT DESCRIPTION

10

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 11

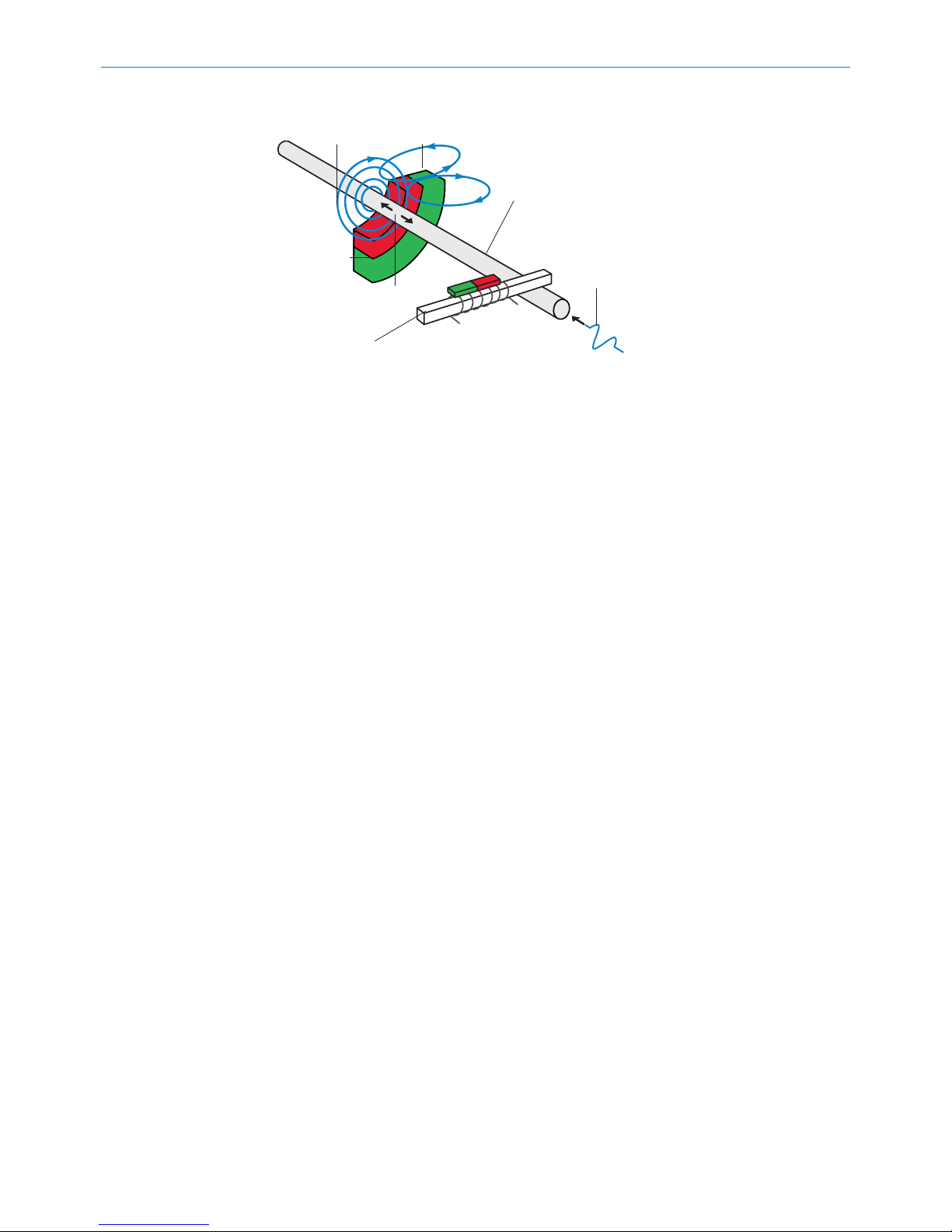

Principle of operation

21

3

4

5

6

7

Figure 2: Schematic of the magnetostrictive measurement principle

1

Magnet field of the current pulse

2

Magnet field of the position magnet

3

Magnetostrictive sensor component

4

Current pulse

5

Sound wave converter

6

Structure-borne sound wave

7

Position magnet

The device operates on the magnetostrictive measurement principle that records the

actual path of a position magnet:

The radial magnet field (1) generated by the current pulse (4) interacts with the magnet

field (2) of the position magnet (7).

As a result of the interaction of the two magnet fields, a wave (ultrasonic) (6) is pro‐

duced in the magnetostrictive device component (3). This travels to the converter (5),

and the electronics produce an electrical output signal.

The time interval between the current pulse and the detection of the structure-borne

sound wave is measured, thereby enabling the precise position of the magnet – which

changes as the cylinder moves – to be determined. As this measurement principle does

not require a reference point, no recalibration is necessary for this type of device.

The device is also maintenance-free as a result of the non-contact measurement.

PRODUCT DESCRIPTION

3

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

11

Subject to change without notice

Page 12

4 Mounting

4.1 Preparation before installing the encoder

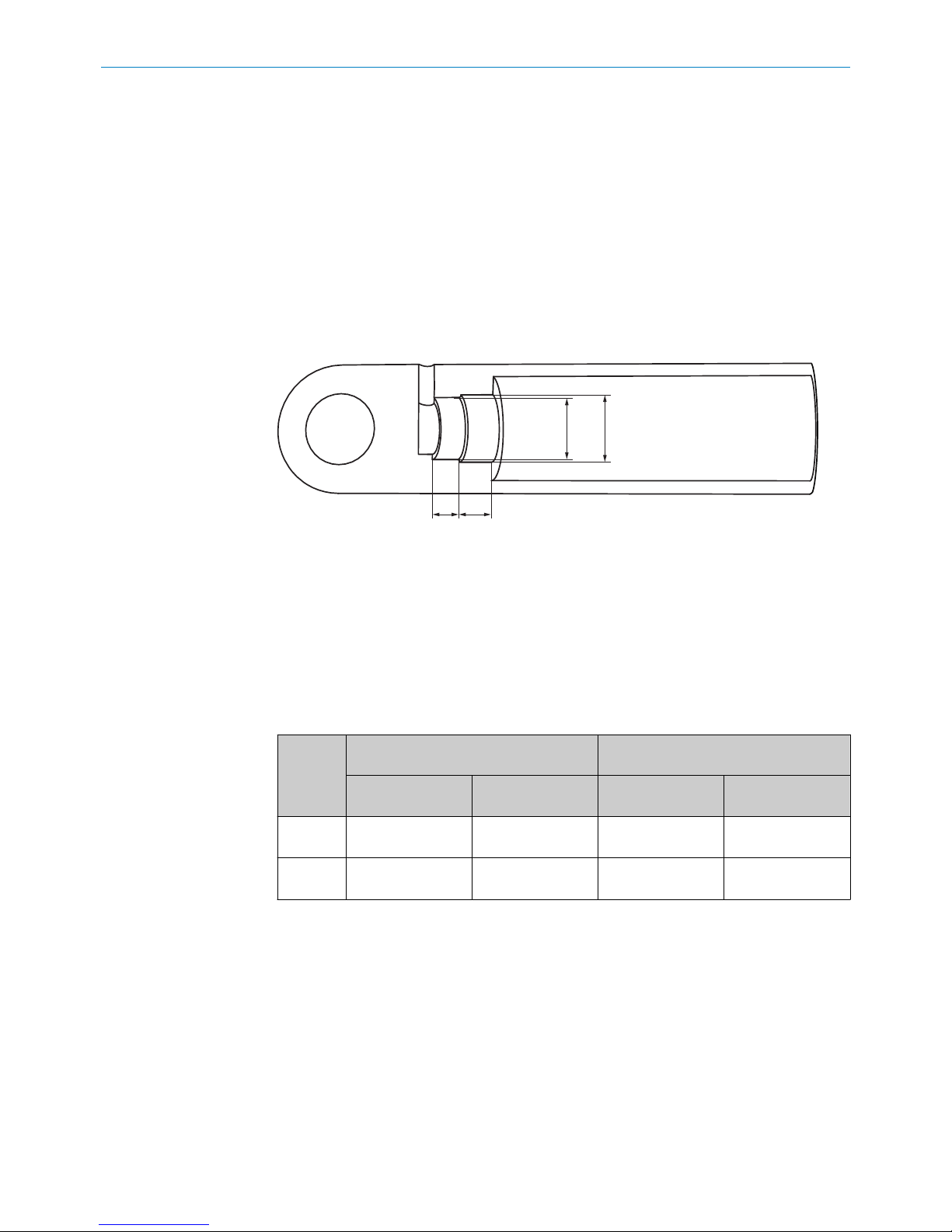

4.1.1 Installation cavity for the linear encoder

The method of installation depends on the cylinder design. Generally, the sensor is

installed from the piston rod side. It is also possible to install the sensor from the head

side of the cylinder.

The encoder dimensions are listed in the technical specifications: see "Encoder dimen‐

sions", page 48.

Fit dimensions and tolerances

4 2

3 1

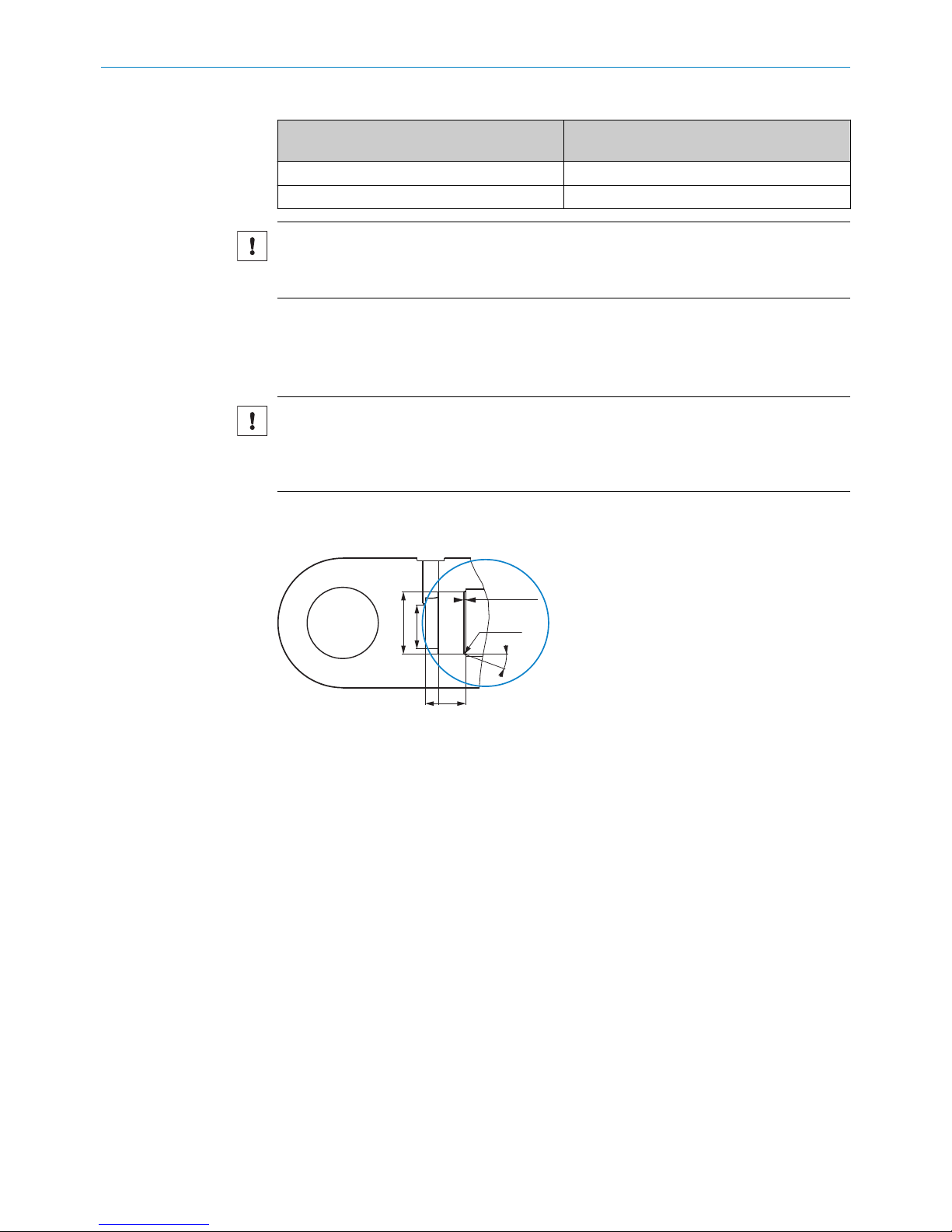

Figure 3: Encoder installation cavity dimensions

1

Diameter for housing bore hole

2

Depth for housing bore hole

3

Installation cavity diameter for electrical connection

4

Installation cavity depth for electrical connection

b

Prepare an installation cavity for the encoder according to the following dimen‐

sions.

Table 4: Installation cavity for the housing and electrical connection

Type Installation cavity for housing Installation cavity for electrical connec‐

tion

1

Ø

2

Depth [D]

3

Ø min. ... Ø max.4Depth [d]

MAX48 48H8 21.2 mm + 0.2 d > 32.5 mm

d < 40 mm

≥ 10 mm

MAX30 31H8 22.7 mm +0.2 d > 26 mm

d < 28 mm

≥ 10 mm

Mean roughness value of the surface: Ra < 0.8 mm.

4

MOUNTING

12

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 13

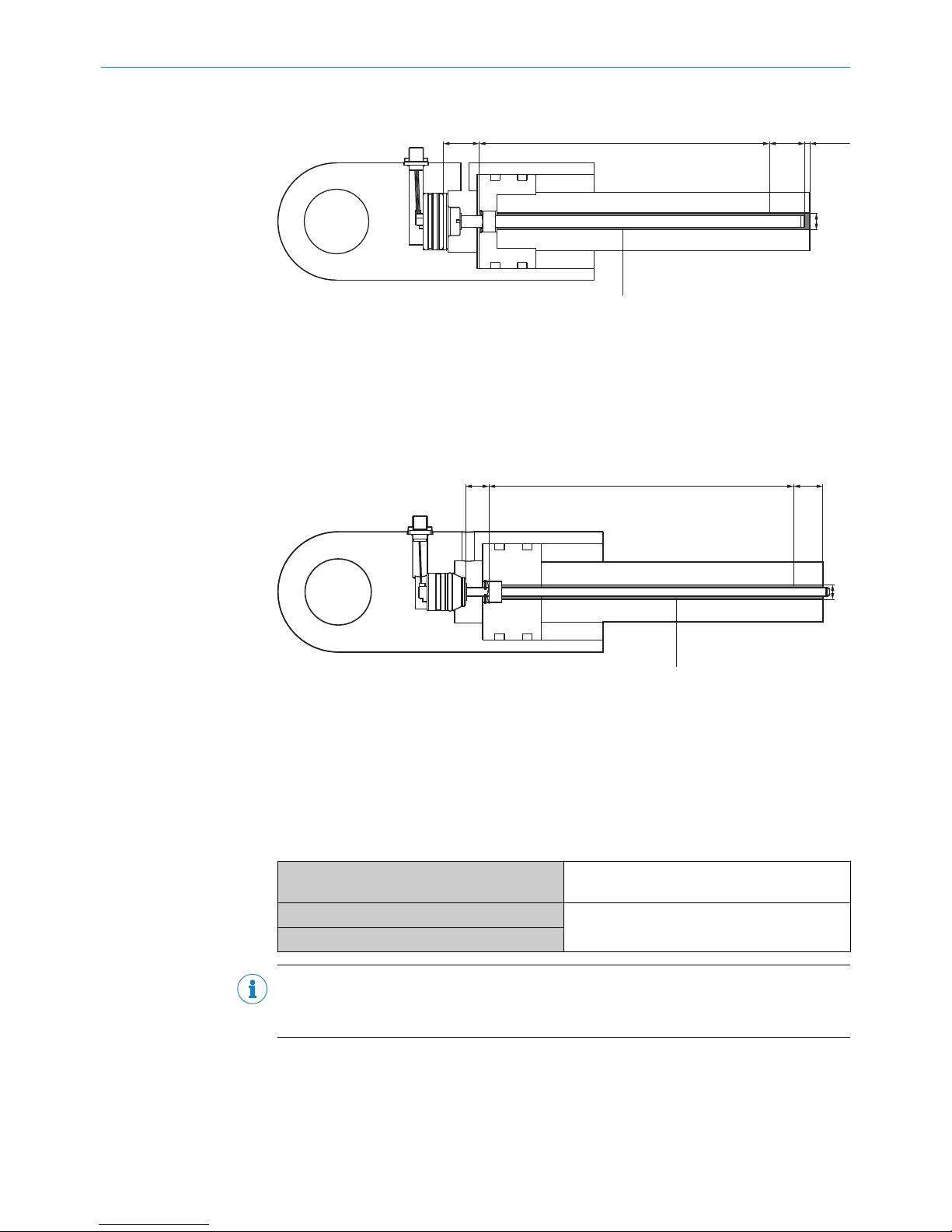

4.1.2 Installation cavity for the piston and piston rod

4

1

2

3

5

>3 mm

(0.12)

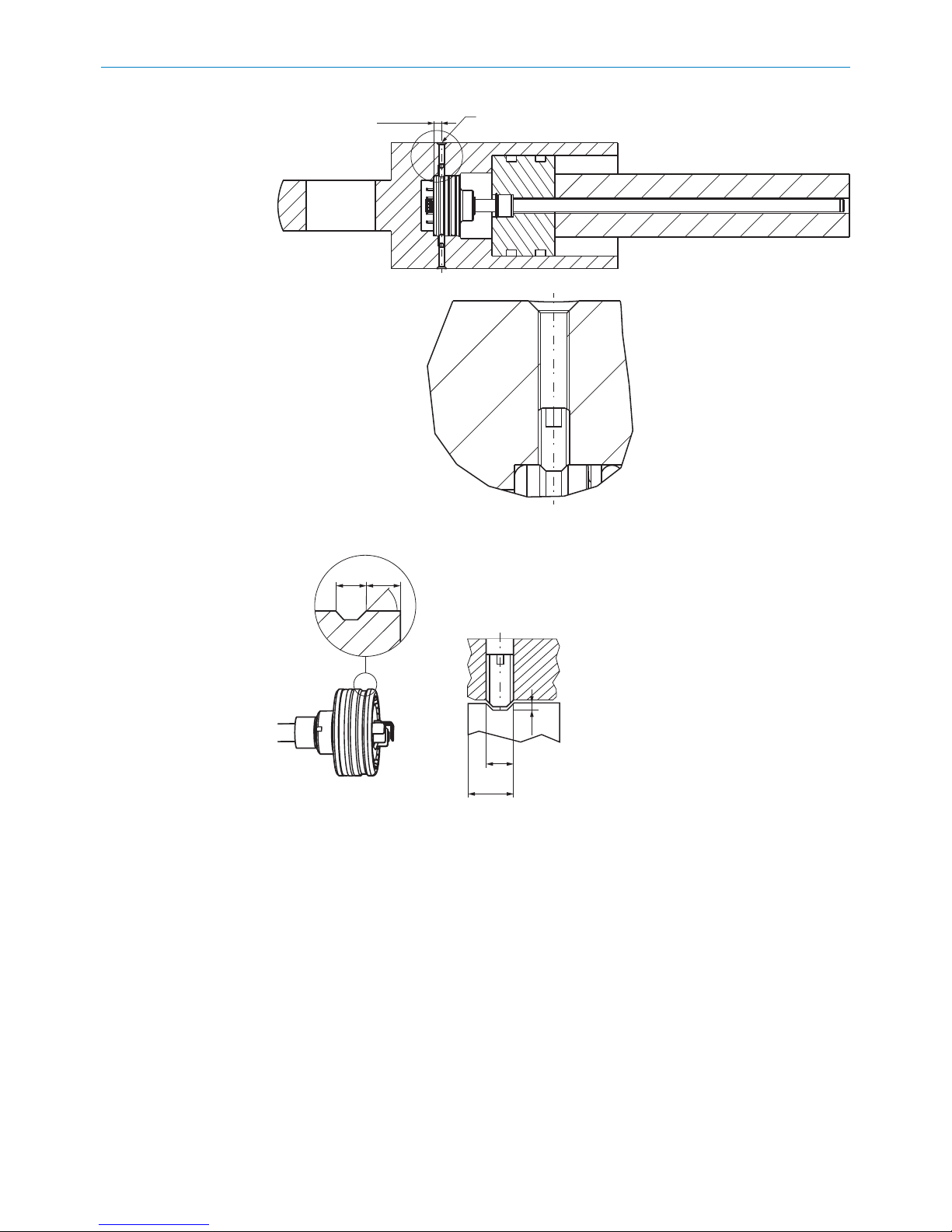

Figure 4: Encoder installed in the hydraulic cylinder – MAX48

1

Null zone

2

Measuring range

3

Damping

4

Diameter of the pressure pipe

5

Diameter of the piston rod bore hole

1 2 3

4

5

Figure 5: Encoder installed in the hydraulic cylinder – MAX30

1

Null zone

2

Measuring range

3

Damping

4

Diameter of the pressure pipe

5

Diameter of the piston rod bore hole

Table 5: Bore hole depth for the piston rod

1 = Null zone

MAX48: 30 mm

MAX30: 19.5 mm

2 = Measuring range

as per the applicable data sheet and selected

device variant

3 = Damping

NOTE

The total bore hole depth comprises the measuring range (2), the damping (3), and an

addition distance of 3 mm to the pressure pipe.

b

Prepare an installation cavity for the piston rod in accordance with the following

dimensions.

MOUNTING

4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

13

Subject to change without notice

Page 14

Table 6: Bore hole diameter for the piston rod

4

Ø Pressure pipe

5

Ø Bore hole in the piston rod

Ø 7 mm Ø 10 mm

Ø 10 mm Ø 12 mm / 13 mm

NOTICE

Ensure a consistent bore hole diameter of at least 12 mm.

Take into consideration the design and loading of the piston rod.

4.1.3 Insertion chamfer

To ensure proper and secure installation of the device in the cylinder, a insertion cham‐

fer must be provided.

NOTICE

Risk of damage to the device during installation

The device can be damaged by any sharp edges present at the transition from the cylin‐

der bore hole to the insertion chamfer on the O-ring.

b

Prepare an insertion chamfer with a radius of 0.6 mm at the end of the cylinder

bore hole.

d

21.2 +0.2

(0.83 +0.01)

min. 10

(0.39)

1.5 (0.06)

20°

R 0.6

(0.06)

Ø MAX

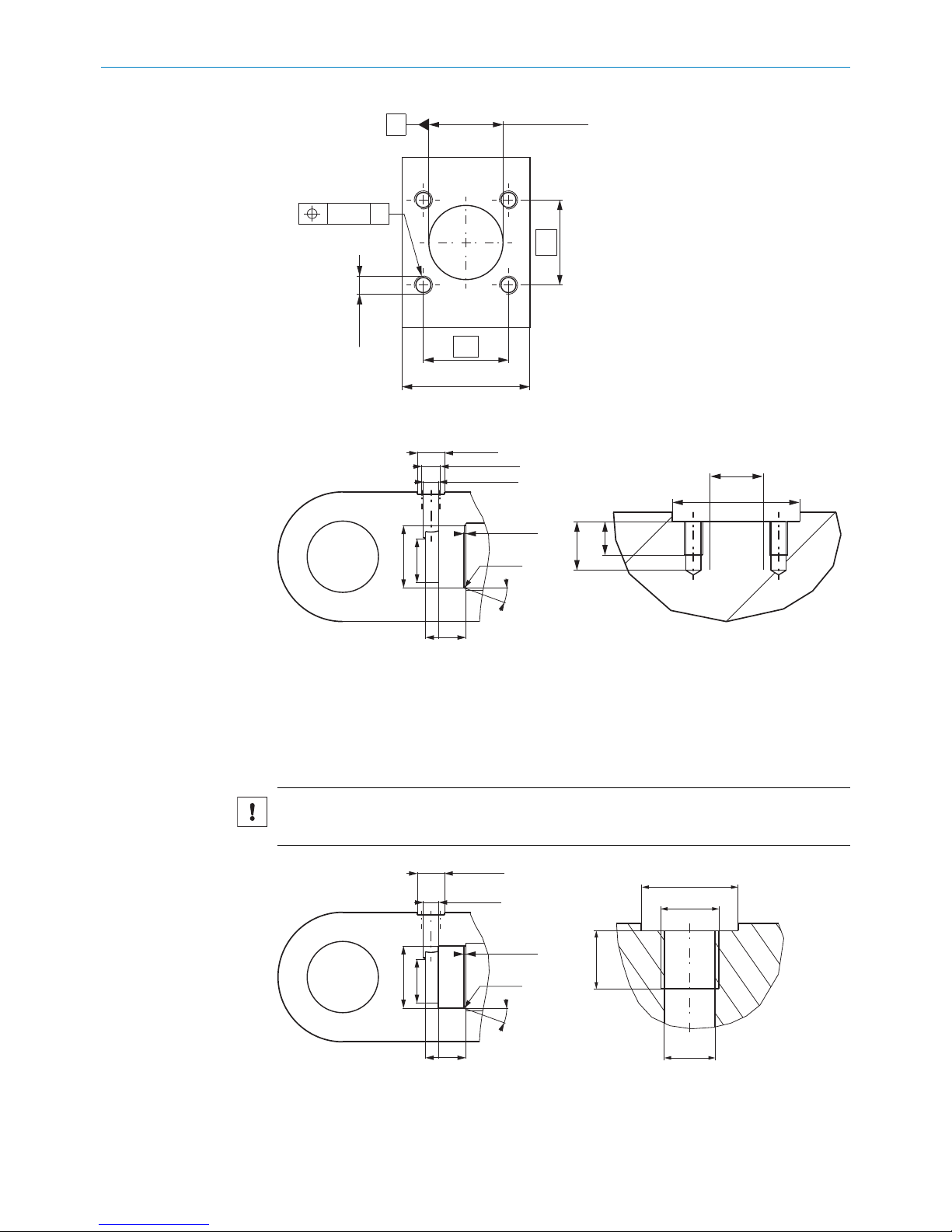

Figure 6: Insertion chamfer

4.1.4 Bore hole for the retaining screw

b

Prepare a bore hole for the retaining screw in accordance with the following dimen‐

sions.

4 MOUNTING

14

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 15

6.25 ±0.1

(0.25)

M5 x 8

Figure 7: Installation cavity for the retaining screw

45°

4

(0.16)

4.5

(0.18)

8.5

(0.33)

1

(0.04)

4.5

(0.18)

Figure 8: Retaining screw on the encoder housing

Permissible tightening torque for fastening screw: 0.5 Nm ... 1.0 Nm (taking into

account the maximum force on the housing surface).

4.1.5 Bore hole for the electrical connection

M12 flange

b

Prepare an installation cavity for the connector system and flange plate in accor‐

dance with the following dimensions.

MOUNTING 4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

15

Subject to change without notice

Page 16

14

14

21 ±0.2

(0.38 ±0.01)

Ø 12.2 ±0.1

(0.48)

A

AØ 0.1

4x

4 x M3

Figure 9: Dimensions of the flange plate bore holes

21 (0.83)

14 (0.55)

M12 x 1.5

(0.06)

d

min. 10

(0.39)

1.5 (0.06)

20°

R 0.6

(0.06)

8

(0.31)

5.5

(0.22)

21

(0.83)

Ø 12.2

(0.48)

Ø MAX

T

Figure 10: Dimensions of the connector system bore hole

Cable gland

b

Prepare an installation cavity for the cable gland according to the following dimen‐

sions.

NOTICE

b

Prepare a counterbore to suit the cable gland, see figure 40, page 52.

Ø 21 (0.83)

M 12 x 1.5

Ø 10.5

(0.41)

12

(0.47)

Ø 21 (0.83)

M 12 x 1.5

d

min. 10

(0.39)

1.5 (0.06)

20°

R 0.6

(0.06)

Ø MAX

T

Figure 11: Dimensions of the cable gland bore hole

4 MOUNTING

16

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 17

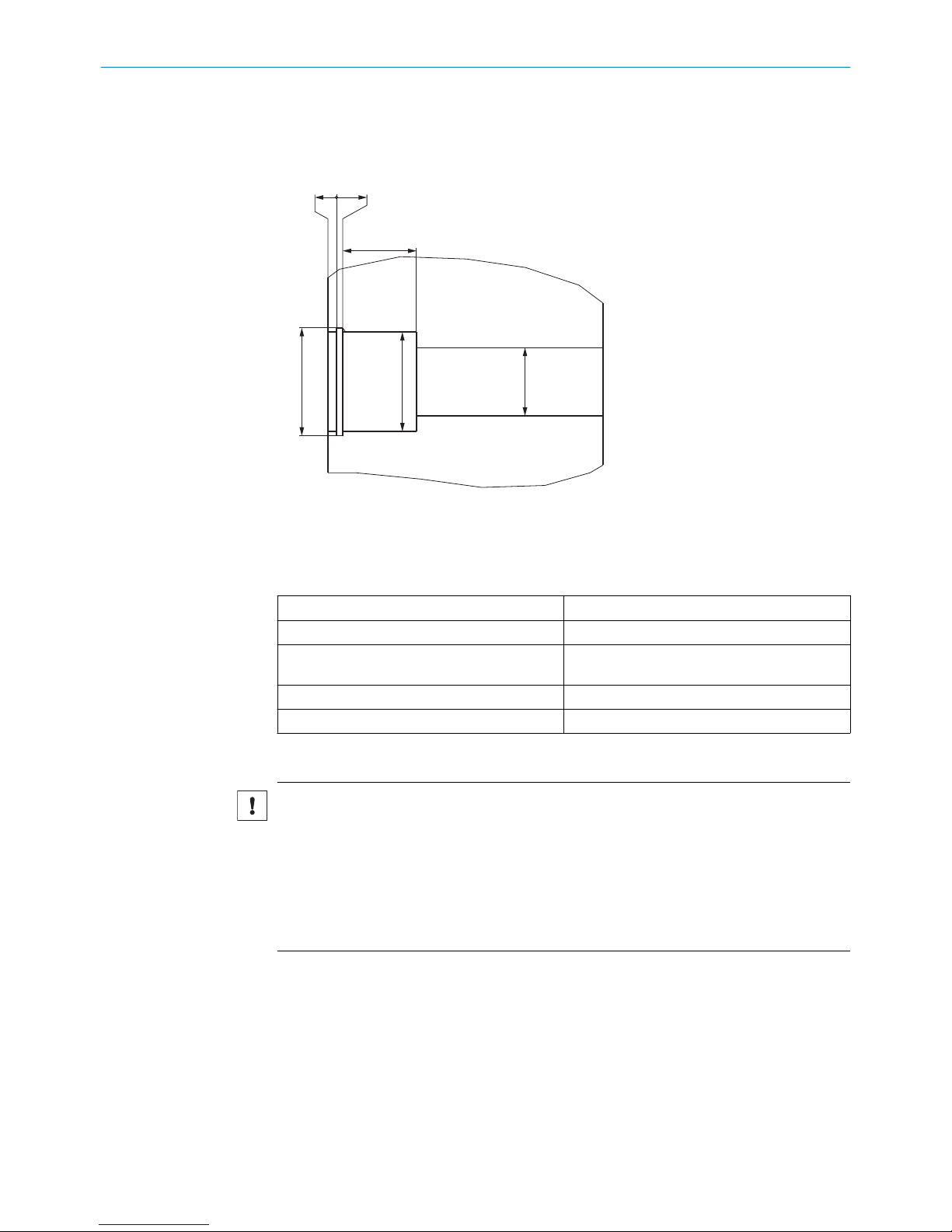

4.1.6 Installation cavity for the position magnet

b

Prepare an installation cavity for the position magnet in accordance with the fol‐

lowing dimensions.

1.5

(0.06)

1.1 H13

(0.04)

13.2 +0.1

(0.52)

Ø 17.5 +0.1

(0.69)

Ø 19 H11

(0.75)

Ø 12

(0.45)

Figure 12: Dimensions of the position magnet installation cavity

4.2 Installing the position magnet

Table 7: Position magnet installation dimensions

1 Corrugated spring washer

see figure 37, page 51

2 Position magnet

17.4 x 12.0 x 10.6 mm

3 Circlip

DIN 472 - 18x1, alternatively see figure 39,

page 52

Diameter of the position magnet bore hole 17.5 + 0.1 mm

Depth of the position magnet bore hole 13.2 + 0.1 mm

Sequence of work steps:

NOTICE

b

Ensure that the retaining ring and the wave spring are made from non-magnetic

material (non-ferritic steel).

b

Ensure that the position magnet and the retaining ring do not rub against the pres‐

sure pipe.

°

Smalley retaining ring (see figure 39, page 52): does not contain any inter‐

nal edges or eyes for the pressure pipe.

b

Observe the operating pressures: see "Technical data", page 43.

MOUNTING 4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

17

Subject to change without notice

Page 18

3 2 1 4

Figure 13: Installation of the position magnet

1

Corrugated spring washer

2

Position magnet

3

Circlip

4

Piston

1. Prepare the piston for installation of the magnet: see "Installation cavity for the

position magnet", page 17.

2. Mount the corrugated spring washer.

3. Mount the position magnet.

4. Mount the retaining ring.

4.3

Installing the encoder

4.3.1 Positioning the O-ring and support ring

1

2

Figure 14: O-ring and support ring

1

Support ring

2

O-ring

The O-ring and support ring are pre-installed as shown in the figure and prevent oil from

penetrating into the connector area.

4 MOUNTING

18

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 19

4.3.2 Insertion in the cylinder

Figure 15: Encoder lubrication points

1. Lubricate the O-ring, support ring and pressure pipe.

Figure 16: Tensile load at edges

NOTICE

Risk of damage to the connecting cables during installation.

Tensile loads and sharp edges can damage the stranded wires and connecting

cables of the connector system.

b

Avoid tensile loads and look out for sharp edges when installing the connec‐

tor system.

2. Carefully insert the encoder into the cylinder.

3. Guide the connecting cable carefully through the cylinder wall (bore hole).

4. Depending on the device variant, following the relevant steps below:

°

M12 male connector system: see "Installation with an M12 connector sys‐

tem", page 20.

°

Cable connector/cable gland: see "Installation with a cable connector and

cable gland", page 21.

5. Use a specially prepared sleeve (e.g., made from polyamide) to locate the device in

its final position.

6. Carefully tap in the sleeve using a mallet.

Figure 17: Profile side – MAX48 Figure 18: Profile side – MAX30

MOUNTING 4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

19

Subject to change without notice

Page 20

1

Ø 24

(0.94)

Ø 46

(1.81)

Figure 19: Face side – MAX48

1

Mounting surface

1

Ø 14

(0.55)

Ø 22

(0.87)

Figure 20: Face side – MAX30

NOTICE

Risk of damage to the device during installation.

Forces acting on the load-bearing features of the housing can damage the device.

b

Do not apply any load on the pressure pipe or behind the head of the device

when mounting the sensor.

1

222

Figure 21: Areas requiring lubrication

1

Oil inlet

2

Areas requiring lubrication

7. Lubricate the indicated areas via the oil inlet.

4.3.3 Installation with an M12 connector system

The M12 connector system has an enclosure rating of IP69K and is pre-assembled

ready for installation.

NOTE

When selecting the mating connector, ensure that it also has an enclosure rating of

IP69K.

4 MOUNTING

20

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 21

Figure 22: M12 connector system

1. Mount and engage the contact carrier in the flange plate.

NOTICE

b

When mounting the contact carrier in the flange, ensure the lug of the con‐

tact carrier is aligned correctly.

2. Press the flange plate into the bore in the cylinder wall.

3. Fasten the flange plate using suitable screws or rivets.

4. Proceed to the next step, see step 5, page 19.

Recommended screws for mounting the M12 flange

The screws should be selected so that no collision with the coupling nuts of the con‐

nected mating connectors can occur, e.g.,:

•

M3 socket head cap screw with flat head

•

DIN 912 hexagon socket head cap screw

•

ISO 14580 Torx screw

•

DIN 84 slotted-head screw

•

Comparable Phillips head screws or self-tapping screws

A soluble screw locking adhesive should be used when installing the screws.

Alternatively, the flange plate can be fastened using DIN 6660 button-head rivets.

4.3.4 Installation with a cable connector and cable gland

Figure 23: Encoder installed in the hydraulic cylinder with cable connector and cable gland

1. Guide the cable through the cable gland.

2. Mount the cable gland in the threaded bore.

3. Secure the tapered seal and coupling nut.

4. Proceed to the next step, see step 5, page 19.

MOUNTING 4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

21

Subject to change without notice

Page 22

Recommendations regarding the cable gland

For devices with a cable connection, a protection class rated (preferably IP68) metallic

cable gland should be used for sealing and strain relief. The cable glands should also

be protected against damage by surrounding them with metal profiles (e.g. U-steel). A

suitable cable gland is available as an accessory, see figure 40, page 52.

Recommendations regarding connectors for devices with a cable connector

When installing connector plugs on devices with a cable connector, please consider the

following:

•

Enclosure rating: (preferably IP68)

•

Connector housing:

Metal or impact-resistant plastic (check media resistance)

•

Protect against external influences: enclose the cable sheath and male connector

•

Prevent fluid ingress: the cable sheath should ideally be coated with sealing com‐

pound at offset locations

•

Polarity: ensure correct polarity

•

Male connector with screw terminals:

Apply ferrules and clamp all strands in the ferrule

•

Soldered connections: no projecting strands or “cold joints”

•

Crimp contacts: use a suitable tool to produce a gas tight crimp

•

ESD protection: protect workplaces and persons from electrostatic discharge

•

Prevent fluid ingress:

Use suitable caps to seal the male connector after installation

•

Screwed cable glands: protect by enclosing within steel profiles

4.4 Install the retaining screw

The retaining screw prevents the housing from moving in the axial direction. A DIN 913

M5x10 threaded pin with tapered head should be used for this purpose. Use a soluble

screw locking adhesive when installing the threaded pin.

NOTICE

Risk of damage to the device during installation.

The screw must only rest in the slot and not be tightened too hard.

b

Tighten the screws with a torque of 0.5 Nm ... 1.0 Nm.

4.5 Cylinder handling after encoder installation

4.5.1 Washing and drying the cylinder

To protect the connecting cable and male device connector from ingress of cleaning

agents, please observe the following:

Encoder with M12 connector system

•

Drying temperature: max. 90 °C

•

Pressure of the cleaning fluid: ≤ 5 bar

•

Protective cap: use the supplied plastic protective cap

•

In case of higher pressures: use a metallic protector

•

Protection class: IP69K

4 MOUNTING

22

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 23

Preventing ingress of cleaning agents into the electronics when washing cylinders with

an already installed M12 male connector.

To protect cylinders with an installed linear encoder against water ingress during wash‐

ing, a brass cap can be screwed onto the M12 male connector. Contact SICK for the

relevant information.

Encoder with cable connector / installed male device connector

•

Cable connectors/male device connector: protect against ingress of cleaning

agents using suitable sheathing

•

Screwed cable glands: protect against ingress of moisture

4.5.2 Electrostatic painting of the cylinder

The electrostatic painting process uses very high voltages (up to 100 kV) which can

damage the electronics of the encoder integrated into the cylinder. To avoid damage,

observe the following when painting the cylinder:

•

To avoid electrical isolation of the piston rod and the cylinder/sensor housing, do

not the suspend the cylinder by the piston rod

•

Clean off all lacquer and other residues from the hanging devices in the paint

shop, all connectors used to short-circuit the connecting wires, and all connec‐

tions to the paint shop earth

Painting of cylinders with an installed encoder and M12 connector system or male

device connector

To protect the sensor electronics, use metal protective caps that meet the following

requirements:

•

The cap must not be made from aluminum

•

The cap must be made from a permanently electrically-conductive material

•

The cap must have an M12x1 thread

•

The cap must be screwed on until it contacts the flange plate on the connector

as desired

•

Always use a torque of ≥ 5 Nm when tightening the cap

•

Make sure no paint particles get onto the thread or

pin contacts

Any paint particles on the outside of the cap will not impair the sensor.

A suitable cap can be purchased from the manufacturer as an accessory.

Painting of cylinders with an installed encoder and cable connector or third-party con‐

nector

Cylinders with an installed encoder and cable connector cannot be electrostatically

painted because the cable connector is not protected against over voltages. Reliable

electrostatic painting is only possible when using a combination of M12 connector sys‐

tem and protective cap.

4.5.3 Mounting the cylinder on mobile hydraulic machines

When mounting the cylinder on mobile hydraulic machines, ensure no male connectors,

cables or cable ends can be damaged in the process.

4.5.4 Electrical and electrostatic interference

Insulation tests

When performing insulation tests on mobile hydraulic machines, disconnect all encoder

connection cables to avoid damage from high voltages.

MOUNTING 4

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

23

Subject to change without notice

Page 24

Welding

Welding currents may be produced when carrying out welding work on nearby compo‐

nents. Welding currents can damage the pressure pipe or the electronics.

The following must also be observed when welding:

•

Disconnect all electrical connections during welding

•

Never fasten the grounding point to the piston rod or cylinder pipe

•

Never perform welding work directly on the cylinder

•

Never perform welding work near a cylinder with an encoder installed in it

•

Welding currents and similar effects can also arise at any bearing location on the

machine

4 MOUNTING

24

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 25

5 Electrical installation

5.1 Electrical connection

The encoder is equipped with an M12 connector system.

A variant with a cable connection is also available. Male device connectors must be

used in this case.

Enclosure ratings

To guarantee an IP69K enclosure rating (M12 connector system), a suitable mating

connector must be used.

5.1.1 Connection diagram, pin assignment for 4-pin M12 male connector

4

3

1

2

Figure 24: Pin assignment for 4-pin M12 connector

Pin assignment as per position 13 of the type code.

Table 8: Pin assignment for 4-pin M12 connector

Type code A B M

12/24 VDC 1 1 2

GND (0 V) 3 3 3

Signal 4 2 4

n.c. 2 4 1

5.1.2 Cable connection diagram

Connection scheme as per position 13 (= “K”) of the type code.

Table 9: Allocation of wire colors (voltage)

12/24 VDC BR (brown)

GND (0 V) BL (blue)

Voltage signal BK (black)

Table 10: Allocation of wire colors (current)

12/24 VDC BR (brown)

GND (0 V) BL (blue)

Current signal WH (white)

5.1.3 Connection diagram, pin assignment for 5-pin M12 male connector

4

3

1

2

5

Figure 25: Pin assignment for 5-pin M12 connector

Pin assignment as per position 13 of the type code.

ELECTRICAL INSTALLATION 5

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

25

Subject to change without notice

Page 26

Table 11: Pin assignment for 5-pin M12 connector

Type code C D

12/24 VDC 2 1

GND (0 V) 3 3

CAN_HI 4 4

CAN_LO 5 5

n.c. 1 2

5.1.4 Connection sequence

Connect the wires in the following sequence:

1. Connect the 12/24 VDC voltage supply.

2. Connect the GND (0 V).

3. Connect the signal.

5.2 Connection diagram for vehicle electronics

SIG

GND

+VDC

ECU

BAT

+

–

GEN

M

2

1

Figure 26: Connection diagram

1

Chassis GND

2

Cable shielding (optional)

To guarantee fault-free operation of the device, the cylinder must be connected to

machine ground (Chassis GND).

The physical contact with another machine component equalizes the potential of the

cylinder. If the cylinder is mounted in an insulated manner, a separate grounding must

be provided, e.g., by connecting a ground strap directly to the cylinder.

Cable shielding

The encoder is adequately shielded by the cylinder when installed, and therefore has

not been provided with its own shielding. If a shielded cable is used, it is necessary to

check, depending on the application, whether one side or both sides of the shield

should be connected to machine ground. Any high voltage or high frequency fields in

the vicinity can influence the shielding and the signal in the cable.

5 ELECTRICAL INSTALLATION

26

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 27

6 Commissioning

6.1 Putting the encoder into operation

1. Check that the connectors have been connected correctly: see "Connection dia‐

gram, pin assignment for 4-pin M12 male connector", page 25.

2. Select a suitable fuse: see "Select a suitable fuse", page 27.

3. Set up the filter wiring: see "Set up the filter wiring - analog", page 27.

4. Put the device into operation.

5. Check the functioning of the encoder: see "Checking the functioning of the

encoder", page 38.

6.2 Select a suitable fuse

When selecting a suitable fuse, the transient peak current when switching on the

device for the time must be taken into consideration:

Table 12: Inrush current when switching the device on

Inrush current for an supply voltage of 12 VDC 2.5 A / 50 μsec typical

Inrush current for an supply voltage of 24 VDC 5.0 A / 50 μsec typical

6.3 Set up the filter wiring - analog

Thermal noise, for example from resistors, becomes evident when the signal output is

amplified sufficiently. The supply voltage ripple (see "Technical data", page 43) and

other sources of interference, e.g., electromagnetic interference, can also affect the

quality of the analog output signal. To reduce the noise when acquiring analog mea‐

surement data, it is essential to use a filter.

A suitable filter, for example, is a combination of R1 = 50 Ω and C1 = 100 nF to 1 µF.

This will keep the signal delay time within the cycle time (internal measurement fre‐

quency) while not changing the dynamic behavior significantly.

VDC

+

GND GND GND

GND

R1

C1

1µF

ECU

Input

A/D converter

e.g., 12 bit →

4,096 steps

SIG

Figure 27: Filter wiring

NOTICE

The A/D converter at the input of the installed electrical controller will determine the

resolution of the encoder, e.g.,:

•

8 bit = 256 steps

•

10 bit = 1,024 steps

•

12 bit = 4,096 steps

6.4 Power-up and output signal in the event of a fault

When switching on the device, the signal output is ≥ F.S.O = Full Scale Output. After that

the device is ready for use.

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

27

Subject to change without notice

Page 28

Table 13: Operational statuses and output signal

Output signal

F.S.O during power-up in the event of a fault

4.00 ... 20.00 mA

Unusable signal

> 21.0 mA

0.50 ... 4.50 V > 5.1 V

0.25 ... 4.50 V > 5.1 V

0.50 ... 9.50 V > 10.0 V

PWM (duty cycle) ≥ 99%

Digital: CANopen / SAE J1939 Boot message Error message “FFFF”

Fault:

a) Position magnet missing

b) Position magnet in null or cushion zone

c) Malfunction or failure of the magnetostrictive element

During power-up (see "Technical data", page 43), the output signal is defined as an

unusable signal. The machine controller must take this into consideration in its pro‐

cessing. After power-up, the linear encoder is ready for operation. The output signal

behaves as described in the event of a fault.

6.5 Bus termination - digital

VDC

+

GND

ECU

CAN_LO

120 Ω

CAN_HI

Figure 28: Bus termination

Data transmission in the CAN bus is serial (2-wire bus system). The voltage difference

between the CAN_HI and CAN_LO data lines is one bit of information. To prevent signal

reflections, the data lines must be terminated with a 120 Ω terminator on the open bus

end. The terminator must be inserted between CAN_HI and CAN_LO.

6.6 Tolerance considerations for the set point

The set points (zero/end point) of the device are adjusted by the manufacturer to a tol‐

erance of ± 1 mm.

NOTICE

Further tolerances must be observed when installing the cylinder.

During teach-in, the piston rod moves to the zero point and to the end point in order to

eliminate all tolerances in the cylinder/encoder combination. The measured signals are

programmed in the controller accordingly. When operating the device without teach-in,

please note the following tolerance-related information:

Table 14: Tolerances when operating the device without teach-in

Example for a measuring range of 400 mm

Analog VDC Analog mA PWM (duty

cycle)

CANopen

SAE J1939

6 COMMISSIONING

28

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 29

Example for a measuring range of 400 mm

Signal 0.5 ... 4.5 V 4 ... 20 mA 10 … 90% PDO

Range 4000 mV 16 mA 80% 4,000 digits

Zero/end point ± 1.0 mm ± 10 mV ± 0.04 mA ± 0.2% ± 10 digits

Position magnet ± 1.0 mm ± 10 mV ± 0.04 mA ± 0.2% ± 10 digits

Mechanical assembly ± 0.5 mm ± 5 mV ± 0.02 mA ± 0.1% ± 5 digits

Total of all tolerances ± 2.5 mm ± 25 mV ± 0.10 mA ± 0.5% ± 25 digits

Table 15: Zero end point

Example for a measuring range of 400 mm

Output Analog VDC Analog mA PWM (duty

cycle)

CANopen

SAE J1939

Signal 0.5 ... 4.50 V 4 ... 20 mA 10 … 90% PDO value

Zero point ± 25 mV ± 0.10 mA ± 0.5% ± 25 digits

min. zero point 0.475 V 3.90 mA 9.5% 275 digits

max. zero point 0.525 V 4.10 mA 10.5% 325 digits

End point (F.S.) ± 25 mV ± 0.10 mA ± 0.5% ± 25 digits

min. end point 4.475 V 19.90 mA 89.5% 3,975 digits

max. end point 4.525 V 20.10 mA 90.5% 4,025 digits

After installation of the encoder in the cylinder, deviations from the target values will

arise due to these permissible tolerances. These deviations must be taken into consid‐

eration when setting limit values in the controller:

Table 16: Deviation from the limit values

Typical values

Cylinder stroke (mm)

200 mm 400 mm 800 mm

Output signal Tolerances

Analog VDC ± 25 mV ± 25 mV ± 15 mV

Analog mA ± 0.20 mA ± 0.10 mA ± 0.05 mA

PWM (10 … 90% duty cycle) ± 1.0% ± 0.5% ± 0.25%

CANopen / SAE J1939 ± 25 digits ± 25 digits ± 25 digits

6.7 CAN bus protocols

CAN bus is a machine level, open field bus for serial data transmission between a cen‐

tral controller (master) and decentralized field devices (slaves). Various protocols can

be used for the data transmission depending on the application. The device can be

ordered with either CANopen or SAE J1939 protocol support. Each protocol is config‐

ured differently, which affects how the device is integrated into the network, and the

operating characteristics of the device.

CANopen

The CANopen version of the device is suitable for operation as a slave in CAN bus net‐

works using the CiA Standard DS 301 V3.0 data protocol. This protocol corresponds to

the DS 406 V3.1 encoder profile. The device is connected directly to the bus as a node

of the bus system. The device distinguishes between four different operating modes ini‐

tiated by the controller. These modes are defined in the CANopen standard:

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

29

Subject to change without notice

Page 30

•

Initialization: The device performs a hardware initialization and loads the most

recently saved standard configuration.

•

Pre-operational: The device can be configured via the CAN bus.

•

Operational: The device sends its measurement data via the CAN bus.

•

Stopped: The device stops transmitting data and waits for further commands.

SAE J1939

SAE J1939 is a multi-master protocol developed especially for applications in the

mobile field, i.e. for commercial and conveyor vehicles, as well as for construction, agri‐

cultural and forestry machines. An SAE J1939 network consists of various ECUs (Elec‐

tronic Control Units). An ECU can address messages to multiple CAs (Controller Applica‐

tions). After commissioning, the bus subscribers are automatically assigned addresses.

The CAN bus subscribers are now fully operable.

6.8 Communication objects

6.8.1 CANopen

When the device is in operational mode, the evaluation electronics integrated into the

device convert the measurement data into CAN messages, and transmit these mes‐

sages on the CAN bus. Where they can be received and processed by the controller. The

CAN bus uses the following communication objects for data transmission:

•

SDO (Service Data Object):

SDOs are used to set or query parameters relating to the encoder configuration.

These are accessed from the internal object directory of the device. To process

SDOs, the device must be in either the pre-operational or operational mode.

•

PDO (Process Data Object):

PDOs transmit process data, such as position and speed, to the controller. PDOs

are only generated in operational mode.

•

NMT (Network Management):

NMTs control the status of the network and individual components. They can also

be used for monitoring purposes using the following objects:

°

SYNC object:

The SYNC object synchronizes the bus communication, i.e. synchronous PDOs

are sent to the controller after a SYNC object is received.

°

Emergency object:

The emergency object sends error messages. As they generally have a higher

priority than PDOs, these emergency objects will be transmitted first.

°

Nodeguard object:

The CANopen linear encoder uses the node guarding protocol to perform the

error control services of the CANopen network.

The bus master uses a remote frame to send a nodeguard message to the

CANopen slave, and in response the slave reports its current NMT status

using a standard nodeguard message. The nodeguard frame format, and the

NMT state value definitions are shown in the following tables. The nodeguard

protocol is activated as default.

According to the CANopen protocol, each message has the following structure:

Table 17: Message in CANopen

SOF Arbitration Control Data Field CRC ACK EOF Interframe Space

1 11 1 6 0..8 bytes 15 1 1 1 7 ≥ 3

6 COMMISSIONING

30

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 31

6.8.2 SAE J1939

SAE J1939 features an extended message arbitration and a 29-bit extended message

identifier. This extension features a different message prioritization and assignment of

bus subscribers. For large quantities of data, it is possible to utilize a separate trans‐

port protocol. The communication objects for SAE J1939 are:

•

PDU (Protocol Data Unit):

There are two types of PDUs. PDU1 is used for peer-to-peer data transmission,

PDU2 is addressed to all bus subscribers.

•

PG (Parameter Groups):

PG refers to the grouping of process data and parameters for transmission in a

message. This parameter group data structure ensures efficient bus loading.

•

PGN (Parameter Group Number):

The PGN is a unique and standardized identifier of the parameter group.

•

SPN (Suspect Parameter Number):

The SPN uniquely identifies a parameter signal and is prescribed by the protocol.

This ensures that every SAE J1939 compatible device knows the parameter struc‐

ture.

•

TP (Transport Protocol):

TP is used for separate data transmission above 8 bytes.

According to the SAE J1939 protocol, each message has the following structure:

Table 18: CAN bus data protocol with J1939 identifier

PDU

SOF Arbitration Identifier Control Data

Field

CRC ACK EOF

1 Priority 3 2 PDU

Format 8

PDU

Specific 8

Source 8 6 0..8 bytes15 1 1 1 7

6.9 Configuration and system startup

After electrical connection to the network, the device is ready for commissioning and

configuration. Before actual system startup, the communication parameters for opera‐

tion need to be set in the CAN bus. Only the basic procedure is described in these oper‐

ating instructions. Please refer to the accompanying programming instructions for

details of all the available commands for configuring the device.

6.9.1 Configuring CANopen

Setting the node parameters

To be able to operate the device in a CAN bus network, it is necessary to first configure

the network characteristics. The basic settings for integrating a bus subscriber are

made using LSS (Layer Setting Services). Every device (node) in the CAN network is

uniquely identified by its LSS address. This address is composed as follows:

Table 19: LSS address

CANopen

Vendor-ID 0x1000056

Product code as per product key

Revision number as per product key

Serial Number actual serial number of the CANopen encoder

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

31

Subject to change without notice

Page 32

Parameters specific to the CAN bus, such as baud rate and node ID, are also configured

and saved via the LSS service. Both the baud rate and node ID of the encoder must be

configured for operation in the specific CAN bus implementation.

Setting the node ID

NOTE

When programming the node ID, only one device or node must be connected.

Every device or node must be assigned a number (node ID). This number is used to

identify the node within the CANopen network. Each node ID must be unique. The

CANopen node ID must be in the range of 1 - 127, and can be preset when ordering. To

ensure error-free operation of the network, the ID of every node in the CAN bus must be

unique.

The node ID of the device can be set using the following command sequence:

Table 20: Setting the node ID

Data source COB-ID Data Destination

Controller 0x7e5 04; 01; 00; 00; 00; 00; 00; 00 Sensor

Controller 0x7e5 11; 7d*; 00; 00; 00; 00; 00; 00 Sensor

Sensor 0x7e4 11; 00; 00; 00; 00; 00; 00; 00 Controller

*

Node address values can be between 1 and 127 (for example 125).

A change in node address is effective immediately.

To permanently save the node address, the following command must be sent:

Table 21: Saving the node ID

Data source COB-ID Data Destination

Controller 0x7e5 17 Sensor

Sensor 0x7e4 17; 00; 00; 00; 00; 00; 00; 00 Controller

Setting the baud rate

The baud rate indicates the speed of operation of the device and also the entire CAN

bus. The device and entire network must be set to the same baud rate.

The maximum baud rate is limited by the cable length used for the CAN network as a

whole. The device is delivered with a preset, order-dependent baud rate. If this baud

rate needs to be changed, it can be configured via the LSS.

Table 22: Baud rate as a function of cable length

Cable length Baud rate (kBit/s) Table index

< 25 m 1000 00

< 50 m 800 01

< 100 m 500 02

< 250 m 250 03

< 500 m 125 04

< 1000 m 50 06

< 2500 m 20 07

< 5000 m 10 08

The baud rate can be set using the following commands:

6 COMMISSIONING

32

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 33

Table 23: Setting the baud rate

Data source COB-ID Data Destination

Controller 0x7e5 04; 01; 00; 00; 00; 00; 00; 00 Sensor

Controller 0x7e5 13; 00; 02*; 00; 00; 00; 00; 00 Sensor

Sensor 0x7e4 13; 00; 00; 00; 00; 00; 00; 00 Controller

*

Table index

The baud rate becomes active after saving the changes, and the next time the encoder

is switched on. To save the baud rate, the following command must be sent:

Table 24: Saving the baud rate

Data source COB-ID Data Destination

Controller 0x7e5 17; 00; 00; 00; 00; 00; 00; 00 Sensor

Sensor 0x7e4 17; 00; 00; 00; 00; 00; 00; 00 Controller

6.9.2 Configuring SAE J1939

In the SAE J1939 specification, the maximum length of the network is limited to

40 meters, and the baud rate is fixed at 250 kBit/sec. It is therefore not necessary to

configure these parameters when integrating the device. Furthermore, the number of

nodes is limited to 30 ECUs (Electronic Control Units). Each ECU can, however, control

multiple CAs (Controller Applications). Up to 253 CAs in total can be implemented in the

network.

NMT (Network Management)

SAE J1939 supports extended network management. This requires subscribers to first

register themselves in the network with a unique address prior to system startup

(address claiming). Normal bus operation is only started after all subscribers have suc‐

cessfully logged in. Correct address assignment is checked continuously during opera‐

tion. A new source address can be assigned during operation. In addition to the source

address, every bus subscriber is provided with a unique name to identify it within the

network and to prioritize the allocation of addresses. The naming conventions are

defined in SAE J1939 and are structured as follows:

Table 25: Naming structure for subscribers according to J1939

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Identify

Number

Manufacturer Code ECU Instance Function

Table 26: Naming structure for subscribers according to J1939

Byte 6 Byte 7

Reserved Vehicle System Vehicle System

Instance

Industry Group Arbitrary Address

Capable

Table 27: Setting the source address

Data source COB-ID Data Destination

Controller 0x10ff54d4 01; nSA*; 23; 01; 20; 07; 00; 00 Transducer

Transducer No response Controller

*

nSA: new source address

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

33

Subject to change without notice

Page 34

6.9.3 System startup for CANopen

After configuring the node parameters, the device can be integrated into the network.

When switched on or reset, the encoder performs a hardware initialization to bring all

components into a defined initial state. Next the device- and communication-specific

parameters are loaded from an EEPROM and the configuration adopted.

Once the initialization has been completed, the device reports its node ID and pre-opera‐

tional mode to the network master by means of a boot-up message. While in this mode,

the device can be configured via service data objects (SDOs).

The SDO identifiers are generated automatically based on the node ID. The communi‐

cation via SDOs to configure the device takes the form of a peer-to-peer connection

between the network master and the device. The identifiers for the other objects are

also allocated according to the CANopen standard. They can, however, be changed at

any time in the CANopen network via a DBT master. If necessary, the changed parame‐

ters can be saved in the EEPROM and loaded automatically the next time the device is

switched on and configured.

Once the configuration process is finished, the encoder is switched from pre-operational

to operational mode using a Start_Remote_Node command. While in this mode, user

data can be transmitted (via PDOs). The transmission of the PDOs can occur in one of

two ways:

Either the encoder sends its data cyclically, or data transmission is triggered by the

receipt of a SYNC object.

To initiate the sending of position messages by the encoder, it is necessary to first send

a node start message:

Table 28: Node start message

Data source COB-ID Data Destination

Controller 0x000 01; 00*; 00; 00; 00; 00; 00; 00 Sensor

*

00: Starts all CAN nodes

To stop the sending of position data, it is necessary to send a pre-operational message:

Table 29: Pre-operational message

Data source COB-ID Data Destination

Controller 0x000 80; 00*; 00; 00; 00; 00; 00; 00 Sensor

*

00: Sets all nodes to pre-operational mode

6.9.4 System startup for SAE J1939

After the device is connected to the network and switched on, it attempts to register

itself with the network master using a source address. This address claiming is per‐

formed automatically by the network. After assignment of a unique network address,

the device starts sending position data and is also ready to receive configuration data.

6.9.5 Setting CANopen operating parameters

At system startup (power on, reset), the device loads the operating parameters stored

in the EEPROM. These are either the factor-set values, or previously changed and saved

values.

Changes are made, for example, via SDOs while in pre-operational mode. The identifiers

are automatically set to suitable default values and saved when programming the node

ID. They can subsequently be changed.

6 COMMISSIONING

34

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 35

These operating parameters are stored in the object directory of the device, which pro‐

vides the means for implementing the internal characteristics and functions of the

device, as well as external communication. For this purpose, the object directory is

divided into two parts: a Communication Profile, and a Device Profile.

•

Communication Profile:

The Communication Profile contains the parameters relevant to communication,

e.g., identifier settings and PDO configuration settings. The device is equipped

with the encoder communication protocol (Device Profile for Encoder – DS406

Vers. 3.1). This enables devices from different manufacturers to be easily linked to

one another and replaced.

•

PDO transmission type:

By default, the PDO transmission type is set to asynchronous, i.e. the encoder

transmits its process data independently according to the configured cycle time.

The PDO transmission type can also be set in such a way that process data is only

sent after a SYNC message is received.

•

PDO object mapping:

The device does not support dynamic mapping or changing of the mapping para‐

meters. PDO1 transmits the position and speed.

•

Error messages:

The device automatically sends an emergency object when an error arises.

•

Device profile:

The parameters important to the operation of the encoder, such as position reso‐

lution, speed resolution, and cycle time, are stored in the Device Profile. Two

important operating parameters are:

°

Resolution:

The factory-default resolution of the device is 100 μm. The resolution for

motion speed is set to 1 mm/s by default. For more information, see the pro‐

gramming instructions.

°

Cycle time:

This setting is the cycle time for transmission of PDOs. The value can be in

the range of 1 ... 65535 ms. Programming the cycle time (object 6200) only

affects the PDO1 event timer (see DS406 V3.0).

The cycle time setting must match the setting configured for the CAN bus net‐

work. If the cycle time is too short, and the baud rate is low and there are

many subscribers, the bus can become overloaded due to the increased vol‐

ume of data.

The cycle time can be set using the following commands (e.g., 10, node ID =

127*):

Table 30: Setting the cycle time

Data source COB-ID Data Destination

Controller 0x67f* 22; 00; 62; 00; 0A; 00; 00; 00 Sensor

Sensor 0x5ff* 60; 00; 62; 00; 00; 00; 00; 00 Controller

To permanently save the cycle time, the Save parameters command must be executed:

Table 31: Saving the cycle time

Data source

COB-ID Data Destination

Controller 0x67f* 22; 10; 10; 01; 73; 61; 76; 65 Sensor

Sensor 0x7ff* 60; 10; 10; 01; 00; 00; 00; 00 Controller

NOTE

The encoder may take up to 600 ms to respond.

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

35

Subject to change without notice

Page 36

6.9.6 Setting SAE J1939 operating parameters

The operating parameters of the SAE J1939 device variant can be set analogously to

the CANopen variant. The device can receive configuration messages during operation,

and will adopt the settings immediately after receiving the message.

The cycle time can be set using the following commands (e.g., 100*):

Table 32: Setting the cycle time

Data source COB-ID Data Destination

Controller 0x18B2SAMA 4D; 54; 53; 00; 64*; 00*; 00; 00 Sensor

SA

MAX CAN J1939 standard sensor source address

MA

Master source address

*

e.g., 64; 00: Bytes to configure transmission repetition rates

6.9.7 CANopen encoder data during operation

Data is outputted by means of a Process Data Object (PDO). The PDO contains the posi‐

tion and speed data.

Data format

The resolution of the position data is fixed at 100 μm, and the resolution of the speed

data is 1 mm/s. The currently set values can be read under index 6005 of the object

directory. All position data are stored as 32-bit integer values, and speed data as 16-bit

integer values.

Table 33: PDO allocation when using the default settings

Identifier DLC D0 D1 D2 D3 D4 D5

180h + nodeID6 Position magnet 1 Speed magnet 1

The position and speed are calculated as follows:

Position [μm] = position value [counts] * 100μm

Speed [mm/s] = speed value [counts] * 1 mm/s

6.9.8 SAE J1939 encoder data during operation

Data is outputted by means of a Data Record Message.

Table 34: Data Record Message

Identifier DLC D0 D1 D2 D3 D4 D5 D6 D7

0 x 18

PFPSSA

8 Position Speed Status Error Code Limit Sta‐

tus

0xFF

PF

PDU format is fixed to 255 (0xFF)

PS

PDU Specific can be 0-255 (0x00 - 0xFF)

SA

MAX CAN J1939 standard sensor source address

6.9.9 CANopen error messages

An emergency object is sent whenever there is a change to the internal error status reg‐

ister (even if the error has since been rectified). The object comprises 8 data bytes and

is structured as follows:

Table 35: Emergency object

Identifier DLC D0 D1 D2 D3 D4 D5 D6 D7

0x80 + nodeID8 Error Code Error register Manufacturer-specific

The following errors are reported in the emergency object:

6 COMMISSIONING

36

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 37

Table 36: Error codes

Error code Relevance

0x0000 Device is operating without errors

0x5000 Device hardware error

0X6300 Data set error

6.9.10 SAE J1939 error messages

SAE J1939 does not provide separate error objects. The device status is reported with

every PDU that is sent.

COMMISSIONING 6

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

37

Subject to change without notice

Page 38

7 Maintenance

7.1 Error table

Table 37: Errors during installation

Error cause Possible consequences

Incorrect pin assignment No signals

Ambient temperature too high Damage to the device components

Cylinder bore hole too small Damage to the device components when

installing the device

Not noticing pointy or sharp edges Damage to male connectors, wires, cables

Careless handling of the device Damage to the device components

Welding work after installation Damage to the sensor housing or

electronics due to welding currents

Damage to the cable Short-circuiting or failure of the electronics

Male connector not sealed Short-circuiting or corrosion of

electronic components due to liquids

Ground or shielding connected incorrectly Signal interference, possible damage to the

electronics

Table 38: Errors during commissioning/operation

Output signal

F.S.O Output signal in the event of a fault

4.00 ... 20.00 mA > 21.0 mA

0.50 ... 4.50 V > 5.1 V

0.25 ... 4.50 V > 5.1 V

0.50 ... 9.50 V > 10.0 V

PWM (duty cycle) > 99%

Digital: CANopen / SAE J1939 Error message “FFFF”

Fault:

a) Position magnet missing

b) Position magnet in null or cushion zone

c) Malfunction or failure of the magnetostrictive element

7.2 Checking the functioning of the encoder

Encoder with analog interface

To verify the proper operation of the device, perform the following checks:

•

Connections and pin assignments

•

Supply voltage

•

Check the device by disconnecting it and testing it using an external supply

•

Check the device using a multimeter as described below

Measure the VDC output signal

Measure the following output signals:

•

0.25 ... 4.75 VDC

•

0.5 ... 4.5 VDC

•

0.5 ... 9.5 VDC

7 MAINTENANCE

38

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 39

+

_

VDC

Figure 29: Measuring the output signal in VDC

1. Switch the measuring range of the multimeter to VDC.

2. Connect the multimeter to the signal lead and 0 V lead.

3. Connect the voltage supply (+12/24 V).

4. Connect 0 V (-0 V).

Measuring the 4 ... 20 mA output signal

+

_

mA

Figure 30: Measuring the output signal in mA

1. Switch the measuring range of the multimeter to mA.

2. Connect the multimeter to the signal lead and 0 V lead.

3. Connect the voltage supply (+12/24 V).

4. Connect 0 V (-0 V).

Alternative measuring method: using a resistor (e. g., 100 W):

+

_

VDC

R

Figure 31: Measuring the output signal using a resistor

1. Connect the resistor to the signal lead and 0 V lead.

2. Switch the measuring range of the multimeter to VDC.

3. Connect the multimeter in parallel to the resistor.

When using a resistor of, for example, 100 W, the following values are displayed:

Table 39: Example measurement values

Supply at 4 mA (null zone) at 20 mA (end position)

12 V, 24 V 0.4 V 2 V

7.3 Repairs

All repair work on the device must be carried out by SICK Service.

MAINTENANCE 7

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

39

Subject to change without notice

Page 40

7.4 Testing and programming

A test device is available for checking the device functionality.

To minimize error sources during functional testing, the test device must be connected

directly to the encoder. A PC can be used to test the functioning of the device, and to

configure the basic settings.

7 MAINTENANCE

40

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 41

8 Transport and storage

8.1 Transport and storage conditions

When transporting the fully assembled cylinders, ensure the cable and male connector

of the electrical connection are not subjected to tensile loads.

Store the cylinders in a dry place. When storing the cylinders on top of one another,

ensure no male connectors or cables are crushed.

Cover the connectors and any free cable ends with an anti-static bag. The original pack‐

aging, for example, is suitable for this purpose. Also reuse the dust protection caps of

the connector system when storing the device.

For the part numbers of the original packaging and the dust protection caps, see: see

"Accessories", page 51.

TRANSPORT AND STORAGE 8

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

41

Subject to change without notice

Page 42

9 Decommissioning

9.1 Dismantling

When dismantling the cylinder and when removing the encoder, ensure no male con‐

nectors, cables or cable ends can be damaged in the process.

9.2 Disposal

Any device which can no longer be used must be disposed of in an environmentally

friendly manner in accordance with the applicable country-specific waste disposal regu‐

lations. As the device is categorized as electronic waste, it must never be disposed of

with household waste.

9 DECOMMISSIONING

42

O PE R AT I NG IN S TR U CT I ON S | MA X 8022793/ZXZ4/2018-07-24 | SICK

Subject to change without notice

Page 43

10 Technical data

10.1 MAX Analog/PWM

Table 40: Technical data – MAX48 Analog / PWM

Performance

Measurand Position

Measuring range MAX48: 0050 … 2,500 mm (in 1 mm steps)

MAX30: 0050 ... 1,500 mm (in 1 mm steps)

Unusable measuring range:

Null zone (zero point) MAX48: 30.0 mm

MAX30: 19.5 mm

Damping (end point) 30.0 mm/ 36.0 mm/ 63.0 mm (depending on type)

Power-up delay < 250 ms

Measuring frequency (internal) 2 ms

Setpoint tolerance

Zero and end point of the usable piston stroke

≤ 1.0 mm

Resolution 0.1 mm typical (noise-free)

Hysteresis ± 0.1 mm

Linearity:

Measuring ranges 50 ... 500 mm F.S. typically ± 0.25 mm

Measuring ranges 501 ... 2,500 mm F.S. typically ± 0.04%

Temperature drift (warm-up phase) max. ± 0.25 mm

Analog interface

Electrical interface Analog

Voltage signal 0.25 … 4.75 VDC

0.50 … 4.50 VDC

0.50 … 9.50 VDC

1.00 … 9.00 VDC

Current signal 4 … 20 mA

PWM interface

Pulse width 05 … 95%

10 … 90%

15 … 85%

20 … 80%

25 … 75%

Pulse rate 250 Hz

300 Hz

400 Hz

500 Hz

Electrical connection

M12 male connector 4-pin, wire length

060 … 240 mm (depending on type)

3-wire cable 3 x 0.32 mm² (AWG22),

stripped 300 … 10,000 mm (depending on type)

Electrical data

Supply voltage 12 VDC (8 ... 16 VDC)

24 VDC (8 ... 30 VDC)

TECHNICAL DATA 10

8022793/ZXZ4/2018-07-24 | SICK O PE R AT I NG IN S TR U CT I ON S | MA X

43

Subject to change without notice

Page 44

Electrical data

Supply voltage ripple < 1% p-p

Power consumption:

12 VDC voltage signal ≤ 0.5 W

24 VDC voltage signal ≤ 0.5 W

24 VDC current signal / PWM ≤ 1.0 W

Current consumption:

12 VDC voltage signal ≤ 30 mA

24 VDC voltage signal ≤ 20 mA

24 VDC current signal / PWM ≤ 40 mA

Load resistance:

Voltage signal RL ≥ 10 kΩ

Current signal 100 Ω < RL < 500 Ω

Switch-on current:

12 VDC supply voltage 2.5 A / 50 µsec typical

24 VDC supply voltage 5.0 A / 50 μsec typical

Over voltage protection ISO 16750-2: ≤ + 36 VDC on all poles

Reverse polarity protection ISO 16750-2: on all poles

Insulation resistance ISO 16750-2: Riso ≥ 10 MΩ, 60 sec

Dielectric strength ISO 16750-2: 500 VDC (0 VDC to housing)

Dimensions

Size MAX48: 48f7 mm (for installation in a 48H8 clearance)

MAX30: 31f7 mm (for installation in a 31H8 clearance)

Unusable range:

Null zone (zero point) MAX48: 30.0 mm

MAX30: 19.5 mm