Page 1

MASTER DATA ANALYZER

Track and trace systems

OPERATING INSTRUCTIONS

Page 2

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

2

Product described

Product name: Master Data Analyzer

Document identification

Title: Operating instructions for Master Data Analyzer

Status: 2017-08-10

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

only used here for identification purposes.

Original documents

The German issue 8020064-ZSP4 of this document is an original SICK AG

In case of doubt, contact SICK AG or your local dealer.

Legal notes

Subject to change without notice

© SICK AG. All rights reserved

Part number: 8020065-ZSP4

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be trademarks and are

document.

SICK AG does not assume liability for the correctness of a non-authorized

translation.

Page 3

3

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

Contents

CONTENTS

1 About these operating instructions ..............................................................................7

1.1 Purpose of this document .................................................................................... 7

1.2 Information depth ................................................................................................ 7

1.3 Abbreviations used ............................................................................................... 7

1.4 Symbols used ....................................................................................................... 8

2 Safety ..............................................................................................................................9

2.1 Qualified safety personnel ................................................................................... 9

2.2 Applications of the system ................................................................................... 9

2.3 Intended use ...................................................................................................... 10

2.4 General safety notes and protective measures .............................................. 11

2.4.1 Safety notes and symbols ................................................................. 11

2.4.2 General safety notes .......................................................................... 12

2.4.3 Additional operating instructions ...................................................... 12

2.4.4 Dangers connected with handling of the device .............................. 13

2.4.4.1 Danger due to electrical current ...................................... 13

2.4.4.2 Risks during transport and installation ............................ 14

2.4.4.3 Risks during operation ...................................................... 15

2.4.5 Protective devices .............................................................................. 17

2.4.6 Work station ....................................................................................... 18

2.4.7 Protective equipment ......................................................................... 18

2.4.8 The operating entity’s responsibilities .............................................. 18

2.5 Protecting the environment .............................................................................. 19

2.5.1 Power consumption ........................................................................... 19

2.5.2 Disposal after final decommissioning ............................................... 19

3 System description ..................................................................................................... 20

3.1 Scope of delivery ............................................................................................... 20

3.2 System components ......................................................................................... 21

3.3 The system’s operating principle...................................................................... 26

3.4 Project planning ................................................................................................ 31

3.5 Status indicators ............................................................................................... 32

3.5.1 Status indicators – Light grids .......................................................... 32

3.5.2 Status indicators – Hand-held scanner (only in operating

mode with bar code scanning) .......................................................... 33

3.5.3 Status indicators – IP camera ........................................................... 34

3.5.4 Status indicators – Display ................................................................ 34

3.5.5 Status indicators – Electronic scales ................................................ 35

3.5.6 Status indicators – WLAN module .................................................... 35

3.6 Interfaces ........................................................................................................... 36

4 Transport, assembly, and mounting .......................................................................... 37

4.1 Accepting the delivery ....................................................................................... 37

4.1.1 Packaging ........................................................................................... 37

4.1.2 Checking delivery for visible transport damage ............................... 37

4.2 Transporting the MDA to its location of use .................................................... 38

4.3 Unpacking and setting up the device ............................................................... 39

4.3.1 Unpacking the MDA ........................................................................... 39

4.3.2 Checking delivery for hidden transport damage .............................. 40

4.3.3 Setting up the MDA ............................................................................ 41

4.4 Removing the transport locks ........................................................................... 43

Page 4

CONTENTS

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

4

4.5 Mounting ............................................................................................................44

4.5.1 Ready to go .........................................................................................44

4.5.2 Mounting the WLAN module ..............................................................44

5 Electrical installation .................................................................................................. 45

5.1 Connections on the MDA ...................................................................................46

5.1.1 Components connected as standard ................................................46

5.1.2 Connections on the controller housing ..............................................46

5.2 Connecting the MDA to the supply voltage ......................................................47

5.3 Connecting the MDA to the target network ......................................................48

5.4 Connecting the sliding table with rechargeable battery ..................................48

5.5 Connecting the WLAN adapter ..........................................................................49

6 Commissioning ............................................................................................................ 50

6.1 Starting the MDA ................................................................................................50

6.1.1 Starting up the MDA ...........................................................................50

6.1.2 Checking operational readiness ........................................................50

6.2 Preparing the configuration PC .........................................................................52

6.2.1 Establishing a connection with the configuration PC .......................52

6.2.2 Service and data interface .................................................................52

6.2.3 Installing SOPAS .................................................................................53

6.2.4 Launching SOPAS ...............................................................................54

6.3 Adding the MDA to the SOPAS project ..............................................................55

6.3.1 Starting the device search .................................................................55

6.3.2 Transferring the controller to a SOPAS project .................................57

6.3.3 Loading device drivers into the SOPAS project .................................57

6.3.4 Setting the controller to online...........................................................59

6.4 Configuring the MDA in SOPAS .........................................................................60

6.4.1 Incorporating the MDA controller into the customer’s network .......61

6.4.1.1 Issuing the Data interface IP address ..............................61

6.4.1.2 Testing the server connection ...........................................62

6.4.2 Storing connection data for the customer server .............................63

6.5 Saving data permanently ...................................................................................64

6.6 Performing a test run .........................................................................................65

6.7 Setting up the IP camera ...................................................................................66

6.8 Configuring the WLAN module ..........................................................................67

7 Operation ...................................................................................................................... 68

7.1 Safety information .............................................................................................68

7.2 Steps for preparing for your first measurement ...............................................70

7.2.1 Adjusting the display and operating position ....................................70

7.2.2 Starting up the MDA ...........................................................................71

7.2.3 Structure of the measurement window .............................................72

7.2.4 Moving the measurement gantry to a start position ........................74

7.2.5 Positioning a measuring object ..........................................................75

7.3 Performing measurements ................................................................................76

7.3.1 Starting the measurement process ...................................................76

7.3.1.1 Scanning the bar code (only for the operating mode

with bar code scanning) ....................................................76

7.3.1.2 Weighing the object (only for the operating mode

without bar code scanning) ...............................................78

7.3.2 Measuring the volume ........................................................................79

Page 5

CONTENTS

5

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

7.3.3 Checking the measurement results .................................................. 80

7.3.3.1 Reading measurement data ............................................. 80

7.3.3.2 Checking measurements with the 2D display ................. 81

7.3.3.3 Displaying the measuring object in a live view ................ 81

7.4 Transmitting measurement results .................................................................. 82

7.4.1.1 Direct data output if the device is connected

to a server .......................................................................... 82

7.4.1.2 Saving measurement data internally (only for

operating mode with bar code scanning) ........................ 82

7.4.1.3 Displaying the transmission status (only for

operating mode without bar code scanning) .................. 84

7.4.1.4 Restoring a server connection manually ......................... 85

7.5 Performing new measurements ....................................................................... 86

7.6 Repeating incorrect measurements ................................................................. 88

7.6.1 Object was positioned incorrectly ..................................................... 88

7.6.2 Volume measurement without bar code (only for operating

mode with bar code scanning) .......................................................... 89

7.6.3 Volume measurement without a stable weight (only for

operating mode without bar code scanning) .................................... 90

7.7 Performing mobile measurements ................................................................... 91

7.8 Using the sliding table with rechargeable battery ........................................... 91

7.9 Configuration ..................................................................................................... 92

7.9.1 Logging into the configuration area .................................................. 92

7.9.2 General settings ................................................................................. 93

7.9.2.1 Selecting a language ......................................................... 93

7.9.2.2 Correcting the zero point .................................................. 93

7.9.2.3 Performing teach-in ........................................................... 93

7.9.3 Display settings .................................................................................. 95

8 Maintenance and repairs ........................................................................................... 96

8.1 Maintenance and repairs.................................................................................. 97

8.1.1 Visual inspection for mechanical and electrical damage ................ 98

8.1.2 Cleaning the light grids ...................................................................... 99

8.1.3 Cleaning the display ......................................................................... 100

8.1.4 Cleaning the glass panel ................................................................. 101

8.1.5 Cleaning the internal housing area ................................................. 101

8.1.6 Cleaning the IP camera’s dust shield housing ............................... 103

8.2 Replacing components ................................................................................... 104

8.2.1 Replacing the hand-held scanner (only in operating mode

with bar code scanning) ................................................................... 105

8.2.2 Replacing the display ....................................................................... 105

8.2.3 Replacing the glass panel ............................................................... 106

8.2.4 Replacing the IP camera .................................................................. 108

8.2.5 Replacing the WLAN module ........................................................... 109

9 Fault diagnosis .......................................................................................................... 110

9.1 Response to faults .......................................................................................... 110

9.2 Fault indicators ................................................................................................ 110

9.2.1 Status indicator on the display ........................................................ 110

9.2.1.1 Dealing with status messages ........................................ 110

9.2.1.2 Overview of status messages ......................................... 111

9.2.2 Status indicators for components ................................................... 114

9.3 SICK support .................................................................................................... 115

Page 6

CONTENTS

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

6

10 Technical specifications .......................................................................................... 116

10.1 Data sheets ..................................................................................................... 116

10.1.1 System data sheet ........................................................................... 116

10.1.2 Data sheet for the IDM26x hand-held scanner (wired) ................. 116

10.1.3 IP camera Axis M3005-V ................................................................. 117

10.1.4 WLAN Ethernet port adapter FL WLAN EPA.................................... 117

10.2 Dimensional drawings .................................................................................... 118

10.3 Spare parts list ................................................................................................ 118

10.4 Data interface ................................................................................................. 119

11 Appendix .................................................................................................................... 120

11.1 List of tables .................................................................................................... 120

11.2 List of figures ................................................................................................... 121

11.3 Keywords index ............................................................................................... 123

Page 7

ABOUT THESE OPERATING INSTRUCTIONS 1

7

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

Tasks

Target group

Mounting, electrical installation,

components

Qualified personnel, such as service technicians or

Commissioning

Qualified personnel, such as service technicians or

industrial electricians

Operation

Qualified personnel

1 About these operating instructions

Please read through this chapter carefully before you use the documentation and work

with the Master Data Analyzer (also abbreviated to MDA in these operating instructions).

1.1 Purpose of this document

These operating instructions are intended for people who install, connect, commission,

operate, and maintain the Master Data Analyzer.

maintenance, and replacement of

Tab. 1: Target group

1.2 Information depth

Note

These operating instructions contain information on the Master Data Analyzer relating to

the following topics:

• Safety

• System description

• Transport, assembly, and mounting

• Electrical installation

• Commissioning

• Operation

• Maintenance and repairs

• Fault diagnosis and troubleshooting

• Technical data and dimensional drawings

industrial electricians

1.3 Abbreviations used

FTP

LED

MDA

MLG

MSC

File Transfer Protocol

Light emitting diode

Master Data Analyzer

Modular light grid

Modular system controller (MSC800)

Page 8

1 ABOUT THESE OPERATING INSTRUCTIONS

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

8

1.4 Symbols used

Recommendation

Note

1. / 2. ...

,

Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or technical measure.

Notes provide information about the features of a device, application tips, or other useful

information.

Instructions that must be carried out in the described order are referred to as step-by-step

instructions and are indicated by numbered lists. Carefully read and follow the

instructions for action.

Instructions for taking action are indicated by an arrow. Carefully read and follow the

instructions for action.

LED symbols describe the status of a diagnostics LED. Examples:

The LED is illuminated continuously.

The LED is flashing.

The LED is off.

Page 9

9

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

2 Safety

Tasks

Qualification

Mounting and maintenance

Practical technical training

Knowledge of the current safety regulations in the workplace

Electrical installation and

device replacement

Practical electrical training

Knowledge of current electrical safety regulations

Commissioning, operation,

Basic knowledge of data transmission

Basic knowledge of the Windows operating system used

This chapter concerns your own safety and the safety of the system operator.

Please read this chapter carefully before you begin working with the Master Data

▸

Analyzer.

2.1 Qualified safety personnel

The Master Data Analyzer must only be set up, commissioned, operated, and maintained

by adequately qualified personnel.

The following qualifications are necessary for the various tasks:

and configuration

SAFETY 2

Basic knowledge of the design and setup (addressing)

of Ethernet connections when connecting the system to

the Ethernet

Basic knowledge of how to use an HTML browser

(e.g., Internet Explorer) to access the online help

Basic knowledge of 1D/2D code technology

Tab. 2: Qualified safety personnel

2.2 Applications of the system

The Master Data Analyzer is a stationary DWS system (Dimensioning-Weighing-Scanning).

It enables master data for products to be logged in a standardized manner for goods entry

or shipping. The products are measured, weighed, identified, and visualized in a single

operation. Data are processed in real time, regardless of their shape, surface, and

material properties.

Operating modes

The Master Data Analyzer is set up at the factory to support two operating modes:

• Operating mode with bar code scanning: The object is identified using its bar code

and is then measured. In this case, the Master Data Analyzer supplies the complete set

of master data with bar code, weight, and dimensions.

• Operating mode without bar code scanning. This variant assumes that the bar code

for the object is already available, meaning that only the weights and dimensions have

to be logged. The measurement results are assigned to an existing bar code in the

customer’s system.

Page 10

2 SAFETY

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

10

WARNING

Note

Brief description

• The object is placed on a rugged glass plate. The object does not need to be aligned.

• In the operating mode with bar code scanning, the object is identified using a wired bar

code scanner. Electronic scales measure the weight of the object.

In the operating mode without bar code scanning, the measuring process starts with

the system detecting a stable weight value. There is no hand-held scanner.

• To measure the dimensions, a gantry with two pairs of light grids is moved manually

over the object using two linear guides. Measurements can be taken in both directions.

The object’s dimensions and volume are measured.

• The data are sent to the warehouse management system in a stationary solution via

Ethernet. An external PC or screen is not required. In the mobile variant of the Master

Data Analyzer, the data are sent via a WLAN access point.

• All system components are pre-assembled in a rugged industrial design and are ready

for operation immediately after commissioning.

The majority of the images and screenshots in these operating instructions visualize the

Master Data Analyzer in the operating mode with bar code scanning.

2.3 Intended use

The Master Data Analyzer may only be used as described in 2.2 Applications of the

system. It may only be used by qualified personnel in the environment in which it was

mounted and initially commissioned by qualified safety personnel in accordance with

these operating instructions.

The equipment may only be operated in an industrial environment. Operation of the

system is not allowed outdoors or in an explosion-protected environment.

If used in any other way or if alterations are made to the system or the devices are

opened – including in the context of mounting and installation – this will void any warranty

claims directed to SICK AG.

Examples of non-intended use:

• Measurement of products not defined in the contract or in these operating instructions.

• Non-observance of the permitted parameters for measuring objects.

• Failure to observe the operating instructions.

• Use of parts other than original spare parts.

Danger due to improper use

Non-intended use of the device can lead to danger to the life and limb of persons and

damage to the plant.

The device must only be used for the intended use.

Page 11

11

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

2.4 General safety notes and protective measures

HAZARD

WARNING

CAUTION

NOTE

2.4.1 Safety notes and symbols

The following safety and hazard symbols are used for your own safety, for the safety of

third parties, and for the safety of the system. You must therefore observe these symbols

at all times.

Denotes an immediate hazard that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from electrical current).

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from suspended loads).

SAFETY 2

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of damage to the eye by laser beams).

Denotes a potential risk of damage or functional impairment of the device or the devices

connected to it.

This symbol refers to supplementary technical documentation.

Page 12

2 SAFETY

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

12

WARNING

2.4.2 General safety notes

General, recognized safety-related rules and regulations were taken into account in the

design and manufacture of the Master Data Analyzer. However, risks for the user resulting

from the MDA cannot be completely ruled out. The safety notes below must therefore be

observed.

Safety notes

Observe the following to ensure the safe use of the system as intended.

• The notes in these operating instructions (e.g., regarding use, mounting, installation,

or integration into the machine controller) must be observed.

• All official and statutory regulations governing the operation of the system must be

complied with.

• The national and international legal specifications apply to the installation and use of

the system, to its commissioning, and to recurring technical inspections, in particular:

– The accident prevention regulations and work safety regulations

– Any other relevant safety regulations

• The manufacturer and user of the system are responsible for coordinating and

complying with all applicable safety specifications and regulations in cooperation with

the relevant authorities.

• The checks must be carried out by qualified safety personnel or specially qualified and

authorized personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

• These operating instructions must be made available to the operator of the system.

The system operator must be instructed by qualified safety personnel and must read

the operating instructions.

• Maintenance and repair work may only be performed by trained and authorized

SICK AG service technicians or qualified safety personnel of the customer.

2.4.3 Additional operating instructions

Other operating instructions of the individual components are enclosed along with these

operating instructions.

When working on or with these components, please observe the notes in the operating

instructions of the relevant manufacturer.

Page 13

13

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

2.4.4 Dangers connected with handling of the device

HAZARD

The Master Data Analyzer has been designed and built in a way that allows for safe

operation. Protective devices reduce potential risks to the maximum possible extent.

Furthermore, the system has been subjected to an internal safety check.

However, certain residual risks apply in the event of misconduct or misuse.

Awareness of potential sources of danger in the Master Data Analyzer will help you to

work in a safer manner and thus prevent accidents.

That is why all persons involved with the transport and storage, mounting, commissioning

and decommissioning, operation, maintenance, and repair must carefully read and

observe the following safety notes.

In order to avoid danger, also follow the special warning information in the individual

chapters as well as the current national accident prevention regulations and any company

work, operation, and safety regulations.

2.4.4.1 Danger due to electrical current

SAFETY 2

Risk of injury due to electrical current

The Master Data Analyzer is connected to the power supply (AC 100 to 264 V/50 to 60 Hz).

Only a qualified electrician or trained person working under the guidance and supervision

of a qualified electrician is permitted to work on electrical systems or equipment, and they

must comply with the electrical regulations.

Improper handling of live devices may lead to severe personal injury or death by electric

shock.

Measures

Electrical installation and maintenance work must only be performed by electrically

▸

qualified personnel.

Standard safety requirements must be met when carrying out any work on electrical

▸

systems or equipment.

Do not touch any live parts.

▸

In the event of danger, immediately disconnect the device from the grid.

▸

Electrical connections may only be made or disconnected when there is no power in the

▸

system.

Only switch on the supply voltage when the connection tasks have been completed and

▸

the wiring has been thoroughly checked.

Only carry out maintenance and repair work when the power is off.

▸

Always use original fuses with the specified current rating.

▸

Page 14

2 SAFETY

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

14

WARNING

WARNING

WARNING

WARNING

2.4.4.2 Risks during transport and installation

Risk of injury from suspended load

The Master Data Analyzer is delivered in a transport crate on a pallet. Use a suitable

lifting device to unload and transport the device.

During transport, tipping or falling loads pose a risk of severe injury or damage to

property.

Measures

Only use lifting equipment which is suitable for the weight and dimensions of the

▸

freight.

Make sure that the center of gravity is in the center between the forks of the lifting

▸

device and the forks are completely entrenched under the transport pallet.

Do not stop underneath the suspended load.

▸

Wear safety shoes in addition to your personal protective equipment.

▸

Risk of injury due to components falling over

The side panels and lid of the transport crate are heavy and difficult to handle.

Falling objects pose a risk of crushing during dismantling.

Measures

Always use 2 people to mount the side panels and lid.

▸

Wear protective shoes in addition to your personal protective equipment.

▸

Risk of injury when lifting heavy objects

There is a risk of injury when lifting heavy objects.

Depending on the system variant, the MDA weighs around 65 kg to 80 kg.

Measures

Use 4 people to lift the MDA.

▸

In order to do this, use the four handles on the two long sides of the MDA.

▸

Lift and carry the MDA according to ergonomic principles.

▸

Wear protective shoes in addition to your personal protective equipment.

▸

Impermissible handling of the device

There is a risk of damage to the device when lifting the MDA using the measurement

gantry.

Measures

Do not lift the MDA using the measurement gantry under any circumstances!

▸

Page 15

SAFETY 2

15

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

WARNING

WARNING

WARNING

WARNING

Risk of crushing when settings down the MDA

The adjustable feet are designed so that the safety distance between the bottom of the

device and the tabletop can be observed.

There is a risk of crushing when installing the MDA on the tabletop.

Measures

Do not put your hands under the base of the housing when installing the MDA.

▸

Risk of crushing due to the device tipping over

There is a risk of the MDA tipping over during installation. An unsuitable surface may also

lead to the device tipping over.

The device tipping over can lead to the severe crushing or even loss of limbs.

There is also the risk of inflicting damage to the device.

Measures

Place the MDA on a sufficiently stable and steady table.

▸

Secure the table against rolling away.

▸

Make sure that all four adjustable feet are completely on the tabletop.

▸

2.4.4.3 Risks during operation

Risk of injury and/or damage caused by faulty operation.

Risk of injury and/or property damage from absence of qualification and/or incorrect and

non-intended use.

Measures

Follow the instructions on proper operation.

▸

Only use the device in perfect working order and for its intended purpose, keeping

▸

safety and potential dangers in mind, and in compliance with the operating

instructions.

Never exceed the permitted technical limit values.

▸

Do not do work on the device

▸

• If you do not have the required qualification

• If you have not received full instructions from the operating entity

• If you have not completely read or understood these operating instructions.

Risk of injury when lifting heavy objects.

There is a risk of injury when placing down and removing the objects to be measured.

Objects weighing up to 30 kg can be measured.

Measures

Consider ergonomic aspects when placing down and removing the objects.

▸

Page 16

2 SAFETY

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

16

WARNING

WARNING

WARNING

WARNING

Risk of injury when moving the measurement gantry

There is a risk of crushing when moving the measurement gantry.

Hands may be crushed between the measurement frame and the side recesses in the

housing.

The device has been designed with sufficient safety distances to prevent fingers from

being crushed.

Measures

Always use the handles to move the measurement gantry.

▸

Do not grip onto the side recesses in the housing.

▸

Risk of tripping due to cables. Risk of damage to cables

Exposed cables on the floor in areas used by people can pose a risk.

Measures

Lay the connecting cables for the hand-held scanner and the voltage supply so that

▸

there is no risk of people tripping over them and the cables are protected against

damage.

Risk of injury when transporting the MDA to the place of use

The measurement gantry may accidentally be damaged when the MDA is transported on

a sliding table. Hands may be crushed between the measurement frame and the side

recesses in the housing.

Measures

Use cable ties to secure the handles of the measurement gantry so that it does not

▸

move accidentally during transport.

Danger due to malfunction!

Cease operation if the cause of the malfunction has not been clearly identified.

Measures

Immediately stop system operation if you cannot clearly identify the fault and if you

▸

cannot safely remedy the problem.

Page 17

SAFETY 2

17

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

WARNING

NOTE

Risk of injury caused by accidental movement of the measurement gantry

Whenever work is performed on the housing interior, there is a risk of crushing if the

measurement gantry moves accidentally.

There is also a risk of damage to the wire draw encoder.

Measures

Use cable ties to secure the handles of the measurement gantry so that it does not

▸

move accidentally during maintenance and repair work.

Claims under the warranty rendered void

If the device is opened, any warranty claims against SICK AG will be void.

Measure

Do not open the device housing.

▸

2.4.5 Protective devices

The Master Data Analyzer has been built in a way that allows for safe operation.

Protective devices reduce potential risks to people and the device to the maximum

possible extent.

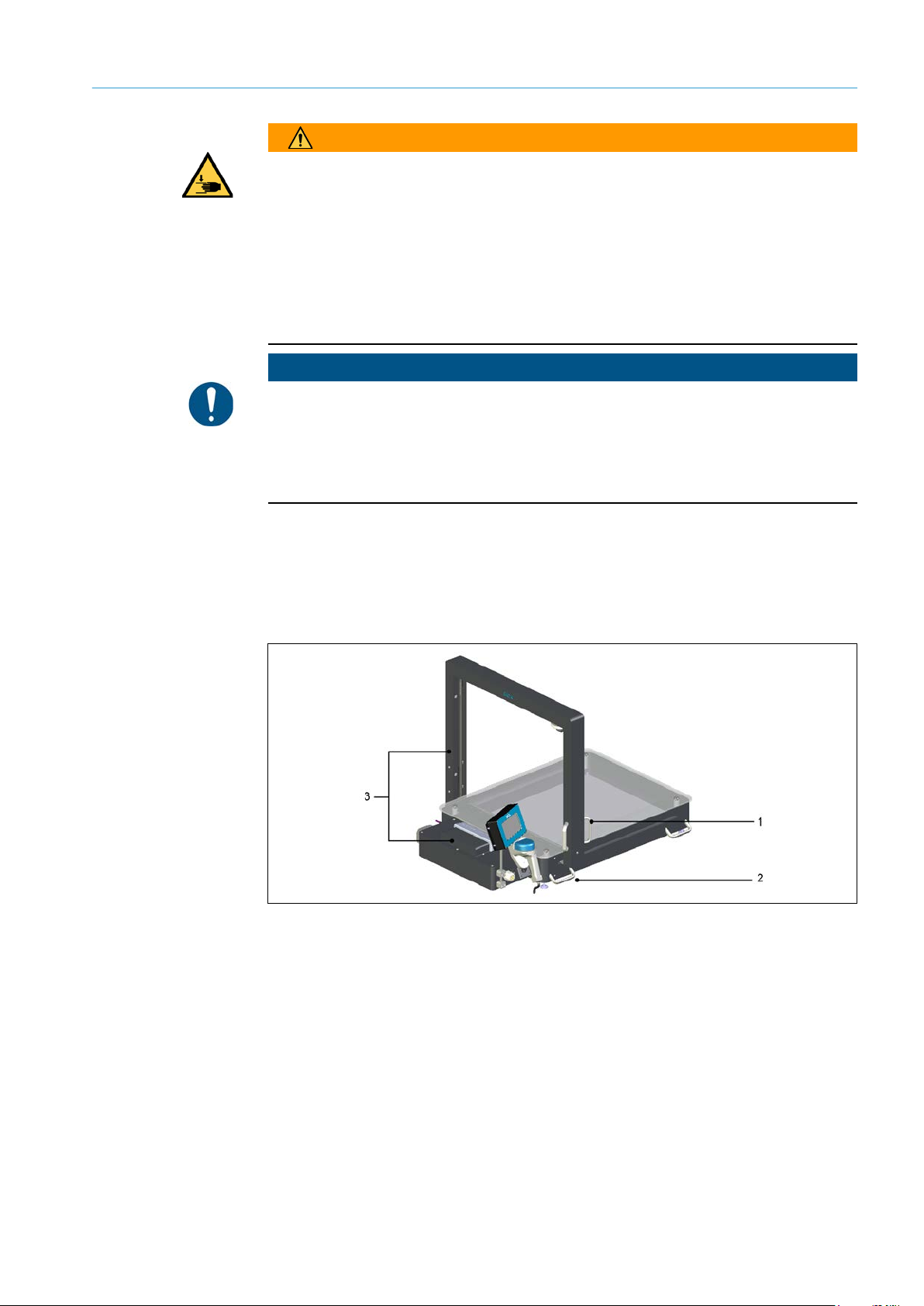

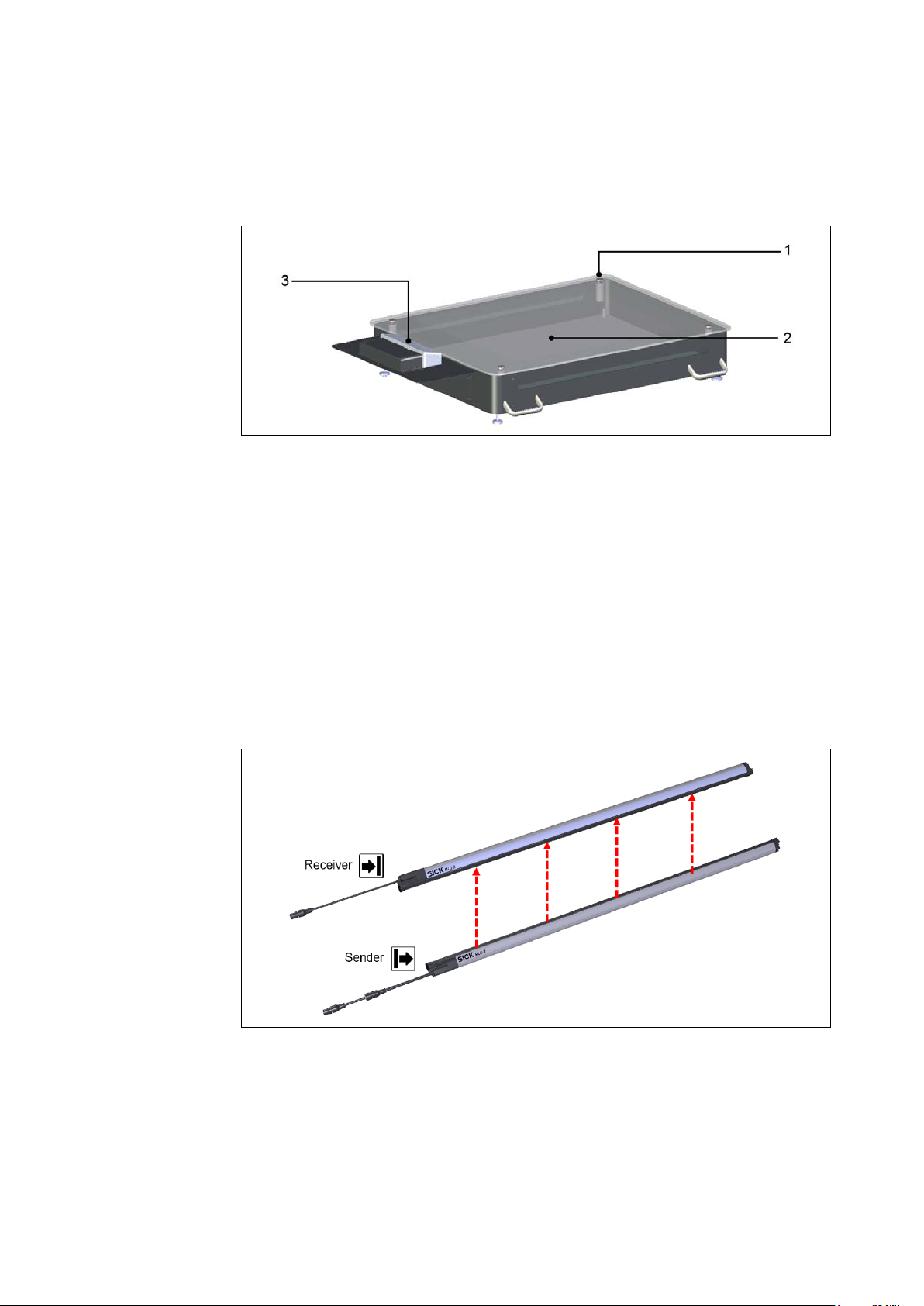

Fig. 1: Protective devices

• Four handles (1) make it easier to unpack and lift the MDA in line with ergonomic

principles.

• Handles (2) allow the measurement gantry to be moved safely over the object to be

measured.

• Cover plates (3) protect cables and electronic components.

Page 18

2 SAFETY

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

18

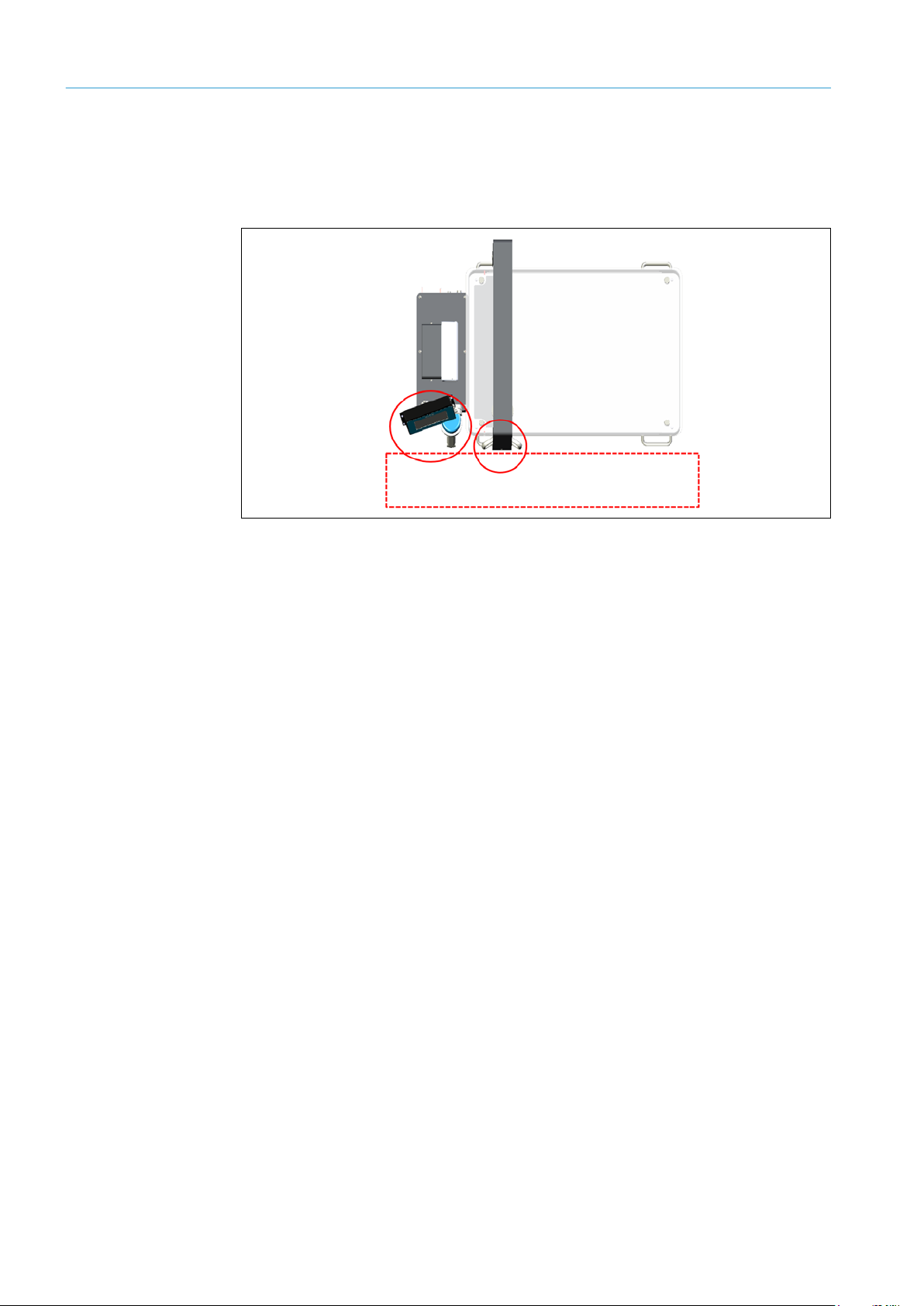

2.4.6 Work station

The work station for measuring objects is located on the side of the display and the handheld scanner. The handles for moving the measurement gantry are also located on this

side.

Fig. 2: Work station

We recommend placing the Master Data Analyzer on a sufficiently stable and steady table

so that the measuring objects can be loaded and unloaded in line with ergonomic

principles. The table must be secured against rolling away.

A sliding table is available as an accessory.

2.4.7 Protective equipment

The operating entity must wear personal protective equipment (PPE) in accordance with

the locally applicable safety regulations.

Personal protective equipment for transport and installation

Wear safety shoes in addition to your basic safety equipment during transport and

▸

installation.

2.4.8 The operating entity’s responsibilities

The operating entity must execute the electrical installation in compliance with the

respective provisions of the local electricity supply company as well as applicable

standards.

The following directive applies to the Master Data Analyzer:

• EMC Directive: 2014/30/EU

Page 19

19

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

2.5 Protecting the environment

The Master Data Analyzer is designed to minimize its impact on the environment. Apart

from the housing, the system contains no materials using silicon.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information regarding disposal.

2.5.1 Power consumption

All components in the Master Data Analyzer are supplied centrally with voltage via a

power cable.

The MDA’s typical power consumption in running operation is around 36 watts.

2.5.2 Disposal after final decommissioning

SICK does not currently take back devices that are unusable or irreparable.

Always dispose of unusable or irreparable devices in an environmentally safe manner in

accordance with the relevant national waste disposal regulations.

Always dispose of unusable or irreparable devices in an environmentally safe manner

▸

in accordance with the relevant national waste disposal regulations.

Dispose of all electronic assemblies as hazardous waste. The electronic assemblies are

▸

easy to dismantle.

Dispose of the controller’s battery separately as per the ROHS directives (Europe).

▸

SAFETY 2

Page 20

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

20

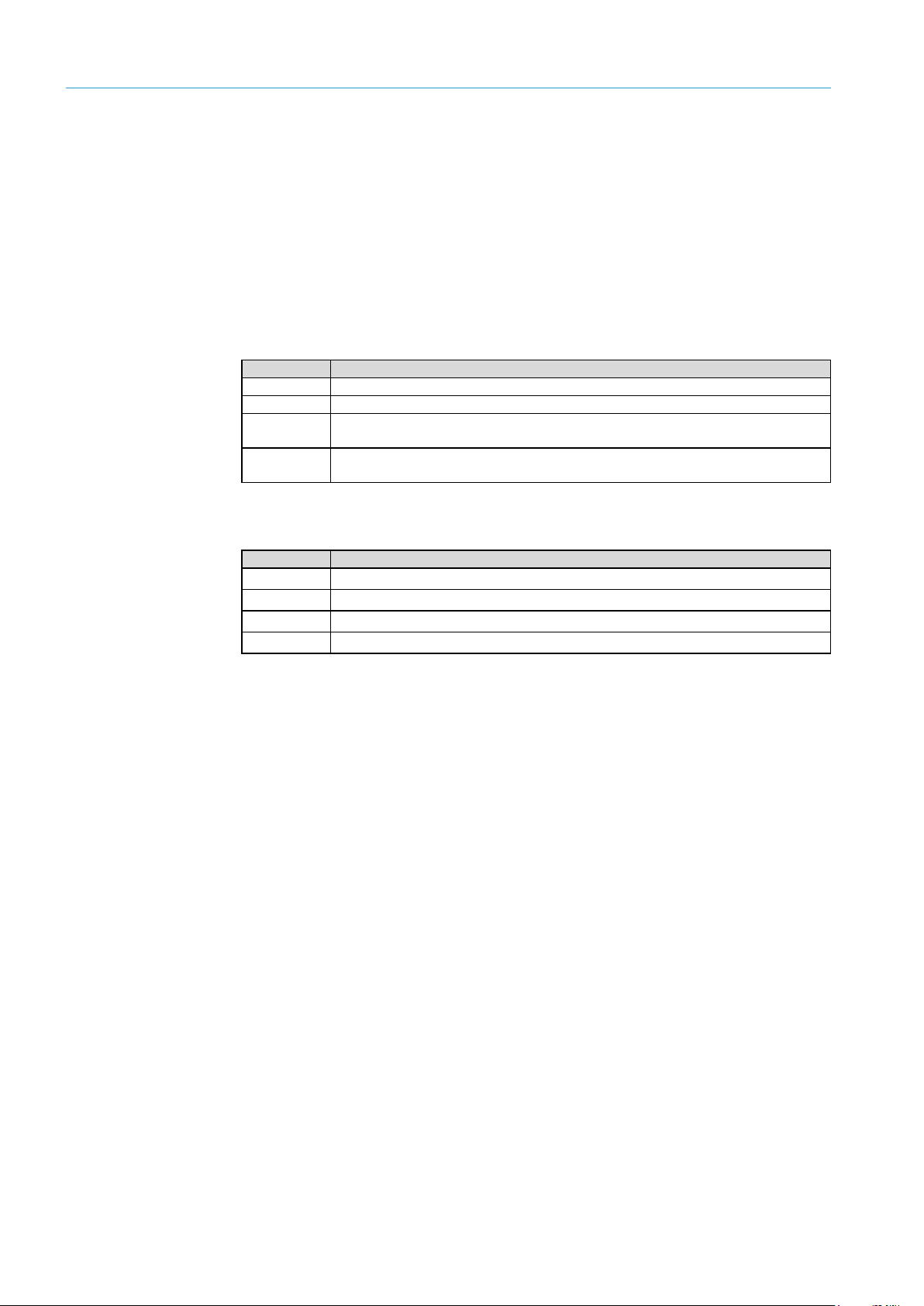

Part no.

Description

1079161

Master Data Analyzer MDA650 with a monitoring length of 650 mm

1079162

Master Data Analyzer MDA800 with a monitoring length of 800 mm

1079163

Master Data Analyzer MDA650 Image with a monitoring length of 650 mm

and a fixed IP camera

1079164

Master Data Analyzer MDA800 Image with a monitoring length of 800 mm

and a fixed IP camera

Part no.

Description

2087193

WLAN module with mounting kit for mobile applications

2087216

Sliding table

2087217

Sliding table with built-in rechargeable battery

6062161

Power supply unit

3 System description

This chapter provides information on the special properties of the DWS system. It describes

the design and operating principle of the system solution.

3.1 Scope of delivery

The Master Data Analyzer is available in two different monitoring lengths, each of which is

available with and without an IP camera.

System variants

Tab. 3: System variants

Optional accessories

Note

Tab. 4: Optional accessories

On request, the Master Data Analyzer is available with scales that can be verified.

Verification takes place at the factory.

Operating the scales in LFT mode (Legal for Trade mode) is useful if the logged data are

used for invoicing purposes or if certified accuracy must be ensured.

Page 21

21

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

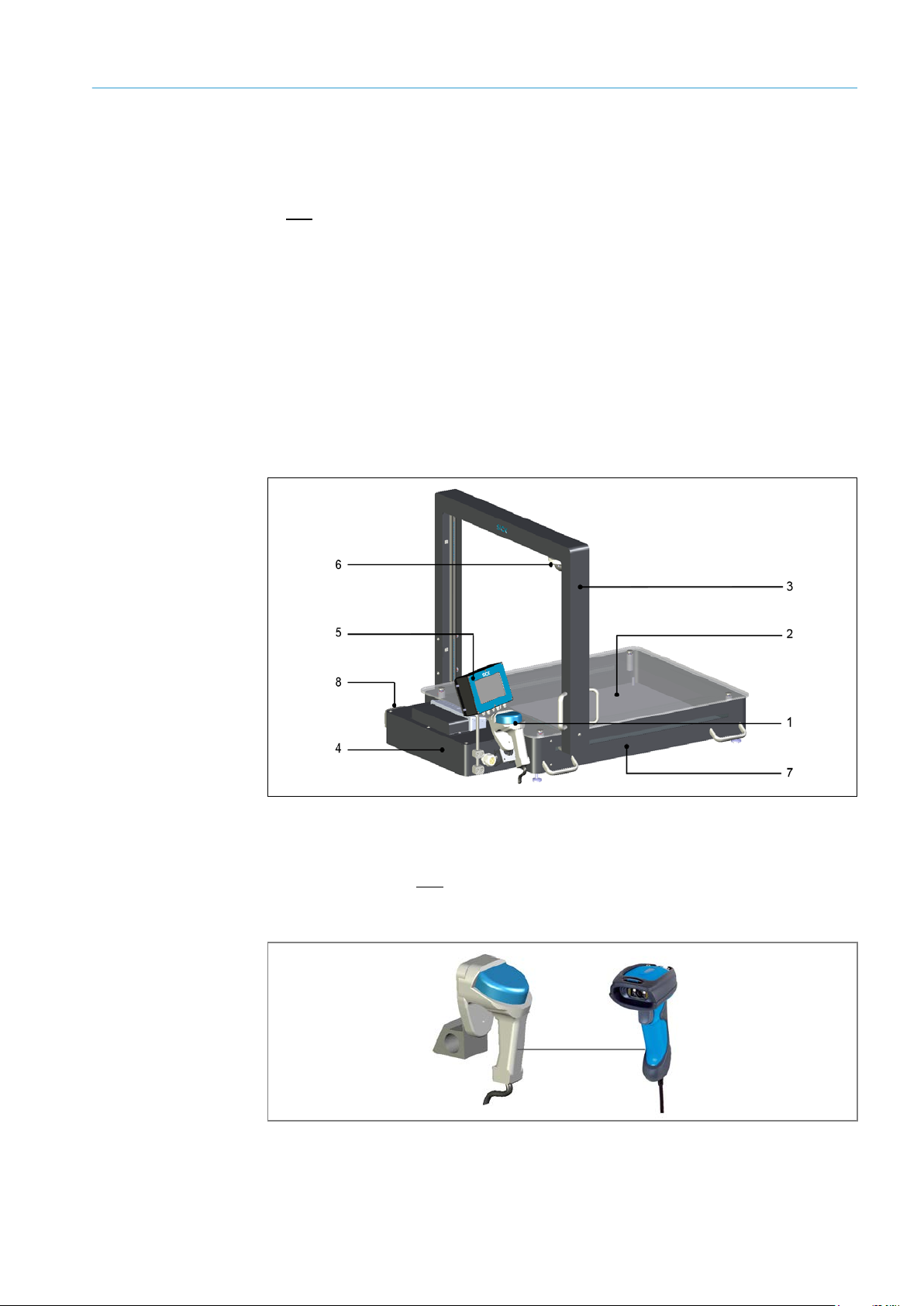

3.2 System components

The Master Data Analyzer consists of:

1. One hand-held scanner for scanning bar code information (only in the operating mode

with bar code scanning).

2. One set of rugged electronic scales with a glass panel for supporting the measuring

object.

3. One moving measurement gantry with two pairs of light grids for recording the

object’s dimensions and a wire draw encoder for calculating the length.

4. One controller for recording the measurement data and emitting the measurement

results to the customer’s system.

5. One display for visualizing the measurement results.

6. One IP camera (only for MDA650 Image/MDA800 Image).

7. One stable mechanism for holding the components

8. One WLAN module available as an accessory for mobile applications of the MDA.

SYSTEM DESCRIPTION 3

Fig. 3: System components

1 – Hand-held scanner

In the operating mode with bar code scanning, the number used to identify the object is

detected using a wired hand-held scanner. The IDM26x hand-held scanner recognizes 1D

and 2D bar codes and all common stacked codes.

Fig. 4: Hand-held scanner

The hand-held scanner is connected to the MDA’s controller by a cable. This cable is used

to both supply the hand-held scanner with voltage and transmit data.

Page 22

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

22

2 – Electronic scales

The electro-mechanical scales consist of a glass panel as the weighing surface (1),

four weighing cells at the corners (2), one electronic evaluating system, and a separate

display (3).

Fig. 5: Electronic scales

Four positioning points are used for measurement. These points transfer the force to the

weighing cells installed on the corners. The glass panel made of safety glass makes sure

the force is distributed evenly on all four corners.

The scales’ display only visualizes the recorded object weight.

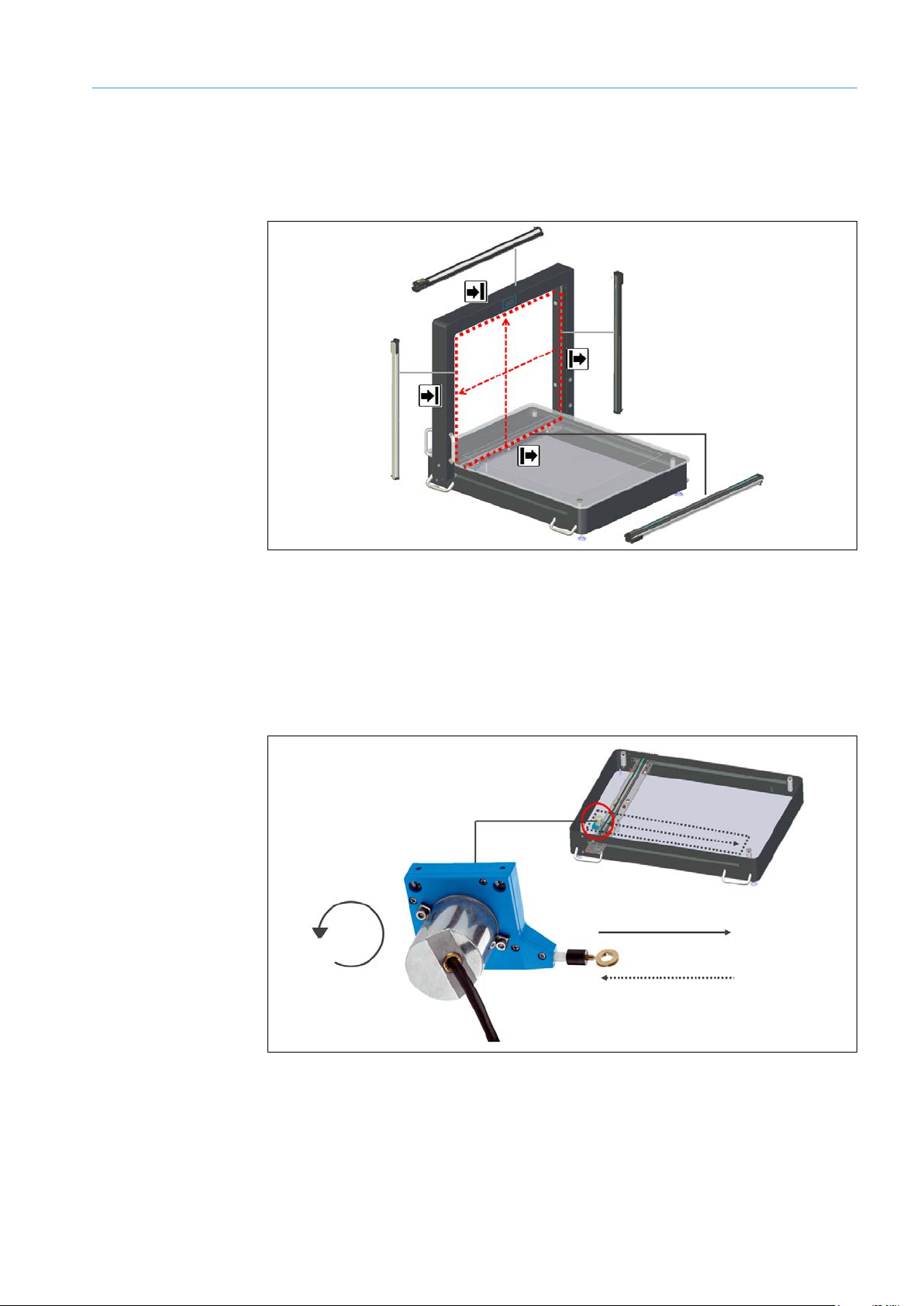

3 – Measurement gantry with MLG-2 light grids and wire draw encoder

The measurement gantry consists of a horizontal and vertical pair of light grids, which are

arranged at right angles. Both pairs of light grids determine the object’s contour based on

the principles of shadows.

Each pair of light grids consists of a sender unit with emitting diodes and a receiver unit

with receiving diodes.

Fig. 6: MLG-2 light grids

Page 23

SYSTEM DESCRIPTION 3

23

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

The horizontal light grid’s is mounted on the frame underneath the glass plate with the

receiver above it. This minimizes any interference caused by ambient light or dirt. The

beam from the lower light grid passes through the glass plate to the upper light grid. The

vertical light grid’s sender is secured to the frame with two handles.

Wire draw encoder

Fig. 7: Measurement gantry with light grids

A wire draw encoder mounted in the housing interior supplies the positional data of the

light grids above the object which is required for measuring lengths. The encoder

transfers the linear movement obtained from the path of the measurement gantry into a

rotational movement. The drum rotation, which is proportional to the length, is output to

the controller via corresponding incremental signals regarding the exact positioning of the

light grids.

Fig. 8: Wire draw encoder

Page 24

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

24

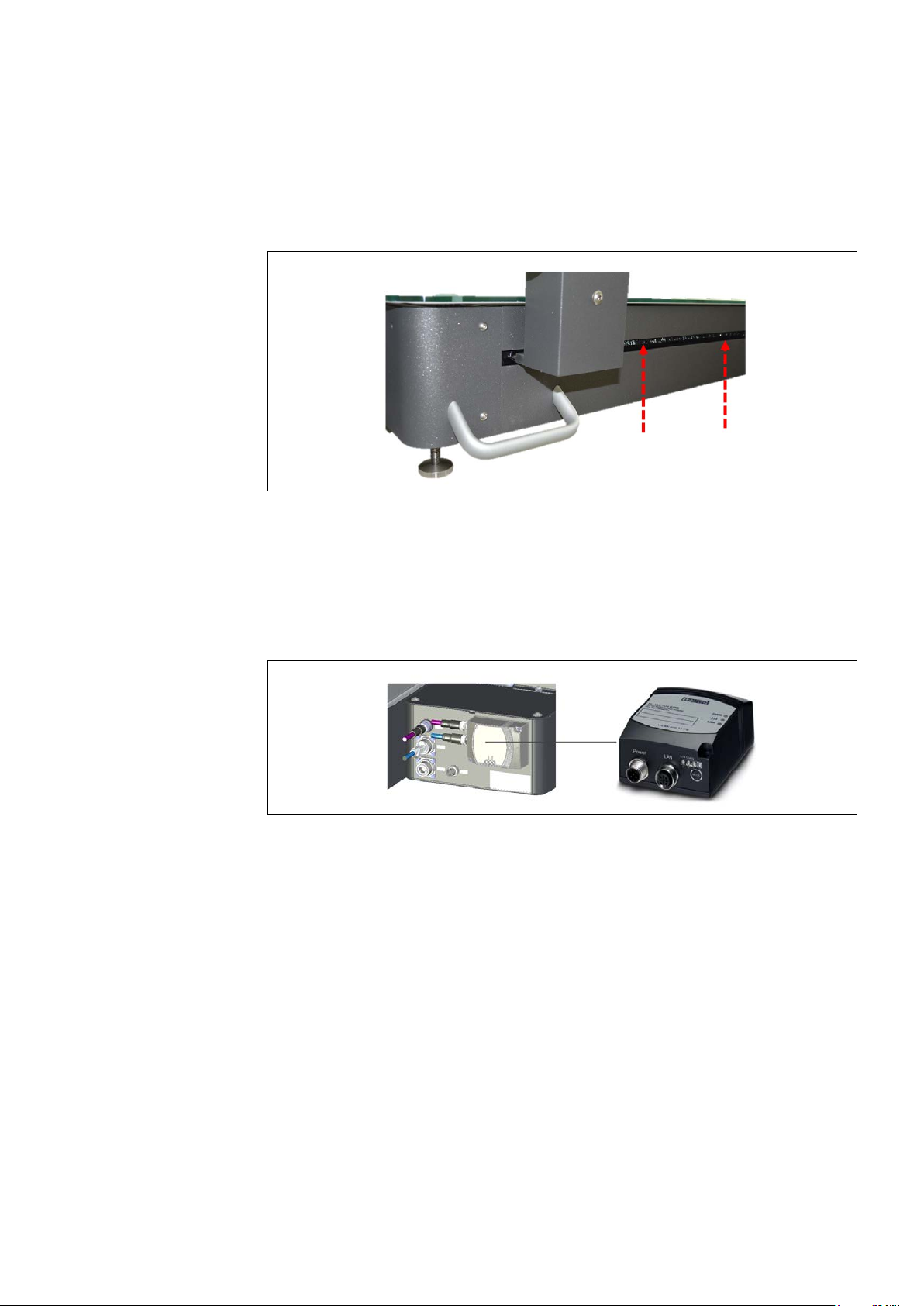

4 – Controller MSC800

The controller housing contains the MSC800 system controller and the power supply unit

for the central voltage supply.

Fig. 9: Controller MSC800

The MSC800 is the system’s central control unit. It controls the coordination of the

individual components and processes all incoming signals. The measurement results are

transmitted via the Ethernet interface to the higher-level customer system.

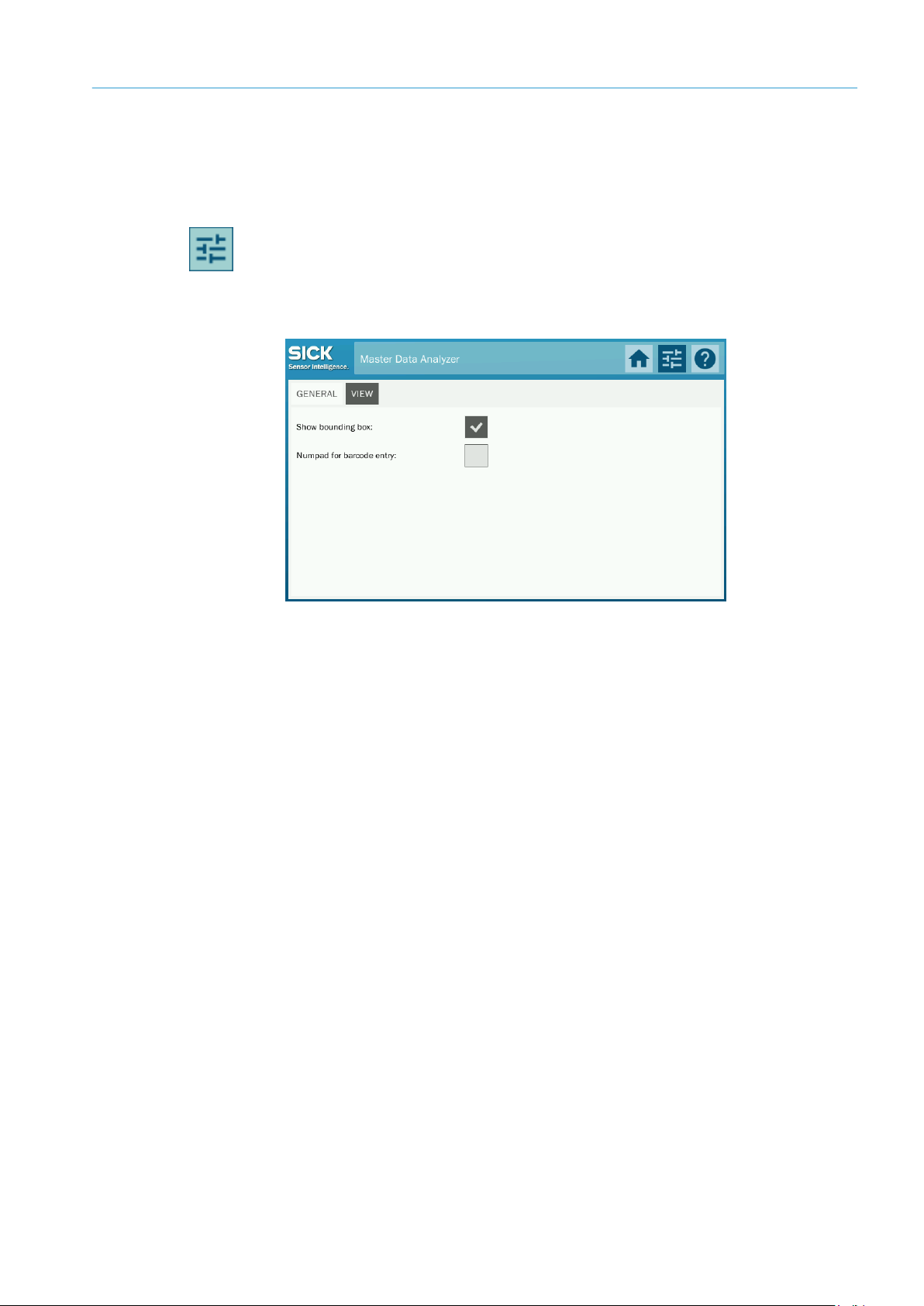

5 – Display

The display is the system’s central visualization unit. It displays the measured values from

the various components during operation and allows for the convenient handling of error

messages.

Fig. 10: Display

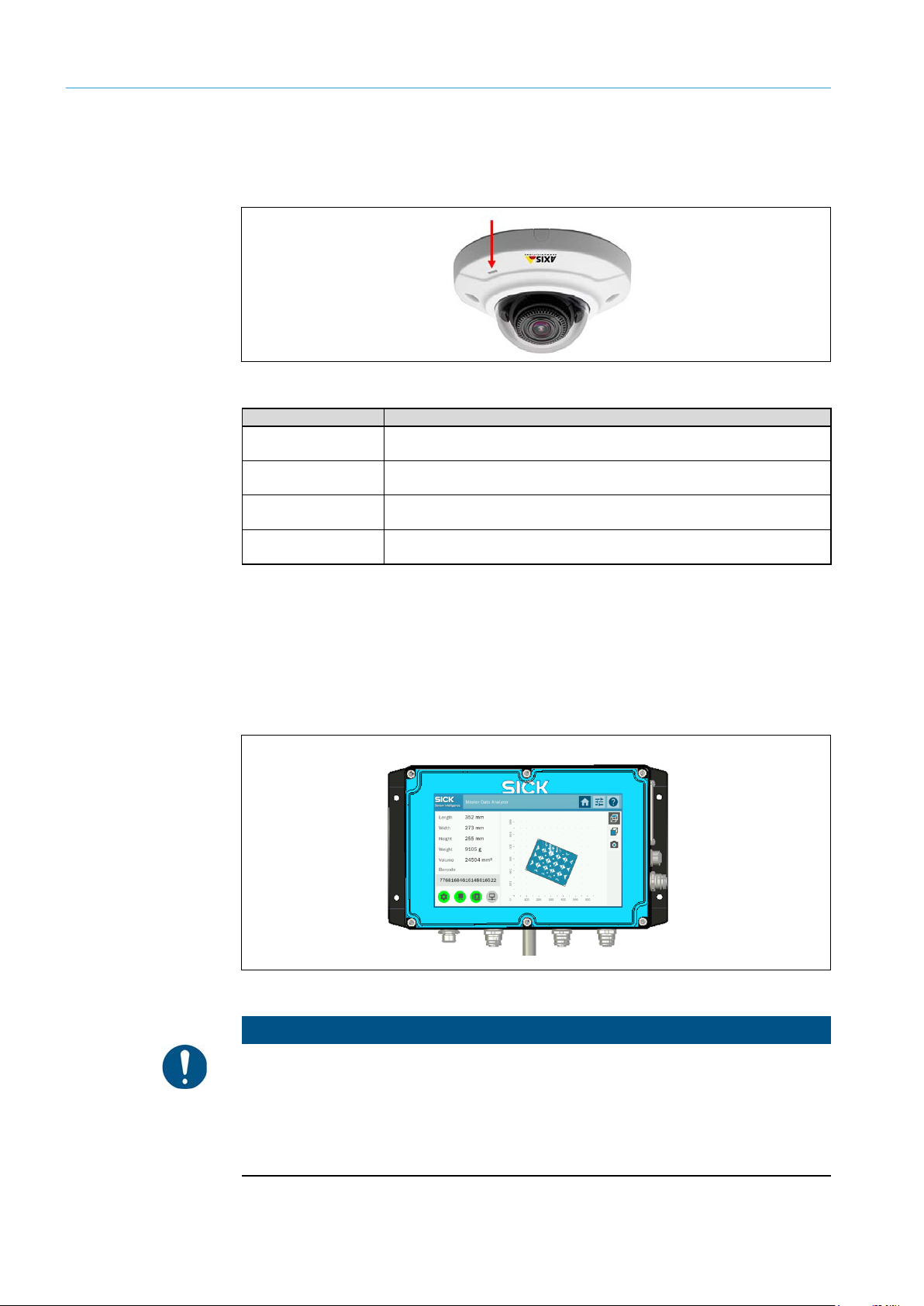

6 – IP camera (MDA650 Image/MDA800 Image only)

An IP camera mounted on the measurement gantry generates a photo-realistic image of

the object during the measurement process. The photo is transmitted to the higher-level

customer system together with the measurement data.

The IP camera is supplied with power via PoE (power over Ethernet).

Fig. 11: IP camera (MDA650 Image/MDA800 Image only)

Page 25

SYSTEM DESCRIPTION 3

25

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

7– Housing

All of the Master Power Analyzer’s components are integrated into a stable mechanical

system.

The recesses on the long sides of the housing are required for the measurement gantry to

travel along the linear guides. The recesses are sealed on both sides with brushes.

Fig. 12: Housing

8 – WLAN module

The WLAN Ethernet Port Adapter, which is available as an accessory for the controller

housing, enables the Ethernet interface to be connected wirelessly to a WLAN access

point. This enables measurement results to be transmitted to the customer system when

using the MDA in a mobile setup, regardless of the measurement location.

Fig. 13: WLAN module

The WLAN Ethernet Port Adapter has a circular, polarized 5 dB directional antenna that

also enables it to be used in surroundings with a high number of reflections from metals.

Sliding table

On request, the Master Data Analyzer is available with a sliding table, with or without a

rechargeable battery.

Page 26

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

26

3.3 The system’s operating principle

The Master Data Analyzer is designed for stationary and mobile use, depending on the

system variant.

In the stationary variant, the Master Data Analyzer is placed at a fixed location and

connected (e.g., at the receiving work station). With the mobile variant, data can be

recorded at any chosen location (e.g., right on the high-bay racking). A WLAN adapter

must be connected in this case.

The measurement process depends on the operating mode in question.

Fig. 14: Measurement process for each operating mode

In the operating mode with bar code scanning, the measuring process starts once the

object has been placed on the measurement field and the bar code has been scanned.

The volume and weight are then measured in one procedure.

In the operating mode without bar code scanning, the measuring process starts with the

weight measurement. The volume cannot be measured until a stable weight value is

present.

Page 27

SYSTEM DESCRIPTION 3

27

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

Placing an object in the measurement field

The measurement object is placed in the clear-glass area of the glass plate. This area

marks the measurement field, i.e., the area in which the object can be captured by the

light grids. If the object, or any part of it, is outside of the measurement field (in the opal

glass area) an error message will be issued.

Fig. 15: Marked measurement field on the glass panel

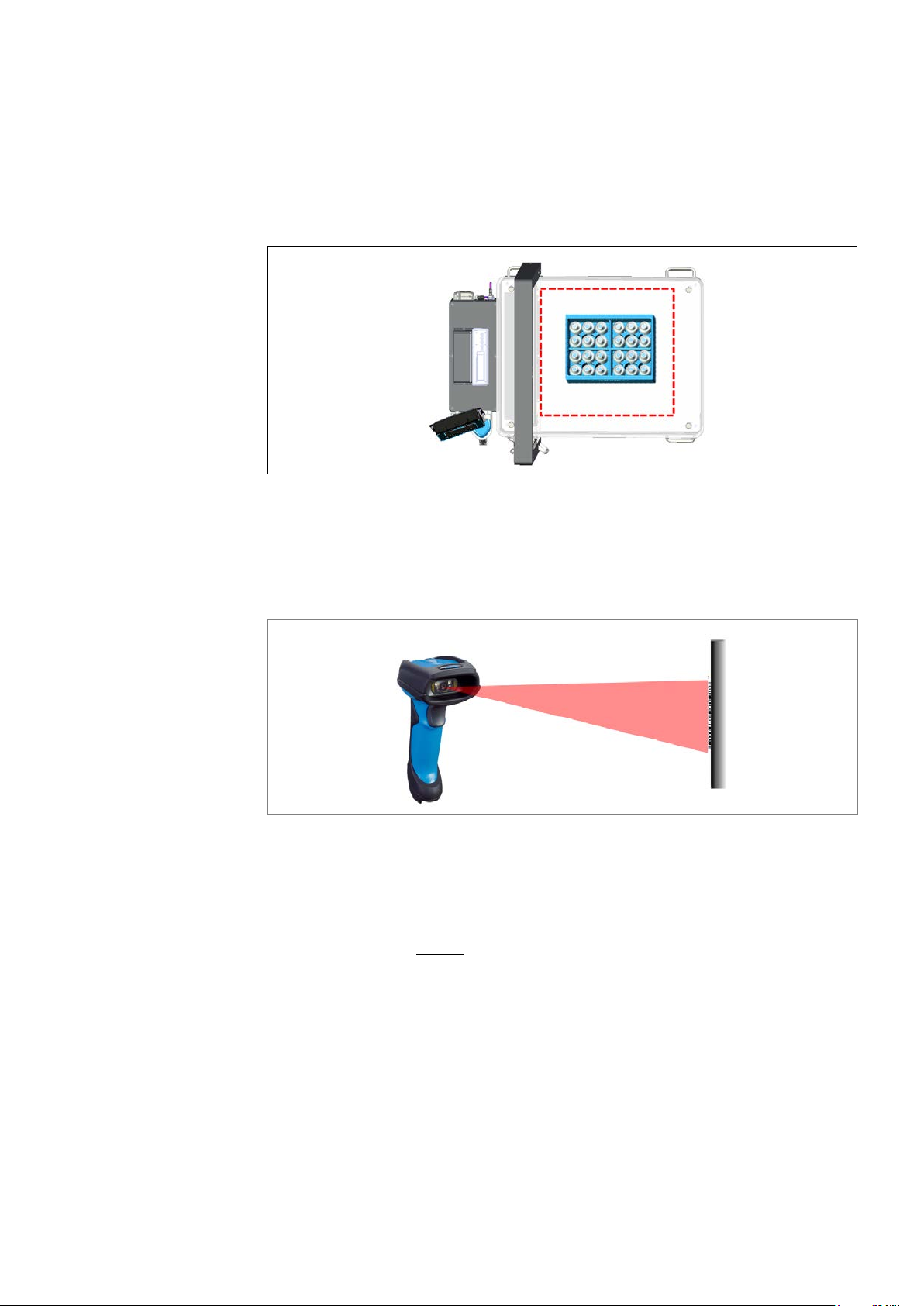

Bar code reading (only for operating mode with bar code scanning)

The wired hand-held scanner identifies the object and transmits the shipping number to

the controller. The scanner creates a scan line on the object to read the bar code using a

red light. The bar code that is read is then shown on the display.

Fig. 16: Operating principle – bar code reading

Note

The bar code can also be entered manually using the display.

Weight measurement (only for operating mode with bar code scanning)

In the operating mode without bar code scanning, the measuring process starts with the

system detecting a stable weight value. Bar codes cannot be scanned or processed.

Page 28

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

28

Measuring the volume

The volume measurement is carried out if a valid bar code or stable weight value is

available.

To do so, the light grids mounted on the measurement gantry are manually moved over

the measurement object using the two linear guides. Measurements can be taken in both

directions, stopped whilst doing so, and then recommenced.

If the monitoring field is interrupted by an object, the shadowing and the resulting number

of interrupted light beams on the receiver lines can be used to detect the profile of the

object.

The change in the number of beams on the receiver lines as a result of the shadowing is

transmitted via the light grids’ interfaces to the MSC800 as a digital signal.

Two-dimensional cross sections are created by moving the light grids across the object.

The controller then combines the individual 2D cross sections of the object.

Fig. 17: Operating principle – volume measurement

By taking into consideration the speed with which the measurement gantry is moved

across the object and the respective position of the light grids above the object, a spatial

image is produced which is used to calculate the smallest possible cuboid which could

surround the object as well as its volume.

Page 29

SYSTEM DESCRIPTION 3

29

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

Weighing process

In the operating mode with bar code scanning, the weighing process takes place in

parallel to the volume measurement; in the operating mode without bar code scanning,

the weight is calculated once the object has been positioned, i.e., before the volume

measurement.

The weighing cells determine the weight of the object by using the four recording points at

the corners of the glass panel whilst the object is situated on the glass panel.

The electronic scales use weighing cells with strain gauges to bear the weight to be

measured. Strain gauges are metallic conductors which convert mechanical actions of

force into an electronic signal. Strain gauge weighing cells use the physical principle that

an electrical conductor changes its electrical resistance as a result of mechanical

changes.

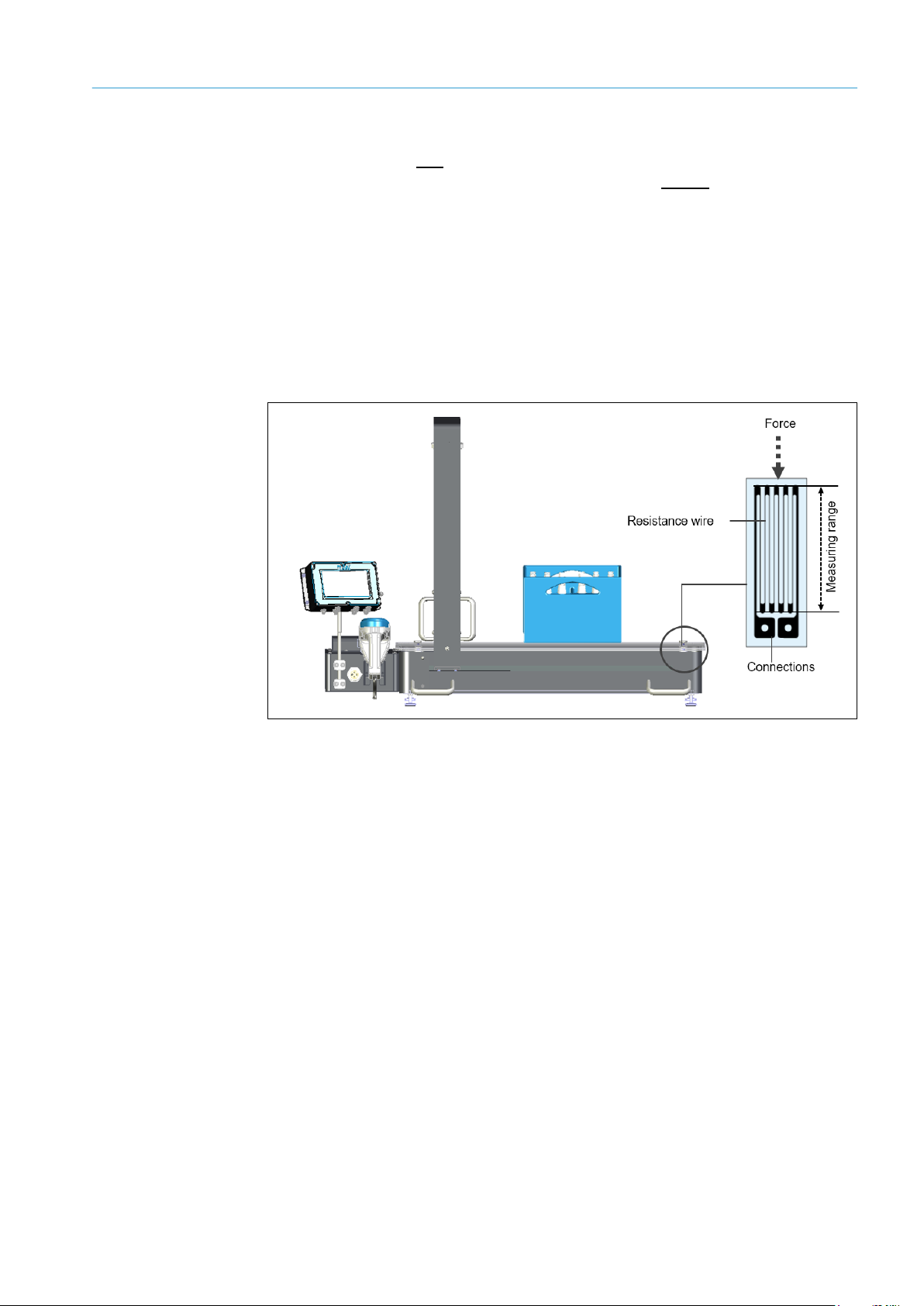

Fig. 18: Operating principle – Weighing process

If a load is placed on the glass panel, this causes the strain gauges to deform. As a result

of this deformation causing the resistance in the strain gauges to change, the weight of

the load can be determined by using the electronic scales. The greater the deformation,

the greater the resistance due to the strain and, as a result, the heavier the weight of the

measured object.

In order to achieve maximum measurement accuracy, the electronic signal resulting from

the change in resistance is converted to a digital signal by an integrated A/D converter

(analog-digital transducer).

The weight recorded is then shown on the display. It is added to the bar code already

displayed.

If the weight value of an object is outside of the pre-configured absolute limit values, this

is output as an error in the measurement report.

Page 30

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

30

Visualization of measurement results

All of the measurement data recorded by the MDA is constantly shown on the display. The

measurement is additionally displayed in the form of a 2D visualization.

If the MDA650 Image / MDA 800 Image system variant is in use, the symbol for the live

display appears on the right, next to the measurement field.

Fig. 19: Operating principle – Visualization of measurement results

Output of measured values

All information converges in the MSC800 central control unit. The MSC800 processes the

encoder signals and assigns the measurement results from the individual systems to the

respective object.

Depending on the system variant, the output of measured values are sent to the higherlevel customer system via Ethernet (LAN) or via a WLAN access point.

When using the MDA650 Image/MDA800 Image), a photo-realistic image of the

measuring object can be emitted with the measurement results.

Note

• In the operating mode with bar code scanning, the measurement results are stored

temporarily during the output of measured values if the device is not connected to

the customer server. This allows multiple measurements to be carried out in sequence,

even without a connection. Data are transmitted automatically as soon as the

connection is available again.

• In the operating mode without bar code scanning, the data must be transferred directly

after the measurement otherwise the data cannot be allocated to the bar code in

the customer system. The temporary storage of measurement results is not supported.

Page 31

31

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

3.4 Project planning

Dimension

Explanation

Minimum object size (L x W x H)

10 mm x 10 mm x 5 mm

Maximum object size (L x W x H)

MDA800 / MDA800 Image

800 mm x 600 mm x 600 mm

Object rotation

Omni

Minimum object weight

20 g

Maximum object weight

30,000 g

Singulation

Yes

System requirements

The following conditions must be met to operate the Master Data Analyzer:

• Supply voltage: AC 100 to 264 V/50 to 60 Hz

• Ethernet connection of WLAN access point for forwarding the measurement results

to the customer’s system

Requirements for the operation site

• Closed room

• Flat and firm surface

• Low-vibration environment

• Protected from wind and free of drafts

• Well-lit

• Clean and dry

• Room temperature below 40 °C

Regardless of the space requirements of the MDA, there must be enough space at the

operation site for the following activities:

• Operating the system

• Cleaning, repair, and service

Ethernet connection requirements

In the operating mode without bar code scanning, a permanent Ethernet connection

must be in place otherwise the measurement results will not be able to be assigned to the

bar code in the customer’s system.

Object requirements

SYSTEM DESCRIPTION 3

Notes

MDA650 / MDA650 Image

Tab. 5: Conveying system and object requirements

650 mm x 600 mm x 600 mm

If the object moves suddenly or vibrates on the MDA during the measurement process,

the accuracy may be reduced and less data may be recorded by the system.

Page 32

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

32

No.

LED indicator

Description

1

Green

Green LED permanently on

Supply voltage on

1

Red

Red LED permanently on

Hardware fault

No.

LED indicator

Description

1

Green

Green LED permanently on

Supply voltage on

Green

Green LED off

Supply voltage off or too low

2

Yellow

Yellow LED permanently on

Light path interrupted (at least one beam is interrupted)

Yellow

Yellow LED off

Light path is unobstructed

Yellow 3 Hz

Yellow LED flashing rapidly

The alignment mode is not permanently deactivated until after teach-in

Yellow 1 Hz

Yellow LED flashing slowly

Teach-in active

Red

Red LED permanently on

combination of the yellow and the green LEDs.

Red 10 Hz

Red LED flashing rapidly

An error has occurred during teach-in.

3.5 Status indicators

The Master Data Analyzer’s accessible status indicators can be found on the following

devices:

3.5.1 Status indicators – Light grids

The receivers on the light grids have three LEDs on the connection side. These provide a

visual indication of the operational status and any occurring faults.

Fig. 20: Status indicators – Light grids

LEDs on the MLG-2 sender

Tab. 6: Status indicators – Light grids (senders)

LEDs on the MLG-2 receiver

Contamination warning or alignment mode is active (the signal from

the receiver is too weak)

A fault has occurred. The type of fault will be indicated by a

Tab. 7: Status indicators – Light grids (receivers)

Page 33

SYSTEM DESCRIPTION 3

33

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

LED indicator

Description

Blue

LED is permanently blue: Supply voltage on

Green

LED flashes green once: The bar code has been scanned successfully

Indicator

Description

Beeper

1 beep following successful scan.

Vibration

Vibration following successful scan.

3.5.2 Status indicators – Hand-held scanner (only in operating mode with bar code scanning)

Optical indicators

The wired hand-held scanner has an LED to display the operational and reading status.

Fig. 21: Status indicators – Hand-held scanner

Tab. 8: Status indicators – Hand-held scanner

Further indicators

Page 34

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

34

LED indicator

Description

LED is off

Connection and normal operation

Green

Permanently green for 10 seconds for normal operation following system

start

Yellow

Permanently on during start-up.

Flashes during firmware update.

Yellow/red

Flashes yellow/red if the network connection is not available or has been

lost.

NOTE

3.5.3 Status indicators – IP camera

The IP camera mounted to the measurement gantry for the MDS650/800 is equipped

with a status LED.

Fig. 22: Status indicators – IP camera

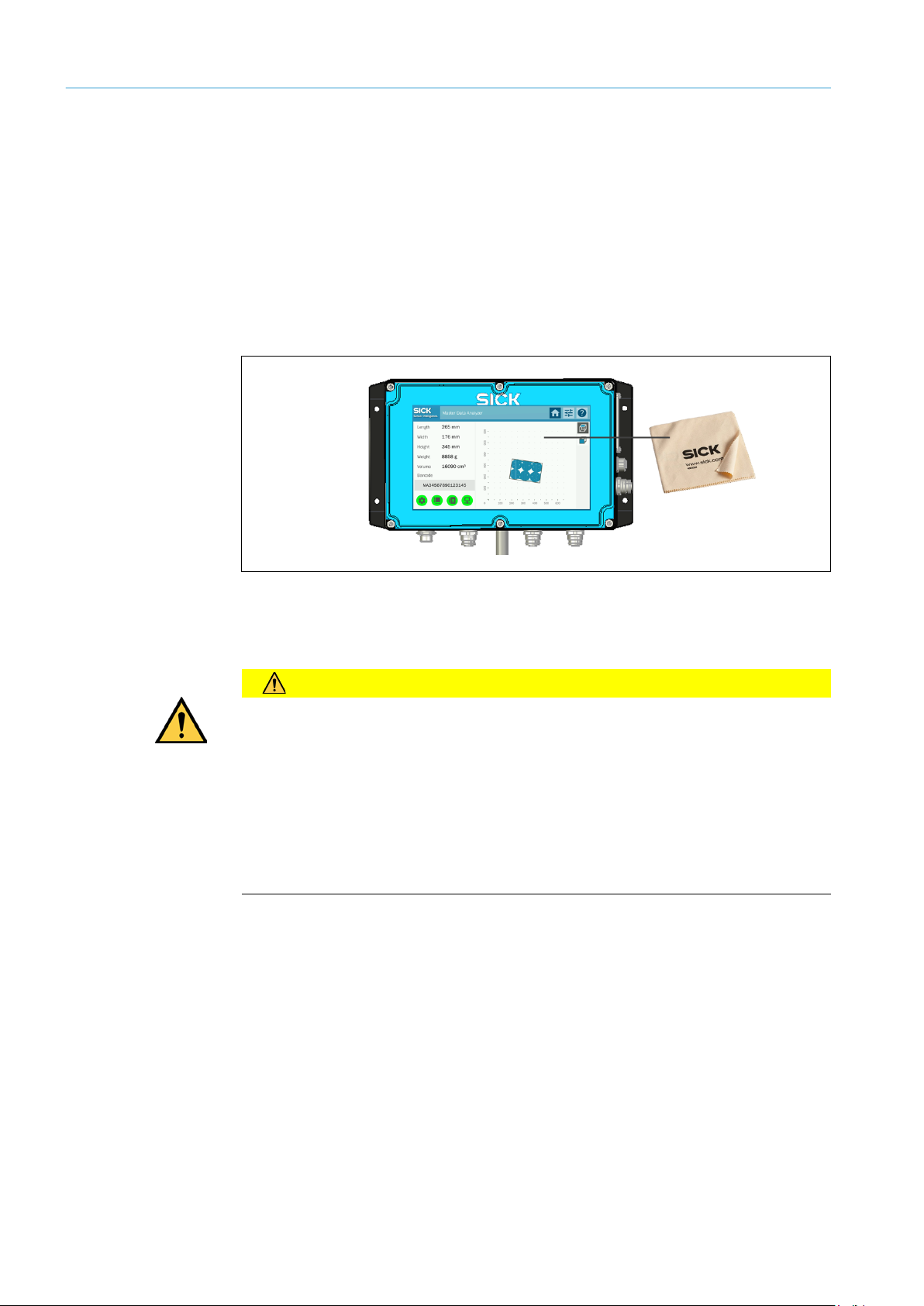

Tab. 9: Status indicators – IP camera

3.5.4 Status indicators – Display

The display is used to visualize the measurement results as well as for interacting with the

system to troubleshoot error messages.

The screen is controlled by gently touching the respective touch pads. The touch pads on

the touch screen vary according to the operational context.

Fig. 23: Status indicators – Display

Notes on the correct use of the touch screen

You are only permitted to touch the touch screen with your fingers. Gently press the touch

pads to operate them; do not apply force.

Do not operate the touch screen with pointed or sharp objects; otherwise, the surface of

the touch screen will become damaged.

Page 35

35

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

3.5.5 Status indicators – Electronic scales

Designation

Color

Status

Description

PWR

Green

On

Supply voltage is on

Flashing

Supply voltage is too low

Off

Supply voltage is not on

>>>

Blue/purple/red

Blue light

A WLAN connection has been established

Purple

The device is attempting to connect to

another WLAN device

Flashing blue

Data transmission

Red

Fault

Off LAN

Yellow

On

Ethernet link available

Flashing

Ethernet communication is active

Off

No Ethernet connection

Designation

Color

Status

Description

Link quality

Green

On

A: Weak connection quality

A, B, C, D: Excellent connection quality

The scales display affixed to the controller housing only shows the measurement results

from the electronic scales.

The additional display is required if the MDA’s electric scales are to be operated in the

verified mode.

3.5.6 Status indicators – WLAN module

The WLAN module which can be added as an optional accessory has the following status

and diagnostics displays.

SYSTEM DESCRIPTION 3

Fig. 24: Status indicators – WLAN module

Tab. 10: Status indicators – WLAN module

Quality

Four LEDs are located on the underside of the device which display different information

depending on the operating mode.

A and B: Sufficient connection quality

A, B, and C: Good connection quality

Tab. 11: Status indicators – WLAN module (quality)

Page 36

3 SYSTEM DESCRIPTION

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

36

Name

Description

The measurement results are transmitted to the customer’s higher-level system

configured for this interface.

The separate Service configuration interface is available for configuring the

system.

3.6 Interfaces

The Master Data Analyzer has two Ethernet interfaces.

Data

Service

Tab. 12: MSC800 Ethernet interfaces

using the Data Ethernet data interface. The TCP/IP and FTP protocols can be

Page 37

TRANSPORT, ASSEMBLY, AND MOUNTING 4

37

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

Icon

Meaning

Transport the crate with this side facing up!

The contents of this transport crate are fragile!

Keep dry!

Do not place anything on top of this box!

4 Transport, assembly, and mounting

All system components are delivered assembled and cabled to each other.

The system must be transported by the customer to the place of utilization.

It can then be removed from the box, put into position, and operated.

4.1 Accepting the delivery

4.1.1 Packaging

The Master Data Analyzer is delivered in a strong wooden crate on a transport pallet.

This protects the system against the impacts of transportation such as sudden jolts and

knocks, dirt and dust or moisture such as rain, snow or condensed water throughout

the entire transportation process, during loading and unloading, and whilst in storage.

Signs with notes ensuring secure transportation

The packaging bears signs with notes to ensure the system is securely transported and

appropriately stored. These symbols must be observed.

Tab. 13: Signs with notes ensuring secure transportation

4.1.2 Checking delivery for visible transport damage

The package should be checked immediately after unloading to ensure all items have

been delivered by using the delivery note as well as checking for any external damage.

If visible external transport damage is discovered on receipt of the package, we

recommend you take the following action:

Visible damage

Immediately record the discovered transport damage in the freight documents and

▸

ask the delivery carrier to countersign this.

In the event of serious damage, the manufacturer and insurance company should be

▸

notified immediately.

Do not attempt to make any changes to the damage from when it is discovered and

▸

keep the packaging material until the transport company or transport insurance

company have come to a decision whether to visit your location.

If possible, take photos of the damage to packaging and packaged goods.

▸

Page 38

4 TRANSPORT, ASSEMBLY, AND MOUNTING

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

38

WARNING

4.2 Transporting the MDA to its location of use

It is best to transport the package in its packaging until you reach the location where the

device is to be used.

The transport crate must always be kept upright and in a horizontal position when being

transported.

Under no circumstances, and not even for a short time, should it be turned over or stored

on its side.

Risk of injury from suspended load

The Master Data Analyzer is delivered in a transport crate on a pallet. Use a suitable lifting

device to unload and transport the device.

During transport, tipping or falling loads pose a risk of severe injury or damage to

property.

Measures

Only use lifting equipment which is suitable for the weight and dimensions of the

▸

freight.

Make sure that the center of gravity is in the center between the forks of the lifting

▸

device and the forks are completely entrenched under the transport pallet.

Do not stop underneath the suspended load.

▸

Wear safety shoes in addition to your personal protective equipment.

▸

Note

Transport with manned forklift truck/lifting truck

Use a manned forklift truck or a suitable lifting truck to transport the crate.

1. Pick up the pallet with the forks.

Make sure that the center of gravity is in the center between the forks and the forks

▸

are completely entrenched under the transport pallet.

Fig. 25: Transporting with a lifting device

2. Transport the load to the place of use.

3. Carefully set down the pallet at the operation site.

Page 39

TRANSPORT, ASSEMBLY, AND MOUNTING 4

39

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

NOTE

WARNING

WARNING

WARNING

4.3 Unpacking and setting up the device

4.3.1 Unpacking the MDA

Instructions for unpacking can be found on the outside of the transportation crate which

is used to deliver the device.

While unpacking, follow all stages in the unpacking instructions.

▸

All work relating to the installation of the device must only be done in consideration of the

relevant safety regulations.

Risk of injury due to components falling over

The side panels and lid of the transport crate are heavy and difficult to handle.

Falling objects pose a risk of crushing during dismantling.

Measures

Always use 2 people to mount the side panels and lid.

▸

Wear protective shoes in addition to your personal protective equipment.

▸

Risk of injury when lifting heavy objects.

There is a risk of injury when lifting heavy objects.

Depending on the system variant, the MDA weighs around 65 kg to 80 kg.

Measures

Use 4 people to lift the MDA.

▸

In order to do this, use the four handles on the two long sides of the MDA.

▸

Lift and carry the MDA according to ergonomic principles.

▸

Wear protective shoes in addition to your personal protective equipment.

▸

Impermissible handling of the device

There is a risk of damage to the device when lifting the MDA using the measurement

gantry.

Measures

Do not lift the MDA using the measurement gantry under any circumstances!

▸

Disassembling the transport crate

The lid and side panels are secured with screws.

1. Unscrew and remove the screws from the lid and lift the lid from the transportation crate.

2. Unscrew and remove the screws in order from the four side panels and then remove

them.

3. The Master Data Analyzer can now be accessed from all sides.

Page 40

4 TRANSPORT, ASSEMBLY, AND MOUNTING

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

40

NOTE

NOTE

Removing the device from the pallet

1. Remove all of the secondary packaging.

2. Use 4 people to each hold the MDA by one of the handles on the long side of the

housing.

Fig. 26: Lifting the MDA from the transport pallet

3. Lift the device straight from the pallet taking ergonomic aspects into account.

Storing packaging

The packaging should be kept for the period of the warranty.

The steps should be repeated in reverse order if the package is to be sent back.

Disposing of the packaging

The packaging used for the Master Data Analyzer is made from wood and plastic.

The customer is responsible for proper disposal of the packaging.

The national regulations at the operation site must be observed.

4.3.2 Checking delivery for hidden transport damage

We recommend that the MDA is thoroughly checked for all types of (hidden) transport

damage once it is unpacked. Any damage should then be reported.

All components should be examined for mechanical damage.

▸

Inspect all cableways to the connected components.

▸

Check that all cable connections are securely attached.

▸

Note

Always document the damage by taking photographs.

▸

Page 41

41

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

4.3.3 Setting up the MDA

WARNING

WARNING

The Master Data Analyzer is set up on a table.

Risk of injury due to the device tipping over

There is a risk of the MDA tipping over during installation. An unsuitable surface may also

lead to the device tipping over.

The device tipping over can lead to the severe crushing or even loss of limbs.

There is also the risk of inflicting damage to the device.

Measures

Place the device on a sufficiently stable and steady table.

▸

Secure the table to prevent rolling away.

▸

All four of the adjustable feet must be completely on the table.

▸

TRANSPORT, ASSEMBLY, AND MOUNTING 4

Risk of crushing when settings down the MDA

The adjustable feet are designed so that the safety distance between the bottom of the

device and the tabletop can be observed.

There is a risk of crushing when installing the MDA on the tabletop.

Measures

Do not put your hands under the base of the housing when installing the MDA.

▸

Fig. 27: Risk of crushing when settings down the MDA

Page 42

4 TRANSPORT, ASSEMBLY, AND MOUNTING

8020065-ZSP4/2017-08-10|SICK

OPERATING INSTRUCTIONS | Master Data Analyzer

Subject to change without notice

42

Placing the MDA on a table

1. Put the MDA with the four adjustable feet on a table. The table must be stable, of a

sufficient size and secured against rolling away.

A non-slip base is recommended.

Note

Note

Make sure that all four adjustable feet are completely on the tabletop.

2. Align the Master Data Analyzer. You can use a spirit level or the spirit level visible on

the interior housing to do this.

A sliding table is available as an accessory with or without a rechargeable battery (see

also chapter 3.1 Scope of delivery).

The sliding table is equipped with an anti-slip surface as standard.

Page 43

43

8020065-ZLP4/2017-08-10|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | Master Data Analyzer

4.4 Removing the transport locks

CAUTION

The scales, measurement gantry, and hand-held scanner are protected against damage

whilst being transported.

The transport locks must be removed before commissioning the MDA.

Removing the transport lock on the electronic scales

The glass panel is locked to the housing in order to protect the weighing cells.

1. Unscrew the screws in the transport locks. The non-removable screws cannot be

completely unscrewed.

2. Swivel the transport locks downwards and tighten the screws once again. The transport

locks remain on the housing and can be returned to their initial position in case the

device is transported again.

TRANSPORT, ASSEMBLY, AND MOUNTING 4

Fig. 28: Removing the transport locks on the electronic scales

Removing the transport lock on the measurement gantry

The measurement gantry is secured to the handle with a cable tie on the operator’s side.