Page 1

MARSIC300

Ship Emission Measuring Device

Installation and Initial Start-up

T E C H N I C A L I N F O R M A T I O N

Page 2

Described product

MARSIC300

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Function of this document....................................................................... 6

1.2 Target group.............................................................................................. 6

1.3 Further information................................................................................... 6

1.4 Symbols and document conventions...................................................... 6

1.4.1 Warning symbols...................................................................... 6

1.4.2 Warning levels / Signal words................................................. 7

1.4.3 Information symbols................................................................ 7

2 Installation.......................................................................................... 8

2.1 Gas supply terminology............................................................................ 8

2.2 Installation information............................................................................ 8

2.2.1 Information on power supply.................................................. 8

2.2.2 Notes on the gas supply.......................................................... 8

2.2.3 Tube screw fitting..................................................................... 9

2.3 Scope of delivery....................................................................................... 9

2.4 Provision by operator................................................................................ 9

2.5 Installation overview................................................................................. 10

2.6 Checklist for mechanical and electrical installation............................... 10

2.7 Assembly information for sample gas lines and tube bundle cable..... 11

2.8 Installing the analyzer cabinet................................................................. 13

2.9 Connect the sample gas line to the analyzer.......................................... 14

2.10 Connecting the tube bundle cable to the analyzer................................. 16

2.11 Connecting the signal lines to the analyzer............................................ 19

2.12 Air and gas connections on analyzer....................................................... 20

2.13 Electrical connections on the analyzer.................................................... 23

2.14 Installing the gas sampling system......................................................... 25

2.15 Setting up the Modbus-Profinet converter (optional)............................. 27

2.16 Setting up the Modbus-Profinet converter (optional)............................. 32

3 Initial start-up..................................................................................... 37

4 Configuration software..................................................................... 39

4.1 Software SOPAS ET................................................................................... 39

4.2 Saving parameters.................................................................................... 40

4.3 Backing up the logbook with SOPAS ET.................................................. 41

4.4 Passwords................................................................................................. 41

4.5 Using the menus....................................................................................... 42

4.6 Menu tree (SOPAS ET).............................................................................. 42

5 Measuring screens and data storage............................................. 44

5.1 Measuring screen..................................................................................... 44

5.2 Data storage function............................................................................... 45

6 Parameterization............................................................................... 47

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

3

Page 4

CONTENTS

6.1 Measuring components............................................................................ 47

6.2 Measuring screens................................................................................... 47

6.3 Adjustment functions............................................................................... 50

6.3.1.1 Concentrations of test gases................................. 51

6.3.1.2 Adjustment factors................................................. 51

6.3.1.3 Start times.............................................................. 51

6.3.1 Manual adjustment................................................................. 52

6.3.2 Automatic adjustment............................................................. 52

6.4 Measuring point switchover / Sequence control program..................... 52

6.5 Data interfaces / IO.................................................................................. 55

6.5.1 Digital inputs............................................................................ 55

6.5.2 Digital outputs.......................................................................... 56

6.5.3 OPC outputs............................................................................. 56

6.5.4 Modbus..................................................................................... 56

6.6 Device parameters................................................................................... 58

6.6.1 Temperature control................................................................ 58

6.6.2 Pressure control....................................................................... 59

6.6.3 Flow rate................................................................................... 59

6.6.4 O2 sensor................................................................................. 59

6.6.5 Logbook.................................................................................... 59

6.6.6 Instrument display................................................................... 60

6.6.7 System ..................................................................................... 60

6.6.8 Emitter...................................................................................... 61

7 Diagnosis............................................................................................ 62

7.1 Control values adjustment, sensors and signals.................................... 62

7.2 Sensor values........................................................................................... 63

7.3 Signals....................................................................................................... 63

7.4 Logbook..................................................................................................... 66

7.5 System info................................................................................................ 67

7.5.1 System status.......................................................................... 68

7.5.2 System info............................................................................... 68

7.5.3 Timemeter................................................................................ 68

8 Maintenance...................................................................................... 69

8.1 Test digital I/O........................................................................................... 69

8.2 Setting operating states........................................................................... 69

8.3 System maintenance (Stand-by, Leakage test, etc.).............................. 70

8.4 Restart....................................................................................................... 71

8.5 Service log................................................................................................. 71

8.6 Acknowledging messages........................................................................ 72

8.7 Loading/saving the parameters.............................................................. 72

8.8 Loading/saving the parameters after replacing the analyzer................ 73

8.9 Loading/saving the parameters after replacing the electronics........... 74

9 Maintenance...................................................................................... 75

4

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 5

CONTENTS

9.1 Leak tightness check during initial startup............................................. 75

9.2 Leak tightness check with pressure test tool......................................... 76

10 Technical data.................................................................................... 78

10.1 Dimensional drawings.............................................................................. 78

10.2 Design........................................................................................................ 79

10.3 Measuring parameters............................................................................. 79

10.4 Ambient conditions................................................................................... 80

10.5 Sample gas conditions............................................................................. 80

10.6 Heated sample gas lines.......................................................................... 81

10.7 Tube bundle cable.................................................................................... 81

10.8 Interfaces and protocols.......................................................................... 82

10.9 Power supply............................................................................................. 82

10.10 Connections in analyzer........................................................................... 83

10.11 Circuit breakers......................................................................................... 86

10.12 Supply gases............................................................................................. 87

10.13 Tube connections...................................................................................... 87

10.14 Torques...................................................................................................... 87

11 Annex.................................................................................................. 89

11.1 Gas flow plan............................................................................................ 89

11.2 Modbus register........................................................................................ 90

11.2.1 Device status (Discrete Inputs [1xxxx], Function Code 02)... 90

11.2.2 Measured variables (Input Register [3xxxx], Function Code

04)............................................................................................ 90

11.2.3 Device-internal monitoring values (Input Register [3xxxx],

Function Code 04)................................................................... 91

11.2.4 Triggering the MARSIC 300 (Coils [0xxxx], Function Code

15, write multiple Coils).......................................................... 92

11.2.5 VDI 4301 conform range (Holding Register [4xxxx], Func‐

tion Code 03)........................................................................... 92

11.3 Error messages and possible causes..................................................... 93

11.4 Tags (variable names).............................................................................. 100

12 Index.................................................................................................... 102

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Function of this document

This document describes:

Installation

•

Initial start-up

•

Operation via SOPAS ET

•

NOTICE

This technical documentation is only valid in combination with the MARSIC300 Operat‐

ing Instructions.

1.2 Target group

This document is addressed to technicians (persons with technical understanding)

operating and maintaining the measuring system.

The technicians must have been trained on the device.

Requirements for the technician

The technician must be familiar with the exhaust gas technology on the ship (over‐

•

pressure, toxic and hot flue gases) and be able to avoid hazards when working on

gas ducts.

The technician must be familiar with handling compressed gas cylinders (test

•

gases).

The technician must be able to avoid hazards caused by noxious test gases.

•

Only allow an authorized electrician to work on the electrical system or electrical

•

subassemblies.

1.3 Further information

SFU Gas Sampling System Operating Instructions

•

Sample Gas Line Operating Instructions

•

System documentation

•

Short instructions for MARSIC300

•

Optional: MPR (Meeting Point Router) Operating Instructions

•

Optional: Instrument Air Conditioning Operating Instructions

•

Optional: External Measuring Point Switchover Operating Instructions

•

Optional: Pressure Test Tool Operating Instructions

•

Optional: Profibus/Profinet Converter Operating Instructions

•

Optional: HOTSAMPLER (measuring point extension) Operating Instructions

•

1.4 Symbols and document conventions

1.4.1 Warning symbols

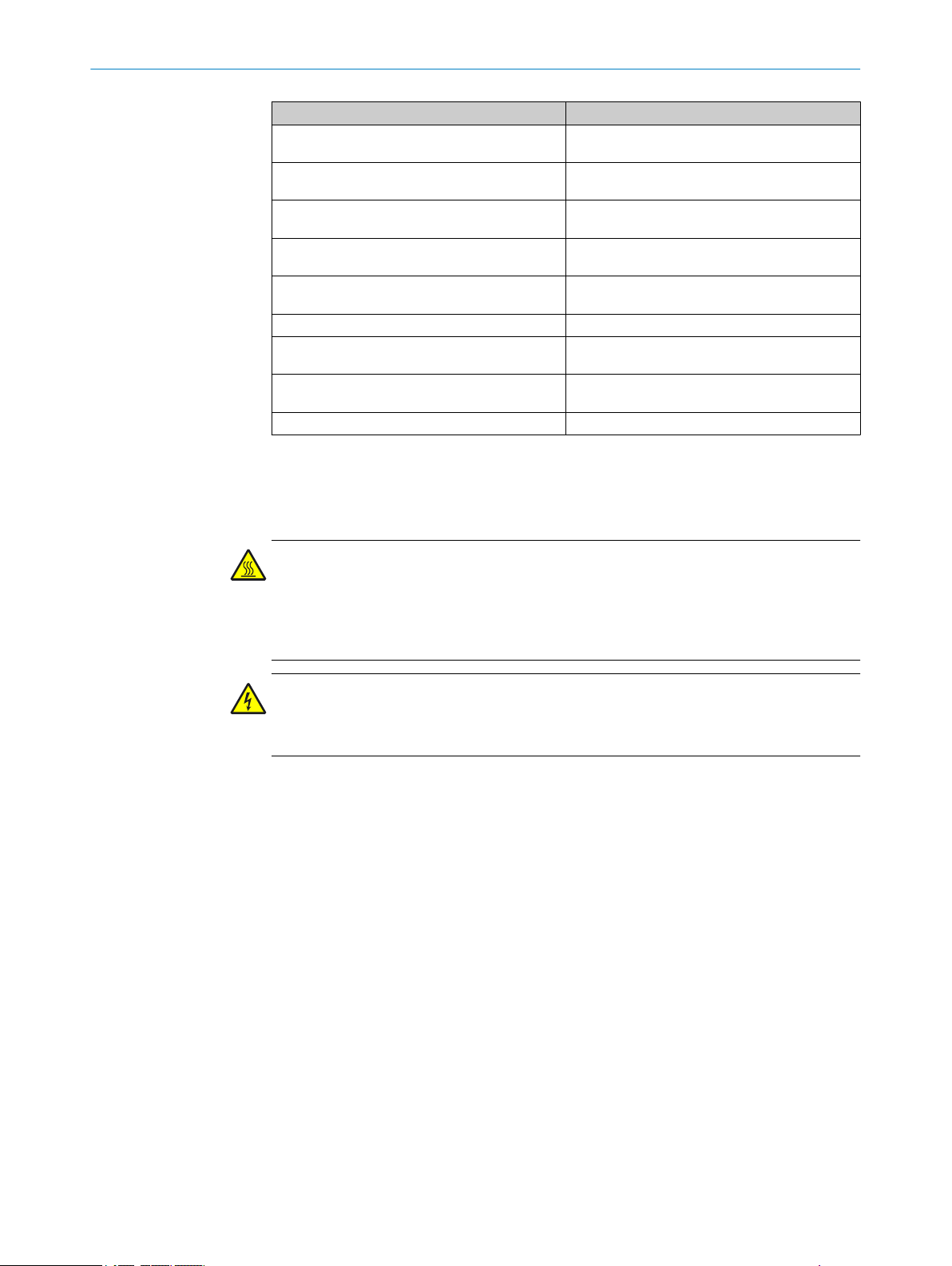

Table 1: Warning symbols

Symbol Significance

6

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Hazard (general)

Hazard by voltage

Subject to change without notice

Page 7

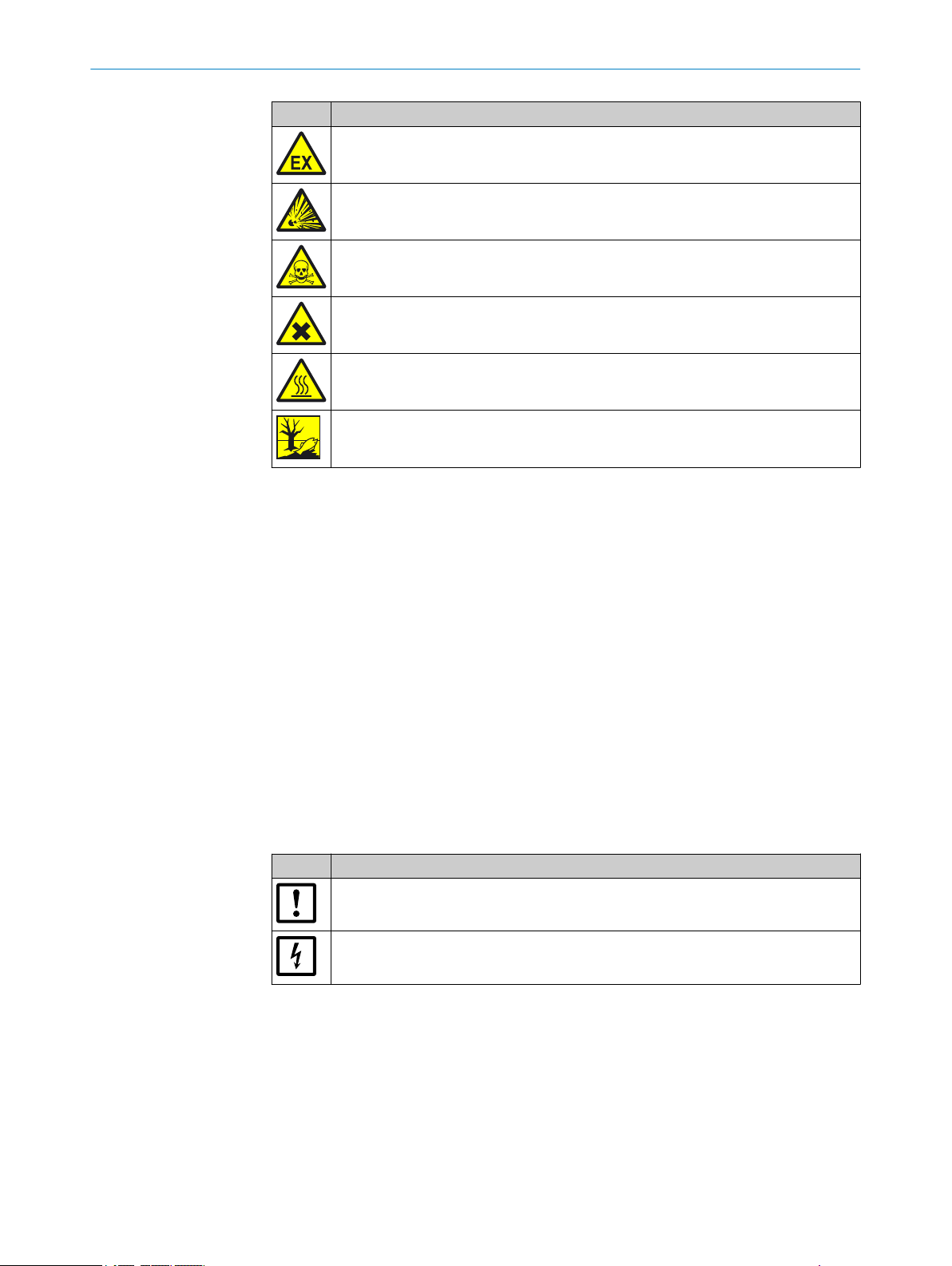

Symbol Significance

Hazard in potentially explosive atmospheres

Hazard by explosive substances/mixtures

Hazard by toxic substances

Hazards by noxious substances

Hazard by high temperature

Hazard for the environment/nature/organic life

1.4.2 Warning levels / Signal words

ABOUT THIS DOCUMENT 1

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

Note

Hints

1.4.3 Information symbols

Table 2: Information symbols

Symbol Significance

Important technical information for this product

Important information on electric or electronic functions

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

7

Page 8

2 INSTALLATION

2 Installation

2.1 Gas supply terminology

Definition of utility gases:

Zero gas: Gas to adjust the zero point. Instrument air or nitrogen (N2)

•

Span gas: Gas to adjust the upper measuring range value

•

Test gas: Generic term for zero and span gas

•

Instrument air: Clean compressed air

•

Gas quality: see "Supply gases", page 87.

2.2 Installation information

2.2.1 Information on power supply

The operator is responsible for correct laying and connection of the electric lines.

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system

b

ATTENTION

The analyzer power supply is configured for an individual power system

Check the configured power system against the system documentation provided.

If the analyzer power system does not match the power system on board: Please

b

contact SICK Customer Service.

When selecting and laying the electric lines for power supply, observe the applicable

local standards and guidelines.

2.2.2 Notes on the gas supply

The operator is responsible for the correct laying of the sample gas lines.

ATTENTION

Risk of contamination of the analyzer by unclean instrument air.

Only use instrument air corresponding to the mandatory specification (see "Techni‐

b

cal data", page 78).

Install a suitable instrument air conditioning when necessary.

b

8

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 9

2.2.3 Tube screw fitting

1

Swagelok screw fitting

Figure 1: Swagelok screw fitting

INSTALLATION 2

Push the tube up to the stop in the

b

tube screw fitting.

Turn the cap nut finger-tight.

Push-in fitting (pneumatic)

Figure 2: Push-in fitting with

retaining ring

Retaining ring

1

During initial assembly: Hold the fitting

b

bolt steady and tighten the cap nut

with 1 1/4 revolutions.

During refitting: Tighten the cap nut to

b

the previous position (the resistance

increases noticeably) and then slightly

tighten.

Figure 3: Using the pressure tool

Pressure tool

Connecting the tube: Push tube in.

b

Disconnecting the tube: Press the retaining ring in and pull the tube out.

b

It is easier to press the retaining ring in using the pressure tool provided.

2.3 Scope of delivery

Please see the delivery documents for the scope of delivery.

2.4 Provision by operator

To be provided by operator, especially:

Suitable flange on the exhaust duct (see “Operating Instructions SFU”)

•

Fixing accessories of enclosures (dowels, screws, etc.)

•

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

9

Page 10

1

2

3 3

4

5 6

7

8

1

2

1

4

2 INSTALLATION

Fixing accessories for heated sample gas line and tube bundle cable

•

Power cable: see "Power supply", page 82

•

External power disconnection unit

•

Compressed air, instrument air as zero gas when necessary

•

Observe quality of operator's instrument air: see "Supply gases", page 87

Optional span gases

•

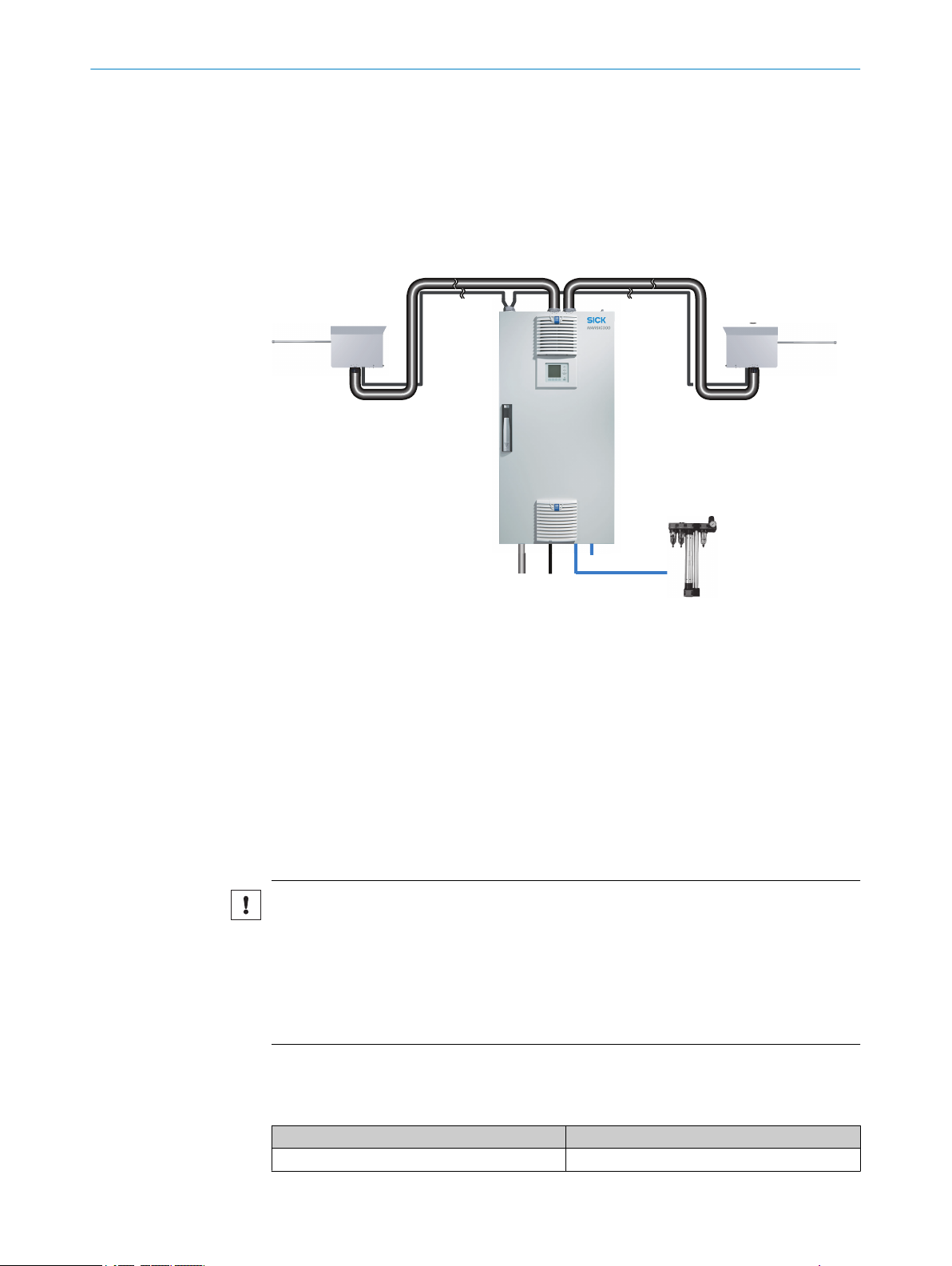

2.5 Installation overview

Figure 4: Installation - overview

Gas sampling system

1

Heated sample gas line (with 2 measuring points: 2 sample gas lines)

2

Tube bundle cable (with 2 measuring points: 2 tube bundle cables) with pneumatic and elec‐

3

tric lines

Analyzer

4

Energy supply

5

Interfaces

6

Instrument air inlet

7

Option: Instrument air conditioning

Sample gas outlet

8

2.6 Checklist for mechanical and electrical installation

NOTICE

Observe the sequence during installation. Connect the gas sampling units on the

exhaust duct as last task.

Incorrect assembly can create a risk of contaminating the gas extraction system. In this

case, exhaust gas can penetrate the unheated analyzer and possibly condensate.

1. First connect instrument air and power supply.

2. Then install the gas sampling system in the exhaust duct.

Observe laying information (Chapter see "Assembly information for sample gas lines

and tube bundle cable", page 11).

Table 3: Fitting and connecting system components

System component Reference

Install analyzer cabinet see "Installing the analyzer cabinet", page 13

10

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 11

System component Reference

Connect sample gas line to analyzer see "Connect the sample gas line to the analyzer",

Connect tube bundle cable to analyzer see "Connecting the tube bundle cable to the ana‐

Connect signal lines to analyzer see "Connecting the signal lines to the analyzer",

Air and gas connections on analyzer see "Air and gas connections on analyzer",

Electrical connections on analyzer see "Electrical connections on the analyzer",

Install SFU gas sampling system see "Installing the gas sampling system", page 25

Optional: Configure Modbus-Profinet /Profibus con‐

verter

Optional: Install measuring point switchover HOT‐

SAMPLER

Optional: Install MPR See Operating Instructions MPR

page 14

lyzer", page 16

page 19

page 20

page 23

see "Setting up the Modbus-Profinet converter

(optional)", page 27

See Operating Instructions HOTSAMPLER

2.7 Assembly information for sample gas lines and tube bundle cable

Installing the sample gas lines

INSTALLATION 2

WARNING

Risk of fire

Observe the laying instructions provided with the line.

b

Minimum clearance to other lines (for example, tube bundle cable): 10 cm.

b

Do not lay or roll up lines directly next to each other.

b

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system

b

Start laying at the analyzer.

b

The end with the electric connection belongs on the analyzer.

°

Important: The screw fitting for the enclosure duct must be located at the

end of the electrical connection (analyzer side).

The end without electrical connection belongs on the gas sampling system.

°

Roll-up excess length on the gas sampling system.

Leave enough length for pulling the gas sampling system.

Protect the line from damage (chafing through vibration, mechanical load).

b

Observe minimum bend radius of 300 mm.

b

Installing the tube bundle cable

Start laying the tube bundle cable at the analyzer and roll-up excess length at the gas

sampling probe.

1. Assembly on the analyzer: see "Air and gas connections on analyzer", page 20

and see "Electrical connections on the analyzer", page 23.

2. Lay the tube bundle cable to the analyzer cabinet.

Attach excess length to the gas sampling probe.

°

Leave enough length for pulling the probe.

°

Protect the line from damage (chafing through vibration, mechanical load).

°

Minimum bend radius: 300 mm.

°

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

11

Page 12

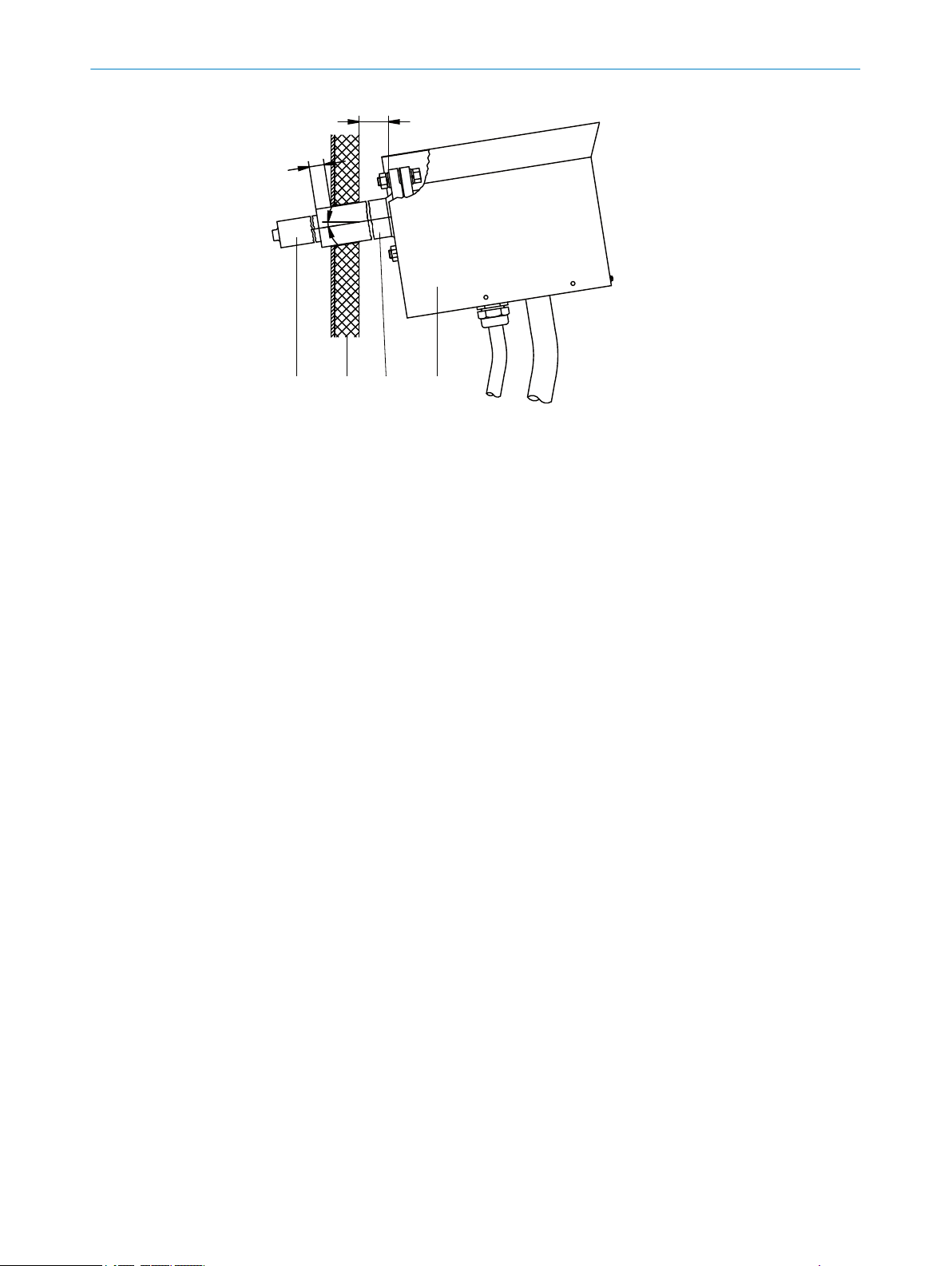

≥ 100 mm

250 mm

R

≥ 30

0 mm

2 INSTALLATION

3. Assembly on the gas sampling probe: see "Installing the gas sampling system",

page 25.

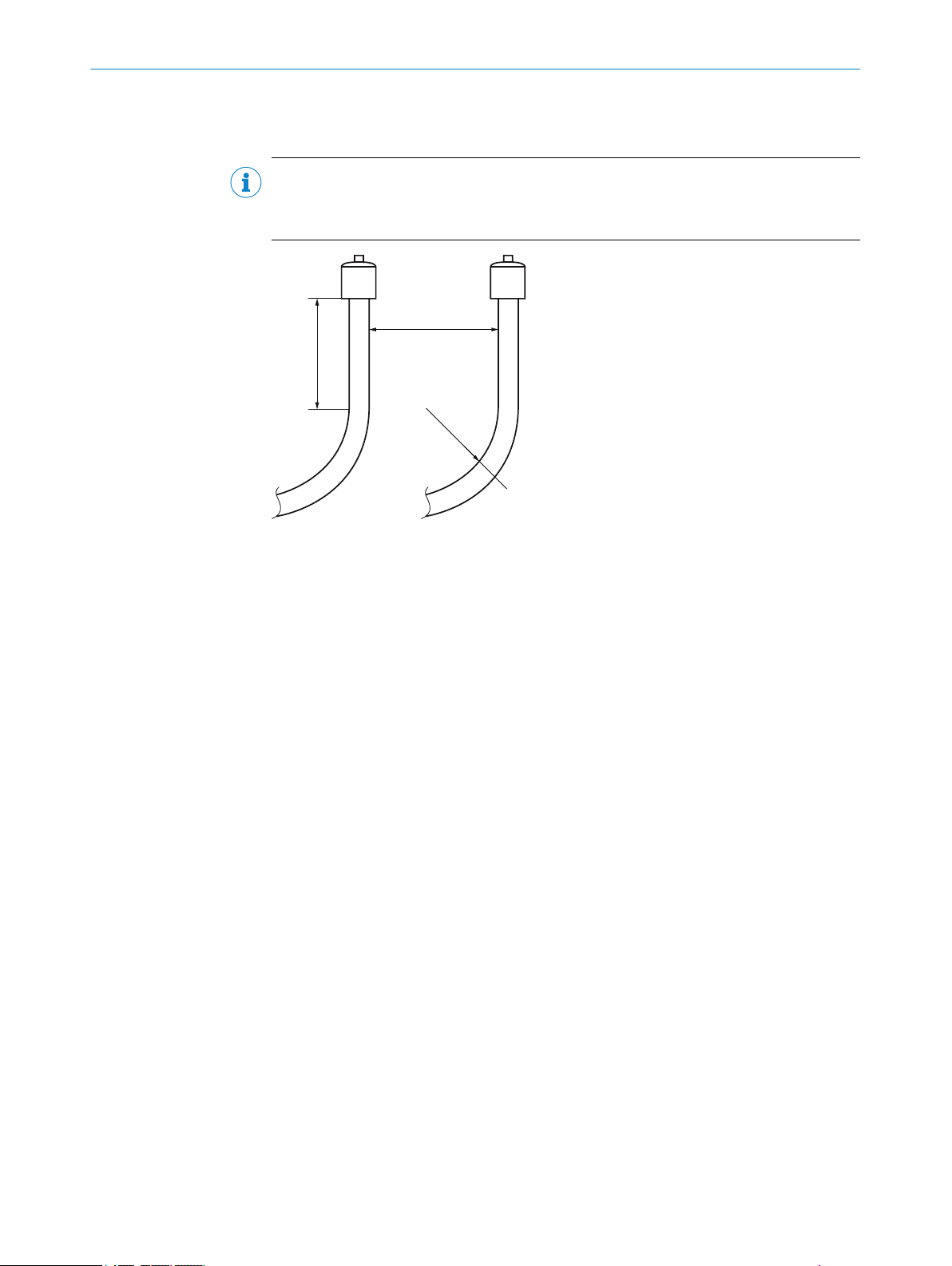

NOTE

Fit the sample gas lines and tube bundle cable on the cable strips with holes.

Observe the minimum distance and bend radius.

b

Figure 5: Sample gas line - distance and radius

12

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 13

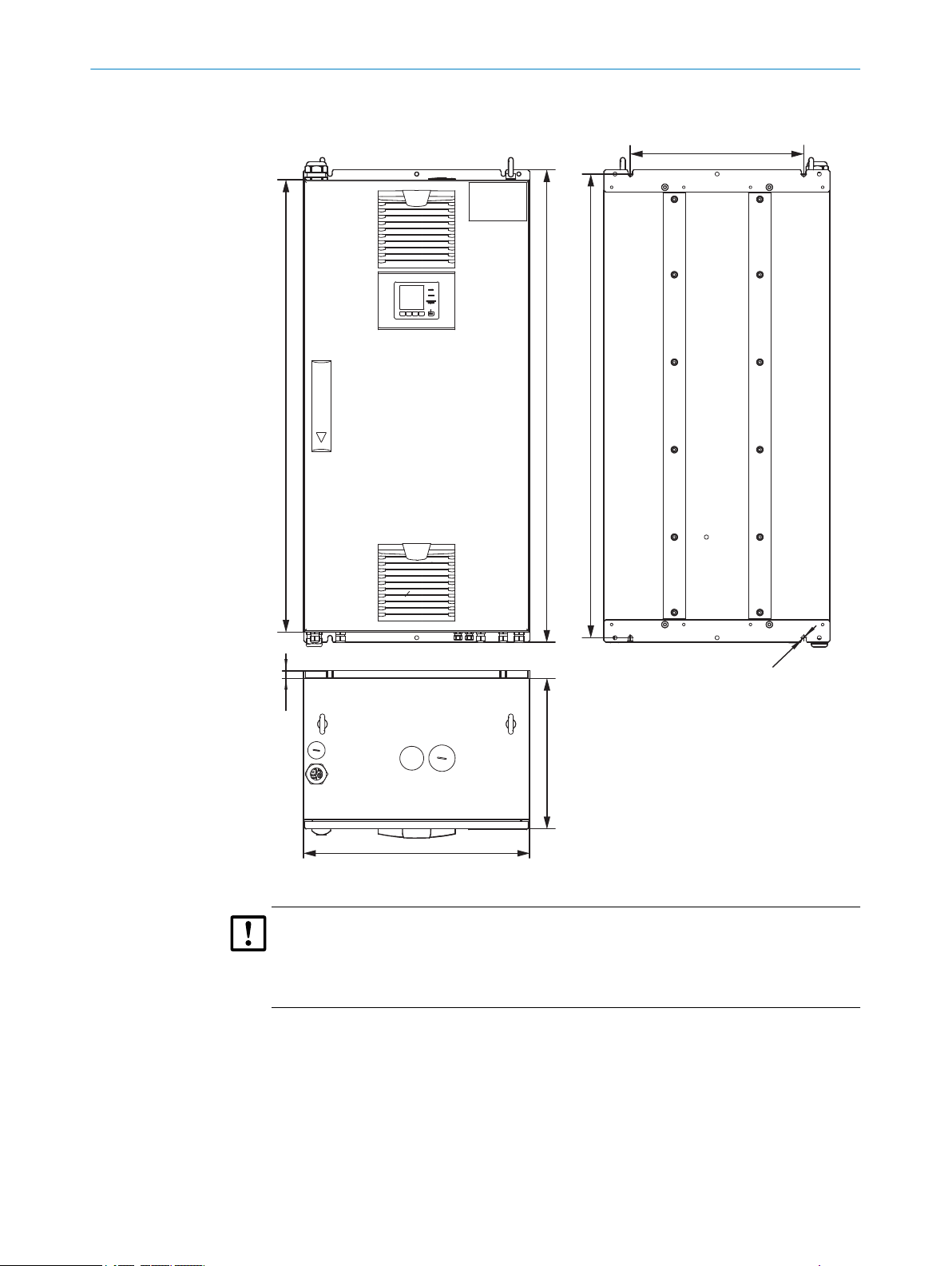

2.8 Installing the analyzer cabinet

Ø 12

1200

1254

1230

20

400

460

600

INSTALLATION 2

Figure 6: Analyzer cabinet - dimensional drawing

NOTICE

Observe clearances:

Top: 30 cm

•

Bottom: 20 cm

•

Observe the clearances for the heated sample gas line.

•

Install the analyzer in a well ventilated room at a location, when possible, with con‐

stant temperature conditions.

Observe the relevant ambient conditions: see "Ambient conditions", page 80.

•

Attach the enclosure with the mounting brackets provided on a suitable wall with

•

•

sufficient load-bearing capacity.

Secure the enclosure with 4 x M10 screw fittings (2 at bottom, 2 at top) with prop‐

•

erty class 8.8 (or higher).

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

13

Page 14

1

5

4

7

6

3 2

1

6

7

8

5

2

3

4

2 INSTALLATION

Secure the screw fittings against loosening.

•

Drilling plan: See dimension drawings above.

•

Install the enclosure horizontal.

•

2.9 Connect the sample gas line to the analyzer

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system

b

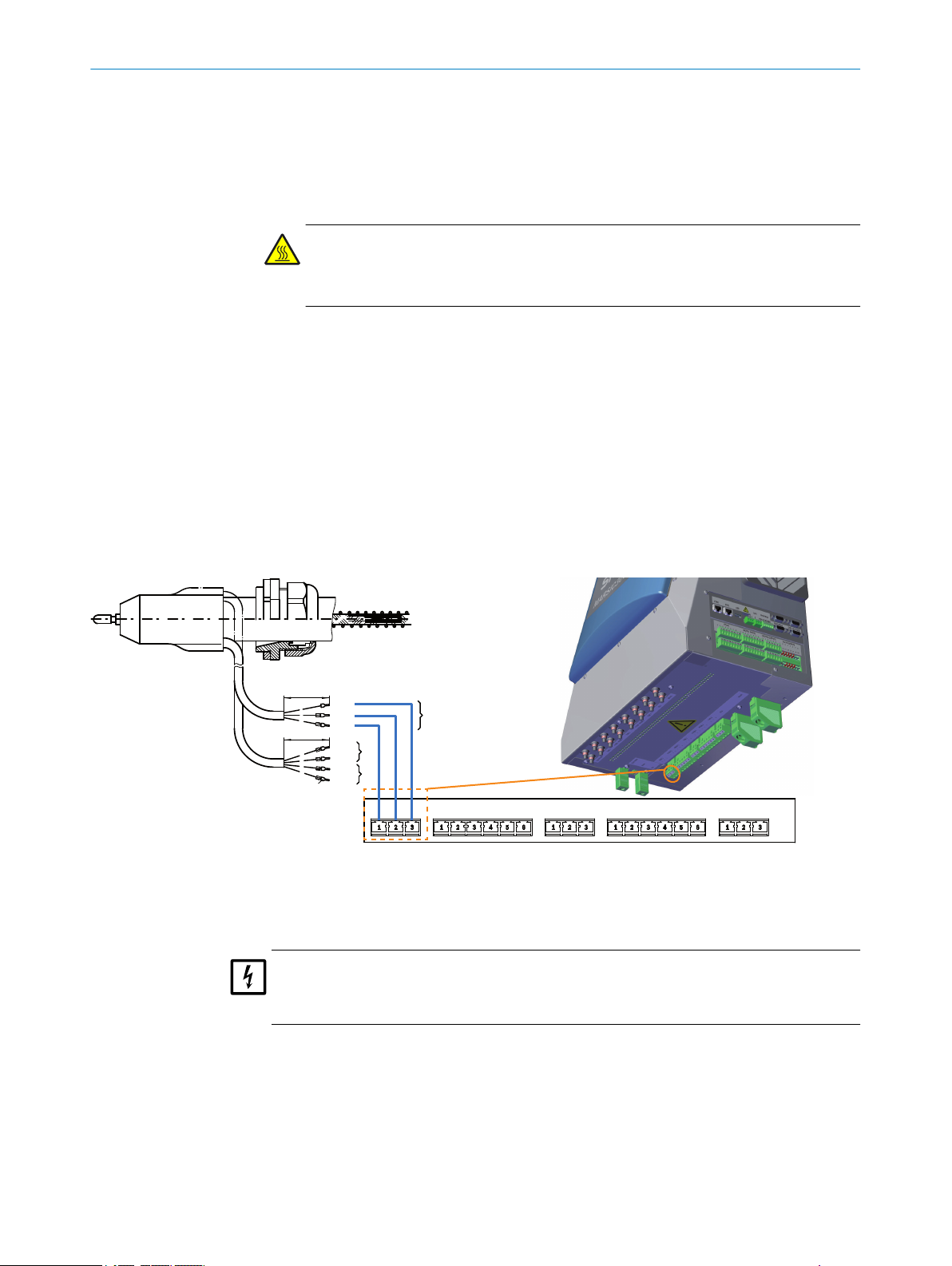

Connect heated sample gas line to analyzer

The flexible wires of the heated sample

gas line are numbered.

Line assignment: see "Heated sample

gas lines", page 81

Figure 7: Heated sample gas line

Connection side without electric connec‐

1

tions on gas sampling system

Connection side with electric connec‐

2

tions on analyzer

Protective cap

3

2 x Pt100 connections (1 as reserve)

4

Power supply

5

Cable gland

6

Counter nut

7

1. Unscrew counter nut from the cable gland and pull off the sample gas line.

2. Lead sample gas line together with electrical connections from above through the

housing opening on the analyzer.

3. Push counter nut back over the sample gas line and electric connections.

14

Figure 8: Sample gas line - connection diagram

Sample gas line 1

1

Sample gas line 2 (option)

2

Cable gland

3

Counter nut

4

Clamping ring screw connection (cell)

5

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 15

TUBE 1

100

100

gnge

sw 2

sw 1

sw 3

sw 4

sw 5

sw 6

PT100 I

PT100 II

Heizkreis I

FILTER 1 PROBE 1 FILTER 2 PROBE 2TUBE 2 TUBE 3

INSTALLATION 2

Cable duct

6

Foam insulation

7

Finished assembly

8

4. Screw counter nut tight on the cable gland.

5. Unscrew cell cover and remove.

CAUTION

Hot parts in cell.

Let cell cool down before working on the cell.

b

6. Remove protective cap from sample gas line.

7. Insert sample gas line to stop in the clamping ring screw connection on the cell.

With 2 sample gas lines: Observe inlets:

Right inlet: Measuring point 1

°

Left inlet: Measuring point 2

°

8. Screw sample gas line tight on the clamping ring screw connection.

9. Attach red foam insulation on the clamping ring screw connection and bind

together with a cable clip. No thermal bridges may remain.

10. Close cell again.

11. Screw cable gland tight.

12. Push electric lines downwards through the cable duct.

13. Connect power supply of the sample gas line:

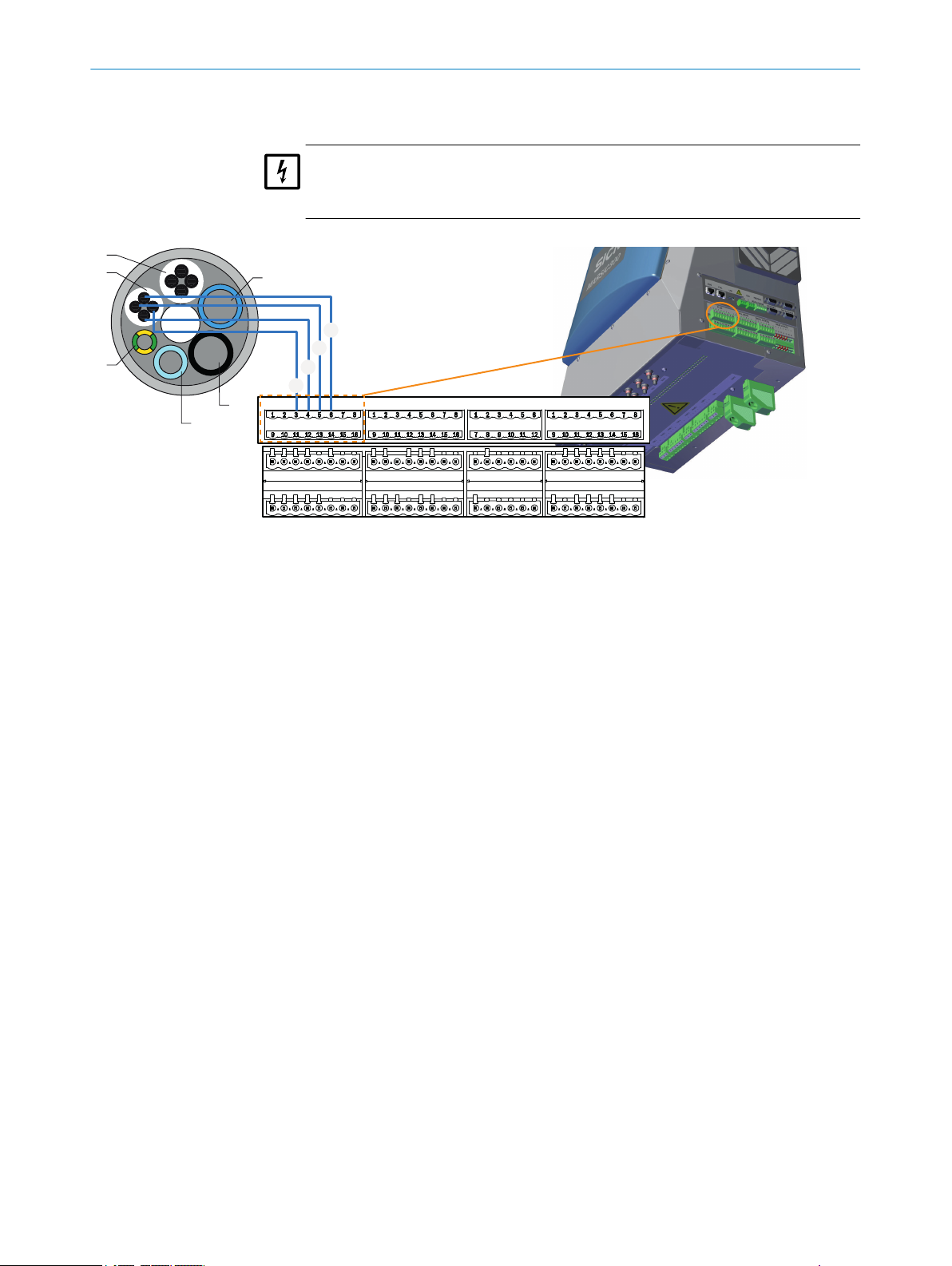

Figure 9: Power supply connection

Complete description of the interface on page 82.

Connect the optional second sample gas line (TUBE 2).

b

NOTICE

The connections on MARSIC300 must match the connections of the gas sampling sys‐

tem.

14. Connect Pt100 of the sample gas line:

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

15

Page 16

PT100 DIGITAL INPUTS DIGITAL OUTPUTS VALVE OUTPUTS

100

100

gnge

sw 2

sw 1

sw 3

sw 4

sw 5

sw 6

PT100 I

PT100 II

Heizkreis I

1

2

3

4

2 INSTALLATION

Figure 10: Pt100 connection

Complete description of the interface on page 86.

15. Connect Pt100 from the sample gas line 2 to pins 9 and 10.

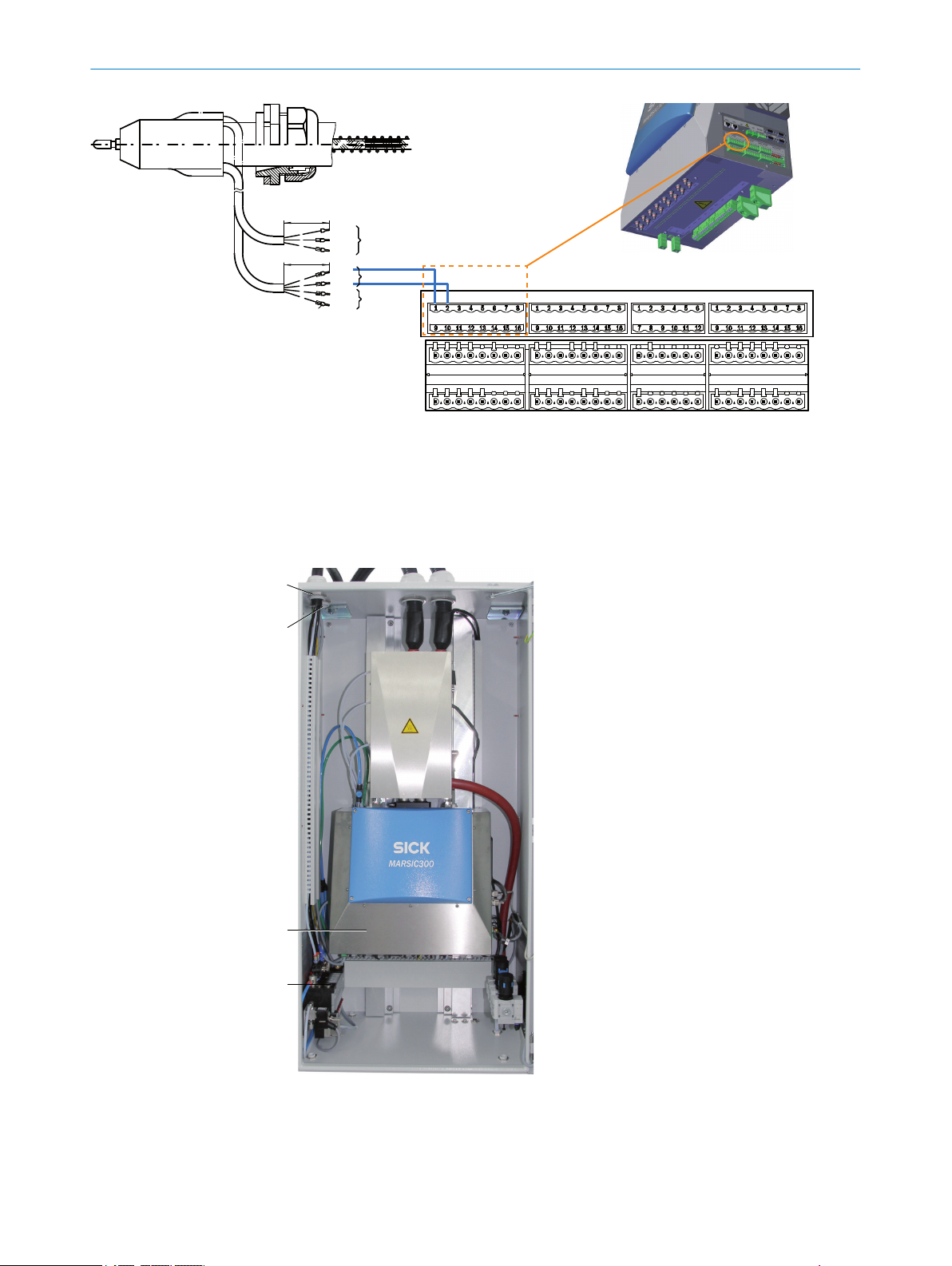

2.10 Connecting the tube bundle cable to the analyzer

16

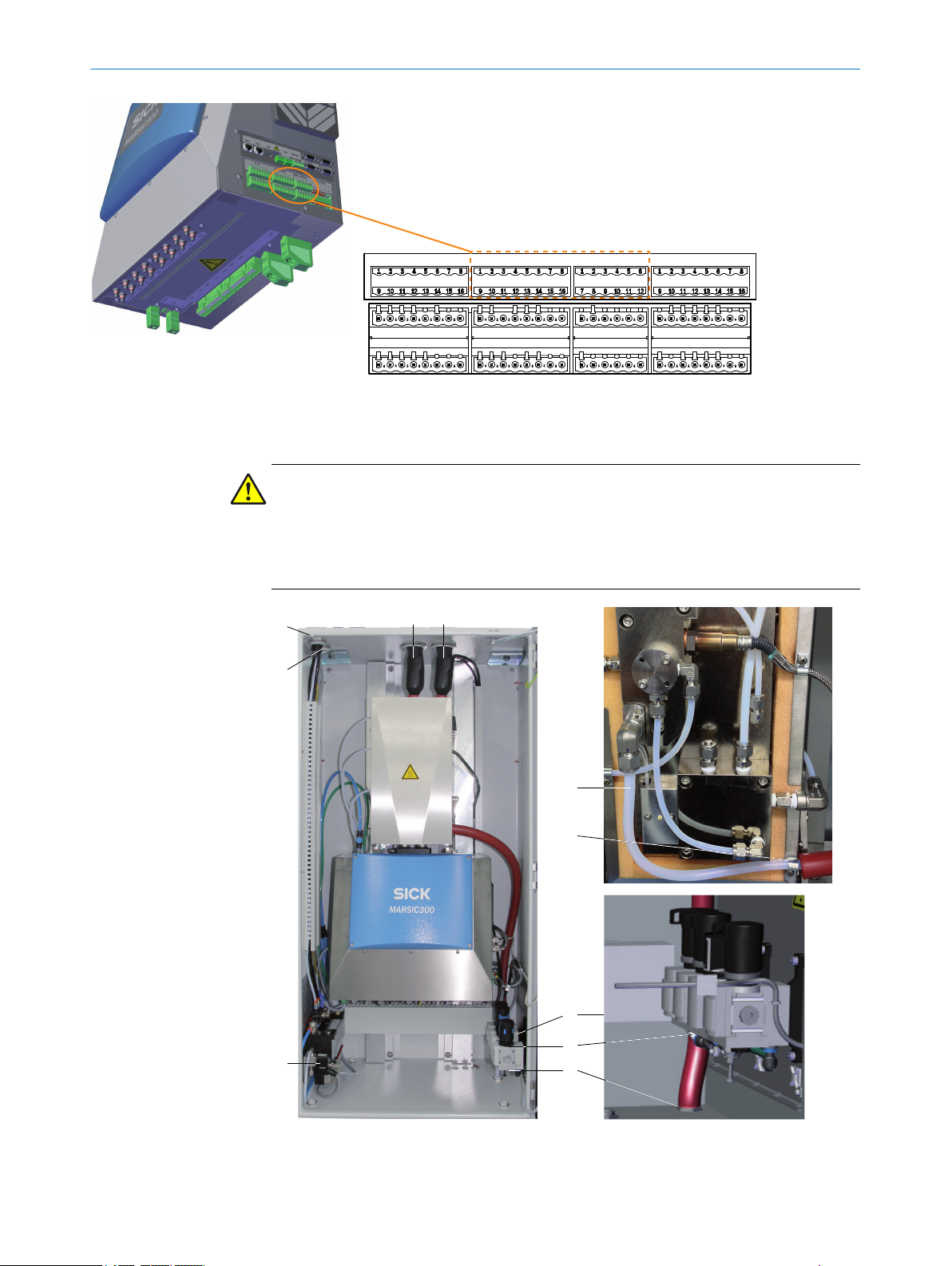

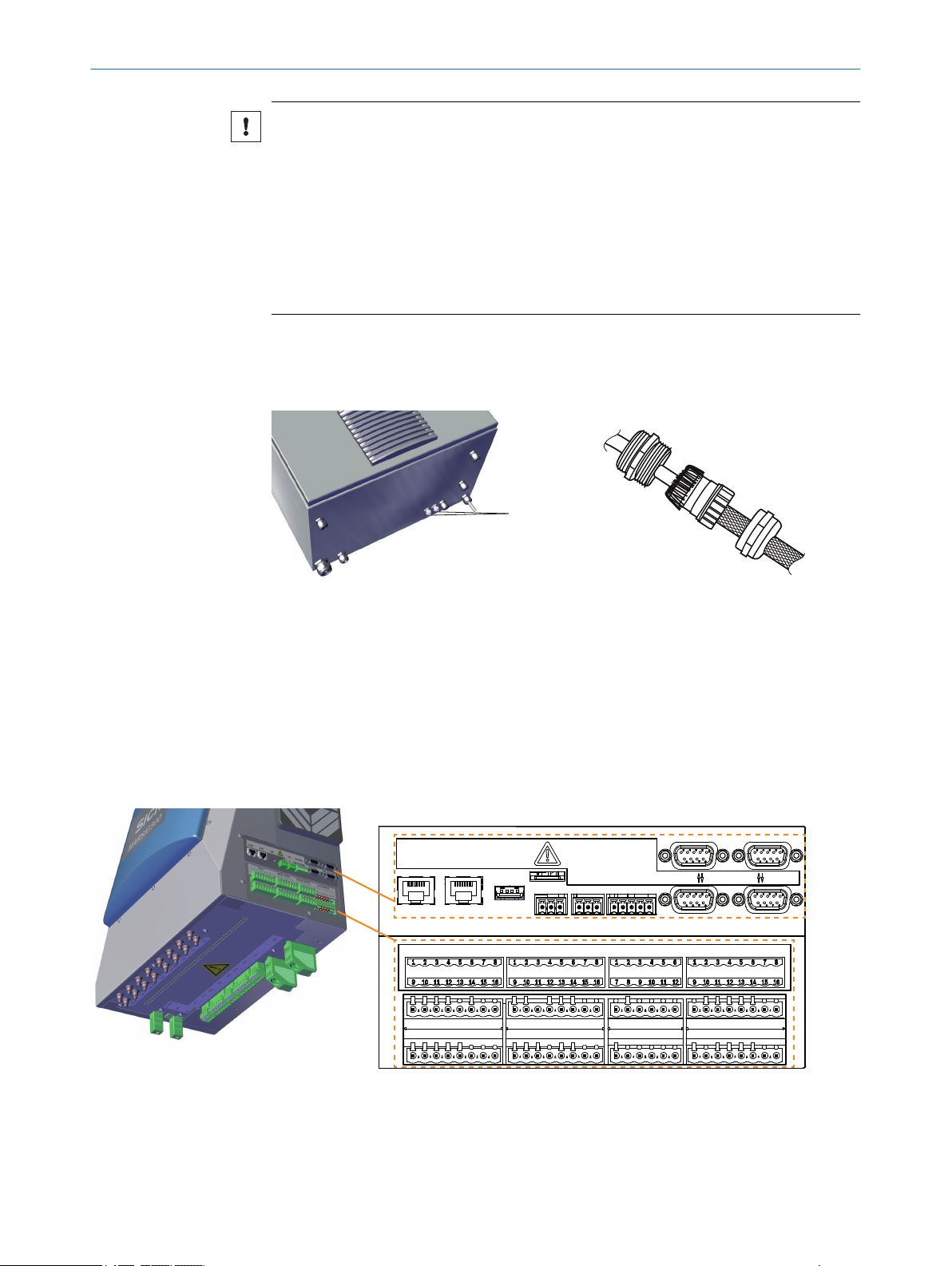

Figure 11: Analyzer - overview

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Tube bundle cable 1

1

Tube bundle cable 2 (optional)

2

3

4

Valve block

Electronics unit

Subject to change without notice

Page 17

1

4

2

3

6

5

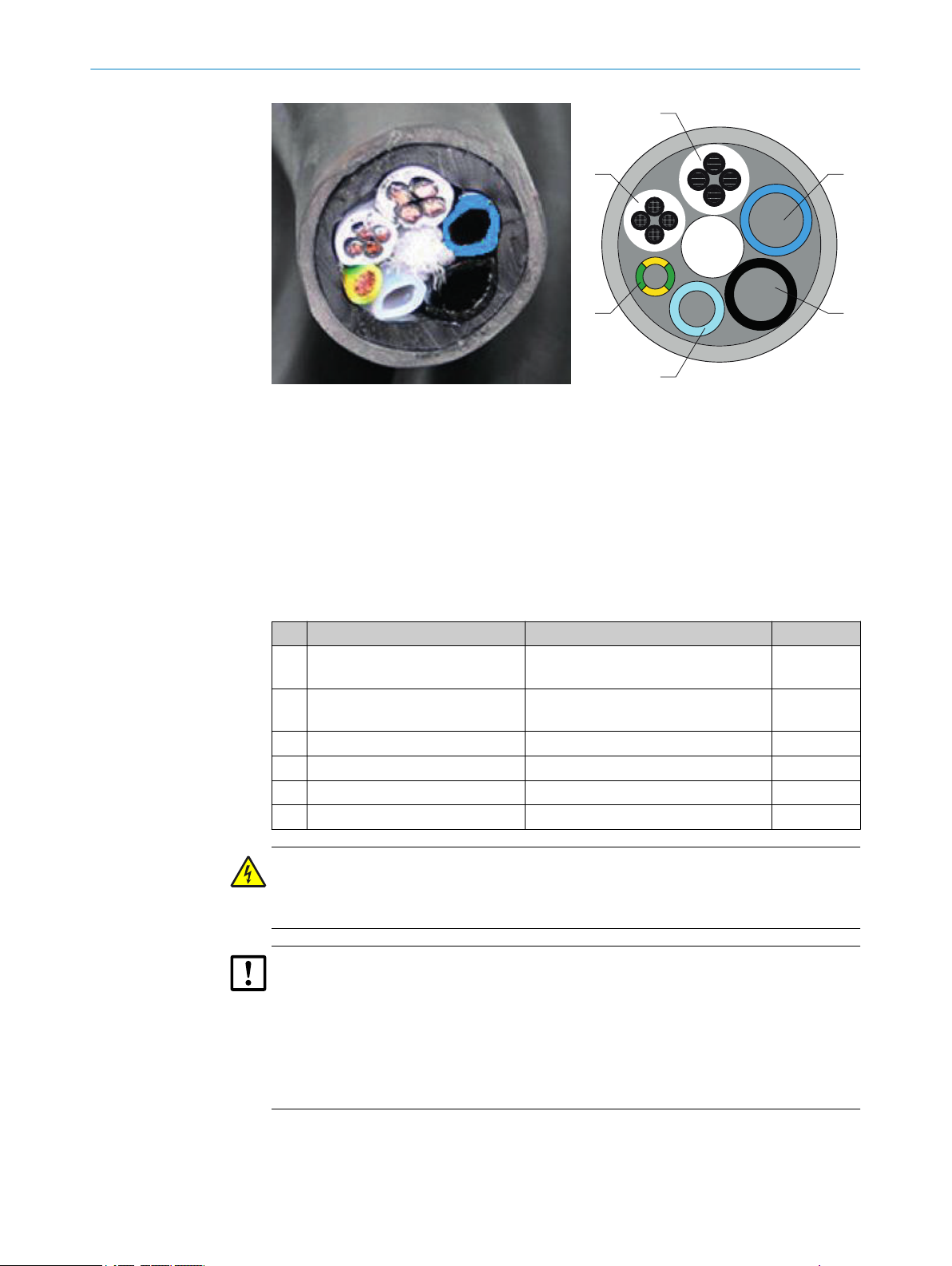

Figure 12: Tube bundle cable - overview

Power supply

1

Pt100 lines

2

Grounding conductor

3

PTFE tube DN4/6

4

PA tube black DN6/8; Imprint “1”

5

Connections on analyzer and gas sampling probe must match

PA tube black DN6/8; Imprint “2”

6

Connections on analyzer and gas sampling probe must match

INSTALLATION 2

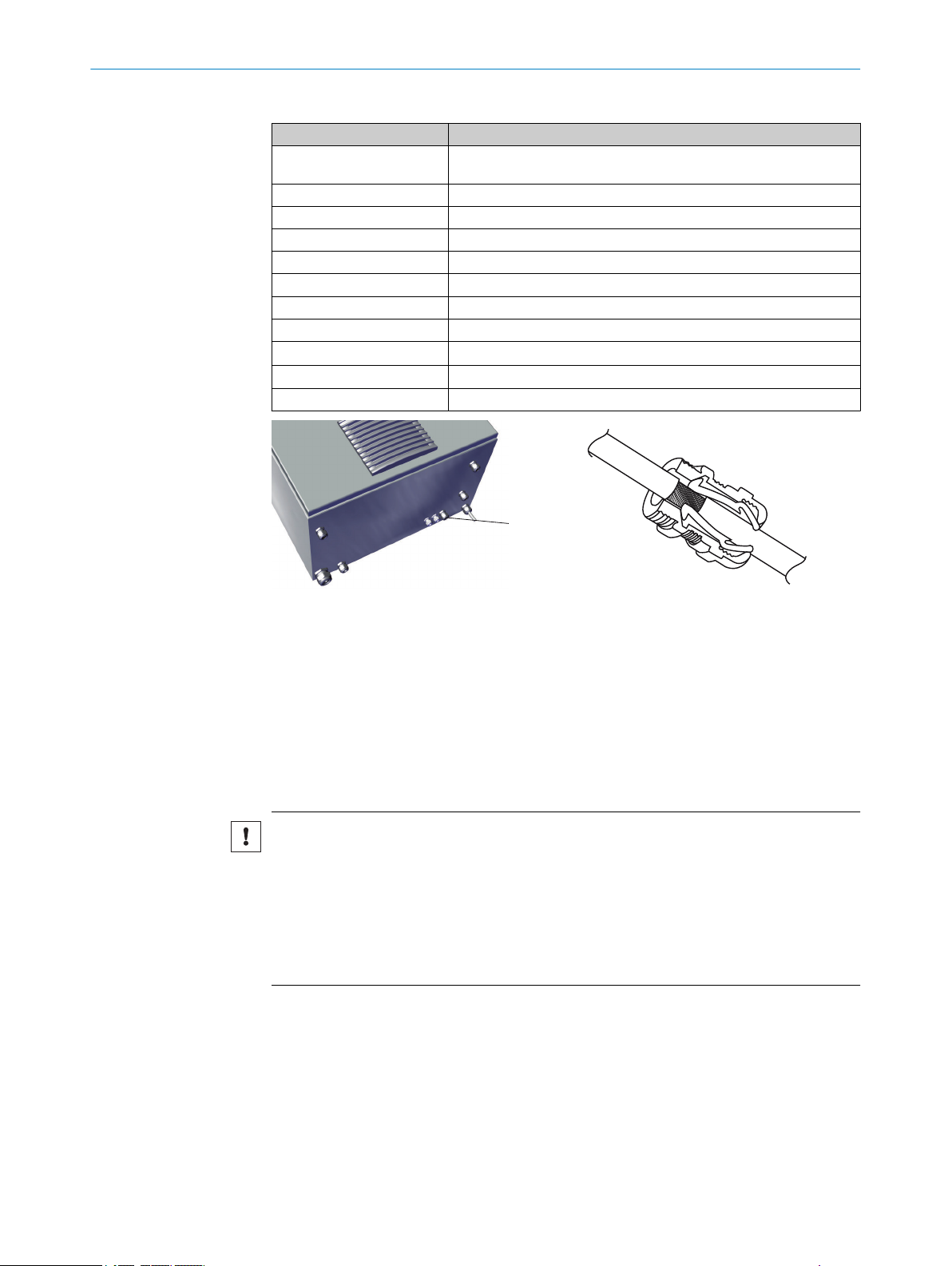

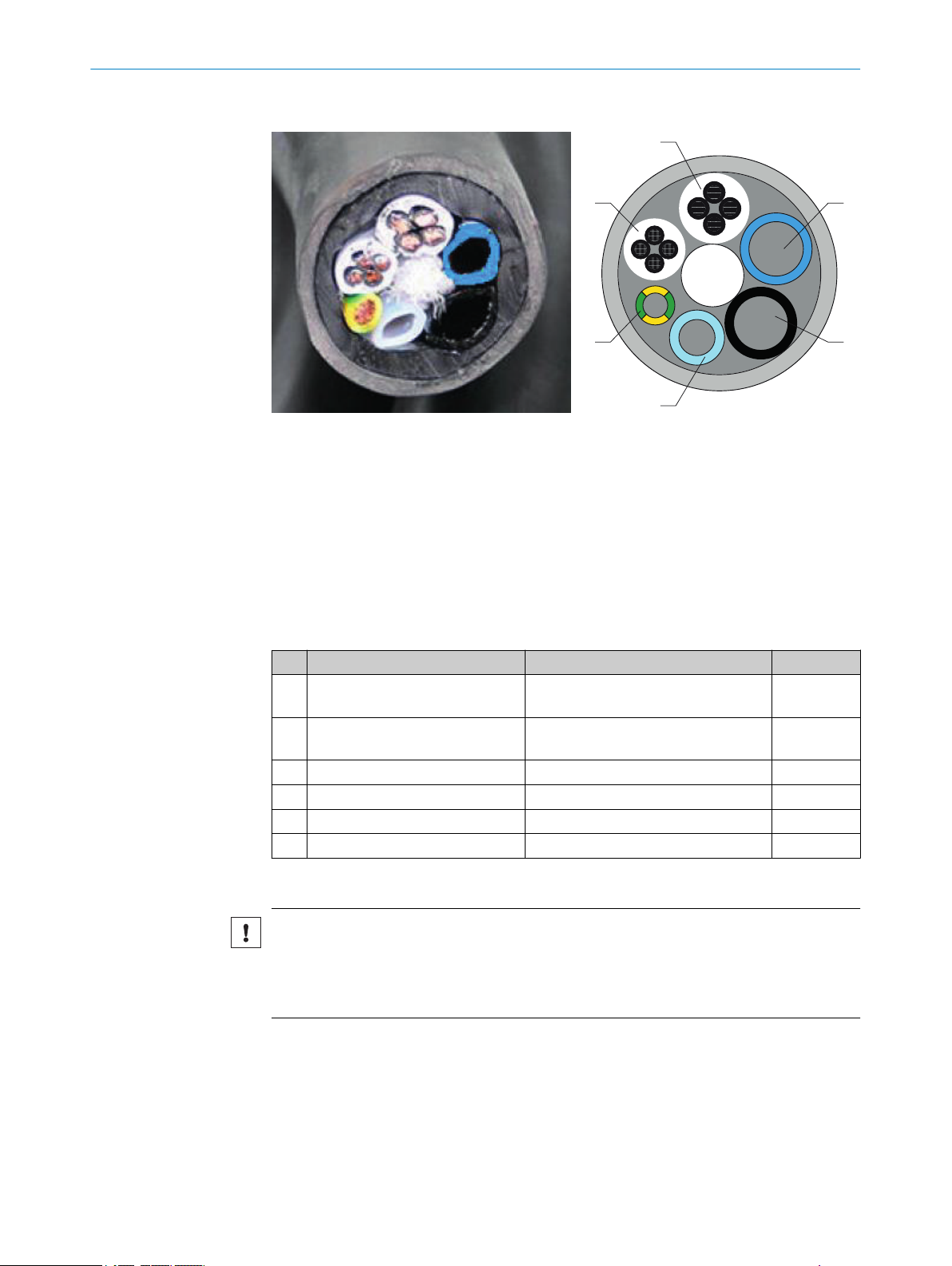

No. Designation Function Dimension

Power supplies Lines 1 and 2: Gas sampling filter

1

Lines 3 and 4: Probe tube (optional)

Signal lines (Pt100) Lines 1 and 2: Gas sampling filter

2

Lines 3 and 4: Probe tube (optional)

Grounding conductor (gnge) Ground 1 x 4.0 mm

3

PTFE hose (white) Zero gas DN 4/6

4

PA hose (black) Control air main valve DN 6/8

5

PA hose (blue) Backflush air DN 6/8

6

4 x 1.5 mm

4 x 1.0 mm

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system

b

CAUTION

The tube bundle cable is unusable when it is cut off too short.

The tube bundle cable is unusable when a lead inside is damaged when removing the

sheath.

If the tube bundle cable is long enough: Leave a piece as “reserve”.

b

Only remove the sheath from the tube bundle cable when you are technically capa‐

b

ble of doing this.

2

2

2

1. Remove 1900 mm of the tube bundle cable sheath.

2. Lead the tube bundle cable through the screw fitting on the enclosure top.

3. Lead tubes and lines of the tube bundle cable downwards in the cable duct.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

17

Page 18

1 2 3 4 5 67

8

9

1

4

2

3

6

5

TUBE 1 FILTER 1 PROBE 1 FILTER 2 PROBE 2TUBE 2 TUBE 3

!

$

§

"

gnge

2 INSTALLATION

4. Connect the 3 gas lines of one tube bundle cable to the valve block (connections

marked as “outlet” in the Figure below).

NOTICE

The gas connections on the valve block must match the gas connections of the

gas sampling system (see "SFU Gas Sampling System Operating Instructions").

Figure 13: Valve block

Outlet: Zero gas measuring point 1

1

Outlet: Zero gas measuring point 2 (option)

2

Outlet: Control air measuring point 1

3

Outlet: Backflush air measuring point 1

4

Outlet: Control air measuring point 2 (option)

5

Outlet: Backflush air measuring point 2 (option)

6

Inlet: Zero gas

7

Inlet: Control/backflush air

8

Inlet: Auxiliary control air

9

Red plug = dummy plug

-

5. Connect the heating of the gas sampling system (heated sample gas filter and

optional heated probe tube).

NOTICE

The connections on MARSIC300 must match the connections of the gas sampling

system.

Figure 14: Supply lines - tube bundle cable connection diagram

Complete description of the interface, see "Tube bundle cable", page 81 Tube bundle

cable 2 optional to tube bundle cable 1.

18

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 19

1

4

2

3

6

5

PT100 DIGITAL INPUTS DIGITAL OUTPUTS VALVE OUTPUTS

!

$

§

"

INSTALLATION 2

6. Connect the Pt100 of the gas sampling system (heated sample gas filter and

optional heated probe tube).

NOTICE

The connections on MARSIC300 must match the connections of the gas sampling

system.

Figure 15: Signal lines - tube bundle cable connection diagram

2.11 Connecting the signal lines to the analyzer

4 digital inputs and outputs each are available as an option that must then be config‐

ured, see "Data interfaces / IO", page 55.

4 digital inputs

Fill level signal, condensate container

•

Condition, instrument air

•

Scrubber system on/off (can be linked with StBy MARSIC300)

•

Temperature error, weatherproof cover or other external alarm

•

4 digital outputs

Status (OK / Maintenance)

•

Status (OK / Failure)

•

Coefficient SO2/CO2 less than/greater than xy (definable)

•

The inputs and outputs are deactivated as standard. The inputs and outputs can be

activated and negated in SOPAS ET.

Digital inputs and outputs can also be redefined differently to the above description.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

19

Page 20

PT100 DIGITAL INPUTS DIGITAL OUTPUTS VALVE OUTPUTS

3

12

4

7

5

6

8

9

ß

2 INSTALLATION

Figure 16: Connection diagram - digital connections

2.12 Air and gas connections on analyzer

WARNING

Hazard when pressure is too high

Hoses can burst when the pressure is too high.

Observe the maximum pressures of the gases provided by the operator: see "Sup‐

b

ply gases", page 87.

20

Figure 17: Overview - air and gas connections

Heated sample gas line for measuring point 1

1

Heated sample gas line for measuring point 2 (option)

2

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 21

INSTALLATION

Tube bundle cable 1

3

Tube bundle cable 2 (option)

4

Pressure reducer unit

5

Instrument air as zero gas/test gas (option)

6

Test gas inlet

7

Sample gas outlet

8

Sample gas outlet on cell

9

Fixing of line sample gas outlet on the cell

ß

Connect instrument air

Connect instrument air to the pressure control unit.

ATTENTION

Risk of contamination of the analyzer by unclean instrument air.

Only use instrument air corresponding to the mandatory specification (see "Techni‐

b

cal data", page 78).

Install a suitable instrument air conditioning when necessary.

b

2

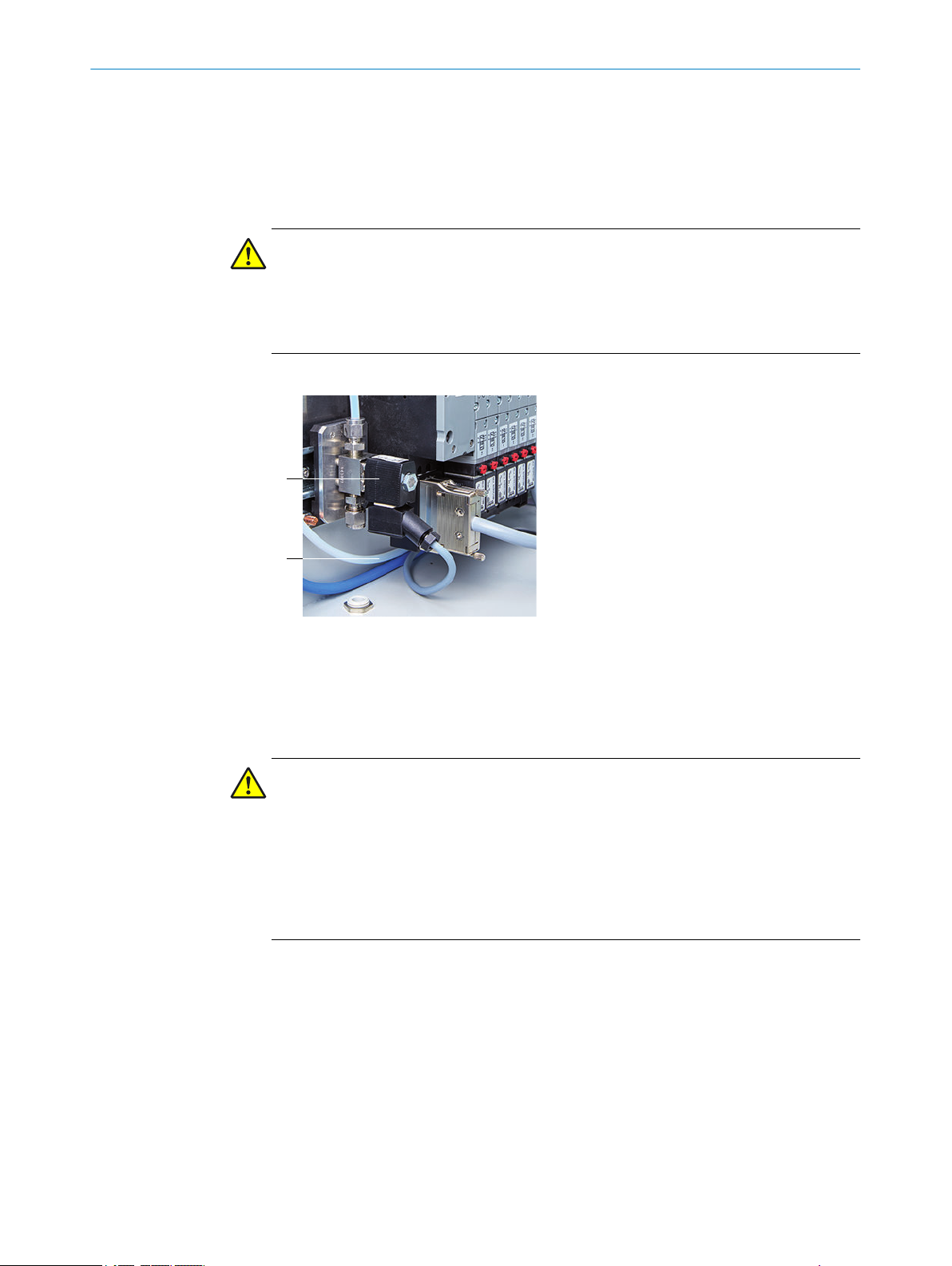

Figure 18: Pressure reducer unit

Instrument air inlet with zero gas quality

1

Instrument air inlet for induction air ejector only

2

Manual valve for instrument air selection

3

3 pressure reducers (adjustable)

4

Manual valve - closed position

5

Manual valve - open position

6

The instrument air is used as both induction air for the ejector (cell) and zero/control

air.

Instrument air can be connected in 2 ways:

One common instrument air supply for ejector air and zero/control air (inlet 1).

b

Separate instrument air supply for:

b

Ejector air (inlet 2)

°

and zero/control air (inlet 1)

°

Instrument air quality

The requirements for instrument air quality are lower when the air is only used as

ejector air than when used as zero/control air (zero gas quality) (see "Supply

gases", page 87).

When connected just as instrument air supply with zero gas quality to be used as

b

common air for both ejector air and zero/control air (on inlet 1):

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

21

Page 22

1

2

2 INSTALLATION

Set manual valve to position “open”.

w

When connected as one instrument air supply for the ejector (on inlet 2) and one

b

instrument air supply with zero gas quality (on inlet 1):

Set manual valve to position “closed”.

w

Connect span gas (option)

WARNING

Hazard when pressure is too high

Hoses can burst when the pressure is too high.

Observe the maximum pressures of the gases provided by the operator: see "Sup‐

b

ply gases", page 87.

Connect span gas to the span gas valve.

Figure 19: Test gas valve connection

Test gas valve

1

Test gas inlet

2

Connect sample gas outlet

CAUTION

Acidic condensate in sample gas outlet - risk of blockage

Acidic condensate forms in the sample gas outlet.

Always lay the sample gas outlet line running downwards so that no condensate

b

can accumulate.

Lay the line end in a suitable disposal device (drain or condensate collection con‐

b

tainer).

Do not kink the line and protect against frost.

b

The analyzer is fitted with an outlet hose (DIN 8/10) about 30 cm long when delivered.

Lay the sample gas outlet in a suitable exhaust duct.

•

The sample gas outlet must be open to the ambient pressure.

•

Recommendation for lengthening the outlet hose:

To prevent the outlet line clogging, it is recommended to lay a (1) new line starting at

the sample gas outlet of the cell to the disposal location.

22

To do this, see figure 17, page 20:

1. Open cell cover (loosen 4 screws on the side).

2. Unscrew sample gas outlet line on the sample gas outlet (bracket piece).

3. Loosen fixing of sample gas outlet line.

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 23

1

INSTALLATION 2

4. Remove the thermal insulation from the existing line and remove the line.

5. Lead a new line through the enclosure duct at the bottom on the enclosure floor

and connect it to the sample gas outlet of the cell.

6. Refit the fixing.

7. Refit the thermal insulation.

8. Close cell again.

To lengthen the existing hose piece: No cross-section narrowing may occur when con‐

necting the lengthening hose.

Sample gas outlet on housing:

Figure 20: Sample gas outlet - enclosure under‐

side

Sample gas outlet at bottom rear of the

1

housing

2.13 Electrical connections on the analyzer

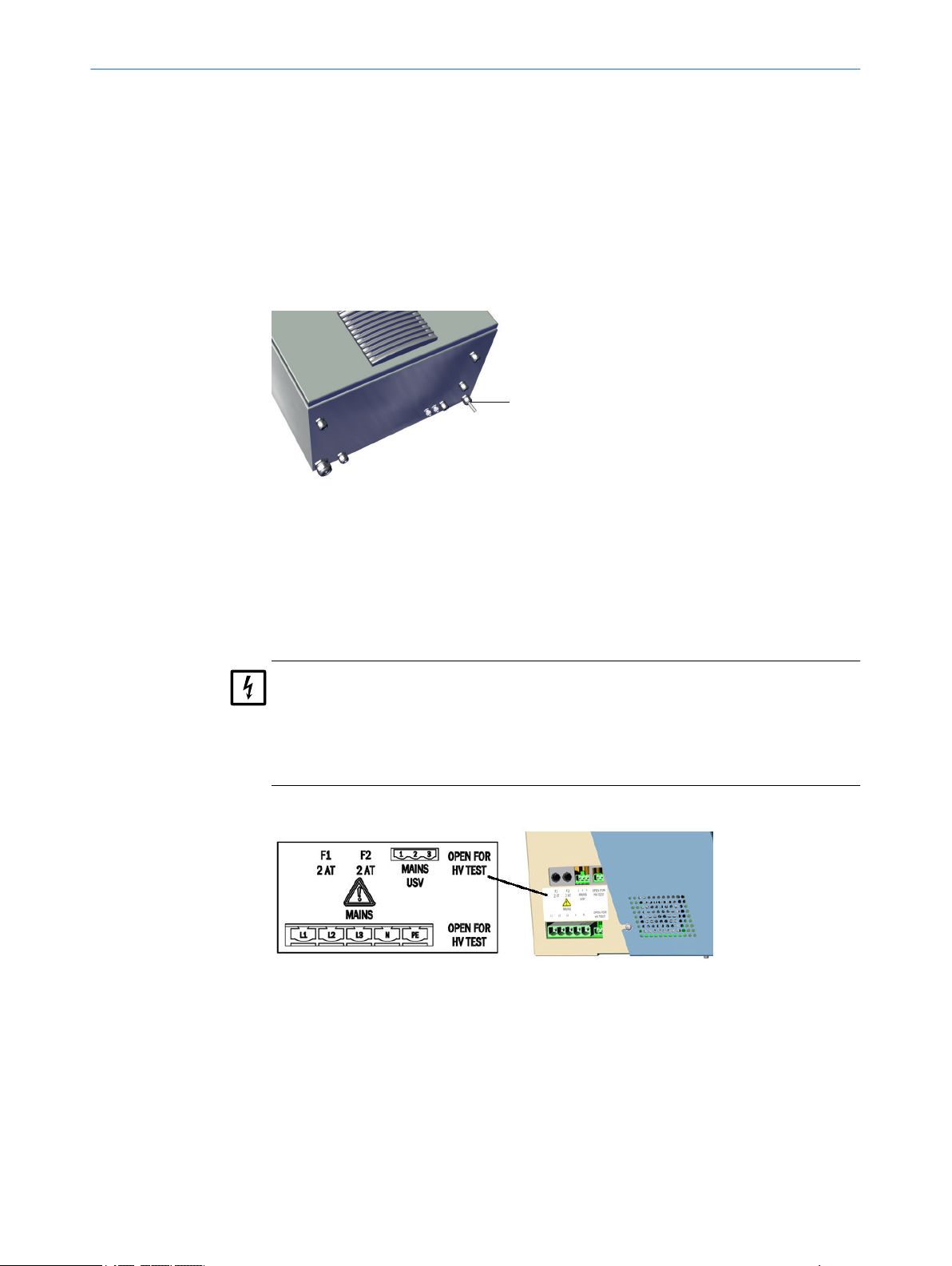

Connect power supply

ATTENTION

The analyzer power supply is configured for an individual power system

Check the configured power system against the system documentation provided.

If the analyzer power system does not match the power system on board: Please

b

contact SICK Customer Service.

The power supply is located on the left on the analyzer.

Figure 21: Power supply connections

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

23

Page 24

1

ETHO E TH1 USB CAN PROFIBUS

1 2 RS422/RS485 RS232 02 DISP.

PT100 DIGITAL INPUTS DIGITAL OUTPUTS VALVE OUTPUTS

I/0-MOD.

2 INSTALLATION

NOTICE

Install an external power disconnection unit which disconnects all connectors

°

and fuses near the analyzer.

The power disconnection unit must be marked clearly and be easily accessi‐

°

ble.

Observe the maximum power input of the complete system: see "Power sup‐

ply", page 82.

The onsite wiring system to the power source of the system must be installed

°

and fused according to the relevant regulations.

Always connect a protective ground to PE.

°

Route the electric lines through the screw fittings of the enclosure.

b

Connect the electric lines.

b

Connect signal line (optional)

1

b

b

Connect Ethernet (optional)

Figure 22: Connections overview

2 x signal line ducts

Lead cable through the enclosure duct.

Attach shield as shown in the Figure above.

24

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 25

1

INSTALLATION 2

Table 4: Data interfaces - overview

Plug Connection for

ETH0 Ethernet (e.g. SOPAS ET), MPR (remote maintenance), communication via

ETH1 Internal

USB Internal

SD card SD card (on the right, next to USB)

CAN1 Internal

CAN2 Internal

RS422, RS485 Internal

RS232 (top plug) Internal

O2 (bottom plug) O2 sensor

DISP (top plug) Display

I/O-MOD (bottom plug) Internal

Modbus TCP

Ethernet cable duct

1

Lead cable through the enclosure duct.

b

Attach shield as shown in the corresponding Figure above.

b

Connect Ethernet to ETH0 (network or computer with SOPAS ET).

b

Plug type: RJ 45.

Connect MPR (remote maintenance via SICK Meeting-Point Router) to ETH0.

b

Further information, see “MPR Operating Instructions”.

2.14 Installing the gas sampling system

NOTICE

Observe the ambient conditions of the gas sampling system: See “SFU Gas Sam‐

b

pling System Operating Instructions”.

Leave the sample gas line and tube bundle cable long enough to be able to pull

b

the sample gas system out of the exhaust duct.

All connections must match the connections in the analyzer (see "Connecting the

b

tube bundle cable to the analyzer", page 16 and see "Connect the sample gas line

to the analyzer", page 14).

Fitting the flange

Install the flange of the gas sampling system as described in the “SFU Gas Sam‐

b

pling System Operating Instructions”.

Observe the 10° tilt of the probe tube during installation.

°

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

25

Page 26

min.70

10°

~

~30

1

2

3 4

2 INSTALLATION

Figure 23: Flange assembly

Probe tube

1

Stack wall

2

Welding neck flange

3

Gas sampling filter

4

Gas connections

Connect the following gas connections on the gas sampling system:

b

Heated sample gas line

°

Tube bundle cable

°

Electrical connections

Connect the following electric lines of the tube bundle cable on the gas sampling

b

system:

°

°

°

°

Black line 1: Main valve

•

Blue line 2: Backflush

•

White PTFE tube: Instrument air/test gas

•

Power supply, gas sampling system

Power supply, probe tube (when heated)

Filter Pt100 line

Pt100 line, probe tube (optional, when heated)

26

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 27

Tube bundle cable

1

4

2

3

6

5

Figure 24: Tube bundle cable - overview

Power supply

1

Pt100 lines

2

Grounding conductor

3

PTFE tube DN4/6

4

PA tube black DN6/8; Imprint “1”

5

Connections on analyzer and gas sampling probe must match

PA tube black DN6/8; Imprint “2”

6

Connections on analyzer and gas sampling probe must match

INSTALLATION 2

2.15

No. Name Function Dimension

Power supplies Lines 1 and 2: Gas sampling filter

1

Lines 3 and 4: Probe tube (optional)

Signal lines (Pt100) Lines 1 and 2: Gas sampling filter

2

Lines 3 and 4: Probe tube (optional)

Grounding conductor (gnge) Ground 1 x 4.0 mm

3

PTFE hose (white) Zero gas DN 4/6

4

PA hose (black) Control air, main valve DN 6/8

5

PA hose (blue) Backflush air DN 6/8

6

Fit the gas sampling system on the flange

NOTICE

Risk of contamination of gas sampling system

First install the gas sampling system on the exhaust duct just before the analyzer

b

is switched on.

Install the gas sampling system: See “SFU Gas Sampling System Operating

b

Instructions”.

Setting up the Modbus-Profinet converter (optional)

4 x 1.5 mm

4 x 1.0 mm

2

2

2

As an option to Modbus, the MARSIC300 can also be configured with a Profinet or Profi‐

bus protocol. This requires an external Modbus-Profinet converter that may require

some adjustments.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

27

Page 28

INSTALLATION

2

Configuration:

1. Install the converter onsite on a DIN rail and create a connection to the MAR‐

SIC300 (Modbus-TCP).

2. Connect the converter to 24 V DC.

3. Connect a PC via one of the Modbus-TCP connections of the converter with a net‐

work cable (crossover not required).

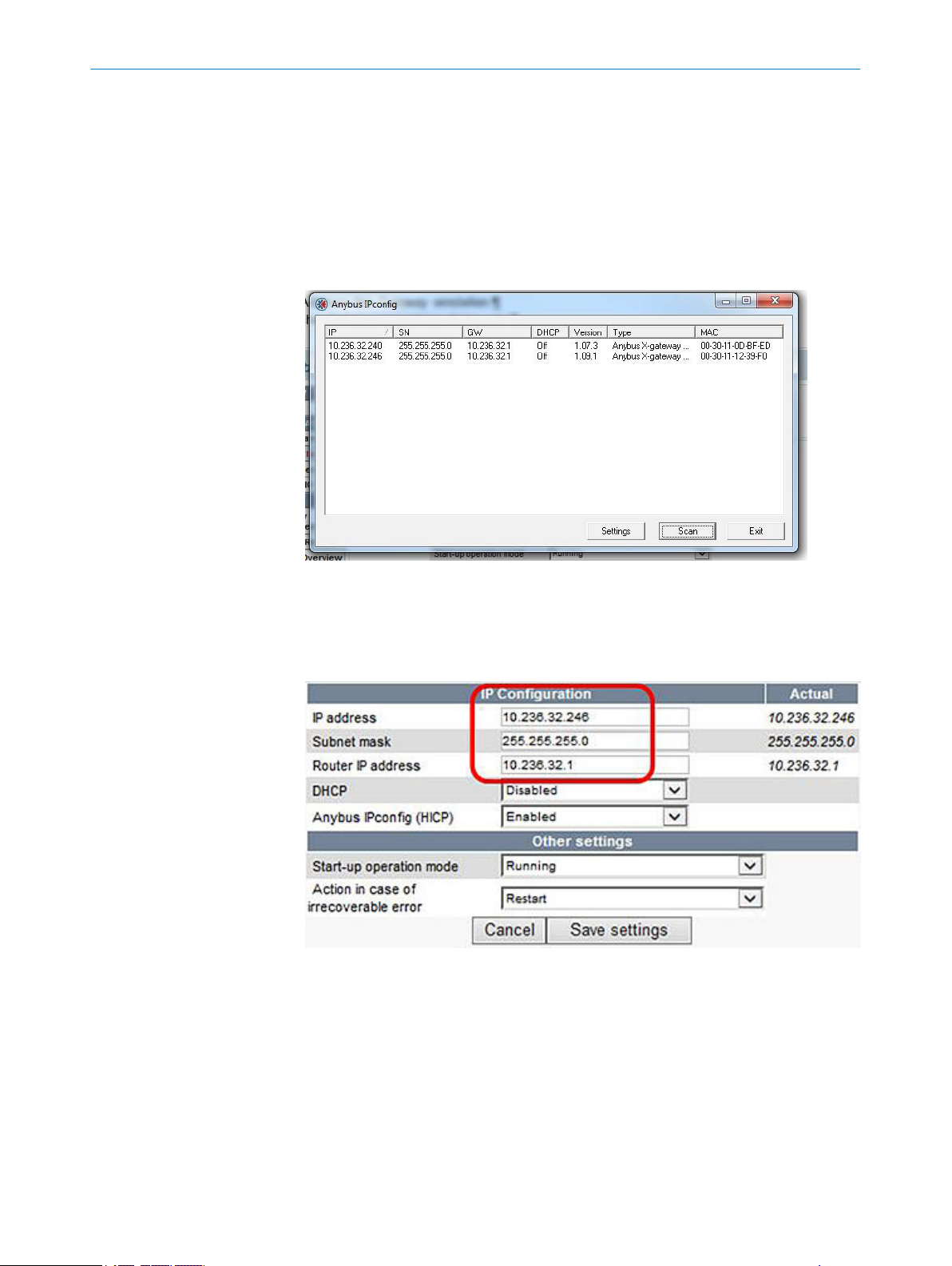

Use the “IP config” software on the Product-CD to find the IP address of the con‐

verter in the network using its MAC address (the MAC address is on a label on the

converter (next to the TCP interface).

Figure 25: Menu window Anybus IPconfig

4. Start a web browser (IE7.0 or 8.0), enter the IP address and a connection to xGateway to the web interface.

5. Define your specific IP address incl. subnet of the converter that matches your net‐

work and safety settings.

Figure 26: Menu Configuration/Modbus Client

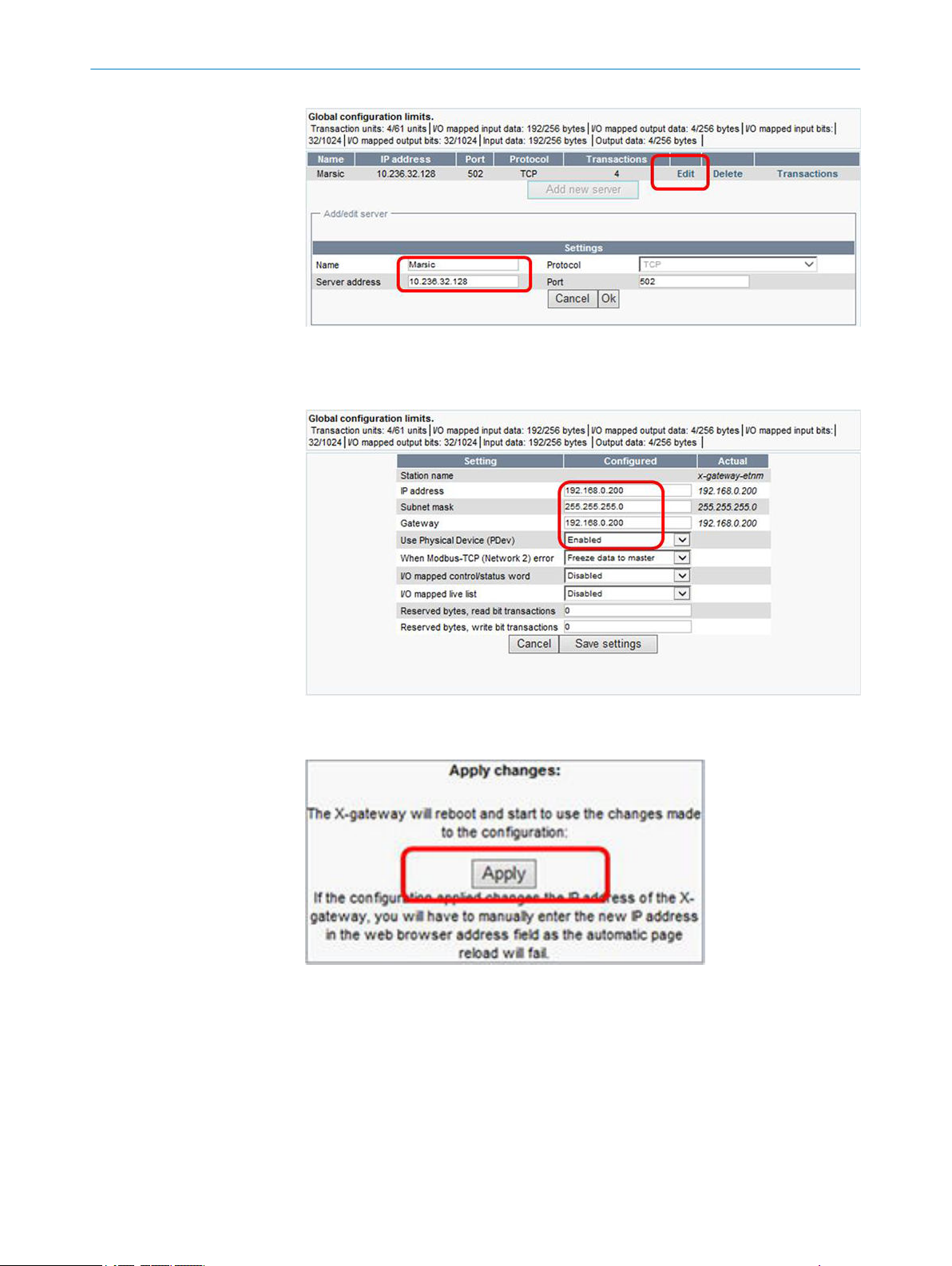

6. Enter the name, IP address and port of the MARSIC300.

28

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 29

INSTALLATION

Figure 27: Menu Configuration/Modbus Servers

7. Enter address from PROFINET and save the settings. The address must be the

same as in the operator-side SPS.

2

Figure 28: Menu Configuration/PROFINET IO

8. Click “Apply” to activate all changes.

Figure 29: Menu Tools/X-gateway management

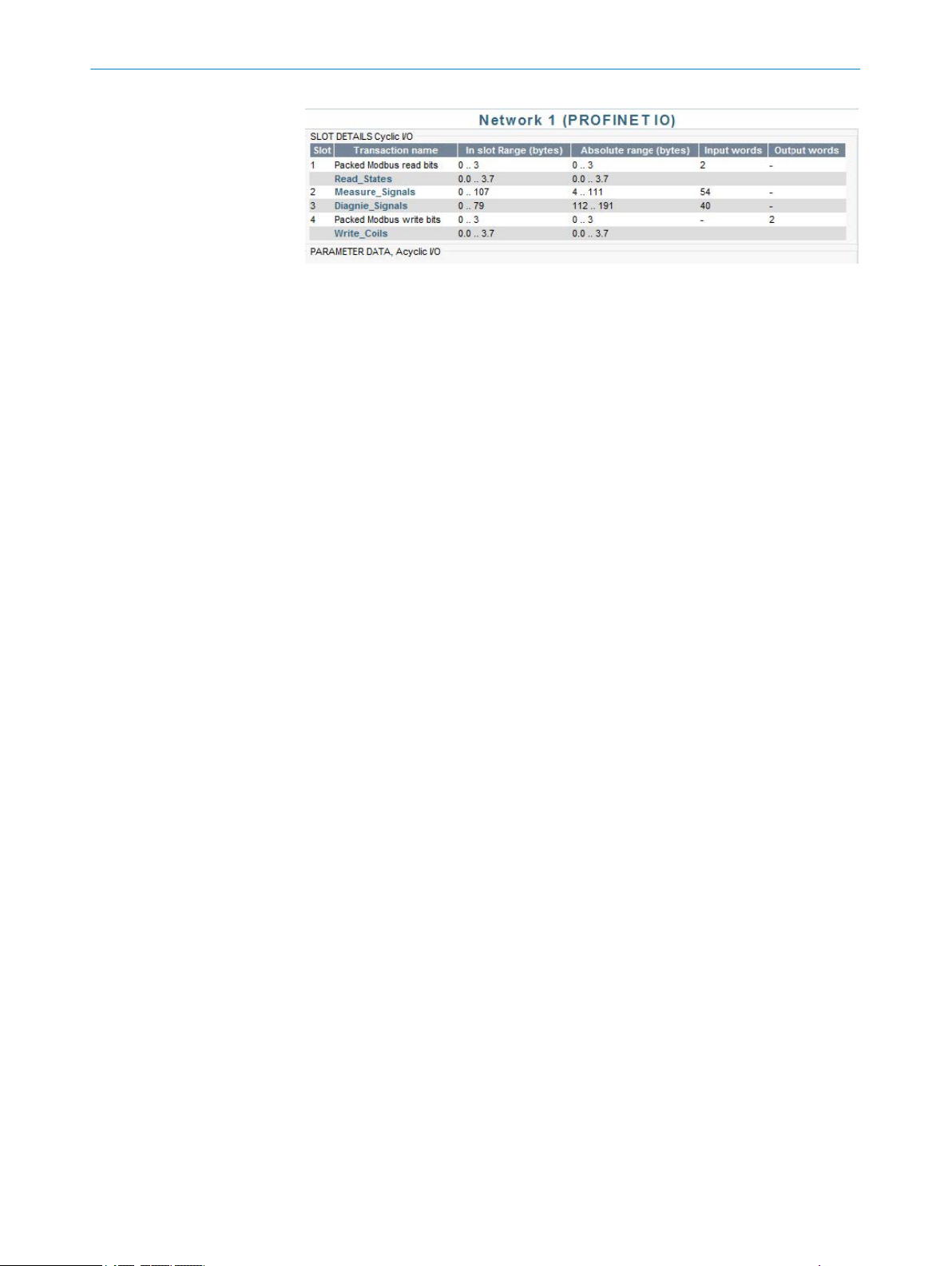

9. Setup the hardware configuration on the operator-side (operator SPS) according to

the following Table:

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

29

Page 30

2 INSTALLATION

Figure 30: Byte sequence

10. Set the byte sequence. The byte sequence can be set in MARSIC300 when

desired.

A connection to the PC with SOPAS ET is then necessary.

30

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 31

INSTALLATION 2

Figure 31: Menu Tree Parameters/Modbus in SOPAS ET

Set the register swap in SOPAS ET to CD_AB for Siemens controls.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

31

Page 32

INSTALLATION

2

Figure 32: Menu Modbus in SOPAS ET

2.16 Setting up the Modbus-Profinet converter (optional)

As an option to Modbus, the MARSIC300 can also be configured with a Profinet or Profi‐

bus protocol. This requires an external Modbus-Profibus converter that may have to be

adjusted.

How to configure the external converter is described in the following:

1. Install the converter onsite on a DIN rail and create a connection to the MAR‐

SIC300 (Modbus-TCP).

2. Connect the converter to 24 V DC.

3. Connect a PC via one of the Modbus-TCP connections of the converter with a net‐

work cable (crossover not required).

Use the “IP config” software on the Product-CD to find the IP address of the con‐

verter in the network using its MAC address (the MAC address is on a label on the

converter (next to the TCP interface).

32

Figure 33: Menu window Anybus IPconfig

4. Start a web browser (IE7.0 or 8.0), enter the IP address and a connection to xGateway to the web interface.

5. Define your specific IP address incl. subnet of the converter that matches your net‐

work and safety settings.

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 33

Figure 34: Menu Configuration/Modbus Client

6. Enter the name, IP address and port of the MARSIC300.

INSTALLATION

2

Figure 35: Menu Configuration/Modbus Servers

7. Enter the address of PROFIBUS and save the settings. The address must be the

same as in the operator-side SPS.

Figure 36: Menu Configuration/PROFIBUS DP-V1

8. Click “Apply” to activate all changes.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

33

Page 34

2 INSTALLATION

Figure 37: Menu Tools/X-gateway management

9. Setup the hardware configuration on the operator-side (operator SPS) according to

the following Table:

Figure 38: Byte sequence

10. Set the byte sequence. The byte sequence can be set in MARSIC300 when

desired.

A connection to the PC with SOPAS ET is then necessary.

34

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 35

INSTALLATION 2

Figure 39: Menu Tree Parameters/Modbus in SOPAS ET

Set the register swap in SOPAS ET to CD_AB for Siemens controls.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

35

Page 36

2 INSTALLATION

Figure 40: Menu Modbus in SOPAS ET

36

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 37

3 Initial start-up

NOTE

Prerequisite: The system is completely installed and connected.

Before switching on

1. Check connections are connected properly as described in the “Installation” Chap‐

2. Relieve the pressure on all pressure regulators in the analyzer (see "Air and gas

3. Adjust the manual valve in the analyzer as described in see "Air and gas connec‐

4. Open the external instrument air supply.

5. Set pressures: see "Air and gas connections on analyzer", page 20.

6. Check the power supply of the analyzer matches the setting on the ship network:

7. Check the voltage connection on the gas sampling system.

8. Install the gas sampling system on the flange of the exhaust duct: See “SFU Gas

INITIAL START-UP 3

ters.

connections on analyzer", page 20): Turn the regulators counterclockwise.

tions on analyzer", page 20 .

see "Electrical connections on the analyzer", page 23.

Sampling System Operating Instructions”.

Switching on

1. Switch on the external power disconnection unit.

2. The green "Power" LED on the control panel goes on:

Energy supply is available.

3. The yellow and red LEDs go on sporadically.

4. Booting appears several times on the screen.

5. The Measuring screen appears.

6. The system heats up:

Only the green LED is on.

°

Display: Init/Heating up.

°

A downwards counter displays the maximum duration of the process.

7. Display: Conditioning.

8. Only the green LED is on and Measuring is shown in the status line.

The system is ready for operation.

If a measured values blinks: The measured value is outside the calibration range.

When the yellow or red LED is on: Press the Diag button and clear the error: Error

list see "Error messages and possible causes", page 93.

Final tests and parameter settings

1. Perform a leak tightness check: see "Leak tightness check during initial startup",

page 75.

2. Perform an internal adjustment: Display menu Adjustment/internal adjustment.

3. Connect computer with SOPAS ET on ETH0 (see "Connections in analyzer",

page 83) (see "Software SOPAS ET", page 39).

If the customer network is already connected: Disconnect the customer network.

4. If required: Set the times for automatic adjustments.

To change in SOPAS ET: Menu Adjustment/Parameter/Start times.

w

5. If required: Configure the measuring point switchover.

In SOPAS ET: Menu Parameterization/Sequence Controls/Sampling point pro‐

w

gram.

6. Set the IP address of the customer network for the ETH0.

°

In the SOPAS ET user interface: Click the pen symbol in the device tile of the

MARSIC300.

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

37

Page 38

3 INITIAL START-UP

Figure 41: SOPAS ET device

tile

7. Disconnect the computer from ETH0 and connect the customer network to ETH0.

Initial start-up is completed.

38

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 39

4 Configuration software

4.1 Software SOPAS ET

SOPAS ET can also be used to the configure MARSIC300 and to access the MAR‐

SIC300 logbook.

SOPAS ET runs on an external PC connected to the MARSIC300 via the Ethernet inter‐

face.

Connect MARSIC300 with software SOPAS ET

1. Make sure all electric and pneumatic connections are connected properly, start-up

has been carried out correctly and the system is running without error messages.

Connect your computer with SICK software SOPAS ET installed (on the Product CD

or free in internet under www.sick.com):

CONFIGURATION SOFTWARE

4

Figure 42: MARSIC300 network connection

NOTE

SOPAS ET connects automatically the first time MARSIC300 is started and

inquires whether the driver files (SDD files) for the connected device should be

downloaded. Downloading is not necessary because SOPAS ET loads the driver

files direct from the MARSIC300.

2. Start SOPAS ET on the PC and search for devices. When the MARSIC300 appears

in the right area in SOPAS ET, drag & drop it to the left Project area.

To change the IP setting of the MARSIC300, click on the pen icon (marked red in

the Figure) and confirm the message with “Yes”.

Figure 43: Menu dialog TCP/IP settings

3. If the MARSIC300 was not found, login on the MARSIC300 on the control panel as

“Authorized Operator” (password is “1234”). You can change the network settings

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

39

Page 40

Back Enter

Measure

1 Digital outputs

2 Digital inputs

3 Ethernet

I/O config. 3.3

/Diag/I/O

4 CONFIGURATION SOFTWARE

for the MARSIC300 here. Make sure the PC and the MARSIC300 are in the same

subnet and no firewall is active.

Set the device parameters matching your network in this menu and confirm with

“OK”. A warning appears to confirm that the device is set offline. Confirm with

“Yes”. The network configuration has been changed, however the old configuration

can still be seen. The IP configuration is updated on the operator panel and in

SOPAS ET after a restart (switching the MARSIC300 off and on).

4.2 Saving parameters

Figure 44: Menu settings IP configuration

After configuration, the MARSIC300 must be adjusted to the network settings of

the customer network.

SOPAS ET can be used to backup and restore the MARSIC300 parameters:

40

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 41

CONFIGURATION SOFTWARE 4

1. Click the left mouse button to select the desired device in the main window.

2. Select “Project / Project save as” to save the SOPAS ET-Project file in a local direc‐

tory on the PC.

Figure 45: Menu dialog - Save Project file

4.3 Backing up the logbook with SOPAS ET

It is useful for diagnostic purposes when the MARSIC300 logbook is made available to

Service. It can be downloaded easily and, e.g. sent per e-mail.

1. Login as “Authorized User”.

2. Select path: MARSIC300 / Diagnosis / Logbook.

3. Select “All” in the scroll down menu.

4. Select “Export” to save the log file in a local directory on the PC.

Figure 46: Menu Logbook in SOPAS ET

4.4 Passwords

There are 2 passwords:

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

41

Page 42

4 CONFIGURATION SOFTWARE

Table 5: Passwords

Password for Password Change password

Device display access "Authorized

User"

SOPAS ET HIDE Cannot be changed

4.5 Using the menus

Example: Menu: Parameterization/I/O/Data/External Data/Analog inputs

Figure 47: Menu Analog inputs

Table 6: Menu fields legend

Entry field Significance

1

2

3

4

5

6

1234 Changing the password: see "Instrument display",

Save current entries.

Create group

Click "Mark" and then click the desired lines.

b

To cancel "Mark": Click "Mark" again and then click an empty line.

b

In editable menus: Call up the setting menu for lines.

Click desired line. Then click "Edit".

b

Copy selected lines

Insert copied lines before a selected line

Call up "Next function group"

page 60

4.6

42

(The bottom lines in the example depend on the menu)

Menu tree (SOPAS ET)

The menu tree shown here shows the menus for user level "Authorized User".

Menu Reference

Measuring screen chapter 5.1

Measuring screens

Diagnosis chapter 7

Control values chapter 7.1

Zero drift

Span gas drift

Internal adjustment drift

Reference energy

Intensity

Sensor values chapter 7.2

Temperatures

Pressures

Flow rate

Cell

O2 sensor

Emitter

Motors

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 43

CONFIGURATION SOFTWARE 4

Hardware

Signals chapter 7.3

External signals

Measuring signals (MVi)

Diagnosis internal (IDOi, ID

Boolean values (BVi, LIi)

Real values (RVi)

Modbus values (MBVi)

Modbus input values (MBIVi)

Modbus input flags (MBIFi)

Modbus reference flags (MBIRi)

Filtered values (FVi)

Integer values (IVi)

Real constant (RCi)

Logbook chapter 7.4

System status chapter 7.5.1

System info chapter 7.5

Timemeter chapter 7.5

Parameter chapter 6

Measuring components chapter 6.1

Global definitions

Measuring screen chapter 6.2

Measuring Screen x

I/O chapter 6.5

Hardware plan

Data

– External data

– OPC outputs (OPCOi)

– Modbus values (MBVi)

– Modbus input values (MBIVi)

– Modbus input flags (MBIFi)

– Modbus reference flags (MBIRFi)

Sequence control programs chapter 6.4

Sampling point program (MPP)

Temperature control chapter 6.6.1

Pressure control chapter 6.6.2

Flow rate chapter 6.6.3

O2 sensor chapter 6.6.4

Logbook chapter 6.6.5

Instrument display chapter 6.6.6

Device chapter 6.6.7

Emitter chapter 6.6.8

Modbus chapter 6.6.7

Adjustment chapter 6.5.4

Parameter chapter 6

Concentrations

Adjustment factors

Start times

Manual adjustment chapter 6.3

Automatic adjustment chapter 6.3

Maintenance chapter 8

Tests chapter 8.1

Digital inputs

Digital outputs

Operating states chapter 8.2

System maintenance chapter 8.3

Service log chapter 8.5

Restart system chapter 8.4

Confirm active messages chapter 8.6

Replacing the analyzer chapter 8.8

Replacing the electronics chapter 8.9

Loading/saving the parameters chapter 8.7

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

43

Page 44

5 MEASURING SCREENS AND DATA STORAGE

5 Measuring screens and data storage

Only the configured Measuring screens are shown.

b

Figure 48: Menu Measuring

Screens

Configuring Measuring screens: see "Measuring screens", page 47.

•

Scaling Measuring screens.

•

5.1 Measuring screen

The Measuring screen is shown as measured value box, bar graph or line writer

depending on the configuration.

Measured value box

Here, the measured values are shown in numeric format.

Double-click the desired Measuring screen

Component

1

Unit

2

Measured value

3

44

Figure 49: Menu Measuring Screen/Measuring Screen 1 ... x

Bar graph

Here, the measured values are shown as a bar graph.

Component

1

Unit

2

Measured value

3

Figure 50: Bar graph

Line Writer and data storage

Here, the measured values are shown in numeric format as measured value box and in

a time chart.

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 45

Figure 51: Line Writer

MEASURING SCREENS AND DATA STORAGE 5

Component

1

Line Writer - shows the

2

activated measured val‐

ues (see under “Scaling

Measuring screens”).

The Line Writer first

starts the display when

it is called up for the

first time.

Changing the user level

deletes the history of

the line display.

5.2 Data storage function

Start:

b

Start data storage.

Data that have been configured are stored (independent of the graphic represen‐

tation).

Maximum 65536 entries per curve are stored in a file and then a new file created

automatically (with an incremental index).

A dialog field appears above the line diagram to enter a target file name (.txt):

w

Figure 52: Storing the recording

Stop:

b

Stop recording.

View:

b

View recorded data.

A dialog field appears to select the file with the stored values.

The following then appears above the line diagram:

Figure 53: Loading the recording

Reset:

b

Delete all line displayed (no effect on data storage).

Scaling Measuring screens

Tap on a display to call up a screen for scaling:

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

45

Page 46

5 MEASURING SCREENS AND DATA STORAGE

Figure 54: Menu Scaling

Font color (Line Writer colors are prede‐

1

fined)

Measuring screen precision

2

Example:

-2: 123.45

-1: 1234.5

0 : 12345

1 : 123450

Scale start value

3

Scale end value

4

(for Line Writer: for y-axis)

Line display active / not active

5

(for Line Writer)

46

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 47

6 Parameterization

6.1 Measuring components

Global definitions

This menu displays the global device information (e.g.: number of filter wheels, number

of activated components).

Figure 55: Menu Parameterization/Measuring component/Global Definitions

Active measuring components. Checkmark: Active

1

Internal use: Error threshold of reference energy as from which a message is generated.

2

Definition of measuring components

This menu displays the setting for the respective measuring component.

This menu only serves as information.

PARAMETERIZATION 6

Figure 56: Menu Parameterization/Measuring components/Definition of

components

6.2 Measuring screens

Up to 8 Measuring screens can be configured and displayed:

Figure 57: Menu Tree Parame‐

ters/Measuring Screens in

SOPAS ET

Select the desired Measuring screen

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

47

Page 48

6 PARAMETERIZATION

Double-clicking a Measuring screen opens a screen in which the Measuring screen can

be configured:

Selected Measuring screen

1

Do not display the Measuring screen

2

Line Writer (see example below)

3

1 measured value box

4

4 measured value boxes

5

16 measured value boxes (see example

6

below)

2 large, 8 small measured value boxes

7

6 bar graphs (see below)

8

3 bar graphs + 2 measured value boxes

9

3 bar graphs + 8 measured value boxes

ß

(hidden)

Click “Save” to store

à

Figure 58: Menu Measuring Screens - Lay‐

out selection

Measured value box

Example: Measuring screen 1 with layout III

(16 measured value boxes)

1 b

Enter desired names (tags). MAR‐

SIC300 tags: see "Tags (variable

names)", page 100

Scaling the measured value box: see

"Measuring screen", page 44

Figure 59: Menu Measuring Screens Example layout

The Measuring screen now looks like this.

Figure 60: Menu Measuring Screens - Com‐

ponent names

Bar graph

The component names and units can be, for

example, from the factory settings (e.g. RVi) the

source of a filter (e.g. FVi) or from the analyzer.

48

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 49

Figure 61: Menu Measuring Screens - Bar

graph

The Measuring screen then looks like this:

PARAMETERIZATION 6

Example: Measuring screen 1 with bar

graph layout I (6 bars)

1 b

Enter desired names (tags). MAR‐

SIC300 tags: see "Tags (variable

names)", page 100

Scaling the measured value box: see

"Measuring screen", page 44

Figure 62: Bar graph - example

Line Writer

Figure 63: Menu Measuring Screens - Tags

The Measuring screen then looks like this:

Enter desired names (tags).

b

1

Scaling the measured value box: see

"Measuring screen", page 44

2

Scaling the time axis [sec, min or hrs],

scaling the y-axis: see "Measuring

screen", page 44

Measured value box

1

Line Writer

2

Figure 64: Menu Measuring Screens - Line

Writer

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

49

Page 50

6 PARAMETERIZATION

6.3 Adjustment functions

Start times

Menu: Adjustment/Parameter/Start times

This menu displays the start times of the “Cyclic triggers (CT1 .. CT16)”.

Figure 65: Menu Start times

Manual adjustment

Menu: Adjustment/Manual adjustment

Further information, see “MARSIC300 Operating Instructions”

Cyclic trigger name

1

Next start time

2

Deactivation via operator

panel or menu: Parameter/

Variables and functions/

Cyclic trigger (CTi)

Measured value of this

1

component is set to

zero

Measured value of this

2

component is set to the

nominal concentration

of the test medium

Measured values of all

3

components listed

above are set to zero

Figure 66: Menu Manual adjustment

Automatic adjustment

Menu: Adjustment/Automatic adjustment

Further information, see “MARSIC300 Operating Instructions”

50

Figure 67: Menu Automatic adjustment

Start adjustment of program displayed

1

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 51

The available programs are system-specific: see System documentation.

Parameter

6.3.1.1 Concentrations of test gases

Menu: Adjustment/Parameter/Concentrations

This menu displays the concentrations of the span gases and internal adjustment filter.

The concentrations of the test gases can be set.

Figure 68: Menu Concentrations

PARAMETERIZATION 6

Enter the concen‐

1

tration of the test

medium

Only internal signif‐

2

icance

6.3.1.2 Adjustment factors

Menu: Adjustment/Parameter/Adjustment factors

This menu serves to set the correction factors (adjustment filter wheel optional).

•

•

•

Figure 69: Menu Adjustment factors

1

2

3

6.3.1.3 Start times

Menu: Adjustment/Parameter/Start times

This menu displays the start times of the "Cyclic triggers (CT1 .. CT16)“.

The measured value is computed with both adjustment factors.

Factor "Internal adjust." is set automatically to "1.000" when factor "Span gas" is

changed.

Checkmark “Active”: This measuring component is computed.

Display: Current factor

Input: New factor

Confirm: Use new factor

Cyclic trigger name

1

Next start time

2

Deactivation via operator

panel or menu: Parameter/

Variables and functions/

Cyclic trigger (CTi)

Figure 70: Menu Start times

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

51

Page 52

6 PARAMETERIZATION

6.3.1 Manual adjustment

Menu: Adjustment/Manual adjustment

Further information, see "MARSIC300 Operating Instructions”

Figure 71: Menu Manual adjustment

6.3.2 Automatic adjustment

Menu: Adjustment/Automatic adjustment

Further information, see "MARSIC300 Operating Instructions”

Measured value of this

1

component is set to

zero

Measured value of this

2

component is set to the

nominal concentration

of the span gas

Measured values of all

3

components listed

above are set to zero

Figure 72: Menu Automatic adjustment

Start adjustment of program displayed

1

The available programs are system-specific: see System documentation.

6.4 Measuring point switchover / Sequence control program

Sampling point program

Menu: Parameterization/Sequence control program/Sampling point program

This menu serves to configure "measuring at several sampling points".

52

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 53

1 2

3 4 4

5 5

6

3

PARAMETERIZATION 6

CAUTION

The programs are automatically controlled.

The device no longer measures correctly when a program is interrupted with Start/

Pause/Stop/Continue.

Only use these functions when you are sure you can assess the consequences.

b

Figure 73: Measuring point switchover - diagram

Measuring point 1

1

Measuring point 2

2

Hold time

3

Active

4

Duration

5

Cycle time

6

Cycle time

The complete defined measuring cycle including measuring point switchover is com‐

pleted within the cycle time.

Duration

The time during which a measuring point is active and measuring (including run-in time

after measuring point switchover).

Hold time

After measuring point switchover: The time in which the last valid measured value of

the measuring point is held until the new measuring point has run-in (purge processes

etc.).

The hold time can be entered individually for each measuring point and serves, for

example, to control the release of the measured value to Modbus or similar.

Active

Valid measured values of the active measuring point are available after the run-in time.

Figure 74: Menu Sampling point program (MPP)

Display: Internal tag to enable the sampling point program

1

Display: Run-time for the current sampling point

2

Start the sampling point program

3

Interrupt the sampling point program (pause)

4

Display: Active sampling point

8017585/YXD9/V3-1/2017-05 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC300

Subject to change without notice

5

Display: Index of active sampling point

6

53

Page 54

6 PARAMETERIZATION

Cancel the sampling point program

7

Continue the sampling point program after "Pause"

8

Input: Number of sampling points

9

Minimum measuring time per sampling point

ß

Checkmark: Fixed cycle time 285 s (“DeSOx time”)

à

Checkmark: Fixed cycle time from "Cycle time"

á

Checkmark: Fixed sampling point time

â

Input: Cycle time

ã

DeSOx-Time (à)

The DeSOx-Time is based on Guideline MEPC.259(68). This requires that each measur‐

ing point must be measured once within 4:45 minutes (285 seconds).

To enter in the menu below: Subtract the hold times from the 4:45 minutes and divide

the remaining time by the number of measuring points. For example: For 2 measuring

points with the same hold time, each measuring point is active for 142 seconds.

This can be used, for example, to control the release of the measured value on Modbus.

Fix.Cycle-Time (á)

The“Fix.Cycle-Time” corresponds to the “DeSOx-Time”, however the cycle time is not

specified fixed but can be entered explicitly (see menu above).

Fix.Msp-Time (â)

Measuring on each measuring point continues for the time specified under “Duration”

in the menu.

This means different measuring times can be defined per measuring point. If the dura‐

tion set is shorter than the “hold time + minimum measuring time”, the duration is

automatically set to this time. The following is also valid - the total of “hold times + the

minimum measuring time” per measuring point may not be longer than the cycle time.

Otherwise the cycle time is increased accordingly.

54

Figure 75: Measuring point program - menu description

Sampling point index

1

Sampling point name

2

Sampling point sequence

3

Measuring time at the sampling point including run-in times

4

Run-in time

5

Checkmark active: Sampling point active

6

Figure 76: Measuring point program - setting options

Display: Sampling point index

1

Checkmark: Sampling point active

2

Sampling point name

3

Overall duration at the sampling point

4

T EC H NI C AL IN F OR M AT I ON | MARSIC300 8017585/YXD9/V3-1/2017-05 | SICK

Subject to change without notice

Page 55

Run-in time

5

Position in the sequence of the sampling point program

6

NOTICE

The green arrow (load all parameters) must be pressed after making changes in order

to see the effect of the changes for both measuring points. This then updates the data