Page 1

MARSIC200

Ship Emission Measuring Device

Installation and Initial Start-up

T E C H N I C A L I N F O R M A T I O N

Page 2

Described product

MARSIC200

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Function of this document....................................................................... 6

1.2 Target group.............................................................................................. 6

1.3 Further information................................................................................... 6

1.4 Symbols and document conventions...................................................... 6

1.4.1 Warning symbols...................................................................... 6

1.4.2 Warning levels / Signal words................................................. 7

1.4.3 Information symbols................................................................ 7

2 Installation.......................................................................................... 8

2.1 Gas supply terminology............................................................................ 8

2.2 Installation information............................................................................ 8

2.2.1 Power supply information........................................................ 8

2.2.2 Notes on the gas supply.......................................................... 8

2.2.3 Tube screw fitting..................................................................... 9

2.3 Scope of delivery....................................................................................... 10

2.4 Provision by operator................................................................................ 10

2.5 Installation overview................................................................................. 11

2.5.1 System layout for 1 ... 4 measuring points............................ 13

2.6 Checklist for mechanical and electrical installation............................... 15

2.6.1 Installing the enclosure........................................................... 15

2.6.2 Laying and connecting the gas lines...................................... 15

2.6.3 Lay and connect the electric lines between sampling

probe with sample conditioning and distribution unit........... 16

2.6.4 Lay and connect the electric line between distribution unit

and analyzer............................................................................. 19

2.7 Installing the sampling probe.................................................................. 21

2.8 Installing the sample gas line.................................................................. 22

2.9 Installing the sample conditioning........................................................... 24

2.9.1 Fitting the sample conditioning.............................................. 24

2.9.2 Gas connections on sample conditioning ............................. 25

2.9.3 Electrical installation of sample conditioning........................ 27

2.10 Installing the distribution unit.................................................................. 27

2.10.1 Fitting the distribution unit...................................................... 29

2.10.2 Gas connections on distribution unit..................................... 30

2.10.3 Electrical installation of distribution unit............................... 31

2.10.4 Measuring point switchover.................................................... 32

2.11 Installing the analyzer.............................................................................. 33

2.11.1 Fitting the analyzer.................................................................. 34

2.11.2 Gas connections on analyzer.................................................. 34

2.11.3 Electrical installation of analyzer............................................ 35

3 Initial start-up..................................................................................... 36

3.1 Initial start-up............................................................................................ 36

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

3

Page 4

CONTENTS

4 Configuration software..................................................................... 38

4.1 Software SOPAS ET................................................................................... 38

4.2 Passwords................................................................................................. 38

5 Adjustment functions....................................................................... 39

5.1 Configuring test gases (Test Gas Table).................................................. 39

5.2 Performing a manual adjustment............................................................ 41

5.3 Automatic adjustments/validations........................................................ 44

5.3.1 Function of automatic adjustments/validations.................... 45

5.3.2 Start options............................................................................ 45

5.3.3 Programming automatic adjustments/validations................ 45

6 Tests and settings............................................................................. 47

6.1 Information................................................................................................ 47

6.2 Setting the time........................................................................................ 47

6.3 Interfaces (I/O)......................................................................................... 47

6.3.1 Digital inputs............................................................................ 47

6.3.2 Digital outputs.......................................................................... 48

6.3.3 Analog outputs......................................................................... 49

6.4 Adapting the hardware............................................................................. 49

6.4.1 Setting analog interfaces........................................................ 50

6.5 Configuring measured values.................................................................. 50

6.6 Measuring points - automatic.................................................................. 52

6.6.1 Function of the measuring points automatic......................... 52

6.6.2 Criteria for measuring point automatic.................................. 52

6.6.3 Configuring measuring point automatic................................. 53

6.7 Backup of settings.................................................................................... 53

7 Technical data.................................................................................... 55

7.1 Dimensional drawings.............................................................................. 55

7.1.1 Dimensional drawing of sample conditioning........................ 55

7.1.2 Dimensional drawing of distribution unit............................... 56

7.1.3 Dimensional drawing of analyzer............................................ 57

7.1.4 Dimensional drawing of sampling probe................................ 58

7.1.5 Sample gas line, heated.......................................................... 58

7.2 Gas flow diagram...................................................................................... 59

7.3 Measuring parameters............................................................................. 61

7.4 Ambient conditions................................................................................... 61

7.5 Sample gas conditions............................................................................. 62

7.6 Design as wall enclosure.......................................................................... 62

7.7 Sample gas line, heated........................................................................... 63

7.8 Interfaces and protocols.......................................................................... 63

7.9 Energy supply............................................................................................ 64

7.10 Emissions.................................................................................................. 65

7.11 Torques for screw fittings......................................................................... 65

7.12 Tube connections...................................................................................... 66

4

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 5

CONTENTS

7.13 Sample gas conditions............................................................................. 66

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Function of this document

This document describes:

Installation

•

Initial start-up

•

Operation via SOPAS ET

•

NOTICE

This Manual is only valid in combination with the MARSIC Operating Instructions.

1.2 Target group

This document is addressed to technicians (persons with technical understanding)

operating and maintaining the measuring system.

The technicians must have been trained on the device.

Requirements for the technician

The technician must be familiar with the exhaust gas technology on the ship (over‐

•

pressure, toxic and hot flue gases) and be able to avoid hazards when working on

gas ducts.

The technician must be familiar with handling compressed gas cylinders (test

•

gases).

The technician must be able to avoid hazards caused by noxious test gases.

•

Only allow an authorized electrician to work on the electrical system or electrical

•

subassemblies.

1.3 Further information

“MARSIC200” Operating Instructions

•

Sampling Probe Operating Instructions

•

Instructions for laying the sample gas line

•

Sample Gas Cooler Operating Instructions

•

GMS800 BCU Operating Instructions

•

GMS800 Technical Information

•

Optional: MPR (Meeting Point Router) Operating Instructions

•

System documentation (parts list, device data, wiring diagram, system-relevant

•

components)

1.4 Symbols and document conventions

1.4.1 Warning symbols

Table 1: Warning symbols

Symbol Significance

Hazard (general)

Hazard by voltage

6

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 7

Symbol Significance

Hazard in potentially explosive atmospheres

Hazard by explosive substances/mixtures

Hazard by toxic substances

Hazards by noxious substances

Hazard by high temperature

Hazard for the environment/nature/organic life

1.4.2 Warning levels / Signal words

ABOUT THIS DOCUMENT 1

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

Note

Hints

1.4.3 Information symbols

Table 2: Information symbols

Symbol Significance

Important technical information for this product

Important information on electric or electronic functions

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

7

Page 8

2 INSTALLATION

2 Installation

2.1 Gas supply terminology

Definition of the gases used:

Zero gas: Gas used to adjust the zero point. Instrument air or nitrogen (N2).

•

Span gas: Gas used to adjust the upper measuring range value.

•

Test gas: Generic term for zero and span gas.

•

Instrument air: Clean compressed air.

•

Quality of gases: see "Sample gas conditions", page 66.

2.2 Installation information

2.2.1 Power supply information

The operator is responsible for correct laying and connection of the electric lines.

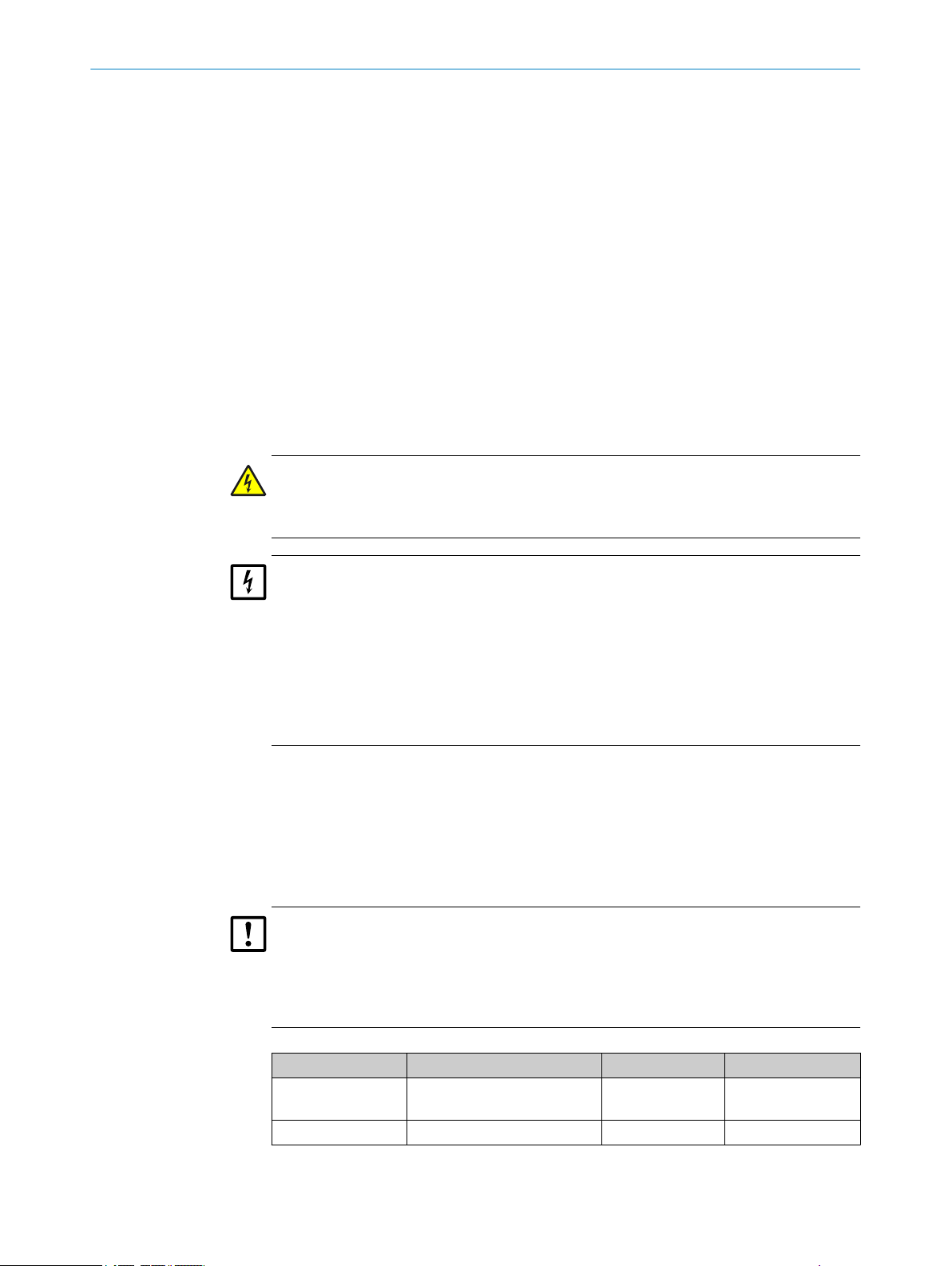

WARNING

Danger to life by electric voltage

Only allow an authorized electrician to work on the electric system

b

ATTENTION

Observe 115 V or 230 V versions.

The following subassemblies have a 115 V or 230 V version:

Sample gas line

•

Sample gas pump (in distribution unit)

•

Cooler (in sample conditioning)

•

Analyzer

•

Check that the voltage on the type plate matches the power supply.

When selecting and laying the electric lines for power supply, observe the technical

data (see "Energy supply", page 64) and the applicable local standards and guide‐

lines.

2.2.2 Notes on the gas supply

The operator is responsible for the correct laying of the sample gas lines.

ATTENTION

Risk of contamination of the analyzer by unclean instrument air.

Only use instrument air corresponding to the prescribed specification (see Techni‐

b

cal Data).

Install a suitable instrument air conditioning when necessary.

b

Gas Quality Inlet pressure Flow rate

Instrument air Particle size max. 1 μm

Oil content max. 0.1 mg/m

Zero point gas Nitrogen 5.0 Max. +300 hPa Typically 60 l/h

8

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Max. +300 hPa Typically 60 l/h

3

Subject to change without notice

Page 9

INSTALLATION 2

Gas Quality Inlet pressure Flow rate

Span gas External span gas

Precision: ± 2 %

Concentration: 80% ... 100%

of measuring range

The span gas must comply

with the specifications of the

standards to be applied (e.g.,

MARPOL Annex VI)

Flow plan see "Gas flow diagram", page 59

Dimension of connections of PTFE tubes: DN4/6.

The operator is responsible for the correct laying of the sample gas lines.

Observe the enclosed information concerning the laying of the heated sample gas line.

CAUTION

The PTFE tubes are susceptible to kinks.

Lay PTFE tubes in large arcs and plan a kink protection as necessary.

b

Observe the clearances when fitting the enclosures: see "Dimensional drawings",

b

page 55.

Max. +300 hPa Typically 60 l/h

2.2.3 Tube screw fitting

Swagelok screw fitting

b

Push the tube up to the stop in the tube

screw fitting.

Turn the cap nut finger-tight.

During initial assembly: Hold the fitting

b

bolt steady and tighten the cap nut with

1 1/4 revolutions.

During refitting: Tighten the cap nut to

b

the previous position (the resistance

increases noticeably) and then slightly

tighten.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

9

Page 10

2 INSTALLATION

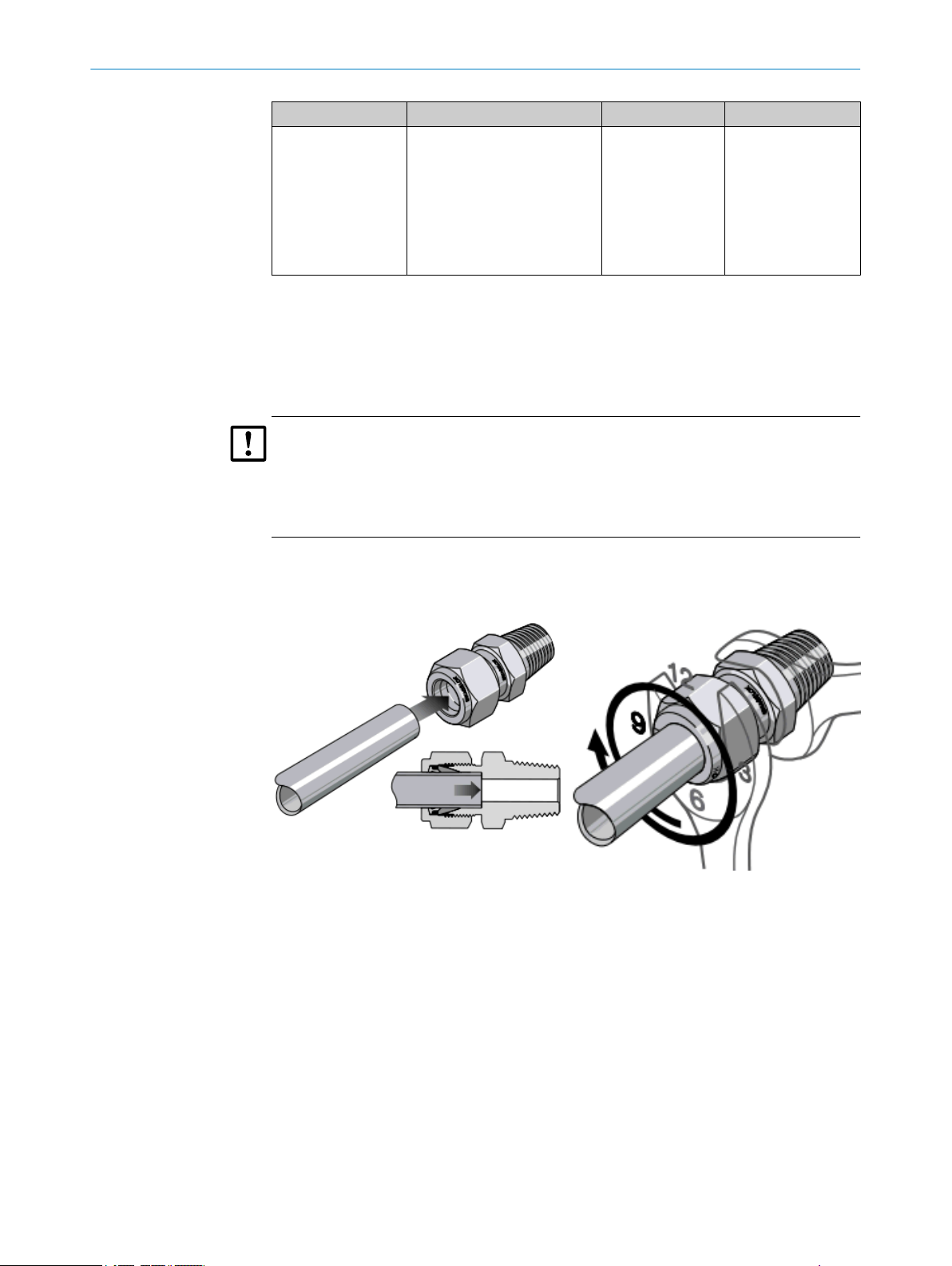

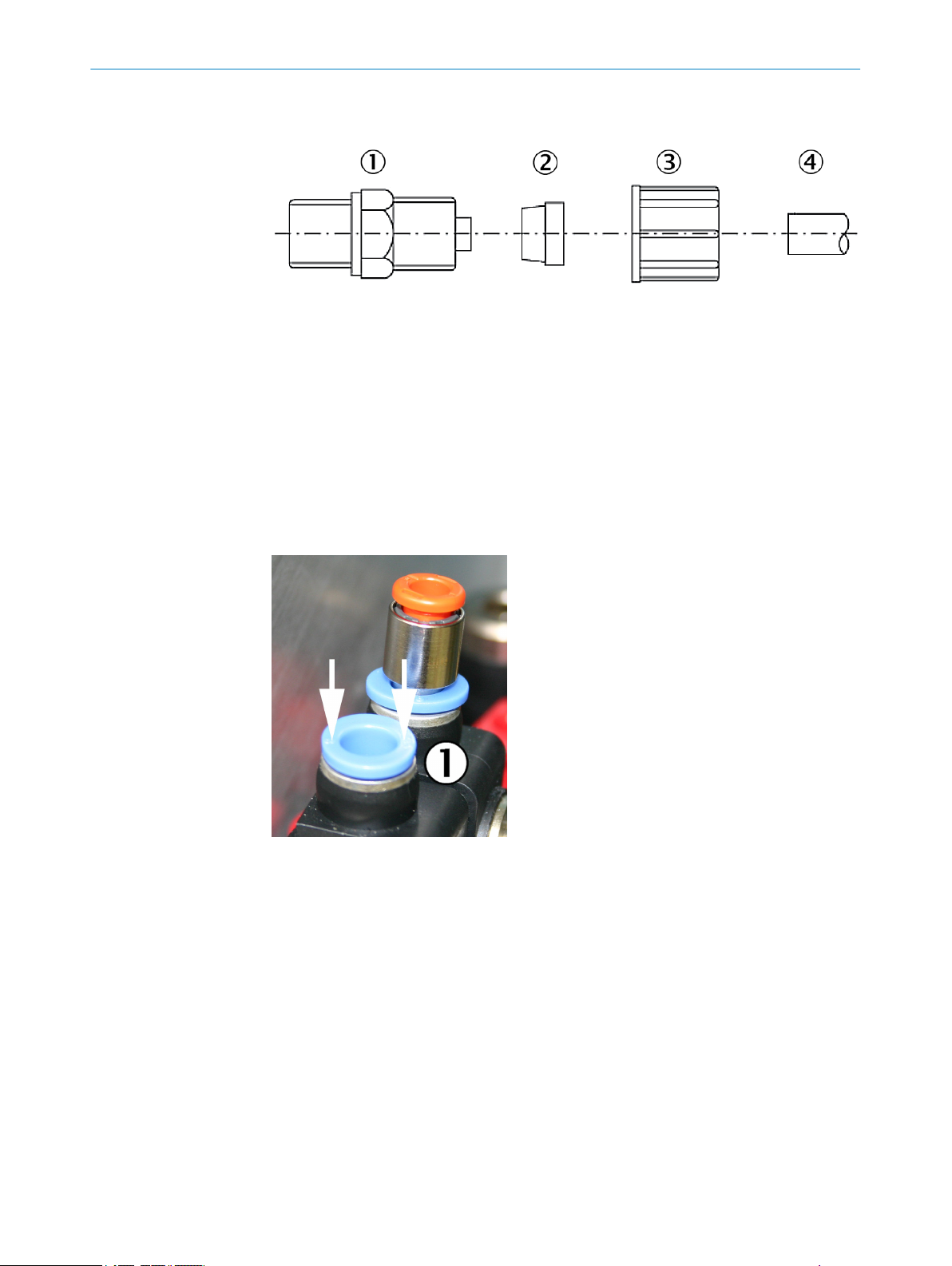

Plastic fitting

Figure 1: Hose fitting

Screw-in piece

1

Clamping ring

2

Knurled nut

3

Hose

4

Place the knurled nut and the clamping ring on the hose.

b

Observe the location of the clamping ring (see drawing).

Place the hose on the screw-in piece.

b

Turn the knurled nut hand-tight.

b

Push-in fitting pneumatic

Retaining ring

1

2.3 Scope of delivery

Please see the delivery documents for the scope of delivery.

2.4 Provision by operator

Inserting the tube: Push the tube in.

b

Removing the tube: Press the retaining ring

b

in and pull the tube out.

10

To be provided by operator:

Fixing accessories of enclosures (dowels, screws, etc.)

•

PTFE tubes and screw fittings: Depending on order

•

Grounding conductor for analyzer

•

Fixing accessories for heated sample gas line

•

Fixing accessories for PTFE tubes

•

Nitrogen or instrument air as zero gas: Observe the required quality: see "Sample

•

gas conditions", page 66

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 11

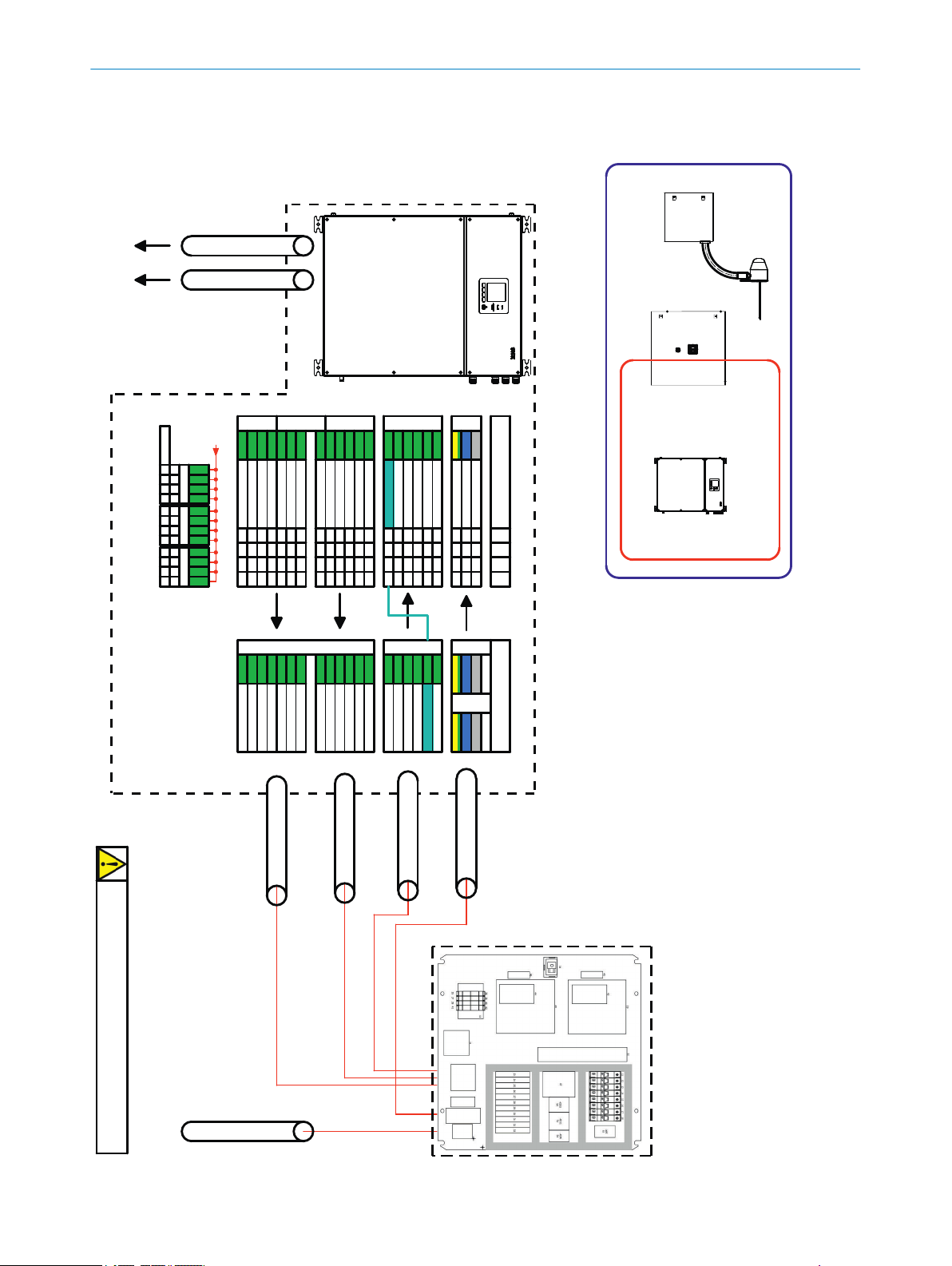

2.5 Installation overview

7

7

8

9

1

ß

2

3

3

4

5

5

6

à

à

á

â

ã

ä

NOTE

Gas flow diagram see "Gas flow diagram", page 59

INSTALLATION 2

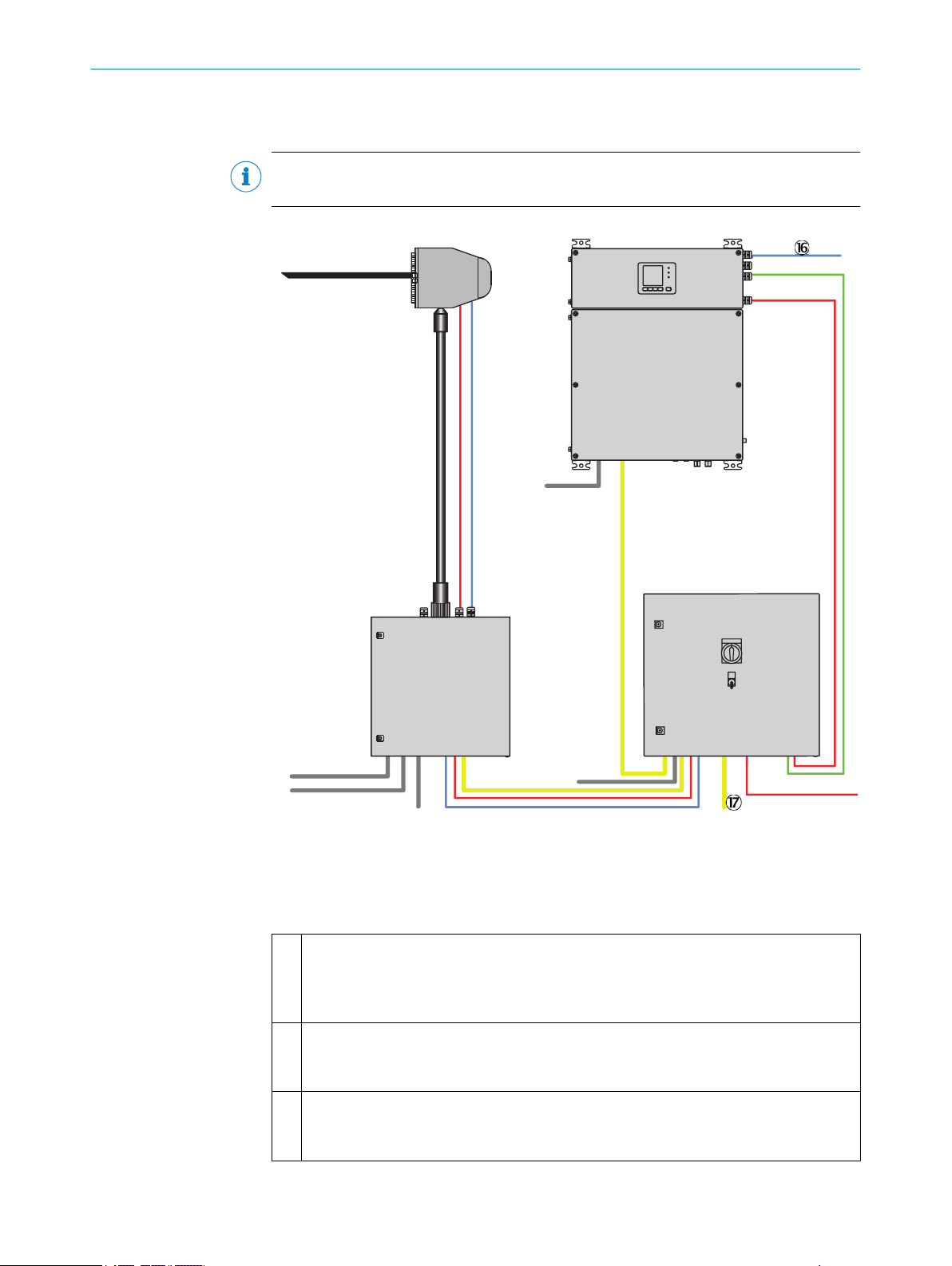

Figure 2: Installation - overview

Red Power supply

Blue and green Signal line

Yellow PTFE gas line

Heated sampling probe with:

1

Sampling tube

•

Sample gas filter

•

Backflushing

•

Heated sample gas line, sampling probe - sample conditioning:

2

Sample gas

•

Instrument air/test gas (optional)

•

Lines, sampling probe - sample conditioning

3

Power supply of the sampling probe

•

Signal line

•

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

11

Page 12

2 INSTALLATION

Sample conditioning with:

4

Sample gas cooler

•

Solenoid valve for feeding instrument air/test gas to the sampling probeTest gas feed

•

Gas inlets of sample conditioning:

5

Instrument air to backflush the probe

•

Only possible for measuring point 1: Test gas for adjustment via probe (optional)

•

Unheated sample gas line, sample conditioning - distribution unit

6

Lines, sample conditioning - distribution unit:

7

Power supply of sample conditioning

•

Signal line

•

Distribution unit with:

8

Power supply, complete system with central power distribution

•

System fuses

•

Main switch

•

“Stand-by” switch

•

Flow indicator

•

Sample gas fine filter

•

Water trap

•

Sample gas pump

•

Sample gas valve (test gas feed optional)

•

Measuring point switchover (for 2 ... 4 measuring points)

•

Bypass pump (for 2 ... 4 measuring points)

•

Inlet for central power supply for the complete system

9

The distribution unit provides electrical power for all system modules.

•

Unheated sample gas line from distribution unit to analyzer

ß

Lines, distribution unit - analyzer:

à

Analyzer power supply

•

Signal lines

•

Analyzer

á

Control unit

•

Measuring modules:

•

Gas module (flow, humidity and pressure)

°

DEFOR (NO, NO2 and SO2)

°

FINOR (CO2)

°

OXOR (O2), option

°

Analog and digital interfaces

•

Ethernet

•

Sample gas outlet

â

Test gas inlet

ã

Test gas connection during adjustment

Condensate outlet

ä

Signal lines/Ethernet to periphery

å

12

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 13

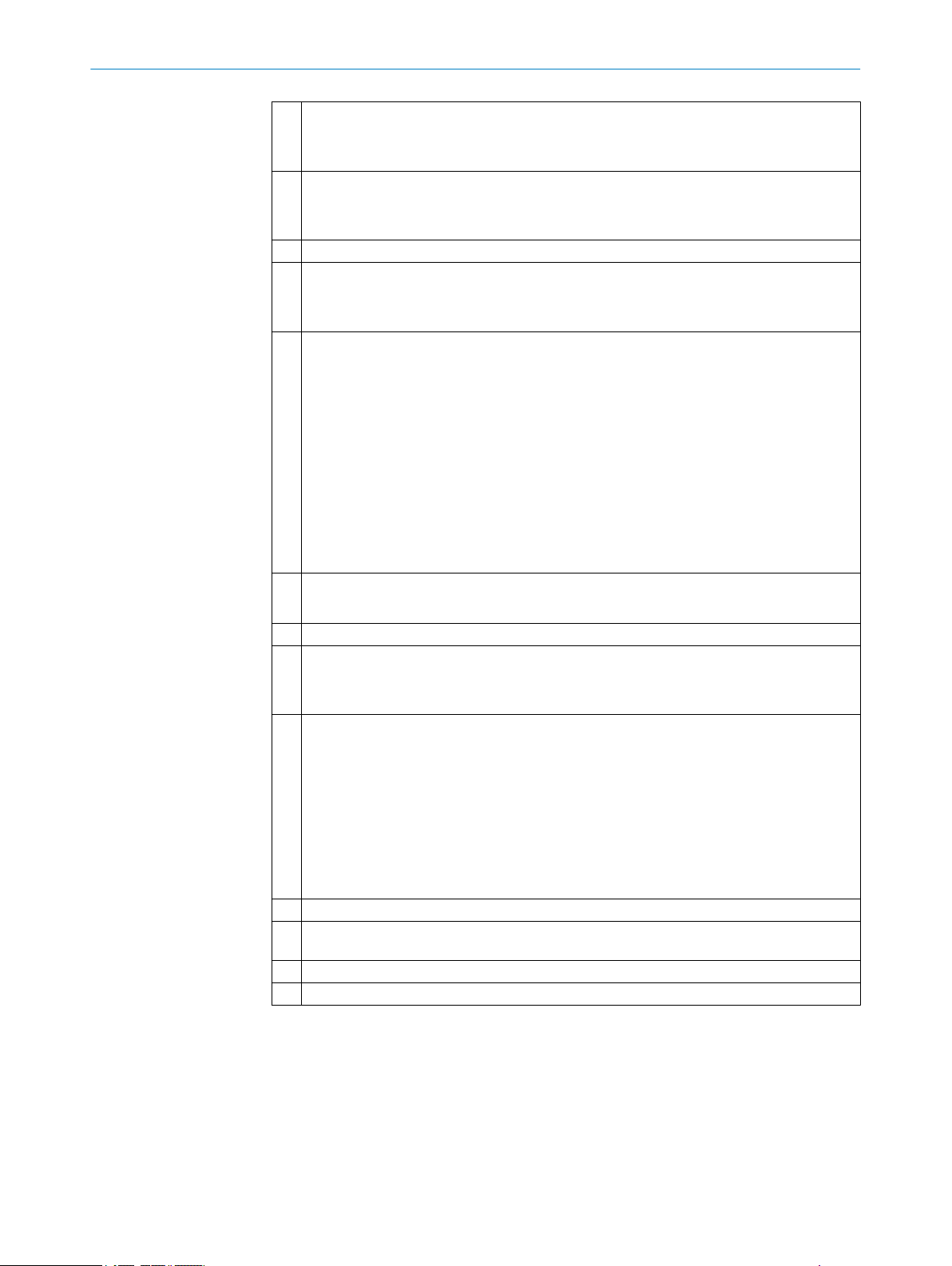

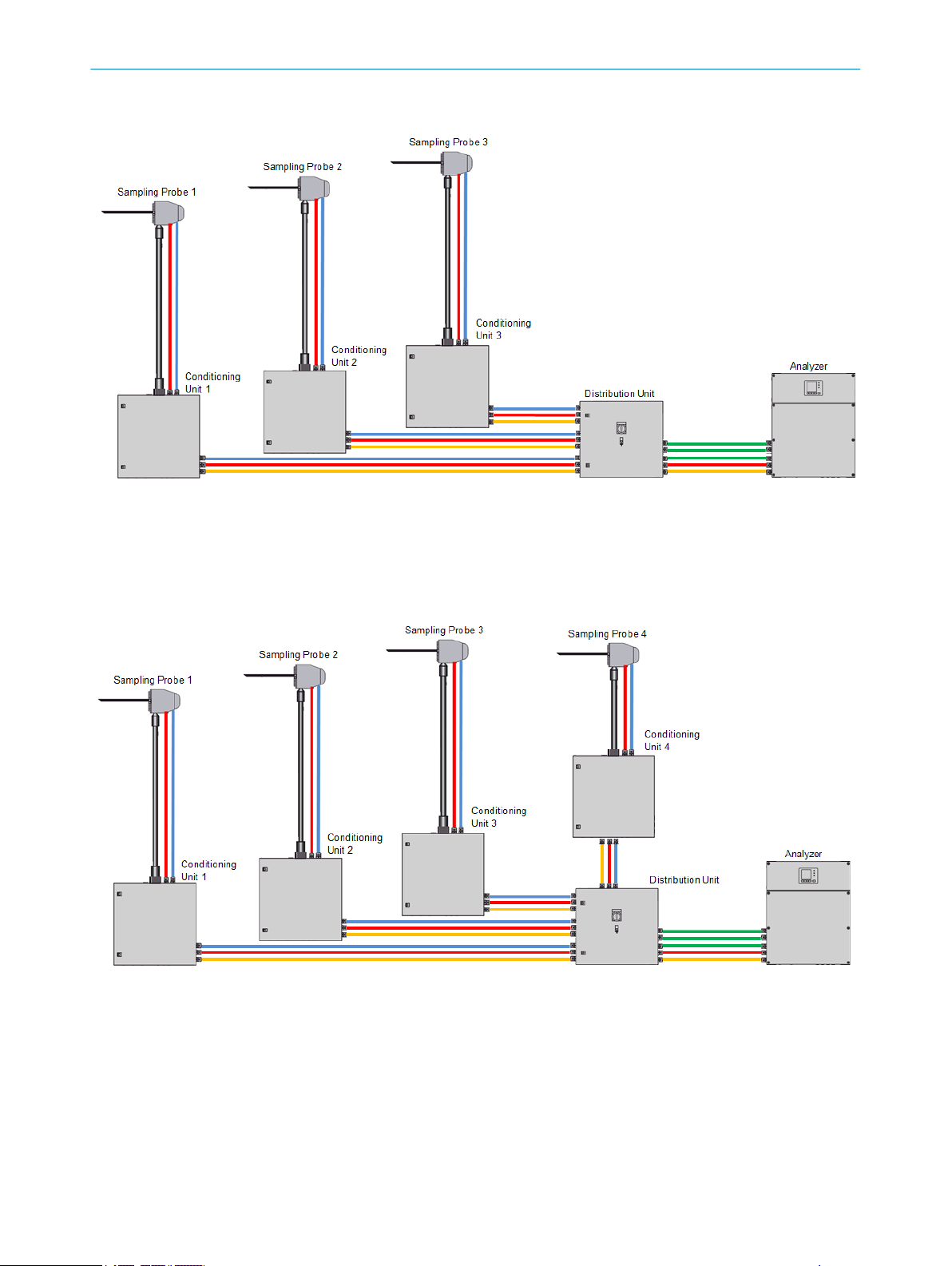

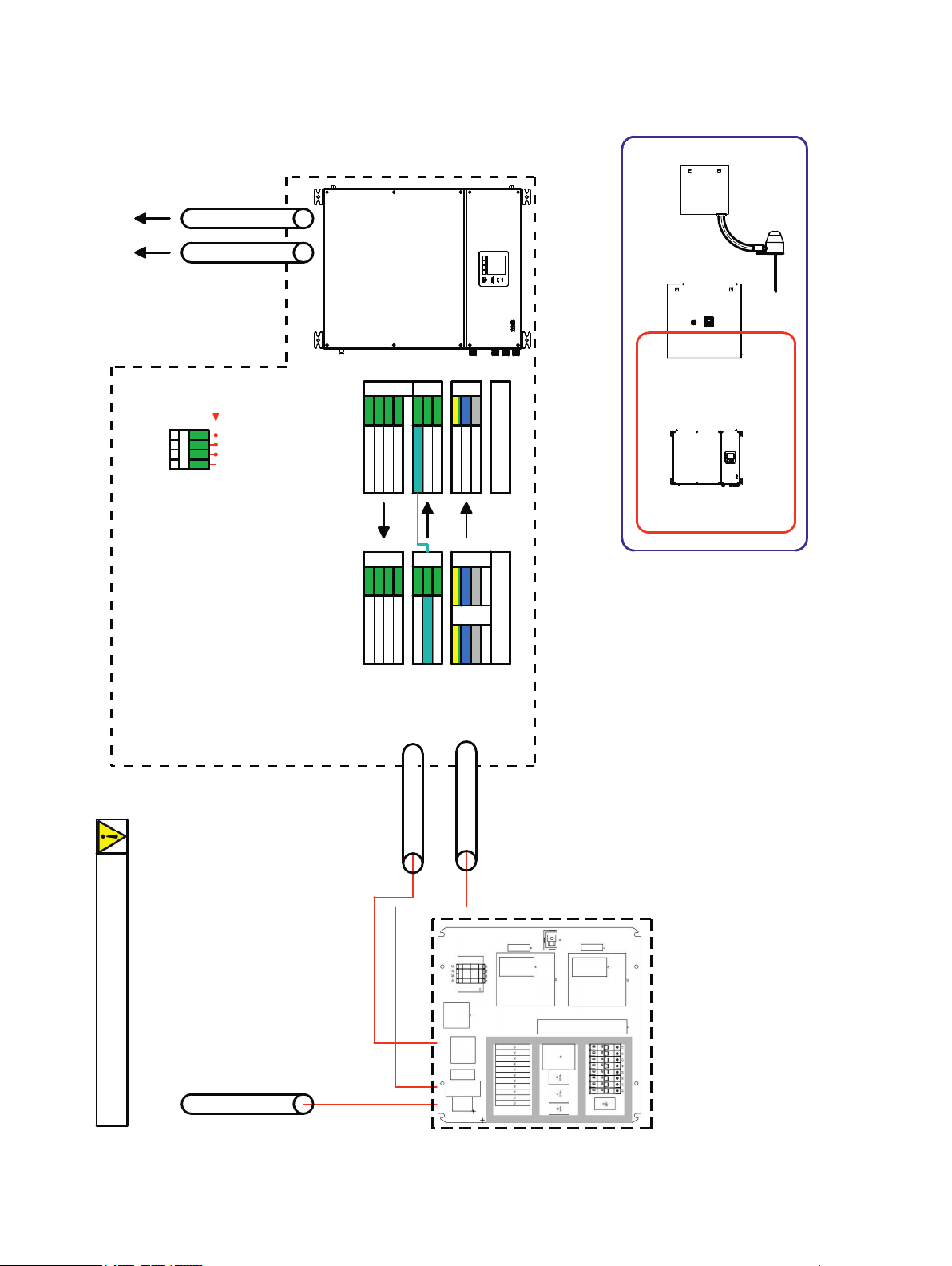

2.5.1 System layout for 1 ... 4 measuring points

1 measuring point

Red Power (3x1.5; Order no: 6056215)

Blue Signal (4x0.75; Order no: 6056229)

Green Signal (7x1.5; Order no: 6056230)

Yellow PTFE line (4/6; Order no: 5310243)

INSTALLATION 2

2 measuring points

Red Power (3x1.5; Order no: 6056215)

Blue Signal (4x0.75; Order no: 6056229)

Green Signal (7x1.5; Order no: 6056230)

Yellow PTFE line (4/6; Order no: 5310243)

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

13

Page 14

2 INSTALLATION

3 measuring points

Red Power (3x1.5; Order no: 6056215)

Blue Signal (4x0.75; Order no: 6056229)

Green Signal (7x1.5; Order no: 6056230)

Yellow PTFE line (4/6; Order no: 5310243)

4 measuring points

Red Power (3x1.5; Order no: 6056215)

Blue Signal (4x0.75; Order no: 6056229)

Green Signal (7x1.5; Order no: 6056230)

Yellow PTFE line (4/6; Order no: 5310243)

14

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 15

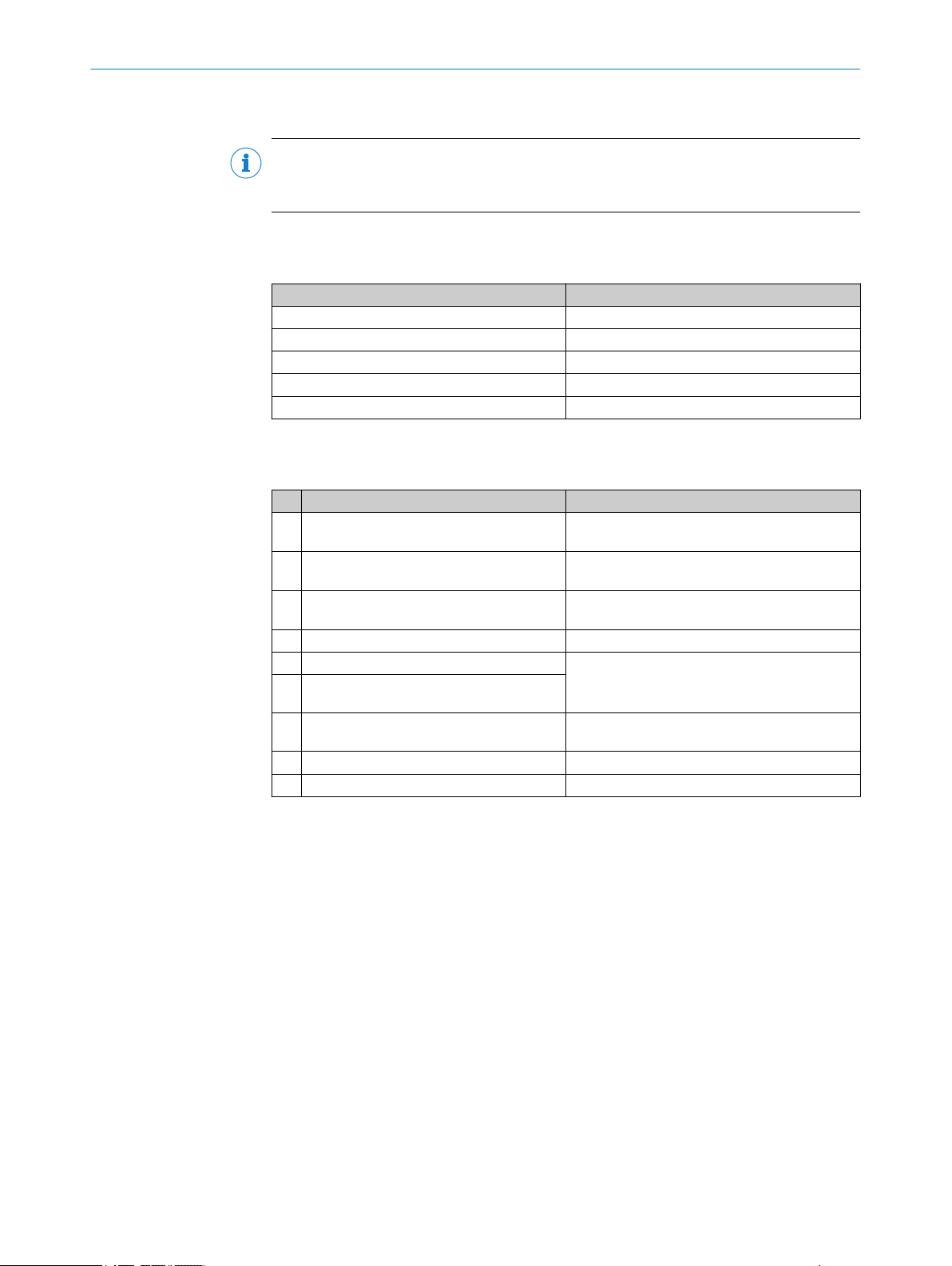

2.6 Checklist for mechanical and electrical installation

NOTE

The circuit diagrams shown in this Chapter are also available in larger format in the sys‐

tem documentation..

2.6.1 Installing the enclosure

Table 3: Installing the enclosure

Enclosure Reference

Installation of sampling probe see "Installing the sampling probe", page 21

Installation of sample conditioning see "Fitting the sample conditioning", page 24

Installation of distribution unit see "Installing the distribution unit", page 27

Installation of analyzer see "Fitting the analyzer", page 34

Optional: Installation of MPR see enclosed “MPR Operating Instructions”

2.6.2 Laying and connecting the gas lines

Table 4: Connecting gas lines

1

Gas line Connection

Heated sample gas line: From sampling probe

2

to sample conditioning

Sample gas line: From sample conditioning to

6

distribution unit

Sample gas line: From distribution unit to ana‐

ß

lyzer

Analyzer sample gas outlet Analyzer: see chapter 2.11.2

â

Instrument air feeding to sample conditioning Sample conditioning: see chapter 2.9.2

5

Test gas feeding to sample conditioning

5

(optional)

Instrument air feeding from sample condition‐

3

ing to sampling probe (optional)

Zero gas feeding to distribution unit Distribution unit: see chapter 2.10.2

ã

Sample conditioning condensate outlet Sample conditioning: see chapter 2.9.2

ä

1

Numbering see "Installation overview", page 11

Sampling probe: see chapter 2.7

Sample conditioning: see chapter 2.9.2

Sample conditioning: see chapter 2.9.2

Distribution unit: see chapter 2.10.2

Distribution unit: see chapter 2.10.2

Analyzer: see chapter 2.11.2

Sample conditioning: see chapter 2.9.2

Sampling probe: see chapter 2.7

INSTALLATION 2

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

15

Page 16

To sampling Probe (Power)

Marine Line (3x1,5) 6056215

Preparation Unit (UM1) Distribution unit (UM5)

101314

15

147

1

2

14

18

123

Alarm

Valve KK10

Power

Marine Line

(4x0,75)

6056229

Marine Line

(3x1,5)

6056215

XD21

XD61

XD2

To distributor unit (Power)

Marine Line (3x1,5) 6056215

To distributor unit (Signal)

Marine Line (4x0,75) 6056229

Power

+24V

XD1

DI 10Vcontrol

2

2

gy

3

3

gy

bu

4

4

bu bu

556

6

gnye

7

7

gnye

8

8

gnye

9

9

1

1

gy

10

10

gy

gy

11

11

gy

12

12

gy

13

13

gy

14

14

gy

15

15

PELN

Line 1

Distribution unit

(see next Page for details)

UM1

UM5

BQ1

UC1

sample gas line

UM1

junction box

UM5

XD2XD21 XD61

All cable diameters are proposals! The customer must check this diameters!

Parameters are e.g.: voltage drop, cable cluster, laying procedure etc.

WD3

WD6

WD2

WD1

Preparation Unit (UM2) Distribution unit (UM5)

101314

15

147

3

4

15

19

123

Alarm

Valve KK10

Power

Marine Line

(4x0,75)

6056229

Marine Line

(3x1,5)

6056215

XD21

XD61

XD2

Power

+24V

XD1

DI 20Vcontrol

Line 2

XD1

Preparation Unit

L PEN

PELN

Preparation Unit (UM3) Distribution unit (UM5)

101314

15

147

5

6

16

20

123

Alarm

Valve KK10

Power

Marine Line

(4x0,75)

6056229

Marine Line

(3x1,5)

6056215

XD21

XD61

XD2 Power

+24V

XD1

DI 30Vcontrol

Line 3

4 5

5

4

To sampling Probe (signal)

Marine Line (4x0,75) 6056229

Preparation Unit (UM4) Distribution unit (UM5)

101314

15

147

7

8

17

21

123

Alarm

Valve KK10

Power

Marine Line

(4x0,75)

6056229

Marine Line

(3x1,5)

6056215

XD21

XD61

XD2 Power

+24V

XD1

DI 40Vcontrol

Line 4

Connection of the sample preparation

is always the same

5...15m

54

L

2

N

3

6

200W

200W

PE

1

PE

rdbu

KK10

A

EC1

IN

rd

bu

13

-EC1

x1

x2

-KK10

INSTALLATION

2

2.6.3 Lay and connect the electric lines between sampling probe with sample conditioning and distribu‐

tion unit

MULTI version distribution unit for two to four measuring points

Figure 3: Wiring diagram

16

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 17

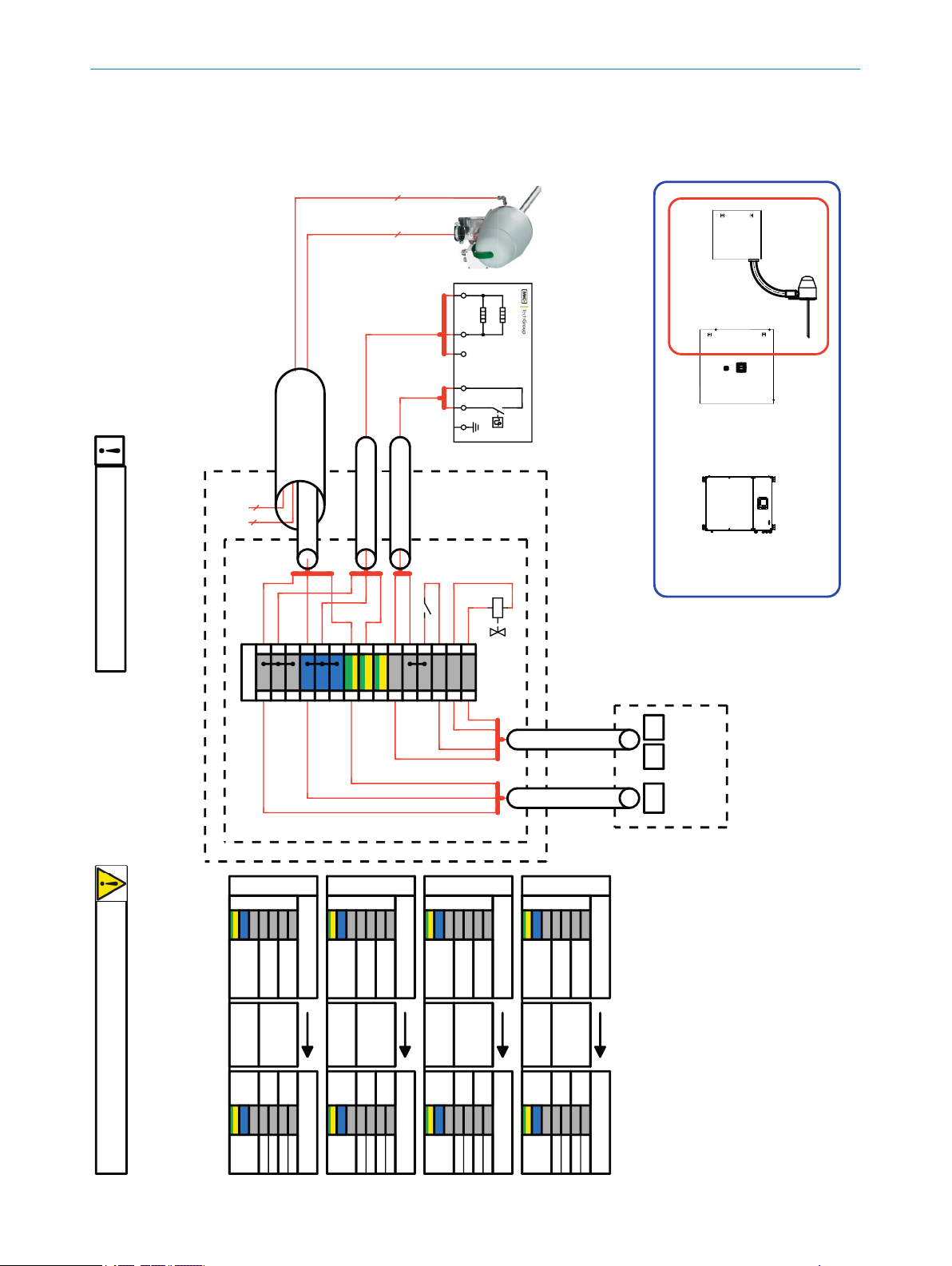

SINGLE version distribution unit for one measuring point

Preparation Unit

L PEN

PELN

4 5

5

4

To sampling Probe (signal)

Marine Line (4x0,75) 6056229

To sampling Probe (Power)

Marine Line (3x1,5) 6056215

Preparation Unit (UM1) Distribution unit (UM5)

101314

15

147

1

2

14

18

123

Alarm

Valve KK10

Power

Marine Line

(4x0,75)

6056229

Marine Line

(3x1,5)

6056215

XD21

XD61

XD2

To distributor unit (Power)

Marine Line (3x1,5) 6056215

To distributor unit (Signal)

Marine Line (4x0,75) 6056229

Power

+24V

XD1

DI 10Vcontrol

2

2

gy

3

3

gy

bu

4

4

bu bu

556

6

gnye

7

7

gnye

8

8

gnye

9

9

1

1

gy

10

10

gy

gy

11

11

gy

12

12

gy

13

13

gy

14

14

gy

15

15

XD1

PELN

Line 1

UM1

UM5

BQ1

UC1

UM1

junction box

UM5

XD2XD21 XD61

All cable diameters are proposals! The customer must check this diameters!

Parameters are e.g.: voltage drop, cable cluster, laying procedure etc.

WD3

WD6

WD2

WD1

Connection of the sample preparation

is always the same

5...15m

sample gas line

Distribution unit

(see next Page for details)

54

L

2

N

3

6

200W

200W

PE

1

PE

rdbu

KK10

A

EC1

IN

rd

bu

13

-EC1

x1

x2

-KK10

INSTALLATION

2

Figure 4: Wiring diagram

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

17

Page 18

2 INSTALLATION

Line Connection

Power supply from distribution unit to sample conditioning Distribution unit: see "Electrical installation of distribution

unit", page 31

Sample conditioning: see chapter 2.9.3

Power supply from sample conditioning to sampling probe Sample conditioning: see chapter 2.9.3

Sampling probe: see chapter 2.7

Status signals between analyzer and sample conditioning Distribution unit: see "Electrical installation of distribution

unit", page 31

Sample conditioning: see chapter 2.9.3

Status signals from sampling probe to sample conditioning Sampling probe: see chapter 2.7

Sample conditioning: see chapter 2.9.3

18

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 19

XD61

Analog Signals

supplyes by customer

All cable diameters are proposals! The customer must check this diameters!

Parameters are e.g.: voltage drop, cable cluster, laying procedure etc.

MARSIC200 Analyzer

Status Signals

supplyes by customer

WD1

UM1

UM5

BQ1

WD4

WD6

WD2

WD3

WD5

WD7

Marine Line

(7x1,5) 6056230

Marine Line

(3x1,5) 6056215

Marine Line

(7x1,5) 6056230

Marine Line

(7x1,5) 6056230

35678

9

1-X3

State SP 10VState SP 2

State SP 3

State SP 4

Standby

SP2

X

X

X

124710

1-X5

bypass pump

sample gas pump

Purge gas

Test gas

1

4710

2-X4

MP1 Bypass (KF4)

MP2 Bypass (KF5)

MP3 Bypass (KF6)

MP4 Bypass (KF7)

147

10

2-X5

MP1 Active (KF8)

MP2 Active (KF9)

MP3 Active (KF10)

MP4 Active (KF11)

24V*

SP3

SP4

SP1

XXX

XXXXX

X

XXXXXXX

Analyzer (BQ1)

L

N

XXX X

X

X

XXX

XXX

XXXXXXX

XXXXX

XXXXX

X

X

X

XXX

XXX

X

X

X

X

X

XXX

X

X

1-X5

2

5

8

11

2-X4

2

5

8

11

2-X5

2

5

8

11

SP1...SP4

X X X X

X X X X X X X X X X X X

External Power supply

supplyes by customer

distributor unit

XD61

XD2

XD21

XD1

12345

6

XD61

12345

6

789

101112

13

Distribution unit (UM5)

456

XD2

5

5N

5PE

SP1 SP2...SP4

State SP 10VState SP 2

State SP 3

State SP 4

Standby

bypass pump

sample gas pump

Purge gas

Test gas

MP Bypass (KF4)

MP2 Bypass (KF5)

MP3 Bypass (KF6)

MP4 Bypass (KF7)

MP1 Active (KF8)

MP2 Active (KF9)

MP3 Active (KF10)

MP4 Active (KF11)

24V*

XD62

* connect 24V at 1-X5; 2-X4 and 2-X5

according to the wiring diagram

24V+

/1-X5

PE

INSTALLATION

2

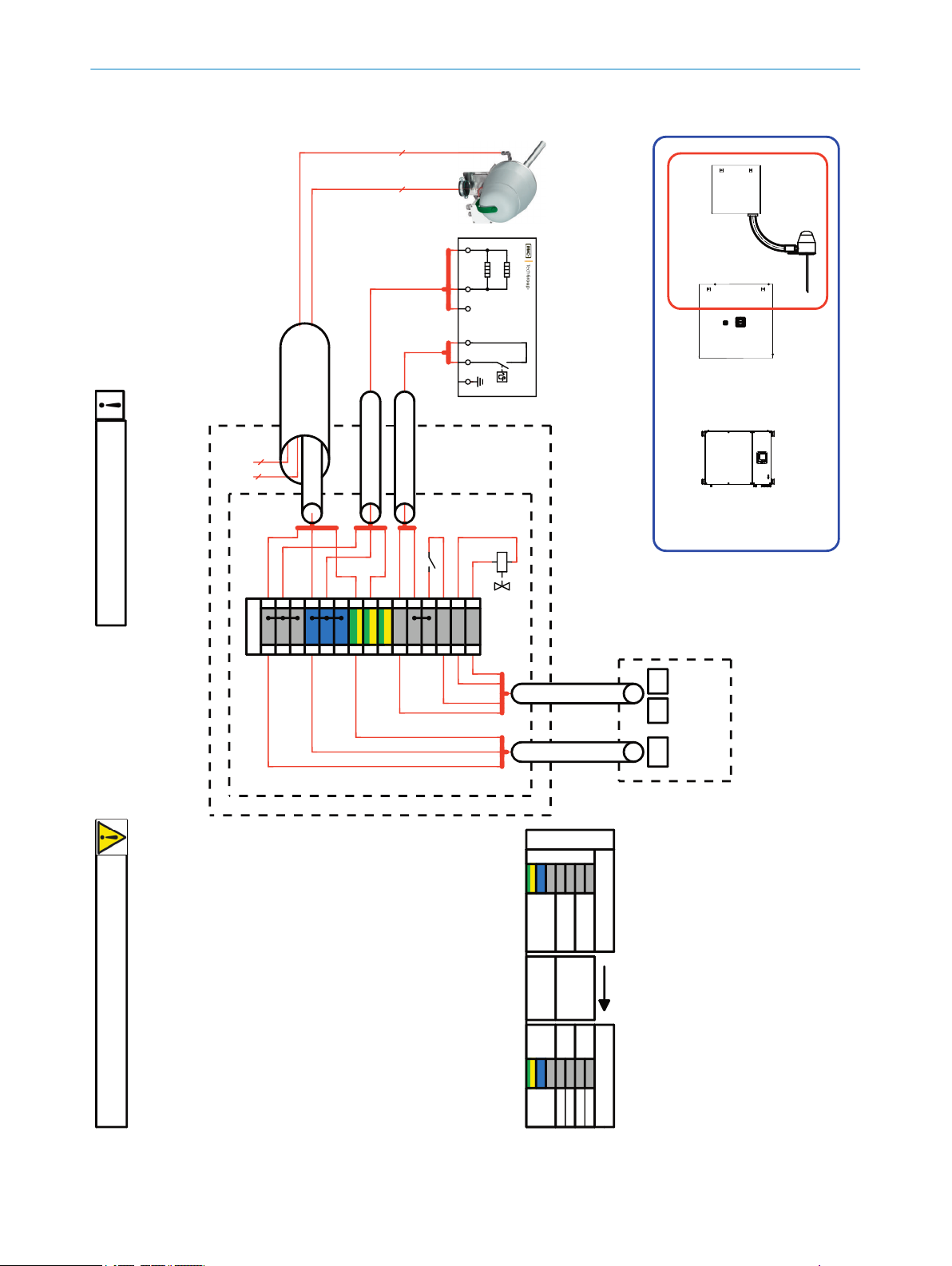

2.6.4 Lay and connect the electric line between distribution unit and analyzer

MULTI version distribution unit for two to four measuring points

19

Figure 5: Wiring diagram

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

Page 20

XD61

Analog Signals

All cable diameters are proposals! The customer must check this diameters!

Parameters are e.g.: voltage drop, cable cluster, laying procedure etc.

MARSIC200 Analyzer

Status Signals

supplyes by customer

WD1

UM1

UM5

BQ1

WD4

WD6

WD2

WD3

Marine Line

(7x1,5) 6056230

Marine Line

(3x1,5) 6056215

supplyes by customer

359

1-X3

Status SP10VStandby

2

10

1-X5

sample gas pump

Purge gas

Analyzer (BQ1)

L

N

1-X5

2

5

8

11

X X X X

24V*7Test gas

1

External Power supply

supplyes by customer

distributor unit

XD61

XD2

XD21

XD1

123

XD62

* connect 24V at 1-X5

according to the wiring diagram

Distribution unit (UM5)

456

XD2

5

5N

5PE

SP1 SP2...SP4

Status SP10VStandby

123

sample gas pump

Purge gas

Test gas

24V*

4

XD61

24V+

/1-X5

PE

INSTALLATION

2

SINGLE version distribution unit for one measuring point

Figure 6: Wiring diagram

20

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 21

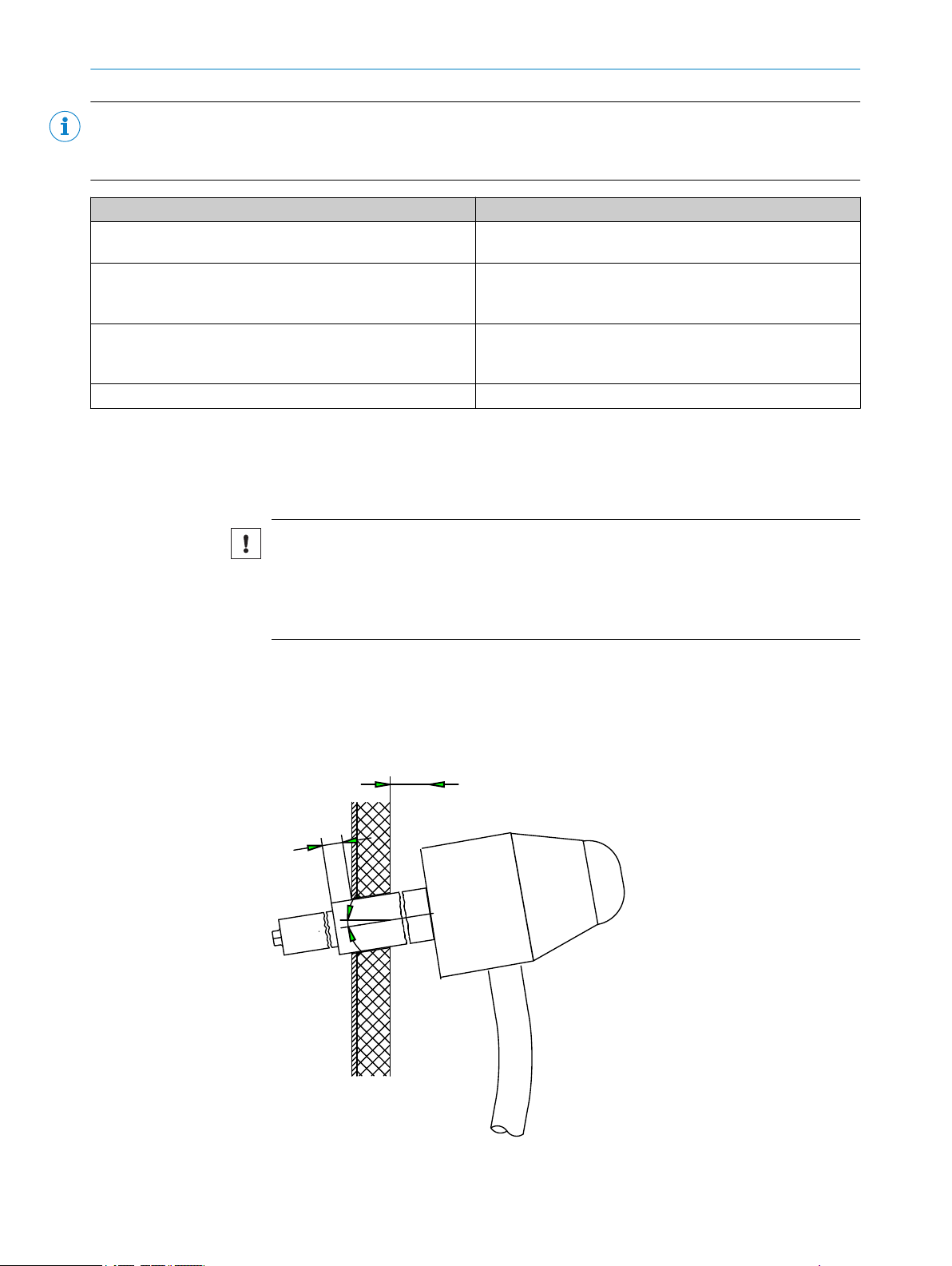

min.70

10°

~

~30

INSTALLATION 2

NOTE

Pay attention to the function indicator of the terminals!

Example: 1-X3:9 “Standby” to XD62:2 “Standby”.

Line Connection

External power supply on distribution unit Distribution unit: see "Electrical installation of distribution

unit", page 31

Power supply from distribution unit to analyzer Distribution unit: see "Electrical installation of distribution

unit", page 31

Analyzer: see chapter 2.11.3

Status signals between analyzer and distribution unit Analyzer: see chapter 2.11.3

Distribution unit: see "Electrical installation of distribution

unit", page 31

External analog and digital signals, Ethernet to analyzer Analyzer: see chapter 2.11.3

2.7 Installing the sampling probe

The sampling probe is system-specific: For information on the installation of the sam‐

pling probe, see the enclosed Operating Instructions of the sampling probe.

NOTICE

Risk of soiling the measuring system

First install the gas sampling system on the exhaust duct just before the analyzer

b

is switched on.

Switch the instrument air feed on immediately after installing the sampling tube.

b

Installation

Install the sampling probe in accordance with the specifications in the Operating

b

Instructions of the sampling probe.

w

Fit the sampling tube with the probe tip tilted down about 10°.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

21

Page 22

2 INSTALLATION

Gas connections

Connect the following gas connections:

b

Heated sample gas line

°

Avoid cold bridges

No cold bridges may occur on the sample gas line connection on the gas sampling

probe.

Line marked red: Sample gas line

•

Line marked blue: Instrument air

•

No cold bridges here, close flush or insu‐

1

late

Electrical connections

Connect the following electric lines:

b

Power supply from sample conditioning

°

“Heating” signal line to sample conditioning

°

2.8 Installing the sample gas line

Figure 7: Heated sample gas line

Installation

•

Lay the sample gas line, starting from the sample conditioning towards the sam‐

pling probe.

22

ATTENTION

Observe the laying instructions for the sample gas line (enclosed with the sample gas

line).

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 23

INSTALLATION

Assembly on the sampling probe

ATTENTION

Do not damage the core of the sample gas line.

A hose cutter must be used to cut off the core.

b

Shorten the PTFE core of the heated sample gas line to the length of the cap nut

•

of the screw fitting.

Assembly on the sampling probe: see "Installing the sampling probe", page 21.

•

Assembly on the sample conditioning

1. Clamp the cable bushing on the corrugated hose approx. 10 cm behind the start

of the corrugated hose.

The groove on the cable bushing must point away from the hose end.

2

Corrugated hose

1

Cable bushing

2

Groove in cable bushing

3

2 clamping screws (from below or above)

4

4 frame screws

5

Frame

6

Groove in frame

7

2. Push the frame with 2 clamping screws over the cable bushing and fasten lightly.

The groove of the frame must point towards the hose end (in the direction of the

enclosure side).

3. Insert the line in the enclosure.

4. Preassemble the frame on the enclosure.

5. Align the sample gas line so that the electric line points upwards.

°

The line marked red (sample gas) must continually lead downwards (danger

of clogging by condensate).

6. Connect the lines:

w

The line marked red on the cooler inlet (cooler is system-specific).

w

The line marked blue on the solenoid valve KK10, connection “A”.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

23

Page 24

P

A

R

2 INSTALLATION

Sample gas cooler (system-specific)

1

Solenoid valve KK10 for feeding test gas to the sampling probe

2

Terminal box

3

R Instrument air connection

P Connection of span gas/test gas

A Connection to heated sample gas line

7. Screw the lines tight (see "Tube screw fitting", page 9).

8. Check the red mark (sample gas line) and the blue mark (instrument air line)

match the connections on the sample gas cooler (see Operating Instructions,

Chapter “Removing and fitting the sampling probe”).

9. Screw the frame tight (1.5 Nm).

10. Screw the clamping screws tight (1.5 Nm).

11. Electrical connection: See the wiring diagram on the inside of the terminal box

cover.

Core cross-section: 1.5 mm

°

Connections: BK 1, BK 2, GNYE: See identification rings on the crimp lead

°

end sleeves.

2.

2.9

Installing the sample conditioning

2.9.1 Fitting the sample conditioning

Figure 8: Sample conditioning (exterior view)

Enclosure duct for heated sample gas line

1

Sample gas cooler with hose pump

2

Cooler sample gas inlet (inlet of heated sample gas line)

3

Figure 9: Sample conditioning (interior view,

the sample gas cooler is system-specific)

24

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 25

INSTALLATION 2

Sample gas outlet from cooler (outlet of unheated sample gas line)

4

Solenoid valve KK10 for feeding test gas to the sampling probe

5

Hose pump for draining the condensate

6

Acid condensate escapes from the condensate outlet.

Make sure the condensate is safely collected or drained off.

b

The hose end can end max. 10 m above the condensate outlet.

b

CAUTION

Risk of chemical burns by acid medium

Take appropriate protective measures for work (for example, by wearing a safety

b

mask, protective gloves and acid resistant clothes).

In case of contact with the eyes, rinse immediately with clear water and consult a

b

doctor.

Fasten the enclosure on a suitable panel using the mounting bracket provided.

b

Drilling plan: see "Dimensional drawings", page 55.

°

Fit the enclosure horizontal.

°

Observe the clearances for the heated sample gas line and the PTFE lines:

°

see "Dimensional drawings", page 55.

Observe the relevant ambient conditions: see "Technical data", page 55.

°

2.9.2 Gas connections on sample conditioning

Overview of connection positions

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

25

Page 26

2 INSTALLATION

Connections

Cooler inlet (observe designation on

1

cooler)

Cooler outlet (observe designation on

2

cooler)

Solenoid valve KK10, always acti‐

3

vated during normal operation (LED

on)

1

2

Gas inlet

Gas outlet

Condensate inlet in hose pump

1

Condensate outlet from hose pump

2

Lay all PTFE tubes into the enclosure from the bottom.

b

Enclosure duct of heated sample gas line: see "Installing the sample gas line",

b

page 22.

Connect the lines.

b

Line Connect to:

Line marked red (sample gas line) from heated sam‐

ple gas line

Line marked blue (instrument air/span gas) from

heated sample gas line

PTFE line from external instrument air Solenoid valve KK10: Inlet “R”

PTFE line from external span gas (only possible for

measuring point 1)

PTFE line sample gas outlet to distribution unit Cooler: Gas outlet (see Figure above)

Condensate outlet Cooler: Condensate outlet of hose pump

Cooler: Gas inlet (see Figure above)

Solenoid valve KK10: Outlet “A”

Solenoid valve KK10: Inlet “P”

If span gas is not connected: Close off the inlet with

a dummy plug.

Cooler

The sample gas cooler is system-specific.

For further information concerning the sample gas cooler, see the Operating

b

Instructions of the sample gas cooler.

26

Condensate outlet

The condensate outlet is at the bottom of the cooler.

Acid condensate escapes from the condensate outlet.

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 27

Make sure the condensate is safely collected or drained off.

b

The hose end can end max. 10 m above the condensate outlet.

b

2.9.3 Electrical installation of sample conditioning

Terminal box

1

Lay the electric lines through the enclosure openings.

b

Connect the electric lines.

b

For the circuit diagram, see the attached system documentation and inside

°

the cover of the terminal box.

INSTALLATION 2

Electric line Connect to:

Power supply from distribution unit

Power supply to sampling probe

Cooler and probe status on distribution unit

Control signals to sample conditioning from distribu‐

tion unit

“Heating” status from sampling probe

Enclosure grounding optional

2.10 Installing the distribution unit

View

MULTI version distribution unit for two to four measuring points (example)

See enclosed system documentation

Figure 10: Distribution unit (exterior view)

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

Figure 11: Distribution unit (interior view sys‐

tem-specific)

27

Page 28

2 INSTALLATION

Main switch

1

ON: Voltage is on

OFF: Voltage is off

“Stand-by” switch

2

OFF: Regular operation

ON: Stand-by

Sample gas inlet from sam‐

3

ple conditioning(s)

Solenoid valve KK1, inlet

4

“R”

Connection: D/N 4/6

Solenoid valve KK1, inlet

“P”

Connection: D/N 4/6

Solenoid valve KK1, outlet

“A”

Connection: D/N 4/6

Sample gas pump For extraction of the respective active measuring point

5

Bypass pump For advance extraction of the sample gas for 2 ... 4 measur‐

6

Flow indicator with adjust‐

7

ment wheel

Sample gas fine filter Serves to filter the sample gas for all measuring points before

8

Water trap The water trap protects the analyzer against damp sample

9

Sample gas outlet to ana‐

ß

lyzer

Main switch set to “OFF”:

Sample conditioning voltage: “OFF”

•

Sampling probe voltage: “OFF”

•

The purge air valve is “open when no current is

°

applied”: The sampling tube is flushed with instrument

air

Sample gas line heating: “OFF”

•

Analyzer voltage: “OFF”

•

Main switch set to “ON”:

All voltages come on.

•

“Stand-by” switched to ON:

The maintenance signal on the analyzer becomes “active”

•

and the yellow LED lights

The measured values continue to “live”

•

A zero point validation is performed

•

The sample gas pump and the (optional) bypass pump go

•

off

The heaters remain switched on

•

The sampling tube is flushed with instrument air

•

“Stand-by” switched to OFF:

Sample gas pump and the (option) bypass pump are

•

switched on

The system goes into measuring operation: Only the green

•

LED lights on the analyzer

Sample gas inlet

For 1 measuring point: From sample conditioning

For 2 ... 4 measuring points: From measuring point switchover

in distribution unit

Test gas inlet

During test gas adjustment with gas feed on the distribution

unit, the test gas is passed directly to the analyzer.

Gas outlet to analyzer

ing points

Setpoint flow rate: Approx. 60 l/h.

The flow is displayed as measured value on the analyzer.

feeding to the analyzer.

The analyzer signals the flow is too low when the filter clogs

up.

gas.

The analyzer signals the flow is too low when the filter clogs

up.

28

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 29

Fuse 1 24 V power supply unit

à

Fuse 2...5 1 fuse per measuring point (probe, line, sample conditioning)

Fuse 6 Sample gas pump

Fuse 7 Bypass pump (as from 2 measuring points)

Fuse 8 Analyzer

Measuring point switchover

á

2.10.1 Fitting the distribution unit

INSTALLATION 2

Figure 12: MULTI version distribution unit for

two to four measuring points (example)

Connection of PTFE line from sample

1

conditioning

Connection of PTFE line to analyzer

2

Valve KK1

3

Fasten the enclosure on a suitable panel using the mounting bracket provided.

b

Drilling plan: see "Dimensional drawings", page 55.

°

Fit the enclosure horizontal.

°

Observe the clearance for the PTFE line: see "Dimensional drawings",

°

page 55.

Observe the relevant ambient conditions: see "Technical data", page 55.

°

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

29

Page 30

2 INSTALLATION

2.10.2 Gas connections on distribution unit

Figure 13: SINGLE version distribution unit for

one measuring point (example)

Gas inlet from sample conditioning(s)

1

Gas outlet to analyzer

2

Valve KK1

3

Lay all PTFE tubes into the enclosure from the bottom.

b

Connect the lines.

b

Line Connection of

SINGLE version

PTFE line from sample conditioning

Valve KK1, inlet “R” Measuring point

(sample gas inlet)

PTFE line to analyzer (sample gas out‐

Figure 14: MULTI version distribution unit for

two to four measuring points (example)

Connection of PTFE line from sample

1

conditioning

Connection of PTFE line to analyzer

2

Valve KK1

3

Connection of

MULTI version

switchover “P1-P4”

Sample gas outlet on the enclosure outside

let)

Test gas inlet (zero gas: nitrogen or

instrument air)

1

This gas is used as zero gas during automatic zero point adjustment. When the reference point is

adjusted via the distribution unit (not via the sampling probe), the span gas must be connected to this

inlet during the adjustment.

1

Valve KK1, inlet “P”

30

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 31

2.10.3 Electrical installation of distribution unit

Figure 15: SINGLE version distribution unit for

one measuring point (example)

Terminal strips

1

Grounding

2

INSTALLATION 2

Lay the electric lines through the enclosure openings.

b

Connect the electric lines.

b

For the circuit diagram, see the attached system documentation and inside

°

the cover of the terminal box.

Electric line Signal Connect to:

External power supply See the wiring diagram in the system documentation

Power supply to sample conditioning See the wiring diagram in the system documentation

Power supply to analyzer See the wiring diagram in the system documentation

Status signals from sample conditioning DI Sampling probe and cooler

See the wiring diagram in the system documentation

Control signals to sample conditioning DO See the wiring diagram in the system documentation

Signal lines to/from analyzer DI See the wiring diagram in the system documentation

DO See the wiring diagram in the system documentation

AI See the wiring diagram in the system documentation

AO See the wiring diagram in the system documentation

Signal lines to/from external DI See the wiring diagram in the system documentation

Optional for stand-by operation

DO See the wiring diagram in the system documentation

Maintenance and status

AI See the wiring diagram in the system documentation

optional

AO See the wiring diagram in the system documentation

Meas. values

Enclosure grounding Inside, bottom right.

Install an external power disconnection unit which disconnects all connectors and

b

fuses near the analyzer. The power disconnection unit must have a unique mark‐

ing and be easily accessible.

Observe the max. power input of the complete system: see "Energy supply",

page 64.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

31

Page 32

INSTALLATION

2

The local power network for power supply to the system must be installed and

b

safeguarded in accordance with the relevant regulations.

A protective conductor must always be connected to PE.

b

2.10.4 Measuring point switchover

Measuring point switchover

For systems with 2 to 4 measuring points, a measuring point switchover with advance

extraction of the sample gas is installed.

Figure 16: Measuring pont

switchover for 4 measuring points

(example)

Measuring point

1

switchover

Advance extraction

2

Installation: see "Gas flow diagram", page 59.

b

Programming the measuring point switchover: see "Measuring points - automatic",

b

page 52.

32

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 33

2.11 Installing the analyzer

Exterior view

INSTALLATION 2

Figure 17: Analyzer (exterior view)

Analyzer top part with electronics

1

Control unit

2

Analyzer bottom part with measurement technology

3

Sample gas inlet Screw fitting: DN4/6 stainless steel

4

Sample gas outlet Screw fitting: DN4/6 stainless steel

5

On/Off switch The On/Off switch switches the analyzer on/off.

6

Data interfaces Analog and digital inputs and outputs

7

Fuse Check the fuse

8

Measuring module CO2 (FINOR)

9

Measuring module O2 (OXOR E) optional

ß

Measuring module SO2/NOx (DEFOR)

à

Measuring module flow/humidity/pressure (gas

á

module)

Figure 18: Analyzer (interior view)

The digital outputs switch to “Zero”

•

The analog outputs switch to “Zero”

•

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

33

Page 34

2 INSTALLATION

2.11.1 Fitting the analyzer

Figure 19: Clearance for PTFE lines

PTFE line (sample gas inlet)

1

PTFE line (sample gas outlet)

2

Fasten the analyzer on a suitable panel using the mounting bracket provided.

b

Drilling plan: see "Dimensional drawings", page 55.

°

Fit the enclosure horizontal.

°

Observe the clearance for the PTFE line: see "Dimensional drawings",

°

page 55.

Observe the relevant ambient conditions: see "Technical data", page 55.

°

2.11.2 Gas connections on analyzer

34

Sample gas inlet (seen from the front,

1

bottom left)

Sample gas outlet (seen from the front,

2

bottom right)

Lay all PTFE tubes into the enclosure from the bottom.

b

Connect the lines.

b

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 35

Line Connect to:

PTFE line from distribution unit (sample gas

inlet)

PTFE line sample gas outlet Lower part of analyzer, to enclosure duct “Out‐

Sample gas outlet

Discharge the sample gas outlet in a suitable environment.

b

The sample gas output must be open against the ambient pressure.

b

WARNING

The exhaust gases are toxic

Dispose of the exhaust gases in a suitable manner.

b

2.11.3 Electrical installation of analyzer

INSTALLATION 2

Lower part of analyzer, to enclosure duct

“Inlet”

let”

Power voltage connection at terminal

1

strip

Signal connections (I/O)

2

Distributor board with Ethernet for MPR

3

(option), Modbus, service interface (LAN)

Electric line Connect to:

Power supply from distribution unit Terminal strip near On/Off switch

Signal lines to/from distribution unit See attached circuit diagram

Analyzer grounding On the right of the enclosure outside

MPR for remote maintenance via Ethernet

(option)

PC with SOPAS ET (Ethernet) (option)

Modbus

In analyzer upper part on distribution board

RJ45 connection 0X5 “LAN”

NOTE

The green coiled network line in the analyzer bottom part serves as spare line and does

not have to be connected.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

35

Page 36

Back Enter

See logbook

1 1

2 2

3 3

4 4

Meas.point (MPi) .5.10.1.1

./Parameter/Special fct.

On

On

On

On

INITIAL START-UP

3

3 Initial start-up

3.1 Initial start-up

NOTE

Prerequisite: The system has been fully installed and connected

1. Check installation is correct.

2. Instrument air must be available on the sample conditioning and zero gas on the

3. Remove the red protective foil from the control unit on the analyzer.

4. Switch on all fuses in the distribution unit.

✓

5. Set the Stand-by switch on the distribution unit to OFF (normal operation).

6. Set the number of available measuring points.

distribution unit.

The LEDs on the control unit are on, the measured values blink.

Four measuring points are activated upon delivery

°

Set the available number of measuring points:

Login as “Service” on the operator panel in menu Login.

b

Call up menu Parameter/Special fct./Meas.point autom./Meas.point

b

(MPi).

Activate each measuring point desired (set to “On”).

b

7. Set the date and time in menu Parameter/Date-Time.

8. Wait until the system has warmed up (approx. 2 hours).

9. The system performs an automatic zero point adjustment.

10. The green LED goes on, the measured values do not blink and MEASURE is shown

on the screen

11. Check the flow rate on the flowmeter (in the distribution unit): Approx. 60 l/h. Set

on the flowmeter when necessary.

12. Check that only the green LED lights on the control unit.

When the yellow or red LED is on: Press the “DIAG” button and/or check in

°

the logbook.

13. Check the time. Set the time, if required: Menu: Parameter/Date-Time.

14. Configure the test gas concentration in the respective menu on the control unit:

See “Operating Instructions MARSIC200”.

15. Perform manual test gas adjustment: See “Operating Instructions MARSIC200”.

16. Check measured values for plausibility.

17. Perform the leak tightness check: See “Operating Instructions MARSIC200”.

✓

The system is in operation.

36

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 37

INITIAL START-UP 3

NOTICE

If you change parameters in the control unit (BCU) as required by the operating com‐

pany:

Save the BCU settings in a suitable manner (for example on a USB stick) and keep

b

this backup.

To do this, connect the analyzer to a PC and use the SICK SOPAS-ET software (see

"Backup of settings", page 53).

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

37

Page 38

4 CONFIGURATION SOFTWARE

4 Configuration software

4.1 Software SOPAS ET

The MARSIC200 can be easily configured on a PC with SOPAS ET.

SOPAS ET runs on an external PC connected to the MARSIC200 via the Ethernet inter‐

face.

You can download SOPAS ET free of charge from the SICK website.

Install SOPAS ET on a laptop.

•

Connect the laptop to the MARSIC200 analyzer (Ethernet cable): see "Electrical

•

installation of analyzer", page 35.

Open SOPAS ET.

•

In SOPAS ET: Click “Device search”.

•

The MARSIC200 modules are displayed:

•

Gas module (measuring module for flow, moisture and pressure of the sam‐

°

ple gas in the analyzer)

DEFOR (measuring module for NO, NO2 and SO2 of the sample gas in the

°

analyzer)

FINOR (measuring module for CO2 of the sample gas in the analyzer)

°

OXOR (measuring module for O2 of the sample gas in the analyzer (optional)

°

Mark all modules and drag and drop them into the left window (Project).

•

Save the project.

•

Login to configure the modules (click “Login”).

•

Enter the password, see "Passwords", page 38.

To configure: Double-click on the module window.

•

4.2 Passwords

NOTE

See “Technical Information BCU” for menus based on SOPAS ET.

There are three user levels each with an own password.

The passwords are the same for operation using the analyzer control unit and for using

SOPAS ET.

User level Password (case-sensitive)

MARSIC EMI

Authorized operator HIDE

Service hidden

38

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 39

5 Adjustment functions

5.1 Configuring test gases (Test Gas Table)

Function

The Test Gas Table serves as basis for adjustments. 12 different test gas settings can

be programmed. Each test gas setting can be used for up to 8 components. The test

gas settings can also be used for validation measurements.

NOTE

The same real test gas can be used in several test gas settings. This means a cer‐

•

tain test gas can be used for different adjustment procedures.

Recommendation: Only program one adjustment or validation function for each

•

test gas.

Suitable test gas settings are normally preprogrammed at the factory.

•

Procedure

1. Call up BCU/Parameter/Test gas table.

ADJUSTMENT FUNCTIONS 5

Figure 20: Menu “Test gas table” – Table (example)

2. Deactivate Live view.

3. Select the desired Table rows.

4. Select Edit.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

39

Page 40

5 ADJUSTMENT FUNCTIONS

Figure 21: Menu “Test gas Table” – Edit (example)

1

2

3

4

5

6

7

8

9

ß

Test gas number (cannot be changed).

= this test gas can be used for adjustments/validations.

Test gas name (free text field, max. 20 characters).

Boolean variable to control this test gas (cannot be changed).

= the sample gas pump is switched off automatically when this test gas is

used.

= this test gas can be used for the specified component.

Tag of the component for which this test gas is to be used.

Component name in the Sensor module (cannot be changed).

Setpoint value of the test gas in the physical unit of the measuring component.

▸ Use the decimal point (.) for numerical values.

Wait time after switching to the test gas. The measurement for the adjust‐

ment/validation first starts after the flush time/wait time.

à

á

Cuvette: Concentration of the adjustment cuvette

= the test gas is used for zeo point validations.

Simultaneous use for reference point validations is not possible.

â

= the test gas is used for reference point validations..

Simultaneous use for zero point validations or reference point validations with

adjustment cuvette is not possible.

ã

= the test gas is used for zero point adjustments.

Simultaneous use for reference point adjustments is not possible.

ä

= the test gas is used for reference point adjustments.

Simultaneous use for zero point validations or reference point validations with

adjustment cuvette is not possible.

1

2

40

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 41

ADJUSTMENT FUNCTIONS 5

å

= the test gas is used for reference point validations with adjustment

cuvette.

Simultaneous use for reference point validations is not possible.

æ

= the test gas is used for reference point adjustments with adjustment

cuvette.

Simultaneous use for reference point adjustments is not possible.

ç

= the test gas is used for linearity adjustments.

Simultaneous use for other adjustments is not possible.

1

Tag format: SiMVj (i = Sensor module number, j = measured value number in the Sensor module)

2

The longest flush time is effective when the test gas is used simultaneously for several components.

NOTE

The settings are first effective after Save has been selected.

5.2 Performing a manual adjustment

Function

“Manual adjustment” means a single adjustment or validation procedure is selected

and manually started.

NOTE

The standard setting with checkbox “Automatic” selected (see figure 23, page 43)

means the test gas is fed automatically via solenoid valves controlled by the MAR‐

SIC200 digital outputs. The controlling output is defined in the respective test gas set‐

ting (“Action on start” see "Configuring test gases (Test Gas Table)", page 39). The test

gas can also be fed manually.

Procedure

Inform connected locations on the impending interruption in measuring operation.

b

1. Call up BCU/Maintenance/Manual adjust.

2. Select the measuring component for which the procedure is to be applicable

([ << ] [ >> ]).

3. Select the desired function ([ << ] [ >> ]).

✓

The Start button is displayed when a suitable test gas setting exists for the mea‐

suring component and function combination.

4. Select Start.

With manual test gas feed With automatic test gas feed

✓

Actual state = Test gas

5 Feed the suitable test gas into the sam‐

ple gas inlet of the MARSIC200.

6 Wait until Sample gas is displayed as

actual state.

7 Now feed sample gas into the sample

inlet again.

1

8 Wait until Stop is displayed as actual

state.

✓

The manual adjustment has com‐

✓

The automatic procedure starts.

Actual state = part of the procedure

currently running (see table 5,

page 42)

5 Wait until Stop is displayed as actual

state.

✓

The manual adjustment has com‐

pleted.

pleted.

1

Alternative (when a further manual adjustment is to follow): The test gas for the next manual adjust

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

41

Page 42

5 ADJUSTMENT FUNCTIONS

Table 5: Procedure phases during manual adjustment

Actual state Internal function

Stop Function idle

Test gas Wait for flush time to elapse (after switching to test gas)

Measuring Determine measured values with the test gas

Calculate Calculate mean value from measuring time, calculate devia‐

Sample gas Wait for flush time to elapse (after switching to sample gas)

Table 6: Information in menu Manual adjustment during the procedure

Identifier Significance

Actual state Part of the procedure running (see table 5, page 42)

Meas. value Current measured value of component

Actual countdown timer (SCCDGi) Name of countdown timer running

Remaining time Remaining time of countdown timer running

tion from setpoint, adapt adjustment

42

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 43

ADJUSTMENT FUNCTIONS 5

Figure 22: Menu Manual adjust (example)

1

2

3

4

5

6

7

8

9

ß

à

á

â

Name of the measured values to be calculated from this sensor component

Measuring component for which this manual adjust is applicable

Number of the Sensor module to measure the measuring component

Number of sensor component in the Sensor module

= standard setting: Adjustment runs with preset time sequences.

= adjustment steps are started singly by the user (manual test gas feed).

Select measured value(s)

Adjustment or validation to be performed

Select function

Name of test gas to be used

Setpoint value of the test gas / concentration of the adjustment cuvette

Wait time after switching to the test gas; then measurement starts

Defines how long the measured values of the test gas are measured

Internal interval for computation of the values measured

1

2

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

43

Page 44

5 ADJUSTMENT FUNCTIONS

ã

Wait time after switching to sample gas, then the manual adjustment is

regarded as completed

ä

1

2

Start the selected manual adjustment

Empty field: No suitable test gas setting programmed for the selected function

Actual value for the adjustment = mean value of measured values within the measuring time

Result

Figure 23: Menu Manual adjust with result (example)

1

2

3

Cancel the running manual adjust

Error shown when no result available. Erroneous sequence or drift overrun.

The actual measured value measured

5.3 Automatic adjustments/validations

44

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 45

5.3.1 Function of automatic adjustments/validations

8 adjustment or validation procedures that can run fully automatically can be pro‐

grammed. Each procedure uses one of the test gases configured in the Test Gas Table

(see "Configuring test gases (Test Gas Table)", page 39).

Programming defines which measuring component is to be adjusted or validated with

the procedure and which adjustment or validation function is to be used. Several com‐

ponents can be adjusted in one function.

5.3.2 Start options

Manual start:

•

Use menu Operator commands (see "Start options", page 45).

Automatic start (in regular intervals):

•

Use a long-term timer in the start conditions (see “Technical Information BCU”).

Remote-controlled start:

•

Control the value of a Boolean variable (VBVi) with a digital input (see “Technical

Information BCU”).

Programmed start conditions:

•

Calculate the value of a Boolean variable (BVIi) with a formula (see “Technical

Information BCU”).

For representation of the adjustment and validation results (see “Technical Information

BCU”).

ADJUSTMENT FUNCTIONS

5

5.3.3 Programming automatic adjustments/validations

1. Menu: Call up BCU/Parameter/Adjustment/Validation.

Figure 24: Menu Adjustment / Validation – Table (example)

1

2

3

4

5

6

7

Index number of the adjustment or validation procedure

Programmed name

= automatic starts activated

Start time of next automatic function

Start date of next automatic function

Component X that will be addressed by the respective function

Number of the next function to start automatically (only when procedures are

chained)

2. Deactivate Live view.

3. Select the desired Table rows.

4. Select Edit.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

45

Page 46

5 ADJUSTMENT FUNCTIONS

Figure 25: Menu Adjustment / Validation – Edit (example)

1

2

Index number of the adjustment or validation procedure

Procedure name (freely selectable text)

Settings for automatic start of this procedure:

3

4

5

Time of first start of this procedure (format: hh:mm = Hours:Minutes)

Date of first start of this procedure (format: yyj-mm-dd = Year-Month-Day)

Time interval in which this procedure regularly starts automatically (hours,

days or weeks).

6

7

= starts are activated (time-controlled starts).

The fields below start time and start date show the next start.

Component X (up to 8 components can be processed by one procedure):

8

9

ß

à

á

â

ã

ä

å

æ

ç

1

2

3

4

5

6

Tag of component

Name of component in Sensor module

Function selected for this component

Flush time set from the test gas settings (information)

Name of test gas from the test gas settings (information)

Sequence for procedure execution

Test gas flush time for this adjustment/validation procedure

Duration of measurements (seconds)

Internal processing duration (drift calculation, data storage)

Flush time with sample gas after the adjustment (seconds)

If required: Index number of the procedure to be started automatically after

this procedure.

When the same function is selected for all components and the same test gas is planned, the function is

executed simultaneously for all components during the procedure. Otherwise the functions are executed

sequentially during the procedure.

Functions with identical execution position run at the same time.

When the same test gas is used for all functions: The longest of the individual test gas flush times (used

automatically by the procedure). Otherwise: “0” (= the individual test gas flush times are valid).

The mean value of measured values during the measuring time is used as actual value of the measure‐

ment.

The procedure first has the status completed after this flush time.

Starts immediately after the end of this procedure.

1

2

3

4

5

6

46

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 47

6 Tests and settings

6.1 Information

NOTE

SOPAS ET is required for the tests and settings: see "Software SOPAS ET", page 38.

6.2 Setting the time

Date and time setting is synchronized to that of the PC.

Open SOPAS ET and connect to the MARSIC200.

b

Menu: Parameter/Device.

b

Click “Time XX:XX” to transfer the time setting of the PC to MARSIC200.

b

TESTS AND SETTINGS 6

6.3 Interfaces (I/O)

1

2

3

For 2 “Signal connections”: See the wiring diagram in the system documentation for

the terminal plan.

Ref. 3 “Modbus”: Setting the IP address, see “Operating Instructions BCU” and “Tech‐

nical Information BCU”.

6.3.1 Digital inputs

Menu: Parameter/I/O/Digital input

Figure 26: BCU: Internal clock

Power voltage connection at terminal

strip

Signal connections (I/O)

Distributor board with Ethernet for MPR

(option), Modbus, service interface (LAN)

Select the digital output to be tested and click “Test”. A LED (green) is on when the

selected digital input is active.

8017324/15A2/V6-0/2019-10 | SICK T EC H NI C AL IN F OR M AT I ON | MARSIC200

Subject to change without notice

47

Page 48

TESTS AND SETTINGS

6

6.3.2 Digital outputs

Figure 27: Test digital inputs

Significance

Number of selected input.

1

Topographic addressing.

2

[State]

3

Computed value of [Source] (“Inverted” is taken into consideration).

[Source]

4

LED is off: Physical contact open.

LED is on: Physical contact closed.

Menu: Parameter/I/O/Digital output

Select the digital output to be tested and click “Test”.

The digital output can be activated or deactivated for the function check using the

checkmark (see “Test value” in the Figure below).

Figure 28: Test of digital outputs

Significance

Number of selected output.

1

Topographic addressing.

2

No checkmark: Physical contact should be open.

3

Checkmark: Physical contact should be closed.

[State]

4

LED is off: Relay energized.

LED is on: Relay de-energized.

[Source]

5

LED is off: Program specification: Physical contact should be open.

LED is on: Program specification: Physical contact should be closed.

48

Set the checkmark next to the Test value checkbox.

The status of the LEDs changes.

Use an ohmmeter to check the status of the relay outputs on X4 (DO 1-4) and X5 (DO

5-8).

If relay outputs do not function, the I/O modules must be exchanged because they can‐

not be repaired onsite.

T EC H NI C AL IN F OR M AT I ON | MARSIC200 8017324/15A2/V6-0/2019-10 | SICK

Subject to change without notice

Page 49

6.3.3 Analog outputs

Menu: Parameter/I/O/Analog output

This menu checks the analog outputs.