Page 1

M4000 Advanced,

M4000 Advanced A/P and

M4000 Area 60/80

Multiple Light Beam Safety Device

OPERATING INSTRUCTIONS

en

Page 2

Operating Instructions

M4000 Adv., Adv. A/P, Area

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 3

Operating Instructions

M4000 Adv., Adv. A/P, Area

Contents

Contents

1 About this document.........................................................................................................7

1.1 Function of this document....................................................................................7

1.2 Target group ..........................................................................................................7

1.3 Depth of information............................................................................................. 7

1.4 Scope ..................................................................................................................... 8

1.5 Abbreviations and terms.......................................................................................8

1.6 Symbols used ........................................................................................................9

2 On safety...........................................................................................................................10

2.1 Qualified safety personnel..................................................................................10

2.2 Applications of the device...................................................................................10

2.3 Correct use ..........................................................................................................11

2.4 General safety notes and protective measures ................................................11

2.5 Environmental protection ...................................................................................12

2.5.1 Disposal .............................................................................................12

2.5.2 Separation of materials ....................................................................12

3 Product description.........................................................................................................13

3.1 Special features ..................................................................................................13

3.2 Operating principle of the device .......................................................................14

3.2.1 The principle of the multiple light beam safety device ...................14

3.2.2 Device components ..........................................................................14

3.3 Application examples..........................................................................................16

3.3.1 Access protection..............................................................................16

3.3.2 Access protection on several sides with the aid of deflector

mirrors ...............................................................................................17

3.4 Controls and status indicators ...........................................................................19

3.4.1 End cap with integrated LED (optional, only on receiver) ...............19

3.4.2 Status indicators of the sender........................................................20

3.4.3 Status indicators of the receiver or of the

M4000 Advanced A/P ......................................................................21

4 Muting...............................................................................................................................22

4.1 Muting principle ..................................................................................................23

4.1.1 Muting cycle ......................................................................................23

4.1.2 Muting sensors..................................................................................24

4.1.3 Muting lamp ......................................................................................25

4.2 Placement of muting sensors.............................................................................25

4.2.1 Muting with two sensors (one sensor pair), crossed

placement..........................................................................................26

4.2.2 Muting with two sensors (one sensor pair), crossed

placement, and an additional signal C1..........................................28

4.2.3 Muting using two sensors, serial placement (one sensor pair

in the hazardous area), exit monitoring with End of muting

by ESPE..............................................................................................30

4.2.4 Muting using two sensors, serial placement (one sensor pair

in the hazardous area), with additional signal C1, exit

monitoring with End of muting by ESPE...........................................32

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Page 4

Contents

M4000 Adv., Adv. A/P, Area

4.2.5 Muting with four sensors (two sensor pairs), serial

placement .........................................................................................34

4.2.6 Muting with four sensors (two sensor pairs), parallel

placement .........................................................................................36

5 Configurable functions ................................................................................................... 38

5.1 Restart interlock ................................................................................................. 38

5.2 Beam coding .......................................................................................................40

5.3 Application diagnostic output (ADO).................................................................. 41

5.4 Scanning range................................................................................................... 42

5.4.1 Scanning range of the M4000 Advanced ....................................... 43

5.4.2 Scanning range of the M4000 Advanced Curtain system ............. 43

5.4.3 Scanning range of the M4000 Advanced A/P................................ 44

5.4.4 Scanning range of the M4000 Area 60/80.................................... 45

5.5 External device monitoring (EDM) .....................................................................46

5.6 Sender test.......................................................................................................... 47

6 Configurable muting functions...................................................................................... 48

6.1 Number of muting sensors ................................................................................48

6.2 Sensor test.......................................................................................................... 50

6.2.1 Testable sensors............................................................................... 50

6.2.2 Non-testable sensors ....................................................................... 50

6.3 Time monitoring.................................................................................................. 51

6.3.1 Concurrence monitoring................................................................... 51

6.3.2 Monitoring of the total muting time................................................. 51

6.3.3 Sensor gap monitoring ..................................................................... 52

6.3.4 Belt stop ............................................................................................52

6.3.5 End of muting by ESPE..................................................................... 53

6.3.6 Exit monitoring .................................................................................. 53

6.4 Direction detection .............................................................................................55

6.5 Sequence monitoring ......................................................................................... 55

6.6 Partial blanking................................................................................................... 56

6.7 Partial blanking/muting changeover................................................................. 57

6.8 Override............................................................................................................... 59

6.8.1 Override realised using an external circuit...................................... 59

6.8.2 Override realised with the integrated override function................. 60

6.9 Monitoring the muting lamp...............................................................................62

6.10 Combinable muting functions and facilities for connecting............................. 63

Operating Instructions

7 Mounting.......................................................................................................................... 64

7.1 Determining the minimum distance.................................................................. 64

7.1.1 Minimum distance to the hazardous area...................................... 65

7.1.2 Minimum distance to reflective surfaces........................................ 68

7.2 Steps for mounting the device........................................................................... 69

7.2.1 Mounting with Omega bracket......................................................... 71

7.2.2 Mounting with swivel mount bracket...............................................72

7.2.3 Mounting with side bracket..............................................................74

7.2.4 Mounting with rigid mounting bracket ............................................76

7.2.5 Mounting with pivoting mounting bracket.......................................78

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 5

Operating Instructions

M4000 Adv., Adv. A/P, Area

Contents

8 Electrical installation......................................................................................................80

8.1 System connection M26×11 + FE ....................................................................82

8.1.1 M4000 Advanced or M4000 Advanced A/P...................................82

.1.2 M4000 Area 60/80 ..........................................................................83

8

8.2 Extension connection M12× 4 + FE for UE403.................................................84

8.3 Configuration connection M8× 4 (serial interface)...........................................85

8.4 External device monitoring (EDM)......................................................................86

8.5 Reset button........................................................................................................87

8.6 Application diagnostic output (ADO) ..................................................................88

8.7 Test input (sender test).......................................................................................89

8.8 sens:Control applications ...................................................................................89

9 Commissioning ................................................................................................................90

9.1 Display sequence during start-up ......................................................................90

9.2 Alignment of the M4000 ....................................................................................90

9.2.1 Meaning of the 7Esegment display during alignment .....................91

9.2.2 Aligning sender and receiver............................................................93

9.2.3 Special aspects of alignment with deflector mirrors.......................94

9.2.4 Alignment of the M4000 Advanced with integrated laser

alignment aid (optional)....................................................................95

9.3 Test notes ......................................................................................................... 100

9.3.1 Pre-commissioning test notes....................................................... 100

9.3.2 Regular inspection of the protective device by qualified

safety personnel............................................................................. 100

9.3.3 Daily functional checks of the protective device.......................... 101

10 Configuration ................................................................................................................ 103

10.1 Default delivery status..................................................................................... 103

10.2 Preparation of the configuration ..................................................................... 103

11 Care and maintenance ................................................................................................ 104

12 Fault diagnosis ............................................................................................................. 105

12.1 In the event of faults or errors......................................................................... 105

12.2 SICK support..................................................................................................... 105

12.3 Error displays of the LEDs................................................................................ 106

12.4 Error displays of the 7Esegment display.......................................................... 107

12.5 Extended diagnostics....................................................................................... 112

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

Page 6

Contents

M4000 Adv., Adv. A/P, Area

13 Technical specifications ..............................................................................................113

13.1 Data sheet.........................................................................................................113

13.2 Table of weights................................................................................................119

3.2.1 M4000 Advanced and M4000 Advanced A/P .............................119

1

13.2.2 M4000 Passive...............................................................................119

13.2.3 M4000 Area 60/80........................................................................119

13.3 Dimensional drawings......................................................................................120

13.3.1 M4000 Advanced, M4000 Advanced A/P....................................120

13.3.2 M4000 Passive...............................................................................122

13.3.3 M4000 Area 60/80........................................................................124

13.3.4 Omega bracket ...............................................................................125

13.3.5 Swivel mount bracket.....................................................................126

13.3.6 Side bracket....................................................................................126

13.3.7 Rigid mounting bracket ..................................................................127

13.3.8 Pivoting mounting bracket .............................................................127

13.3.9 Deflector mirror PNS75E008..........................................................128

13.3.10 Deflector mirror PSK45 ..................................................................129

14 Ordering information ....................................................................................................130

14.1 M4000 Advanced .............................................................................................130

14.1.1 Delivery............................................................................................130

14.1.2 Type code ........................................................................................130

14.1.3 Default delivery status....................................................................132

14.2 M4000 Advanced A/P......................................................................................132

14.2.1 Delivery............................................................................................132

14.2.2 Type code ........................................................................................132

14.2.3 Default delivery status....................................................................133

14.3 M4000 Area 60/80..........................................................................................134

14.3.1 Delivery............................................................................................134

14.3.2 Type code ........................................................................................134

14.3.3 Default delivery status....................................................................135

14.4 Additional front screen (weld spark guard) .....................................................136

14.5 Deflector mirrors and mirror columns.............................................................138

14.6 Device columns ................................................................................................138

14.7 Accessories .......................................................................................................139

Operating Instructions

15 Annex..............................................................................................................................141

15.1 Compliance with EU directives.........................................................................141

15.2 Checklist for the manufacturer........................................................................142

15.3 Alignment templates ........................................................................................143

15.4 Alignment instructions......................................................................................145

15.5 List of tables .....................................................................................................147

15.6 List of illustrations ............................................................................................149

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 7

Operating Instructions Chapter 1

M4000 Adv., Adv. A/P, Area

About this document

1 About this document

lease read this chapter carefully before working with this documentation and the M4000

P

multiple light beam safety device.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

configuration, electrical installation, commissioning, operation and maintenance of the

M4000 multiple light beam safety device.

These operating instructions do not provide instructions for operating machines on which

the multiple light beam safety device is, or will be, integrated. Information on this is to be

found in the appropriate operating instructions for the machine.

1.2 Target group

These operating instructions are addressed to planning engineers, machine designers and

operators of plants and systems which are to be protected by one or several M4000

multiple light beam safety devices. It also addresses people who integrate the M4000

multiple light beam safety device into a machine, initialise its use, or who are in charge of

servicing and maintaining the device.

Note

1.3 Depth of information

These operating instructions contain the following information on the M4000 multiple light

beam safety device:

mounting

electrical installation

commissioning and configuration

care and maintenance

Planning and using protective devices such as the M4000 multiple light beam safety

device also require specific technical skills which are not detailed in this documentation.

When operating the M4000 multiple light beam safety device, the national, local and

statutory rules and regulations must be observed.

General information on accident prevention using opto-electronic protective devices can

be found in the SICK brochure “Safe Machines with opto-electronic protective devices”.

We also refer you to the SICK homepage on the Internet at www.sick.com.

Here you will find information on:

sample applications

a list of frequently asked questions regarding the M4000

these operating instructions in different languages for viewing and printing

EU declaration of conformity

fault diagnosis and troubleshooting

part numbers

conformity and approval

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

Page 8

Chapter 1 Operating Instructions

M4000 Adv., Adv. A/P, Area

About this document

1.4 Scope

hese operating instructions are original operating instructions.

T

hese operating instructions apply to the M4000 Advanced, M4000 Advanced A/P and

Note

Note

T

M4000 Area 60/80 multiple light beam safety devices with one of the following entries on

the type label in the field Operating Instructions:

8010794_WP70

8010794_YT72

This document is part of SICK part number 8010794 (operating instructions

“M4000 Advanced, M4000 Advanced A/P and M4000 Area 60/80 — Multiple light beam

safety device” in all available languages).

For the configuration and diagnostics of these devices you require CDS (Configuration &

Diagnostic Software) version 3.6.4 or higher. To determine the version of your software

version, select the Module-Info... option in the ? menu.

The general requirements for muting are defined in CLC/TS 62046.

1.5 Abbreviations and terms

ADO

Beam separation

CDS

EDM

EFI

ESPE

Muting

OSSD

OWS

PLC

Resolution

SDL

sens:Control

UE403

Application diagnostic output = configurable signal output that indicates a specific status

of the protective device

Distance between two neighbouring beams, measured from the middle of one beam to the

middle of the other.

SICK Configuration & Diagnostic Software = software for the configuration and diagnostics

of your M4000 multiple light beam safety device

External device monitoring

Enhanced function interface = safe SICK device communication

Electro-sensitive protective equipment (e.g. M4000)

A temporary automatic suppression of one or more safety function/s by safety-related

parts of the control system.

Output signal switching device

Output weak signal = contamination signal

Programmable logic controller

Minimum size of a test rod that is reliably detected by the protective device The resolution

is measured from the outside edge of a beam to the opposite outside edge of the

neighbouring beam.

Safety Data Link = SICK safety interface (connection for OSSD and EFI of an ESPE)

The SICK products in the sens:Control series include safety relays, safety controllers and

network solutions. If reference is made in this document to sens:Control devices, safety

controllers and network solutions are meant.

The UE403 safety relay is an accessory for the SICK M4000 Advanced multiple light beam

safety device. It extends the technical application possibilities of the M4000 Advanced.

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 9

Operating Instructions Chapter 1

,,

M4000 Adv., Adv. A/P, Area

About this document

1.6 Symbols used

ecommendations are designed to give you some assistance in your decision-making

Recommendation

Note

, ,

Take action …

R

process with respect to a certain function or a technical measure.

Refer to notes for special features of the device.

Display indications show the status of the 7Esegment display on sender or receiver:

Constant display of the letter E

Flashing display of the digit 8

Alternating display of E and 4

The depiction of digits on the 7Esegment display oft the M4000 can be rotated by 180°

with the aid of the CDS. In this document the depiction of the 7Esegment display is

however always in the normal, non-rotated position.

LED symbols describe the status of an LED:

The LED is constantly illuminated.

The LED is flashing.

The LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

WARNING

,

Warning!

A warning indicates an actual or potential risk or health hazard. They are designed to help

you to prevent accidents.

Read carefully and follow the warning notices!

Software notes show the location in the CDS (Configuration & Diagnostic Software) where

you can make the appropriate settings and adjustments.

Sender and receiver

In drawings and diagrams, the symbol denotes the sender and the symbol denotes

the receiver.

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and

diagrams of this document as a movement of a machine part. In practical operation, there

may be a number of different dangerous states:

machine movements

electrical conductors

visible or invisible radiation

a combination of several risks and hazards

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

Page 10

Chapter 2 Operating Instructions

M4000 Adv., Adv. A/P, Area

On safety

2 On safety

his chapter deals with your own safety and the safety of the equipment operators.

T

Please read this chapter carefully before working with the M4000 multiple light beam

safety device or with the machine protected by the M4000 multiple light beam safety

device.

2.1 Qualified safety personnel

The M4000 multiple light beam safety device must only be installed, commissioned and

serviced by qualified safety personnel. Qualified safety personnel are defined as persons

who

have undergone the appropriate technical training

and

who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

who have access to these operating instructions.

WARNING

2.2 Applications of the device

The M4000 system is a type 4 electro-sensitive protective equipment (ESPE) as defined by

IEC 61496E1 and IEC 61496E2 and is therefore allowed for use with controls in category 4

according to EN ISO 13849E1. The preconfiguration of the M4000 multiple light beam

safety device is suitable for:

hazardous area protection

access protection

The multiple light beam safety devices must be installed such that the hazardous area can

only be reached by interrupting the light path between sender and receiver. It must not be

possible to start the plant/system as long as personnel are within the hazardous area.

The M4000 system is intended only for use in industrial environments. When used in resi-

dential areas it can cause interference.

Refer to page 16 for an illustration of the protection modes and an example application.

Only use the multiple light beam safety device as an indirect protective measure!

An opto-electronic protective device provides indirect protection, e.g. by switching off the

power at the source of the hazard. It cannot provide protection from parts thrown out, nor

from emitted radiation. Transparent objects are not detected.

Depending on the application, mechanical protective devices may be required in addition

to the M4000 system.

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 11

Operating Instructions Chapter 2

M4000 Adv., Adv. A/P, Area

On safety

2.3 Correct use

he M4000 system must be used only as defined in chapter 2.2 “Applications of the

T

device”. It must be used only by qualified personnel and only on the machine where it has

been installed and initialised by qualified safety personnel in accordance with these

operating instructions.

All warranty claims against SICK AG are forfeited in the case of any other use, or altera-

tions being made to the system, even as part of their mounting or installation.

2.4 General safety notes and protective measures

Safety notes

Please observe the following items in order to ensure the correct and safe use of the

WARNING

M4000 multiple light beam safety device.

The national/international rules and regulations apply to the installation, commission-

ing, use and periodic technical inspections of the multiple light beam safety device, in

particular …

– Machinery Directive

– Work Equipment Directive

– the work safety regulations/safety rules

– other relevant safety regulations.

Manufacturers and operators of the machine on which the multiple light beam safety

device is used are responsible for obtaining and observing all applicable safety regula-

tions and rules.

The notices, in particular the test regulations (see “Test notes” on page 100) of these

operating instructions (e.g. on use, mounting, installation or integration into the existing

machine controller) must be observed.

Changes to the configuration of the devices can degrade the protective function. After

every change to the configuration you must therefore check the effectiveness of the

protective device.

The person who makes the change is also responsible for the correct protective function

of the device. When making configuration changes, please always use the password

hierarchy provided by SICK to ensure that only authorised persons make changes to the

configuration. The SICK service team is available to provide assistance if required.

The tests must be carried out by qualified safety personnel or specially qualified and

authorised personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

The operating instructions must be made available to the operator of the machine

where the M4000 multiple light beam safety device is fitted. The machine operator is to

be instructed in the use of the device by qualified safety personnel and must be instructed to read the operating instructions.

The external voltage supply of the devices must be capable of buffering brief mains

voltage failures of 20 ms as specified in EN 60204E1. Suitable power supplies are

available as accessories from SICK (Siemens type series 6 EP 1).

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Page 12

Chapter 2 Operating Instructions

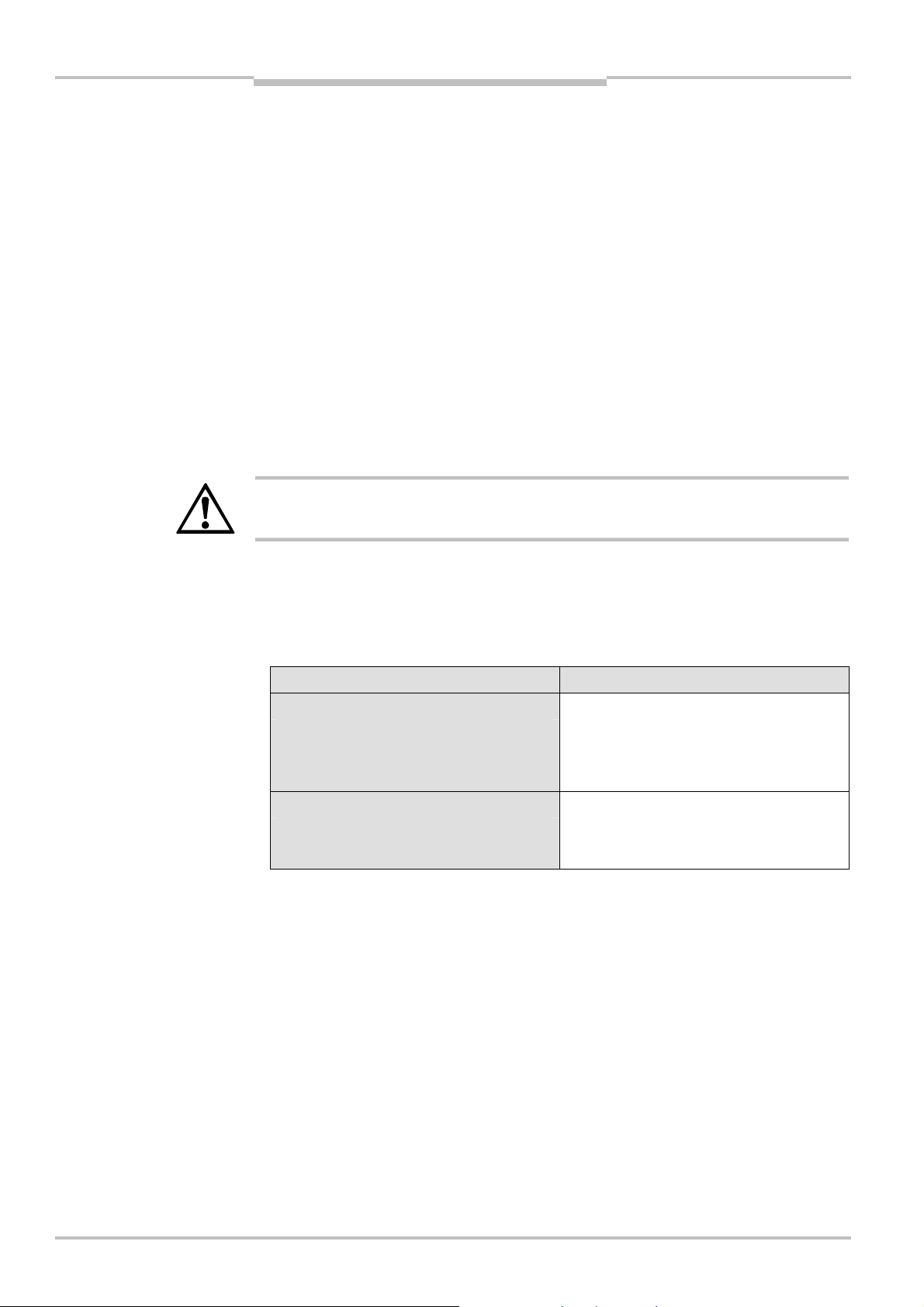

Tab.1:

Overview on disposal

M4000 Adv., Adv. A/P, Area

On safety

2.5 Environmental protection

he M4000 multiple light beam safety device is constructed in such a way that it adversely

T

affects the environment as little as possible. It uses only a minimum of power and natural

resources.

At work, always act in an environmentally responsible manner.

2.5.1 Disposal

Unusable or irreparable devices should always be disposed as per the applicable national

regulations on waste disposal (e.g. European waste code 16 02 14).

Notes

WARNING

We would be pleased to be of assistance on the disposal of this device. Contact your

local SICK representative.

Information on the individual materials in the M4000 is given in chapter 13 “Technical

specifications” on page 113.

2.5.2 Separation of materials

Only appropriately trained personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

by components

Before you send the devices for appropriate recycling, it is necessary to separate the

different materials in the M4000.

Separate the housing from the rest of the parts (in particular the circuit board).

Send the separated parts for recycling as appropriate (see Tab. 1).

Components Disposal

Product

Housing Metal recycling (aluminium)

Circuit boards, cable, connector and

electrical connecting pieces

Packaging

Cardboard, paper Paper/cardboard recycling

Polyethylene packaging Plastic recycling

Electronic recycling

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 13

Operating Instructions Chapter 3

M4000 Adv., Adv. A/P, Area

Product description

3 Product description

his chapter provides information on the special features and properties of the M4000

T

multiple light beam safety device. It describes the construction and the operating principle

of the device.

Please read this chapter before mounting, installing and commissioning the device.

3.1 Special features

Properties of all devices described in these operating instructions

protective operation with either internal or external (realised on the machine) restart

interlock

external device monitoring (EDM)

beam coding

configurable application diagnostic output (ADO)

status display with 7Esegment display

SDL interface

M4000 Advanced

muting configurable (only with UE403 or sens:Control)

2, 3 or 4 beams

scanning range up to 70 m

integrated laser alignment aid (optional)

end cap with integrated LED (optional)

M4000 Advanced A/P

less wiring costs: Only one device needs to be connected electrically.

quick and straightforward alignment in conjunction with the M4000 Passive (deflector

unit)

2 beams, scanning range to 7.5 m (M4000 Passive with mirror deflection)

2 or 4 beams, scanning range to 4.5 m (M4000 Passive with fibre-optic deflection)

muting configurable (only with UE403 or sens:Control)

end cap with integrated LED (optional)

M4000 Area 60/80

horizontal area protection

M4000 Area 60:

– 60 mm resolution

– length of the monitored area 300-1800 mm

– scanning range 19 m

M4000 Area 80:

– corresponds: 80 mm resolution

– length of the monitored area 600-1800 mm

– scanning range 70 m

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Page 14

Chapter 3 Operating Instructions

M4000

Advanced

Beam diameter

Beam separation

Dimension of the light path between

M4000

Advanced

A/P

Beam separation

Dimension of the light path between

M4000

Advanced

A/P

M4000

Passive (deflector

unit)

M4000 Adv., Adv. A/P, Area

Product description

3.2 Operating principle of the device

3.2.1 The principle of the multiple light beam safety device

The M4000 multiple light beam safety device secures the access to a hazardous area and

signals the entry of objects as soon as a light beam is interrupted. The machine or plant

controller that evaluates this message must then bring the dangerous movement to a halt.

You can secure two sides of a hazardous area by using a deflector mirror, with two deflec-

or mirrors you can secure three sides (see chapter 3.3.2 “Access protection on several

t

sides with the aid of deflector mirrors” on page 17ff).

3.2.2 Device components

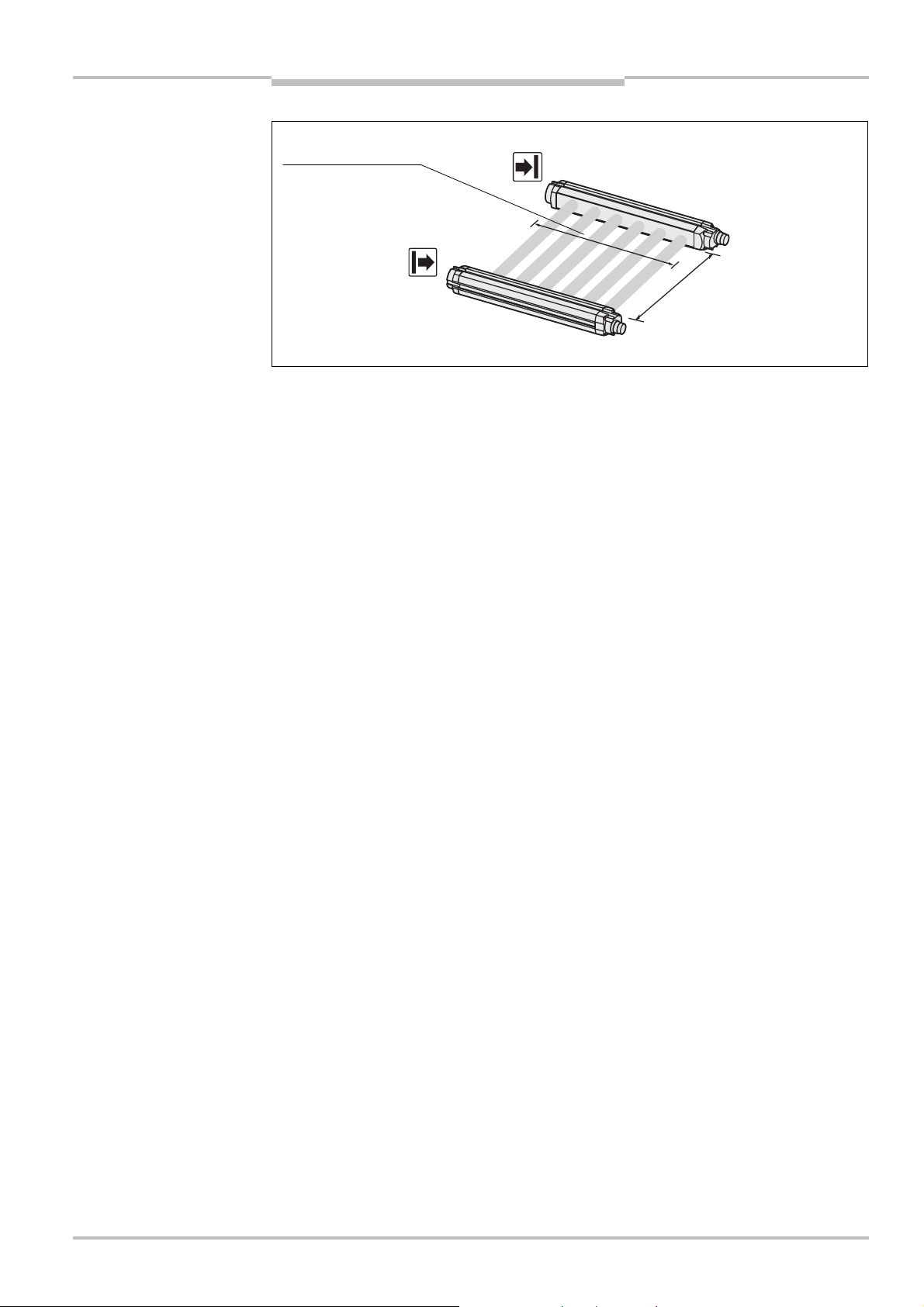

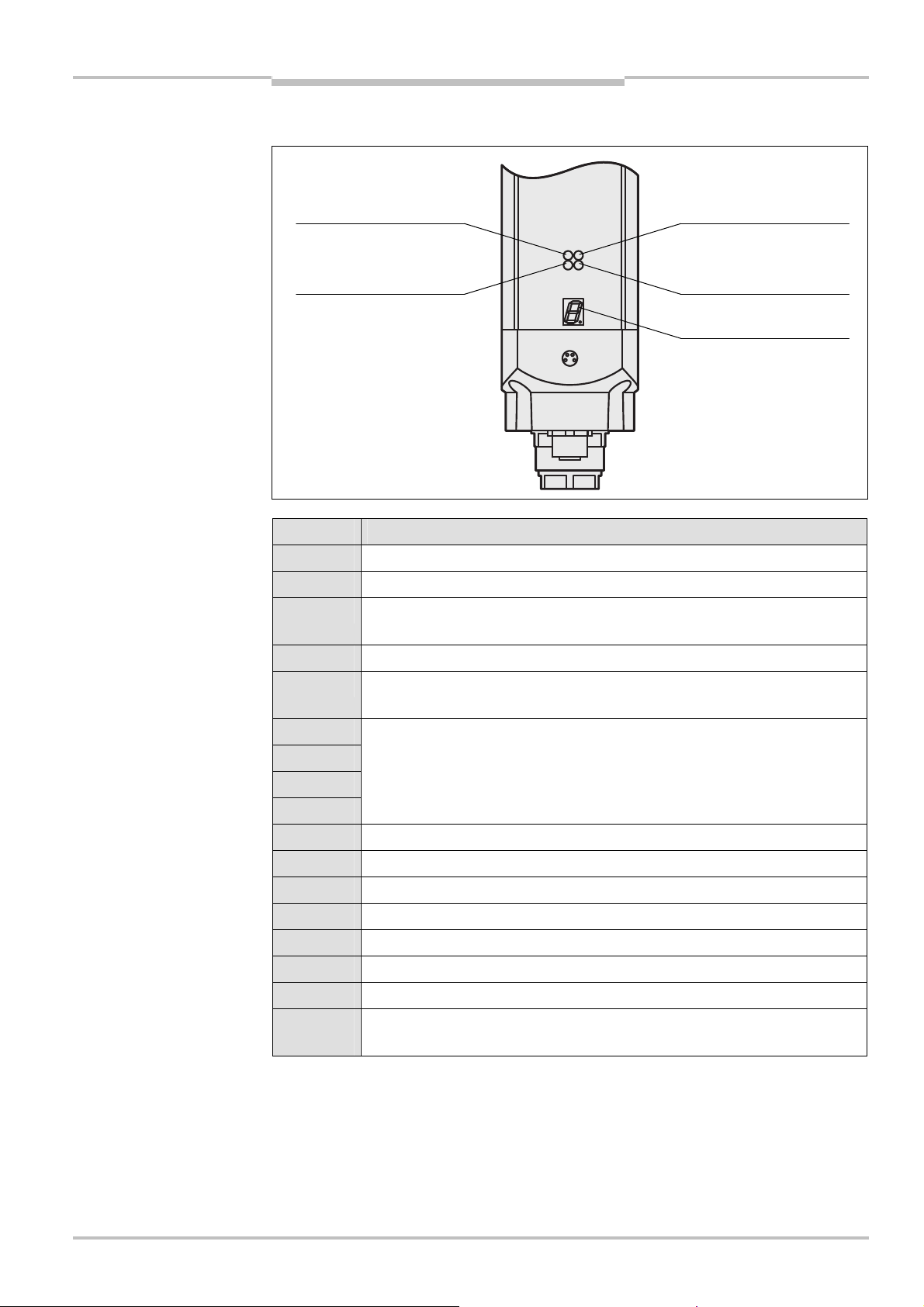

Fig. 1: Device components of

the M4000 Advanced

(23 mm)

Fig. 2: Device components of

the M4000 Advanced A/P

sender and receiver

M4000 Advanced A/P and M4000 Passive

(deflector unit)

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 15

Operating Instructions Chapter 3

M4000

Area 60/80

Length of the

Dimension o

f the light path

M4000 Adv., Adv. A/P, Area

Fig. 3: Components of the

M4000 Area 60/80

Product description

monitored area

between sender and receiver

Principles of operation

The M4000 multiple light beam safety device consists of a sender unit and a receiver unit.

A distinction should be made between active/active systems and active/passive systems:

On the active/active system, sender unit and receiver unit are in separate housings, the

sender and the receiver. The light beam is emitted from the sender and is incident to

the receiver.

On the active/passive system, sender unit and receiver unit are in a common housing

(M4000 Advanced A/P). The light beam is emitted from the sender unit and is deflected

by the deflector unit M4000 Passive (mirror deflection or fibre-optic deflection) by 180°

back to the receiver unit (see Fig. 2). As a passive element, the deflector unit does not

require any electrical connections.

For the exact number and distance of beams, please see chapter 13.3 “Dimensional

drawings” on page 120ff.

The dimension of the light path between sender and receiver (or between the M4000

Advanced A/P and M4000 Passive) must not exceed the maximum permissible scanning

range (see “Technical specifications” on page 113ff.).

On active/active systems, sender unit and receiver unit synchronise automatically by

optical means. An electrical connection between both components is not required.

The M4000 is modular in structure. All optical and electronic components and assemblies

are housed in a slim and torsionally rigid housing.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Subject to change without notice

M4000 Advanced

The M4000 Advanced multiple light beam safety device is available with 2, 3 or 4 beams.

Other configurations with up to 12 beams are possible on request. The maximum scanning

range (dimension of the light path between sender and receiver) is 70 m.

M4000 Advanced A/P

The M4000 Advanced A/P is available with 2 or 4 beams. The maximum scanning range

(dimension of the light path between the M4000 Advanced A/P and the M4000 Passive) is

dependent of the number of beams as well as the utilized M4000 Passive and is 7.5 m

max.

M4000 Area 60/80

The M4000 Area 60/80 multiple light beam safety device is available with a monitored

area length from 300/600 mm to 1800 mm. The beam separation is 50 or 57 mm (resolution of 60 or 80 mm). The maximum scanning range is 19 m (M4000 Area 60) or 70 m

(M4000 Area 80).

Page 16

Chapter 3 Operating Instructions

M4000 Adv., Adv. A/P, Area

Product description

3.3 Application examples

3.3.1 Access protection

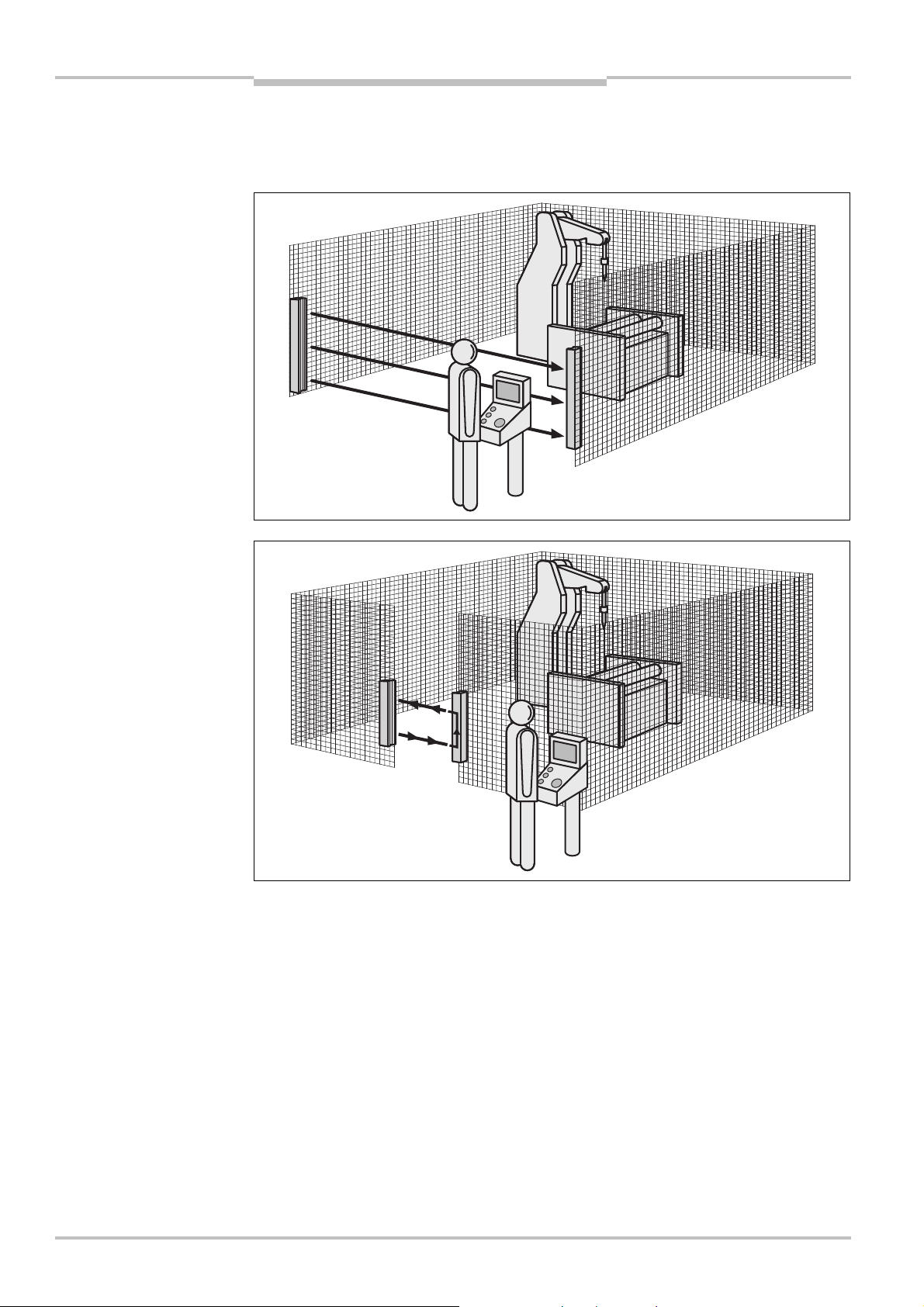

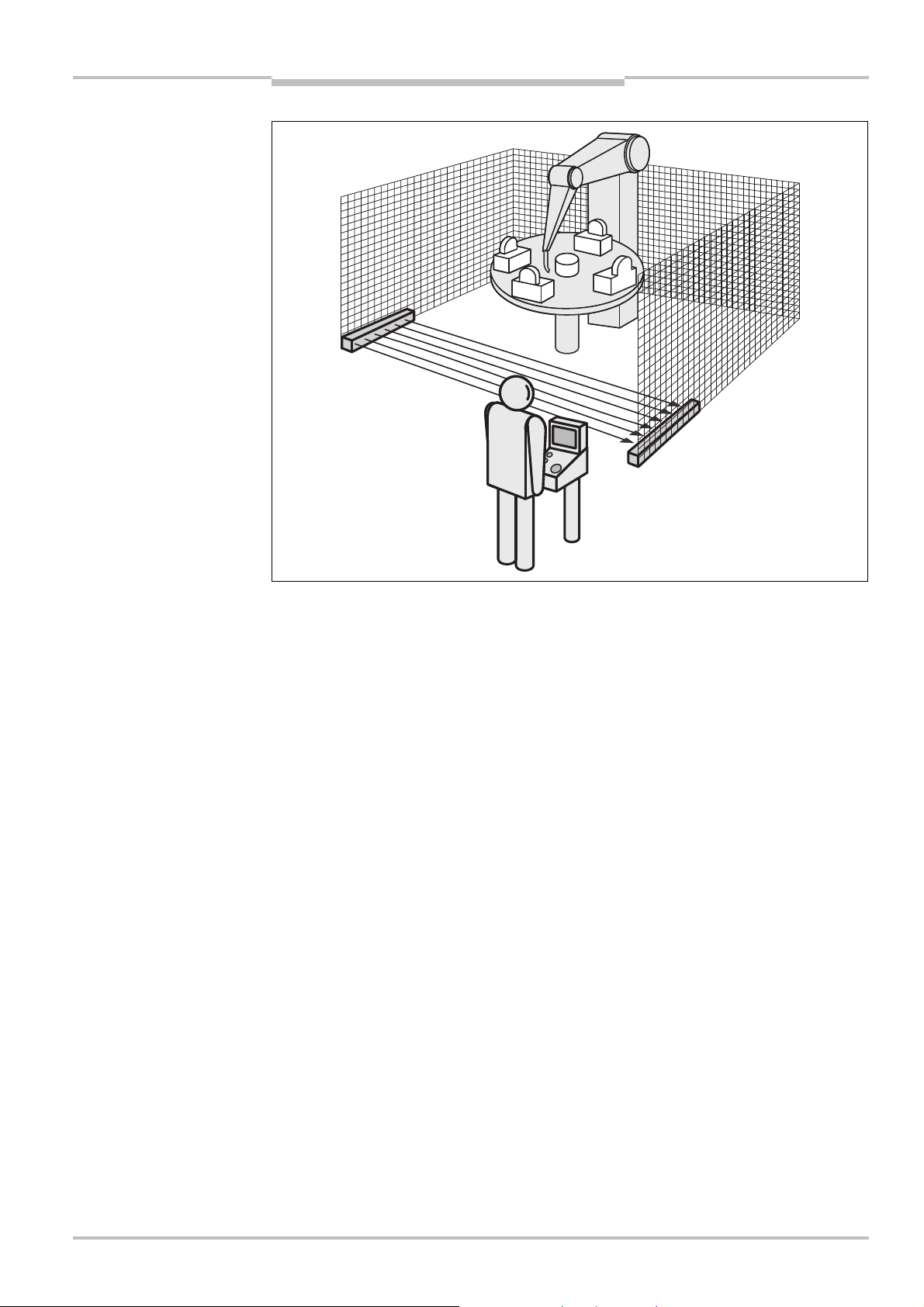

Fig. 4: Access protection with

an M4000 Advanced multiple

light beam safety device

Fig. 5: Access protection with

an M4000 Advanced A/P

multiple light beam safety

device

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 17

Operating Instructions Chapter 3

M4000 Adv., Adv. A/P, Area

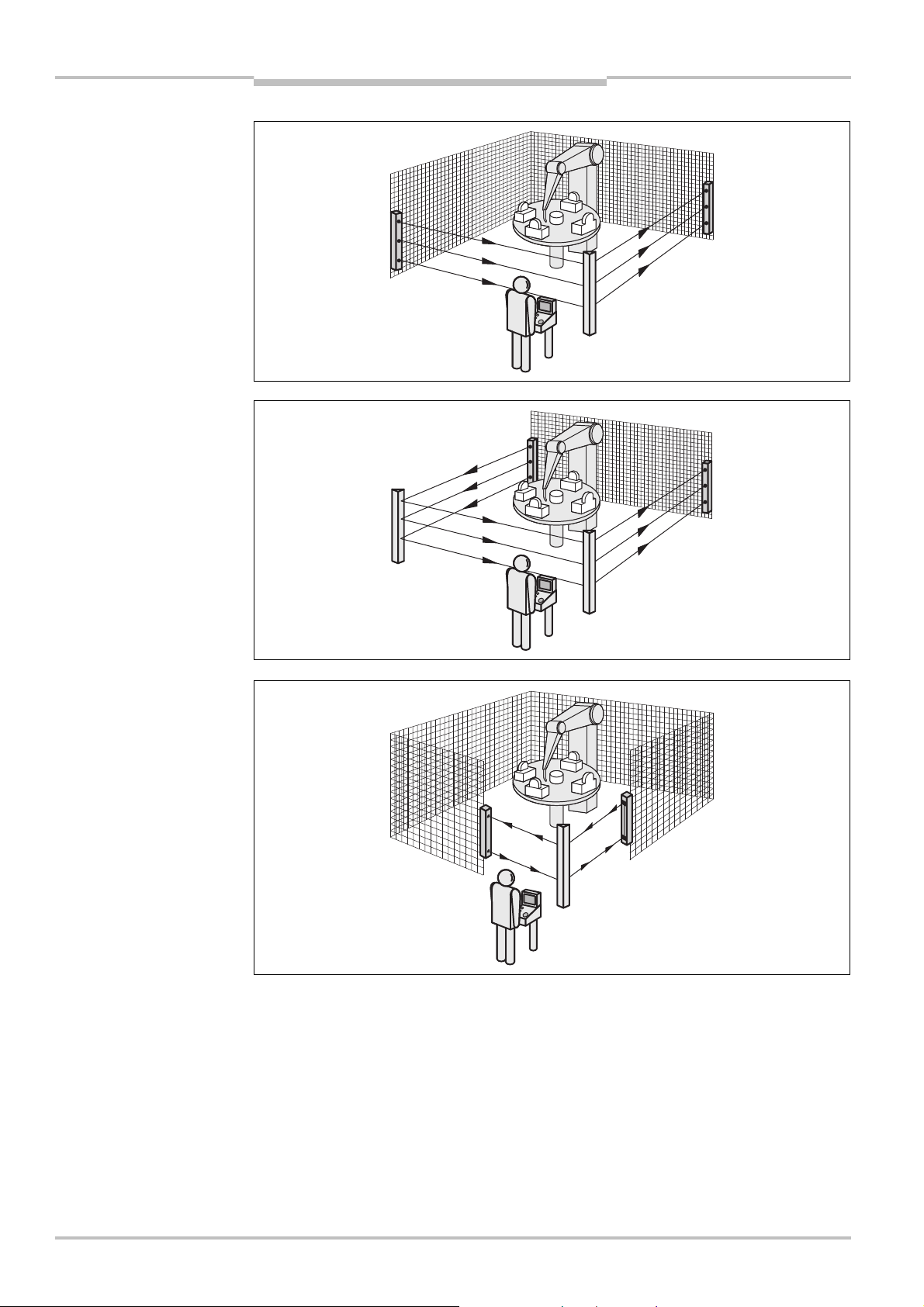

Fig. 6: Access protection with

an M4000 Area 60/80

multiple light beam safety

device

Product description

The M4000 multiple light beam safety device operates correctly as a protective device only

if the following conditions are met:

The control of the machine must be electrical.

It must be possible to achieve a safe state on the machine at any time.

Sender and receiver must be mounted in a way that objects penetrating the hazardous

area are safely identified by the M4000.

The reset button must be fitted outside the hazardous area such that it cannot be ope-

rated by a person working inside the hazardous area. When operating the reset button,

the operator must have full visual command of the hazardous area.

The statutory and local rules and regulations must be observed when installing and

using the device.

3.3.2 Access protection on several sides with the aid of deflector mirrors

You can secure two sides of a hazardous area by using one deflector mirror (see Fig. 7),

with two deflector mirrors you can secure three sides (see Fig. 8).

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Subject to change without notice

Page 18

Chapter 3 Operating Instructions

M4000 Adv., Adv. A/P, Area

Fig. 7: Access protection with

an M4000 Advanced multiple

light beam safety device and

one deflector mirror

Fig. 8: Access protection with

an M4000 Advanced multiple

light beam safety device and

two deflector mirrors

Product description

Fig. 9: Access protection with

an M4000 Advanced A/P

multiple light beam safety

device and one deflector

mirror

Notes

The formation of droplets of heavy contamination can be detrimental to the reflection

behaviour. Take the necessary organisational measures to avoid the formation of drop-

lets on the deflector mirrors. The deflector mirrors are available as accessories (see

page 128f.).

Deflector mirrors reduce the effective scanning range. The effective scanning range

depends on the number of deflector mirrors in the light path (see chapter 5.4 “Scanning

range” on page 42ff).

You can extend the M4000 Advanced A/P multiple light beam safety device with a maxi-

mum of one deflector mirror.

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 19

Operating Instructions Chapter 3

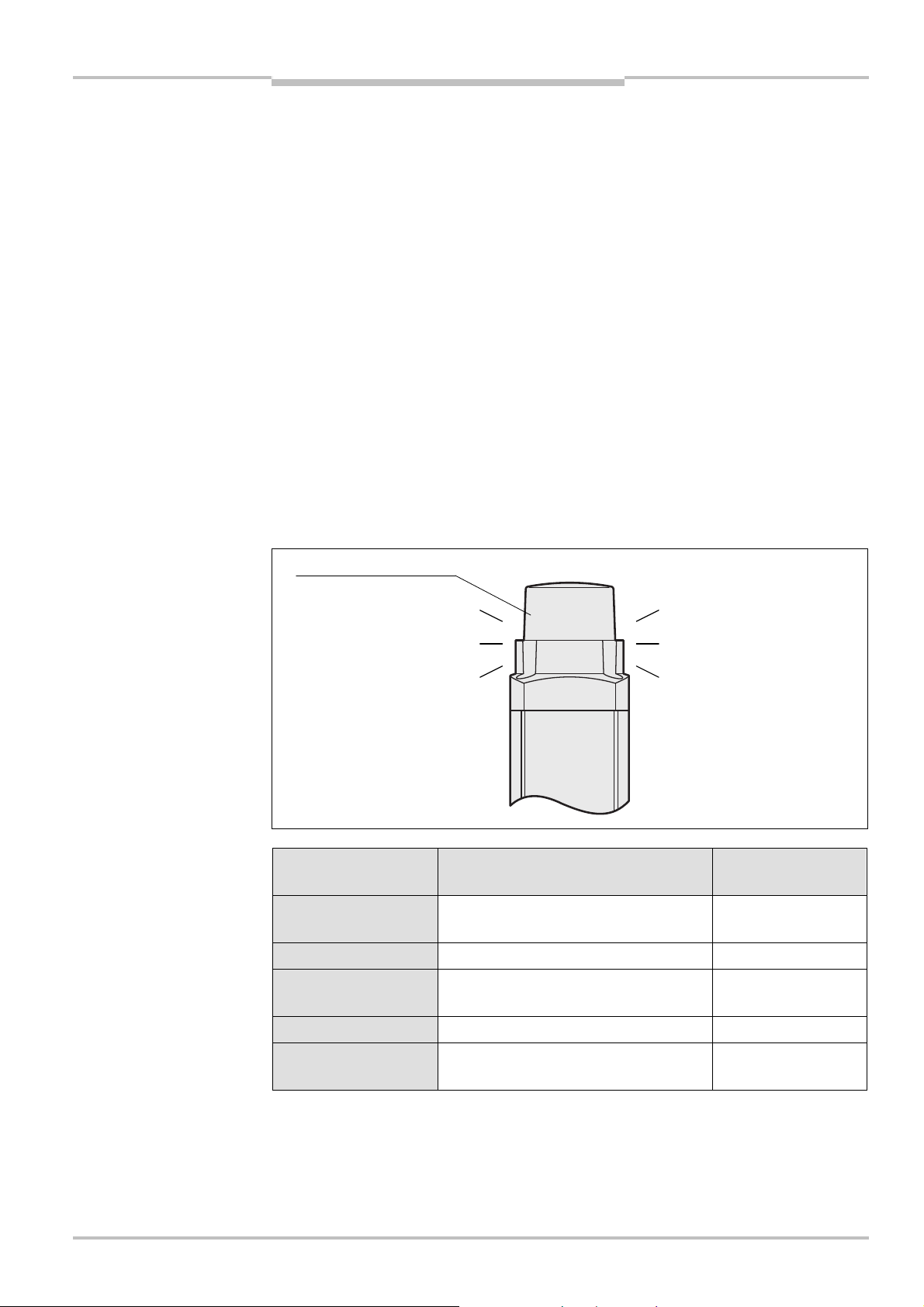

Tab.2:

Significance of the

End cap with integrated

M4000 Adv., Adv. A/P, Area

Product description

3.4 Controls and status indicators

he LEDs and the 7Esegment display of sender and receiver signal the operating status of

T

the M4000.

Note

The depiction of numbers on the 7Esegment display can be rotated by 180° with the aid of

the CDS (Configuration & Diagnostic Software). If you rotate the numbers of the 7Esegment

display, the point in the 7Esegment display goes out:

Point visible: The bottom edge of the numbers on the 7Esegment display is pointing

towards the configuration connection.

Point not visible: The bottom edge of the numbers on the 7Esegment display is pointing

towards the LED display.

Device symbol M4000 Advanced (sender or receiver), M4000 Advanced (A/P) or M4000

Area (sender or receiver), context menu Open device window, parameter node General.

3.4.1 End cap with integrated LED (optional, only on receiver)

Notes

Fig. 10: End cap with

integrated LED

indications on the integrated

LED

The end cap with integrated LED is available only for the receiver of the M4000 Ad-

vanced and the M4000 Advanced A/P.

The integrated LED is not monitored. This means that a failure of the integrated LED has

no effect on the function of the M4000.

LED

Display Meaning Output signal

switching devices

Red System providing signals for shutting

down the machine

Green System clear On

Off

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Subject to change without notice

Yellow Muting

(only with UE403 or sens:Control)

Yellow/red (1 Hz) Reset required Off

Yellow/red (2 Hz) Override required

(only with UE403 or sens:Control)

On

Off

Page 20

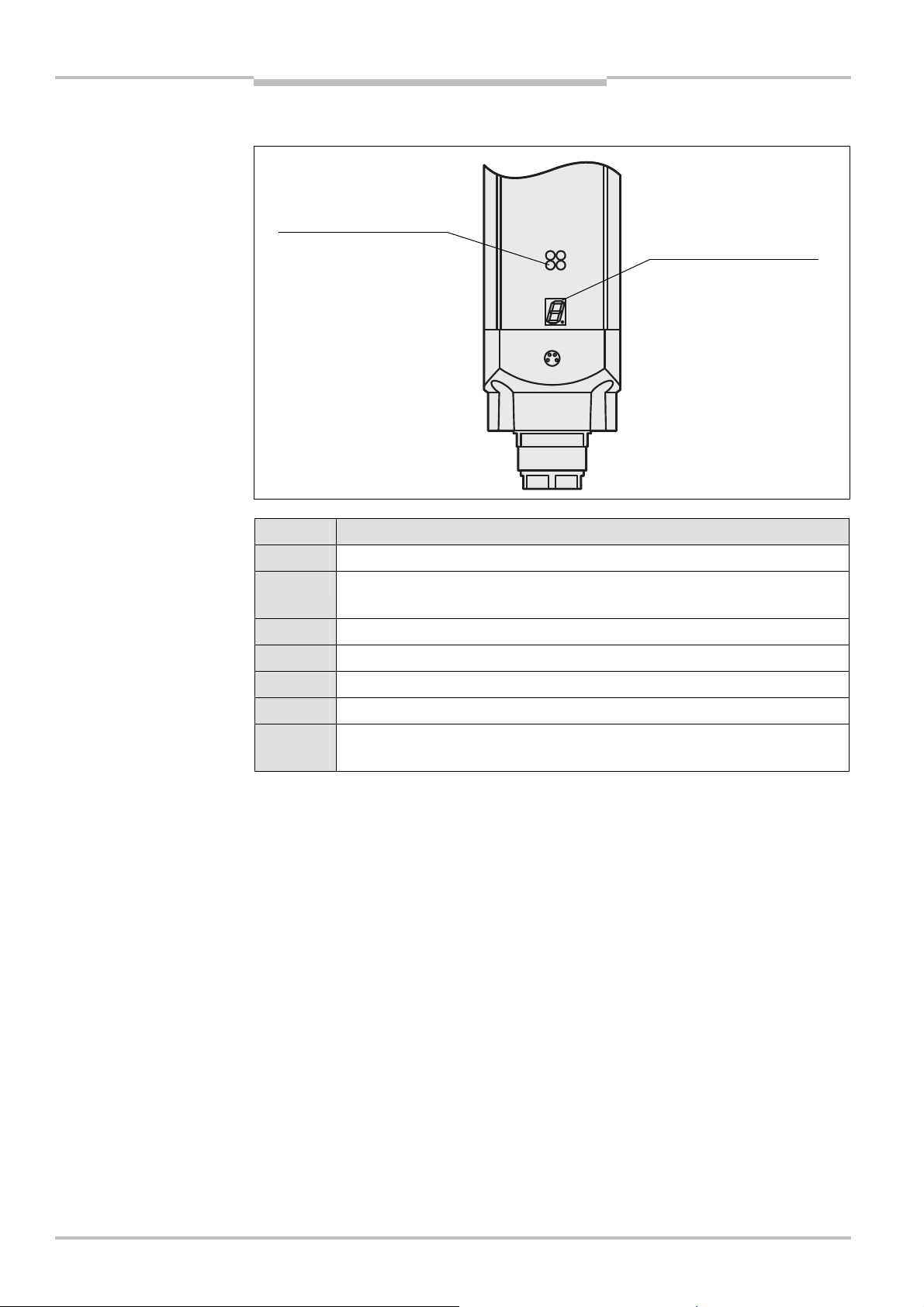

Chapter 3 Operating Instructions

Tab.3:

Meaning of the status

Yellow

74segment display

M4000 Adv., Adv. A/P, Area

Product description

3.4.2 Status indicators of the sender

Fig. 11: Status indicators of

the sender

indicators of the sender

Display Meaning

Yellow Supply voltage o.k.

System error. Disconnect the supply voltage to the M4000 for at least

3 seconds. If the problem persists, replace the unit.

The device is in the test mode.

Non-coded operation (only after switching on)

Operation with code 1 (only after switching on)

Operation with code 2 (only after switching on)

Other

displays

All other displays are error messages. Please refer to chapter 12 “Fault

diagnosis” on page 105.

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 21

Operating Instructions Chapter 3

Tab.4:

Meaning of the status

Orange

Red

Yellow

Green

74segment display

M4000 Adv., Adv. A/P, Area

Product description

3.4.3 Status indicators of the receiver or of the M4000 Advanced A/P

Fig. 12: Status indicators of

the receiver or of the

M4000 Advanced A/P

indicators of the receiver or

the M4000 Advanced A/P

Display Meaning

Orange Cleaning or realignment required

Yellow Reset required

Red System providing signals for shutting down the machine: output signal

switching devices off

Green System clear: output signal switching devices on

System error. Disconnect the supply voltage to the M4000 for at least

3 seconds. If the problem persists, replace the unit.

Poor alignment to sender.

Please refer to chapter 9.2 “Alignment of the M4000” on page 90.

Note: In normal operation, the display indicates the state “The light path

is interrupted”.

Muting (only with UE403 or sens:Control)

Override (only with UE403 or sens:Control)

Operation with blanking (only with UE403 or sens:Control)

Operation with large scanning range (only after switching on)

Non-coded operation (only after switching on)

Operation with code 1 (only after switching on)

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Subject to change without notice

Operation with code 2 (only after switching on)

Other

displays

All other displays are error messages. Please refer to chapter 12 “Fault

diagnosis” on page 105.

Page 22

Chapter 4 Operating Instructions

Ensure that muting cannot be unintentionally triggered

M4000 Adv., Adv. A/P, Area

Muting

4 Muting

When using the muting functions of the M4000 Advanced please observe the operating

Note

WARNING

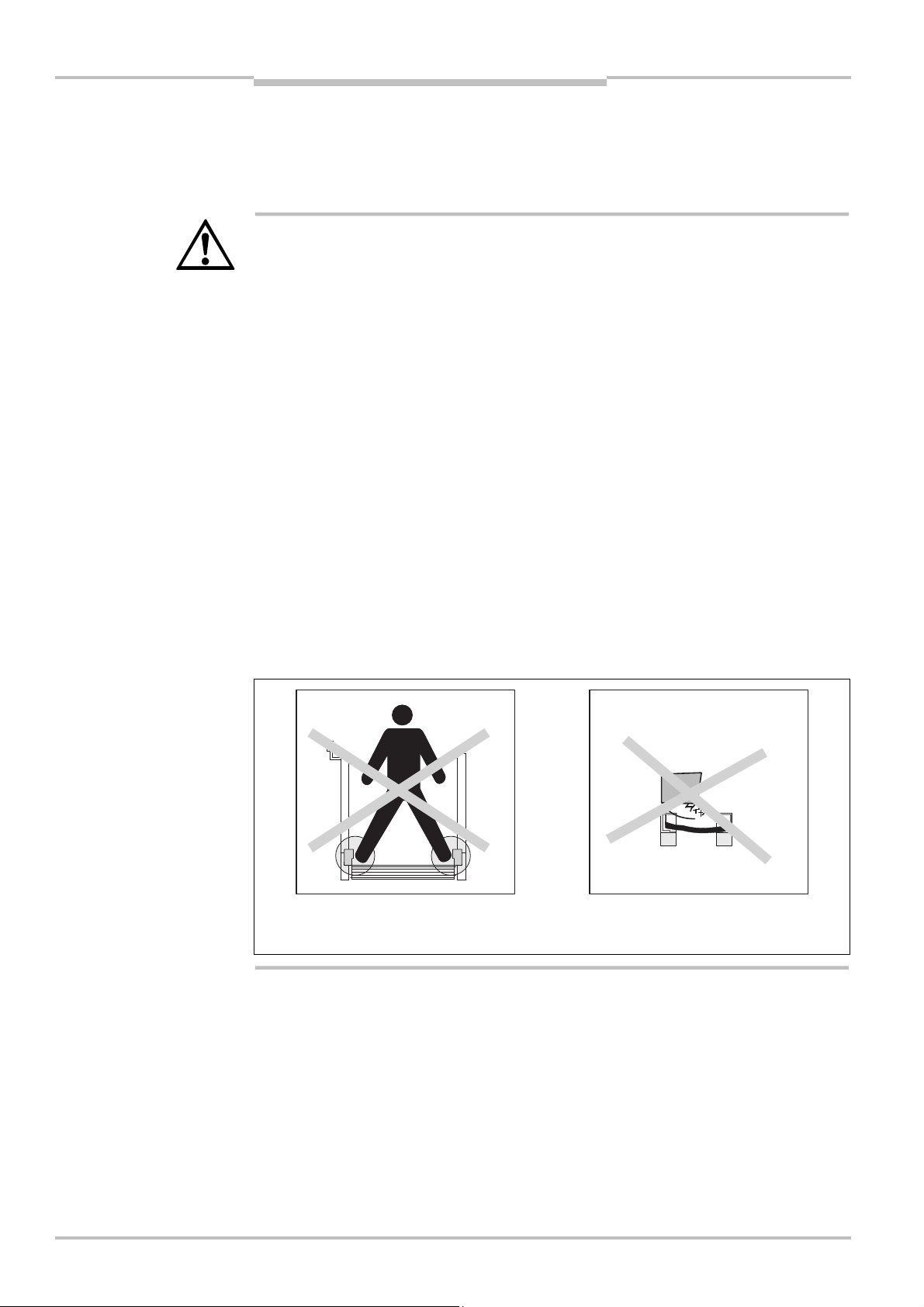

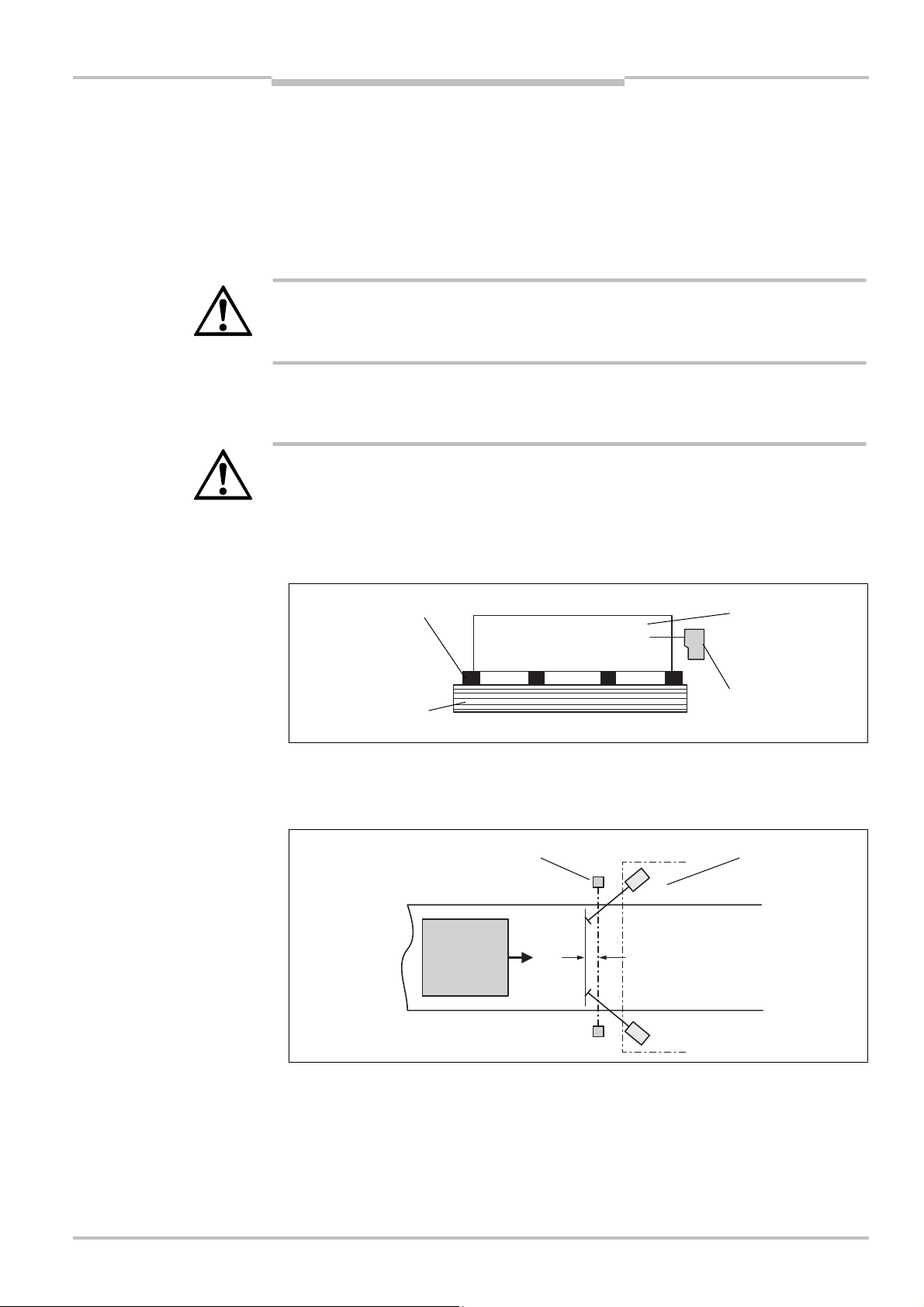

Fig. 13: Safety on mounting

the muting sensors

instructions of the corresponding UE403 or sens:Control device.

Pay attention to the following safety notes!

Muting is only allowed to be activated during the period when the material to be trans-

ported (e.g. on a pallet) blocks the access to the hazardous area.

Muting must be performed automatically, but must not depend on a single electrical

signal.

Muting must be triggered by at least two independently wired signals (e.g. from muting

sensors) and must not depend entirely on software signals (for instance from a PLC).

Muting must be removed immediately as soon as the material to be transported no

longer blocks the access to the dangerous movement so that the protective device is

once more effective.

The material to be transported must be detected over its entire length, i.e. there must

be no interruption in the output signals.

Mount the control switch for reset or override outside the hazardous area such that it

cannot be operated by a person in the hazardous area. When operating the control

switch, the operator must have full visual command of the hazardous area.

Always mount the sensors so that the minimum distance to the protective device is

maintained.

Prevent the unintentional triggering of muting by a person by mounting the sensors

appropriately (see Fig. 13)!

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

by a person!

Subject to change without notice

Page 23

Operating Instructions Chapter 4

A1

Hazardous area

A2

ESPE

Material

Means of transport

M4000 Adv., Adv. A/P, Area

Muting

4.1 Muting principle

uting temporarily mutes the protection provided by a safety device. In this way it is possi-

M

ble to move material to or from a machine without the need to interrupt the work process.

During muting a differentiation is made between people and material with the aid of addi-

tional sensor signals. In the event of a valid muting condition the protective device is overridden on the basis of a logical evaluation of these external sensor signals so that the ma-

terial to be transported can pass through the protective device. As soon as anything other

than material enters the hazardous area, the work process is interrupted.

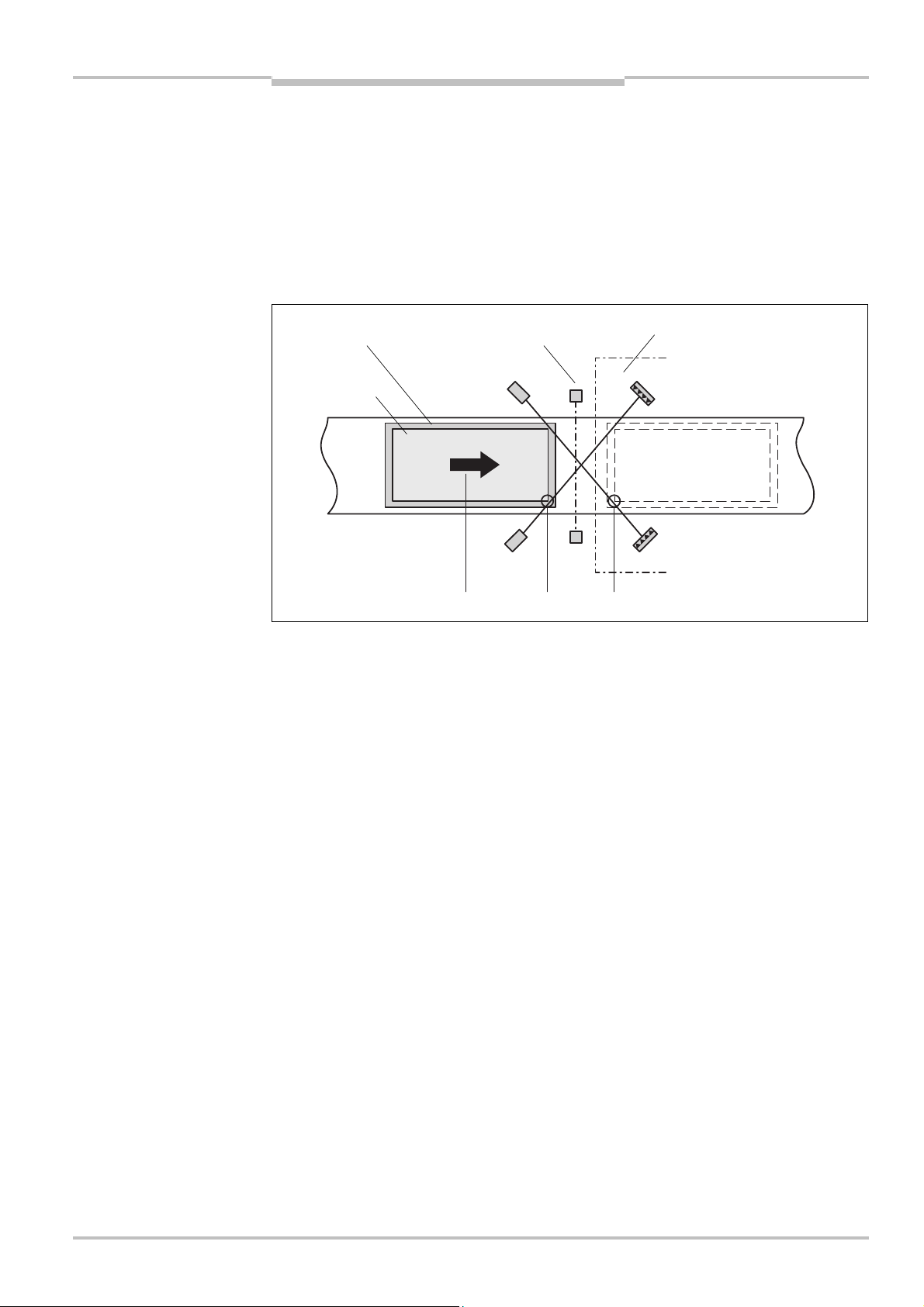

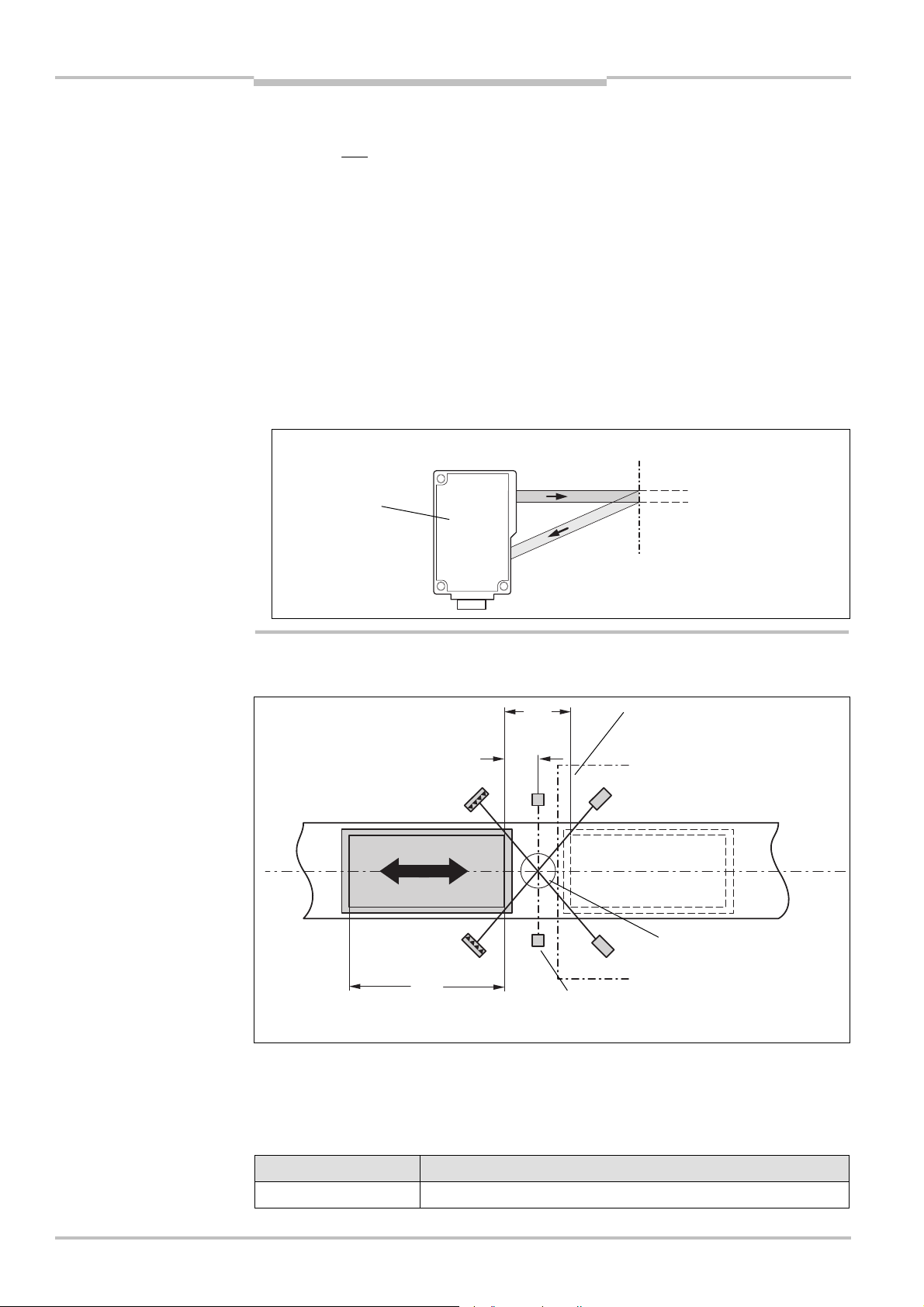

Fig. 14: Schematic

illustration of muting

In the example, the material moves from left to right on a conveyor belt . As soon as the

muting sensors A1 and A2 are activated , the protection provided by the ESPE protective

device is muted and the material can move into the hazardous area. As soon as the

muting sensors are clear again , the protection provided by the protective device is reactivated.

4.1.1 Muting cycle

The muting cycle is the defined sequence of all processes that take place during muting.

The cycle starts when the first muting sensor is activated. The cycle ends when the last

muting sensor returns to its initial state (e.g. clear light path for optical sensors). Only then

is it possible to activate muting again.

Material can be transported several times during a muting cycle, if the muting condition is

maintained continuously, i.e. at least one pair of sensors remains activated continuously.

Exception: With the Exit monitoring function activated (see sections 4.2.3 and 4.2.4 from

page 30), multiple material transport within a muting cycle is not possible.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Subject to change without notice

Page 24

Chapter 4 Operating Instructions

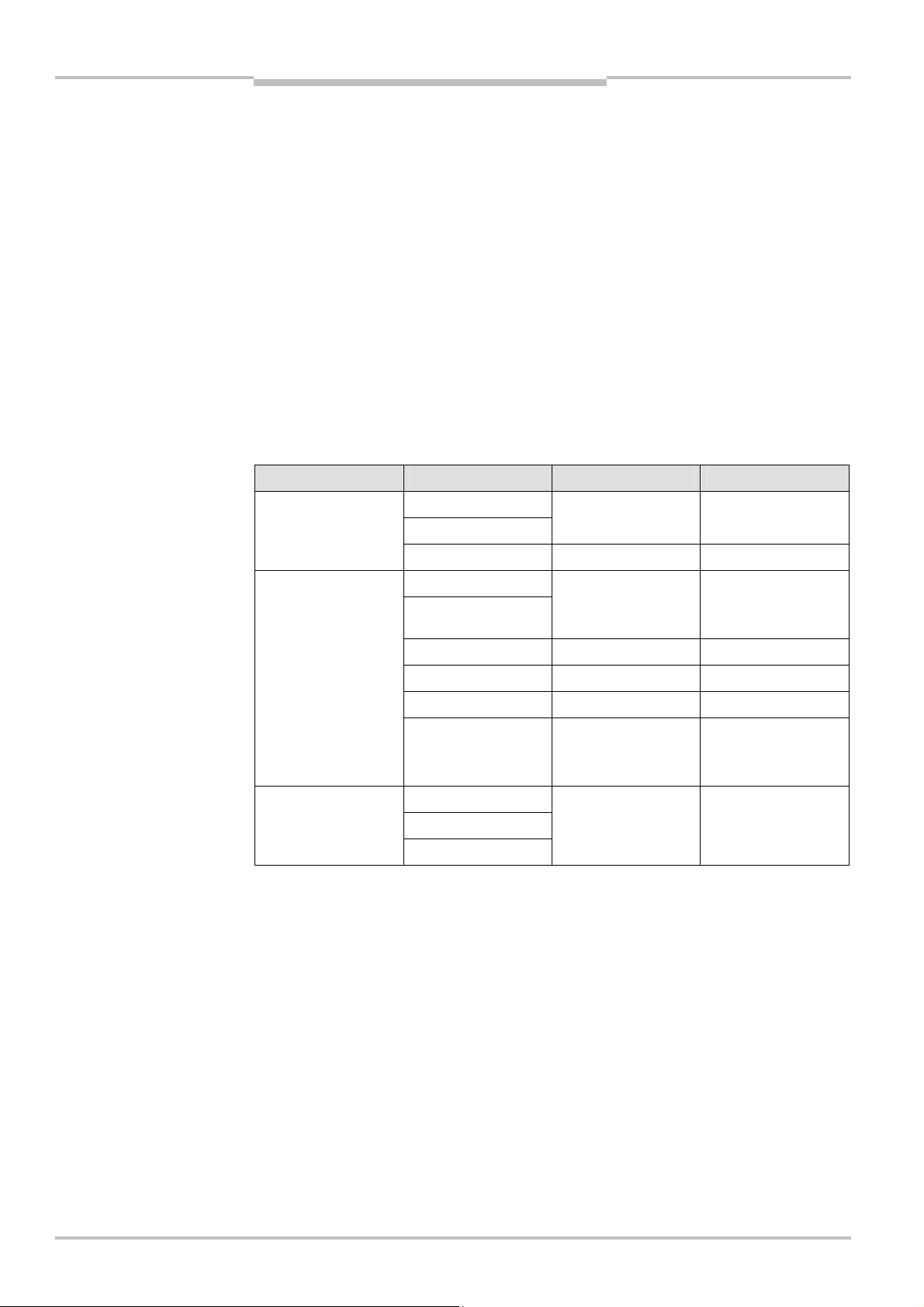

Tab.5:

Sel

ection and set

-

M4000 Adv., Adv. A/P, Area

Muting

4.1.2 Muting sensors

Muting sensors detect material and supply the signals which an evaluation unit requires

for the logic operation.

Sensor signals can be generated by the following external sensors:

optical sensors

inductive sensors

mechanical switches

controller signals

SICK muting sensors

Recommendation

A selection of optical muting sensors is given in the following. Depending on the type (lightswitching or dark-switching), you can use these as testable or non-testable sensors.

Note

You can use testable muting sensors in conjunction with the UE403 safety relay or a

sens:Control device. For this purpose, the sensor test function of the M4000 multiple light

beam safety device must be configured (see section 6.2 “Sensor test” on page 50ff.).

tings for the SICK optical

muting sensors in muting

applications

Note

Sensor Type Testable Non-testable

Photoelectric

proximity switch

WT24

WT27

Dark switching Light switching

WT280 Not possible Light switching

Photoelectric reflex

switch

WL24

WL27

Dark switching,

reflector moving on

Dark switching

the object

WL280 Not possible Dark switching

WL12 Not possible Dark switching

WL14 Not possible Dark switching

WL18 Dark switching,

Dark switching

reflector moving on

the object

Through-beam

photoelectric switch

WS24/WE24

WS27/WE27

Not possible Dark switching

WS280/WE280

For the selection and settings for the SICK optical muting sensors in muting applications,

the following applies:

Outputs must be PNP switching.

Other series are possible.

Pay attention to the output signals in chapter 6.2.

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 25

Operating Instructions Chapter 4

Material

Muting sensor

Means of transport

Transport level

v

L

Ha

zardous area

ESPE

M4000 Adv., Adv. A/P, Area

Muting

4.1.3 Muting lamp

To signal muting, the use of a muting lamp or a muting status signal is stipulated. The

muting lamp signals the temporary muting. You can use an external lamp (monitored/not

onitored) or the integrated LED on the M4000 Advanced multiple light beam safety

m

device (not monitored).

Depending on the national legal situation, the monitoring of the external muting lamp may

ote

N

be deactivated with the aid of the CDS.

Always mount the muting lamp where it can be clearly seen!

The muting lamp must be clearly visible from all sides of the hazardous area and for the

WARNING

system operator.

4.2 Placement of muting sensors

Pay attention to the following notes on the placement of the muting sensors!

Always position the muting sensors such that only the material is detected and not the

WARNING

Fig. 15: Detection of material

during muting

means of transport (pallet or vehicle).

Always position the muting sensors such that material can pass unhindered, but people

are reliably detected.

Note

Fig. 16: Minimum distance,

material detection to the

ESPE on muting

Always position the muting sensors such that, on the detection of the material , a

minimum distance to the light beams on the ESPE is maintained.

The minimum distance provides the processing time necessary until muting is activated.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Subject to change without notice

Page 26

Chapter 4 Operating Instructions

Tab.6:

Conditions for muting

Detection zone

Background

Sensor

Material is

Material is not

ESPE

A1A2L3L2L

Hazardous area

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the minimum distance:

t

vL

res

t

d

+

+× 0.004

2

Where …

L = Minimum distance [m]

v = Velocity of the material (e.g. of the conveyor belt) [m/s]

t

= Input delay of the UE403 or the sens:Control device [s]

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

Use optical sensors with background suppression. These detect material only up to a

specific distance. Objects that are further away than the material to be detected are not

detected.

Fig. 17: Principle of operation

of sensors with background

suppression

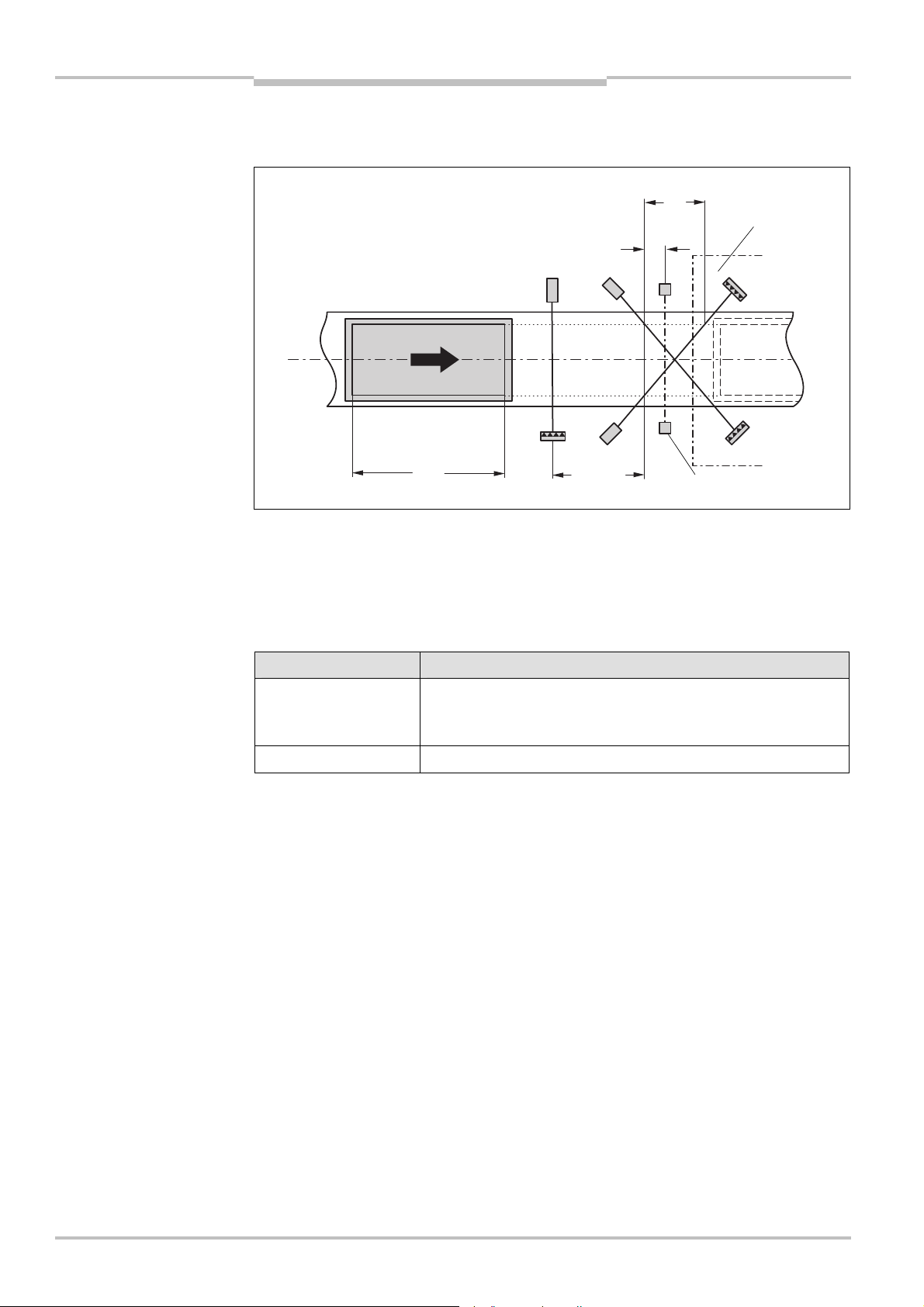

Fig. 18: Muting with two sensors, crossed placement

detected

detected

4.2.1 Muting with two sensors (one sensor pair), crossed placement

1

with two sensors, crossed

placement

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

In the example, the material moves from left to right or, alternatively, from right to left. As

soon as the muting sensors A1 and A2 are activated, the protection provided by the protective device (ESPE) is muted.

The following requirements must be met:

Condition Description

A1 & A2 Muting applies as long as this condition is met.

Subject to change without notice

Page 27

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

Notes

t

2

here …

= Minimum distance between the light beams on the ESPE and the detection by the

W

L

1

1

res

tvL

d

LLtv

+>×

++×

2

3

0.004

muting sensors [m]

v = Velocity of the material (e.g. of the conveyor belt) [m/s]

= Input delay of the UE403 or the sens:Control device [s]

t

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

es

r

(see section 13.1 “Data sheet” on page 115)

t = Total muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Distance between the two sensor detection lines (sensors activated/sensors clear)

L

2

[m]

= Length of the material on the conveyor [m]

L

3

The material can flow in both directions.

Place the cross-over point for the muting sensors exactly in the path of the ESPE’s

light beams. If this is not possible, place the cross-over point in the direction of the

hazardous area (see Fig. 14).

This placement is suitable for through-beam photoelectric switches and photoelectric

reflex switches.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50 ff.

– Concurrence monitoring, see page 51 ff.

– Monitoring of the total muting time, see page 51 ff.

– End of muting by ESPE, see page 53 ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

Page 28

Chapter 4 Operating Instructions

Tab.7:

Conditions for muting

C1

Hazardous

A1A2ESPE

L3L

L

L

M4000 Adv., Adv. A/P, Area

Muting

4.2.2 Muting with two sensors (one sensor pair), crossed placement, and an

dditional signal C1

a

Fig. 19: Muting with two sensors, crossed placement, and

an additional signal

4

2

area

1

The protection provided by the protective device is muted when the muting sensors are

activated in a defined sequence. The muting sensor (signal C1) must always be activated,

before both muting sensors in the first sensor pair (e.g. A1 and A2) are active (see section

“Additional signal C1” on page 49).

with two sensors and an additional signal

The following requirements must be met:

Condition Description

C1 & A1 & A2 Brief, to the start of the muting. C1 must always be activated,

before both muting sensors in the first sensor pair (e.g.

A1 and A2) are active.

A1 & A2 Muting applies as long as this condition is met.

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 29

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

t

LL

<

34

res

tvL

d1

LLtv

+>×

++×

2

32

0.004

Where …

= Minimum distance between the light beams on the ESPE and the detection by the

L

1

muting sensors [m]

v = Velocity of the material (e.g. of the conveyor belt) [m/s]

= Input delay of the UE403 or the sens:Control device [s]

t

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

t = Total muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Distance between the two sensor detection lines (sensors activated/sensors

L

2

clear) [m]

= Length of the material on the conveyor [m]

L

3

L

= Maximum distance between C1 and the detection line for A1, A2 [m]

4

Notes

The material can only flow in one direction.

This placement is suitable for through-beam photoelectric switches and photoelectric

reflex switches.

Avoid mutual interference between the sensors.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50 ff.

– Concurrence monitoring, see page 51 ff.

– Monitoring of the total muting time, see page 51 ff.

– End of muting by ESPE, see page 53 ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Subject to change without notice

Page 30

Chapter 4 Operating Instructions

Tab.8:

Conditions for muting

Hazardous area

A2A1ESPE

L1L

M4000 Adv., Adv. A/P, Area

Muting

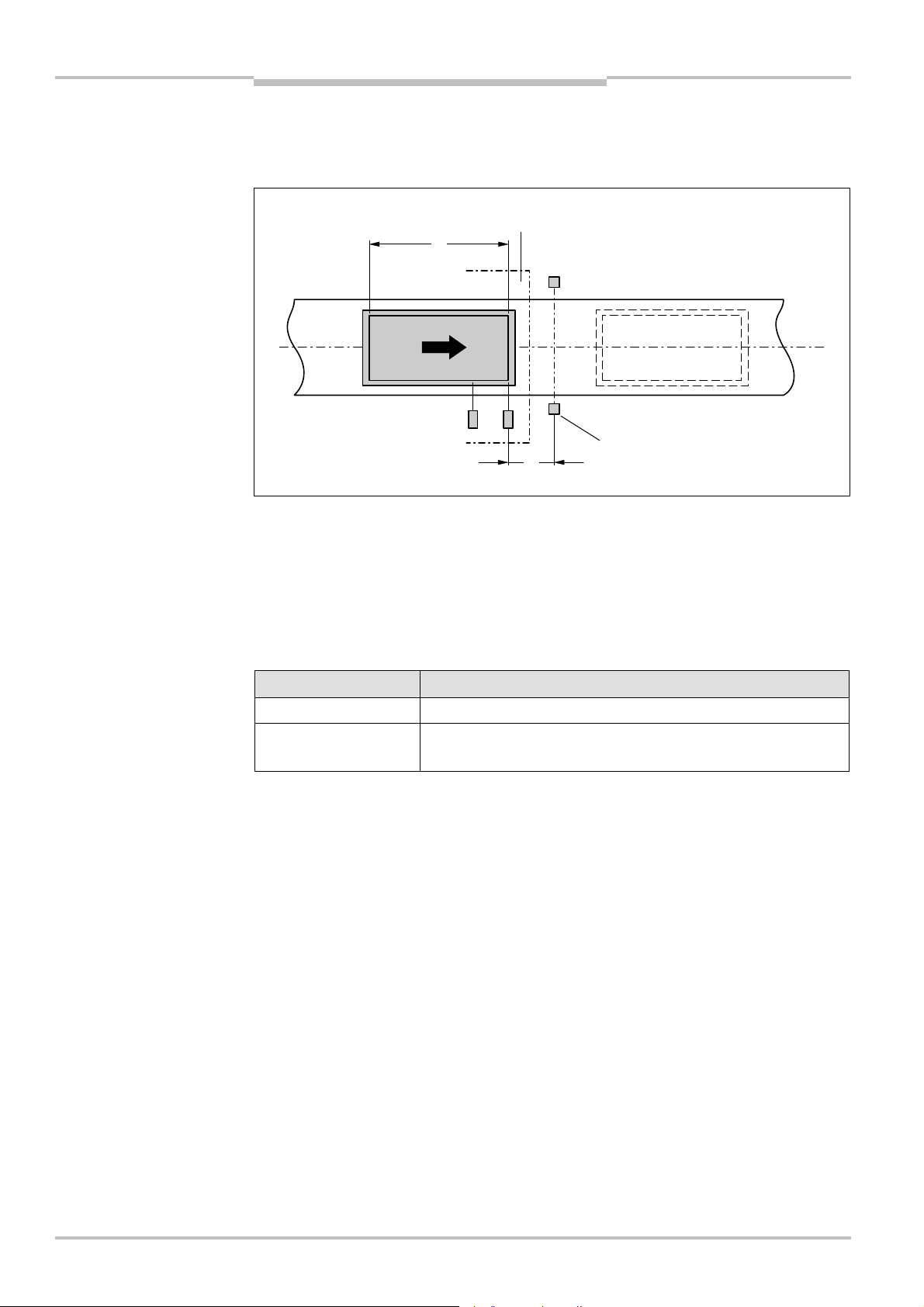

4.2.3 Muting using two sensors, serial placement (one sensor pair in the hazardous

rea), exit monitoring with End of muting by ESPE

a

Fig. 20: Muting with two

sensors, serial placement

Note

The Exit monitoring function is supported by M4000 systems with firmware V1.50.

2

In the case of the Exit monitoring function the muting sensors are at the side of the hazardous area. The material moves out of the hazardous area. As soon as all muting sensors

(A1 and A2) are actuated, the protection provided by the protective device (ESPE) is

bypassed and this situation remains in force until the configured muting hold time

(0.5 s … 4 s) has elapsed or the protective device becomes clear. The muting hold time

starts as soon as one of the muting sensors becomes clear.

with two sensors, serial

placement

The following requirements must be met:

Condition Description

A1 & A2 Muting starts as soon as this condition is met.

A1 & ESPE or

A2 & ESPE or ESPE

Muting applies as long as this condition is met. The muting

hold time counts down.

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 31

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

Notes

t

res

tvL

d1

LLtv

+>×

++×

2

21

0.004

Where …

L

< 200 mm; Minimum distance between the light beams on the ESPE and the

1

detection by the muting sensors [m]

v = Velocity of the material (e.g. of the conveyor) [m/s]

t

= Input delay of the UE403 or the sens:Control device [s]

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

t = Muting hold time set[s] (with End of muting by ESPE function activated) or total

muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Length of the material on the conveyor [m]

L

2

Only material flow out of the hazardous area is possible.

Position the two muting sensors at the side of the hazardous area.

This placement is suitable for through-beam photoelectric switches and photoelectric

reflex switches.

Avoid mutual interference between the sensors.

If you activate the Exit monitoring function, you must either activate the End of muting

by ESPE function or configure the Total muting time.

The functions Direction detection and Sequence monitoring can not be configured.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50ff.

– Concurrence monitoring, see page 51ff.

– Monitoring of the total muting time, see page 51ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Subject to change without notice

Page 32

Chapter 4 Operating Instructions

Tab.9:

Conditions for muting

Hazardous area

A2A1ESPE

L1L2C1

L

M4000 Adv., Adv. A/P, Area

Muting

4.2.4 Muting using two sensors, serial placement (one sensor pair in the hazardous

rea), with additional signal C1, exit monitoring with End of muting by ESPE

a

Note

Fig. 21: Muting with two

sensors, serial placement,

with additional signal C1

The Exit monitoring function is supported by M4000 systems with firmware V1.50.

3

In the case of the Exit monitoring function the muting sensors are at the side of the haz-

ardous area. The material moves out of the hazardous area. As soon as all muting sensors

(A1 and A2 and C1) are actuated, the protection provided by the protective device (ESPE)

is bypassed and this situation remains in force until the muting hold time configured

(0.5 s … 4 s) has elapsed or the protective device becomes clear. The muting hold time

starts as soon as one of the muting sensors becomes clear. The muting sensor (additional

signal C1) muss always be activated before the muting sensors A1 and A2 (see section

“Additional signal C1” on page 49).

with two sensors, serial

placement, with additional

signal C1

The following requirements must be met:

Condition Description

C1 & A1 & A2 Muting starts as soon as this condition is met. C1 must always

be activated before A1 and A2.

A1 & ESPE or

A2 & ESPE

Muting applies as long as this condition is met. The muting

hold time counts down.

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 33

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

Notes

t

1

LL

<

23

res

tvL

d1

LLtv

+>×

++×

2

2

0.004

Where …

< 200 mm; Minimum distance between the light beams on the ESPE and the

L

1

detection by the muting sensors [m]

v = Velocity of the material (e.g. of the conveyor) [m/s]

t

= Input delay of the UE403 or the sens:Control device [s]

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

t = Muting hold time set [s] (with End of muting by ESPE function activated) or total

muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Length of the material on the conveyor [m]

L

2

L

= Maximum distance between C1 and the detection line of the sensor which is closest

3

to the ESPE [m]

Only material flow out of the hazardous area is possible.

Position the two muting sensors at the side of the hazardous area.

This placement is suitable for through-beam photoelectric switches and photoelectric

reflex switches.

Avoid mutual interference between the sensors.

If you activate the Exit monitoring function, you must either activate the End of muting

by ESPE function of configure the Total muting time.

The functions Direction detection and Sequence monitoring can not be configured.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50ff.

– Concurrence monitoring, see page 51ff.

– Monitoring of the total muting time, see page 51ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Subject to change without notice

Page 34

Chapter 4 Operating Instructions

Tab.10:

Conditions for

ESPE

L2L1L3Hazardous area

A1A2B1

B2

M4000 Adv., Adv. A/P, Area

Muting

4.2.5 Muting with four sensors (two sensor pairs), serial placement

Fig. 22: Muting with two

serial sensor pairs

In the example, the material moves from left to right. As soon as the muting sensors

A1 & A2 are activated, the protection provided by the protective device (ESPE) is muted.

The protection remains muted until one of the sensors in the muting sensor pair B1 & B2

is clear again.

The following requirements must be met:

muting with four sensors,

serial placement

Condition Description

A1 & A2

(or B1 & B2)

Brief, to the start of the muting. The first sensor pair is acti-

vated as a function of the direction of transport of the material.

A1 & A2 & B1 & B2 Brief, for accepting the muting condition.

B1 & B2

(or A1 & A2)

Muting applies as long as this condition is met. The second

sensor pair is activated as a function of the direction of transport of the material.

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 35

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

t

LLtv

+>×

LL

<

32

res

t2vL

d1

31

++××

2

0.004

Where …

= Distance between the inner sensors (placement symmetrical in relation the ESPE’s

L

1

light beams) [m]

v = Velocity of the material (e.g. of the conveyor belt) [m/s]

= Input delay of the UE403 or the sens:Control device [s]

t

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

t = Total muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Distance between the outer sensors (placement symmetrical in relation the ESPE’s

L

2

light beams) [m]

= Length of the material on the conveyor [m]

L

3

Notes

The material can flow in both directions.

The direction can also be defined as fixed:

– Using the additional signal C1: The signal C1 must always be activated, before both

muting sensors in the first sensor pair (e.g. A1 and A2) are active (see section

“Additional signal C1” on page 49).

– Using the Direction detection function that can be configured in software (page 55ff.).

All types of sensor can be used in this placement.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50 ff.

– Concurrence monitoring, see page 51 ff.

– Monitoring of the total muting time, see page 51 ff.

– End of muting by ESPE, see page 53 ff.

– Sequence monitoring, see page 55 ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 35

Subject to change without notice

Page 36

Chapter 4 Operating Instructions

Tab.11:

Conditions for

A1

ESPEL

L

A2

Hazardous area

B1

B2

M4000 Adv., Adv. A/P, Area

Muting

4.2.6 Muting with four sensors (two sensor pairs), parallel placement

Fig. 23: Muting with two

parallel sensor pairs

muting with four sensors,

parallel placement

1

3

In the example, the material moves from left to right. As soon as the first muting sensor

pair A1 & A2 is activated, the protection provided by the protective device (ESPE) is muted.

The protection remains muted until the muting sensor pair B1 & B2 is clear again.

The following requirements must be met:

Condition Description

A1 & A2

(or B1 & B2)

Brief, to the start of the muting. The first sensor pair is acti-

vated as a function of the direction of transport of the material.

A1 & A2 & B1 & B2 Brief, for accepting the muting condition.

B1 & B2

(or A1 & A2)

Muting applies as long as this condition is met. The second

sensor pair is activated as a function of the direction of transport of the material.

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010797/YT72/2016-02-19

Subject to change without notice

Page 37

Operating Instructions Chapter 4

M4000 Adv., Adv. A/P, Area

Muting

How to calculate the distance:

t

LLtv

+>×

LL

<

31

res

t2vL

d1

31

++××

2

0.004

Where …

= Distance between the inner sensors (Placement symmetrical to the light path

L

1

between sender and receiver) [m]

v = Velocity of the material (e.g. of the conveyor belt) [m/s]

= Input delay of the UE403 or the sens:Control device [s]

t

d

(see the operating instructions of the UE403 or sens:Control device)

= Response time of the M4000 [s]

t

res

(see section 13.1 “Data sheet” on page 115)

t = Total muting time set [s]

(see section 6.3.2 “Monitoring of the total muting time” on page 51)

= Length of the material on the conveyor [m]

L

3

Notes

The material can flow in both directions.

With the parallel placement, the width of the object allowed is also checked due to the

position of the muting sensors. The objects must always fit in an identical width to suit

the muting sensors.

The direction can also be defined as fixed:

– Using the additional signal C1: The signal C1 must always be activated, before both

muting sensors in the first sensor pair (e.g. A1 and A2) are active (see section

“Additional signal C1” on page 49).

– Using the Direction detection function that can be configured in software (page 55ff.).

In this placement, optical proximity sensors and all types on non-optical sensors can be

used. Use sensors and proximity sensors with background suppression.

Avoid mutual interference between the sensors.

You can usefully increase the protection against manipulation and safety using the

following configurable functions:

– Sensor test, see page 50 ff.

– Concurrence monitoring, see page 51 ff.

– Monitoring of the total muting time, see page 51 ff.

– End of muting by ESPE, see page 53 ff.

8010797/YT72/2016-02-19 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 37

Subject to change without notice

Page 38

Chapter 5 Operating Instructions

The person who makes the change is also responsible for the correct protective function of

M4000 Adv., Adv. A/P, Area

Configurable functions

5 Configurable functions

his chapter describes the functions on the M4000 multiple light beam safety device that

T

can be set via software. Some of the functions can be combined.

Test the protective device after any changes!