Page 1

T E C H N I C A L I N F O R M A T I O N

LiDAR Localization Hardware Integration

LiDAR localization

Page 2

Described product

L

iDAR Localization Hardware Integration

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 4

1.1 Purpose of this document........................................................................ 4

1.2 Scope......................................................................................................... 4

1.3 Target groups............................................................................................ 4

1.4 Symbols and document conventions...................................................... 4

2 Safety information............................................................................ 5

2.1 General safety notes................................................................................ 5

3 Supported hardware......................................................................... 6

3.1 2D LiDAR sensors..................................................................................... 6

3.2 Localization controllers............................................................................ 6

4 Device overview................................................................................. 8

4.1 Device overview microScan3................................................................... 8

4.2 Device overview SIM1000 FXA................................................................ 9

5 Electrical installation........................................................................ 10

5.1 Important notes........................................................................................ 10

5.2 MicroScan3............................................................................................... 10

5.2.1 Electrical setup........................................................................ 10

5.3 SIM1000 FXA............................................................................................ 11

5.3.1 Preparations and overview...................................................... 12

5.3.2 Pin allocations of the connections......................................... 12

5.3.3 Network setup.......................................................................... 13

6 MicroScan3 configuration of the data output............................... 17

6.1 Important notes........................................................................................ 17

6.2 Overview.................................................................................................... 17

6.3 Activating and configuring data output................................................... 17

6.4 Single receiver of measurement data..................................................... 18

6.4.1 Configuring with the Safety Designer..................................... 18

6.5 Multiple receivers of measurement data via broadcast........................ 19

7 Operation............................................................................................ 21

7.1 Status LEDs SIM1000 FXA...................................................................... 21

8 List of figures..................................................................................... 23

9 List of tables....................................................................................... 24

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

3

Page 4

1 A

BOUT THIS DOCUMENT

1 About this document

1.1 Purpose of this document

This additional technical note describes the hardware integration and how to enable the

asurement data of the 2D LiDAR sensor.

me

The full operating instructions of the used 2D LiDAR sensor must be made available to

all people who work with the device.

1.2 Scope

This document is included with the following SICK part numbers (this document in all

a

vailable language versions):

8024819

•

1.3 Target groups

This document is written for system specialists working in the field of hardware development int

ending to integrate the LiDAR localization system in their application.

1.4 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indic

ates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

ates a situation presenting possible danger, which may lead to moderate or minor

Indic

injuries if not prevented.

NOTICE

Indic

ates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

he arrow denotes instructions to action.

T

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

4

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 5

2 Safety information

2.1 General safety notes

DANGER

D

anger of using data output for safety function

Data output may only be used for general monitoring and control tasks.

Do not use data output for safety-related applications.

b

DANGER

Danger of using CoLa2 for safety function

CoLa2 may only be used for general monitoring and control tasks.

Do not use CoLa2 for safety-related applications.

b

SAFETY INFORMATION 2

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

5

Page 6

3 SUP

PORTED HARDWARE

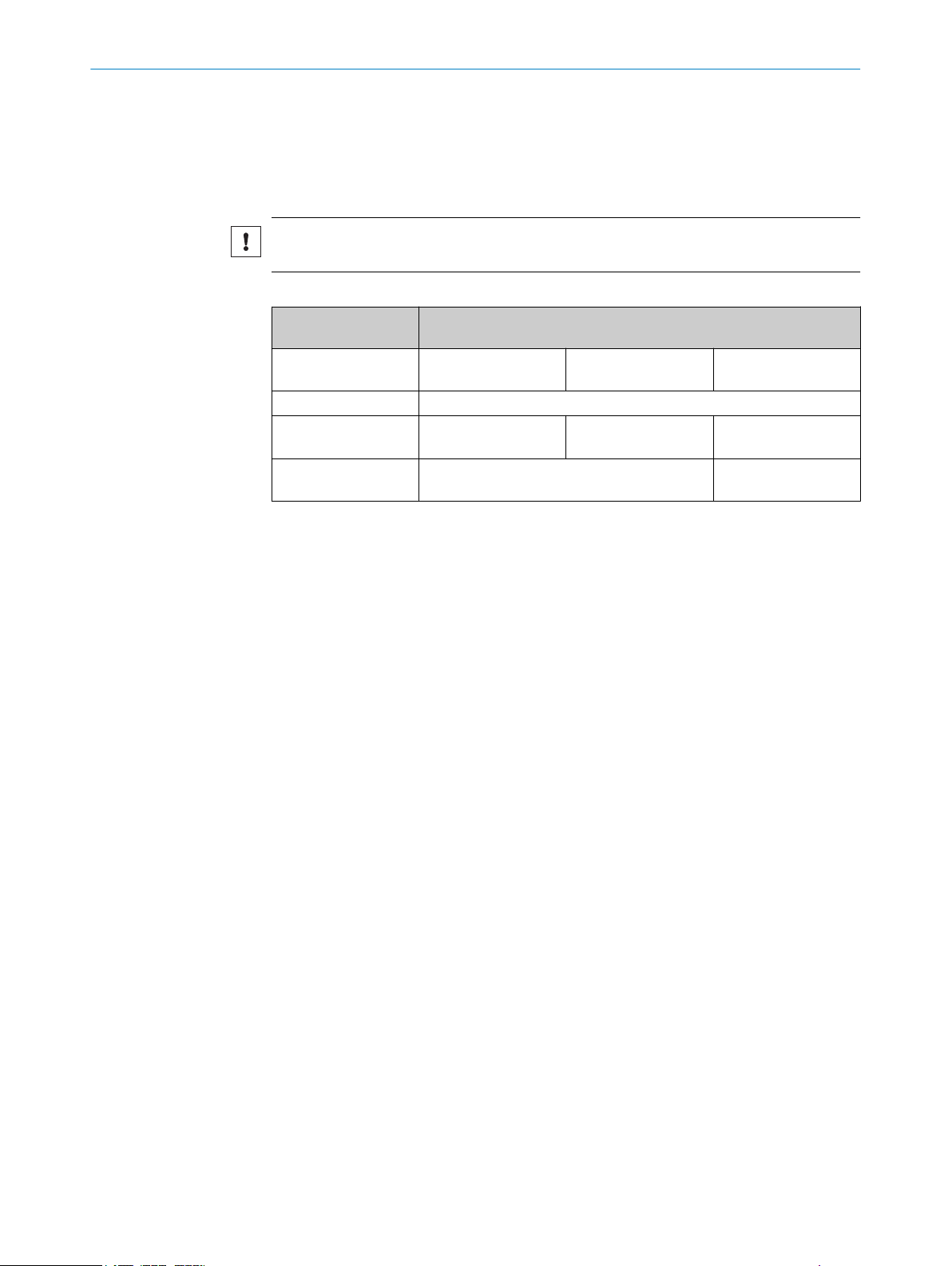

3 Supported hardware

3.1 2D LiDAR sensors

LiDAR-LOC is qualified for the SICK sensor family microScan3.

NOTICE

SIC

K does not guarantee that the system functions with other sensors.

Table 1: Supported sensor data

Supported sensor

ata

d

Supported device (pro‐

tective field range)

Aperture angle 275°

Distance range 1.8 %: 4 m

Scan cycle time 30 ms

2D LiDAR sensor

microScan3

4.0 m

100 %: 40 m

40 ms

microScan3

5.5 m

1.8 %: 5.5 m

100 %: 40 m

microScan3

9.0 m

1.8 %: 9 m

100 %: 64 m

40 ms

50 ms

For additional information, consult the operation instructions of the corresponding sen‐

.

sor

For high quality of the localization, we recommend to consider the following information

about the sensors.

microScan3

Protective field range 9 m (64 m warning field range)

•

The sensors with 64 m measurement range are preferred over the ones with 40 m

me

asurement range. They can be used in both configurations, 50 ms and 40 ms

scan cycle time. Smaller scan cycle times allow potentially higher velocities, how‐

ever, are primarily dependent on your risk assessment.

Pr

otective field range 4 m and 5.5 m (40 m warning field range)

•

When using the sensors with 40 m measurement range, they can be used in both

igurations, 40 ms and 30 ms scan cycle time, with corresponding 0.39° and

conf

0.51° resolution. A smaller scan cycle time allows potentially higher velocities. A

higher resolution allows the detection of smaller objects. However, the configura‐

tion is primarily dependent on your risk assessment.

Complementary information

ou can find additional information of the microScan3 in the operating instructions:

Y

8020198 microScan3 EtherNet/IP

•

8021217 microScan3 PROFINET

•

8021911 microScan3 EFI-pro

•

TM

3.2 Localization controllers

Localization controllers

iDAR-LOC uses the SIM1000-FXA. For quick integration, some information is provided

L

in this document.

6

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 7

SUPPORTED HARDWARE 3

NOTICE

y default, the localization controller is a programmable device. When using the local‐

B

ization controller with the application software LiDAR-LOC, the controller is converted

into an application device. This means that the device cannot be programmed any

longer; it is locked for any additional application and cannot be unlocked.

Complementary information

Y

ou can find additional information of the localization controller in the operating instruc‐

tions 8023299.

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

7

Page 8

4 DEVICE OVERVIEW

4 Device overview

4.1 Device overview microScan3

Figure 1: microScan3 – overview

Optics cover

1

Display

2

Keypad

3

USB port

4

Status LEDs

5

Additional LEDs for ON state and OFF state

6

Network LEDs

7

Safety laser scanner without system plug

8

System plug

9

Cover plate

ß

8

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 9

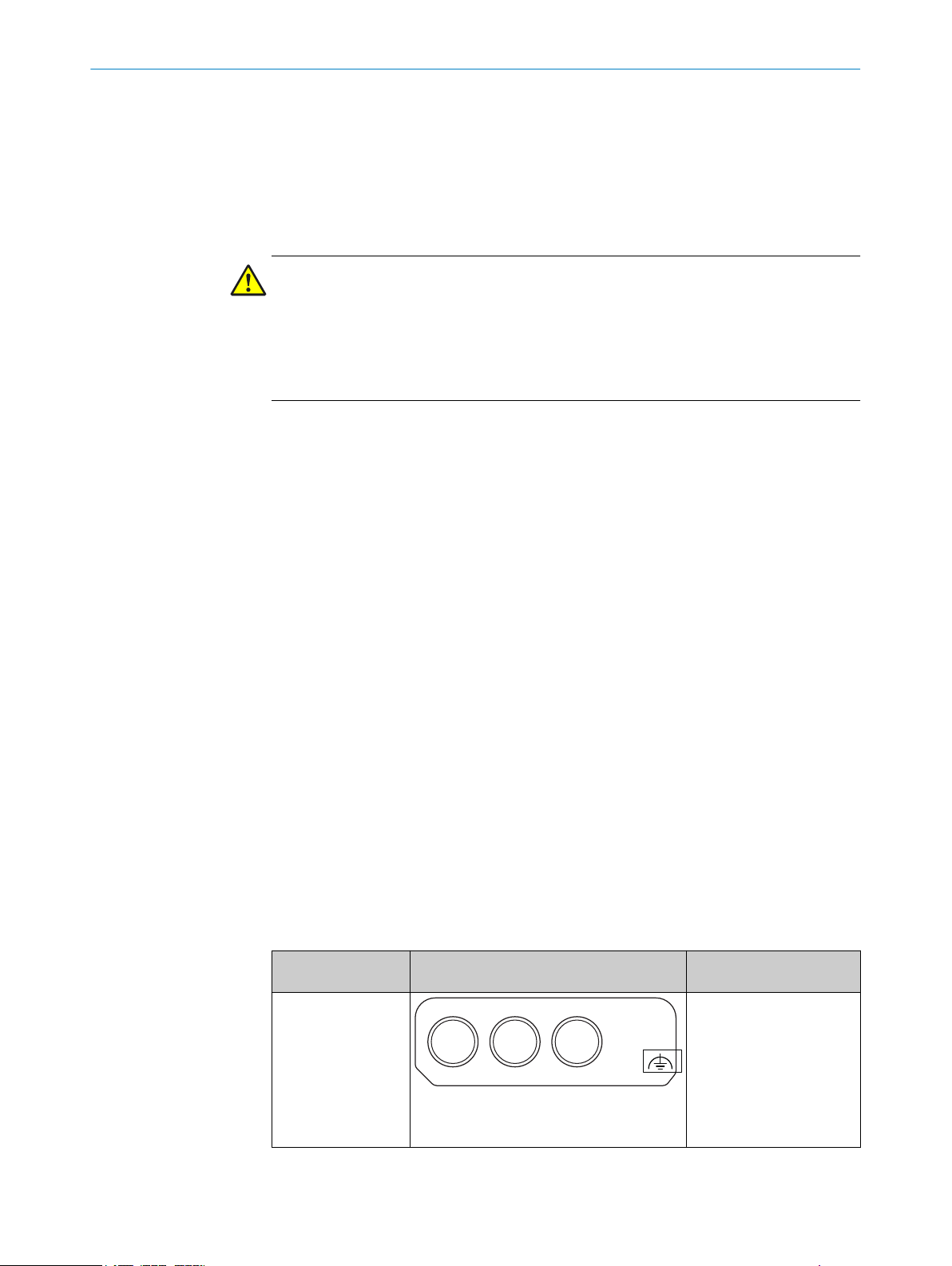

4.2 Device overview SIM1000 FXA

Figure 2: SIM1000 FXA – overview

Connections for switching input/output, IO-Link, CAN, and voltage supply

1

Serial connections

2

Ethernet connections

3

DEVICE OVERVIEW 4

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

9

Page 10

XD1 XF1 XF2

5 ELECTRICAL INSTALLATION

5 Electrical installation

5.1 Important notes

Information on the requirements that must be met for safe integration of the localiza‐

ion controller and 2D LiDAR sensors into the control and electronics of the machine,

t

see the corresponding operating instructions.

DANGER

H

azard due to electrical voltage

Hazard due to unexpected starting of the machine

Make sure that the machine is (and remains) disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is (and remains) switched off.

b

arry out the electrical installation work in conformity with EN 60204-1.

C

b

Use suitable power supply.

b

Check that all earthing points are connected with the same ground potential.

b

Connect the shielding of all data lines (Ethernet, CAN, serial) directly to the func‐

b

tional earth (FE) at the control cabinet entry point.

5.2 MicroScan3

The electrical installation is described in detail in the operating instructions:

The examples are given for microScan3 EFI-pro variant but are also applicable for Ether‐

Net/IP™ and PROFINET.

5.2.1 Electrical setup

Supply voltage and power consumption

Suppl

The microScan3 consumes the following:

System plug and connections

T

8021911

•

y voltage:

24 V DC (16.8 … 30 V DC) (SELV/PELV) according to IEC 60364441

•

Must be able to bridge a brief power outage of 20 ms with a starting voltage of

•

≤ 3 A

Power consumption ≤ 11 W (typ. 7.2 W)

•

Power consumption Standby typical 7 W

•

able 2: Position of the electrical connections

Safety laser scan‐

s

ner

microScan3 – Ether‐

Net/IP™

Suitable system plug Plug connector

XD1: voltage supply,

•

XF1, XF2: 2 × Ethernet

•

for EtherNet/IP –

CIP Safety, data output,

configuration, and diag‐

nostics.

MICSX-BANNZZZZ1 (part number:

2086102)

10

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 11

12

3 4

43

2 1

ELECTRICAL INSTALLATION 5

Voltage supply (XD1)

V

oltage supply is supplied via a 4-pin, A-coding M12 male connector on the device side.

Figure 3: Pin assignment of the voltage supply (male connector, M12, 4-pin, A-coded)

Table 3: Pin assignment of the voltage supply

Pin Marking Function Wire color

1 +24 V DC 24 V DC supply voltage Brown

2 NC Not connected White

3 0 V DC 0 V DC supply voltage Blue

4 FE Functional earth/shield Black

1)

Applies to the connecting cables recommended as accessories.

Ethernet for EFI-pro, data output, configuration, and diagnostics (XF1, XF2)

1)

On t

connectors. There is a network switch in the safety laser scanner which connects the

two Ethernet female connectors. The two Ethernet female connectors therefore have

the same function. The pin assignment corresponds to EN 61918, Appendix H.

Figure 4: Ethernet pin assignment (female connector, M12, 4-pin, D-coding)

Table 4: Ethernet pin assignment

Pin Designation Function

1 TX+ Send data +

2 RX+ Receive data +

3 TX– Send data -

4 RX– Receive data -

Housing SH Shielding

5.3 SIM1000 FXA

The electrical installation is described in detail in the operating instructions:

he device side, Ethernet and EFI-pro are connected via 4-pin, D-coding M12 female

8023298

•

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

11

Page 12

5 ELE

CTRICAL INSTALLATION

5.3.1 Preparations and overview

Preparing the electrical installation

T

o carry out the electrical installation, you will need:

Connection cables for the peripheral devices, including the corresponding data

•

sheets

Voltage supply cable

•

If customers assemble the cables: crimping tool, ferrules, soldering iron, and other

•

installation material

Overview of connections

Terminal block 1 and 2

1

Terminal block 3 and 4

2

Ethernet connections

3

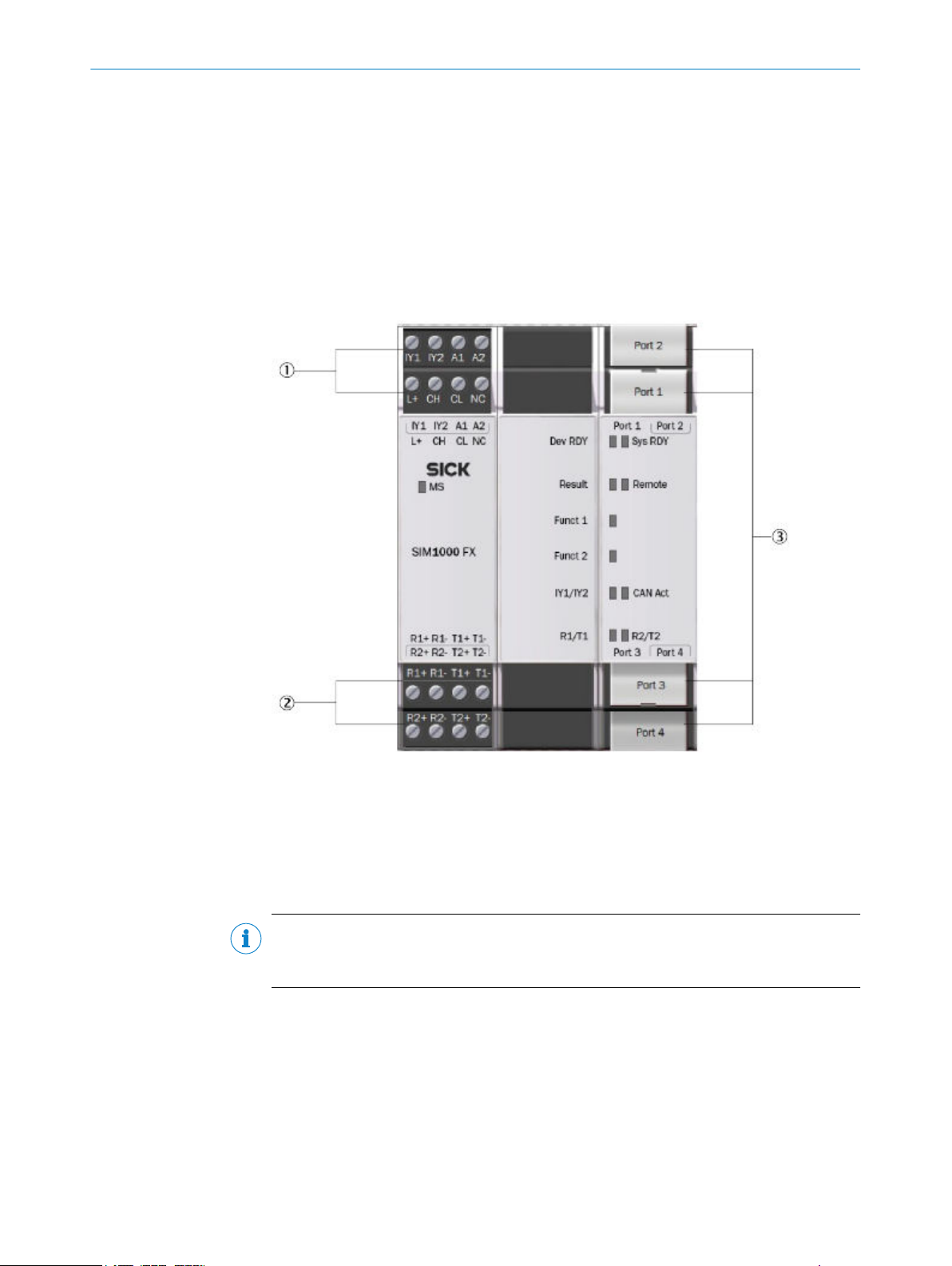

5.3.2 Pin allocations of the connections

Important information

NOTE

he SIM1000 FXA device is supplied with power from an external power supply unit via

T

the pins A1 and A2.

Pin allocations of the connections

Onl

y the pins for supply voltage, ground, and input/outputs are used in the LiDAR local‐

ization applica-tion.

For the power supply of the SIM1000 FXA, connect the open ends of the power supply

cable to the pins of the terminal block 1.

When using the CoLa-A synchronization methods, connect the I/O port of the vehicle

controller with IY2 of the terminal block 2 of the SIM1000 FXA.

12

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 13

ELECTRICAL INSTALLATION 5

Figure 5: Terminal block 1 and 2

T

able 5: Pin allocations of the connections

Designation Signal Function

IY2 Output 1 Synchronization I/O when using command L

stamp

A1 +24 V Supply voltage IN

A2 GND Ground

Switching output

x. output current: 100 mA

Ma

•

Min. high output logic level: VCC – 3 V

•

Max. low output logic level: 3 V

•

Push/Pull, NPN, PNP configurable

•

ocRequestTime‐

5.3.3 Network setup

5.3.3.1 Preset Ethernet interfaces

NOTE

eset IP addresses of the Ethernet interfaces:

Pr

Port 1: 192.168.0.1 (e.g. connection to the service computer)

•

Port 2: 192.168.1.1 (e.g. connection to the 2D LiDAR sensor)

•

Port 3: 192.168.2.1 (e.g. connection to the vehicle controller)

•

Port 4: 192.168.3.1

•

When expanding the GigE interfaces with one or more Ethernet switches, it is essential

t

o use only jumbo-frame compatible GigE switches. Switches limited to just 100 MB do

not support the data packet mode used by cameras and can cause transmission

errors.

Changing the IP addresses

The individual IP addresses can be changed using the SICK SOPAS ET PC tool. This is

described in detail in the “SIM Getting Started Guide”, which is available for download

from the SICK AppSpace area of the SICK Support Portal. This guide also includes fur‐

ther notes on how to connect SICK sensors and the SICK picoCam and midiCam cam‐

eras to the Ethernet interfaces.

5.3.3.2 Ethernet connections

Important information

NOTICE

S

hielded Ethernet cables must be used. The shielding of the Ethernet cables must be

connected to functional earth.

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

13

Page 14

5 ELE

CTRICAL INSTALLATION

Ethernet connections

Figure 6: Ethernet connections

P

ort 1: 100 MBit/s

Port 2: 1 GBit/s

Port 3: 100 MBit/s

Port 4: 1 GBit/s

5.3.3.3 Connecting peripheral devices

The device can be connected to a wide range of sensors and cameras.

T

he required pin assignments can be found in the data sheets for the peripherals to be

connected as well as in the relevant connection descriptions.

Connect the cables to peripheral devices.

•

Route the cables to the device using installation materials (cable channels, cable

•

ties, etc.). When doing so, pay attention to cable strain relief.

Connect cables to the relevant device connections and screw together tightly.

•

Further topics

in allocations of the connections", page 12

"P

•

14

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 15

5.3.3.4 Example connections

Figure 7: Example of a connection with SIM1000 FXA, a service computer (PC), and one 2D

iDAR sensor

L

ELECTRICAL INSTALLATION 5

Figure 8: Example of a connection with SIM1000 FXA, a service computer (PC), a switch, a SICK

afety controller, and two 2D LiDAR sensors

s

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

15

Page 16

5 ELE

CTRICAL INSTALLATION

Figure 9: Example of a connection with SIM1000 FXA, a service computer (PC), a SICK safety

ontroller, and two 2D LiDAR sensors

c

16

Figure 10: Example of a connection with a SIM1000 FXA, a service computer (PC), a SICK safety

ontroller, two 2D LiDAR sensors, and measurement data to the vehicle controller

c

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 17

MICROSCAN3 CONFIGURATION OF THE DATA OUTPUT 6

6 MicroScan3 configuration of the data output

6.1 Important notes

Using the safe 2D LiDAR sensor does require the safety-related functions of the sensor

o be fully configured. The configuration needs to be valid and verified and the sensor

t

must not be in error mode.

When using PROFINET scanners, the inputs have to be configured in the same way as

the scanner is integrated. E.g. if there is an input signal configured, the input source

has to be electrically applied.

6.2 Overview

For more information on the microScan3’s data output via UDP and TCP/IP, refer to the

doc

ument with the following SICK part numbers:

8022706

•

DANGER

Danger of using data output for safety function

Data output may only be used for general monitoring and control tasks.

Do not use data output for safety-related applications.

b

Data output allows for the output of measurement data and other data via the Ethernet

erface. Other network participants, the receivers, can call up and use the data.

int

The data output works in different send modes:

On request: Data is output when there is an explicit request from a host computer

•

via TCP/IP using CoLa2

Continuous and on request: Data is output continuously via UDP to a defined target

•

address and also when there is an explicit request from a host computer via

TCP/IP using CoLa2

6.3 Activating and configuring data output

You can activate and configure the data output in two ways:

ith the Safety Designer

W

•

Via the CoLa2 protocol

•

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

17

Page 18

6 MICR

OSCAN3 CONFIGURATION OF THE DATA OUTPUT

6.4 Single receiver of measurement data

6.4.1 Configuring with the Safety Designer

Overview

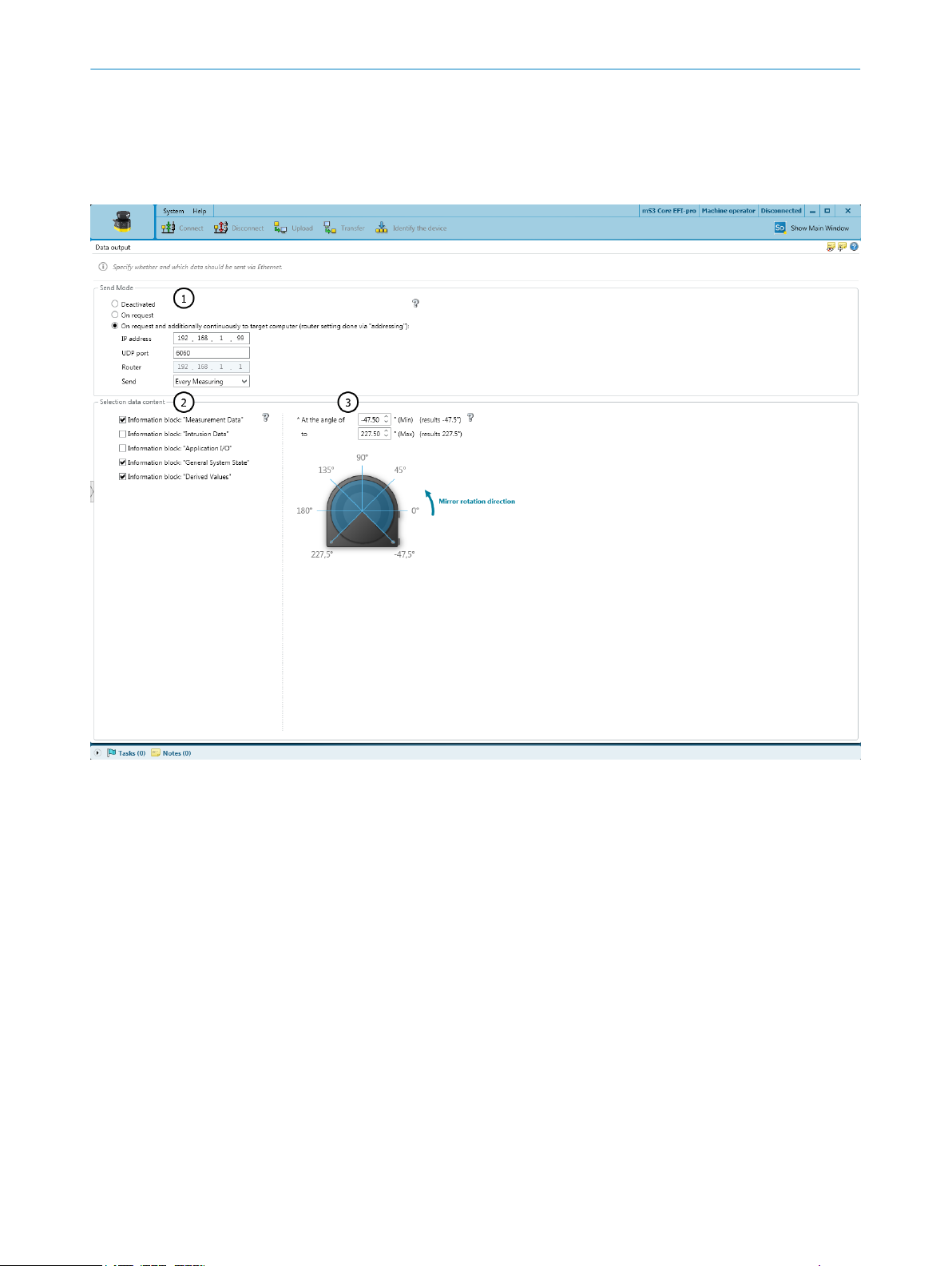

Figure 11: Data output

Send mode

1

Data content

2

Angular range

3

18

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Using Safety Designer, you can configure the safety laser scanner and the data output.

A c

onfiguration that is created with the Safety Designer is saved in the device and is

also active after restarting the device.

Send mode

Deactivated: Data output is deactivated

•

On request: Data is output when there is an explicit request from a host computer

•

via TCP/IP using CoLa2

Continuous and on request: Data is output continuously via UDP to a defined target

•

address and also when there is an explicit request from a host computer via

TCP/IP using CoLa2

Data content

Measurement data: Distance data with reflector detection and RSSI

•

Field interruption: Data on the light beams in interrupted fields of the active monitor‐

•

ing case

Subject to change without notice

Page 19

MICROSCAN3 CONFIGURATION OF THE DATA OUTPUT 6

ation data: Status of inputs and outputs that are used in the monitoring case

Applic

•

table

Device status: Information on the status of the safety laser scanner (e.g., cut-off

•

paths, errors)

Configuration of data output: Information on the angular range actually being used

•

(for technical reasons, data from a slightly larger angular range than the one set

may be output in some cases)

Angular range

You can define the range within which measurement data and data relating to field

interruptions is output.

6.5 Multiple receivers of measurement data via broadcast

Overview

If y

ou want to transmit measurement data from the safety laser scanner to multiple

clients, you must use broadcasting.

For the default Ethernet configuration of the SIM, the port 2 is:

IP: 192.168.1.1

•

Subnet mask: 255.255.255.0

•

The broadcast IP address for this subnet (derived from IP of the SIM) is:

192.168.1.255

•

Important information

NOTE

W

hen using multiple LiDARs, a different receiver port for each sensor must be config-

ured (UDP port). For example:

UDP port Safety Scanner 1: 6060

•

UDP port Safety Scanner 2: 6061

•

If multiple sensors use the same receiver port, the scans may interfere with each other.

This may cause a fault in LiDAR-LOC or any customer application. Setting a receiver port

number in the range between 51000 and 51100 may cause interference with other

sensor configurations and should be avoided.

NOTE

hen localizing, please close the SICK Safety Designer. The CoLa-A communication of

W

the SICK Safety Designer interferes with the CoLa-A communication of LiDAR-LOC.

Approach

1.

In the Safety Designer, open Configuration → Addressing.

2. In the section IP address, configure the Ethernet interface IP of the microScan3 to

an unused IP address in the subnet, e.g. 192.168.1.2.

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

19

Page 20

6 MICROSCAN3 CONFIGURATION OF THE DATA OUTPUT

Figure 12: Setting the IP address with the SICK Safety Designer

3. In D

ata output, choose On request and additionally continuously.

4. In section Send Mode, enter the IP address of the target computer to the broadcast

UDP address, e.g. 192.168.1.255.

5. Enter the UDP port, for example, 6060.

6. In Send, select Every Measuring.

7. In section Selection data content, select the information blocks Measurement Data and

Derived Values.

20

Figure 13: Configuring the data output with the SICK Safety Designer

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 21

7 Operation

7.1 Status LEDs SIM1000 FXA

Status LEDs SIM1000 FXA

hen the device is operating, the operational status of the connections is indicated

W

visually by status LEDs.

Using these status indicators, the operator can find out quickly and easily whether the

device and the peripherals are working properly or whether any faults or errors have

occurred.

Monitoring the visual indicators is part of the routine inspection carried out on the

device and the machine/plant area into which the device is incorporated.

Table 6: Meaning of symbolse

Symbol Meaning

OPERATION 7

LED off

LED on

LED flashes

LED goes out briefly

LED lights up briefly

Situation and function of the LEDs

T

able 7: Situation and function of the LEDs

Designation LED behavior Description

2)

MS

Dev RDY Runlevel READY, no errors detected.

Voltage connected.

Runlevel READY, boot process error.

1)

Sys RDY Application software LiDAR-LOC is booting

Application software LiDAR-LOC is ready

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

21

Page 22

7 OPERATION

Designation LED behavior Description

Result Localization is disabled/not running

Localization is running and application results

ar

e available

Funct 1

Sensor is not configured or cannot be con‐

ted to

nec

All active sensors are OK and are providing

ata

d

One of the active sensors is not supported, or

there is an error in the configuration, or the

sensor was unplugged during operation

Funct 2 Reserved

IY1 / IY2 Voltage not applied to the connection.

Voltage applied. No signal activity.

Voltage applied. Signal activity.

Voltage not applied to the connection. Signal

tivity.

ac

22

Link

Connection not established with Ethernet.

Connection established with Ethernet.

Act No activity.

Data transmission via Ethernet.

1)

Time delay before availability due to boot process (approx. 20 s)

2)

Module status

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 23

8 List of figures

1. microScan3 – overview................................................................................................ 8

2. SIM1000 FXA – overview............................................................................................. 9

3. Pin assignment of the voltage supply (male connector, M12, 4-pin, A-coded)...... 11

4. Ethernet pin assignment (female connector, M12, 4-pin, D-coding)...................... 11

5. Terminal block 1 and 2...............................................................................................13

6. Ethernet connections................................................................................................. 14

7. Example of a connection with SIM1000 FXA, a service computer (PC), and one 2D

8. Example of a connection with SIM1000 FXA, a service computer (PC), a switch, a

9. Example of a connection with SIM1000 FXA, a service computer (PC), a SICK

10. Example of a connection with a SIM1000 FXA, a service computer (PC), a SICK

11. Data output.................................................................................................................18

12. Setting the IP address with the SICK Safety Designer............................................. 20

13. Configuring the data output with the SICK Safety Designer....................................20

LIST OF FIGURES 8

iDAR sensor...............................................................................................................15

L

SICK safety controller, and two 2D LiDAR sensors...................................................15

safety controller, and two 2D LiDAR sensors............................................................16

safety controller, two 2D LiDAR sensors, and measurement data to the vehicle

controller..................................................................................................................... 16

8024819/2019-09-02 | SICK T E CH N IC A L I NF O RM A TI O N | LiDAR Localization Hardware Integration

Subject to change without notice

23

Page 24

9 LIST OF TABLES

9 List of tables

1. Supported sensor data................................................................................................. 6

2. Position of the electrical connections....................................................................... 10

3. Pin assignment of the voltage supply........................................................................11

4. Ethernet pin assignment............................................................................................11

5. Pin allocations of the connections............................................................................ 13

6. Meaning of symbolse................................................................................................. 21

7. Situation and function of the LEDs............................................................................21

24

T EC H NI C AL IN F OR M AT I ON | LiDAR Localization Hardware Integration 8024819/2019-09-02 | SICK

Subject to change without notice

Page 25

Detailed addresses and further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 234 719 500

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 010

E-Mail info@sick.de

Greece

Phone +30 210 6825100

E-Mail office@sick.com.gr

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 97110 11

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mexico@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 10 060 0550

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail infokorea@sick.com

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail contact@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

8024819/2019-09-02/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...