Page 1

en

Lector®632

Image-based code readers

QUICKSTART

Mount

Assemble the optical kit on the Lector63x. For details

see section C at the end of this quickstart.

NOTICE

SOPAS ET main window

The SOPAS ET main window is split into two panes,

the project view to the left and a list of connected devices to the right. To add the Lector63x to the project,

drag the device to the left project pane.

Additional expandable panels are available to the left

of and below the image area.

Use only Lector63x optics to ensure optimal image

quality and to avoid damage to the device.

Mount the device at a suitable working distance from

the object, for example using a mounting bracket

(angled bracket part no. 2076735, cooling bracket

2078970, or bracket kit 2076735). For information

about suitable working distances, see section E.

1. Filmstrip

2. Information area

Double-click the product icon to open the device

window and start the conguration.

If there are IP address connection issues, click the

Fig. 1: Mounting

Mount the Lector63x with a 10 to 20 degree tilt to

avoid reections.

Connect

To connect the Lector63x:

Product information

The Lector63x is an industrial image-based code

reader family for all common 1D (bar codes / stacked

codes) and 2D (matrix) codes. The result is sent to the

control system via digital output or its host interfaces:

Serial, CAN or Ethernet.

The Lector63x Flex variants feature exchangeable S-

or C-mount optics, internal lighting and lter options

to meet a wide range of application requirements.

About this document

This quickstart contains instructions that support

the set up and operation of the Lector63x Flex. Make

sure that the installation is performed by a qualied

technician.

This quickstart as well as the Lector63x operating

instructions, containing additional information, are

available in English and German online. To download:

www.SICK.com > type a document number in the

number eld: quickstart EN/DE, 8018061/8018060,

operating instructions EN/DE, 8018071/8018070.

8018061/2015-04-13• Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 1Lector®632 | SIcK

Part

1. Connect the Gigabit Ethernet to a network or

directly to a PC.

2. Connect the power I/O to a 24 V power source.

WARNING

Ensure that the ground potential is the same at all

grounding points. Incorrect grounding or connection

can damage the device and cause re.

Ensure that any loose cable ends are isolated. Do

not connect external I/O signals to the Lector63x

while it is powered.

Congure with PC

The SOPAS Engineering Tool (ET) software for PC is

used to connect and congure the Lector63x and

other SICK devices.

To install SOPAS ET:

1. Download SOPAS ET (version 3.0.1 or newer)

from www.mysick,com/en/SOPAS_ET.

2. Run the downloaded installation le.

3. Follow the instructions on the screen.

text next to the warning symbol in the project pane to

make adjustments.

If the device driver is missing, click the text next to

the warning symbol in the project pane and follow the

instructions. The device will be in ofine mode after

installing the driver. Put the device in online mode by

clicking the

Offline button next to the product icon.

SOPAS ET device window

The Lector63x is congured in the SOPAS ET device

window. The code in the image below can be used to

test your device.

1. SOPAS functions

2. Image handling controls

3. Device controls

4. Parameter pane with workow

5. Image area

Device controls

The device controls are used to change between

image acquisition modes and to activate related

functions.

Button Mode Description

Stop Stops image acquisition.Exter-

Live Activates live image acquisi-

Operation Activates image acquisition

Button Function Description

Manual

trigger

Start trigger Start image series

Stop trigger Stop image series

Record Records images to a folder on

Settings Recording settings.

nal interfaces including inputs

are disabled. The device does

not receive triggers.

tion. External interfaces are

disabled.

as congured in the triggering

settings. External interfaces are

enabled.

Trigger a single image

(single image mode).

(image series mode).

(image series mode).

the PC.

Page 2

Image handling controls

The image handling controls are used to change how

images are viewed.

Button Function Description

Select Click and drag to change region

Move Click and drag to move the image.

Zoom Click and drag upwards to zoom in

Home Click to t image area to view.

size and position.

and downwards to zoom out.

Filmstrip

The expandable lmstrip area shows the image history as thumbnails. When the image acquisition is

stopped it is possible to click a thumbnail to see it

enlarged.

Information area

The expandable information area contains the Device

infO, lOgs and system status tabs.

Device infO tab displays device-related information

The

such as IP address and serial number.

lOgs tab contains controls to retrieve logged

The

images.

system status tab shows system warnings and

The

errors.

Workow

Follow the workow in the parameter panel to congure the Lector63x. While the steps are arranged in the

typical conguration order, it is possible to navigate

freely between the steps.

1. Image

The image workow step controls how and when im-

ages are acquired.

lens & fOcus section controls lens type selection

The

and displays focus feedback.

brightness section controls the visual quality of

The

acquired images. Use the autO gain button to automatically adjust the gain.

illuminatiOn section controls the internal and exter-

The

nal lighting behavior. The internal lighting is enabled

by default.

NOTICE

For Lector632x Flex, the focusing of the image is

done mechanically on the device (S-mount) or on

the lens (C-mount). To protect the device (S-mount)

from focus manipulation attach the supplied round

label to the hole in the device lid.

The

triggering section controls the acquisition mode

and triggering method:

Acquisition

mode

Single image • Acquires one image and outputs one

Image series • Acquires a series of images and typically

Image series is enabled by default.

Description

result per trigger signal.

• Used when there is only one acquisition

and analysis per object.

• Used when the code is precisely

positioned on the object in high speed

applications.

outputs one combined result per trigger

signal.

• Used when the object is larger than the

eld of view and the exact code position

is unknown.

• Used to increase read rate by acquiring

each code multiple times.

2. Task

The task workow step contains the code reading

parameters.

cODe reaDer settings section determines which

The

code types to read. Advanced settings are available

for performance optimization.

cODe reaDer results section contains unformatted

The

results for the current image, such as the read result

and code print quality.

The results are presented in a table where each row

represents one code.

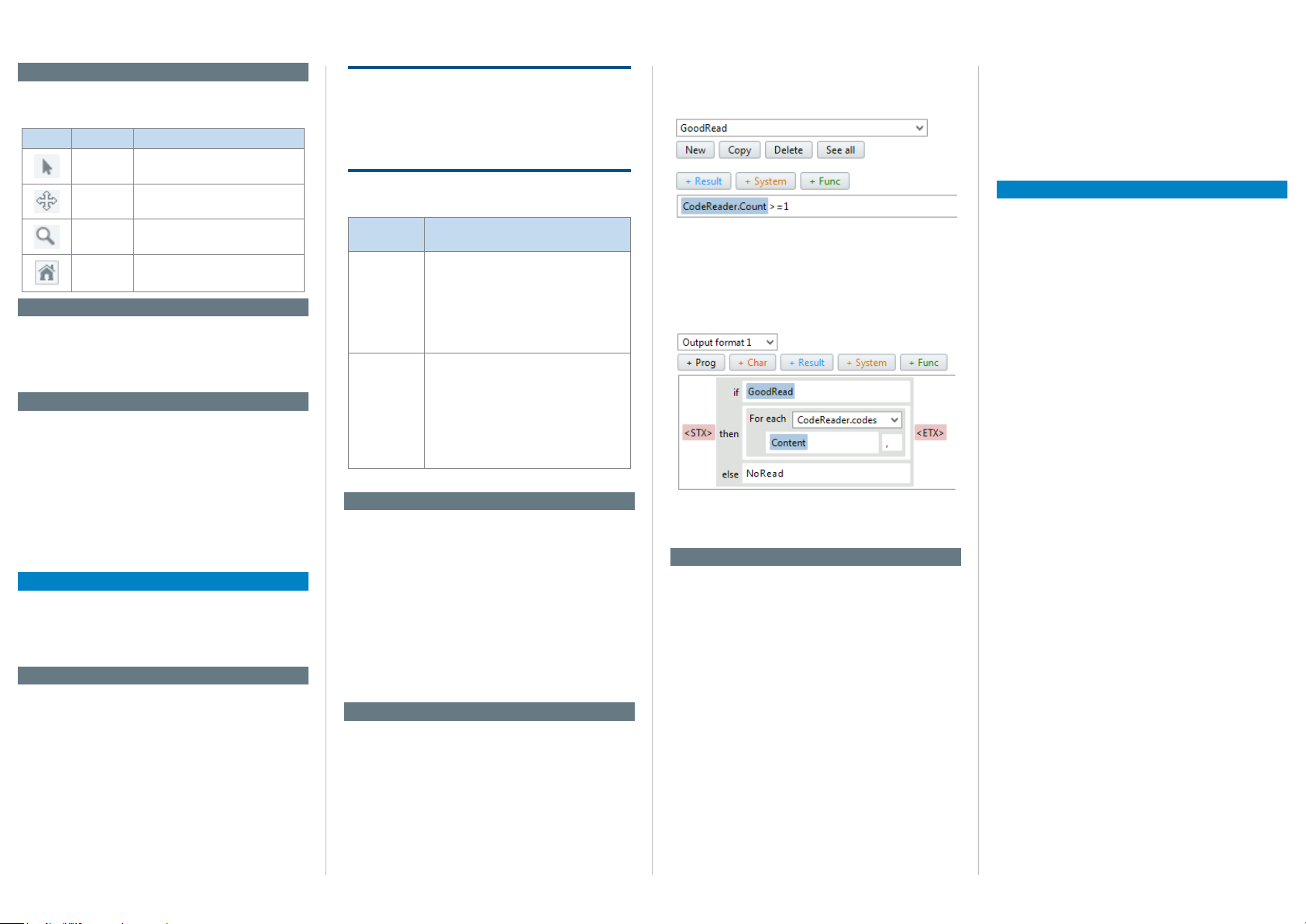

3. Results

The results workow step contains settings for result

timing, post-processing and formatting.

OutPut cOntrOl section determines when the result

The

shall be output, either:

• Directly when processing is ready

• At a xed response time

The

cOunters section contains counters which for

example can be used to set conditional outputs.

The cOnDitiOns section allows creation of custom conditions for device control and result logic. The gOODreaD

condition is pre-dened as an example:

The Digital OutPuts section species which results are

published on the available outputs.

OutPut fOrmat section, the decoding result

In the

can be formatted to a string in a visual editor. The

example below shows how the GoodRead condition is

used to output the content of all read codes.

The beePer, functiOn leD and feeDback sPOtlight sec-

tions contain settings to dene custom outputs for

monitoring results without a screen.

4. Interfaces

The interfaces workow step contains settings for con-

nections to external interfaces.

i/O DefinitiOns section denes the physical behav-

The

ior of the digital inputs and outputs.

ethernet section sets up Ethernet communica-

The

tions with peripheral equipment.

serial section sets up serial communications with

The

peripheral equipment.

lOgging section controls logging of data from the

The

device to internal and external destinations: Device

RAM, MicroSD card and external FTP server.

encODer section sets up one of the digital inputs

The

to receive encoder signals. For example, incrementcontrolled acquisition and result output make the

system independent of conveyor speed.

master/slave section sets up camera-to-camera

The

communication in a SICK CAN network.

functiOn buttOns On Device section denes the

The

behavior of the device buttons.

Device time section species how to set the device

The

time manually or to synchronize with an external time

server.

License text

SICK uses open source software in its Lector63x sensors. This software is licensed by the rights holders

using the following licenses among others: the free

licenses GNU General Public License (GLP Version2,

GPL Version3) and GNU Lesser General Public

License (LGPL), the MIT license, zLib license, and the

licenses derived from the BSD license.

This Program is distributed in the hope that it will be

useful, but WITHOUT ANY WARRANTY; without even

the implied warranty for merchantability or tness

for a particular purpose. See the GNU General Public

License for more details.

View the complete license texts here: www.sick.com/

licencetexts. A printed copy of the license texts is also

available on request.

8018061/2015-04-13• Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 2Lector®632 | SIcK

Page 3

A. Dimensional drawings

5.9

12

56

è

11

7

10

16

1

2

4

3

1

2

3

4

7

6

1

2

3

4

5

1. External light connector

2. Gigabit Ethernet connector

3. USB connector

4. Power, serial, CAN and I/O connector

5. 23 mm protection hood for lens and lighting

6. 38 mm protection hood for lens and lighting

7. Plug to ensure IP67 for unused connectors

8. Blind hole thread M5, 5.5 mm deep (4 x)

9. Sliding nut M5, 5.5 mm deep (4 x)

ß Integrated lighting connector

à Aiming laser (2 x)

á S- or C-mount optical module

â Blind hole thread 2.5 mm (4 x) for mounting

integrated lighting

ã Optical axis and center of image sensor

(4.25)

ä Manual focus screw, hidden under cover/

108

sticker (S-mount Flex)

å Function button (2 x)

æ Bar graph LED display (5 x)

ç Removable cover for microSD card and

manual focus screw

è Status LED display (5 x 2 levels)

8

(3.61)

91.8

(0.23)

6.5

(0.26)50(1.97)

23.9

(0.94)

9

45.8

(1.80)

3

4

0.5

(0.05)

min. 8 – max. 50

(0.31 – 1.97)

á

à

ß

(2.32)

59

63.1

(2.48)

â

7

ã

10.8

(2.91)

74

(3.02)

76.6

(0.43)

å

ä

æ

ç

B. Connection diagram

External light

ICL

1

Connection

box

3

FIeldbuses

I/O

box

24 V DC

Encoder

Photoelectric

switch

8018061/2015-04-13• Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 3Lector®632 | SIcK

External light

Power I/O

USB

2

â

4

5

6

7

Ethernet

ã

External light

VLR + CCS

8

9

PC

ß

FTP

à

á

HMI

PLC

1. External light (ICL)

2. Connection box

3. Fieldbuses

4. I/O box

5. 24 V DC, power source

6. Encoder

7. Photoelectric switch

8. External light (VLR + CCS)

9. PC

ß External FTP server

à HMI, operator interface

á PLC, control system

â Power cable, for example no. 2055419

(2 m)

ã Ethernet cable, for example no. 6034414

(2 m)

C. Optical conguration

Example with compact C-mount optics:

2

1

6

7

3

8

D. Pin assignment

Power/SerialData/

CAN/IO

15

8

9

1

13

2

12

3

Pin Signal Signal Signal Signal

1 Ground +5V DC 24V switchable out TRD0_P

DC 24V +20% - Data - TRD0_N

2

3 CAN L + Data Ground TRD1_P

4 CAN H Ground - TRD1_N

5 TD+ (RS 422/485) TRD3_P

6 TD- (RS422/485)

TxD (RS 232)

7 TxD (RS 232) TRD2_P

8 RxD (RS 232) TRD2_N

9 Sens GND

10 Input 1

11 RD+ (RS 422/485)

12 RD- (RS 422/485)

RxD (RS 232)

13 Input/output 3

14 Input/output 4

15 Input 2

16 Input/output 5

17 Input/output 6

17

6

14

5

4

USB

(no image transfer)

4

9

5

ß

à

External light Gb Ethernet

1. Optical module (C-mount)

2. Focus locking screws

3. Spacers

4. Integrated lighting

5. Protection hood

6. Metallic screws

7. Integrated lighting connector extension

8. Focus adjustment ring

9. Filter ring (replace with lter)

ß Black screws

à Filter holder

Note: parts vary between optical

congurations. To prevent focus

changes, x the C-mount lens with

at least one of the supplied screws

before starting operation.

TRD3_N

8

Page 4

E. Field of view diagram

Field of view width x height in mm² (sq inch), typical values

Working distance in mm (inch)

Min. resolution in mm (mil)

Field of view width x height in mm² (sq inch), typical values

Working distance in mm (inch)

Min. resolution in mm (mil)

f = 12.0 mm

f = 12.5 mm

f = 16.0 mm

f = 17.5 mm

f = 25.0 mm

f = 35.0 mm

f = 50.0 mm

Short range up to 0.3 m working distance

300 x 225

(11.81 x 8.86)

200 x 150

(7.87 x 5.91)

100 x 75

(3.94 x 2.95)

0

0 200

100

(3.94)

a

(7.80)

1D code 2D code

b

c

0.2

(7.9)

d

e

f

0.1

g

(3.9)

h

i

0.05

(2.0)

j

300

(11.81)

0.3

(11.8)

0.2

(7.9)

0.1

(3.9)

0.05

(2.0)

Lens focal length

a: f = 6.0 mm

b: f = 8.0 mm

c: f = 9.6 mm

d:

e:

f:

g:

h:

i:

j:

Long range up to 2.2 m working distance

1,200 x 900

(47.24 x 35.43)

1,000 x 750

(39.37 x 29.53)

800 x 600

(31.50 x 23.62)

2

600 x 450

(23.62 x 17.72)

400 x 300

(15.75x 11.81)

200 x 150

(7.87 x 5.91)

0

0 200

(7.80)

400

(15.75)

abcd

3

600

800

1,000

1,200

(39.37)

(47.24)

1,400

(55.12)

(23.62)

(31.50)

1,600

(62.99)

1,800

(70.87)

e

2,000

(78.74)

4

f

1D code 2D code

1.0

(39.4)

0.9

(35.4)

0.8

g

(31.4)

0.7

(27.6)

0.6

h

(23.6)

0.5

(19.7)

i

0.4

(15.7)

0.3

j

(11.8)

0.2

(7.9)

0.1

(3.9)

2,200

(86.61)

Interpreting the diagrams

Use the diagrams to determine:

1.4

(55.1)

• The maximum working distance

1.2

(47.2)

1.0

(39.4)

0.8

(31.4)

0.6

(23.6)

0.4

(15.7)

0.2

(7.9)

for a selected code resolution

1

• The dimensions of the available

eld of view

Example

Given (in red):

2D code resolution 1: 1.0 mm

Read (in green):

Field of view 2: 800x600 mm

Working distance 3: 1400 mm

Lens focal length 4: 12.5 mm

(example, other lenses possible)

2

F. LED denitions

First level, runtime operation

Green

O Red O Yellow O Blue O

Ready Operation Stop Live Busy

Result Decision OK Decision NOK - -

Light Lighting on - - -

Function User-dened User-dened User-dened User dened

Second level, manual conguration (not active)

Green

O Red O Yellow O Blue O

Tes t - - - -

Teach - - - -

Setup - - - -

Focus - - - -

8018061/2015-04-13 • Subject to change without notice • SICK AG • Waldkirch • Germany • www.sick.com 4Lector®632 | SIcK

G. Technical data

Attribute Value

Features

Task Reading

Technology 2D, snapshot, image analysis

Sensor CMOS matrix sensor, gray scale

Spectral range Approx. 400 nm ... 900 nm

LED class White light: Risk group 1 (low risk,

Laser class 1 (IEC 60825-1 (2014)) complies

Focus Manually adjustable

Lens Exchangeable S- or C-mount, de-

Reading distance 30 mm ... 2000 mm

Performance

Scanning frequency Max 50 Hz

Sensor resolution 1600 x 1200 px

Bar code types Interleaved 2 of 5, Codabar, Code

2D code types Data Matrix ECC200, GS1 Data-

Stacked code types PDF417, Postal

Code qualication On the basis of ISO/IEC 16022,

Interfaces

Data store and

retrieve

Switching inputs Max 6 internal 24V (4 congurable

Congurable inputs Encoder input, external trigger

Switching outputs Max 4 internal 24V (congurable as

Congurable

outputs

Output current ≤ 100 mA per output

IEC62471: 2006)

with 21 CFR 1040.10 except for the

tolerance according to “Laser Notice

No.50” from June 24.2007

pending on optical kit

128, Code 32, Code 39, Code 93,

GS1 DataBar, GS1-128/EAN 128,

Pharma, UPC/GTIN/EAN

Matrix, MaxiCode, QR code

ISO/IEC 15415, ISO/IEC 15416,

ISO/IEC 18004

Image and le logging via MicroSD

memory card, internal RAM and

external FTP

as in/out), additional 2 inputs via

optional CMC600 in CDB650/

CDM420

in/out) additional 2 external outputs

via CMC600 in CDB650/CDM420

Good read, external light trigger,

conditional output

Attribute Value

Maximum encoder

1 kHz

frequency

Control of external

illumination

Serial

- Function

- Rate

Via digital output (24V trigger) or via

external light connector

RS-232, RS-422

- Host, AUX

- 300 Baud ... 115.2 kBaud, AUX:

57.6 kBaud (RS-232)

USB USB 2.0

Ethernet

- Function

- Data transmission

rate

- Host, AUX, image transmission

- 10/100/1000 Mbit/s

- TCP/IP, FTP

- Protocol

CAN bus

- Function

- Rate

- Protocol

- Master/Slave

- 250 kbit/s ... 500 kbit/s

- CSN (SICK CAN Sensor Network)

Optical indicators 11 LEDs (5 x status display, 5 x bar

graph, 1 green/red feedback spot)

Acoustic indicators Congurable beeper

Control elements 2 function buttons

Memory card MicroSD memory card, optional

Mechanics/electronics

Electrical connection

1 x M12, 17-pin plug (serial, CAN,

I/Os, power supply), 1 x M8, 4-pin

socket (USB), 1 x M12, 8-pin socket

(Ethernet), 1 x M12, 4-pin socket

(external light control)

Power consumption Typ. 10 W, ± 20 %

Enclosure rating IP 67 (with hood and plugged

unused connectors)

Housing Aluminium

Window material PMMA or glass

Weight 430 g excluding optics

Operating voltage 24 V DC ± 20 %

Ambient data

Shock resistance EN60068-2-27:2009-5

Vibration resistance EN60068-2-6:2008:02

Ambient operating

0 °C ... +50 °C

temperature

Ambient storage

-20 °C ... +70 °C

temperature

8018061/2015-04-13 • 8M_AS • Printed in Germany (2015-03) • All rights reserved • Subject to change without notice

Loading...

Loading...