Page 1

FOR THE HARSHEST CONDITIONS –

THE HEAVY-DUTY LINEAR ENCODER

A

KH53 LINEAR ENCODERS

B

C

D

E

F

G

H

I

Additional information

Product description

The POMUX KH53 non-contact linear encoder can measure absolute lengths up

to 1,700 m. The encoder consists of two

main components: The non-contact read

head determines the absolute position

using a series of measuring elements

attached along the measurement path.

Each measuring element consists of a

number of permanent magnets. Since

the distances between the magnets are

unique, they can be used to develop an

absolute measuring code. No reference

At a glance

• Non-contact length measurement

– maintenance-free, rugged, long

service life

• High reproducibility (0.3 mm / 1 mm),

high system resolution (0.1 mm)

• SSI and PROFIBUS interfaces

• Determination of absolute position

• Measuring lengths of up to 1,700 m

possible

Your benets

• After installation, the system is

immediately available and completely

maintenance-free, which leads to time

and cost savings

• Reliable determination of position

under harshest ambient conditions

such as the effects of dirt, dust, fog,

shock, and vibration

run is required due to the absolute position being determined. The read head

is passed parallel to these measuring

elements at a distance of 25 mm or

55 mm. With a measuring length of

up to 1,700 m, the KH53 is ideal for

use in cranes, in storage and conveyor

systems, and for railed vehicles. Due to

the non-contact technology, this system

works wear-free even in harsh ambient

conditions,so that a long lifetime is

ensured.

• Can be used in the harshest ambient

conditions

• High traversing speedds of up to

6.6 m/s

• Distance tolerance between read

head and measuring element: up to

55 mm ± 20 mm possible

• High efciency and productivity levels

• Time savings – no reference run nec-

essary on initial commissioning due

to absolute position measurement

• Accurate positioning even with high

mounting tolerances

Detailed technical data. . . . . . . . . J-645

Ordering information. . . . . . . . . . . J-647

J

K

L

Dimensional drawings . . . . . . . . . J-651

Pin assignment ...............J-652

Implementation ..............J-654

Switch settings ...............J-655

General information ...........J-655

Position tolerance . . . . . . . . . . . . . J-655

Recommended accessories. . . . . J-656

J-644

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

LINEAR ENCODERS KH53

Fields of application

• Position determination for container cranes in container

terminals

• Positioning of the trolley on cranes

Detailed technical data

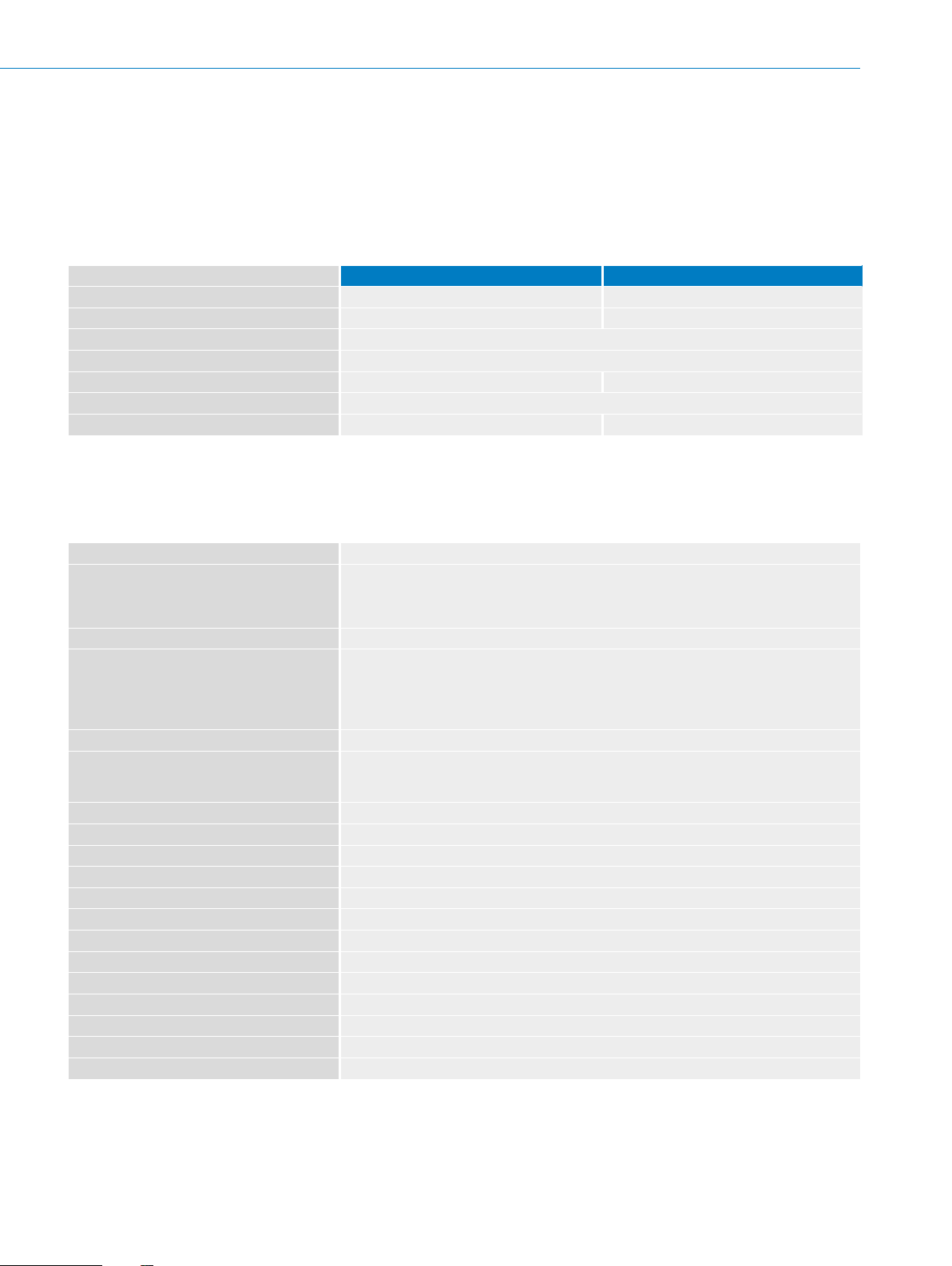

Performance

Measuring length

Measuring range

Interfaces

Resolution

Reproducibility

Max. traversing speed

Measurement accuracy

1)

An error message appears if the max. traversing speed is exceeded or the read head cannot detect a measuring element (with SSI FF FF FE hex).

2)

Related to the start of a measuring element if a position tolerance of ± 1 mm is maintained based on the nominal distance in the N and Y directions. ME = Length of

the measuring element (see illustration on page J-652), Tu = ambient temperature in °C, Tk = coefcient of thermal expansion (see "Mechanical Data" table on page

J-646).

1)

2)

0 m ... 1,700 m 0 m ... 548 m

38 m, 107 m, 354 m, 1,700 m 54 m, 548 m

SSI and PROFIBUS

0.1 mm

0.3 mm 1 mm

6.6 m/s

± 1000 + ME (Tu –25 °C) Tk µm ± 2000 + ME (Tu –25 °C) Tk µm

• Positioning of automated guided vehicles in storage and

conveyor systems

KH53 KH53 Advanced

A

B

C

D

Electrical data

Initialization time

Position forming time

PROFIBUS 1.1 ms

Supply voltage

Electrical connection

PROFIBUS 3 x M12 male connectors

SSI

RS422 interface for parameterizing

Interface digital, serial

Default setting SSI standard

SSI power consumption

PROFIBUS DP

Electrical interface

Address setting (node number)

Protocol

Bus termination

SET (electronic adjustment)

Encoder prole

Data transmission rate (baud rate)

Status information

PROFIBUS power consumption in operation

1)

According to ISO13849. This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on

nominal load of components, average ambient temperature of 40°C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more informa-

tion, see document no. 8015532.

2 s

SSI 0.8 ms

10 … 32 V

SSI Cable

M23 male connector

Four wire transmission, asynchronous, full-duplex

Data format: 1 start bit, 8 data bits, 1 stop bit, no parity

Data protocol: ASCII, Baud rate 9,600

SSI 24 bit, gray

RS 422 OFF

250 mA

RS485 (as per EN 50 170-2 (DIN 19245 Parts 1–3) electrically isolated by optocoupler

0 ... 127 (hex switch or protocol)

PROFIBUS DP basic functions (DP-V0)

Via external male connectors

Via protocol

Proles for encoders (07hex) – Class 2

9.6 kBaud ...12 Mbaud (autodetect)

Operation (LED green), bus activity (LED red)

2.5 W

E

F

G

H

I

J

K

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

J-645

L

Page 3

A

B

C

D

E

F

KH53 LINEAR ENCODERS

MTTFd: mean time to dangerous failure

SSI Measuring range up to 38 m: 45 years

Measuring range up to 107 m: 40 years

Measuring range up to 354 m: 31 years

Measuring range up to 1,700 m:

21 years

PROFIBUS Measuring range up to 38 m: 40 years

Measuring range up to 107 m: 35 years

Measuring range up to 354 m: 28 years

1)

According to ISO13849. This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on

nominal load of components, average ambient temperature of 40°C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more informa-

tion, see document no. 8015532.

Measuring range up to 1,700 m: 20 years

1)

Mechanical data

KH53 KH53 Advanced

Mass

Read head 38 2.4 kg –

Read head 107 2.7 kg –

Read head 354 3.6 kg –

Read head 1,700 5.2 kg –

Read head 54 – 4.4 kg

Read head 548 – 6.7 kg

Measuring element 0.5 kg/m 0.65 kg/m

Length of measuring element

Coefcient of thermal expansion

Position tolerance (see diagram on Page

J-655)

Read head material

Measuring element material

See tables on Page J-647 and Page J-649

28 µm/°C/m

± 10 mm ± 20 mm

AIMgSiPbF28

AIMgSiO,5F22

1)

Measuring range up to 54 m: 34 years

1)

Measuring range up to 548 m: 22 years

1)

1)

Measuring range up to 54 m: 30 years

1)

Measuring range up to 548 m: 20 years

1)

1)

1)

1)

1)

1)

G

H

I

J

K

Ambient data

1)

EMC

Enclosure rating

SSI read head with cable IP 66

SSI read head with screw-in system IP 65 (with mating connector tted)

Read head with PROFIBUS connectors IP 67 (with mating connector tted)

Operating temperature range

Read head storage temperature range

Resistance to shocks

Read head 30 g/10 ms

Measuring element 50 g / 10 ms

Resistance to vibrations

Read head 10 g/20 ... 250 Hz

Measuring element 30 g / 20 ... 250 Hz

1)

The EMC according to the standards quoted is achieved if shielded connecting cables are used.

According to EN 61000-6-2 and EN 61000-6-4

–20 ... +60 °C –30 … +70 °C

–40 … +85 °C

According to EN 61000-2-27

According to DIN EN 61000-2-6

L

J-646

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 4

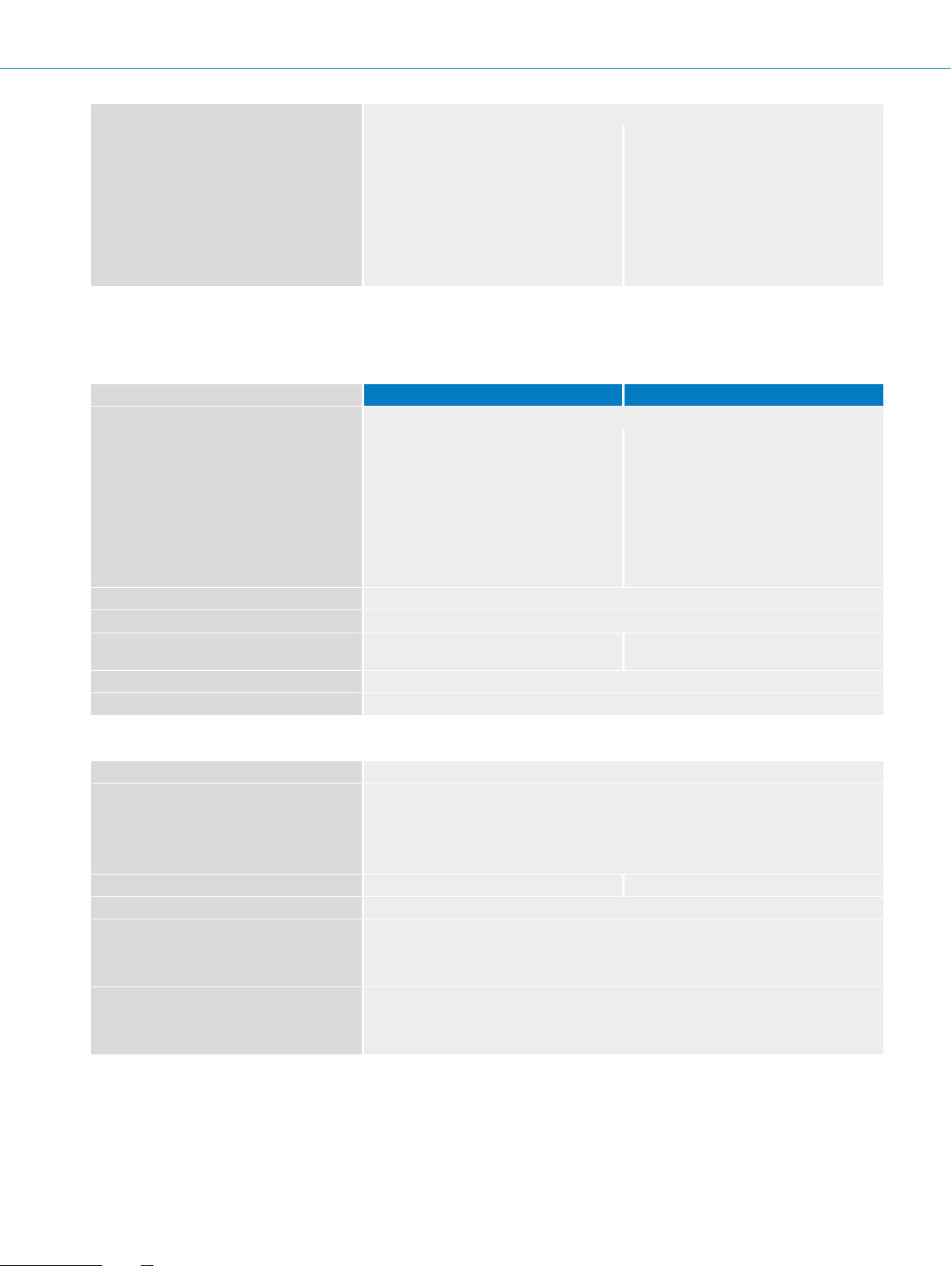

SSI ordering information

Length of measuring element

LINEAR ENCODERS KH53

incl. separation

Dimensions and calculation table - KH53

Measuring range

up to

39.90 m 0.886 m 2.304 m

107.40 m 1.051 m 1.8688 m

351.20 m 1.376 m 2.5088 m

1676.40 m 2.026 m 1.9072 m

The dimensions given are slightly rounded.

Read head length Length of measuring element including

distance

Identication letters A1 ... ≤ A18

Identication letters B1 ... ≤ B58

Identication letters C1 ... ≤ C141

Identication letters D1 ... ≤ D880

Measurement and calculation table - KH53 Advanced

Measuring range

up to

53.50 m 1.58 m 1.408 m

546.40 m 2.506 m 2.3552 m

The dimensions given are slightly rounded.

Read head length Length of measuring element including

distance

Identication letters F1 ... ≤ F39

Identication letters G1 ... ≤ G233

Mounting systems per measuring element

(suggestion)

4 clamp holders or 8 mounting brackets

3 clamp holders or 6 mounting brackets

4 clamp holders or 8 mounting brackets

3 clamp holders or 6 mounting brackets

Mounting systems per measuring element

(suggestion)

3 clamp holders or 6 mounting brackets

4 clamp holders or 8 mounting brackets

A

B

C

D

E

Calculation example for a measurement distance of 100 m

Selected system with measuring range up to 107 m

Number of measuring elements required = measurement path + length of the read head / length of measurement element (according to table above)

Number of measuring elements required = 101.051 m / 1.8688 m = 54.07

Ordering amount therefore 55 measuring elements and 55 * 3 = 165 clamp holders

If two separate measurement paths are to be implemented, then please order 2 x 55 measuring elements (not 110 measuring elements)

Attention! For position determination, the read head must not travel beyond the last measuring element.

KH53 length measurement systems (absolute, linear)

Measuring range up to 38 meters

Description Type Part no.

Read head 38, SSI, cable 1.5 m KHK53-AXR00038 1030048

Read head 38, SSI, cable 3.0 m KHK53-AXS00038 1030049

Read head 38, SSI, cable 5.0 m KHK53-AXT00038 1030050

Read head 38, SSI, cable 10.0 m KHK53-AXU00038 1030051

Read head 38, SSI, M23 male, 12 pin KHK53-AXB00038 1030052

Measuring element up to 38 m, coded

Measuring element up to 38 m, universally codeable

Assembly gauge 38 KHM53-XXX00038 1030057

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

1)

2)

KHT53-XXX00038 1030055

KHU53-XXX00038 1030056

F

G

H

I

J

K

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

J-647

L

Page 5

KH53 LINEAR ENCODERS

Measuring range up to 107 meters

A

B

C

D

E

F

Description Type Part no.

Read head 107, SSI, cable 1.5 m KHK53-AXR00107 1030058

Read head 107, SSI, cable 3.0 m KHK53-AXS00107 1030059

Read head 107, SSI, cable 5.0 m KHK53-AXT00107 1030060

Read head 107, SSI, cable 10.0 m KHK53-AXU00107 1030061

Read head 107, SSI, M23 male device connector, 12 pin KHK53-AXB00107 1030062

Measuring element up to 107 m, coded

Measuring element up to 107 m, universally codeable

Assembly gauge 107 KHM53-XXX00107 1030067

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Measuring range up to 354 meters

Description Type Part no.

Read head 354, SSI, cable 1.5 m KHK53-AXR00107 1030068

Read head 354, SSI, cable 3.0 m KHK53-AXS00354 1030069

Read head 354, SSI, cable 5.0 m KHK53-AXT00354 1030070

Read head 354, SSI, cable 10.0 m KHK53-AXU00354 1030071

Read head 354, SSI, M23 male device connector, 12 pin KHK53-AXB00354 1030072

Measuring element up to 354 m, coded

Measuring element up to 354 m, universally codeable

Assembly gauge 354 KHM53-XXX00354 1030077

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

1)

2)

1)

2)

KHT53-XXX00107 1030065

KHU53-XXX00107 1030066

KHT53-XXX00354 1030075

KHU53-XXX00354 1030076

G

H

I

J

K

Measuring range up to 1,700 meters

Description Type Part no.

Read head 1700, SSI, cable 1.5 m KHK53-AXR01700 1030078

Read head 1700, SSI, cable 3.0 m KHK53-AXS01700 1030079

Read head 1700, SSI, cable 5.0 m KHK53-AXT01700 1030080

Read head 1700, SSI, cable 10.0 m KHK53-AXU01700 1030081

Read head 1700, SSI, M23 male device connector, 12 pin KHK53-AXB01700 1030082

Measuring element up to 1,700 m, coded

Measuring element up to 1,700 m, universally codeable

Assembly gauge 1700 KHM53-XXX01700 1030087

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

1)

2)

KHT53-XXX01700 1030085

KHU53-XXX01700 1030086

L

J-648

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

KH53 advanced length measurement systems (absolute, linear)

Length of measuring element

LINEAR ENCODERS KH53

Measuring range up to 54 meters

Description Type Part no.

Read head 54, SSI, cable 5.0 m KHK53-AXT00054 1035442

Read head 54, SSI, M23 male device connector, 12 pin KHK53-AXB00054 1035443

Measuring element up to 54 m, coded

Measuring element up to 54 m, universally codeable

Assembly gauge 54 KHM53-XXX00054 1035447

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Measuring range up to 548 meters

Description Type Part no.

Read head 548, SSI, cable 5.0 m KHK53-AXT00548 1035448

Read head 548, SSI, M23 male device connector, 12 pin KHK53-AXB00548 1035449

Measuring element up to 548 m, coded

Measuring element up to 548 m, universally codeable

Assembly gauge 548 KHM53-XXX00548 1035453

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

1)

2)

1)

2)

KHT53-XXX00054 1035445

KHU53-XXX00054 1035446

KHT53-XXX00548 1035451

KHU53-XXX00548 1035452

A

B

C

D

E

PROFIBUS ordering information

incl. separation

Dimensions and calculation table - KH53

Measuring range

up to

39.90 m 0.905 m 2.304 m

107.40 m 1.070 m 1.8688 m

351.20 m 1.395 m 2.5088 m

1676.40 m 2.045 m 1.9072 m

The dimensions given are slightly rounded.

Read head length Length of measuring element including

distance

Identication letters A1 ... ≤ A18

Identication letters B1 ... ≤ B58

Identication letters C1 ... ≤ C141

Identication letters D1 ... ≤ D880

Measurement and calculation table - KH53 Advanced

Measuring range

up to

53.50 m 1.599 m 1.408 m

546.40 m 2.525 m 2.3552 m

The dimensions given are slightly rounded.

Read head length Length of measuring element including

distance

Identication letters F1 ... ≤ F39

Identication letters G1 ... ≤ G233

Mounting systems per measuring element

(suggestion)

4 clamp holders or 8 mounting brackets

3 clamp holders or 6 mounting brackets

4 clamp holders or 8 mounting brackets

3 clamp holders or 6 mounting brackets

Mounting systems per measuring element

(suggestion)

3 clamp holders or 6 mounting brackets

4 clamp holders or 8 mounting brackets

F

G

H

I

J

Subject to change without notice

K

ENCODERS | SICK8015560/2015-09-01

J-649

L

Page 7

KH53 LINEAR ENCODERS

Calculation example for a measurement distance of 100 m

A

B

C

D

E

F

G

Selected system with measuring range up to 107 m

Number of measuring elements required = measurement path + length of the read head / length of measurement element (according to table above)

Number of measuring elements required = 101.070 m / 1.8688 m = 54.08

Ordering amount therefore 55 measuring elements and 55 * 3 = 165 clamp holders

If two separate measurement paths are to be implemented, then please order 2 x 55 measuring elements (not 110 measuring elements)

Attention! For position determination, the read head must not travel beyond the last measuring element.

KH53 length measurement systems (absolute, linear)

Measuring range up to 38 meters

Description Type Part no.

Read head 38, PROFIBUS DP KHK53-PXF00038 1036163

Measuring element up to 38 m, coded

Measuring element up to 38 m, universally codeable

Assembly gauge 38 KHM53-XXX00038 1030057

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Measuring range up to 107 meters

Description Type Part no.

Read head 107, PROFIBUS DP KHK53-PXF00107 1036164

Measuring element up to 107 m, coded

Measuring element up to 107 m, universally codeable

Assembly gauge 107 KHM53-XXX00107 1030067

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

1)

2)

1)

2)

KHT53-XXX00038 1030055

KHU53-XXX00038 1030056

KHT53-XXX00107 1030065

KHU53-XXX00107 1030066

H

I

J

K

L

Measuring range up to 354 meters

Description Type Part no.

Read head 354, PROFIBUS DP KHK53-PXF00354 1036165

Measuring element up to 354 m, coded

Measuring element up to 354 m, universally codeable

Assembly gauge 354 KHM53-XXX00354 1030077

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Measuring range up to 1,700 meters

Description Type Part no.

Read head 1700, PROFIBUS DP KHK53-PXF01700 1036166

Measuring element up to 1,700 m, coded

Measuring element up to 1,700 m, universally codeable

Assembly gauge 1700 KHM53-XXX01700 1030087

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

J-650

ENCODERS | SICK 8015560/2015-09-01

1)

2)

1)

2)

KHT53-XXX00354 1030075

KHU53-XXX00354 1030076

KHT53-XXX01700 1030085

KHU53-XXX01700 1030086

Subject to change without notice

Page 8

KH53 advanced length measurement systems (absolute, linear)

61.1 (2.41)

Bending radius > 80 (3.15)

57 (2.24)

LINEAR ENCODERS KH53

Measuring range up to 54 meters

Description Type Part no.

Read head 54, PROFIBUS DP KHK53-PXF00054 1036167

Measuring element up to 54 m, coded

Measuring element up to 54 m, universally codeable

Assembly gauge 54 KHM53-XXX00054 1035447

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Measuring range up to 548 meters

Description Type Part no.

Read head 548, PROFIBUS DP KHK53-PXF00548 1036168

Measuring element up to 548 m, coded

Measuring element up to 548 m, universally codeable

Assembly gauge 548 KHM53-XXX00548 1035453

1)

When ordering replacements for individual defective measuring elements, please enter the code for the measuring element in question .

2)

For the temporary replacement of defective, coded measuring elements.

Dimensional drawing SSI read head (dimensions in mm)

1)

2)

1)

2)

KHT53-XXX00054 1035445

KHU53-XXX00054 1035446

KHT53-XXX00548 1035451

KHU53-XXX00548 1035452

A

B

C

D

E

(0.31)

51 (2.01)

Plugged on

Bending radius

≥ 80 (3.15)

8

20

(0.79)

F

With 12-pin connector

G

Length read head

With PG outlet

H

I

J

Subject to change without notice

K

ENCODERS | SICK8015560/2015-09-01

J-651

L

Page 9

Length read head

13.5

51 (2.01)

+0.3

(0.30)

Ø 10

Ø 23.5

29.05

A

KH53 LINEAR ENCODERS

Dimensional drawing PROFIBUS read head (dimensions in mm)

±1

(0.53)

B

C

D

E

F

Mounting slot designed for

non-magnetic M6 DIN 933

screws.

Dimensional drawing for measuring element

(0.39)

15

(0.59)

Length measuring element (ME)

(1.14)

3

(0.12)

(0.93)

24

(0.28)

6

(0.24)

10

(0.39)

Ø 7

Pin assignment for SSI interface

Mounting slot

5.7

7.7

(0.22)

3.5

(0.14)

10.2

6.2

(0.24)

61.1 (2.41)

A

A

(0.40)

+0.2

G

H

I

J

K

View of M23 male device connector on SSI encoder

PIN Signal Wire colors

1 GND Blue Ground connection

2 Data + White Interface signals

3 Clock + Yellow Interface signals

4 R x D + Gray RS-422 programming cables

5 R x D – Green RS-422 programming cables

6 T x D + Pink RS-422 programming cables

7 T x D – Black RS-422 programming cables

8 + U

9 N. C. Orange Not connected

10 Data – Brown Interface signals

11 Clock – Violet Interface signals

12 N. C. – Not connected

N. C. = Not Connected.

Other interfaces on request.

S

Explanation

(cable outlet)

Red Operating voltage

L

J-652

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

Pin assignment for PROFIBUS interface

LED1

re

een

LINEAR ENCODERS KH53

A

d

Male connector, 4

pin

1 – – US (24 V) Operating voltage 10 ... 32 V

3 – – 0 V (GND) Ground (0 V)

– – 4 B B cable PROFIBUS DP (out)

– – 2 A A cable PROFIBUS DP (out)

– 4 – B B cable PROFIBUS DP (in)

– 2 – A A cable PROFIBUS DP (in)

– – 1 2P5

– – 3 2M

4 1 – Not connected –

2 3 – Not connected –

– 5 5 Screen Housing potential

1)

Use for external bus termination.

Male connector, 5

pin

LED2

gr

Female connector

5 pin

Signal Explanation

1)

1)

+ 5 V (potential free)

0 V (potential free)

B

C

D

E

F

G

H

I

J

K

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

J-653

L

Page 11

S1

S2

A

B

C

D

E

KH53 LINEAR ENCODERS

Implementation

DP functionalities

according to PROFIBUS-DP basic functionalities.

DP services

• Data exchange (Write_Read_Data)

• Address allocation (Set_Slave_Address)

• Control commands (Global_Control)

• Reading inputs (Read_Inputs)

• Reading outputs (Read_Outputs)

• Reading diagnostic data (Slave_Diagnosis)

• Sending parameter data (Set_Param)

• Checking conguration data (Chk_Cong)

Communication

• Cyclic master-slave data trafc.

Safety mechanisms

• Transfer of data with HD = 4.

• Time monitoring of data trafc.

Conguration

Settings according to encoder prole

• Counting direction (CW, CCW)

• Class 2 functionality (ON, OFF)

• Scaling function (ON, OFF)

Conguration

Setting the formats (IN/OUT) for the cyclic data exchange

through a conguration byte (K-1).

2 words IN/OUT data (I-1/O-1)

4 words IN/OUT data (I-1, I-2, I-3/O-1)

Data exchange: – Input data (IN)

I-1 Position value 1) 4 bytes

I-2 Speed (0.1 m/min)

I-3 Time stamp

Data exchange: – Output data (out)

O-1 PRESET – Value 1) 4 bytes

Diagnostic information

• Station related diagnostic (63 bytes according to encoder

prole Class 2)

Setting: – PRESET value

The PRESET function is used for commissioning and the allocation of a particular position value to current physical positioning.

The following settings are possible:

• Via software: – (see Output Data)

2)

2 bytes

2)

2 bytes

1)

2)

F

G

H

I

J

• “Activation of SSA service”

• Selection of the station address

1)

In accordance with encoder prole.

2)

Manufacturer specic function.

Setting: – Counting direction

• Via hardware via hex switch S2

• Via software via telegram

Count direction increasing:

Movement of the encoder from prole item n in the direction of

prole item n+1

2)

2)

Setting: – Station address

• Via hardware via hex switch S1/S2

• Via software via telegram

Setting by software only occurs with prior activation of the “SSA

service”.

Device specic le (*.GS_)

The *.GS_ le is designed for automatic commissioning of the

encoder. Within it all the characteristic features of the device

are dened.

STEG05F6.GSD German

STEG05F6.GSE English

K

L

J-654

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

Switch settings

Zero mark on the read head

Zero

Connector or cable outlet always at this position

last permanent magnet

The following settings are possible via hex switches:

S1/S2 Address setting (0 ... 127)

S2 Counting direction (CW/CCW)

Access is via a screw connection on the side of the read head

male connector.

General information

The KH53 PROFIBUS is an absolute length measurement

system with a resolution of 100 µm. The bus coupling is inside

the encoder and is an interface connection as PROFIBUS DP

slave according to EN 50170 Vol. 2. Implementation is with the

Siemens PROFIBUS ASIC SPC3.

The KH53 PROFIBUS contains all Class 2 functionalities ac-

cording to the encoder prole (V1.1)

Implementation of the encoder is as a DP slave with the DP

basic functions.

LINEAR ENCODERS KH53

Status information via LEDs

LED-1 Bus activity (red)

LED-2 Operating voltage (green)

Conformity with PROFIBUS DP is ensured by a PNO certied test

center.

The following options are available:

• M12 plug connector system

A

B

C

D

Position tolerances

Start of measurement path

Read head

Measuring element

End of measurement path

Last measuring element

Assumed position of the

E

F

G

Read head

H

I

Subject to change without notice

J

K

ENCODERS | SICK8015560/2015-09-01

J-655

L

Page 13

11

22

All dimensions in mm (inch)

11

22

All dimensions in mm (inch)

A

KH53 LINEAR ENCODERS

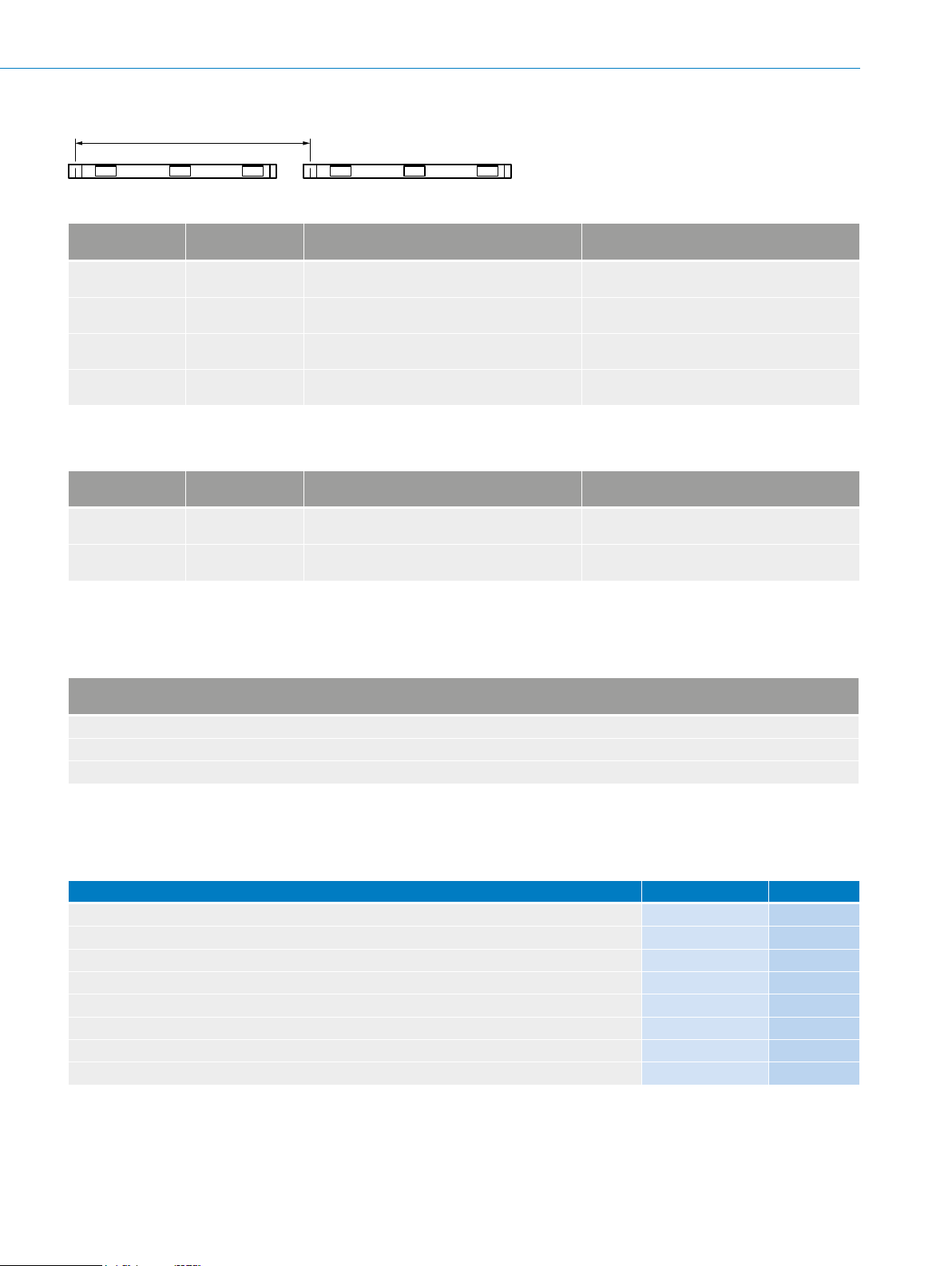

The operating reliability and accuracy of the measuring system depends on (amongst other things) compliance with the position

tolerances. Magnetic or magnetizable materials are not permitted within 80 mm of the encoder or the measuring element.

KH53

KH53 Advanced

B

C

D

E

F

1 Read head

2 Measuring element

)

±10

±0.39

(0.98

N = 25

±10

(0.39)

)

±20

±0.0.79

N = 55

(2.17

Y

±20

(0.79)

1 Read head

2 Measuring element

Y

G

Only use non ferro-magnetic materials for the assembly base of the read head.

A separation distance of 80 mm must be observed for ferro-magnetic materials (e.g., iron).

H

I

J

K

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

Mounting bracket for KH53 measuring elements, without mounting hardware for the

base

Clamp and alignment brackets

Terminal brackets

Figure Brief description Type Part no.

Spacer for KH53 measuring elements, without mounting hardware for the base BEF-KHA-KHT53 2042468

BEF-WK-KHT53 2029159

L

J-656

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 14

Connectors

LINEAR ENCODERS KH53

Plug connectors and cables

Connecting cables with female connector

Figure Brief description Length

Head A: M12 female connector, 4-pin, straight

Head B: cable

Cable: for power supply, suitable for drag chain, PVC, unshielded,

4 x 0.25 mm², Ø 5.0 mm

Head A: M12 female connector, 5-pin, straight

Head B: cable

Cable: suitable for drag chain, PROFIBUS DP, PUR, halogen-free, shielded,

2 x 0.34 mm², Ø 8.0 mm

Head A: M23 female connector, 12-pin, straight

Head B: cable

Cable: SSI, RS-422, suitable for drag chain, PUR, shielded, 4 x 2 x 0.25 mm²

+ 2 x 0.5 mm² + 2 x 0.14 mm², Ø 7.8 mm

Connecting cables with male connector

Figure Brief description Length

Head A: M12 male connector, 5-pin, straight, B-coded

Head B: cable

Cable: PROFIBUS DP, suitable for drag chain, PUR, halogen-free, shielded,

2 x 0.34 mm², Ø 8.0 mm

Wire shielding: AL-PT foil, total shield, tin-plated C shield

Type Part no.

of

cable

5 m DOL-1204-G05M 6009866

5 m DOL-1205-G05MQ 6026006

10 m DOL-1205-G10MQ 6026008

1.5 m DOL-2312-G1M5MA1 2029200

3 m DOL-2312-G03MMA1 2029201

5 m DOL-2312-G05MMA1 2029202

10 m DOL-2312-G10MMA1 2029203

20 m DOL-2312-G20MMA1 2029204

30 m DOL-2312-G30MMA1 2029205

Type Part no.

of

cable

5 m STL-1205-G05MQ 6026005

10 m STL-1205-G10MQ 6026007

12 m STL-1205-G12MQ 6032635

A

B

C

D

E

F

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: M12 female connector, 4-pin, straight, unshielded, for power supply, for cable

diameter 4 mm ... 6 mm

Head B: -

Head A: M12 female connector, 5-pin, straight, B-coded, PROFIBUS DP, shielded, for

cable diameter 4 mm ... 9 mm

Head B: -

Head A: M23 female connector, 12-pin, straight, HIPERFACE®, SSI, incremental, shielded, for cable diameter 5.5 mm ... 10.5 mm

Head B:

Operating temperature: –20 °C ... +130 °C

DOS-1204-G 6007302

DOS-1205-GQ 6021353

DOS-2312-G 6027538

G

H

I

J

K

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

J-657

L

Page 15

KH53 LINEAR ENCODERS

Cables (ready to assemble)

A

B

C

D

E

F

Figure Brief description Length

of

cable

Head A: cable

Head B: cable

Cable: PROFIBUS DP, suitable for drag chain, PUR, shielded, 2 x 0.25 mm²,

Ø 8.0 mm

Head A: cable

Head B: cable

Cable: SSI, suitable for drag chain, PUR, halogen-free, shielded,

4 x 2 x 0.25 mm² + 2 x 0.5 mm² + 2 x 0.14 mm², Ø 7.8 mm

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free,

shielded, UV and saltwater resistant, 4 x 2 x 0.25 mm² + 2 x 0.5 mm²

+ 2 x 0.14 mm², Ø 7.8 mm

Other plug connectors and cables

Figure Brief description Type Part no.

Head A: M12 male connector, 4-pin, straight, B-coded

Cable: PROFIBUS DP, terminator

Male connector (ready to assemble)

Figure Brief description Type Part no.

Head A: M12 male connector, 5-pin, straight, B-coded, PROFIBUS DP, shielded, for cable

diameter 4 mm ... 9 mm

Head B: -

Head A: M23 male connector, 12-pin, straight, HIPERFACE®, SSI, incremental, RS-422,

shielded, for cable diameter 5.5 mm ... 10.5 mm

Head B:

Operating temperature: –20 °C ... +130 °C

By the

meter

Type Part no.

LTG-2102-MW 6021355

LTG-2512-MW 6027531

LTG-2612-MW 6028516

STE-END-Q 6021156

STE-1205-GQ 6021354

STE-2312-G 6027537

G

H

I

J

K

Additional accessories

Programming and conguration tools

Figure Brief description Type Part no.

Programming tool for ATM60, ATM90 and KH53 SSI PGT-01-S 1030111

- For additional accessories, please see page K-668 onwardsw

L

J-658

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

LINEAR ENCODERS KH53

A

B

C

D

E

F

G

H

I

Subject to change without notice

J

K

ENCODERS | SICK8015560/2015-09-01

J-659

L

Loading...

Loading...