Page 1

Application Programming

IVC-2D

R EFERENCE M ANUAL

Page 2

ISM Radio Frequency Classification - EN55011 –

Group1, Class A

Warning:Class A equipment is intended for use in an industrial environment. There may be potential difficulties in

ensuring electromagnetic compatibility in other environments, due to conducted as well as radiated disturbances.

Explanations:

Group1 – ISM equipment (ISM = Industrial, Scientific and Medical)

Group 1 contains all ISM equipment in which there is intentionally generated and/or used conductively coupled

radio-frequency energy which is necessary for the internal functioning of the equipment itself.

Class A equipment

connected to a low voltage power supply network which supplies buildings used for domestic purposes.

Class A equipment

Note:

may allow, with whatever additional measures are necessary, the installation and use of class A ISM equipment in

a domestic establishment or in an establishment connected directly to domestic electricity power supplies.

German versions of the Operating Instructions and Reference manual are available on the CD.

Eine deutsche Version der Bedienungsanleitung und des Referenzhandbuchs finden Sie auf der

beigelegten CD.

is equipment suitable for use in all establishments other than domestic and those directly

shall meet class A limits.

Although class A limits have been derived for industrial and commercial establishments, administrations

© SICK AG 2013-09-09

All rights reserved

Subject to change without prior notice.

Page 3

Reference Manual

IVC-2D

Contents

Contents

1 Functional Overview.......................................................................................................................................7

The Camera ..........................................................................................................................................................7

1.1

1.2 IVC Studio ..............................................................................................................................................................8

1.3 Handling Multiple Products .......................................................................................................................... 10

Getting Started ............................................................................................................................................. 11

2

2.1

Creating a product...........................................................................................................................................11

2.2 About Writing Programs ................................................................................................................................14

2.3 Adding Program Steps................................................................................................................................... 16

2.4 Setting Parameter Values ............................................................................................................................17

2.5 Testing and Running the Program.............................................................................................................23

2.6 Saving the Program ........................................................................................................................................24

2.7 What’s Next?.....................................................................................................................................................25

Using IVC Studio ..........................................................................................................................................27

3

Handling Devices.............................................................................................................................................27

3.1

3.2 Handling the Emulator ...................................................................................................................................30

3.3 Handling Products ...........................................................................................................................................33

3.4 Handling Programs.......................................................................................................................................... 35

3.5 Handling Tables................................................................................................................................................ 37

3.6 Handling Images ..............................................................................................................................................38

3.7 IVC Studio Settings .........................................................................................................................................39

3.8 Programming ..................................................................................................................................................... 39

3.9 Efficient Programming....................................................................................................................................45

Tools ................................................................................................................................................................. 47

4

4.1

Image....................................................................................................................................................................48

Grab Setup .................................................................................................................................................48

Start Snapshot .......................................................................................................................................... 49

Grab...............................................................................................................................................................50

Ping-Pong Grab .........................................................................................................................................51

Copy Image Bank.....................................................................................................................................52

Image Bank Operation ........................................................................................................................... 53

Add Text.......................................................................................................................................................55

Draw Line ....................................................................................................................................................56

Draw ROI......................................................................................................................................................57

Reset Image Banks.................................................................................................................................58

Display..........................................................................................................................................................59

Mirror Image...............................................................................................................................................60

Rotate Image ............................................................................................................................................. 61

4.2 Region of Interest (ROI).................................................................................................................................62

ROI Rectangle............................................................................................................................................62

ROI Rotated Rectangle...........................................................................................................................63

ROI Circle.....................................................................................................................................................65

ROI Ellipse ...................................................................................................................................................66

ROI Perimeter ............................................................................................................................................67

ROI Union.....................................................................................................................................................68

ROI Intersection ........................................................................................................................................69

ROI Difference ........................................................................................................................................... 70

4.3 Filter ......................................................................................................................................................................71

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 3

Page 4

Contents

Dilate.............................................................................................................................................................71

Erode.............................................................................................................................................................72

Filter............................................................................................................................................................... 73

Stretch Gray ...............................................................................................................................................74

Detail Extraction........................................................................................................................................76

Binarize.........................................................................................................................................................78

4.4 Edge......................................................................................................................................................................79

Find Row Edge...........................................................................................................................................79

Find Column Edge....................................................................................................................................80

Find Row ......................................................................................................................................................81

Find Column ...............................................................................................................................................83

Find Line Edge...........................................................................................................................................85

Find Subpixel Edge ..................................................................................................................................88

Find Multiple Edges .................................................................................................................................89

Find Mean of Edges................................................................................................................................92

Find Circle Edges......................................................................................................................................94

4.5 Measure ..............................................................................................................................................................97

Centroid .......................................................................................................................................................97

Area ............................................................................................................................................................... 98

Single Blob Analysis ................................................................................................................................99

Perimeter..................................................................................................................................................100

Mean Intensity........................................................................................................................................ 101

Line Intersection....................................................................................................................................102

Distance and Angle ..............................................................................................................................103

Blob Finder...............................................................................................................................................104

Blob Analyzer ..........................................................................................................................................106

4.6 Matching...........................................................................................................................................................109

Shape Locator........................................................................................................................................109

Add Shape Runtime .............................................................................................................................112

Get Shape................................................................................................................................................113

Transform Image...................................................................................................................................114

Transform ROI.........................................................................................................................................116

Teach Rotation.......................................................................................................................................118

Match Rotation....................................................................................................................................... 119

Teach Pattern .........................................................................................................................................120

Inspect Pattern....................................................................................................................................... 122

4.7 Circular..............................................................................................................................................................128

External Perimeter ................................................................................................................................128

Internal Perimeter .................................................................................................................................130

Circular Perimeter ROI.........................................................................................................................132

Circular Analysis..................................................................................................................................... 133

Check Circular Surface........................................................................................................................134

Check Circular Shape..........................................................................................................................135

4.8 Calculation.......................................................................................................................................................136

Mathematical Operation.....................................................................................................................136

Mathematical Expression...................................................................................................................137

In Range.................................................................................................................................................... 138

Polar to Cartesian Coordinates........................................................................................................139

Fit Circle ....................................................................................................................................................140

Fit Ellipse...................................................................................................................................................141

Sort .............................................................................................................................................................142

Update Statistics ................................................................................................................................... 143

Reference Manual

IVC-2D

4 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 5

Reference Manual

Contents

IVC-2D

Reset Statistics...................................................................................................................................... 144

Coordinate Alignment..........................................................................................................................145

Get Calibrated Point.............................................................................................................................146

4.9 Program............................................................................................................................................................147

Goto............................................................................................................................................................147

If Then Goto.............................................................................................................................................148

If Error Goto............................................................................................................................................. 149

If in Range Goto.....................................................................................................................................150

If All in Range Goto............................................................................................................................... 151

If................................................................................................................................................................... 152

Else............................................................................................................................................................. 153

For...............................................................................................................................................................154

While...........................................................................................................................................................155

Subroutine Start ....................................................................................................................................156

End.............................................................................................................................................................. 157

Run Flash Program ............................................................................................................................... 158

Program Protection...............................................................................................................................159

4.10 System..............................................................................................................................................................160

Get Timer..................................................................................................................................................160

Wait............................................................................................................................................................. 161

Read from Table.................................................................................................................................... 162

Write to Table .........................................................................................................................................163

Fill Table....................................................................................................................................................164

Load Data Block from Flash .............................................................................................................165

Save Data Block to Flash...................................................................................................................166

Load Image from Flash....................................................................................................................... 167

Save Image to Flash............................................................................................................................ 168

Write Table To Flash ............................................................................................................................170

Read Table From Flash....................................................................................................................... 171

Web Status Page ..................................................................................................................................172

4.11 Communication .............................................................................................................................................174

Setup RS485.......................................................................................................................................... 174

Read RS485 Values ............................................................................................................................175

Write RS485 Values ............................................................................................................................176

Read RS485 String ..............................................................................................................................177

Write RS485 String ..............................................................................................................................178

Enable Ethernet ..................................................................................................................................... 179

Open Ethernet Raw .............................................................................................................................. 180

Close Ethernet Raw.............................................................................................................................. 182

Read Ethernet Bytes............................................................................................................................ 183

Read Ethernet Bytes Formatted .....................................................................................................184

Read Ethernet String ........................................................................................................................... 186

Write Ethernet Bytes............................................................................................................................ 187

Write Ethernet Bytes Formatted .....................................................................................................188

Write Ethernet String............................................................................................................................190

Communication Setup.........................................................................................................................191

Communication Read/Write..............................................................................................................192

Send to FTP............................................................................................................................................. 193

Get from FTP........................................................................................................................................... 196

Get SNTP Time.......................................................................................................................................198

4.12 Input/Output ................................................................................................................................................... 199

Read Input ...............................................................................................................................................199

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 5

Page 6

Reference Manual

Contents

IVC-2D

Set Output................................................................................................................................................ 200

Set All Outputs........................................................................................................................................201

Set Timed Output..................................................................................................................................202

Set LED .....................................................................................................................................................204

4.13 Reader...............................................................................................................................................................205

Read Barcode.........................................................................................................................................205

2D Code ...................................................................................................................................................207

5 Interactive Setups .....................................................................................................................................209

Shape Locator Interactive Setup........................................................................................................................209

Add/Edit Shape Interactive Setup...................................................................................................................... 212

Locating Shapes (tips and tricks).......................................................................................................................214

Find Line Edge............................................................................................................................................................218

Coordinate Alignment..............................................................................................................................................220

Communication Setup ............................................................................................................................................223

2D Code .......................................................................................................................................................................228

Detail Extraction Setup ........................................................................................................................................... 232

Binarize Setup ............................................................................................................................................................ 234

Blob Finder Setup .....................................................................................................................................................235

Blob Analyzer Setup................................................................................................................................................. 238

6 Troubleshooting .........................................................................................................................................240

6.1 Connecting to Devices................................................................................................................................240

6.2 Saving to Flash ..............................................................................................................................................242

6.3 Running IVC Studio.......................................................................................................................................243

6.4 Debugging Step Programs........................................................................................................................243

6.5 IVC Emulator...................................................................................................................................................243

6.6 Trouble report ................................................................................................................................................244

Appendix ................................................................................................................................................................245

A Mathematical Expressions........................................................................................................................245

B Setting Device Parameters....................................................................................................................... 249

6 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 7

Reference Manual Chapter 1

The Camera

IVC-2D

1 Functional Overview

1.1 The Camera

The camera contains a powerful microprocessor that is tailored for image analysis. The

processor can perform a number of commands – or tools – that are used for example for

capturing an image, finding an edge in an image or setting one of the camera’s output

signals.

Working Memory

x1=1.273

y1=9.742

z1=6.37

...

Active

Program

Active

Table

Image

Banks

Data

Blocks

Flash Memory

1

2

3

4

5

...

Program

Banks

1

2

3

4

5

...

Saved

Images

1

2

3

4

5

...

Saved

Data Blocks

The camera also has a working memory, which contains the following:

Active program, which is a sequence of commands that are used for analyzing the

images.

Active table, which is used for reading and storing values that are used during the

analysis.

A number of image banks, which each contains an image captured and processed by

the camera.

Data blocks, which are used by some tools for storing or reading additional data. For

example, some pattern recognition tools (Teach tools) create and save data in a data

block, which can later be used by other tools (Match tools).

In addition, the camera has a flash memory, which is used for additional storage. The flash

memory contains the following:

Program banks, which are used for storing programs and tables that can be loaded into

the camera’s working memory. A program bank always contains both one program and

one table.

Saved images, which can be used for example as a basis when teaching the camera

patterns to recognize.

Saved data blocks, containing for example pattern recognition data to be used by

Match tools, so that the pattern does not have to be taught before running a program.

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 7

Page 8

Chapter 1 Reference Manual

Functional Overview

IVC-2D

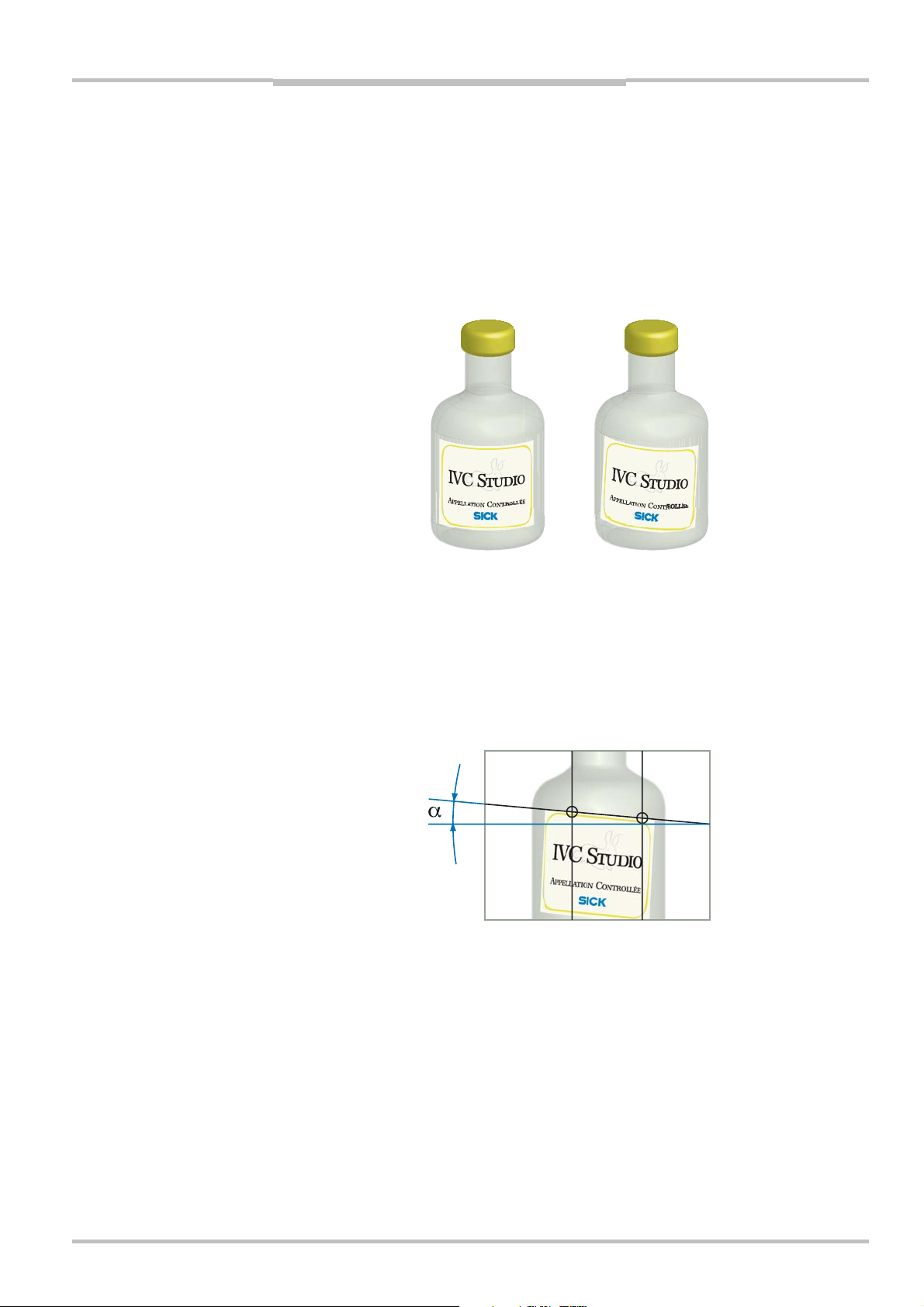

1.2 IVC Studio

IVC Studio is used for developing the programs that are used by the cameras when performing inspections – that is, analyzing images. IVC Studio can handle both 2D and 3D

cameras.

When you develop a program in IVC Studio, you work with a product. A product in IVC

Studio is a great help for handling all the devices (usually cameras), programs and tables

that are needed for a certain inspection.

The product contains a list of the used devices, and copies of all programs and tables that

are used by the devices. Normally, each device has one program and one table associated

to it, which is also the program and table that are currently in the working memory.

To be able to work with a program in IVC Studio, it must be associated with a device. The

device can be either a hardware camera or the Emulator, see below. A program is always

executed on a device – and never on the computer. The computer is mainly used for

building and modifying the programs on the devices, and to display the results sent from

the devices.

Product

Devices

Camera1

Programs Tables

Camera2 Emulator

<< uses >>

Label LabelTable

FillLevel FillTable

1.2.1 IVC Emulator

The Emulator is a software behaving like an IVC camera, and can be used instead of an

IVC camera. The Emulator is available in the IVC Studio development environment, and it

makes it possible to develop programs when there is no IVC camera available. The Emulator can emulate both 2D and 3D cameras. The main difference between the Emulator and

a camera is that the former uses a pre-recorded set of images stored in an image folder

on the PC, whereas the latter views live images.

1.2.2 Programs in Development and Production

During development, you build the program in IVC Studio but the program is automatically

downloaded to the associated device.

When a program (or program step) is executed it is executed in the camera, and the

results are sent back to IVC Studio where they are displayed.

Program steps

Table values

Images

Result values

8 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 9

Reference Manual Chapter 1

IVC Studio

IVC-2D

When the development of a program is finished and it is ready to be used, the program

(and table) is downloaded to the device and started.

After this it is not necessary to use IVC Studio any more. It may be used to display the

results from the program, for example to signal when faults occur. But the device can also

be used as a stand-alone unit, where other equipment is used for controlling the device

and displaying the output. For example, you could set up a web page on the camera and

then monitor the camera from a web browser on any computer on the network.

Programs

Tables

Input

Output

1.2.3 Saving Programs

When you save a product in IVC Studio, the included programs and tables are saved with

the product on the computer. Nothing is saved on the device when you save the product.

This is not a problem since the program associated with the device is automatically loaded

into the device as soon as the program is started or edited in IVC Studio.

Product

Devices

Camera 1

Camera 2

Associated

Program

Associated

Table

Copied

automatically

Copy values

manually

Working

Memory

Active

Program

Active

Table

Save in

lash

F

Flash

Memory

1

2

3

4

5

...

Program

Banks

The programs and tables may be stored manually on the device as well. The flash memory

in the device contains a number of program banks, each of which can contain a program

and a table.

When you store a program in the flash memory, you always store the active program and

table, which are currently in the working memory of the device.

A program stored in program bank 0 will automatically be started when the device is

powered up.

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 9

Page 10

Chapter 1 Reference Manual

Functional Overview

IVC-2D

1.3 Handling Multiple Products

A device may be used in several products, using different programs and tables depending

on the product. This makes it easy to use the same camera for performing different inspections. Just create one product for each inspection, and in each product associate the

program and table to be used for the specific inspection.

For example, there are three cameras set up by a production line, and we are producing

two different items on this production line – a transparent bottle and an opaque jar. For the

bottle we can use IVC-2D cameras to inspect both the label on the front and the fill level,

but for the jar we need to use an IVC-3D camera to inspect the fill level.

Device 3

Device 2

Device 1

Product: Bottle

Dev Program Table

1 Label Bottle_Label_Table

2 Bottle_FillLevel Bottle_FillLevel_Table

Device 1

Product: Jar

Dev Program Table

1 Label Jar_Label_Table

3 Jar_FillLevel Jar_FillLevel_Table

To achieve this we create two products in IVC Studio with the following contents:

Product: Bottle

Device Program Table

1 Label Bottle_Label_Table

2 Bottle_FillLevel Bottle_FillLevel_Table

Product: Jar

Device Program Table

1 Label Jar_Label_Table

3 Jar_FillLevel Jar_FillLevel_Table

When switching between producing the two products, we can simply open the product in

IVC Studio to load the corresponding programs and tables into the devices. If we would

change the design of the label for the bottle, we can just change the values in the table

Bottle_Label_Table to suit the new design. If necessary we could also make a copy of the

program Label, modify it, and associate the modified program with device 1.

10 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 11

Reference Manual Chapter 2

IVC-2D

Creating a product

2 Getting Started

In this chapter we will introduce the basics in IVC Studio, and learn how to:

Set up IVC Studio to write a program

How to write the program - that is adding program steps and setting parameters

How to test and debug the program

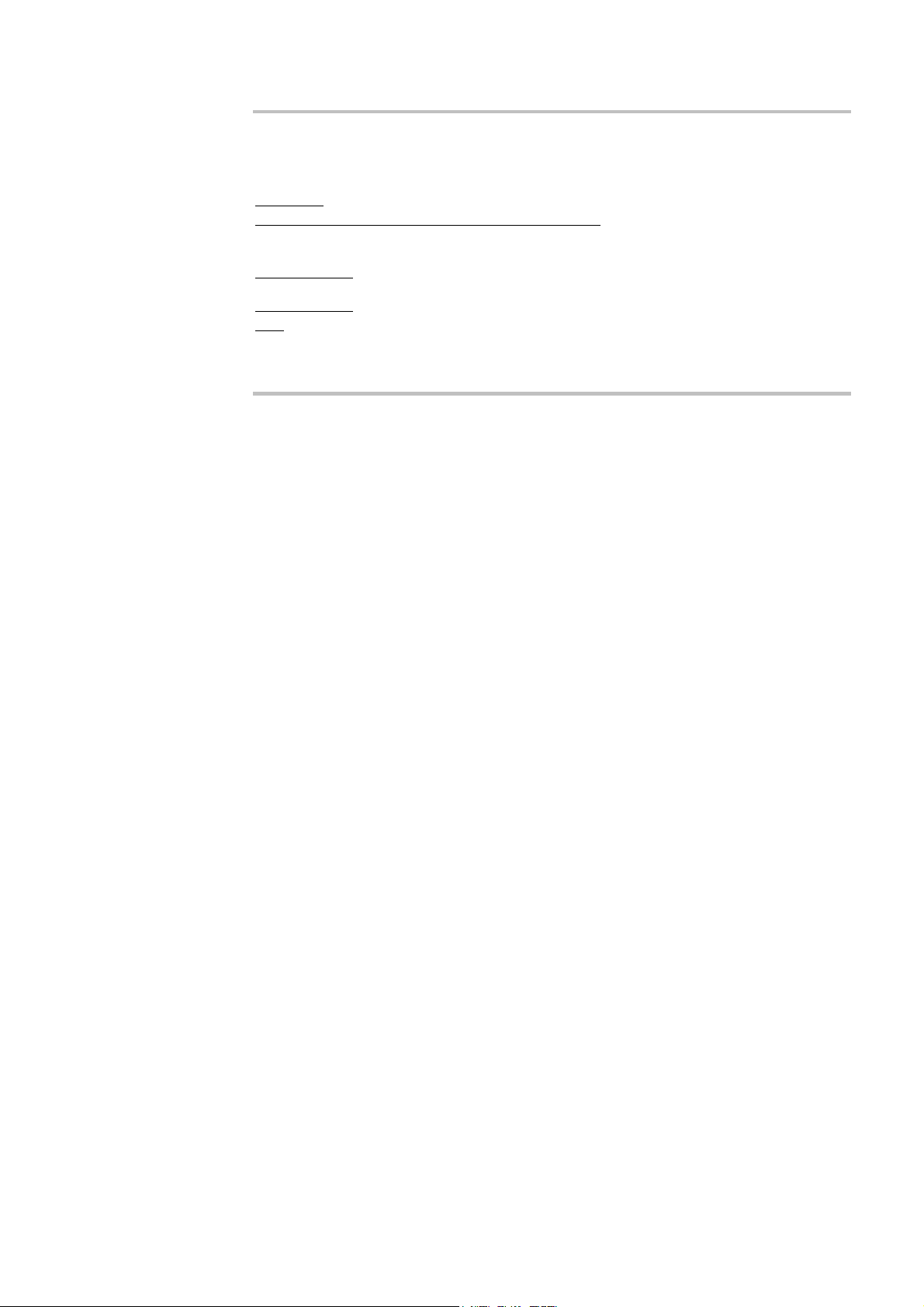

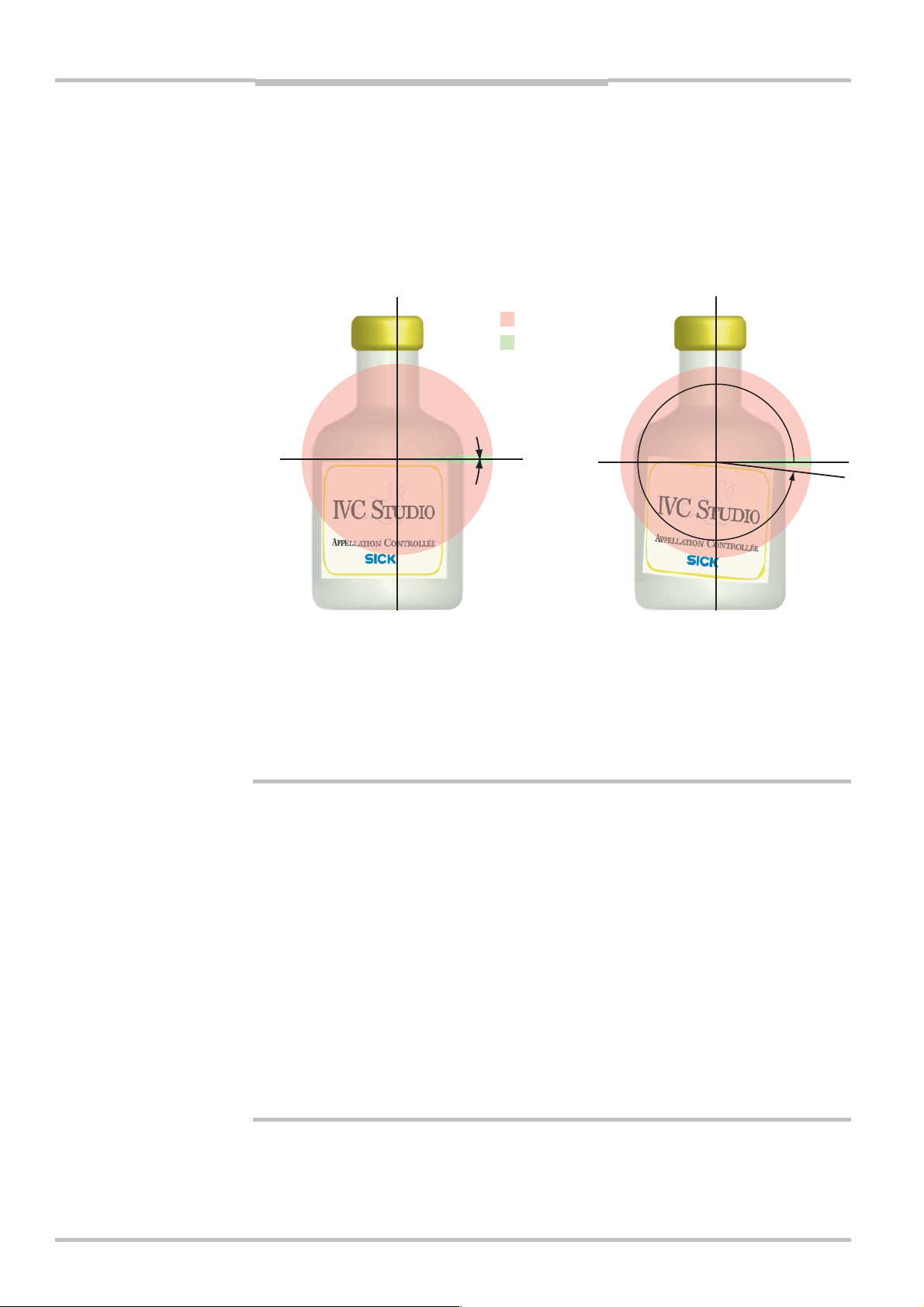

As an example we will build a simple program that checks whether or not a label has been

placed correctly on a bottle, that is if it is tilted or not.

OK Fail

A simple way of checking this is to:

Capture an image of the bottle

Search the image along two lines to find the edge of the label in two locations

Calculate the angle between the two locations

If this angle is too large then the label is tilted, and the program changes the state of an

output. In a real application this output could for example control a lever that pushes the

faulty bottle to the side.

When writing a program in IVC Studio you can use either a hardware camera or, if no such

is available, the Emulator.

In the following sections it is assumed that a hardware camera is used, and that both the

camera and IVC Studio are installed and are working properly. How to install the camera

and IVC Studio is described in the installation instruction.

How to use the Emulator is described in section Using IVC Studio in the IVC-2D Reference

Manual.

2.1 Creating a product

Before starting to write the program that performs the inspection, you need the following:

A product to work in

A device to use in the product (in this case a camera)

A program written for the device

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 11

Page 12

Chapter 2 Reference Manual

Getting Started

IVC-2D

A table used for the program in the device

A product in IVC Studio is a collection of devices (usually cameras) that are used for per-

forming an inspection, for example of bottles on a production line. Each device contains

one or more programs that instruct the device how to perform the inspection.

A program is a list of commands, or tools, that the device executes one by one, in order to

capture images, analyze them and draw conclusions from. To its help, the program has a

table that it can read values from and store results to.

Product

Devices

2.1.1 Create a

Camera1

Programs Tables

Product

Camera2 Emulator

<<

uses

>>

Label LabelTable

FillLevel FillTable

The first step is to create the product to work in:

1. Start IVC Studio and log in.

If you just installed IVC Studio, the default user and password can be found in the

installation instruction.

2. Choose File

Æ New Product from the IVC Studio menu bar.

A new empty product named New Product is opened.

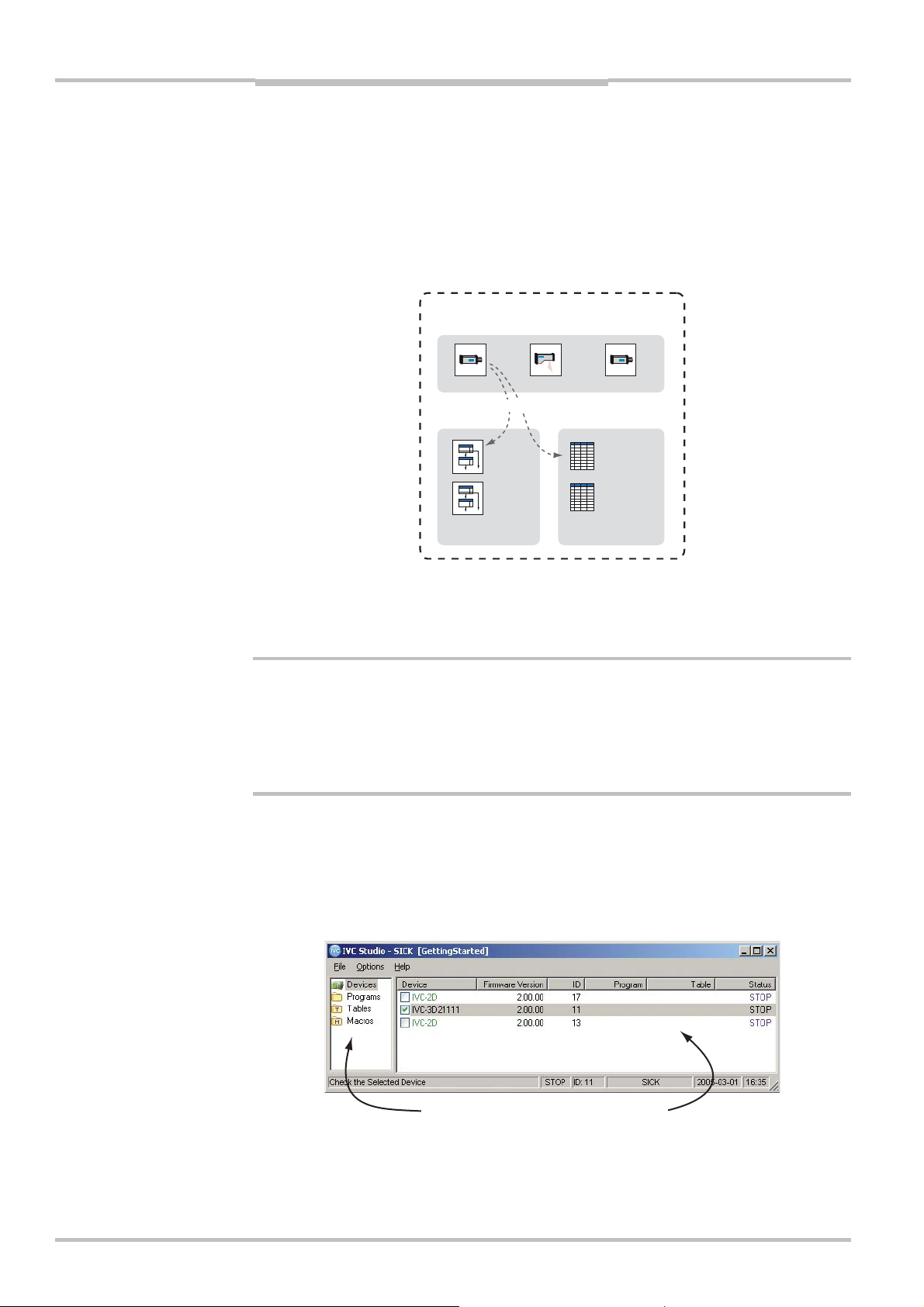

The main window shows the contents of the currently open product. The left pane shows

the different types of objects that the product may contain, that is; devices, programs and

tables.

Clicking on one of the categories will display the objects contained in the product. Since

the product was just created, all the categories are empty, with the exception of Devices,

which displays all available devices.

Left pane Right pane

12 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 13

Reference Manual Chapter 2

IVC-2D

Creating a product

There is also a fourth type that we haven’t mentioned yet - macros. Macros are basically

small programs that you can call from within regular programs. They can be useful for

reusing blocks of program steps when writing advanced programs.

2.1.2 Select a Device

The next step is to select the device used for the inspection:

3. Click Devices in the left pane of the main window.

The camera is displayed in the right pane. If there are more devices that can be used

by IVC Studio in your network, those will also be displayed in the right pane.

4. Select a device by clicking in the checkbox in front of it in the right pane.

You should always select the devices that you intend to use in your product. IVC Studio

periodically updates the information in the device list by polling the devices that are selected in the list.

If no device is selected in the list, IVC Studio will poll every device it can find for information.

This slows down IVC Studio may affect the performance of devices used by other users.

2.1.3 Create a Program

Now we are ready to create the program that we intend to build and associate it with a

device.

The reason for associating the program with a device before building it is that the program

is always run in a device and not on the computer. What you see in IVC Studio when

running a program are just the results, which are sent from the device. If you didn’t associate the program with a device, you would not be able to see any result of the program or

even test the program.

5. Right-click Programs in the left pane in the main window, and choose New Program

from the pop-up menu.

6. Fill in a name for the program in the dialog box, and click OK.

7. Click Devices in the left pane of the main window.

8. Right-click the device in the right pane that is selected for the product, and choose

Select Program from the pop-up menu.

9. Select the program in the list in the dialog box, and click OK.

2.1.4 Create a Table

There must also be a table associated with the device, so before starting to build the

program we must create a table and associate it with the device:

10. Right-click Tables in the left pane in the main window, and choose New Table from the

pop-up menu

11. Fill in a name for the table in the dialog box, and click OK.

12. Click Devices in the left pane of the main window.

13. Right-click the device in the right pane that is selected for the product and chose

Select Table from the pop-up menu.

14. Select the table in the list in the dialog box, and click OK.

15. Finally, save your changes to the product on the PC by choosing File

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 13

Æ Save Product.

Page 14

Chapter 2 Reference Manual

Getting Started

IVC-2D

2.2 About Writing Programs

Before starting to write the program, we will take a look at what a program consists of and

the programming environment.

2.2.1 Tools

A program is a list of commands – or tools – that are performed by the camera. When the

program runs, the commands are carried out one by one in the order that they appear in

the program list. So when you build a program in IVC Studio, you work with this list of

commands.

Most of the tools have a number of input parameters that can be set. For example when

starting to take a snapshot from a camera, you may specify the exposure time and which

input that should trigger the capture.

0. Retrieve an image

1. Find edge (left)

Y coordinate of edge 220

2. Find edge (right)

Y coordinate of edge 340

3. Calculate angle

Angle

4. Measurement OK?

!

Result

5. Measurement OK

(

)

" #

(-

45¡

$%&

'%&

. (-

*

Table

Row

Value

#/

%

6. Measurement not OK

(

)

+,

Many tools also produce results that are available as output parameters. These parameters can be stored in the table or be used directly by other steps in your program.

14 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 15

Reference Manual Chapter 2

About Writing Programs

IVC-2D

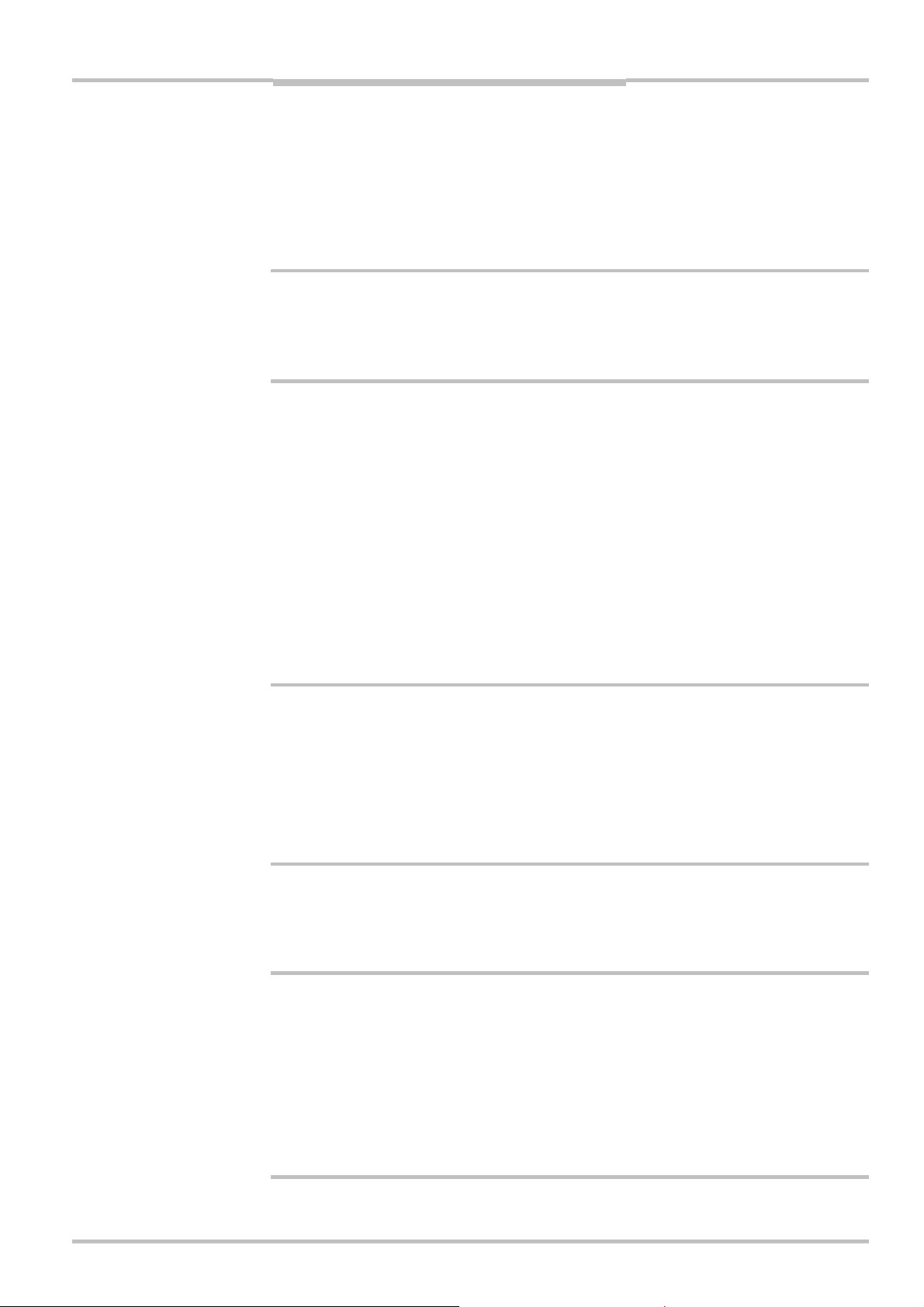

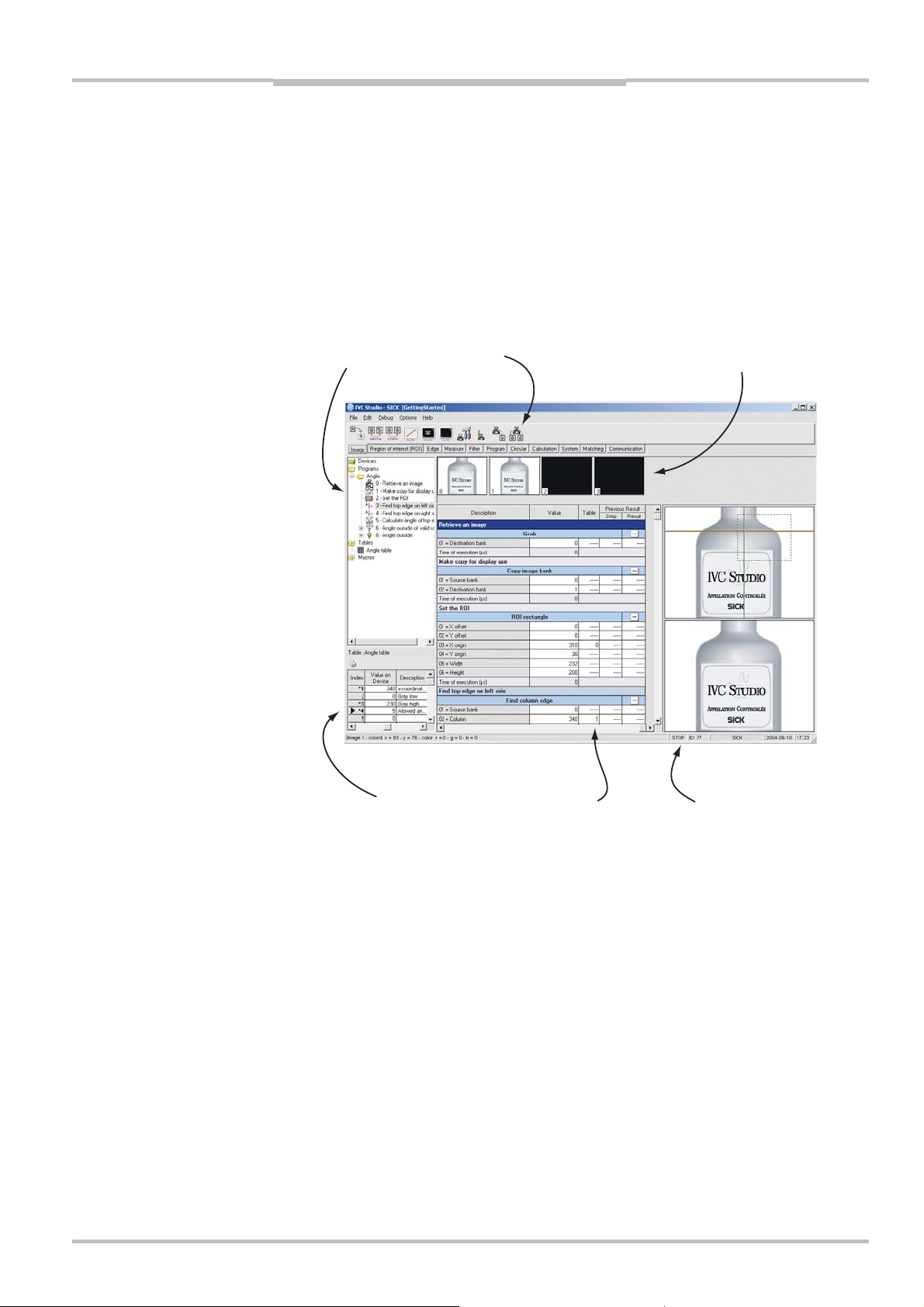

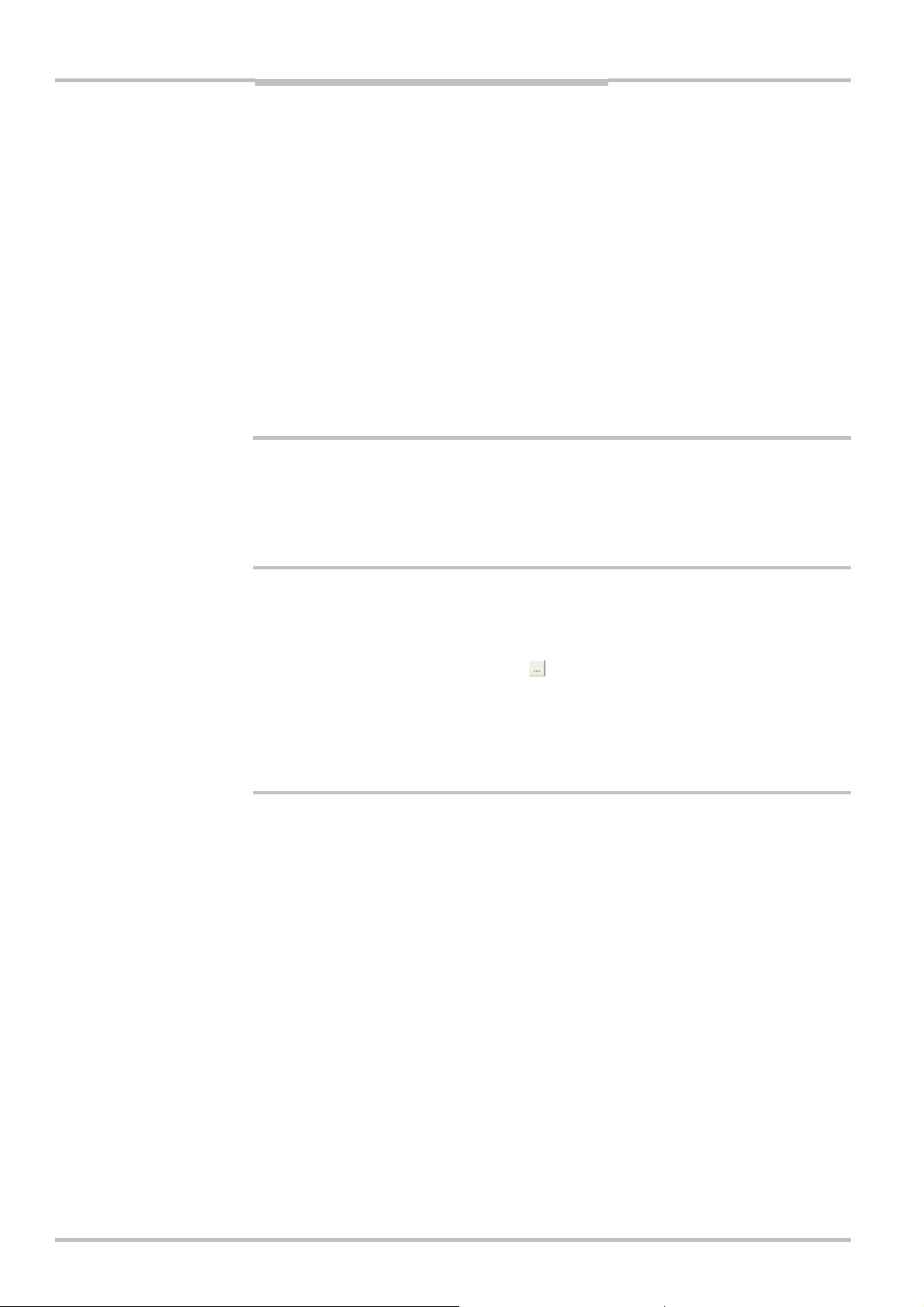

2.2.2 Programming Window

When you write a program, the main window contains a few additional parts:

Toolbar – contains the tools that can be used with the device.

Program List – shows the tools used in the program and the parameters for each tool.

Table – shows the contents of the device’s table

Image Banks – shows thumbnails of the images currently in the image banks of the

device (if any)

Preview – shows the result of the program step when applied to an image.

ToolbarTree View

Image Banks

PreviewTable Program Steps

The toolbar actually contains several toolbars on which the tools are grouped into categories. You switch between the categories by clicking the tabs at the bottom of the toolbar.

The program list shows each step in the programs as a table. Each step contains:

The input parameters that can be set for the tool

The execution time for the tool when executed

The result (return values) from the tool

There are four columns in the program list, which are used for specifying parameter values;

Value, Table, Step and Result. Which column to use depends on what type of parameter

value you want to use; constant values, values stored in the table, or results from previous

steps.

Image banks are used for storing images, just like the table is used for storing values. This

can be very useful, for example if you want to modify the image, but need to use the

original image later on in the program. Note that the images are stored in the camera, and

that the images in the image banks remain there until they are removed or overwritten by

other images.

The preview window is used by some tools to visualize the result of the tool. This preview is

useful when you develop your program, but is not generated when the program is running.

The preview window may also be used for setting parameters for certain tools. This is

further described later on in this chapter.

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 15

Page 16

Chapter 2 Reference Manual

Getting Started

IVC-2D

2.3 Adding Program Steps

Now we are ready to start writing our program for inspecting the label on the bottles.

Start by adding the first program step to the program, which should grab an image from

the camera:

1. Click on the name of your program in the left pane in the main window.

A toolbar is displayed at the top of the window, which contains a number of tools that

can be used with the device. Below the toolbar there is a row of tabs, which are used

for switching between different categories.

2. Click the Grab tool in the Image category on the toolbar to add the first step to the

program.

The Grab tool is added to the program’s folder in the left pane, and the Image Banks,

Program List and Previews are displayed in the right pane.

3. Double-click the blue field at the top of the program step, and type a description for

the step, for example “Retrieve an image”.

Description Value Table

Retrieve an image

0 - Grab

01 - Destination bank 0 ------ ------ ------

Time of execution (µs) 0

Previous result

Step Result

The command is now added to our program, but in order to see the effect of the command, it has to be executed by the camera.

4. Click the Grab step in the program list to select the step.

5. Press F1 to open up the Reference manual for the Grab step.

6. Close the manual again and remember to use the F1 button whenever you want to

learn more about a tool.

7. Choose Debug

Æ Execute Step from the IVC Studio menu, or press the F5 key on the

keyboard.

An image is now retrieved from the camera and stored in image bank 0.

16 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 17

Reference Manual Chapter 2

Setting Parameter Values

IVC-2D

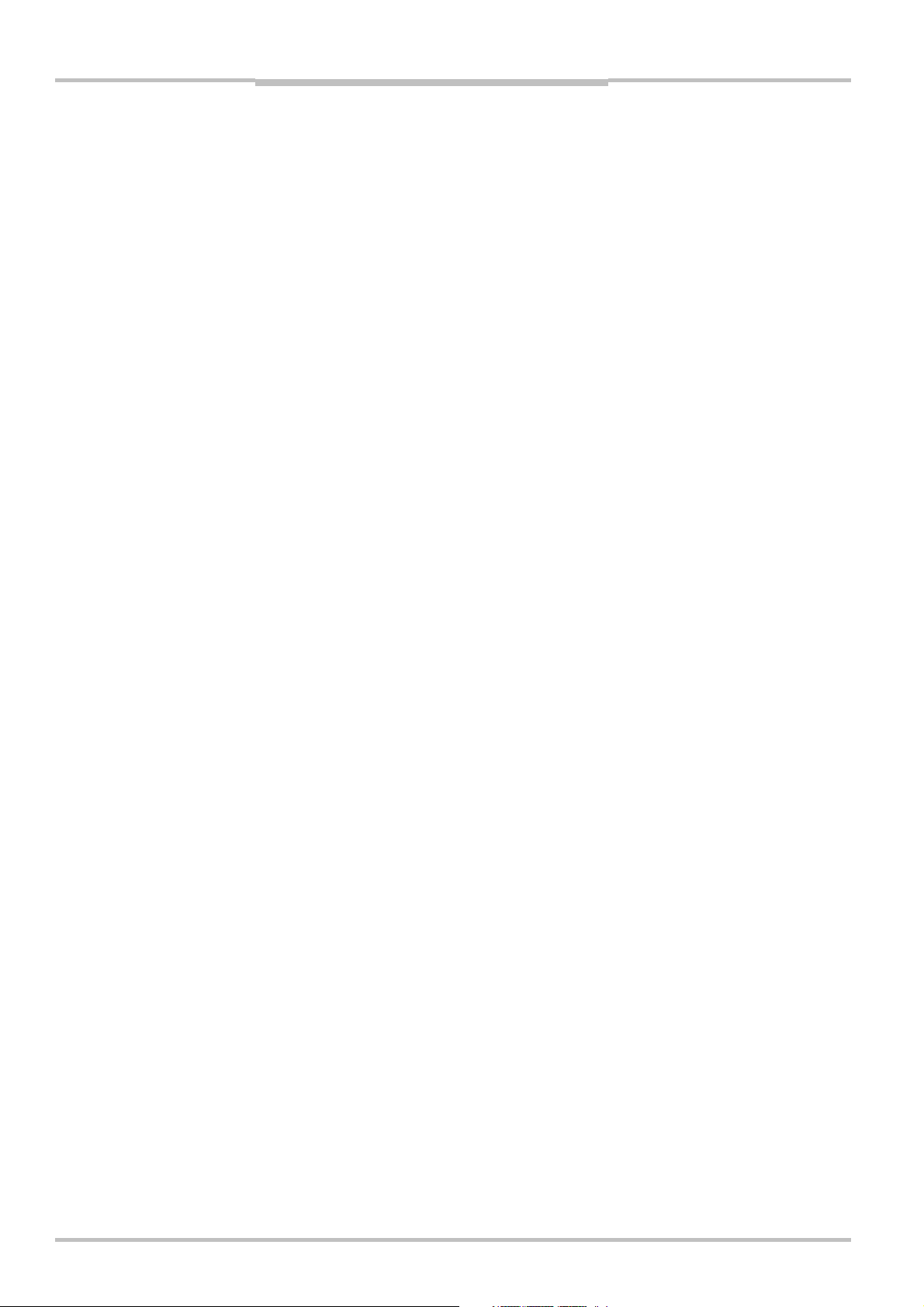

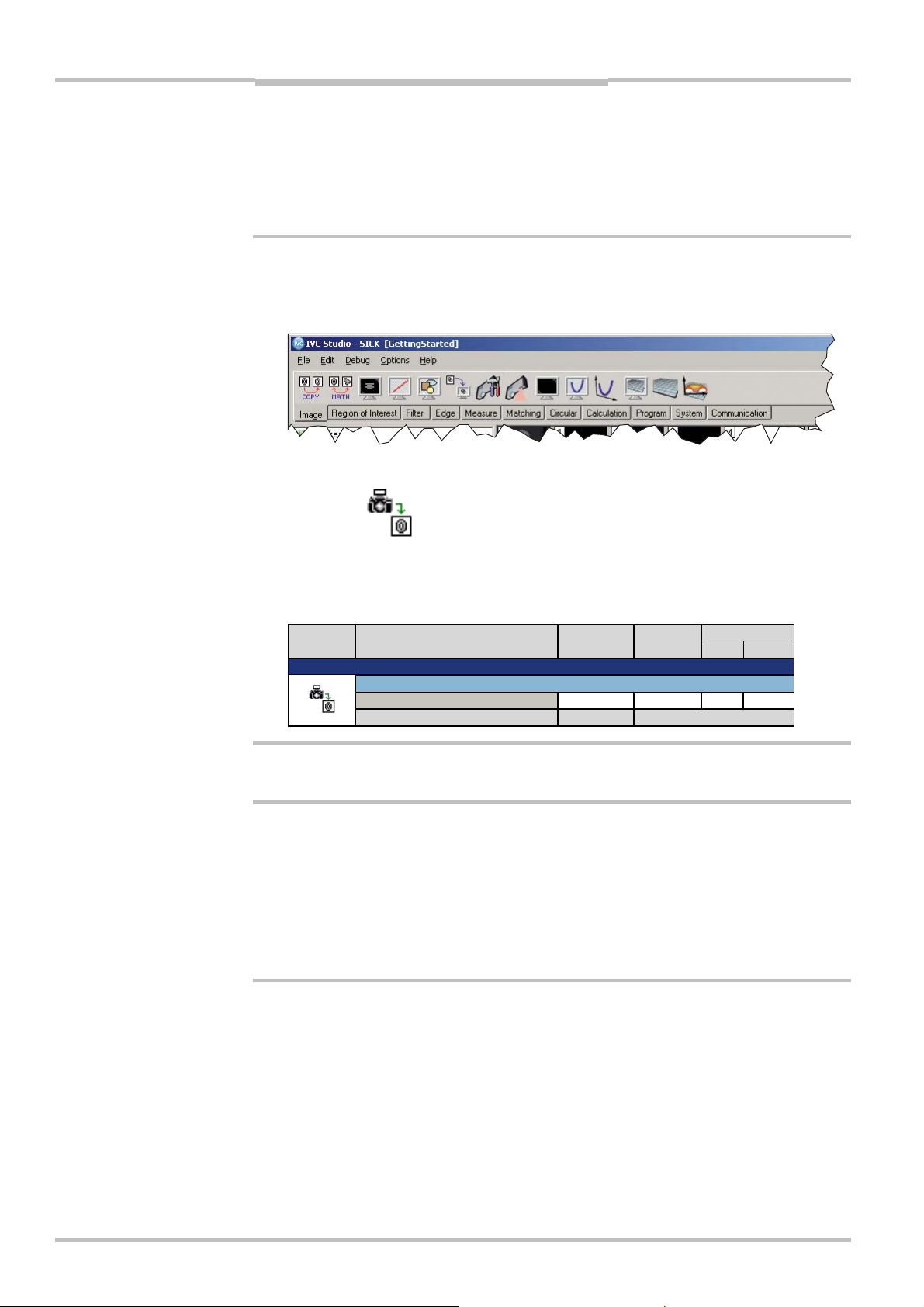

To search the image for the edge we need two tools:

A ROI Rectangle that creates a Region of Interest, which defines where in the image we

expect to find the edge of the label.

A Find Column Edge that looks for the upper edge of the label on the left side of the

image.

Scan line

Left point

Region of interest

(ROI)

We also need a step that finds the upper edge on the right side, but we will add that step

after we have set the necessary parameters.

8. Click the ROI rectangle tool on the ROI toolbar.

9. In the dialog box that is displayed, choose ...after current step and click OK.

The ROI Rectangle step is added to the program list.

10. Add a description to the step, such as “Set ROI to the top of the label”

11. In a similar manner, add a Find column edge tool (from the Edge toolbar) to the

program and give it the description “Find left edge”.

2.4 Setting Parameter Values

The input parameters can be set in a number of different ways:

By manually entering a constant value

By using interactive setup to set constant values

By retrieving a value from the table

By using the result from a previous step

By writing an expression that may combine the methods above

In this section we will look at different ways of setting constant parameter values. Using

tables, results from previous steps and expressions will be shown in the following sections.

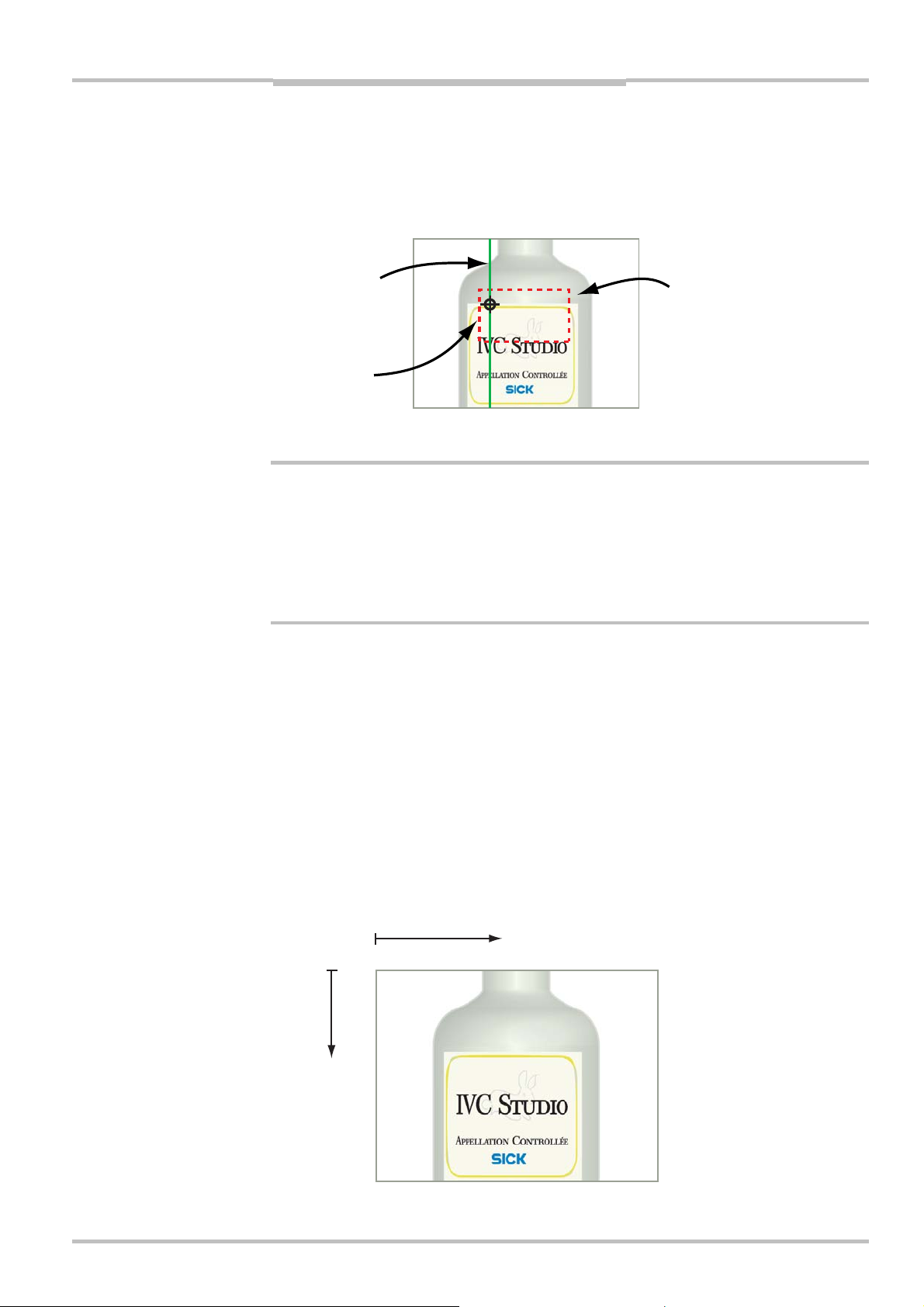

One important thing when specifying coordinates in images – coordinates are always

measured from the top, left corner of the image.

X coordinate

Y coordinate

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 17

Page 18

Chapter 2 Reference Manual

IVC-2D

Getting Started

2.4.1 Setting Constant Parameter Values

Both the ROI rectangle and the Find column edge tools need a number of parameters to be

set:

ROI rectangle • The rectangle that is our region of interest.

Find column edge • An image bank containing the image to scan.

• A Region of Interest (ROI), which is specified by entering the number

of the program step in which we defined the ROI that we want to use.

• The line along which the image should be scanned and the direction

to scan in. Since this tool always scans along vertical lines, the line

can be specified by entering the x coordinate for the line.

• The range of grayscale values in which we expect to find the edge

that we are searching for.

To set a constant value manually is really straight-forward – just enter the value in the Value

column for the parameter:

12. Select the Find column edge step.

13. Double-click the Value column for the parameter 06=ROI definition step, and enter the

program step in which you specified the ROI.

14. Set the scan direction by double-clicking the Value column for the parameter

03=Analysis direction, and choose Up

ÆDown from the menu.

Interactive setup windows are also used for entering constant values, but in this case

captured images are used to provide feedback for the settings. Parameters can be set

interactively in three different ways:

In the Preview window

By clicking the button with three dots (

double-clicked

By double-clicking the Setup field that is displayed at the bottom left corner of certain

program steps

For example, when defining a ROI it is usually much easier to mark it directly in the image in

a preview window than entering coordinates for the rectangle in the Value column:

15. Select the ROI rectangle step.

A rectangle is shown in the upper preview window. This is the default ROI that is set

for a new ROI rectangle.

), that is displayed when a parameter is

18 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 19

Reference Manual Chapter 2

IVC-2D

Setting Parameter Values

16. Move and resize the rectangle in the preview, so that it marks the area where you can

see a part of the upper edge of the label.

17. Select the Find column edge step

18. Set the line to scan along by moving it in the preview window.

The line must be inside the ROI, which is also displayed in the preview window. By

default, the line is placed at the left edge of the preview window.

If you need a larger window to work in, you can double-click a preview to open it in a

separate window. In this window you can fine-tune the parameters settings, for example if

there are small details in the image.

Some parameters can be set in special interactive setup windows. These windows are

similar to the preview windows, but contain additional controls that are used for setting the

parameter values.

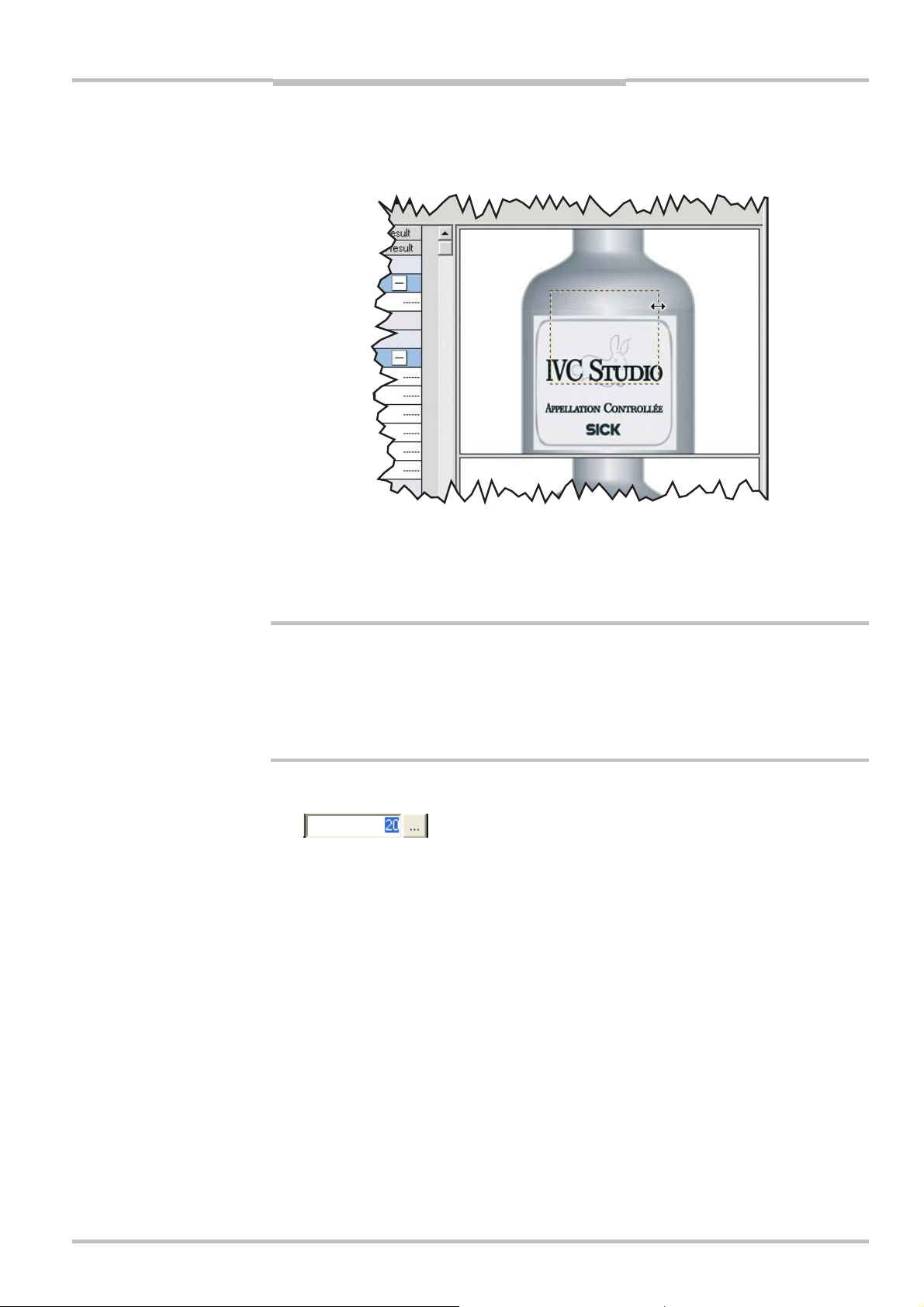

19. Double-click the Value column for the parameter 04=Gray low, and click the button with

the three dots.

A preview of the image is displayed in a separate window, which also shows the ROI,

the line along which the image is searched (yellow), and the edge that is detected

using the current parameter values (red/green).

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 19

Page 20

Chapter 2 Reference Manual

IVC-2D

Getting Started

20. Click on the H (Gray High) or L (Gray Low) button, and adjust the upper or lower gray

value with the slider, so that the edge of the label is clearly visible within the ROI.

Certain tools have interactive setup windows in which you can set all parameters. These

tools have a Setup field in the bottom left corner of the program step in the program list. To

open the setup window, double-click the Setup field.

When all parameters have been set for the Find Column Edge step, we can duplicate the

step and use the copy to find the edge on the right side – just change the line to search

along.

21. Select the Find column edge and choose Edit Æ Copy from the main menu.

22. Choose Edit

23. Set the line to scan along in the new Find column edge step by moving it in the preview

window.

24. Change the description of the program step to “Find right edge”.

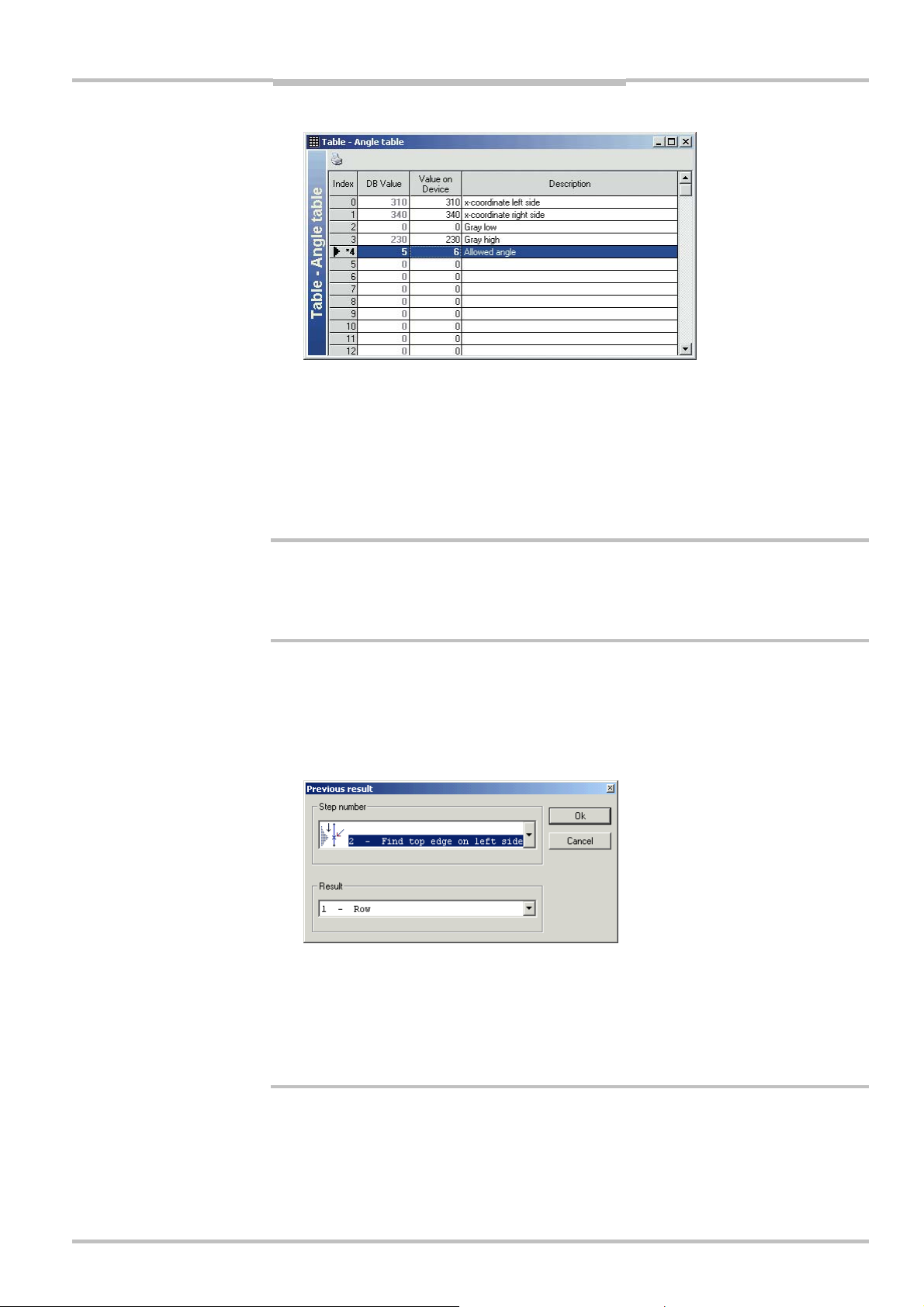

2.4.2 Using Tables and Results from Other Steps

We will need the x coordinates for the lines when we calculate the angle of the top edge of

the label. Therefore it is useful to store these values in the table instead of having to set

them manually for each step in which they are used:

Æ Paste.

25. Select the “Find left edge” step, and copy the value of the parameter 02=Column.

This value is the x coordinate for the left point of the label.

26. Paste the value into an empty row in the Value on Device column in the table.

The row is now highlighted in the table, indicating that the value on the device differs

from the value in the database.

You may also enter a description for the row, describing what the value is used for.

20 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 21

Reference Manual Chapter 2

IVC-2D

Setting Parameter Values

27. In the table, right-click the value in the Value on Device column, and choose Copy

Device Value to DB to synchronize the value on the PC with the value in the device.

28. Select the “Find left edge” step again, and double-click in the Table column for the

parameter 02=Column.

29. Fill in the number of the table row in which you pasted the value of the x coordinate.

30. In a similar way, copy the value of the parameter 02=Column in the “Find right edge”

step to the table, and replace the value in the program step with a reference to the

table row.

Now we are ready to add a step that calculates the angle of the top edge of the label.

The tool we are going to add takes the x and y coordinates of two points as parameters.

We just stored the x coordinates in the table, and the y coordinates are the results (output

parameters) of the two Find Column Edge steps in the program.

31. Add a Distance and angle tool (from the Measure toolbar) to the program.

32. Set the parameters 01=Start point X and 03=End point X to refer to the table rows

where you stored the x coordinates of the left and the right point on the label edge.

33. Double-click the Step column of the parameter 02=Start point Y.

A Previous result dialog box is displayed, in which you can select which result from

which program step number to use as parameter value.

34. Choose the step number of the first Find column edge step and then the first result

from that step (there is only one result to choose from), and click OK.

The numbers of the step and the result are entered in the Step and Result columns of

the 02=Start point Y parameter and the current value is displayed in the Value column.

35. In a similar way, set the parameter 04=End point Y to the result of the second Find

Column Edge step.

2.4.3 Using Conditions and Jumps

The angle of the label should now be tested to see whether or not it falls within the valid

range of angles, and accept or reject the bottle according to the result. This is done by

adding the following steps:

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 21

Page 22

Chapter 2 Reference Manual

IVC-2D

Getting Started

In range, which tests if a value lies within a range specified by the upper and lower limit

of the range, and returns 1 if the value is within the range or 0 if it is not within the range.

If then goto, which jumps to a specified program step if a value is not zero.

The Distance and angle tool returns an angle between 0 and 360 degrees, but we would

like to specify an angle between for example -5 to +5 degrees as being a valid angle. One

way to get around this is to state that angles between 5 and 355 degrees are not accepted, and any other angle is accepted.

90°

Angle Out of Range

Angle In Range

90°

α

0°

180°

0°

α

270°

• Angle is not OK

• The test if the angle is

within “Out of Range” returns 1, and the program

jumps

180°

270°

• Angle of the label is OK

• The test if the angle is

within “Out of Range”

returns 0, and no jump is

made

To make it even more flexible, we will store the highest angle that is accepted in the table,

and calculate the range directly in the program step.

36. Add an In range tool (from the Calculation toolbar).

37. Set the parameter 01=Value to the angle that was calculated by the previous step by

referring to the result of that step.

38. Enter the highest acceptable angle, for example 5 degrees, in a row in the table.

39. Set the parameter 02=Min value allowed to refer to the table row in which the angle is

stored.

40. Set the parameter 03=Max value allowed to the following value:

=360-V<table row>

where <table row> is replaced with the number of the row where the angle is

stored.

41. Add an If then goto tool (from the Program toolbar).

42. Set the parameter 01=Control expression to the result of the In range step.

Do not set the parameter 02=Goto step yet, since we are going to jump to a program

step that we have not added to the program.

22 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 23

Reference Manual Chapter 2

IVC-2D

Testing and Running the Program

The value of the parameter 03=Max value allowed is an expression that calculates a value

each time this step is performed. An expression always begins with an equal sign (=), and

may contain:

Constant values 360, 4/7, etc.

Table values Vn for the value in row n

Results from other steps SmRn for result n of step m

Parameters (arguments) in other steps SmAn input parameter n of step m

Functions sin(), abs(), etc.

Instead of writing an expression, we could have used a Ma the matical oper ation tool. Which

to choose depends on the complexity of the calculation – the more complex a calculation

the more efficient is the Mathematical Expression.

Finally, we add program steps that set one of the outputs of the camera to high or low,

depending on the result of the analysis. This can be used for example to control a lever

that pushes the faulty bottle to the side.

43. Add a Set output tool (from the Communication toolbar), and set the following

parameters:

01=0utput number 0

02=Signal value Low

Name the step “Angle within range”

44. Add a Goto tool (from the Program toolbar) and set the parameters so that this step

jumps to step 0.

45. Add another Set output tool, and set the following parameters:

01=0utput number 0

02= Signal value High

Name the step “Angle out of range”

46. Add a Goto tool and make sure that this step jumps to step 0.

47. Select the If then goto step, and set the parameter 02=Goto step to the step number of

the “Angle out of range” step.

It is not necessary to add the last Goto step, since the program automatically jumps to

step 0 when it comes to the end. It is however a good practice to make sure that the

program jumps to the right place at the end. For example, you may add steps at the

beginning of the program that initialize the program, and that we only intend to run when

the program starts.

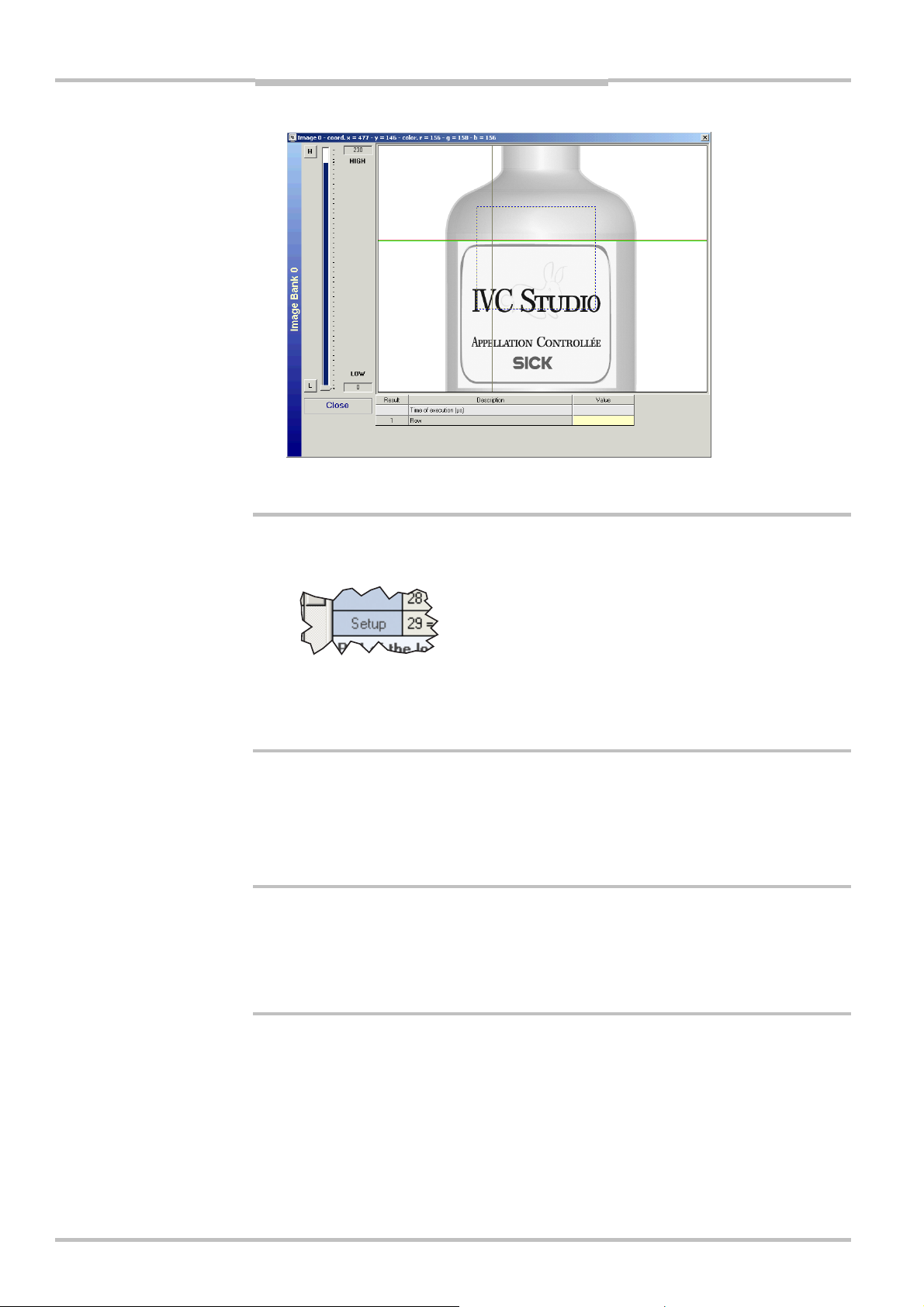

2.5 Testing and Running the Program

Now the program is written, but how do we know that it is working properly?

One way is to step through the program using Debug

Step. The result of each step is shown in the preview window and the Value column of each

parameter.

48. Use Debug Æ Execute Step and Debug Æ Step by Step to step through the program and

make sure that it gives the correct result. Move the bottle (or what you are using) to

get both accepted and rejected labels.

Another way is to add some program steps that show the result of the analysis, and run

the program.

49. Add a Copy image bank tool after the first Grab step.

Æ Execute Step and Debug Æ Step by

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 23

Page 24

Chapter 2 Reference Manual

Getting Started

IVC-2D

We add this step in order to have a copy of the image to draw in. If we draw in the

original image the analysis is affected by our drawings.

50. Add a Draw ROI tool after the ROI rectangle step.

This step draws the region of interest in the image. Make sure to draw in the image

bank with the copy of the image.

51. Add a Add text tool after the “Angle within range” step. Set the following parameters:

04=String ‘OK

06=String color Choose a green color

08=Size 2

You should also specify the location of the text to be displayed with the parameters

01=X origin and 02=Y origin. Make sure to draw in the correct image bank.

52. Add a Display tool after the Add text step, and set the parameter so that it displays

image bank 1.

53. Copy the Add text and the Display steps to after the “Angle within range” step. Change

the text to be displayed to ”Failed” and coloured red.

54. Choose Debug

Æ Run and watch the result in the Display window.

2.6 Saving the Program

To save the program we have written, use File Æ Save Product. This will save the program

on the PC (along with all other programs and tables in the product), but not on the device.

The program is present on the device as well, since it is downloaded to the device as you

build it.

But if the power to the device is cut, your program will be lost from the device and has to

be downloaded again from the PC. To prevent this from happening, you may save the

program in the flash memory on the device.

IVC Studio Device

Product

Devices

Camera 1

Camera 2

Associated

Program

Associated

Table

Copied

automatically

Copy values

manually

Working

Memory

Active

Program

Active

Table

Save in

lash

F

To download a program to a device without saving it in the flash memory:

Flash

Memory

1

2

3

4

5

...

Program

Banks

1. Open the product containing the program.

2. Make sure the program is associated with the device, and that a table is associated

as well.

3. Right-click the device in the list of devices, and choose Start Program from the pop-up

menu.

The program is downloaded to the device and started. The status of the device is

changed from STOP to RUN.

24 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 25

Reference Manual Chapter 2

IVC-2D

What’s Next?

When you save the program in the flash memory on the device, you choose the program

bank in which the program is saved. You always save the program that is currently in the

working memory of the device, and the table that is active is also saved with the program.

To save the program on the flash memory of the device:

4. Right-click the device in the list of devices and choose Flash Æ Write Program in Flash.

5. Select the program bank in which to save the program, and click OK.

The program is now saved in the selected program bank.

If you save a program in program bank 0, this program will start when the device is powered up. If you want the device to run a different program, you can load that program using

a PC, either by using an existing product (containing the program to be used), or by downloading the program from the device’s flash memory.

2.7 What’s Next?

In this chapter we have looked at the basics of how to handle IVC Studio, such as setting

up a product and writing a simple program. However, there are many features in IVC Studio

and the camera that we have not looked at, and that makes it possible to write advanced

programs for inspections and automation of production. Some of the features are:

Using the camera as a stand-alone unit

Using several devices in a product

Using several programs on a single device

Using Cameras Stand-alone

Once the program is developed it can be downloaded to the device and started. Now the

program will run in the device until it is stopped, and it is no longer necessary to use IVC

Studio. If the program is also saved in program bank 0 on the flash memory, the program

will be started when the device is powered up.

If you want to interact with the device, you can write a program that for example communicates with other equipment via the RS485 port, or uses the inputs and outputs of the

device to communicate with a simple control panel.

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 25

Page 26

Chapter 2 Reference Manual

Getting Started

IVC-2D

Using Several Devices

A product may use several devices that each performs a certain inspection. It is also

possible to use the same device in several products, and running different programs in the

device depending on in which products it is used.

Device 3

Device 2

Device 1

Product: Bottle

Dev Program Table

1 Label Bottle_Label_Table

2 Bottle_FillLevel Bottle_FillLevel_Table

Device 1

Product: Jar

Dev Program Table

1 Label Jar_Label_Table

3 Jar_FillLevel Jar_FillLevel_Table

To use several devices in the product, simply select the devices by clicking the checkbox in

front of them in the main window.

When the development is finished you can easily download the programs and tables to all

included devices at once by right-clicking Devices in the left pane of the main window and

choosing Product Transmission. This will also start the programs in the devices.

Using Several Programs

While there can be only one program in the working memory, additional programs can be

stored in the flash memory of the device. These programs can either be loaded manually

into the working memory, or they can be called from the active program.

To load a program manually, use IVC Studio to associate the program with the device

and then start the program. This requires that the program is available in the product

that is open in IVC Studio.

If the program is not available on the PC, you can retrieve it from the device by right-

clicking the device in the list of devices, and choosing Flash

Æ Import Program from Flash.

To call a program stored in flash from the active program, please refer to the Tools

section of this manual for information on which tool to use.

Note that calling a program stored in flash will load both a program and a table into the

working memory of the device, replacing the previous program and table there.

26 ©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Page 27

Reference Manual Chapter 3

IVC-2D

Handling Devices

3 Using IVC Studio

3.1 Handling Devices

Note: Do not connect to, configure or view live images from a camera that is already

used through another PC. A camera can only be connected to one PC at a time.

IVC Studio will only detect an Emulator running on the same PC.

3.1.1 Installing and Configuring

Configuring Ethernet

The Ethernet configuration depends on how the device (camera) is connected to the PC.

To configure a

device

Viewing Live Image

To view a camera

image for IVC-2D

To view a camera

image for IVC-3D

Setting Number of Image Banks

Choose Options

A window containing a tree view is displayed.

Select Ethernet Devices in the tree view.

The Ethernet devices dialog is displayed in the right pane in the

window.

Click the Ethernet Device Configuration button.

The Ethernet Device Settings window is displayed, containing a list

of available devices.

Select a device from the list.

The current settings of that device are displayed in the right pane.

Double-click the IP number parameter value and change it.

Click Update.

Click Devices in the left pane.

The available cameras, devices, are listed in the right pane.

Double-click the device or right-click the device and choose Live

Device from the pop-up menu.

A live image is displayed in a pop-up window.

Clicking the handle of the drawer on the right of the image window

displays sliders for Shutter, Gain, and Strobe.

Select the program currently associated with the device, or create

a new program and associate it with the device.

Add a Grab Setup tool to the program by clicking on the Grab

Setup icon in the Image toolbar.

Double-click the Setup button at the bottom left corner of the

program step.

The Grab Setup window is displayed. A live image of the profile is

shown in side the white box in the right pane in the window.

Æ Configuration from the IVC Studio menu bar.

To change the

number of Image

Banks used by the

device

©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved 27

Choose Options

A window containing a tree view is displayed.

Select Ethernet Devices in the tree view.

Ethernet devices are displayed in the right pane in the window.

Click the Ethernet Device Configuration button.

The Ethernet Device Settings window is displayed containing a list

of available devices.

Select a device from the list.

The current settings of that device are displayed in the right pane.

Change the value of the parameter Image Banks.

For IVC-3D, change the value of the parameter Profile Banks.

Click Update.

Æ Configuration from the IVC Studio menu bar.

Page 28

Chapter 3 Reference Manual

Using IVC Studio

IVC-2D

Loading Device Firmware

Firmware contains information on the available tools and how they perform. You load new

firmware to upgrade IVC Studio with new tools.

To load device firmware

Choose File

Note:

Æ Load Device Firmware.

Do not interrupt the loading of firmware once it has started.

Do not disconnect the power or the network connection to

the device until the device is shown again in the list of devices in the IVC Studio main window (that is listed with the

status RUNNING or STOP)

3.1.2 Starting, Stopping, and Resetting Devices

The device can be in one of three states:

run

stop

error

Resetting the device restarts the processor in the camera. This may be necessary if the

device is stalled.

To start running a

program in a device

Right-click the device and choose Start Program from the popup menu, or press F6. The program keeps running until it is

stopped.

To view the result when using an IVC-2D, right-click the

device and choose Live Device from the pop-up menu.

To stop a program

Right-click the device and choose Stop Program from the pop-

up menu.

To reset a device

Choose Options

Æ Configuration from the IVC Studio menu

bar.

A pop-up window containing a tree view appears.

Select Ethernet Devices in the tree view.

Ethernet devices appear in the right panel of the pop-up

window.

Click the Ethernet Device Configuration button.

The Ethernet Device Settings window appears containing

available devices.

Right-click the device and choose Reset Device from the pop-

up menu.

3.1.3 Handling Memory in Camera

Saving camera memory is useful for backup purposes. The camera contains image banks,

a data block memory and a Flash memory. For more information on the Flash memory see

section Handling Programs on the Camera.

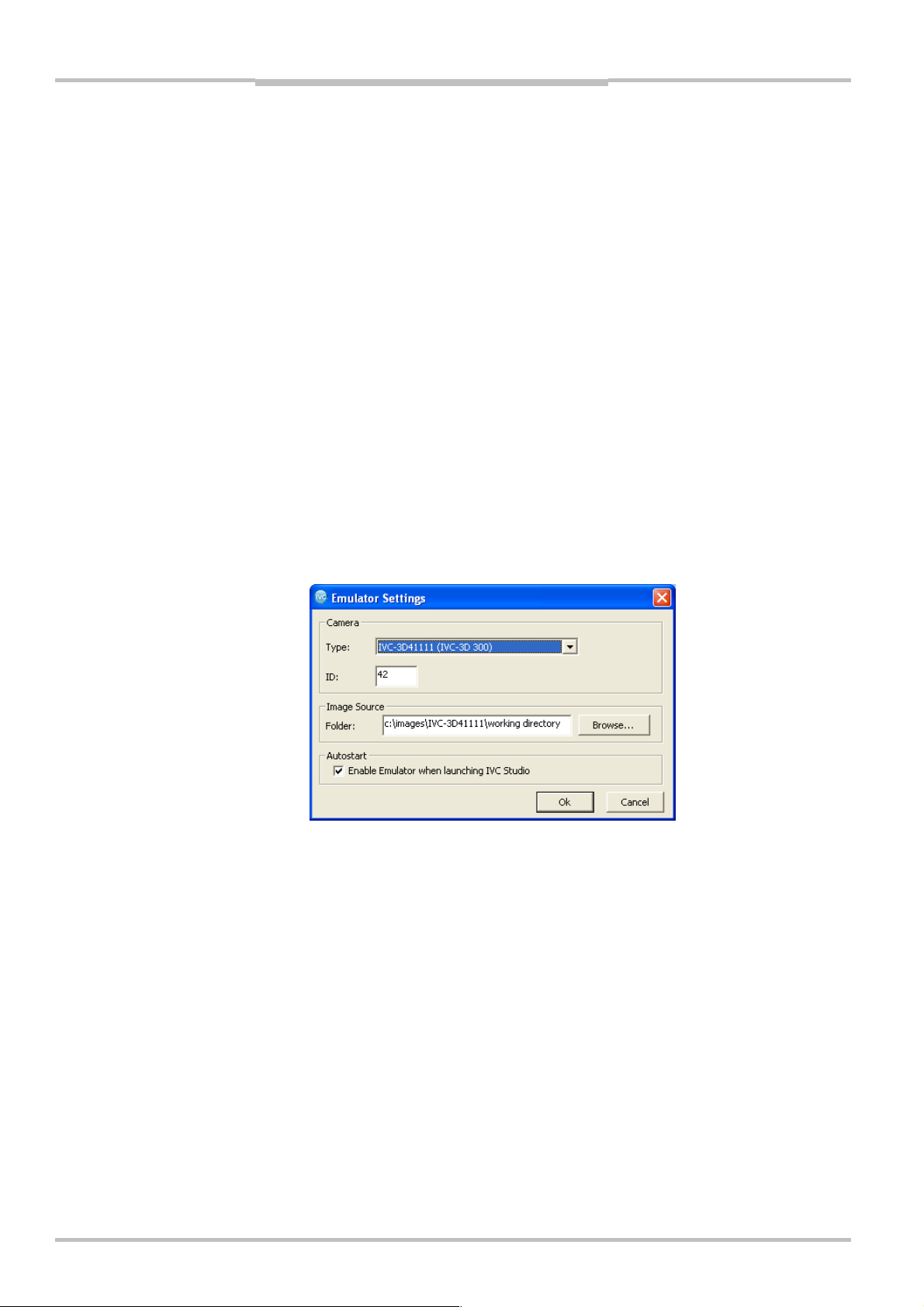

Image banks and data block memory are used for storage during program execution.