Page 1

IME2S

Safety switches

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

IME2S

Manufacturer

SIC

K AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Function of this document....................................................................... 5

1.2 Scope......................................................................................................... 5

1.3 Target groups of these operating instructions........................................ 5

1.4 Additional information.............................................................................. 5

1.5 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Requirements for the qualification of personnel.................................... 7

3 Product description........................................................................... 9

3.1 Structure and function............................................................................. 9

3.2 Product characteristics............................................................................ 9

4 Project planning................................................................................ 11

4.1 Manufacturer of the machine.................................................................. 11

4.2 Operating entity of the machine.............................................................. 11

4.3 Design........................................................................................................ 11

4.4 Integration in the electrical control.......................................................... 13

4.5 Thorough check concept.......................................................................... 14

5 Mounting............................................................................................. 15

5.1 Flush mounting......................................................................................... 15

5.2 Non-flush mounting.................................................................................. 16

6 Electrical installation........................................................................ 18

6.1 Safety......................................................................................................... 18

6.2 Notes on cULus......................................................................................... 19

6.3 System connection (M12, 4-pin)............................................................. 19

6.4 System connection (open cable end, 4-pin)........................................... 20

7 Commissioning.................................................................................. 21

7.1 Safety......................................................................................................... 21

7.2 Switching on.............................................................................................. 21

7.3 Adjustment................................................................................................ 21

8 Troubleshooting................................................................................. 22

8.1 Safety......................................................................................................... 22

8.2 Fault indicators......................................................................................... 22

9 Maintenance...................................................................................... 23

9.1 Cleaning..................................................................................................... 23

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

3

Page 4

CONTENTS

10 Decommissioning............................................................................. 24

10.1 Disposal..................................................................................................... 24

11 Technical data.................................................................................... 25

11.1 Data sheet................................................................................................. 25

11.2 Table of weights........................................................................................ 28

11.3 Dimensional drawings.............................................................................. 28

12 Ordering information........................................................................ 32

12.1 Scope of delivery....................................................................................... 32

12.2 Ordering information................................................................................. 32

13 Annex.................................................................................................. 33

13.1 Compliance with EU directives................................................................. 33

4

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Function of this document

These operating instructions contain the information needed during the life cycle of the

afety switch.

s

They must be made available to all people who work with the safety switch.

1.2 Scope

These operating instructions apply only to the following safety switches:

he IME2S product family

T

•

This document is included with the following SICK part numbers (this document in all

available language versions):

8023339

1.3 Target groups of these operating instructions

Some chapters of these operating instructions are intended for certain target groups.

Ho

wever, the entire operating instructions are relevant for intended use of the product.

Table 1: Target groups and selected chapters of these operating instructions

Target group Chapter of these operating instructions

Project developers (planners, developers,

designers)

Installers "Mounting", page 15

Electricians "Electrical installation", page 18

Safety experts (such as CE authorized repre‐

atives, compliance officers, people who

sent

test and approve the application)

Operators "Troubleshooting", page 22

Maintenance personnel "Maintenance", page 23

ABOUT THIS DOCUMENT 1

"Project planning", page 11

"Technical data", page 25

"Project planning", page 11

"Commissioning", page 21

"Technical data", page 25

roubleshooting", page 22

"T

1.4 Additional information

www.sick.com

T

he following information is available on the Internet:

This document in other languages

•

Data sheets and application examples

•

CAD data and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery Six steps to a safe machine

•

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

5

Page 6

1 A

BOUT THIS DOCUMENT

Safety notes and other notes

DANGER

ates a situation presenting imminent danger, which will lead to death or serious

Indic

injuries if not prevented.

WARNING

Indic

ates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

ates a situation presenting possible danger, which may lead to property damage if

Indic

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

he arrow denotes instructions to action.

T

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

6

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 General safety notes

This chapter contains general safety information about the safety switch.

urther safety information is provided in the respective chapters to cover the specific

F

situations in which the product may be used.

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Please read this document carefully and make sure that you understand the con‐

b

tent fully before working with the device.

Follow all safety notes in this document.

b

NOTICE

T

he adhesive strip above the LED displays must not be removed in order to achieve the

specified enclosure rating.

SAFETY INFORMATION 2

2.2 Intended use

The safety switch is an inductive safety switch which is activated by actuating elements

(me

applications:

•

The safety switch is used for protecting people.

The safety switch must only be used within the limits of the prescribed and specified

technical data and operating conditions at all times.

Incorrect use, improper modification or manipulation of the safety switch will invalidate

any warranty from SICK; in addition, any responsibility and liability of SICK for damage

and secondary damage caused by this is excluded.

2.3 Improper use

The safety switch is no

•

•

•

tal objects) without making contact. The safety switch is suitable for the following

Safe position and area determination of metal objects

t suitable for the following applications, among others:

Environments with increased levels of ionizing radiation

Applications in which the safety switch is exposed to chemicals, for example clean‐

ing in food processing.

Outdoors (only suitable for weather-protected areas of application, Class C accord‐

ing to IEC 60654-1)

2.4 Requirements for the qualification of personnel

The safety switch must be configured, mounted, connected, commissioned, and ser‐

iced by qualified safety personnel only.

v

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

7

Page 8

AFETY INFORMATION

2 S

Mechanical mounting, electrical installation, and commissioning

F

or the task, a person is considered qualified when he/she has the expertise and expe‐

rience in the relevant field and is sufficiently familiar with the application of the protec‐

tive device on the machine to be able to assess whether it is in an operationally safe

state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

8

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 9

3 Product description

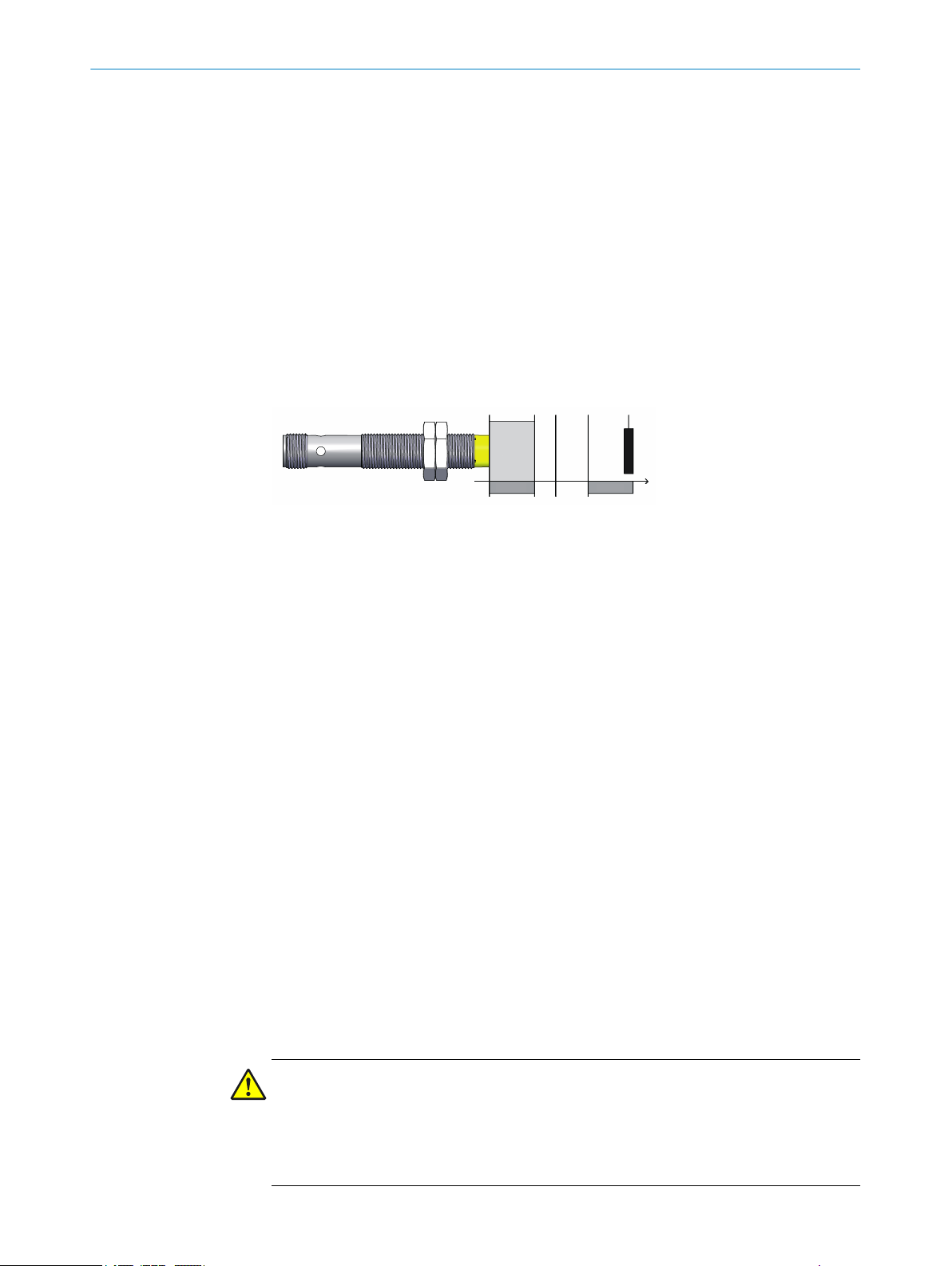

1 2 3 4 5

OSSD ON OSSD OFF

3.1 Structure and function

Description of operation

he safety switch is an inductive safety switch which is activated by actuating elements

T

(metal objects) without making contact.

If an actuating element is situated between the active sensor surface and assured

switch-off distance Sao, safety outputs (OSSDs) are safe in the ON state. If an actuating

element is situated outside assured safe switch-off distance Sar, safety outputs

(OSSDs) are in the OFF state.

The machine or its control must safely analyze the signals (for example using a safe

control or safety relays) and stop the dangerous state.

PRODUCT DESCRIPTION 3

Safety switches

1

Assured switch-on distance S

2

Sensing range Sn (switch-on distance under laboratory conditions)

3

Assured switch off distance S

4

Actuating element

5

ao

ar

Assured switch on distance (Sao)

tance from the active sensor surface within which the presence of the actuating ele‐

Dis

ment can be safely detected.

The assured switch-on distance is the important value for safe applications.

Sensing range (Sn)

Is de

tected under laboratory conditions.

Typical sensing range of the safety switch. The sensing range can change with the

shape and material of the actuating element. Manufacturing tolerances as well as

external influences such as temperature or supply voltage are not considered.

Assured switch off distance (Sar)

Dis

tance from the active sensor surface outside of which the presence of the actuating

element is reliably detected.

3.2 Product characteristics

3.2.1 Protective functions

DANGER

L

oss of cross-circuit monitoring when output load at the OSSDs is too high

Loss of safety function

The safety switch must always be operated within the limits of the prescribed and

b

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

specified technical data.

9

Page 10

1

RODUCT DESCRIPTION

3 P

The safety switch is available for the following internal protective functions:

•

•

•

•

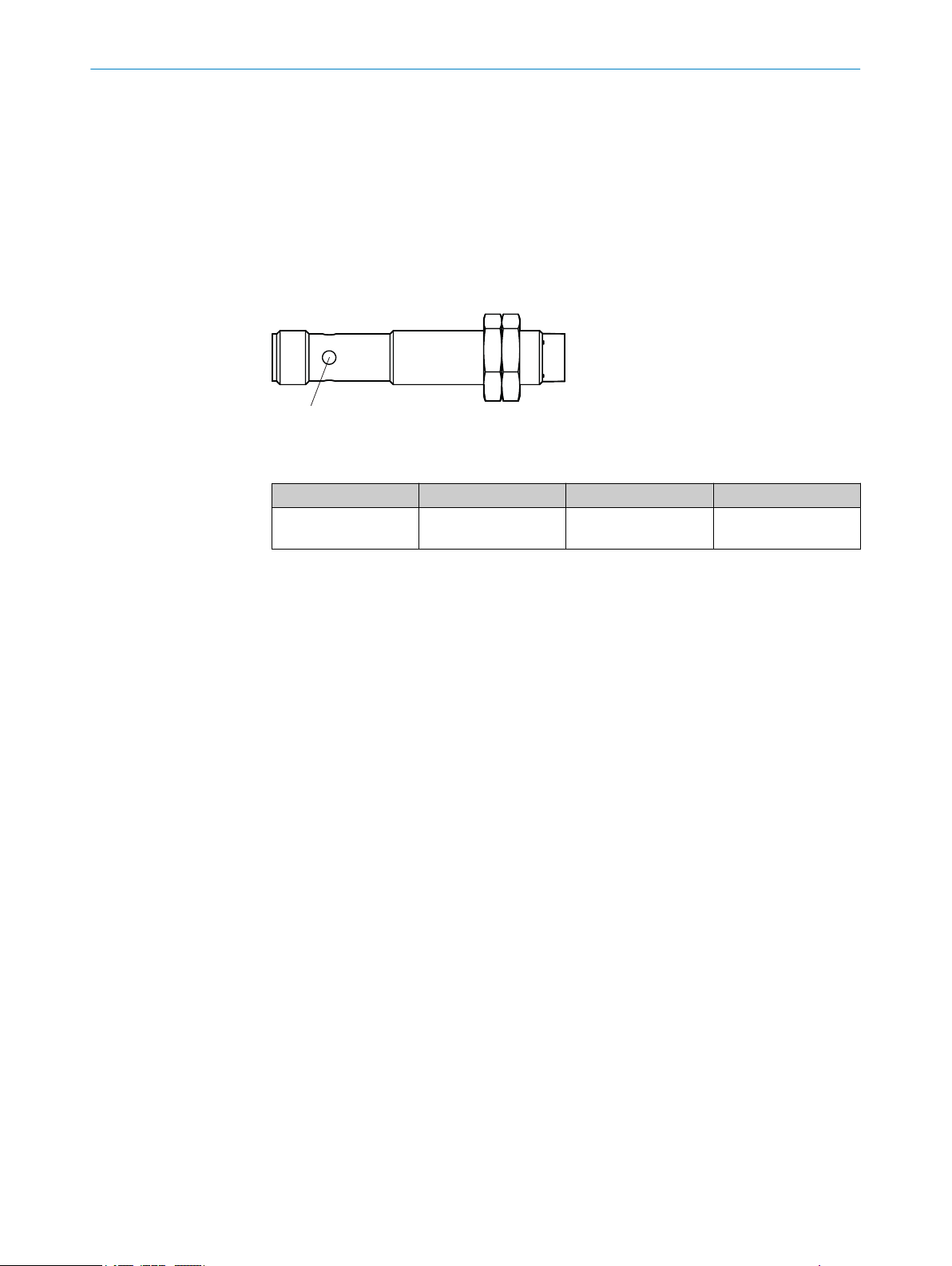

3.2.2 Status indicators

LEDs on the device

T

he safety switch signals the operational status via an LED.

Figure 1: LED IME2S

Table 2: LED

Item Name Color Purpose

1

hort-circuit protection at all outputs

S

Cross-circuit monitoring at the OSSDs

Overload protection at the OSSDs

Supply voltage reverse polarity protection

STATE Green/Red Signals when an

ject is detected.

ob

Further topics

see "F

•

ault indicators", page 22

10

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 11

4 Project planning

4.1 Manufacturer of the machine

DANGER

F

ailure to comply with manufacturer’s obligations

Hazard due to lack of effectiveness of the protective device

Carry out a risk assessment before using the safety switch.

b

Do not tamper with, open, or modify the components of the safety switch.

b

Do not repair defective devices – they must be replaced instead.

b

Make sure that switch-on commands which bring about a dangerous state of the

b

machine are not enabled until the protective device is closed.

Ensure that a stop command is triggered if the actuating element is no longer

b

detected (e.g. when the protective device is opened during a hazardous machine

status).

The safety switches must not be circumvented (contacts bypassed), rotated away,

b

removed, or rendered ineffective in any other way. Put measures in place to

reduce possibilities for circumvention.

PROJECT PLANNING 4

4.2 Operating entity of the machine

DANGER

F

ailure to observe operator obligations

Hazard due to lack of effectiveness of the protective device

Changes to the machine and changes to the mechanical mounting of the safety

b

switch necessitate a new risk assessment. The results of this risk assessment

may require the entity operating the machine to meet the obligations of a manu‐

facturer.

Apart from the procedures described in this document, the components of the

b

safety switch must not be opened or modified.

Do not carry out any repair work on components. Improper repair of the safety

b

switch can lead to a loss of the protective function.

4.3 Design

Important information

DANGER

B

ypassing the protective device

Hazard due to lack of effectiveness of the protective device

Avoid incentives to manipulate the safety switch by taking at least one of the fol‐

b

lowing measures:

Attach safety switch outside of the sensing range.

°

Cover safety switch with obstacles or shield.

°

Attach safety switch at the covered position.

°

If possible, do not mount the safety switch with the active sensor surface fac‐

°

ing upwards.

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

11

Page 12

4 P

ROJECT PLANNING

DANGER

amage to the safety switch due to mechanical stress

D

Loss of safety function

Protect the safety switch from mechanical stress such as impacts or permanent

b

contact pressure, for example with an additional stop

Mounting location

Se

lect the mounting location so that the safety switch is protected from impacts and

mechanical pressure. If necessary, attached additional stop.

Measures to protect against unintentional actuation

The safety switch can be actuated by any metal objects such as metal chips, doors or

moving machine elements. Constructive measures must be taken so that the safety

switch is only actuated by the intended actuating element.

Distance

If several safety switches are mounted on the machine, they must be mounted at a min‐

imum distance to one another.

Alignment

The safety switch can be mounted with any alignment. If the safety sensor is mounted

with the sensor surface facing upwards, the risk of unintended actuation by loose metal

objects (for example metal chips) or manipulation of the safety switch increases.

Possible mounting methods

There are several mounting methods. The permitted mounting method depends on the

product variant:

Flush mounting. The active sensor surface is at the same level as the surrounding

•

material.

Non-flush mounting. The active sensor surface protrudes a bit out of the surround‐

•

ing material.

Further topics

lush mounting", page 15

see "F

•

see "Non-flush mounting", page 16

•

4.3.1 Determining the sensing ranges

Sensing ranges Sao, Sar and Sn depend on t

ment. The specified values assume the following prerequisites:

Length and width of the actuating element: Diameter of the active sensor surface

•

Material thickness: 1 mm

•

Material of the actuating element: Structural steel (FE360)

•

Ambient temperature: 25 °C

•

If the actuating element consists of another material, the specified values for Sao, S

and Sn must be multiplied with the respective correction factor (see table 3, page 13)

(values of sensing ranges see table 11, page 25).

he material and form of the actuating ele‐

ar

12

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 13

OSSD 1

V

t

1

2

V

t

2

OSSD 2

2 2

PROJECT PLANNING 4

Table 3: Correction factor for sensing ranges Sao, Sar and S

Material Correction factor

Mu-metal 1.2

Molded metal 1.1

Structural steel (Fe 360) 1.0

Rust-free steel (V2A, 304) 0.8

Aluminum 0.45

Copper 0.3

Brass 0.4

Example calculation

F

or a copper actuating element, the safe switch-off distance changes as follows:

S

ao/copper

= Sao * 0.3

4.4 Integration in the electrical control

Switch-on commands that put the machine in a dangerous state may only be activated

he safety switch detects an actuating element. When the machine goes into a

when t

dangerous state, a stop command must be triggered if no suitable object is detected.

Depending on the safety concept, the signal is analyzed by safety relays or a safety con‐

troller, for example.

n

The connected control and all devices responsible for safety must comply with the

required performance level and the required category (for example, according to

EN ISO 13849-1:2015).

4.4.1 Course of the OSSD test over time

The safety locking device tests the OSSDs for self-diagnosis at regular intervals. To

do t

his, the safety locking device switches each OSSD briefly to the OFF state and

checks whether this channel is voltage-free during this time.

Make sure that the machine’s control does not react to these test pulses and the

machine does not switch off.

Figure 2: Course of the OSSD test over time

Legend number Description Value

1

2

Test pulse interval Usually every 20 ms

Test pulse width 300 μs

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

13

Page 14

ROJECT PLANNING

4 P

4.5 Thorough check concept

The safety switch must be tested by appropriately qualified safety personnel during

ommissioning, after modifications, and at regular intervals; see "Requirements for the

c

thorough check during commissioning and in certain situations", page 14.

Regular thorough checks serve to investigate the effectiveness of the safety switch and

discover defects resulting from modifications or external influences (such as damage or

manipulation).

The manufacturer and operating entity must define the type and frequency of the thor‐

ough checks on the machine on the basis of the application conditions and the risk

assessment. The process of defining the thorough checks must be documented in a

traceable manner.

4.5.1 Requirements for the thorough check during commissioning and in certain situations

The protective device and its application must be thoroughly checked in the following

sit

uations:

Before commissioning

•

After changes to the configuration or the safety function

•

After changes to the mounting, the alignment, or the electrical connection

•

After exceptional events, such as after a manipulation has been detected, after

•

modification of the machine, or after replacing components

The thorough check ensures the following:

All relevant regulations are complied with and the protective device is active for all

•

of the machine’s operating modes.

The documentation corresponds to the state of the machine, including the protec‐

•

tive device

The thorough checks must be carried out by qualified safety personnel or specially qual‐

ified and authorized personnel and must be documented in a traceable manner.

k whether the protective device of the machine is effective in all operating

Chec

b

modes in which the machine can be set.

Make sure that operating personnel have been instructed in the function of the

b

protective device before starting work on the machine. The machine operator has

overall responsibility for the instruction, which must be carried out by qualified per‐

sonnel.

4.5.2 Minimum requirements for regular thorough checks

The following thorough checks must be carried out at least once a year:

horough check of the principal protective function of the safety switch

T

•

Thorough check of assured sensing range S

•

Thorough check for damage on the switch housing

•

Thorough check for damage on the switch cables

•

Thorough check for signs of misuse or manipulation on the safety switch

•

ar

14

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 15

5 Mounting

2

1

3

6

5.1 Flush mounting

Important information

DANGER

If t

he safety switch is not mounted with the intended mounting method, the switching

behavior is affected. The safety switch might not switch as intended.

b

b

b

Approach

b

MOUNTING 5

Only use safety switches for flush mounting which are intended for flush mounting.

Only use safety switches for non-flush mounting which are intended for non-flush

mounting.

If something is unclear, use the part number to check for which mounting method

the safety switch is suited (see "Ordering information", page 32).

serve the max. tightening torque during mounting.

Ob

IME2S: 12 Nm

°

Figure 3: Distances for flush mounting

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

Figure 4: Distance with 2 opposing safety

switches

15

Page 16

2

1

3

4

4

5

5 MOUNTING

Table 4: Dimensions for flush mounting in mm

Variant

IME2S12-04***** 12 > 24 > 12 > 32

IME2S18-05***** 18 > 36 > 15 > 40

IME2S18-08***** 18 > 36 > 24 > 64

IME2S30-12***** 30 > 60 > 36 > 96

General formula –

5.2 Non-flush mounting

1

Diame

ter of the safety switch

2

Minimum dis‐

tance to the

neighboring

safety switch

2 × 1

3

Minimum free

space above the

active sensor

surface

> 3 × S

n

6

Minimum dis‐

tance to the

opposing safety

switch

> 8 × S

Important information

DANGER

If t

he safety switch is not mounted with the intended mounting method, the switching

behavior is affected. The safety switch might not switch as intended.

n

Only use safety switches for flush mounting which are intended for flush mounting.

b

Only use safety switches for non-flush mounting which are intended for non-flush

b

mounting.

If something is unclear, use the part number to check for which mounting method

b

the safety switch is suited (see "Ordering information", page 32).

Approach

or mounting, observe max. tightening torque: 12 Nm

F

b

16

Figure 5: Distances for non-flush mounting

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 17

6

MOUNTING 5

Figure 6: Distance for 2 opposing safety

switches

Table 5: Dimensions for non-flush mounting in mm

Variant

General formula –

IME2S12-04***** 12 > 24 > 12 > 12 > 8 > 32

IME2S12-08***** 12 > 24 > 24 > 12 > 16 > 64

IME2S18-08***** 18 > 36 > 24 > 18 > 16 > 64

IME2S30-15***** 30 > 60 > 45 > 30 > 30 > 120

1

Diame

ter of

the safety

switch

2

Minimum

distance to

the neighbor‐

ing safety

switch

> 2 × 1

3

Minimum free

space above the

active sensor

surface

> 3 × S

n

4

Minimum

free space

around the

active sensor

surface

> 1 × 1

5

Overrun of

the active

sensor sur‐

face

> 2 × S

n

6

Minimum

distance to

the opposing

safety switch

> 8 × S

n

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

17

Page 18

6 ELE

CTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

Important information

DANGER

H

azard due to electrical voltage

Hazard due to unexpected starting of the machine

Make sure that the machine is and remains disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is and remains switched off

b

during electrical installation.

Make sure that the outputs of the safety switch have no effect on the machine

b

during electrical installation.

DANGER

Hazard due to lack of effectiveness of the protective device

The dangerous state may not be stopped in the event of non-compliance.

Always connect the two OSSDs separately. The two OSSDs must not be connected

b

to each other.

Connect the OSSDs such that the machine controller processes both signals sepa‐

b

rately.

Isolated connection of OSSD1 and OSSD2

Figure 7: Dual-channel and isolated connection of OSSD1 and OSSD2

Avoiding any potential difference between load and protective device

18

ou connect loads to the output signal switching devices (switching outputs) that then

If y

also switch if controlled with negative voltage (e.g., electro-mechanical contactor with‐

out reverse polarity protection diode), you must connect the 0 V connections of these

loads and those of the corresponding protective device separately and also directly to

the same 0 V terminal strip. In the event of a fault, this is the only way to ensure that

there can be no potential difference between the 0 V connections of the loads and

those of the corresponding protective device.

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 19

Figure 8: No potential difference between load and protective device

12

3 4

6.2 Notes on cULus

Important information

DANGER

k of burns from hot housing

Ris

ELECTRICAL INSTALLATION 6

Take measures to make sure the safety switch cannot be touched during opera‐

b

tion.

For use according to the requirements of UL 60947-5-2, the following conditions must

also be me

•

•

t:

The voltage supply must correspond to Class 2 in accordance with UL 508

Voltage supply Uv secured with 1 A fuse

6.3 System connection (M12, 4-pin)

Figure 9: System connection pin assignment (male connector)

Table 6: Device connection pin assignment (male connector, M12, 4-pin, A-coded)

Pin Wire color

1 Brown +24 V DC Voltage supply 24 V DC

2 White OSSD 1 Output OSSD1

3 Blue 0 V Voltage supply 0 V DC

4 Black OSSD 2 Output OSSD2

1)

Applies to the extension cables recommended as accessories.

1)

Designation Description

P

ay attention to seal tightness of the plug connector.

b

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

19

Page 20

6 ELECTRICAL INSTALLATION

6.4 System connection (open cable end, 4-pin)

Table 7: Device connection pin assignment (open cable end, 4-pin)

Wire color Designation Description

Brown +24 V DC Voltage supply 24 V DC

White OSSD 1 Output OSSD1

Blue 0 V Voltage supply 0 V DC

Black OSSD 2 Output OSSD2

20

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 21

7 Commissioning

7.1 Safety

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

1. Before commissioning the machine, have it checked and released by qualified

safety personnel.

2. Make sure that the time for the safety requirement (closing the protective device

again) is longer than the response time.

7.2 Switching on

Approach

1. Verify that the actuating element is not located within the assured switch-off dis‐

tance.

2. Switch on the supply voltage.

COMMISSIONING 7

7.3 Adjustment

As soon as the supply voltage is applied, the safety switch initializes automatically.

When the STATE LED permanently lights up red, the safety switch is ready for operation.

Table 8: LED displays and OSSD status during commissioning

STATE LED OSSDs Device state

Ö Gr

O R

ed

OGr

een/Red

een

OFF state Safety switch initializes.

OFF state The safety switch is switched

ctuating object is not

on. A

detected.

ON state The safety switch is switched

ctuating object is

on. A

detected.

Further topics

ault indicators", page 22

see "F

•

Adjusting distance

A

djust the distance between the safety switch and actuating element so that the

b

actuating object is reliably detected within assured switch-off distance Sao (LED

STATE permanently green).

Complementary information

NOTE

F

or variants with cylindrical housing, the distance can be adjusted by rotating the safety

switch in or out.

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

21

Page 22

8 TROUBLESHOOTING

8 Troubleshooting

8.1 Safety

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Immediately shut the machine down if the behavior of the machine cannot be

b

clearly identified.

If a machine fault cannot be definitively determined or safely rectified, immediately

b

shut the machine down.

Secure the machine so that it cannot switch on unintentionally.

b

NOTE

A

dditional information on troubleshooting can be found at the responsible SICK sub‐

sidiary.

8.2 Fault indicators

Table 9: Fault indicators

LED STATE Possible cause Corrective measure

Green Red

o o

o Ö (4 Hz)

o Ö (1 Hz)

No supply voltage

Internal error

Supply voltage too high or

t

oo low

External error

witch on the supply voltage.

S

•

Switch the voltage supply off and

•

on.

If the error occurs again, the sen‐

•

sor is defective. Replace sensor.

k the supply voltage.

Chec

•

k wiring for cross-circuit and

Chec

•

short-circuit.

Switch the voltage supply off and

•

on.

If the error occurs again, the sen‐

•

sor is defective. Replace sensor.

22

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 23

9 Maintenance

9.1 Cleaning

NOTICE

b

b

b

MAINTENANCE 9

D

o not use aggressive cleaning agents (such as isopropanol or spirit).

Do not use any substances that hinder the wetting properties of lacquers.

We recommend anti-static cleaning agents.

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

23

Page 24

10 DECOMMISSIONING

10 Decommissioning

10.1 Disposal

Approach

ways dispose of unusable devices in accordance with national waste disposal

Al

b

regulations.

Complementary information

SICK will be glad to help you dispose of these devices on request.

24

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 25

11 Technical data

11.1 Data sheet

Table 10: Safety-related parameters

Safety-related parameters

Performance level PL d (EN ISO 13849-1:2015)

Category Category 2 (EN ISO 13849-1:2015)

Safety integrity level SIL 2 (IEC 61508)

SIL claim limit SILCL 2 (IEC 62061)

PFHd (mean probability of a dangerous failure per hour)

For operating heights ≤ 1,000 m above sea

vel

le

For operating heights 1,001 m … 2,000 m

above sea level

For operating heights 2,001... 3,000 m

above sea level

TM (mis

Type Type 3 (ISO 14119)

Safe status when a fault occurs At least one safety-related semiconductor out‐

TECHNICAL DATA 11

6 × 10–8 at 40 °C

7 × 10–8 at 40 °C

8 × 10–8 at 40 °C

sion time) 20 years (EN ISO 13849–1:2015)

SSD) is in the OFF state.

put (O

Table 11: Features

Features

Assured switch-on distance Sao

1)

IME2S**-04***** 3.2 mm

IME2S**-08***** 6.5 mm

IME2S**-05***** 4 mm

IME2S**-12***** 9.6 mm

IME2S**-15***** 12 mm

Assured switch off distance Sar

1)

IME2S**-04***** 6 mm

IME2S**-08***** 12 mm

IME2S**-05***** 7.5 mm

IME2S**-12***** 18 mm

IME2S**-15***** 22.5 mm

Sensing range Sn

1)

IME2S**-04***** 4 mm

IME2S**-08***** 8 mm

IME2S**-05***** 5 mm

IME2S**-12***** 12 mm

IME2S**-15***** 15 mm

Actuating frequency ≤ 100 Hz

1)

Specified values apply to steel (FE360). A correction factor must be used for other materials see

table 3.

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

25

Page 26

11 TECHNICAL DATA

Table 12: Correction factor for sensing ranges Sao, Sar and S

n

Material Correction factor

Mu-metal 1.2

Molded metal 1.1

Structural steel (Fe 360) 1.0

Rust-free steel (V2A, 304) 0.8

Aluminum 0.45

Copper 0.3

Brass 0.4

Table 13: Interfaces

Interfaces

System connection (voltage supply and local inputs and outputs)

IME2S12 Cable with M12 male connector, 4-pin

M12 male connec

tor, 4-pin

Open cable

IME2S18 M12 male connector, 4-pin

IME2S30 M12 male connector, 4-pin

Table 14: Electrical data

Electrical data

Protection class III (EN 61140/IEC 61140)

Supply voltage V

S

Residual ripple ±10%

Rated insulation voltage U

i

Voltage drop (of supply voltage) ≤ 3 V

DC 24 V (19.2 V DC … 28.8 V DC)

1)

28.8 V

2)

Contamination degree 3 (external, according to EN 60947-1)

Rated impulse withstand voltage U

p

im

1,500 V

Utilization category (IEC 60947-5-1) DC-12: 24 V / 20 mA

Device fuse 1 A

Current consumption at 24 V < 20 mA

Hysteresis ≤ 15% of S

n

Repeatability 2%

Power-up delay (after supply voltage applied) 3)< 1 s

Response time (removal from response range) < 1 ms

Release time (response time when approaching response range)

IME2S12 < 1 ms

IME2S18-05B4DC0 < 2 ms

IME2S18-05B4DC0 < 1 ms

IME2S18-08N4DC0 < 1.5 ms

IME2S30-15B4DC0 < 5 ms

IME2S30-15N4DC0 < 1 ms

26

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 27

TECHNICAL DATA 11

Electrical data

Risk time

1)

2)

3)

4)

Table 15: Mechanical data

Dimensions see "Dimensional drawings", page 28

Material IME2S

Tightening torque for mounting

Weight see "Table of weights", page 28

4)

Within the limits of UV.

AT 50 mA at each OSSD channel

Once the supply voltage has been switched on, the OSSDs are in the OFF state during the time delay

be

fore availability.

The risk time is the time needed to detect internal and external faults. External errors affect the OSSDs

(short-circuit to an OSSD and cross-circuit between the two OSSDs). At least one of the two OSSDs is

safely switched off during the risk time.

< 20 ms

Housing Nickel plated brass

Sensor surface Vistal

®

Cable PVC

Fixing nuts Brass alloy

IME2S 12 Nm

Table 16: Outputs

Outputs

Switching outputs 2 PNP semiconductors

Switching voltage

ON state 19.2 V DC … 28.8 V DC

OFF state 0 V DC … 2 V DC

Switching current

ON state ≤ 50 mA

OFF state < 500 µA

Load capacity 80 nF

Short-circuit protection Yes

Reverse polarity protection Yes

Test pulse width 300 µs

Table 17: Ambient data

Ambient data

Enclosure rating IP 67 (IEC 60529)

1)

Ambient operating temperature –25 °C … +70 °C

Temperature change rate ≤ 1 °K/min

Storage temperature –25 °C … +70 °C

Area of application (IEC 60654-1) Class C; weather-protected area of application

Operating altitude ≤ 3,000 m above sea level

Relative humidity 50% at 70 °C (IEC 60947-5-2)

Vibration resistance 1 mm / 10 Hz … 55 Hz (IEC 60947-5-2)

Shock resistance In accordance with IEC 60947-5-2

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

27

Page 28

M12 x 1

63

52,3

40,9

LED 2 x 180°

17

4

2000

4

M12 x 1

17

LED 2 x 180°

63

52,3

36,9

2000

5

11 T

ECHNICAL DATA

Ambient data

EMC In accordance with IEC 60947-5-2, IEC

Minimum distance between 2 safety switches see "Mounting", page 15

1)

The adhesive strip above the LED displays must not be removed in order to achieve the specified enclo‐

sur

11.2 Table of weights

Table 18: Weight IME2S

Type code Weight in g

IME2S12-04B4DQ9 33

IME2S12-04N4DQ9 33

IME2S12-04B4DC0 18

IME2S12-04B4DW2 60

IME2S12-04N4DC0 18

IME2S12-04N4DW2 60

IME2S12-08N4DC0 18

IME2S18-05B4DC0 42

IME2S18-08N4DC0 38

IME2S18-08B4DC0 42

IME2S30-12B4DC0 102

IME2S30-15N4DC0 94

e rating.

60947-5-3 and IE

C 61000-6-7

11.3 Dimensional drawings

IME2S12

Figure 10: IME2S12-**B**W2 dimensional drawing

28

Figure 11: IME2S12-**N**W2 dimensional drawing

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 29

M12 x 1

M12 x 1

65

52,3

40,9

LED 2 x 180°

17

4

Figure 12: IME2S12-**B**C0 dimensional drawing

M12 x 1

M12 x 1

65

52,3

36,9

LED 2 x 180°

17

4

5

M12 x 1

63

52,3

40,9

300

LED 2 x 180°

17

4

M12 x 1

63

52,3

36,9

300

LED 2 x 180°

17

5

4

TECHNICAL DATA 11

Figure 13: IME2S12-**N**C0 dimensional drawing

Figure 14: IME2S12-**B**Q9 dimensional drawing

Figure 15: IME2S12-**N**Q9 dimensional drawing

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

29

Page 30

M18 x 1

M12 x 1

69

56,3

44,2

6,5

LED 2 x 180°

24

4

M18 x 1

M12 x 1

69

56,3

35,2 10

6,5

LED 2 x 180°

24

4

M30 x 1,5

M12 x 1

71

58,3

45,9

6,2

LED 2 x 180°

36

4

11 TECHNICAL DATA

IME2S18

Figure 16: IME2S18-**B**C0 dimensional drawing

Figure 17: IME2S18-**N**C0 dimensional drawing

IME2S30

Figure 18: IME2S30-**B**C0 dimensional drawing

30

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 31

M30 x 1,5

M12 x 1

71

58,3

34,6

6,2

LED 2 x 180°

36

4

12,3

Figure 19: IME2S30-**N**C0 dimensional drawing

TECHNICAL DATA 11

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

31

Page 32

12 ORDERING INFORMATION

12 Ordering information

12.1 Scope of delivery

Scope of delivery, IME2S

1 × IME2S s

•

2 × fixing nuts

•

1 × safety notes

•

Operating instructions for download: www.sick.com

•

afety switch

12.2 Ordering information

Table 19: IME2S ordering information

Design Housing diame‐

t

er

Cylindrical M12 Cable with M12

M18 M12 male con‐

M30 M12 male con‐

Sensor connec‐

tion type

male connec

4-pin

Cable with M12

male connector,

4-pin

M12 male con‐

nector, 4-pin

Open cable Flush IME2S12-04B4DW2 1091945

M12 male con‐

tor, 4-pin

nec

Open cable Non-flush IME2S12-04N4DW2 1091947

M12 male con‐

nector, 4-pin

tor, 4-pin

nec

M12 male con‐

nector, 4-pin

M12 male con‐

tor, 4-pin

nec

nector, 4-pin

M12 male con‐

tor, 4-pin

nec

Structural state Type code Part number

Flush IME2S12-04B4DQ9 1091142

tor,

Non-flush IME2S12-04N4DQ9 1091943

Flush IME2S12-04B4DC0 1091944

Non-flush IME2S12-04N4DC0 1091946

Non-flush IME2S12-08N4DC0 1091948

Flush IME2S18-05B4DC0 1091949

Non-flush IME2S18-08N4DC0 1091950

Flush IME2S18-08B4DC0 1091951

Flush IME2S30-12B4DC0 1091952

Non-flush IME2S30-15N4DC0 1091953

32

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 33

13 Annex

13.1 Compliance with EU directives

EU declaration of conformity (extract)

he undersigned, representing the manufacturer, herewith declares that the product is

T

in conformity with the provisions of the following EU directive(s) (including all applicable

amendments), and that the standards and/or technical specifications stated in the EU

declaration of conformity have been used as a basis for this.

Complete EU declaration of conformity for download

You can call up the EU declaration of conformity and the current operating instructions

for the protective device by entering the part number in the search field at

www.sick.com (part number: see the type label entry in the “Ident. no.” field).

ANNEX 13

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

33

Page 34

13 ANNEX

34

O PE R AT I NG IN S TR U CT I ON S | IME2S 8023341/14TD/2019-08-08 | SICK

Subject to change without notice

Page 35

ANNEX 13

8023341/14TD/2019-08-08 | SICK OP E RA T IN G I N ST R UC T IO N S | IME2S

Subject to change without notice

35

Page 36

Detailed addresses and further locations at www.sick.com

Australia

Phone +61 (3) 9457 0600

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Austria

Phone +43 (0) 2236 62288-0

E-Mail office@sick.at

Belgium/Luxembourg

Phone +32 (0) 2 466 55 66

E-Mail info@sick.be

Brazil

Phone +55 11 3215-4900

E-Mail comercial@sick.com.br

Canada

Phone +1 905.771.1444

E-Mail cs.canada@sick.com

Czech Republic

Phone +420 234 719 500

E-Mail sick@sick.cz

Chile

Phone +56 (2) 2274 7430

E-Mail chile@sick.com

China

Phone +86 20 2882 3600

E-Mail info.china@sick.net.cn

Denmark

Phone +45 45 82 64 00

E-Mail sick@sick.dk

Finland

Phone +358-9-25 15 800

E-Mail sick@sick.fi

France

Phone +33 1 64 62 35 00

E-Mail info@sick.fr

Germany

Phone +49 (0) 2 11 53 010

E-Mail info@sick.de

Greece

Phone +30 210 6825100

E-Mail office@sick.com.gr

Hong Kong

Phone +852 2153 6300

E-Mail ghk@sick.com.hk

Hungary

Phone +36 1 371 2680

E-Mail ertekesites@sick.hu

India

Phone +91-22-6119 8900

E-Mail info@sick-india.com

Israel

Phone +972 97110 11

E-Mail info@sick-sensors.com

Italy

Phone +39 02 27 43 41

E-Mail info@sick.it

Japan

Phone +81 3 5309 2112

E-Mail support@sick.jp

Malaysia

Phone +603-8080 7425

E-Mail enquiry.my@sick.com

Mexico

Phone +52 (472) 748 9451

E-Mail mexico@sick.com

Netherlands

Phone +31 (0) 30 229 25 44

E-Mail info@sick.nl

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

E-Mail sales@sick.co.nz

Norway

Phone +47 67 81 50 00

E-Mail sick@sick.no

Poland

Phone +48 22 539 41 00

E-Mail info@sick.pl

Romania

Phone +40 356-17 11 20

E-Mail office@sick.ro

Russia

Phone +7 495 283 09 90

E-Mail info@sick.ru

Singapore

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

Slovakia

Phone +421 482 901 201

E-Mail mail@sick-sk.sk

Slovenia

Phone +386 591 78849

E-Mail office@sick.si

South Africa

Phone +27 10 060 0550

E-Mail info@sickautomation.co.za

South Korea

Phone +82 2 786 6321/4

E-Mail infokorea@sick.com

Spain

Phone +34 93 480 31 00

E-Mail info@sick.es

Sweden

Phone +46 10 110 10 00

E-Mail info@sick.se

Switzerland

Phone +41 41 619 29 39

E-Mail contact@sick.ch

Taiwan

Phone +886-2-2375-6288

E-Mail sales@sick.com.tw

Thailand

Phone +66 2 645 0009

E-Mail marcom.th@sick.com

Turkey

Phone +90 (216) 528 50 00

E-Mail info@sick.com.tr

United Arab Emirates

Phone +971 (0) 4 88 65 878

E-Mail contact@sick.ae

United Kingdom

Phone +44 (0)17278 31121

E-Mail info@sick.co.uk

USA

Phone +1 800.325.7425

E-Mail info@sick.com

Vietnam

Phone +65 6744 3732

E-Mail sales.gsg@sick.com

8023341/14TD/2019-08-08/en

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...