Page 1

OPERATING INSTRUCTIONS

ICR890

High-end CCD Camera System

Camera System for Reading 1-D and 2-D Codes with Superb

Image Quality suitable for OCR and Video Coding Applications

Page 2

Operating Instructions

ICR890 High-end CCD Camera System

Software Versions

Software/Tool Function Version

ICR890 System SICK Firmware From version

1.0 0000

ICR890 Device

Description

SOPAS-ET Configuration software From version

RF interference in case of use in residential areas.

¾ ICR890 High-end CCD Camera System is exclusively intended for use in an industrial

environment.

Device-specific software module for SOPAS-ET

Configuration Software

From version

1.00

2.10

Copyright

Copyright © 2006

SICK AG Waldkirch

Auto Ident, Reute Plant

Nimburger Strasse 11

79276 Reute

Germany

Trademark

Windows98

TM

, NTTM, METM, 2000TM, XPTM and Internet ExplorerTM are registered trademarks

or trademarks of the Microsoft Corporation in the USA and other countries.

Latest manual version

For the latest version of this manual (PDF), see www.sick.com.

2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 3

Operating Instructions

ICR890

Quick Finder

ICR890 High-end CCD Camera System

Quick Finder …

• Included in the delivery ...

– Chapter 3.1.2 Included in delivery, page 25

• System projection

– Chapter 3.2 System requirements, page 26

• PLEASE NOTE

– Chapter 2 Safety information, page 17

• Installing the device in the reading station

– Chapter 4 Installation, page 45

• Connecting the device to the electricity supply

– Chapter 5 Electrical installation, page 53

• Familiarizing yourself with the device and its functions

– Chapter 3 Product description, page 23

– Chapter 6.3.6 Changing the device password for the user level "Authorized Client",

page 88

– Chapter 9 Technical data, page 103

• Starting up the device with the default setting

– Chapter 6.3 First startup, page 80

• Installing the SOPAS-ET Configuration Software on the PC

– Chapter 6.2.3 Installation of the Configuration Software SOPAS-ET, page 79

• Optimizing the device to the reading conditions

– Chapter 6.3.3 Configuring the ICR890 System/MSC800, page 83

• Assistance in case of problems

– Chapter 8 Troubleshooting, page 97

• Where is everything?

– Chapter Contents, page 5

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 3

Page 4

Quick Finder

ICR890 High-end CCD Camera System

Operating Instructions

Overview of installation sequence

The following list summarizes the most important installation sequences for the ICR890

System as a stand-alone device in combination with the MSC800 for reading from above:

1. Check delivery for completeness.

2. Insert the ICI890 Illumination into two 180° brackets on the frame and screw tight. The front

window of the ICI890 Illumination should face downwards.

3. Remove the yellow and black protective caps from the lens protection tube and from ICD890

Camera lens.

Do not touch the lens!

4. Align the ICD890 Camera from the correct side to the illumination and carefully insert the lens

protection tube into the ICI890 Illumination opening.

5. Attach the ICD890 Camera to the ICI890 Illumination. Align the entire unit parallel to the

conveyor level and screw on the 180° brackets.

6. Connect the control line and the ICI890 Illumination power supply to the ICD890 Camera.

7. Insert and tighten the deflection mirror incl. the protective film on the opposite side to the ICI890

Illumination in two additional 180° brackets, parallel to the conveyor level.

The deflection mirror must be positioned at the same height as and exactly parallel to the

illumination.

8. Install the MSC800 close to the reading location.

9. Install the photoelectric reflex switch on the conveyor system in front of the reading location in

opposite direction of transport.

10. Install the MLG Light Grid on the conveyor system in front of the photoelectric reflex switch in

opposite direction of transport.

11. Install the incremental encoder on the conveyor system at the reading location.

12. Electrically connect the ICR890 System to the MSC800.

13. Connect the photoelectric reflex switch, MLG Light Grid, incremental encoder as well as data

processing host and PC to the MSC800 configuration.

14. Connect the MSC800 to the supply voltage (100 to 264 V AC/50 to 60 Hz).

15. Switch on the MSC800 using the main switch.

The ICR890 System and the MSC800 start up automatically.

16. Switch on the PC and install the SOPAS-ET Configuration Software (minimum requirements:

Windows 98

17. Start the SOPAS-ET Configuration Software and set up the new SOPAS-ET Project by choosing the

appropriate ICR890 and MSC800 Device Descriptions.

18. Establish communication with the MSC800.

19. Configure the ICR890 System via the register tabs in the SOPAS-ET Configuration Software

(position of the ICR890 in relation to conveyor system, focus control, code configuration, reading

pulse, etc.).

20. Trigger the ICR890 System (start reading pulse). To achieve this, move the object into the range

of the photoelectric reflex switch and keep it in this position.

The illumination switches on.

21. Remove the protective film from the deflection mirror and set up the deflection mirror ensuring

that the ICI890 Illumination light hits the stationary object (code) at a 15° angle (skew angle on

the conveyor level).

22. Carry out a test reading with the 1-D/2-D code. Move the object carrying the code several times

across the conveyor level beneath the ICR890 System and display the reading results in the

SOPAS-ET Configuration Software.

23. Repeat the test reading under real conditions and check that the data has been transferred to

the host.

24. Correct or optimize the parameter values where necessary via the SOPAS-ET Configuration

Software.

25. Save the parameter set as an “*.spr” configuration file to the SOPAS-ET Configuration Software.

The ICR890 System is ready for operation once the application-specific setting has been set.

TM

).

Note Detailed instructions can be found in Chapters 4 „Installation“, 5 „Electrical installation“

and 6 „Operation“.

4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 5

Operating Instructions

ICR890

Contents

Contents

1 Notes on this document ................................................................................................. 15

1.1 Purpose............................................................................................................15

1.2 Target audience ..............................................................................................15

1.3 Information content ........................................................................................15

1.4 Symbols used ..................................................................................................16

2 Safety information ..........................................................................................................17

2.1 Authorized users .............................................................................................17

2.1.1 Installation and maintenance....................................................................17

2.1.2 Electrical installation and the replacement of system components.......17

2.1.3 Startup, operation and configuration........................................................17

2.2 Intended use ...................................................................................................18

2.3 General safety precautions and protection measures.................................19

2.3.1 Radio interferences ....................................................................................19

2.3.2 Installation work .........................................................................................19

2.3.3 Electrical installation work .........................................................................19

2.3.4 LED radiation from the ICI890 Illumination..............................................19

2.4 Quick stop and quick start..............................................................................20

2.4.1 Switch off the ICR890 System...................................................................20

2.4.2 Switch on the ICR890 System ...................................................................20

2.5 Environmental information.............................................................................21

2.5.1 Energy requirements ..................................................................................21

2.5.2 Dispose of the device after decommissioning .........................................21

3 Product description.........................................................................................................23

3.1 Design..............................................................................................................23

3.1.1 Device view .................................................................................................24

3.1.2 Included in delivery.....................................................................................25

3.1.3 Contents of the CD-ROM ............................................................................26

3.1.4 Device versions...........................................................................................26

3.2 System requirements......................................................................................26

3.2.1 General system requirements ...................................................................26

3.2.2 Installation requirements...........................................................................27

3.2.3 Electrical installation requirements ..........................................................28

3.2.4 Operation requirements.............................................................................28

3.3 Product features and functions (overview) ...................................................29

3.4 Method of operation .......................................................................................31

3.4.1 Reading configuration ................................................................................32

3.4.2 Object trigger control..................................................................................33

3.4.3 Focus control ..............................................................................................33

3.4.4 Illumination control.....................................................................................33

3.4.5 Position........................................................................................................35

3.4.6 Increment configuration.............................................................................35

3.4.7 Image requirement .....................................................................................36

3.4.8 Code configuration .....................................................................................37

3.4.9 Data processing.............................................................................................37

3.4.10 Output format .............................................................................................39

3.4.11 Network.......................................................................................................39

3.4.12 Data interfaces ...........................................................................................39

3.4.13 Digital outputs.............................................................................................40

3.4.14 Digital inputs...............................................................................................40

3.5 Indicators and control elements....................................................................41

3.5.1 User interface .............................................................................................41

3.5.2 LEDs of the ICD890 Camera......................................................................42

3.6 Impacts on the reading quality.......................................................................43

4 Installation .......................................................................................................................45

4.1 Overview of installation sequence.................................................................45

4.2 Installation preparations ................................................................................45

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 5

Page 6

Contents

ICR890 High-end CCD Camera System

4.2.1 Layout the components which are to be installed................................... 45

4.2.2 Layout accessories ....................................................................................45

4.2.3 Selecting the installation location.............................................................46

4.2.4 Arrangement at the conveyor system.......................................................47

4.3 Installing and adjusting the device................................................................49

4.3.1 Installing the deflection mirror .................................................................. 50

4.3.2 Installing the ICI890 Illumination and the ICD890 Camera.................... 50

4.4 Installing external components .....................................................................51

4.4.1 External sensors for triggering .................................................................. 51

4.4.2 Installing the incremental encoder ........................................................... 52

4.4.3 Installing the MLG Light Grid..................................................................... 52

4.4.4 Installing the MSC800 Controller.............................................................. 52

4.5 Removing the device ......................................................................................52

5 Electrical installation...................................................................................................... 53

5.1 Overview of installation sequence.................................................................53

5.2 Electrical installation preparation ................................................................. 54

5.2.1 Electrical installation of the ICR890 System (without MSC800)............ 54

5.2.2 Electrical installation of the ICR890 System with MSC800

(single-side reading)................................................................................... 56

5.2.3 Electrical installation of the ICR890 System with MSC800

(multi-side reading)....................................................................................58

5.3 Electrical connections and cables.................................................................60

5.3.1 Electrical connections of the ICD890 Camera.........................................60

5.3.2 Electrical connections of the ICI890 Illumination.................................... 61

5.3.3 Electrical connections of the MSC800 (overview) ................................... 62

5.3.4 Assembled cables (overview) .................................................................... 63

5.4 Performing electrical installation...................................................................64

5.4.1 Connecting the power supply cable and the ICI890 Illumination

control line.................................................................................................. 64

5.4.2 Power supply of the ICR890 System ........................................................64

5.4.3 Data interfaces HOST/AUX........................................................................ 65

5.4.4 Data interface CAN 1-IN/OUT....................................................................66

5.4.5 Wiring the Ethernet interface HOST ETHERNET....................................... 68

5.4.6 Wiring the Ethernet interfaces GBIT 1 and GBIT 2 .................................. 69

5.4.7 Wiring the switching inputs IN 1 and IN 2 ............................................... 69

5.4.8 Wiring the switching outputs Result 1 and Result 2 (OUT connection). 70

5.5 Pin assignments and conductor colouring assignment............................... 71

5.5.1 ICD890 Camera connections .................................................................... 71

5.5.2 ICI890 Illumination connections............................................................... 75

5.5.3 Wire colours assignment of assembled cables with open end............... 75

6 Operation ......................................................................................................................... 79

6.1 Overview of the startup procedure................................................................ 79

6.2 Configuration Software SOPAS-ET................................................................. 79

6.2.1 Functions of the SOPAS-ET Configuration Software for the

ICR890 System/MSC800 (overview)........................................................ 79

6.2.2 System requirements for the SOPAS-ET Configuration Software ........... 79

6.2.3 Installation of the Configuration Software SOPAS-ET.............................. 79

6.2.4 Default setting for the SOPAS-ET Configuration Software....................... 80

6.3 First startup..................................................................................................... 80

6.3.1 Overview of the configuration procedure ................................................. 81

6.3.2 Establishing communication with the ICR890 System/MSC800........... 81

6.3.3 Configuring the ICR890 System/MSC800 ............................................... 83

6.3.4 Load changed parameter sets into the device ........................................ 87

6.3.5 Save, display and print the current parameter set.................................. 87

6.3.6 Changing the device password for the user level "Authorized Client".... 88

6.4 Default setting ................................................................................................ 88

6.4.1 Resetting the default setting in the ICR890 System ............................... 88

Operating Instructions

6 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 7

Operating Instructions

ICR890

Contents

6.4.2 Default setting MSC800 ............................................................................88

7 Maintenance ....................................................................................................................89

7.1 Maintenance during operation.......................................................................89

7.2 Cleaning the ICR890 System .........................................................................89

7.2.1 Cleaning the front window .........................................................................89

7.2.2 Cleaning the housing..................................................................................90

7.2.3 Cleaning the deflection mirror ...................................................................91

7.2.4 Cleaning further optical effective surfaces...............................................92

7.3 Replacing a system or a component .............................................................93

7.3.1 Replacing the ICD890 Camera or ICI890 Illumination ............................93

7.3.2 Replacing the deflection mirror .................................................................94

7.4 Disposal...........................................................................................................95

8 Troubleshooting...............................................................................................................97

8.1 Overview of errors and malfunctions which could occur..............................97

8.1.1 Installation error .........................................................................................97

8.1.2 Electrical installation error .........................................................................97

8.1.3 Configuration error .....................................................................................97

8.1.4 Malfunctions during operation ..................................................................97

8.2 Detailed malfunction analysis .......................................................................98

8.2.1 LEDs at the camera ....................................................................................98

8.2.2 System information ....................................................................................98

8.2.3 Status protocol ...........................................................................................98

8.3 ST error status in the reading result of a 1-D code (bar code) ................. 101

8.4 SICK support................................................................................................. 102

9 Technical data .............................................................................................................. 103

9.1 Data sheet for ICR890 Camera................................................................... 103

9.2 Data sheet for ICI890 Illumination ............................................................. 105

9.3 Data sheet for deflection mirror.................................................................. 105

9.4 Specification diagram.................................................................................. 106

9.4.1 Reading conditions for the diagram....................................................... 106

9.4.2 Reading areas of the ICR890 System.................................................... 106

9.4.3 Max. resolution across the direction of transport ................................. 107

9.4.4 Max. resolution in the direction of transport ......................................... 107

9.5 System dimensional drawing ICR890......................................................... 108

9.6 Deflection mirror dimensional drawing ...................................................... 110

10 Appendix........................................................................................................................ 111

10.1 Appendix overview ....................................................................................... 111

10.2 Configuring the ICR890 System with command strings............................ 111

10.3 Calculating code length of a bar code ........................................................ 112

10.4 Ordering information.................................................................................... 113

10.4.1 ICR890 High-end CCD Camera System ................................................. 113

10.4.2 Accessories: Controller and object distance detector .......................... 114

10.4.3 Accessories: Cables and connectors ..................................................... 115

10.4.4 Accessories: Incremental encoder......................................................... 116

10.4.5 Accessories: Cleaning agents for front window of the illumination ..... 116

10.5 Supplementary documentation................................................................... 117

10.6 Glossary ........................................................................................................ 118

10.7 EC Declaration of Conformity ...................................................................... 124

10.8 Code samples (decodeable)........................................................................ 127

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 7

Page 8

Contents

Operating Instructions

ICR890 High-end CCD Camera System

8 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 9

Operating Instructions

ICR890

Figures and tables

Abbreviations

BMP

Bitmap (pixel-oriented Windows format for saving photos)

CAN Controller Area Network (field bus protocol based on the CAN bus)

CCD Charge Coupled Device

DOF Depth Of Field

dpi dots per inch ( 1 inch = 25.4 mm)

EEPROM Electrically Erasable Programmable Read Only Memory

FTP File Transfer Protocol

HTML Hyper Text Markup Language

IInput

ICD Image Capture Device

ICI Image Capture Illumination

ICR Image Code Reader (High-end CCD Camera System)

JPEG Joint Photographic Expert Group (pixel-oriented file format for saving high compression photos,

compression process for tiff formats)

LED Light Emitting Diode

lpi Lines per inch ( 1 inch = 25.4 mm)

MAC Medium Access Control

MLG Modular Light Grid

MSC Modular System Controller (MSC800)

MTBF Mean Time Between Failure

MTTR Mean Time To Repair

OOutput

RAM Random Access Memory

ROM Read Only Memory

SD Secure Digital Card

SMART SICK Modular Advanced Recognition Technology

SOPAS-ET SICK Open Portal for Application and Systems Engineering Tool (PC software for Windows for

configuration of the ICR890 System and the MSC800)

PLC ProgrammableLogic Controllers

TCP/IP Transmission Control Protocol/Internet Protocol

UDP User Datagram Protocol

VMS Volume Measuring System

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 9

Page 10

Figures and tables

ICR890 High-end CCD Camera System

Note The ICR890 System components and other components in this document are referred to in

the following simplified terms:

• ICR890 High-end CCD Camera System , simplified: ICR890 System

• ICD890 Image Capture Device, simplified: ICD890 Camera

• ICI890 Image Capture Illumination, simplified: ICI890 Illumination

• MSC800 Modular System Controller, simplified: MSC800

• MLG Light Grid (Modular Light Grid), simplified: MLG Light Grid

• VMS4xx/5xx Volume Measuring System, simplified: VMS4xx/5xx

• SICK Open Portal for Application and Systems Engineering Tool, simplified:

SOPAS-ET Configuration Software

The register tabs for configuration of the ICR890 System are referred to in the SOPAS-ET

Configuration Software online help as "device pages".

Operating Instructions

10 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 11

Operating Instructions

ICR890

Figures and tables

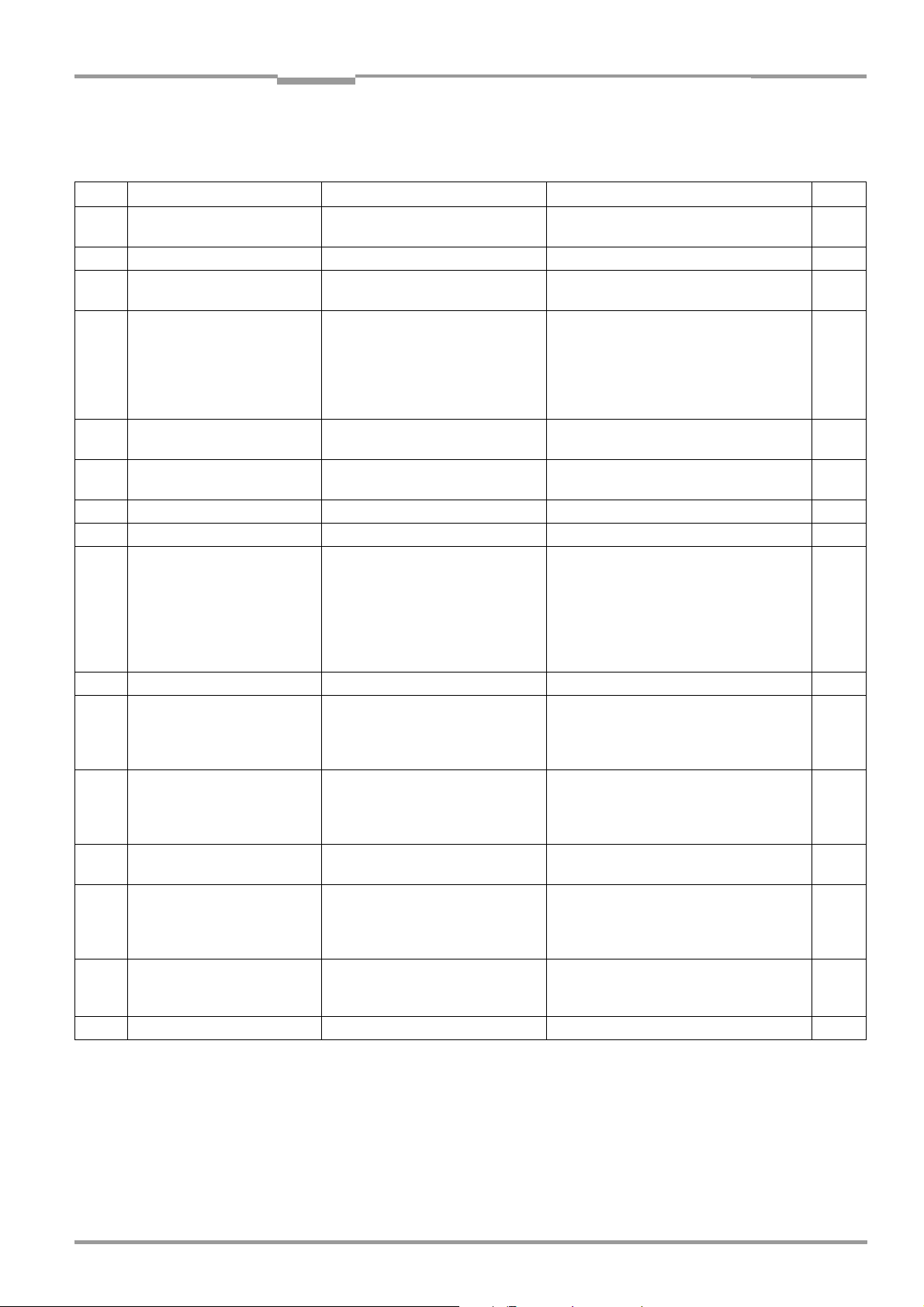

Tables

Tab. 1-1: Target audience ................................................................................................15

Tab. 3-1: Included in the delivery of the ICR890 High-end CCD Camera System........ 25

Tab. 3-2: System component versions............................................................................ 26

Tab. 3-3: General system requirements (standard device) ........................................... 27

Tab. 3-4: Data interface function..................................................................................... 39

Tab. 3-5: LED indications ................................................................................................. 42

Tab. 5-1: ICR890 System (stand-alone device) without MSC800: Overview of

the ICD890 Camera connections which have to be established ..................55

Tab. 5-2: ICR890 System (stand-alone device) with MSC800: Overview of

the ICD890 Camera connections which have to be established ..................56

Tab. 5-3: ICR890 System (stand-alone device) with MSC800: Overview of

the MSC800 connections which have to be established...............................57

Tab. 5-4: ICR890 System with MSC800 (multi-side reading): Overview of

the ICD890 Camera connections which have to be established ..................58

Tab. 5-5: ICR890 System with MSC800 (multi-side reading): Overview of

the MSC800 connections which have to be established...............................59

Tab. 5-6: ICR890 System with MSC800 (multi-side reading): Overview of

the VMS4xx/5xx connections which have to be established.........................59

Tab. 5-7: ICD890 Camera: Function of the electrical connections ............................... 61

Tab. 5-8: ICI890 Illumination: Function of the electrical connections.......................... 61

Tab. 5-9: MSC800-0000 logic controller: Function of the electrical

connections (overview)..................................................................................... 62

Tab. 5-10: Cables for connecting the ICR890 System .....................................................63

Tab. 5-11: Maximum cable lengths between ICR890 and the host................................65

Tab. 5-12: CAN bus: Maximum cable lengths, depending on the data transfer rate..... 66

Tab. 5-13: CAN bus: Maximum stub cable lengths, depending on the data

transfer rate ...................................................................................................... 66

Tab. 5-14: CAN bus: Required wire cross section, depending on the data

cable length.......................................................................................................67

Tab. 5-15: Ratings of the switching inputs IN1 and IN 2 .................................................69

Tab. 5-16: Ratings of the switching outputs Result 1 and Result 2................................ 70

Tab. 5-17: ICD890 Camera: Pin assignment of the 8-pole RJ-45 sockets

“GBIT1“ and “GBIT2“........................................................................................ 71

Tab. 5-18: ICD890 Camera: Pin assignment of the 5-pole M12 sockets

“CAN 1-OUT“/“CAN 2-OUT“ ..............................................................................71

Tab. 5-19: ICD890 Camera: Pin assignment of the 5-pole M12 plugs

“CAN 1-IN“/“CAN 2-IN“.....................................................................................72

Tab. 5-20: ICD890 Camera: Pin assignment of the 8-pole M12

socket “ILLUMINATION“.................................................................................... 72

Tab. 5-21: ICD890 Camera: Pin assignment of the 8-pole M12 plug “AUX“.................. 72

Tab. 5-22: ICD890 Camera: Pin assignment of the 8-pole M12 plug “HOST“ ...............72

Tab. 5-23: ICD890 Camera: Pin assignment of the 4-pole M12 plug “OUT“.................. 73

Tab. 5-24: ICD890 Camera: Pin assignment of the 5-pole M12 socket “IN 1“.............. 73

Tab. 5-25: ICD890 Camera: Pin assignment of the 5-pole M12 socket “IN 2“.............. 73

Tab. 5-26: ICD890 Camera: Pin assignment of the 4-pole M12 socket

“HOST ETHERNET“............................................................................................ 73

Tab. 5-27: ICD890 Camera: Pin assignment of the 8-pole Harting HanQ8 plug

“POWER IN“....................................................................................................... 74

Tab. 5-28: ICD890 Camera: Pin assignment of the 8-pole Harting HanQ8 socket

“POWER OUT“.................................................................................................... 74

Tab. 5-29: ICI890 Illumination: Pin assignment of the 8-pole Harting HanQ8 plug

“POWER IN“....................................................................................................... 75

Tab. 5-30: ICI890 Illumination: Pin assignment of the 8-pole M12 plug

“ILLUMINATION“................................................................................................ 75

Tab. 5-31: Wire colours assignment: Cable no. 6028420 (HOST/AUX), standard ........ 75

Tab. 5-32: Wire colours assignment: Cables no. 6021166/no. 6021175

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 11

Page 12

Figures and tables

ICR890 High-end CCD Camera System

(CAN 1-IN), PVC-free ..........................................................................................76

Tab. 5-33: Wire colours assignment: Cable no.6024861 (IN 1/IN 2), standard............76

Tab. 5-34: Wire colours assignment: Cable no. 6027559 (OUT), standard....................76

Tab. 5-35: Wire colours assignment: Cable no. 2039398 (ICD890 Camera

power supply), standard....................................................................................77

Tab. 5-36: Wire colours assignment: Cable no. 2032926 (ICD890 Camera

power supply), PVC-free ....................................................................................77

Tab. 6-1: Default setting for the SOPAS-ET Configuration Software (excerpt)..............80

Tab. 6-2: Connection between the PC with the SOPAS-ET Configuration

Software and the ICR890 System/MSC800 ...................................................81

Tab. 6-3: ICR890 System (stand-alone device) with MSC800: Overview

of parameters which have to be set.................................................................83

Tab. 6-4: ICR890 System (stand-alone device) with MSC800: Overview

of parameters which have to be set.................................................................85

Tab. 6-5: ICR890 System (stand-alone device) without MSC800: Overview

of parameters which have to be set.................................................................86

Tab. 8-1: Request “Query warnings“................................................................................99

Tab. 8-2: Answer to the request “Query warnings“.........................................................99

Tab. 8-3: Request “Query errors“.................................................................................. 100

Tab. 8-4: Answer to the request “Query errors“........................................................... 100

Tab. 8-5: Request “Query fatal errors“ ......................................................................... 100

Tab. 8-6: Answer to the request “Query fatal errors“................................................... 100

Tab. 8-7: Meaning of the ST error status in the reading result................................... 101

Tab. 9-1: Technical specifications for the ICR890 Camera......................................... 103

Tab. 9-2: Technical specifications for the ICI890 Illumination ................................... 105

Tab. 9-3: Technical specifications for deflection mirror .............................................. 105

Tab. 9-4: Reading conditions for the specification diagram ....................................... 106

Tab. 10-1: Help table for calculating code length of a bar code................................... 112

Tab. 10-2: Ordering information: ICR890 High-end CCD Camera System ................... 113

Tab. 10-3: In stock accessories: Controller and object distance detector ................... 114

Tab. 10-4: In stock accessories: Cables and connectors .............................................. 115

Tab. 10-5: In stock accessories: Incremental encoder.................................................. 116

Tab. 10-6: In stock accessories: Cleaning agents for front window of the

illumination ..................................................................................................... 116

Tab. 10-7: Supplementary documentation for the ICR890 System.............................. 117

Operating Instructions

12 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 13

Operating Instructions

ICR890

Figures and tables

Figures

Fig. 2-1: LED radiation outlet opening ........................................................................... 19

Fig. 3-1: ICR890 System in combination with the MSC800 (single-side reading)...... 23

Fig. 3-2: View of the ICD890 camera and the ICI890 Illumination.............................. 24

Fig. 3-3: Work area of the ICR890 System (standard device)...................................... 26

Fig. 3-4: Example of simple system installation on the installation frame.................. 27

Fig. 3-5: The ICR890 System at a conveyor system, single-side reading from above 31

Fig. 3-6: System diagram for single-side reading from above...................................... 32

Fig. 3-7: Diagram of the illumination with illuminated area ......................................... 33

Fig. 3-8: ICR890 System with deflection mirror for reading from above..................... 34

Fig. 3-9: Position of the ICR890 System and the tilt angle........................................... 35

Fig. 3-10: Example of an image recording for analysis ...................................................36

Fig. 3-11: Image analysis (blue rectangle: Regions of interest; green rectangle:

Successful decoding; green line: Decoder runtime at end of the

reading pulse) ................................................................................................... 36

Fig. 3-12: Reading operation modi of the ICR890 System in stand-alone operation... 38

Fig. 3-13: SD memory card for parameter set ................................................................. 41

Fig. 3-14: LEDs at the ICD890 Camera............................................................................42

Fig. 3-15: Pixel resolution across the direction of transport (standard device,

135 mm (5.32 in) lens) .................................................................................... 43

Fig. 3-16: Line resolution in the direction of transport (standard device,

8,192 pixels CCD sensor)................................................................................. 43

Abb. 4-1: Example of a project-specific dimensional sheet for installation.................. 46

Abb. 4-2: Free space required for connecting the camera and the illumination.......... 47

Abb. 4-3: Arrangement above the conveyor system for single-side reading

from above ........................................................................................................ 47

Abb. 4-4: Arrangement at the conveyor system for multi-side reading with

VMS4xx/5xx....................................................................................................... 48

Abb. 4-5: Arrangement at the conveyor system.............................................................. 48

Abb. 4-6: Position of the components ............................................................................. 49

Abb. 4-7: 180° bracket for the deflection mirror and the illumination.........................49

Abb. 4-8: Removeable protective camera caps.............................................................. 51

Abb. 4-9: Position of the external components...............................................................51

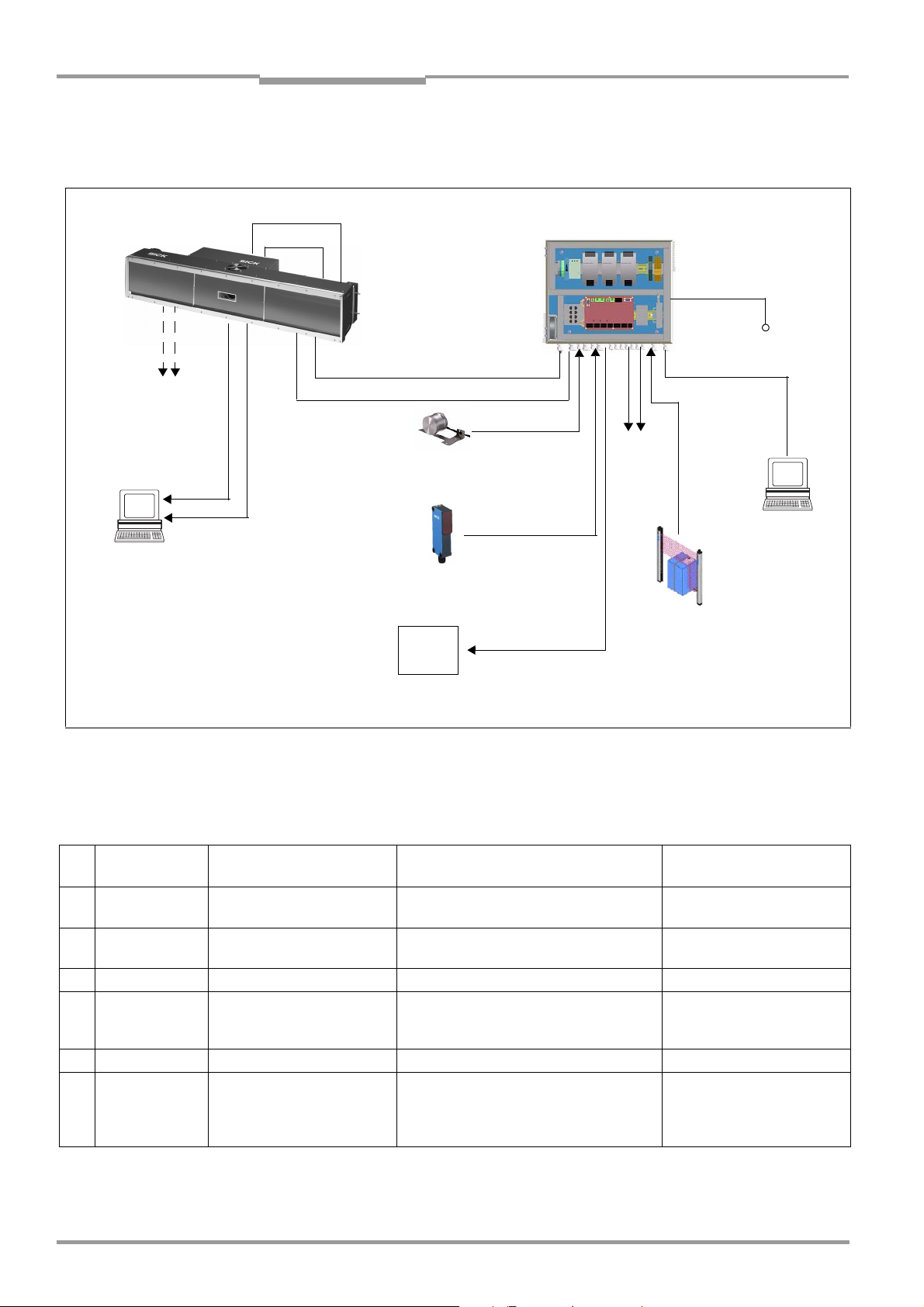

Abb. 5-1: Block diagram: connection principle of the ICR890 (standard system) .......54

Abb. 5-2: Block diagram: Connection principle of a ICR890 (standard system)

with MSC800.....................................................................................................56

Abb. 5-3: Block diagram: Connection principle of several ICR890

(standard systems) with MSC800 ...................................................................58

Abb. 5-4: ICD890 Camera: Position of the electrical connections

(standard system) ............................................................................................. 60

Abb. 5-5: MSC800-0000 logic controller: Position of the electrical connections ........ 62

Abb. 5-6: ICD890 Camera: Wiring of the HOST/AUX data interfaces............................66

Abb. 5-7: Block diagram: Function of the Ethernet interface.........................................68

Abb. 5-8: Wiring of the switching inputs IN 1 and IN 2................................................... 69

Abb. 5-9: Wiring of the switching outputs Result 1 and Result 2.................................. 70

Abb. 5-10: ICD890 Camera: Electrical connections (standard system).......................... 71

Abb. 6-1: Configuration with SOPAS-ET ........................................................................... 80

Abb. 7-1: Cleaning the front window................................................................................90

Abb. 7-2: Cleaning the air inlet and outlet openings at the system's

illumination ICR890.......................................................................................... 90

Abb. 7-3: Cleaning of the external optical sensors (reading pulse generator,

detector for object distance)............................................................................92

Abb. 7-4: 180° bracket: Loosening clamping screws.................................................... 93

Abb. 7-5: ICD890 Camera: Position of the battery on the internal PC card.................. 95

Abb. 9-1: Reading areas of the ICR890 System (standard).........................................106

Abb. 9-2: Pixel resolution across the direction of transport (standard device,

135 mm (5.32 in) lens) ..................................................................................107

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 13

Page 14

Figures and tables

ICR890 High-end CCD Camera System

Abb. 9-3: Line resolution in the direction of transport (standard device,

8,192 pixels CCD sensor) .............................................................................. 107

Abb. 9-4: Dimensions of the ICR890 System ............................................................... 108

Abb. 9-5: Total dimensions of the ICR890 System and the free space

required for connecting.................................................................................. 109

Abb. 9-6: Dimensions of the deflection mirror ............................................................. 110

Abb. 10-1: EC Declaration of Conformity for the ICD890 Camera

(page 1, scaled down version)....................................................................... 124

Abb. 10-2: EC Declaration of Conformity for the ICI890 Illumination

(page 1, scaled down version)....................................................................... 125

Abb. 10-3: Code samples of 1-D codes of various module widths

(print ratio 2:1) and 2-D code of various cell sizes ...................................... 127

Operating Instructions

14 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 15

Operating Instructions Chapter 1

ICR890

Notes on this document

1 Notes on this document

1.1 Purpose

This document provides instructions for technical staff on the installation and operation of

the following ICR890 System models:

• The ICR890 System equipped with focus control, CCD sensor 8,192 pixels, standard

lens (focal distance 135 mm (5.32 in))

This document contains the following information:

• Installation and electrical installation

• Startup

• Operation and configuration

• Maintenance

• Troubleshooting

• Replacing system components

A step-by-step approach is taken for all tasks.

1.2 Target audience

The target audience of this document is persons assigned the following tasks:

Tasks Target audience

Installation, electrical installation,

maintenance, replacing system

components

Startup, operation and configuration Qualified staff, e. g. technicians and engineers

Operation of the conveyor system Qualified staff for startup and operation of the conveyor

Tab. 1-1: Target audience

Qualified staff, e. g. service technicians and factory

electricians

system

1.3 Information content

This document contains all the required information for installation, electrical installation

and operation of the ICR890 System at the installation location. The factory configuration

(default setting) of the ICR890 System as a stand-alone device is optimized to a

single-side reading (from above or from the side).

Configuration of the ICR890 System for the application-specific reading conditions and

operation is carried out via the SOPAS-ET Configuration Software at a Windows

SOPAS-ET Configuration Software contains an online help system to facilitate configuration.

Electrical installation of the MSC800 controller for a ICR890 System as stand-alone device

and its configuration is detailed in the MSC800 Operating Instructions (no. 8011540).

These instructions also described use of the MSC800 as a controller for a multi-side

reading.

Note Further information on High End CCD Camera Systems, Volume Measurement Systems and

Bar Code Scanners is available from SICK AG, Auto Ident division.

On the Internet at www.sick.com.

TM-

PC. The

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 15

Page 16

Chapter 1 Operating Instructions

Notes on this document

ICR890 High-end CCD Camera System

1.4 Symbols used

Some of the information in this document is marked specially so that you can access it

quickly:

Warning!

Warnings are provided to prevent injury to operating personnel or serious damage to the

ICR890 System.

¾ Always read warnings carefully and observe them at all times.

Reference Italics are used to refer to more detailed information elsewhere.

Note Notes indicate special features or characteristics.

Explanation Explanations provide background information on technical correlations.

Recommendation Recommendations help you carry out certain procedures more effectively.

TIP Tips explain settings in the SOPAS-ET Configuration Software.

P

ROJECT This font indicates a term in the user interface of the SOPAS-ET Configuration Software.

Icons refer to buttons in the user interface of the SOPAS-ET Configuration Software.

“0x0“ This font indicates messages output by the ICR890 System.

This symbol identifies sections that describe steps carried out with the SOPAS-ET

Configuration Software.

This symbol refers to additional technical documentation.

¾ There is a procedure which needs to be carried out. This symbol indicates operational

instructions which only contain one operational step or operational steps in warning notices

which do not have to be followed in any particular order.

Operational instructions comprising several steps are denoted using consecutive numbers.

Ö This symbol indicates a glossary entry.

16 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 17

Operating Instructions Chapter 2

ICR890

Safety information

2 Safety information

This chapter deals with your safety and operator safety.

¾ Read this chapter carefully before using the ICR890 System.

2.1 Authorized users

For correct and safe functioning, the ICR890 System must be installed, operated and

maintained by sufficiently qualified staff.

Repairs to the ICR890 System should only be carried out by qualified and authorized SICK

AG service staff.

¾ The operating instructions should be made available to the end user.

¾ The end user should be briefed and urged to read the operating instructions by the

technicians.

The following chapters summarize the required qualifications for the various tasks.

2.1.1 Installation and maintenance

• Practical technical training

• Knowledge of current health and safety regulations at the workplace

2.1.2 Electrical installation and the replacement of system components

• Practical electrical training

• Knowledge of current electrical safety regulations

• Knowledge of startup and operation of the device in each operational area

(e. g. conveyor system)

2.1.3 Startup, operation and configuration

• Knowledge of the mechanical and electrical parameters of the conveyor system and

the characteristics of the conveyor system regarding startup and operation

• Basic knowledge of the Windows

• Basic knowledge of data transfer

• Basic knowledge of designing and setting up (addressing) Ethernet connections for

connecting the ICR890 System to the Ethernet

• Basic knowledge of working with an HTML browser (e.g. Internet Explorer) for using the

online help

• Basic knowledge of 1-D/2-D code technology

TM

operating system

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 17

Page 18

Chapter 2 Operating Instructions

Safety information

ICR890 High-end CCD Camera System

2.2 Intended use

The ICR890 High-end CCD Camera System is an intelligent sensor for the automatic

recognition and decoding of 1-D/2-D codes on moving objects in a reading station.

In combination with the MSC800 modular system controller, the ICR890 System is used as

a stand-alone device for single-side reading, e.g. from above or from the side. For a similarly

possible multi-side reading on the conveyor system, the corresponding number of systems

is combined with other SICK bar code scanners and with the co-coordinating MSC800.

The intended use of the system results from the following description of the system

components and their functions:

• The system consists of the ICD890 Camera, the ICI890 Illumination and a deflection

mirror. The ICD890 Camera is installed in a frame together with the ICI890 Illumination

as a unit parallel to the deflection mirror, either above the conveyor system (reading

from above) or at the side (side reading).

• The necessary object distance information is contained in the ICR890 System either by

an MLG Light Grid (in the case of readings from above) or by a VMS4xx/5xx Volume

Measurement System for focus control during

• The ICR890 System transfers the reading data via its HOST main data interface (serial

RS 232, RS 422/485, Ethernet or CAN), with optionally selectable diagnosis data, to a

superordinate host processor for further processing.

The ICR890 System transfers its data via the CAN interface to the MSC800, in

combination with the MSC800. The data can then be accessed from the HOST data

interface.

• The processed image information of the ICD890 Camera is located on two fast GBit

Ethernet channels. The image information can be transferred to the client display at

extremely high data transfer rates on a special PC with compatible GBit Ethernet

interface cards and GigE Vision Standard licence (real time image data transfer). The

high image quality also allows use in OCR and video coding applications.

• Configuration/Operation of the ICR890 System is carried out as standard via the AUX

auxiliary data interface (serial RS 232 or Ethernet) using the SOPAS-ET Configuration

Software, which runs on a standard client PC. Alternatively, the configuration can also

be carried out via the PC connection to the MSC800 (serial RS 232 or Ethernet).

Any warranty claims against SICK AG shall be deemed invalid in the case of other system

use or system modifications, this includes modifications during installation and electrical

installation or changes to the SICK software.

Note The ICD890 Camera and ICI890 Illumination must not be opened. If the devices are

opened, the manufacturer's warranty shall not apply.

Single or multi-side reading.

18 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 19

Operating Instructions Chapter 2

ICR890

Safety information

2.3 General safety precautions and protection measures

¾ Read the general safety precautions thoroughly and observe them during all ICR890

System activities. Also observe the warning notices above the operational instructions

of each chapter.

2.3.1 Radio interferences

RF interference in case of use in residential areas.

¾ ICR890 High-end CCD Camera System is exclusively intended for use in an industrial

environment.

2.3.2 Installation work

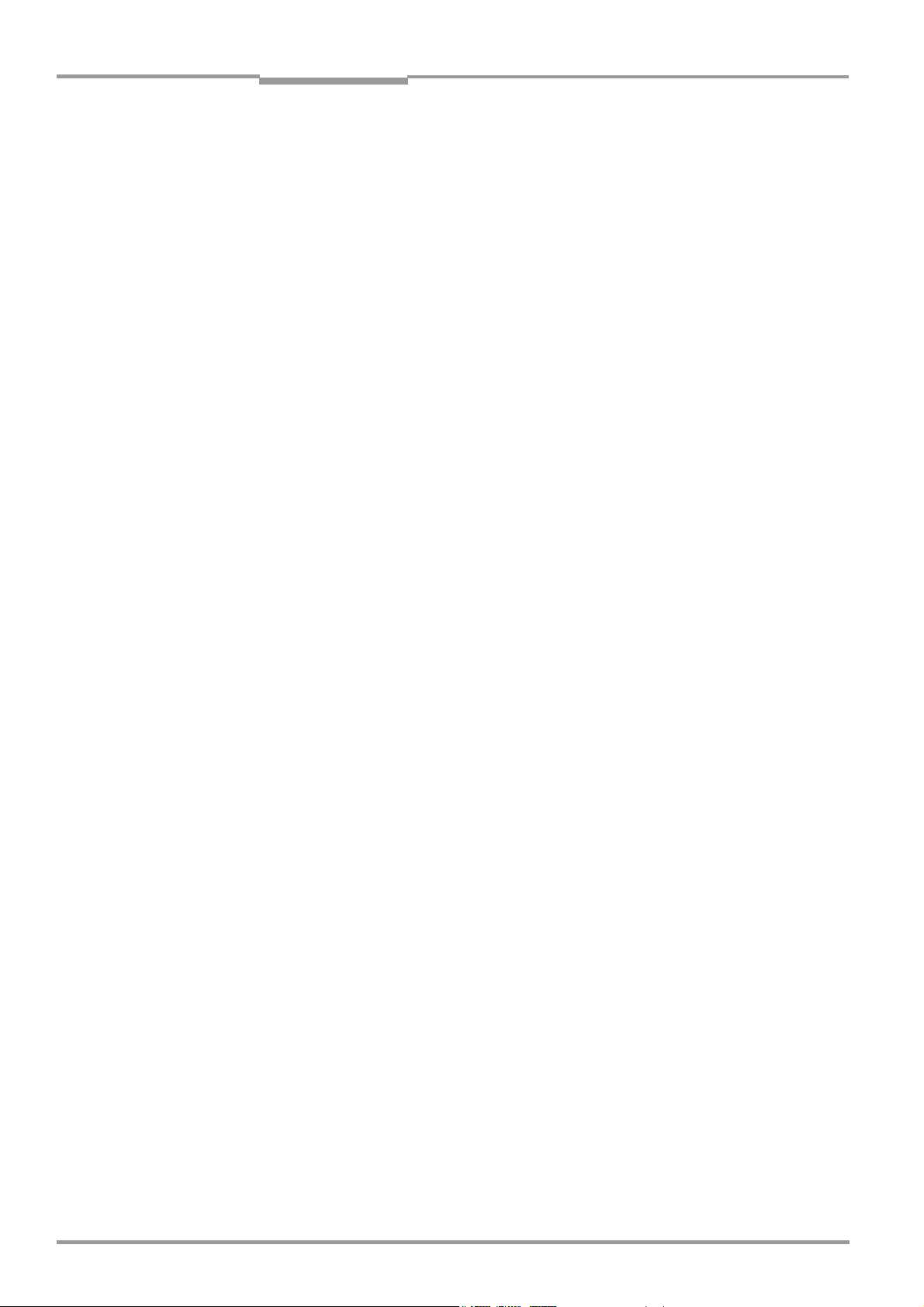

Risk of injuries due to falling components!

The combined weight of the ICD890 Camera and the ICI890 Illumination is approx. 37 kg

(81.6 lb) without installation accessories.

¾ Do not carry out installation work alone.

¾ A second person should always secure components during installation.

2.3.3 Electrical installation work

Risk of injuries due to electrical current!

Connect the MSC800 Controller to the mains power supply (100 to 264 V AC/50 to 60 Hz).

¾ Observe current safety regulations when working with electrical equipment.

2.3.4 LED radiation from the ICI890 Illumination

Output opening

Fig. 2-1: LED radiation outlet opening

LED radiation escapes from the entire front window of the ICI890 Illumination.

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 19

Page 20

Chapter 2 Operating Instructions

Note The ICI890 Illumination works with LEDs on the λ = 620 nm (red light) wavelength.

Safety information

ICR890 High-end CCD Camera System

Class 1M LED radiation (in accordance with EN/IEC 60825-1)!

Incorrect use can result in hazardous radiation exposure and the LED class being

exceeded!

The accessible radiation of the ICI890 Illumination is not hazardous under reasonably

foreseeable conditions, provided that the beam width is not reduced by optical instruments,

e.g. magnifying glass, lenses or telescopes. Visual glare, loss of colour vision and eye

injuries cannot be ruled out.

The entire window surface is the LED radiation outlet opening.

¾ Do not look directly into the radiation source with optical instruments.

¾ Do not open the housing. (The illumination is not switched off if the housing is opened).

¾ Always observe the latest valid version of laser protection regulations.

The radiation emitted is not harmful to human skin.

Regular maintenance is not required to ensure compliance with laser class 1M.

The ICI890 Illumination operates as follows:

• The reading pulse (pulse source) controls the on and off mechanism of the LED

illumination during the reading process. The LEDs are switched on in pulsed mode

during the reading operation depending on the reading gate duration.

• A time stage (illumination timeout) automatically switches off the illumination during

the reading operation after 3 seconds (default setting) following the start of a

continuous reading pulse. This, however, does not switch off the reading pulse. The

reading pulse should be stopped via a relevant pulse signal. The next reading pulse

switches the illumination back on.

• The illumination timeout can be set or switched off within a range of 3 s to 25 h. For

safety reasons, the minimum illumination power on time is 3 seconds.

2.4 Quick stop and quick start

The ICR890 System is operated via the MSC800 Controller as standard and can be

switched on and off using the controller main switch.

2.4.1 Switch off the ICR890 System

¾ Switch off the power supply of the MSC800.

When the system is switched off the following data is lost:

• Application-specific parameter sets in the ICR890 System and in the MSC800

Controller which were only temporarily saved in the devices

• The last reading result of the ICR890 System

• Daily operating hours counter of the ICR890 System

2.4.2 Switch on the ICR890 System

¾ Switch on the power supply of the MSC800 again.

The ICR890 System starts up using the most recent permanently saved configuration.

The daily operating hours counter is reset.

20 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 21

Operating Instructions Chapter 2

ICR890

Safety information

2.5 Environmental information

The ICR890 System has been constructed with minimum environmental pollution in mind.

Excluding the housing, the system does not contain any materials using silicone.

2.5.1 Energy requirements

The ICR890 System is electrically powered via the MSC800 Controller as standard

(functional extra-low voltage in accordance with IEC 364-4-41).

The following power consumption details apply to the system components and the

controller:

• ICD890 Camera: typically 75 W with 24 V DC ± 10 % (via MSC800 power supply)

• ICI890 Illumination: typically 350 W with 24 V DC ± 10 % (via MSC800 power supply)

• MSC800-0000 logic controller: typically 10 W with 24 V DC ± 10 %

2.5.2 Dispose of the device after decommissioning

At present SICK AG will not accept the return of any devices which can no longer be

operated or repaired.

¾ Inoperable or irreparable devices must be disposed of in an environmentally friendly

manner and in accordance with valid country-specific waste disposal guidelines.

The design of the ICR890 System allows for its separation as recyclable secondary raw

materials and hazardous waste (electronic scrap).

Please see Chapter 7.4 Disposal, page 95.

Note The battery on the internal PC card of the ICD890 Camera must be removed before the

device is scrapped.

¾ Dispose of the battery separately in accordance with ROHS regulations (Europe).

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 21

Page 22

Chapter 2 Operating Instructions

Notes:

Safety information

ICR890 High-end CCD Camera System

22 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 23

Operating Instructions Chapter 3

ICR890

Product description

3 Product description

This chapter describes the design, the features and the functions of the ICR890 System.

¾ For installation, electrical installation and startup assistance as well as system

configuration using the SOPAS-ET Configuration Software, please read this chapter

prior to carrying out any of the tasks.

3.1 Design

The ICR890 System consists of the ICD890 Camera (Image Capture Device), the ICI890

Illumination (Image Capture Illumination) and a deflection mirror. The ICR890 System is

operated in combination with the MSC800 (Modular System Controller) via a CAN bus. The

MSC800 supplies the ICR890 System with power.

For further information on the MSC800, see the MSC800 Operating Instructions

(no. 8011540).

External sensors are required for the reading pulse, detection of the object distance and for

creation of the increment signal. These sensors and the superordinate host processor are

connected to the MSC800.

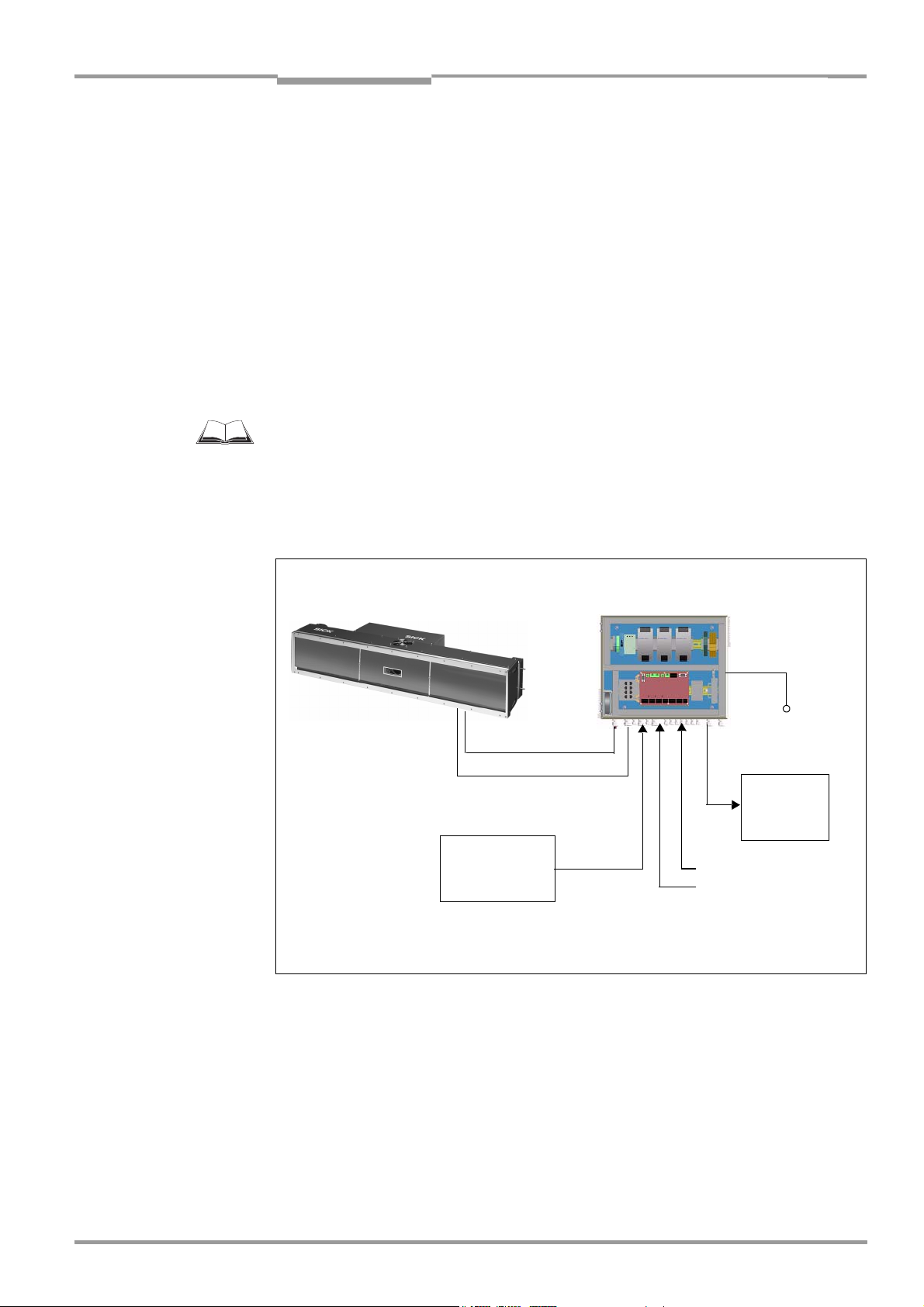

ICR890 System

Power supply

CAN bus

MLG Light Grid/

VMS4xx/5xx

Object distance/

Object geometry

Fig. 3-1: ICR890 System in combination with the MSC800 (single-side reading)

MSC800

Mains connection

HOST

Reading pulse

Conveyor speed

Alternatively, connection of the external sensors and the superordinate host processor can

be carried out directly at the ICR890 System.

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 23

Page 24

Chapter 3 Operating Instructions

Product description

ICR890 High-end CCD Camera System

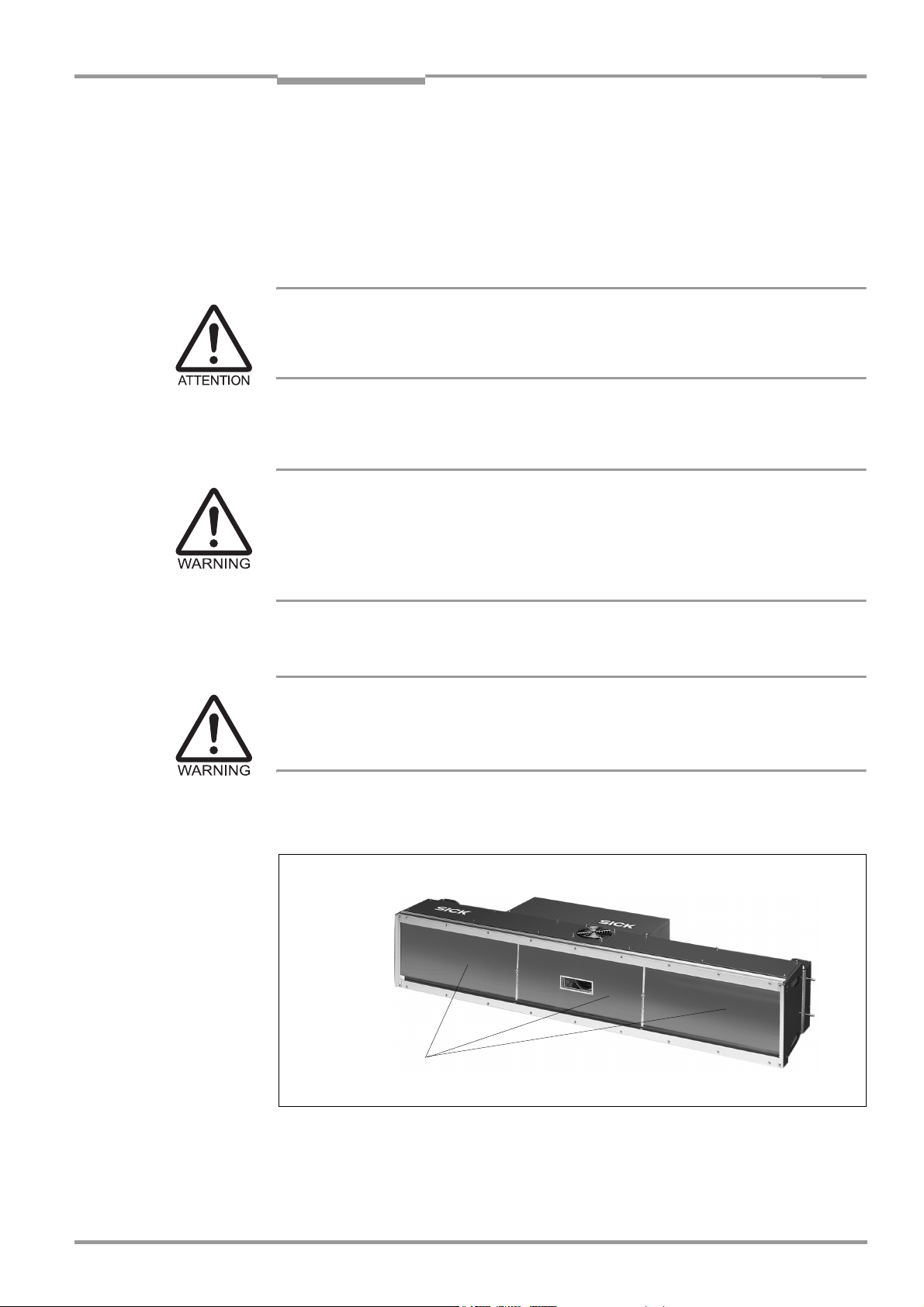

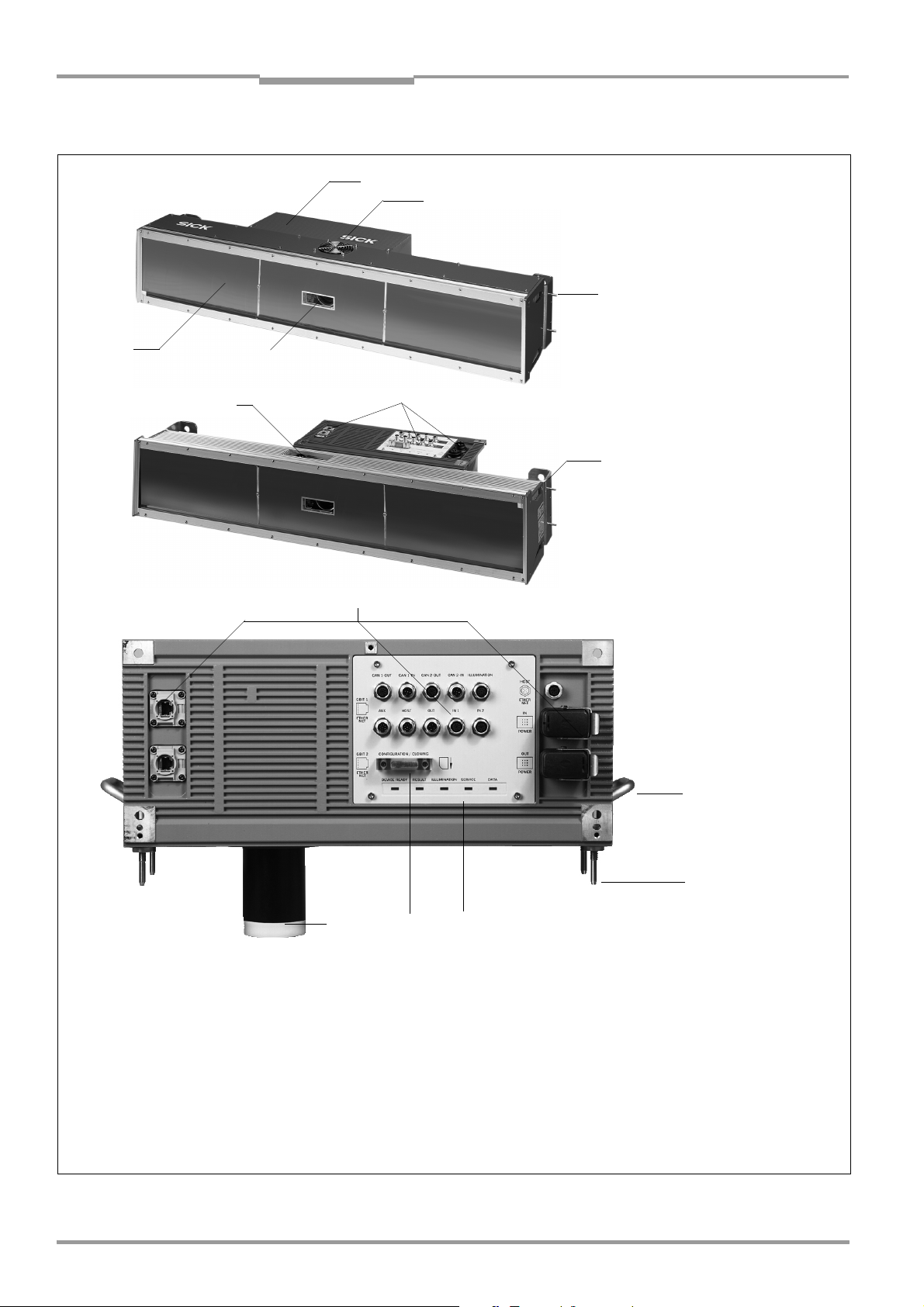

3.1.1 Device view

2

3

4

1

6

5

Complete ICR890 System, from above

7

8

Complete ICR890 System, from below

7

ICD890 Camera,

from below

Legend:

1 ICI890 Illumination

2 ICD890 Camera

3 Air inlet opening for cooling

the ICI890 Illumination

4 Guide pins (4 x) for use in

180° bracket

Fig. 3-2: View of the ICD890 camera and the ICI890 Illumination

5 ICD890 Camera reading window

6 Electrical connections for the

ICI890 Illumination

7 Electrical connections for the

ICD890 Camera

8 Fixing for bracket (2 x)

9

bl

bm bn bo

9

Handhold for camera (2 x)

bl Threaded centering pin for

fixing to the ICI890 Illumination

bm LEDs for status indicator (5 x)

bn SD memory card for parameter cloning

bo Lens protection tube

24 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 25

Operating Instructions Chapter 3

ICR890

Product description

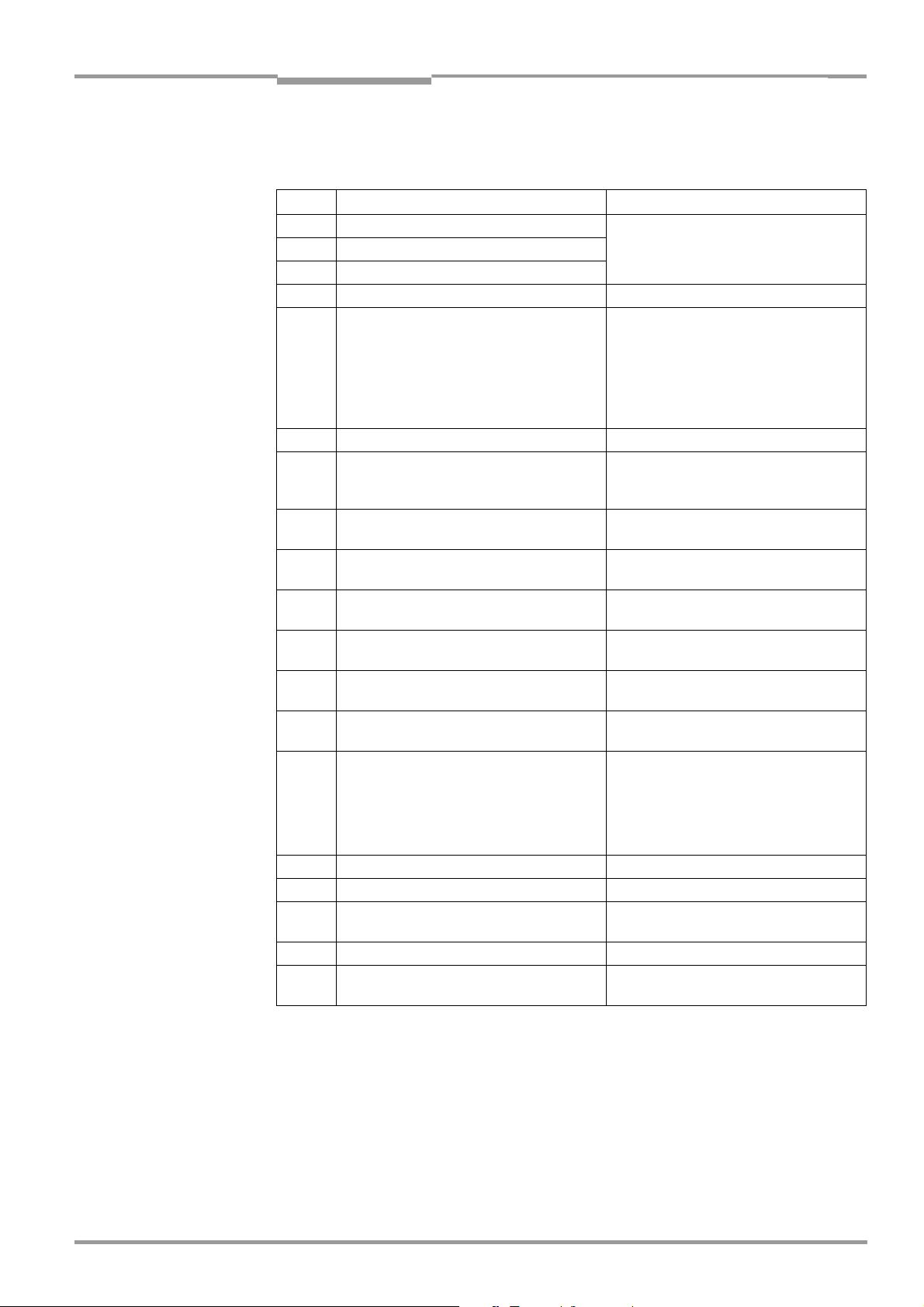

3.1.2 Included in delivery

Delivery of the ICR890 System includes the following components:

Piece(s) Components Comment

1 ICD890 Camera ICR890 System

1 ICI890 Illumination

1Deflection mirror

1 MSC800 Without connection cables

1 MLG Light Grid (preconfigured) height

distance detector with connection cable and

installation kit

- or -

1 Object distance detector VMS4xx/5xx with

connection cables and installation kit

4 180° brackets with installation accessories For ICR890 System and deflection mirror

1 WL18-3 Reading Pulse Sensor (pulse

photoelectric reflex switch) with connection

cable and installation kit

1 Connection cable For the power supply of the ICR890

1 Connection cable For the power supply of the ICI890

1 Connection cable For control of the ICI890 Illumination via

1 CAN bus data link For networking the ICR890 System with

1 Terminal resistance For CAN bus termination at the ICR890

1 GigE Vision Standard licence for real time

image data transfer

1 Incremental encoder, resolution

10 mm (394 mil)/pulse

- or -

1 Incremental encoder, resolution

0.2 mm (7.9 mil)/pulse (using VMS4xx/5xx)

Installation frames Optional (application-specific)

Application-specific

Triggering the reading procedure

System

Illumination via the camera

the camera

MSC800 via the CAN bus

System

Optional (application-specific)

Optional (application-specific)

1 Notes on Device with electrical connection

diagram as primary information

min. 1 CD-ROM Depending on number of ordered devices

Operating Instructions ICR890 System in

printed form, in German and/or English

Tab. 3-1: Included in the delivery of the ICR890 High-end CCD Camera System

Included in the device packaging of the

ICR890 System

Optional, depending on the number of

issues explicitly ordered upon purchase

An overview of system components, in stock installation accessories, incremental

encoders, cables and plug connections is available in Chapter 10.4 Ordering information,

page 113.

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 25

Page 26

Chapter 3 Operating Instructions

Product description

ICR890 High-end CCD Camera System

3.1.3 Contents of the CD-ROM

• “SOPAS-ET Engineering Tool“: Configuration software for Windows

TM

PCs with

integrated online help system (HTML files)

• ICR890 Operating Instructions: PDF version in German and English as well as further

publications for MSC800, VMS4xx/5xx

• “Acrobat Reader“: Freely available PC software for reading PDF files

Note The current versions of publications and programs on the CD-ROM can be downloaded at

www.sick.com.

3.1.4 Device versions

The system components are available in the following versions:

Type Order no. Description

ICD890-0000000 1027582 Camera with lens (focal distance 135 mm (5.32 in)), standard

device

ICD890-0000001 1040277 the same as 1027582, but includes GigE Vision licence

ICI890-00000 1028219 ICI890 Illumination

Tab. 3-2: System component versions

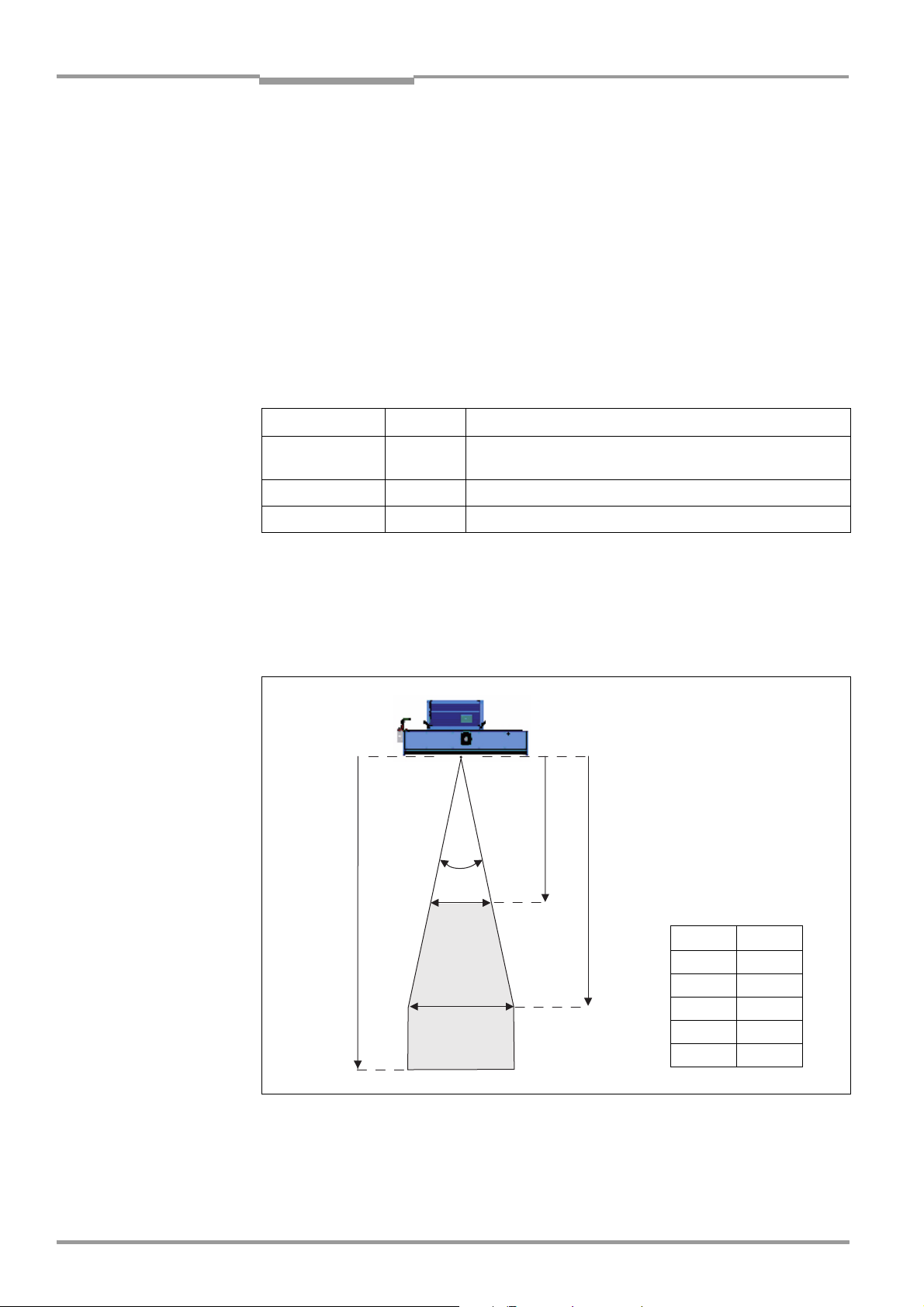

3.2 System requirements

3.2.1 General system requirements

25°

3.000 mm

600 mm

1.000 mm

1.400 mm

2.400 mm

mm inch

600 23.6

1,000 39.4

1,400 55.2

2,400 94.6

3,000 118.2

Fig. 3-3: Work area of the ICR890 System (standard device)

26 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 27

Operating Instructions Chapter 3

ICR890

Product description

Requirement Value Comment

Max. reading

distance

Shortest

permissible

distance to the

object

Aperture angle

Max. track width 1,000 mm (39.4 in) also see reading area diagram in Fig. 9-1,

Achievable ICD890

Camera resolution

Max. conveyor

speed

Tab. 3-3: General system requirements (standard device)

3,000 mm (118.2 in) from reading window (Fig. 3-3, page 26)

1,400 mm (55.2 in)

25

°

4.8 m/s (945 ft/min) with pixel size 0.25 mm (9.8 mil)

Work area up to 2,400 mm (94.6 in)

page 106

depends on the distance to the object and on the

conveyor speed (see Chapter 3.4.12 Data

interfaces, page 39)

3.2.2 Installation requirements

• Typical space requirements above the highest object (for reading from above):

application-specific

• Unobstructed view of the objects for the ICR890 System

• Stable installation frames with sufficient load capacity and measurements suited to the

ICR890 System (see Chapter 9.5 System dimensional drawing ICR890, page 108)

• Four 180° brackets for the ICR890 System and the deflection mirror (included in

delivery)

• Shock absorbent and vibration free attachment

Note An installation frame made of 80 mm (3.15 in) item aluminium profiles can be used for

simple system installation (Fig. 3-4). The 180° brackets are aligned to these profiles.

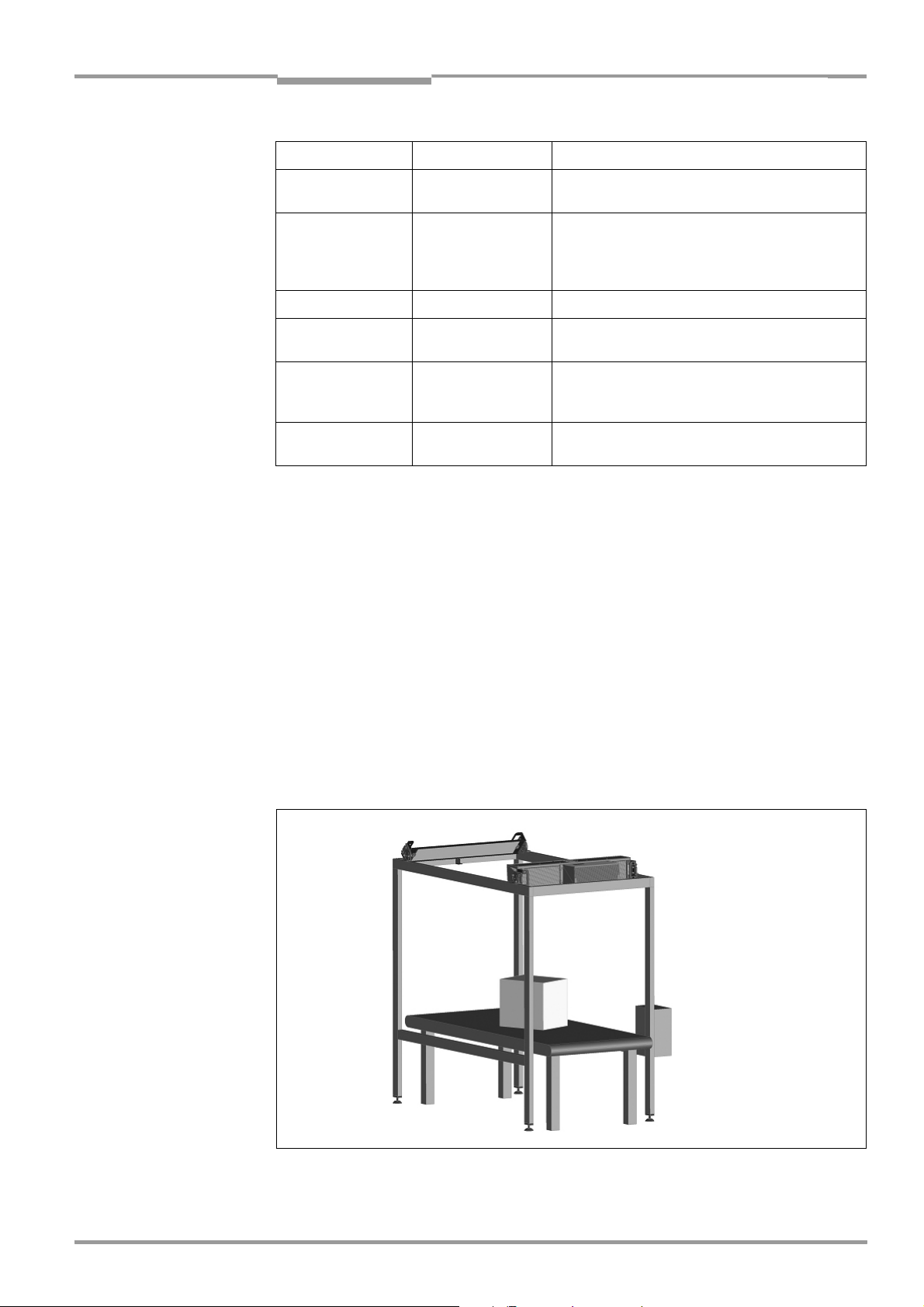

Fig. 3-4: Example of simple system installation on the installation frame

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 27

Page 28

Chapter 3 Operating Instructions

Product description

ICR890 High-end CCD Camera System

3.2.3 Electrical installation requirements

• Power supply (via MSC800): 100 to 264 V AC/50 to 60 Hz

• Reading pulse sensor (start/stop), e.g. photoelectric reflex switch (included in delivery):

For detecting an object with external reading pulse

• Additional appropriate reading pulse sensor (stop), e.g. photoelectric reflex switch: For

detecting the end of pulse with extended external reading pulse

• Preconfigured MLG Light Grid(included in delivery): when reading from above to detect

the object distance

• VMS4xx/5xx Volume Measurement System: when reading from the side or for multiside reading to detect the object distance

• Suitable incremental encoder, e.g. no. 2039455 (resolution 10 mm (394 mil)/pulse) or

no. 2039457 (resolution 0.2 mm (7.9 mil)/pulse) when using the VMS4xx/5xx.

Device is included in delivery depending on the system configuration

• Host processor with RS 232, RS 422/485 data interface or Ethernet: For further

processing of the reading data via MSC800 also PROFIBUS-DP

• Suitable visualization PC or PLC: To display the system status

• Connection cables: See Chapter 5.3.4 Assembled cables (overview), page 63

3.2.4 Operation requirements

• PC in the following version:

– Minimum Pentium III, 500 MHz, 128 MB RAM, CD drive, RS 232 serial data interface

or Ethernet interface card, mouse (recommended) and colour monitor

(recommended resolution 1,024 x 768 pixels)

– Operating system Windows 98

2000

TM

or Windows XP

TM

TM

, Windows NT4.0TM, Windows METM, Windows

– Free storage space on the hard drive: Approx. 100 MB for the SOPAS-ET

Configuration Software (V. 2.08) with help files and approx. 70 MB for “Acrobat

Reader“

• Connection cables see Chapter 5.3.4 Assembled cables (overview), page 63

• PC HTML browser, e.g. Internet Explorer

TM

: For online help system to the SOPAS-ET

Configuration Software

• Special PC for client display of the processed camera image information in real time

equipped with the following:

– Two 1 GBit Ethernet “IntelPro/1000 network card“ interface cards with 8254x

(x = 0, 1, 2, 4, 5, 6, 7) chip set

– GigE vision standard licence for real time image data transfer

28 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 29

Operating Instructions Chapter 3

ICR890

Product description

3.3 Product features and functions (overview)

High-end CCD Camera ICD890

• CCD line with 8,192 pixels (standard device)

• Dynamic focus setting

• Lens with 135 mm (5.32) focal distance (standard device)

• Reading area 1,400 to 3,000 mm (55.2 to 118.2 in) (standard device)

• Image resolution 170 to 350 dpi (standard device)

• Conveyor speed max. 4.8 m/s (945 ft/min) with 0.25 mm (9.8 mil) pixel size

• Scanning frequency max. 19.1 kHz (standard device)

• Can be adapted to the print quality of the code

• Analysis area of the CCD line can be restricted

• Real time image output (grey values: “*.bmp“ or “*.jpg“)

User safety and convenience

• Robust, compact metal housing, enclosure rating max. IP 64, CE mark

• Laser class 1M, switching off the LED ICI890 Illumination in case of prolonged active

reading gate or if the output capacity is exceeded, minimum power on-time 3 s

• Automatic self-test on system startup

• Diagnosis tools for system setup and system (distance) monitoring

• Configurable reading diagnosis data display in two reading result formats

• Operational data retrieval, error code display on request in case of errors

• Activatable test string function for signalling readiness for operation

• Password protected configuration mode

• Back up of configuration parameter values (cloning) also on SD memory card

(can be removed when replacing the camera)

• Future proof due to firmware update (flash PROM) via data interface

• Future proof SOPAS-ET Configuration Software

• Extended power supply scope

• Necessary maintenance or service task displayed via LED and system report

• The camera or illumination can be replaced within 20 mins

Convenient operation/configuration

• Configuration (online/offline) and display of image memory contents via the SOPAS-ET

Configuration Software (incl. help system)

• Status indicators via five LEDs

Operating modes

• Configuration mode

• Reading operation

Reading operation modi

• Start/Stop operation

• Object tracking (max. 10 objects per second, minimum gap 50 mm (1.97 in))

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 29

Page 30

Chapter 3 Operating Instructions

Product description

ICR890 High-end CCD Camera System

1-D/2-D code detection

• Data Matrix ECC200 (PDF417 in preparation)/all conventional bar codes

• Max. number of 1-D codes: 50 per reading pulse

• Max. number of 2-D codes: 10 per reading pulse

• Separation of identical codes of the same code type using the code position

• Output sorting: Code position, FIFO, LIFO, code lengths list

• Manipulation of output strings via filter or format masks

Data communication

• Main data interface HOST: Configurable output format of the reading result,

communication redirectable to Ethernet interface

• AUX auxiliary data interface: Permanent output format with special diagnosis functions,

communication redirectable to Ethernet interface

• Two 1 GBit Ethernet interfaces for fast image output

Reading pulse

• External reading pulse via switching input(s) or data interface

Electrical interfaces

• HOST data interface: RS 232, RS 422/485 serial, Ethernet or CAN (various transfer

rate and protocol configurations possible)

• AUX data interface: RS 232, RS 422/485 serial, Ethernet or CAN (permanent transfer

rate, data format and protocol)

• CAN interface for integration into SICK CAN-SENSOR Network with the MSC800 or into

a CAN Open Network

• Ethernet interface (10/100 MBps), TCP/IP and FTP

• Two 1 GBit Ethernet interfaces, FTP and GigE Vision Standard

• Two digital switching inputs for external reading pulse sensor and incremental encoder

via optocoupler

• Two digital switching outputs for signalling definable results in the reading process

(system status)

• Connection to PROFIBUS-DP via MSC800

Connection technology (design)

• Data and function interfaces: M12 connector for industrial use

• GBit Ethernet: Phoenix VARIOSUB RJ-45 sockets, enclosure rating IP 67

• Power supply: Harting connectors

30 © SICK AG · Division Auto Ident · Germany · All rights reserved 8011325/0000/2006-10-24

Page 31

Operating Instructions Chapter 3

ICR890

Product description

3.4 Method of operation

This ICR890 System is an intelligent sensor system for automatic and non-contact detection

and decoding of 1-D/2-D codes. In principle, the codes can be detected on any side of

moving objects in a conveyor system.

For single-side readings, the codes are detected from above, below or from the side using

a camera. In order to allow easier installation and setup of the system, the camera image

is recorded using a deflection mirror.

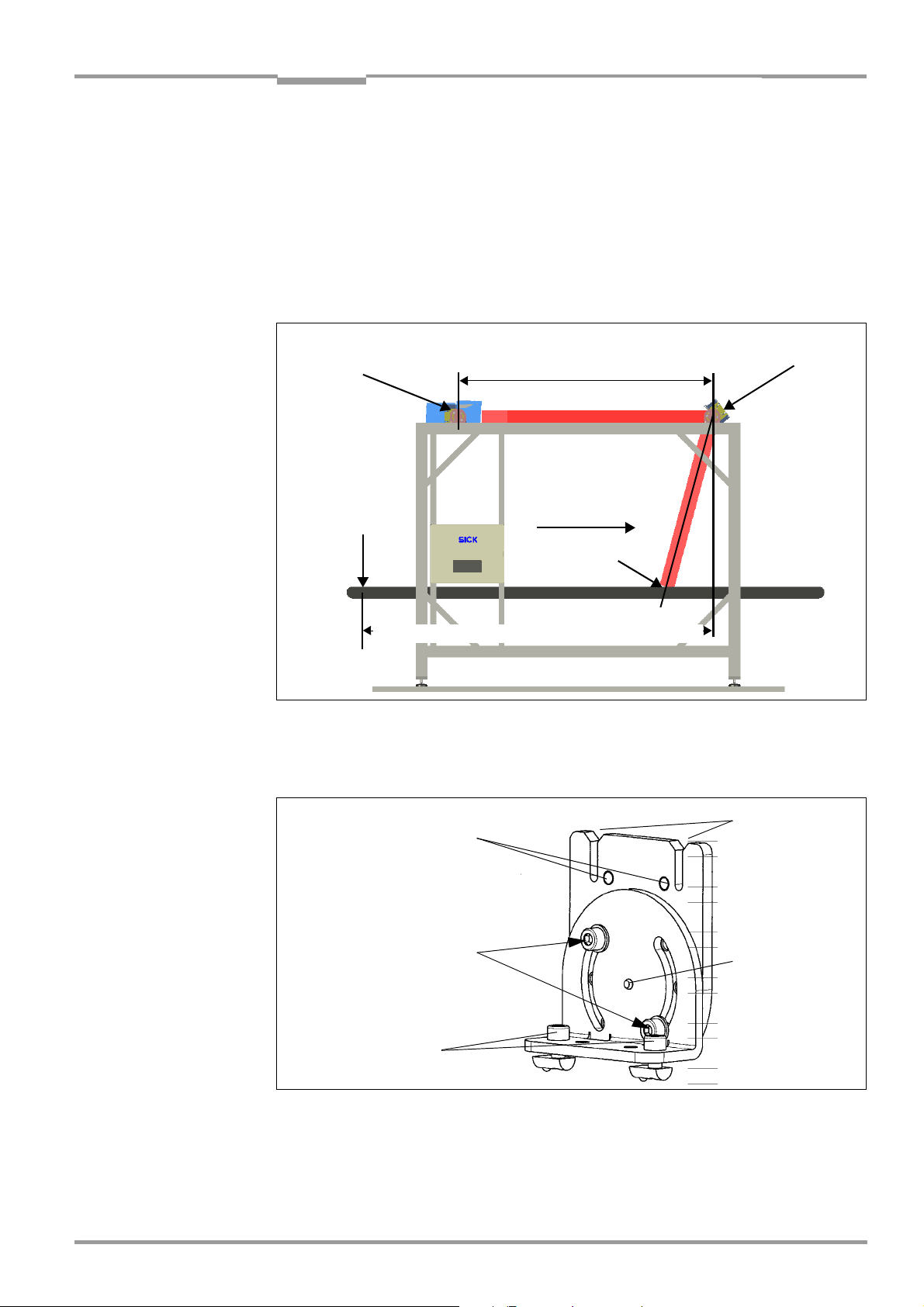

Fig. 3-5: The ICR890 System at a conveyor system, single-side reading from above

Note Several cameras can be combined to allow detection of several sides in one passage (multi-

side reading). The method of operation is described here using the example of single-side

reading from above.

8011325/0000/2006-10-24 © SICK AG · Division Auto Ident · Germany · All rights reserved 31

Page 32

Chapter 3 Operating Instructions

Product description

ICR890 High-end CCD Camera System

The system is operated in combination with an MSC800 Controller. The reading results are

output at the data interfaces via the controller. External sensors deliver information via the

reading pulse, the object distance and the conveyor speed.

Deflection mirror

Direction

of transport

Fig. 3-6: System diagram for single-side reading from above

Object

Conveyor system

ICD890 Camera

and ICI890

Illumination

MSC800

Controller

Incremental encoder

Object distance

Direction of

transport

VMS4xx/5xx

or MLG

Light Grid

(Top view)

Reading pulse

(start/stop)

Photoelectric

reflex switch

Reading area

ICR890 System

(camera, illumination

and deflection mirror)

Object

release

point

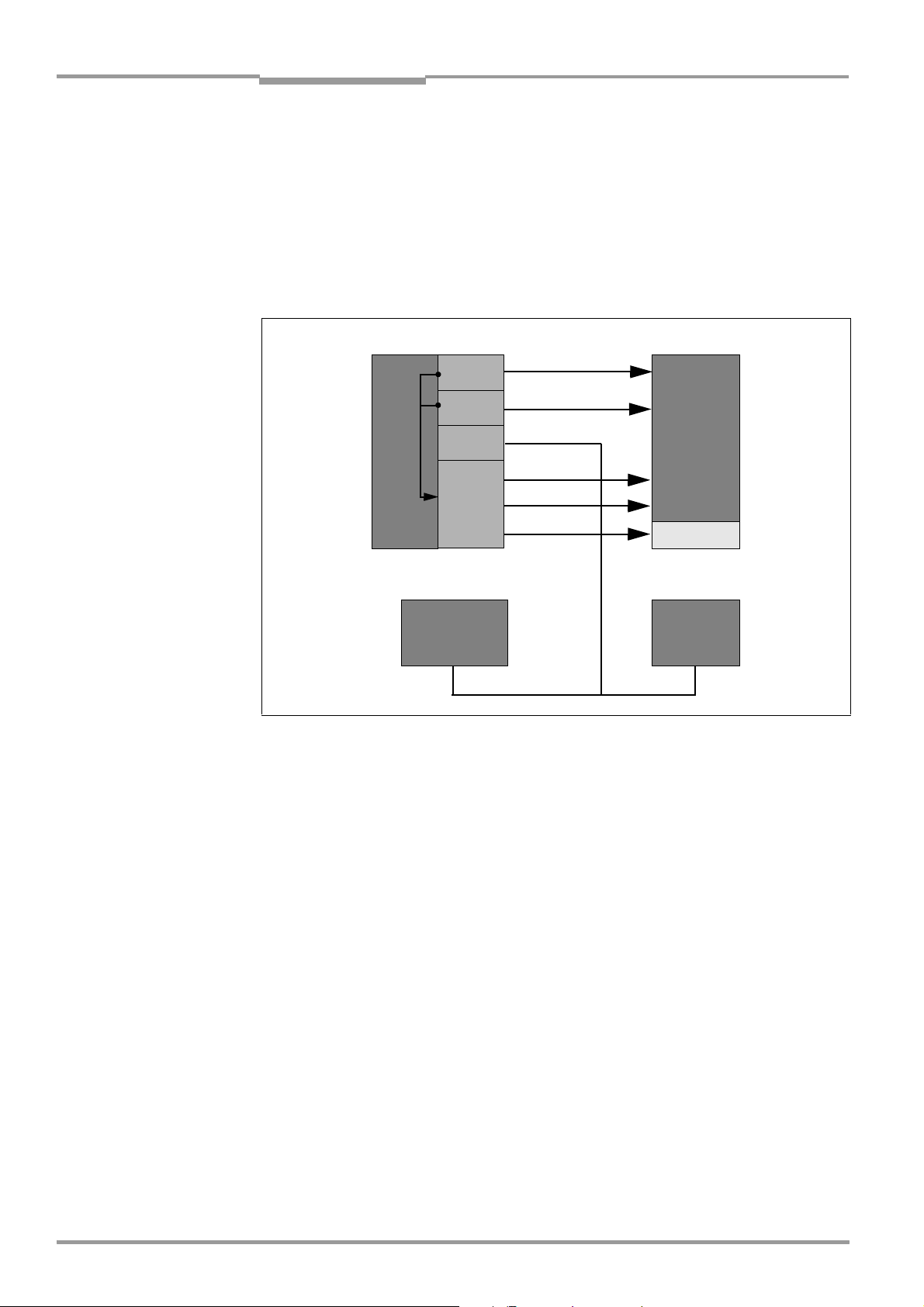

3.4.1 Reading configuration

The ICD890 Camera detects 1-D/2-D codes line by line with the help of a CCD line. The

lines are written successively and with a high frequency into an image storage. Continuous

feeding of the object on the conveyor system produces a two-dimensional image of the

object.

Note The ICR890 System cannot recognize codes on stationary objects.

A moving 1-D/2-D code on an object is displayed as a grey level matrix in the image storage.

Contrast jumps are analyzed in order to scan the codes. The threshold value can be adapted

to the ambient conditions.

For more rapid analysis, the analysis area can be restricted to across the direction of

transport (code position).

The SOPAS-ET Configuration Software can, among other things, be used to configure

features, such as the code position and the symbol contrast:

P

ROJECT TREE, ICR890, PARAMETER, READING CONFIGURATION, register tab CODELABEL PROPERTIES

Moreover, the image resolution across the direction of transport (digital zoom in dpi) and in