Page 1

ICR 84x

Image Code Reader

Scanner family for reading

1-D and 2-D codes

OPERATING INSTRUCTIONS

Page 2

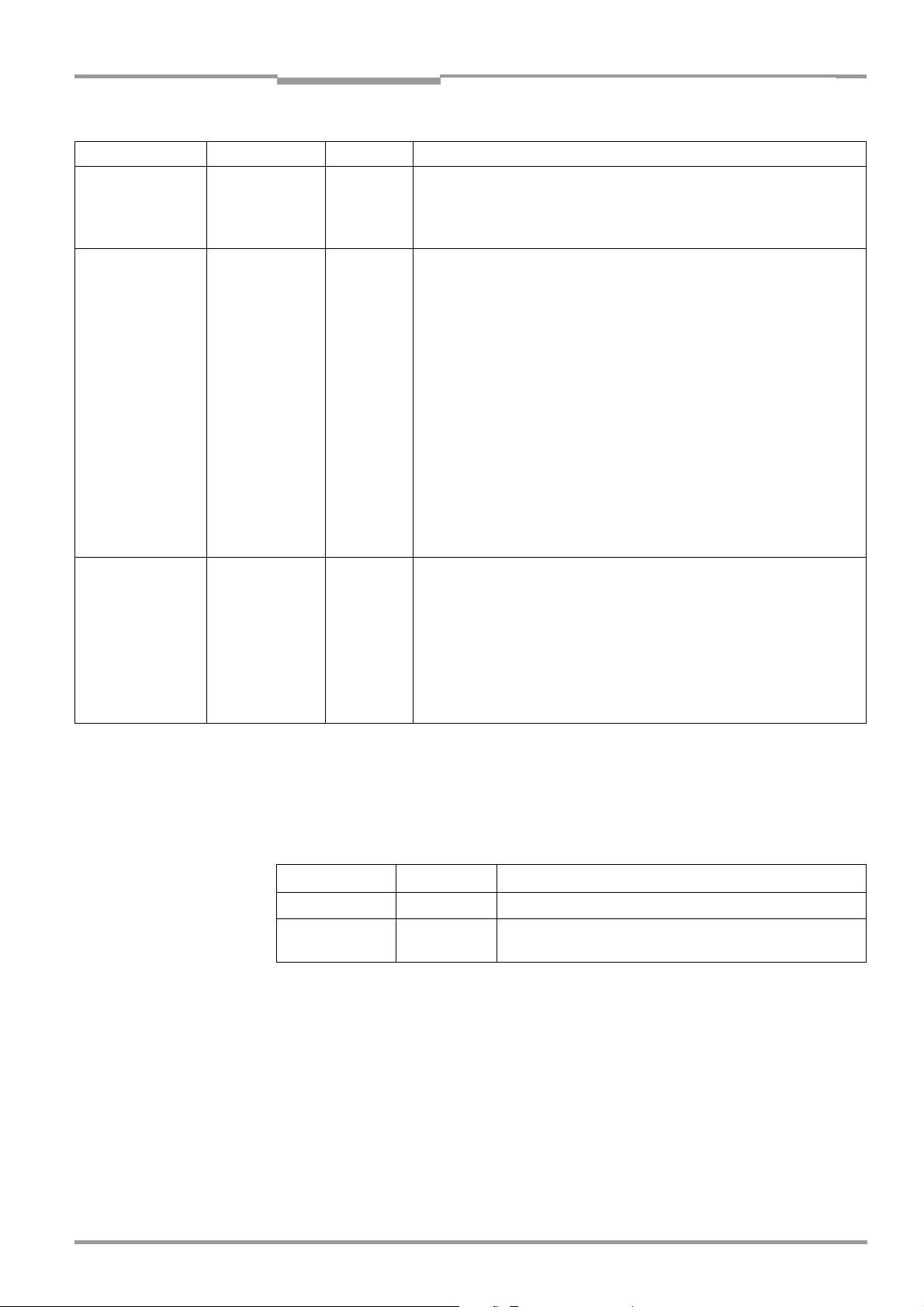

Software versions

Operating instructions

ICR 84x Image Code Reader

Software versions

Software/Tool Function Version

ICR 84x Firmware V 1.90 000O

CLV Setup Operating software (Windows-based) V 4.2 P658

CLV Setup Help Online help (HTML) V 4.2 P658

The ICR 84x is exclusively intended for use in an industrial environment.

In case of use in residential areas, RF interference may occur.

Copyright

Copyright © 2005

SICK AG Waldkirch

Auto Ident, Reute Plant

Nimburger Strasse 11

79276 Reute

Germany

Trademarks

TM

Windows 95

Explorer

TM

are registered trademarks or trademarks of the Microsoft Corporation in the USA

TM

/98

, Windows NTTM, Windows 2000TM, Windows XPTM and Internet

and other countries.

Latest manual version

For the latest version of this manual (PDF), see www.sick.com.

I-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 3

Operating instructions

ICR 84x Image Code Reader

Quick Finder

ICR 84x Image Code Reader

Quick Finder

• Scope of delivery

– Chapter 3.1.1 “Scope of delivery“, Page 3-1

• CAUTION!

– Chapter 2 “Safety information“, Page 2-1

• Installing device at reading station

– Chapter 4 “Installation“, Page 4-1

• Electrical connection of device

– Chapter 5 “Electrical installation“, Page 5-1

• Overview of device and its functions

– Chapter 3 “Product description“, Page 3-1

– Chapter 6.2 “Default setting“, Page 6-1

– Chapter 6.5 “Operating modes and outputting the reading result“, Page 6-28

– Chapter 9 “Technical data“, Page 9-1

• Starting device with default settings

– Chapter 6.3 “Quick start“, Page 6-3

– Chapter 6.3.2 “Configuring the ICR for the application with the Setup Assistant“,

Page 6-4

• Installing "CLV Setup" to PC

– Chapter 10.3 “Installation and operating instructions for the PC-based “CLV Setup“

program“, Page 10-3

• Adapting device to reading application

– Chapter 6.3.2 “Configuring the ICR for the application with the Setup Assistant“,

Page 6-4

• Troubleshooting

– Chapter 8 “Troubleshooting“, Page 8-1

• Finding information

– Table of contents, Page I-5

– Chapter 10.14 “Index“, Page 10-52

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved I-3

Page 4

Quick Finder

Installation procedure (overview)

Procedure for reading 2-D codes (DataMatrix):

Reading pulses via "Sensor 1" switching input (default setting)

Note In the default setting, the ICR does not read any bar codes.

Do not switch off the power supply during configuration.

1. Check the scope of delivery to ensure that it is complete.

2. Install the ICR in the reading station and align it with the stationary object with the 2-D

code (DataMatrix ECC 200) at a reading distance of 80 mm (3.15 in)(standard

device). Available reading area 40 mm x 32 mm (1.58 in x 1.26 in).

3. Install the CDB 420 or CDM 420 Connection Module.

4. Connect the ICR to the CDB 420 or CDM 420 Connection Module.

5. Install the reading pulse sensor.

6. Connect the sensor to the "Sensor 1" switching input in the CDB 420 or CDM 420.

7. Connect the host to the "host interface" in the CDB 420 or CDM 420.

8. Switch on the power supply for the CDB 420 or CDM 420.

Once the ICR has been started, the "Device Ready" LED lights up. The beeper beeps

twice to indicate that reading mode has been started.

9. Switch on the PC and start Windows

10. Install the CLV Setup operating software and the CLV Setup Help online help software,

which is supplied on the accompanying CD-ROM (“Manuals & Software“), on your PC.

11. Establish a physical connection between the PC and the Ethernet interface. To do so,

connect the PC directly to the ICR by means of a crossover cable or connect the PC and

ICR to the Ethernet by means of patch cables (OK = green "Ready" LED (Ethernet) lights

up on the ICR)

12. Start "CLV Setup". To initiate communication, select the Ethernet interface (O

INTERFACE). CLV Setup establishes communication with the ICR (standard IP address).

13. Upload the parameter set of the ICR (displayed on the tab pages).

14. Start the CLV Assistant and carry out the following steps consecutively: C

A

SSISTANT, ETHERNET ASSISTANT, SCANNER ADJUSTMENT, and DATAMATRIX AUTOSETUP.

15. To check the image online, launch the I

A

DJUSTMENT step.

16. Scanner Adjustment: Represent the 2-D code statically in the red illumination field

(pulsed) of the ICR. In I

MAGEFTP, make sure that the image is of a good quality in the

image memory.

17. DataMatrix AutoSetup: prepare AutoSetup and, when prompted, start the reading

trigger. Represent the 2-D code statically again in the red illumination field. When doing

so, retain the reading distance you adjusted previously.

18. Start DataMatrix AutoSetup. If successful, exit the Assistant after the final check. If not,

repeat AutoSetup.

19. Continue configuring the ICR using the setting options on the tabs in CLV Setup (reading

clock, data output). Download the modified parameter set to the ICR temporarily. Make

sure that data is transferred properly to the ICR.

20. If necessary, check and optimize the set parameter values. Download the parameter

set to the ICR permanently and save the parameter set as an "*.scl" configuration file

in CLV Setup.

The ICR can now be operated with the application-specific settings.

TM

(minimum requirement: Windows 95TM).

MAGEFTP program in parallel with the SCANNER

Operating instructions

ICR 84x Image Code Reader

PTIONS/

ONNECTION

I-4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 5

Operating instructions

ICR 84x Image Code Reader

Contents

Table of Contents

1 Notes on this document ...............................................................................................1-1

1.1 Purpose ..........................................................................................................................................1-1

1.2 Target audience...........................................................................................................................1-1

1.2.1 Installation, electrical installation, maintenance and replacement.................... 1-1

1.2.2 Startup, operation and configuration ............................................................................ 1-1

1.3 Information content....................................................................................................................1-1

1.4 Symbols..........................................................................................................................................1-2

2 Safety information ..........................................................................................................2-1

2.1 Authorized users .........................................................................................................................2-1

2.1.1 Installation and maintenance .......................................................................................... 2-1

2.1.2 Electrical installation and replacement ........................................................................ 2-1

2.1.3 Startup, operation and configuration ............................................................................ 2-1

2.2 Intended use.................................................................................................................................2-1

2.3 General safety precautions and protection measures.................................................2-2

2.3.1 RF interferences ...................................................................................................................2-2

2.3.2 Electrical installation............................................................................................................ 2-2

2.3.3 LED illumination for reading area ................................................................................... 2-2

2.4 Quick stop and quick restart...................................................................................................2-3

2.4.1 Switching the ICR off...........................................................................................................2-3

2.4.2 Switching the ICR on again............................................................................................... 2-3

2.5 Environmental information.......................................................................................................2-4

2.5.1 Power requirements............................................................................................................2-4

2.5.2 Disposal after final removal from service ................................................................... 2-4

3 Product description .......................................................................................................3-1

3.1 Design .............................................................................................................................................3-1

3.1.1 Scope of delivery..................................................................................................................3-1

3.1.2 Variants....................................................................................................................................3-1

3.1.3 System requirements.........................................................................................................3-2

3.1.4 Product features and functions (overview) ................................................................3-3

3.1.5 View of the device ............................................................................................................... 3-5

3.2 Method of operation..................................................................................................................3-6

3.3 Indicators and control elements ........................................................................................... 3-8

3.3.1 Control elements.................................................................................................................. 3-8

3.3.2 Function of the LEDs...........................................................................................................3-8

3.3.3 Function of the beeper ................................................................................................... 3-10

4 Installation ........................................................................................................................4-1

4.1 Overview of installation sequence........................................................................................4-1

4.2 Installation preparations........................................................................................................... 4-1

4.2.1 Laying out the components to be installed................................................................4-1

4.2.2 Laying out accessories ......................................................................................................4-1

4.2.3 Laying out the required tools...........................................................................................4-1

4.2.4 Selecting the installation site...........................................................................................4-2

4.2.5 Mounting accessories........................................................................................................ 4-3

4.2.6 Distance between ICR and code ...................................................................................4-4

4.2.7 Count direction of the code position CP ..................................................................... 4-6

4.3 Installing and adjusting the device.......................................................................................4-8

4.3.1 Installing the ICR........................................................................................................

4.4 Installing external components.............................................................................................. 4-9

4.4.1 Installing the CDB 420 or CDM 420 Connection Module.................................... 4-9

4.4.2 Installing the external reading pulse sensor .............................................................. 4-9

4.4.3 Installing the incremental encoder ............................................................................. 4-10

4.5 Removing the device.............................................................................................................. 4-10

5 Electrical installation ....................................................................................................5-1

5.1 Overview of the installation sequence................................................................................ 5-1

5.1.1 SICK Connection Modules (Overview) .........................................................................5-1

........... 4-8

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved I-5

Page 6

Contents

5.2 Electrical connections and cables ........................................................................................5-1

5.2.1 Pre-fabricated cables (Overview) ...................................................................................5-2

5.2.2 Connections/cables for the CDB 420 or CDM 420 Connection Module ......5-2

5.3 Pin assignments...........................................................................................................................5-4

5.3.1 Cable plug................................................................................................................................5-4

5.3.2 RJ 45 socket 10baseT (Ethernet) .................................................................................5-4

5.4 Electrical installation preparations ........................................................................................5-5

5.4.1 Requirements for the host interface.............................................................................5-5

5.4.2 Power supply..........................................................................................................................5-5

5.4.3 Non-SICK power supply unit/connections without the SICK

connection module ..............................................................................................................5-6

5.5 Performing electrical installation............................................................................................5-7

5.5.1 Overview of connection procedure................................................................................5-7

5.5.2 Tools..........................................................................................................................................5-7

5.5.3 Connecting the power supply ..........................................................................................5-7

5.5.4 Connecting the host interface .........................................................................................5-8

5.5.5 Connecting the CAN interface .........................................................................................5-9

5.5.6 Connecting the Ethernet interface..............................................................................5-10

5.5.7 Connecting the PC.............................................................................................................5-12

5.5.8 Connecting the “Sensor 1“ switching input.............................................................5-13

5.5.9 Connecting the “Sensor 2“ switching input.............................................................5-14

5.5.10 Connecting the “Result 1“ and “Result 2“ switching outputs...........................5-15

6 Operation ..........................................................................................................................6-1

6.1 Overview of the startup procedure.......................................................................................6-1

6.2 Default setting ..............................................................................................................................6-1

6.2.1 Default setting........................................................................................................................6-2

6.3 Quick start ......................................................................................................................................6-3

6.3.1 Starting up the ICR for test reading with the factory default setting.................6-3

6.3.2 Configuring the ICR for the application with the Setup Assistant.......................6-4

6.4 Configuration (Parameterizing)............................................................................................6-17

6.4.1 Configuring the ICR with the user interface of CLV Setup..................................6-17

6.4.2 Function of tabs in CLV Setup (overview)................................................................6-19

6.4.3 Parameterization guide....................................................................................................6-21

6.5 Operating modes and outputting the reading result...................................................6-28

6.5.1 Reading mode (standard operating mode).............................................................6-28

6.5.2 Percentage Evaluation.....................................................................................................6-34

6.5.3 Image Acquisition .............................................................................................................6-36

6.5.4 Displaying and editing operating data .......................................................................6-39

6.5.5 Reading diagnosis .............................................................................................................6-39

6.5.6 Monitor Host Interface.....................................................................................................6-40

6.5.7 Auxiliary input.......................................................................................................................6-42

6.5.8 Self-test .................................................................................................................................6-42

6.5.9 Performing device functions of ICR in the dialog box ..........................................6-44

6.6 ICR messages............................................................................................................................6-45

6.6.1 Displaying messages .......................................................................................................6-45

6.6.2 Error messages..................................................................................................................6-46

6.7 Switching the ICR off ...............................................................................................................6-46

7 Maintenance....................................................................................................................7-1

7.1 Cleaning during operation........................................................................................................7-1

7.2 Maintenance .................................................................................................................................7-2

7.3 Disposal ..........................................................................................................................................7-2

8 Troubleshooting ..............................................................................................................8-1

8.1 Overview of errors and malfunctions which could occur .............................................8-1

8.1.1 Installation errors..................................................................................................................8-1

8.1.2 Electrical connection errors..............................................................................................8-1

8.1.3 Parameterization errors...................................................................................................

8.1.4 Malfunctions during operation .........................................................................................8-1

Operating instructions

ICR 84x Image Code Reader

...8-1

I-6 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 7

Operating instructions

ICR 84x Image Code Reader

Contents

8.2 Monitoring errors and malfunctions.....................................................................................8-1

8.3 Error messages ........................................................................................................................... 8-2

8.4 ST error status in the reading result of a bar code........................................................8-3

8.5 Troubleshooting...........................................................................................................................8-5

8.5.1 General malfunction: ICR not ready..............................................................................8-5

8.5.2 Malfunctions in Reading mode: Reading pulse errors...........................................8-6

8.5.3 Malfunctions in Reading mode: Result output errors.............................................8-9

8.5.4 Malfunctions in Reading mode: Errors when outputting the result status .. 8-13

8.5.5 Malfunctions: Configuration errors (parameterization) .......................................8-14

8.5.6 Malfunctions: Errors when using the image outputting in reading mode .... 8-15

8.6 SICK support.............................................................................................................................. 8-15

9 Technical data .................................................................................................................9-1

9.1 Data sheet for ICR 84x Image Code Reader .................................................................. 9-1

9.1.1 Suitable bar code lengths in the reading area..........................................................9-2

9.2 ICR 84x dimensional drawing................................................................................................. 9-3

9.3 Specification diagram................................................................................................................9-4

9.3.1 Reading conditions for the diagrams............................................................................9-4

9.3.2 Reading ranges of ICR – preliminary –........................................................................9-4

9.3.3 Reading area mapped in the image buffer memory – preliminary –...............9-5

10 Appendix ........................................................................................................................ 10-1

10.1 Appendix overview .................................................................................................................. 10-1

10.2 System messages................................................................................................................... 10-2

10.3 Installation and operating instructions for the PC-based

“CLV Setup“ program .............................................................................................................10-3

10.3.1 Preparing for installation.................................................................................................10-3

10.3.2 Performing installation.....................................................................................................10-3

10.3.3 Starting “CLV Setup“........................................................................................................10-6

10.3.4 CLV Setup user interface ...............................................................................................10-8

10.3.5 Functions.............................................................................................................................. 10-9

10.3.6 Hot keys................................................................................................................................10-9

10.3.7 Opening and closing tabs............................................................................................ 10-10

10.3.8 Online help program “CLV Setup Help“................................................................. 10-10

10.3.9 Transferring parameter sets between CLV Setup and the ICR.................... 10-11

10.3.10 Unknown parameters ................................................................................................... 10-11

10.3.11 Logging file in Terminal Emulator ............................................................................. 10-12

10.3.12 Starting CLV Setup with an INI file as an argument .......................................... 10-12

10.3.13 The CLV Assistant.......................................................................................................... 10-12

10.4 Settings for reading DataMatrix ECC 200................................................................... 10-13

10.4.1 Improving the image quality....................................................................................... 10-14

10.4.2 Optimizing reading characteristics for special applications ........................... 10-20

10.5 Configuring the ICR with command strings................................................................. 10-25

10.6 Auxiliary tables ....................................................................................................................... 10-27

10.6.1 Calculating code length of a bar code ................................................................... 10-27

10.7 Special applications and procedures............................................................................ 10-28

10.7.1 Triggering the Teach-in match code 1 via the “Sensor 2“

switching input................................................................................................................. 10-28

10.7.2 Auxiliary input via the auxiliary interface ................................................................ 10-34

10.7.3 Connection to Profibus DP.......................................................................................... 10-37

10.7.4 Connection to DeviceNet............................................................................................ 10-37

10.7.5 Building up a CAN scanner network ....................................................................... 10-37

10.8 Replacing an ICR (transferring the parameter set).................................................. 10-38

10.8.1 Transferring the parameter set using a download............................................ 10-38

10.9 Accessories...................................................................................................................... 10-40

10.9.1 Installation accessories ............................................................................................... 10-40

10.9.2 Connection modules..................................................................................................... 10-40

10.9.3 Extensions for connection modules........................................................................ 10-41

10.9.4 Cables and plug-in connections ............................................................................... 10-42

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved I-7

Page 8

Contents

10.9.5 Reading pulse generators...........................................................................................10-42

10.9.6 Incremental encoder.....................................................................................................10-42

10.10 Dimensional drawings of the accessories...................................................................10-43

10.10.1 Mounting bracket (for an ICR) ...................................................................................10-43

10.11 Supplementary documentation .......................................................................................10-44

10.11.1 CLV Connect (from version > 2.0)...........................................................................10-44

10.12 Glossary ....................................................................................................................................10-45

10.13 EC Declaration of Conformity............................................................................................10-51

10.14 Index...........................................................................................................................................10-52

10.15 Code samples.........................................................................................................................10-57

10.15.1 1-D and 2-D code samples for ICR 840 (standard type)...............................10-57

Operating instructions

ICR 84x Image Code Reader

I-8 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 9

Operating instructions

ICR 84x Image Code Reader

CAN Controller Area Network (standardized field-bus system with a message-oriented data

CDB Connection Device Basic.

CDM Connection Device Modular.

DOF Depth of Field

EEPROM Electrically Erasable Programmable Read Only

HTML Hyper Text Markup Language (language of Internet websites)

MTBF Mean Time Between Failure

RAM Random Access Memory. Temporary memory which is accessed directly

ROM Read Only Memory

SMART SICK Modular Advanced Recognition Technology

Figures and tables

Abbreviations

transfer protocol)

DSP Digitar signal processor

Memory

ICR Image Code Reader.

LED

Light Emitting Diode

PLC Progammable Logic Controller

RTF Rich Text Format (standardized document format with format descriptions)

Tables

Table 3-1: ICR 84x variants.................................................................................................................3-1

Table 3-2: Meaning of the general LEDs........................................................................................3-9

Table 3-3: Meaning of the LEDs of the Ethernet interface .....................................................3-9

Table 3-4: Beeper function...............................................................................................................3-10

Table 4-1: Permissible reading angle between the reading area and the

bar code/2-D code when reading with omni-directional decoder..................4-5

Table 4-2: Permissible reading angles between the reading area and bar

code when reading with standard/SMART decoder ............................................4-5

Tab. 5-1: Connection modules for the ICR..................................................................................5-1

Tab. 5-2: Cables for connecting the ICR......................................................................................5-2

Table 5-3: Pin assignment of the 15-pin D-Sub HD plug.........................................................5-4

Table 5-4: Pin assignment of the 8-pin RJ 45 10baseT socket ...........................................5-4

Table 5-5: Maximum cable lengths between the ICR and host ............................................5-5

Table 5-6: Power-up delay as a function of the device number GN ...................................5-5

Table 5-7: Wiring color assignment of cable no. 6 010 137 (open end)........................5-6

Table 5-8: Communication parameters for the host interface (default setting) .............5-8

Table 5-9: Ethernet interface communication parameters (default setting).................5-10

Table 5-10: Communication parameters for the auxiliary interface.................................... 5-12

Table 5-11: Characteristic data of the “Sensor 1“ switching input......................................5-13

Table 5-12: Characteristic data of the “Result 1“ switching output....................................5-15

Table 5-13: Characteristic data of the “Result 2“ switching output....................................5-16

Table 6-1: Extract: Default setting of the ICR parameter values ..........................................6-2

Table 6-2: Guide: Parameterizing the reading trigger and output of reading result ... 6-22

Table 6-3: Guide: Parameterizing the illumination timeout...................................................6-25

Table 6-4: Guide: Settings to be made for the evaluation of identical codes ..............6-26

Table 6-5: ImageFTP: Functions of the icon buttons..............................................................6-37

Table 6-6: ImageFTP: Colors for displaying the reading diagnosis data .........................6-38

Table 6-7: “Monitor Host Interface“ function.............................................................................6-40

Table 8-1: Error message output to the auxiliary interface.....................................................8-2

Table 8-2: Meaning of the ST error status in the reading result...........................................8-3

Table 8-3: Troubleshooting: Restoring operation (Reading mode)......................................8-5

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved I-9

Page 10

Figures and tables

Table 8-4: Troubleshooting: Reading pulse errors in Reading mode ................................. 8-6

Table 8-5: Troubleshooting: Result output errors in Reading mode (general

malfunctions) ...................................................................................................................... 8-9

Table 8-6: Troubleshooting: Result-status output errors in Reading mode

(reading 2-D codes).......................................................................................................8-11

Table 8-7: Troubleshooting: Result-status output errors in Reading mode

(reading bar codes)........................................................................................................8-12

Table 8-8: Troubleshooting: Errors in the result status output in Reading mode ........8-13

Table 8-9: Troubleshooting: Errors when using the Setup Assistant................................8-14

Table 8-10: Troubleshooting: Errors when using the image transfer via the

Ethernet interface ...........................................................................................................8-15

Table 9-1: Technical specifications of ICR 84x ........................................................................... 9-1

Table 9-2: Suitable bar code lengths at focus position (distance 80 mm

(3.15 in), reading area 42 mm x 35 mm (1.65 in x 1.26 in))......................... 9-2

Table 9-3: Reading conditions for specification diagrams ...................................................... 9-4

Table 10-1: System messages of the ICR.....................................................................................10-2

Table 10-2: Default settings in CLV Setup (extract)...................................................................10-6

Table 10-3: Formulas for calculating the code length of a bar code ...............................10-27

Table 10-4: Communication parameter settings for the terminal/PC for

the auxiliary input .........................................................................................................10-36

Table 10-5: Communication parameter settings for the SICK Hand-held

Scanner from the IT 38xx/46xx/48xx/58xx series........................................10-37

Table 10-6: Accessories: Installation accessories ..................................................................10-40

Table 10-7: Accessories: Connection modules CDB 420/CDM 420..............................10-40

Table 10-8: Accessories: Extensions for connection modules CDB 420/CDM 420 10-41

Table 10-9: Accessories: Cables and plug-in connections..................................................10-42

Table 10-10: Accessories: Incremental encoder........................................................................10-42

Table 10-11: Supplementary documentation ..............................................................................10-44

Operating instructions

ICR 84x Image Code Reader

Figures

Fig. 2-1: Black-yellow signed warning labels found on the ICR .......................................... 2-3

Fig. 3-1: Design of the ICR................................................................................................................ 3-5

Fig. 3-2: Reading area of the ICR in the focus position (standard type)......................... 3-6

Fig. 3-3: Block diagram: functions of the ICR ............................................................................ 3-6

Fig. 3-4: LEDs ........................................................................................................................................ 3-8

Fig. 4-1: Position of the securing threads on the ICR............................................................. 4-3

Fig. 4-2: ICR installation options using the mounting bracket no. 2 025 491............. 4-3

Fig. 4-3: Alignment of the ICR reading area with the code .................................................. 4-4

Fig. 4-4: Definition of the reading distance ................................................................................ 4-4

Fig. 4-5: Reading angles between the reading area and the code .................................. 4-5

Fig. 4-6: Installing the ICR parallel to the object surface....................................................... 4-6

Fig. 4-7: Count direction of the code position CP for bar codes along

the reading window............................................................................................................ 4-6

Fig. 4-8: Line scanner: Installation example for the external reading pulse sensor... 4-9

Fig. 5-1: Block diagram: Connection of the ICR to the CDB 420 or CDM 420

Connection Module............................................................................................................ 5-2

Fig. 5-2: Connections of the host interface................................................................................ 5-8

Fig. 5-3: Block diagram: Function of the Ethernet interface ..............................................5-10

Fig. 5-4: Connection of the auxiliary interface.........................................................................5-12

Fig. 5-5: Connections of the “Sensor 1“ switching input ....................................................5-13

Fig. 5-6: Connections of the “Sensor 2“ switching input ....................................................5-14

Fig. 5-7: Connection of the “Result 1“ switching output .....................................................5-15

Fig. 5-8: Connection of the “Result 2“ switching output .....................................................5-16

Fig. 6-1: 2-D code sample (DataMatrix ECC200; cell size 0.3 mm (11.8 mil)) .......... 6-3

Fig. 6-2: Bar code sample (code 39; module width 0.35 mm (13.8 mil);

print ratio 2:1)...................................................................................................................... 6-3

I-10 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 11

Operating instructions

ICR 84x Image Code Reader

Figures and tables

Fig. 6-3: CLV Assistant: Starting up window ...............................................................................6-5

Fig. 6-4: CLV Assistant: “Connection Assistant“ dialog box .................................................6-6

Fig. 6-5: CLV Assistant: “Ethernet Assistant“ dialog box after an ICR has

been detected in the network (here: IP address in the default setting

of the ICR)..............................................................................................................................6-6

Fig. 6-6: CLV Assistant: “Ethernet Assistant“ dialog box after a new IP address/

mask has been assigned to the ICR (here: 010.224.055.084/

255.255.248.000)............................................................................................................6-7

Fig. 6-7: CLV Assistant: Dialog box confirming that communication with

the ICR via Ethernet (TCP/IP) is successful ..............................................................6-8

Fig. 6-8: CLV Assistant: “Scanner Adjustment“ dialog box ...................................................6-8

Fig. 6-9: ImageFTP: “IP address“ dialog box ..............................................................................6-9

Fig. 6-10: ImageFTP: Program window............................................................................................6-9

Fig. 6-11: ImageFTP: Image output when adjusting the ICR (before starting

the AutoSetup)..................................................................................................................6-10

Fig. 6-12: ImageFTP: “User accounts“ dialog box ...................................................................6-10

Fig. 6-13: ImageFTP: “Edit Directory“ dialog box .....................................................................6-11

Fig. 6-14: ImageFTP: “Visualization“ dialog box........................................................................6-12

Fig. 6-15: CLV Assistant: “DataMatrix AutoSetup“ dialog box (part 1)............................6-12

Fig. 6-16: CLV Assistant: “DataMatrix AutoSetup“ dialog box (part 2)............................6-13

Fig. 6-17: ImageFTP: Image output when preparing the AutoSetup ................................6-13

Fig. 6-18: CLV Assistant: “DataMatrix AutoSetup“ dialog box after successful

reading .................................................................................................................................6-14

Fig. 6-19: CLV Assistant: Display of the performed steps and determined values.... 6-14

Fig. 6-20: CLV Setup: Status line with IP address/port of the Ethernet connection ..6-15

Fig. 6-21: CLV Setup: “Interface Options“ dialog box line with IP adress/port of

the Ethernet connection................................................................................................6-15

Fig. 6-22: ImageFTP: Image output, with the markings for CP limitations (violet),

the 2-D symbol (green) and the position of the DataMatrix decoder at

the end of reading pulse (blue) ..................................................................................6-16

Fig. 6-23: CLV Setup: Output of the reading result of the auxiliary interface for

2-D codes in the Terminal Emulator.........................................................................6-30

Fig. 6-24: Position of the symbol in the image field of the image memory ...................6-31

Fig. 6-25: CLV Setup: Output of the reading result of the auxiliary interface for

bar codes in the Terminal Emulator..........................................................................6-32

Fig. 6-26: CLV Setup: Display of the percentage evaluation of the auxiliary

interface for bar codes in the Terminal Emulator................................................6-35

Fig. 6-27: ImageFTP: Program window.........................................................................................6-37

Fig. 6-28: ImageFTP: Image output, with the marks for CP limitations (violet),

the 2-D symbol (green) and the position of the DataMatrix decoder

at the end of reading pulse (blue).............................................................................6-38

Fig. 6-29: CLV Setup: “Operating Data“ dialog box .................................................................6-39

Fig. 6-30: CLV Setup: Output of the reading result of the host interface in the

Terminal Emulator (in this case: O = Output)........................................................6-41

Fig. 6-31: CLV Setup: Displaying the self-test result in the Terminal Emulator ............6-43

Fig. 6-32: CLV Setup: Dialog box for executing Matchcode Teach-in..............................6-44

Fig. 6-33: CLV Setup: Displaying the system messages in the Terminal

Emulator when starting the ICR..................................................................................6-45

Fig. 7-1: Cleaning the reading window..........................................................................................7-1

Fig. 7-2: Cleaning the external optical sensor (reading pulse generator).......................7-2

Fig. 9-1: Dimensions of the ICR ......................................................................................................9-3

Fig. 9-2: ICR 840 (standard type): Reading range and length of the reading area .... 9-4

Fig. 9-3: ICR 840 (standard type): Reading range and width of the reading area......9-5

Fig. 9-4: ICR 840 (standard type): Reading area and reading range in

dependence of the reading distance..........................................................................9-5

Fig. 10-1: CLV Setup: Results of the AutoBaud detect function ........................................10-7

Fig. 10-2: User interface of the “CLV Setup“ software ..........................................................10-8

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved I-11

Page 12

Figures and tables

Fig. 10-3: CLV Setup: “Reading Configuration“ tab...............................................................10-14

Fig. 10-4: CLV Setup: “Code configuration“ tab.....................................................................10-14

Fig. 10-5: CLV Setup: “DataMatrix“ tab.....................................................................................10-15

Fig. 10-6: CLV Setup: “Code Properties Parameters“ tab .................................................10-16

Fig. 10-7: CLV Setup: using the "Deviation of dot size" slider .........................................10-17

Fig. 10-8: CLV Setup: “Optimisation“ tab..................................................................................10-17

Fig. 10-9: CLV Setup: “Code Properties Parameters“ tab .................................................10-19

Fig. 10-10: CLV Setup: “Reading Configuration“ tab...............................................................10-19

Fig. 10-11: CLV Setup: “Code Configuration“ tab....................................................................10-20

Fig. 10-12: CLV Setup: “DataMatrix“ tab.....................................................................................10-20

Fig. 10-13: CLV Setup: “Code Properties Parameters“ tab .................................................10-21

Fig. 10-14: Limiting the active evaluation area in the image memory.............................10-22

Fig. 10-15: CLV Setup: “Optimization“ tab..................................................................................10-22

Fig. 10-16: CLV Setup: “Reading Configuration“ tab...............................................................10-23

Fig. 10-17: CLV Setup: “Code Properties Parameters“ tab .................................................10-24

Fig. 10-18: CLV Setup: Entering commands in the Terminal Emulator ...........................10-26

Fig. 10-19: “Sensor 2“ configuration for triggering the teach-in match code 1...........10-28

Fig. 10-20: Auxiliary input via the auxiliary interface of the ICR ..........................................10-34

Fig. 10-21: CLV Setup: Auxiliary input via the Terminal Emulator ......................................10-36

Fig. 10-22: Dimensions of the mounting bracket no. 2 025 491 ...................................10-43

Fig. 10-23: Copy of the Declaration of Conformity (Page 1, scaled down)....................10-51

Fig. 10-24: Scannable 1-D codes with various module widths (print ratio 2:1)/

2-D code...........................................................................................................................10-57

Operating instructions

ICR 84x Image Code Reader

I-12 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 13

Operating instructions Chapter 1

ICR 84x Image Code Reader

Notes on this document

1 Notes on this document

1.1 Purpose

This document contains instructions for operating the 2-D code reader with fixed focus

• ICR 840 standard

The device is available

• with side reading window

• with front reading window

The Image Code Reader reads 2-D codes (DataMatrix ECC 200) using an image

recording and processing system. To do so, the device provides a rectangular reading

area in the reading plane. Currently, only images of stationary objects can be reliably

evaluated.

This document provides information on

• Installation and electrical installation

• Startup

• Operation and configuration (parameterizing)

• Maintenance

• Exchanging the device while retaining the parameter set

• Special applications and procedures

The ICR 84x Image Code Reader with all its variants is simply referred to as “ICR“ in the

document, except where a distinction is necessary.

1.2 Target audience

This document is intended for persons who are responsible for the following activities:

1.2.1 Installation, electrical installation, maintenance and replacement

Electricians and service technicians

1.2.2 Startup, operation and configuration

Technicians and engineers

1.3 Information content

This document contains all of the information necessary for the installation, electrical

installation and startup of the ICR with the factory default settings.

A series of step-by-step instructions is provided for each of these activities.

The ICR is configured for specific applications using the Windows-based “CLV Setup“

program. Further assistance is also available in the form of the online help system “CLV

Setup Help“. The procedure for installing and operating the software is described in the

Appendix.

Additional information on the structure of the Image Code Reader and 2-D code/bar code

technology is available from the Auto Ident division of SICK AG.

Internet address: www.2d-code.com.

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 1-1

Page 14

Chapter 1 Operating instructions

Notes on this document

ICR 84x Image Code Reader

1.4 Symbols

Some of the information in this document is marked specially so that you can access it

quickly:

Warning

Warnings are provided to prevent injury to operating personnel or serious damage to the

Image Code Reader.

¾ Always read warnings carefully and observe them at all times.

Note Notes indicate special features or characteristics.

Explanation Explanations provide background information on technical correlations.

Recommendation Recommendations help you carry out certain procedures more effectively.

Tip Tips explain settings in the user interface of the CLV Setup program.

Default setting Marks a section containing the values of the factory default settings.

S

CANNING FREQUENCY This font indicates a term in the user interface of the CLV Setup program.

Icons refer to buttons in the user interface of the CLV Setup program.

“Host receive fault“ This font indicates messages output via the auxiliary interface of the ICR.

This symbol identifies sections that describe steps carried out with the user interface of the

CLV Setup program.

This symbol refers to additional technical documentation.

¾ This symbol identifies single-step instructions. An action must be performed.

Instructions consisting of several steps are numbered consecutively.

Ö Here you select a function of the user interface of CLV Setup.

1-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 15

Operating instructions Chapter 2

ICR 84x Image Code Reader

Safety information

2 Safety information

2.1 Authorized users

For the ICR to function properly and safely, it must be installed and setup by sufficiently

qualified personnel.

The end user must be supplied with the operating instructions.

The end user must be provided with expert tuition and is advised to read the operating

instructions.

The following qualifications are required for the various tasks involved:

2.1.1 Installation and maintenance

• General technical training

• Knowledge of the standard guidelines relating to safety in the workplace

2.1.2 Electrical installation and replacement

• Practical electrical training

• Knowledge of the common electrical safety guidelines

• Knowledge regarding the operation of the devices in the relevant application

(e.g. conveyor belt)

2.1.3 Startup, operation and configuration

• Knowledge regarding the operation of the devices in the relevant application

(e.g. conveyor belt)

• Knowledge of the hardware and software environment of the relevant application

(e.g. conveyor belt)

• Basic knowledge of Windows 95

Windows XP

• Basic knowledge of an HTML browser (e.g. Internet ExplorerTM)

• Basic knowledge of data transmission

• Basic knowledge of Ethernet connections

• Basic knowledge of 2-D code/bar code technology

TM

TM

/98TM, Windows NT4.0TM, Windows 2000TM or

2.2 Intended use

The ICR automatically scans and decodes 2-D codes and bar codes. It is installed in a

reading station and reads these codes on objects which are not moved.

The ICR transfers the data content of the decoded codes via its data interface (Host, CAN

or Ethernet) to a host for further processing.

Any warranty claims vis-à-vis SICK AG will be rendered invalid if the device is used for any

other purpose or if changes are made to the device, also as part of the installation and

electrical installation procedures.

Note Don’t open the device. The producer warranty will be forfeited if the device is opened.

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 2-1

Page 16

Chapter 2 Operating instructions

Safety information

ICR 84x Image Code Reader

2.3 General safety precautions and protection measures

¾ Read the general safety precautions carefully and observe them at all times. This also

applies to the warnings and operating instructions in the individual chapters of this

document.

2.3.1 RF interferences

The ICR 84x is exclusively intended for use in an industrial environment.

In case of use in residential areas, RF interference may occur.

2.3.2 Electrical installation

Risk of injury by electrical current

In the CDM 420 Connection Module, the CMP 400 Power Supply Module is connected to a

mains voltage of 100 to 250 V AC/50 to 60 Hz.

¾ When working with electrical equipment, always follow the relevant safety regulations.

2.3.3 LED illumination for reading area

The ICR 84x is classified in LED class 1.

Under normal and sensible conditions, the accessible beam of the LED illumination is not

hazardous. Blinding, impairment of ability to see color, or other irritations, however, cannot

be excluded.

¾ The entire glass window acts as a LED outlet aperture.

¾ Caution – use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

¾ Do not open the housing.

(Opening the housing does not deactivate the laser diodes).

¾ Observe the laser protection specifications (latest version).

Radiation power

The LEDs of the illumination operate at a wavelength of λ =617nm ± 15 nm (visible red

light) with a pulse duration of max. 5 ms. The energy in the human eye is < 1,7 J/m

The product is classified in LED class 1 in accordance with EN 60825-1 and IEC 60825-1

(for publication date, see the warning sign on the device).

Warning labels

The warning label (Fig. 2-1, Page 2-3) in three languages is located on the wide side of the

housing (see Fig. 3-1, Page 3-5).

2

.

2-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 17

Operating instructions Chapter 2

ICR 84x Image Code Reader

Safety information

Fig. 2-1: Black-yellow signed warning labels found on the ICR

If the ICR is installed in a machine/panel with the result that the warning labels are no

longer visible, additional warnings (not included in the scope of delivery) must be

provided on the machine beside the emergence aperture of the LED radiation.

Activation and deactivation of the LEDs when reading is controlled by the reading pulse

(trigger source).

A timer (illumination timeout) automatically deactivates the LEDs 10 minutes (default

setting) after a continuous reading pulse is initiated in Reading mode with switching input

pulse modes “Sensor Input“ and “Serial Interface“. However, it does not end the reading

interval. In this case, the ICR outputs the following message to the auxiliary interface:

“Illumination safety timeout“

The reading interval must be terminated by resetting the trigger signal. The LEDs activated

again by the next reading pulse.

The illumination timeout can be set in the range of 1 min to 25 h or deactivated (see

Table 6-3, Page 6-25).

The Illumination LEDs are periodically activated in the operating mode “Percentage

Evaluation“ and are always activated in the pulse mode “Free Running“ in Reading

mode.

2.4 Quick stop and quick restart

2.4.1 Switching the ICR off

¾ Switch off the power supply or remove the ICR cable plug from the connection module.

This can result in loss of the following (at the most):

• The application-specific parameter set, if it was only stored temporarily in the ICR

• The last reading result

• Daily operating data

(operating hours counter, reading interval count, good read count, no read count,

maximum duration reading interval, minimum duration reading interval, number of

matches with match code 1, number of matches with match code 2, number of No

Matches.)

2.4.2 Switching the ICR on again

¾ Switch on the supply voltage or reattach cable plug of the ICR to the connection module.

The ICR resumes operation with the last permanently stored parameter set and resets

the daily operating data.

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 2-3

Page 18

Chapter 2 Operating instructions

Safety information

ICR 84x Image Code Reader

2.5 Environmental information

The ICR is designed to cause minimum impact on the environment. It does not contain any

silicone-based materials on the housing surface and, therefore, does not represent any

problems for paint sprayers in paint shops, for example.

2.5.1 Power requirements

The power requirements are particularly low: The ICR has a max. power consumption of

typically 7 W (max. 10 W).

The value is given for devices with disconnected switching outputs.

2.5.2 Disposal after final removal from service

Dispose of unusable or irreparable devices in accordance with the respective state

regulations on waste disposal in a manner compatible with the environment. The ICR can be

separated into recyclable secondary raw materials and special-category waste (electronic

scrap) (see Chapter 7.3 “Disposal“, Page 7-2).

At present SICK AG does not take back devices which have become unusable or

irreparable.

2-4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 19

Operating instructions Chapter 3

ICR 84x Image Code Reader

Product description

3 Product description

3.1 Design

3.1.1 Scope of delivery

The ICR is supplied with the following:

• An information sheet (note on device) with terminal diagram and Quick Start instructions

Depending on the number of devices ordered, one or more copies of the following:

• CD ROM (no. 2 029 112) with

– "CLV Setup" program for Windows

(HTML files)

– "CLV-Connect" PC software (HTML files showing terminal diagrams)

– ICR 84x Operating Instructions in English and German as PDF edition as well as

additional publications (connections module, other SICK bar code scanners)

– freely available "Acrobat Reader" PC software for reading PDF files

TM

and the "CLV Setup Help" online help system

Note The latest versions of all the current publications/programs on the CD ROM can also be

downloaded from www.sick.com.

Depending on the number of copies ordered, the delivery includes (optional):

• ICR 84x Operating Instructions in English and/or German (printed edition)

An overview of the available installation accessories, connection modules, incremental

encoder, cables, plug connections, and sensors for reading pulse generation is contained in

Chapter 10.9 “Accessories“, Page 10-40.

3.1.2 Variants

The ICR is available in the following variants:

Type (red light) Part No. Category Host interface type Reading window

ICR 840-0020 1 027 176 Standard RS 232/422/485, Ethernet Front

ICR 840-1020 1 028 254 RS 232/422/485, Ethernet Side

Table 3-1: ICR 84x variants

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 3-1

Page 20

Chapter 3 Operating instructions

Product description

ICR 84x Image Code Reader

3.1.3 System requirements

The following are required to start up and operate the ICR:

Electrical connecting:

1. A SICK connection module for power supply of the ICR (15 to 30 V DC) and connection

of the data and functional interfaces.

Available types:

– CDB 420-001 (no. 1 023 885) for 10 to 30 V DC, enclosure rating max. IP 65

– CDB 420-101 (no. 1 024 305) for 10 to 30 V DC, enclosure rating max. IP 65

– CDM 420-0001 (no. 1 025 362) for 10 to 30 V DC, enclosure rating max. IP 65

– or –

Alternatively, a non-SICK power supply unit with a voltage output of 15 to 30 V DC

(functional extra-low voltage pursuant to IEC 364-4-41) and at least 12 W power

output.

Use cable no. 6 010 137 with 15-pin D-Sub HD socket and one open end for

connecting the ICR to the power supply unit.

2. The following operating voltages/power output values

– CDB 420-001: 10 to 30 V DC, pursuant to IEC 364-4-41, at least 10 W

– CDM 420-0001: 10 to 30 V DC, pursuant to IEC 364-4-41, at least 10 W.

100 to 250 V AC, 50 to 60 Hz when using the CMP 400 Power Supply Module

– If the following modules are additionally built-in in the CDB 420 module:

CMC 400 Connection Module Cloning: 10 to 30 V DC, additionally 0.5 W

– If the following modules are additionally built-in in the CDM 420 module:

CMC 400 Connection Module Cloning: 10 to 30 V DC, additionally 0.5 W

CMD 400 Connection Module Display: 18 to 30 V DC, additionally 1 W

CMF 400 Connection Module Fieldbus: 18 to 30 V DC, additionally 2 W

3. With external clock pulse (start/stop of reading interval) supply via the “Sensor 1“

switching input: a suitable reading pulse sensor for signaling the presence of an object

with a bar code, e. g. a photoelectric reflex switch.

4. With optional external clock pulse (stop of reading interval) supply via the “Sensor 2“

switching input: a suitable reading pulse sensor for signaling the end of reading intervall,

e. g. a photoelectric reflex switch.

5. If an external field illumination is necessary: a suitable light source to be connected to

the “Result 1“ switching output.

6. To delay the external reading pulse using a track controll: a suitable incremental

encoder.

7. A higher-level computer (host) with a data interface of type RS 422/485 or RS 232.

8. To connect the ICR to the Profibus DP and the DeviceNet: the corresponding CMF 400

Connection Module Fieldbus (Operating instructions see Chapter 10.11

“Supplementary documentation“, Page 10-44).

9. For connection of the ICR to the CAN bus: the operating instructions “Using the CAN

interface“ (no. 8 009 180, English).

Starting-up and configuring:

10. A PC (at least 80486, 66 MHz, 16 MB RAM, CD ROM drive, serial interface, mouse

(recommended) with Windows 95

Windows XP

TM

).

TM

/98TM, Windows NT4.0TM, Windows 2000TM or

3-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 21

Operating instructions Chapter 3

ICR 84x Image Code Reader

Product description

11. For configuring the ICR via the auxiliary interface a 3-core RS 232 data cable (null

modem cable) with two 9-pin D-Sub sockets for connecting the PC to the auxiliary

interface of the ICR in the CDB 420 or CDM 420 Connection Module,

e. g. no. 2 014 054. Pin 2 (RxD) and pin 3 (TxD) are crossed.

12. For configuring the ICR and outputting images via the Ethernet interface:

For the connection of the ICR to the network: a standard Ethernet data cable (patch

cable), e.g. no. 6 026 083.

For the connection of the ICR to the PC (network card): an Ethernet crossover line,

e. g. no. 6 026 084.

13. To use the online help system “CLV Setup Help“, an HTML browser is required,

e. g. “Internet Explorer

TM

“ browser.

3.1.4 Product features and functions (overview)

High-performance scanner:

• CMOS sensor of newest technology (1.3 Mega pixel)

• Fixed focus

• Front reading window, variant: side reading window

• Reading range (DOF) 58 to 106 mm (2.29 to 4.18 in), standard type

• Reading area (dependent of the reading distance), 40 mm x 32 mm (1.58 in x 1.26 in),

at reading distance 80 mm (3.15 in), standard type

• Resolution 0.15 to 2.0 mm (5.9 to 78.7 mil), standard type

• Image refresh rate/decoding frequency 25 Hz at highest resolution

• Function to adjust on the code print quality

• Variable active evaluation range of the image buffer, thereby higher image refresh rate

Safety and user-friendly features:

• Robust, compact metal housing, max. IP 65, CE certification

• LED class 1, illumination diodes switches off if reading interval is active for too long and

if the output power is exceeded

• Automatic self-test on startup. Can also be triggered at any time

• Diagnosis tools for installing and monitoring the system

• Parameterized output of reading diagnosis data in the read result

• Operating data query, and error messages on request

• Test string function for signaling readiness for operation

• Future proof thanks to firmware update via serial data interface (flash PROM)

• Low power consumption, other voltage range

Easy operation/configuration:

• With "CLV Setup" PC software for Windows (online), Help system and four assistants

(Connection Assistant, Ethernet Assistant, Scanner Adjustment, and DataMatrixAutoSetup).

Displaying the image memory content via the ImageFTP program.

• Alternatively with simple command strings, also for use with special devices

• Four status LEDs

• Beeper to confirm device functions or operating steps (can be switches off)

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 3-3

Page 22

Chapter 3 Operating instructions

Product description

ICR 84x Image Code Reader

Operating modes:

• Reading mode

• Percentage evaluation - for assessing the quality of the reads (bar codes only)

• Special functions for system installation

2-D code/Bar code evaluation:

• DataMatrix ECC 200/all standard bar code types

• Max. 50 codes per reading pulse (max. 4,000 characters)

• Separation of identical bar codes of the same code type

• Code comparison (max. 2 matchcodes), can also be used as filter or sort criterion for

the reading result

• Sort sequences: code position, FIFO, LIFO, code length list

• Manipulation of the data output string via filter or format mask

Data communication:

• Main data interface: Host interface (with variable telegram structure), communication

can be routed via the Ethernet interface

• Auxiliary data interface: Terminal interface (with fixed telegram structure) with special

diagnosis functions, communication can be routed via the Ethernet interface

Reading pulse:

• External reading pulse, via switching input(s) or serial data interface

• Free running with timeout

Electrical interfaces:

• Serial host interface (RS 232, RS 422/485) with variable transfer rate and protocol

• Serial terminal interface (RS 232) as auxiliary data interface with fixed transfer rate and

fixed protocol

• CAN interface for integration in the SICK CAN scanner network or a CANopen network

• Ethernet interface with TCP/IP or FTP

• 2 switching inputs for external reading pulse and special function (e. g. teach-in of match

code or encoder increment)

• 2 switching outputs for signaling defined events in reading mode as well as for

triggering or direct powering an external field illumination

Connections:

• All interfaces excepting the Ethernet interface are connected via one 15-pin D Sub HD

plug, Ethernet interface: RJ 45 10 base T socket

• CDB 420 or CDM 420 Connection Module for connection to host (stand-alone) and for

integration in SICK CAN scanner network

• CMF 400 Connection Module Fieldbus in the CDM 420 Connection Module for

connection to field bus systems

3-4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 23

Operating instructions Chapter 3

ICR 84x Image Code Reader

Product description

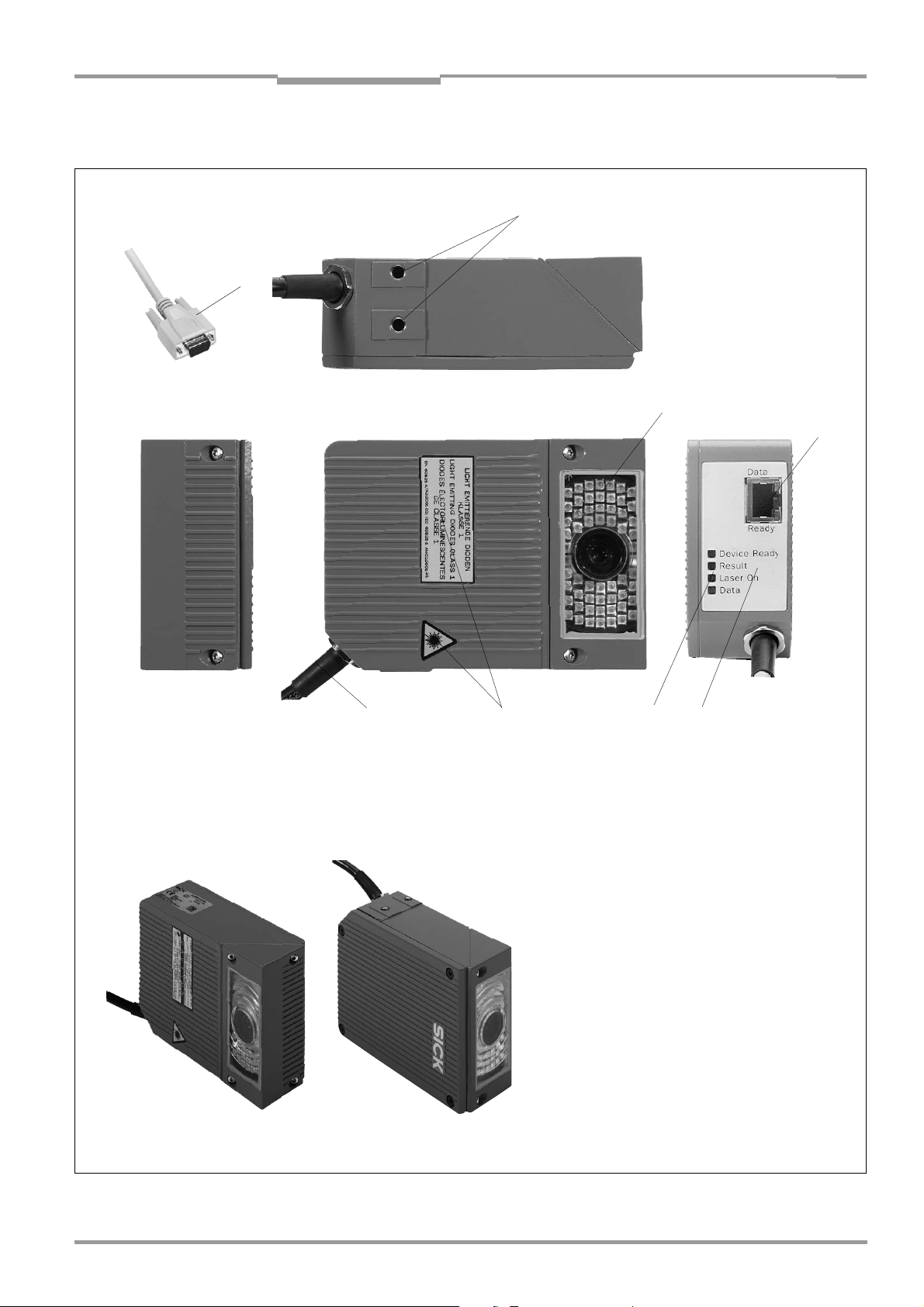

3.1.5 View of the device

2

1

3

4

Side reading window

8

Front reading window

7

6

Key:

5

1 D-Sub HD cable plug, 15-pin

2 Tapped blind holes M5,

8 mm (0.31 in) deep

3 Reading window with lens and

illumination LEDs

4 RJ 45 10baseT socket for Ethernet

connection with LEDs

5 Sound opening of the

beeper (covered)

6 LEDs (status indicators)

7 Laser warning labels

8 Connection cable

Fig. 3-1: Design of the ICR

8 010 961/0000/10-05-2005 © SICK AG · Division Auto Ident · Germany · All rights reserved 3-5

Page 24

Chapter 3 Operating instructions

Product description

ICR 84x Image Code Reader

3.2 Method of operation

The ICR uses an image recording and processing system (CMOS matrix sensor with 1280

x 1024 pixels) to scan 2-D codes and bar codes with a rectangular reading area. To do so,

LEDs integrated in the housing illuminate the area to be read. The LEDs generate a red

illumination field (pulsed) with a configurable flash duration. To start a reading cycle, the ICR

switches on the illumination. It absorbs the light reflected from the reading area (Fig. 3-2)

through the lens as gray values of an image area, which are stored in an electronic image

memory (image refresh rate: 25 Hz at full memory utilization).

To prevent distorted images in the image buffer memory, the object with the code must

remain stationary while the image is being recorded.

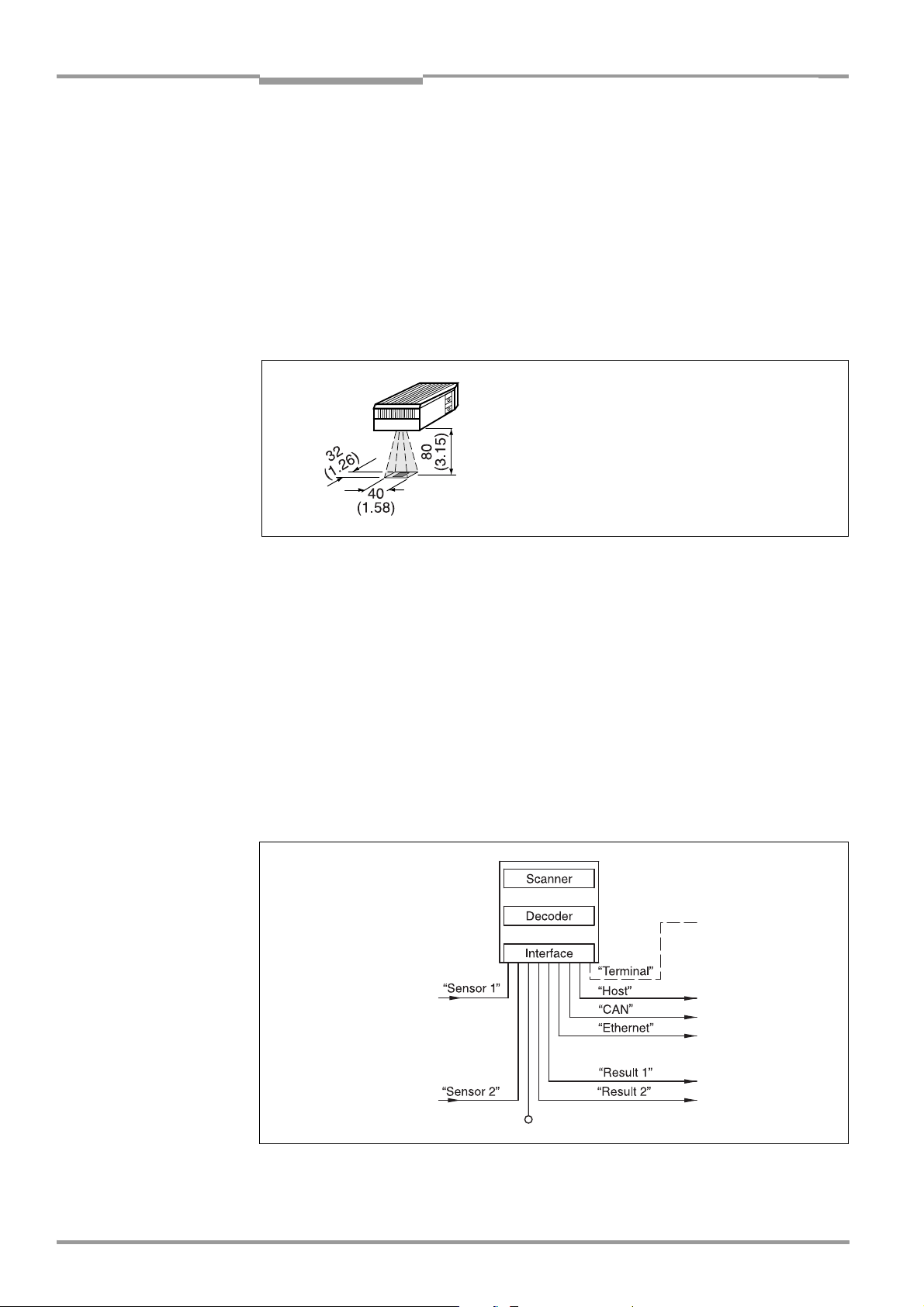

All dimensions in mm (in)

Fig. 3-2: Reading area of the ICR in the focus position (standard type)

The reading area (surface), which is mapped in sharp focus by the ICR in its image memory,

depends on the reading distance and, depending on the resolution, must be within the

reading area (DOF). Fig. 9-4, Page 9-5 shows the available reading area.

If the appropriate configuration settings are made to reduce the image buffer memory area

(image geometry) used for the evaluation, this increases the potential image refresh rate.

The refresh rate with the VGA resolution (640 x 480 pixels) is 60 Hz, for example. The ICR

automatically adjusts the flash frequency. With a maximum of two working areas, a

maximum of just two separate strips in the image field can be evaluated.

As 2-D-codes or bar codes are detected in the image data, the ICR's decoding algorithms

determine the code(s) contents. At the end of the reading cycle or immediately after

successful decoding, the ICR outputs the code data information via its data interface (main

data interface: Host, CAN or Ethernet interface) to a host/PC for further processing.

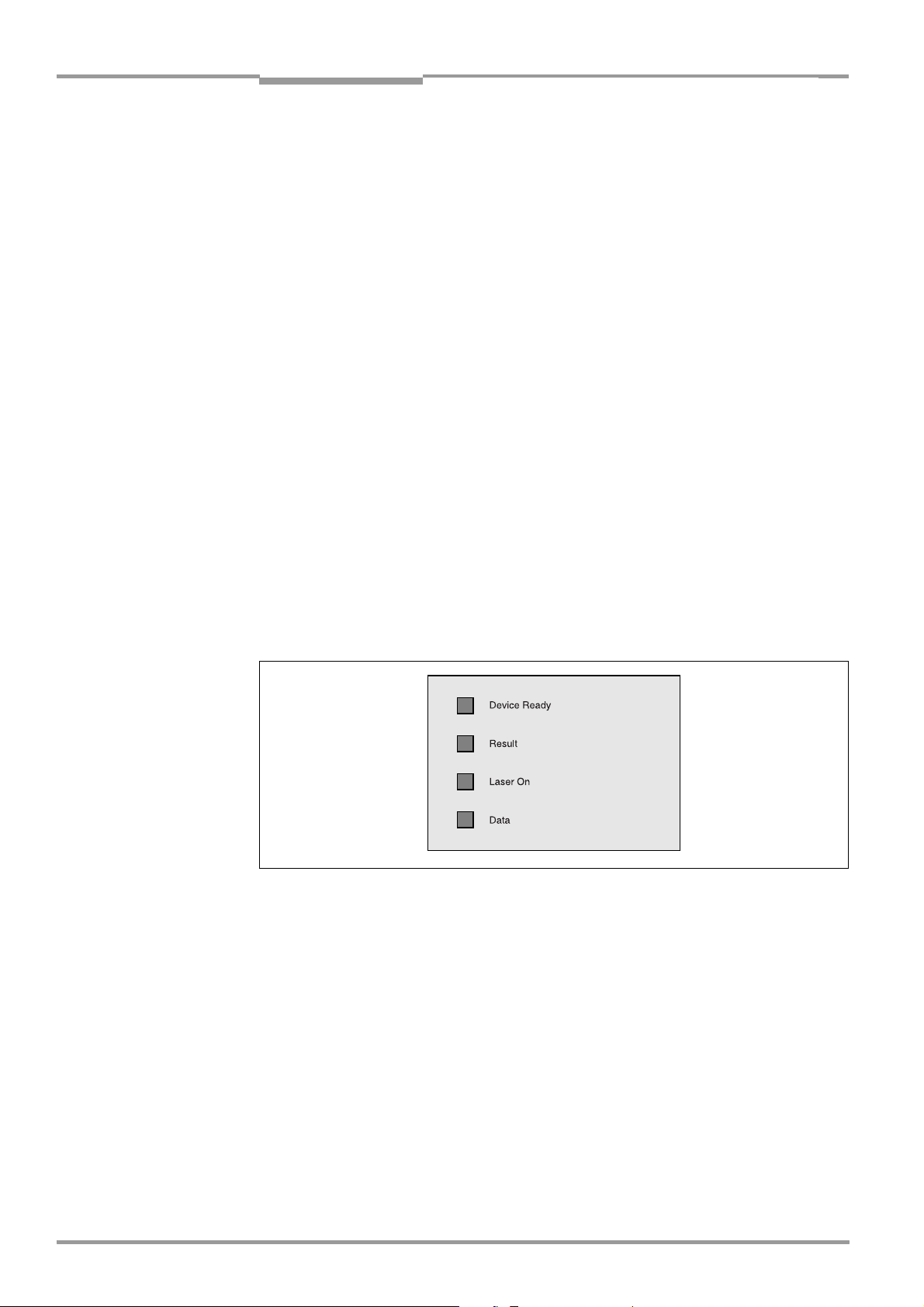

PC

Operation

Parameterizing etc.

Photoelectric switch

Reading pulse

Signal

Path increment

Teach-in match code 1

End of reading interval

HOST

CAN bus

Image output

Status indicator

e.g. Good Read

e.g. No Read

Fig. 3-3: Block diagram: functions of the ICR

3-6 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 961/0000/10-05-2005

Page 25

Operating instructions Chapter 3

ICR 84x Image Code Reader

Product description

The ICR is equipped with three decoders:

• The decoder for 2-D codes

• The SMART decoder (SICK Modular Advanced Recognition Technology) for decoding

bar codes with a small aspect ratio (ratio of the code height to the code length), bar

codes that are dirty or damaged, as well as bar codes that are tilted excessively

(azimuth angle)

• The tried-and-tested standard decoder of the CLV series for bar codes

The ICR derives useful diagnosis data from the reading process and transfers it to the host.

It also records operating data that can be requested at any time. The reading quality

of bar codes can be checked in the “Percentage Evaluation“ operating mode. The reading

quality of 2-D codes can be checked using the reading diagnosis data in normal Reading

mode. On request, the ICR outputs the image buffer memory content as binary or grey scale

bitmap via the Ethernet interface.

To start the reading process when an object is located in the reading area, the ICR requires

a suitable trigger. This opens a time window (“reading interval“) in the ICR for the reading

procedure. In the default setting, this trigger is supplied by an external reading pulse sensor.

Alternative trigger sources include Free Running mode and a command sent via the host

interface.

The current operating status is indicated by four LEDs. A beeper indicates the status of the

reading result. In the default setting, the “Good Read“ function is selected for this.

If the trigger is supplied externally by a sensor, the “Sensor 1“ switching input signals the

start of the reading procedure to the ICR. The “Sensor 2“ switching input is used to signal

the end of reading procedure or to enter a path increment. Alternatively, it can be used

e. g. to teach in a match code. The “Result 1“ and “Result 2“ switching outputs can be

assigned various functions and trigger external devices, such as a PLC. Using the “Result 1“

output, an external field illumination can additionally be triggered or directly powered (max.

100 mA) by the ICR.

The ICR is operated and configured via the serial auxiliary interface (auxiliary data interface)

with the user interface of the “CLV Setup“ software or via the host/auxiliary interface and

command strings. Alternatively, the Ethernet interface is available for both types of

operation.