Page 1

ICR 803

Bar Code Scanner

BAR CODE MANUAL

Page 2

Using This Manual

This manual contains bar codes used to program the ICR803.

For initial setup, product identification, and general product information, please refer to

the following manuals:

ICR803 Quick Start Manual

ICR803 Command & Communication Guide

Plug and Play Bar Codes

Plug and Play bar codes provide instant engine set up for commonly used interfaces. Please note

that the ICR803 interfaces are configured by the factory at time of order. These bar codes are

therefore used to default the scanner to get back to the factory setup.

RS-232

The RS-232 Interface bar code is used when connecting to the serial port of a PC or terminal. The

following RS-232 Interface bar code also programs a carriage return (CR) and a line feed (LF)

suffix, baud rate, and data format as indicated below:

Option Setting

Baud Rate 115200 bps

Data Format 8 data bits, no parity bit, 1 stop bit

RS-232 Interface

USB HID

Scan the following code to default the USB version of the ICR803 for USB HID bar code

imagers. Scanning this code changes the terminal ID to 131.

USB HID Bar Code Imager

ICR803 Bar Code Manual – Rev A – 04/2007 - 2 -

Page 3

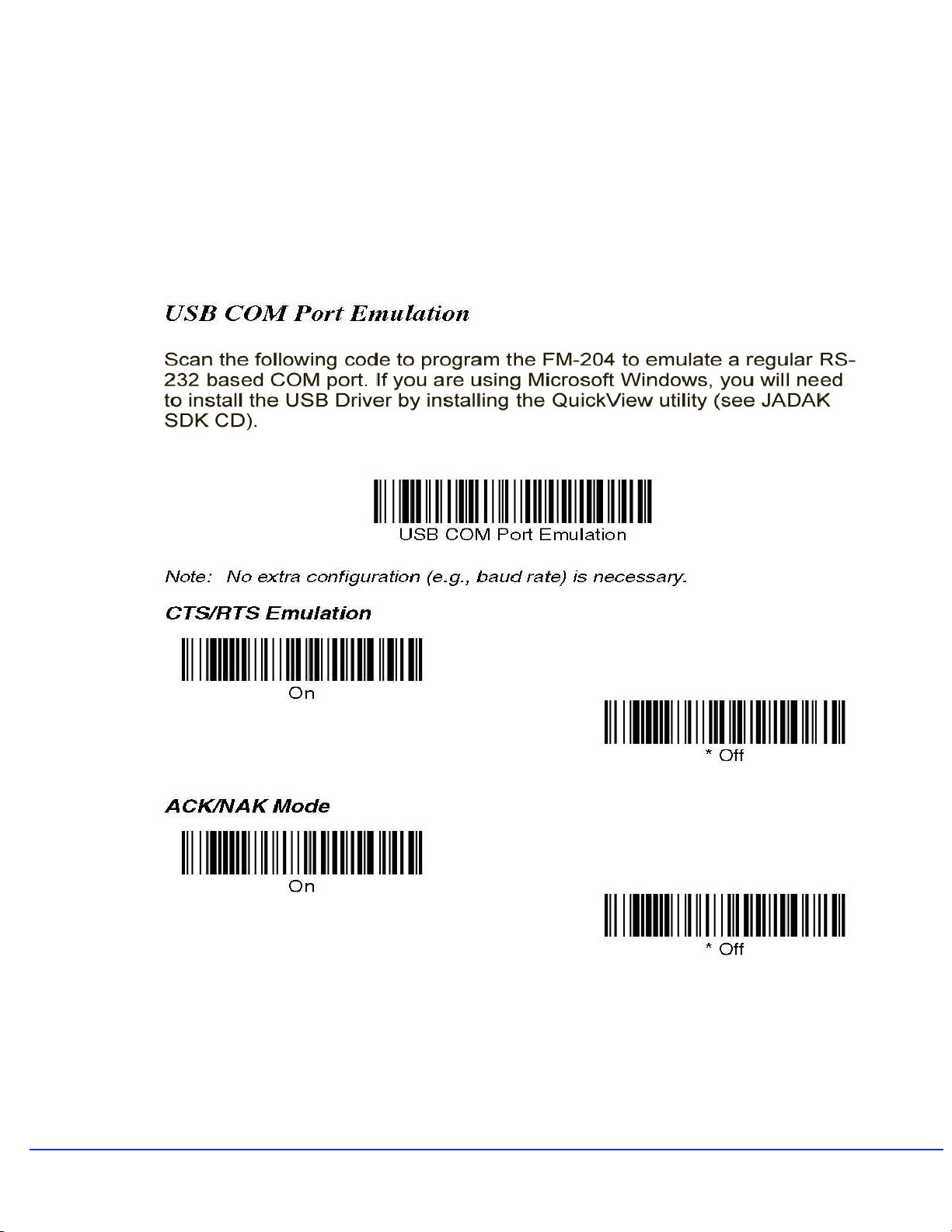

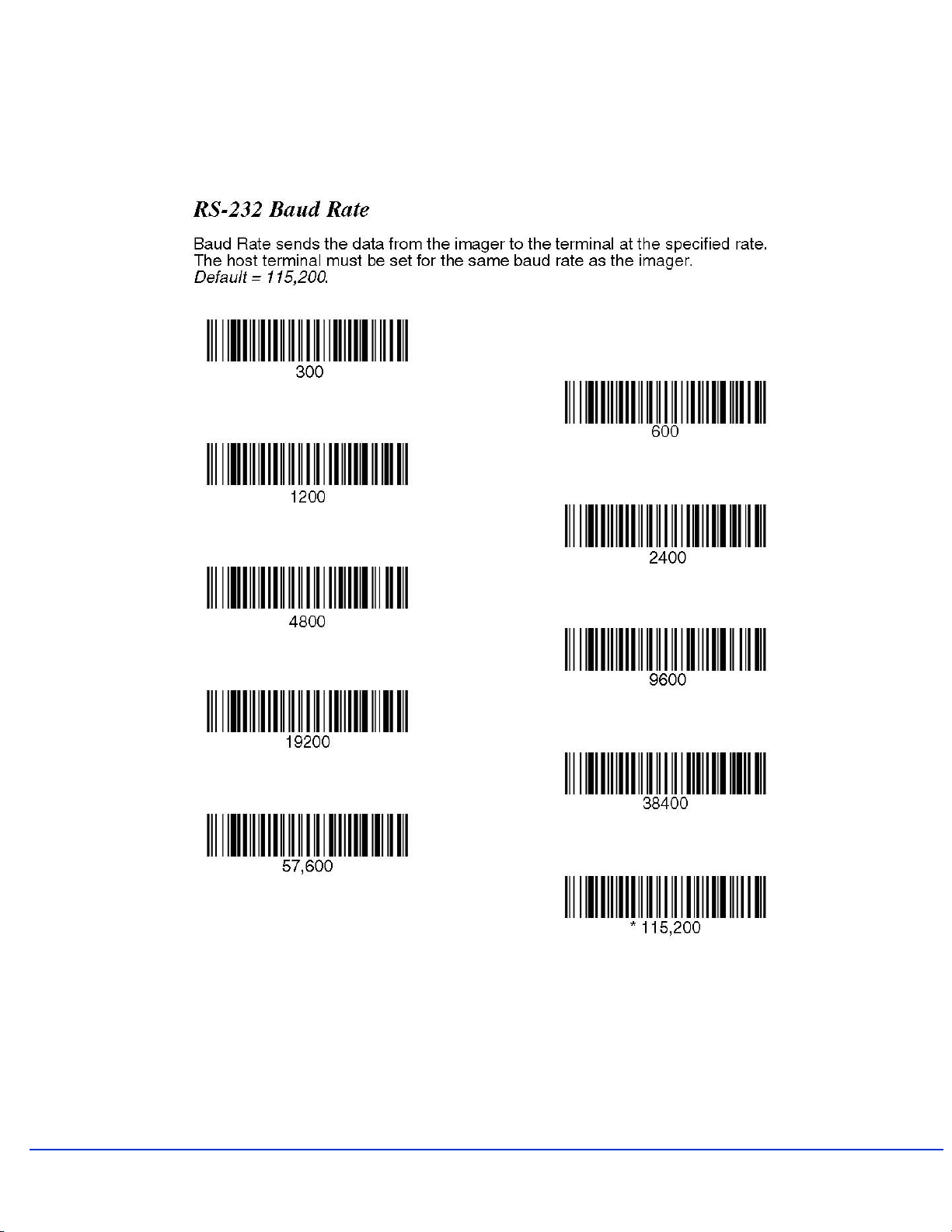

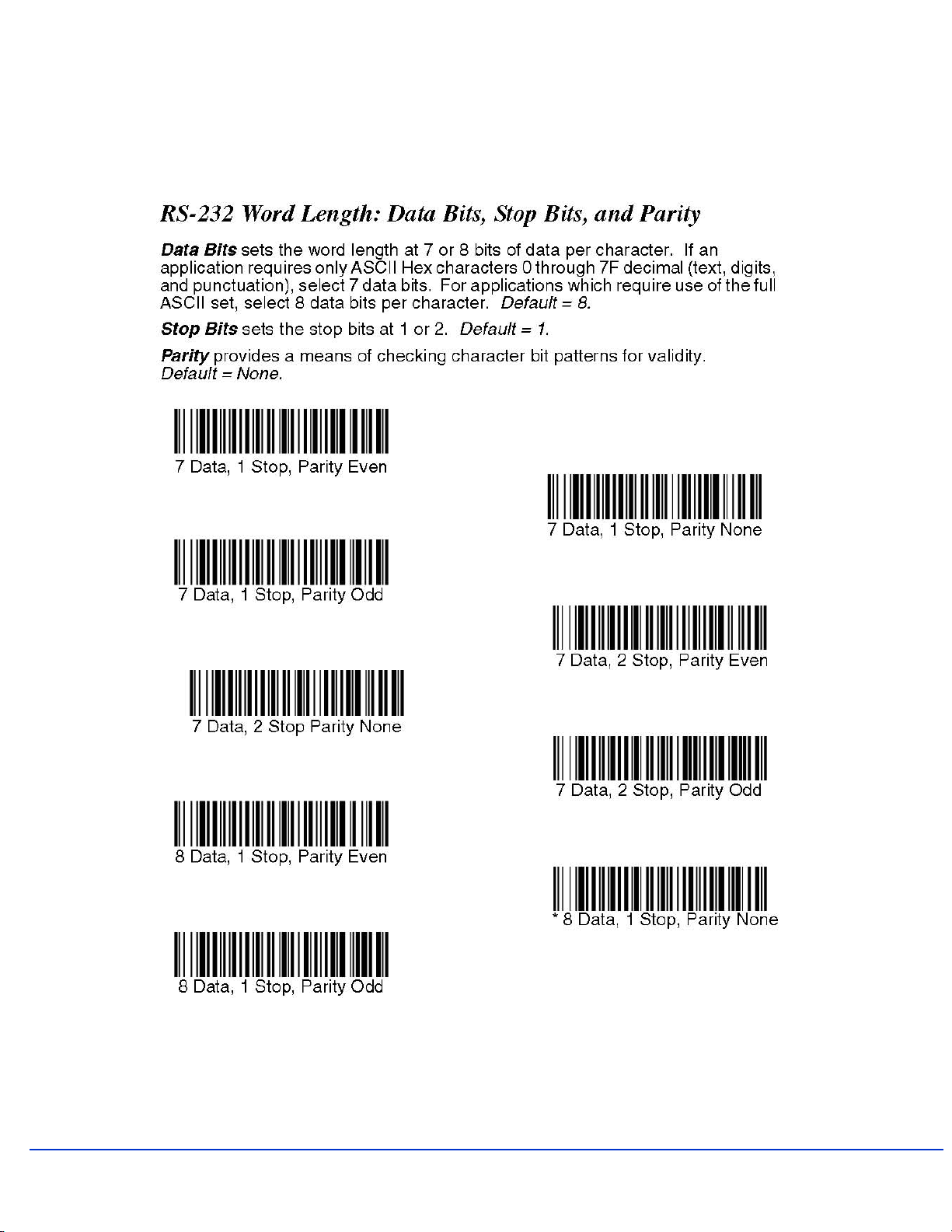

USB COM Port Emulation

Scan the following code to program the USB version of the ICR803 to emulate a regular RS-232 based

COM port. If you are using Microsoft Windows, you will need to install the USB Driver for the scanner.

ICR803 Bar Code Manual – Rev A – 04/2007 - 3 -

Page 4

ICR803 Bar Code Manual – Rev A – 04/2007 - 4 -

Page 5

ICR803 Bar Code Manual – Rev A – 04/2007 - 5 -

Page 6

ICR803 Bar Code Manual – Rev A – 04/2007 - 6 -

Page 7

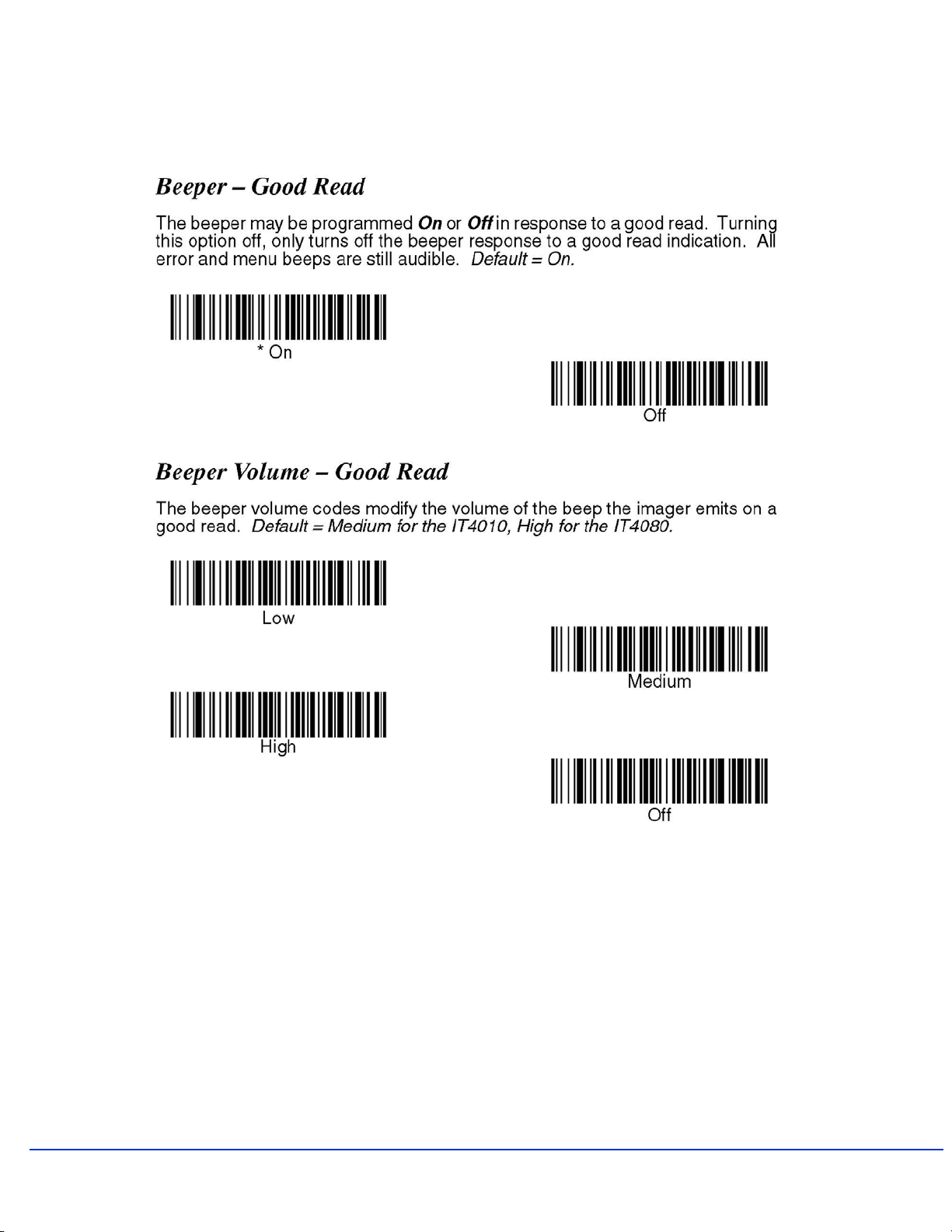

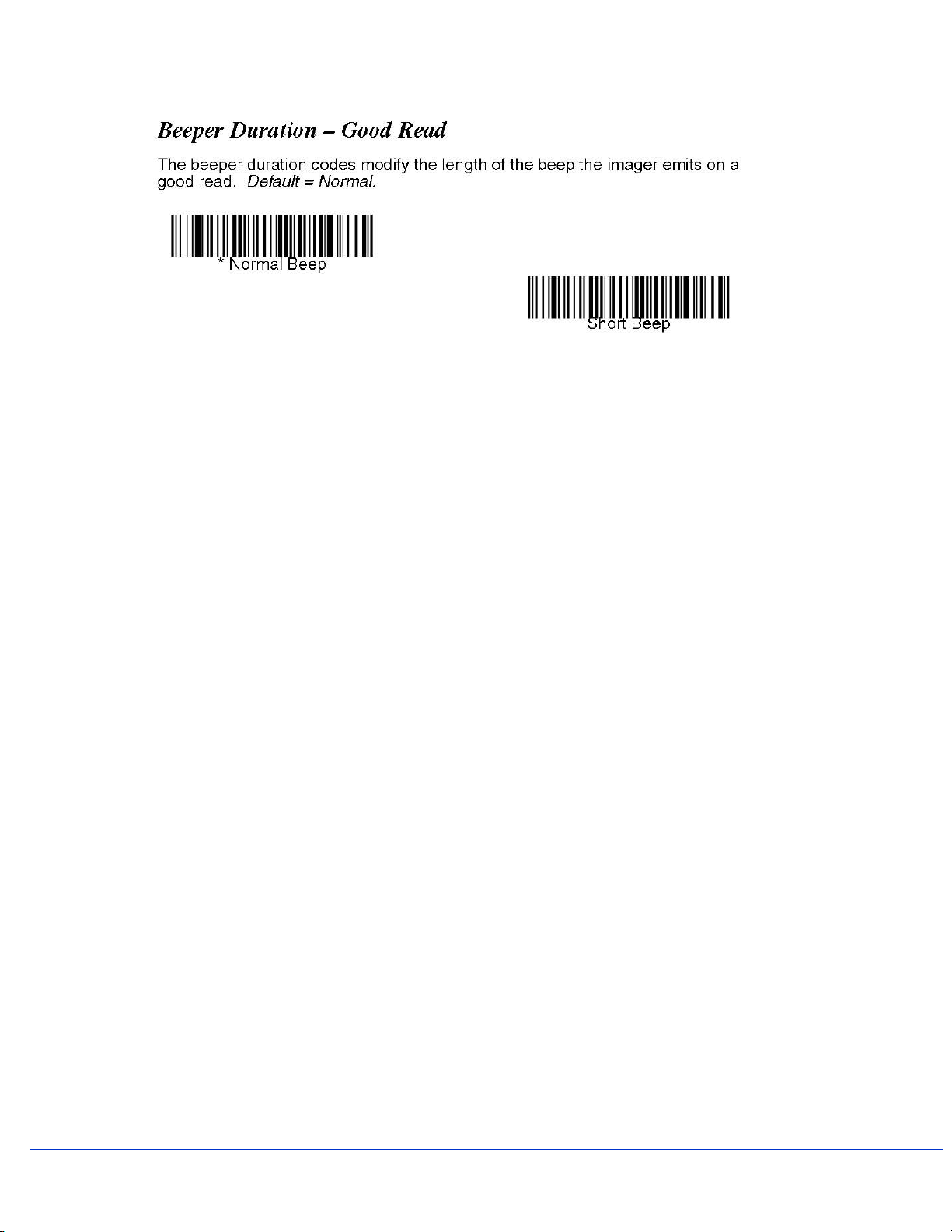

Good Read Indicators

ICR803 Bar Code Manual – Rev A – 04/2007 - 7 -

Page 8

.

ICR803 Bar Code Manual – Rev A – 04/2007 - 8 -

Page 9

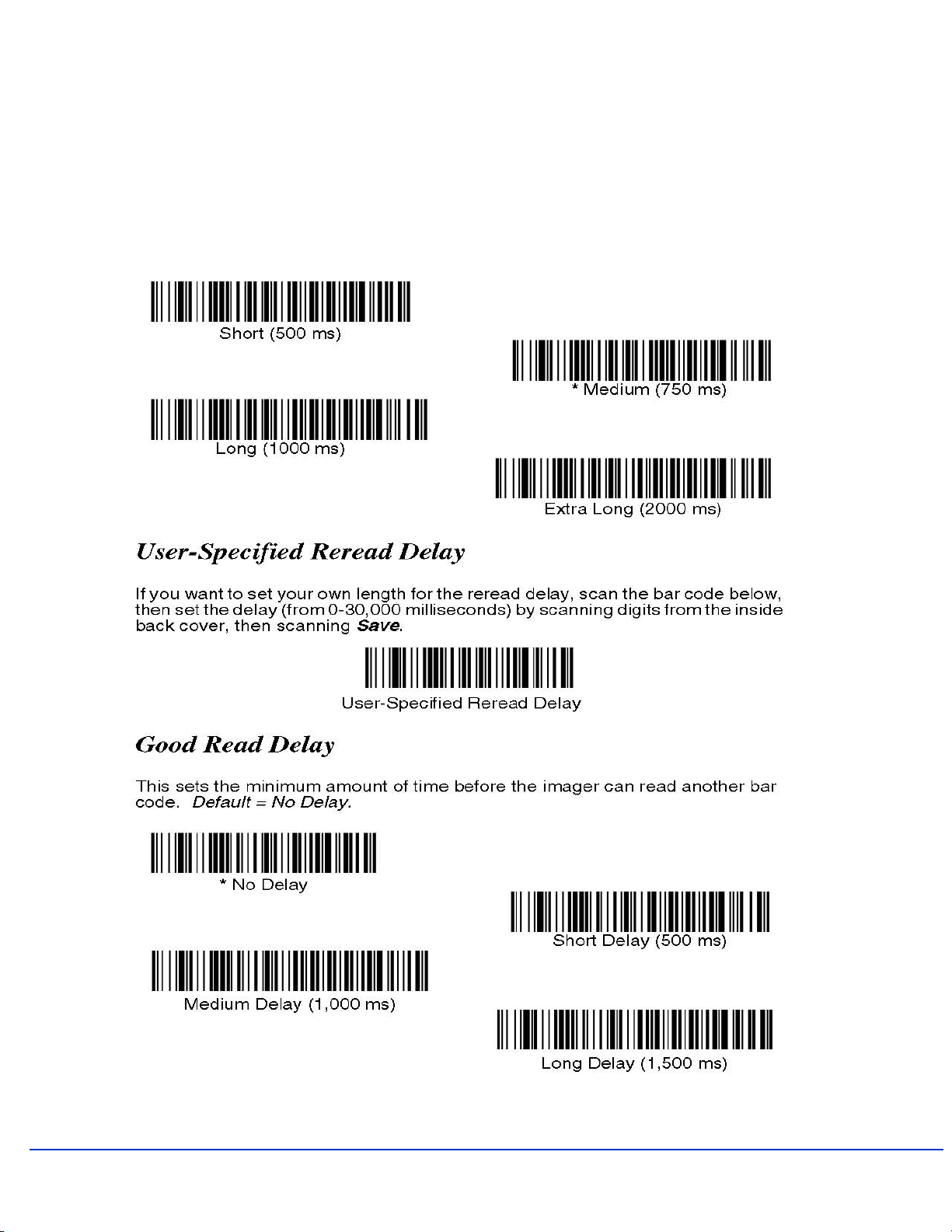

Reread Delay

This sets the minimum amount of time before the imager can read the same bar code a second time.

Setting a reread delay protects against accidental rereads of the same bar code. Longer delays are

effective in minimizing rereads in POS (Point Of Sale) applications. Use shorter delays for applications

where repetitive scanning is required. (Default = Medium)

ICR803 Bar Code Manual – Rev A – 04/2007 - 9 -

Page 10

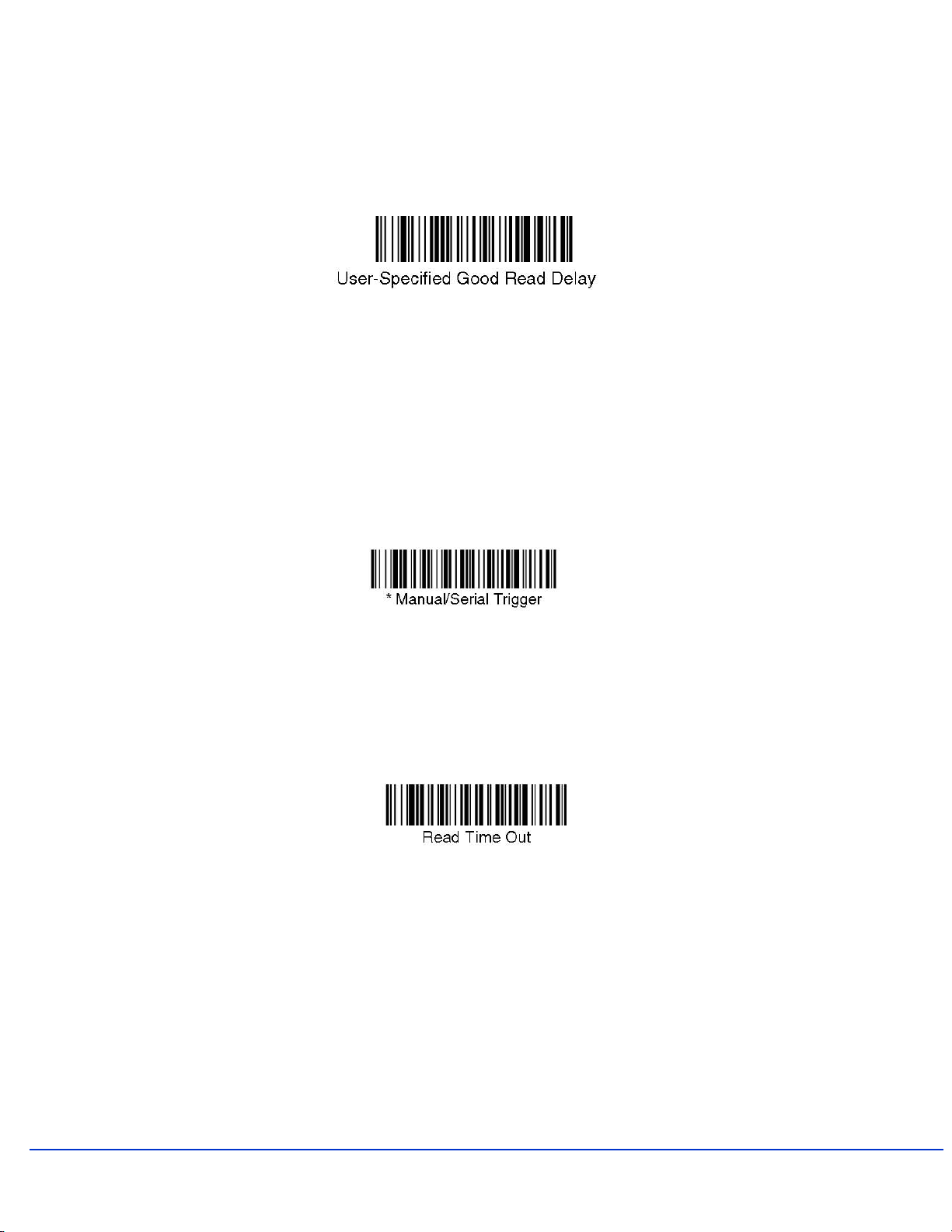

User-Specified Good Read Delay

If you want to set your own length for the good read delay, scan the bar code below, then set the delay (from

0-30,000 milliseconds) by scanning digits from Appendix D, then scanning Save.

Trigger Modes

Manual/Serial Trigger

You can activate the imager either by providing an external hardware trigger, or using a serial

trigger command. When in manual trigger mode, the imager scans until a bar code is read, or until

the hardware trigger is released.

When in serial mode, the imager scans until a bar code has been read or until the deactivate

command is sent. In serial mode, the imager can also be set to turn itself off after a specified time

has elapsed (see Read Time Out, which follows).

Read Time Out

Use this selection to set a time out (in milliseconds) of the imager’s trigger when using serial

commands to trigger the imager, or if the imager is in manual trigger mode. Once the imager has

timed out, you can activate the imager either by pressing the trigger or using a serial trigger

command. After scanning the Read Time Out bar code, set the time out duration (from 0-300,000

milliseconds) by scanning digits from Appendix D, then scanning Save. Default = 0 (infinite, or no

time out).

ICR803 Bar Code Manual – Rev A – 04/2007 - 10 -

Page 11

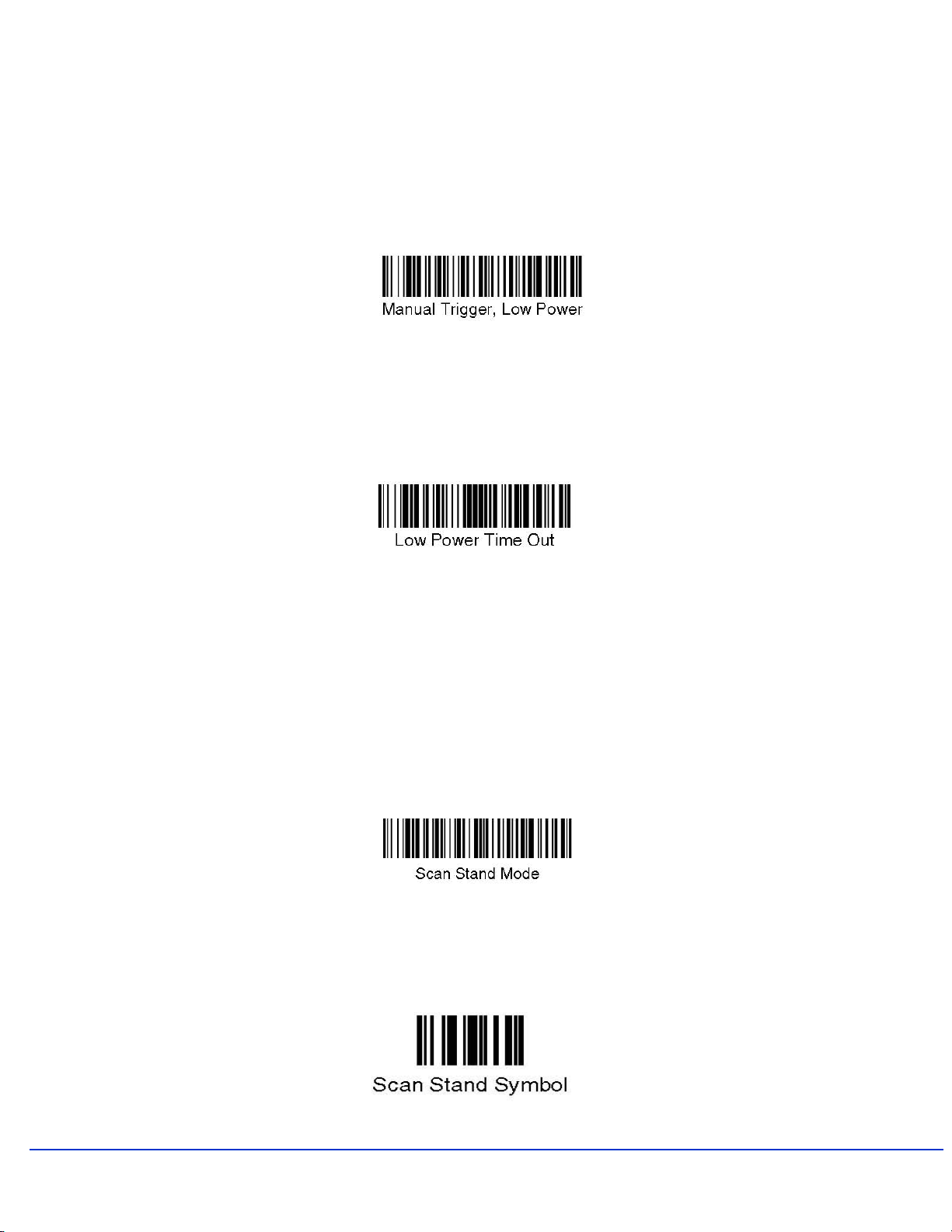

Manual Trigger, Low Power

The imager powers down until the trigger is pulled. When the trigger is pulled, the imager powers

up and operates until there is no triggering for the time set with the Low Power Time Out bar code

below. There is a delay of up to one second in operation when the imager is first triggered, but

there is no delay when operating in low power timeout mode.

Low Power Time Out Timer

Scan the Low Power Time Out bar code to change the time out duration (in seconds). Then scan

the time out duration (from 0-300 seconds) from Appendix D, and Save. Default = 120 seconds.

If the unit remains idle during the low power time out interval, the unit goes into low power mode.

Whenever the trigger is enabled, the low power time out timer is reset.

Note: This timeout does not begin until the imager timeout setting has expired.

Scan Stand Mode

When a unit is in Scan Stand mode, it remains idle as long as it sees the Scan Stand symbol. (See

Scan Stand Symbol that follows.) When a different code is presented, the Imager is triggered to

read the new code.

Note:The imager automatically adjusts the illumination LEDs to the lo west light level possible to

maintain a good lock on the Scan Stand symbol. When a symbol is presented, the imager’s light

levels adjust to the saved LED power setting.

Scan Stand Symbol

When a unit is in Scan Stand mode, the LEDs shine at the Scan Stand symbol on the base of the

stand which tells it to remain idle. When the Scan Stand symbol is covered, the imager turns the

LEDs on at the configured power level (Default High) and attempts to find and decode bar codes in

its field of view.

ICR803 Bar Code Manual – Rev A – 04/2007 - 11 -

Page 12

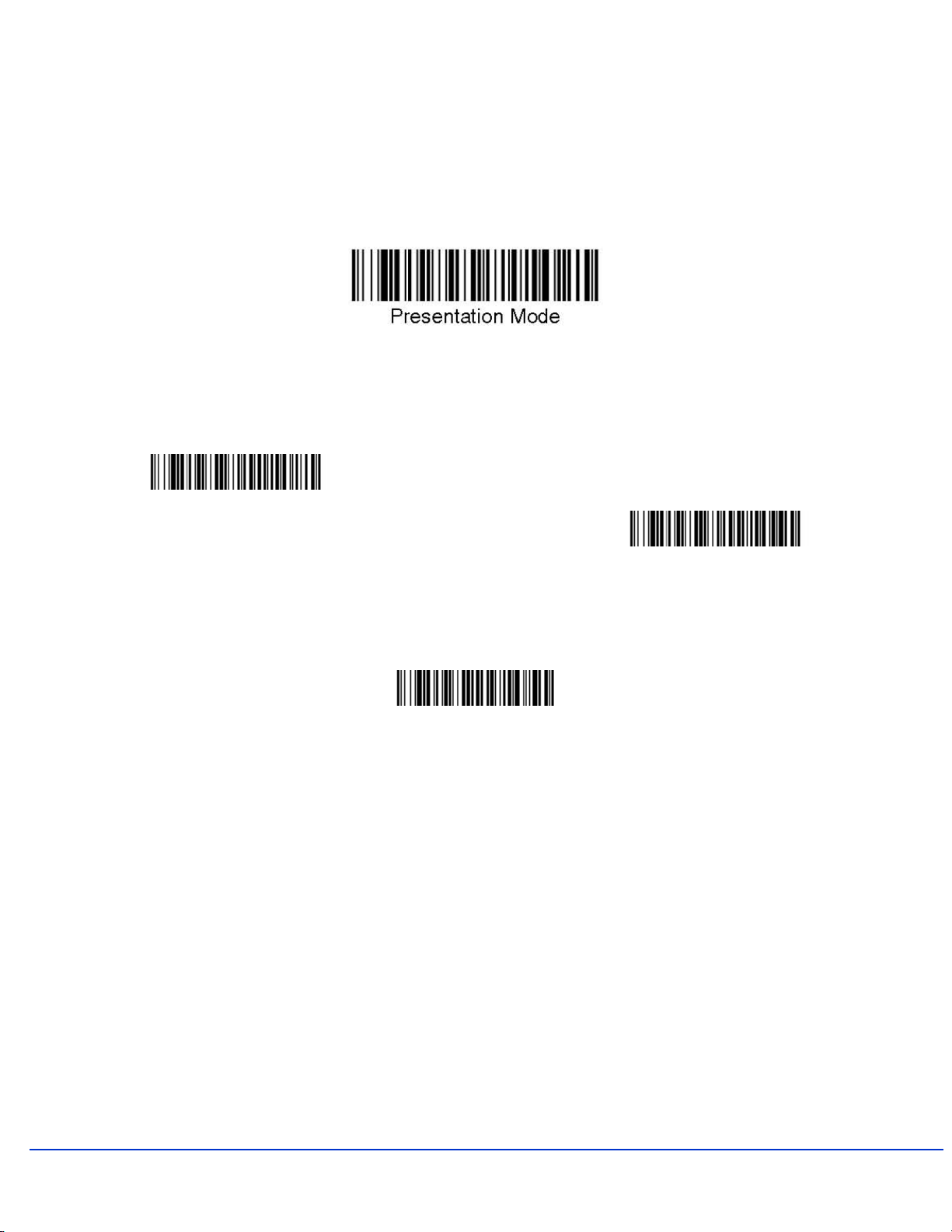

Presentation Mode

This programs the imager to work in Presentation mode. The LEDs are either off or at the lowest power for

ambient conditions until a bar code is presented to the imager. Then the LEDs turn on aut omatically to read

the code. Presentation Mode uses ambient light to detect the bar codes. If the light level in the room is not

high enough, Presentation Mode may not work properly.

Presentation LED Behavior after Decode

When an imager is in presentation mode, the LEDs remain on and continue scanning for a short time after a

bar code is decoded. If you wish to turn the LEDs off immediately after a bar code is decoded, scan the

LEDs Off bar code, below. Default = LEDs On.

* LEDs On

LEDs Off

Presentation Sensitivity

Presentation Sensitivity is a numeric range that increases or decreases the imager's reaction time to bar

code presentation. To set the sensitivity, scan the Sensitivity bar code, then scan the degree of sensitivity

(from 0-20) from the inside back cover, and Save. 0 is the most sensitive setting, and 20 is the least

sensitive. Default = 1.

Sensitivity

Hands Free Time Out

The Scan Stand and Presentation Modes are referred to as “hands free” modes. If the imager’s

trigger is pulled when using a hands free mode, the imager changes to manual trigger mode. You

can set the time the imager should remain in manual trigger mode by setting the Hands Free Time

Out. Once the time out value is reached, (if there have been no further trigger pulls) the imager

reverts to the original hands free mode.

Scan the Hands Free Time Out bar code, then scan the time out duration (from 0-300,000

milliseconds) from Appendix D, and Save. Default = 5,000 ms.

ICR803 Bar Code Manual – Rev A – 04/2007 - 12 -

Page 13

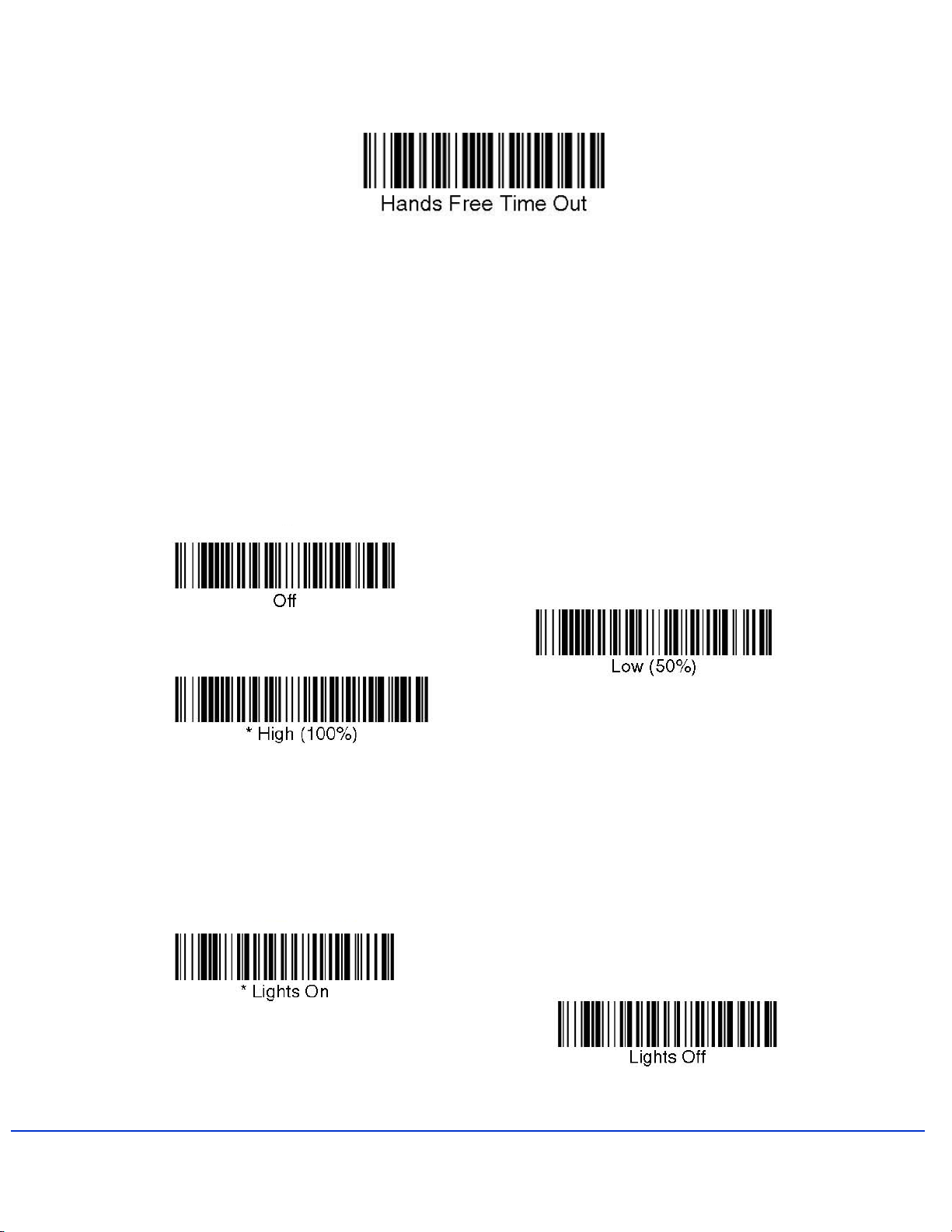

LED Power Level

This selection allows you to adjust LED and aimer brightness. Off is used when no illumination is

needed. Low is used if low illumination is sufficient. High (the default) is the brightest setting. If you

have an aimer delay programmed (see Aimer Delay), the aimer will be at 100% power during the

delay, regardless of the LED Power Level.

Note: If you scan the Off bar code, both the aimer and illumination lights turn off, making it impossible to

scan bar codes in low light. To turn the LED Power Level back on, move to a brightly lit area and scan either

the Low or the High bar code below.

Illumination Lights

If you want the illumination lights on while reading a bar code, scan the Lights On bar code, below.

However, if you want to turn just the lights off, scan the Lights Off bar code.

Note: This setting does not affect the aimer light.

- 13 -

Page 14

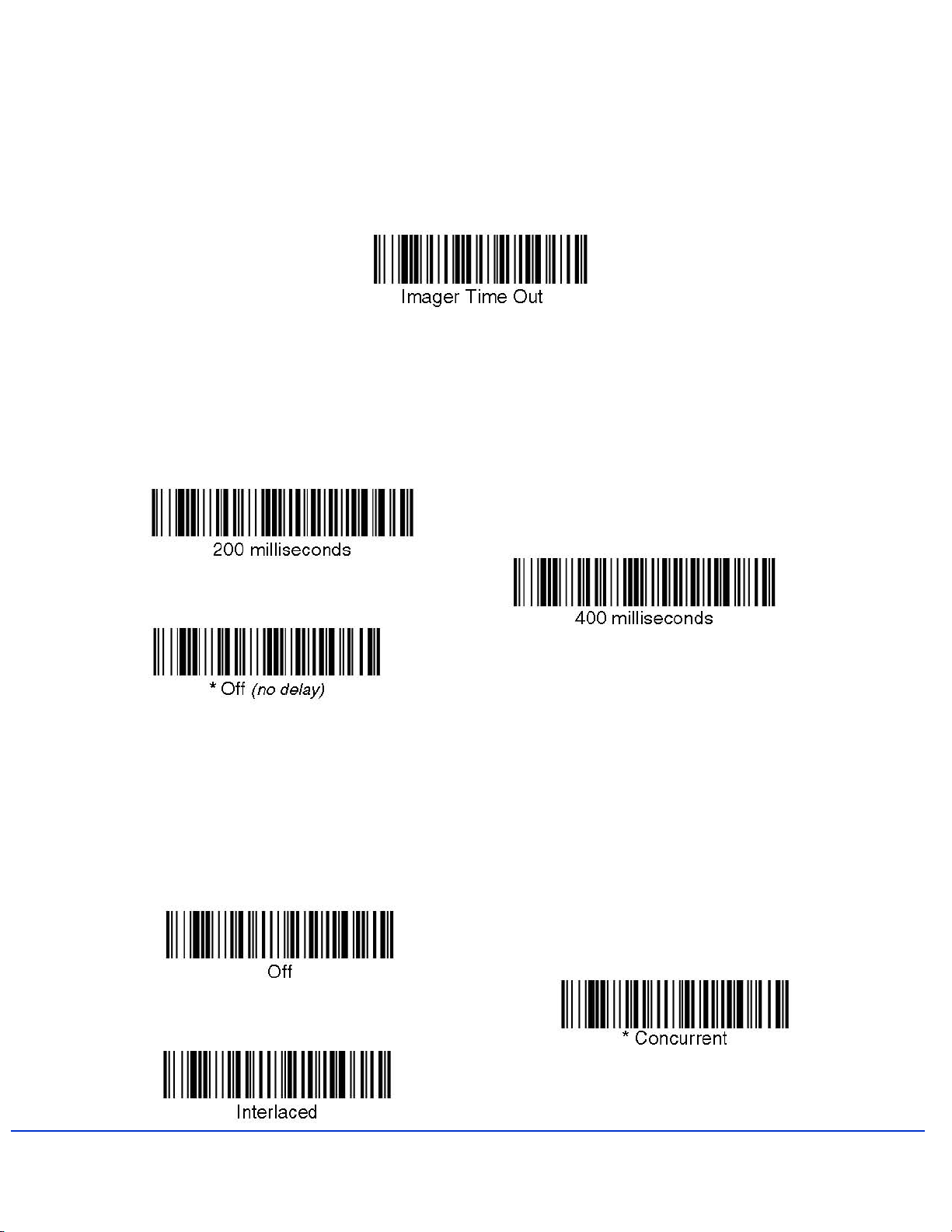

Imager Time Out

Imager Time Out powers down the imager after the unit has been idle for the specified time. To

prevent the imager from powering down, set this time out to 0. Scan the bar code below, then set

the time out by scanning digits (from 0 - 999,999 ms) from Appendix D, then scanning Save.

Aimer Delay

The aimer delay allows a delay time for the operator to aim the imager before the picture is taken.

Use these codes to set the time between when the trigger is pulled and when the picture is taken.

During the delay time, the aiming light will appear, but the LEDs won’t turn on until the delay time is

over.

Aimer Mode

This feature allows you to lower peak current during scanning by alternating the aimer a nd

illumination LEDs. When the Interlaced bar code is scanned, the aimer and illumination LEDs are

not allowed to be on at the same time. While this does limit peak current during scanning, the

scanner performance may be slower. When the Concurrent bar code is scanned, the aimer and

illumination LEDs are allowed to light at the same time. Select Off if you don’t want to use either

aimer mode.

- 14 -

Page 15

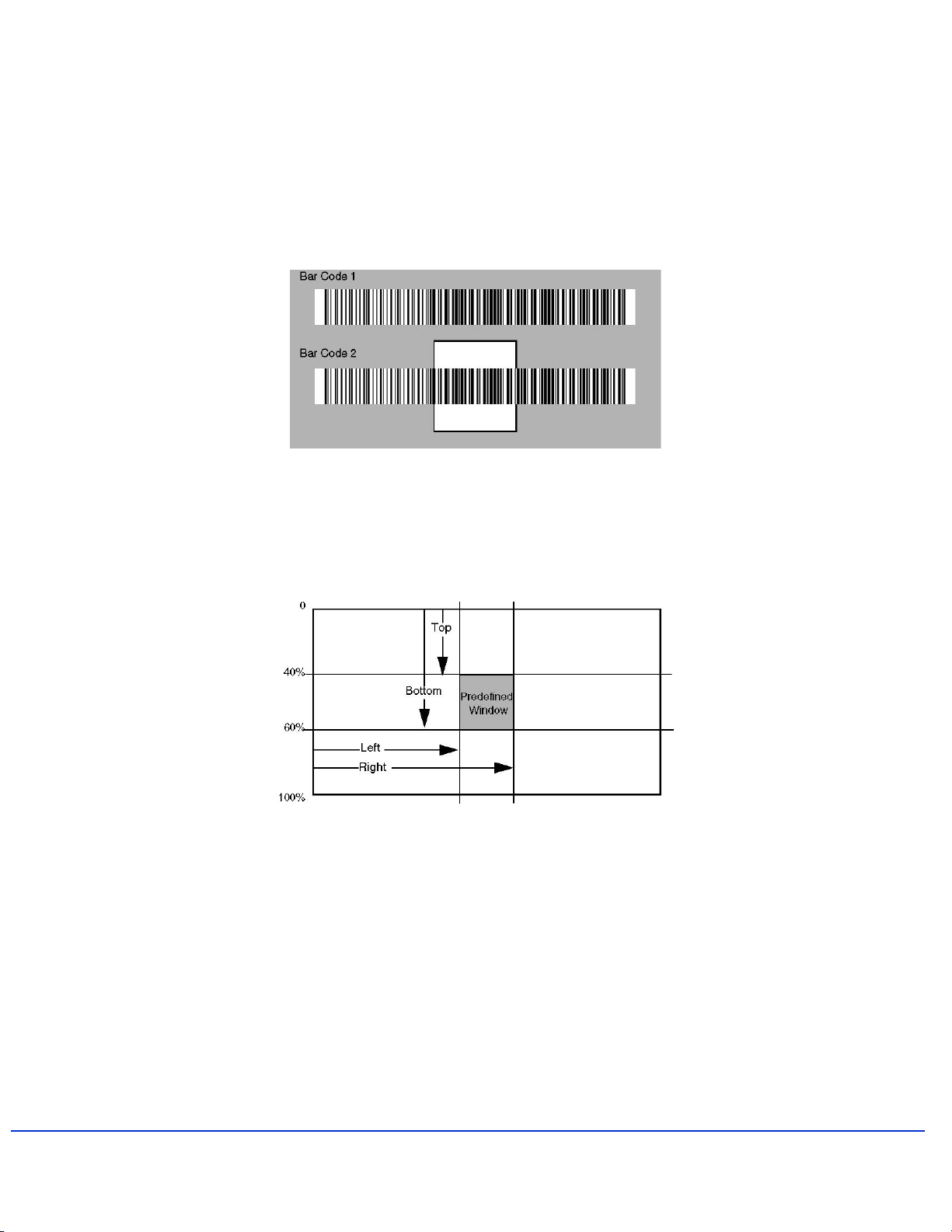

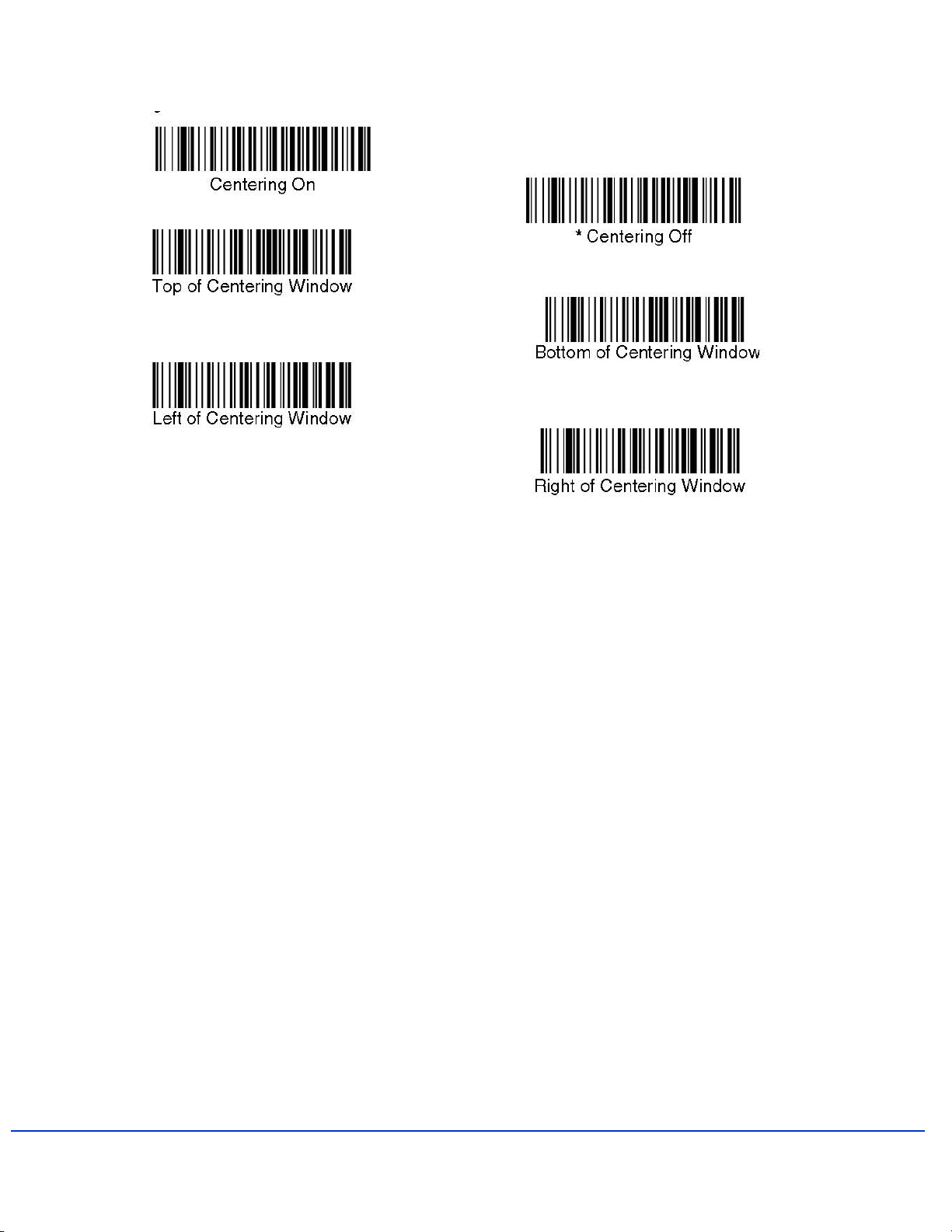

Centering

Use Centering to narrow the imager’s field of view to make sure the imager reads only those bar

codes intended by the user. For instance, if multiple codes are placed closely together, centering

will insure that only the desired codes are read.

In the example below, the gray area is the full imager field of view and the white area is the

centering window. Bar Code 1 will not be read, while Bar Code 2 will be.

The default centering window is a 60 pixel square area in the center of the imager’s field of view.

The following diagram illustrates the default top, bottom, left, and right pixel positions, measured

from the top and the left side of the imager’s field of view, which is 640 by 480 pixels.

40% 60% 100%

The centering window must intersect the center of the image. If a bar code is not within the

predefined window, it will not be decoded or output by the imager. If centering is turned on by

scanning Centering On, the imager only reads codes that intersect the centering window you

specify using the Top, Bottom, Left, or Right bar codes.

Scan Centering On, then scan one of the following bar codes to change the top, bottom, left, or

right of the centering window. Then scan the percent you want to shift the centering window using

digits in Appendix D of this manual. Scan Save. Default Centering = 40% for Top and Left, 60% for

Bottom and Right.

- 15 -

Page 16

- 16 -

Page 17

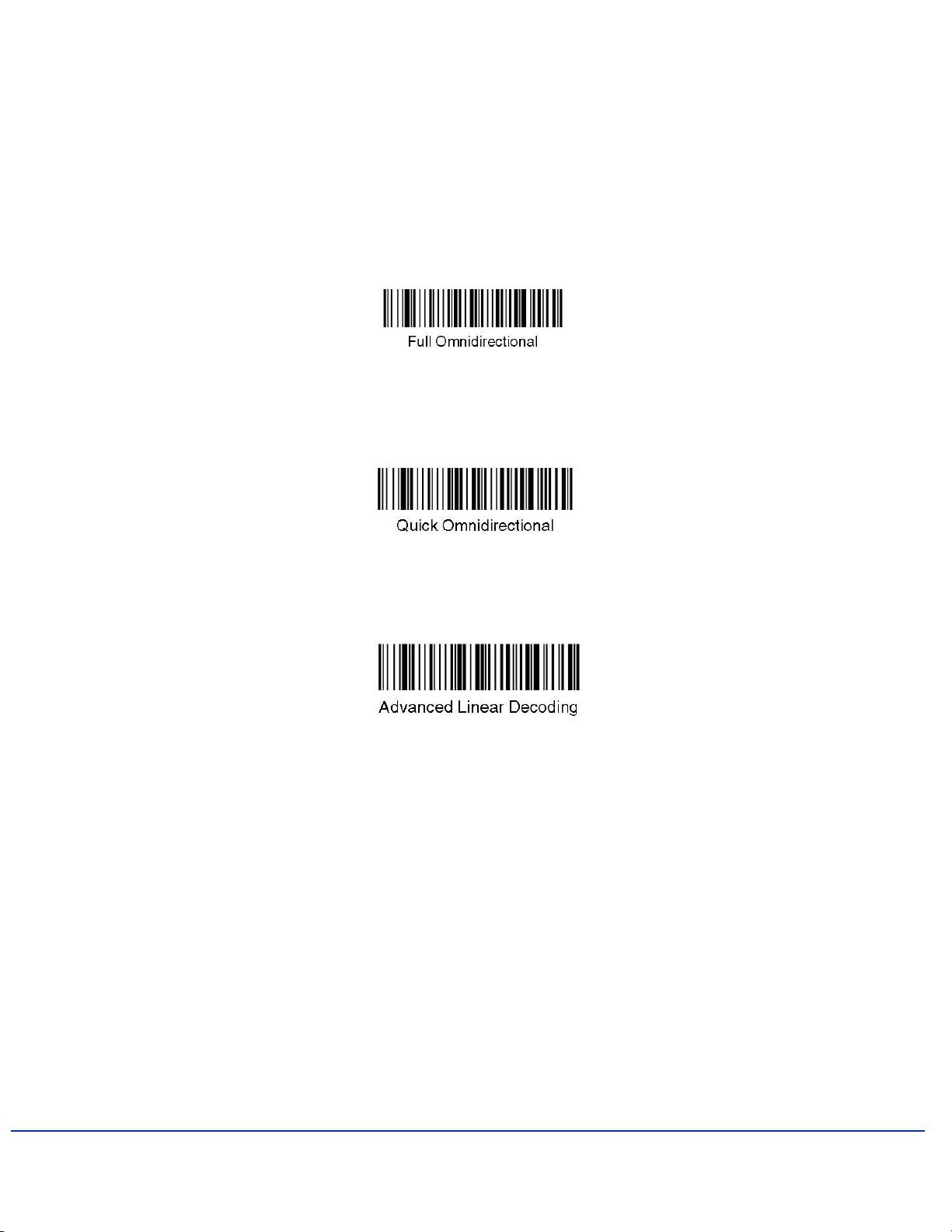

Decode Search Mode

There are three selectable decode (scanning) modes:

Full Omnidirectional (default) - Searches for bar code features beginning at the center of an

image, and searches to the image’s limits. This mode reads all symbologies (including OCR), in

any orientation. The Full Omnidirectional search is very thorough which may slow performance

time.

Quick Omnidirectional - This is an abbreviated search for bar code features around the center

region of an image. This mode quickly reads all symbologies in any ori entation. The Quick

Omnidirectional mode may miss some off-center symbols, as well as larger Data Matrix and QR

Code symbols.

Advanced Linear Decoding - Performs quick horizontal linear scans in a center band of the

image. This mode is not omni-directional, but does quickly read linear and stacked bar codes.

Advanced Linear Decoding cannot read 2D, OCR, or Postal symbols.

- 17 -

Page 18

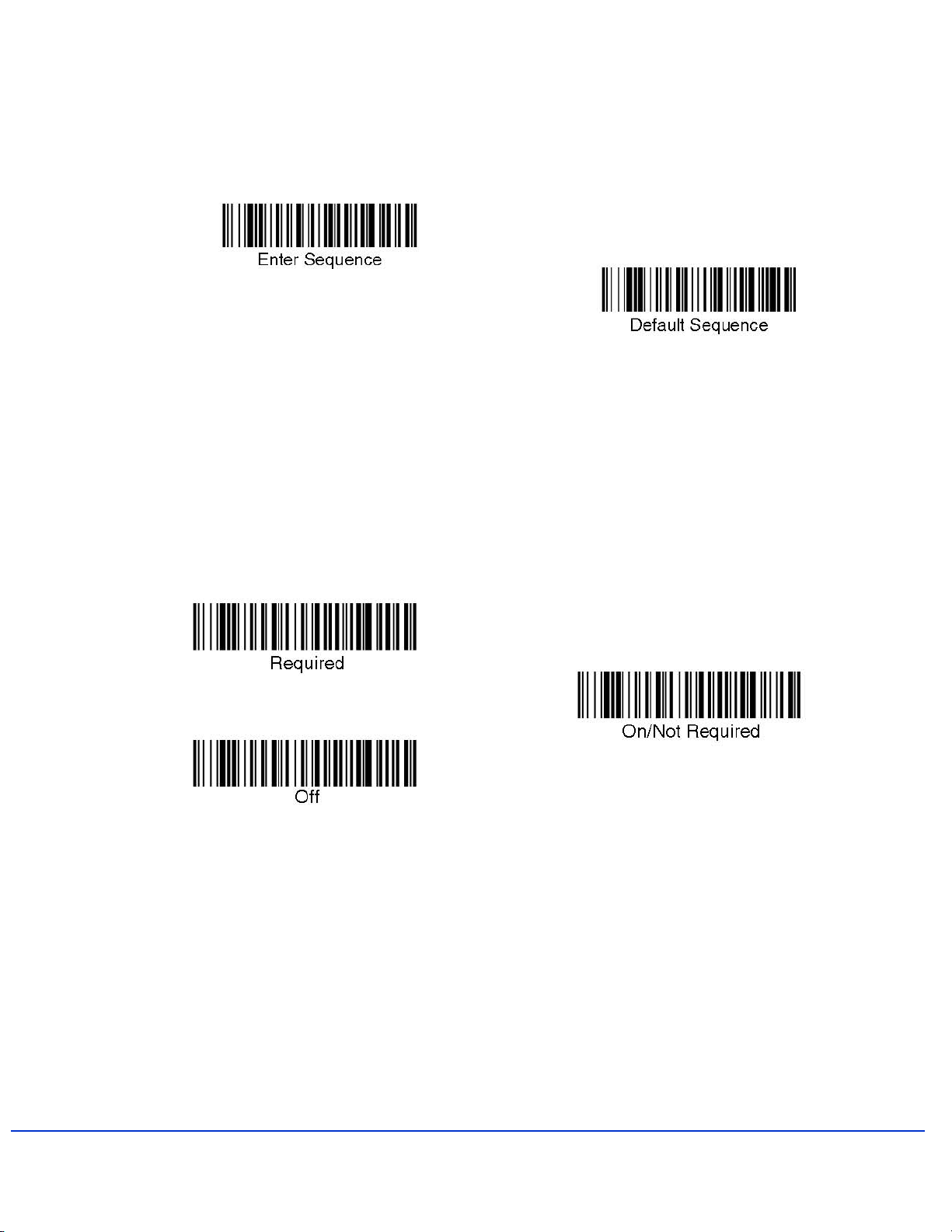

Output Sequence Overview

Require Output Sequence

When turned off, the bar code data will be output to the host as the Imager decodes it. When turned

on, all output data must conform to an edited sequence or the Imager will not transmit the output

data to the host device.

Note: This selection is unavailable when the Multiple Symbols Selection is turned on.

Output Sequence Editor

This programming selection allows you to program the Imager to output data (when scanning more

than one symbol) in whatever order your application requires , regardless of the order in which the

bar codes are scanned. Reading the Default Sequence symbol programs the Imager to the

Universal values, shown below. These are the defaults. Be certain you want to delete or clear all

formats before you read the Default Sequence symbol.

Note: To make Output Sequence Editor selections, you’ll need to know the code I.D., code length,

and character match(es) your application requires. Use the Alphanumeric symbols (in Appendix D)

to read these options.

To Add an Output Sequence

1. Scan the Enter Sequence symbol.

2. Code I.D. On the Symbology Chart (Appendix A), find the symbology to which you want to apply

the output sequence format. Locate the Hex value for that symbology and scan the 2 digit hex

value from the Programming Chart (Appendix D).

3. Length Specify what length (up to 9999 characters) of data output will be acceptable for this

symbology. Scan the four digit data length from the Programming Chart. (Note: 50 characters is

entered as 0050. 9999 is a universal number, indicating all lengths.)

4. Character Match Sequences On the ASCII Conversion Chart (Appendix B), find the He x value

that represents the character(s) you want to match. Use the Programming Chart to read the

alphanumeric combination that represents the ASCII characters. (99 is the Universal number,

indicating all characters.)

5. End Output Sequence Editor Scan F F to enter an Output Sequence for an additional symbology,

or Save to save your entries.

Other Programming Selections

• Discard

This exits without saving any Output Sequence changes.

- 18 -

Page 19

Output Sequence Example

In this example, you are scanning Code 93, Code 128, and Code 39 bar codes, but yo u want the imager to

output Code 39 1st, Code 128 2nd, and Code 93 3rd, as shown below.

Note: Code 93 must be enabled to use this example.

You would set up the sequence editor with the following command line:

SEQBLK62999941FF6A999942FF69999943FF

The breakdown of the command line is shown below:

SEQBLK sequence editor start command, 62 code identifier for Code 39, 9999 code length that must match

for Code 39 (9999 = all lengths), 41 start character match for Code 39 (41h = “A” ), FF termination string for

first code, 6A code identifier for Code 128, 9999 code length that must match for Code 128 (9999 = all

lengths), 42 start character match for Code 128 (42h = “B”), FF termination string for second code, 69 code

identifier for Code 93, 9999 code length that must match for Code 93 (9999 = all lengths), 43 start character

match for Code 93 (43h = “C”), FF termination string for third code

- 19 -

Page 20

Output Sequence Editor

Require Output Sequence

When an output sequence is Required, all output data must conform to an edited sequence or the

imager will not transmit the output data to the host device. When it’s On/Not Required, the imager

will attempt to get the output data to conform to an edited sequence, but if it cannot, the imager

transmits all output data to the host device as is.

When the output sequence is Off, the bar code data is output to the host as the imager decodes it.

Note: This selection is unavailable when the Multiple Symbols Selection is turned on.

- 20 -

Page 21

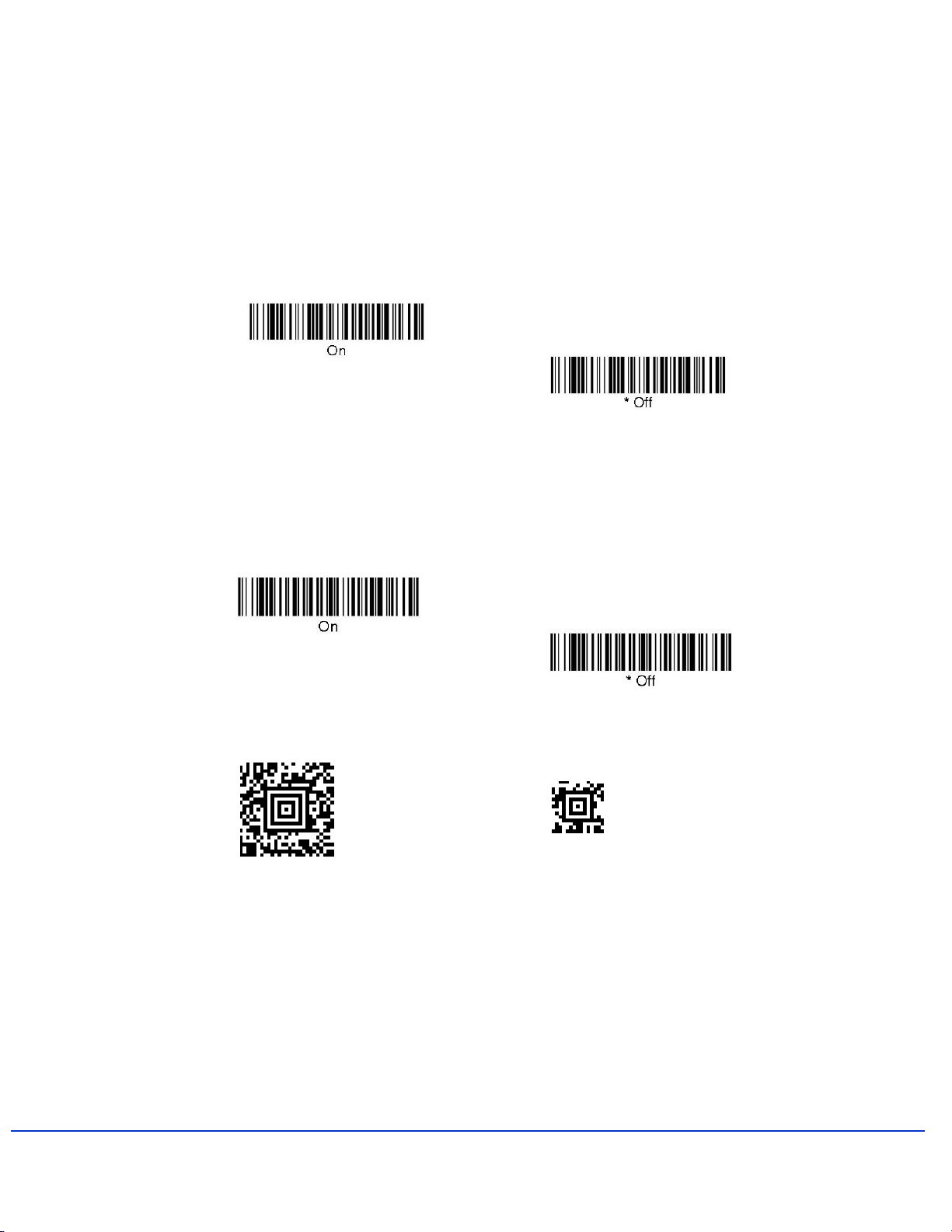

Multiple Symbols

Note: This feature does not work when the Imager is in Low Power mode.

When this programming selection is turned On, it allows you to read multiple symbols with a single

pull of the Imager’s trigger. If you press and hold the trigger, aiming the Imager at a series of

symbols, it reads unique symbols once, beeping (if turned on) for each read. The imager attempts

to find and decode new symbols as long as the trigger is pulled. When this programming selection

is turned Off, the Imager will only read the symbol closest to the aiming beam.

No Read

With No Read turned On, the Imager notifies you if a code cannot be read. If using a Quick*View

Scan Data Window, an “NR” appears when a code cannot be read. If No Read is turned Off, the

“NR” will not appear.

The default no read message of ‘NR’ can be changed to ‘No Read’ by scanning the barcode below:

Output Default back

“No Read” to ‘NR’ message

If you want a different notation, for example, “Error,” or “Bad Code,” you can edit the output

message using the Data Formatter. The hex code for the No Read symbol is 9C.

- 21 -

Page 22

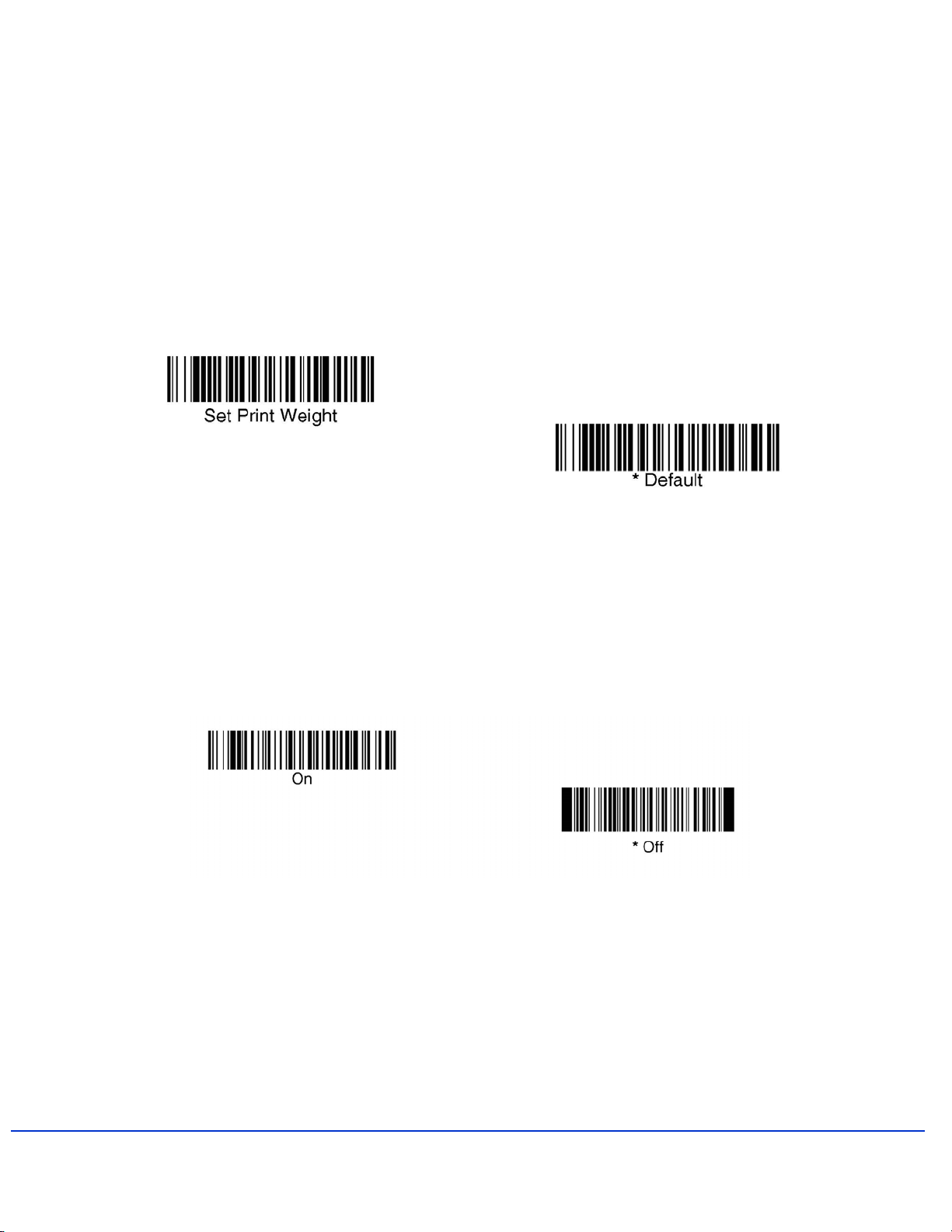

Print Weight

Print Weight is used to adjust the way the imager reads Matrix symbols. If a imager will be seeing

consistently heavily printed matrix symbols, then a print weight of 6 may improve the reading

performance. For consistently light printing, a print weight of 2 may help. After scanning the Set

Print Weight bar code, set the print weight (from 1-7) by scanning digits from Appendix D, then

scanning Save. Default = 4.

Video Reverse

Video Reverse is used to allow the imager to read bar codes that are inverted. The “Off” bar code

below is an example of this type of bar code. If additional menuing is required, Video Reverse must

be disabled to read the menu bar codes and then re-enabled after menuing is completed. Note:

Images downloaded from the unit will not be reversed. This is a setting for decoding only.

- 22 -

Page 23

- 23 -

Page 24

Data Editing

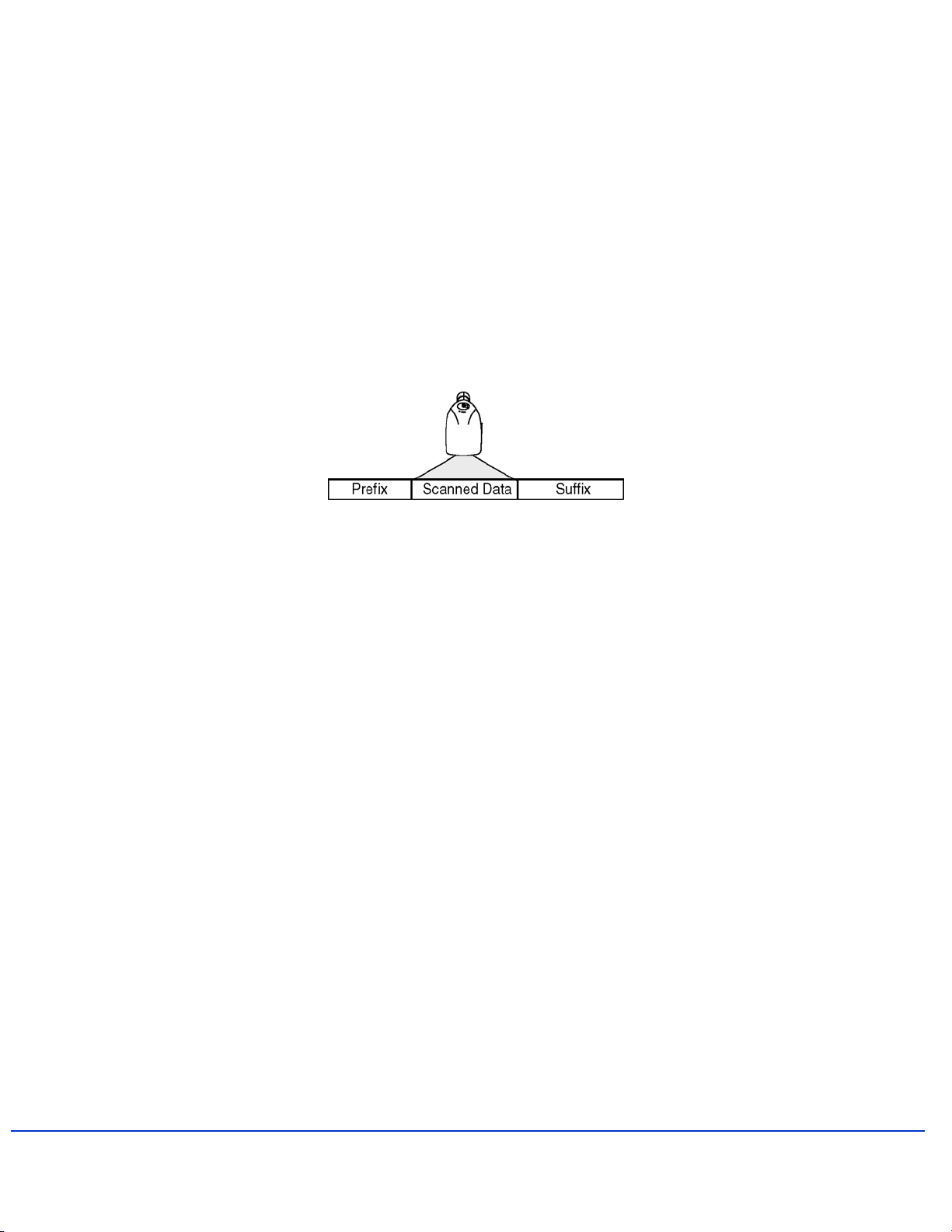

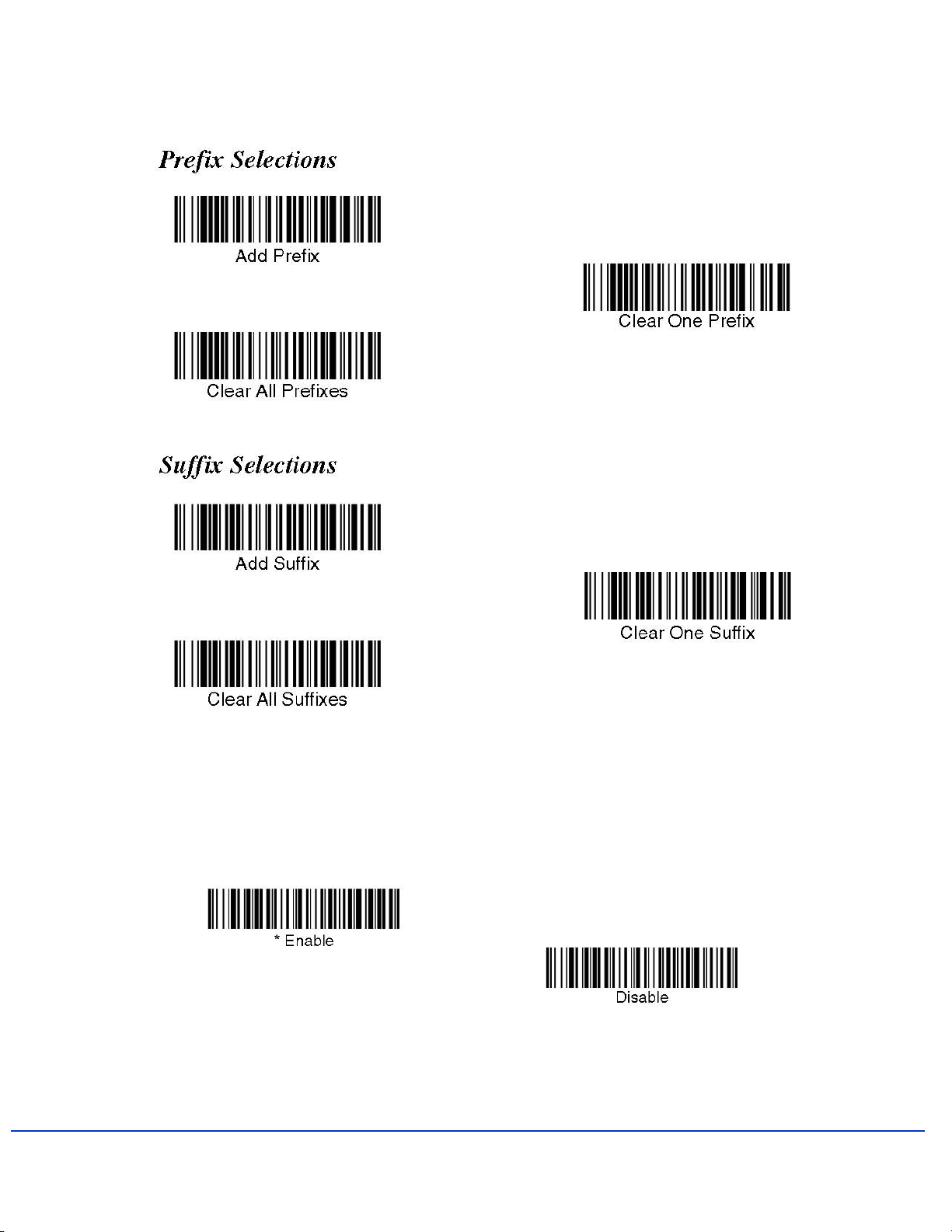

Prefix/Suffix Overview

When a bar code is scanned, additional information is sent to the host computer along with the bar

code data. This group of bar code data and additional, user-defined data is called a “message

string.” The selections in this section are used to build the user-defined data into the message

string.

Prefix and Suffix characters are data characters that can be sent before and after scanned data.

You can specify if they should be sent with all symbologies, or only with specific symbologies. The

following illustration shows the breakdown of a message string:

1-11 variable length 1-11 alpha numeric alpha numeric characters characters

Points to Keep In Mind

• It is not necessary to build a message string. The selections in this chapter are only used if

you wish to alter the default settings. Default prefix = None. Default suffix = None.

• A prefix or suffix may be added or cleared from one symbology or all symbologies.

• You can add any prefix or suffix from the ASCII Conversion Chart (Appendix B), plus Code I.D.

and AIM I.D.

• You can string together several entries for several symbologies at one time.

• Enter prefixes and suffixes in the order in which you want them to appear on the output.

To Add a Prefix or Suffix:

Step 1. Scan the Add Prefix or Add Suffix symbol

Step 2. Determine the 2 digit Hex value from the Symbology Chart (included in Appendix A) for

the symbology to which you want to apply the prefi x or suffix. For example, for Code 128, Code ID

is “j” and Hex ID is “6A”.

Step 3. Scan the 2 hex digits from the Programming Chart (Appendix D) or scan 9, 9 for all

symbologies.

Step 4. Determine the hex value from the ASCII Conversion Chart (Appendix B), for the prefix or

suffix you wish to enter.

Step 5. Scan the 2 digit hex value from the Programming Chart (Appendix D)

Step 6. Repeat Steps 4 and 5 for every prefix or suffix character.

Step 7. To add the Code I.D., scan 5, C, 8, 0.

To add AIM I.D., scan 5, C, 8, 1.

- 24 -

Page 25

To add a backslash (\), scan 5, C, 5, C.

Note: To add a backslash (\) as in Step 7, you must scan 5C twice

– once to create the leading backslash and then to create the

backslash itself.

Step 8. Scan Save to exit and save, or scan Discard to exit without saving. Repeat

Steps 1-6 to add a prefix or suffix for another symbology.

Example: Add a Suffix to a specific symbology

To send a CR (carriage return)Suffix for UPC only: Step 1. Scan Add Suffix.

Step 2. Determine the 2 digit hex value from the Symbology Chart for UPC.

Step 3. Scan 6, 3 from the Programming Chart Step 4. Determine the hex

value from the ASCII Conversion Chart , for the CR (carriage return). Step 5.

Scan 0, D from the Programming Chart Step 6. Scan Save, or scan Discard

to exit without saving.

To Clear One or All Prefixes or Suffixes:

You can clear a single prefix or suffix, or clear all prefixes/suffixes for a symbology. When you Clear One

Prefix (Suffix), the specific character you select is deleted from the symbology you want. When you Clear

All Prefixes (Suffixes), all the prefixes or suffixes for a symbology are deleted.

Step 1. Scan the Clear One Prefix or Clear One Suffix symbol.

Step 2. Determine the 2 digit Hex value from the Symbology Chart (included in Appendix A) for the

symbology from which you want to clear the prefix or suffix.

Step 3. Scan the 2 digit hex value from the Programming Chart in Appendix D of this manual or scan 9, 9 for

all symbologies.

Your change is automatically saved.

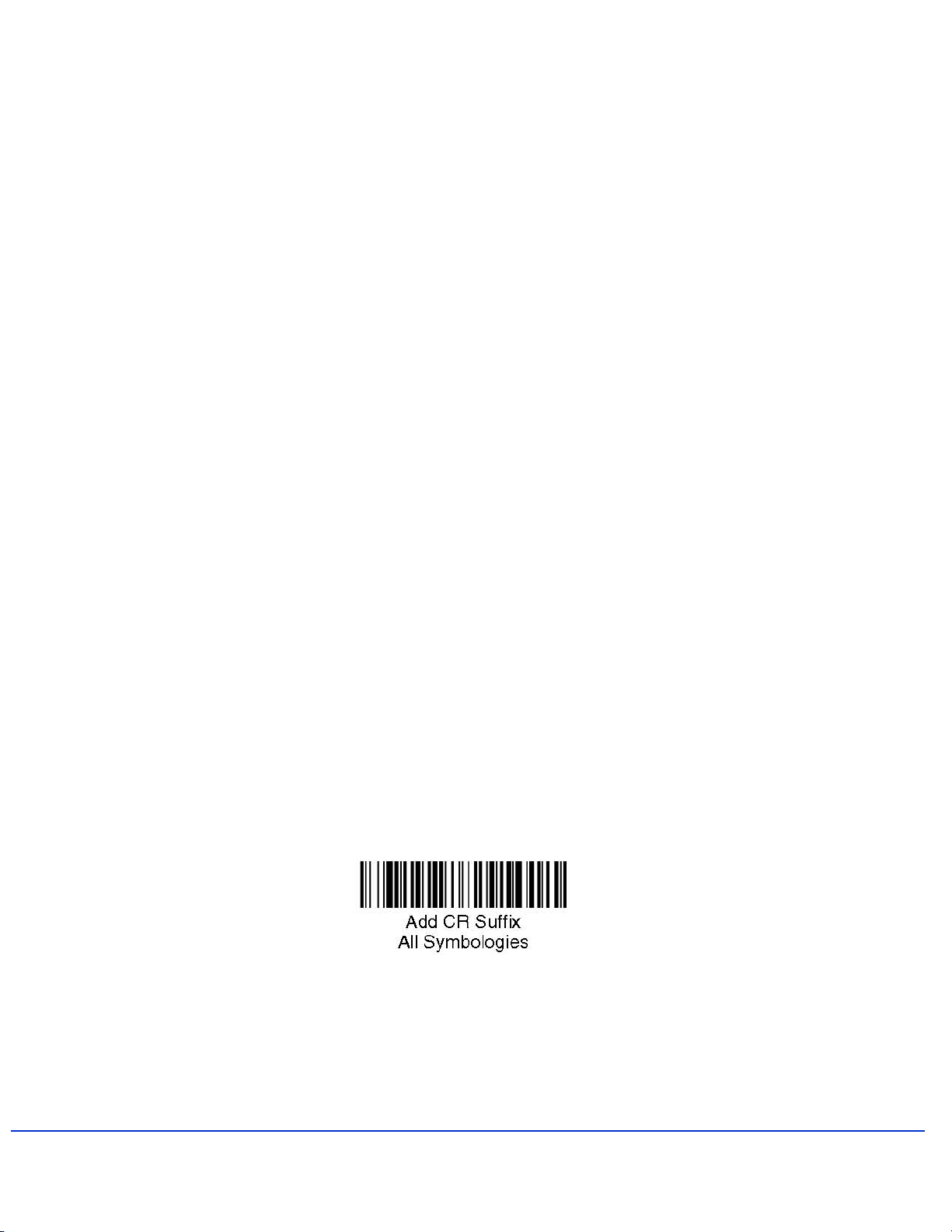

To Add a Carriage Return Suffix to all Symbologies

Scan the following bar code if you wish to add a carriage return suffix to all symbologies at once. T his action

first clears all current suffixes, then programs a carriage return suffix for all symbologies.

- 25 -

Page 26

Function Code Transmit

When this selection is enabled and function codes are contained within the scanned data, the imager

transmits the function code to the terminal. Default = Enable.

- 26 -

Page 27

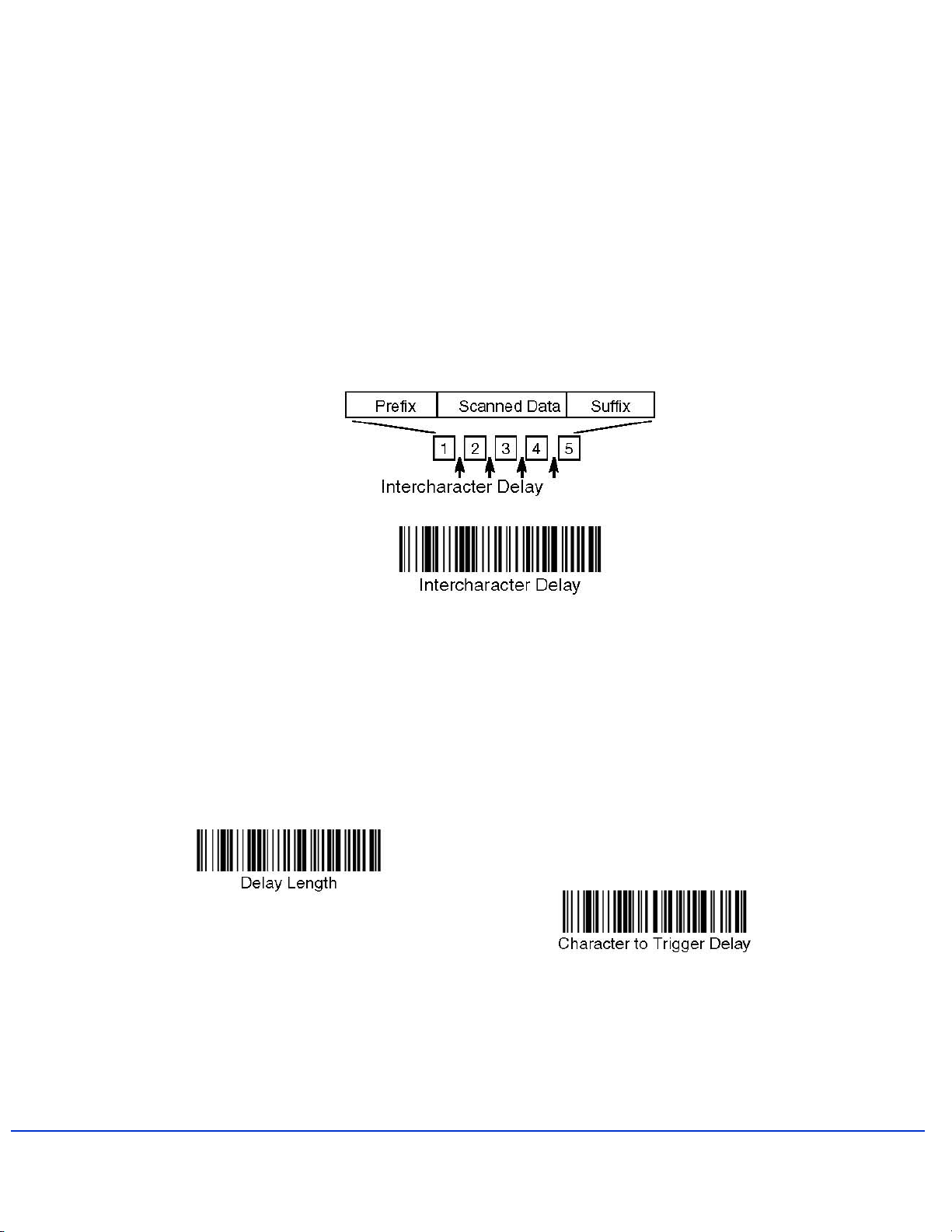

Intercharacter, Interfunction, and Intermessage Delays

Some terminals drop information (characters) if data comes through too quickly. Intercharacter,

interfunction, and intermessage delays slow the transmission of data, increasing data integrity.

Each delay is composed of a 5 millisecond step. You can program up to 99 steps (of 5 ms each)

for a range of 0-495 ms.

Intercharacter Delay

An intercharacter delay of up to 495 milliseconds may be placed between the transmission of each

character of scanned data. Scan the Intercharacter Delay bar code below, then scan the number

of milliseconds and the SAVE bar code using the Programming Chart (Appendix D)

To remove this delay, scan the Intercharacter Delay bar code, then set the number of steps to 0.

Scan the SAVE bar code using the Programming Chart (Appendix D).

User Specified Intercharacter Delay

An intercharacter delay of up to 495 milliseconds may be placed after the transmission of a

particular character of scanned data. Scan the Delay Length bar code below, then scan the

number of milliseconds and the SAVE bar code using the Programming Chart (Appendix D).

Next, scan the Character to Trigger Delay bar code, then the 2-digit hex value for the ASCII

character that will trigger the delay ASCII Conversion Chart (Appendix B).

To remove this delay, scan the Delay Length bar code, and set the number of steps to 0. Scan the SAVE

bar code using the Programming Chart (Appendix D).

- 27 -

Page 28

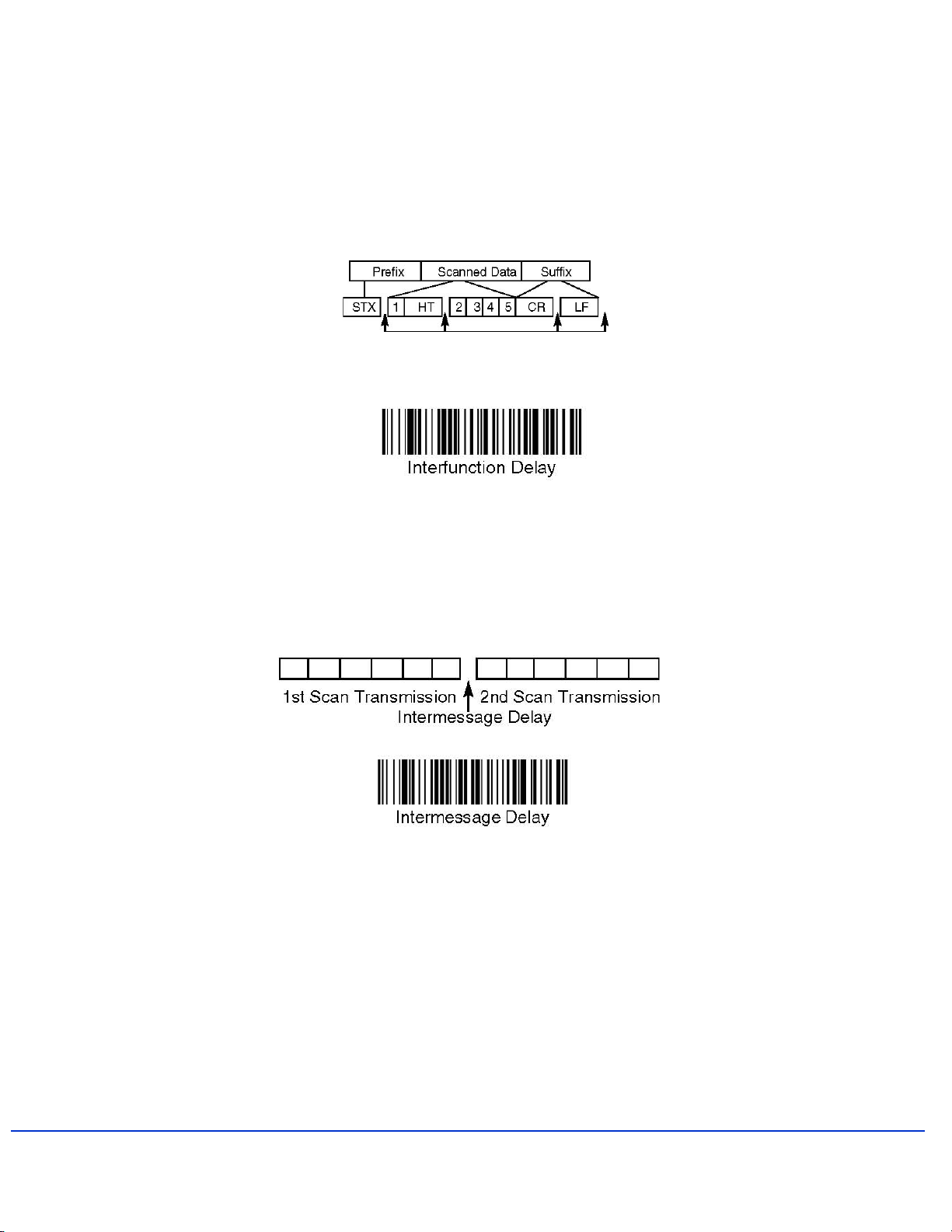

Interfunction Delay

An interfunction delay of up to 495 milliseconds may be placed between the transmission of each

segment of the message string. Scan the Interfunction Delay bar code below, then scan the

number of milliseconds and the SAVE bar code using the Programming Chart (Appendix D)

To remove this delay, scan the Interfunction Delay bar code, then set the number of steps to 0.

Scan the SAVE bar code using the Programming Chart (Appendix D).

Intermessage Delay

An intermessage delay of up to 495 milliseconds may be placed between each scan transmission.

Scan the Intermessage Delay bar code below, then scan the number of milliseconds and the

SAVE bar code using the Programming Chart (Appendix D).

Interfunction Delays

To remove this delay, scan the Intermessage Delay bar code, then set the number of steps to 0.

Scan the SAVE bar code using the Programming Chart (Appendix D).

- 28 -

Page 29

Data Formatting

Data Format Editor Introduction

You may use the Data Format Editor to change the imager’s output. For example, you can use the

Data Format Editor to insert characters at certain points in bar code data as it is scanned. The

selections in the following pages are used only if you wish to alter the output. Default Data Format

setting = None.

Normally, when you scan a bar code, it gets outputted automatically; however when you do a

format, you must use a “send” command (see Send Commands on page 28) within the format

program to output data.

Multiple formats may be programmed into the imager. They are stacked in the order in which they

are entered. However, the following list presents the order in which formats are applied:

1. Specific Term ID, Actual Code ID, Actual Length

2. Specific Term ID, Actual Code ID, Universal Length

3. Specific Term ID, Universal Code ID, Actual Length

4. Specific Term ID, Universal Code ID, Universal Length

5. Universal Term ID, Actual Code ID, Actual Length

6. Universal Term ID, Actual Code ID, Universal Length

7. Universal Term ID, Universal Code ID, Actual Length

8. Universal Term ID, Universal Code ID, Universal Length

If you have changed data format settings, and wish to clear all formats and return to the factory

defaults, scan the Default Data Format code.

To Add a Data Format

Step 1. Scan the Enter Data Format symbol.

Step 2. Primary/Alternate Format

Determine if this will be your primary data format, or one of 3 alternate formats. (Alternate

formats allow you “single shot” capability to scan one bar code using a different data

format. After the one bar code has been read, the imager reverts to the primary data

format. If you are programming the primary format, scan 0 using the Programming Chart

(Appendix D) If you are programming an alternate format, scan 1, 2, or 3, depending on

the alternate format you are programming.

Step 3. Terminal Type

Scan three numeric bar codes from Appendix D for your terminal ID: 0 0 0 = RS232,

Note: The wildcard for all terminal types is 0 9 9.

Step 4. Code I.D.

In Appendix A, find the symbology to which you want to apply the data format. Locate the

Hex value for that symbology and scan the 2 digit hex value from the Programming Chart

(Appendix D).

Step 5. Length

Specify what length (up to 9999 characters) of data will be acceptable for this symbology.

Scan the four digit data length from the Programming Chart (Appendix D). Note: 50

characters is entered as 0050. 9999 is a universal number, indicating all lengths.

Step 6. Editor Commands

Refer to Data Format Editor Commands. Scan the symbols that represent the command

you want to enter. 94 alphanumeric characters may be entered for each symbology data

format.

Step 7. Scan Save from the Programming Chart (Appendix D)

- 29 -

Page 30

Other Programming Selections

• Clear One Data Format This deletes one data format for one symbology. If you are clearing the

primary format, scan 0 from the Programming Chart (Appendix D). If you are clearing an alternate

format, scan 1, 2, or 3, depending on the alternate format you are clearing. Scan the Terminal

Type and Code I.D. and the bar code data length for the specific data format that you want to

delete. All other formats remain unaffected.

• Save from the Programming Chart. This exits, saving any Data Format changes.

• Discard from the Programming Chart. This exits without saving any Data Format changes.

Data Format Editor Commands

Send Commands

F1 Send all characters followed by “xx” key or function code, st arting from current cursor position. Syntax =

F1xx(xx stands for the hex value for an ASCII code, see ASCII Conversion Chart (Appendix B).

F2 Send “nn” characters followed by “xx” key or function code, starting from current cursor position. Syntax

= F2nnxx(nn stands for the numeric value (00-99) for the number of characters and xx stands for the

hex value for an ASCII code. See ASCII Conversion Chart (Appenix B).

F3 Send up to but not including “ss” character (Search and Send) starting from current cursor position,

leaving cursor pointing to “ss” character followed by “xx” key or function code. Syntax = F3ssxx(ss and

xx both stand for the hex values for ASCII codes, see ASCII Conversion Chart (Appendix B).

F4 Send “xx” character “nn” times (Insert) leaving cursor in current cursor position. Syntax = F4xxnn (xx

stands for the hex value for an ASCII code, see ASCII Conversion Chart (Appendix B) and nn is the

numeric value (00-99) for the number of times it should be sent.)

E9 Send all but the last “nn” characters, starting from the current cursor position. Syntax = E9nn (nn is

the numeric value (00-99) for the number of characters that will not be sent at the end of the

message.)

Move Commands

F5 Move the cursor ahead “nn” characters from current cursor position. Syntax = F5nn (nn stands for the

numeric value (00-99) for the number of characters the cursor should be moved ahead.)

F6 Move the cursor back “nn” characters from current cursor position. Syntax = F6nn (nn stands for the

numeric value (00-99) for the number of characters the cursor should be moved back.)

F7 Move the cursor to the beginning of the data string. Syntax = F7.

EA Move the cursor to the end of the data string. Syntax = EA

Search Commands

F8 Search ahead for “xx” character from current cursor position, leaving cursor pointing to “xx” character.

Syntax = F8xx (xx stands for the hex value for an ASCII code, see see ASCII Conversion Chart

(Appendix B)

F9 Search back for “xx” character from current cursor position, leaving cursor pointing to “xx” character.

Syntax = F9xx (xx stands for the hex value for an ASCII code, see see ASCII Conversion Chart

(Appendix B).

E6 Search ahead for the first non “xx” character from the current cursor position, leaving cursor pointing

to non “xx” character. Syntax = E6xx (xx stands for the hex value for an ASCII code, see ASCII

Conversion Chart (Appendix B).

E7 Search back for the first non “xx” character from the current cursor position, leavin g cursor pointing to

non “xx” character. Syntax = E7xx (xx stands for the hex value for an ASCII code, see ASCII

Conversion Chart (Appendix B).

Miscellaneous Commands

FB Suppress all occurrences of up to 15 different characters, starting at the current cursor position, as the

cursor is advanced by other commands. When the FC command is encountered, the suppress function

is terminated. The cursor is not moved by the FB command. Syntax = FBnnxxyy . .zz where nn is a

- 30 -

Page 31

count of the number of suppressed characters in the list and xxyy .. zz is the list of characters to be

suppressed. (xx stands for the hex value for an ASCII code, see ASCII Conversion Chart (Appendix B)

FC Disables suppress filter and clear all suppressed characters. Syntax = FC.

E4 Replaces up to 15 characters in the data string with user specified characters. Replacement continues

until the E5 command is encountered. Syntax = E4nnxx1xx2yy1yy2...zz1zz2 where nn is the total count

of both characters to be replaced plus replacement characters; xx1 defines characters to be replaced

and xx2 defines replacement characters, continuing through zz1 and zz2.

E5 Terminates character replacement. Syntax = E5.

FE Compare character in current cursor position to the character “xx.” If characters are equal, increment

cursor. If characters are not equal, no format match. Syntax = FExx (xx stands for the hex value for an

ASCII code, see ASCII Conversion Chart (Appendix B).

EC Check to make sure there is an ASCII number at the current cursor position. If character is not numeric,

format is aborted. Syntax = EC.

ED Check to make sure there is a non-numeric ASCII character at the current cursor position. If character

is numeric, format is aborted. Syntax = ED.

- 31 -

Page 32

- 32 -

Page 33

Symbologies

This programming section contains the following menu selections.

- 33 -

Page 34

All Symbologies

If you want to decode all the symbologies allowable for your imager, scan the All Symbologies On

code. If on the other hand, you want to decode only a particular symbology, scan All Symbologies

Off followed by the On symbol for that particular symbology.

Message Length Description

You are able to set the valid reading length of some of the bar code symbologies. If the data length

of the scanned bar code doesn’t match the valid reading length, the imager will issue an error beep.

You may wish to set the same value for minimum and maximum length to force the imager to read

fixed length bar code data. This helps reduce the chances of a misread.

EXAMPLE: Decode only those bar codes with a count of 9-20 characters. Min. length = 09

Max. length = 20 EXAMPLE: Decode only those bar codes with a count of 15

characters. Min. length = 15 Max. length = 15

For a value other than the minimum and maximum message length defaults, scan the bar codes

included in the explanation of the symbology, then scan the digit value of the message length and

Save bar codes on the Programming Chart (Appendix D). The minimum and maximum lengths and

the defaults are included with the respective symbologies.

- 34 -

Page 35

- 35 -

Page 36

Codabar Concatenation

Codabar supports symbol concatenation. When you enable concatenation, the imager looks for a Codabar

symbol having a “D” start character, adjacent to a symbol having a “D” stop character. In this case the two

messages are concatenated into one with the “D” characters omitted. Default = On.

Character Start Stop Start Stop

Select Require to prevent the imager from decoding a single “D” Codabar symbol without its companion.

This selection has no effect on Codabar symbols without Stop/Start D characters.

- 36 -

Page 37

Codabar Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 2-60.

Minimum Default = 4, Maximum Default = 60.

- 37 -

Page 38

- 38 -

Page 39

Code 39 Message Length

Scan the bar codes below to change the message length. Minimum and

Maximum lengths = 0-48. Minimum Default = 0, Maximum Default = 48.

Code 39 Append

This function allows the imager to append the data from several Code 39 bar codes together before

transmitting them to the host computer. When this function is enabled, the imager stores those

Code 39 bar codes that start with a space (excluding the start and stop symbols), and does not

immediately transmit the data. The imager stores the data in the order in which the bar codes ar e

read, deleting the first space from each. The imager transmits the appended data when it reads a

Code 39 bar code that starts with a character other than a space. Default = Off.

- 39 -

Page 40

Code 32 Pharmaceutical (PARAF)

Code 32 Pharmaceutical is a form of the Code 39 symbology used by Italian pharmacies. This

symbology is also known as PARAF.

Note: Trioptic Code must be turned off while scanning Code 32 Pharmaceutical codes.

- 40 -

Page 41

FULL ASCII

Full ASCII Code 39 decoding is enabled, certain character pairs within the bar code symbol will be

interpreted as a single character. For example: $V will be decoded as the ASCII character SYN,

and /C will be decoded as the ASCII character #. Default = On.

Character pairs /M and /N decode as a minus sign and period respectively. Character

pairs /P through /Y decode as 0 through 9.

NUL

%U

SOH

$A

STX

$B

ETX

$C

EOT

$D

ENQ

$E

ACK

$F

BEL

$G

BS

$H

HT

$I

LF

$J

VT

$K

FF

$L

CR

$M

SO

$N

SI

$O

DLE

SP SPACE 0 0 @ %V P P ‘ %W

$P

DC1

! /A 1 1 A A Q Q a +A

$Q

DC2

“ /B 2 2 B B R R b +B r +R

$R

DC3

# /C 3 3 C C S S c +C

$S

DC4

$ /D 4 4 D D T T d +D t +T

$T

NAK

% /E 5 5 E E U U e +E

$U

SYN

& /F 6 6 F F V V f +F

$V

ETB

‘ /G 7 7 G G W W g +G

$W

CAN

( /H 8 8 H H X X h +H

$X

EM

) /I 9 9 I I Y Y i +I

$Y

SUB

* /J : /Z J J Z Z j +J

$Z

ESC

+ /K ; %F K K [ %K k +K

%A

FS

, /L < %G L L \ %L l +L

%B

GS

- - = %H M M ] %M m +M

%C

RS

. . > %I N N ^ %N n +N

%D

US

/ /O ? %J O O

%E

_

%O o +O

p

+P

q

+Q

s

+S

u

+U

v

+V

w

+W

x

+X

y

+Y

z

+Z

{

%P

|

%Q

}

%R

~

%S

DEL

%T

- 41 -

Page 42

Interleaved 2 of 5 (or I 2 of 5)

Check Digit

No Check Digit indicates that the imager reads and transmits bar code data with or without a

check digit.

When Check Digit is set to Validate, but Don’t Transmit, the unit only reads Interleaved 2 of 5

bar codes printed with a check digit, but will not transmit the check digit with the scanned data.

When Check Digit is set to Validate and Transmit, the imager only reads Interleaved 2 of 5 bar

codes printed with a check digit, and will transmit this digit at the end of the scanned data. Default =

No Check Digit.

- 42 -

Page 43

Interleaved 2 of 5 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 2-80. Minimum

Default = 4, Maximum Default = 80.

- 43 -

Page 44

Code 93

Code 93 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 0-80. Minimum

Default = 0, Maximum Default = 80.

- 44 -

Page 45

Code 2 of 5

Code 2 of 5 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-48. Minimum

Default = 4, Maximum Default = 48.

- 45 -

Page 46

IATA Code 2 of 5

IATA Code 2 of 5 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-48. Minimum

Default = 4, Maximum Default = 48.

- 46 -

Page 47

Matrix 2 of 5

Matrix 2 of 5 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-80.

Minimum Default = 4, Maximum Default = 80.

- 47 -

Page 48

Code 11

Check Digits Required

This option sets whether 1 or 2 check digits are required with Code 11 bar codes. Default = T wo

Check Digits.

Code 11 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-80.

Minimum Default = 4, Maximum Default = 80.

- 48 -

Page 49

Code 128

ISBT 128 Concatenation

In 1994 the International Society of Blood Transfusion (ISBT) ratified a standard for communicating

critical blood information in a uniform manner. The use of ISBT formats requires a paid license.

The ISBT 128 Application Specification describes 1) the critical data elements for labeling blood

products, 2) the current recommendation to use Code 128 due to its high degree of security and its

space-efficient design, 3) a variation of Code 128 that supports concatenation of neighboring

symbols, and 4) the standard layout for bar codes on a blood product label. Use the bar codes

below to turn concatenation on or off. Default =Off.

- 49 -

Page 50

Code 128 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 0-80.

Minimum Default = 0, Maximum Default = 80.

- 50 -

Page 51

Telepen

Telepen Output

Using AIM Telepen Output, the imager reads symbols with start/stop pattern 1 and decodes them

as standard full ASCII (start/stop pattern 1). When Original Telepen Output is selected, the imager

reads symbols with start/stop pattern 1 and decodes them as compressed numeric with optional full

ASCII (start/stop pattern 2). Default = AIM Telepen Output.

Telepen Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-60.

Minimum Default = 1, Maximum Default = 60.

- 51 -

Page 52

UPC-A

UPC-A Check Digit

This selection allows you to specify whether the check digit should be transmitted at the end of the

scanned data or not. Default = On.

UPC-A Number System

The numeric system digit of a U.P.C. symbol is normally transmitted at the beginning of the

scanned data, but the unit can be programmed so it will not transmit it. Default = On.

- 52 -

Page 53

UPC-A Addenda

This selection adds 2 or 5 digits to the end of all scanned UPC-A data. Default = Off for both 2 Digit

and 5 Digit Addenda.

UPC-A Addenda Required

When Required is scanned, the imager will only read UPC-A bar codes that have addenda. You must then

turn on a 2 or 5 digit addenda. Default = Not Required.

UPC-A Addenda Separator

When this feature is on, there is a space between the data from the bar code and the data from

the addenda. When turned off, there is no space. Default = On.

UPC-A/EAN-13 with Extended Coupon Code

Use the following codes to enable or disable UPC-A and EAN-13 with Extended Coupon Code. Default =

On.

- 53 -

Page 54

UPC-E0

UPC-E0 Expand

- 54 -

Page 55

UPC-E0 Addenda Required

When Addenda Required is set to on, the imager will only read UPC-E bar codes that have

addenda. Default = Not Required.

UPC-E0 Addenda Separator

When this feature is on, there is a space between the data from the bar code and

the data from the addenda. When turned off, there is no space.

Default = On.

UPC-E0 Check Digit

Check Digit specifies whether the check digit should be tra nsmitted at the end of the scanned data or not.

Default = On.

- 55 -

Page 56

EAN/JAN-13

- 56 -

Page 57

- 57 -

Page 58

ISBN Translate

This selection causes EAN-13 Bookland symbols to be translate d into their equivalent ISBN number f ormat.

Default = Off.

EAN/JAN-8

- 58 -

Page 59

- 59 -

Page 60

- 60 -

Page 61

- 61 -

Page 62

- 62 -

Page 63

- 63 -

Page 64

- 64 -

Page 65

Code 49 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-81. Minimum

Default = 1, Maximum Default = 81.

- 65 -

Page 66

PDF417

PDF417 Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-2750.

Minimum Default = 1, Maximum Default = 2750.

- 66 -

Page 67

MicroPDF417

- 67 -

Page 68

UPC/EAN Version

Scan the UPC/EAN Version On bar code to decode EAN•UCC Composite symbols that have a

UPC or EAN linear component. (This does not affect EAN•UCC Composite symbols with a

UCC/EAN-128 or RSS linear component.)

EAN•UCC Composite Code Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-

2435. Minimum Default = 1, Maximum Default = 2435.

- 68 -

Page 69

EAN•UCC Emulation

The imager can automatically format the output from any EAN•UCC data carrier to emulate what

would be encoded in an equivalent UCC/EAN-128 or RSS and Composite symbol. EAN•UCC data

carriers include UPC-A and UPC-E, EAN-13 and EAN-8, ITF-14, UCC/EAN-128, and EAN•UCC

RSS and Composites. Data from 2D symbols such as Aztec Code, Data Matrix, or QR Code,

which encode a leading FNC1, also invoke EAN•UCC emulation. If UCC/EAN-128 Emulation is

selected, the AIM Symbology Identifier is reported as “]C1”. If RSS Emulation is selected, the AIM

Symbology Identifier is reported as “]e0.” Any application that accepts EAN•UCC data can be

simplified since it only needs to recognize one data carrier type. Default = No Emulation.

TCIF Linked Code 39 (TLC39)

This code is a composite code since it has a Code 39 linear component and a MicroPDF417

stacked code component. All bar code readers are capable of reading the Code 39 linear

component. The MicroPDF417 component can only be decoded if TLC39 On is selected. The

linear component may be decoded as Code 39 even if TLC39 is off.

- 69 -

Page 70

Postal Symbologies

Postal Codes

Note: For best performance when reading a postal s ymbolog y, all oth er po stal s ymbologi es shoul d be

turned off.

- 70 -

Page 71

- 71 -

Page 72

China Post

China Post Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 0-80.

Minimum Default = 4, Maximum Default = 80.

- 72 -

Page 73

Korea Post

Korea Post Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 2-80.

Minimum Default = 4, Maximum Default = 48.

- 73 -

Page 74

2D Matrix Symbologies

QR Code

QR Code Message Length

Scan the bar codes below to change the message length. Minimum and Maximum

lengths = 1-3500. Minimum Default = 1, Maximum Default = 3500.

- 74 -

Page 75

Data Matrix

Data Matrix Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-1500.

Minimum Default = 1, Maximum Default = 1500.

- 75 -

Page 76

MaxiCode

MaxiCode Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-150.

Minimum Default = 1, Maximum Default = 150.

- 76 -

Page 77

Aztec Code

Aztec Code Message Length

Scan the bar codes below to change the message length. Minimum and Maximum lengths = 1-3750.

Minimum Default = 1, Maximum Default = 3750.

Aztec Runes

Select En able Runes if you are scanning Aztec runes, which are the smallest type of Aztec Code s ymbol

with the ability to encode a very short license plate message.

- 77 -

Page 78

OCR Programming

- 78 -

Page 79

OCR

Default All OCR Settings turns off all OCR capability in the imager, so the imager will be able to scan

linear, stacked, matrix, and composite bar codes, but not OCR fonts. In addition, any OCR templates you

have created are erased. The 8 digit default templates are reinstated for any future use of the OCR On

codes listed below.

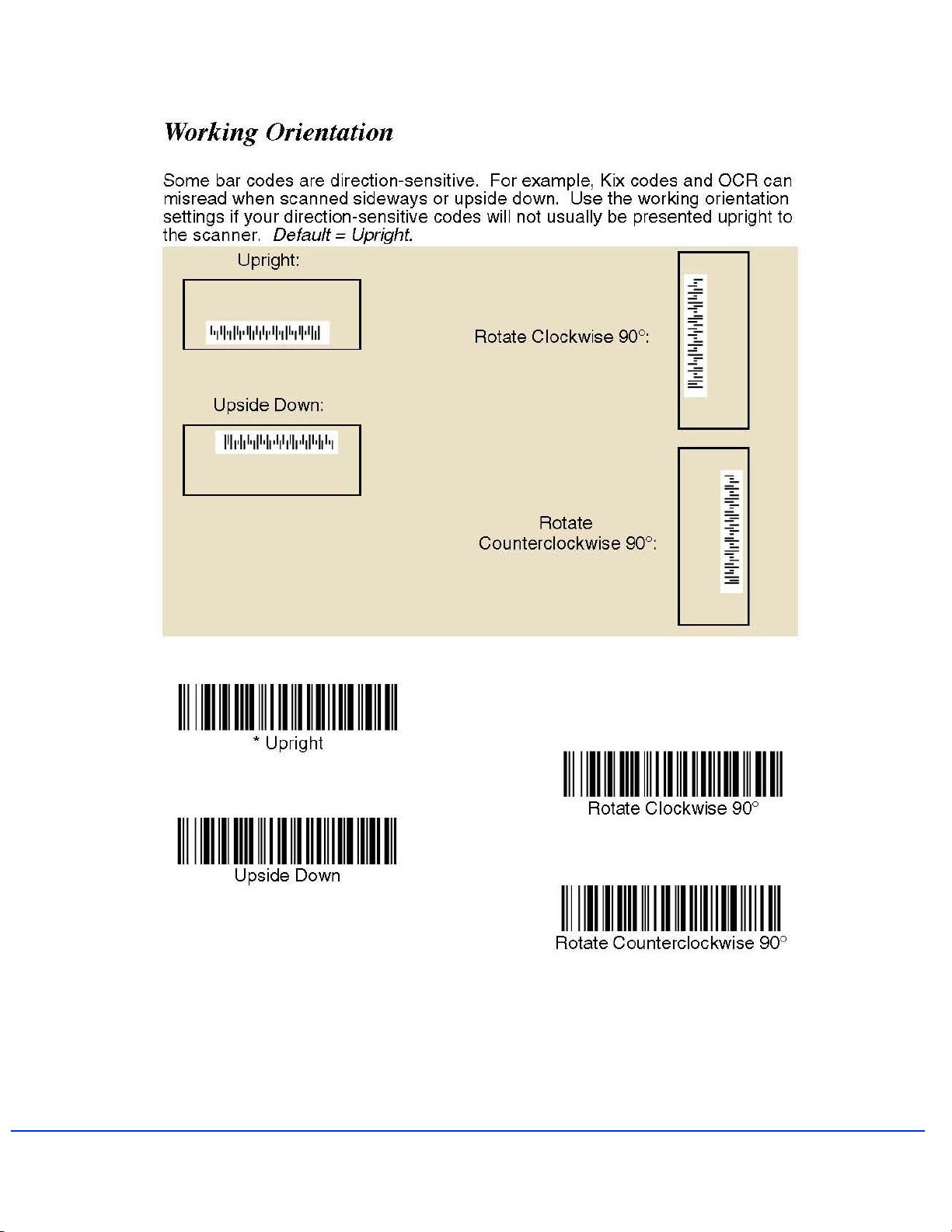

OCR

Note: OCR symbols can misread when scanned sideways or upside down. Use Working Orientation if your

OCR symbols will not usually be presented upright to the scanner.

Only one OCR symbology can be read at a time.

OCR-A On allows you to scan characters in the OCR-A font. The default setting allows you to scan any 8

digit combination. If you have created an OCR template, character combinations that fit the template can be

scanned (see Creating an OCR Template, page 82).

OCR-B On allows you to scan characters in the OCR-B font. The default setting allows you to scan any 8

digit combination. If you have created an OCR template, character combinations that fit the template can be

scanned (see Creating an OCR Template, page 82).

- 79 -

Page 80

U.S. Currency

U.S. Currency On allows you to scan characters in the font used on U.S. currency. The default setting

allows you to scan any 8 digit combination. If you have created an OCR template, character combinations

that fit the template can be scanned.

MICR E13 B

MICR E13 B On allows you to scan MICR characters on a bank check. The default setting allows you to

scan any 8 digit combination. If you have created an OCR template, character combinations that fit the

template can be scanned.

SEMI Font

SEMI Font On allows you to scan the SEMI font used in the semiconductor industry.

All OCR Off turns off all OCR capability in the imager, so the imager will be able to scan linear, stacked,

matrix, and composite bar codes, but not OCR fonts. However, any OCR templates you have created will

be retained in memory.

- 80 -

Page 81

Creating OCR Templates

You can create a custom “template,” or character string that defines the length and content of OCR strings

that will be read with your imager. There are several choices when creating a custom template for your

application. You can create a template for a single format, you can string together several formats, and you

can create a template for a user-defined variable. These choices are described in deta il below.

Creating an OCR Template

A single template allows you to program the imager to read any combination of characters in the order you

specify. Refer to examples that follow the Template Characters table below.

Template Characters

a represents any alphanumeric character (digit or letter)

c represents a check character position

d represents any digit

e represents any available OCR character

g represents character from user-defined variable “g”

h represents character from user-defined variable “h”

l represents any uppercase letter

t marks the start of a new template

r multi row indicator

All other characters represent themselves. Spaces can be used.

To Add an OCR Template

1. Begin building the template. Scan the Enter OCR Template symbol.

2. Scan the characters for the string. Use the Template Characters chart above to determine what

characters you need to create your format. Use the OCR Programming Chart (after the Sample

Codes in Appendix D) to scan the characters for your template.

Example A: You need to read any combination of 8 digits. The template would be:

dddddddd

To create this template, you would scan the Enter OCR Template symbol, then scan the d from the

OCR Programming Chart after the Sample Codes (in Appendix D) 8 times. Scan Save OCR Template.

This would let you read any string of 8 digits, for example:

37680981

3. Character Match Sequences On the ASCII Conversion Chart (Appendix B), find the Hex value that

represents the character(s) you want to match. Use the Programming Chart (Appendix D) to scan the

numbers that represent these characters.

Example B: You need to read 3 digits, 3 specific characters (ABC), 3 digits. The template would be:

ddd414243ddd

- 81 -

Page 82

}

hex codes for

letters A, B, and C

To create this template, you would scan the Enter OCR Template symbol, scan the d from the Sample

Symbols (see Appendix D) 3 times, scan 414243 from Appendix D (the hex characters for “A,” “B,” and

“C”), then scan the d from Appendix D 3 more times. Scan Save OCR Template. This would let you read

any string of 3 digits, “ABC,” then any string of 3 digits, for example:

551ABC983

4. Adding Spaces You may also need to put spaces in your template.

Example C: You need to read 3 digits, space, 3 specific characters (ABC), space, 3 digits. The template

would be:

ddd2041424320ddd

hex code for a space

To create this template, you would scan the Enter OCR Template symbol, scan the d from the OCR

Programming Chart after the Sample Codes in the back of this manual 3 times, scan 2041424320 from the

Programming Chart in Appendix D (the hex characters for “space,” “A,” “B,” “C,” “space”), then scan the d

from Appendix D 3 more times. Scan Save OCR Template (page 80). This would let you read any string of

3 digits, space, “ABC,” space, then any string of 3 digits, for example:

551 ABC 983

Note: If using Quick*View to program, use the space bar to designate a space and not the hex value of 20.

5. Exit OCR Template Editor Scan Save OCR Template to save your entries. Discard OCR Template exits

without saving any OCR Template changes.

Stringing Together Multiple Formats (Creating “Or” Statements)

You may want to program the imager to accept many OCR formats. To do this, you would string together

each format with a “t.” This tells the imager to read optical characters that match any one of the formats in

the template.

Example D: You need to read any combination of 8 digits, ora combination of 4 digits, 2 upp ercase

letters, and 2 digits. The template would be:

ddddddddtddddlldd

To create this template, you would scan the Enter OCR Template symbol (page 80), scan the d from the

OCR Programming Chart after the Sample Codes in the back of this manual 8 times, then scan the t to

create the “or” statement. Then you would scan the characters for the 2nd template. Scan the d 4 times,

scan l 2 times, then scan d 2 more times. Scan Save OCR Template (page 80). This would let you read

either type of format, for example:

99028650

or

- 82 -

Page 83

9902XZ50

You can string together as many templates as you need.

Creating a User-Defined Variable

You can create up to two of your own user variables for an OCR template. These variables will represent

any OCR readable characters. The user-defined variables are stored under the letters “g” and “h.” Crea ting

a user variable follows the same steps as creating a template, but instead of scanning the Enter OCR

Template symbol, you scan the Enter User-Defined Variable symbol . The letters g and h can then be

used in an OCR template to define the variable you specified.

Example E: You need a variable to represent the letters “A,” “B,” or “C.” The template for this variable

would be:

414243

To create the template, you would scan the Enter User-Defined Variable g symbol. Scan 414243 from

Appendix D (the hex characters for “A,” “B,” and “C”). Scan Save OCR Template. This will let you read

either A or B or C in any position where you place the g. For example, you could create the following

template:

ddddddggg

This template would then let you read data that began with 6 digits, and had an A, B, or C trailing. So you

would be able to read:

654321ABC

or

654321BAC

or

654321CCC

Reading Multi-Row OCR

The OEM Engine is capable of decoding multi-row OCR text. Consider the following example. This example

shows serial commands as would be entered using Quick*View.

Example G: You need to read multiple rows of OCR data as shown below:

12345678 ABCDEFGH

To read the first row of OCR data, you would menu the following template:

OCRTMP"dddddddd".

This template is the default OCR template. If you wanted to read the sec ond line of dat a, you would us e

the following template:

OCRTMP"llllllll".

To read both lines of OCR at one time, use the variable rto indicate the start of a new row. All of the other

templating variables for the individual rows work the same as previously described. For instance, in the

above example, you would use the following template to read both rows:

OCRTMP"ddddddddrllllllll".

To read the three rows below, you would use the template command

"OCRTMP"ddddddddrllllllllrlllldddd".

- 83 -

Page 84

Adding an OCR Check Character

You may want to print and verify a check character in order to enhance the security of your OCR

application. The OEM Engine can be programmed for almost any type of check character. A number of

presets are provided for common check character uses (e.g., modulo 10 and modulo 36).

Scan the OCR Modulo 10 or OCR Modulo 36 Check Character bar code to specify the type of check

character used in the OCR strings you’re scanning. The imager will then only read OCR character strings

with a valid check character. The OEM Engine transmits the OCR data without the check character data.

You must specify the location of the check character in the template with a c.

Example F: You need to read any combination of 7 digits, with a modulo 10 check chara cter in the 8th

position. The template would be:

dddddddc

To create this template, you would scan the Modulo 10 Check Character symbol. Then scan the Enter

OCR Template symbol, scan the d from Appendix D 7 times, and scan the c once. Scan Save OCR

Template. This template will let you read any combination of 6 digits with a correct check character after.

(If the check character is invalid, the imager will issue an error beep.) For example, the following string

could be scanned:

01234569

and the output would be: 0123456

OCR Modulo 10 Check Character

Scan this symbol to program the OCR template for a simple modulo 10 checksum of the digits 0

through 9.

- 84 -

Page 85

OCR Modulo 36 Character Set

Scan this symbol to program the OCR template for a simple modulo 36 checksum of

the digits 0 through 9 and the letters A through Z.

OCR Modulo 36 Check Character

OCR Template Codes

Note: Reading more than three rows of OCR is not recommended. Contact the factory if you have an

application that requires reading 4 or more rows of OCR.

One or more two-digit numbers and Save are required after reading this programming symbol. Refer to

†

the Programming Chart in Appendix D of this manual.

Exit Selections

- 85 -

Page 86

To Add a Test Code I.D. Prefix to All Symbologies

This selection allows you to turn on transmission of a Code I.D. before the decoded symbolog y.

(See the Symbology Chart, included in the Appendix A, for the single character code that identifies

each symbology.) This action first clears all current prefixes, then programs a Code I.D. prefix for

all symbologies. This is a temporary setting that will be removed when the unit is power cycled.

Show Software Revision

Scan the bar code below to output the current software revision, unit serial number, and other product

information.

Show Data Format

Scan the bar code below to show current data format settings.

Resetting the Standard Product Defaults

If you aren’t sure what programming options are in your imager, or you’ve changed some options a nd want

the standard product default settings restored, scan the Standard Product Default Settings bar code

below.

- 86 -

Page 87

Test Menu

When you scan the Test Menu On code, then scan a programming code in this manual, the imager displays

the content of a programming code. The programming function will still occur, but in addition, the content of

that programming code is output to the terminal.

Note: This feature should not be used during normal imager operation.

Quick*View

Quick*View is a Microsoft Windows program that displays decoded symbol messages and captures

images (for instance, ID photographs) from the OEM Engine. Bar code information and images are

displayed in the Quick*View window.

Temporary Quick*View Configuration

For a quick download communication configuration, scan the Quick*View bar code and t he imager will be

temporarily configured for Quick*View settings.

Note: Scan the bar code below and the unit will communicate in RS-232 mode, allowing it to work with

Quick*View. To convert the imager back to the original settings, cycle the power.

- 87 -

Page 88

APPENDIX A: Symbology Chart

Symbology AIM ID

All Symbologies

Australian Post

Aztec Code

British Post

Canadian Post

China Post

Codabar

Codablock F

Code 11

Code 128

Code 16K

Code 32 Pharmaceutical (PARAF)

Code 39

Code 49

Code 93 and 93i

Data Matrix

EAN- 13

EAN- 8

EAN•UCC Composite

EAN-13 with Extended Coupon Code ]E3

]X0

]zm 0-9, A-C z (0x7A)

]X0

]X0

]X0

]Fm 0-1 a (0x61)

]Om 0, 1, 4, 5, 6 q (0x71)

]H3

]Cm 0, 1, 2, 4 j (0x6A)

]Km 0, 1, 2, 4 o (0x6F)

]X0

]Am 0, 1, 3, 4, 5, 7 b (0x62)

]Tm 0, 1, 2, 4 l (0x6C

]Gm

]dm 0-6 w (0x77)

]E0

]E4

]em 0-3 y (0x79)

Possible AIM

ID Modifiers

(m)

0-9, A-Z, a-m

HHP Code

ID (hex)

(0x99)

A (0x41)

B (0x42)

C (0x43)

Q (0x51)

h (0x68)

< (0x3C)

i (0x69

d (0x64)

D (0x44)

d (0x64)

Interleaved 2 of 5

Japanese Post

KIX (Netherlands) Post

Korea Post

Matrix 2 of 5

MaxiCode

]lm 0, 1, 3 e (0x65)

]X0

]X0

]X0

]X0

]Um 0-3 x (0x78)

J (0x4A)

K (0x4B)

? (0x3F)

m (0x6D)

Symbology AIM ID

MICR E 13 B ]ZE

MicroPDF417

MSI

OCR-A

OCR-B

OCR US Money Font

SEMI Font

PDF417

Planet Code

]Lm 3-5 R (0x52)

]Mm 0 g (0x67)

]o1

]o2

]o3

]o3

]Lm 0-2 r (0x72)

]X0

Possible AIM

ID Modifiers

(m)

HHP Code

ID (hex)

“ (0x22)

O (0x4F)

O (0x4F)

O (0x4F)

O (0x4F)

L (0x4C)

- 88 -

Page 89

Plessey Code

PosiCode

Postnet

QR Code

Reduced Space Symbology (RSS-

14, RSS Limited, RSS Expanded)

Straight 2 of 5 IATA (two-bar start/

stop)

TCIF Linked Code 39 (TLC39)

Telepen

Trioptic Code

UCC/EAN-128

UPC-A

UPC-A with Extended Coupon Code

UPC-E

VeriCode

]P0

]pm 0, 1, 2 W (0x57)

]X0

]Qm 0-6 s (0x73)

]em 0 y (0x79)

]Rm 0, 1, 3 f (0x66)

]L2

]Bm 0, 1, 2, 4 t (0x74)

]X0

]C1

]E0

]E3

]E0

]X0

n (0x6E)

P (0x50)

T (0x54)

= (0x3D)

I (0x49)

c (0x63)

c (0x63)

E (0x45)

v (0x76)

Note: “m” represents the AIM modifier character. Refer to International Technical Specification, Symbology

Identifiers, for AIM modifier character details.

Note: Prefix/Suffix entries for specific symbologies override the universal (All Symbologies, 99) entry.

Refer to Data Editing and Data Formatting for information about using Code ID and AIM ID.

- 89 -

Page 90

APPENDIX B: ASCII Conversion Chart

Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex Char

0 00 NUL 32 20

SOH 33 21 !

STX 34 22 “

ETX 35 23 #

EOT 36 24 $

ENQ 37 25 %

ACK 38 26 &

BEL 39 27 ‘

BS 40 28 (

HT 41 29 )

0A LF 42 2A *

0B VT 43 2B +

0C FF 44 2C ,

0D CR 45 2D 0E SO 46 2E .

0F SI 47 2F /

10 DLE 48 30 0

11 DC1 49 31

12 DC2 50 32

13 DC3 51 33

14 DC4 52 34

15 NAK 53 35

16 SYN 54 36

17 ETB 55 37

18 CAN 56 38

19 EM 57 39

1A SUB 58 3A :

1B ESC 59 3B ;

1C FS 60 3C <

1D GS 61 3D =

1E RS 62 3E >

1F US 63 3F ?

64 40 @ 96 60 ‘

65 41 A 97 61 a

66 42 B 98 62 b

67 43 C 99 63 c

68 44 D 100 64 d

69 45 E 101 65 e

70 46 F 102 66 f

71 47 G 103 67 g

72 48 H 104 68 h

73 49 l 105 69 i

74 4A J 106 6A j

75 4B K 107 6B k

76 4C L 108 6C l

77 4D M 109 6D m

78 4E N 110 6E n

79 4F O 111 6F o

80 50 P 112 70 p

81 51 Q 113 71 q

82 52 R 114 72 r

83 53 S 115 73 s

84 54 T 116 74 t

85 55 U 117 75 u

86 56 V 118 76 v

87 57 W 119 77 w

88 58 X 120 78 x

89 59 Y 121 79 y

90 5A Z 122 7A z

91 5B [ 123 7B {

92 5C \ 124 7C |

93 5D ] 125 7D }

94 5E ^ 126 7E ~

95 5F

_

127 7F

- 90 -

Page 91

APPENDIX C – Sample Symbols

- 91 -

Page 92

- 92 -

Page 93

APPENDIX D – Programming Charts

- 93 -

Page 94

APPENDIX D – Programming Charts

- 94 -

Page 95

APPENDIX D – Programming Charts

- 95 -

Page 96

SICK AG | Waldkirch | Germany | www.sick.com

8012076/2007-04 ∙ HaWa <PM6.5/Word/PDF>/VD ∙ Printed in Germany ∙ Subject to change without notice ∙ The specified product features and technical data do not represent any guarantee ∙ 05 Pre int61

Australia

Phone +61 3 9497 4100

1800 33 48 02 – tollfree

E-Mail sales@sick.com.au

Belgium/Luxembourg

Phone +32 (0)2 466 55 66

info@sick.be

E-Mail

Brasil

Phone +55 11 3215-4900

sac@sick.com.br

E-Mail

Ceská Republika

Phone +420 2 57 91 18 50

sick@sick.cz

E-Mail

China

Phone +852-2763 6966

ghk@sick.com.hk

E-Mail

Danmark

Phone +45 45 82 64 00

sick@sick.dk

E-Mail

Deutschland

Phone +49 211 5301-270

info@sick.de

E-Mail

España

Phone +34 93 480 31 00

info@sick.es

E-Mail

France

Phone +33 1 64 62 35 00

info@sick.fr

E-Mail

Great Britain

Phone +44 (0)1727 831121

info@sick.co.uk

E-Mail

India

Phone +91–22–4033 8333

E-Mail info@sick-india.com

Israel

Phone +972-4-999-0590

info@sick-sensors.com

E-Mail

Italia

Phone +39 02 27 43 41

info@sick.it

E-Mail

Japan

Phone +81 (0)3 3358 1341

E-Mail support@sick.jp

Nederlands

Phone +31 (0)30 229 25 44

info@sick.nl

E-Mail

Norge

Phone +47 67 81 50 00

austefjord@sick.no

E-Mail

Österreich

Phone +43 (0)22 36 62 28 8-0

office@sick.at

E-Mail

Polska

Phone +48 22 837 40 50

info@sick.pl

E-Mail

Republic of Korea

Phone +82-2 786 6321/4

kang@sickkorea.net

E-Mail

Republika Slowenija

Phone +386 (0)1-47 69 990

office@sick.si

E-Mail

România

Phone +40 356 171 120

office@sick.ro

E-Mail

Russia

Phone +7 495 775 05 34

info@sick-automation.ru

E-Mail

Schweiz

Phone +41 41 619 29 39

contact@sick.ch

E-Mail

Singapore

Phone +65 6744 3732

admin@sicksgp.com.sg

E-Mail

Suomi

Phone +358-9-25 15 800

sick@sick.fi

E-Mail

Sverige

Phone +46 10 110 10 00

info@sick.se

E-Mail

Taiwan

Phone +886 2 2365-6292

sickgrc@ms6.hinet.net

E-Mail

Türkiye

Phone +90 216 587 74 00

info@sick.com.tr

E-Mail

USA/Canada/México

Phone +1(952) 941-6780

1 800-325-7425 – tollfree

E-Mail info@sickusa.com

More representatives and agencies

in all major industrial nations at

www.sick.com

Loading...

Loading...