Page 1

GM

901

CO

Monitor

Н

О

£

р

о

05

SICK

Page 2

GM

901

Introduction

Product

Information

Introduction

Conformities

^

Conforms

to

EMC

specifications pursuant

to EN

50081-1/EN

50082-2

^

CE

certification pursuant

to EC

Guideline

EMC

89/336

EWG and

NSP

72/23/EWG

*•

VDE

Guidelines pursuant

to EN

61010

(IEC

1010-1,

VDE

0411),

class

of

protection

1,

degree

of

protection

IP 65

^

Prototype

tested

by

TUV,

Report

No.

502/0741/96-20

081 751

*•

SICK

AG

Environmental Monitoring

is

certified

to ISO

9001.

Purpose

of

this

Document

This

"Product Information" describes

all of the

procedures required

to

mount

and

install

the GM

901.

The

document

is

intended

to

help

you

plan

your

project

and

prepare

the

meas-

uring point before

the

device

is

delivered.

Among

other things,

the

document contains important information

on:

>•

Areas

of

application

of the GM 901

^-

Features

^

Input

and

output

options

>•

Installation instructions

for

project planning

and

mounting

the GM 901 at the

measuring point

^-

Prerequisites

for

mounting

and

connecting

the

device

>•

Overview

of the

installation activities

^-

Calibrating

the

system

(zero

calibration)

^-

Overview

of the

technical

data

and

dimensioned

drawings

of the GM 901

components

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 3

F

GM

901

Contents

Product

Information

Contents

1

Overview

.....................................................

4

1.1

Benefits

of the

GM

901

......................................

4

1.2

Applications

................................................

4

1.3

Standard

Components

.......................................

5

1.4

Accessories/Options

.........................................

6

1.4.1

Accessories

for the GM 901

...........................

7

1.4.2

Options

..............................................

8

2

Instructions

for

Project Planning

................................

9

2.1

Checklist

...................................................

9

2.2

Installation Sequence

.......................................

10

3

Preparations

for

Installation

..................................

.11

3.1

Preparations

for

Mounting

..................................

11

3.1.1

Installation Proposal

..................................

11

3.1.2

Instructions

for

Mounting

the

Flange with Pipe

...........

11

3.1.3

Installation

on

Steel Ducts

............................

12

3.1.4

Installation

on

Brick Ducts

.............................

12

3.1.5

Installation

on

Thin-Walled Ducts

.......................

12

3.1.6

Auxiliary Pipe

for

Measuring

Paths

of

Less

than

2m

......

13

3.1.7

Aligning

the

Flange with

the

Optical Alignment

Aid

.........

13

3.2

Preparations

for

Electrical Installation

.........................

14

3.2.1

Wiring Specifications/Interfaces

to the

Evaluation

Unit

.....

14

3.2.2 Connection Unit (Accessory)

...........................

15

3.2.3 Purge-Air Unit (Option)

................................

16

4

Preparations

for

Startup

.....................................

.17

4.1

Zero

Calibration

............................................

17

4.2

SPAN

Test (Option)

.........................................

17

4.2.1 Test

Cells

...........................................

17

4.2.2 Calculating

the

Test Values

............................

18

5

Technical Data

.............................................

.19

5.1

Device Data

...............................................

19

5.1.1

Accessories

.........................................

20

5.1.2

Options

.............................................

20

5.2

Dimensioned Drawings

......................................

21

5.2.1

Transmitter

and

Receiver

.............................

21

5.2.2 Evaluation Unit

......................................

22

5.2.3

Purge-Air

Unit

........................................

23

5.2.4

Air

Filter Assembly

...................................

23

P

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 4

GM

901

Overview

Product

Information

тттттнвияяитвтттяятшттвнияаятш£:

_____________тт!т1штттшпттттттттттмтяштттттишшят

1

Overview

l.±

Benefits

of the

GM

9O1

^-

CO

analyzer:

GM 901

measures

the CO

content directly

in the gas

duct.

^

Bus

capability: using

a CAN

bus,

the

evaluation unit

can be

mounted

at a

distance

of up to

1000 m from

the

measuring point, e.g.

in the

control room.

^-

Easy

to

mount

and

connect.

>

Short startup time

- to

install

the

optical units

and

switch

on the

power supply.

^-

User-friendly

operation

by

means

of

function

buttons

on the

evaluation

unit:

- for

settings

the

display

and

output functions

- for

configuring

the

device parameters

^

Low

maintenance

requirements,

no

test

gases

required.

*•

Variable measurement value output:

ppm,

mg/m3,

or

mg/Nm3.

^

Measurement value, measuring range,

and

limit values

are

visible

on the

display.

Additional temperature display

and

plain text information

on the

operating mode.

>

Integrated diagnosis function. Diagnosis data

can be

called

up for

warnings

and

error messages.

±.2

Applications

The

GM 901 is

designed

for

instant

and

no-contact monitoring

of the CO

concen-

tration,

for

example,

for

process control purposes

in the

following areas:

^-

Power stations

>

Coal

processing plants

^-

Refuse incineration plants

^

Plants

in the

cement industry

>•

Paper industry

^-

Pharmaceutical industry

>

Melting/steel

industry

^

Glass industry

^

Chemical industry

^

Food industry

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 5

GM901

Overview

Product

Information

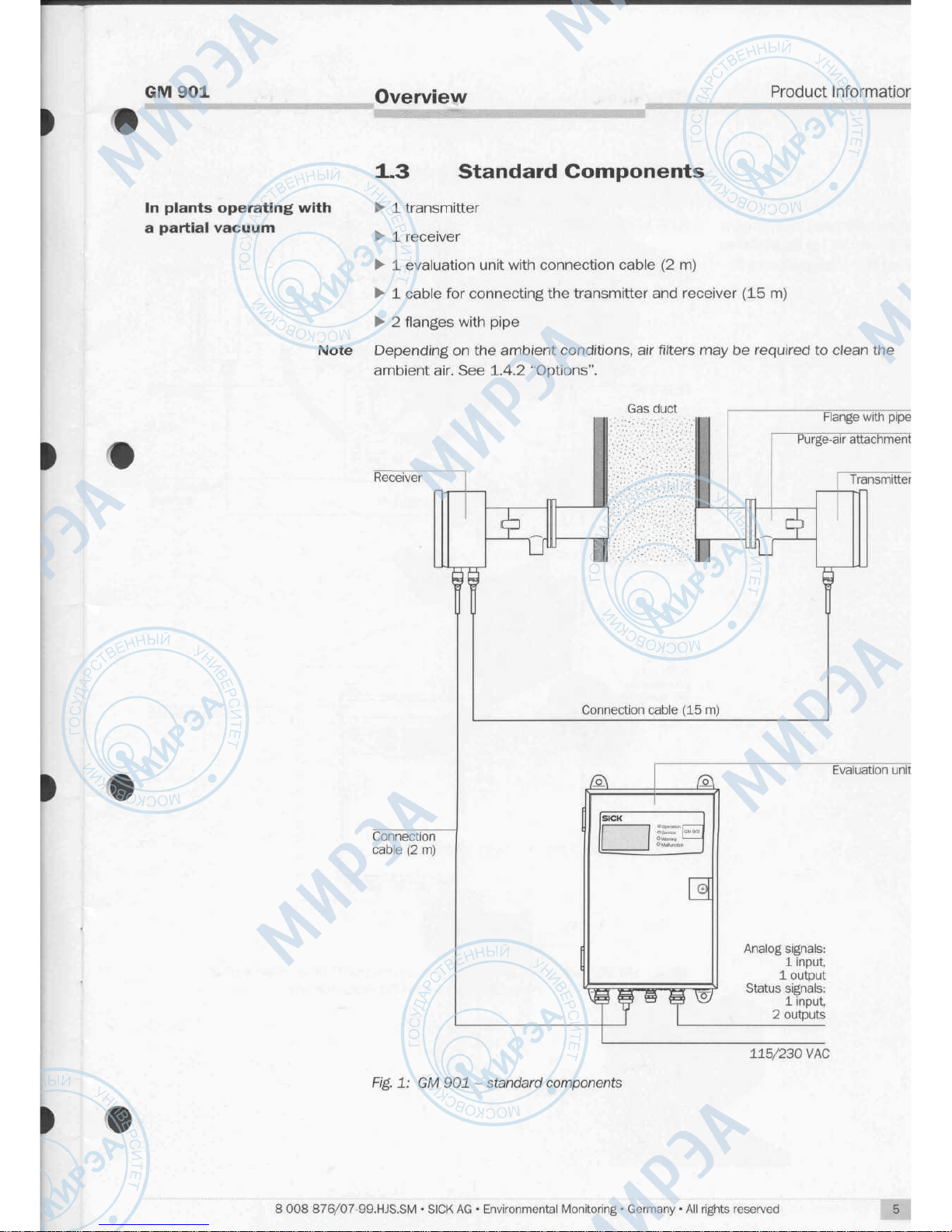

In

plants

operating

with

a

partial

vacuum

±.3

Standard Components

>• 1 transmitter

^ 1 receiver

^ 1 evaluation unit with connection cable

(2

m)

> 1 cable

for

connecting

the

transmitter

and

receiver

(15 m)

^- 2 flanges

with pipe

Note

Depending

on the

ambient

conditions,

air

filters

may be

required

to

clean

the

ambient air.

See

1.4.2 "Options".

Gas

duct

Connection

cable

(2 m)

Connection cable

(15 m)

©

Fig.

1:

GM

901 -

standard

components

Flange with pipe

L

Purge-air attachment

Л

Transmitter

Evaluation unit

Analog signals:

1

input,

1

output

Status

signals:

1

input,

2

outputs

115/230

VAC

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 6

GM901

Overview

Product

Information

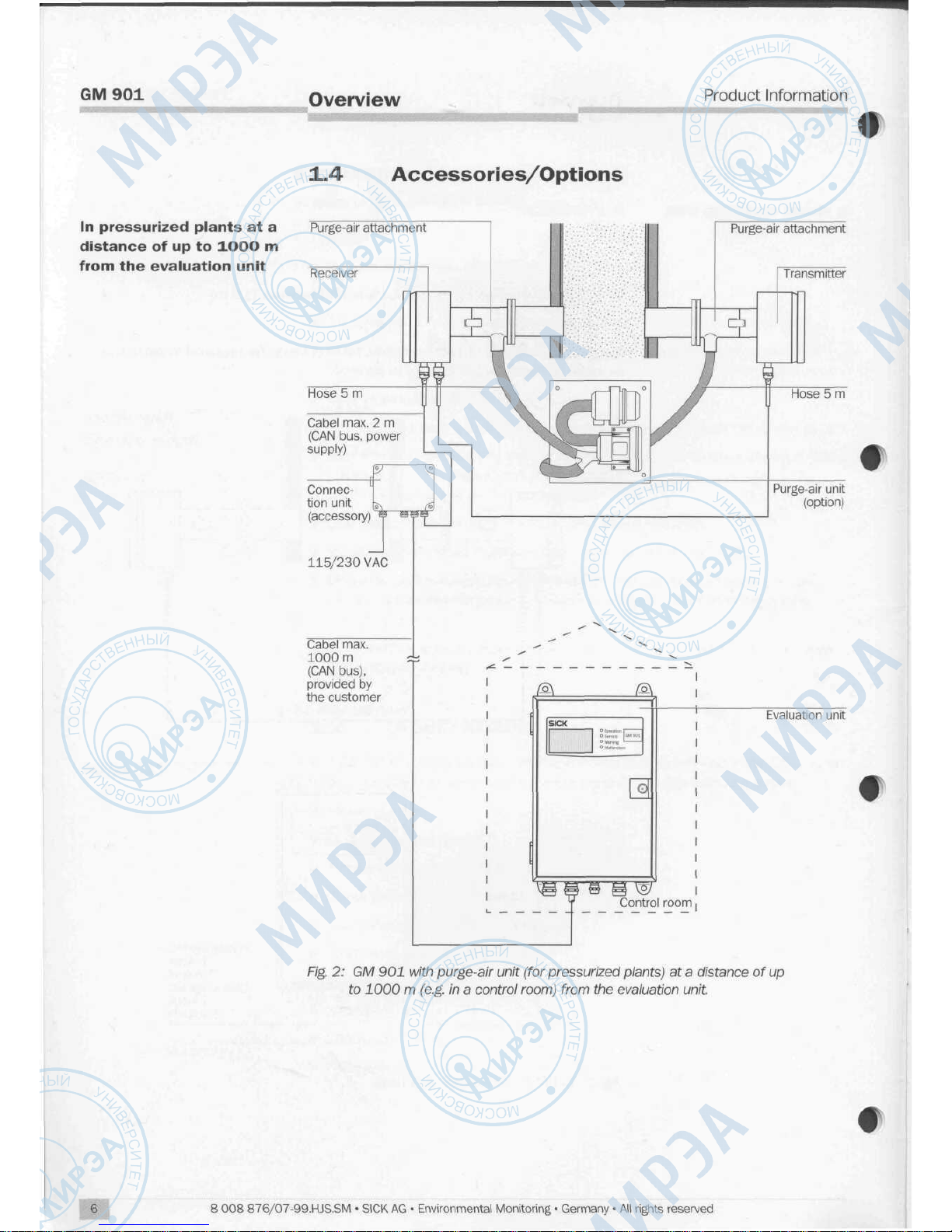

In

pressurized plants

at a

distance

of up to

±OOO

m

from

the

evaluation unit

±.4

Accessories/Options

Purge-air

attachment

Receiver

A

У

г

Purge-air

attachment

A

Transmitter

Hose

5 m

Cabel

max.

2 m

(CAN

bus,

power

supply)

Connec-

tion unit

(accessory)"

115/230

VAC

Purge-air unit

(option)

Cabel

max.

1000m

(CAN

bus),

provided

by

the

customer

©

Control

room

Evaluation

unit

f

Fig.

2: GM 901

with purge-air unit (for pressurized plants)

at a

distance

of up

to

1000 m (e.g.

in a

control room) from

the

evaluation unit.

8 008

876/07-99.HJS.SM • SICK

AG • Environmental Monitoring • Germany

• All

rights reserved

Page 7

GM901

Overview

Product

Informatior

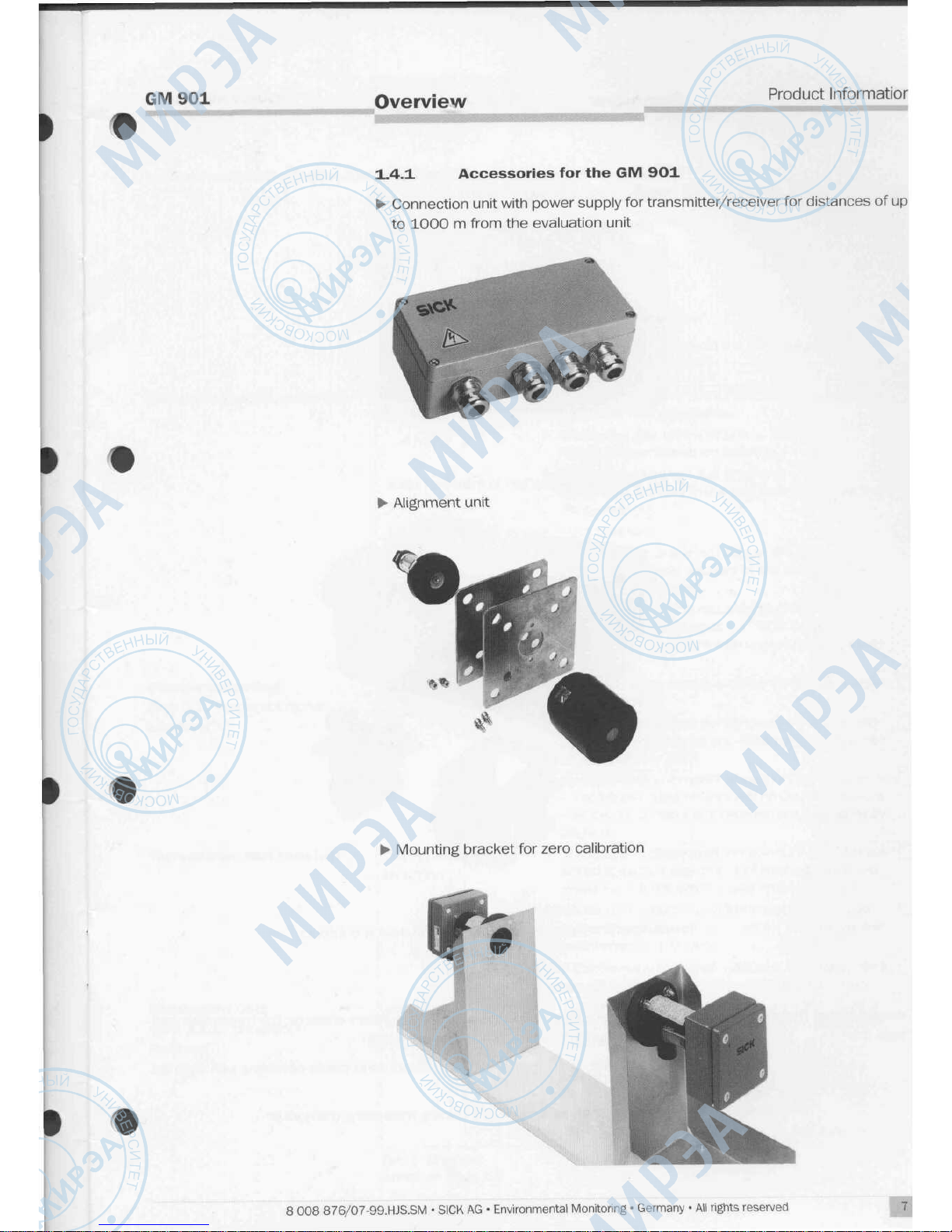

1.4.1

Accessories

for the

GM

9O1

Connection unit with power supply

for

transmitter/receiver

for

distances

of up

to

1000 m from

the

evaluation

unit

Alignment

unit

Mounting

bracket

for

zero

calibration

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 8

GM901

Overview

Product

Information

f

Cover

plate with seal

for

covering

the

duct apertures when

the

transmitter

and

receiver

are

replaced

CO

test

cell with bracket

in

transport case

Weatherproof

covers

for

mounting

the

device outdoors

Dimensioned

Drawings,

Page

21

1.4.2

Options

Purge-air

unit

for

protecting

the

optical boundary areas

on the

transmitter

and

receiver

from dirt (including connection hose)

-

Air

filter

assembly

for

cleaning

the

ambient

air in

plants operating with a partial

vacuum

PT

100

temperature sensor including measuring transducer

f

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 9

GM901

Instructions

for

Project

Planning

Product

Informatior

2

Instructions

for

Project

Planning

2.±

Checklist

See

also Chapter 3 "Preparations

for

Installation".

Check

the

following conditions

by

ticking

the box in the

third column.

I

Check

Measuring

point

selection

Field

service

!

conditions

Flange

mounting

(see

3.1

"Preparations

for

Mounting")

!

Mounting

location

Transmitter

and

receiver

Duct walls

Evaluation

unit

(see

3.1.1.

"Installation

Proposal")

Duct

aperture

selection

Installation

site

Tab.

1:

Checklist

(contd.

on

Page

10)

Measure

The

gas flow in the

vicinity

of the

measuring point

should

be

homogeneous.

Measuring

gas

temperature: s 300

°C;

higher temperatures

on

request.

Dust concentration:

< 1

g/m3 x m

A

high dust content

in the gas

duct

can

impair

the

measurement.

Duct

pressure:

• A

purge-air

unit

is not

required

if

there

is a

constant partial vacuum

in the

duct.

Air

filter

set

recommended.

• A

purge-air unit

is

required

in

pressurized

plants. Please consult

the

SICK

Customer

Service department with regard

to the

correct

fan

type.

Steel ducts:

the

device

is

designed

for

installation

in

steel

ducts.

Brick

or

thick-walled ducts: modified

flange

with

pipe

required.

Can be

provided

by the

customer

or

designed

by

SICK.

Suitable reinforcements

or

support constructions

must

be

provided

on

thin-walled ducts

to

ensure

that

the

transmitter

and

receiver

are

permanently

aligned.

The

size

and

position

of the

aperture must

be

sel-

ected

in

such

a way

that sufficient space

is

pro-

vided

for the

transmitter

and

receiver.

Some

of the

duct insulation must

be

removed

and

sufficient space provided

for

installation

and

maintenance activities.

If the

device

is

mounted outdoors, sufficient space

should

be

provided

for the

weatherproof

cover.

The

unit

should

be

installed

at a

position

that

is

freely accessible. Max. distance from transmitter

and

receiver:

-

standard:

2 m

-

with extension cable:

17 m

-

For

cable

lengths

up to

1000

m:

with

connection unit (accessory)

The

unit should

be

mounted

on a flat

surface.

п

п

In

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 10

GM901

Instructions

for

Project

Plannmg

Product

Information

Purge-air

unit

(option)

Mounting

platform

Check

Measure

Installation site

!

Ambient conditions

Installation

Accident

prevention

Tab.

1:

Checklist

The

purge-air supply must

be

installed

at an

equal

distance

from

the

transmitter

and

receiver

to

ensure that

the air flows

uniformly.

Sufficient space should

be

provided

for

replacing

the filter set and

dust collector.

If

the

unit

is

mounted outdoors, sufficient space

should

be

provided

for

installing/removing

the

weatherproof

cover.

The

temperature

of the

purge

air

entering

the

duct

must

not

fall below

the dew

point.

If

neces-

sary,

the

purge

air

must

be

heated

(SICK

heaters

are

recommended).

"temperature"of

the

intake

air:"6~°C"<~T

< 55

°C.

If

Т < О °С,

heat

the

purge air.

The

intake purge

air

should

be

free

of

dust.

П

-

Height

of

platform: approx.

1.5 m below

the

inten-

ded

location

for the

transmitter

and

receiver.

-

Lighting

and a

power supply should

be

installed

at

the

measuring point

to

facilitate servicing.

All

of the

device

components

should

be

safely

accessible.

Always

observe

the

national accident prevention

regulations!

П

2.2

Installation

Sequence

1.

Step:

Carry

out all of the

planning

activities

(see

2.1

"Checklist")

2.

Step:

Mount

the flange for the

transmitter

and

receiver

at the

measuring

point

3.

Step:

Check

the

wiring

at the

site using

the

wiring specifications (see

3.2.1 "Wiring Specifications/Interfaces

to the

Evaluation

Unit")

4.

Step:

Lay the

cables

and

signal leads

5.

Step:

Check

all the

connections (see

3.2

"Preparations

for

Electrical

In-

stallation")

6.

Step:

In

pressurized plants: mount

the

(optional) purge-air unit

and

check

whether

it is

functioning correctly

7.

Step:

Mount

the

evaluation unit

8.

Step:

Mount

the

transmitter

and

receiver

9.

Step:

If the

cable between

the

receiver

and

evaluation unit

is

longer than

17 m:

install

the

connection unit (accessory)

10.

Step:

If the

devices

are

installed outdoors: mount

the

weatherproof

covers

f

10

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 11

GM901

Preparations

for

Installation

Product

Informatior

3

Preparations

for

Installation

3.1

Preparations

for

Mounting

3.±.1

Installation

Proposal

HI——Measuring

distance-—

Flange-flange

Flange

with

pipe

ArrangementX

~|ч

of

stud bolts x«4Fi

(shown

rota-

ted

through

45°)

Steel

pipe

50x5

DIN

2391

(Mounting

position

marking

Fig.

3:

Installation

proposal

for GM 901

with

mounting

flange

and

purge-air

unit

(optional)

3.1.2

Instructions

for

Mounting

the

Flange

with

Pipe

In

the

description that

follows,

the

term

"flange"

is

used

to

refer

to the flange

with

pipe

The

standard

flange

supplied

by

SICK

has a

total length

of 130 mm and an

oute

diameter

of 76 mm.

>

Mount

the flange in

such

a way

that

the

axes

are

aligned.

The

angular dis-

placement must

be

less than

1°.

Suitable reinforcements

or

support

construe

tions must

be

provided

on

thin-walled ducts.

>

The

pipe stubs

on the flange

should protrude into

the

duct

by

approx.

30 mm

The

pipe stubs must also

be

adapted

if

necessary.

^ A suitable auxiliary pipe

can be

used

to

align

the

flange

for

measuring dis-

tances that

are

easily accessible

(up to 2 m).

(The inner diameter

of

standarc

flanges

is

70.2

± 1

mm.)

>

The

optical alignment

aid

(accessory) must

be

used

for

longer measuring

patl

or

measuring paths that

are

difficult

to

access.

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

11

Page 12

GM901

Preparations

for

Installation

Product

Information

3.1_3

Installation

on

Steel

Ducts

1=130,240,

or

500mm

Mounting

position marking

Arrangement

of

stud

bolts

(shown

rotated

through 45°)

Fig.

4:

Steel

duct

30

3.1.4

Installation

on

Brick

Ducts

On

brick ducts,

the

flange must

be

welded

to a

suitable retaining plate (provided

by

the

customer) mounted

on the

duct.

500mm

Mounting position marking

^Т^ТоГ^ч.

j^

1

"*")

^^.

/^Ж^^^^^У\

У'~"

<

-<_v> /

/

Arrangement

of

\

stud bolts

\

(shown

rotated

Vati

through

45°)

*ЦЩ

$~

k

J

1

—

i

h

E3

^

-

-^

\

у

у

Q

«.

^

С

Sl^

X™

aua'i

30

(0

5:

Brick

duct

3.±.5

Installation

on

Thin-Walled

Ducts

On

thin-walled ducts

or at

locations subject

to

vibrations, reinforcement must

be

provided

in the

form

of

junction plates.

Mounting

position marking

12

Fig.

6:

Junction plates

8

008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 13

GM901

Preparations

for

Installation

Product

Information

3.3-6

Auxiliary Pipe

for

Measuring

Paths

of

Less than

2 m

An

auxiliary pipe should

be

used

to

help mount

the

standard flange.

I

Fig.

7:

Mounting

the

flange with

an

auxiliary pipe

*

Arrangement

of

stud

bolts

(shown

rotated

through 45°)

3.1.7

Aligning

the

Flange

with

the

Optical

Alignment

Aid

A

suitable auxiliary pipe

can be

used

to

align

the flange for

measuring paths that

are

easily accessible

(up to 2 m).

(The inside diameter

of

standard

flanges is

70.2

± 1

mm.) When using

the

optical alignment aid, align

the

light source

and

the

adjustment

tube

as

shown

in the figure

below.

I

Light

source

Flange

1

О

Flange 2 Adjustment tube

Fig.

8:

Mounting

the

flange with

the

optical alignment

aid

*

Arrangement

of

stud bolts

(shown

rotated

through 45°)

Note

When carrying

out the

zero calibration, make sure that

the

mounting bracket

is

installed

at a

distance equal

to the

(flange-flange)

measuring path.

^-

Align

flange 1 in

such a way

that

the

light spot from

the

light source

is

centered

on

the

target

of the

adjustment tube. Tack-weld

flange 1.

^-

Place

the

adjustment

aid on flange 2.

*•

Align

and

tack-weld

flange 2.

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

13

Page 14

GM901

Preparations

for

installation

Product

Information

SICK

О

Operation 1 —————

О

Service

GM

901

O

Warning ' —————

О

Malfunction

3.2

Preparations

for

Electrical Installation

All

installation

and

final wiring activities must

be

carried

out by the

customer,

un-

less otherwise agreed with SICK.

3.2.1

Wiring Specifications/Interfaces

to the

Evaluation Unit

The

conductor

and

jacket material

as

well

as the

insulating coverings must

be

selected

in

accordance with

the

conditions

at the

site.

Analog

out

Digital

out

0...20

mA 48 V

AC/DC

100

Digital

in

30VA.1A

max.

5 V/2 mA

CAN

bus

Temp. Maintenance

CO

Malfunction Limit value

Power

supply

Inputs

and

outputs

CAN

bus

interface

Power

supply

Temperature input

3

wires; cross-section:

0.75

to 2.5

mm

2

Cable

diameter:

6 to 12 mm

Conduit

thread

13.5

CAN

bus

interface

Inputs

and

outputs

Max.

bus

length:

1000

m

Wires:

2x2

plus shield; cross-section:

up

to 500 m

>

0.25

mm2,

up to

1000

m

>

0.75

mm

2

Cable

diameter:

6 to 10 mm

Conduit

thread

12

Digital input, active

<;

500

Q,

relay

Analog output

0 to 20 mA,

max.

load

500

Q

Outside

diameter

of

cable:

6 to 12 mm

Conduit thread

13.5

Temperature input

Analog

input

0 to 20 mA;

sense resistor

100

Q

2

wires plus shield

Outside

diameter

of

cable:

4 to 8 mm

Conduit

thread

9

Fig.

9:

Cable specifications

and

interfaces

to the

evaluation unit

8

008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 15

GM901

Preparations

for

Installation

Product

Information

,

t

3.2.2

Connection

Unit

(Accessory)

The

connection unit

is

required

to

connect

the

evaluation unit

and

receiver

over

distances

> 17

m.

The

unit provides

the

power supply

to the

sensors

and

con-

nects

the CAN

bus.

The

connection unit

is

mounted

at the

receiver with a standard

2 m

cable.

When installing

the

connection unit, disconnect

the

power supply

to the

receiver

at

the

evaluation unit

and

connect

it to the

connection unit.

Operating

voltage

setting

115

V/230

V

230

V

=

or

P^/N/LL

Fuse

2.5

ДГ

1

'

250V

Connection

to

Connection

to

evaluation

unit

GM 901

receiver

Power

supply

CAN

bus

interface

i t

Power

supply

115

V/230

V AC

Conduit thread 13.5

CAN

bus

interface

(Connection

to

evaluation unit)

Max.

bus

length 1000

m

Wires:

2x2

plus

shield,

cross-section:

up

to 500 m

a

0.25

mm2,

up to

1000

m

Cable

diameter:

6 to 10 mm

Conduit thread 13.5

0.75

mm

2

t

Fig.

10:

Connection

unit

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

15

Page 16

GM901

Preparations

for

Installation

Product

Information

Power

supply

3.2.3 Purge-Air

Unit

(Option)

The

three-phase a.c. motor

of the

type

2BH1300

fan is

connected

to the 3 L-

conductors

LI,

L2, and L3. The

rated voltage

of the

motor

in the

running connec-

tion

must

be

equal

to

that

of the

phase-to-phase

voltage

of the

system

(oper-

ating

voltage).

Motors with a winding construction

for 230 V

(A)/400 V (Y)

can be

used

if

they

are

started directly

and if a

suitable circuit

is

provided

on the

terminal board

for

230 V or 400 V.

U2

V1

W2

W1

V

IE

/2

U2 V

I

ft,

1

Ivi

?PE

Low

pressure monitor

W2

U2 V2

q~

_n

nU1О

V1

о

W1

о

РЕ

L1

L2

L3

РЕ

L.

Й

24V

Fig.

11:

Electrical connections

of the

purge-air unit

16

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 17

GM

901

.___

_

Preparations

for

Startup

Product

Information

4

Preparations

for

Startup

•

4.1

Zero

Calibration

A

zero calibration must

be

carried

out on the GM 901

before

the

device

is put

into operation

for the

first

time

or

before

it

resumes operation.

A

СО-free environment

is

required

for the

zero calibration.

The

calibration

can

also

be

carried

out

directly

at the

measuring

point

if the

plant

is

shut

down

and

the

duct

is

free

of CO.

If a

zero calibration

is not

possible

at the

measuring point,

it

must

be

carried

out

with

the

transmitter

and

receiver

at the

mounting brackets.

Optical

axis

Reveiver

Mounting

bracket

Transmitter

Mounting

bracket

-Level

surface :„

Fig.

12:

Mounting

bracket

(accessory)

for

zero

calibration

Note

If

purge-air attachments

are

also used

on the

mounting brackets,

the

transmitter

and

receiver should

be

attached using

the

quick-release locks.

i

•

4.2

SPAN Test (Option)

4.2.1

Test

Cells

The

following

test

cells

are

available

^

250

ppm

x

m

^

750 ppm x m

^

4000

ppm x m

^

10000

ppm

x m

Other concentrations

can

also

be

supplied

on

request.

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights reserved

Page 18

GM

901

Preparations

*or

Startup

Product Information

4.2.2

Calculating

the

Test

Values

The

test

concentration (test cell value)

is

calculated using

the

following

formula*:

TV

[ppm

x

m]

= MR

[ppm]

x x x S

[m]

TV = Test value

MR = Upper measurement range limit

x = Position

of the

test

point

S = Measuring distance

Example:

Upper

measuring range limit

MR = 1500

ppm

Measuring distance

S =

4m

Test point

at 70% of MR x= 0.7

TV

[ppm

x m] = MR

[ppm]

x x x S [m]

TV

[ppm

x m] =

1500 [ppm]

x 0.7 x 4 [m]

TV

[ppm

x m] =

4200

[ppm

x m]

The

test

cell value should

be

4200

ppm x m.

The

nearest

test

cell

has the

test

value

4000

ppm x m.

* If the

concentration values

are in

mg/m3,

they

must

be

converted accordingly.

18 8 008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights

reserved

Page 19

GM901

Technical

Data

Product

Information

5

Technical

Data

5.1

Device

Data

Basic

device

Transmitter

Receiver

Evaluation

unit

I •

Measurement range

Measuring

distance

Gas

temperature

Linearity

Resolution

Adjustment time

Ambient

temperature

Degree

of

protection

Voltage

supply

Line

frequency

100 ppm to

20000

ppm*________

0.5 m to 8

m

300

°C;

higher

temperatures

on

request

± 5% of

upper measurement range limit

approx.

10 ppm

~5

to

360 s ~

^20

°C

to

+55

°C

IP

65

115/230

V

~50/60'Hz

75

VA

Max.

power consumption

Dimensions

incl.

purge-air

attachment

Weight incl. purge-air attachment

3 kg

Lamp

service life

Dimensions incl. purge-air

attachment

240 mm x 150 mm x 150 mm (L x W x H)

approx.

20000

hours

240 mm x 150 mm x 150 mm (L x W x H)

Weight

incl. purge-air attachment

3 kg

Analog

input

Analog

output

electrically

isolated

Relay

1

0 to 20

mA;

input resistor

100

Q

~0

to~20~mA;

maxJoad

500

Q

Break

contact

for

device malfunction, floating,

make contact

Max.

switching current:

1 A

Max.

switching voltage:

125 V DC

150 V AC

Max.

switching capacity:

30 VA DC

60 VA AC

Relay

2

Make

contact

for

limit value violation

Max.

switching current:

1 A

Max.

switching voltage:

125 V DC

150 V AC

Max.

switching capacity:

30 VA DC

60 VA AC

Status

input

Serial

interface

Dimensions incl. purge-air

attachment

Status

input

for

maintenance

Max.

contact

load:

5 V/2 mA

~RS

232 for

service

CAN

bus

(option)

Profi-bus

(option)

200 mm x 90 mm x 300 mm (L x W x H)

Weight

incl. purge-air attachment

4.3 kg

Tab.

2:

Technical

data

*

Depending

on the

measurement

distance

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

19

Page 20

GM901

Technical

Data

Product

Information

5.1_±

Accessories

Part

Optical

alignment

aid

Mounting bracket

for

zero-point

adjustment

Connection unit with

230

V/24 V power supply

for

transmitter

and

receiver

5 m

extension cable

10 m

extension cable

15 m

extension cable

Weatherproof cover

for

purge-air unit

Weatherproof cover

for GM 901

transmitter/receiver

Weatherproof cover

for GM 901

evaluation unit

Cover

plate

with seal

Air

filter assembly

Test case

for

SPAN

test

with cell

Quantity

1

2

1

1

2

1

2

1

1

Order

number

2020436

2020445

2020440

2020437

2020438

2020439

5306108

2702407

4029146

2020435

2020442

2019639

Tab.

3:

Accessories

5.1.2

Part

Options

Quantity

Order

number

Purge-air

unit

with

distributor

and 5 m

hose

Flange with pipe

130 mm, ST 37

Flange with pipe

240 mm, ST 37

Flange

with pipe

500 mm, ST 37

Flange with pipe

130 mm,

1.4571

Flange with pipe

240 mm,

1.4571

Flange with pipe

500 mm,

1.4571

Temperature sensor

PT 100

incl.

measuring transducer

Tab.

4:

Options

1

1

1

1

1

1

1

1

1012424

2017845

2017847

2017849

2017846

2017848

2017850

6007585

20

8 008

876/07-99.HJS.SM • SICK

AG •

Environmental

Monitoring • Germany

• All

rights

reserved

Page 21

I

GM901

I •

за

Technical

Data

5.2

Dimensioned Drawings

5.2.1 Transmitter

and

Receiver

240

80

Fig.

13:

Dimensions

of

transmitter

and

receiver

Product

Information

>

492

239

Fig.

14:

Dimensions

of

weatherproof cover

for

transmitter

and

receiver

8

008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 22

GM901

Technical Data

Product

Information

5.2.2 Evaluation Unit

200

SICK

160

osevfce

,

OWming

<—

OMalfunctkxi

о

0

ro

ro

CM

97.5

Г 90

f

82

I

I

*И

-г

—

'

Fig.

15:

Dimensions

of

evaluation unit

--—-—-—-—-—e-

(239)

184

19

0

(O

CM

CM

190

Fig,

16:

Dimensions

of

weatherproof cover

for

evaluation unit

8

008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 23

GM901

Technical

Data

Product Information

5.2.3 Purge-Air Unit

Fig.

17:

Dimensions

of

purge-air unit

255

550

605

F/g.

18:

Dimensions

of

weatherproof cover

for

purge-air

unit

5.2.4

Air

Filter Assembly

I •

Air

filter

^

Mounting holes

15.5

x

7

•«—

1

f-

f

?

/

\

-—

—

•

—

'A

—

17

———

35

————

-

5

———

-

\

H

1

"t

-^r

Hose connector

+

——— 0 188 ——

1

•

0

4

,——

,

ч

———

0

/

1_:=^

154

—

«•

\

\

———

=

___

Ш

040

0158-

Fig.

19:

Dimensions

of the air

filter

assembly

8

008

876/07-99.HJS.SM • SICK

AG •

Environmental Monitoring • Germany

• All

rights reserved

Page 24

Argentina

Phone

+54

114555

0055

Fax

+54

114555

0444

Australia

Phone

+61 3

9497

4100

(0

08) 33 48 02 -

toll

free

Fax

+61 3

9497

1187

Austria/Slowenia

Phone

+43 22 36 62 28 8-0

Fax

+43 22 36 62 28 85

BeNeLux

Netherlands

Phone

+31 73 599 50 44

Fax

+31 73 599 47 18

Belgium/Luxembourg

Phone

+32 9

2240

394

Fax

+32 9

2235

645

Brazil

Phone

+55 11

50311622

Fax

+55 11

5031 5176

Canada

Phone

+01

(905)

771-1444

+01

(905)

771-1415

Fax

+01

(905)

771-1616

Chile

Phone

+56

2-274

7430

Fax

+56

2-204

9338

China/Hongkong

Phone

+86 21

6485

4767

Fax

+86 21

6485

0938

Croatia/Slovenia

Phone

+3 85

1-363

3055

Fax

+3 85

1-363

3033

Cyprus

Phone

+35 72 49 43 00

Fax

+35 72

3113

62

Czech

Republic

Phone

+42 02 578 10 561

Fax

+42 02 578 10 559

Denmark

Phone

+45

4390 8611

Fax

+45

4369 1340

Egypt

Phone

+202

361

2747

Fax

+202

360

8258

Finland

Phone

+358

97 55 66 11

Fax

+358

97 55 32 97

France

Phone

+33 1 64 62 35 00

Fax

+33 1 64 62 35 77

Germany

Phone

+49 76

4146

90

Fax

+49 76

4146

91149

Phone

+49 75 32

801-0

Fax

+49 75 32

801-104

The

newly formed German

states

Phone

+49 35 20 55 24 10

Fax

+49 35 30 55 24 50

Great

Britain/Ireland

Phone

+17 27 83 11 21

Fax

+17 27 85 67 67

Greece

Phone

+30 16 74 74 64

Fax

+30 16 74 11 59

Hungary

Phone

+36 1-3 80 60 20

Fax

+36 1-2 30 86 98

India

Phone

+91 2 24 93 84 03

Fax

+91 2 24 93

0191

Israel

Phone

+97 29 74 12 657

Fax

+97 29 97 42 419

Italy

Phone

+39

Oil

2 23 66 01

Fax

+39

Oil

2 23 66 09

Japan

Phone

+813

5444-0929

Fax

+8135444-0938

Korea

Phone

+82234448781

Fax

+82 2

3444

7945

Lebanon

Phone

+96

1188

50 61

+96

11 89 07 10

Fax

+96 11 88 50 61

+96

11 89 07 10

Mazedonia

Phone

+38 9 91 29 66 66

Fax

+38 9

9113

33 02

Mexico

Phone

+52 55 63

8188

Fax

+52 56 11 00 03

New

Zealand

Phone

+64 9 415

0459

Fax

+64 9 415

0465

Norway

Phone

+47 63 87 02 00

Fax

+47 63 87 02 01

Pakistan

Phone

+92 25 65 985

Fax

+92 21 25 66 059

Poland

Phone

+48 2 26 44 83 45

Fax

+48 2 26 44 83 42

Portugal

Phone

+351

234 303 900

Fax

+351

234 303 910

Russian Federation

Phone

+70 95 275 22 73

+70 95 275 29 73

+70 95 275 75 63

Fax

+70 95 279 67 76

Romania

Phone

+40 (0) 1 687 34 62

Fax

+40 (0) 1 242 68 24

Singapore/Malaysia/Thai

land

Indonesia/Phillippines

Phone

+65 744 37 32

Fax

+65 841 77 47

Slovac Republic

Phone

+4 21 75 44 34 089

Fax

+4

2175

44 14 964

South Africa

Phone

+27

11455

3809

+27

11455

3816

Fax

+27

11455

4668

Spain

Phone

+34 93 48 03 10 6

+34

91 64 26 112

Fax

+34 93 47 34 46 9

+34

92 64 26 112

Sweden

Phone

+46 8 632 30 00

Fax

+46 8 632 32 99

Switzerland/Liechtenstein

Phone

+4141

612 17 00

Fax

+4141612

17 01

Taiwan

Phone

+8 86

2-8797-1981-6

Fax

+8 86

2-2799-0272

Turkey

Phone

+90 312 435 06 94

Fax

+90 312 435 19 83

United Arabian Emirates

Phone

+97

14-324

75 00

Fax

+97

14-324

25 00

USA

Phone

+1

(952)

941

6780

Fax

+1

(952)

941

9287

SICK

SICK

AG •

Environmental

Monitoring • Nimburger

Str.

11 •

D-79276

Reute • Germany

Phone

+49

76414

69-0 • Fax

+49

7641 4 69-11

49 •

http://www.sick.de

Loading...

Loading...