Page 1

GM700 Ex

Laser Gas Analyzer,

Version with Measuring Probe

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

GM700 Ex

Probe version

Version GM700-05, GM700-09

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Production location

SICK AG

Nimburger Str. 11 · D-79276 Reute · Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Function of this document....................................................................... 7

1.2 Scope of application................................................................................. 7

1.3 Target groups (and document structure)................................................. 7

1.4 Further information................................................................................... 7

1.5 Data integrity............................................................................................. 7

1.6 Symbols and document conventions...................................................... 8

1.6.1 Warning symbols...................................................................... 8

1.6.2 Warning levels / Signal words................................................. 8

1.6.3 Information symbols................................................................ 9

2 Safety information............................................................................ 10

2.1 Main operating information..................................................................... 10

2.2 Warning information on the device.......................................................... 13

2.3 Intended use............................................................................................. 14

2.3.1 Purpose of the device.............................................................. 14

2.4 Responsibility of user............................................................................... 14

3 Product description........................................................................... 16

3.1 Product identification............................................................................... 16

3.2 Product characteristics............................................................................ 16

3.3 Type plate.................................................................................................. 16

3.4 Device variants......................................................................................... 17

3.5 Pressure and temperature sensor........................................................... 17

3.6 Options...................................................................................................... 17

3.7 Layout and function.................................................................................. 17

3.7.1 Function of the pressurized enclosure................................... 18

3.8 Purge air unit............................................................................................. 18

3.9 Check cycle............................................................................................... 19

3.10 Explosion protection in accordance with ATEX....................................... 20

3.10.1 Operation in potentially explosive atmosphere...................... 20

3.10.2 Zone of use GM700 Ex 3G components................................ 21

3.10.3 Pressurized enclosure system................................................ 22

3.10.3.1 Safety functions...................................................... 22

3.11 Sender/receiver unit - evaluation unit connecting hose........................ 22

3.12 GMP measuring probe in detail............................................................... 23

4 Transport and storage....................................................................... 24

4.1 Transport protection................................................................................. 24

4.2 Storage...................................................................................................... 25

5 Mounting............................................................................................. 26

5.1 Information on installation in potentially explosive atmospheres......... 26

5.2 Tools required............................................................................................ 27

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

3

Page 4

CONTENTS

5.3 Material required...................................................................................... 27

5.4 Preparing the sampling point................................................................... 27

5.5 GM700 Ex scope of delivery.................................................................... 28

5.6 Installation sequence............................................................................... 28

5.6.1 Installation example................................................................ 28

5.6.2 Overview of installation steps (duct-side preparation).......... 29

5.6.3 Installing the flange with tube................................................. 29

5.6.4 Install the evaluation unit........................................................ 31

5.6.4.1 Install the FS840.................................................... 31

5.6.5 Installing the purge air unit..................................................... 33

6 Electrical installation........................................................................ 34

6.1 Electrical installation safety information................................................. 34

6.2 Connection overview................................................................................ 36

6.2.1 Lines......................................................................................... 37

6.3 Connecting interfaces ............................................................................. 38

6.3.1 Connect I/O interfaces............................................................ 38

6.3.1.1 GM700 Ex 3G terminal connection diagram........ 38

6.3.1.2 Electrical connection of the evaluation unit EvU.. 40

6.4 Connecting the connecting hose to the SR-unit on the EvU.................. 41

6.5 Connecting pressure, temperature and purge air monitor ................... 41

6.6 Preparing the power supply...................................................................... 41

6.7 Connecting the FS840 Ex overpressure control..................................... 42

6.8 Electrical connection of SR-unit............................................................... 44

6.9 Connecting the potential equalization..................................................... 44

6.9.1 Connecting the potential equalization on the SR-unit........... 45

6.9.2 Connecting the potential equalization on the measuring

probe........................................................................................ 45

6.9.3 Potential equalization - evaluation unit and Ex control unit.. 46

7 Commissioning.................................................................................. 47

7.1 Safety information on commissioning..................................................... 47

7.2 Prerequisites for successful commissioning.......................................... 47

7.3 Material required ..................................................................................... 48

7.4 Overview of commissioning steps........................................................... 48

7.5 Zero adjust................................................................................................ 49

7.6 Fitting the SR-unit on the measuring probe............................................ 49

7.7 Aligning the measuring probe in flow direction...................................... 51

7.8 Feeding protective gas............................................................................. 52

7.8.1 Connecting the protective gas on the SR-unit....................... 52

7.8.2 Switch the pressurized enclosure on...................................... 54

7.9 Optical fine alignment of the sender/receiver unit ............................... 54

7.10 Installing the weatherproof cover ........................................................... 55

7.11 Starting measuring operation.................................................................. 56

7.11.1 Operating states...................................................................... 57

7.11.2 Select the ambient temperature range.................................. 57

4

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 5

CONTENTS

8 Operation............................................................................................ 58

8.1 Safety......................................................................................................... 58

8.1.1 Check before commissioning.................................................. 58

8.2 Operating and display elements (evaluation unit).................................. 58

8.2.1 Function buttons...................................................................... 59

8.3 Menu tree of the evaluation unit............................................................. 60

8.3.1 Menu tree Measuring.............................................................. 60

8.3.2 Menu tree Diagnosis............................................................... 60

8.3.3 Menu tree Parameter.............................................................. 61

8.3.4 Menu tree Calibration.............................................................. 63

8.3.5 Menu tree Maintenance.......................................................... 63

8.4 Operating using the serial interface........................................................ 64

8.4.1 Significance of command line elements................................ 64

8.4.2 Setting for serial interfaces..................................................... 64

8.4.3 Serial interface command - MEAS ......................................... 64

8.4.4 Serial interface commands - Diag.......................................... 65

8.4.4.1 Table with warning messages................................ 65

8.4.4.2 Call up the Table with error messages.................. 65

8.4.4.3 View the device configuration................................ 65

8.4.4.4 Check the system state and configuration........... 65

8.4.4.5 Call up diagnostic data........................................... 65

8.5 Setting the display contrast..................................................................... 65

9 Maintenance...................................................................................... 67

9.1 Safety......................................................................................................... 67

9.2 Maintenance plan..................................................................................... 69

9.2.1 Expendable, wearing and spare parts.................................... 70

9.3 Preparatory work....................................................................................... 70

9.4 Function test of the pressurized enclosure system................................ 70

9.4.1 Maintenance work on the FS840........................................... 71

9.4.2 Repair work on the FS840...................................................... 71

9.5 Removing the sender/receiver unit......................................................... 71

9.6 Visual check of the sender/receiver unit and evaluation unit............... 72

9.7 Cleaning the optical interfaces................................................................ 73

9.8 Etalon tool................................................................................................. 74

9.9 Filter box measurement to check the measuring channels (for dry

gases)........................................................................................................ 75

9.10 Checking the evaluation unit................................................................... 77

9.11 Cleaning the purge air unit....................................................................... 78

10 Troubleshooting................................................................................. 79

10.1 Safety......................................................................................................... 79

10.2 Monitoring and diagnostic system........................................................... 80

10.3 Device not functioning.............................................................................. 81

10.4 Evaluation unit not functioning................................................................ 81

10.4.1 Communication fault between evaluation unit and receiver 82

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

5

Page 6

CONTENTS

10.5 Ex operation malfunction......................................................................... 82

10.6 Error messages......................................................................................... 82

10.6.1 Error messages........................................................................ 82

10.6.2 Warning messages.................................................................. 84

10.7 Repairing inadequate purge air supply................................................... 85

10.8 Corrosion on flange.................................................................................. 85

11 Decommissioning............................................................................. 86

11.1 Safety information for decommissioning................................................ 86

11.2 Decommissioning Ex-relevant subassemblies....................................... 87

11.3 Removing the device................................................................................ 87

11.4 Preparing the device ready for shipping.................................................. 88

11.5 Environmentally compatible disposal ..................................................... 89

12 Technical data.................................................................................... 90

12.1 System: GM700 Ex version 3G / zone 2................................................. 90

12.2 Sender/receiver unit................................................................................ 90

12.3 Measuring probe....................................................................................... 91

12.4 Evaluation unit Ex version I/O module.................................................... 91

12.5 Technical data for pressurized enclosure system................................... 92

12.5.1 Technical data energy supply.................................................. 92

12.5.2 Limit values for terminal assignment FS840......................... 92

12.5.3 Technical data for Protective gas............................................ 92

12.5.4 Technical data for enclosure................................................... 92

12.5.5 Pressurized enclosure system settings.................................. 92

12.6 Dimension drawings: Sender/receiver unit............................................ 94

12.7 Dimension drawings: Open measuring probe (GMP)............................. 95

12.8 Dimension drawing, purge air unit........................................................... 96

12.9 Dimension drawings, evaluation unit with pressurized enclosure sys‐

tem FS840................................................................................................ 97

12.10 Dimension drawings: Mounting flange DN125....................................... 97

12.11 Dimension drawing, weatherproof cover, sender/receiver unit............. 98

13 Annex.................................................................................................. 99

13.1 Conformities.............................................................................................. 99

13.2 Electrical protection.................................................................................. 99

13.3 Ex certifications........................................................................................ 99

13.4 Possible ambient temperatures............................................................... 99

13.4.1 Ambient temperature ranges.................................................. 99

6

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 7

1 About this document

1.1 Function of this document

These Operating Instructions describe:

Device components

•

Installation

•

Operation

•

Maintenance work required for reliable operation

•

1.2 Scope of application

These Operating Instructions are only applicable for the measuring device described in

the product identification.

They are not applicable for other SICK measuring devices.

The standards referred to in these Operating Instructions are to be observed in the

respective valid version.

1.3 Target groups (and document structure)

ABOUT THIS DOCUMENT 1

This Manual is intended for persons installing, operating and maintaining the device.

Operation

The device may only be operated by qualified persons who, based on their device-spe‐

cific training and knowledge as well as knowledge of the relevant regulations, can

assess the tasks given and recognize the hazards involved.

Installation and maintenance

Skilled persons are required for installation and maintenance.

Please observe the information at the beginning of the respective Sections.

1.4 Further information

Operating Instructions of the purge air supply

•

Final inspection record

•

3G / Zone 2

Manual, Pressurized enclosure FS840 and purge medium valve

•

NOTE

Observe all supplied documents.

b

1.5 Data integrity

SICK AG uses standardized data interfaces such as, for example, standard IP technol‐

ogy, in its products. The focus here is on product availability and features.

SICK AG always assumes that the customer is responsible for the integrity and confi‐

dentiality of data and rights involved in connection with using the products.

In all cases, the customer is responsible for the implementation of safety measures

suitable for the respective situation, e.g., network separation, firewalls, virus protection

and patch management.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

7

Page 8

1 ABOUT THIS DOCUMENT

1.6 Symbols and document conventions

1.6.1 Warning symbols

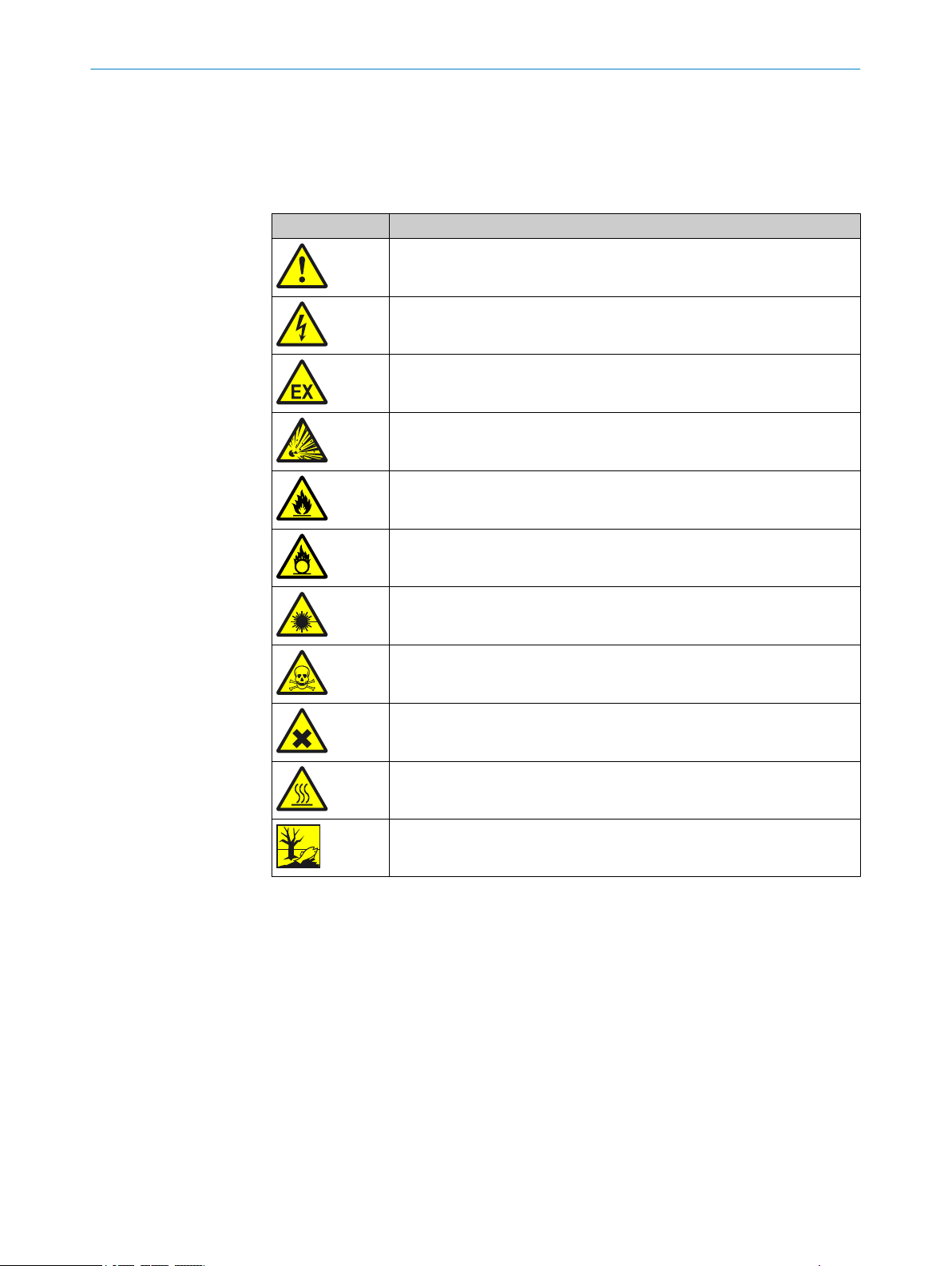

Table 1: Warning symbols

Symbol Meaning

Hazard (general)

Hazard by voltage

Hazard in potentially explosive atmospheres

Hazard by explosive substances

Hazard by inflammable substances

1.6.2 Warning levels / Signal words

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Hazard by oxidizing substances

Hazard by laser radiation

Hazard by toxic substances

Hazard by noxious substances

Hazard by high temperature

Hazard for the environment/nature/organic life

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

Note

Hints

8

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 9

1.6.3 Information symbols

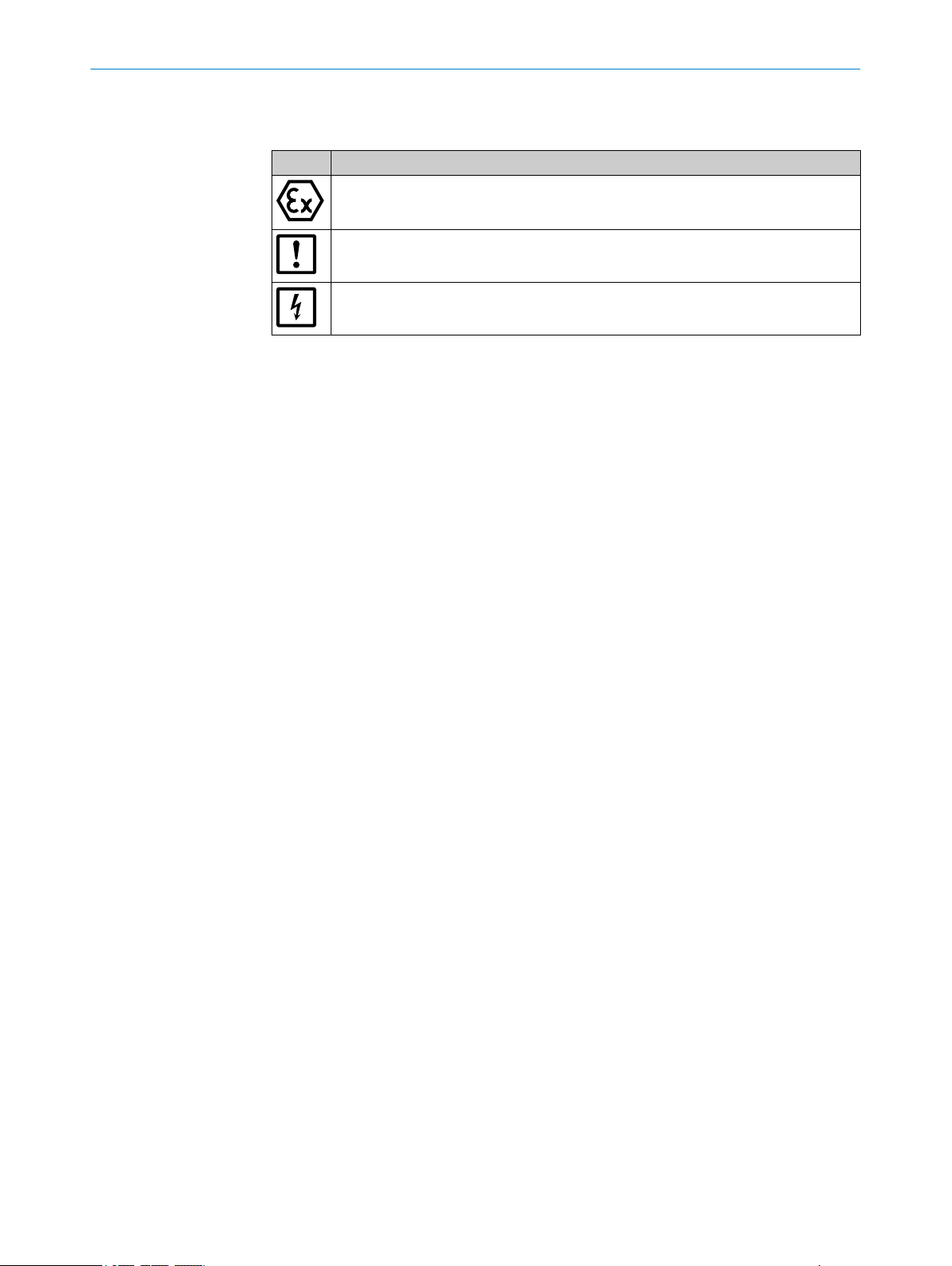

Table 2: Information symbols

Symbol Significance

ABOUT THIS DOCUMENT 1

Information on consistency of the product relative to Guideline 2014/34/EU (ATEX)

Important technical information for this product

Important information on electric or electronic functions

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

2 Safety information

2.1 Main operating information

Work on the device

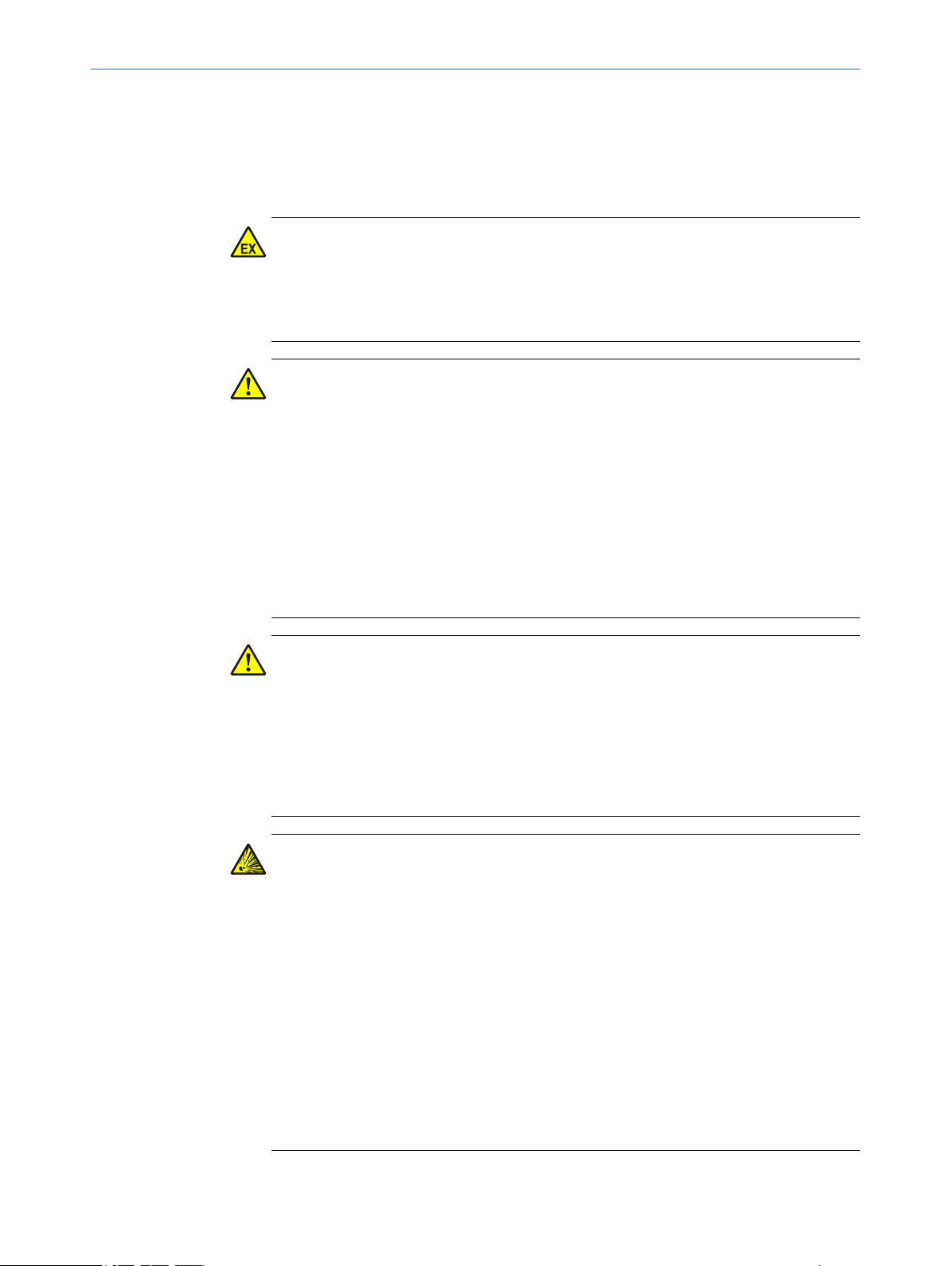

WARNING

Risk of explosion

Work on the device assumes an Ex free zone at the installation location otherwise there

is an explosion risk.

Ensure the work area is Ex free when working on the device.

b

WARNING

Injury risk through incorrect lifting and carrying of the device

Injuries can occur due to the weight and projecting enclosure parts when the equip‐

ment tips over or drops.

Consider the device weight before lifting.

b

Observe the regulations for protective clothing (e.g., safety shoes, non-slip gloves).

b

Grip underneath the equipment when possible to carry it safely.

b

Do not use projecting parts on the device to carry the device.

b

Call in further personnel for assistance as required.

b

Use a hoist or transport equipment as an option.

b

Pay attention to the transport safety device.

b

Clear obstacles that could cause falls and collisions out of the way.

b

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

DANGER

Risk of explosion through incorrect performance of maintenance work

Incorrect performance of maintenance work in potentially explosive atmospheres can

cause serious injuries to people and damage during operation.

Maintenance and commissioning tasks as well as checks should only be carried

•

out by experienced/trained personnel with knowledge of the rules and regulations

for potentially explosive atmospheres, especially:

– Ignition protection types

– Installation procedures

– Zone classification

Standards to be applied:

•

– IEC 60079‑14, Annex F: Knowledge, expertise and competence of responsi‐

ble persons, craftsmen and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

10

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 11

SAFETY INFORMATION 2

Laser radiation

WARNING

Eye injuries through laser radiation

The invisible laser beam within the SR-unit is not accessible when fitted. Observe the

following when the SR-unit of the device is swiveled open during installation work for

test purposes and the laser beam is activated:

Never look directly into the laser aperture when opening the SR-unit.

b

Laser protection class 1: Wear laser protection glasses despite low radiation.

b

Observe national valid limit values and standards that refer to these for industrial

b

safety.

Escaping hot gas

DANGER

Risk of fire through hot gas escaping in installations with overpressure conditions

On installations with overpressure, the purge air hose can be severely damaged by

escaping hot gas and can catch fire depending on the temperature. On installations

with overpressure as well as gas temperatures over 200°C:

Regularly check the functionality of the reverse flow safeguard fitted in the mea‐

b

suring probe.

DANGER

Danger to life by leaking hot/toxic gases

Hot and/or noxious gases can escape during work on the gas duct, depending on the

plant conditions.

Work on the gas duct may only be performed by skilled technicians who, based on

b

their technical training and knowledge as well as knowledge of the relevant regula‐

tions, can assess the tasks given and recognize the hazards involved.

Electrical safety

WARNING

Endangerment of electrical safety during installation and maintenance work when the

power supply is not switched off

An electrical accident can occur during installation and maintenance work when the

power supply to the device and/or lines is not switched off using a power isolating

switch/circuit breaker.

Before starting the work, ensure the power supply can be switched off using a

b

power isolating switch/circuit breaker in accordance with DIN EN 61010.

Make sure the power isolating switch is easily accessible.

b

An additional separation device is mandatory when the power isolating switch can‐

b

not be accessed or only with difficulty after installation of the device connection.

The power supply may only be switched on again after work completion or for test

b

purposes by the persons carrying out the work under consideration of the valid

safety regulations.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

11

Page 12

2 SAFETY INFORMATION

DANGER

Endangerment of electrical safety through missing power isolating switch

An electrical accident can occur during installation and maintenance work when the

power supply to the device and/or lines cannot be switched off using a power isolating

switch/circuit breaker.

b

b

WARNING

Endangerment of electrical safety through power cables with incorrect rating

Electrical accidents can occur when the specifications for replacement of a removable

power cable have not been adequately observed.

b

Contamination of device through purge air failure

Ensure the power supply can be switched off using a power isolating switch/circuit

breaker in accordance with DIN EN 61010-1:2010.

An additional disconnecting device is mandatory when the disconnector switch is

difficult to access or cannot be accessed when connecting the equipment after

installation.

Always observe the exact specifications in the Operating Instructions (Technical

Data Chapter) when replacing a removable power line.

CAUTION

A faulty purge air supply can damage the measuring system

The measuring system can no longer be protected from contaminated sample gas and

is damaged.

When the purge air supply appears faulty, immediately perform all actions

b

described in these Operating Instructions.

Responsibility for the safety of a system

ATTENTION

Responsibility for the safety of a system

The person setting the system up is responsible for the safety of the system in which

the device is integrated.

12

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 13

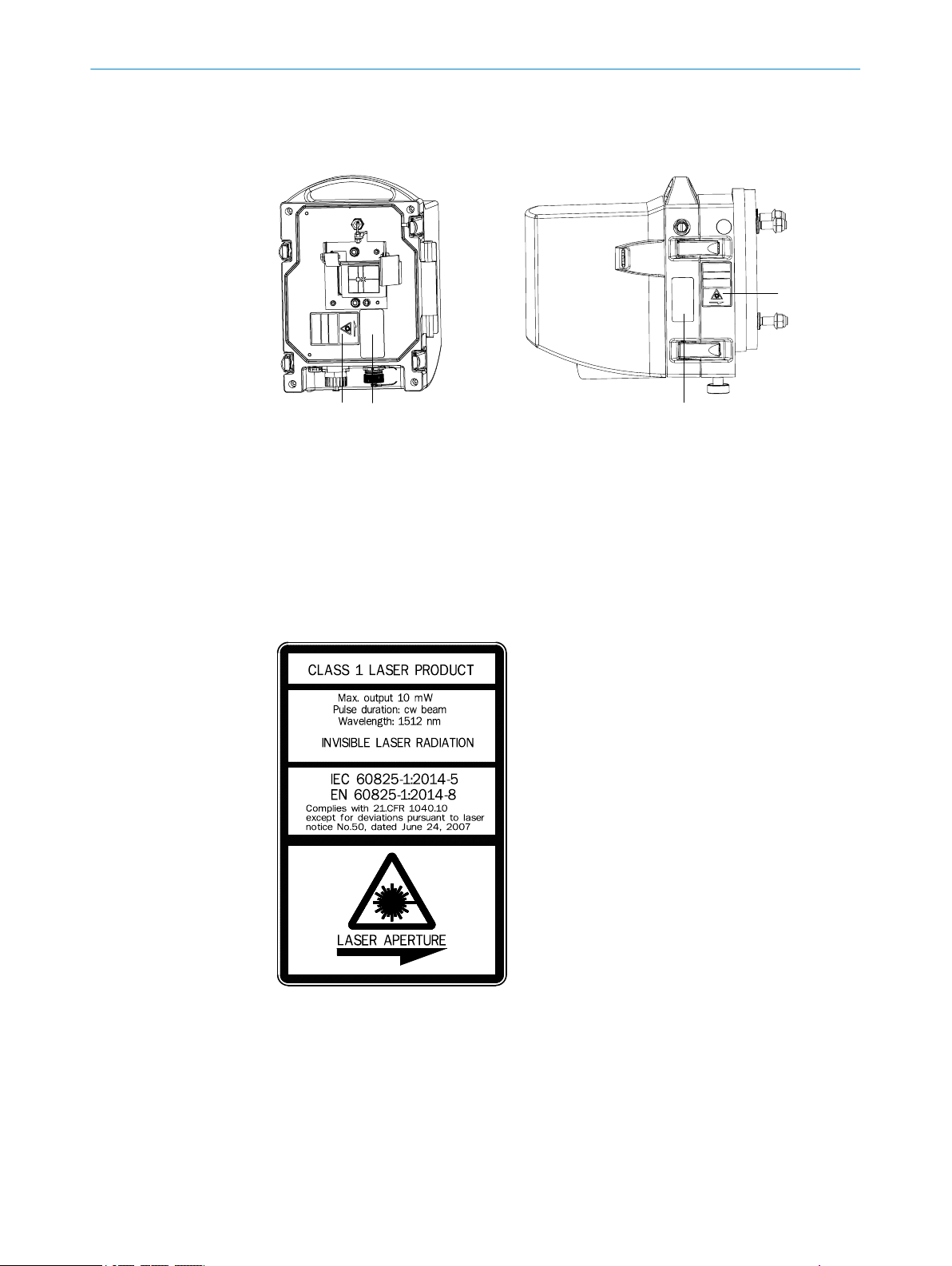

2.2 Warning information on the device

112 2

S/R unit

Figure 1: Warning information on the sender/receiver unit

SR-unit, front side

1 Danger sign: Laser radiation

2 Type plate GM700 Ex

SR-unit, right side

1 Danger sign: Laser radiation

2 Type plate GM700 Ex

SAFETY INFORMATION 2

Figure 2: Laser symbol on device

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

13

Page 14

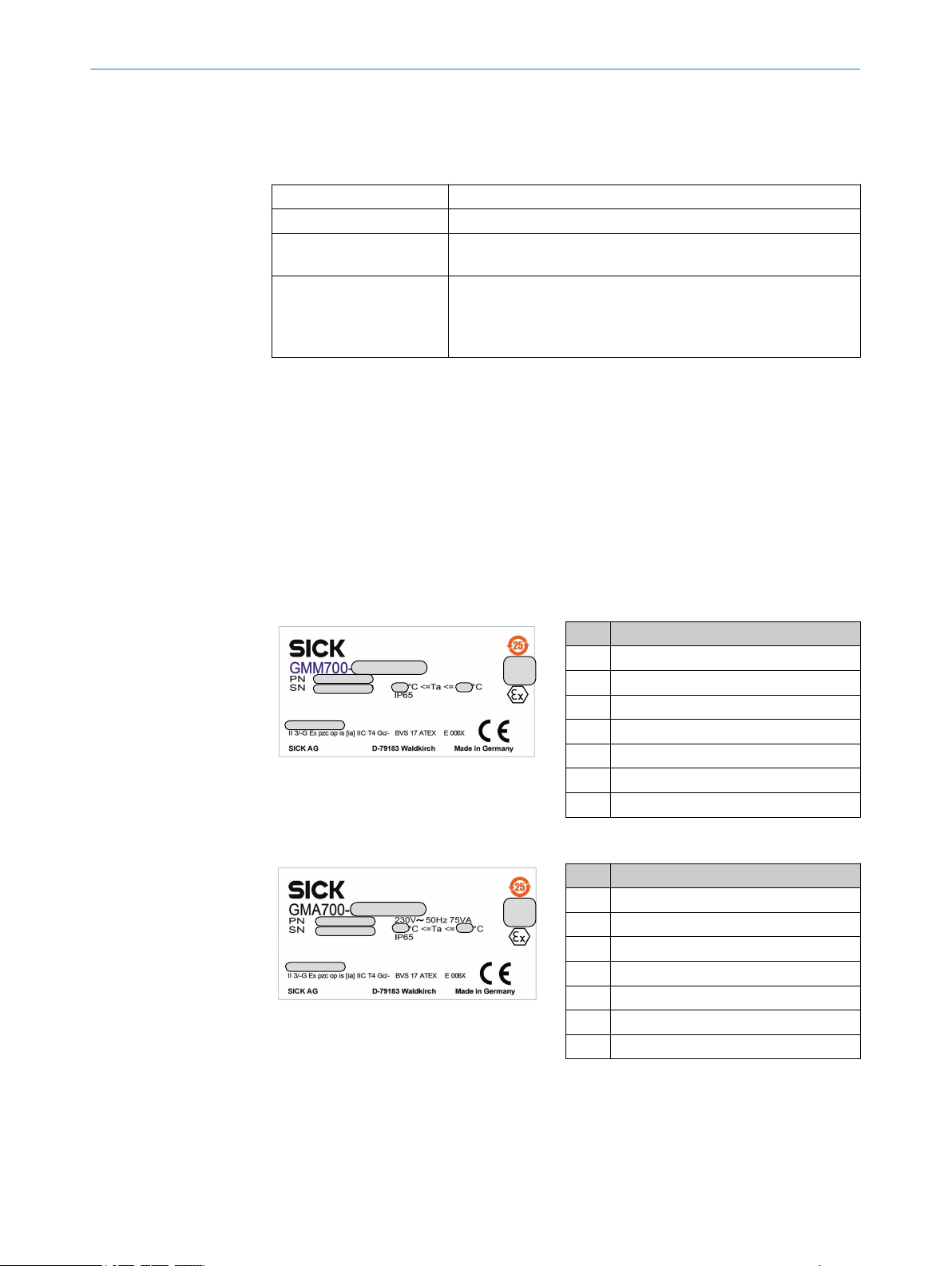

2

1

3

4

2 SAFETY INFORMATION

GM 700 Ex evaluation unit

Figure 3: Warning information on the EvU GMA700 front and right sides

1

2

3

4

Protective gas warning

•

Protective gas outlet

•

Risk of suffocation when using inert gases

•

20 minutes waiting time before opening the enclosure

General warning: Warning of danger area

Warning sign: Pull power plug before opening the device

Type plate

2.3 Intended use

2.3.1 Purpose of the device

The device serves exclusively for emission and process monitoring of gases in industrial

plants.

The device measures continuously directly in the gas duct (in-situ).

2.4 Responsibility of user

NOTICE

Responsibility for the safety of a system

The plant operator may not make any technical changes to the GM700 system. Every

change voids the EU type approval.

Intended users

see "Target groups (and document structure)", page 7.

Correct project planning

Basis of this Manual is the delivery of the device according to the preceding

•

project planning (e.g., based on the SICK application questionnaire) and the rele‐

vant delivery state of the device (see delivered System Documentation).

w

If you are not sure whether the device corresponds to the state defined dur‐

ing project planning or to the delivered system documentation: Please con‐

tact SICK Customer Service.

14

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 15

SAFETY INFORMATION 2

Special local conditions

In addition to the information in these Operating Instructions, follow all local laws, tech‐

nical rules and company-internal operating directives applicable wherever the device is

installed.

Read the Operating Instructions

Read and observe these Operating Instructions.

b

Observe all safety instructions.

b

If anything is not clear: Please contact SICK Customer Service.

b

Document retention

These Operating Instructions:

Must be kept for reference.

b

Must be passed on to new owners.

b

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

15

Page 16

01

02

03

04 05

06

07

01

02

03

04 05

06

07

3 PRODUCT DESCRIPTION

3 Product description

3.1 Product identification

Product name GM700 Ex

Device version Measuring Probe Version

Manufacturer SICK AG

Type plates

3.2 Product characteristics

■

The device serves for continuous measurement of gas concentrations in industrial

plants

■

The device is an in-situ measuring system which means measuring is done directly

in the gas carrying duct

■

Measuring components: NH3, NH3 + H2O

■

Measuring principle: Diode laser spectroscopy (TDLS)

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Sender/receiver unit: On right side

•

Control unit: On right side

•

On measuring probe: On purge air fixture

•

3.3 Type plate

Sender/receiver unit

No. Variable

01 Type code

02 Material number

03 Serial number

04 Min. gas temperature

05 Max. gas temperature

06 QR code

07 Month/year

Evaluation unit and connection unit

No. Variable

01 Type code

02 Material number

03 Serial number

04 Min. gas temperature

05 Max. gas temperature

06 QR code

07 Month/year

16

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 17

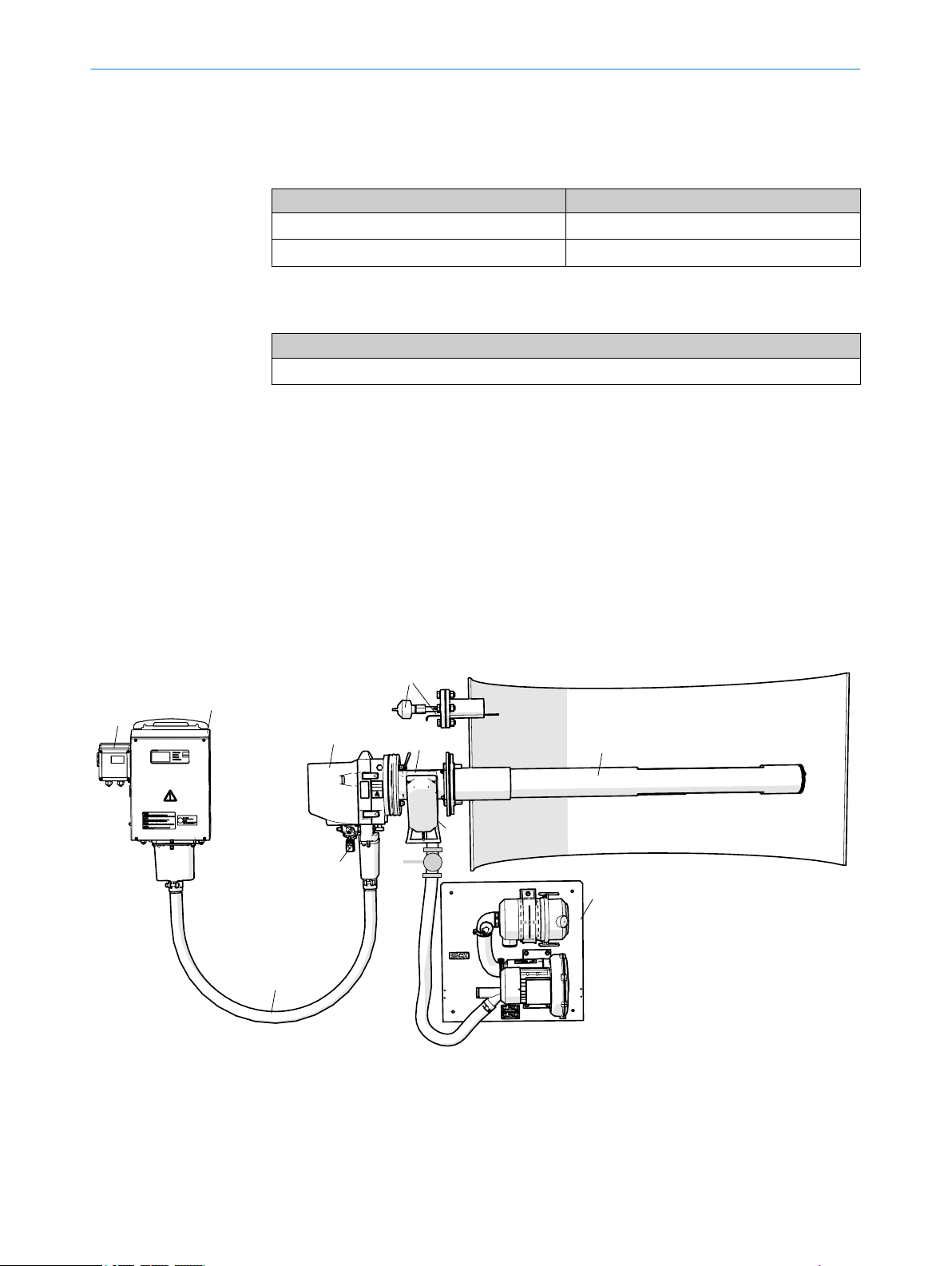

3.4 Device variants

1

8

9

5

3

2

ß

4

6

7

Sender/receiver unit

Table 3: Type code identification

Variants Measured components

Ex zone 2: GMM700-0513EX3G

•

Ex zone 2: GMM700-0913EX3G

•

Connection unit

Table 4: Type code identification

Version

Ex zone 2: GMA700-035X EX3G

•

3.5 Pressure and temperature sensor

A p/T sensor serves to measure pressure and temperature, see "Installation example",

page 28 and page 36.

NH

3

NH3 / H2O

PRODUCT DESCRIPTION 3

3.6 Options

Cover plate for purge air fixture of the sender/receiver unit

•

Weatherproof cover

•

Purge air unit

•

3.7 Layout and function

Figure 4: GM700 Ex layout and function

Sender/receiver unit GM700-0xxEX3G

1

Evaluation unit GM700-035xEX3G

2

Ex-p control FS840

3

Metallic connecting hose between sender/receiver unit and evaluation unit

4

Digital purge medium valve, 230 V, G3/8", 2 mm, Ex-p

5

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

17

Page 18

3 PRODUCT DESCRIPTION

Purge air fixture (without electronics)

6

GMP measuring probe (without electronics)

7

Temperature and pressure measurement

8

Purge air supply

9

Pressure switch for purge air monitoring

ß

Function

The device serves for continuous measurement of gas concentrations in industrial plants

•

The device is an in-situ measuring system which means measuring is done directly in the gas carrying duct

•

Measuring components: NH3, NH3 + H2O as well as reference values temperature and pressure

•

Measuring principle: Diode laser spectroscopy (TDLS) (laser protection class 1)

•

To maintain measuring reliability, a permanent air flow (optics purge air) protects and keeps the optics free

•

from soot and dust particles as well as condensate and moisture condensation

Ignition protection type “pressurized enclosure” is effective when using the GM700 Ex in Zone 2 potentially

•

explosive atmospheres. All relevant enclosures of the sender/receiver unit and connection unit connected

together via a pressure-proof metal hose are purged with a protective gas. The protective gas can be air suc‐

tioned in from the non-potentially explosive atmosphere or an inert gas.

3.7.1 Function of the pressurized enclosure

Purpose of the pressurized enclosure

The pressurized enclosure ensures Ex atmosphere cannot enter the device from out‐

side. To this purpose, the gas analyzer enclosure is filled with a protective gas. Apart

from that, it is ensured that the gas pressure inside the gas analyzer enclosure is higher

than the surrounding air pressure.

Functionality during operation

The pressurized enclosure system functions in “leakage compensation” mode: An over‐

pressure is generated in the device in relation to the atmosphere after pre-purging has

completed. If the protective gas pressure sinks below the minimum pressure set, pro‐

tective gas feed is activated until the selected overpressure is reached again.

Safety functions

If the maximum permitted overpressure is exceeded or the maximum permitted under‐

pressure underrun, the Ex control unit switches an alarm contact which must be perma‐

nently evaluated (responsibility of plant operator, see FS840 Pressurized Enclosure

Manual).

3.8 Purge air unit

•

•

•

The purge air unit must be in an Ex-free area and suction Ex-free purge air

The purge air unit supplies filtered ambient air to the measuring probe

This protects the front window of the SR-unit and the reflector in the measuring

probe against contamination and high gas temperatures

18

The purge air is blown into the gas duct through the “flange with tube”.

•

NOTE

Further information on the purge air unit, see Operating Instructions of the purge air

unit.

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 19

3.9 Check cycle

PRODUCT DESCRIPTION 3

Cyclic check cycle for zero and sensitivity checks

Start a check cycle via

Timer trigger: Configurable 0 ... 1440 minutes (= 1 day), see menu “Settings /

•

Check Cycle”

External digital input signal (Di 1)

•

Purpose of check cycle

■

Checking the zero point and span point without feeding span gases.

Check cycle procedure

The measuring sequence to determine the zero and check point is performed. The digi‐

tal input uses a falling edge for triggering, i.e. performance of a check cycle is sup‐

pressed as long as the signal is high (e.g., for control purposes).

Signaling

“Function control” (relay 3) is signaled per digital output during output of the zero and

check point.

Output

The output runs for 90 seconds each for the zero point followed by the check point.

Unit and scaling for the current zero point according to the settings.

•

Check or span point is displayed as percentage scaled to 70% of the measuring

•

range.

The same calculation method is used for the deviation as for the gas concentration with

the exception of correction factors which result from a gas adjustment as well as cus‐

tomer correction factors from menu PAR/SETTINGS / REGRESS. FUNCT. During the

check cycle output, the zero and span point are displayed in the lower display line paral‐

lel to the analog output. These can be viewed in menu DIAG/CHECK VALUES/<GAS> for

subsequent checks. Prerequisite is that the output has already been made via an ana‐

log output.

Deviations

A warning message is output, e.g., “AO1 NH3 ZEROPoint” when the zero or check point

deviation is above 2% of the upper display limit of an analog output.

The warning message remains until the next check cycle output is within the tolerance.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

19

Page 20

PRODUCT DESCRIPTION

3

3.10 Explosion protection in accordance with ATEX

3.10.1 Operation in potentially explosive atmosphere

3G / Zone 2: Connection unit and sender/receiver unit

The GM700 Ex complies with ATEX Directive 2014/34/EU with the

following characteristics:

X II 3/-G Ex pzc op is [ia] IIC T4 Gc/-

•

Special conditions (X identification):

•

A measuring function for explosion protection is not part of the

°

EC type approval

Explosion protection relating to optical radiation in the measuring

•

channel

The explosion protection relating to optical radiation in the measur‐

ing channel is satisfied in accordance with the temperature range

(-20°... +60 °C) specified by ATX/IECEx. The plant operator must

evaluate Ex atmospheres possibly present for exhaust gas temper‐

atures exceeding this range separately and take suitable protective

measures!

w

Location of Ex relevant subassemblies, see Chapter “Design

and Function”.

w

Do not remove, add or modify any components to or on the

device unless described and specified in the official manufac‐

turer information. Otherwise the approval for the device for

use in potentially explosive atmospheres becomes void.

w

Adhere to the maintenance intervals, see Chapter “Mainte‐

nance plan”.

w

After switching off the main power supply: Wait 20 minutes

before opening the enclosure.

20

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 21

3.10.2 Zone of use GM700 Ex 3G components

DI/DO/

AI/AO

230 /

115 V

ß

à

GM700

Ex ATEX 3G

á

Ex p

[op is]

p/t

Ex ia

Ex m

6

Ex p/ Ex i

Ex na

nc

8

5

1

3

4

â

Non Ex

ã ä

æ

9

å

DIV 1

DIV 2

Non Ex

1G

2G

Non Ex3GNon ExZone 2Zone 1

Zone 0

2

7

PRODUCT DESCRIPTION 3

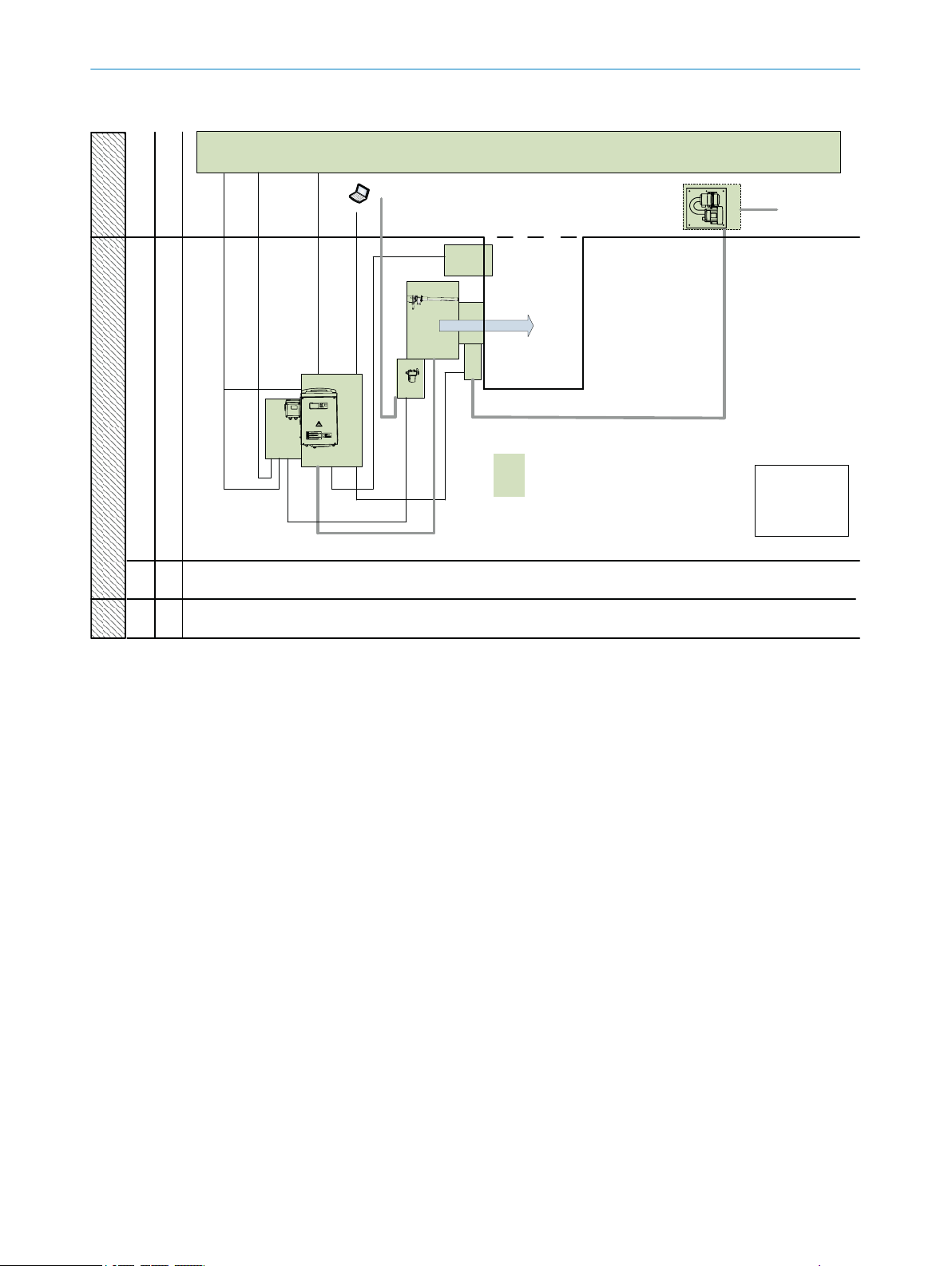

Figure 5: Zone of use GM700 Ex 3G components

Components

Control station / measuring station

1

Sender/receiver unit

2

Measuring beam

3

Ex-p valve

4

Evaluation unit

5

Overpressure control

6

8

7

9

ß

à

á

â

ã

ä

å

æ

p/T sensor

p sensor for purge air unit

Pressure controller for optics purge air as selected by the plant operator

Lines

Purge air hose, optics

Connecting hose, Ex-p

Pressure controller for optics purge air as selected by the plant operator

Ex-p error case signal

Service interface

Ex-p protective gas feed, from plant operator

Feed, optics purge air

Measuring channel

Measuring channel, Ex-free

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

21

Page 22

3 PRODUCT DESCRIPTION

3.10.3 Pressurized enclosure system

Ignition protection type, pressurized enclosure for Zone 2

Purging

All relevant enclosures of the sender/receiver unit and connection unit connected

together via a pressure-proof metal hose are purged with a protective gas. Purging

before starting the device safely removes any possible ignitable mix.

Controlling the overpressure in the enclosure

Control by the purge medium valve SVD.L.2.-AI00 G3/8"-300L Ex-p of the FS840

ensures that the complete enclosure is always kept at an overpressure of at least 0.8

mbar against the atmosphere after pre-purging; this prevents an ignitable gas mix pen‐

etrating the device.

Protective gas types

Instrument air suctioned in from the area outside the potentially explosive atmos‐

•

phere

Inert gas

•

NOTE

The temperature of the protective gas must not be higher than 50°C.

More information, see "Technical data for Protective gas", page 92, and Pressurized

Enclosure Operating Instructions.

3.10.3.1 Safety functions

Alarm signal of pressurized enclosure in case of malfunction

Ex control unit FS840 for Category 3G:

The Ex control unit FS840 provides a falling edge when the pressurized enclosure

is not in the correct operating state (malfunction).

WARNING

Risk of explosion through incorrect parameter settings

Incorrect parameter setting can cause an explosion with fatal consequences.

Only authorized persons are allowed to change the parameters.

b

NOTICE

The operating company is responsible for the evaluation of the alarm signal. See the

Pressurized Enclosure System Manual.

3.11 Sender/receiver unit - evaluation unit connecting hose

The following is applicable for the connecting hose between sender/receiver unit and

evaluation unit:

22

It is part of the pressurized enclosure

•

It contains electrical connection lines

•

It is under overpressure

•

It must be connected to the potential equalization system

•

To ensure potential equalization, the mechanical screw fittings of the hose attach‐

•

ment on GMM700 and GMA700 are secured additionally with sprocket discs.

These sprocket discs may not be removed.

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 23

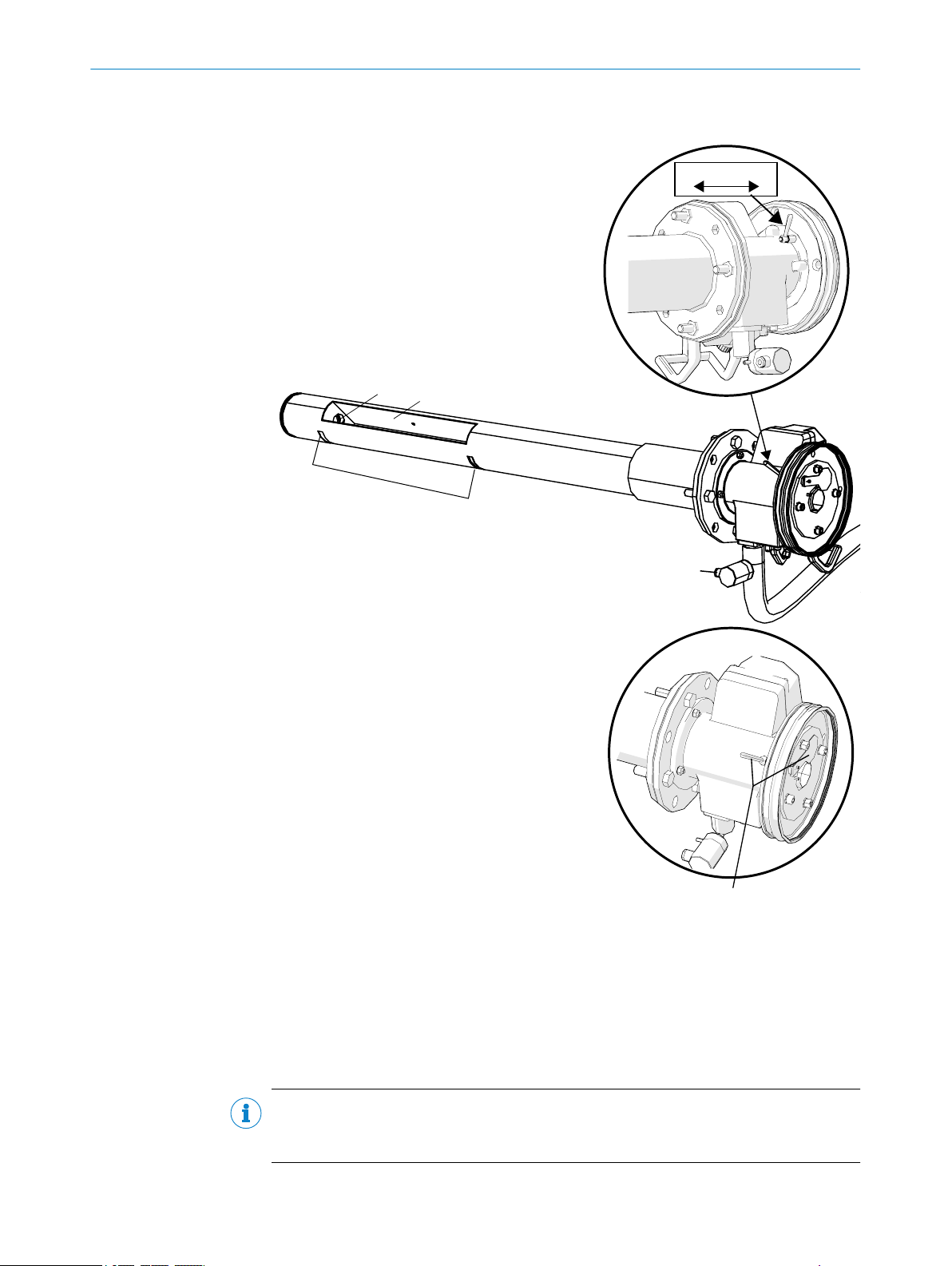

3.12 GMP measuring probe in detail

3

2

open Close

4

6

1

5

PRODUCT DESCRIPTION 3

Figure 6: GMP measuring probe description

Reflector

1

Measuring gap: Exposed measuring path

2

Purge air outlet: Air outlet in the duct 90° to gas flow direction (directed purge air)

3

Lever (locking device of the opening to sample gas)

4

Differential pressure sensor for purge air

5

Lever and locking device in “open” position

6

NOTE

Further characteristics of the GMP measuring probe, see "Measuring probe", page 91

and page 95.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

23

Page 24

3

1

2

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport protection

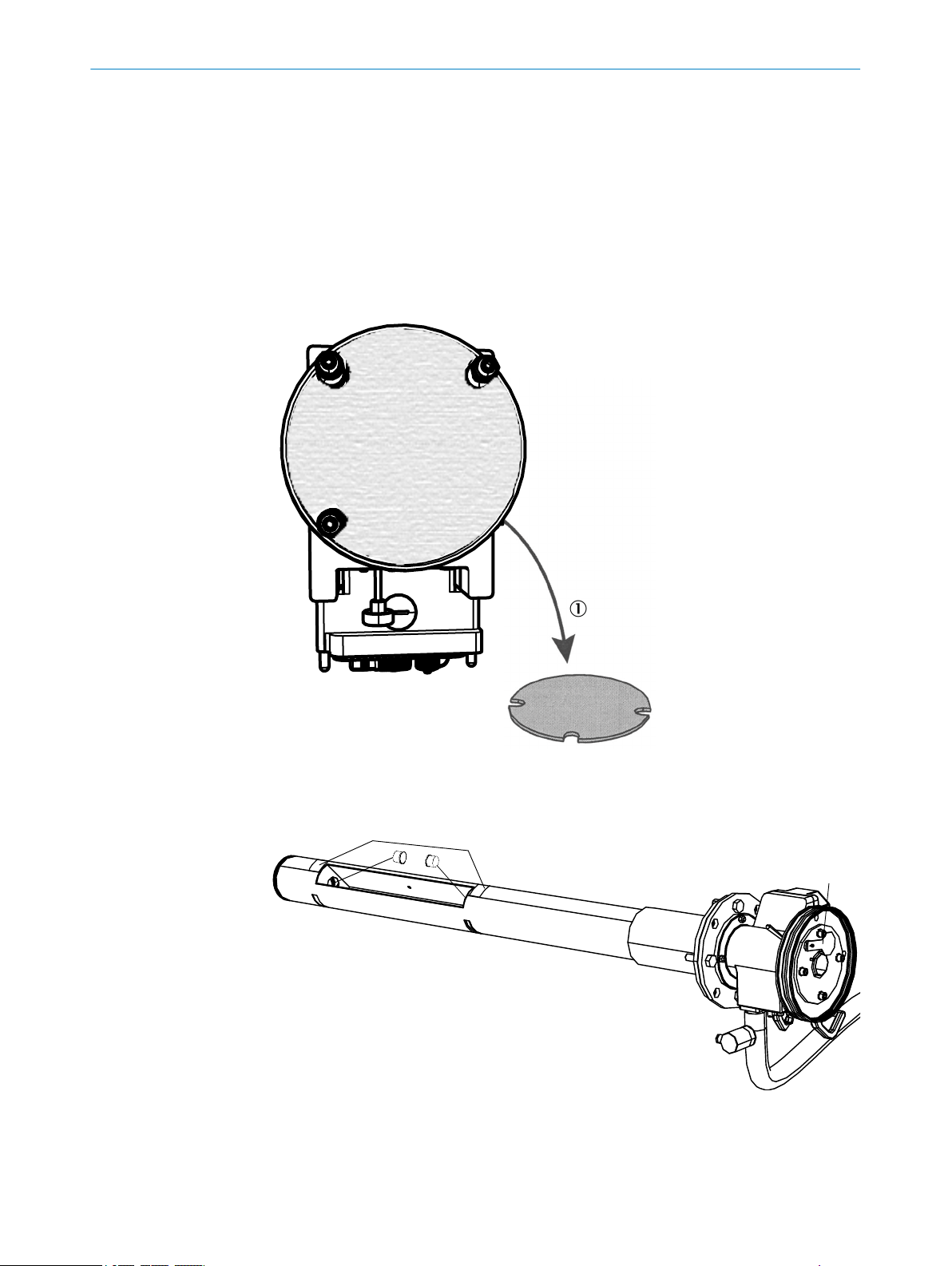

Removing the transport safety device on the SR-unit

1 Open the lock and swivel the flange fixture open.

2 Check the transport safety device for damage.

3 Remove the transport safety devices (see Figure).

4 Store the transport safety device.

24

Figure 7: Transport safety device on the SR-unit

Remove the front cover of the sender/receiver unit

1

Figure 8: Transport safety device on the GMP measuring probe

2 plastic protective caps to cover the optics

1

Remove the protective stickers

2

Set the locking device to the "close" position

3

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 25

4.2 Storage

TRANSPORT AND STORAGE 4

DANGER

Risk to health through contaminated measuring probe

Depending on the composition of the gas in the measuring channel, the measuring

probe could be contaminated with substances which could result in serious health

damage.

Decontaminate the measuring probe before storage.

b

Wear the specified protective clothing for all work with a contaminated measuring

b

probe.

Clean all components of the measuring system with slightly damp cleaning cloths.

b

Use a mild cleaning agent here.

Protect the openings of the sender/receiver-unit and measuring probe from atmos‐

b

pheric influences, preferably with the original transport safety devices.

Pack all components for storage or transport. Preferably use the original packing.

b

Store all components of the measuring system in a dry, clean room.

b

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

25

Page 26

5 MOUNTING

5 Mounting

5.1 Information on installation in potentially explosive atmospheres

Project planning for measuring channel

NOTICE

Observe information in Chapter “Main operating information”.

NOTICE

Hazard when exceeding the temperature classes for hot gas ducts

Temperature class T4 (max. 135 °C), for which the explosion protection of this device is

designed, can be exceeded on hot gas ducts.

Plan appropriate thermal insulation of the duct and the flanges during project

b

planning/assembly.

When necessary, ensure adequate ventilation or cooling.

b

Correct installation

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

DANGER

Risk of explosion through incorrect installation

Incorrect assessment of the installation location as well as all further installation work

in potentially explosive atmospheres can cause serious injuries to people and damage

during operation.

Installation, commissioning, maintenance and inspection may only be carried out

•

by skilled persons having knowledge of the relevant rules and regulations for

potentially explosive atmospheres, especially:

– Ignition protection types

– Installation regulations

– Zone classification

Standards to be applied:

•

– IEC 60079-14, Annex F: Knowledge, skills and competencies of responsible

persons, operatives and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

26

Local work safety regulations must be observed

•

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 27

WARNING

Risk of injury when the device drops down

The weight of the device can cause it to drop down and cause injuries during the work

described in this chapter.

b

Ex-suitable measuring probe

DANGER

Risk of explosion with a measuring probe not suitable for Ex zones

Measuring probes not approved for operation in potentially explosive atmospheres can

cause an explosion.

b

5.2 Tools required

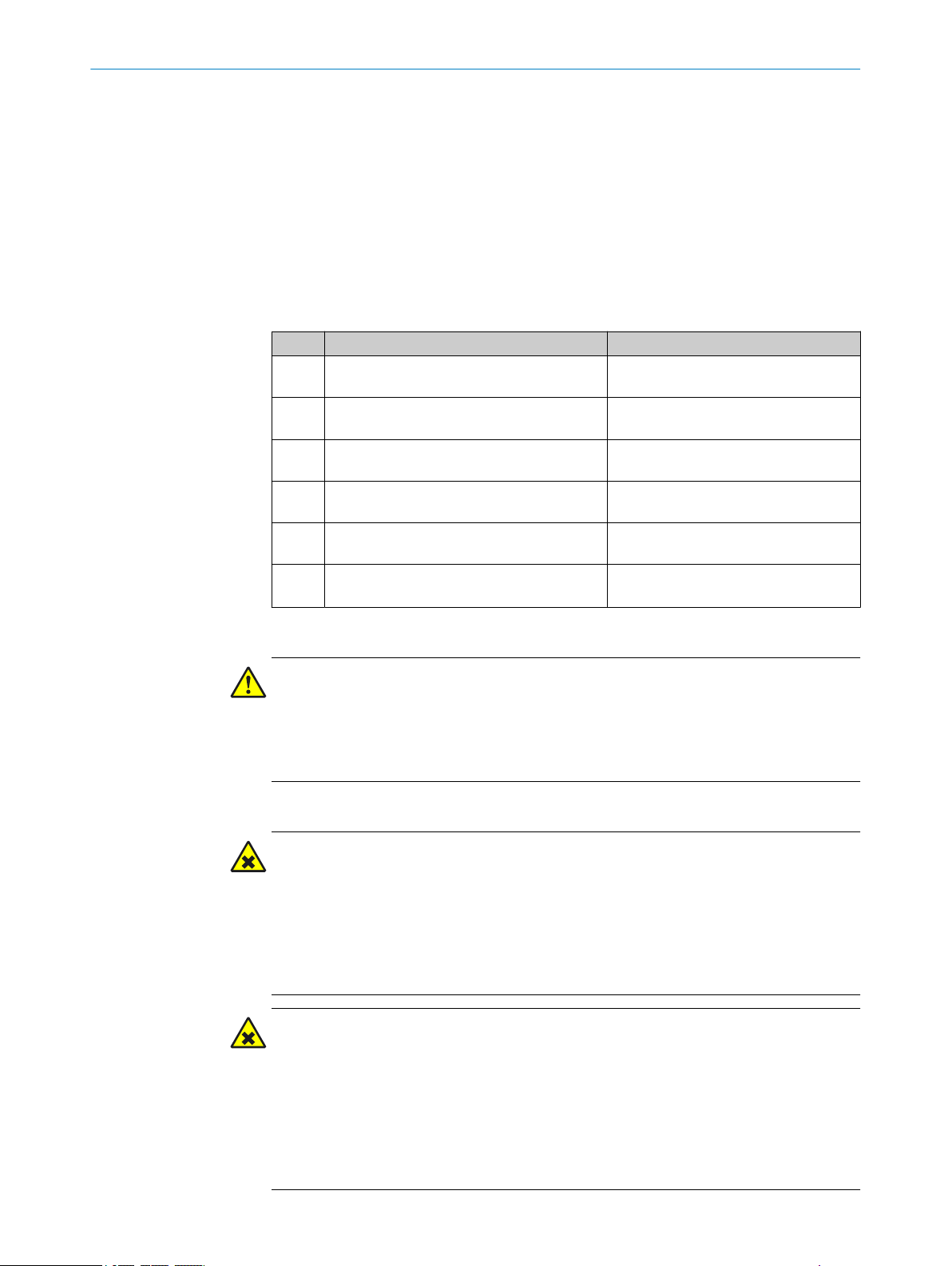

Tools Part No. Required for

Adjustment device 2034121 Alignment of "flanges with tube"

19 mm jaw wrench Flange screw fitting

Screwdriver Connections

Allen key Connections

MOUNTING 5

Carry out assembly work on parts of the device together with another person when

necessary.

Only use the GMP measuring probe included in the scope of delivery from SICK.

5.3 Material required

Material Required for

Personal protective equipment Protection when working at the sampling point

Tubes for protective gas Protective gas feed line, see "Connecting the protective gas

5.4 Preparing the sampling point

The operating company is responsible for preparing the sampling point

NOTICE

Basis for determining the sampling point:

Preceding project planning (e.g., based on the SICK application questionnaire)

•

Regulations of the local authorities

•

Responsibility of the operator

Determine sampling point

•

Preparing the sampling point

•

Feed and drain for protective gas

•

on the SR-unit", page 52.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

27

Page 28

1

2

4

6

3

5

7

8

à

ä

9

ß

á

â

ã

ø133

5 MOUNTING

DANGER

Risk of explosion through suctioning optics purge air from an Ex zone

Zone separation is no longer ensured when the purge air supply to purge the optics is

suctioned in from an Ex zone. This can lead to an explosion.

Always make sure the air for the purge air supply is suctioned in from an Ex-free

b

zone and ensure sufficient tightness of the purge air path when it passes through

an Ex atmosphere.

NOTICE

Observe zone separation, see "Zone of use GM700 Ex 3G components", page 21.

5.5 GM700 Ex scope of delivery

Check the scope of delivery according to the order confirmation/delivery note.

5.6 Installation sequence

5.6.1 Installation example

Carry out assembly according to the project planning and the Inspection protocol. The dimensions specified in the

drawings are guidelines and can deviate strongly from the project planning.

Figure 9: Assembly example, all dimensions in mm

Components

Evaluation unit with Ex-p control FS840

1

GM700 Ex sender/receiver unit

2

GMP measuring probe

3

Purge air unit

4

Pressure and temperature sensor (installation location according to project planning)

5

Ex-p control FS840

6

Dimensions

Max. distance SR-unit -EvU: 4 m, 8 m, depending on hose length

7

Duct wall - SR-unit: depending on flange with tube length + measuring probe length

8

28

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 29

Minimum clearance (center) - working platform: 1300 - 1500 mm

9

Min. flange length in gas duct: 20 mm

ß

Flange with tube length: Standard 240 mm

à

Minimum clearance flange (center) to purge air supply: > 700 mm

á

Vertical clearance fastening drill holes - purge air supply assembly plate: 470 mm

â

Horizontal clearance fastening drill holes - purge air supply assembly plate: 470 mm

ã

Miscellaneous

Working platform

ä

5.6.2 Overview of installation steps (duct-side preparation)

Step Procedure Reference

1 Fit flange with tube. see "Installing the flange with tube",

2 Install evaluation unit. see "Install the evaluation unit",

3 Fit purge air unit or units. see "Installing the purge air unit",

4 Observe protective gas outlet (evaluation

unit).

5 Connect pressure, temperature and purge air

monitor.

6 Connect protective gas feed to sender/

receiver unit.

MOUNTING 5

page 29

page 31.

page 33.

see "Install the FS840", page 31.

see "Connecting pressure, temperature

and purge air monitor ", page 41.

see "Connecting the protective gas on

the SR-unit", page 52.

Information on installing the measuring probe in the gas duct

CAUTION

Device damage through fitting the measuring probe too early on the gas duct

Unsuitable ambient conditions or the atmosphere in the measuring channel can dam‐

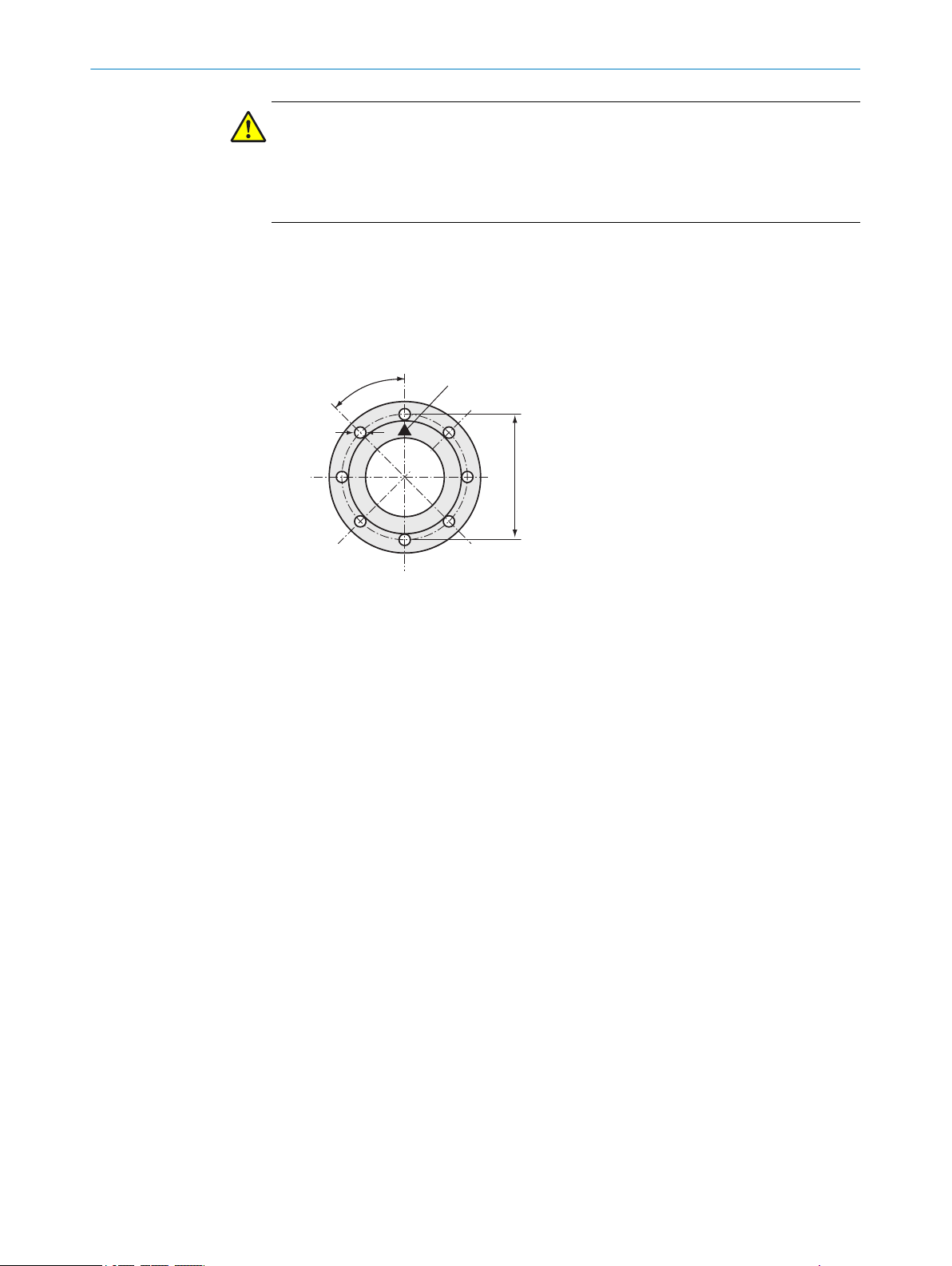

age the measuring system and make commissioning impossible.

Carry out the commissioning steps as described in the Commissioning Chapter.

b

5.6.3 Installing the flange with tube

DANGER

Hazard through hot, explosive or toxic flue gases

Hot and/or noxious gases can escape during assembly work on the gas duct depending

on plant conditions.

Work on the gas duct may only be performed by skilled persons who, based on

b

their technical training and knowledge as well as knowledge of the relevant regula‐

tions, can assess the tasks given and recognize the hazards involved.

DANGER

Hazard through hot, toxic and corrosive flue gases

Hot and/or noxious gases can escape during assembly work on the gas duct depending

on plant conditions.

Switch the plant off when working on the gas duct

b

or

the plant operator determines the safety measures to be observed during work on

b

the plant when switched on based on an evaluation of the danger involved.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

29

Page 30

1

200

18

4

5

°

5 MOUNTING

CAUTION

Device damage through incorrect/missing insulation of the duct when the measuring

channel is hot

When the measuring channel is hot, plan the duct and flange insulation so that

b

the device is protected against high temperatures.

Installing the flange with tube on the gas duct

1 Cut openings on the gas duct for the flange with tube.

2 Insert the flange with tube. Pay attention to the following:

The "Top" marking must point upwards vertically, irrespective of the gas duct

°

angle.

The tube must project at least 30 mm into the gas duct

°

Figure 10: "Top" marking on flange with tube

Marking “Top”

1

3 Attach the flange with tube.

4 Tilt the tube slightly downwards (max. 1°) to allow any condensate to drain off.

5 Now fix the flange with tube properly to the gas duct. Make sure that the alignment

of the flange does not change.

6 If necessary, attach duct insulation to protect the device from heat.

30

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 31

5.6.4 Install the evaluation unit

1

1

MOUNTING 5

Figure 11: Assembly brackets GMA700 Ex 3G

1

b

b

see figure 40, page 97

NOTICE

Do not yet connect the evaluation unit electrically.

5.6.4.1 Install the FS840

Assembly information

When setting up outdoors, it is recommended to protect the explosion-proof device

against direct atmospheric influences, e.g., with a protective roof.

Ensure the protective gas inlet and outlet are in a horizontal axis.

Brackets

•

Drill holes: Ø 8 mm

•

Screws: M6

Fasten the connection unit with 4 M6 screws as shown in the dimension drawing.

Refer to the dimension drawings for the dimensions.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

31

Page 32

1

2

5 MOUNTING

Figure 12: Protective gas outlet

Protective gas outlet: Thread G1"

1

Reference opening (M5 inner thread)

2

Protective gas quality

Instrument air or inert gas

•

Compressed air, class 533 according to ISO 8573-1

•

Solid matter 40 µm (class 1)

•

Pressure dew point ≤ 20 °C (class 3)

•

Oil quality ≤ 0.01 mg/m3 (class 1)

•

The air quality may possibly have to be better depending on the requirements of the

devices fitted in the pressurized enclosure.

Protective gas outlet

It is important that protective gas can flow out of the protective gas outlet against the

atmospheric pressure.

Ensure the unhindered flow of the protective gas.

b

Reference opening

The reference opening must be located in the Ex area.

Make sure the opening is always clear.

b

Line lengths for protective gas supply

Large pressure losses occur during the purge phase (high purge medium throughput)

depending on the supply line diameter. Consider this when dimensioning the supply

line:

Reference values: With 4 mm line diameter (inner diameter), a pressure loss of 500

mbar per meter must be calculated during purging with 2 l/s.

32

The pressure losses are noticeable when the purge medium flow rate is too low so that

the device is possibly not completely pre-purged.

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 33

NOTE

More information on protective gas,

see "Technical data for Protective gas", page 92.

•

5.6.5 Installing the purge air unit

NOTE

Purge air hose to the device according to project planning.

NOTE

For information on installing the purge air unit, see the Operating Instructions of the

purge air unit.

MOUNTING 5

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

33

Page 34

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Electrical installation safety information

NOTICE

Observe information in Chapter “Main operating information”.

Electrical safety

WARNING

Endangerment of electrical safety during installation and maintenance work when the

power supply is not switched off

Before starting the work on the device, ensure the power supply can be switched

b

off using a power disconnector switch/circuit breaker in accordance with DIN EN

61010-1.

Make sure the power disconnector switch is easily accessible.

b

An additional disconnecting device is mandatory when the power disconnector

b

switch cannot be accessed or only with difficulty after installation of the device

connection.

After completion of the work or for test purposes, the power supply may only be

b

activated again by authorized personnel complying with the safety regulations.

WARNING

Endangerment of electrical safety through power cable with incorrect rating

Electrical accidents can occur when the specifications for replacement of a power line

have not been adequately observed.

Always observe the exact specifications in the Operating Instructions (Technical

b

Data Chapter) when replacing a power line.

DANGER

Danger of electrical accidents

Incorrect performance of electrical work could result in serious electrical accidents.

Only let the work described in the following be carried out by electricians familiar

b

with potential hazards.

CAUTION

Risk of device damage

Electronic components are accessible when the enclosure is open. The circuit board

can be severely damaged when a contact is not grounded when the power supply is

switched on.

First switch the power supply on when the sender/receiver unit and the control

b

unit are closed.

34

CAUTION

Device damage through short circuit on the device

The internal electronics can be damaged when signal connections are established and

the power supply is switched on. This is also valid for plug connections.

Disconnect the GM32 Ex and any connected devices from the voltage supply.

b

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 35

ELECTRICAL INSTALLATION 6

Ex information

DANGER

Risk of explosion through incorrect performance of maintenance work

Incorrect performance of maintenance work in potentially explosive atmospheres can

cause serious injuries to people and damage during operation.

Maintenance and commissioning tasks as well as checks should only be carried

•

out by experienced/trained personnel with knowledge of the rules and regulations

for potentially explosive atmospheres, especially:

– Ignition protection types

– Installation procedures

– Zone classification

Standards to be applied:

•

– IEC 60079‑14, Annex F: Knowledge, expertise and competence of responsi‐

ble persons, craftsmen and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

DANGER

The Ex certification becomes void when line inlets and plugs without approval are

used

The line inlets and plugs are part of the Ex protection and therefore require approval.

Do not replace line inlets or plugs with other types.

b

Line inlet dimensions, see "Dimension drawings, evaluation unit with pressurized

b

enclosure system FS840", page 97.

DANGER

Risk of explosion through non-Ex conform installation of the lines to the device

Incorrect installation of the supply lines (power supply, signal and communication lines)

through Ex zones can lead to an electrostatic charge. This creates an increased risk of

explosion.

Install all lines in accordance with EN61010-1 and EN60079-14.

b

Protect lines against electrostatic charges.

b

WARNING

Risk of explosion through incorrect or non-existing grounding

To avoid an explosion due to electrostatic discharge, a correctly connected potential

equalization is mandatory on all system components with external ground connections

in all operating conditions.

Connect a potential equalization on all planned points on the device components.

b

Ensure the potential equalization is connected during all work on the device

b

described in these Operating Instructions.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

35

Page 36

1

4

3

1

2

5

6

7

8

9

6 ELECTRICAL INSTALLATION

DANGER

Risk of explosion through incorrect connection of the external sensors

The explosion protection is endangered when the external sensors p/T (in the stack) as

well as the optics purge air monitor (on the purge air fixture) are not connected to the

intrinsically safe terminals provided in the connection unit.

Always connect the external sensors p/T (in the stack) as well as the optics purge

b

air monitor (on the purge air fixture) to the intrinsically safe terminals specified in

the connection unit for this purpose.

Observe the intrinsically safe connection values for the Ex barriers fitted in the

b

evaluation unit in the Operating Instructions delivered.

DANGER

Risk of explosion through unsuitable screw fittings and lines

Only use lines (according to EN60079-14) with suitable outer diameters.

b

Close off cable inlets “vapor-proof” (virtually gas-tight).

b

Protect lines against electrostatic charges.

b

Only open those cable inlets to be used for installing cables. Keep the plugs. Refit

b

the original plug when a cable inlet must be closed again afterwards.

Electromagnetic compatibility

NOTE

This is a Class A product. This device can cause radio interference in household envi‐

ronments and therefore the user must take suitable measures when necessary.

6.2 Connection overview

Observe zone separation, see "Zone of use GM700 Ex 3G components", page 21.

Figure 13: GM700 Ex 3G / zone 2 connection diagram

Power supply

1

Warning signal, Ex-p control FS840

2

36

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 37

Service interface

3 12

1

1

3

I/O signal lines

4

Protective gas supply

5

Connection line, pressure sensor

6

Connection line, temperature sensor

7

Connection line, purge air monitor, pressure switch

8

Connection line, purge medium valve SVD.L.2.-AI00 G 3/8“-300L Ex p

9

Metallic connecting hose between sender/receiver unit and evaluation unit

ß

6.2.1 Lines

ELECTRICAL INSTALLATION 6

Figure 14: Evaluation unit, version 3G

No. Line opening size Line diameter (clamping

range)

M16 x 1.5 5 - 11 mm 6 Nm 5

1

M20 x 1.5 10 - 14 mm 10 Nm 1

2

M16 x 1.5 5 - 10 mm 6 Nm 4

3

Table 5: Lines

Lines Remark

Power supply From customer: 3 x 1.5 mm

Evaluation unit power supply From customer: 3 x 1.5 mm

Evaluation unit - sender/receiver unit with con‐

necting hose

Differential pressure sensor (measuring probe)

- evaluation unit

Pressure/temperature input From customer, intrinsically safe I/O connec‐

Service interface From customer, RS232

Inputs/outputs From customer: Terminal connections: 6 x

Evaluation unit - temperature sensor From customer

Evaluation unit - pressure sensor From customer

In accordance with project planning

5 m

•

10 m

•

From customer, intrinsically safe I/O connec‐

tion

tion

0,75 mm

Tightening torque Qty.

2

2

2

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

Table 6: Technical data, M screw fittings

Outer thread M20 x 1.5 M16 x 1.5

Thread length 6 mm

Height 23 mm

37

Page 38

1

5

3

2

4

6 ELECTRICAL INSTALLATION

Outer thread M20 x 1.5 M16 x 1.5

Cable diameter 10 ... 14 mm 6 ... 10 mm

Key width 24 mm 20 mm

Continuous service temperature -20 ... 95 °C

Material Nickel-plated brass

6.3 Connecting interfaces

6.3.1 Connect I/O interfaces

CAUTION

Never lay power supply cables directly next to signal cables.

DANGER

Risk of explosion through non-Ex conform installation of the lines to the device

Incorrect installation of the supply lines (power supply, signal and communication lines)

through Ex zones can lead to an electrostatic charge. This creates an increased risk of

explosion.

Install all lines in accordance with EN61010-1 and EN60079-14.

b

Protect lines against electrostatic charges.

b

1 Route the data lines through the M screw fittings.

2 Connect the data line.

NOTE

The analog input assignment shown in the following Chapter is the default setting and

may not be modified.

6.3.1.1 GM700 Ex 3G terminal connection diagram

Figure 15: Connection diagram of connection unit for variant 3G / Ex zone 2

Power supply

1

Connections of temperature sensor (3-wire circuit): Pins 1,2 and 3

2

Connections of pressure sensor: Pins 4 and 5

3

Pressure monitor for purge air monitoring: Pins 6 and 9

4

38

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 39

ELECTRICAL INSTALLATION 6

Connection area for intrinsically safe components

5

NOTICE PAY CLOSE ATTENTION TO THE CONNECTION VALUES ON TERMINALS 1-9

In area5, the intrinsically safe connections for temperature 2, pressure 3 and a digital input 4 to connect the

pressure monitor are provided. Only connect intrinsically safe simple operating means with suitable connection

data to these terminals in accordance with the Table below. Otherwise the explosion protection of the connected

sensors is not ensured. Only connect intrinsically safe devices with appropriate connection data to these termi‐

nals.

Table 7: Connection data for intrinsically safe connections

Termi‐

Inlet sizes Gas

nal

1 Inlet, temperature sensor

PT100, 3-wire circuit RMA42

2 IIB ≤ 360 nF ≤ 2 mH k.A.

group

IIC ≤ 27.3 V ≤ 22.1mA151mWk.A. 8 nF 75 μH ≤ 85 nF ≤ 500 μH k.A.

Uo Io Po Ui Ci1Li Co

3

3 IIB ≤ 530 nF ≤ 5 mH k.A.

4 Analog input, pressure sen‐

sor 4-20 mA RMA42

5 IIB ≤ 683 nF ≤ 17 mH k.A.

IIC ≤ 27.3 V ≤ 96.5mA659mWk.A. 8 nF 75 μH ≤ 88 nF ≤ 4 mH k.A.

IIA ≤ 2 280 nF ≤ 34 mH k.A.

6 Digital input, pressure switch

1 KCD2-SR-Ex

7 IIB ≤ 16.8 µF ≤ 486.3 mH 1628

IIC 10.5V 17.1mA45mW12 V 0 0 2.41 µF ≤ 121.5 mH 801

IIA ≤ 75 µF ≤ 972.7 mH 1628

8 Digital input, pressure switch

2 KCD2-SR-Ex

9 IIB ≤ 16.8 µF ≤ 486.3 mH 1628

IIC 10.5V 17.1mA45mW12 V 0 0 ≤ 2.41 µF ≤ 121.5 mH 801

IIA ≤ 75 µF ≤ 972.7 mH 1628

1

Max. inner capacity

2

Max. inner inductivity

3

Max. outer capacity

4

Max. outer inductivity

5

L/R ratio (inductivity/resistance)

Lo

4

μH/ Ω

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

39

Page 40

+ – + – + –

+ – + – + –

+ – + – + –

PE

N

L1

V

4

2+

230 V AC;

50 Hz

(3 x 1.5

2

)

1 2 3

Power

+5V +24V

Power CAN

+24V

+ – H L GND

Digital inAnalog i n

0.. 20mA

100 100 100

40...60Hz

AO1 AO2 AO3DI1 DI2 AI1 AI2 AI3

Sensor

DO1 DO2 DO3

Digital out

AC/DC 48V 30VA 1A

Analog out

0.. 20mA

Sensor

Fuse 2.5 AT 250V

PE N L1

contrast

1

PE N L1

T

T

CAN H

CAN L

--- +++

2

6 4 3

7 8

DI3

5

6 ELECTRICAL INSTALLATION

6.3.1.2 Electrical connection of the evaluation unit EvU

Figure 16: Electrical connection of the evaluation unit

GM700 Ex evaluation unit

1

Connections on circuit board

2

3

4

5

6

7

8

Power supply GM700

Fuse, 2.5 2,5 AT, 250 V

CAN GM700

Analog outputs: 0 ... 20 mA (6 x 0.75 mm2)

Digital outputs 48 V AC/DC; 60 VA, 1 A (6 x 0.75 mm2)

1 = digital output (NC contact) for malfunction

2 = digital output (NO contact) for maintenance request

3 = digital output (NO contact) for function check

40

O PE R AT I NG IN S TR U CT I ON S | GM700 Ex 8019532/100Q/V1-1/2018-08 | SICK

Subject to change without notice

Page 41

1

2

ELECTRICAL INSTALLATION 6

6.4 Connecting the connecting hose to the SR-unit on the EvU

NOTICE

The connecting hose between the SR-unit and the evaluation unit is part of the pressur‐

ized enclosure. It is under overpressure.

Protect the connecting hose against possible damage.

b

1 Lead the cable through the M screw fittings, see Figure below.

2 Connect the cable in the connection unit.

3 Tighten screws on the terminal strip.

4 Push on the connector housing and screw tight.

Figure 17: Connecting the connecting hose of the SR-unit on the EvU

M screw fitting

1

Connector housing

2

6.5 Connecting pressure, temperature and purge air monitor

NOTE

Purge air monitor - pressure controller for purge air monitoring

Wiring layout, see "Connection overview", page 36.

•

Terminal assignment, see "GM700 Ex 3G terminal connection diagram", page 38.

•

Observe the Operating Instructions of the sensors and the purge air monitor.

•

6.6 Preparing the power supply

1 Check that the connection lines meet the requirements:

– Cross-section: 3 x 1.5 mm

2 Plan a disconnecting device for

– Evaluation unit (see "Evaluation unit Ex version I/O module", page 91).

– Optics purge air units (see technical data of the optics purge air unit).

– Mark the disconnecting device as disconnecting device for the GM700 Ex.

8019532/100Q/V1-1/2018-08 | SICK O P ER A TI N G I NS T RU C TI O NS | GM700 Ex

Subject to change without notice

2

41

Page 42

6 ELECTRICAL INSTALLATION

3 Connect power cable and lines:

w

w

4 Tighten the M screw fitting.

Figure 18: Power connection in the evaluation unit, power supply 230V / 50 Hz

NOTICE

The PE connection must always be connected to the protective ground of the system.

Route the power cable through the M screw fitting.

Connect the lines in the connection unit.

6.7 Connecting the FS840 Ex overpressure control

Electrical safety

The local electrical installation regulations must be observed.

Risk of explosion

DANGER

Risk of explosion through incorrect settings for the pressurized enclosure

The pressurized enclosure is a central safety part of the device. All work is described in

this Manual and the relevant specified documents. If work is performed which is not

described in this Manual, the risk of explosion of the measuring system increases and

the ATEX certification for the device becomes void.

Carry out all work skillfully and in accordance with the delivered documentation.

b

Unsafe measuring operation

CAUTION

Risk of unsafe measuring operation through loss of degree of protection IP65

Ineffective seals of the connection unit and insufficient closed openings for unused line

inlets can lead to loss of degree of protection IP65. Penetration by dust or moisture can

lead to unsafe operation of the FS840.

Close off unused openings for line inlets with impact resistant sealing plugs that

b

have been checked against self-loosening and turning.

Check the seals on the Ex-e enclosure for damage and replace as necessary.

b

Tighten the terminals, especially in the Ex-e area.

b